8500 Tracking System

Operator’s

Manual

CMW

®

Issue 1.0 053-1254

8500 Tracking System Manual Overview - 1

Overview

Chapter Contents

Serial Number Location . . . . . . . . . . . . . . . . . . . . . . 2

Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . 3

• Bulleted Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

• Numbered Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

• “Continued” Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

FCC Statement - Internal Transmitter . . . . . . . . . . . 4

CMW

Overview - 2 8500 Tracking System Operator’s Manual

Serial Number Location

Serial Number Location

Record serial numbers and date of purchase in spaces provided. Serial numbers are located as shown

and displayed briefly in lower left corner of tracker and display screens when unit s are first powered up.

Item

date of purchase:

tracker serial number:

display serial number:

accessory model and serial number:

accessory model and serial number:

accessory model and serial number:

CMW

8500 Tracking System Manual Overview - 3

Intended Use

Intended Use

The 8500 tracking system consists of an 8500TK tracker, an 8500D remote display, and an 850 series

beacon. The system provides advanced locating features to 30’ (9 m) dee p. It also p rovides of fset locating

and depth capability. The system provides projected direction information and offers a Drill-Thru guidance

mode. The system can track grade drilling bores with the addition of an 850 series grade beacon and other

grade drilling accessories.

The system is designed for operation in temperatures typically experienced in earth moving and

construction work environments. Use in any other way is considered contrary to the intended use. The

8500 tracking system should be operated only by persons familiar with its particular characteristics and

acquainted with the relevant safety procedures. The system should be serviced only by Ditch Witch

Electronics repair centers.

About This Manual

This manual contains information for the proper use of this equipment. Cross references such as “See

page 50” will direct you to det ailed procedures.

Bulleted Lists

Bulleted lists provide helpful or important information or contain procedure s that do not have to be

performed in a specific order.

Numbered Lists

Numbered lists contain illustration callouts or list steps that must be performed in order.

“Continued” Indicators

indicates that a procedure is continued on the next page.

CMW

Overview - 4 8500 Tracking System Operator’s Manual

FCC Statement - Internal Transmitter

FCC Statement - Internal Transmitter

Contains FCC ID: TFB-FREESTAR

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

Changes or modifications not expressly approved by The Charles Machine Works, Inc. could void the

user’s authority to operate the equipment.

Contains IC: 5969A-FREESTAR

N 16819

CMW

8500 Tracking System Manual Foreword - 5

Foreword

This manual is an important part of your equipment. It provides safety information and operation

instructions to help you use and maintain your Ditch Witch equipment.

Read this manual before using your equipment. Keep it with the equipmen t at all times for future reference.

If you sell your equipment, be sure to give this manual to the new owner.

If you need a replacement copy, contact your Ditch Witch dealer. If you need assistance in locating a

dealer, visit our website at www.ditchwitch.com or write to the following address:

The Charles Machine Works, Inc.

Attn: Marketing Department

PO Box 66

Perry, OK 73077-0066

USA

The descriptions and specifications in this manual are subject to change without notice. The Charles

Machine Works, Inc. reserves the right to improve equipment. Some product improvements may have

taken place after this manual was publishe d. For the latest information on Ditch Witch equipment, see your

Ditch Witch dealer.

Thank you for buying and using Ditch Witch equipment.

CMW

Foreword - 6 8500 Tracking System Operator’s Manual

8500 Tracking System

Operator’s Manual

Issue number 1.0/OM-4/08

Part number 053-1254

Copyright 2008

by The Charles Machine Works, Inc.

, Ditch Witch, CMW, AutoCrowd, Jet Trac, Roto Witch, Subsite, Fluid Miser,

Power Pipe, Super Witch, Pierce Airrow, The Underground, The Underground Authority Worldwide, and

Zahn are registered trademarks of The Ch ar les Mac hin e Works, Inc.

CMW

8500 Tracking System Operator’s Manual Contents - 7

Content s

Overview

machine serial number, information about the type of work this machine is designed

to perform, basic machine components, and how to use this manual

Foreword

part number, revision level, and publication date of this manual, and factory contact

information

Safety

machine safety alerts and emergency procedures

Controls

machine controls and how to use them

System Operation

procedures for tracking beacon signals

Tracking Concepts

basic information for tracking beacon signals

Systems and Equipment

status messages, beacon information, TMS Plus interface instructions

1

5

9

13

33

47

51

Service

service intervals and instructions for this machine

Specifications

machine specifications including weights and measurements

Support

the warranty policy for this machine, and procedures for obtaining warranty

consideration and training

59

63

67

CMW

Contents - 8 8500 Tracking System Operator’s Manual

CMW

8500 Tracking System Operator’s Manual Safety - 9

Safety

Chapter Contents

Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Safety Alert Classifications . . . . . . . . . . . . . . . . . . 11

Safety Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

CMW

Safety - 10 8500 Tracking System Operator’s Manual

Guidelines

Guidelines

Follow these guidelines before operating any jobsite equipment:

• Complete proper training and read operator’s manual before using equipment.

• Contact One-Call (888-258-0808) and any utility companies which do not subscribe to One-Call. Have

all underground pipes and cables located and marked before operating equipment. If you damage a

utility, contact utility company.

• Classify jobsite based on its hazards and use cor rect tools and machin ery, safety e quipment, and work

methods for jobsite.

• Mark jobsite clearly and keep spectators away.

• Wear personal protective equipment.

• Review jobsite hazards, safety and emergency procedures, and individual responsibilities with all

personnel before work begins.

• Replace missing or damaged safety signs.

• Use equipment carefully. Stop operation and investigate anything that does not look or feel right.

• Contact your equipment dealer if you have any question about operation, maintenance, or equipment

use.

CMW

8500 Tracking System Operator’s Manual Safety - 11

Safety Alert Classifications

Safety Alert Classifications

These classifications and the icons defined on the following pages work together to alert you to situations

which could be harmful to you, jobsite bystanders or your equipment. When you see these words and

icons in the book or on the unit, carefully read and follow all instructions. YOUR SAFETY IS AT STAKE.

Watch for the three safety alert levels: DANGER, WARNING and CAUTION. Learn what each level

means.

indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury.

Watch for two other words: NOTICE and IMPORTANT.

NOTICE can keep you from doing something that might damage the unit or someone's property. It can also

alert you against unsafe practices.

IMPORTANT can help you do a better job or make your job easier in some way.

CMW

Safety - 12 8500 Tracking System Operator’s Manual

Safety Alerts

Safety Alerts

Electric shock. Contacting electric lines will cause death or serious injury.

Know location of lines and stay away.

Jobsite hazards could cause death or serious injury. Use

correct equipment and work methods. Use and maintain proper safety

equipment.

Explosion possible. Serious injury or equipment damage could occur.

Follow directions carefully .

Incorrect procedures could result in death, injury, or property damage.

Learn to use equipment correctly.

Moving traffic - hazardous situation. Death or serious injury could result.

Avoid moving vehicles, wear high visibility clothing, post appropriate warning signs.

Potential radio frequency (RF) hazard. Operating this device within 4” (100

mm) of your body may cause RF exposure levels to exceed FCC RF exposure limits and

should be avoided.

CMW

8500 Tracking System Operator’s Manual Controls - 13

Controls

Chapter Contents

8500TK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

• Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

• Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

• Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

8500D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

• Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

• Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

• Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

CMW

Controls - 14 8500 Tracking System Operator’s Manual

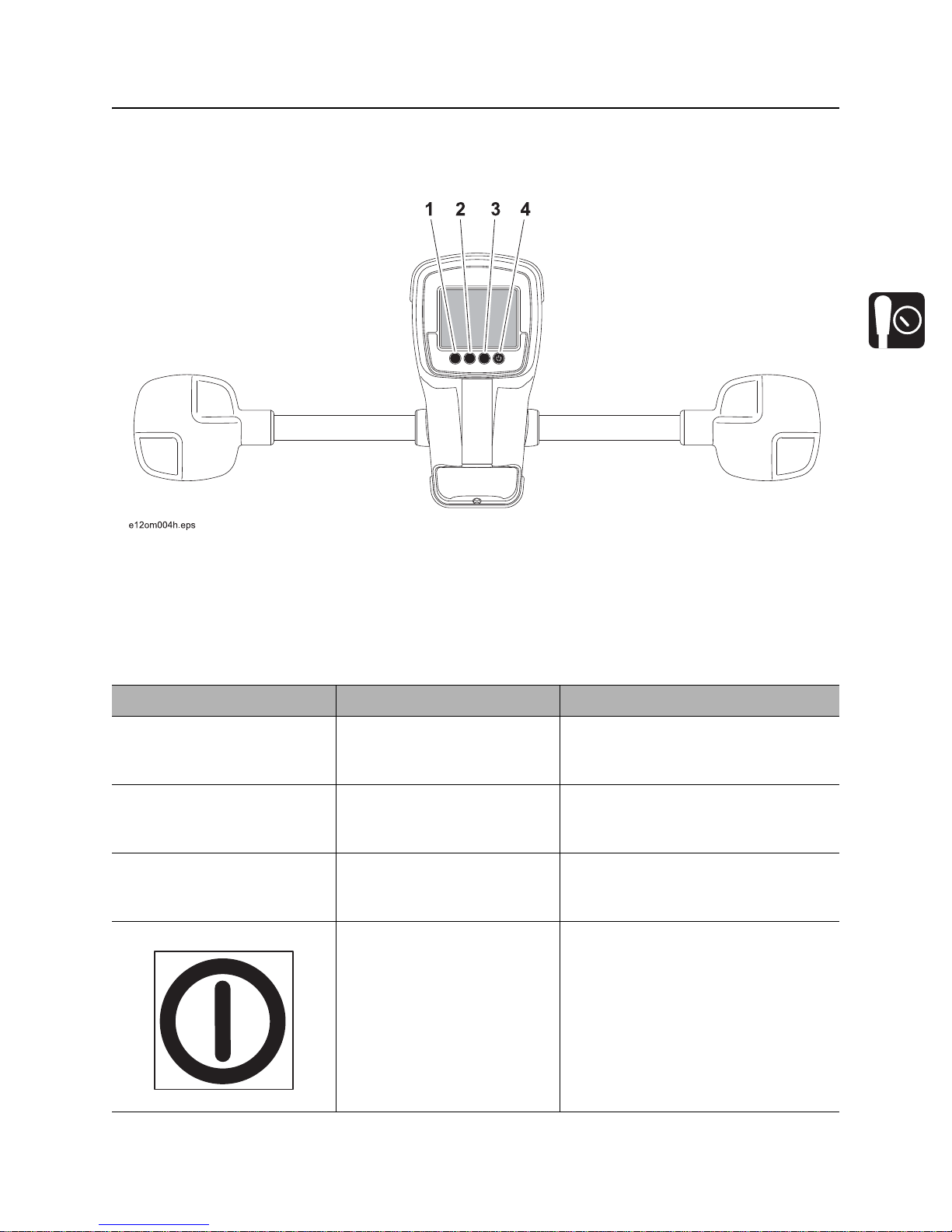

8500TK

8500TK

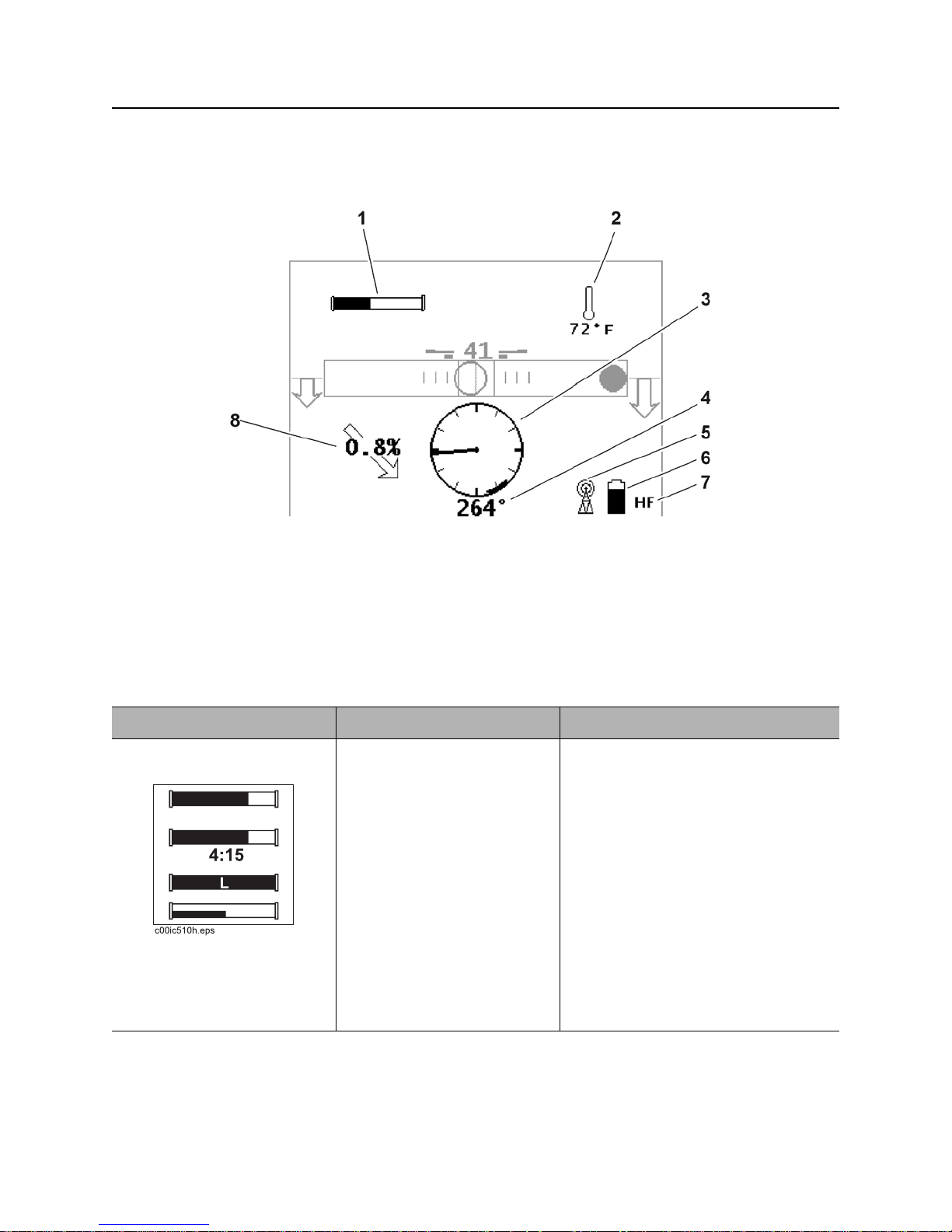

Icons

1. Beacon battery life indicator

2. Beacon temperature

3. Beacon roll indicator

4. Beacon roll value

Item Description Notes

1. Beacon battery life

indicator

Graphically indicates battery

life remaining.

If beacon is within 5 minutes

of entering sleep mode, a

countdown timer will appear

below icon.

An “L” appears in the icon if a

Lithium battery is installed.

In 2-axis view (bottom icon),

replace battery if either axis

disappears.

5. Communication indicator

6. Tracker battery life indicator

7. Frequency indicator

8. Beacon pitch

Battery power (horizontal axis) and

beacon throttle (vertical axis) are

monitored in this view. See “Beacon

Throttle” on page 56.

CMW

8500 Tracking System Operator’s Manual Controls - 15

8500TK

Item Description Notes

2. Beacon temperature Displays beacon temperature

and flashes if temperature

becomes too high.

Icon darkens as temperature

rises and temperature is

displayed numerically below

the icon.

3. Beacon roll indicator Graphically indicates

beacon’s roll position.

4. Beacon roll value Numerically displays

beacon’s roll position in

degrees, minutes or hours.

5. Communication

indicator

Indicates tracker and display

are communicating properly.

IMPORTANT: An audible warning is

activated when beacon temperature is

155°F (68°C).

6. Tracker battery Indicates amount of battery

7. Frequency indicator Displays “HF” when high

power remaining for the

tracker.

Flashes when batteries need

to be replaced.

frequency beacon is selected.

Displays “LF” when low

frequency beacon is selected.

CMW

Controls - 16 8500 Tracking System Operator’s Manual

8500TK

Item Description Notes

8. Beacon pitch Displays pitch of beacon in

percent grade or degrees.

The arrow behind the value

indicates whether pitch is

positive or negative.

CMW

8500 Tracking System Operator’s Manual Controls - 17

8500TK

Buttons

Overview

1. Soft button

2. Soft button

Item Description Notes

1. Soft button Function depends on

selected mode and is

indicated above button.

2. Soft button Function depends on

selected mode and is

indicated above button.

3. Soft button Function depends on

selected mode and is

indicated above button.

4. Power button To turn on, press once.

To turn off, press for 2

seconds.

3. Soft button

4. Power button

Button is also used to access quick

functions.

Button is also used for quick

functions.

Button is also used for quick

functions.

Button is also used for quick

functions.

si1017a-d.eps

CMW

Controls - 18 8500 Tracking System Operator’s Manual

8500TK

Quick Functions

Contrast Adjustment

To adjust contrast, pr ess and hold lef t button (1) and pr ess button 2 to da rken/increase contrast or butto n 3

to lighten/lessen contrast.

Backlight Toggle

To turn backlight on and of f, press and hold left button (1) and press power (4) button. Don’t press power

button for more than 2 seconds to avoid turning unit off.

CMW

8500 Tracking System Operator’s Manual Controls - 19

8500TK

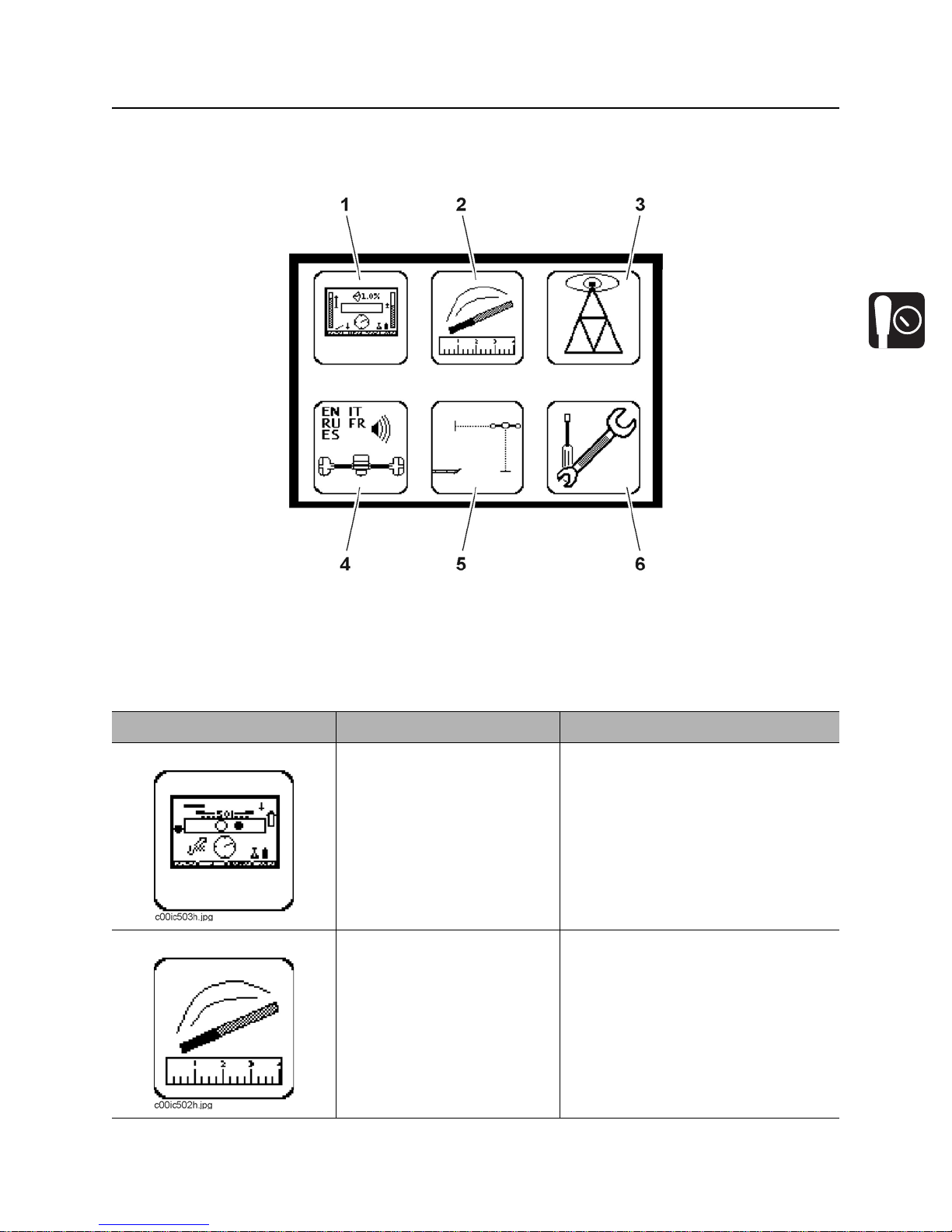

Menu

Overview

1. Display settings

2. Beacon settings

3. Radio options

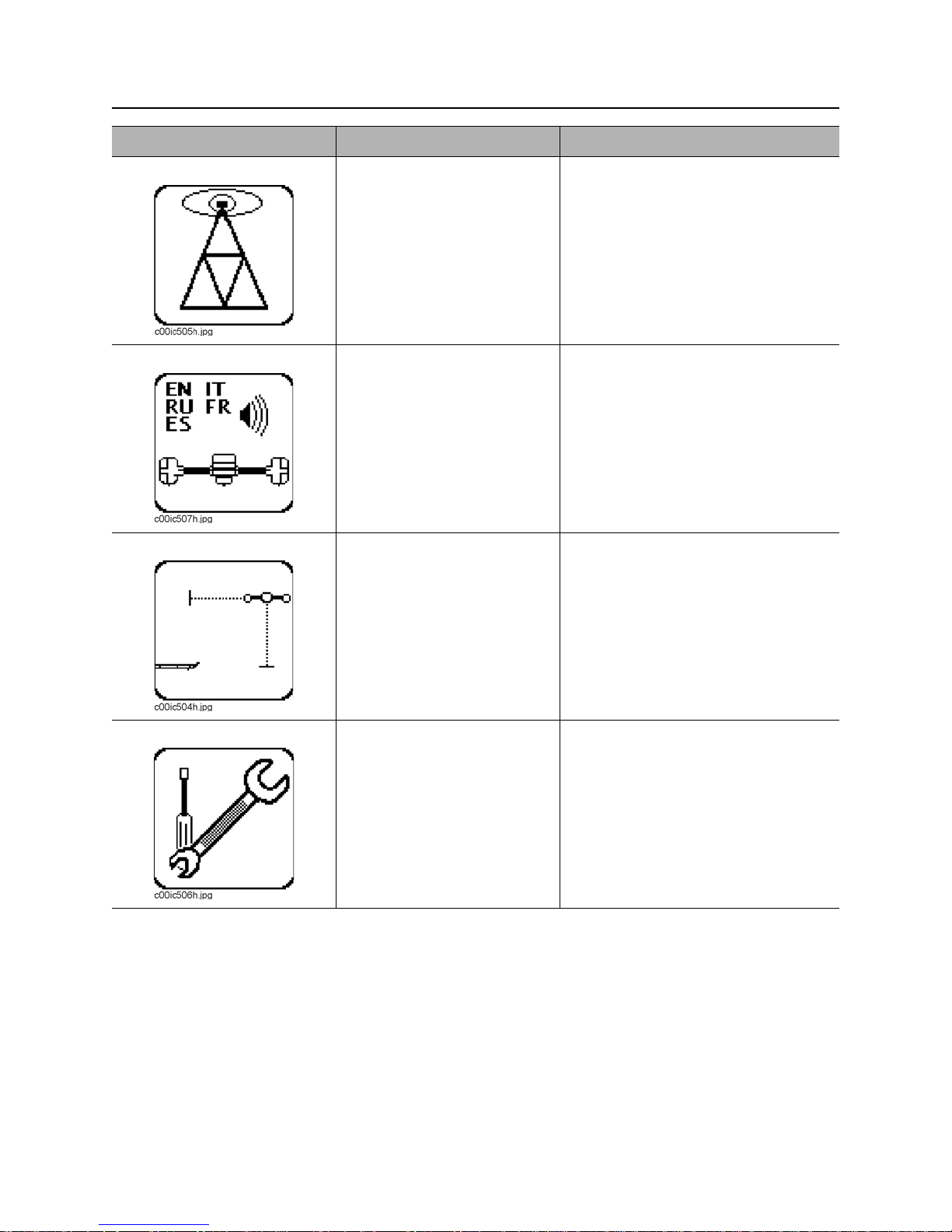

Item Description Notes

1. Display settings Highlight icon and press

select to enter the “display

settings” menu.

2. Beacon settings Highlight icon and press

select to enter the “beacon

settings” menu.

4. System settings

5. Drill-Thru mode

6. Service menu

See “Display Settings” on page 21.

See “Beacon Settings” on page 21.

CMW

Controls - 20 8500 Tracking System Operator’s Manual

8500TK

Item Description Notes

3. Radio options Highlight icon and press

select to enter the “radio

options” mode.

4. System settings Highlight icon and press

select to enter the “system

settings” menu.

5. Drill-Thru mode Highlight icon and press

select to enter the drill-thru

mode.

See “Radio Options” on page 22.

See “System Settings” on page 22.

See “Drill-Thru Mode” on page 43.

6. Service menu Highlight icon and press

select to enter “service

menu.”

CMW

See “Service Menu” on page 22.

8500 Tracking System Operator’s Manual Controls - 21

8500TK

Descriptions

Display Settings

Description Notes

LCD Backlight Controls backlight intensity.

Available settings: 0 (off) to 100 (brightest, default).

LCD contrast Controls contrast of LCD.

Available settings: -20 (lighter) to 20 (darker), 0 is default.

Units Controls displayed units of depth values, tempera tures and other

numbers.

Available distance settings: inches, ft in (default), decimal ft, meters,

centimeters.

Depth disp. time Controls how long depth information is locked on the screen after

pressing depth button.

Available settings: 0-60 seconds, 5 is default.

Roll angle disp. Controls display of numerical value of the roll indicator.

Available settings: off (default), degr ees, minutes, hours.

Pitch disp. Controls display of beacon pitch indicator.

Available settings: percent (default), degrees.

Battery ind. style Controls display of beacon battery indicator.

Available settings: 1-axis (default), 2-axis.

Beacon Settings

Description Notes

Beacon freq. Sets tracker receiving frequency.

Available settings: high (default), low.

Beacon calibration Calibrates tracker to beacon.

Roll calibration Sets roll position for beacon equivalent to bit pointing up (12 o’clock, 0

minutes, 0°).

Pitch calibration Sets 0.0% pitch position for grade beacon (1.0% limit).

Depth adjustment Changes built-in adjustment of depth measurements.

CMW

Loading...

Loading...