Operation &

Maintenance Manual

LIFT TRUCKS

D20S-3, D25S-3, D30S-3, D33S-3

G20E-3, G25E-3, G30E-3

GC20E-3, GC25E-3, GC30E-3

G20P-3, G25P-3, G30P-3, G33P-3

GC20P-3, GC25P-3, GC30P-3

D32S-3 (6,500lb@24"L.C.)

G32E-3 (6,500lb@24"L.C.)

G32P-3 (6,500lb@24"L.C.)

GC32E-3 (6,500lb@24"L.C.)

GC32P-3 (6,500lb@24"L.C.)

SB2302E06

WARNING

Do not start, operate or service this machine unless you have read and understood

these instructions and received proper training.

Unsafe or improper use of the machine may cause serious injury or death.

Operators and maintenance personnel must read this manual and receive training

before operating or maintaining the machine.

This manual should be kept with the machine for reference and periodically

reviewed by the machine operator and by all personnel who will come into contact

with it.

The following warning is provided pursuant to California Health & Safety Code Sections

25247.5 et, seq,

WARNING

California Proposition 65

Engine Exhaust, some of its constituents, and certain vehicle components contain

or emit chemicals known to the State of California to cause cancer and birth

defects or other reproductive harm.

Battery posts, terminals and related accessories contain lead and lead

compounds, chemicals known to the State of California to cause cancer and birth

defects or other reproductive harm.

WASH HANDS AFTER HANDLING.

Table of Contents

Information Section

Information Section

Foreword................................................................ 2

Literature Information............................................. 2

Safety Section

Important Safety Information ................................. 4

Safety..................................................................... 5

Warning Signs and Labels.................................. 5

Parking brake...................................................... 9

General Hazard Information ............................. 10

Operation Information....................................... 11

Maintenance Information.................................. 14

Operator Restraint System(If Equipped) ..........17

Avoiding Lift Truck Tipover ............................... 21

Safety Rules ..................................................... 23

How to Survive in a Tipover.............................. 28

General Section

Specifications....................................................... 30

Noise and Vibration ............................................. 50

Capacity Chart ..................................................... 51

Serial Number...................................................... 61

Operator's Warning and Identification Plate........ 64

Operation Section

Operator's Station and Monitoring Systems ........ 65

Lift Truck Controls................................................ 69

Refueling.............................................................. 72

Before Starting the Engine................................... 75

Starting the Engine .............................................. 78

Dual Fuel System (If G424 Dual Fuel Engine

Equipped) ............................................................ 81

Dual Fuel System (G424E Engine Only)............. 83

Lift Truck Operation ............................................. 86

G424E/G430E Electronic Controlled LP Engines

(If Equipped) ........................................................ 89

Advanced Diagnostics ....................................... 104

Table a. MI-04 Diagnostic Fault Codes (Flash

Codes) ...............................................................106

Auto Shift Controller ASC-100 (If Equipped) ..... 112

Operating Techniques........................................ 115

Parking the Lift Truck......................................... 119

Lift Fork Adjustment........................................... 120

Storage Information ........................................... 121

Transportation Hints........................................... 122

Towing Information............................................. 123

Maintenance Section

Inspection, Maintenance and Repair of Lift Truck

Forks ..................................................................124

Tire Inflation Information.....................................128

Torque Specifications .........................................129

Cooling System Specifications...........................131

Fuel Specifications .............................................133

Lubricant Information .........................................135

Lubricant Viscosities and Refill Capacities.........137

Maintenance Intervals ........................................138

When Required ..................................................142

Every 10 Service Hours or Daily ........................152

First 50 - 100 Service Hours or a Week.............157

First 250 Service Hours or a Month ...................162

Every 250 Service Hours or Monthly..................163

Every 500 Service Hours or 3 Months ...............170

Every 1000 Service Hours or 6 Months .............179

Every 1500 Service Hours or 9 Months .............185

Every 2000 Service Hours or Yearly ..................188

Every 2500 Service Hours or 15 Months ...........195

Every 3000 Service Hours or 18 Months ...........198

Every 4500 Service Hours or two Years ............199

Index Section

Index...................................................................200

-1-

Information Section

Foreword

Literature Information

This manual should be stored in the operator’s

compartment in the literature holder or seat back

literature storage area.

This manual contains safety, operation,

transportation, lubrication and maintenance

information.

Some photographs or illustrations in this publication

show details or attachments that can be different

from your lift truck. Guards and covers might have

been removed for illustrative purposes.

Continuing improvement and advancement of

product design might have caused changes to your

lift truck which are not included in this publication.

Read, study and keep this manual with the lift truck.

Whenever a question arises regarding your lift truck,

or this publication, please consult your DAEWOO

dealer for the latest available information.

Safety

The Safety Section lists basic safety precautions. In

addition, this section identifies the text and

locations of warning signs and labels used on the

lift truck.

Read and understand the basic precautions listed

in the Safety Section before operating or

performing lubrication, maintenance and repair on

this lift truck.

Operator Restraint System (If Equipped)

This manual contains safety, operation and

maintenance information for the DAEWOO operator

restraint system. Read, study and keep it handy.

WARNING

Your DAEWOO truck comes equipped with an

operator restraint system. Should it become

necessary to replace the seat for any reason, it

should only be replaced with another DAEWOO

operator restraint system.

Photographs or illustrations guide the operator

through correct procedures of checking, operation

and maintenance of the DAEWOO operator

restraint system.

SAFE and EFFICIENT OPERATION of a lift truck

depends to a great extent on the skill and alertness

on the part of the operator. To develop this skill the

operator should read and understand the Safe

Driving Practices contained in this manual.

Forklift trucks seldom tipover, but in the rare event

they do, the operator may be pinned to the ground

by the lift truck or the overhead guard. This could

result in serious injury or death.

Operator training and safety awareness is an

effective way to prevent accidents, but accidents

can still happen. The DAEWOO operator restraint

system can minimize injuries. The DAEWOO

operator restraint system keeps the operator

substantially within the confines of the operator’s

compartment and the overhead guard.

This manual contains information necessary for

Safe Operation. Before operating a lift truck, make

sure that the necessary instructions are available

and understood.

Operation

The Operation Section is a reference for the new

operator and a refresher for the experienced one.

This section includes a discussion of gauges,

switches, lift truck controls, attachment controls,

transportation and towing information.

Photographs and illustrations guide the operator

through correct procedures of checking, starting,

operating and stopping the lift truck.

Operating techniques outlined in this publication

are basic. Skill and techniques develop as the

operator gains knowledge of the lift truck and its

capabilities.

-2-

Information Section

Maintenance

The Maintenance Section is a guide to equipment

care. The illustrated, step-by-step instructions are

grouped by servicing intervals. Items without

specific intervals are listed under “When Required”

topics. Items in the “Maintenance Intervals” chart

are referenced to detailed instructions that follow.

Maintenance Intervals

Use the service hour meter to determine servicing

intervals. Calendar intervals shown (daily, weekly,

monthly, etc.) can be used instead of service hour

meter intervals if they provide more convenient

servicing schedules and approximate the indicated

service hour meter reading. Recommended service

should always be performed at the interval that

occurs first.

Under extremely severe, dusty or wet operating

conditions, more frequent lubrication than is

specified in the “Maintenance Intervals” chart might

be necessary.

Perform service on items at multiples of the original

requirement. For example, at “Every 500 Service

Hours or 3 Months”, also service those items listed

under “Every 250 Service Hours or Monthly” and

“Every 10 Service Hours or Daily”.

Environment Management

Note that DAEWOO INDUSTRIAL VEHICLE

DIVISION is ISO 14001 certified which is

harmonized with ISO 9001. Periodic

ENVIRONMENTAL AUDITS & ENVIRONMENTAL

PERFORMANCE EVALUATIONS have been made

by internal and external inspection entities.

LIFE-CYCLE ANALYSIS has also been made

through out the total product life. ENVIRONMENT

MANAGEMENT SYSTEM includes DESIGN FOR

ENVIRONMENT from the initial stage of the design.

ENVIRONMENT MANAGEMENT SYSTEM

considers environmental laws & regulations,

reduction or elimination of resource consumption as

well as environmental emission or pollution from

industrial activities, energy saving,

environment-friendly product design(lower noise,

vibration, emission, smoke, heavy metal free,

ozone depleting substance free, etc.), recycling,

material cost reduction, and even environmentally

oriented education for the employee.

-3-

Safety Section

Important Safety Information

Most accidents involving product operation, maintenance and repair are caused by failure to observe basic

safety rules or precautions. An accident can often be avoided by recognizing potentially hazardous situations

before an accident occurs. A person must be alert to potential hazards, and use common sense. Persons

must also have the necessary training, skills and tools before attempting to perform these functions.

Improper operation, lubrication, maintenance or repair of this product can be dangerous and could

result in injury or death.

Do not operate or perform any lubrication, maintenance or repair on this product, until you have read

and understood the operation, lubrication, maintenance and repair information.

Safety precautions and warnings are provided in this manual and on the product. If these hazard

warnings are not heeded, bodily injury or death could occur to you or other persons.

The hazards are identified by the “Safety Alert Symbol” and followed by a “Signal Word” such as “WARNING”

as shown below.

WARNING

The meaning of this safety alert symbol is as follows:

Attention! Become Alert! Your Safety is involved.

The message that appears under the warning, explaining the hazard, can be either written or pictorially

presented.

Operations that may cause product damage are identified by NOTICE labels on the product and in this

publication.

DAEWOO cannot anticipate every possible circumstance that might involve a potential hazard, and common

sense is always required. The warnings in this publication and on the product are therefore not all inclusive.

Before any tool, procedure, work method or operating technique not specifically recommended by DAEWOO

is used, you must be sure that it is safe for you and others. You should also ensure that the product will not be

damaged or made unsafe by the operation, lubrication, maintenance or repair procedures you choose.

The information, specifications, and illustration in this publication are on the basis of information available at

the time it was written. The specifications, torques, pressures, measurements, adjustments, illustrations, and

other items can change at any time. These changes can affect the service given to the product. Obtain the

complete and most current information before starting any job. DAEWOO dealers have the most current

information available.

-4-

Safety

The safety rules and regulations in this section are

representative of some, but not all rules and

regulations noted under the Occupational Safety

and Health Act (OSHA) and are paraphrased

without representation that the OSHA rules and

regulations have been reproduced verbatim.

Please refer to 1910. 178 in Federal Register Vol.

37, No. 202, the National Fire Protection

Association No. 505 (NFPA), American National

Standard, ANSI B56. 1 Safety Standard for Low lift

and High Lift Trucks and subsequent revisions for a

complete list of OSHA rules and regulations as to

the safe operation of powered industrial lift trucks.

Since regulations vary from country to country

outside in U.S.A., operate this lift truck in

accordance with local regulations.

DAEWOO lift trucks are manufactured according to

the regulations and standards laid down in EU

Machinery Directive 98/37/EC and EMC directive

89/336/EC. Please refer to the Directives

89/655/EC and 89/391/EC and its amendments for

the safe use of DAEWOO lift trucks.

The most effective method of preventing serious

injury or death to the lift truck operator or others is

for the lift truck operator to be familiar with the

proper operation of the lift truck, to be alert and to

avoid actions or conditions which can result in an

accident.

Do not operate a lift truck if in need of repair,

defective or in any way unsafe. Report all defects

and unsafe conditions immediately. Do not attempt

any adjustments or repairs unless trained and

authorized to do so.

Safety Section

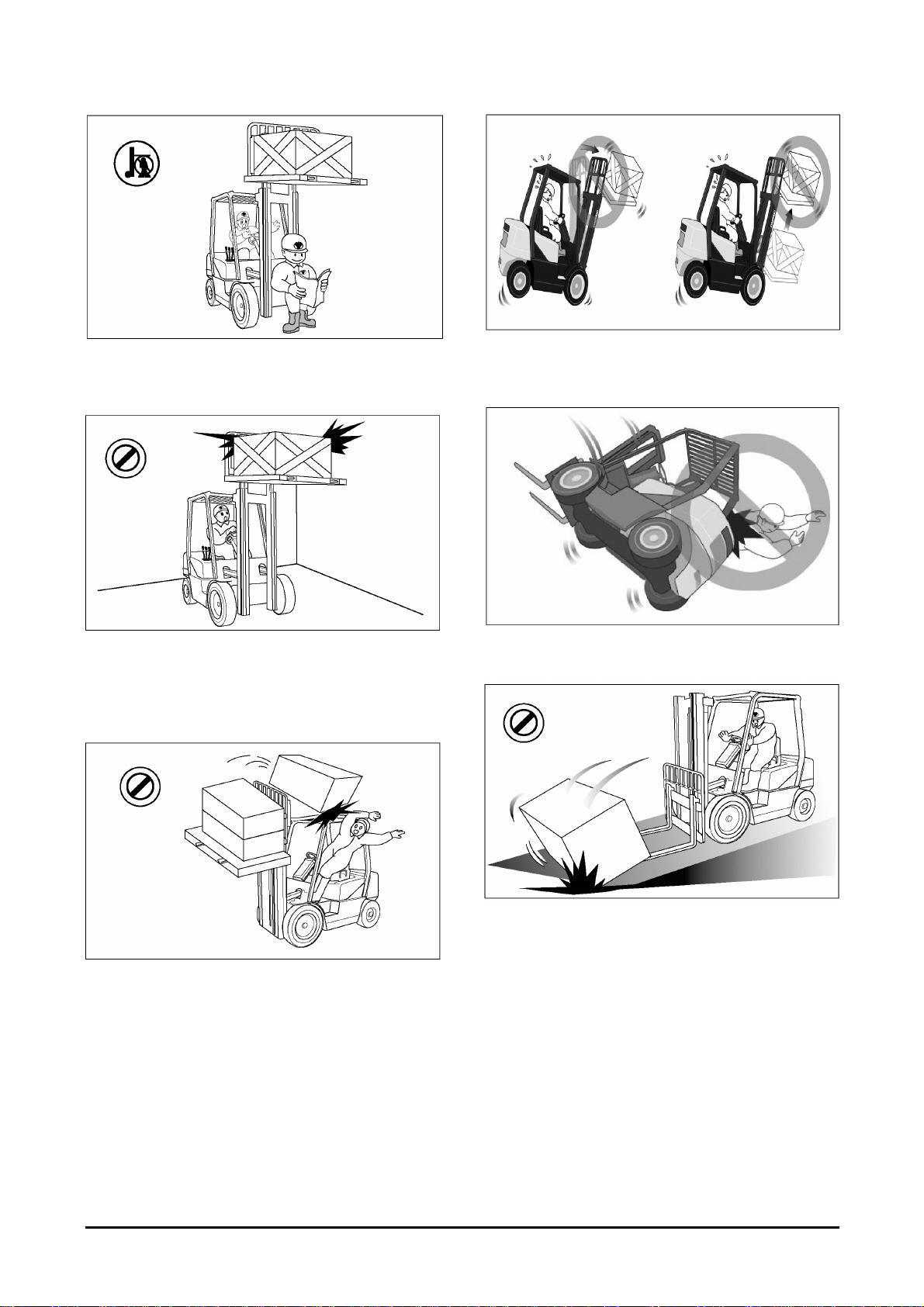

Warning Signs and Labels

There are several specific safety signs on your lift

truck. Their exact location and description of the

hazard are reviewed in this section. Please take the

time to familiarize yourself with these safety signs.

Make sure that you can read all warning and

instruction labels. Clean or replace these labels if

you cannot read the words or see the pictures.

When cleaning the labels use a cloth, water and

soap. Do not use solvent, gasoline, etc.

You must replace a label if it is damaged, missing

or cannot be read. If a label is on a part that is

replaced, make sure a new label is installed on the

replaced part. See your dealer for new labels.

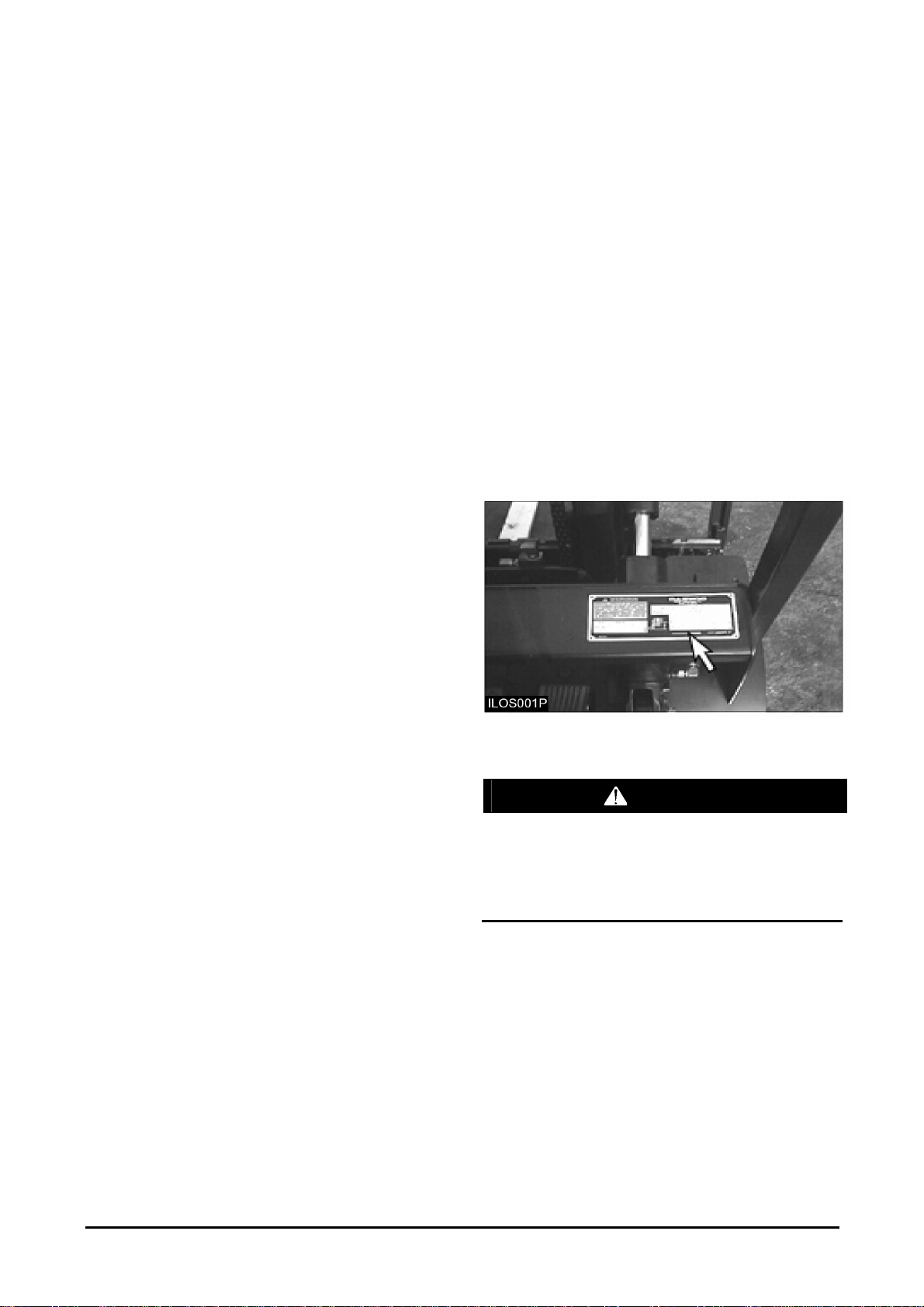

Traing Required To Operate or Service

Warning

Located on the right side of the steering wheel.

WARNING

Improper operation or maintenance could result

in injury or death. Do not operate or work on the

lift truck unless you are properly trained. Read

and understand the Operation and Maintenance

Manual. Additional manuals are available from

DAEWOO Lift Truck dealers.

This label also provides allowable lift truck capacity

information

-5-

Safety Section

General Warning to Operator

Located on the right side of the operator's seat

(STD).

Located on the overhead guard (If Convenience

Package Equipped).

WARNING

Only trained and authorized personnel may

operate this machine. For safe operation, read

and follow the operation and maintenance

Manual furnished with this lift truck and

observe the following warnings:

1. Before starting machine. Check all controls and

warning devices for proper operation.

2. Refer to machine identification plate for

allowable machine capacity. Do not overload.

Operate machines equipped with attachments

as partially loaded machines when not handling

a load.

3. Put directional control or shift lever in neutral

before “ON - OFF” switch is turned on.

4. Start, turn and brake smoothly. Slow down for

turns, slippery or uneven surfaces. Extremely

poor surfaces should be repaired. Avoid running

over loose objects or holes in the roadway

surfaces. Use extreme caution when turning on

inclines.

5. Travel with load as low as possible and tilted

back. If load interferes with visibility, travel with

load trailing.

6. On grade operations travel with load up grade.

7. Watch out for pedestrians and obstructions.

Check overhead clearances.

8. Do not permit riders on forks or machine at any

time.

9. Do not allow anyone to stand or pass under the

elevated portion of any machine.

10. Be sure operating surface can safely support

machine.

11. Operate machine and attachments only from

operator's position.

12. Do not handle unstable or loosely stacked

loads.

13. Use minimum tilt when picking up or depositing

a load.

14. Use extreme care when handling long, high, or

wide loads.

15. Forks should be completely under load and

spread apart as far as load permits.

16. Machine should be equipped with overhead

guard or equivalent protection. Where load

requires it, use a load backrest extension. Use

extreme caution if operating without these

devices.

17. Parking - Lower lifting mechanism to floor. Put

directional control or shift lever in neutral. Set

parking/secondary brake. Turn “ON - OFF”

switch off. Chock wheels if machine is on incline.

Disconnect battery when storing electric

machines.

18. Observe safety rules when handling fuel for

engine powered machine and when changing

batteries for electric machines.

-6-

Safety Section

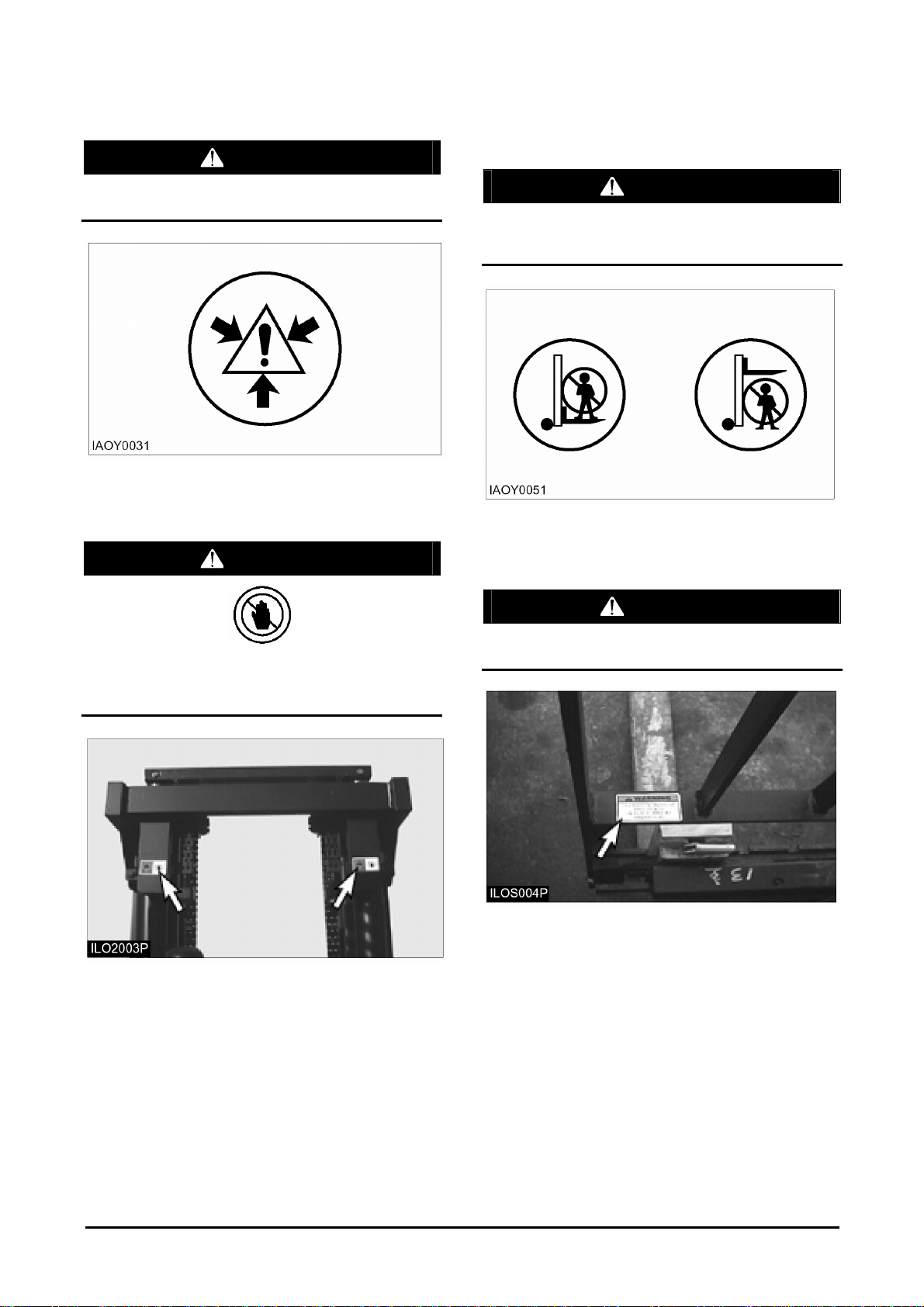

Pressure Warning

WARNING

Contents under pressure may be hot. Allow to

cool before opening.

Located on the radiator top tank by the radiator

cap.

Hand Placement Warning

WARNING

No Standing On Fork Warning

No Standing Under Fork Warning

WARNING

Do not stand or ride on the forks. Do not stand

or ride on a load or pallet on the forks. Do not

stand or walk under the forks.

Located on the lift cylinder.

Load Backrest Must Be In Place

Warning

No hands. Do not place hands in this area. Do

not touch, lean on, or reach through the mast or

permit others to do so.

Located on the mast.

WARNING

Operation without this device in place may be

hazardous.

Located on the load backrest.

-7-

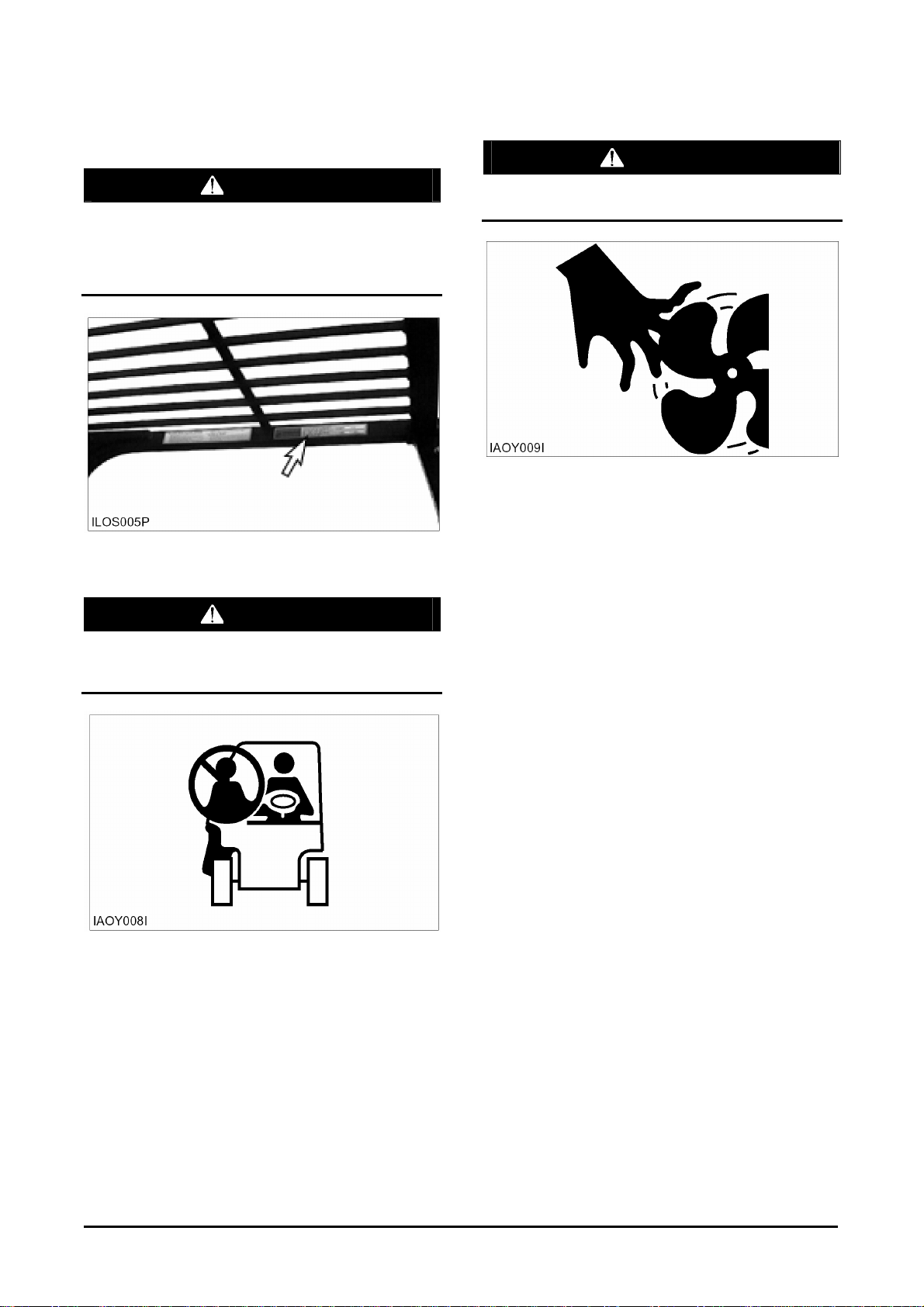

Safety Section

Overhead Guard Must Be In Place

Warning

WARNING

Operation without this device in place may be

hazardous. This guard conforms to

A.N.S.I.B56.1 and F.E.M.Section IV. This design

has been tested with an impact of appropriate

valve.

Located on the Overhead Guard.

No Riders Warning

Moving Fan Warning

WARNING

To avoid personal injury, stay clear of moving

fan.

Located inside the engine compartment cover.

WARNING

To avoid personal injury, allow no riders. A lift

truck is designed for only one operator and no

riders.

Located beside the operator's station (STD) or on

front of the hood (Convenience Package).

-8-

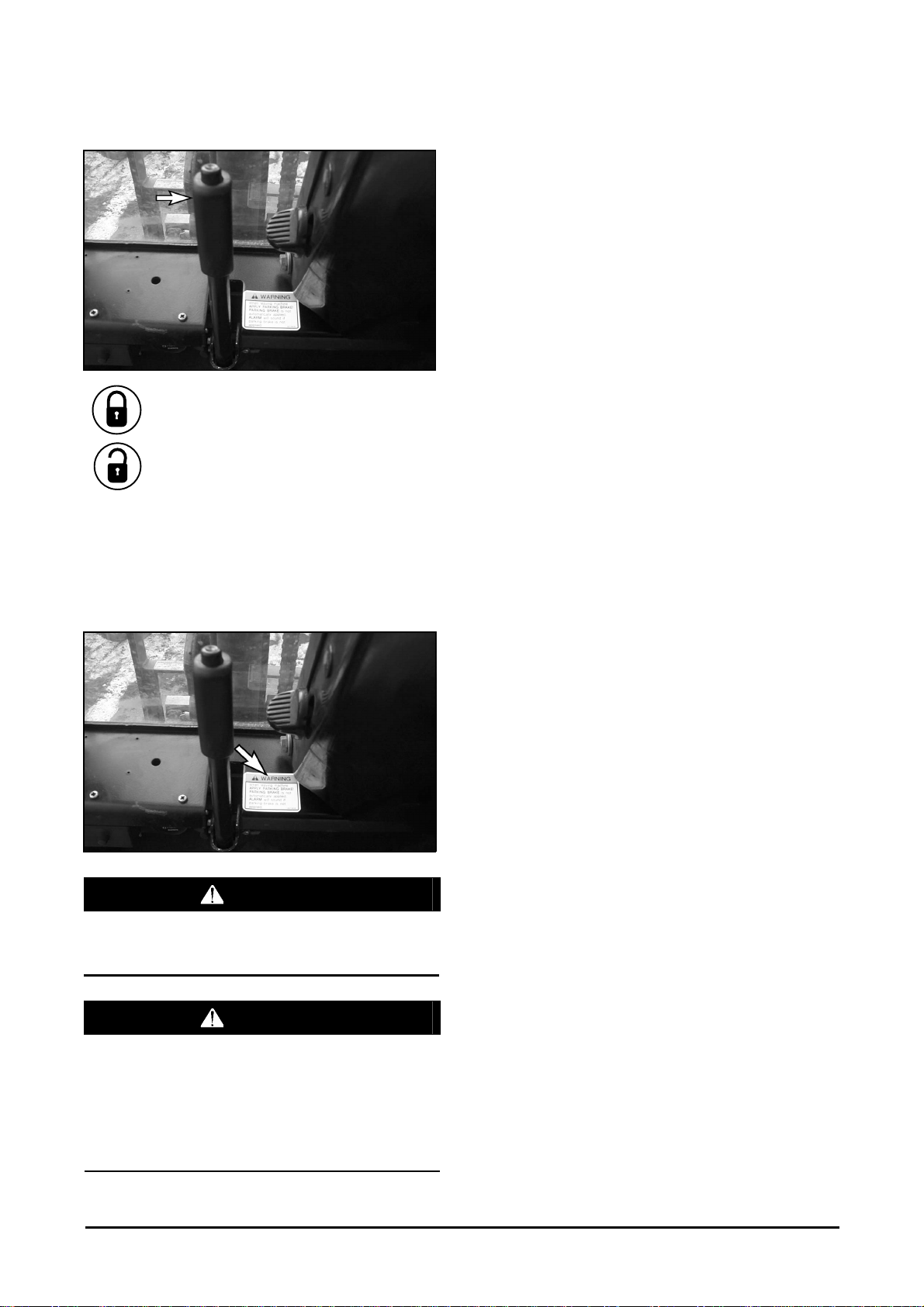

Safety Section

Parking brake

Pull the lever BACK to engage the

parking brake.

Push the lever FORWARD to release

the parking brake.

Applying the parking brake puts the transmission in

NEUTRAL. The parking brake must be applied

when leaving the lift truck and when starting the

engine. If the operator leaves the seat without

applying the parking brake, an audible alarm will

sound.

WARNING

When leaving machine apply parking brake!

Parking brake is not automatically applied.

Alarm will sound if parking brake is not applied.

WARNING

Correct adjustment is necessary to provide

adequate braking. See the MAINTENANCE section

for adjustment procedures. The lift truck may creep

at engine idle and can cause damage, injury or

death. Always apply the parking brake when

leaving the lift truck. The parking brake is NOT

automatically applied.

-9-

Safety Section

General Hazard Information

Attach a “Do Not Operate” or similar warning tag to

start switch or controls before servicing or repairing

the lift truck.

Do not start or service the lift truck when a “DO

NOT OPERATE” or similar warning tag is attached

to the start switch or controls.

Wear a hard hat, protective glasses and other

protective equipment as required by job conditions.

Know the width of your attachments so proper

clearance can be maintained when operating near

fences, boundary obstacles, etc.

Do not wear loose clothing or jewelry that can catch

on controls or other parts of the lift truck.

Keep the lift truck, especially the deck and steps,

free of foreign material such as debris, oil tools and

other items which are not part of the lift truck.

Secure all loose items such as lunch boxes, tools

and other items which are not part of the lift truck.

Know the appropriate work-site hand signals and

who gives them. Accept signals from one person

only.

Always use the overhead guard. The overhead

guard is intended to protect the lift truck operator

from overhead obstructions and from falling

objects.

A truck that is used for handing small objects or

uneven loads must be fitted with a load backrest.

If the lift truck must be operated without the

overhead guard in place due to low overhead

clearance, use extreme care. Make sure there is no

possibility of falling objects from any adjacent

storage or work area. Make sure the load is stable

and fully supported by the carriage and the load

backrest extension (if equipped).

Do not raise loads any higher than necessary and

never raise a load higher than 1830 mm (72 in) with

the overhead guard removed.

Always use load backrest extension when the

carriage or attachment does not fully support the

load. The load backrest extension is intended to

prevent the load or any part of the load from falling

backwards into the operator's station.

When operating the lift truck, do not depend only on

flashing lights or back-up alarm (if equipped) to

warn pedestrians.

Always be aware of pedestrians and do not

proceed until the pedestrians are aware of your

presence and intended actions and have moved

clear of the lift truck and/or load.

Do not drive lift truck up to anyone standing in front

of an object.

Obey all traffic rules and warning signs.

Keep hands, feet and head inside the operator

station. Do not hold onto the overhead guard while

operating the lift truck. Do not climb on any part of

the mast or overhead guard or permit others to do

so.

Do not allow unauthorized personnel to ride on the

forks or any other part of the lift truck, at any time.

When working in a building or dock, observe floor

load limits and overhead clearances.

-10-

Safety Section

Inhaling Freon gas through a lit cigarette or other

smoking method or inhaling fumes released from a

flame contacting Freon can cause bodily harm or

death. Do not smoke when servicing air

conditioners or wherever Freon gas may be

present.

Never put maintenance fluids into glass containers.

Use all cleaning solutions with care.

Do not use steam, solvent, or high pressure to

clean electrical components.

Report all needed repairs.

Inspect the part of the chain that is normally

operated over the crosshead roller. When the chain

bends over the roller, the movement of the parts

against each other causes wears.

Inspect to be sure that chain link pins do not extend

outside of the bore hole.

If any single link pin is extended beyond its

connecting corresponding link, it should be

suspected of being broken inside of its bore hole.

Inspect the chain anchor and the anchor links for

wear.

Do not change any factory set adjustment values

(including engine rpm setting) unless you have both

authorization and training. Especially Safety

equipment and switches may not be removed or

adjusted incorrectly. Repairs, adjustments and

maintenances that are not correct can make a

dangerous operating condition.

For any checkup, repair, adjustments, maintenance

and all other work concerning your forklift truck,

please contact your DAEWOO dealer. We would

like to draw your attention to the fact that any

secondary damages due to improper handling,

insufficient maintenance, wrong repairs or the use

of other than original DAEWOO spare parts waive

any liability by DAEWOO.

Operation Information

Mounting and Dismounting

Mount and dismount the lift truck carefully.

Clean your shoes and wipe your hands before

mounting.

Use both hands and face the lift truck when

mounting and dismounting.

Use the handgrips for mounting and dismounting.

Do not try to climb on or off the lift truck when

carrying tools or supplies.

Do not use any controls as handholds when

entering or leaving the operator's station.

Never get on or off a moving lift truck. Never jump

off the lift truck.

Keep hands and steering wheel free of slippery

material.

Before Starting the Lift Truck

Perform a walk-around inspection daily and at the

start of each shift. Refer to the topic “Walk-around

Inspection” in “Every 10 Service Hours or Daily”

section of this manual.

Adjust the seat so that full brake pedal travel can

be obtained with the operator's back against the

seat back.

Make sure the lift truck is equipped with a lighting

system as required by conditions.

Make sure all hydraulic controls are in the HOLD

position.

Make sure the direction control lever is in the

NEUTRAL position.

Make sure the parking brake is engaged.

Make sure no one is standing and/or working on,

underneath or close to the lift truck before operating

the lift truck.

Operate the lift truck and controls only from the

operator's station.

-11-

Safety Section

Make sure the lift truck horn, lights, backup alarm (if

equipped) and all other devices are working

properly.

Check for proper operation of mast and

attachments. Pay particular attention to unusual

noises or erratic movement which might indicate a

problem.

Make sure service and parking brakes, steering,

and directional controls are operational.

Make sure all personnel are clear of lift truck and

travel path.

Refer to the topic “Lift Truck Operation” in the

“Operation Section” of this manual for specific

starting instructions.

Starting the Lift truck

Operating the Lift Truck

Always keep the lift truck under control.

Obey all traffic rules and warning signs.

Never leave the lift truck with the engine operating,

or with the parking brake disengaged.

Operate the engine only in a well ventilated area.

Lower a mast, with or without load, before turning

or traveling. Tip over could result. Watch out for

overhead obstructions.

Always observe floor load limits and overhead

clearance.

Start, turn, and brake smoothly. Slow down for

turns, grades, slippery or uneven surfaces.

Do not start the engine or move any of the controls

if there is a “DO NOT OPERATE” or similar warning

tag attached to the start switch or controls.

Before Operating the Lift Truck

Test brakes, steering controls, horn and other

devices for proper operation. Report any faulty

performance. Do not operate lift truck until repaired.

Learn how your lift truck operates. Know its safety

devices. Know how the attachments work. Before

moving the lift truck, look around. Start, turn and

brake smoothly.

An operator must constantly observe his lift truck

for proper operation.

Use special care when operating on grades. Do not

angle across or turn on grades. Do not use lift truck

on slippery grades. Travel with forks downgrade

when unloaded. Travel with load upgrade.

Do not overload, or handle offset, unstable, or

loosely stacked loads. Refer to load capacity plate

on the lift truck. Use extreme caution when

handling suspended, long, high or wide load.

-12-

Tilt the elevated load forward only when directly

over unloading area and with load as low as

possible.

Do not stunt ride or indulge in horseplay.

Always look and keep a clear view of the path of

travel.

Travel in reverse if load or attachment obstructs

visibility. Use extreme caution if visibility is

obstructed.

Stay in designated travel path, clear of dock edges,

ditches, other drop-offs and surfaces which cannot

safely support the lift truck.

Slow down and use extra care through doorways,

intersections and other location where visibility is

reduced.

Slow down for cross aisles, turns, ramps, dips,

uneven or slippery surfaces and in congested areas,

avoid pedestrians, other vehicles, obstruction, pot

holes and other hazards or objects in the path of

travel.

Always use overhead guards except where

operation conditions do not permit. Do not operate

lift truck in high stacking areas without overhead

guards.

When stacking, watch for falling objects. Use load

backrest extension and overhead guard.

Refer to the topic “Operation Techniques” in the

“Operation Section” of this manual.

Safety Section

Loading or Unloading Trucks/Trailers

Do not operate lift trucks on trucks or trailers which

are not designed or intended for that purpose. Be

certain truck or trailer brakes are applied and wheel

chocks in place (or be certain unit is locked to the

loading dock) before entering onto trucks or trailers.

If trailer is not coupled to tractor, make sure the

trailer landing gear is properly secured in place. On

some trailers, extra supports may be needed to

prevent upending or corner dipping.

Be certain dock plates are in good condition and

properly placed and secured. Do not exceed the

rated capacity of dock boards or bridge plates.

Lift Truck Parking

When leaving the operator station, park the lift truck

in authorized areas only. Do not block traffic.

z Park the lift truck level, with the forks lowered and

the mast tilted forward until the fork tips touch the

floor.

z Move the direction control lever to NEUTRAL.

z Engage the parking brake.

z Turn the key switch off and remove the key.

z Turn the disconnect switch to OFF (if equipped).

z Block the drive wheels when parking on an

incline.

-13-

Safety Section

Maintenance Information

Perform all maintenance unless otherwise specified

as follows:

z Park the lift truck in authorized areas only.

z Park the lift truck level, with the forks lowered and

the mast tilted forward until the fork tips touch the

floor.

z Place the transmission controls in neutral.

z Engage the parking brake.

z Stop the engine.

z Remove the start switch key and turn the

disconnect switch OFF (if equipped).

z Block the drive wheels when parking on an

incline.

Pressure Air

Pressure air can cause personal injury. When using

pressure air for cleaning, wear a protective face

shield, protective clothing and protective shoes.

The maximum air pressure must be below 205 kPa

(30 psi) for cleaning purposes.

Fluid Penetration

Always use a board or cardboard when checking

for a leak. Escaping fluid under pressure, even a

pinhole size leak, can penetrate body tissue,

causing serious injury, and possible death. If fluid is

injected into your skin, it must be treated by a

doctor familiar with this type of injury immediately.

Crushing or Cutting Prevention

Support equipment and attachments properly when

working beneath them. Do not depend on hydraulic

cylinders to hold it up. Any attachment can fall if a

control is moved, or if a hydraulic line breaks.

Never attempt adjustments while the lift truck is

moving or the engine is running unless otherwise

specified.

Where there are attachment linkages, the

clearance in the linkage area will increase or

decrease with movement of the attachment.

Stay clear of all rotating and moving parts.

Keep objects away from moving fan blades.

They will throw or cut any object or tool that falls or

is pushed into them.

Do not use a kinked or frayed wire rope cable.

Wear gloves when handling the wire rope cable.

Retainer pins, when struck with force, can fly out

and injure nearby persons. Make sure the area is

clear of people when driving retainer pins.

Wear protective glasses when striking a retainer pin

to avoid injury to your eyes.

Chips or other debris can fly off objects when struck.

Make sure no one can be injured by flying debris

before striking any object.

Falling Objects Protective Structure (FOPS)

This is an attached guard located above the

operator's compartment and secured to the lift

truck.

To avoid possible weakening of the Falling Objects

Protective Structure (FOPS), consult a DAEWOO

dealer before altering, by adding weight to, welding

on, or cutting or drilling holes into the structure.

The overhead guard is not intended to protect

against every possible impact. The overhead guard

may not protect against some objects penetrating

into the operator's station from the sides or ends of

the lift truck.

The lift truck is equipped with an overhead guard

and FOPS as standard. If there is a possibility of

overhead objects falling through the guard, the

guard must be equipped with smaller holes or a

Plexiglas cover.

Any altering done that is not specifically authorized

by DAEWOO invalidates DAEWOO's FOPS

certification. The protection offered by this FOPS

will be impaired if it has been subjected to structural

damage. Structural damage can be caused by an

overturn accident, by falling objects, etc.

Do not mount any item such as fire extinguishers,

first aid kits and lights by welding brackets to or

drilling holes in any FOPS structure. See your

DAEWOO dealer for mounting guidelines.

-14-

Safety Section

Burn Prevention

Coolant

At operating temperature, the engine coolant is hot

and under pressure. The radiator and all lines to

heaters or the engine contain hot water or steam.

Any contact can cause severe burns.

Steam can cause personal injury.

Check the coolant level only after engine has been

stopped and the filter cap is cool enough to remove

with your bare hand.

Remove the cooling system filter cap slowly to

relieve pressure.

Cooling system additive contains alkali that can

cause personal injury. Avoid contact with the skin

and eyes and do not drink.

Allow cooling system components to cool before

draining.

Oils

Hot oil and components can cause personal injury.

Do not allow hot oil or components to contact the

skin.

At operation temperature, the hydraulic tank is hot

and can be under pressure.

Remove the hydraulic tank filter cap only after the

engine has been stopped and the filter cap is cool

enough to remove with your bare hand.

Remove the hydraulic tank filter cap slowly to

relieve pressure.

Relieve all pressure in air, oil fuel or cooling

systems before any lines, fittings or related items

are disconnected or removed.

Batteries

Batteries give off flammable fumes which can

explode.

Do not smoke when observing the battery

electrolyte levels.

Electrolyte is an acid and can cause personal injury

if it contacts skin or eyes.

Always wear protective glasses when working with

batteries.

Fire or Explosion Prevention

All fuels, most lubricants and some coolant

mixtures are flammable.

Fuel leaked or spilled onto hot surfaces or electrical

components can cause a fire.

Do not smoke while refueling or in a refueling area.

Do not smoke in areas where batteries are charged,

or where flammable materials are stored.

Batteries in series can be located in separate

compartments. When using jumper cables always

connect positive(+) cable to positive(+) terminal of

battery connected to starter solenoid and

negative(-) cable from external source to starter

negative(-) terminal.

(If not equipped with starter negative(-) terminal,

connect to engine block.)

See the Operation Section of this manual for

specific starting instructions.

Clean and tighten all electrical connections. Check

daily for loose or frayed electrical wires. Have all

loose or frayed electrical wires tightened, repaired

or replaced before operating the lift truck.

Keep all fuels and lubricants stored in properly

marked containers and away from all unauthorized

persons.

Store all oily rags or other flammable material in a

protective container, in a safe place.

Do not weld or flame cut on pipes or tubes that

contain flammable fluids. Clean them thoroughly

with nonflammable solvent before welding or flame

cutting on them.

Remove all flammable materials such as fuel, oil

and other debris before they accumulate on the lift

truck.

Do not expose the lift truck to flames, burning brush,

etc., if at all possible.

Shields, which protect hot exhaust components

from oil or fuel spray in the event of a line, tube or

seal failure, must be installed correctly.

Do not operate in areas where explosive gases

exist or are suspected.

-15-

Safety Section

Fire Extinguisher

Have a fire extinguisher-type BC and 1.5KG

minimum capacity-on rear overhead guard leg with

latch and know how to use it. Inspect and have it

serviced as recommended on its instruction plate.

Ether

Ether is poisonous and flammable.

Breathing ether vapors or repeated contact of ether

with skin can cause personal injury.

Use ether only in well-ventilated areas.

Do not smoke while changing ether cylinders.

Use ether with care to avoid fires.

Do not store replacement ether cylinders in living

areas or in the operator's compartment.

Do not store ether cylinders in direct sunlight or at

temperatures above 39°C (102°F).

Discard cylinders in a safe place. Do not puncture

or burn cylinders.

Keep ether cylinders out of the reach of

unauthorized personnel.

Lines, Tubes and Hoses

z End fittings damaged or leaking.

z Outer covering chafed or cut and wire reinforcing

exposed.

z Outer covering ballooning locally.

z Evidence of kinking or crushing of the flexible

part of hose.

z Armoring embedded in the outer cover.

z End fittings displaced.

Make sure that all clamps, guards and heat shields

are installed correctly to prevent vibration, rubbing

against other parts, and excessive heat during

operation.

Tire Information

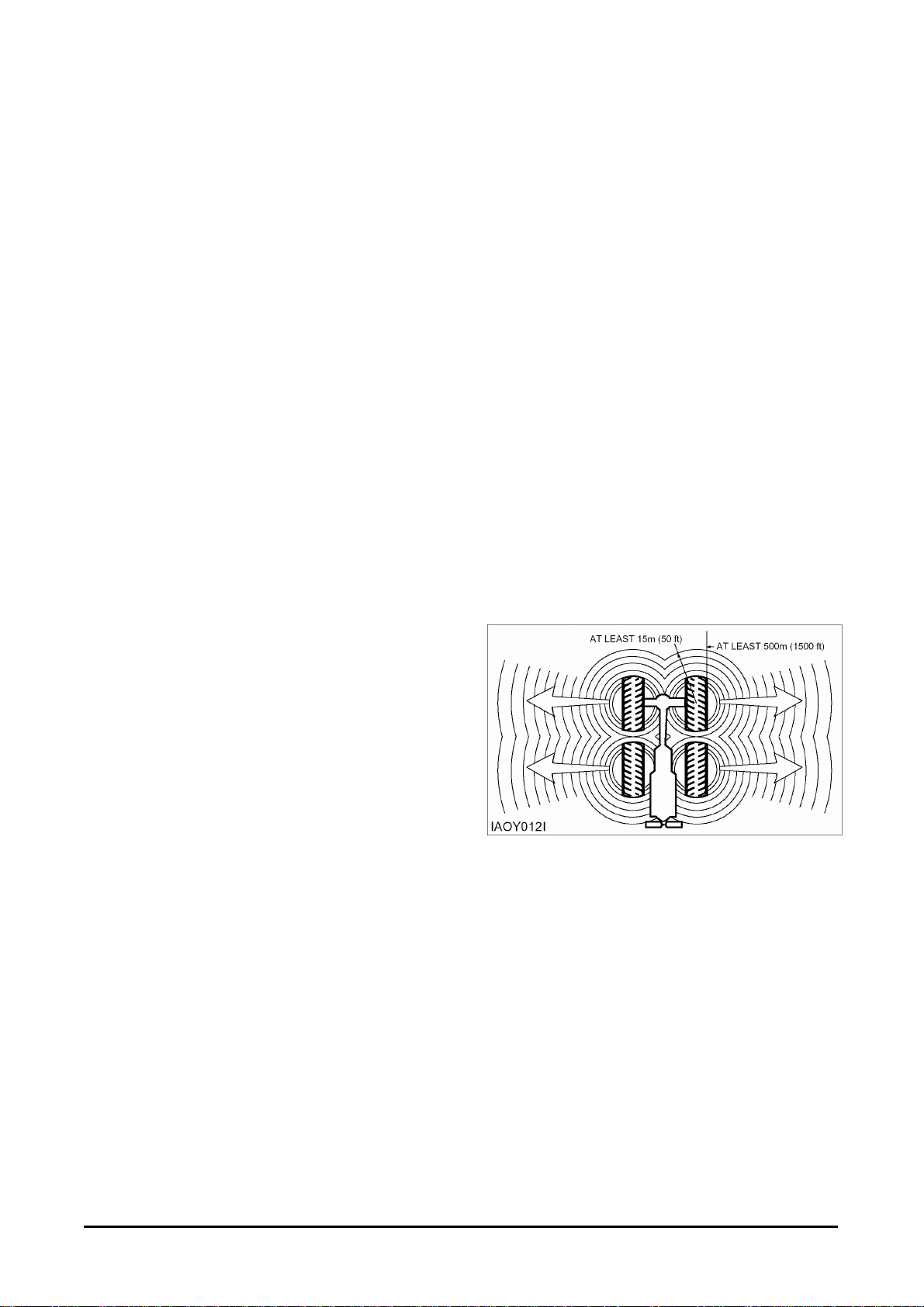

Explosions of air-inflated tires have resulted from

heat-induced gas combustion inside the tires. The

heat, generated by welding or heating rim

components, external fire, or excessive use of

brakes can cause gaseous combustion.

A tire explosion is much more violent than a

blowout. The explosion can propel the tire, rim and

axle components as far as 500 m (1500 ft) or more

from the lift truck. Both the force of the explosion

and the flying debris can cause personal injury or

death, and property damage.

Do not bend or strike high pressure lines. Do not

install bent or damaged lines, tubes or hoses.

Repair any loose or damaged fuel and oil lines,

tubes and hoses. Leaks can cause fires. Contact

your DAEWOO dealer for repair or replacement.

Check lines, tubes and hoses carefully. Do not use

your bare hand to check for leaks. Use a board or

cardboard to check for leaks. See Fluid Penetration

in the Safety Section for more details. Tighten all

connections to the recommended torque. Replace if

any of the following conditions are found.

Do not approach a warm tire closer than the

outside of the area represented by the shaded area

in the above drawing.

-16-

Safety Section

Dry nitrogen (N2) gas is recommended for inflation

of tires. If the tires were originally inflated with air,

nitrogen is still preferred for adjusting the pressure.

Nitrogen mixes properly with air.

Nitrogen inflated tires reduce the potential of a tire

explosion, because nitrogen does not support

combustion. Also, nitrogen helps prevent oxidation

and the resulting deterioration of rubber and

corrosion of rim components.

Proper nitrogen inflation equipment and training in

its use are necessary to avoid over-inflation. A tire

blowout or rim failure can result from improper or

misused equipment.

Stand behind the tread and use a self-attaching

chuck when inflation a tire.

Servicing, changing tires and rims can be

dangerous and should be done only by trained

personnel using proper tools and procedures. If

correct procedures are not followed while servicing

tires and rims, the assemblies could burst with

explosive force and cause serious personal injury

or death. Follow carefully the specific information

provided by your tire or rim servicing personnel or

dealer.

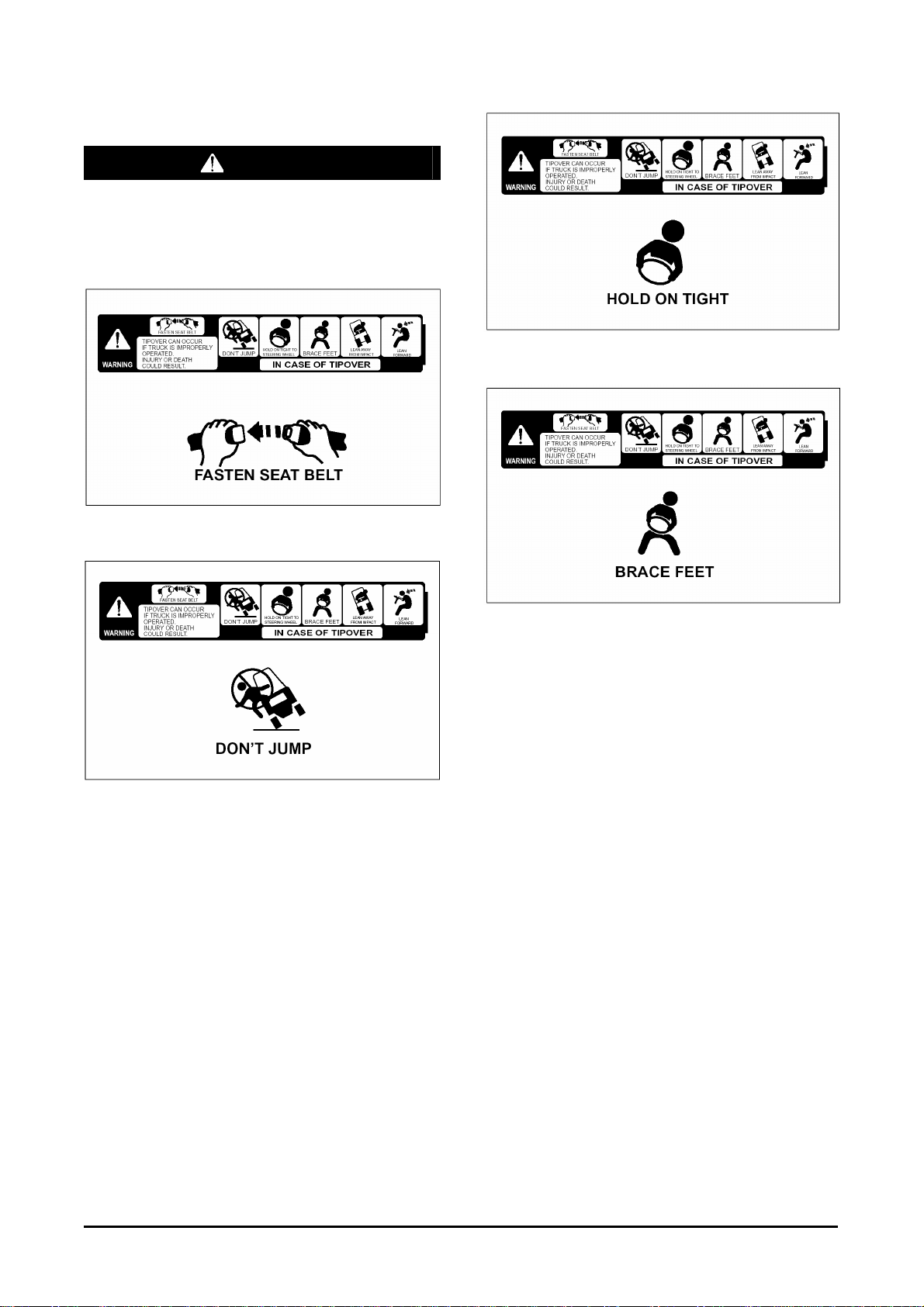

Operator Restraint System(If

Equipped)

Warning Signs and Labels

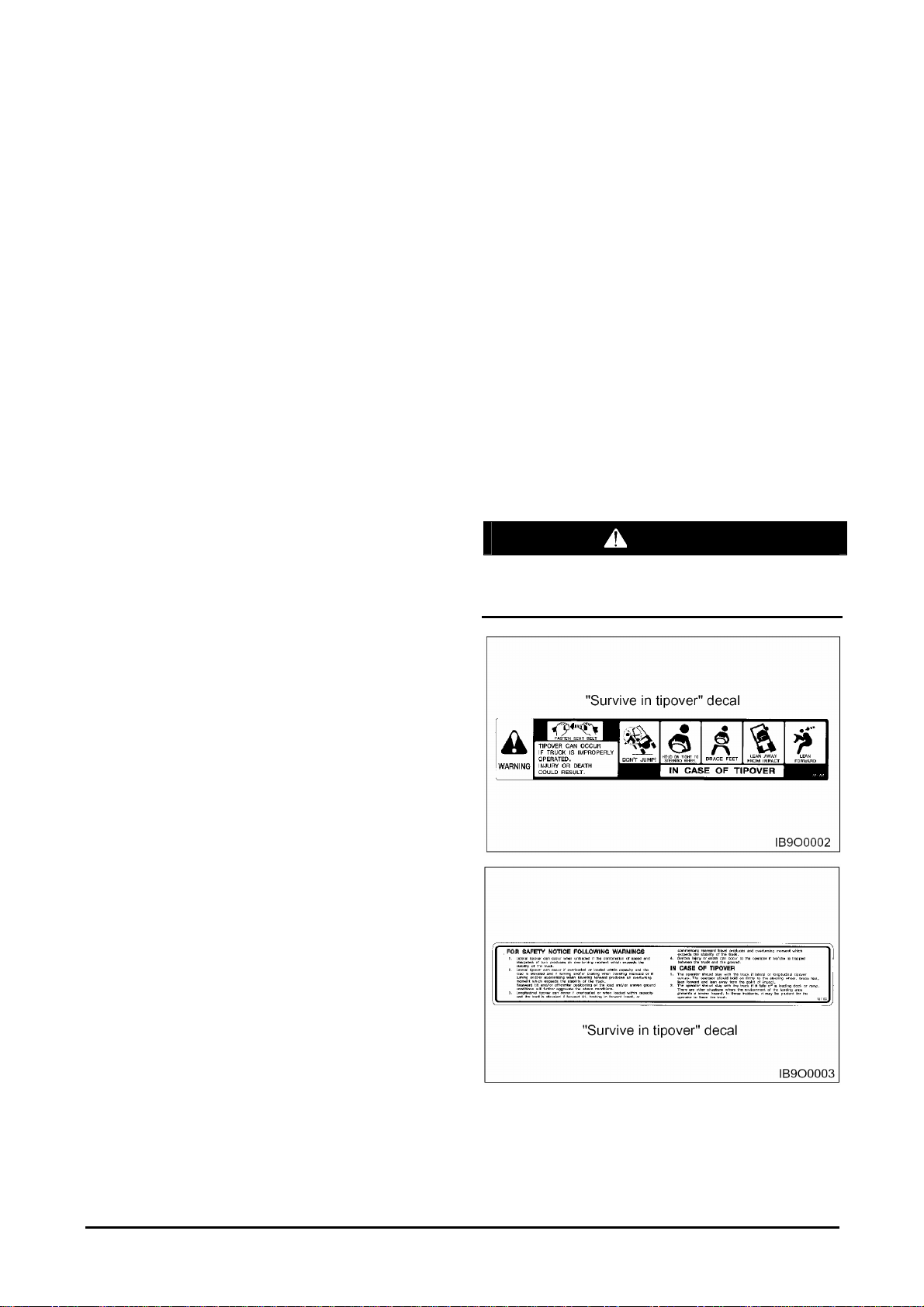

Your DAEWOO lift truck has the following tipover

warning decals.

Make sure that you can read all safety signs. Clean

or replace these if you cannot read the words or

see the pictures. When cleaning the labels use a

cloth, water and soap. Do not use solvent, gasoline,

etc. You must replace a label if it is damaged,

missing or cannot be read. If a label is on a part

that is replaced, make sure a new label is installed

on the replaced part. See you DAEWOO Lift Truck

dealer for new labels.

The most effective method of preventing serious

injury or death to yourself or others is to familiarize

yourself with the proper operation of the lift truck, to

be alert, and to avoid actions or conditions which

can result in an accident.

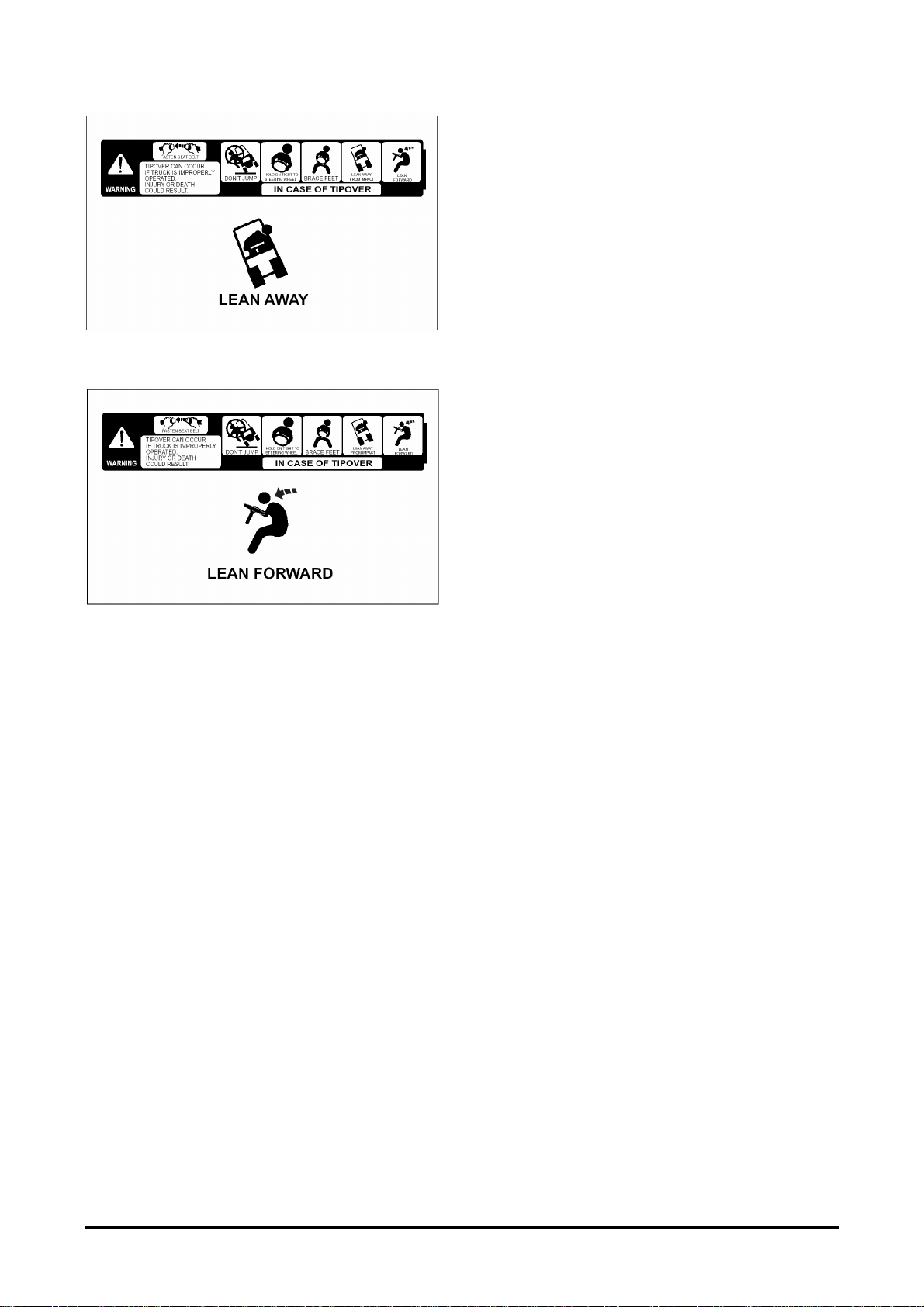

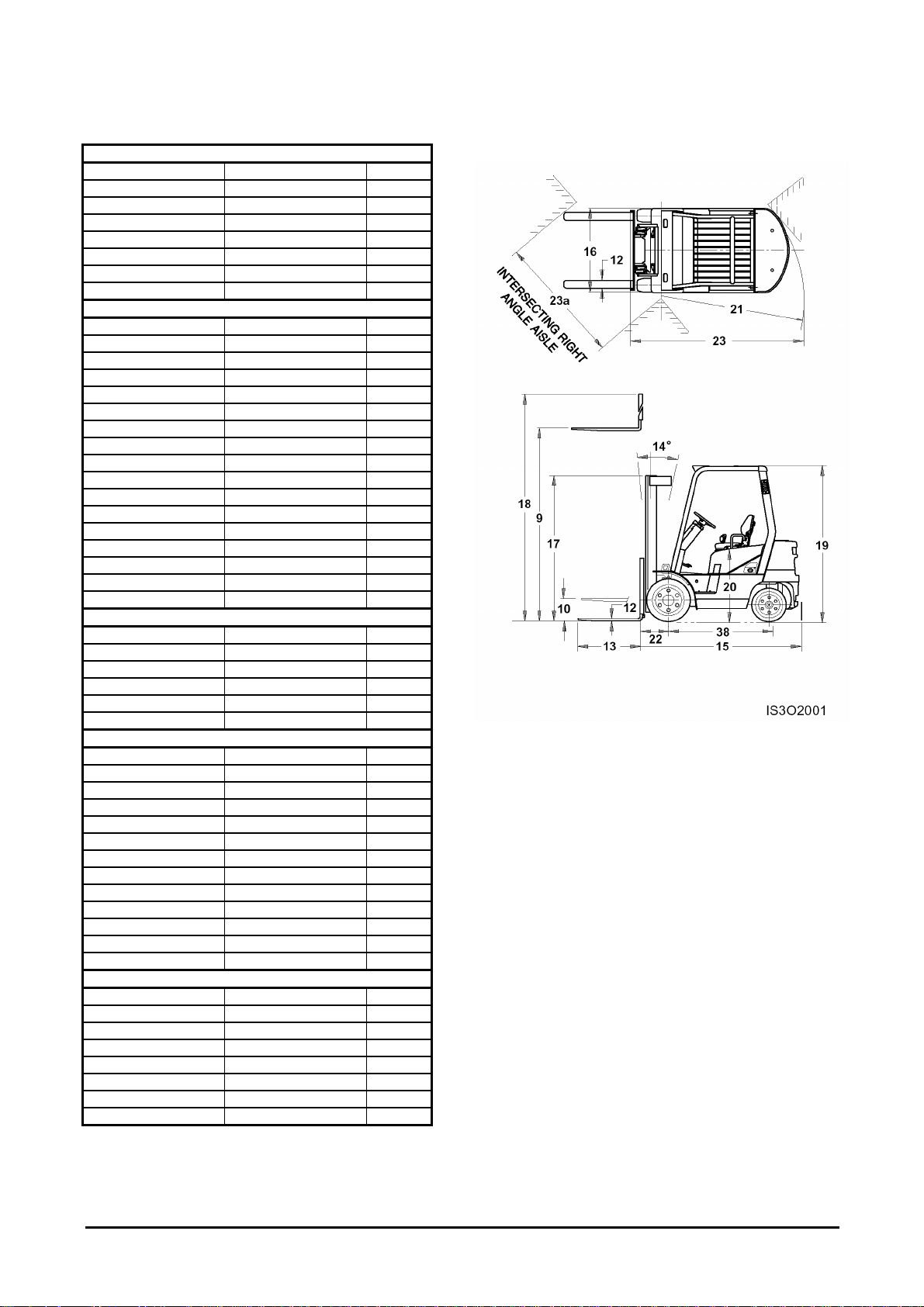

WARNING

Tipover can occur if the truck is improperly

operated. In the event of tipover, injury or death

could result.

-17-

Safety Section

The “Survive in tipover” warning is located on the

overhead guard. It shows the proper use of the

operator restraint system.

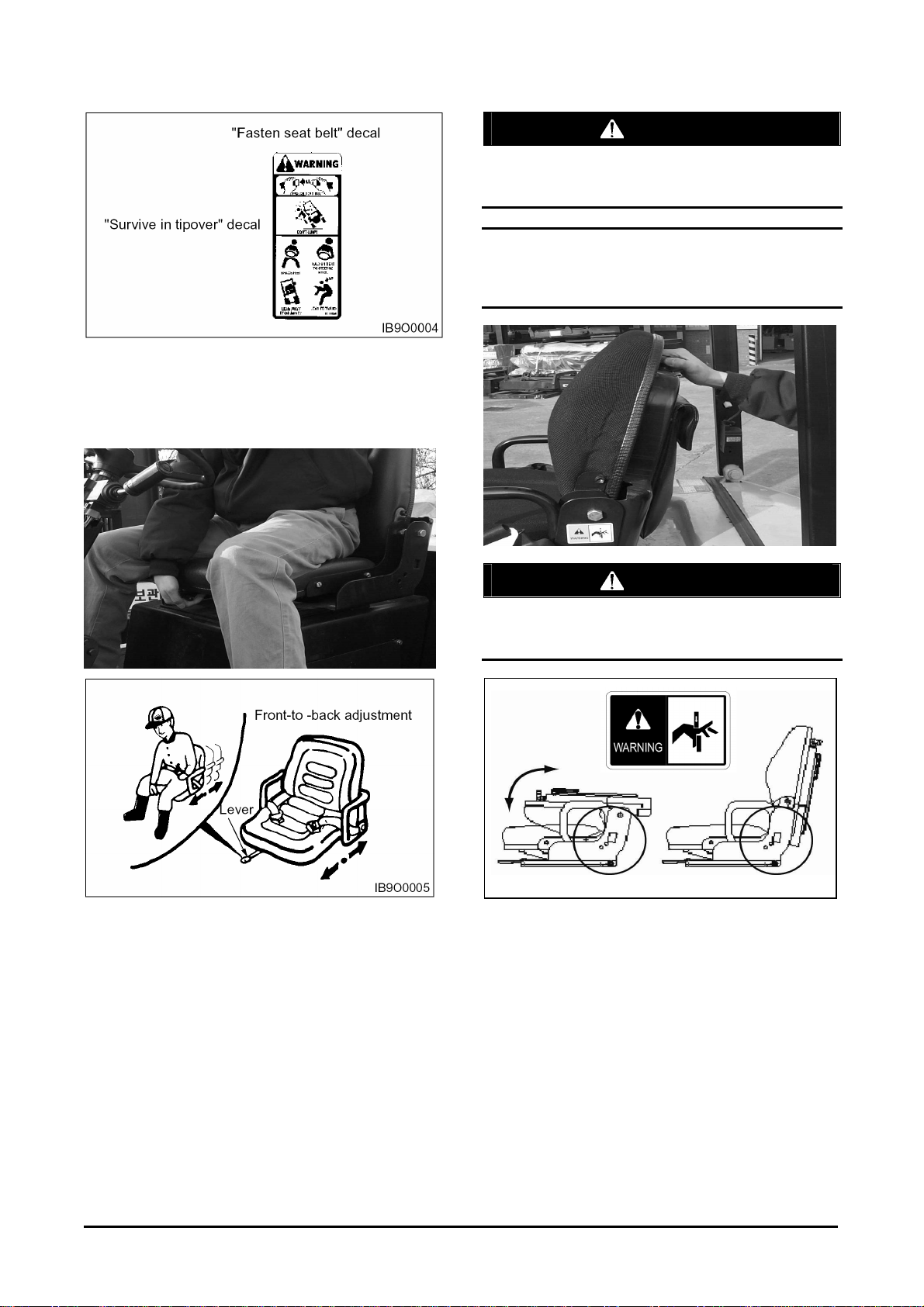

Seat Adjustment

WARNING

Do NOT place your hand or fingers under the

seat. Injury may occur as the seat suspension

mechanism moves up and down.

NOTICE

Before getting on the truck, adjust the level of the

suspension using the grip in the rear of the seat.

Move the lever, slide the seat to the desired

position, and release the lever.

Adjust the seat before operating the lift truck. After

adjusting, set the seat to make sure it is properly

locked. DO NOT adjust the seat while the truck is in

motion.

WARNING

When raising and lowering the seat backrest,

avoid placing hand or fingers in the hinge area

indicated by the circle. Injury may occur.

-18-

Safety Section

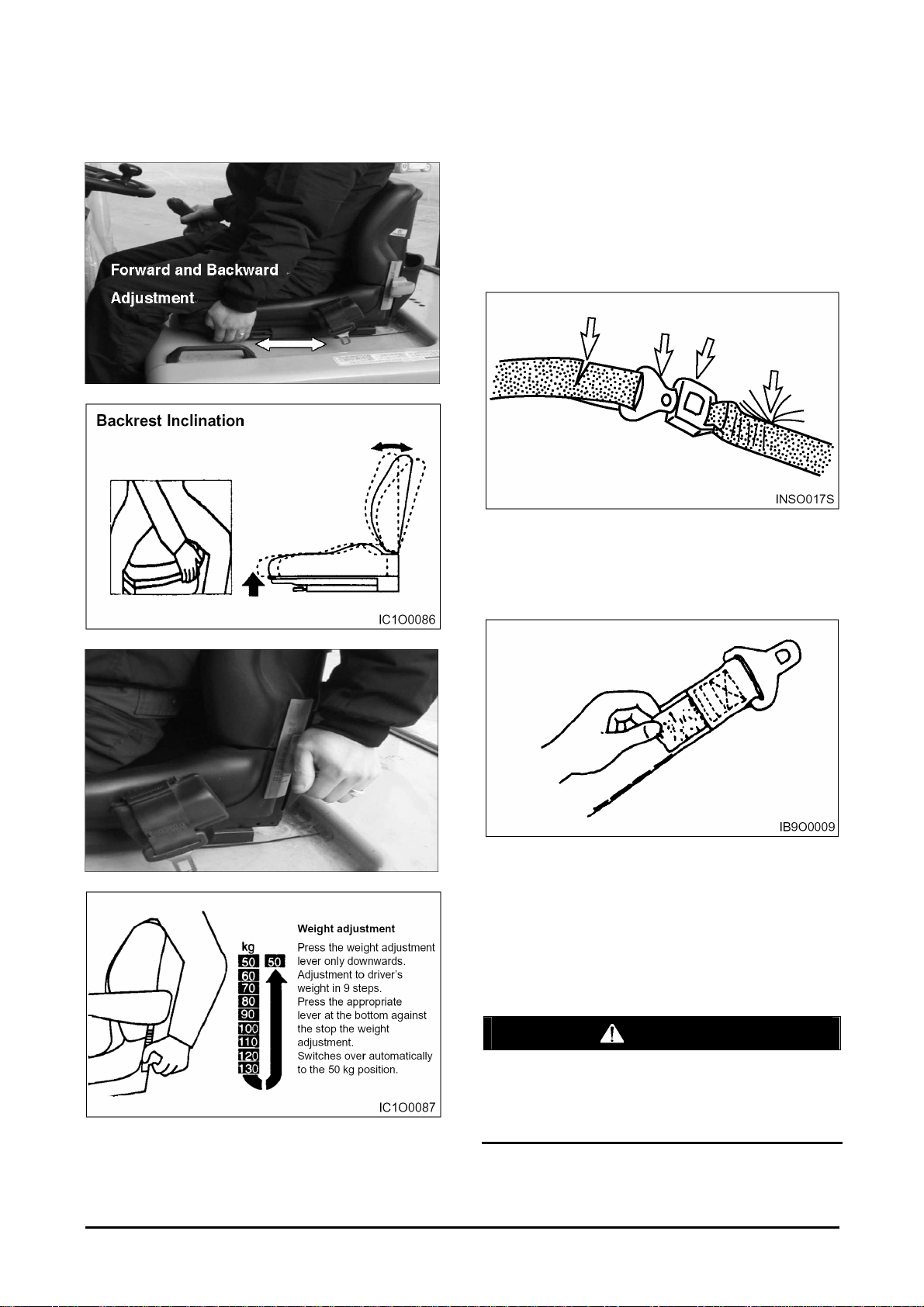

If Optional Suspension Seat (weight

adjusting type) Equipped

Seat Belt

The Operator Restraint System, Prevents the

operator from jumping from the operator’s

compartment in the event of a forward or side

tipover. The system is designed to keep the

operator on the seat and in the operator’s

compartment in the event of a tipover.

Inspection

1. If the seat belt is torn, if pulling motion is

interrupted during extension of the belt, or if the

belt cannot be inserted into the buckle properly,

replace the seat belt assembly.

2. Belt Maintenance - Every 500 service hours.

Check that the belt fastening works properly

and that winding device is free from run lock

when jerked. Check that the belt is suitably

fastened to the seat. Check that the seat is

correctly secured to the hood and the chassis.

On visual inspection, fastenings must be intact,

otherwise, contact the safety manager.

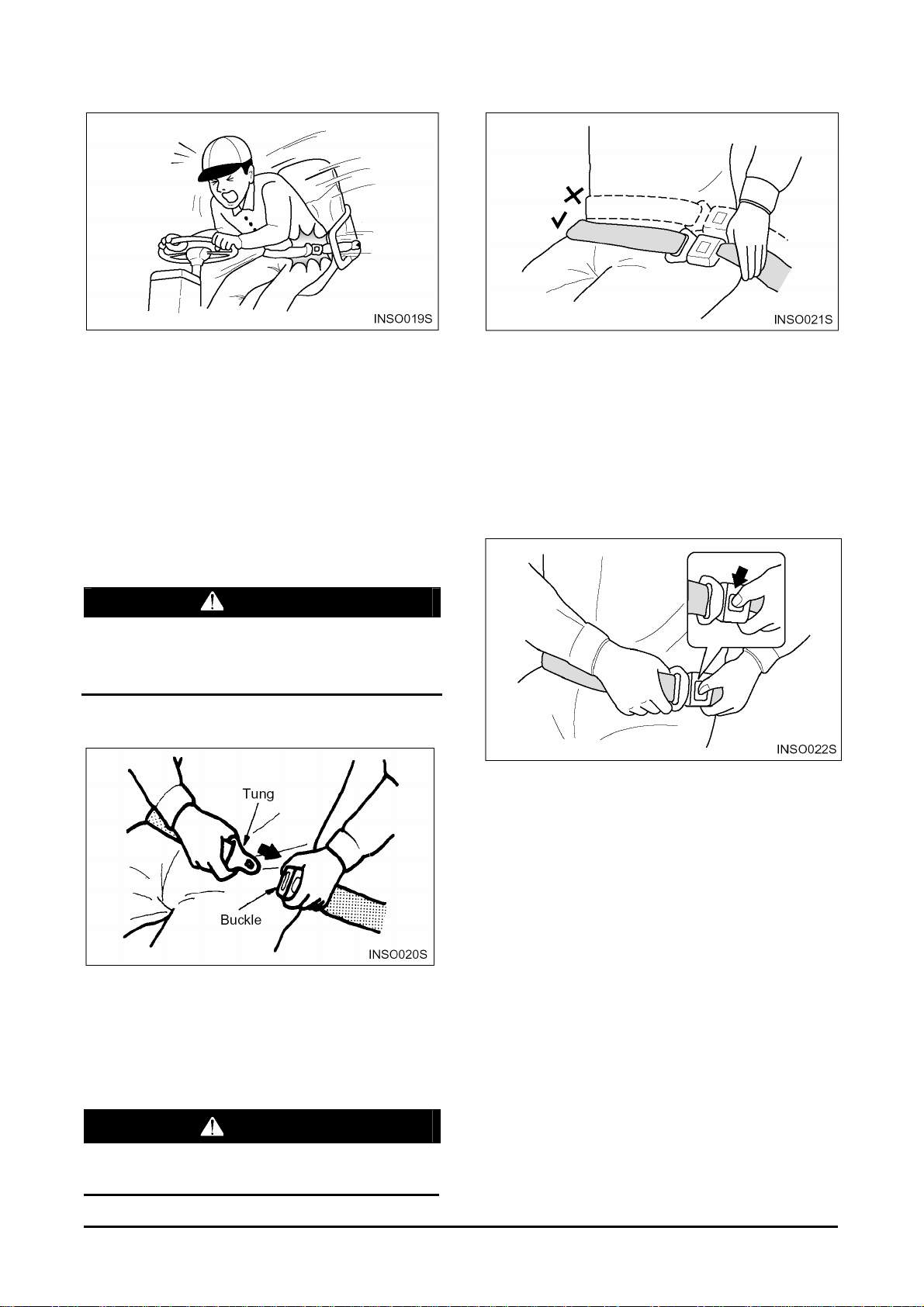

WARNING

Your DAEWOO truck comes equipped with a

DAEWOO operator restraint system. Should it

become necessary to replace the seat for any

reason, it should only be replaced with another

DAEWOO operator restraint system.

-19-

Safety Section

3. In the event of a tipover, the seat and restraint

system should be inspected for damage and

replaced, if necessary.

NOTE: Operator restraints shall be examined at

the regular truck service intervals. It is

recommended that they be replaced if any

of the following conditions are found:

Cut or frayed strap Worn or damaged hardware

including anchor points Buckle or retractor

malfunction

z Loosen stitching

WARNING

The seat belt may cause the operator to bend at

the waist. If you are pregnant or have suffered

from some abdominal disease, consult a doctor

before you use the seat belt.

Fasten the Seat Belt

4. Be sure to fasten the belt across your hips, not

across your abdomen.

NOTE: The belt is designed to automatically adjust

to your size and movement. A quick pull on

the belt will confirm that the automatic

adjuster will hold the belt position in the

event of an accident.

Release the Seat Belt

Push the button of the buckle to release the belt.

The belt will automatically retract when released.

Hold the plate of the belt and allow the belt to

slowly retract.

1. Grip the plate (connector) of the belt and pull the

belt from the retractor. Then insert the plate into

the slot of the buckle until a snap is heard. Pull

on the belt to confirm it is latched.

2. Make sure the belt is not twisted.

WARNING

If you fasten the belt across your abdomen, the

belt may injure your abdomen in an accident.

-20-

Safety Section

Avoiding Lift Truck Tipover

Lift Truck Stability

Counterbalanced lift truck design is based on the

balance of two weights on opposite sides of a

fulcrum (the front axle). The load on the forks must

be balanced by the weight of the lift truck. The

location of the center of gravity of both the truck

and the load is also a factor. This basic principle is

used for picking up a load. The ability of the lift

truck to handle a load is discussed in terms of

center of gravity and both forward and sideways

stability.

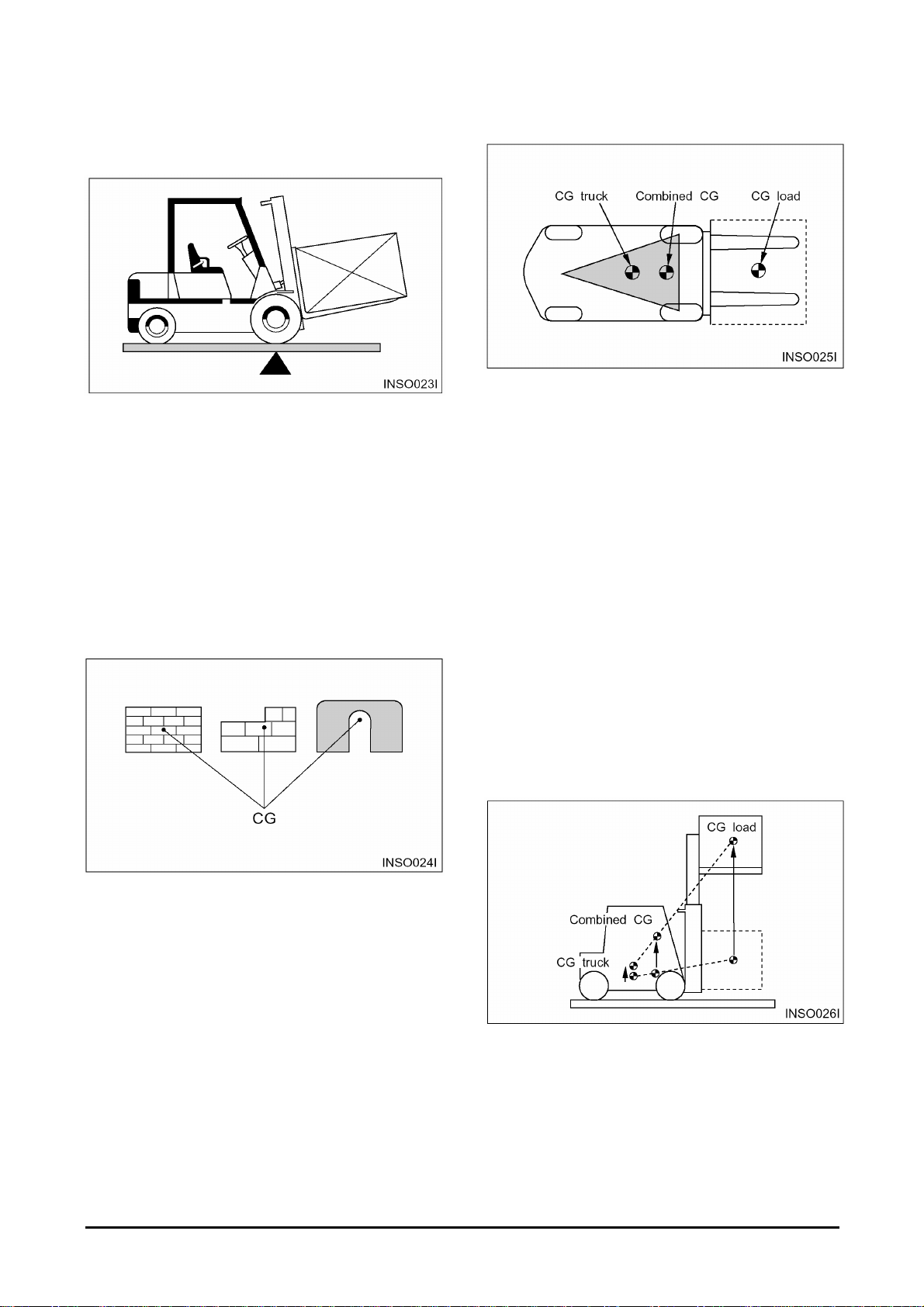

Center of Gravity (CG)

Stability and Center of Gravity

The stability of the lift truck is determined by the

location of its CG; or, if the truck is loaded, the

combined CG of the truck and load. The lift truck

has moving parts and, therefore, has a CG that

moves. The CG moves forward or backward as the

mast is tilted forward or backward. The CG moves

up or down as the mast moves up or down. The CG

and, therefore, the stability of the loaded lift truck,

are affected by a number of factors such as:

z the size, weight, shape and position of the load

z the height to which the load is lifted

z the amount of forward or backward tilt

z tire pressure

z dynamic forces created when the lift truck is

accelerated, braked or turned

z condition and grade of surfaces on which the lift

truck is operated

The point within an object, at which the whole

weight of the object may be regarded as being

concentrated, is called the center of gravity or CG.

If the object is uniform, its geometric center will

coincide with its CG. If it is not uniform, the CG

could be at a point outside of the object. When the

lift truck picks up a load, the truck and load have a

new combined CG.

These same factors are also important for unloaded

lift trucks. They tip over sideways easier than a

loaded lift truck carrying its load in the lowered

position.

-21-

Safety Section

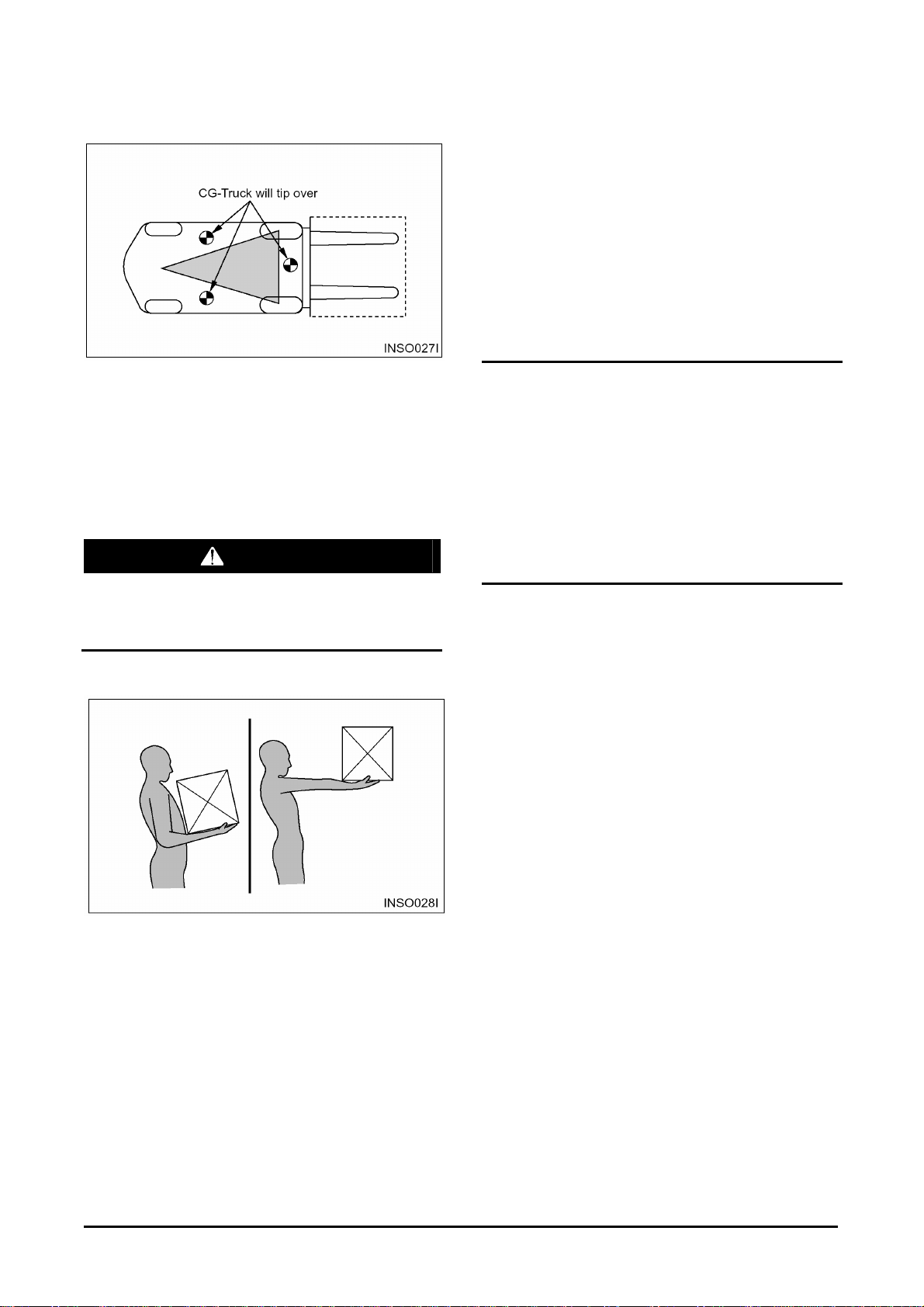

Lift Truck Stability Base

For the lift truck to be stable (not tip over forward or

to the side), the CG must stay within the area of the

lift truck stability base – a triangular area between

the front wheels and the pivot of the steer wheels. If

the CG moves forward of the front axle, the lift truck

will tip forward. If the CG moves outside of the line

on either side of the stability base, the lift truck will

tip to the side.

WARNING

Dynamic forces (braking, acceleration, turning)

also affect stability and can produce tipover

even when the CG is within the stability

triangle.

mast, and having no special-purpose attachment.

In addition, the capacity load assumes that the load

center is no further from the top of the forks than it

is from the face of the backrest. If these conditions

do not exist, the operator may have to reduce the

safe operating load because the truck stability may

be reduced. The lift truck should not be operated if

its capacity/nameplate does not indicate capacity

load.

NOTE: If the load is not uniform, the heaviest

portion should be placed closer to the

backrest and centered on the forks.

NOTICE

1. Capacity/Nameplates originally attached to

forklifts sold by DAEWOO shall not be removed,

altered or replaced without DAEWOO’s approval.

2. DAEWOO assumes no responsibility for lift

trucks placed in service without a valid DAEWOO

Nameplate.

3. If necessary to change your specification, contact

your DAEWOO lift truck dealer.

Capacity Load (Weight and Load Center)

The capacity load of the lift truck is shown on the

capacity/nameplate riveted to the truck. It is

determined by the weight and load center. The load

center is determined by the location of the CG of

the load.

The load center shown on the nameplate is the

horizontal distance from the front face of the forks,

or the load face of an attachment, to the CG of the

load. The location of the CG in the vertical direction

is the same as the horizontal dimension.

Remember that, unless otherwise indicated, the

capacity load shown on the nameplate is for a

standard lift truck with standard backrest, forks and

-22-

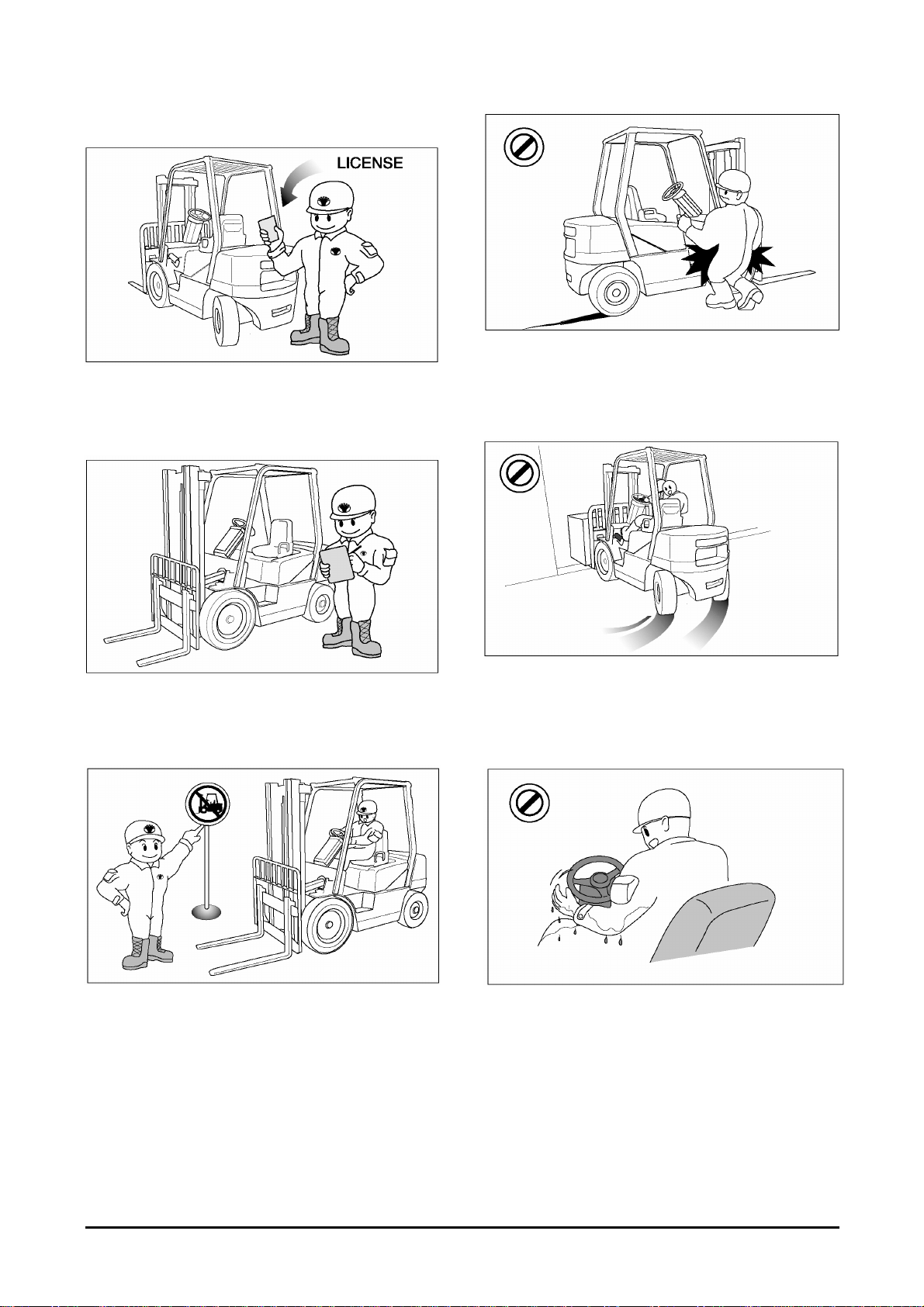

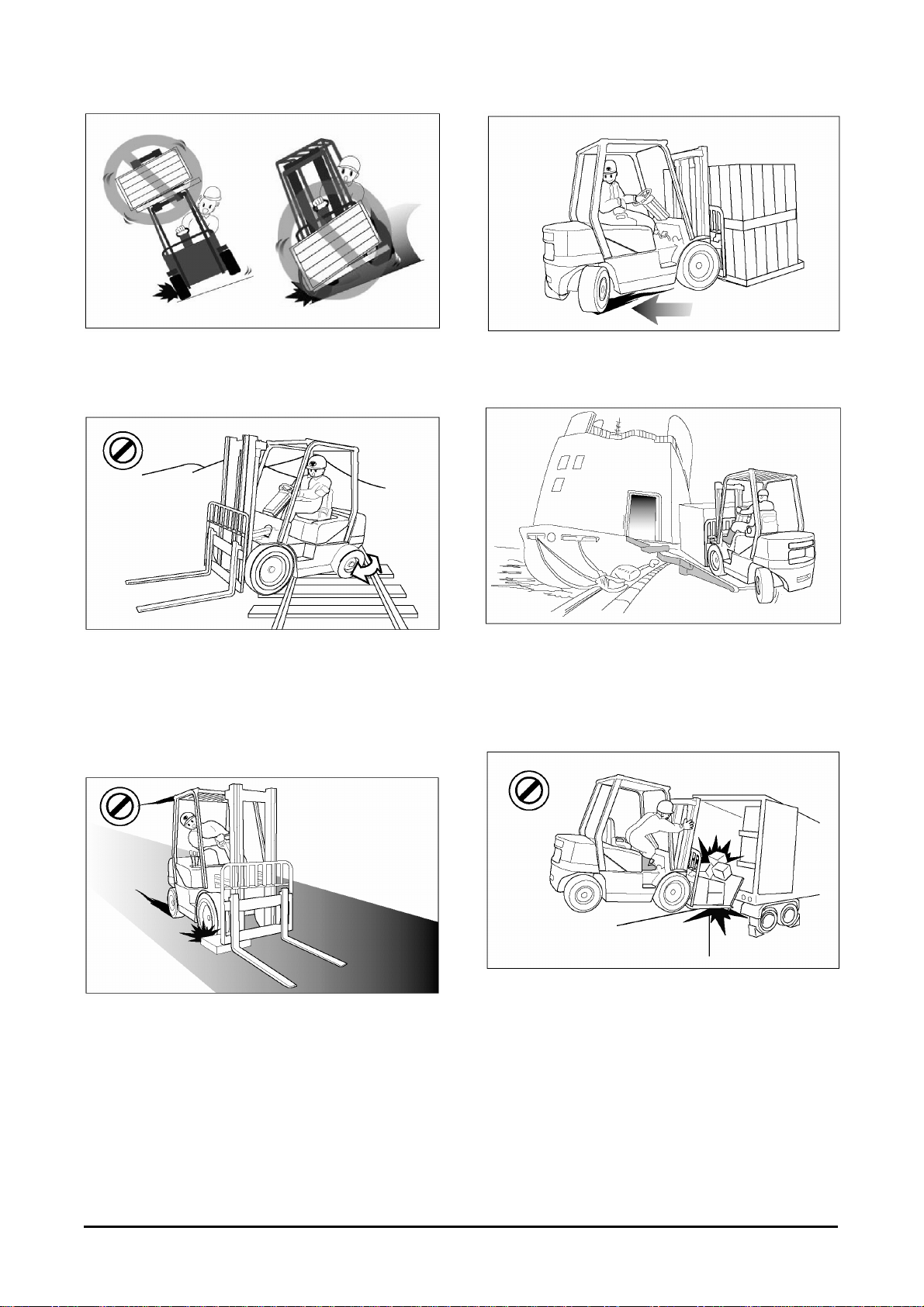

Safety Rules

Only properly trained and authorized personnel

should operate forklift trucks. Wear a hard hat and

safety shoes when operating a lift truck. Do not

wear loose clothing.

Safety Section

Do not operate a lift truck unless you are in the

operator's seat.

Keep arms, legs and head inside the confines of

the operator's area. Keep hands and feet out of the

mast assembly.

Inspect and check the condition of your forklift truck

using the operator's check list before starting work.

Immediately report to your supervisor any obvious

defects or required repairs.

Do not operate your truck in unauthorized areas.

Know your forklift truck and think safety.

Do not compromise safety.

Follow all safety rules and read all warning signs.

Do not start, stop, turn or change direction

suddenly or at high speed. Sudden movement can

cause the lift truck to tip over. Slow the speed of

your truck and use the horn near corners, exits,

entrances, and near people.

Never operate a lift truck with wet hands or shoes.

Never hold any controls with grease on your hands.

Your hands or feet will slide off of the controls and

cause an accident.

-23-

Safety Section

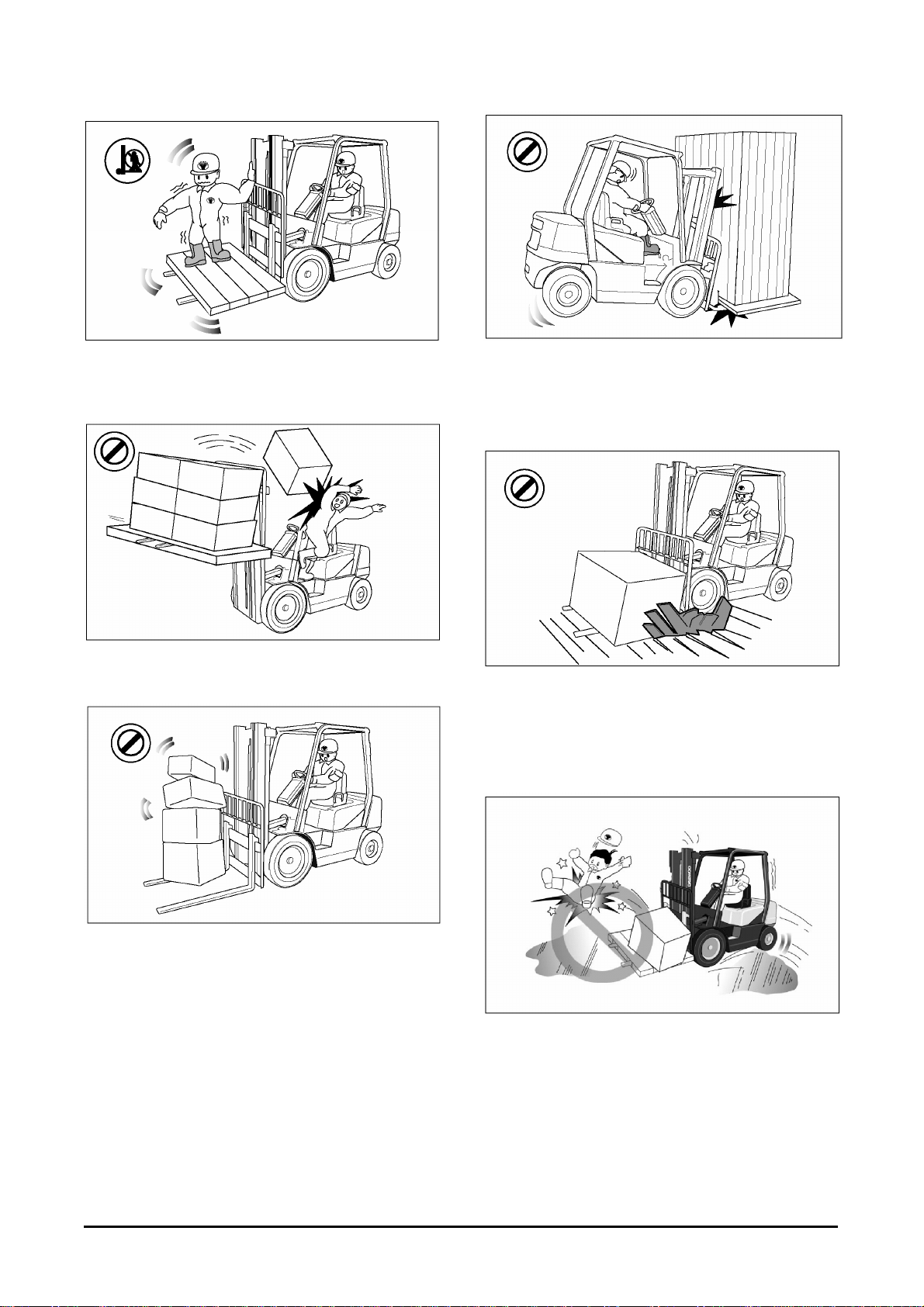

Do not raise anyone on the forks of your lift truck

unless using an approved safety cage.

Do not let other people ride on the truck.

Lift trucks are designed to carry loads, not people.

Do not operate your truck without the load backrest

extension and overhead guard. Keep the load

against the backrest with the mast tilted backward

Do not overload. Always handle loads within the

rated capacity shown on the capacity plate.

Do not add extra counterweight to the truck. An

overload can cause the truck to roll over and cause

injury to personnel and damage to the lift truck.

Do not drive on soft ground.

Observe all signs, especially those on maximum

permitted floor loadings, elevator capacities and

clearance heights.

Handle loads carefully and check them closely for

stability and balance.

Do not lift or move loads that are not safe. Do not

pick up an off center load. Such a load increases

the possibility of a tipover to the side. Make sure

loads are correctly stacked and positioned across

both forks. Always use the proper size pallet.

Position the forks as wide as possible under the

load. Position loads evenly on the forks for proper

balance. Do not lift a load with one fork.

Do not drive on slippery surfaces.

Sand, gravel, ice or mud can cause a tipover.

If unavoidable, slow down.

-24-

Safety Section

Do not permit anyone to stand or walk under the

load or lifting mechanism. The load can fall and

cause injury or death to anyone standing below.

Look out for overhead obstructions when raising or

stacking loads. Do not travel with a raised load. Do

not travel with the mast raised. The lift truck can roll

over and cause injury or death to you or other

personnel.

Do not elevate the load with the mast tilted forward.

Do not tilt the elevated loads forwards.

This will cause the lift truck to tip over forward.

Do not jump off if your truck starts to tip over.

Stay in your seat to survive.

Do not move loose loads that are higher than the

load backrest.

Be alert for falling loads when stacking.

Travel with the load tilted back and the forks as low

as possible.

This will increase stability to the truck and load and

permit better visibility for you.

Go up ramps in forward direction and down ramps

in reverse direction when moving loads.

Never elevate a load with the forklift truck on an

incline.

Go straight off and straight down. Use an assistant

when going up or down a ramp with a bulky load.

-25-

Safety Section

Do not stack or turn on ramps.

Do not attempt to pick-up or deposit a load unless

the lift truck is level. Do not turn on or drive across

an incline.

Do not go over rough terrain. If unavoidable, slow

down.

Cross railroad tracks slowly and diagonally

whenever possible. A railroad crossing can give a

loaded forklift truck a real jolt. For smoother

crossing, cross the railroad diagonally so one wheel

crosses at a time.

Do not drive in forward direction when loads restrict

your visibility. Operate your lift truck in reverse to

improve visibility except when moving up a ramp.

Be careful when operating a lift truck near the edge

of a loading dock or ramp. Maintain a safe distance

from the edge of docks, ramps and platforms.

Always watch tail swing.

The truck can fall over the edge and cause injury or

death.

Avoid running over loose objects.

Look in the direction of travel. Look out for other

persons or obstructions in your path of travel.

An operator must be in full control of his lift truck at

all times.

Do not operate on bridge plates unless they can

support the weight of the truck and load.

Make sure that they are correctly positioned.

Put blocks on the vehicle you enter to keep it from

moving.

-26-

Safety Section

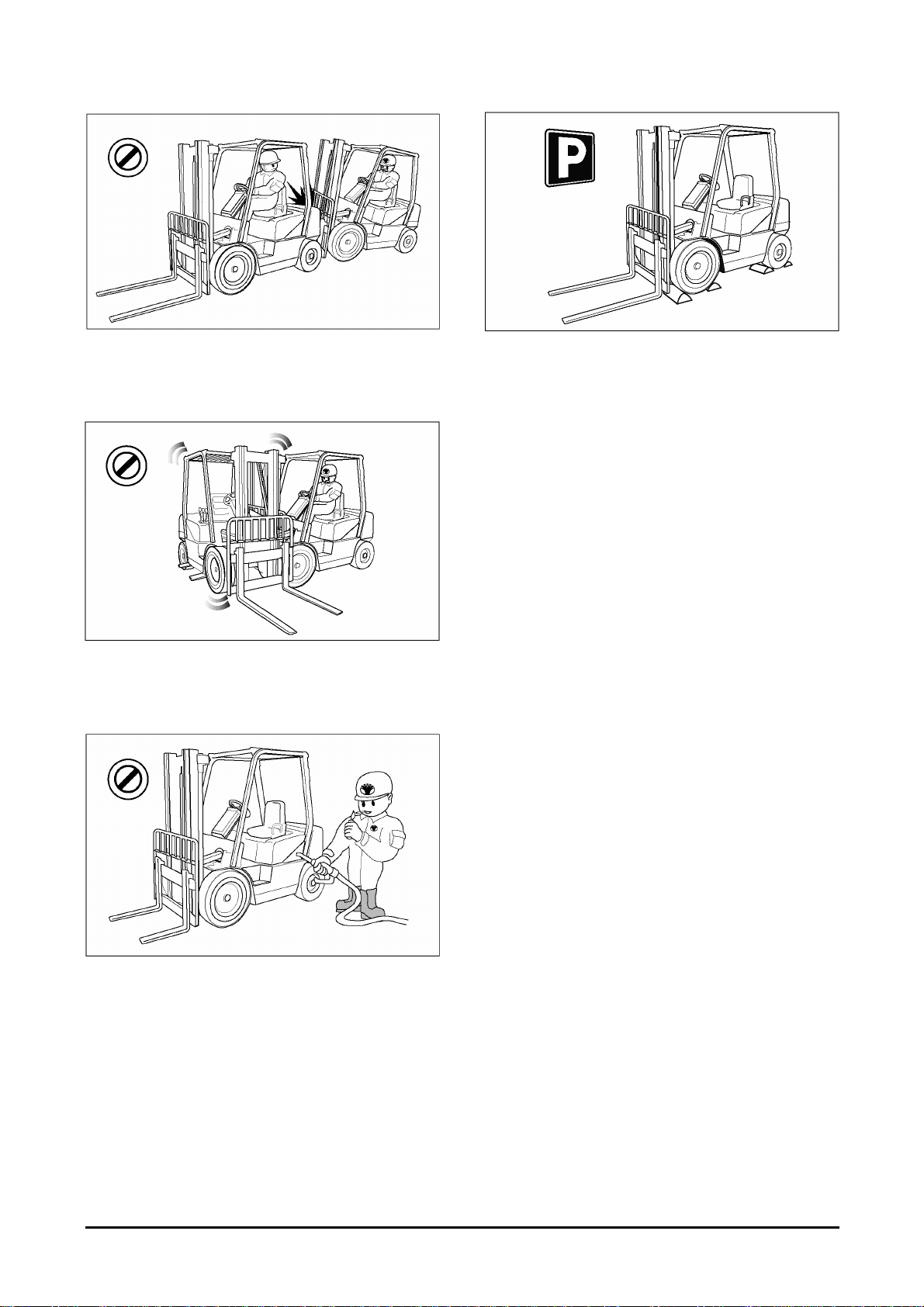

Do not operate your truck close to another truck.

Always keep a safe distance from other trucks and

make sure there is enough distance to stop safely.

Never overtake other vehicles.

Do not use your lift truck to push or tow another

truck.

Do not let another push or tow your truck.

If a truck will not move, call a service technician.

Park your lift truck in authorized areas only. Fully

lower the forks to the floor, put direction lever in

NEUTRAL position, engage the parking brake, and

turn the key to the OFF position. Remove the key

and put blocks behind the wheels to prevent the

truck from rolling. Shut off your forklift truck when

leaving it unattended.

Check the condition of your forklift truck after the

day's work.

Forklift trucks may only be refueled at specially

reserved locations. Switch off the engine when

refueling.

Smoking and handling of naked flames during

refueling are strictly prohibited. This prohibition also

applies during the changing of the LPG (liquefied

propane gas) tank.

Mop up spilt fuel and do not forget to close the fuel

tank before restarting the engine.

-27-

Safety Section

How to Survive in a Tipover

WARNING

In the event of a tipover, the risk of serious injury or

death will be reduced if the operator is using the

operator restraint system and follows the

instructions provided.

Always use operator restraint system.

DON’T jump.

Hold on tight.

Brace your feet and keep them within the operator’s

compartment.

-28-

Safety Section

Lean away from the direction of fall.

Lean forward.

-29-

General Section

Specifications

CHARACTERISTICS

Manufacturer

1

Model

2

Capacity at rated load center

3

Load center distance

4

Power type electric, diesel, gasoline, LPG

5

Operator type stand-on, rider seated

6

Tires* c = cushion, p = pneumatic

7

Wheels (x = driven) number, front/rear

8

DIMENSIONS

9

Lift with STD

10

two - stage mast

11

Fork carriage

12

Forks

Tilt of mast

14

15

16

17

Overall

dimensions

18

19

20

Outside turning radius

21

Load moment constant (from center of front wheel to fork face)

22

90° stacking aisle (add load length and clearance)

23

90° intersecting aisle

23a

maximum fork height with rated load

free lift

special free lift

ISO class

thickness X width X length

fork spacing (minimum X maximum)

forward/backward

length without forks

width

mast lowered height

mast extended height

overhead guard height

seat height

PERFORMANCE

24

Speeds

25

26

Drawbar pull

28

Gradeability

30

Acceleration time

31

travel, loaded/unloaded

lift, loaded/unloaded

lowering, loaded/unloaded

at 1.6 km/h, loaded/unloaded

at 1.6 km/h, loaded/unloaded

traveling loaded/unloaded

WEIGHT

Total weight at unloaded

32

33

34

Axle load

with load front/rear

without load front/rear

CHASSIS

35

Tires

36

37

Wheelbase

38

Tread front/rear

39

40

Ground clearance

41

Service brake

42

Parking brake

43

number of front/rear

front size

rear size

at the lowest point

at the center of wheelbase

DRIVE

Battery voltage/capacity

45

49

50

51

52

53

55

56

Engine

Transmission

manufacturer/model

rated output (at rpm) gas/LPG

max. torque (at rpm) gas/LPG

cycle/cylinders/displacement

fuel consumption

type

number of speeds forward/reverse 1/1 1/1

* Solid soft rider tires are available instead of pneumatic as an option.

DHI&M DHI&M

D20S-3 D25S-3

kg 2000 2500

mm 500 500

mm 3230 3230

mm 152 152

mm

ll ll

mm 45 X 100 X 1050 45 X 100 X 1050 13

mm 275 X 1035 275 X 1035

deg 6/10 6/10

mm 2505 2573

mm 1170 1170

mm 2170 2170

mm 4470 4470

mm 2183 2183

mm 1026 1026

mm 2220 2265

mm 485 485

mm 2705 2750

mm 1970 2000

km/h 19.5/20 19.4/19.9

mm/s 550/600 530/600

mm/s 510/460 510/460

kg 1610/ 1620/

% 28.6/ 24.9/

s

kg 3910 4280

kg 5180/730 5925/855

kg 1970/1940 1910/2370

mm 1625 1625

mm 975/1000 975/1000

mm 115 115

mm 153 153

V/AH 12/85 12/85

kW 44.1(2300) 44.1(2300)

kg - m 20(1600) 20(1600)

cc 4/4/3268 4/4/3268

l/hr

diesel diesel

rider - seated rider - seated

p p

X2/2 X2/2

2/2 2/2

7.00 X 15 - 12PR 7.00 X 15 - 12PR

6.50 X 10 - 10PR 6.50 X 10 - 10PR

foot/hydraulic foot/hydraulic

hand/mechanical hand/mechanical

DHI&M/DB33A DHI&M/DB33A

Powershift Powershift

-30-

DHI&M DHI&M 1

D30S-3 D32S-3 2

3000 3000(6500lb) 3

500 600(24in) 4

diesel diesel 5

rider - seated rider-seated 6

p p 7

X2/2 X2/2 8

3230 3230 9

152 152 10

11

lll lll 12

45 X 125 X 1050 45X125X1050

286 X 1044 286X1044 13

6/10 6/10 14

2636 2690 15

1197 1197 16

2160 2160 17

4470 4470 18

2183 2183 19

1026 1026 20

2364 2414 21

485 485 22

2849 2899 23

2050 2100 23a

19.2/19.7 19.0/19.5 24

520/600 520/600 25

510/460 510/460 26

1705/ 1705/ 28

23.0/ 23/ 30

31

4715 5070 32

6705/1010 6810/1260 33

1890/2825 1810/3260 34

2/2 2/2 35

28 X 9 X 15 - 12PR 28X9X15-12PR 36

6.50 X 10 - 10PR 6.50X10-10PR 37

1625 1625 38

982/1000 982/1000 39

105 105 40

153 153 41

foot/hydraulic foot/hydraulic 42

hand/mechanical hand/mechanical 43

12/85 12/85 45

DHI&M/DB33A DHI&M/DB33A 49

44.1(2300) 44(2300) 50

20(1600) 20/1600 51

4/4/3268 4/4/3268 52

53

Powershift Powershift 55

1/1 1/1 56

General Section

-31-

General Section

Specifications

CHARACTERISTICS TIER - II

Manufacturer

1

Model

2

Capacity at rated load center

3

Load center distance

4

Power type electric, diesel, gasoline, LPG

5

Operator type stand-on, rider seated

6

Tires* c = cushion, p = pneumatic

7

Wheels (x = driven) number, front/rear

8

kg 2000 2500

mm 500 500

DIMENSIONS

9

Lift with STD

10

two - stage mast

11

Fork carriage

12

Forks

13

Tilt of mast

14

15

16

17

Overall dimensions

18

19

20

Outside turning radius

21

Load moment constant (from center of front wheel to fork face)

22

90° stacking aisle (add load length and clearance)

23

90° intersecting aisle

23a

maximum fork height with rated load

free lift

special free lift

ISO class

thickness X width X length

fork spacing (minimum X maximum)

forward/backward

length without forks

width

mast lowered height

mast extended height

overhead guard height

seat height

mm 3230 3230

mm 152 152

mm

ll ll

mm 45 X 100 X 1050 45 X 100 X 1050

mm 275 X 1035 275 X 1035

deg 6/10 6/10

mm 2505 2573

mm 1170 1170

mm 2170 2170

mm 4470 4470

mm 2183 2183

mm 1026 1026

mm 2220 2265

mm 485 485

mm 2705 2750

mm 1970 2000

PERFORMANCE

24

Speeds

25

26

Drawbar pull

28

Gradeability

30

Acceleration time

31

travel, loaded/unloaded

lift, loaded/unloaded

lowering, loaded/unloaded

at 1.6 km/h, loaded/unloaded

at 1.6 km/h, loaded/unloaded

traveling loaded/unloaded

km/hr 19.5/20 19.5/20

mm/s 550/600 530/600

mm/s 510/460 510/460

kg 1850 1860

% 32 28

s

WEIGHT

32

33

34

Total weight

Axle load

at unloaded

with load front/rear

without load front/rear

kg 3910 4280

kg 5180/730 5925/855

kg 1970/1940 1910/2370

CHASSIS

35

Tires

36

37

Wheelbase

38

Tread

39

40

Ground clearance

41

Service brake

42

Parking brake

43

number of front/rear

front size

rear size

front/rear

at the lowest point

at the center of wheelbase

mm 1625 1625

mm 975/1000 975/1000

mm 115 115

mm 153 153

DRIVE

45

49

50

51

52

53

55

56

Battery

Engine

Transmission

voltage/capacity

manufacturer/model

rated output (at rpm) gas/LPG

max. torque (at rpm) gas/LPG

cycle/cylinders/displacement

fuel consumption

type

number of speeds forward/reverse

V/AH 12/85 12/85

kW 43.4(2200) 43.4(2200)

kg - m 20.5(1600) 20.5(1600)

cc 4/4/3260 4/4/3260

l/hr

* Solid soft rider tires are available instead of pneumatic as an option.

DHI&M DHI&M

D20S-3 D25S-3

diesel diesel

rider - seated rider - seated

p p

X2/2 X2/2

2/2 2/2

7.00 X 15 - 12PR 7.00 X 15 - 12PR

6.50 X 10 - 10PR 6.50 X 10 - 10PR

foot/hydraulic foot/hydraulic

hand/mechanical hand/mechanical

CUMMINS/B3.3 CUMMINS/B3.3

Powershift Powershift

1/1 1/1

-32-

TIER - II

DHI&M DHI&M DHI&M 1

D30S-3 D32S-3 D33S-3 2

3000 3000(6500lb) 3250 3

500 600(24in) 500 4

diesel diesel diesel 5

rider - seated rider-seated rider-seated 6

p p p 7

X2/2 X2/2 X2/2 8

3230 3230 3230 9

152 152 152 10

11

lll lll lll 12

45 X 125 X 1050 45X125X1050 45X125X1050

286 X 1044 286X1044 286X1044

6/10 6/10 6/10 14

2636 2690 2690 15

1197 1197 1197 16

2160 2160 2160 17

4470 4470 4470 18

2183 2183 2183 19

1026 1026 1026 20

2364 2414 2414 21

485 485 485 22

2849 2899 2899 23

2050 2100 2100 23a

19.0/19.5 19.0/19.5 19.0/19.5 24

520/600 520/600 500/600 25

510/460 510/460 510/460 26

1890 1890 1900 28

25 25 23.5 30

31

4715 5070 5070 32

6705/1010 6810/1260 7030/1290 33

1890/2825 1810/3260 1810/3260 34

2/2 2/2 2/2 35

28 X 9 X 15 - 12PR 28X9X15-12PR 28X9X15-12PR 36

6.50 X 10 - 10PR 6.50X10-10PR 6.50X10-10PR 37

1625 1625 1625 38

982/1000 982/1000 982/1000 39

105 105 105 40

153 153 153 41

foot/hydraulic foot/hydraulic foot/hydraulic 42

hand/mechanical hand/mechanical hand/mechanical 43

12/85 12/85 12/85 45

CUMMINS/B3.3 CUMMINS/B3.3 CUMMINS/B3.3 49

43.4(2200) 43.4(2200) 43.4(2200) 50

20.5(1600) 20.5(1600) 20.5(1600) 51

4/4/3260 4/4/3260 4/4/3260 52

53

Powershift Powershift Powershift 55

1/1 1/1 1/1 56

General Section

13

-33-

General Section

Specifications

CHARACTERISTICS

1 Manufacturer DHI&M DHI&M

2 Model G20E-3 G25E-3

3 Capacity at rated load center kg 2000 2500

4 Load center distance mm 500 500

5 Power type electric, diesel, gasoline, LPG gasoline / LPG gasoline / LPG

6 Operator type stand-on, rider seated rider - seated rider - seated

7 Tires* c = cushion, p = pneumatic p p

8 Wheels (x = driven) number, front/rear X2/2 X2/2

DIMENSIONS

9 maximum fork height with rated load mm 3230 3230

Lift with STD two - stage mast

10 free lift mm 152 152

11

12 Fork carriage ISO class ll ll

13 Forks

14 Tilt of mast forward/backward deg 6/10 6/10

15 length without forks mm 2505 2573

16 Overall width mm 1170 1170

17 dimensions mast lowered height mm 2170 2170

18 mast extended height mm 4470 4470

19 overhead guard height mm 2183 2183

20 seat height mm 1026 1026

21 Outside turning radius mm 2220 2265

22 Load moment constant (from center of front wheel to fork face) mm 485 485

23 90° stacking aisle (add load length and clearance) mm 2705 2750

23a 90° intersecting aisle mm 1970 2000

PERFORMANCE

24 travel, loaded/unloaded km/hr 18.2/19.3 18.0/19.3

Speeds

25 lift, loaded/unloaded mm/s 530/600 510/600

26

28 Drawbar pull at 1.6 km/h, loaded/unloaded kg 1500/ 1480/

30 Gradeability at 1.6 km/h, loaded/unloaded % 26.7/ 22.7/

31 Acceleration time traveling loaded/unloaded s

WEIGHT

32 Total weight at unloaded kg 3750 4120

33 with load front/rear kg 5095/655 5820/800

Axle load

34

CHASSIS

35 number of front/rear 2/2 2/2

Tires

36 front size 7.00 X 15 - 12PR 7.00 X 15 - 12PR

37

38 Wheelbase mm 1625 1625

39 Tread front/rear mm 975/1000 975/1000

40 at the lowest point mm 115 115

Ground clearance

41

42 Service brake foot/hydraulic foot/hydraulic

43 Parking brake hand/mechanical hand/mechanical

DRIVE

45 Battery voltage/capacity V/AH 12/45 12/45

49 manufacturer/model DHI&M/G424 DHI&M/G424

50 rated output (at rpm) gas/LPG kW 34.5(2300) 34.5(2300)

Engine

51 max. torque (at rpm) gas/LPG kg - m 16.3(1600) 16.3(1600)

52 cycle/cylinders/displacement cc 4/4/2350 4/4/2350

53

55 type Powershift Powershift

Transmission

56

* Solid soft rider tires are available instead of pneumatic as an option.

special free lift mm

thickness X width X length mm 45 X 100 X 1050 45 X 100 X 1050

fork spacing (minimum X maximum) mm 275 X 1035 275 X 1035

lowering, loaded/unloaded mm/s 510/460 510/460

without load front/rear

rear size 6.50 X 10 - 10PR 6.50 X 10 - 10PR

at the center of wheelbase mm 153 153

fuel consumption l/hr

number of speeds forward/reverse 1/1 1/1

kg 1880/1870 1810/2310

-34-

DHI&M DHI&M 1

G30E-3 G32E-3 2

3000 3000(6500lb) 3

500 600(24in) 4

gasoline / LPG LPG 5

rider - seated rider-seated 6

p p 7

X 2/2 X2/2 8

3230 3230 9

152 152 10

11

lll lll 12

45 X 125 X 1050 45X125X1050

286 X 1044 286X1044

6/10 6/10 14

2636 2690 15

1197 1197 16

2160 2160 17

4470 4470 18

2183 2183 19

1026 1026 20

2364 2414 21

485 485 22

2849 2899 23

2050 2100 23a

17.0/18.4 17.0/18.0 24

500/600 500/600 25

510/460 510/460 26

1550/ 1550/ 28

20.8/ 20.8/ 30

31

4530 4830 32

6605/925 6690/1140 33

1790/2740 1680/3150 34

2/2 2/2 35

28 X 9 X 15 - 12PR 28X9X15-12PR 36

6.50 X 10 - 10PR 6.50X10-10PR 37

1625 1625 38

982/1000 982/1000 39

105 105 40

153 153 41

foot/hydraulic foot/hydraulic 42

hand/mechanical hand/mechanical 43

12/45 12/45 45

DHI&M/G424 DHI&M/G424 49

34.5(2300) 34.5(2300) 50

16.3(1600) 16.3(1600) 51

4/4/2350 4/4/2350 52

53

Powershift Powershift 55

1/1 1/1 56

General Section

13

-35-

General Section

Specifications

CHARACTERISTICS

1 Manufacturer DHI&M DHI&M

2 Model GC20E-3 GC25E-3

3 Capacity at rated load center kg 2000 2500

4 Load center distance mm 500 500

5 Power type electric, diesel, gasoline, LPG gasoline / LPG gasoline / LPG

6 Operator type stand-on, rider seated rider - seated rider - seated

7 Tires* c = cushion, p = pneumatic c c

8 Wheels (x = driven) number, front/rear X 2/2 X 2/2

DIMENSIONS

9 maximum fork height with rated load mm 3230 3230

Lift with STD

10 free lift mm 152 152

two - stage mast

11

12 Fork carriage ISO class ll ll

13 Forks

14 Tilt of mast forward/backward deg 6/8 6/8

15 length without forks mm 2218 2268

16 width mm 1110 1110

Overall

17 mast lowered height mm 2125 2125

dimensions

18 mast extended height mm 4470 4470

19 overhead guard height mm 2150 2150

20

21 Outside turning radius mm 2000 2045

22 Load moment constant (from center of front wheel to fork face) mm 374 374

23 90° stacking aisle (add load length and clearance) mm 2374 2419

23a 90° intersecting aisle mm 1798 1822

PERFORMANCE

24 travel, loaded/unloaded km/h 17.5/17.9 17.4/17.8

Speeds

25 lift, loaded/unloaded mm/s 530/600 510/600

26

28 Drawbar pull at 1.6 km/h, loaded/unloaded kg 1630/ 1590/

30 Gradeability at 1.6 km/h, loaded/unloaded % 31.2/ 26.2/

31 Acceleration time traveling loaded/unloaded s

WEIGHT

32 Total weight at unloaded kg 3380 3680

33

Axle load

34

CHASSIS

35 number of front/rear 2/2 2/2

Tires

36 front size 21 X 7 - 15 21 X 7 - 15

37

38 Wheelbase mm 1410 1410

39 Tread front/rear mm 932/983 932/983

40 at the lowest point mm 90 90

Ground clearance

41

42 Service brake foot/hydraulic foot/hydraulic

43 Parking brake hand/mechanical hand/mechanical

DRIVE

45 Battery voltage/capacity V/AH 12/45 12/45

49 manufacturer/model DHI&M/G424 DHI&M/G424

50 rated output (at rpm) gas/LPG kW 34.5(2300) 34.5(2300)

Engine

51 max. torque (at rpm) gas/LPG kg - m 16.3(1600) 16.3(1600)