Page 1

Dräger Medizintechnik

D

Contents

Function description

1 General 3

2 Mechanical system 3

2.1 Trolley ..................................................................................................... 3

2.2 Base plate for resting surface ................................................................. 3

2.3 Socket strip ............................................................................................. 4

2.4 Resting surface ....................................................................................... 5

2.4.1 Tilt mechanism for resting surface ............................................ 6

2.4.2 Pneumatic system (extraction) ................................................. 6

3 Mattress heating 7

3.1 Resting-surface heating concept ............................................................ 7

3.1.1 Mattress .................................................................................... 7

3.1.2 Heating panel ............................................................................ 8

3.1.3 Control unit ............................................................................... 8

3.1.4 Block diagram of mattress heating ........................................... 9

3.2 Functional description and software specifications ............................... 10

3.2.1 Front panel .............................................................................. 10

3.2.2 Measurement of mattress temperature ....................................11

3.2.3 Alarms ......................................................................................11

3.2.4 Software safety features ......................................................... 13

3.3 Mattress heating electronics ................................................................. 15

3.3.1 Design and general overview ................................................. 15

3.3.2 Block diagram of mattress heating ......................................... 17

3.3.3 Power PCB ............................................................................. 18

3.3.4 Controller PCB ........................................................................ 23

Schutzvermerk DIN 34 beachten. Copyright reserved.

F6132200T01IVZ.fm 09.03.01

6132.200 Babytherm 8000 Version 2.0 Contents Page 1 of 28

Page 2

Dräger Medizintechnik

D

Contents

3.3.5 Display PCB and keypad ........................................................ 27

3.3.6 Mains switch with auxiliary contacts ....................................... 27

3.3.7 Transformer and mains voltage conversion ............................ 28

4 Radiant heater 600 W 28

Schutzvermerk DIN 34 beachten. Copyright reserved.

F6132200T01IVZ.fm 09.03.01

6132.200 Babytherm 8000 Version 2.0 Contents Page 2 of 28

Page 3

Dräger Medizintechnik

Function description

1 General

The Babytherm 8000 is a modular system for providing:

− Heat therapy

− Oxygen and aerosol therapy

− Reanimation

− Intensive care for premature babies, new-born babies and infants.

D

2 Mechanical system

2.1 Trolley

The Babytherm 8000 is available with various trolleys:

Units with no electrical height adjustment:

Small base plate for heated cot

Large base plate for intensive-care model or reanimation unit. This version permits

installation of a radiant heater.

Units with electrical height adjustment

Small trolley for heated cot

Large trolley for intensive-care module or reanimation unit. This version permits

installation of a radiant heater.

2.2 Base plate for resting surface

The resting surface is attached to the base plate. The Babytherm 8000 is available

with various base plates:

− Small base plate and small trolley for heated cot.

− Large base plate and large trolley for intensive-care model or reanimation unit.

This version permits installation of a radiant heater

Schutzvermerk DIN 34 beachten. Copyright reserved.

F6132200T01.fm 09.03.01

6132.200 Babytherm 8000 Version 2.0 Function description Page 3 of

28

Page 4

Dräger Medizintechnik

D

2.3 Socket strip

Caution: The 3x socket strip beneath the base plate of the resting surface is only

intended for:

− Babytherm mattress heating

− Dräger radiant heater 600W

− Babytherm height adjustment

Other loads are not permitted!

Electrical safety is checked by way of the common power cord.

Schutzvermerk DIN 34 beachten. Copyright reserved.

F6132200T01.fm 09.03.01

6132.200 Babytherm 8000 Version 2.0 Function description Page 4 of

28

Page 5

Dräger Medizintechnik

D

2.4 Resting surface

The resting-surface assembly is made up of the following:

− Resting surface

− Tilt-mechanism bottom section, bolted to base plate

− Mechanical system for tilt mechanism

− 4 corners for holding glass

Various side panels can be attached to the resting surface:

− 23 cm high side panels for heated cot or

− 15 cm deep side panels for reanimation unit

The resting surface comes with (heated cot and without reanimation unit) mattress

heating:

With mattress heating:

− Gel mattress 2M 20 827

The mattress heating panel is only intended for the gel mattress 2M 20 827!

Danger:

The gel mattress 2M 20 827 may only be used in the Babytherm 8000 if

resting-surface heating has been fitted!

The gel mattress 2M 20 827 is not to be used in the Babytherm 4200 or in

other heated cots with a heating-panel temperature in excess of 40 °C

danger of burns!

Keep sharp objects away from gel mattress danger of damage!

Without mattress heating:

− Foam mattress 2M 21 012

− Openings which are not needed are sealed with dummy plugs.

Schutzvermerk DIN 34 beachten. Copyright reserved.

F6132200T01.fm 09.03.01

6132.200 Babytherm 8000 Version 2.0 Function description Page 5 of

28

Page 6

Dräger Medizintechnik

D

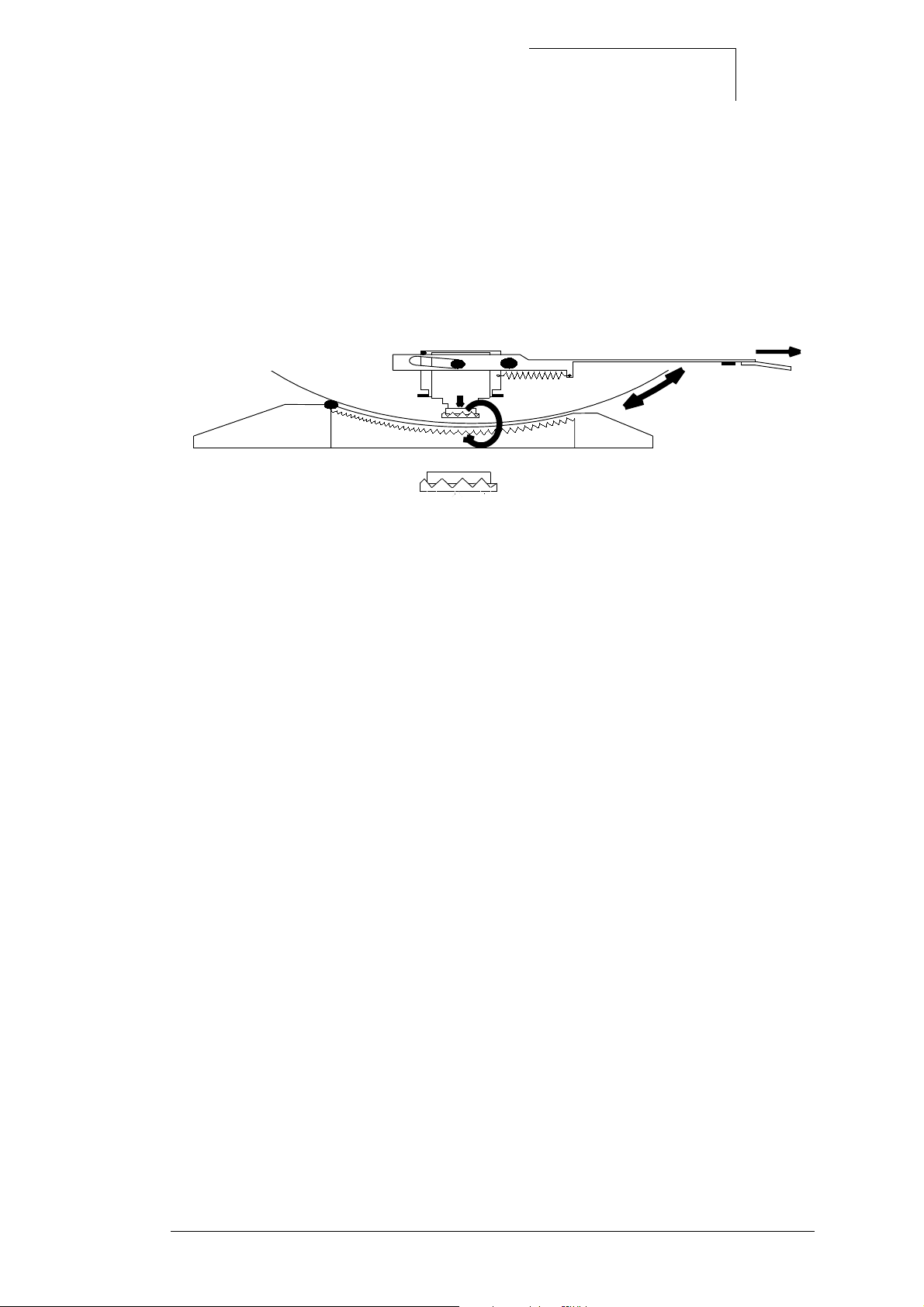

2.4.1 Tilt mechanism for resting surface

The bottom section of the resting-surface tilt mechanism is connected to the base

plate by means of 4 hexagon socket-head bolts. The resting surface is positioned in

this section and is supported on one side by rollers and on the other by teflon strips as

anti-friction bearings. The resting surface is fixed by means of gear teeth in the bottom section and the mechanical-system latch of the resting-surface tilt mechanism.

A

B

C

E

F

G

D

Fig. 1: Tilt mechanism for resting surface

Pulling the lever A presses the latch B downwards out of the gear teeth C and the resting surface D can be swivelled +15° to -20° out of the basic position. The lever is

pulled back again in each case by 2 springs and the resting surface thus fixed in position.

2.4.2 Pneumatic system (extraction)

Two extractors are provided for the Babytherm 8000:

− Extractor -0.9 bar 2M 85 040

− Extractor -0.5 bar 2M 85 045

The infinite vacuum is generated by an ejector. The extractor is supplied by way of

the O2 or compressed-air system. All plastic parts subject to contamination can be

sterilised in an autoclave at temperatures up to 134 °C.

Schutzvermerk DIN 34 beachten. Copyright reserved.

F6132200T01.fm 09.03.01

6132.200 Babytherm 8000 Version 2.0 Function description Page 6 of

28

Page 7

Dräger Medizintechnik

D

3 Mattress heating

3.1 Resting-surface heating concept

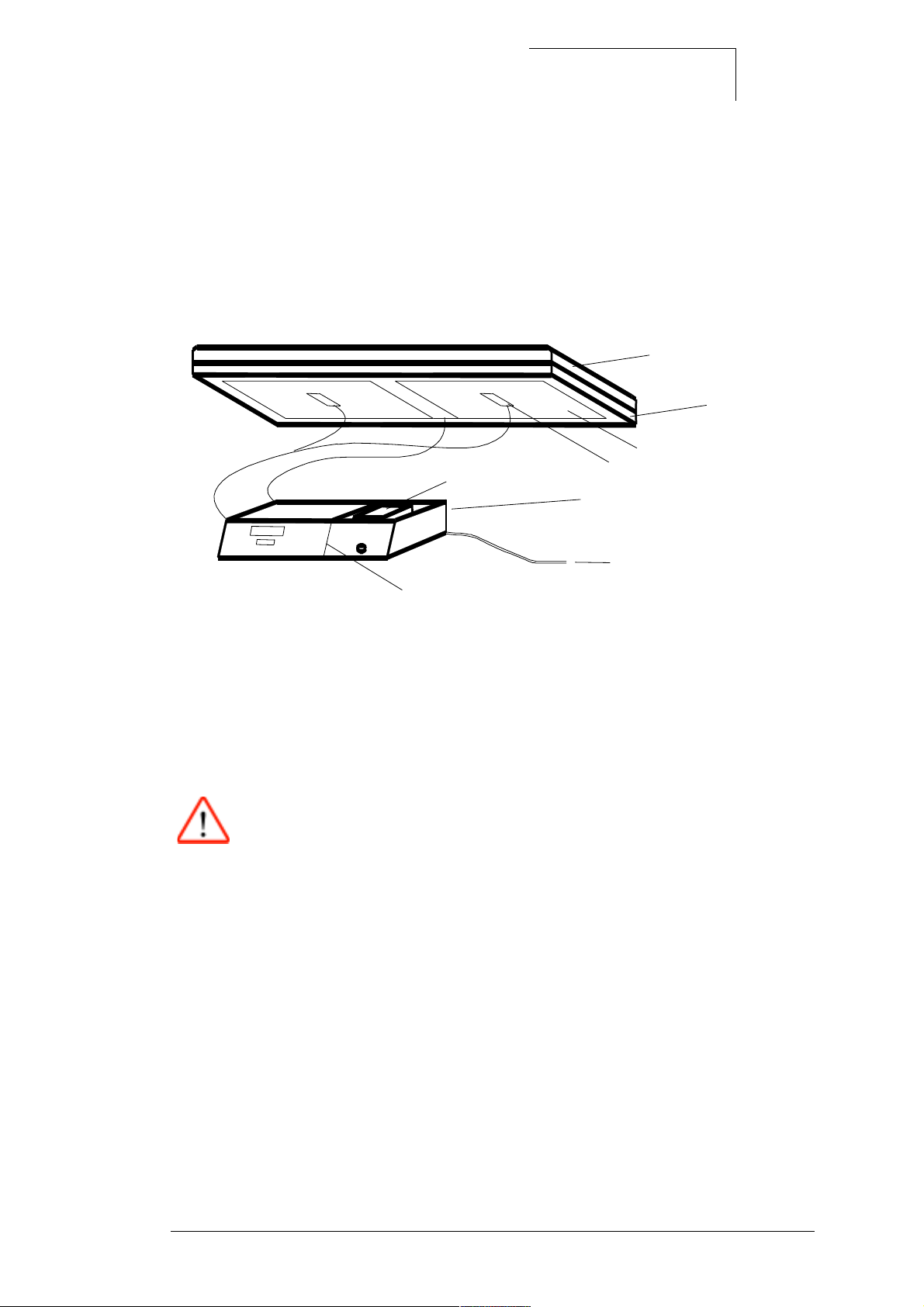

The heated cot and OC versions feature a new resting-surface heater. The heating

system is made up of the following components:

HHT Gel Mattress

Aluminium plate 6mm

Heating foil

Temp. Sensors(2x2 NTCs)

Control unit

Power cord

Partition of prim./ sec. voltage

Fig. 2: Heating system

3.1.1 Mattress

The mattress consists of a thermally conductive gel (HHT = high heat transfer).

Danger:

This gel mattress is not to be used in the Babytherm 4200!

Schutzvermerk DIN 34 beachten. Copyright reserved.

F6132200T01.fm 09.03.01

6132.200 Babytherm 8000 Version 2.0 Function description Page 7 of

28

Page 8

Dräger Medizintechnik

D

3.1.2 Heating panel

The heating panel is inserted from above into the resting surface and secured with 4

screws. An all-round seal prevents the ingress of dirt and moisture. The heating

panel is made of a backing plate (6 mm aluminium) with bonded -on heating foil

24V/120W and 2 bolted-on twin temperature sensors.

3.1.3 Control unit

This unit is secured in position in the resting-surface housing with 2 slide locks.

The control unit is made up of the following components:

Connection protective

ground PCB Power + PCB Controller

V2 V11

Transformer

Connection heating

Mains input with fuses

PCB Power

R22

Horn

Relay

Connection

Sensors

Keyboard

Fuses

F2 F1

EPROM

Test points

Gold Cap

PCB Controller

4 Service-LEDs

Switch

PCB Display

Fig. 3: Control unit

− Touch-sensitive keys with LEDs

− Transformer with 4KV isolation

− Controller PCB (P 68332, EPROM, I/Os, AD conversion ...)

− Power PCB (actuation of heating, voltage regulator ...)

− Display PCB (7-segment displays with actuation, keypad interrogation)

− Accessory set for voltage version (adapter 100-127 V and other fuse links in

mains input)

Schutzvermerk DIN 34 beachten. Copyright reserved.

F6132200T01.fm 09.03.01

6132.200 Babytherm 8000 Version 2.0 Function description Page 8 of

28

Page 9

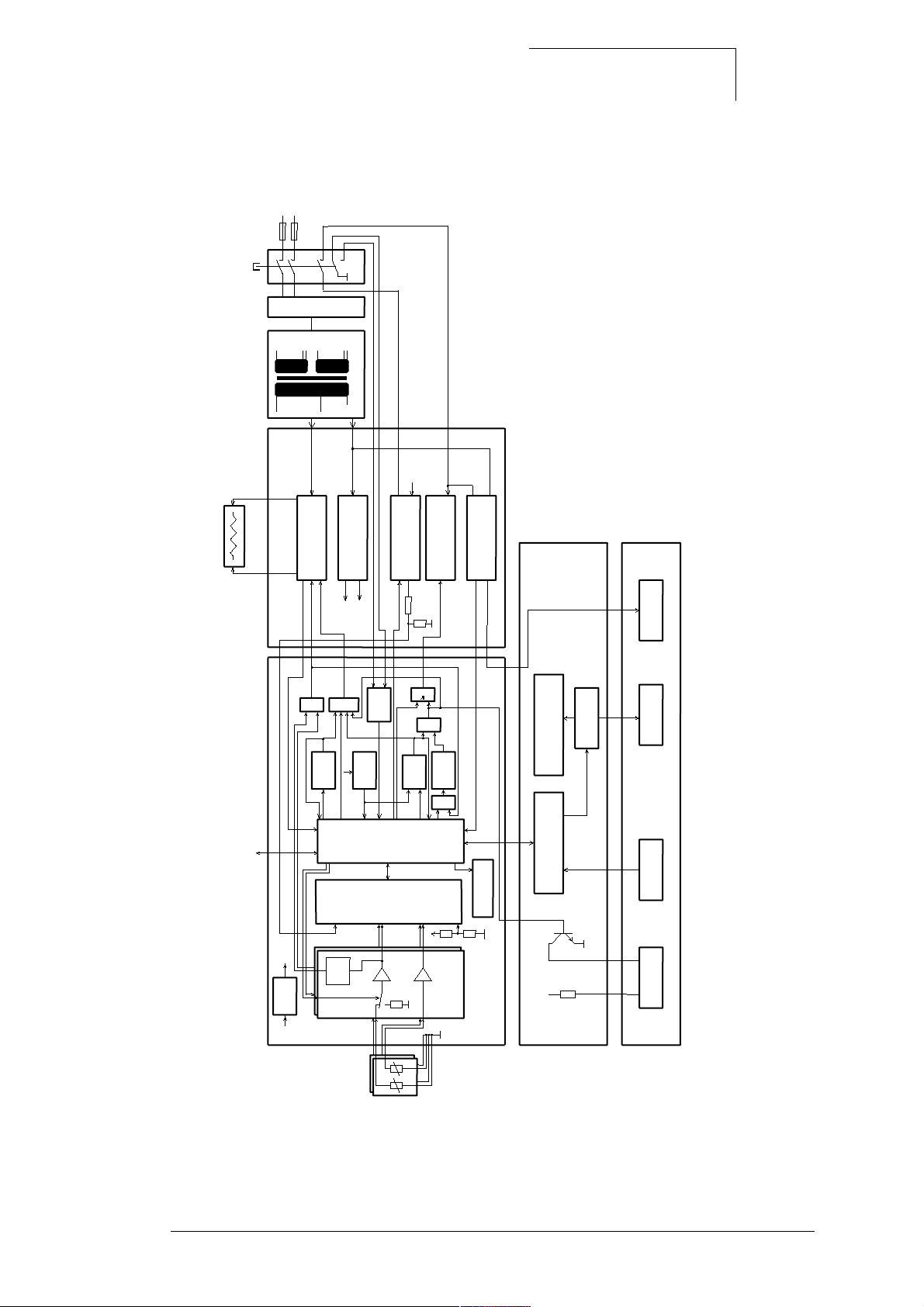

3.1.4 Block diagram of mattress heating

Main switch

120V

Voltage selection *

100V

0V

100V

24V

120V

9V

120V

0V

9V

Transformer

+5VD

100 V = Adapter YY YY YYY

230 / 240 V = no adapter necessary

110 / 127 V = Adapter XX XX XXX

* Voltage selection

0V

24V

PCB Power

Dräger Medizintechnik

D

Heater 24V/120W

Feedb. Heater

RS232

Overtemp.

+5VA

Heater Control

and monitoring

Relay on

Heater on

&

Heater

Mono

Comp.

41,6 C

+5VD

Power supply

+5VD

+9VDC

SQ

&

+5VD

Powerfail

Reset

Akku test

RQ

Q

12 bit ADC

CPU

68332

12 bit ADC

41,6 C

Horn

Gold Cap (Battery)

Horn on

1

INOP

&

Q

Mono

INOP LED

SQ

RQ

&

+5VA

Amplifier (2x)

and LED control

Powerfail monitoring

Powerfail

Powerfail

4x Service LEDs

Decoder

7-Segment-Display

Display and Key Controller

INOP

+5VD

Powerfail LED

LEDs

Keys

INOP LED

PCB Display

+9VDC

2 NTCs (2x)

PCB Controller

Keyboard

Fig. 4: Block diagram of mattress heating

Schutzvermerk DIN 34 beachten. Copyright reserved.

F6132200T01.fm 09.03.01

6132.200 Babytherm 8000 Version 2.0 Function description Page 9 of

28

Page 10

Dräger Medizintechnik

D

3.2 Functional description and software specifications

3.2.1 Front panel

The front panel contains the following components:

Touch-sensitive keys

− Range expansion

− Positive setpoint temperature and negative setpoint temperature. The setpoint

can be adjusted in 0.1 °C increments: 35.0 °C - 37.0 °C (standard range without

expansion) or 30.0 °C - 38.5 °C (with range expansion)

− 15 min. suppression for active alarms

− "Check" key for testing display elements and horn

Mains on/off switch

7-segment displays

− 3-digit display for measured value. Display range 5 °C - 45 °C.

− 3-digit display for setpoint. 35.0 °C - 37.0 °C (standard range without expansion)

or 30.0 °C - 38.5 °C (with range expansion)

LEDs

− Range expansion on (in range expansion key)

− Alarm tone suppression on (in alarm tone suppression key)

− Excess temperature

− Desired/actual-value difference 1.0 °C

− Power failure

− Heating status optional: A heating LED can be called up as decimal point by

jointly pressing for 5s the positive and negative setpoint keys in the 7-segment

display of the setpoint display. The display is generated from the heating checkback signal.

Schutzvermerk DIN 34 beachten. Copyright reserved.

F6132200T01.fm 09.03.01

6132.200 Babytherm 8000 Version 2.0 Function description Page 10 of

28

Page 11

Dräger Medizintechnik

3.2.2 Measurement of mattress temperature

The temperatures are measured at two different locations on the heating panel. The

higher temperature in each case is displayed:

T Mattress = T Display = T Meas. - T Offset

T Offset = 1.0 °C over entire measuring range

A second temperature sensor in each case at the measurement location supplies redundant measured values. A sensor warning is given in the case of a deviation of

more than 0.5 °C at a measurement point.

To avoid temperatures which could endanger patients, a processor-independent

deactivation path ensures that the maximum heating-panel temperature of 42 °C is

not exceeded.

D

3.2.3 Alarms

The mattress heating features a graded warning system. Faults detected are reported in line with their significance.

A setpoint deviation results in an intermittent alarm tone which can be acoustically

suppressed for 15 minutes by way of the "alarm suppression" key. All other faults

lead to a continuous alarm tone which cannot be suppressed. Corresponding alarm

LEDs or the measured value display flash(es) with all alarms.

Setpoint deviation alarm

− Measured value display flashes

− Appropriate alarm LED flashes

− Intermittent alarm tone (can be suppressed for 15 minutes)

The alarm tone for inadequate mattress temperature is suppressed automatically following cold start for a maximum of one hour. If the value is more than 1.0 °C below

the setpoint during this period, the alarm is displayed during the suppression period

by the corresponding LED; the measured value display does not flash and the horn is

not active.

The warning suppression time is prematurely cancelled if the measured value is not

more than 1.0 °C below the setpoint.

The LED "alarm tone suppression" lights continuously if acoustic alarms have been

suppressed.

If a further alarm situation arises during the alarm tone suppression time, the acoustic

warning is reactivated and the alarm tone suppression period cancelled.

Schutzvermerk DIN 34 beachten. Copyright reserved.

F6132200T01.fm 09.03.01

6132.200 Babytherm 8000 Version 2.0 Function description Page 11 of

28

Page 12

Dräger Medizintechnik

Excess temperature alarm 40.0 °C

− Measured value display flashes

− Appropriate alarm LED flashes

− Continuous horn tone cannot be suppressed

− Heating off

The alarm is automatically retracted if the displayed value is 0.5 °C over the setpoint.

Safety shutdown 42 °C

If a heating panel temperature of 42.0 °C is reached, the heating is automatically shut

down via a processor-independent deactivation path employing a safety relay.

− Measured value display flashes

D

− Appropriate alarm LED flashes

− INOP LED lights

− Continuous horn tone cannot be deactivated

This alarm can only be reset with the on/off switch.

Sensor alarm

Faults in the temperature sensors or in the sensing procedure in the following alarm

message:

− The three centre segments flash in the measured value display

− Continuous horn tone cannot be deactivated

− Heating off

INOP

Serious hardware or software errors, which make operation impossible for technical

or safety reasons, lead to total failure of the mattress heating. The independent shutdown path ensures that the heating is always deactivated. The following alarm message is given:

− INOP LED lights

− Continuous horn tone cannot be deactivated

− Where technically possible, the current measured value flashes on the display

The unit is inoperative.

Schutzvermerk DIN 34 beachten. Copyright reserved.

F6132200T01.fm 09.03.01

6132.200 Babytherm 8000 Version 2.0 Function description Page 12 of

28

Page 13

Dräger Medizintechnik

3.2.4 Software safety features

All errors detected in the course of the tests described below produce an INOP error

message.

RAM test

The address area of the RAM is tested in the time period between switch-on and

bootstrapping of the operating system.

EEPROM test

The EEPROM is checked following switch-on of the unit by interrogating one test cell.

The test cells are then rewritten and compared to the reference pattern again if there

is a lack of coincidence with the reference pattern. An INOP alarm is triggered if the

reference pattern can still not be read back.

D

ROM test

After switching on the unit, the ROM contents is checked by way of signature formation (CRC). ROM tests are executed cyclically during operation.

Watchdog tests

The run time of the two watchdogs is checked by way of a software counter.

Display driver test

The internal RAM of the keypad and display module 82C79 is read back immediately

after display writing and compared to the data request.

Logic monitoring of program run

The function of tasks relevant to safety are checked logically by a monitoring task.

Schutzvermerk DIN 34 beachten. Copyright reserved.

F6132200T01.fm 09.03.01

6132.200 Babytherm 8000 Version 2.0 Function description Page 13 of

28

Page 14

Dräger Medizintechnik

10-minute test

The 10-minute test is a routine in which the function of all testable hardware safety

features is checked at intervals of 10 minutes:

− Excess temperature comparator and independent shutdown path for heating

− Accuracy of mattress-temperature sensor circuit

− A/D converter and multiplexer

− Heating watchdog

− Analog +5 V voltage monitoring

Switch-on test

Switch on unit:

D

− All displays and horn are actuated for approx. 2 s

A self-test which checks the function of the processor and its peripherals is implemented during this period.

Following completion of the self-test, a setpoint of 37.0 °C is indicated with the

measured value and the label "SEt" being alternately presented on the measured

value display. The "SEt" display is a prompt for adjusting or acknowledging the setpoint.

The first ten minute test is implemented after the self-test as can be heard from the

safety relay switching.

Schutzvermerk DIN 34 beachten. Copyright reserved.

F6132200T01.fm 09.03.01

6132.200 Babytherm 8000 Version 2.0 Function description Page 14 of

28

Page 15

3.3 Mattress heating electronics

3.3.1 Design and general overview

Integration of electronics in housing

Dräger Medizintechnik

D

Fig. 5: Electronic module

The electronics module is held in place in the opening in the housing by two locks on

the side. The mains input is located on the back with the connectors for the sensors

and the heating being provided on the cover.

Schutzvermerk DIN 34 beachten. Copyright reserved.

F6132200T01.fm 09.03.01

6132.200 Babytherm 8000 Version 2.0 Function description Page 15 of

28

Page 16

Dräger Medizintechnik

D

Mechanical integration of electronic components into electronics module

In the illustration below the keypad with the display PCB has been tilted forwards and

the power PCB (which is above the controller PCB in the installed condition) swivelled

out:

V2 V11

Connection

heating

R22

Relay

Fuses

F2 F1

Connection protective

conductorr PCB Power

+ PCB Controller

Connection

Sensors

Keyboard

PCB Power

Test points

PCB Controller

EPROM

RS232

Gold Cap

4 Service-LEDs

PCB Display

Horn

Mains input with fuses

Transformer

Switch

Fig. 6: Electronic components

Schutzvermerk DIN 34 beachten. Copyright reserved.

F6132200T01.fm 09.03.01

6132.200 Babytherm 8000 Version 2.0 Function description Page 16 of

28

Page 17

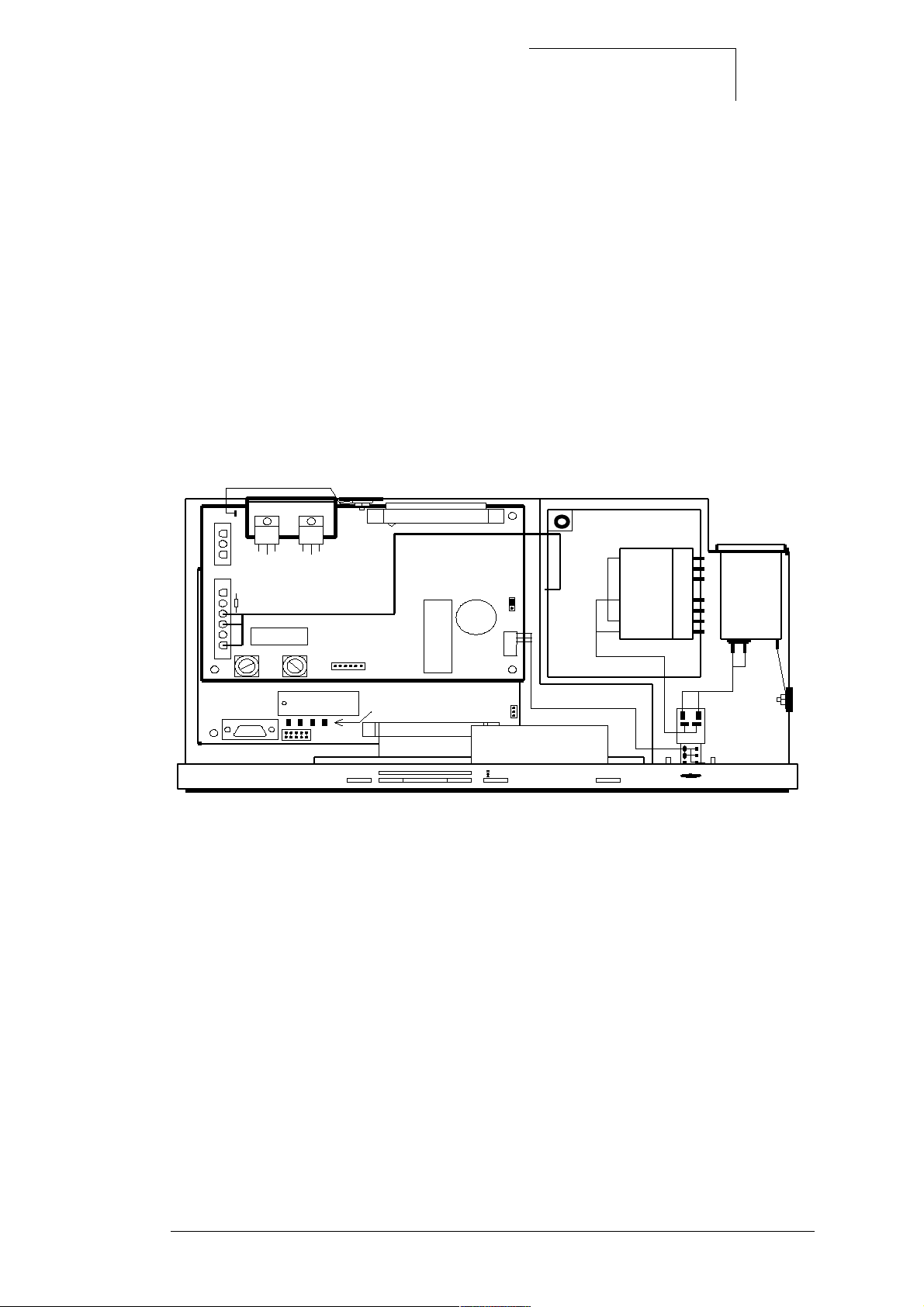

3.3.2 Block diagram of mattress heating

Main switch

120V

Voltage selection *

100V

0V

100V

120V

9V

24V

120V

0V

9V

Transformer

+5VD

230 / 240 V = no adapter necessary

* Voltage selection

0V

24V

PCB Power

Dräger Medizintechnik

100 V = Adapter YY YY YYY

110 / 127 V = Adapter XX XX XXX

D

Heater 24V/120W

Feedb. Heater

RS232

Overtemp.

+5VA

Heater Control

and monitoring

Relay on

Heater on

&

Heater

Mono

Comp.

+5VD

Power supply

+5VD

+9VDC

&

+5VD

Powerfail

Reset

41,6 C

Akku test

SQ

RQ

Q

12 bit ADC

CPU

68332

12 bit ADC

Gold Cap (Battery)

Horn on

1

&

Q

Mono

SQ

RQ

+5VA

41,6 C

Horn

INOP

INOP LED

&

Amplifier (2x)

and LED control

Powerfail monitoring

Powerfail

Powerfail

4x Service LEDs

Decoder

7-Segment-Display

Display and Key Controller

INOP

+5VD

Powerfail LED

LEDs

Keys

INOP LED

PCB Display

+9VDC

2 NTCs (2x)

PCB Controller

Keyboard

Fig. 7: Block diagram of mattress heating

Schutzvermerk DIN 34 beachten. Copyright reserved.

F6132200T01.fm 09.03.01

6132.200 Babytherm 8000 Version 2.0 Function description Page 17 of

28

Page 18

Dräger Medizintechnik

3.3.3 Power PCB

The power PCB features the following function blocks:

− Heating actuation and monitoring

− Voltage generation 5 V DC

− Actuation of horn and power failure recognition

D

Schutzvermerk DIN 34 beachten. Copyright reserved.

F6132200T01.fm 09.03.01

6132.200 Babytherm 8000 Version 2.0 Function description Page 18 of

28

Page 19

Heating actuation and monitoring

+ 5 VD

K1

Relay on

+ 5 VD

Heating on

Dräger Medizintechnik

F2

V2

24 V AC

D

Feedback

heating

Mono

Heating

24 V / 5 A

Fig. 8: Heating actuation and monitoring

− The heating runs on 24 VAC.

− The heating circuit is electrically isolated from the remainder of the electronic

system

− The heating circuit is fused (F2) on the power PCB.

− The safety relay K1 can interrupt the heating circuit in the event of a fault.

− In normal operation the heating is switched by the triac VA. An upstream zero-

voltage and phase-group switch ensures that the heating is only switched on in a

positive AC voltage pass and switched off when negative.

− The voltage drop at the heating generates pulses by way of a parallel optocoup-

ler which in turn actuate a monoflop. The output of the mono indicates the operating status of the heating.

Schutzvermerk DIN 34 beachten. Copyright reserved.

F6132200T01.fm 09.03.01

6132.200 Babytherm 8000 Version 2.0 Function description Page 19 of

28

Page 20

Voltage generation 5 V DC

F1

9 V AC

Dräger Medizintechnik

V11

+ 5 V

Regl.

D

+ 5 VD

GNDD

+ 5 V

Regl.

PCB Controller

+ 5 VA

GNDA

Fig. 9: Voltage generation 5 V DC

− The voltage supply for the 5 V is fused (F1) on the power PCB.

− The + 5 V digital supply voltage (+ 5 VD) is regulated on the power PCB.

− The + 5 V analog supply voltage (+ 5 VA) is regulated on the controller PCB.

Schutzvermerk DIN 34 beachten. Copyright reserved.

F6132200T01.fm 09.03.01

6132.200 Babytherm 8000 Version 2.0 Function description Page 20 of

28

Page 21

Dräger Medizintechnik

Actuation of horn and mains failure recognition

+ 5 VD

D

9 V AC

Batt.-Test

Test VGC

+ 5 VD

V15

VGC

Horn

V4

Gold CAP

Mono

Mains-switch auxiliary contact

Mains failure

V10

Horn

Test

mains failure

ResetQ

PCB Controller

V12 V14

V13

+ 5 VD

Fig. 10: Actuation of horn and mains failure recognition

Schutzvermerk DIN 34 beachten. Copyright reserved.

F6132200T01.fm 09.03.01

6132.200 Babytherm 8000 Version 2.0 Function description Page 21 of

28

Page 22

Dräger Medizintechnik

− The signal "mains failure" is generated if there are no rectified 9 VAC half-waves

and the monoflop is not retriggered.

− The supply for the horn and the mains failure LED is provided by a "gold cap" 3.3

F capacitor with the voltage VGC by way of the mains-switch auxiliary contact

which is made during operation.

− The voltage of the gold cap "VGC" can be measured by way of the deactivation

of the charging voltage via V15 (battery test) using a voltage divider (VGC test).

− The horn is normally switched by the processor via V12.

− In the event of mains failure, actuation of the horn and mains failure LED is by

way of the controller PCB using the signals "ResetQ" or "Mains failure test":

ResetQ ==> + 5 VD is less than 4.6 V

Mains failure test ==> Test signal from processor

Using these low-active signals the horn is actuated via V13 and V14 with the mains

failure LED being actuated via V13 and V10. The mains failure LED is located on the

keypad.

D

Schutzvermerk DIN 34 beachten. Copyright reserved.

F6132200T01.fm 09.03.01

6132.200 Babytherm 8000 Version 2.0 Function description Page 22 of

28

Page 23

Dräger Medizintechnik

3.3.4 Controller PCB

The following function blocks are located on the controller PCB:

− Processor

− Processor clock pulse generation

− RAM, EPROM

− EEPROM

− I/O lines

− LEDs

− INOP watchdogs

− Voltage monitoring

− Measured value acquisition

D

− Read-in of position of mains-switch auxiliary contacts

Processor

Use is made as Processor D1 of the MC68332 microcontroller. This controller is part

of the 683XX Motorola family. The 68332 features the following in addition to a 32-bit

CPU.

"SIM" (system integration module) with:

− Timer

− Chip-select decoder

− Bus-error decoder

− DTACK generator

2K-byte static RAM

"QSM" (Queued serial module) with:

− Asynchronous interface

− Synchronous interface

TPU (Timing processor unit), which provides time-controlled functions on 16 channels. For example pulse-duration modulation for actuation of heating.

Schutzvermerk DIN 34 beachten. Copyright reserved.

F6132200T01.fm 09.03.01

6132.200 Babytherm 8000 Version 2.0 Function description Page 23 of

28

Page 24

Dräger Medizintechnik

Processor clock pulse generation

The circuit with the quartz clock generator G1 corresponds to the recommendation

given in the Motorola user's manual. This clock pulse is multiplied in the 68332 by a

PPL up to a level of max. 16.67 MHz. The voltage supply for the internal PPL is provided by way of the PIN VDDSyn.

RAM, EPROM

The RAM (D3) and EPROM (D2) both feature 128K-bytes. The EPROM range can be

extended with 0 ohm resistors to 512K-bytes.

EEPROM

The serial EEPROM (N9) has a memory capacity of 128-words and is used to store

non-volatile data such as warm/cold-start recognition.

D

I/O lines

The following lines of the processor D1 are used as simple outputs for the Babytherm

mattress heating.

Signal name Pin Significance

ANASW1 IRQ1 Signal "analog switch 1" switches analog

channel 0 between sensor and reference

resistance 41.6 °C:

Low = Reference resistance

High = Temperature sensor, resting surface

ANASW2 IRQ2 Signal "analog switch 2" switches analog

channel 2 between sensor and reference

resistance 41.6 °C :

Low = Reference resistance

High = Temperature sensor, resting surface

HUPE1Q SIZO Actuation, horn

LED1 DSACK1Q Actuation, service LED 1

LED2 AVECQ Actuation, service LED 2

LED3 RMCQ Actuation, service LED 3

NTZAUSFTST DSQ Horn and mains failure LED test

TP2 TP2 Heating on (linked to AND gate with emer-

gency stop = excess temperature comparators and watchdog)

OUTNTZ0 IRQ5 Gold cap test

Schutzvermerk DIN 34 beachten. Copyright reserved.

F6132200T01.fm 09.03.01

6132.200 Babytherm 8000 Version 2.0 Function description Page 24 of

28

Page 25

Dräger Medizintechnik

LEDs

There are four service SMD LEDs on the controller PCB:

− Reset LED (V14):

off when processor is in "halt" or "reset" status

lights in normal operation

− LED 1 - 3 (V1, V2, V3):

Assigned by software depending on operating status.

INOP watchdogs

There are two watchdogs (D21, D22) on the controller PCB as safety features. Both

watchdogs take the form of counters which have an independent 32.678 KHz quartz

oscillator (G2) as time base.

The watchdog D21 switches off the heating if there is no retriggering. This watchdog

is tested during operation.

D

The watchdog D22 activates the INOP LED and the horn if there is no retriggering.

This watchdog is tested during operation.

Voltage monitoring

A voltage detector (V50) monitors the 5 V digital voltage. If this voltage drops below

4.6 V, the horn and INOP LED are actuated and the heating switched off independently of the processor.

Schutzvermerk DIN 34 beachten. Copyright reserved.

F6132200T01.fm 09.03.01

6132.200 Babytherm 8000 Version 2.0 Function description Page 25 of

28

Page 26

Measured value acquisition

V5

+ 5 VA

Vref

Temp.Hybrid M1

Dräger Medizintechnik

Comp.

41,6 C

UETEMP1Q

D

V8

V4

41,6 C

V9

41,6 C

+ 5 VA

V6

Temp.Hybrid M2

Temp.Hybrid M3

V7

ANASW1

Vref

Vref

ANASW2

+ 5 VA

Comp.

41,6 C

Vref

Vref

-

+

N6

UETEMP2Q

Vref

Temp.Hybrid M4

ADC

+ 5 VD + 5 VA

Test VGC

Fig. 11: Measured value acquisition

The four temperature sensors are read in on the controller PCB via four temperature

hybrids and a serial 12-bit A/D converter with integrated multiplexer.

Schutzvermerk DIN 34 beachten. Copyright reserved.

F6132200T01.fm 09.03.01

6132.200 Babytherm 8000 Version 2.0 Function description Page 26 of

28

Page 27

Dräger Medizintechnik

With two temperature channels the temperature hybrids can be switched via FETS

with the signals "ANASW1" and "ANASW2" by the NTCs to 41.6 °C resistors, so as to

be able to test the comparators with the processor-independent heating deactivation

path (excess temperature test):

ANASW1/2 = LOW ==> Reference resistance

ANASW1/2 = High ==> Measurement resistance

The outputs of the comparators are additionally read in by the processor. The temperature hybrids and the A/D converter have their own reference voltage. Furthermore,

the gold cap voltage from the power PCB and a test channel can be read in by the

A/D converter.

The +5 V analog voltage is generated on the controller PCB (refer also to block diagram in Voltage generation 5 V DC.

D

Read-in of position of mains-switch auxiliary contacts

The flip-flop D9 is used to read in the position of the mains-switch auxiliary contacts

for mains failure recognition.

3.3.5 Display PCB and keypad

The display PCB has an intelligent display and keypad controller for reading in the

keys and actuating the displays. All LEDs are located on the keypad. The LED

"INOP" is actuated by the controller PCB and the "Mains failure" LED by the power

PCB.

3.3.6 Mains switch with auxiliary contacts

The mains switch in the keypad has four switching/changeover contacts:

− 2 switching contacts for mains voltage

− 1 switching contact for mains failure alarm

− 1 changeover contact for readout of switch position for warm/cold-start recogni-

tion

Schutzvermerk DIN 34 beachten. Copyright reserved.

F6132200T01.fm 09.03.01

6132.200 Babytherm 8000 Version 2.0 Function description Page 27 of

28

Page 28

Dräger Medizintechnik

3.3.7 Transformer and mains voltage conversion

The two-chamber transformer has a minimum insulation voltage of 4 KV. By way of

an adapter the mattress heating can be switched from 230/240 V to 100 V or 120 V on

the primary side. Caution: Other mains input fuses are then required.

Note: The electrical height adjustment of Babytherm cannot be switched over.

24 V/5 A can be tapped for the heating on the secondary side. The supply voltages for

the electronics are generated by way of the 9 V centre tap.

D

4 Radiant heater 600 W

Refer to technical documentation radiant heater RH 600.

Schutzvermerk DIN 34 beachten. Copyright reserved.

F6132200T01.fm 09.03.01

6132.200 Babytherm 8000 Version 2.0 Function description Page 28 of

28

Loading...

Loading...