Page 1

Specifications

Systems Operation

Testing & Adjusting

Lift Trucks Power Train

D20S-3, D25S-3, D30S-3, D32S-3

D20S-3(B3.3), D25S-3(B3.3), D30S-3(B3.3),

D32S-3(B3.3), D33S-3(B3.3)

G20S-3, G25S-3, G30S-3

GC20S-3, GC25S-3, GC30S-3

G20E-3, G25E-3, G30E-3, G32E-3

GC20E-3, GC25E-3, GC30E-3, GC32E-3

G20P-3, G25P-3, G30P-3, G32P-3

GC20P-3, GC25P-3, GC30P-3, GC32P-3

SB2102E01

Jan.2004

Page 2

Important Safety Information

Most accidents involving product operation, maintenance and repair are caused by failure to observe basic safety

rules or precautions. An accident can often be avoided by recognizing potentially hazardous situations before an

accident occurs. A person must be alert to potential hazards. This person should also ha v e the necessary

training, skills and tools to perform these functions properly.

Read and understand all safety precautions and warnings before operating or performing lubrication,

maintenance and repair on this product.

Basic safety precautions are listed in the “Safety” section of the Service or Technical Manual. Additional safety

precautions are listed in the “Safety” section of the owner/operation/maintenance publication.

Specific safety warnings for all these pub lications are pro vided in the description of operations where hazards

exist. W ARNING labels have also been put on the product to provide instructions and to identify specific hazards.

If these hazard warnings are not heeded, bodily injury or death could occur to you or other persons. W arnings in

this publication and on the product labels are identified by the f ollo wing symbol .

WARNING

Improper operation, lubrication, maintenance or repair of this product can be dangerous and could result

in injury or death.

Do not operate or perform any lubrication, maintenance or repair on this product, until you have read and

understood the operation, lubrication, maintenance and repair inf ormation.

Operations that may cause product damage are identified by NOTICE labels on the product and in this

publication.

DAEWOO cannot anticipate every possible circumstance that might involv e a potential hazard. The warnings in

this publication and on the product are therefore not all inclusiv e. If a tool, procedure, work method or operating

technique not specifically recommended by DAEWOO is used, you must satisfy yourself that it is safe for you and

others. Y ou should also ensure that the product will not be damaged or made unsafe by the operation, lubrication,

maintenance or repair procedures you choose.

The information, specifications, and illustration in this publication are on the basis of information available at the

time it was written. The specifications, torques, pressures, measurements, adjustments, illustrations, and other

items can change at any time. These changes can affect the service given to the product. Obtain the complete

and most current information before starting any job. DAEWOO dealers have the most current inf ormation

available.

1

Page 3

Page 4

Index

Specifications

Drive Axle Mounting Group....................................... 14

Drive Tire Installation ................................................ 12

Drive Wheel Installation ............................................ 13

Final Drives And Wheels...........................................11

Forward / Reverse Clutch Elements ........................... 6

Forward And Reverse Control Group ......................... 5

Tightening Torques .....................................................9

Torque Converter........................................................ 5

Transmission Solenoid ...............................................5

Valve Block Elements .................................................7

Valve Spring in Transmission Bearing Plate ...............8

Systems Operation

General Information .................................................. 15

Transmission and Drive Axle ....................................16

Basic Control Scheme........................................... 34

Drive Axle .............................................................. 21

Hydraulic System .................................................. 24

Torque Converter ..................................................16

Transmission......................................................... 17

Transmission Hydraulic System............................ 25

Testing And Adjusting

Troubleshooting ........................................................ 38

Check List During Operation.................................39

Check List From Operation Noises ....................... 40

Check List From Pressure Tests ........................... 41

Visual Checks .......................................................38

Transmission and Drive Axle Tests And Adjustments

.................................................................................. 44

Adjustment of Crown Wheel.................................. 58

Adjustment of Wheel Bearings.............................. 60

Adjustments on Drive Axle and Transmission ....... 55

Converter Stall Test ............................................... 46

Electric Control System Tests ............................... 50

Inching Pedal Adjustment......................................53

Installation of Pinion .............................................. 57

Maintenance Transmission and Drive Axle ........... 48

Transmission Pressure Tests ................................ 44

Power Train Index

3

Page 5

Page 6

Specifications

Torque Converter

(1) Torque for six bolts that hold torque converter drive

plate to the flywheel

…………………………………...45 ± 7 N·m (33 ±5 lb·ft)

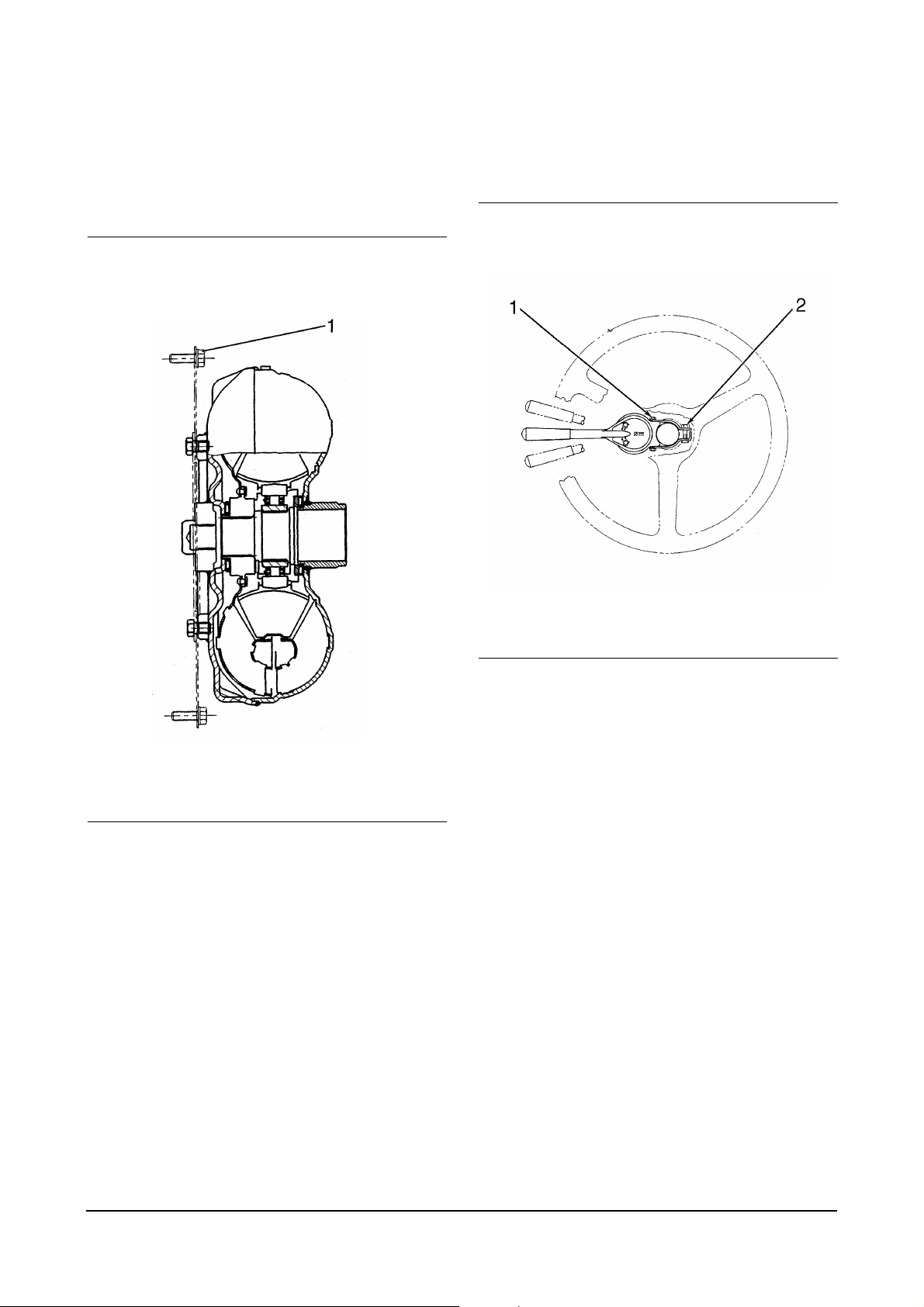

Forward And Reverse Control

Group

(1) Torque for screws (four) that hold clamp to hand

control switch………..3.4 to 3.9 N·m (30 to 35 lb·in)

(2) Torque for bolts (two) that hold clamp to steering

column……………….2.8 to 3.4 N·m (25 to 30 lb·in)

Apply a bead of LOCTITE NO.242 Sealant to inner

radius of the clamp, prior to assembly.

Transmission Solenoid

Valve block elements located on top of transmission

housing…………………………………9.7 to 10.3 ohms

For additional solenoid and valve group

specifications see section “Valve block elements”

Power Train Specifications

5

Page 7

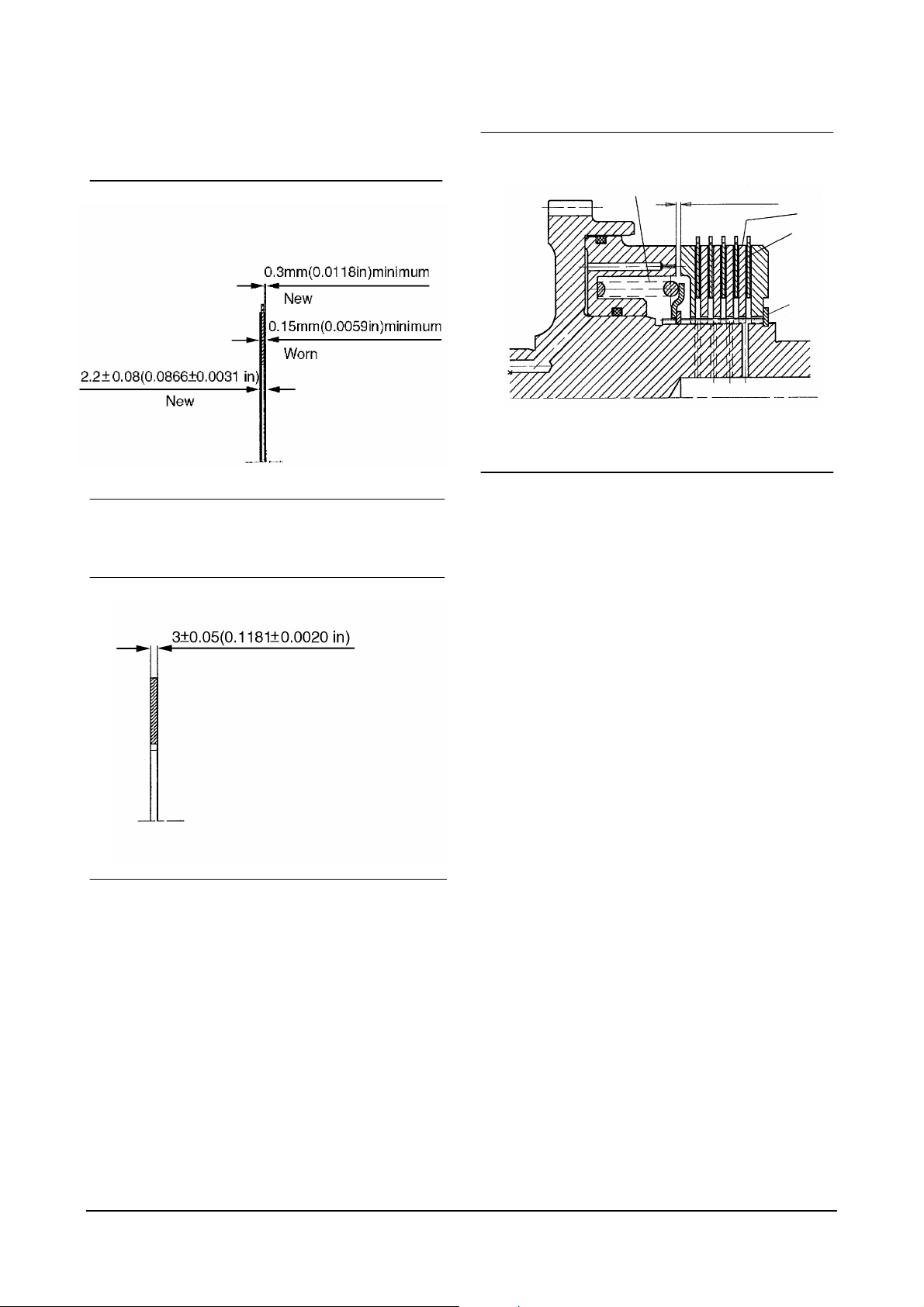

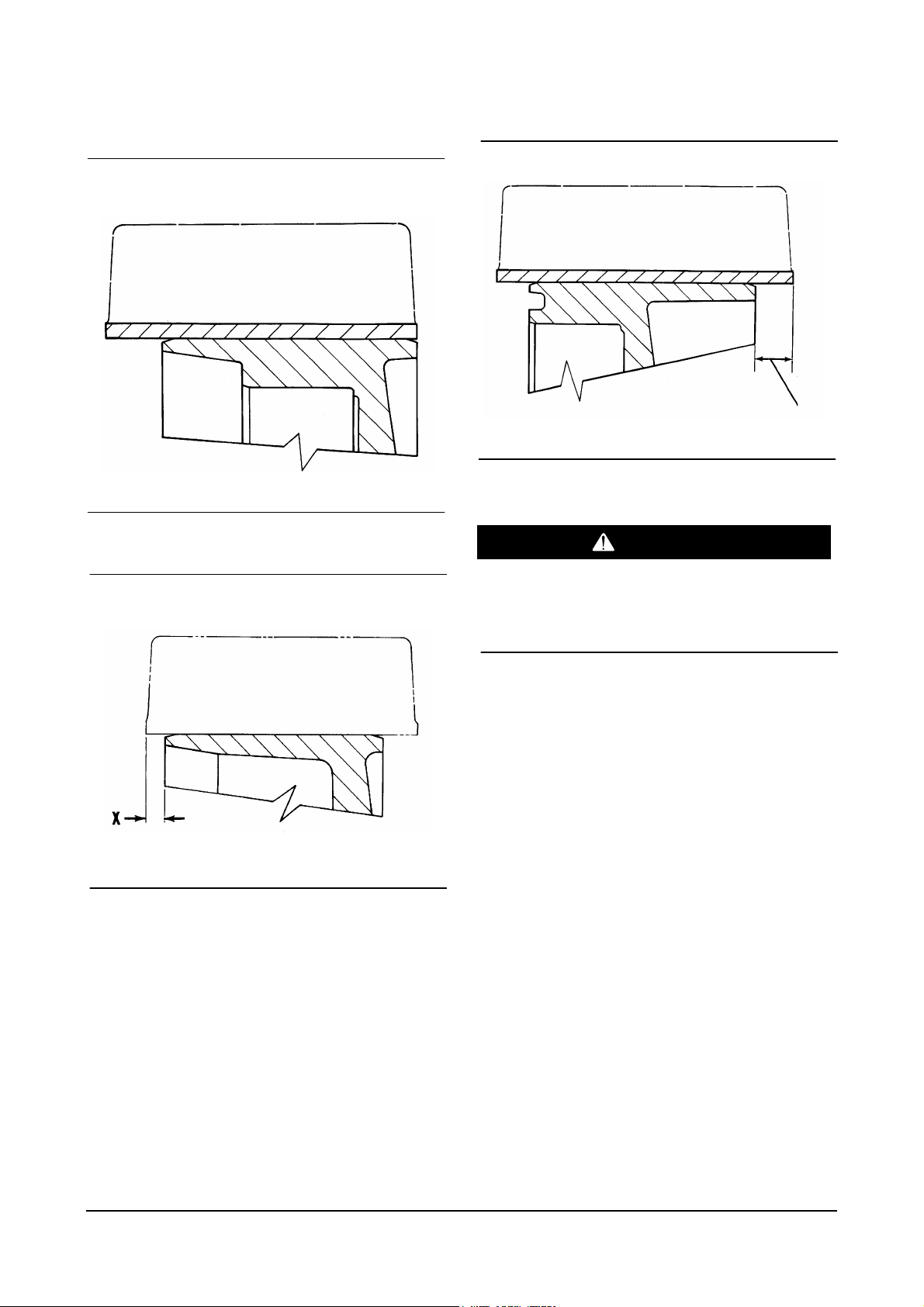

Forward / Reverse Clutch

Elements

a) Outer clutch Disc

b) Inner clutch Plate

c) Piston return spring

Length under test force……………...29 mm (1.14 in)

Test force………………..970.9 ±50 N (218.4 ± 11 lb)

Free length after test(nominal) ..…56.6 mm (2.23 in)

Outside diameter…………………..…95 mm (3.74 in)

d) Clearance between piston and pressure disc (disc

pack pushed against snap ring, piston fully

retracted in gear)………………..1.4 mm (0.0551 in)

C

1.4 minimum

B

A

Snap ring

Power Train Specifications

6

Page 8

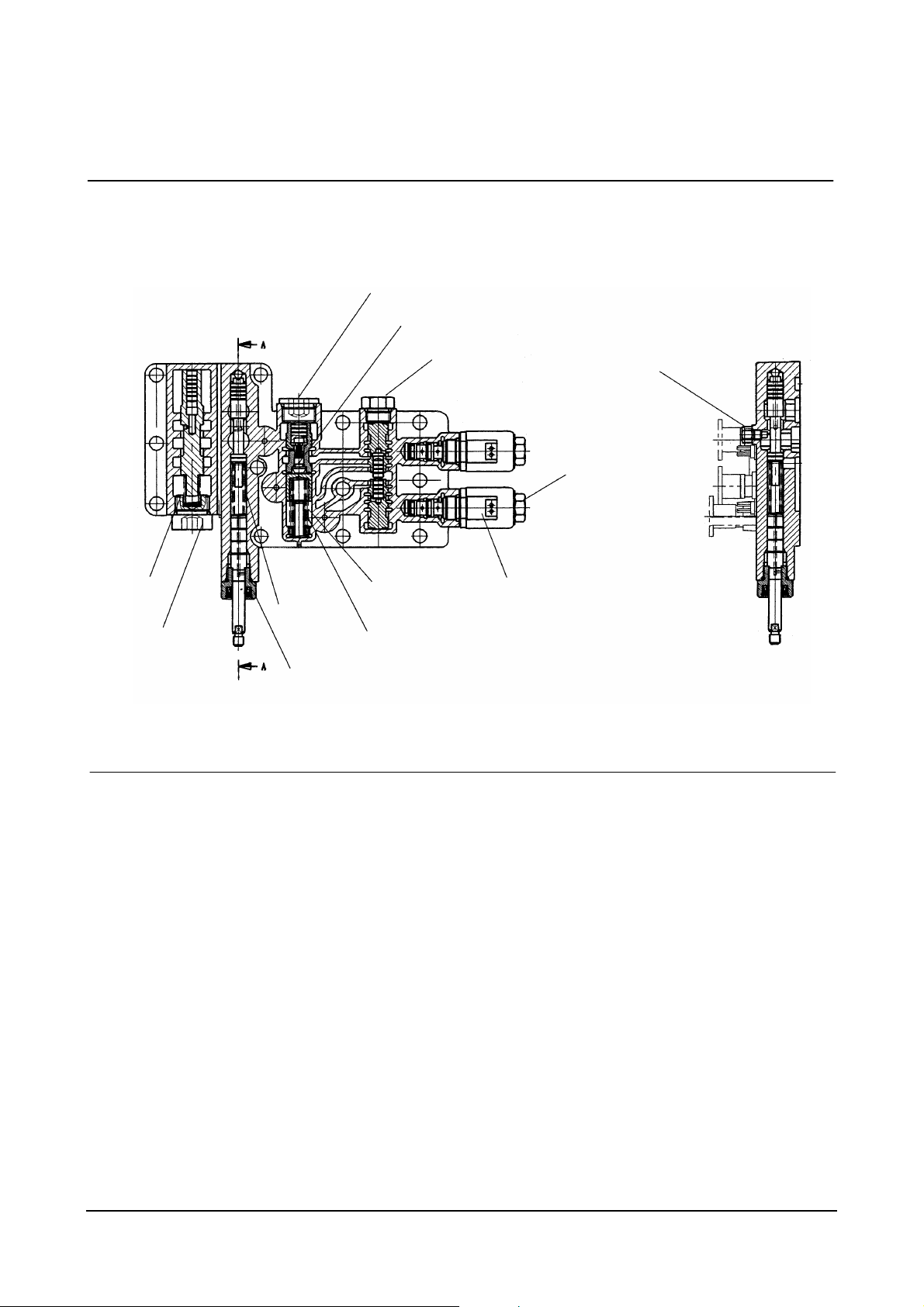

Valve Block Elements

A

(On top of transmission)

Tighten to 50±7 N·m (37±5 Ib·ft)

Tighten to 0.6 N·m (0.44 Ib·ft) min

Tighten to 25±4 N·m (18.5±3 Ib·ft)

Tighten to 50±7 N·m

A) Spring

B) Spring(Inner)

C) Spring(outer)

A

D,E

(37±5 Ib·ft)

Tighten to 50±7 N·m (37±5 Ib·ft)

Length under test force……..…...22.5 mm (0.89 in)

Test force………………,,,….42 ± 3.4 N (9.4±0.8 lb)

Free length after test(nominal)...34.65 mm (1.36 in)

Outside diameter…………………...13 mm (0.51 in)

Length under test force……….….26.6 mm (1.05 in)

Test force……………….….37.8 ± 3.0 N (8.5±0.7 lb)

Free length after test(nominal)….48.2 mm (1.90 in)

Outside diameter………………….10.8 mm (0.43 in)

Length under test force…………..26.6 mm (1.05 in)

Test force………………….75.6 ± 6.0N (17.0±1.3 lb)

Free length after test(nominal)….52.6 mm (2.07 in)

Outside diameter………………..15.24 mm (0.60 in)

C

B

SECTION A-

Tighten to 5±1 N·m (3.7±1 Ib·ft)

Tighten to 5.5±1.5 N·m

(4±1 Ib·ft)

Tighten to 50±5 N·m (37±3.7 Ib·ft)

D) Spring(outer)

Length under test force…………22.22 mm (0.87 in)

Test force…………………...29 to 34 N (6.5 to 7.6 lb)

Free length after test(nominal)….31.7 mm (1.25 in)

Outside diameter………………...11.91 mm (0.47 in)

E) Spring(Inner)

Length under test force………..…20.0 mm (0.79 in)

Test force……………...3.34 ± 0.27 N (0.75±0.06 lb)

Free length after test(nominal)...55.93 mm (2.20 in)

Outside diameter………………..7.75 mm (0.305 in)

Power Train Specifications

7

Page 9

Valve Spring in Transmission Bearing Plate

p

A) Spring

Length under test force…………….30 mm (1.18 in)

Test force…………….......18.1 ± 1.8 N (4.07±0.4 lb)

Free length after test(nominal)...43.25 mm (1.70 in)

Outside diameter…………………10.7 mm (0.42 in)

Tighten to 45 N·m (33.2 Ib·ft)

Converter Inlet Valve

2-S

A

rings

Tighten to 45 N·m (33.2 Ib·ft)

Converter Outlet Valve

Power Train Specifications

8

Page 10

Tightening Torques

Bolt 20 N m (14.8 Ib ft)

Bearing Shims

Bearing Plate

Bolt 55 N m (40.6 Ib ft)

Pump Housing

Bolt 32 N m (23.6 Ib ft)

Flexplate Bolt 55 N m

(40.6 Ib ft)

Bearing Shims

See Instructions

Bolt 40 N m (29.5 Ib ft)

Bearing Shims

See Instructions

Housing Bolt 55 N m (4.6 Ib ft)

Plug 50 N m (36.9 Ib ft)

(40.6 Ib ft)

Housing Bolt 55 N m

U-joint Bolt 70 N m (51.7 Ib ft)

Axle Lube Pump Bolt 12 N m (8.9 Ib ft)

PTO Pump Bolt 30 N m (22.1 Ib ft)

Power Train Specifications

9

Page 11

Tightening Torques

Bolt 115 N m (84.9 Ib ft)

Apply Loctite 242 to thread

Bolt 28 N m (20.7 Ib ft)

Apply Loctite 242 to thread

Nut 150 N m (110.7 Ib ft)

Apply Loctite 242 to thread and face

Spacer and Shims

(See Instructions)

Shims

(See Instructions)

_

+

Bolt 115 N m (84.9 Ib ft)

Apply Loctite 242 to thread

_

+

Bolt 80 8 N m (59.0 5.9 Ib ft)

(Slightly Oiled)

Adjust to

19.6 N m (14.5 Ib ft) drag

(See Instructions)

Grease Bearing

With Molycote BR2

Bolt 285 N m (210.3 Ib ft)

Apply Loctite 242 to thread

Nut 50 N m (36.9 Ib ft)

(See Instructions)

Power Train Specifications

10

Page 12

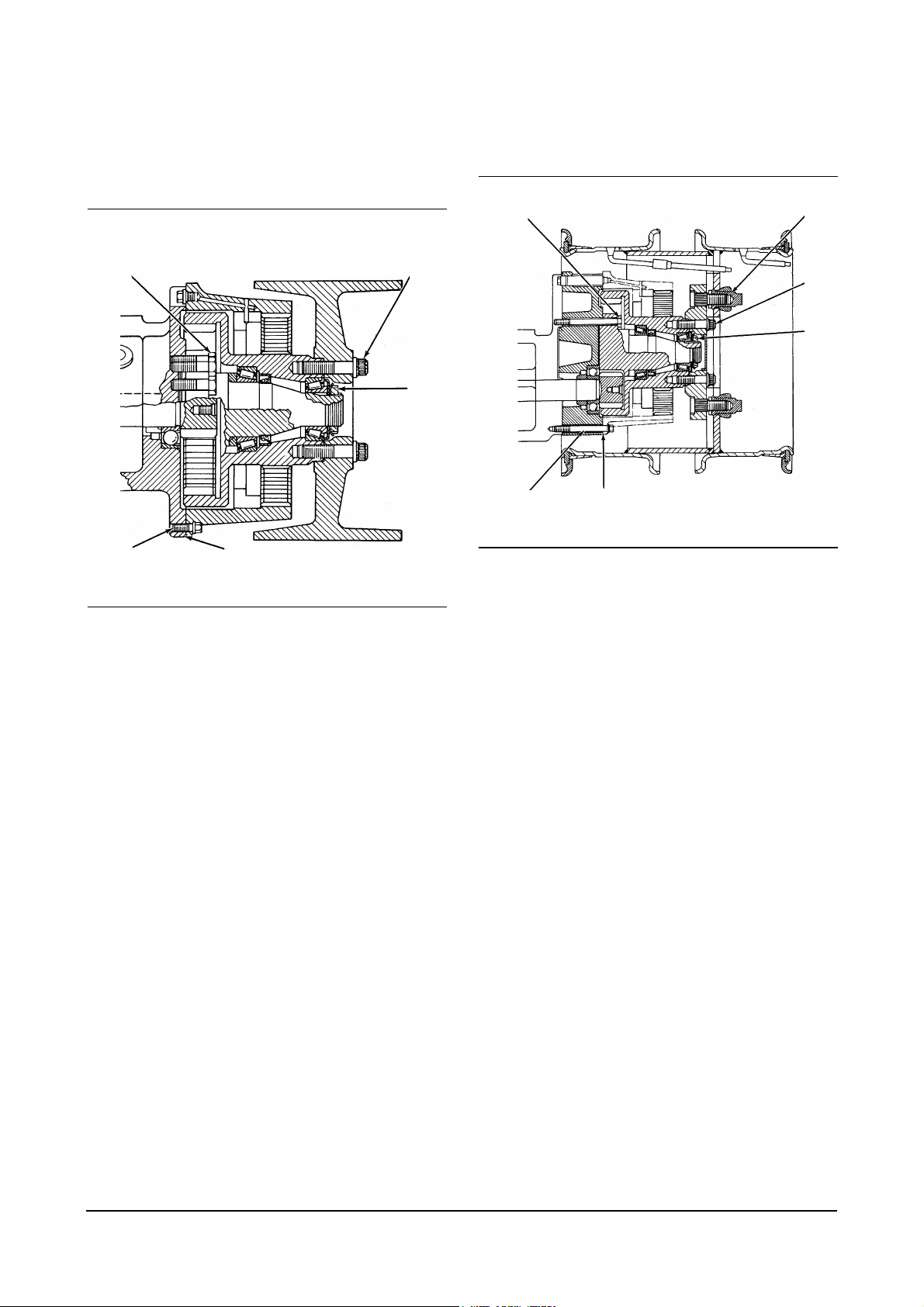

Final Drives And Wheels

GC Model Trucks

1 2

4

5

Oil Cooled Disc Brake Type

(1) Apply LOCTITE NO.242 Thread Lock to threads of

spindle bolts.

Torque for bolts that hold spindle to drive axle

housing……………..115 ± 14 N∙m (85 ± 10 lb∙ft)

(2) Torque for wheel mounting bolts…270 ± 25 N∙m

………………………………………(200 ± 20 lb∙ft)

(3) Wheel bearing adjustment :

(a) Tighten wheel bearing nut to 135 N∙m (100lb∙ft)

while the wheel is turned in both directions.

(b) Loosen the nut completely. Tighten the nut

again to 50 ± 5 N∙m (37 ± 4 lb∙ft).

(c) Bend a tab of the lockwasher into a groove of

the wheel bearing nut.

(4) Torque for bolts that hold cover to axle housing

……………………………55 ± 10 N∙m (40 ± 7 lb∙ft)

(5) Apply Loctite No.515 Sealant to the axle flange and

cover on the contact area.

3

D,G Model Trucks

Dual Drive wheels shown

12

3

4

56

Oil Cooled Disc Brake Type

(1) Apply LOCTITE NO.242 Thread Lock to threads of

spindle bolts.

Torque for bolts that hold spindle to drive axle

housing………………..115 ± 14 N∙m (85 ± 10 lb∙ft)

(2) Use a crisscross procedure to tighten nuts.

(a) Torque for single drive wheel mounting.

nuts………...........644 ± 34 N∙m (470 ± 25 lb∙ft)

(b) Torque for inner and outer dual drive wheel

mounting nuts…………………….644 ± 34 N∙m

(470 ± 25 lb∙ft)

(3) Torque for bolts that hold adapter assembly to

hub………………...285 ± 13 N∙m (210 ± 10 lb∙ft)

(4) Wheel bearing adjustment :

(a) Tighten wheel bearing nut to 135 N∙m(100 lb∙ft)

while the wheel is turned in both directions

(b) Loosen the nut completely. Tighten the nut

again to 50 ± 5 N∙m (37 ± 4 lb∙ft).

(c) Bend a tab of the lockwasher into a groove of

the wheel bearing nut.

(5) Torque for bolts that hold cover to axle housing

………………..…………..55 ± 10 N∙m (40 ± 7 lb∙ft).

(6) Apply Loctite No.515 Sealant to the axle flange or

spacer and cover on the contact area.

Power Train Specifications

11

Page 13

Drive Tire Installation

GC20, GC25 Models

GC30, GC32 Models-Narrow Axle

GC30, GC32 Models-Wide Axle

The drive tire must be installed as shown below.

Failure to do so will decrease the stability of the

truck, and can cause injury to the operator.

WARNING

Y

GC20, GC25 Models

Install the tire so that the edge of the tire is even with

the outside edge of the wheel.

GC30, GC32 Models

Narrow Axle :

Install the tire so there is distance (X) between the

edge of the tire and the inside edge of the wheel.

Distance(X) is……………38.2 ± 0.8 mm (1.50 ± .03 in)

Wide Axle :

Install the tire so there is distance (Y) between the

edge of the tire and the outside edge of the wheel.

Distance(Y) is....................25.0 ± 0.8 mm (.98 ± .03 in)

.

Power Train Specifications

12

Page 14

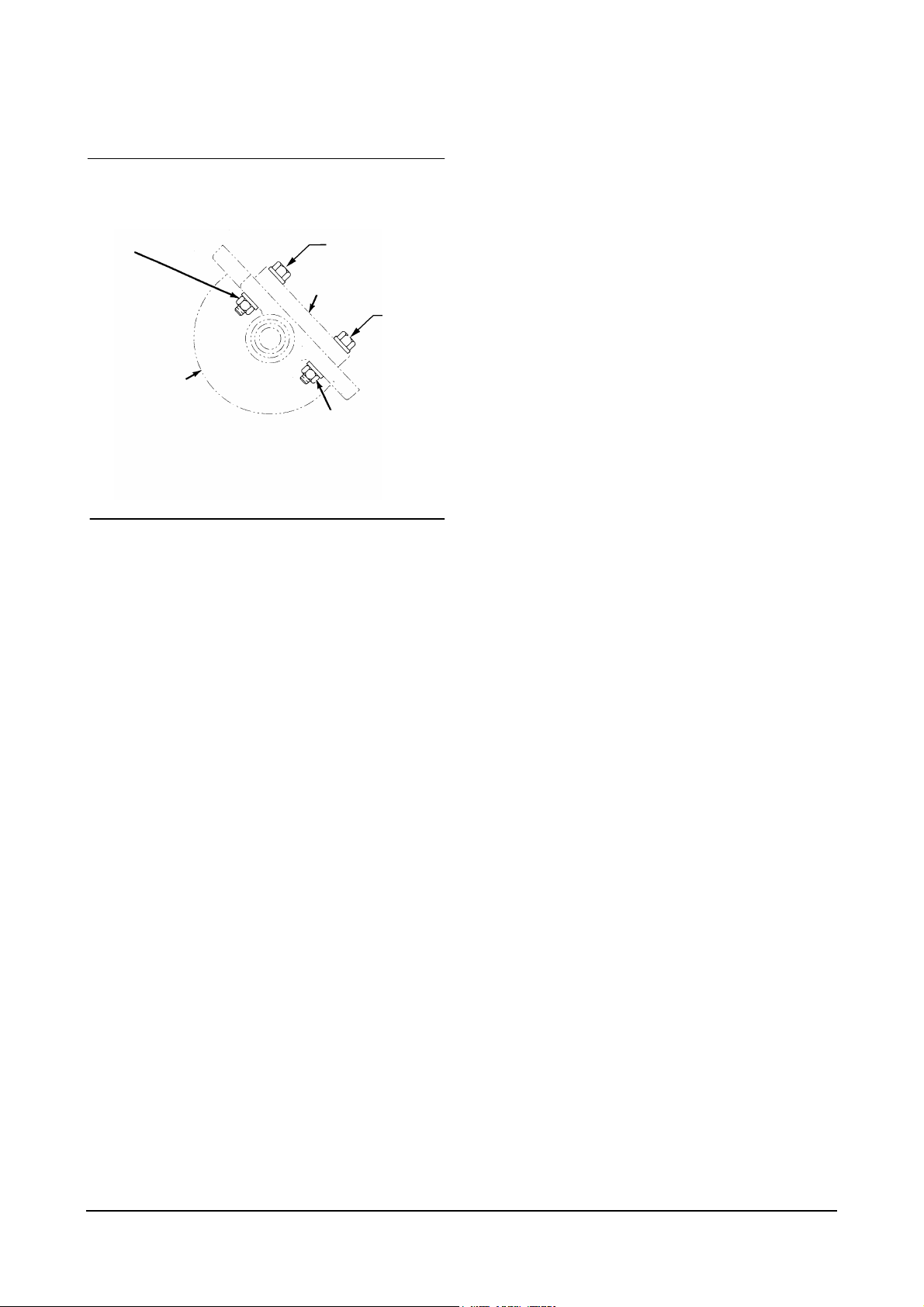

Drive Wheel Installation

GC Model Trucks

(1) Tighten wheel mounting bolts to a torque of

……………………….270 ± 25 N∙m (200 ± 20 lb∙ft)

D,G Model Trucks

1

1

(1) Tighten wheel mounting bolts to a torque of

……………………….644 ± 34 N∙m (470 ± 25 lb∙ft)

Use a crisscross procedure to tighten nuts.

Power Train Specifications

13

Page 15

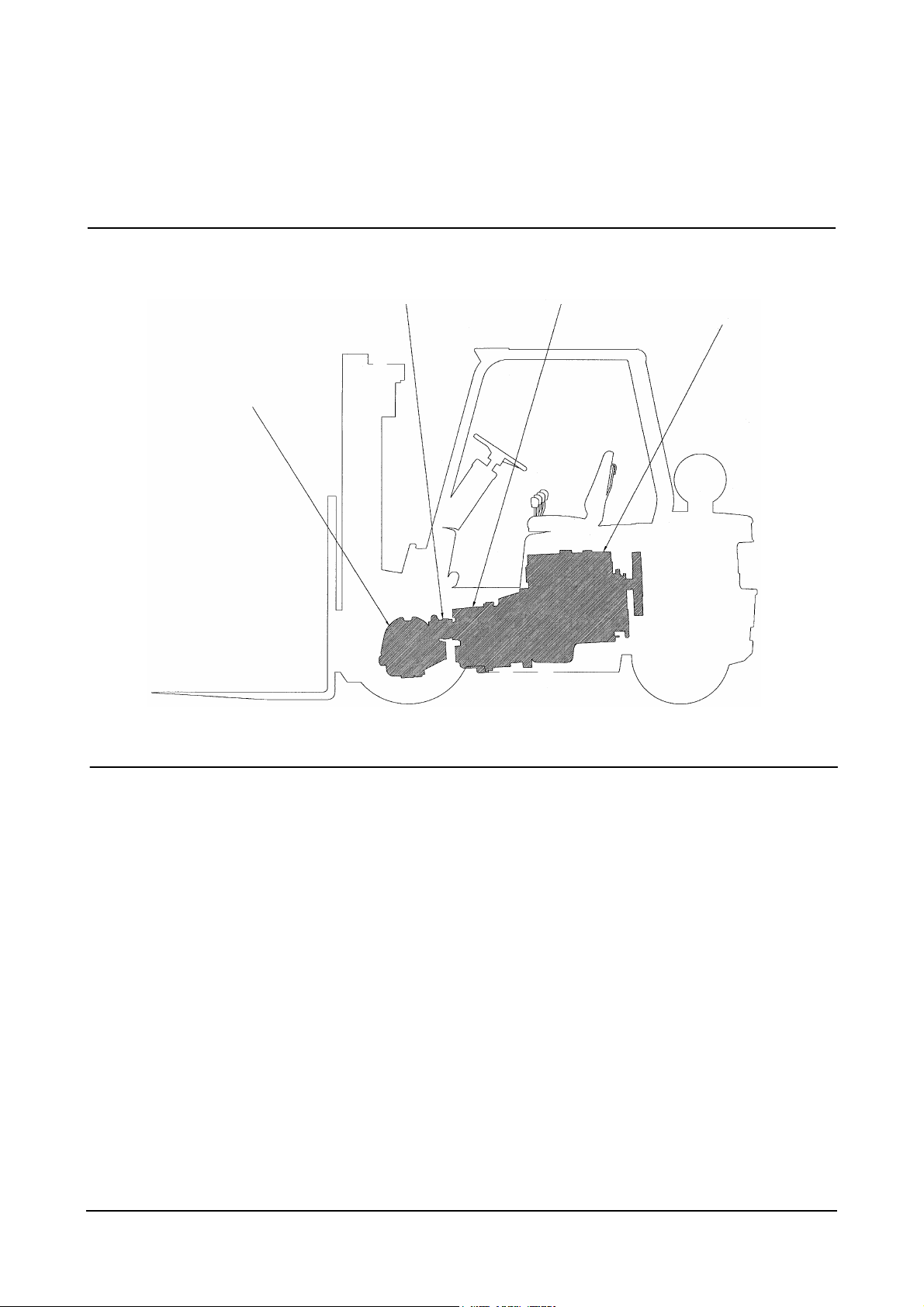

Drive Axle Mounting Group

1

Special shoulder Bolt

Chassis

Standard Bolt

Drive

Axle

Housing

2

(1) Torque for two nuts that hold the axle to the

chassis……………..…488 ± 27 N∙m (360 ± 20 lb∙ft)

(2) Torque for two nuts that hold the axle to the

chassis………...…..….488 ± 27 N∙m (360 ± 20 lb∙ft)

Power Train Specifications

14

Page 16

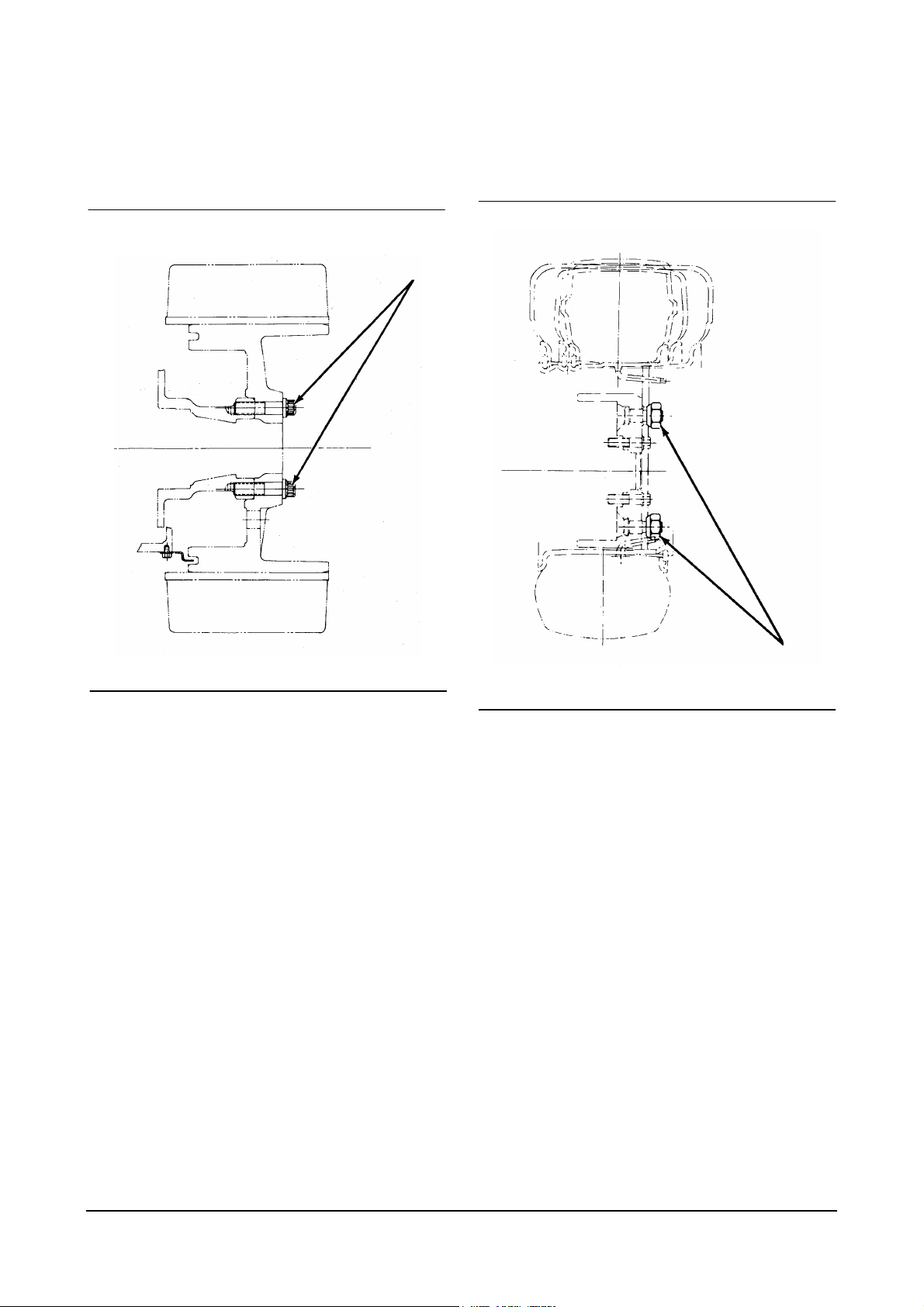

Systems Operation

General Information

Power Flow

(1) Drive axle. (2) U-joint. (3) Transmission. (4) Engine.

The basic components of the power train are engine

(4), Transmission (3), U-Joint(2), Drive axle(1) and the

final drives and wheels.

Two axle shafts connect the differential to two final

drives. The drive wheels are mounted to the final

drives.

Power from the engine goes through the flywheel into

the torque converter. Power then flows through a

transmission (3) and U-joint(2) to yoke of

drive axle(1).

The transmission has two hydraulically operated clutch

packs that are spring released.

The transmission has one speed in forward and one

speed in reverse.

1

32

4

Power from yoke of drive axle is sent through a spiral

bevel gear set to the differential.

The differential sends power out through the axles to

the final drives and wheels.

Power Train Systems Operation

15

Page 17

Transmission and Drive Axle

Torque Converter

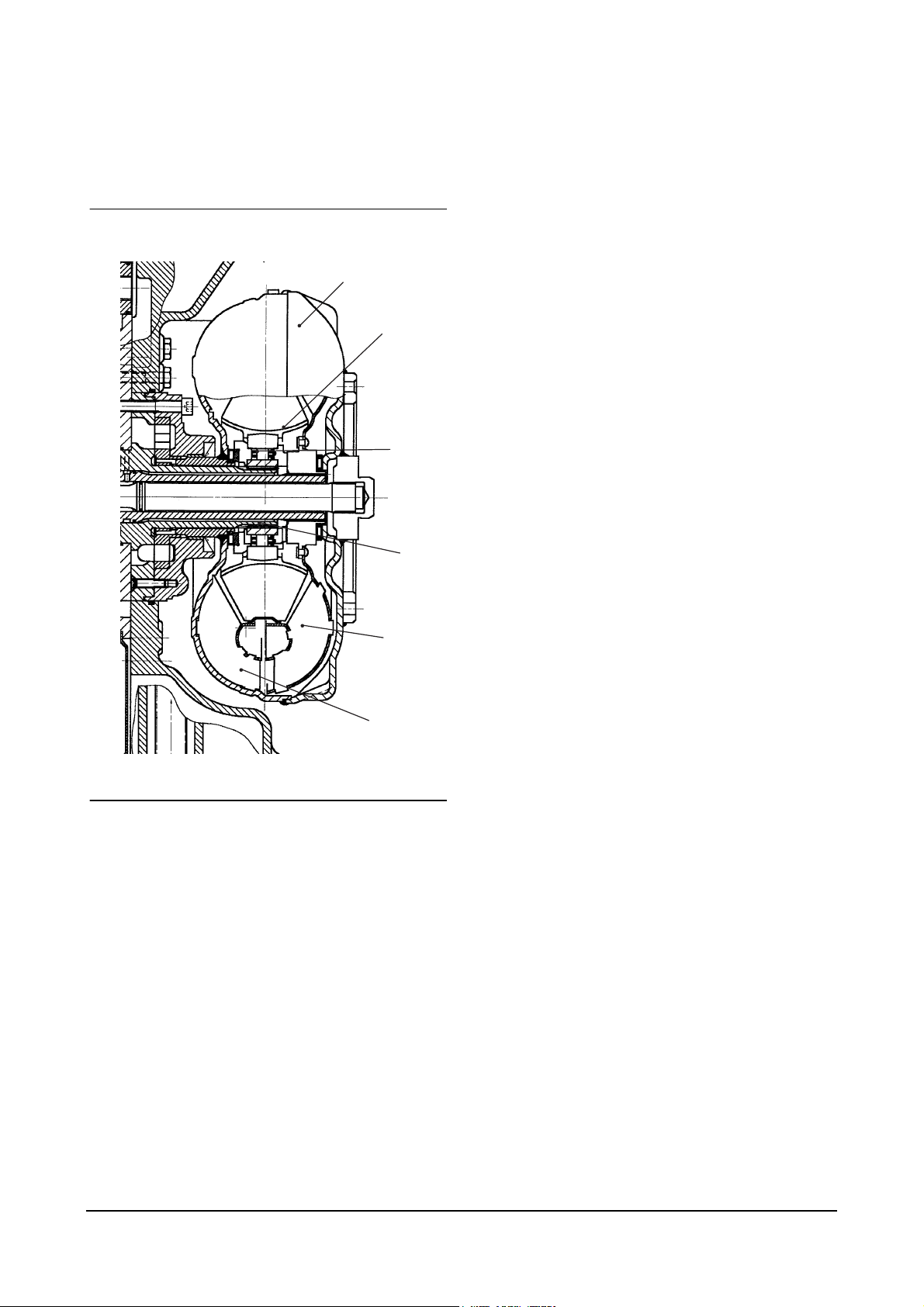

Torque converter

(1) Turbine. (2) Stator. (3) Impeller. (4) Housing.

(5) Stator support. (6) Stator clutch.

There is no direct mechanical connection between

engine and the transmission. Power from the engine is

transferred through the torque converter, which

hydraulically connects the engine to the transmission.

Transmission drive train oil is used to turn the turbine

and transmission input shaft.

When the lift truck works against a load, the torque

converter can multiply the torque from the engine and

send a higher torque to the transmission.

4

2

6

5

1

3

The torque converter has four main parts : housing (4),

impeller(pump) (3), turbine(1) and stator(2). The

housing is connected to the engine flywheel through a

flexplate. Impeller (3) and housing (4) are welded

together and turn with the engine flywheel at engine

speed and in the direction of engine rotation. Turbine

(1) turns the transmission input shaft. Stator (2) is

installed stationary on stator support (5) by a

freewheel clutch that allows one way rotation of the

stator.

The hub, which is part of impeller (3), fits into the

transission oil pump. The turning impeller (3) rotates

the pump to supply oil for the operation of the torque

converter and transmission

When the engine is turning, oil flows through the

converter to lubricate and cool it. With the

transmission in neutral, the impeller, turbine, stator

and oil are all turning together in a direct fluid coupling.

The turbine/impeller speed ratio is 1/1.

Once a direction is selected the direct fluid coupling no

longer exists, the turbine/impeller speed ratio changes

(the turbine will be turning slower than the impeller).

When this happens the impeller outlet pressure to

turbine inlet pressure changes. This causes the oil

flow in the torus (fluid path containing the impeller,

turbine and stator) to gain momentum.

As impeller (3) turns, it increases the energy state of

the oil and directs the oil to the outside diameter of

converter housing (4). Oil leaving impeller (3) is

directed to turbine (1) where much of the oil? energy is

absorbed by turning the turbine. The pressure and

flow change in the torus becomes torque and speed at

the turbine and transmission input shaft.

Oil follows the turbine blades inward toward the center

of the converter. When the turbine/impeller speed ratio

is less than .85/1, oil is directed against the concave

side of stator (2) with enough force to stop its one way

rotation and lock the freewheel clutch.

Most of the energy from the oil that strikes the turbine

is used to turn the turbine, but some energy is left over.

Torque multiplication comes about because the locked

stator (2) directs this left over oil back to impeller (3) in

the same direction as the impeller rotation. This

energy force of the oil increases the torque on the

turbine and transmission input shaft. During operation,

this cycle is repeated over and over.

Without the stator, oil leaving the turbine is travelling in

a direction that is against impeller rotation. Torque

multiplication is only possible because of the stator.

Power Train Systems Operation

16

Page 18

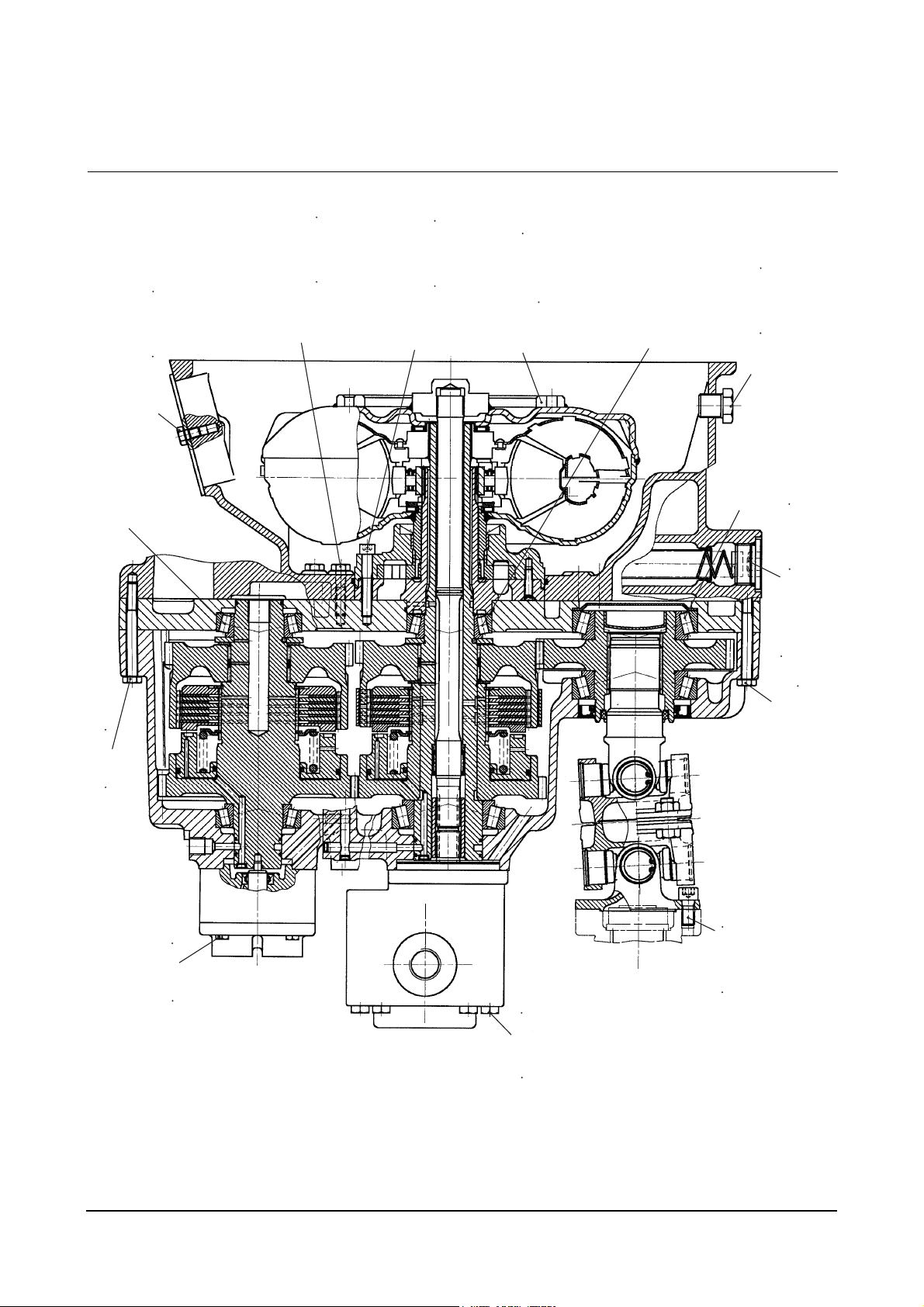

Transmission

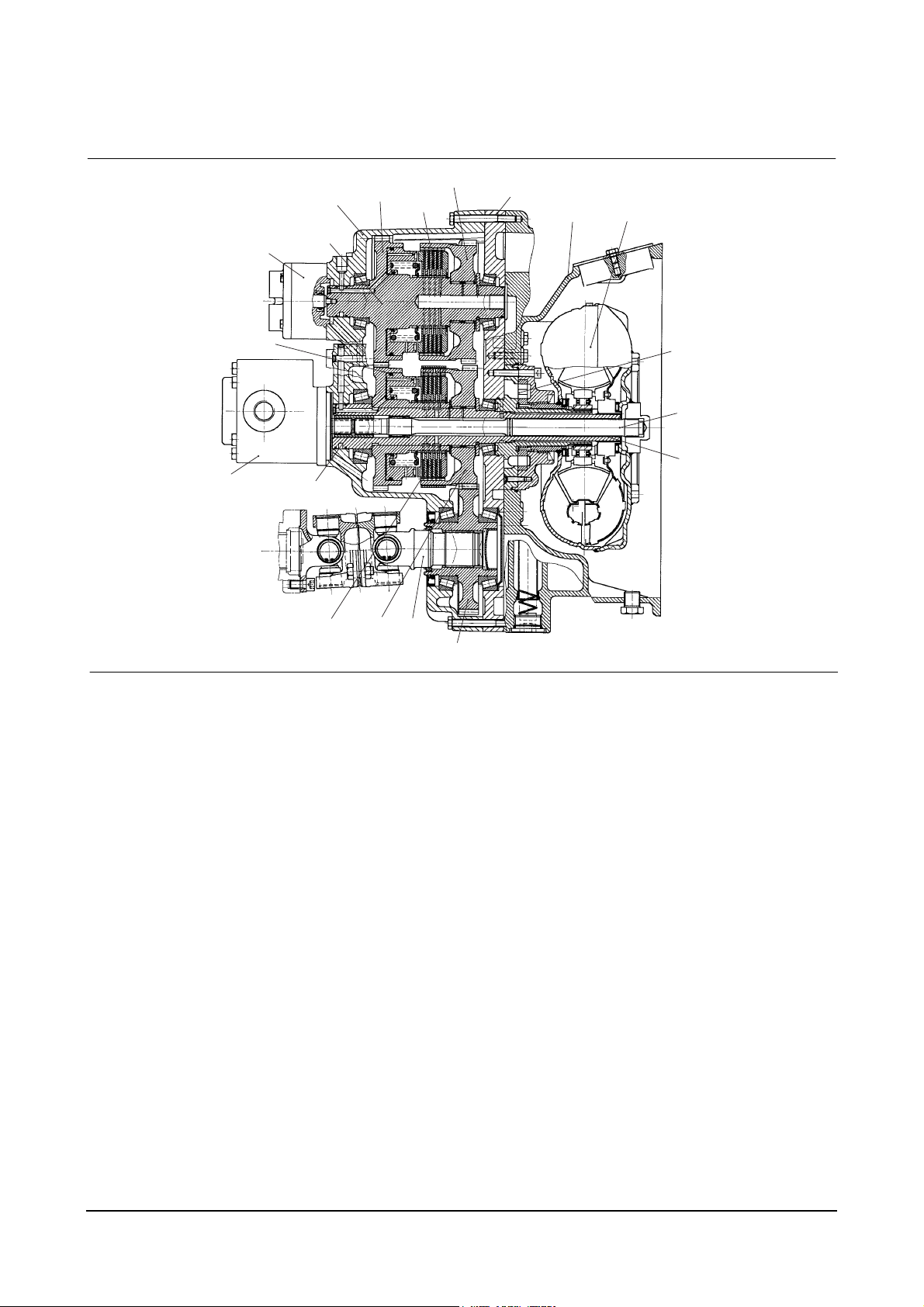

13

10

11

12

2

1

4

6

14

5

which is in mesh and drives the output gear, when

the forward clutch (8) is closed.

The reverse shaft (9) carries the reverse shaft gear

(9A), the reverse clutch (10) and the reverse gear (11)

which is in mesh and drives the output gear (12) when

the reverse clutch (10) is selected.

The quill shaft (14) is splined to the torque converter

and therefore rotates with engine speed and direction.

A coupling (14A) connects the PTO pump (15) to the

quill shaft (14).

The axle lubrication (16) pump engages in and is

driven by the reverse shaft. It always operates when

the engine rotates, but rotating speed varies with

torgue converter output.

16

9

9A

3

5A

15

14A

(1) TC Housing. (2) TM Bearing Plate. (3) TM Housing. (4) Torque Converter. (5) Input Shaft. (5A)Input Shaft Gear.

(6) Oil Pump. (7) Forward Gear. (8) Forward Clutch. (9) Reverse Shaft. (9A) Reverse Shaft Gear. (10) Reverse Clutch. (11)

Reverse gear. (12) Output gear. (13) U-joint. (14) Quill Shaft. (14A) Coupling. (15) PTO Pump. (16) Axle Lubrication Pump.

8

7

The Transmission consists of 3 sections:

a) TC housing (1) which contains torque converter (4)

and the oil pump (6) and its housing. Tangs on the

TC neck engage in and drive the pump.

b) Bearing plate (2) which contains the rear bearings

of input, reverse shaft and output gear and the oil

supply channels. The oil channels are sealed by

the front TC housing wall.

c) Transmission housing (3) containing input shaft (5),

forward clutch (8), forward gear (7), reverse shaft

(9), reverse clutch (10), reverse gear (11), output

gear (12) and parking brake. The input shaft

engages in and is driven by the TC turbine hub

spline and rotates in same direction as the

engine. It carries an input shaft gear (5A) which is

in mesh and drives the reverse shaft gear (9A), the

forward clutch (8) and the forward gear (7),

Power Train Systems Operation

17

Page 19

Transmission Power Flow Forward :

With the transmission control in forward, which will

pressurize the forward clutch (8), power will flow from

the engine through the torque converter to drive the oil

pump (6) and the input shaft (5), also the quill shaft

(14). Since the forward clutch (8) locks the forward

gear (7) to the input shaft, the power flows through the

forward clutch (8), the forward gear (7) to output gear

(12) which is in mesh with the forward gear. The u-joint

(13) which is splined to the output gear will transmit

power to the axle.

Power Train Systems Operation

18

Page 20

Transmission Power Flow Reverse :

With the transmission controls in reverse, which will

pressurize the reverse clutch (10), power will flow from

the engine through the torque converter to drive the oil

pump (6) and the input shaft (5) also the quill shaft

(14). Since the reverse clutch (10) is closed, power will

flow through input shaft gear (5A) which is in mesh

and drives reverse shaft gear (9A) and reverse shaft

(9). The reverse gear (11) which is locked to the

reverse shaft by the reverse clutch (10) is in mesh and

drives the output gear (12). The U-joint, which is

splined to the output gear will transmit power to the

axle.

Power Train Systems Operation

19

Page 21

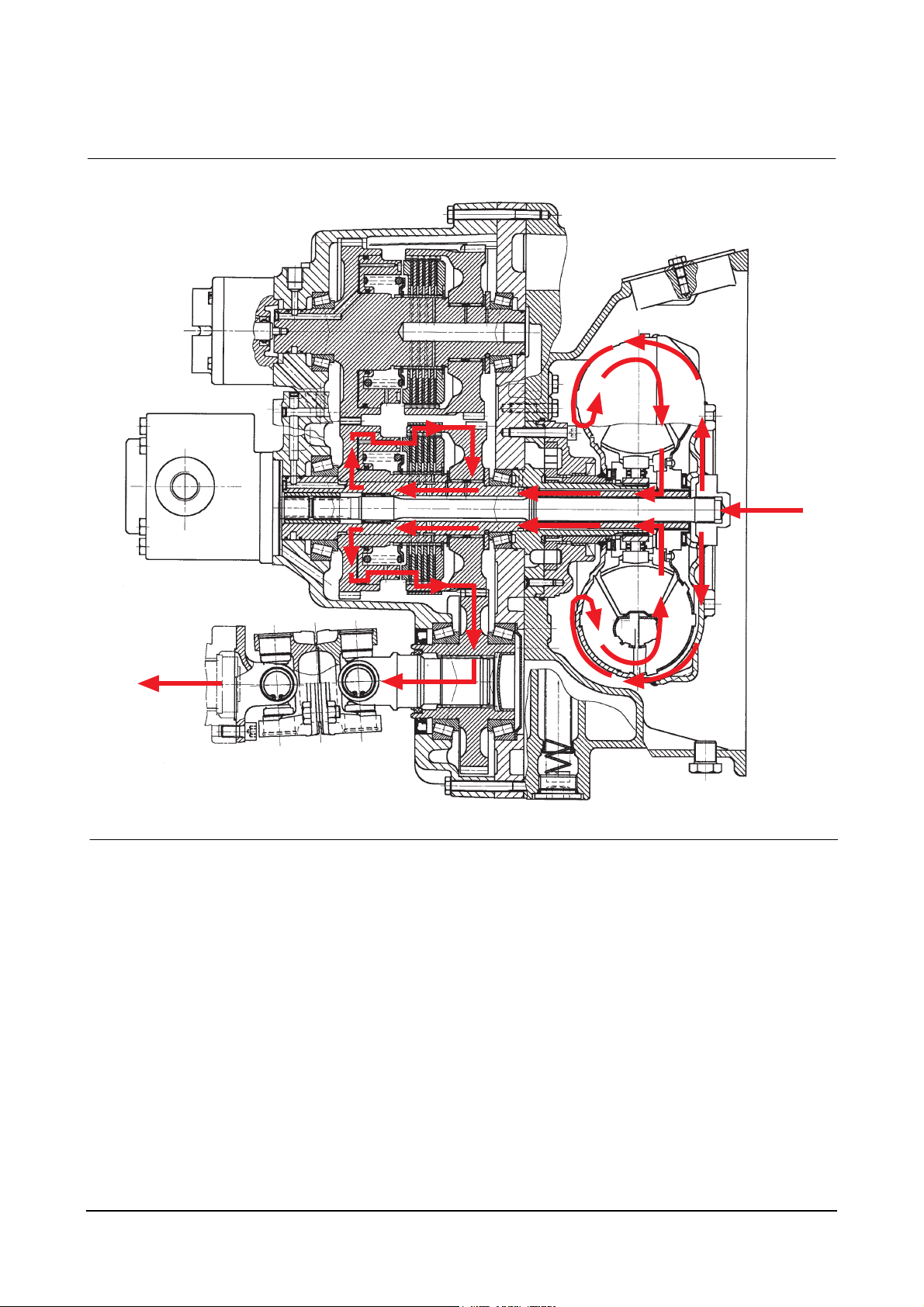

Transmission Lubrication Schematic :

Oil for lubrication of the clutch shaft bearings and

cooling the clutch discs and plates comes from the

outlet passage of oil cooler. Lubrication oil is also

splashed inside the transmission case. Lubrication oil

is especially important for cooling the clutches.

High temperatures can be caused during repeated

shifting of the lift truck.

Oil Cooler

TC

Relieve

Valve

Power Train Systems Operation

20

Page 22

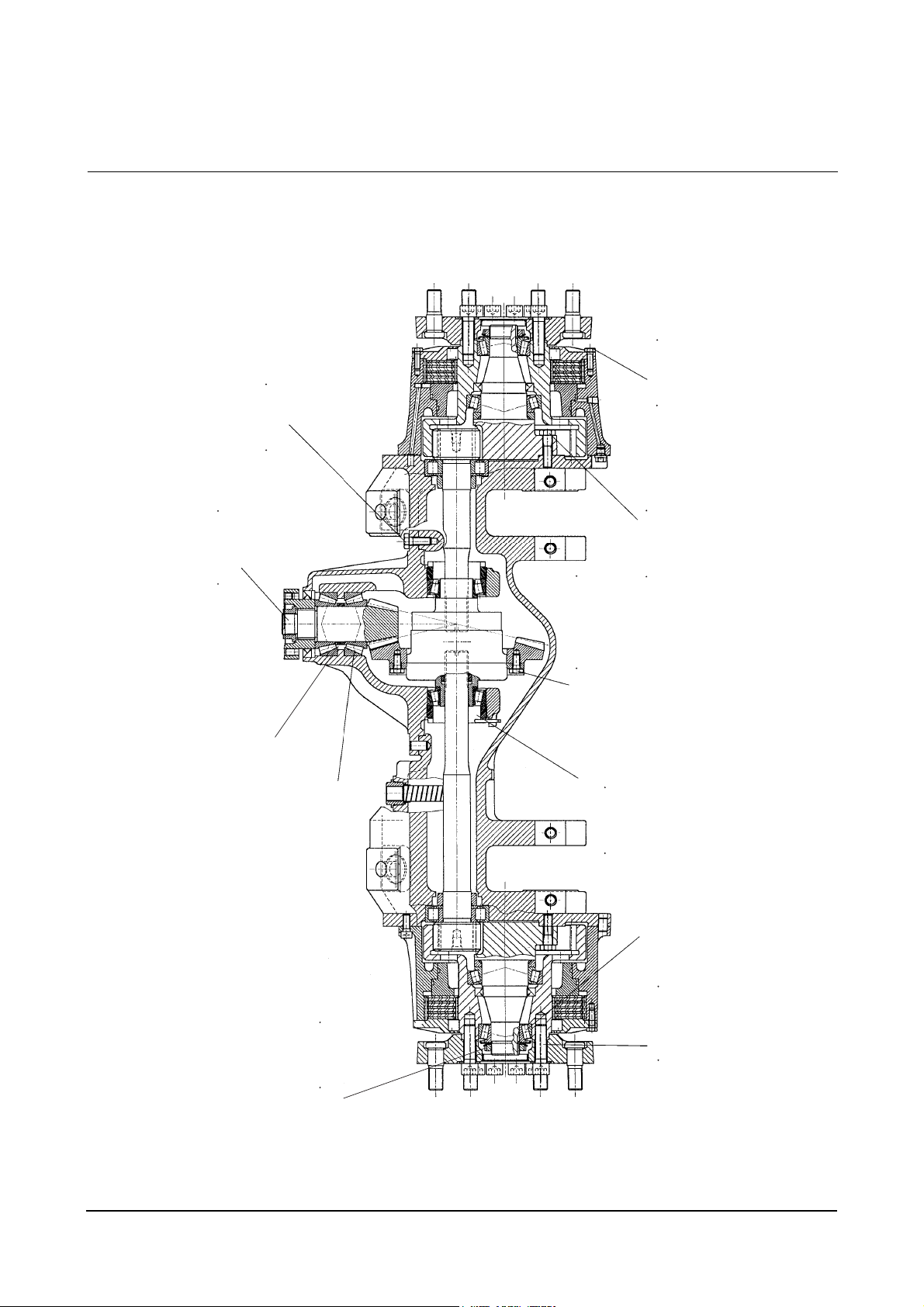

Drive Axle

(1) Axle Housing. (2) Carrier (3) Brake Housing Left/Right. (4) Pinion. (5) Crown wheel/differential.

(6) Drive Shaft Left/right. (7) Ring Gear/Hub. left/right. (8) Pneumatic Tire Wheel Flange Left/right. (9) Multi-disc brake left/right.

(10) Spindle. (11) Axle Mounting Pads. (12) Mast Mounting Hooks.

The Axle Consists of 4 main sections

a) The carrier housing (2), pinion (4) and crownwheel

with differential assembly (5).

b) The axle housing with left and right drive shaft (6),

mounting pads (11) and mast mounting hooks (12).

4

4

11

11

2

2

1

11

11

10

10

3

3

7

7

1

7

7

3

3

6

5,5A,5B,5C

5,5A,5B,5C

6

6

10

10

c,d) Hub section left and right with ring gear (7), wheel

flange (8), spindle (10) and multi-disc brake (9).

Wheel flange (8) used with pneumatic tire trucks only.

8

8

9

9

12

6

12

12

12

9

8

8

9

Power Train Systems Operation

21

Page 23

Axle power flow

Power is transmitted by the transmission output shaft

to the pinion (4) which meshes with and drives the

crownwheel (5), which is mounted to the differential.

The differential is part of the drive axle. It is a single

reduction unit with a differential drive gear fastened on

the differential case.

The differential is used to send the power from the

transmission to the wheels. When one wheel turns

slower than the other, the differential lets the inside

wheel stop or turn slower in relation to the outside

wheel.

Differential case (5A) has four differential pinion gears

(5B) on the differential pinion shaft. The pinion gears

are engaged with two side gears (5C). The side gears

are splined to the axle shafts.

When the lift truck moves in a forward direction and

there is the same traction under each wheel, torgue in

each axle and pinion gears (5B) are balanced. Both

left and right axles roatate the same. During a turn, the

force(traction) that is on the drive wheels is different.

These different forces are also felt on opposite sides

of the differential and cause pinion gears (5) to turn.

The rotation of pinion gears (5) stops or slows the

inside wheel and lets the outside wheel go faster. This

moves the machine through a turn under full power.

The differential gets lubrication from oil thrown about

inside the housing.

5

4

Power Train Systems Operation

22

Page 24

Axle Lubrication Schematic

The axle is lubricated by means of the transmissionmounted lubricant pump (2) which gets oil from the

axle suction port (1) and supplies it to the hub section

pressure parts (3) to lubricate and cool hub drive and

multi-disc brakes.

Oil returns to the sump through the drive shaft

bearings and axle housing.

3 1

3

1

PUMP

PUMP

2

2

3

3

Power Train Systems Operation

23

Page 25

Hydraulic System

(1) Transmission Oil Sump. (2) Oil Pump. (3) Primary Filter. (4) Main Valve. (5) Orifice. (6) Inching Valve. (7) Modulating Valve.

(7A) Load Piston. (7B) Modulating Valve Orifice. (8) Selector Valve. (9) Solenoid Valve Forward. (10) Solenoid Valve Reverse.

(11) Forward Clutch. (12) Reverse Clutch. (13) Relief Valve. (14) Torque Converter. (15) Relief Valve. (16) Converter Bypass.

(17) Oil Cooler. (18) Torque Converter Supply Bypass.

Power Train Systems Operation

24

Page 26

10

The basic components of the hydraulic system for

operating the transmission are transmission oil sump

(1), oil pump (2), primary oil filter (3), valve block,

containing main valve (4), orifice (5), inching valve (6),

modulating valve (7), selection valve (8), forward and

reverse solenoid valves (9,10), forward clutch (11),

reverse clutch (12), torque converter (14) with relief

valves (13,15), bypass (16) and oil cooler (17).

The pump is located in the torque converter housing,

and valve block is located on top of transmission, the

filter is located on the right hand of the transmission

housing.

4

6

7

8

9

Transmission Hydraulic System

The transmission hydraulic system is explained in

three sections. The first section is the oil pump, filter,

torque converter and oil cooler systems. The second

section is the transmission lubrication system. The

third section is the transmission hydraulic control

system which controls the lift truck direction control.

Pump, Filter, Torque Converter And Oil Cooler

Systems

The oil for the operation and lubrication of the

transmission is made available by pump (2). The

pump is located in the torque converter housing and is

driven by Tangs on the torque converter neck.

Oil sump (1), for the transmission, is in the bottom of

the transmission case. Oil from reservoir flows through

the strainer and internal channels to the suction side of

positive displacement pump .

Oil from pump (2) flows to primary oil filter (3). If there

is a restriction in the oil filter or if the oil is cold and

thick, a bypass valve in the filter will open. The

difference in pressure at which the bypass valve will

open is 124 ± 7 kPa (18 ± 1 psi). From the primary oil

filter, the oil flows on to main relief valve (4). In the

spool of main relief valve there is a bypass (18). The

purpose of this bypass is to supply lubrication and

coolant oil to the torque converter at low speeds and

especially during hot oil conditions. Converter relief

valve (13) protects the torque converter from oil

pressure higher than 670 kPa (97 psi), such as during

cold oil start-ups. At this pressure, the oil is released

back to the reservoir. Converter inlet passage has

converter bypass orifice (16). The purpose of this

orifice is to prevent too much of a pressure load on the

torque converter by allowing some of the oil to bypass

the converter. In converter outlet passage, there is

cooler bypass valve (15). Cooler bypass valve (15) will

release oil back to the reservoir if the oil pressure

reaches 400 kPa (58 psi). This can happen if the oil

cooler has a restriction or if the oil is cold and thick.

Power Train Systems Operation

25

Page 27

Power Train Systems Operation

26

Page 28

Neutral Position

Transmission Hydraulic System-Neutral

(1) Transmission Oil Sump.

(2) Oil Pump.

(3) Primary Filter.

(4) Main Valve.

(5) Orifice.

(6) Inching Valve.

(7) Modulating Valve.

(7A) Load Piston.

(7B) Modulating Valve Orifice.

(8) Selector Valve.

(9) Solenoid Valve Forward.

(10) Solenoid Valve Reverse.

(11) Forward Clutch.

(12) Reverse Clutch.

(13) Relief Valve.

(14) Torque Converter.

(15) Relief Valve.

(16) Converter Bypass.

(17) Oil Cooler.

(18) Torque Converter Supply Bypass.

When the transmission is in NEUTRAL position with

the engine running, oil is pulled from reservoir and the

strainer assembly (1) to pump (2). From there, pump

oil flows through the primary filter (3) to main relief

valve (4). Oil will also flow through orifice (18) to

lubricate the torque converter during hot, low speed

conditions.

When the pump pressure reaches 895 kPa (130 psi),

relief valve spool (4A) will move to the left side and

most of the pressure oil flows to the torque converter.

Spool will move left and right to maintain 895 kPa (130

psi). Oil can also bypass the torque converter through

converter bypass orifice (16). The purpose of orifice

(16) is to prevent too much of a pressure load being

put on the torque converter.

Oil flows from the torque converter through a passage

to oil cooler (17). Oil then flows back to transmission to

cool and lubricate the clutches and shaft bearings.

In NEUTRAL position, the remaining pressure oil flows

from main relief valve (4) to inching valve (6).

Without inching (inching pedal up and valve in), oil

flows around and through the center of spool (6A) to

the bottom of the spool. The oil, at the bottom, pushes

the spool to the position shown. Oil flows around the

lands of the spool and through a passage to

modulating valve (7).

In NEUTRAL position, forward solenoid (9) and

reverse solenoid (10) are OFF. Pump oil flow is

blocked at the solenoids. Oil cannot flow through oil

passage to the forward or reverse selector spool.

Pump oil pressure is felt at slugs. This forces forward

selector spool to the right and reverse selector spool

to the left. With the spools in this position, forward

clutch (11) and reverse clutch (12) are open to drain.

Most of the oil still flows through the lube circuit.

Power Train Systems Operation

27

Page 29

Power Train Systems Operation

28

Page 30

Forward Direction

Transmission Hydraulic System-Forward

(1) Transmission Oil Sump.

(2) Oil Pump.

(3) Primary Filter.

(4) Main Valve.

(5) Orifice.

(6) Inching Valve.

(7) Modulating Valve.

(7A) Load Piston.

(7B) Modulating Valve Orifice.

(8) Selector Valve.

(9) Solenoid Valve Forward.

(10) Solenoid Valve Reverse.

(11) Forward Clutch.

(12) Reverse Clutch.

(13) Relief Valve.

(14) Torque Converter.

(15) Relief Valve.

(16) Converter Bypass.

(17) Oil Cooler.

(18) Torque Converter Supply Bypass.

When the transmission is in FORWARD, the oil flow

from the reservoir, through the pump, primary filter,

torque converter and oil cooler circuits will be the

same as explained in NEUTRAL position.

Oil will flow from the main relief valve to inching valve

(6). Without inching (inching pedal up and valve in), oil

flows around and through the center of reducing spool

(6A) to the bottom of the spool. The oil, at the bottom,

pushes the spool up to the position shown. Oil flows

around the lands of the spool and through a passage

to modulating valve group (7).

In FORWARD, forward solenoid (9) is ON, so pump oil

is sent to the forward selector spool through oil

passage. Forward selector spool (8A) moves to the

right, causing reverse selector spool (8B) to move to

the right also.

With the reverse spool in this position, reverse clutch

(12) is open to drain, Forward selector spool (8A)

opens forward clutch (11) to pump oil. This also opens

reverse selector spool (8B) to drain through oil

passage. Forward clutch (11) will fill with pump oil.

Once filled, oil pressure begins to build up. Pump oil

goes through orifice (7B) and moves load piston (7A)

to the left as pump pressure increases. Oil pressure

increases as the load piston moves further to the left.

The pressure increases to the control pressure of 895

kPa (130 psi). Forward clutch (11) will now be fully

engaged. Modulating valve assembly (7) will now

shuttle between pump oil and drain to maintain clutch

pressure. Clutch fill time takes 0.4 seconds and

pressure increase takes 0.7 seconds. This

approximate 1.1 second clutch fill and pressure rise

time, gives a cushion engagement of forward clutch

(11).

Power Train Systems Operation

29

Page 31

Power Train Systems Operation

30

Page 32

Reverse Direction

Transmission Hydraulic System-Reverse

(1) Transmission Oil Sump.

(2) Oil Pump.

(3) Primary Filter.

(4) Main Valve.

(5) Orifice.

(6) Inching Valve.

(7) Modulating Valve.

(7A) Load Piston.

(7B) Modulating Valve Orifice.

(8) Selector Valve.

(9) Solenoid Valve Forward.

(10) Solenoid Valve Reverse.

(11) Forward Clutch.

(12) Reverse Clutch.

(13) Relief Valve.

(14) Torque Converter.

(15) Relief Valve.

(16) Converter Bypass.

(17) Oil Cooler.

(18) Torque Converter Supply Bypass.

When the transmission is in REVERSE, the oil flow

from the reservoir, through the pump, primary filter,

torque converter and oil cooler circuits will be the

same as explained in NEUTRAL position.

Oil will flow from the main relief valve to inching valve

(6). Without inching (inching pedal up and valve in), oil

flows around and through the center of reducing spool

(6A) to the bottom of the spool. The oil, at the bottom,

pushes the spool up to the position shown. Oil flows

around the lands of the spool and through a passage

to modulating valve group (7).

In REVERSE, reverse solenoid (10) is ON, so the

pump oil is sent to the reverse selector spool through

an oil passage. Reverse selector spool (8B) moves to

the left, causing forward selector spool (8A) to move to

the left also.

With the forward selector spool in this position, forward

clutch (11) is open to drain. Reverse selector spool

(8B) opens reverse clutch (12) to pump oil. This also

opens forward selector spool (8A) to drain through

passages. Reverse clutch (12) will fill with pump oil.

Once filled, oil pressure begins to build up. Pump oil

goes through orifice (7A) and moves load piston (7A)

to the left as pump pressure increases. Oil pressure

increases as the load piston moves further to the left.

The pressure increases to the control pressure of 895

kPa (130 psi). Reverse clutch (12) will now be fully

engaged. Modulating valve assembly (7) will now

shuttle between pump oil and drain to maintain clutch

pressure. Clutch fill time takes 0.4 seconds and

pressure increase takes 0.7 seconds. This

approximate 1.1 second clutch fill and pressure rise

time, gives a cushion engagement of reverse clutch

(12).

Power Train Systems Operation

31

Page 33

Power Train Systems Operation

32

Page 34

Forward Direction During Inching

Transmission Hydraulic System-Forward Inching

(1) Transmission Oil Sump.

(2) Oil Pump.

(3) Primary Filter.

(4) Main Valve.

(5) Orifice.

(6) Inching Valve.

(7) Modulating Valve.

(7A) Load Piston.

(7B) Modulating Valve Orifice.

(8) Selector Valve.

(9) Solenoid Valve Forward.

(10) Solenoid Valve Reverse.

(11) Forward Clutch.

(12) Reverse Clutch.

(13) Relief Valve.

(14) Torque Converter.

(15) Relief Valve.

(16) Converter Bypass.

(17) Oil Cooler.

(18) Torque Converter Supply Bypass.

When the transmission is in FORWARD (or

REVERSE) during INCHING, the oil flow from the

reservoir, through the pump, filter, torque converter

and oil cooler circuits will be the same as explained in

NEUTRAL position.

Oil will flow from the main relief valve through a

passage, to inching valve (6). Inching valve (6) lets the

operator control the oil pressure to forward clutch (11)

between 280 and 0 kPa (40 and 0 psi), which permits

a partial engagement of the clutch. Through the use of

the inching valve, the lift truck can move slowly while

the engine is at higher speeds. This lets the operator

move the lift truck slowly up to a load while the mast is

raised rapidly.

When the operator pushes the inching pedal part of

the way down, inching plunger (6B) moves out of the

inching valve. This takes away some of the spring

force between plunger (6B) and reducing spool (6A). It

also removes the balance condition between the pump

pressure, at the bottom of spool (6A), and the spring

force.

Reducing spool (6A) moves to the right, which

causes a restriction for the pump oil flow. The

pressure drops from 895 kPa (130 psi) to 280 kPa (40

psi). The pressure can drop further depending on the

position of plunger (6A). Pressure reduces as plunger

(6A) is moved out (as the inching pedal is pushed

down).

This reduced pressure flows to selector valve group

(8). The oil will flow through the valve as explained in

forward direction. The reduced (inching) pressure will

flow through a passage to partially engage forward

clutch (11). This reduced pressure permits slippage of

the forward clutch plates and discs. Therefore, the

truck will have an operator

controlled movement. The amount of oil pressure to

clutch (11) depends on the position of inching plunger

(6A). As the plunger is pulled out completely (inching

pedal all the way down) clutch pressure will drop to 0

kPa (0 psi). The forward clutch will be

disengaged at approximately 65.5 kPa (9.5 psi).

Power Train Systems Operation

33

Page 35

V

Basic Control Schematic

The control schematic is shown below. The system

consists of 2 valve bores:

1. Modulating valve

2. Forward and reverse selector valves

DR DR

DR

SOLENOID

DR

FWD

CLUTCH

DR

RE

CLUTCH

SOLENOID

DR

PUMP

Power Train Systems Operation

34

Page 36

Modulating valve function

The modulating valve consists of 5 basic elements:

1. Orifice

2. Springs

3. Load piston

4. Modulating valve

5. Reaction slug

The function of the modulating valve is to control

clutch pressure during a shift. It allows the clutch

pressure to raise gently to the maximum

transmission pressure in order to provide a smooth

clutch engagement and a good shift feel for the vehicle

operator.

There are two forces acting on the modulation valve:

Force 1 = Pressure (load piston) / Area 1

Force 2 = Pressure (clutch) / Area 2

In order for the modulating valve to stay in a balance

position Force 1 must be equal to Force 2.

If for example Force 2 is too large (clutch pressure is

too large) then the valve will be forced to the left,

shutting off supply and opening the clutch and slug

SPRING

DR DR

FLOW TO SELECTOR

SPOOLS

LOAD PISTON

ORIFICE REACTION SLUG

Figure 1

PUMP

pressure to drain, and reducing Force 2.

If Force 1 is too large then the valve would be forced

to the right, opening the clutch circuit to supply,

and increasing the value of Force 2 so it balances

Force 1. By regulating clutch pressures between

supply and drain, valve forces are balanced.

MODULATING VALVE

DR

Power Train Systems Operation

35

Page 37

Modulating valve movement during clutch fill

When a new direction is selected by the operator, the

selector spools open up a circuit to the new clutch

piston. System pressure drops as the new clutch

piston is stroking. This drop in supply pressure causes

a force imbalance on the modulating valve / reaction

slug pressure becomes smaller. Since Force 1 is still

the same, Force 1 forces the modulating valve to the

right until the end of the modulating valve opens the

load piston cavity to drain.

The load piston oil dumps to drain and the load piston

immediately moves to the right (shown in fig.2).

This action is called "load piston reset". It happens

very quickly in comparison to the time needed for the

clutch piston to fully stroke. Therefore the modulating

valve and load piston are ready to start controlling the

clutch pressure in a smooth upward manner once the

clutch piston finishes stroking.

Figure 2

Modulation of clutch to top pressure

As long as reaction slug pressure is greater than load

piston pressure, oil will flow across the orifice from

Area 2 to Area 1. As oil flows to the load piston the

springs will continue to compress, allowing the load

piston to move to the left. As the load piston moves to

the left the spring force increases and load piston

pressure increases.

As press (LP) increases the modulating valve will

cause a corresponding increase in clutch pressure in

order to keep the forces balanced. In simple terms as

the load piston strokes to the left the clutch pressure

rises to maximum system pressure.

This controlled rise in clutch pressure takes about 0.7

sec. and is shown in fig.4. It occurs immediately after

the clutch piston completely strokes (end of clutch fill).

Figure 3

MODULATION

Figure 4

Power Train Systems Operation

36

Page 38

Selector spools

The selector spool circuits are arranged in such a way

that once a gear (forward or reverse) is selected the

opposite solenoid supply is shut off and drained. This

is done to prevent any electrical or malfunction of the

other solenoid from giving a sudden and

unexpected shift.

In addition the two selector spools are arranged so

they cannot select both forward and reverse at the

same time because they mechanically interfere with

each other.

The selector spools have two areas:

1. Slug area

2. Spool area

The slug cavity is exposed to system pressure all the

time. If the solenoid allows system oil to flow to the

end of the spool and pressurize the spool area then

the spool will move toward the slug because the spool

area is larger than the slug area and the force will be

higher. When the solenoid is closed, pressure to the

spool is reduced. This allows the pressure at the slug

to move the spool away from the slug.

In fig.5 the selector spools are shown with forward

gear selected. Notice that the reverse solenoid

supply is drained through the forward spool

Figure 5

Power Train Systems Operation

37

Page 39

Testing And Adjusting

Troubleshooting

Troubleshooting can be difficult. A list of possible

problems and corrections is on the pages that follow.

This list of problems and probable causes will only

give an indication of where a problem can be and what

repairs are needed. Normally, more or other repair

work is needed beyond the recommendations on the

list. Remember that a problem is not

necessarily caused only by one part, but by the

relation of one part with other parts. This list cannot

give all possible problems and probable causes. The

serviceman must find the problem and its source, then

make the necessary repairs.

Always make visual checks first. Check the operation

of the machine and then check with instruments.

WARNING

To prevent personal injury, when testing and

adjusting the power train, move the machine to an

area clear of obstructions. There must be

adequate ventilation for the exhaust. When drive

wheels are off the ground for testing, keep away

from wheels that are in rotation.

Operate the machine in each direction. Make note of

all noises that are not normal and find their source. If

the operation is not correct, make reference to the

troubleshooting chart for "problems" and "probable

causes".

Visual Checks

1. Check the oil level in the transmission and axle with

the engine running and with the Transmission in

NEUTRAL.

2. Check all oil lines, hoses and connections for leaks

and damage. Look for oil on the ground under the

machine.

3. Actuate the controls for the forward direction and

then for the reverse direction. The actuation must

give the same positive action to the hydraulic

control circuit for clutch engagement in both

directions.

4. Remove and check the filter element for loose

particles. Check the strainer behind the

transmission oil plug for foreign material.

a. Particles of friction material give an indication of

a clutch failure.

b. Metallic (metal) particles in the filter give an

indication of wear or mechanical failure in the

transmission and/or axle.

c. Rubber particles give an indication of seal or

hose failure.

If metal or rubber particles are found, all components

of the transmission hydraulic system must be flushed.

Make a replacement of all parts that show damage.

NOTICE

Before these checks are started, fill the transmission

and axle with oil to the correct level. See the Operation

& Maintenance Manual for the procedure to check

transmission and axle oil level.

Activate the controls for the FORWARD direction and

then for the REVERSE direction. The modulation will

be seen on pressure gauge in the clutch pressure tap

when the shift is made at low idle. The pressure will

increase to 895 kPa (130 psi) when completely filled.

Operate the machine in each direction. Make note of

noises that are not normal and find their source. If the

operation is not correct, make reference to the check

List During Operation for "problems" and "probable

causes".

Power Train Testing and Adjusting

38

Page 40

Check List During Operation

Problem: Engine starts with directional control

switch in FORWARD or REVERSE.

Probable cause:

1. Directional control switch is defective

Problem: Transmission shifts with parking brake

engaged.

Probable cause:

1. Parking brake switch is defective.

Problem: Transmission will not stay in gear when

shifted.

Probable cause:

1. Parking brake switch mounting is loose.

Problem: Transmission does not operate in either

direction or does not shift.

Probable cause:

1. Problems in the electrical circuit (directional con-

trol)

a. Open circuit between ignition switch and direc-

tional control switch.

b. Defective directional control switch.

c. Defective wiring harness between directional

control switch and transmission.

d. Shorted wiring harness for the solenoids.

2. Low oil pressure or no oil pressure caused by:

a. Iow oil, no oil or thick oil.

b. Inching control valve linkage loose, broken or

adjustment is not correct.

c. Inching valve reducing spool stuck open.

d. Failure of the oil pump or a defect in the oil

pump.

e. Main relief valve stuck open.

f. Restriction in the oil flow circuit such as dirty oil

screen.

g. Leakage inside the transmission.

Worn or broken metal seal rings on input

or reverse shaft.

Worn or broken seals around clutch piston.

Modulating valve assemblies stuck

Because of contaminated oil

3. External oil lines are not connected correctly.

4. Mechanical failure in the transmission.

Problem:Transmission operates only in FORWARD.

Probable cause:

1. Forward clutch is locked up.

2. Reverse solenoid valve does not actuate.

3. Reverse clutch components have damage.

a. Leakage caused by worn or broken metal sea-

ling rings.

b. Leakage caused by worn or broken clutch piston.

c. Failure of shaft seal ring.

Problem: Transmission operates only in REVERSE.

Probable cause:

1. Reverse clutch is locked up.

2. Forward solenoid valve does not actuate.

3. Forward clutch components have damage.

a. Leakage caused by worn or broken metal

sealing rings

b. Leakage caused by worn or broken seal around

clutch piston.

c. Failure of shaft seal ring.

Problem: Transmission gets hot.

Probable cause:

1. Restriction in cooling circuit.

2. Oil level too high or too low.

3. Core of the oil cooler not completely open.

4. Low pump pressure - worn or damaged pump.

5. Converter one-way clutch worn and slipping.

6. Air mixed in the oil. Air leaks on the intake side of

the pump.

Power Train Testing and Adjusting

39

Page 41

7. Low oil flow through converter. Converter relief

valve stuck open (converter bypass orifice plugged)

8. Incorrect use of vehicle. Loads are too heavy for the

lift truck.

9. Too much inching operation (slipping the clutch

plates and discs).

10. Too much stalling of torque converter.

11. Cooler relief valve stuck open, full oil flow does

not go through oil cooler.

Problem: Clutch engagement is slow or loss of

power during engagement.

Probable cause:

1. Low oil pressure

2. Air mixed in the oil.

a. Air leaks on suction side of pump.

b. Low oil level also causes aeration.

3. Inching valve linkage adjustment is not correct.

4. Modulating valve assembly leaks or partially stuck.

Problem: Clutch engagement makes a rough shift.

Probable cause:

1. Modulating valve assembly, load piston and/or

reducing valve stuck.

Problem: Vehicle operates in one direction and

creeps in that direction in NEUTRAL. Engine stalls

when shifted to the other direction.

Probable cause:

1. Failure of clutch in the direction the lift truck moves.

Clutch discs or plates are warped (damaged) or

held together because of too much heat.

2. Failure of the modulating valve assembly in the

direction the lift truck moves. The valve assembly

stuck in the engaged position possibly caused by

metal burrs (particles) or oil contamination.

Check List From Operation Noises

Problem: Noise in NEUTRAL only.

Probable cause:

1. Worn one-way clutch in torque converter.

2. Low oil level (pump cavitation).

3. Worn bearing next to pump.

Problem: Pump noise not normal

Probable cause:

1. A loud sound at short time periods gives an

indication that foreign material is in the

transmission hydraulic system.

2. A constant loud noise is an indication of pump

failure.

Problem: Noise in the Transmission that is not

normal.

Probable cause:

1. Transmission components have wear or damage.

a. Damaged gears.

b. Worn teeth or clutch plates and/or clutch discs.

c. Slipping clutch plates and disc noise.

d. Other component parts have wear or damage.

e. Failure of the thrust washers.

2. Modulating valve assembly makes noise.

Problem: Constant noise in the Drive axle.

Probable cause:

1. Lubricant not to the specific level.

2. Wrong type of lubricant.

3. Wheel bearings out of adjustment or have a defect.

4. Bevel gears not in adjustment for correct tooth

contact.

5. Teeth of bevel gear have damage or wear.

Power Train Testing and Adjusting

40

Page 42

6. Too much or too little gear backlash.

7. Loose or worn pinion bearings.

8. Loose or worn shaft bearings.

9. Loose or worn differential bearings.

Problem: Noise at different intervals.

Probable cause:

1. Bolts on drive gear not tightened correctly.

2. Drive gear has a defect (warped).

3. Loose or broken differential bearings.

4. Bevel gear bearing failure.

Problem: Noise on turns only

Probable cause:

1. Differential pinion gears too tight on the spider or

the pinion shaft.

2. Side gears tight in differential case.

3. Differential pinion or side gears have a defect.

4. Thrust washers worn or have damage.

5. Too much clearance (backlash) between side gears

and pinion.

6. Worn axle shaft assembly gear.

7. Hub gear worn.

8. Wheel bearings worn or out of adjustment.

Problem: Leakage of lubricant.

Probable cause:

1. Loss through hub seals.

a. Lubricant above specification level.

b. Wrong kind of lubricant.

c. Restriction of axle housing breather.

d. Hub oil seal installed wrong or has damage.

Power Train Testing and Adjusting

2. Loss at bevel input pinion shaft.

a. Lubricant above specification level.

b. Wrong kind of lubricant.

c. Restriction of axle housing breather.

d. Pinion oil seal worn or not installed correctly.

Problem: Drive wheels do not turn.

Probable cause:

1. Broken axle shaft.

a. Loose wheel bearings.

b. Axle shaft too short.

2. Side gear or differential pinion broken.

3. Differential pinion shaft or spider broken.

Check List From Pressure Tests

Problem: Low pressure to FORWARD and

REVERSE clutches.

Probable cause:

1. Inching valve linkage adjustment is not correct.

2. Inching valve reducing spool stuck open.

3. Clutch piston seals cause leakages.

4. Main relief valve setting too low caused by a

defective relief valve spring.

5. Low oil pressure. See Probable Cause for Low Oil

Pressure.

6. External oil lines are not connected correctly.

7. Modulating valve assembly stuck.

Problem: Clutch pressure and pump pressure are

high.

Probable cause:

1. Main relief valve is stuck.

2. A restriction in the hydraulic circuit.

3. Main relief valve not adjusted properly.

41

Page 43

Problem: Pressure to one clutch is low.

Probable cause:

1. Clutch piston seal alignment is not correct, oil leaks

through.

2. Seal rings on shaft or clutch piston seals are broken

or worn.

3. Modulating valve assembly stuck.

Problem: Low pump pressure.

Probable cause:

1. Low oil level.

2. Main relief valve movement is restricted.

3. Transmission oil pump is worn.

4. Inner oil leakage.

5. Main relief valve not adjusted properly.

Problem: Low lubrication pressure or no

lubrication pressure.

Probable cause:

1. Low oil pressure or no oil pressure caused by:

a. Failure of the oil pump or a defect in the oil

pump.

b. Restriction in the oil flow circuit such as a dirty

oil screen.

c. Inching valve reducing spool stuck open.

d. Leakage inside of transmission caused by com-

ponent defects.

2. Oil cooler has restriction to oil flow.

Problem: High lubrication pressure.

Probable cause:

1. Restricted external oil lines or internal passages.

2. External oil lines are not connected correctly.

Problem: High converter charge pressure.

Probable cause:

1. A plugged converter bypass orifice.

2. A restriction inside the converter assembly.

3. A plugged oil flow passage.

Problem: Low converter charge pressure.

Probable cause:

1. Converter relief valve stuck open.

2. Main relief valve movement is restricted.

Problem: Low converter outlet pressure or cooler

inlet pressure.

Probable cause:

1. Low oil pressure.

2. Cooler relief valve stuck open.

Problem: High converter outlet pressure or cooler

inlet pressure.

Probable cause:

1. Restriction in oil cooler lines or a plugged oil

cooler.

Problem: Low stall speed.

Probable cause:

1. Engine performance is not correct.

2. The one-way clutch of the torque converter does not

hold.

Problem: High stall speed in both directions.

Probable cause:

1. Low oil level.

2. Air in the oil.

3. Clutches slip (clutch plates slide in relation to one

another).

4. Torque converter failure.

Power Train Testing and Adjusting

42

Page 44

Problem: High stall speed in one direction.

Probable cause:

1. There is a leak in the clutch circuit.

2. There is a failure in that clutch assembly (clutch

slipping).

Problem: Selector spool problems.

1. Transmission stays in neutral, no shift.

Probable cause:

1. Spools mechanically stuck

a. Contamination

b. Case or body not flat

c. Bore / spool worn

2. Solenoids not working

a. O-rings leaking (cut)

b. O-rings missing

Problem: Modulation spool problems.

1. Slow or no modulation of both clutches

(If only 1 clutch does not modulate correctly then

the problem is either with the selector spool or it is

a problem in the transmission).

Probable cause:

1. orifice plugged with debris

2. Modulation valve stuck

3. Modulation valve not correctly assembled.

4. Load piston problem

a. Stuck in bore

b. Excessive valve / bore clearance

c. Missing springs

5. Porosity in body in the area of load piston cavity

2. Modulation time is too quick

Probable cause:

c. Ports not machined properly

d. Contamination in solenoid

e. Electrical problem

3. orifice plugged

a. With debris

b. Bad part

4. Modulation valve stuck in "off" position

5. Modulation valve not correctly assembled.

2. Transmission will not shift into or out of 1 gear

Probable cause:

1. Spools mechanically stuck(same as above)

2. Solenoids not working(same as above)

3. Valve not correctly assembled(same as above)

4. Holes not drilled into case properly

1. The upstream orifice (in the oil supply) is not

installed. (The orifice is located in the valve block)

2. The load piston is only moving a small amount

before it sticks. Check the spool to see if it freely

fits in the bore. This check must be made while the

aluminum body is still bolted down to the

transmission.

3. The plastic orifice is not installed or the hole in the

plastic housing is too large.

4. The modulating valve is stuck in an open position.

Check to see if the valve moves freely while the

aluminum body is still bolted down.

5. The springs are not installed or the pin has jammed

the load piston

5. Excessive leakage internally in body

a. Porosity in body

b. Selector bore too large

c. Spool too small

d. Slug/spool fit not right.

Power Train Testing and Adjusting

43

Page 45

Transmission and Drive Axle

Tests And Adjustments

Transmission Pressure Tests

Tools Needed

Pressure Gauge Group 1

WARNING

To prevent personal injury, when the transmission

is tested, move the truck to a clear area, that is

level. Keep all other personnel away from the lift

truck. Use lifting equipment or a save method to

lift the front of the lift truck until the drive wheels

are off the floor. Put wood blocks or jack stands of

the correct capacity under it to hold it in this

position while pressure tests are performed.

When the transmission tests are made, the

transmission oil must be at the correct level. The

pressure given in the chart are taken with the

transmission oil temperature at 49 to 71°C (120 to

160°F). If the oil temperatue is lower than 49°C

(120°F) the oil pressure will be higher than that shown.

If the oil temperature is higher than 71°C (160°F), the

pressure will be lower than that shown.

Raise the front of the lift truck off the floor. Put wood

blocks or jack stands of the correct capacity under it to

hold it in this position while pressure tests are

performed.

WARNING

Before any pressure tap plugs or connections are

removed, the engine must be stopped with the

transmission controls in NEUTRAL. This will

release hydraulic pressure in the transmission.

For more identification of transmission problems, the

pressures that follow can be checked.

a. Pump pressure in neutral.

b. Forward clutch pressure in forward.

c. Reverse clutch pressure in reverse.

d. Converter charge pressure in neutral.

e. Converter outlet or cooler inlet pressure in neutral.

f. Lubrication pressure in neutral.

Most problems in the hydraulic circuit can normally be

found when the pump pressure is checked. If more

information is necessary, gauges can be installed at

each pressure tap location. Locations of the pressure

taps and procedures for testing are given as follows. If

any of the pressures are not correct, refer to

Troubleshooting For Problems and Probable Causes.

1. Be sure the transmission control adjustments are

correct before tests are made.

See Inching Pedal Adjustment in Testing And

Adjusting.

2. Install a tachometer to the engine to show engine

speed during the test.

3. Put a thermistor probe in place of the dipstick in the

transmission oil reservoir.

4. Remove each of the following pressure tap plugs in

the order shown and install the 0 to 2050 kPa (0 to

300 psi) pressure gauge. After the pressure check

is done, remove the gauge and install the plug

again.

5. Check pump pressure with the transmission in

neutral at pressure tap (6) on the valve body first. If

it is not correct, then check pump pressure at

pressure tap (1) on the bearing plate.

a. If the pressure is low at pressure tap (6), but

correct at pressure tap (1), there could be an oil

line restriction or a defective inching valve.

NOTE: Pump pressure should be checked at

pressure tap (6) first because pressure tap (6) is

easier to get to than pump pressure tap (1) on the

bearing plate. If pump pressure is correct at

pressure tap (6), it will be correct at pressure tap

(1) also.

b. If the pressure is low at both locations, see

Problem: Low pump pressure in Troubleshooting.

NOTE: Pump pressure is adjusted by adding or

removing shims in the D700296 Plug. The plug is

located in the main relief valve on the valve body.

6. Check clutch pressure as follows:

a. Check forward clutch pressure at pressure tap

(4) with the transmission in forward. If the

pressure is not correct, see Problem: Low

forward clutch pressure in Troubleshooting.

b. Check reverse clutch pressure at pressure tap

(5) with the transmission in reverse. If the

pressure is not correct, see Problem: Low

reverse clutch pressure in Troubleshooting.

Power Train Testing and Adjusting

44

Page 46

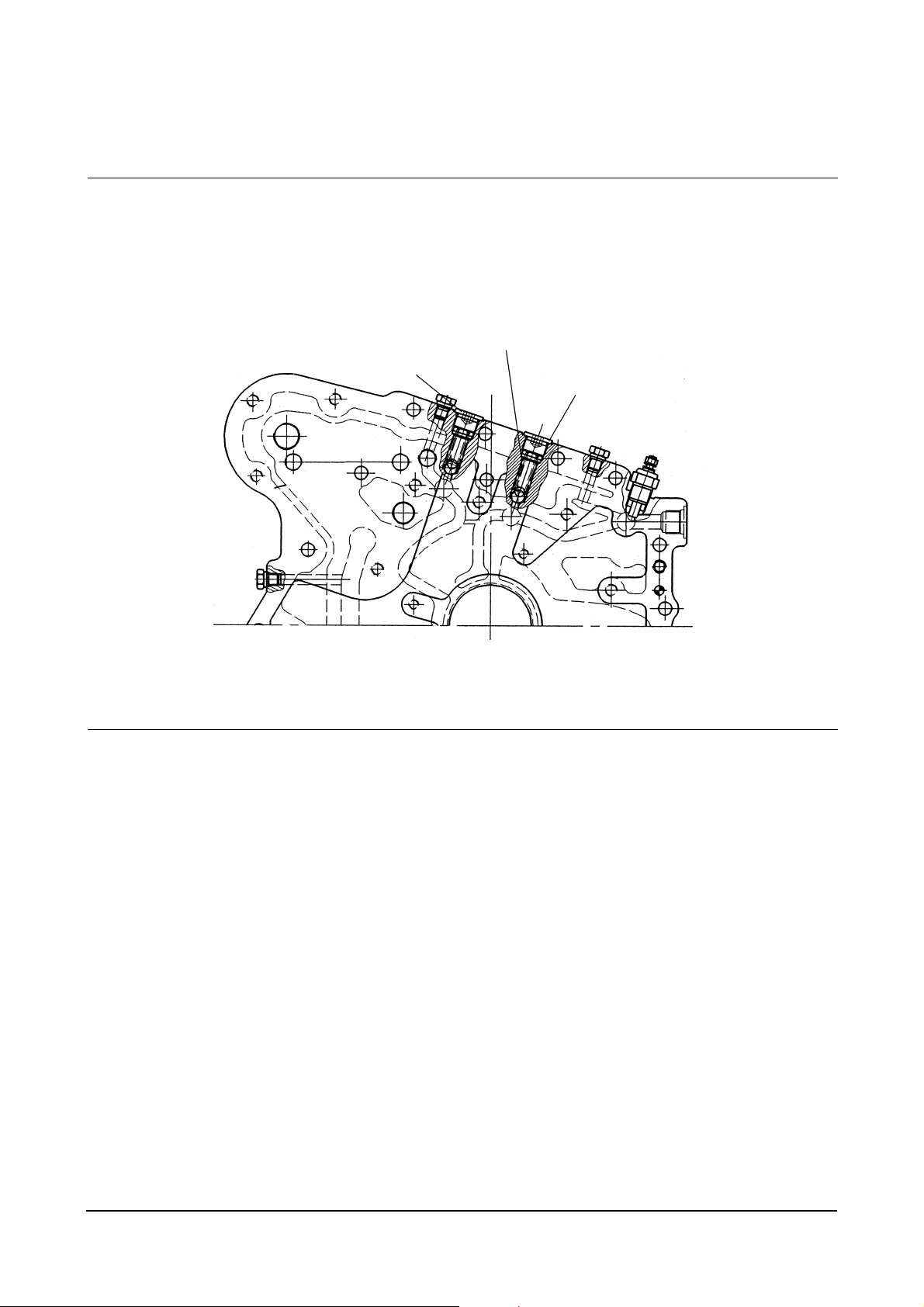

Pressure Tap Locations – Transmission Control Group

Converter Charge Pressure Tap 3

Main Pressure Tap 6

Forward Pressure Tap 4

Reverse Pressure Tap 5

Converter Outlet Pressure Tap 2

Temperature Sensor

To Cooler

From Cooler

Lubrication Pressure Tap 7

Power Train Testing and Adjusting

45

Page 47

7. Check lubrication pressure at pressure tap (7) with

the transmission in neutral.

a. If lubrication pressure is low, see Problem: Low

lubrication pressure in Troubleshooting.

b. If lubrication pressure is high, see Problem:

High lubrication pressure in Troubleshooting.

8. Check converter charge (inlet) pressure at pressure

tap (3) with the transmission in neutral.

a. If converter charge pressure is low, see

Problem:

Low converter charge pressure in

Troubleshooting.

b. If converter charge pressure is high, see

Problem:

High converter charge pressure in

Troubleshooting.

9. Check converter outlet or cooler inlet pressure at

pressure tap (2) with the transmission in neutral.

a. If the pressure is low, see Problem: Low

converter outlet or cooler inlet pressure in

Troubleshooting.

b. If the pressure is high, see Problem: High

converter outlet or cooler inlet pressure in

Troubleshooting.

NOTE: Do not activate the inching pedal when

pressure checks are made. Check for the pressures

as shown in Transmission Pressure Chart in the order

that follows:

Converter Chage

Converter Outlet

or Cooler Inlet

Converter Chage - -

Converter Outlet

or Cooler Inlet

Transmission Pressure Chart

Low idle 2000 rpm

Shift position - Neutral

Main Line

Clutch

Lubrication

Shift position – Forward or Reverse

Main Line - -

Clutch

Lubrication - -

830 to 1030 kPa

(120 to 150psi)

0 kPa

(0 psi)

14 to 70 kPa

(2 to 10 psi)

70 to 140 kPa

(10 to 20 psi)

25 to 55 kPa

(4 to 8 psi)

725 to 860 kPa

(105 to 125 psi)

-

-

895 to 1100kPa

(130 to 160psi)

0 kPa

(0 psi)

240 to 345 kPa

(35 to 50 psi)

590 to 795 kPa

(85 to 115 psi)

250 to 400 kPa

(36 to 58 psi)

725 to 965 kPa

(105 to 140 psi)

-

-

Converter Stall Test

NOTE: Make sure that the transmission oil is at the

correct temperature for operation before tests are

made.

The converter stall test is a test to check engine power.

It can also be used to locate a problem in the

transmission or torque converter when the condition of

the engine is known. An engine, which does not have

correct performance, will give an indication of a stall

speed that is not correct. If the engine performance is

correct and the stall speed is not correct, the problem

in the converter or transmission can be found with this

test.

NOTE: To check the engine performance, see the

respective engine module. This test checks the

maximum RPM that the engine, at full throttle, can turn

the converter with the turbine held stationary. To hold

the converter turbine, engage the brakes with the

transmission in FORWARD or REVERSE.

The drive wheels must not turn during the stall test.

Put a heavy load on the forks. Also put the truck in

position against a solid object that will not move (such

as a loading dock). When the tests are made, the

wheel brakes must be engaged with the left foot. The

accelerator pedal can be operated with the right foot.

WARNING

Make tests in a clear level area only. There must be

one operator. Keep all other personnel away from

the lift truck. Check the operation of the brakes

before the tests are made.

Check the high idle setting before the stall test is made.

Set the high idle to the specification, as given in the

respective engine module.

NOTE: Make sure that the transmission oil is at the

correct temperature for operation before tests are

made.

1. Connect a tachometer to the engine. Start the

engine. Engage the wheel brakes with the left foot.

2. Put the transmission control lever in FORWARD

and push the accelerator pedal down completely

with the right foot. Read the RPM on the

tachometer, then release the accelerator pedal.

Power Train Testing and Adjusting

46

Page 48

NOTICE

To make sure that the transmission oil does not

get hot, do not hold the transmission in a stall

condition for more than ten seconds. After the

transmission is stalled, put the controls in

NEUTRAL and run the engine at 1200 to 1500 RPM

to cool the oil.

3. Repeat the procedure above for the REVERSE

direction.

4. The stall speeds for the different trucks are listed

in the charts that follow:

LIFT TRUCK STALL SPEED

RPM±100

Engine

DB33A 1778 1678 2450±50

B3.3 1830 1730 2450±50

Hercules

2.7 LP

Hercules

2.7 Gas

Hercules

2.7 Dual

MMC

G424 LP

MMC

G424 Gas

MMC

G424 Dual

GM

G430 LP

Without Power

Brakes Applied

1633 1533 2500±100

1633 1533 2500±100

1520±75 1420±75 2500±100

1830 1730 2700±50

1890 1790 2700±50

1740±75 1640±75 2700±50

1750 1650 2600 ± 50

RPM±100

With Power

Brakes Applied

Engine

Max.RPM

-

Stall speeds that are low are an indication that the

engine performance is not correct or the one-way

cutch of the torque converter does not hold in reverse

direction. If the one-way clutch has a defect, the stall

speed will probably be more than 800 rpm low.

The stall speed must be the same in FORWARD and

REVERSE. If the stall speed is high in FORWARD and

REVERSE, check the following:

a. Check for air in the oil.

b. Check the torque converter and the clutch

pressures according to transmission Pressure

Tests in Testing And Adjusting.

c. If clutch pressure is correct, make an inspection of

the clutch assembly for that direction for possible

damage to clutch components.

Power Train Testing and Adjusting

47

Page 49

Maintenance

Transmission and Drive Axle

Transmission

ATTENTION : When changing oil, replace filter and clean suction strainer.

Change

Filter

Grease Parking

Brake Lever

Oil Filler And Dipstick

Pin And Nut

Of Parking Brake

Oil Drain Plug

Suction Strainer

And

Power Train Testing and Adjusting

48

Page 50

Drive Axle

Brake Cooling Port

ATTENTION : Clean suction strainer when replacing oil.

Oil Drain Plug Port

Pump Suction Port Brake Cooling Port

Combined Oil Filler and

Dipstick

Power Train Testing and Adjusting

49

Page 51

Electric Control System Tests

Tools Needed

Digital Multimeter 1

NOTE : Refer to Schematic.

Checks on the transmission directional control

electrical circuit can be done with a Digital Multimeter.

All voltage checks are made at the wiring harness

connectors with the ignition switch ON, DO NOT start

the engine. All continuity checks are done with the

ignition switch OFF.

A beginning check of the direction control system

should be performed before testing the individual

components and wiring

harness. When the direction solenoids are energized

they become magnetized. By holding a metal

screwdriver next to the solenoids it can be

determined whether they are energized or not.

Turn the ignition switch ON, DO NOT start the engine.

Release the parking brake. Place the

direction control switch in forward and check the

forward solenoid for magnetism. Do the same for the

reverse direction.

z If the solenoids didn’t energize begin testing the

control system with step 1.

z If the solenoids did energize, go to step 10.

Power To Directional Control Switch Check

1. Put the directional control lever in neutral. Remove

the cover from the front side of the steering

support assembly.

2. Disconnect harness connector (2) from directional

control switch connector(1).

1

2

Directional Control Switch Connector

(1) Directional Control Switch Connector.

(2) Harness Connector.

3. Engage the parking brake and turn the ignition

switch ON, DO NOT start the engine. Put the

multimeter on the 20 volt range.

2

Power To Directional Control Switch Check

(2) Harness Connector.

4. Put the (-) probe on a good ground. Put the (+)

probe on socket 1 of harness connector (2).

a. If the indication is battery volts, do Step 5.

b. If the indication is 0 volts, check the

Forward/Reverse fuse (No.3) located in the fuse

box and check the connecting wires for continuity.

Power Train Testing and Adjusting

50

Page 52

Directional Control Switch Check

5. Turn the ignition switch OFF and put the

multimeter on the 200 ohm range.

6. Check continuity between pins 4 and 7 of

connector (1) with the switch in neutral. forward

and then reverse positions. There should be

continuity in neutral and no continuity in forward

and reverse.

a. If the above checks are correct, do Step 7.

b. If any of the above checks are not correct, replace

the directional control switch.

1

Directional Control Switch Continuity Check

(1) Directional control switch connector.

7. Check continuity between pins 1 and 2 of

connector (1) in forward and then neutral position.

There should be continuity in forward and no

continuity in neutral. While the continuity is

checked in forward position, move the lever back

and forth (but stay in forward position) to see if the

resistance goes up or down. The resistance should

be constant.

a. If the above checks are correct, do step 8.

b. If the above checks are not correct, replace the

directional control switch.

8. Check continuity between pins 1 and 3 of connector

(1) in reverse and then neutral positions. There

should be continuity in reverse and no continuity in

neutral. While the continuity is checked in reverse

position, move the lever back and forth (but stay in

reverse position) to see if the resistance goes up or

down. The resistance should be constant.

a. If the above checks are correct, do Step 9.

b. If any of the above checks are not correct, replace

the directional control switch.

Power Train Testing and Adjusting

51

Page 53

12

Transmission Directional Control Schematic