8500 Tracking System

Operator’s

Manual

CMW

®

Issue 1.0 053-1254

8500 Tracking System Manual Overview - 1

Overview

Chapter Contents

Serial Number Location . . . . . . . . . . . . . . . . . . . . . . 2

Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . 3

• Bulleted Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

• Numbered Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

• “Continued” Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

FCC Statement - Internal Transmitter . . . . . . . . . . . 4

CMW

Overview - 2 8500 Tracking System Operator’s Manual

Serial Number Location

Serial Number Location

Record serial numbers and date of purchase in spaces provided. Serial numbers are located as shown

and displayed briefly in lower left corner of tracker and display screens when unit s are first powered up.

Item

date of purchase:

tracker serial number:

display serial number:

accessory model and serial number:

accessory model and serial number:

accessory model and serial number:

CMW

8500 Tracking System Manual Overview - 3

Intended Use

Intended Use

The 8500 tracking system consists of an 8500TK tracker, an 8500D remote display, and an 850 series

beacon. The system provides advanced locating features to 30’ (9 m) dee p. It also p rovides of fset locating

and depth capability. The system provides projected direction information and offers a Drill-Thru guidance

mode. The system can track grade drilling bores with the addition of an 850 series grade beacon and other

grade drilling accessories.

The system is designed for operation in temperatures typically experienced in earth moving and

construction work environments. Use in any other way is considered contrary to the intended use. The

8500 tracking system should be operated only by persons familiar with its particular characteristics and

acquainted with the relevant safety procedures. The system should be serviced only by Ditch Witch

Electronics repair centers.

About This Manual

This manual contains information for the proper use of this equipment. Cross references such as “See

page 50” will direct you to det ailed procedures.

Bulleted Lists

Bulleted lists provide helpful or important information or contain procedure s that do not have to be

performed in a specific order.

Numbered Lists

Numbered lists contain illustration callouts or list steps that must be performed in order.

“Continued” Indicators

indicates that a procedure is continued on the next page.

CMW

Overview - 4 8500 Tracking System Operator’s Manual

FCC Statement - Internal Transmitter

FCC Statement - Internal Transmitter

Contains FCC ID: TFB-FREESTAR

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

Changes or modifications not expressly approved by The Charles Machine Works, Inc. could void the

user’s authority to operate the equipment.

Contains IC: 5969A-FREESTAR

N 16819

CMW

8500 Tracking System Manual Foreword - 5

Foreword

This manual is an important part of your equipment. It provides safety information and operation

instructions to help you use and maintain your Ditch Witch equipment.

Read this manual before using your equipment. Keep it with the equipmen t at all times for future reference.

If you sell your equipment, be sure to give this manual to the new owner.

If you need a replacement copy, contact your Ditch Witch dealer. If you need assistance in locating a

dealer, visit our website at www.ditchwitch.com or write to the following address:

The Charles Machine Works, Inc.

Attn: Marketing Department

PO Box 66

Perry, OK 73077-0066

USA

The descriptions and specifications in this manual are subject to change without notice. The Charles

Machine Works, Inc. reserves the right to improve equipment. Some product improvements may have

taken place after this manual was publishe d. For the latest information on Ditch Witch equipment, see your

Ditch Witch dealer.

Thank you for buying and using Ditch Witch equipment.

CMW

Foreword - 6 8500 Tracking System Operator’s Manual

8500 Tracking System

Operator’s Manual

Issue number 1.0/OM-4/08

Part number 053-1254

Copyright 2008

by The Charles Machine Works, Inc.

, Ditch Witch, CMW, AutoCrowd, Jet Trac, Roto Witch, Subsite, Fluid Miser,

Power Pipe, Super Witch, Pierce Airrow, The Underground, The Underground Authority Worldwide, and

Zahn are registered trademarks of The Ch ar les Mac hin e Works, Inc.

CMW

8500 Tracking System Operator’s Manual Contents - 7

Content s

Overview

machine serial number, information about the type of work this machine is designed

to perform, basic machine components, and how to use this manual

Foreword

part number, revision level, and publication date of this manual, and factory contact

information

Safety

machine safety alerts and emergency procedures

Controls

machine controls and how to use them

System Operation

procedures for tracking beacon signals

Tracking Concepts

basic information for tracking beacon signals

Systems and Equipment

status messages, beacon information, TMS Plus interface instructions

1

5

9

13

33

47

51

Service

service intervals and instructions for this machine

Specifications

machine specifications including weights and measurements

Support

the warranty policy for this machine, and procedures for obtaining warranty

consideration and training

59

63

67

CMW

Contents - 8 8500 Tracking System Operator’s Manual

CMW

8500 Tracking System Operator’s Manual Safety - 9

Safety

Chapter Contents

Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Safety Alert Classifications . . . . . . . . . . . . . . . . . . 11

Safety Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

CMW

Safety - 10 8500 Tracking System Operator’s Manual

Guidelines

Guidelines

Follow these guidelines before operating any jobsite equipment:

• Complete proper training and read operator’s manual before using equipment.

• Contact One-Call (888-258-0808) and any utility companies which do not subscribe to One-Call. Have

all underground pipes and cables located and marked before operating equipment. If you damage a

utility, contact utility company.

• Classify jobsite based on its hazards and use cor rect tools and machin ery, safety e quipment, and work

methods for jobsite.

• Mark jobsite clearly and keep spectators away.

• Wear personal protective equipment.

• Review jobsite hazards, safety and emergency procedures, and individual responsibilities with all

personnel before work begins.

• Replace missing or damaged safety signs.

• Use equipment carefully. Stop operation and investigate anything that does not look or feel right.

• Contact your equipment dealer if you have any question about operation, maintenance, or equipment

use.

CMW

8500 Tracking System Operator’s Manual Safety - 11

Safety Alert Classifications

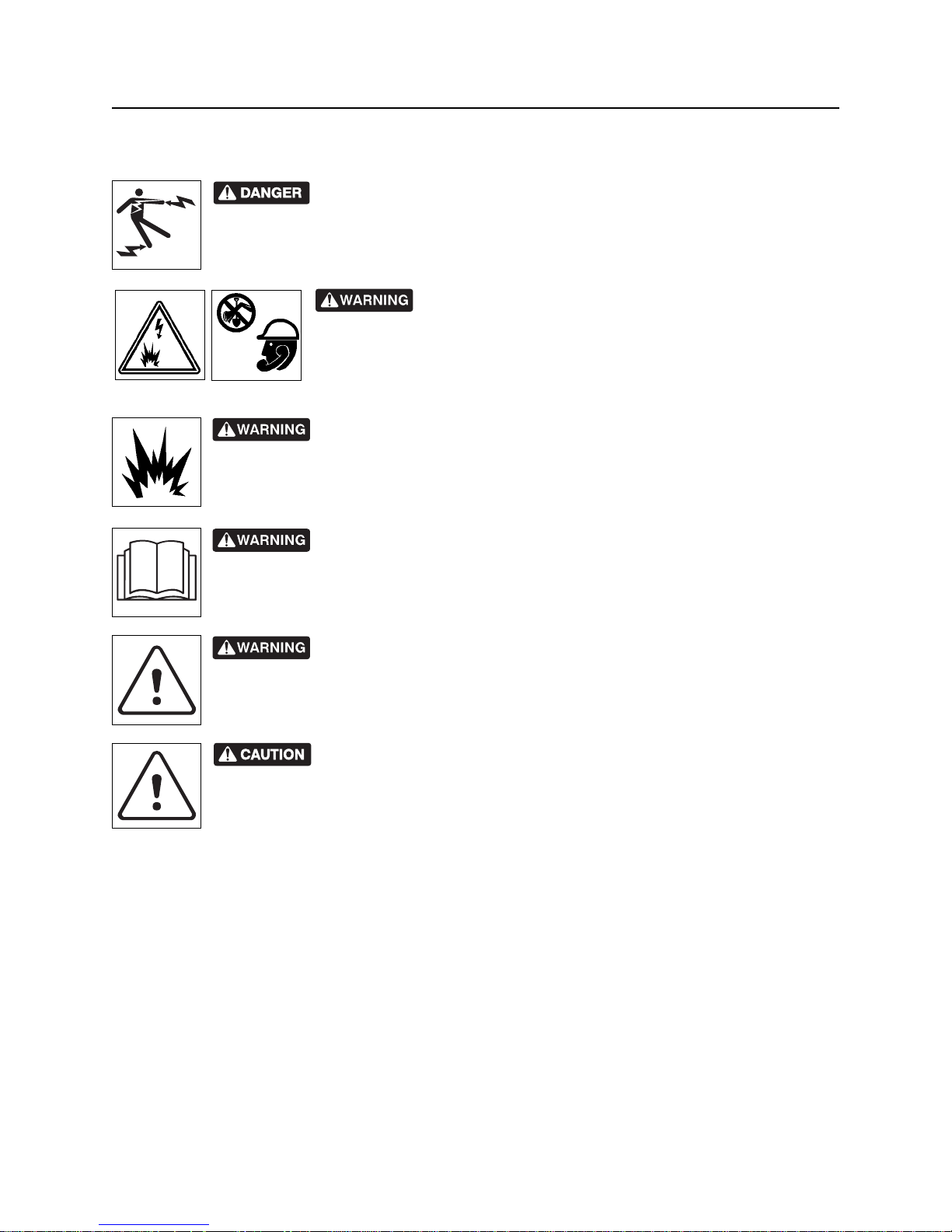

Safety Alert Classifications

These classifications and the icons defined on the following pages work together to alert you to situations

which could be harmful to you, jobsite bystanders or your equipment. When you see these words and

icons in the book or on the unit, carefully read and follow all instructions. YOUR SAFETY IS AT STAKE.

Watch for the three safety alert levels: DANGER, WARNING and CAUTION. Learn what each level

means.

indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury.

Watch for two other words: NOTICE and IMPORTANT.

NOTICE can keep you from doing something that might damage the unit or someone's property. It can also

alert you against unsafe practices.

IMPORTANT can help you do a better job or make your job easier in some way.

CMW

Safety - 12 8500 Tracking System Operator’s Manual

Safety Alerts

Safety Alerts

Electric shock. Contacting electric lines will cause death or serious injury.

Know location of lines and stay away.

Jobsite hazards could cause death or serious injury. Use

correct equipment and work methods. Use and maintain proper safety

equipment.

Explosion possible. Serious injury or equipment damage could occur.

Follow directions carefully .

Incorrect procedures could result in death, injury, or property damage.

Learn to use equipment correctly.

Moving traffic - hazardous situation. Death or serious injury could result.

Avoid moving vehicles, wear high visibility clothing, post appropriate warning signs.

Potential radio frequency (RF) hazard. Operating this device within 4” (100

mm) of your body may cause RF exposure levels to exceed FCC RF exposure limits and

should be avoided.

CMW

8500 Tracking System Operator’s Manual Controls - 13

Controls

Chapter Contents

8500TK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

• Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

• Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

• Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

8500D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

• Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

• Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

• Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

CMW

Controls - 14 8500 Tracking System Operator’s Manual

8500TK

8500TK

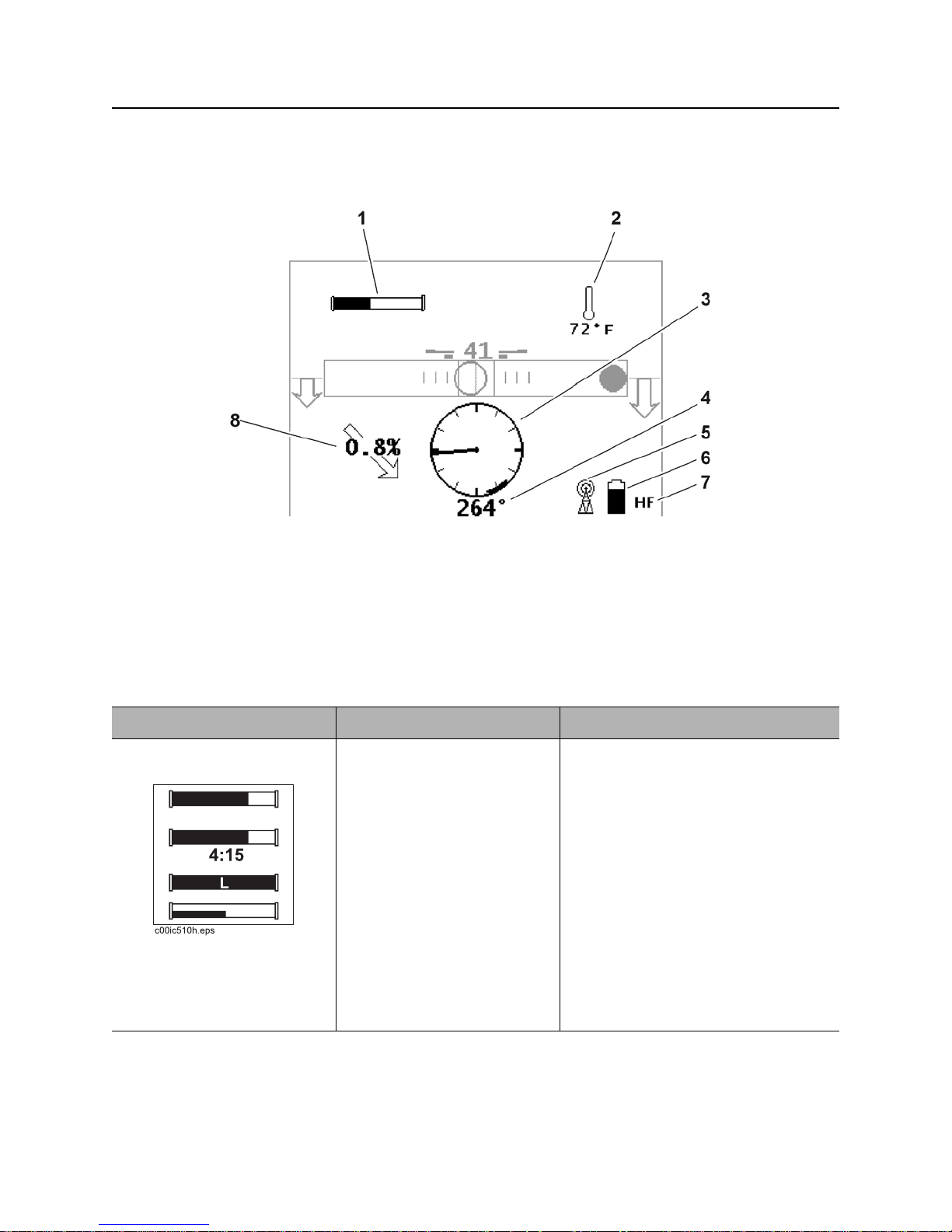

Icons

1. Beacon battery life indicator

2. Beacon temperature

3. Beacon roll indicator

4. Beacon roll value

Item Description Notes

1. Beacon battery life

indicator

Graphically indicates battery

life remaining.

If beacon is within 5 minutes

of entering sleep mode, a

countdown timer will appear

below icon.

An “L” appears in the icon if a

Lithium battery is installed.

In 2-axis view (bottom icon),

replace battery if either axis

disappears.

5. Communication indicator

6. Tracker battery life indicator

7. Frequency indicator

8. Beacon pitch

Battery power (horizontal axis) and

beacon throttle (vertical axis) are

monitored in this view. See “Beacon

Throttle” on page 56.

CMW

8500 Tracking System Operator’s Manual Controls - 15

8500TK

Item Description Notes

2. Beacon temperature Displays beacon temperature

and flashes if temperature

becomes too high.

Icon darkens as temperature

rises and temperature is

displayed numerically below

the icon.

3. Beacon roll indicator Graphically indicates

beacon’s roll position.

4. Beacon roll value Numerically displays

beacon’s roll position in

degrees, minutes or hours.

5. Communication

indicator

Indicates tracker and display

are communicating properly.

IMPORTANT: An audible warning is

activated when beacon temperature is

155°F (68°C).

6. Tracker battery Indicates amount of battery

7. Frequency indicator Displays “HF” when high

power remaining for the

tracker.

Flashes when batteries need

to be replaced.

frequency beacon is selected.

Displays “LF” when low

frequency beacon is selected.

CMW

Controls - 16 8500 Tracking System Operator’s Manual

8500TK

Item Description Notes

8. Beacon pitch Displays pitch of beacon in

percent grade or degrees.

The arrow behind the value

indicates whether pitch is

positive or negative.

CMW

8500 Tracking System Operator’s Manual Controls - 17

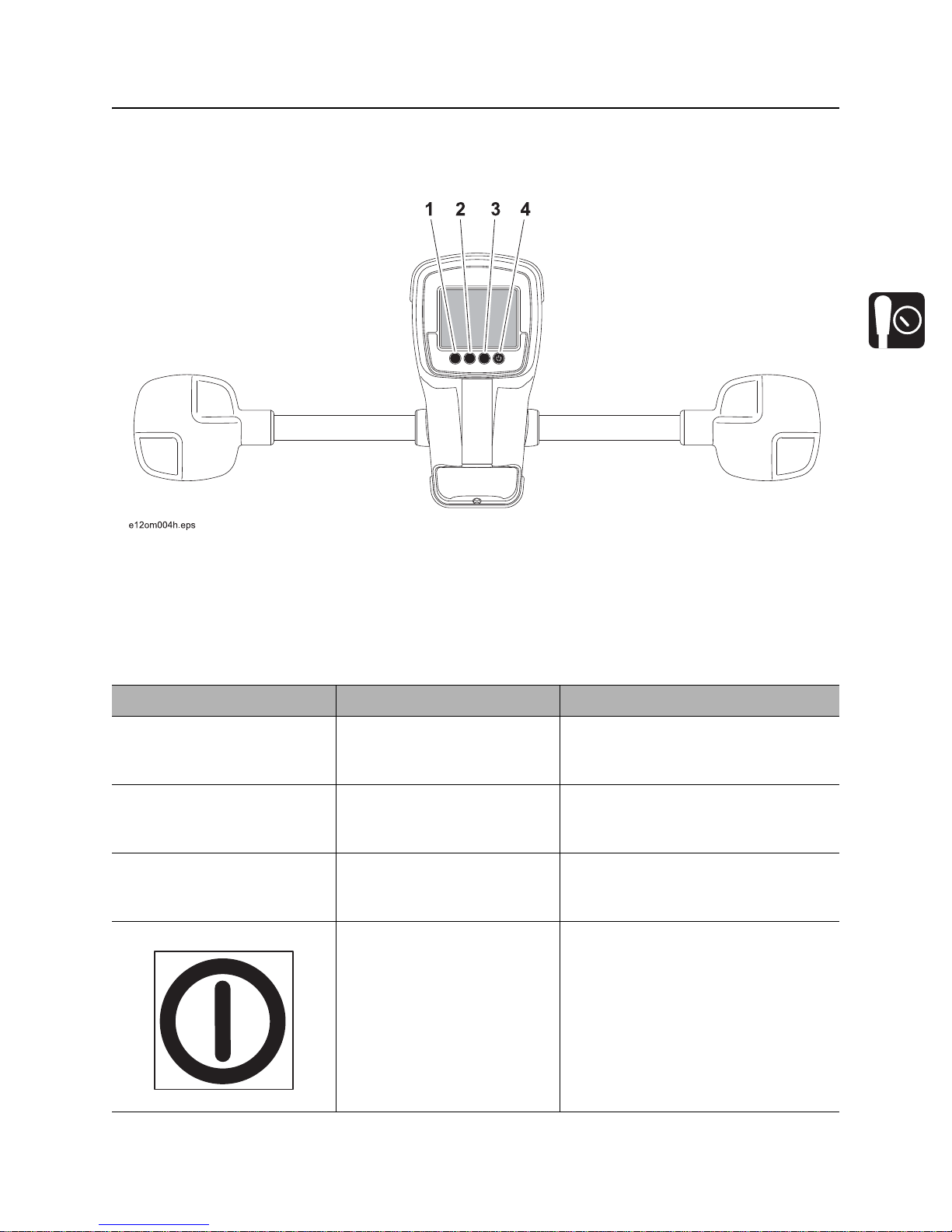

8500TK

Buttons

Overview

1. Soft button

2. Soft button

Item Description Notes

1. Soft button Function depends on

selected mode and is

indicated above button.

2. Soft button Function depends on

selected mode and is

indicated above button.

3. Soft button Function depends on

selected mode and is

indicated above button.

4. Power button To turn on, press once.

To turn off, press for 2

seconds.

3. Soft button

4. Power button

Button is also used to access quick

functions.

Button is also used for quick

functions.

Button is also used for quick

functions.

Button is also used for quick

functions.

si1017a-d.eps

CMW

Controls - 18 8500 Tracking System Operator’s Manual

8500TK

Quick Functions

Contrast Adjustment

To adjust contrast, pr ess and hold lef t button (1) and pr ess button 2 to da rken/increase contrast or butto n 3

to lighten/lessen contrast.

Backlight Toggle

To turn backlight on and of f, press and hold left button (1) and press power (4) button. Don’t press power

button for more than 2 seconds to avoid turning unit off.

CMW

8500 Tracking System Operator’s Manual Controls - 19

8500TK

Menu

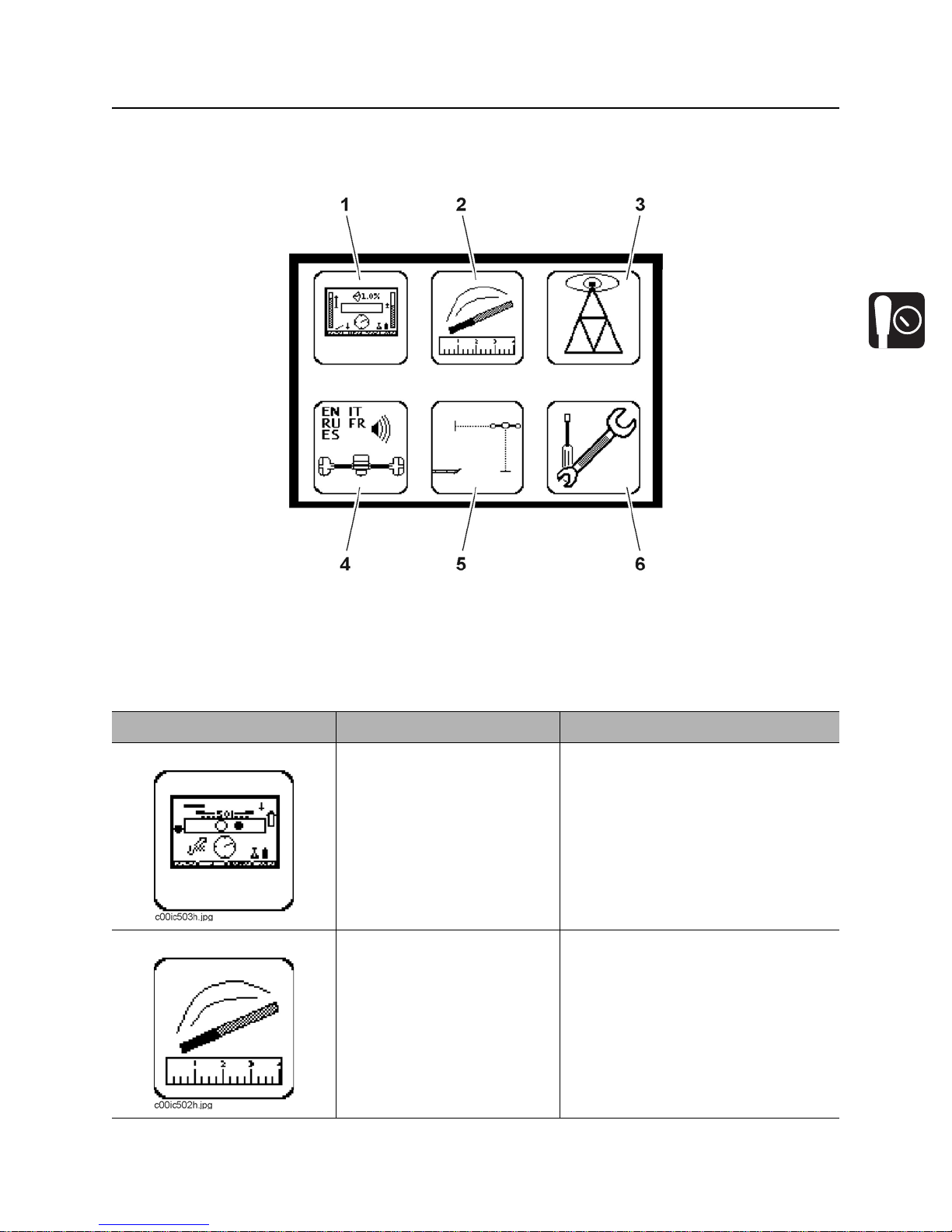

Overview

1. Display settings

2. Beacon settings

3. Radio options

Item Description Notes

1. Display settings Highlight icon and press

select to enter the “display

settings” menu.

2. Beacon settings Highlight icon and press

select to enter the “beacon

settings” menu.

4. System settings

5. Drill-Thru mode

6. Service menu

See “Display Settings” on page 21.

See “Beacon Settings” on page 21.

CMW

Controls - 20 8500 Tracking System Operator’s Manual

8500TK

Item Description Notes

3. Radio options Highlight icon and press

select to enter the “radio

options” mode.

4. System settings Highlight icon and press

select to enter the “system

settings” menu.

5. Drill-Thru mode Highlight icon and press

select to enter the drill-thru

mode.

See “Radio Options” on page 22.

See “System Settings” on page 22.

See “Drill-Thru Mode” on page 43.

6. Service menu Highlight icon and press

select to enter “service

menu.”

CMW

See “Service Menu” on page 22.

8500 Tracking System Operator’s Manual Controls - 21

8500TK

Descriptions

Display Settings

Description Notes

LCD Backlight Controls backlight intensity.

Available settings: 0 (off) to 100 (brightest, default).

LCD contrast Controls contrast of LCD.

Available settings: -20 (lighter) to 20 (darker), 0 is default.

Units Controls displayed units of depth values, tempera tures and other

numbers.

Available distance settings: inches, ft in (default), decimal ft, meters,

centimeters.

Depth disp. time Controls how long depth information is locked on the screen after

pressing depth button.

Available settings: 0-60 seconds, 5 is default.

Roll angle disp. Controls display of numerical value of the roll indicator.

Available settings: off (default), degr ees, minutes, hours.

Pitch disp. Controls display of beacon pitch indicator.

Available settings: percent (default), degrees.

Battery ind. style Controls display of beacon battery indicator.

Available settings: 1-axis (default), 2-axis.

Beacon Settings

Description Notes

Beacon freq. Sets tracker receiving frequency.

Available settings: high (default), low.

Beacon calibration Calibrates tracker to beacon.

Roll calibration Sets roll position for beacon equivalent to bit pointing up (12 o’clock, 0

minutes, 0°).

Pitch calibration Sets 0.0% pitch position for grade beacon (1.0% limit).

Depth adjustment Changes built-in adjustment of depth measurements.

CMW

Controls - 22 8500 Tracking System Operator’s Manual

8500TK

Radio Options

Description Notes

Radio power Turns radio on and off.

Available settings: on (default), off.

Channel Sets telemetry channel

Available settings: 1 (default) through 15

Tracker Control Enables or disables thrust and rotation of drilling unit.

Available settings: Rig ON, Rig OFF (default).

Tracker Control code Selects code for Tracker Control feature corresponding to code on

display.

System Settings

IMPORTANT: Warning sounds such as beacon temperature alert are always audible.

Description Notes

Language Controls displayed user interface language.

Available languages include: English, German, Spanish, French,

Italian, Swedish, Russian.

Tracker sleep Controls tracker sleep feature.

Available settings: on (default), off.

Volume Controls volume of the signal sound and sound effects.

Available settings: mute, low, med, high (default).

Service Menu

Description Notes

Versions Lists hardware and software versions, serial number, and copyright

information.

Uptime Displays uptime and life timers.

Support Enters support menu.

Factory Enters factory menu. Password protected.

CMW

8500 Tracking System Operator’s Manual Controls - 23

8500D

8500D

Icons

1. Beacon battery life indicator

2. Beacon roll indicator

3. Communication indicator

4. Display battery life indicator

Item Description Notes

1. Beacon battery life

indicator

Graphically indicates battery

life remaining.

If beacon is within 5 minutes

of entering sleep mode, a

countdown timer will appear

below icon.

An “L” appears in the icon if a

Lithium battery is installed.

In 2-axis view (bottom icon),

replace battery if either axis

disappears.

5. Beacon temperature

6. Beacon roll value

7. Beacon pitch

Battery power (horizontal axis) and

beacon throttle (vertical axis) are

monitored in this view. See “Beacon

Throttle” on page 56.

2. Beacon roll indicator Graphically indicates

beacon’s roll position.

CMW

Controls - 24 8500 Tracking System Operator’s Manual

8500D

Item Description Notes

3. Communication

indicator

4. Display battery life

indicator

5. Beacon temperature Displays beacon temperature

Indicates tracker and display

are communicating properly.

Indicates amount of battery

power remaining for the

display.

Flashes when batteries need

to be replaced.

and flashes if temperature

becomes too high.

Icon darkens as temperature

rises and temperature is

displayed numerically below

the icon.

6. Beacon roll value Displays numeric value in

degrees, minutes or hours.

7. Beacon pitch Displays pitch of beacon in

percent grade or degrees.

The arrow behind the value

indicates whether pitch is

positive or negative.

CMW

8500 Tracking System Operator’s Manual Controls - 25

8500D

Buttons

Overview

1. Save button

2. Review button

IMPORTANT:

• Some icons and functions will change when display is properly connected to TMS Plus. These are

shown and explained in the following table.

• SD card must be installed and have active log file or display must be connected to TMS Plus to

store, review or delete logged data.

3. Delete button

4. Power button

CMW

Controls - 26 8500 Tracking System Operator’s Manual

8500D

Item Description Notes

1. Save button

Send button

2. Review button

Press to save data for current

pipe.

When connected to TMS

Plus:

Press to send data for current

pipe to TMS Plus.

Press to review previous pipe

data.

Press again to review pipe

before that.

IMPORTANT: Display must have

received a depth reading from tracker

to save.

Recall button

CMW

When connected to TMS

Plus:

Press to review target

information for next pipe.

8500 Tracking System Operator’s Manual Controls - 27

8500D

Item Description Notes

3. Delete button Press to delete previous pipe

data.

4. Power/Menu button To turn on, press once.

To turn off, press for 2

seconds.

si1017a-d.eps

Press button less than 2 seconds to

access menu.

Quick Functions

Contrast Adjustment

To adjust contrast, pr ess and hold lef t button (1) and pr ess button 2 to da rken/increase contrast or butto n 3

to lighten/lessen contrast.

Backlight Toggle

To turn backlight on and of f, press and hold left button (1) and press power (4) button. Don’t press power

button for more than 2 seconds to avoid turning unit off.

CMW

Controls - 28 8500 Tracking System Operator’s Manual

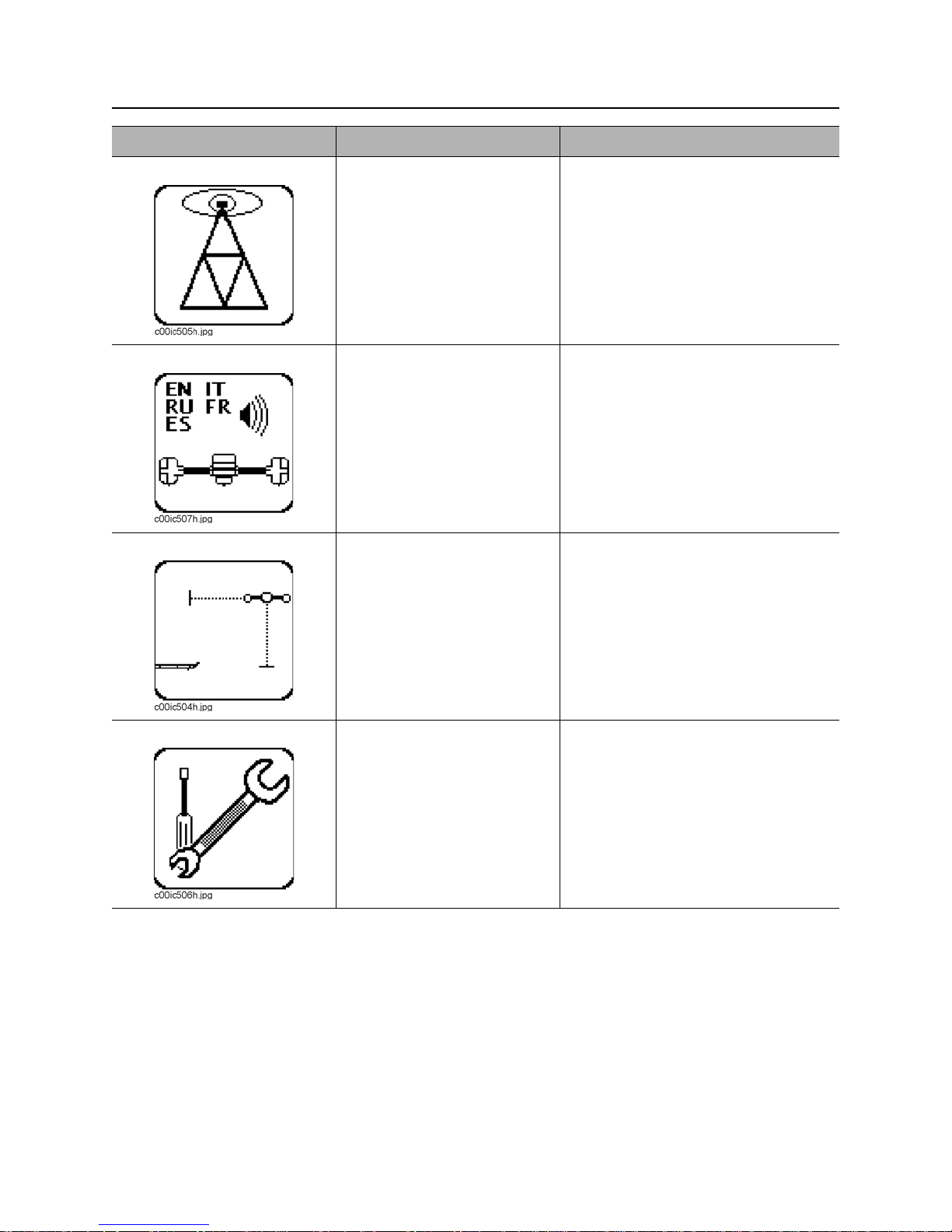

8500D

Menu

Overview

1. Display settings

2. File management

3. Radio options

Item Description Notes

1. Display settings Highlight icon and press

select to enter the “display

settings” menu.

2. File Management Highlight icon and press

select to start new job or

review saved job files.

4. System settings

5. Time/Date settings

6. Service menu

See “Display Settings” on page 30.

See “File Management” on page 31.

CMW

8500 Tracking System Operator’s Manual Controls - 29

8500D

Item Description Notes

3. Radio options Highlight icon and press

select to enter the “radio

options” mode.

4. System settings Highlight icon and press

select to enter the “system

settings” menu.

5. Time/Date settings Highlight icon and press

select to enter the “time/date

settings” menu.

See “Radio Options” on page 31.

See “System Settings” on page 32.

See “Date/Time Settings” on page 32.

6. Service menu Highlight icon and press

select to enter “service

menu.”

See “Service Menu” on page 32.

CMW

Controls - 30 8500 Tracking System Operator’s Manual

8500D

Descriptions

Display Settings

Description Notes

LCD brightness Controls brightness.

Available settings: 0 (off) to 100 (brightest, default).

LCD contrast Controls contrast of LCD.

Available settings: -20 (lighter) to 20 (darker), 0 is default.

Units Controls displayed units of depth values, tempera tures and other

numbers.

Available distance settings: inches, f t in ( defau lt), decim al feet, m eters,

centimeters.

Depth disp. time Controls how long depth information is locked on the screen after depth

is received from tracker.

Available settings: 0-60 seconds, 5 is default.

Log review time Controls how long log information is locked onscreen after pressing

any logging button.

Available settings: 0-60 seconds, 5 is default.

Roll angle disp. Controls display of numerical portion of the roll indicator.

Available settings: off (default), degr ees, minutes, hours.

Pitch disp. Controls display of beacon pitch indicator.

Available settings: percent (default), degrees.

Battery ind. style Controls display of beacon battery indicator.

Available settings: 1-axis (default), 2-axis.

CMW

8500 Tracking System Operator’s Manual Controls - 31

8500D

File Management

Description Notes

Active file Indicates name of log file that is currently active.

Load file Displays a list of log files currently on the SD card. Select a file to make

it the active log file.

Create file Creates a new log file and makes it the active file.

Delete file Displays a list of log files currently on the SD card. Select a file to

delete it.

Delete all Deletes all files on the SD card and formats it for use.

Make .750 files Creates .750 files out of all log files on the SD card for import into TMS

Plus. Select this before removing SD card and importing data into TMS

Plus. See “TMS Plus Data Transfer” on page 57.

Upload all Uploads all log files to TMS Plus when connected through USB cable.

See “TMS Plus Data Transfer ” on page 57. Follow prompts.

Auto-Log St ores a log point every time depth information is sent from tracker.

Options: disabled (default), enabled.

IMPORTANT: Display must have SD card installed with valid log file

active or be connected to TMS Plus.

Radio Options

IMPORTANT: In order for information on tracker and display to match, ensure units are set on the same

channel.

Description Notes

Channel Sets telemetry channel

Available settings: 1 (default) through 15

Tracker Control code Displays code for Tracker Control feature.

CMW

Controls - 32 8500 Tracking System Operator’s Manual

8500D

System Settings

Description Notes

Connect to TMS Plus Activates TMS Plus connected mode.

Language Controls displayed user interface language.

Available languages include: English, German, Spanish, French,

Italian, Swedish, Russian.

Date/Time Settings

Description Notes

Time format Controls display of time.

Available settings: 12 (default), 24

Year Sets year.

Month Sets month.

Day Sets day.

Hour Sets hour.

Minutes Sets minutes.

Service Menu

Description Notes

Versions Lists hardware and software versions, serial number, and copyright

information.

Uptime Displays uptime and life timers.

Support Enters support menu.

Factory Enters factory menu. Password protected.

CMW

8500 Tracking System Operator’s Manual System Operation - 33

System Operation

Chapter Contents

Beacon Tracking Overview . . . . . . . . . . . . . . . . . . 34

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Walkover Location Mode . . . . . . . . . . . . . . . . . . . . 36

• Locate Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

• Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

• Depth Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

• Displayed Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

• Sample Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Drill-Thru Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

• Drill-Thru View Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

• Beacon View Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

• Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

• Sample Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

CMW

System Operation - 34 8500 Tracking System Operator’s Manual

Beacon Tracking Overview

Beacon Tracking Overview

Potential radio frequency (RF) hazard. Operating this device within 4”

(100 mm) of your body may cause RF exposure levels to exceed FCC RF exposure limit s

and should be avoided.

NOTICE:

• This device must not be co-located with any other radio transmitter.

• The maximum antenna gain is 0.8 dBi.

The tracker has two modes: walkover location and drill-thru. Use walkover location mode to find position of

the beacon. Once tracker is in or near the beacon plane, select the depth view to determine the depth and

the left/right offset. With tracker in front of and parallel to beacon, press the L/R button while in the main

locate view to see the projected path of the beacon. In drill-thru mode, the tracker is placed along the

intended bore path and provides the necessary steering corrections for the drilling unit operator to drill that

path.

Setup

1. Install battery in beacon.

2. Place beacon in beacon housing away from

metal objects.

3. Set up beacon and tracker 10’/305 cm (A)

apart, as shown.

4. Select “Beacon Calibration” in “Beacon

Settings” menu and follow prompts. See

page 21.

IMPORTANT:

• Error conditions will be reported onscreen below diagram.

• Pressing “clear” button will restore factory default. This will not provide accurate depth and

offset measurements. Calibrate beacon and tracker properly.

• Pressing “cancel” will exit calibration menu without changing tracker’s calibration.

• If using a dual-frequency beacon, calibrate both frequencies.

CMW

8500 Tracking System Operator’s Manual System Operation - 35

Setup

5. Select “Roll Calibration” in “Beacon Settings” menu and follow prompts.

6. Select “Pitch Calibration” in “Beacon Settings” menu and follow prompts.

7. Select “Depth Adjustment” in “Beacon Settings” menu and follow prompts.

CMW

System Operation - 36 8500 Tracking System Operator’s Manual

Walkover Location Mode

Walkover Location Mode

Locate Screen

1. Field balance bar

2. Signal strength

3. Locate arrows

Item Description Notes

1. Field Balance Bar Indicates tilt of tracker (hollow

circle) and magnetic field

balance (solid circle).

2. Signal Strength Average signal strength is

displayed numerically.

Gain and signal strength bars

are also displayed to each

side of numeric value.

4. L/R button

5. Send button

6. Depth screen button

Beacon is properly located when both

circles are located in the square in the

center of the bar and fore/aft arrows

form diamonds.

Bars get longer as number gets

smaller.

CMW

8500 Tracking System Operator’s Manual System Operation - 37

Walkover Location Mode

Item Description Notes

3. Locate Arrows Indicate fore-aft direction to

move antenna pod to locate

beacon plane.

Arrows change to diamonds

when antenna pods are in

beacon plane.

4. L/R Button Press and hold to display

projected direction.

5. Send Button Press to send depth to

remote display.

6. Depth Screen Button Press to enter depth screen.

Longer arrows indicate the tracker is a

greater distance from beacon plane.

Advanced depth features are

available when both arrows or

diamonds are solid.

Tracker pods must be parallel with

beacon. See “Projected Direction” on

page 39.

CMW

System Operation - 38 8500 Tracking System Operator’s Manual

Walkover Location Mode

Procedure

The 8500 tracking system provides three ways to locate a beacon using walkover location mode. Choose

which method to use based on your tracking situation.

Single-Point Location

If concerned with ghost signals or bore path is

unknown, use single-point location to find general

location of beacon.

1. Position tracker parallel (shown) to suspected

bore path.

2. Walk along bore path until solid and hollow

circles are approximately centered in field

balance bar.

3. Rotate tracker 90° so that tracker is

perpendicular to bore path.

4. Move tracker left or right to center both circles.

Tracker is now roughly over the beacon.

5. To locate beacon more precisely, follow peak or advanced location procedure.

Peak Location

If beacon depth is greater than 30’ (9 m), use peak

location procedure to position tracker over beacon.

This procedure works well at any depth.

1. With tracker perpendicular to bore path

(shown), follow locate arrows to beacon plane.

2. Move tracker laterally until signal strength is

minimized.

3. Place tracker on the ground and press SEND

button to take depth reading and send it to

display.

The signal strength reading is the approximate distance from the beacon in inches. A reading of 122

means the tracker is 122” (3.1 m) from the beacon. This reading reflects how many inches the tracker is

from the beacon regardless of the units setting in the display menu.

CMW

8500 Tracking System Operator’s Manual System Operation - 39

Walkover Location Mode

Advanced Location

If beacon depth is less than 30’ (9 m), use advanced

location procedure to position tracker over beacon.

1. With tracker perpendicular to bore path, follow

locate arrows to beacon plane.

2. Place tracker on the ground and press DEPTH

button. If desired, move tracker side-to-side

until offset is at 0.

3. Press SEND button to take depth reading and

send it to display. Press and hold SEND button

for 1/2 second if 0.1” (1 cm) precision is

required.

Quick Range

To get a quick estimate of how far away the beacon is, pr ess the SEND button while the tracker is in

walkover locate view. The average of the distance to the beacon for each pod will be displayed in place of

the signal strength.

Projected Direction

1. Hold down the L/R button to switch from foreaft arrows to left-right arrows.

2. Move approximately 10’ (3 m) in front of the

beacon position and rotate tracker until tracker

is parallel with bore path with left antenna pod

closer to drilling unit.

3. Align arrows to check beacon heading.

4. When arrows turn solid, the projected depth

will be displayed in a dotted box (shown

below) in place of the signal strength value.

CMW

System Operation - 40 8500 Tracking System Operator’s Manual

Walkover Location Mode

Depth Screen

1. Tracker tilt indicator

2. Depth

3. Locate mode button

Item Description Notes

1. Tracker tilt indicator Graphically represents the tilt

of the tracker antenna pods

with a numeric reading to the

left of the visual

representation.

2. Depth Displays vertical depth

measurement.

3. Locate mode button Press to return to locate

screen.

4. View button Press to switch between

depth and side views.

4. View button

5. Send button

6. Left/right offset

CMW

8500 Tracking System Operator’s Manual System Operation - 41

Walkover Location Mode

Item Description Notes

5. Send button Press to send depth to

remote display.

Press for 1/2 second to get

average with 0.1” (1 cm)

resolution and send depth to

display.

Continue pressing for

continuous average. Release

to send depth to display.

6. Left/right offset Indicates left/right offset with

respect to center of beacon

and middle of tracker handle.

Tracker provides both graphical and

numeric offset information.

Displayed Features

Advanced depth features (vertical depth, left/right offset , 0.1”/1 cm precision) are no t available when any of

the following conditions are met:

• Beacon is more than 30’ (9 m) away from tracker

• Tracker tilt is greater than 20°

• Beacon pitch is greater than 10% and tracker tilt is greater than 5°

• Fore/aft arrows are hollow (tracker is outside the beacon plane)

CMW

System Operation - 42 8500 Tracking System Operator’s Manual

Walkover Location Mode

Sample Screens

Depth screen, standard view

Beacon is pitched up 1%, is offset from tracker 9.7” to the left and is 1’ 9.4”

deep. The tracker is tilted left 4°. Depth reading bar will become solid as values

are averaged. Once it is solid, the value is locked and sent to remote display.

Depth screen, side view

Beacon is pitched up 4%, is 10” ahead of tracker and is 22’ deep. The tracker

is 22’ 1” away from beacon.

CMW

8500 Tracking System Operator’s Manual System Operation - 43

Drill-Thru Mode

Drill-Thru Mode

Drill-Thru View Screen

1. Pitch

2. Horizontal distance

3. Current depth

1. Pitch Displays pitch of beacon in

percent grade or degrees.

The orientation of the icon

indicates whether pitch is

positive or negative.

2. Horizontal distance Displays distance from

beacon to tracker.

3. Current depth Displays current depth of

beacon relative to tracker

position.

4. Projected depth Displays the projected depth

when beacon reaches tracker

if current pitch is maintained.

5. Locate mode button Press to return to locate

mode.

4. Projected depth

5. Locate mode button

6. View button

6. View button Press to switch between drill-

thru and beacon view.

CMW

System Operation - 44 8500 Tracking System Operator’s Manual

Drill-Thru Mode

Beacon View Screen

1. Horizontal distance

2. Direction indicator arrows

3. Signal strength

4. Steering correction arrow

5. Projected depth

1. Horizontal distance Displays distance from

beacon to tracker.

2. Direction indicator

arrows

3. Signal strength Displays numeric signal

4. Steering correction

arrow

5. Projected depth Displays the projected depth

6. Current depth Displays current depth of

Indicates beacon direction

relative to the tracker.

strength value.

Represents the direction of

steering correction needed.

when beacon reaches tracker

if current pitch is maintained.

beacon relative to tracker

position.

6. Current depth

7. Locate mode button

8. Current depth indicator

9. View button

Inward arrows mean the beacon is

approaching tracker and outward

arrows mean beacon is moving away.

CMW

8500 Tracking System Operator’s Manual System Operation - 45

Drill-Thru Mode

7. Locate mode button Press to return to locate

mode.

8. Current depth indicator Indicates current position

relative to tracker.

9. View button Press to switch between drillthru and beacon view.

Procedure

Incorrect procedures could result in death, injury, or property damage.

Learn to use equipment correctly.

NOTICE: If location and depth are critical, confirm by hand-digging.

1. Place tracker on the ground along intended bore path with left pod closest to drilling unit.

2. Drill as usual.

• While beacon is on the drilling unit side of tracker, a left/right steering correction arrow, current

depth, horizontal distance and projected depth are provided.

• After beacon passes under tracker, current depth and horizontal distance are provided. Projected

depth and the left/right steering arrow are no longer provided.

Sample Screens

Drill-Thru View Beacon View

Beacon is approaching tracker pitched down 38%. Beacon is 30” (2’ 6”) deep and the projected depth

at tracker is 57” (4’ 9”). The horizontal distance to the tracker is 42” (3’ 6”). The beacon is on the

projected path as indicated by the diamond in the center of the Beac on View.

CMW

System Operation - 46 8500 Tracking System Operator’s Manual

Drill-Thru Mode

Drill-Thru View Beacon View

Beacon is approaching tracker pitched up 7%. Beacon is 28” (2’ 4”) deep and the projected depth at

tracker is 22” (1’ 10”). The horizont al dist a nce to the tracke r is 48” (4 ’). The beacon must be steered to

the left to pass under the tracker as indicated by the arrow in the ce nter of the Beacon Vi ew . The ar row

will get longer as beacon gets farther off target and shorter as it gets closer to the target path.

Drill-Thru View

Beacon is past tracker pitched up 1.6%. Beacon is 22” (1’ 10”) deep and the horizontal distance from

the tracker is 15” (1’ 3”).

CMW

Beacon View

8500 Tracking System Operator’s Manual Tracking Concepts - 47

Tracking Concepts

Chapter Contents

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . 48

• System overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

• Beacon plane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

• Drill-Thru . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Ghost Signal Responses . . . . . . . . . . . . . . . . . . . . 50

CMW

Tracking Concepts - 48 8500 Tracking System Operator’s Manual

Theory of Operation

Theory of Operation

System Overview

The 8500 tracking system uses a magnetic field generator in an 850 series beacon and two receiving

antenna pods in an 8500TK advanced tracker to determine beacon position. The tracker detects the

generated magnetic field and calculates the beacon’s position. Downhole information is relayed from the

beacon to the tracker. The tracker sends all received and calculated data to a remote display over a radio

link.

The dual antenna pod design provides the ability to approach the beacon location without encountering

ghost signals and can determine the beacon’s location and heading. When placed along the in tended bore

path, the tracker can be used in Drill-Thru mode to provide the beacon’s current depth, projected depth at

the tracker location, horizontal distance (range) and horizontal steering correction.

Beacon Plane

The 8500TK locates the beacon plane

perpendicular to the center of the beacon. Once

the tracker is within range of the beacon and within

the beacon plane, the advanced depth calculations

of the tracker are enabled.

The beacon plane extends outward from th e center

of the beacon and runs perpendicular to the

beacon as shown. Because of this, the ground

level location may be slightly in front of or behind

the true vertical position of the beacon’s center.

This is only apparent at extreme pitches and

increasing depths. For example, at 30’ (9 m) deep

and 10% pitch, the beacon plane and vertical plane

will be approximately 3’ (914 mm) apart at ground

level. The tracker calculates this difference and

presents it in the depth mode side view.

Beacon plane: side view

Beacon plane: top view

CMW

8500 Tracking System Operator’s Manual Tracking Concepts - 49

Theory of Operation

Drill-Thru

The tracker calculates the beacon’s current depth, horizontal distance to the tracker and the predicted

depth at the tracker position. The tracker allows you to drill toward, under and away from the tracker while

providing depth and horizontal distance. The horizontal steering guides the operator to the intended bore

path, assuming a straight line along the tracker.

Sample beacon positions and resulting horizontal steering correction arrows.

CMW

Tracking Concepts - 50 8500 Tracking System Operator’s Manual

Ghost Signal Responses

Ghost Signal Responses

The locate arrows will change direction and point

away from the beacon (as shown) as the tracker

reaches a ghost signal. The distance from the

beacon plane to the ghost signals increases with

increasing depth.

To avoid locating ghost signals, rotate tracker

parallel to bore path (shown below) and watch the

solid circle in the field balance bar to get near the

beacon plane.

CMW

8500 Tracking System Operator’s Manual Systems and Equipment - 51

Systems and Equipment

Chapter Contents

8500TK Status Messages . . . . . . . . . . . . . . . . . . . 52

8500D Status Messages . . . . . . . . . . . . . . . . . . . . 54

850 Beacons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

• Sleep . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

• Dual frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

• Beacon throttle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

TMS Plus Data Transfer . . . . . . . . . . . . . . . . . . . . . 57

• Via cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

• Via SD card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

CMW

Systems and Equipment - 52 8500 Tracking System Operator’s Manual

8500TK Status Messages

8500TK Status Messages

Messages that communicate tracking system

information requiring user intervention or provide

important operation information appear in the top

center area of the display as shown.

Message Description Solution

SA TURATED Signal from beacon or other noise is too larg e to

receive accurate signal.

Auto-Gain Active... Tracker’s auto-gain feature is active. Some

features and data values will stop updating until

auto-gain is complete.

Beacon Regulating Beacon is adjusting it s output to provide a st able

signal. Depth values and beacon calibration are

unavailable while beacon is regulating.

BEACON BATT LOW Beacon battery voltage is low. Replace Power Stick or

BEACON POWER

LOW

TILT The tracker can no longer compensate for its

Beacon is close to being unable to provide a

stable output signal (is out of throttle).

position when calculating depth and offset

values. This occurs when the tilt of the tracker is

greater than 20° or the beacon pitch is greater

than 10% and the tracker tilt is greater than 5°.

Move tracker away from

beacon (at least 2’/610 mm)

or eliminate noise source.

Wait until message

disappears.

Wait until message

disappears.

lithium beacon batteries.

1. Replace Power Stick

beacon battery.

2. Use lithium beacon

battery.

3. Change to compatible

beacon housing or call

your Ditch Witch dealer.

Adjust tracker so it is closer

to level until message

disappears.

CMW

8500 Tracking System Operator’s Manual Systems and Equipment - 53

8500TK Status Messages

Message Description Solution

No Comm Beacon signal is too weak to communicate with

tracker.

Out of Range Beacon is out of range for requeste d feat ur es .

Beacon must be within within 30’ (9 m) of

tracker for advanced features.

TRACKER BATT

LOW

F/A Align Tracker is too far out of the beacon plane to

Beacon Rolling... Beacon is rolling. Stop rolling beacon for more

BEACON MEM

ERROR

BEACON HOT Beacon is reporting temperature above 155°F

Tracker batteries are low and unit will soon shut

off.

enable advanced depth features while in depth

screen.

Calibration memory of beacon has been

corrupted.

(68°C). Permanent damage is imminent. An

audible alert will also sound.

1. Ensure beacon and

tracker are operating at

same frequency.

2. Move tracker within

range of beacon.

3. Ensure beacon is not

asleep.

Move tracker within 30’ (9

m) of beacon.

Replace tracker batteries.

Use fore/aft arrows to move

within beacon plane.

accurate readings.

Return beacon for service.

Stop rotation, pull back 3’

(915 mm) and continue

drilling fluid flow until

beacon cools down.

HIGH NOISE The signal-to-noise ratio is too low for tracker to

receive reliable data from beacon. Depth

calculation and beacon calibration are disabled.

Eliminate noise source or

switch beacon and tracker

operating frequencies.

CMW

Systems and Equipment - 54 8500 Tracking System Operator’s Manual

8500D Status Messages

8500D Status Messages

Messages that provide important operation

information appear in the top center area of the

display as shown.

Message Description Solution

SA TURATED Signal from beacon or other noise is too larg e to

receive accurate signal.

Auto-Gain Active... Tracker’s auto-gain feature is active. Some

features and data values will stop updating until

auto-gain is complete.

BEACON BATT LOW Beacon battery voltage is low. Replace Power Stick or

BEACON POWER

LOW

No Comm Beacon signal is too weak to communicate with

Beacon is close to being unable to provide a

stable output signal (is out of throttle).

tracker.

Move tracker away from

beacon (at least 2’/610 mm)

or eliminate noise source.

Wait until message

disappears.

lithium beacon batteries.

1. Replace Power Stick

beacon battery.

2. Use lithium beacon

battery.

3. Change to compatible

beacon housing or call

your Ditch Witch dealer.

1. Ensure beacon and

tracker are operating at

same frequency.

2. Move tracker within

range of beacon.

DISPLAY BATT LOW Display batteries are low and unit will soon shut

off.

Beacon Rolling... Beacon is rolling. Stop rolling beacon for more

BEACON MEM

ERROR

CMW

Calibration memory of beacon has been

corrupted.

Replace display batteries.

accurate readings.

Return beacon for service.

8500 Tracking System Operator’s Manual Systems and Equipment - 55

850 Series Beacons

Message Description Solution

BEACON HOT Beacon is reporting temperature above 155°F

(68°C). Permanent damage is imminent.

850 Series Beacons

Sleep

850 series beacons enter sleep (power-saving)

mode after 20 minutes of inactivity. Rotate the

beacon at least 3 times at 1 rotation per second to

wake the beacon.

To enter Express Sleep mode, roll beacon to the

Express Sleep window (shown) and leave it

inactive. Beacon will enter power-saving mode

after only 5 minutes.

Stop rotation, pull back 3’

(915 mm) and continue

drilling fluid flow until

beacon cools down.

CMW

Systems and Equipment - 56 8500 Tracking System Operator’s Manual

850 Series Beacons

Dual Frequency

Select operating frequency when batteries are inserted or downhole.

Select at Power Up

The orientation of the flat top on the forwar d isolator

when batteries are installed determines frequency.

• If flat top (shown) is up, beacon will operate at

11.2 kHz.

• If flat top is down, beacon will operate at 1.75

kHz.

Switch Downhole

1. Allow the beacon to enter sleep mode.

2. Wake the beacon within one minute of entering

sleep mode and beacon will switch frequencies.

Beacon Throttle

The beacon continuously monitors and adjusts its output power in order to maintain a constant signal

strength. Beacon housing properties, battery chemistry and battery voltage impact the beacon’s ability to

maintain this output. Beacon throttle is a measure of the remaining time a beacon will be able to maintain

its output level.

When beacon battery life indicator (see page 14) is in 2-axis view, battery power is shown on the ho rizontal

axis and beacon throttle is shown on the vertical axis.

CMW

8500 Tracking System Operator’s Manual Systems and Equipment - 57

TMS Plus Data Transfer

TMS Plus Data Transfer

Via Cable

Follow prompts in TMS Plus. Connect cable at

connector (shown).

Via SD Card

1. Remove cover (shown).

2. Press SD card down. Card will pop up.

3. Remove card from slot.

4. Transfer dat a to TMS Plus and in stall SD card in

display.

5. Install cover.

CMW

Systems and Equipment - 58 8500 Tracking System Operator’s Manual

TMS Plus Data Transfer

CMW

8500 Tracking System Operator’s Manual Service - 59

Service

Chapter Contents

General Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

As Needed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

CMW

Service - 60 8500 Tracking System Operator’s Manual

General Care

General Care

Under normal operating conditions, tracking system components need only minor maintenance. Following

these care instructions can ensure longer equipment life:

• Do not drop the equipment.

• Do not expose the equipment to high heat (such as in the rear window of a vehicle).

• Clean equipment with a damp cloth and mild soap. Never use scouring powder.

• Do not immerse in any liquid.

• Inspect housing daily for cracks or other damage. If housing is damaged, contact your equipment

dealer for replacement.

• Do not mix new and used batteries.

• Remove battery if storing for an extended period.

As Needed

Location Task Notes

Tracker Change batteries 6 “C” alkaline

Display (in Case) Change batteries 6 “C” alkaline

Beacon Change batteries 1 Lithium or Power Stick

Tracker

Change Batteries

IMPORTANT: Do not mix new and used

batteries.Do not mix battery brands.

Use six C-cell alkaline batteries in tracker.

1. Remove battery caps.

2. Insert batteries as shown.

3. Install and tighten battery caps.

4. Check operation.

CMW

8500 Tracking System Operator’s Manual Service - 61

As Needed

Display (in Case)

Change Batteries

IMPORTANT: Do not mix new and used

batteries. Do not mix battery brands.

Use 6 C-cell alkaline batteries in cased display.

1. Open battery cover.

2. Insert batteries as shown.

3. Close and tighten battery cover.

4. Check operation.

Beacon

Change Battery

Use one lithium or one Power Stick battery in

beacon.

1. Remove battery cap.

2. Insert battery as shown.

3. Install and tighten battery cap.

4. Check operation.

CMW

Service - 62 8500 Tracking System Operator’s Manual

As Needed

CMW

8500 Tracking System Operator’s Manual Specifications - 63

Specifications

Chapter Contents

8500TK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

8500D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

850 Beacons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

CMW

Specifications - 64 8500 Tracking System Operator’s Manual

8500TK

8500TK

Dimensions U.S. Metric

H Height 6.4” 163 mm

L Length 13.2” 335 mm

W Width 35.5” 902 mm

Operating weight 8.3 lb 3.8 kg

Operation U.S. Metric

Operating temperature range -4°F to 122°F -20°C to 50°C

Operating modes: 1.75 kHz beacon, 11.2 kHz beacon

Radio channels: 15

Radio range 2000’ 609.6 m

Radio frequency: 2.4 GHz

Batteries

Type: 6 C-cell alkaline

Life (use at 70°F/21°C): approximately 10 hours

Battery saver: unit shuts down after 5 minutes if no key is pressed and no beacon communication is

detected. This feature can be disabled in a menu setting.

CMW

8500 Tracking System Operator’s Manual Specifications - 65

8500D

8500D

Module Only U.S. Metric

Operating weight 2.5 lb 1.1 kg

Power input: 6.5V DC - 16V DC @ approximately 150 mA

Interface connectors: USB-B

Data storage: SD card

Radio channels: 15

Radio range 2000’ 609.6 m

Radio frequency: 2.4 GHz

Module with Case

Operating weight 6.5 lb 3.0 kg

Type: 6 C-cell alkaline

Life (intermittent use at 70°F/21°C): approximately 20 hours

Interface: USB-B

Antenna: TNC female

CMW

Specifications - 66 8500 Tracking System Operator’s Manual

850 Series Beacons

850 Series Beacons

Dimensions U.S. Metric

L Length 17.6” 447 mm

W Width 1.5” 38 mm

Weight 2.2 lb 998 g

Operation U.S. Metric

Operating frequency: 1.75 kHz, 11.2 kHz

Roll: 60 positions (every 6 degrees)

Depth range

850B/850BG 50’ 15.2 m

850BH/850BGH 60’ 18.3 m

850BD/850BGD (11.2 kHz) 50’ 15.2 m

850BD/850BGD (1.75 kHz) 30’ 9.1 m

850BHD/850BGHD (11.2 kHz) 60’ 18.3 m

850BHD/850BGHD (1.75 kHz) 40’ 12.2 m

Maximum temperature 176°F 80°C

Maximum fluid pressure 60 psi 4 bar

Pitch

850 series: 1% increments up to 100%

850 grade series: 0.1% increments up to 100%

Batteries

Type: 1 CC lithium or 1 CC Power Stick

Life (intermittent use at 70°F/21°C): approximately 20 hours (10 hours with H option)

Battery saver: unit shuts off after 20 minutes of inactivity or 5 minutes of inactivity in Express Sleep

window.

CMW

8500 Tracking System Operator’s Manual Support - 67

Procedure

Support

Procedure

Notify your dealer immediately of any malfunction or failure of Ditch Witch equipment.

Always give model, serial number, and approximate date of your equipment purchase. This information

should be recorded and placed on file by the owner at the time of purchase.

Return damaged unit to dealer for inspection and warranty consideration if in warranty time frame.

All repairs must be done by an authorized Ditch Witch Electronics repair facility. Repairs done elsewhere

will void warranty.

Resources

Publications

Contact your Ditch Witch dealer for publications and videos covering safety, operation, service, and repair

of your equipment.

Training

For information about on-site, individualized training, contact your Ditch Witch dealer.

CMW

Warranty - 68 8500 Tracking System Operator’s Manual

Limited Product Warranty Policy

Warranty

Limited Product W arranty Policy

Warranty Periods

New Product

A twelve-month period starts on the date of delivery to the end user:

trackers, remote displays, receivers, transmitters, radars, fault finders

A six-month period starts on the date of delivery to the end user:

directional and locate beacons

A three-month period starts on the date of delivery to the end user:

accessories: cables, clamps, canoes, bags, and adapters

Used Product (Cosmetics)

A three-month warranty starts on the date of delivery to the end user on used and refurbished products

sold from Ditch Witch Electronics dealers. Used products are non-returnable.

Service and Repair

A one-month warranty on labor st art s on the date th e unit is repai red, and a three-mo nth warranty on parts

starts on the date the unit is repaired for all products.

Extended Warranty

The extended warranty may be purchased at the time the equipment is sold or anytime within the original

warranty period. The extension is for an additional twelve or twenty-four months, for a total coverage of

twenty-four to thirty-six months. Exclusions: All beacons and accessories.

CMW

8500 Tracking System Operator’s Manual Warranty - 69

Limited Product Warranty Policy

Details and Exclusions

• The warranty includes only Ditch Witch Electronics products and accessories that are manufactured

and distributed by Ditch Witch Electronics. The warranty compensates on defects in material or

workmanship.

• Defects will be determined through inspection by Ditch Witch Electronics or authorized repair centers.

Original purchaser must make the defective item available for inspection within 30 days of the date th e

part fails.

• The warranty is limited to replacement of the defective part. The replacement part may be new or

remanufactured. Repair and installation of defective part will be at no charge when product or item is

delivered to Ditch Witch Electronics or an authorized repair center . The product or item will be returned

at no charge for return freight.

• The warranty periods do not represent the useful life of Ditch Witch Electronics products and

accessories.

• If Ditch Witch Electronics products are purchased for commercial purposes, as defined by the

Commercial Code, no warranties extend beyond the specific terms set forth in this limited warranty. All

other provisions of this limited warranty apply, including the duties imposed.

• Ditch Witch Electronics products have been tested to deliver acceptable performance in most

conditions.

• This limited warranty applies to the original purchaser only. Some states or jurisdictions do not allow

exclusion or limitation of incidental or consequential damages, so abo ve limitation may not apply. This

limited warranty gives original purchaser specific rights that vary from state to state or jurisdiction to

jurisdiction.

• Each serial-numbered piece of equipment must be registered by the selling dealer to determine

warranty start date.

• When a registration is not received, the Ditch Witch Electronics shipping date is used to establish the

warranty period start date.

• Product inspection and estimates may require that the unit be disassembled and tested.

• Out-of-warranty inspection costs include labor accrued at the full labor rate plus return freight.

• Approved out-of-warranty repair costs include parts, labor accrued at full labor rate, plus return freight.

Revision F, September 2006

CMW

Warranty - 70 8500 Tracking System Operator’s Manual

Limited Product Warranty Policy

CMW

Loading...

Loading...