Page 1

Operation and Maintenance

Instructions Manual

DDFP SERIES ENGINES

FOR

FIRE PUMP APPLICATIONS

Printed in U.S.A.

This manual covers Detroit Diesel engines

modified by Clarke DD-A

for fire pump service

LISTED APPROVED LISTED

FM

C13194

MP-4 7/96

Page 2

ABBREVIATIONS

AC Alternating Current

AEC Automatic Engine Controller

API American Petroleum Institute

CCW Counter-clockwise engine rotating (front view)

CDD-A Clarke Detroit Diesel-Allison

CW Clockwise engine rotation (front view)

DC Direct Current

DDC Detroit Diesel Corporation

DDFP Detroit Diesel Engines approved for Fire Pump Service

as certified by FM/UL/ULC for Clarke Detroit Diesel-Allison

FM Factory Mutual Research

GM General Motors Corporation

ID Identification

IP Instrument Panel

I-53 In-Line Cylinder arrangement 53 Series DDC Engine

I-71 In-Line Cylinder arrangement 71 Series DDC Engine

NA Naturally Aspirated

NC Normally Closed

NO Normally Open

NFPA National Fire Protection Association

P/N Part Number

PSI Pounds Per Square Inch

PTO Power Take Off

RPM Revelutions Per Minute

SAE Society of Automotive Engineers

S/N Serial Number

TTurbocharged

TA Turbocharged and Aftercooled

UL Underwriters Laboratories Inc.

ULC Underwriters Laboratories of Canada

V-92 Vee cylinder arrangement 92 Series DDC engines

V-71 Vee cylinder arrangement 71 Series DDC engines

LISTED APPROVED LISTED

FM

Page 3

TABLE OF CONTENTS

SUBJECT PAG E

ABBREVIATIONS........................................................................................................................................ Inside Front Cover

DESCRIPTION — Section 1

Principles of Operation .................................................................................................................................................... 1

General Description .......................................................................................................................................................... 2

Model and Serial Number Designation ............................................................................................................................ 3

Engine Equipment ............................................................................................................................................................ 4

FM/UL Nameplate ............................................................................................................................................................ 5

General Specifications ...................................................................................................................................................... 6

OPERATING INSTRUCTIONS — Section 2

Engine Start-Up and Operating Instructions .................................................................................................................... 8

Standard Model Views .................................................................................................................................................... 9

Electronic Speed Switch .................................................................................................................................................. 10

Preventative Maintenance Schedule.................................................................................................................................. 11

ENGINE SYSTEMS — Section 3

Fuel System — Section 3.1 .............................................................................................................................................. 12

Operation.................................................................................................................................................................... 12

Maintenance & Service Procedures .......................................................................................................................... 15

Fuel System Schematic.............................................................................................................................................. 14

Air Intake and Exhaust System — Section 3.2 ................................................................................................................ 16

Air System Operation ................................................................................................................................................ 16

Maintenance & Service Procedures .......................................................................................................................... 19

Exhaust Operation...................................................................................................................................................... 19

Lubrication System — Section 3.3 .................................................................................................................................. 20

Operation.................................................................................................................................................................... 20

Lubricating System Schematics ................................................................................................................................ 21

Maintenance & Service Procedures .......................................................................................................................... 22

Cooling System — Section 3.4 ........................................................................................................................................ 25

Operation.................................................................................................................................................................... 25

Maintenance & Service Procedures .......................................................................................................................... 30

Electrical System — Section 3.5 ...................................................................................................................................... 31

Operation.................................................................................................................................................................... 31

Maintenance & Service Procedures .......................................................................................................................... 35

DC Wiring Diagram.............................................................................................................................................. 37, 38

Engine Heater AC Wiring Diagram .......................................................................................................................... 39

Falk Drive Coupling Instructions — Section 3.6 ............................................................................................................ 40

Installation Procedures .............................................................................................................................................. 41

ENGINE TUNE-UP — Section 4

Tune Up ............................................................................................................................................................................ 46

TECHNICAL DATA — Section 5 .......................................................................................................................................... 47

PA RTS INFORMATION — Section 6

Basic Engine Parts ............................................................................................................................................................ 48

Standard Option Parts ...................................................................................................................................................... 49

OWNER ASSISTANCE — Section 7 ............................................................................................................................ 50, 51

WARRANTY — Section 8 ................................................................................................................................................ 52, 53

STORAGE — Section 9 .......................................................................................................................................................... 54

ALPHABETICAL INDEX — Section 10 .......................................................................................................................... 55, 56

Page 4

SECTION 1 DDFP

PRINCIPLES OF OPERATION

FUEL

AIR

AIR

AIR

AIR

AIR

AIR

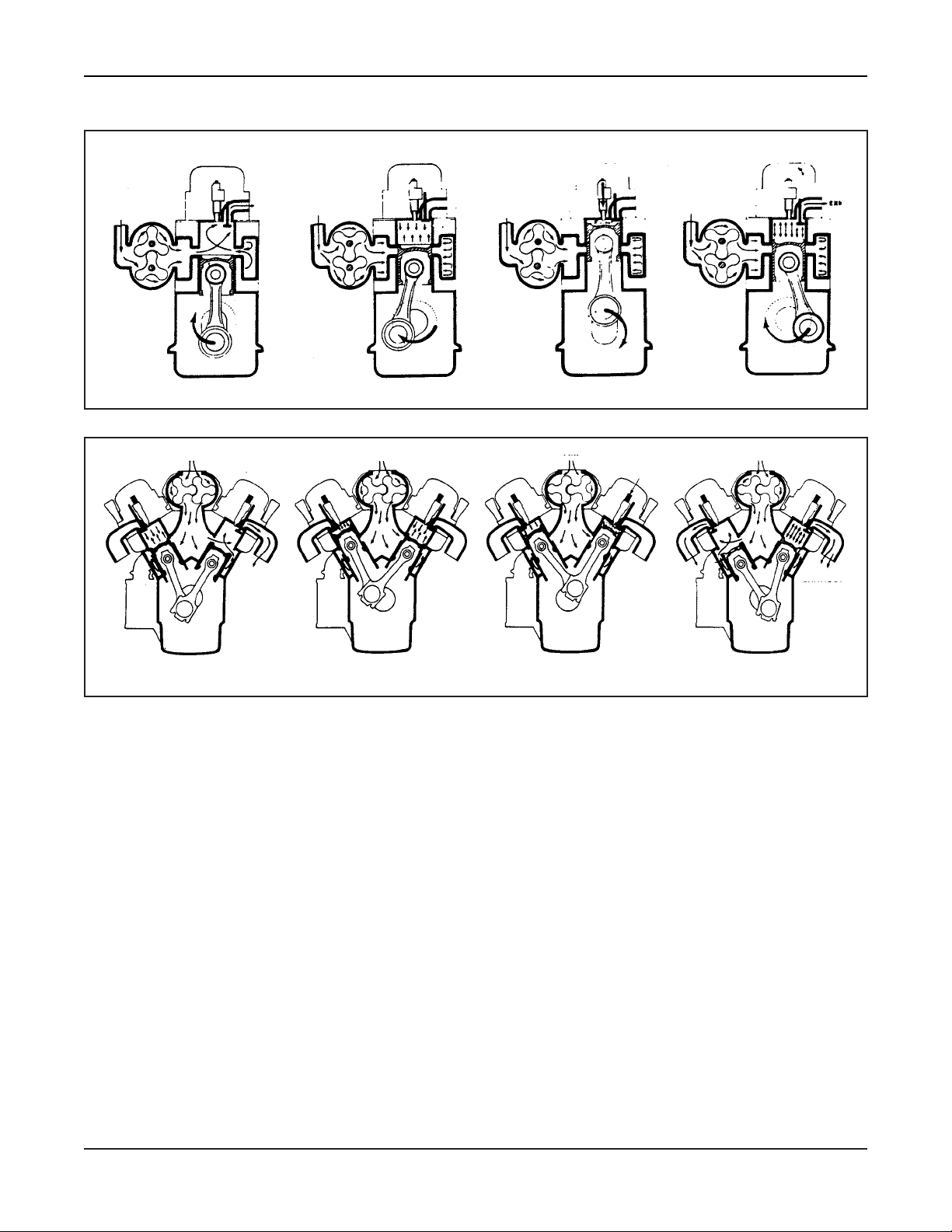

Fig. 1 - In-Line Cylinder Arrangement

AIR

AIR

FUEL

AIR

ExhaustPowerCompressionScavenging

AIR

11826

EXHAUST

SCAVENGING EXHAUSTPOWERCOMPRESSION

Fig. 2 - Vee Block Cylinder Arrangement

The diesel engine is an internal comb ustion power unit, in

which the heat of fuel is converted into work in the cylinder

of the engine.

In the diesel engine, air alone is compressed in the cylinder;

then, after the air has been compressed, a charge of fuel is

sprayed into the c ylinder and ignition is accomplished by

the heat of compression.

The Two-Cycle Principle

In the tw o-cycle engine, intake and e xhaust functions tak e

place during part of the compression and po wer strokes respectively (Fig. 1) or (Fig. 2). In contrast, a four -cycle

engine requires four piston strokes to complete an operating

cycle; thus, during one half of its operation, the four-cycle

engine functions merely as an air pump.

A blo wer is pro vided to force air into the c ylinders for

expelling the exhaust gases and to supply the cylinders with

fresh air for combustion. The cylinder wall contains a row of

ports which are above the piston when it is at the bottom of

its stroke. These ports admit the air from the blower into the

cylinder as soon as the rim of the piston unco vers the ports

(Fig. 1 & 2 - Scavenging).

12240

The unidirectional flow of air toward the exhaust valves produces a scavenging effect, leaving the cylinders full of clean

air when the piston again covers the inlet ports.

As the piston continues on the upw ard stroke, the exhaust

valves close and the charge of fresh air is subjected to compression (Fig. 1 & 2 - Compression).

Shortly before the piston reaches its highest position, the

required amount of fuel is sprayed into the comb ustion

chamber by the unit fuel injector (Fig. 1 & 2 - Po wer). The

intense heat generated during the high compression of the

air ignites the f ine fuel spray immediately. The combustion

continues until the fuel injected has been b urned.

The resulting pressure forces the piston do wnward on its

power stroke. The exhaust valves are again opened when the

piston is about half way down, allowing the burned gases to

escape into the e xhaust manifold (Fig. 1 & 2 - Exhaust).

Shortly thereafter , the do wnward mo ving piston unco vers

the inlet ports and the c ylinder is again swept with clean

scavenging air. This entire combustion cycle is completed in

each c ylinder for each re volution of the crankshaft, or, in

other words, in two strokes; hence, it is a "two-stroke cycle".

Page 1

Page 5

SECTION 1

DDFP

DESCRIPTION

Introduction

NFPA Pamphlet 20 sta tes "The compression ignition diesel

engine has proved to be the most de pendable of the inter nal

combustion engines for dri ving fire pumps." The diesel en gine will operate under emer gency power conditions w here

loss of utility or stand-b y electric po wer renders electric

motor driven pumps useless. The diesel driven fire pump system is preferred by most insurance companies.

This manual co vers Detroit Diesel engines. These engines

have been manuf actured with specif ic options to function

integrally with an automa tic engine controller for stand-by

fire protection service and to meet NFP A-20 requirements.

These systems ar e designed to function under emergenc y

conditions and to assist in holding fire damage to a minimum.

Complete understanding of the operation and maintenance of

this fire protection system is essential to ac hieve this objec tive.

A separate manual co vers the operation and maintenance of

the Automatic Engine Controller (AEC).

The two-cycle engines co vered in this man ual are produced

with v arious c ylinder arrangements. The same bore and

stroke and many of the major working parts such as injectors,

pistons, connecting rods, cylinder liners and other par ts are

interchangeable within eac h engine series. The engines are

either naturally aspirated (NA) or turbocharged (T) and some

units are turbocharged and aftercooled (TA).

The engines ha ve either an in-line or a vee type c ylinder

arrangements. The engine may ha ve clockwise (CW) or

counter-clockwise (CCW) r otation. Rotational reference is

made from a front vie w of the engine to deter mine the r otation of the output shaft. All other engine references, (

left side) are made from a rear view of the engine, looking at

the flywheel.

All DDFP engines are Underwriters Laboratories (UL) listed,

Underwriters Laboratories of Canada (ULC) listed and/or

Factory Mutual (FM) approved and meet the requirements of

the National Fire Protection Association (NFPA) standard 20.

right or

to the oil cooler. From the oil cooler the oil enter s a longitudinal oil g allery in the c ylinder b lock where the suppl y

divides and is channeled to the turbocharger (if included), to

the cam and balance shaft end bear ings and c ylinder head,

with the remainder going to the main bear ings and connecting rod bearings via the drilled crankshaft. The oil then drains

back into the oil pan.

Coolant is circulated through the engine by a centrifugal-type

water pump. Heat is removed from the coolant as it circulates

in a closed system through the heat exchanger. Control of the

engine temper ature is accomplished b y a thermostat which

regulates the f low of the coolant within the cooling system.

Raw water from the f ire pump passes thr ough a tube b undle

in the heat e xchanger to remo ve the heat from the engine

coolant.

Fuel is dra wn from the suppl y tank through a str ainer by a

gear-type fuel pump. It is then forced through a filter and into

the fuel inlet gallery in the cylinder head and to the injectors.

Excess fuel is r eturned to the suppl y tank through the fuel

outlet g allery and connecting lines. Since the fuel is con stantly circulating through the injector s, it serves to cool the

injectors and purges the system of air.

Air for sca venging and combustion is supplied b y a blo wer

which pumps air into the engine cylinders via the air box and

cylinder liner por ts. All air enter ing the blo wer first passes

through an air c leaner. Turbocharges, when included, are

located between the air cleaner and the blower. Some engines

also include an after cooler which cools the air prior to entering the cylinders.

Engine starting is usually provided by an electric starting system. The electric starting motor is energized by a storage battery. A battery-char ging alter nator, with a b uilt-in v oltage

regulator, serves to keep the battery charged while the unit is

running. At rest, a battery charger in the AEC keeps batteries

charged.

Engine speed is regulated by a mechanical type eng ine governor with a tamper proof speed control device.

Each engine is equipped with an oil cooler, lubricating oil filter, fuel f ilters, air cleaner, heat e xchanger, starting motor ,

alternator, instrument panel and engine jacket water heater.

Full lubrication oil pressure is supplied to all main, connecting rod and camshaft bear ings, and to other mo ving parts

within the eng ine. A gear type pump dr aws oil fr om the oil

pan through an intak e screen, through the oil f ilter and then

Model Numbering & Identification

Two model numbers are sho wn on this pr oduct. First is the

Clarke FM/UL/ULC a pproved model n umber sho wing the

prefix DDFP. Figure 3 e xplains the identification system on

DDFP units. Second is the DDC basic engine model number

using eight digits. Figure 4 provides details for understanding

the significance of each digit.

Page 2

Page 6

SECTION 1 DDFP

The DDFP model n umber appears on the FM/UL/ULC ta g

attached to the right rear of the engine flywheel housing. The

DDC basic engine model number appears on the engine rocker cover. The engine S/N should be the same a t both locations.

D D F P — L 6 V T

N Naturally Aspirated

TTurbocharged

ATurbocharged & Aftercooled

H High Output

A 71 Series DDC Engine, In-Line

D 53 Series DDC Engine

F 92 Series DDC Engine

V 71 Series DDC Engine, Vee

(X) Number of Cylinders

O Basic Build Level

L Reduced Output Build

T Alternate Turbo

I Included With Number of Cylinders

on

Engines With 10 or more Cylinders

Detroit Diesel Engines

Modified by Clarke and

Certified by FM/UL/ULC for

Fire Pump Service

Figure 3 - Clarke FM/UL/ULC Model

On some engines, you may find different engine rated horsepower and oper ating RPM on the r ocker co ver name pla te

than on the FM/UL/ULC ta g attached to the f lywheel housing. The FM/UL/ULC tag is the official power data and takes

presi-dence over the rocker cover data.

8 0 6 4 — 7 4 1 2

Specific Engine For

Fire Pump Application

0 NA Engine

3Turbocharged

4Turbo & Aftercooled

6Turbo & Aftercooled

3 LH Rotation

7 RH Rotation

8 RH Rotation

Industrial Power Unit

XX Number of Cylinders

1 71 Series DDC Engine, In-Line

5 53 Series DDC Engine

7 71 Series DDC Engine, Vee

8 92 Series DDC Engine

Figure 4 - DDC Basic Engine Model

(See Page 1)

Page 3

Page 7

DDFP STANDARD ENGINE EQUIPMENT LIST

DDFPSECTION 1

—Air cleaner, oiled gauze or dry type for protected environment.

—Battery charging alternator (12 or 24V-DC) negative

ground

—Engine coolant heater with AC power connection (120,

208 or 240V)

—Engine oil cooler

—Electric starting motor (12 or 24V-DC)

—Exhaust manifold insulation or heat shield

—Fuel inlet check valve

—Fuel filters - Primary and Secondary

—Junction box (DC control) for connection to engine

controller

—Low oil pressure switch

—Manual over-ride of automatic operations including

instruction plate

—Manual start contactors - two provided on each engine

—Oil filter(s) full flow with by-pass

—Oil pan heater (optional)

—Overspeed control and reset switch

—Solenoid Run/Stop control-signal from AEC

—Governor speed control

(10% No Load to Full Load)

—Heat Exchanger with pressure cap

—High water temperature switch

—Instrument panel with water temperature, oil pressure

and voltmeter

—Direct mounted engine half of Falk coupling

—Tachometer with hour meter

—Tamper proof throttle control factory preset

—Wiring harness for DC control

Page 4

Page 8

SECTION 1 DDFP

FM/UL/ULC CERTIFICATION NAME PLATE

The standard nameplate (Fig. 5) contains the follo wing information: FM/UL certified model number; Clark e specification number; production date; rated horsepower; full load

engine speed; basic engine serial number (S/N). The name

plate is located on the right rear of the engine and attached

to the flywheel housing.

The DDC model and S/N are found on the manuf acturer's

I.D. label (Fig. 6) on the v alve rocker cover. This model is

also stamped on the engine block.

On the Inline engines, the model number is stamped into the

cylinder block casting on a machined pad abo ve and to the

right of the engine blower. On the VEE engines, the number

is stamped at the right front of the block just behind the

water pump.

When requested, a ULC nameplate is provided in addition to

the FM & UL nameplate. This plate is mounted separately

on the engine.

Figure 5 Figure 6

Page 5

Page 9

SECTION 1

Type

General Specifications - DDFP Models

03DN

03DT

L3DT

T3DT

2 Cycle

2 Cycle

04AN

04AT

2 Cycle

DDFP

L6VT

T6VT03AN

2 Cycle

Number of Cylinders

Bore (inches)

Bore (mm)

Stroke (inches)

Stroke (mm)

Compression Ration (T Eng)

Compression Ration (N Eng)

Total Displacement (cub. in.)

Total Displacement (liters)

Number of Main Bearings

3

3.875

98

4.5

114

18.7:1

21.0:1

159

2.61

4

General Specifications - DDFP Models

06FA

06FH

3

4.25

108

5

127

– –

18.7:1

213

3.49

4

L8FA

08FA

4

4.25

108

5

127

17:1

18.7:1

284

4.66

5

08FH

12FT

6

4.25

108

5

127

17:1

– –

426

6.99

4

12FH

Type

Number of Cylinders

Bore (inches)

Bore (mm)

Stroke (inches)

Stroke (mm)

Compression Ratio

Total Displacement (cubic inches)

Total Displacement (liters)

Number of Main Bearings

For Specific Operational Data For Each Engine Model, Refer To Technical Data Section 5.

2 Cycle

6

4.84

123

5

127

17:1

552

9.05

4

2 Cycle

6

4.84

123

5

127

15:1

552

9.1

4

2 Cycle

8

4.84

123

5

127

17:1

736

12.07

5

2 Cycle

8

4.84

123

5

127

15:1

736

12.07

5

2 Cycle

12

4.84

123

5

127

17:1

1104

18.1

8

2 Cycle

12

4.84

123

5

127

15:1

1104

18.1

8

Page 6

Page 10

SECTION 1 DDFP

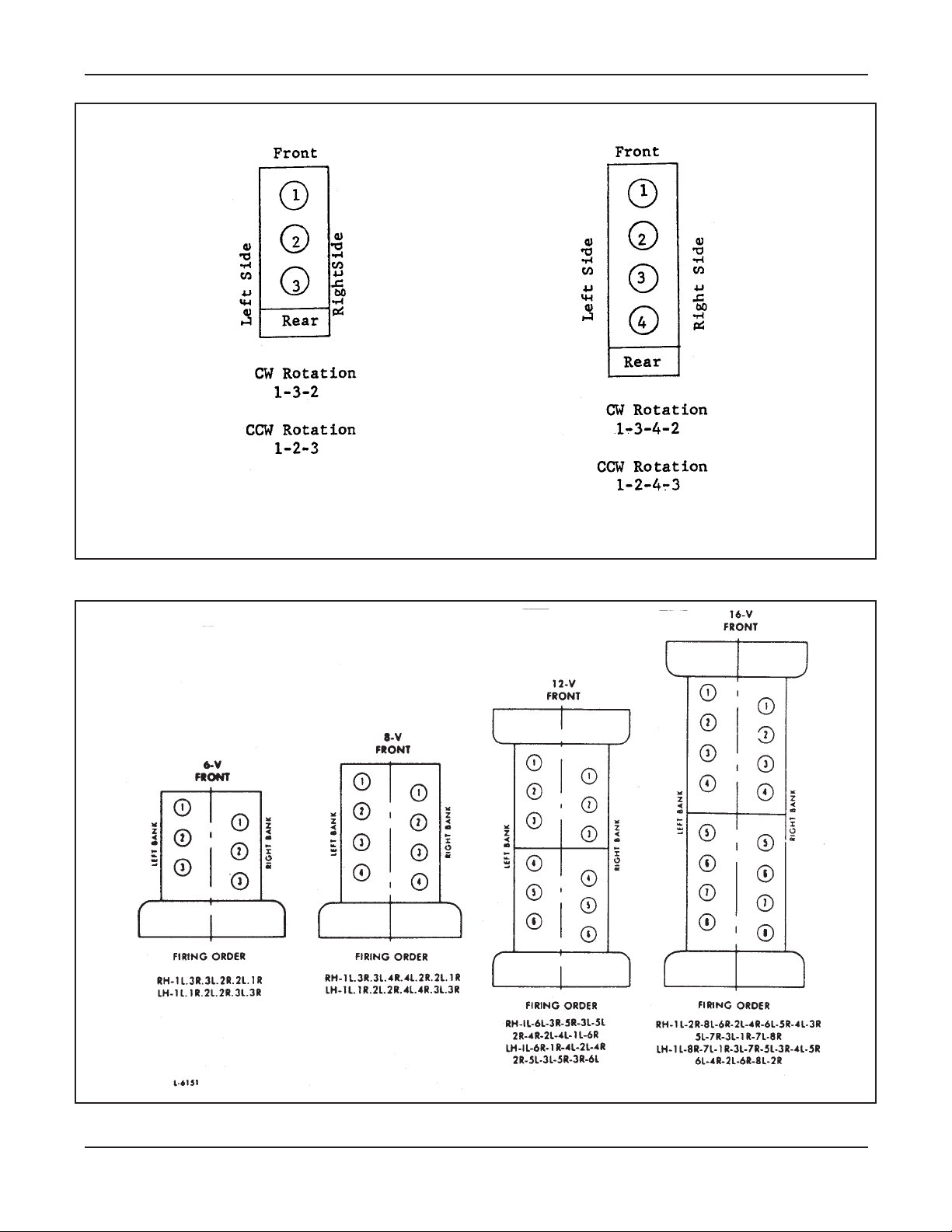

3 - IN-LINE 4 - IN-LINE

Fig. 7 - Cylinder Designation and Firing Order

Fig. 8 VEE Engine Cylinder Designation and Firing Order

Page 7

Page 11

ENGINE START UP AND OPERATING INSTRUCTIONS

DDFPSECTION 2

Preparing New Engine For Start-Up

Before starting a new or overhauled engine for the first time,

carefully read and follow the check list below. Attempting to

run the engine before studying these instructions may result

in serious damage to the engine.

1. Make all electrical (DC) connections between engine

(DC) junction box and engine controller.

2. Make all raw water connections to heat exchanger tank.

Discharge line should be one size larger than supply line and

rise a minimum of 3 inches abo ve heat e xchange outlet to

assure complete co verage of the heat e xchange core. Discharge water is to be piped to an open w aste cone.

NOTE: Do not allo w raw w ater plumbing to stress on

engine heat exchanger.

3. Install all of the drain cocks or plugs in the cooling sys-

tem (drain cocks are removed for shipping engines dry).

4. Fill engine cooling system with PRE-MIXED 50 per -

cent water and 50 percent permanent type antifreeze solution. Fill to top heat exchanger tank.

NOTE: Refer to Section 3.4 for Cooling System

Fill Procedure.

9. Unbox and inspect air cleaner element for damage or de-

terioration. Install air cleaner element on engine.

10. Install batteries, battery cables and service batteries as

required by manufacturer. See battery recommendation under

Section 3.

11. Install exhaust system. A vertical exhaust outlet is furnished for customer/contractor installation. A fle xible e xhaust connector must be installed at outlet.

NOTE: Do not exceed exhaust back pressure limits. See

Section 5 for details for each engine model.

NOTE: Do not allow exhaust system plumbing to stress

on engine.

If any problems or questions develop in performing the above

procedures, advise the authorized DDC Distributor/Dealer of

details when making arrangements for the installation inspection.

NOTE: Only one initial start-up inspection is provided at

no charge for an installation re view. Be sure to

cover items 1-11 thoroughly before calling the

authorized DDC Distributor/Dealer.

Normal Running

5. Connect fuel supply line and fuel return line to supply

tank. Bleed fuel system of all air.

NOTE: Do not use galvanized material for any compo-

nent part of a diesel fuel system. The fuel will

chemically react with the zinc coating.

6. Fill fuel tank with No. 2 diesel fuel.

NOTE: No. 2 diesel fuel is the only recommended fuel,

engine po wer could be af fected by using an y

other type.

7. Fill engine crankcase with SAE 40 weight oil per oil

recommendations of Section 3. Oil filler locations vary by

engine model. Most will be found on the engine valve cover.

8. Pre-lubricate engine to a minimum 25 psi (172 KPA) to

insure an immediate flow of oil to all bearings at the initial

engine start-up. Contact the authorized DDC

Distributor/Dealer if you require assistance with this item.

Fire pump engines are run periodically to assure proper operation. Units may be run automatically as programmed within

the AEC or the y may be run manually for systems e valuation.

NOTE: For specific operating instructions, see Section 3

- Electrical System.

Normal Care And Maintenance Should Be Made On

The Following Systems:

Fuel System

Periodically check fuel tank to assure it is full. Keep the fuel

tank f illed to reduce condensation to a minimum and to

assure full running time during emergency operation. Engine

fuel filter should be changed annually or when fouled with

contamination. If contaminated, locate the source and correct. (See Section 3 page 13 for proper procedure). If the

engine runs out of fuel or if the engine is out of service for a

considerable length of time, it may be necessary to reprime

the fuel system. Refer to Section 3 for proper procedure.

Page 8

Page 12

SECTION 2 DDFP

Drive Belts

Adjust the alternator drive belts as recommended under the

Preventive Maintenance Section 2.

engine coolant between 120 -140 de grees F (49-60° C).

When running, engine coolant temperature should re gister

between 180-200 de grees F (82-93° C). See Section 3 for

detailed information.

Storage Battery

Check the batteries. The top should be clean and dry, the terminals tight and protected, and the electrolyte must be at the

proper level. They should be tested weekly to determine the

condition of cells, and the amount of charge.

NOTE: Once each week, check the batteries with a hy-

drometer; the corrected reading should be 1.265

or higher. Hydrometer readings should be corrected for the temperature of the electrolyte.

Should a problem be detected, locate source and

correct.

Oil Pressure

Normal engine operating oil pressure is 40-70 psi (276-433

kPa). If operating pressure falls below 30 psi (206 kPa), stop

engine and investigate cause.

Coolant Temperature

When unit is not running, Jacket w ater heaters maintain

Standard Model Views

Crankcase

The oil le vel should be maintained between the Full mark

and Low mark. Check the oil le vel weekly prior to normal

exercise. The oil dipstick is located on the right side of the

engine. Do not check oil level when the engine is running. If

the engine crankcase was refilled, stop the engine after normal operating temperature has been reached, allow the oil to

drain back into the crankcase (approximately 10 minutes)

and check the oil le vel. Add oil, if necessary, to bring it to

the proper level on the dipstick.

NOTE: DO NOT OVER-FILL CRANKCASE.

Use only the recommended lubricating oil specif ied under

Section 3 - Lubricating Oil.

Running Inspection

While the engine is running at operating temperature, check

for coolant, fuel or lubricating oil leaks. Tighten the line

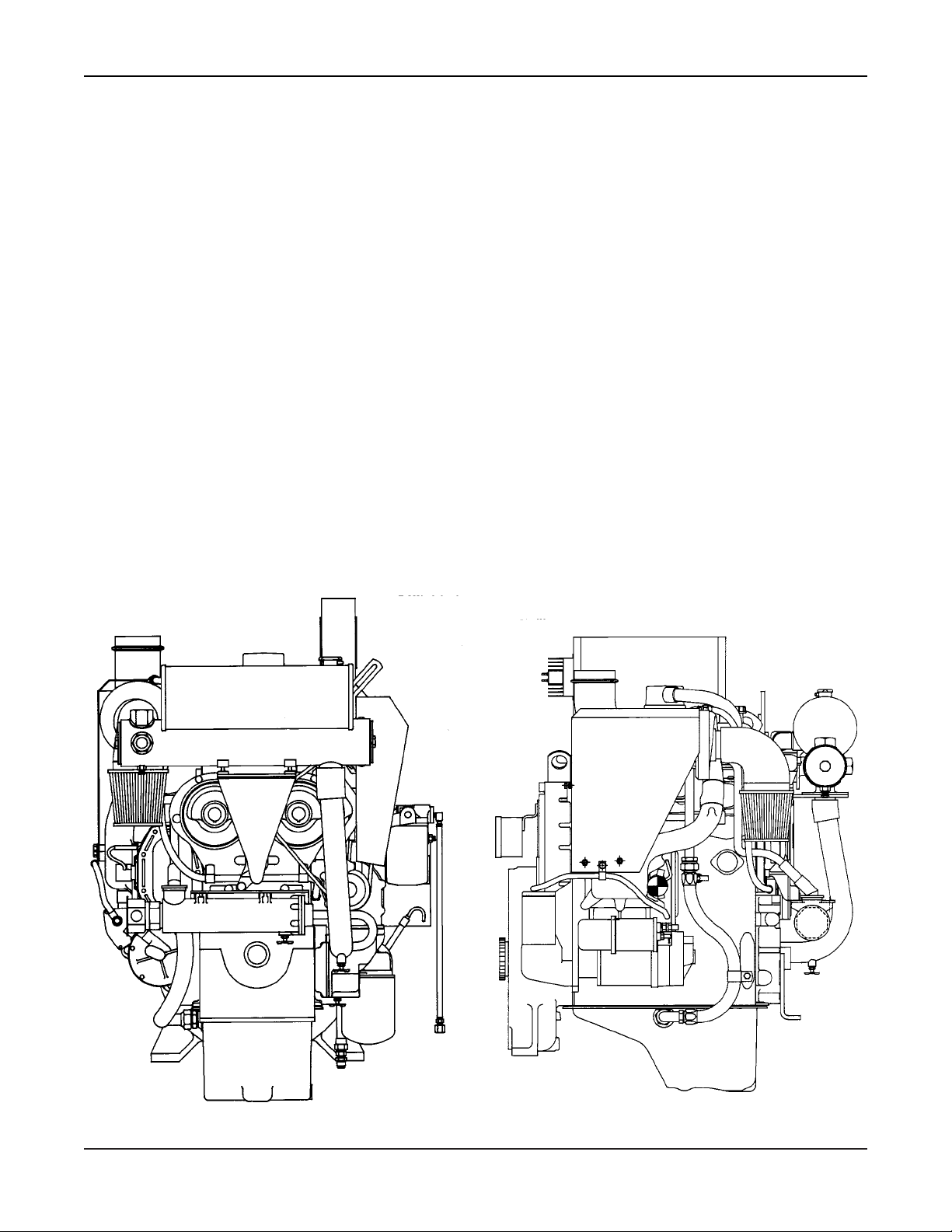

Right Side View (I-53)Front View (I-53)

Page 9

Page 13

DDFPSECTION 2

Front View (I-71)

Right Side View (I-71)

Front View (V-71)

Right Side View (6V-71)

Page 9-A

Page 14

SECTION 2 DDFP

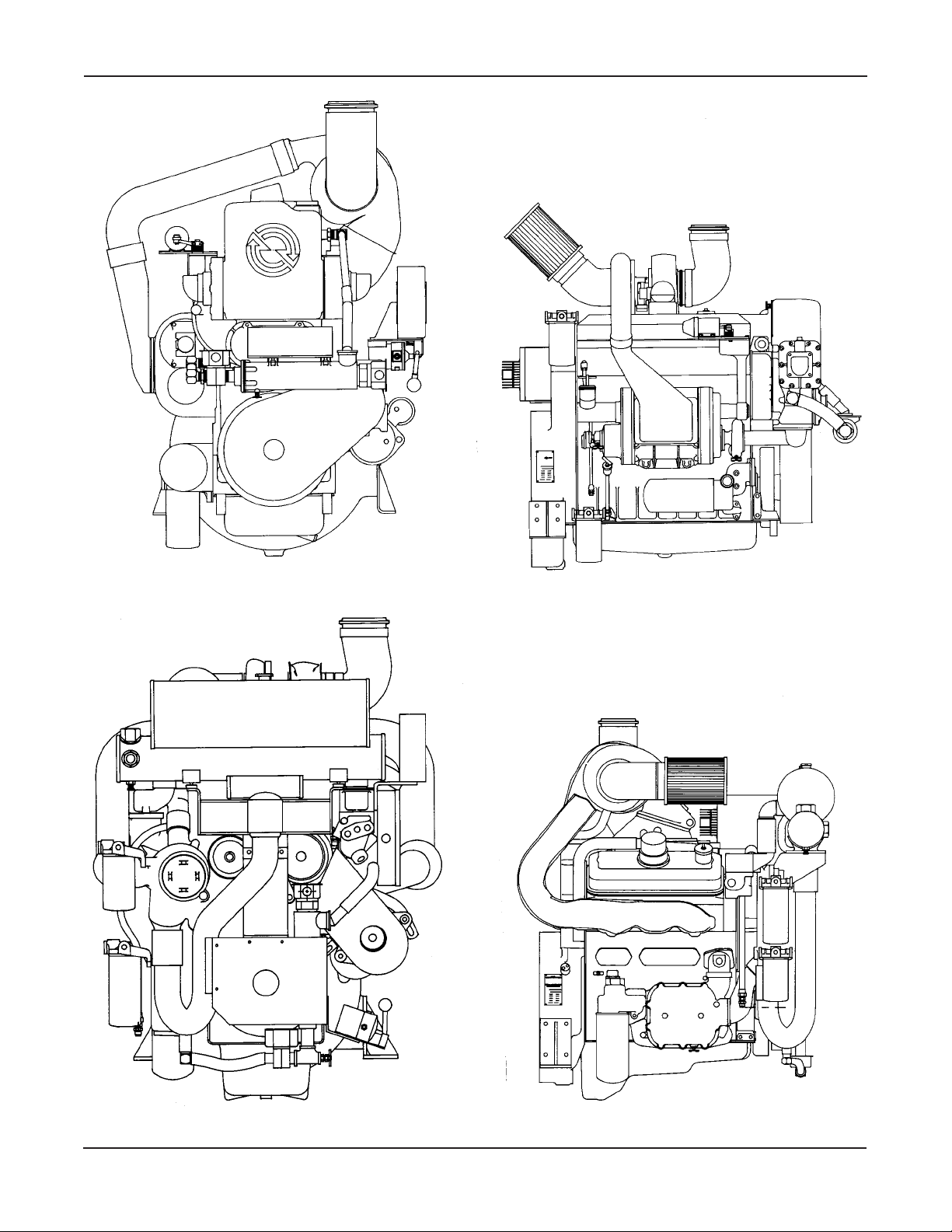

Front View (V-92) Right Side View (V-92)

Front View (12V-92) Left Side View (12V-92)

Page 9-B

Page 15

SECTION 2

DDFP

ELECTRONIC SPEED SWITCH

The speed switch is located on the rear or back side of the

instrument panel.

There are two (2) functions built into the speed switch. First

to terminate starter cranking, once the engine is running.

Second to signal the controller and ef fect an engine shutdown in the event of an engine overspeed condition.

Features of the speed switch are a "manual reset b utton" on

the face of the switch, which must be pushed into reset the

switch should the engine shutdo wn from an o verspeed condition. Additionally, a varification circuit to assist in checking or setting the overspeed set point.

CALIBRATION

Both crank terminate (SW#1) and o verspeed (SW#2) set

points, are set at the factory and should not require additional calibration. Adjustments can be made to the set points of

SW#1 and/or SW#2 if required using a je welers screw driver. Turning the corresponding adjustment scre w CW to

increase or CCW to decrease the set point. To access either

adjustment screw remove the small co ver plate on the f ace

of the speed switch.

OVERSPEED VARIFICATION

To varify the function of the overspeed signal (SW#2) without overspeeding the engine, install a jumper wire on terminals "C & D" of the speed switch. This will provide the controller with an o verspeed signal and engine shutdo wn at

67% of calibrated RPM.

Start the engine via the controller , the speed switch will

effect an overspeed signal and shutdown protecting both the

engine and pump.

EXAMPLE

Rated Speed : 2100 RPM

Overspeed Shutdown : 2520 RPM (120% of 2100 RPM)

Varification Shutdown : 1688 RPM (67% of 2520 RPM)

CAUTION

Crank terminate (SW#1) adjustment should be done reading

"engine crankshaft" speed at the front of the engine using a

hand held tachometer . For starter protection and optimum

engine stability , this switch should be calibrated to 1000

RPM.

Overspeed (SW#2) adjustment should be done r eading "engine crankshaft" speed at the front of the engine using a

hand held tachometer . This switch should be calibrated to

120% of rated speed, but ne ver higher than 3200 RPM.

Refer to the stainless steel nameplate located at the right rear

of the engine for the correct rated speed.

After v arification of SW#2 the jumper wir e must be

removed and the "reset b utton" pushed in to re-instate normal operation of the engine and speed switch.

Page 10

Page 16

SECTION 2 DDFP

PREVENTIVE MAINTENANCE SCHEDULE

Item

Weekly

1. Run Engine

(per NFPA 20 Specifications) X

2. General Inspection X

3. Lubricating Oil X R

4. Fuel Tank X

5. Fuel Lines X

6. Cooling System X R

7. Battery X C

8. Air Cleaner - Dry Type (-03AN & -04AN) X R R

- Oil Gauze (All Other Models) X C R

9. Drive Belts X

10. Speed Control X

11. Fuel & Lube Oil Filters R

12. Exhaust System X X

Inspection Interval

6 Months 1 Year 2 Year

13. Battery Charging Alternator X

14. Manual Contractors X

15. Operating Gauges X

16. Crankcase Vent System X

17. Heat Exchanger Electrode X

18. Governor Run-Stop Mechanism X

19. Jacket Water Heater X

20. Wiring System X

21. Coolant Hose Inspection X R

See Parts Information Section 6 for Lubricating Oil And Coolant Analysis' Kits

IMPORTANT: Set AEC to "of f" while servicing engine.

Before turning the AEC to the "off" position, check with the

maintenance and security supervisors to v erify that all departments concerned will be alerted of the temporary interruption of their f ire protection equipment for normal maintenance or testing. Also, alert the local fire department in the

event that the AEC is connected by silent alarm to headquarters. When servicing is complete,return AEC selector to

"Automatic" position and the manual operating le ver to

"auto - off" position.

X Check

R Replace

C Clean

Page 11

Page 17

SECTION 3

DDFP

ENGINE SYSTEMS

Section 3.1 Fuel System

Section 3.2 Air Intake & Exhaust System

Section 3.3 Lubrication System

Section 3.4 Cooling System

Section 3.5 Electrical System

Section 3.6 Falk Drive Coupling

In this Engine Systems section that follows, data is presented in a generalized way for a description of system operation. For specific operational data and system limits, refer

to Section 5. In addition to kno wing the specif ic DDFP

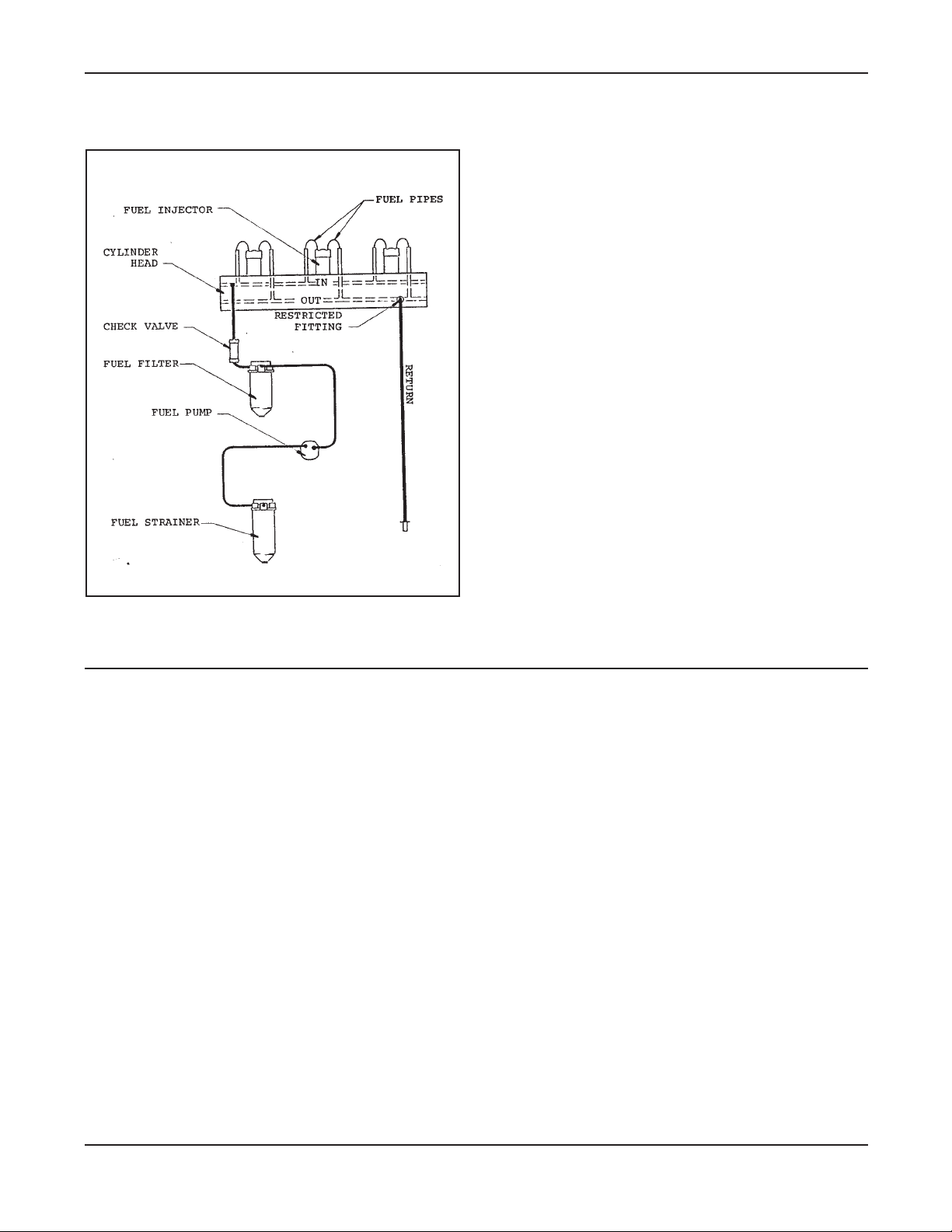

FUEL SYSTEM

OPERATION

Fuel is drawn from the supply tank through the fuel strainer

and enters the fuel pump at the inlet side. Upon lea ving the

fuel pump under pressure, the fuel is forced through the fuel

filter and into the fuel inlet manifold where it passes through

fuel pipes into the inlet side of each fuel injector. The fuel is

atomized through small injector spray tip orif ices into the

combustion chamber. Surplus fuel, returning from the injectors, passes through the fuel return manifold and connecting

fuel lines back to the fuel tank. The continuous flow of fuel

through the injectors helps to cool the injectors and to

remove air from the fuel system.

CHECK VALVE

A check valve is installed between the fuel filter and the fuel

inlet manifold. The check valve is rated to open at approximately 2 psi (13.7 KP A). The fuel tank and supply lines

should be arranged to limit static pressure so that the v alve

remains closed when unit is not running. This valve opens

automatically from fuel pump pressure when the unit starts.

Refer to Figure 1, Page 14, for fuel system components.

FUEL INJECTOR

model being operated, make special note of the certif ied

engine operating speed (RPM). Much of the data v aries by

operating RPM - check the FM/UL/ULC certification tag on

the engine flywheel housing for this speed.

Since the injector is one of the most important and carefully constructed parts of the engine, it is recommended that

the injector be replaced as an assembly if it is not operating

properly. An authorized DDC Distributor/Dealer is equipped

to pro vide ne w and reconditioned replacement injectors.

Under no circumstance should an attempt be made to repair

these injectors. Genuine f actory new or "reliabilt" injectors

should be used for repairs.

FUEL PUMP

DDFP Engines are equipped with a positi ve displacement

gear type fuel transfer pump. Fuel pumps are furnished in

either left or right hand rotation according to the engine

model, and are stamped RH or LH. These pumps are not

interchangeable and cannot be rebuilt to operate in an opposite rotation. The fuel pump used on the 53 series engine is

driven by the go vernor assembly on the left rear . On I-71 it

is attached and driven off the rear of the lower engine blower rotor. On VEE engines, the pump is attached and dri ven

off the right front blo wer rotor located on the v ee of the

block.

A spring-loaded relief valve, incorporated in the pump body,

normally remains in the closed position, operating only

when the pressure on the outlet side (to the fuel f ilter)

becomes excessive due to a plugged filter or fuel line.

The fuel injector combines in a single unit all of the parts

necessary to pro vide complete and independent fuel injection at each c ylinder. The injector creates the high pressure

necessary for fuel injection, meters the proper amount of

fuel, atomizes the fuel, and times the injection into the combustion chamber.

The fuel pump incorporates two oil seals. Two tapped holes

are provided in the underside of the pump body, between the

oil seals, to permit a drain tube to be attached. If fuel leakage exceeds one drop per minute, the seals must be replaced.

An authorized DDC Distributor/Dealer is properly equipped

to replace the seals or to provide reconditioned parts.

Page 12

Page 18

SECTION 3.1 DDFP

SPIN-ON TYPE FUEL FILTER

A spin-on type fuel strainer and fuel filter (Fig. 2) is used on

Clarke DDFP engines. The spin-on filter cartridge consists

of a shell, element and gasket combined into a unitized replacement assembly . No separate springs or seats are required to support the filters.

The filter base incorporates a threaded slee ve to accept the

spin-on f ilter cartridges. The w ord "Primary" or

"Secondary" is cast on the fuel strainer base for identif ication.

No drain cocks are pro vided on the spin-on f ilters. Where

water is a problem, residue may be drained by removing and

inverting the filter. Refill the filter with clean fuel oil before

reinstalling it. Should water be found, locate the source and

correct by draining or cleaning as required.

Replace the Filter as Follows:

1. Unscrew the filter (or strainer) and discard it.

2. Fill a new filter replacement cartridge full with clean fuel

oil. Coat the seal gasket lightly with clean fuel oil.

3. Install the new filter assembly and tighten it to two-thirds

of a turn beyond gasket contact.

4. Start the engine and check for leaks.

General Fuel

Classification

Gravity, °API #

Flash Point, Min. °F (°C)

Viscosity, Kinematic

cST @ 100°F (40°C)

Sulfur Content wt%, Max.

Carbon Residue

on 10%, wt%, Max.

Accelerated Stability

Total Insolubles

mg/100 ml, Max. #

Ash, wt%, Max.

Cetane Number, Min. +

Cetane Index, Min. +

ASTM

Test

D 287

D 93

D 445

D 1266

D 524

D 2274

D 482

D 613

D 4737

No. 2

ASTM 2-D

33 - 37

125 (52)

1.9 - 4.1

0.5

0.35

1.5

0.01

45

40

NOTE: DDFP engines have the "Primary" filter at or below

the fuel pump. One exception to this is current production I-53 engines. Due to f actory designed,

formed steel fuel lines, the I-53 filters are mounted

the reverse of all others. The Primary Filter mounts

to the c ylinder head abo ve the pump. The

Secondary filter mounts to the coolant w ater inlet

elbow below the fuel pump. Inlet fuel check valves

are always located on the discharge side of the secondary filter.

DIESEL FUEL RECOMMENDATIONS

The quality and grade of fuel used is a very important factor

in obtaining satisf actory engine performance, long engine

life, and acceptable e xhaust emission le vels. Certif ied

engine ratings are based at standard SAE conditions using

the recommended #2-D Diesel Fuel. Refer to the Diesel Fuel

Specifications chart Fig 3 for verification of fuel properties.

For additional information on the fuel system, see technical

data Section 5, Page 43. In addition, Sulfur content of the #2

Diesel Fuel used must be limited to 0.5% mass. The com-

Distillation Temperature,

°F (°C)

IBP, Typical #

10% Typical #

50% Typical #

90% +

End Point #

Water & Sediment

%, Max.

# Not Specified in ASTM D 975 ........................................

+ Differs from ASTM D 975

Fig. 3 - Diesel Fuel Specifications Chart

D 86

D 1796

375 (191)

430 (221)

510 (256)

625 (329) Max.

675 (357) Max.

0.05

Page 13

Page 19

SECTION 3.1

DDFP

FUEL SYSTEM SCHEMATICS

1. Fuel Strainer (Primary)

2. Fuel Transfer Pump

3. Fuel Filter (Secondary)

4. Check Valves

5. Cylinder Head with Internal Manifolds

6. Fuel Injectors

7. Fuel Pipes (Inlet and Return to Injector)

8. Restricted Fuel Fitting

Fig. 1 - DDFP Fuel System

ENGINE MECHANICAL GOVERNOR

A v ariable speed mechanical go vernor pro vides speed

control of the engine. The certified engine speed, shown on

FM/UL/ULC label, has been preset at the f actory. Minor

speed adjustments can be made in the f ield to meet specif ic

installation condition, generally ± 50 RPM maximum.

9. Return to Tank

The go vernor is controlled by the R UN-STOP solenoid.

This solenoid is activated by a signal from the AEC. A manual over-ride switch on the instrument panel, placed in the

MANUAL position, allows manual operation should the

AEC malfunction.

Note: Always leave the instrument panel switch in the

AUTO position when the unit is unattended.

Page 14

Page 20

SECTION 3.1 DDFP

MAINTENANCE AND SERVICE PROCEDURES

Weekly

1). Fuel Tank: Keep the fuel tank f illed to reduce condensation to a minimum. Open drain at the bottom of the

fuel tank once a week to drain of f any possible w ater

and/or sediment. Fill tank after each test run.

NOTE: Per NFPA 20 standards, the fuel tank level must

never be less than 50% of capacity.

2). Fuel: Use a proper grade of #2-D diesel fuel only.

6 Months

Check condition of fuel lines for fraying, leaks or poor condition. Replace as necessary.

Yearly

Change primary and secondary fuel filters. Refer to Section

6 for recommended part numbers.

DIESEL FUEL CONTAMINATION

The most common form of diesel fuel contamination is

water. Water is harmful to the fuel system and it also pr omotes the growth of microbiological organisms (microbes).

These microbes clog fuel f ilters with a "slime" and restrict

fuel flow.

Water can be introduced into the fuel supply through poor

maintenance (loose or open fuel tank caps), contaminated

fuel supply or condensation.

Condensation is particularly prevalent on units which stand

idle for e xtended periods of time, such as f ire pump units.

Ambient temperature changes cause condensation in partially filled fuel tanks.

Water accumulation can be controlled by mixing isoprop yl

alcohol (dry gas) into the fuel oil at a ratio of one pint per

125 gallons fuel (or 0.10% by volume).

Microbe growth can be eliminated through the use of commercially available biocides. There are tw o basic types on

the mark et. The w ater soluble type treats only the tank

where it is introduced. Microbe growth can start again if fuel

is transferred from a treated to an untreated tank. Diesel fuel

soluble type, such as "Biobor" manufactured by U.S. Borax

or equivalent, treats the fuel itself and therefore the entire

fuel system. Please follow manufacturer's recommendations

on useage of these materials.

Engine Out of Fuel

The problems of restarting an engine that has run out of fuel

involves the entire fuel system. After the fuel is e xhausted

from the fuel tank, fuel is then pumped from the primary

fuel strainer and sometimes partially removed from the secondary fuel filter before the fuel supply becomes insufficient

to sustain engine firing.

To ensure prompt starting and smooth running, the fuel system must be pur ged of air and full of fuel from the supply

tank to the restricted fitting at the fuel return line. To accomplish this, a manual priming pump, such as tool P/N J5956

or an electrical type priming pump can be adapted easily to

the fittings provided on the secondary f ilter. To be sure the

injectors are lubricated, priming through the secondary filter

is preferred. The system should be primed until no air is present in the fuel flow from the return line. Pressure should not

exceed 15 psi (103kPa) for ease of handling and safety reasons.

Priming is not al ways necessary if the f ilter elements are

filled with fuel when installed and the fuel manifolds in the

head are not drained of fuel. Prolonged use of the starter

motor and engine fuel pump to prime the system can result

in damage to the starter, fuel pump, injectors and erratic running of the engine, due to the amount of air in the lines and

filters from the supply tank to the c ylinder head.

NOTE: Under no circumstances should a starting aid

such as ether be used to run the engine until the

fuel system is primed. Injector damage will

occur if this method is used. The heat generated

by the external fuel source will cause the tips to

be damaged when the fuel cools them. The

I-53 Fuel Filters I-71 Fuel Filters V-92 Fuel Filters V-71 Fuel Filters

Figure 2

Page 15

Page 21

SECTION 3.2

AIR INTAKE AND EXHAUST SYSTEM

AIR INTAKE OPERATION

In the scavenging process employed in the engines, a charge

of air is forced into the c ylinders by the blo wer and thoroughly sweeps out all of the b urned gases through the

exhaust v alves. This air also helps to cool the inter nal

engine parts, particularly the e xhaust valves. At the be ginning of the compression strok e, therefore, each cylinder is

filled with fresh, clean air which provides for efficient combustion.

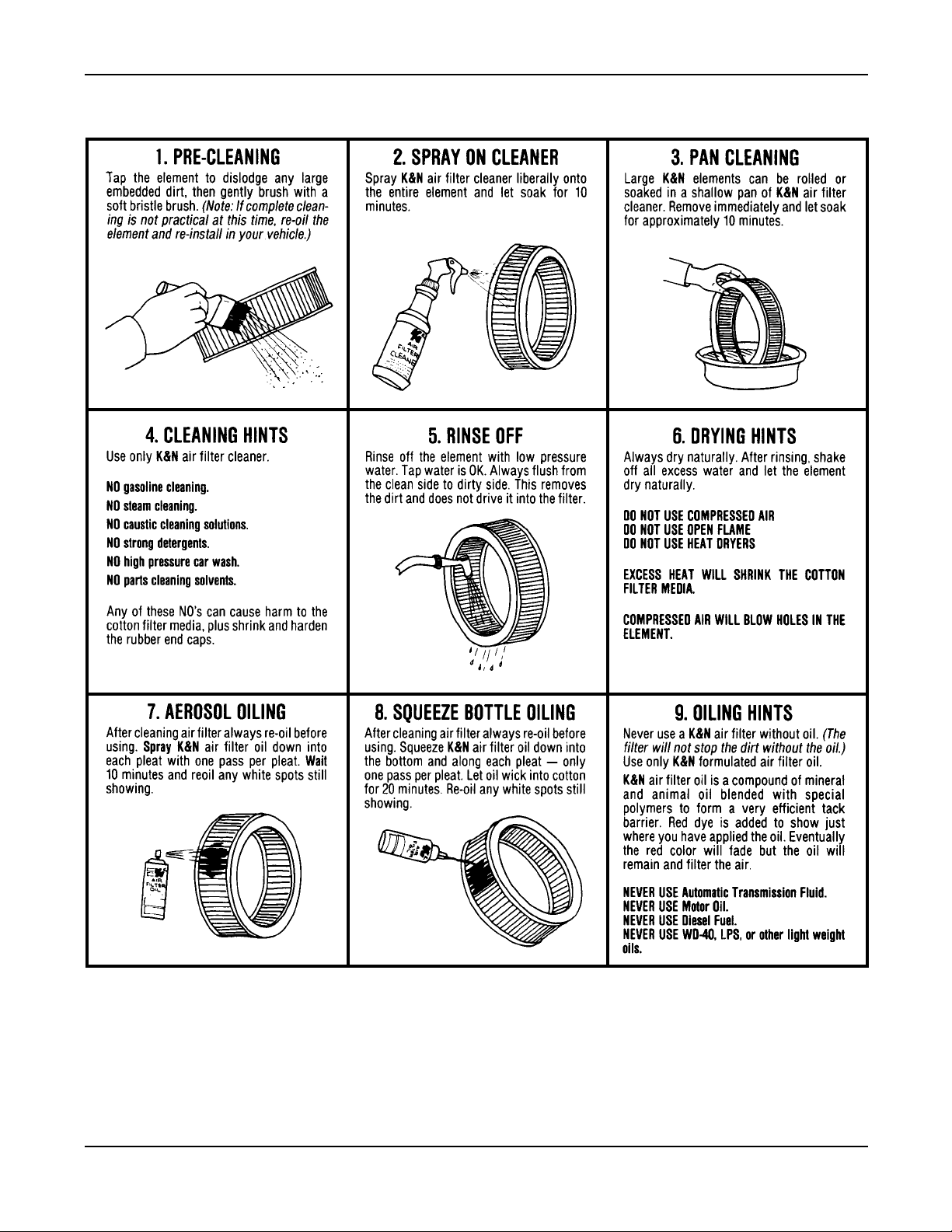

AIR CLEANER

The air cleaner used on DDFP engines is either a dry type or

the reusable type. Should a situation occur where the air

cleaner becomes plugged with dirt (starving the engine for

air), low power and heavy black smoke will be the result; the

air cleaner should be serviced immediately.

CAUTION: Do not attempt to remo ve the air cleaner

while an engine is running nor run the engine

while the air cleaner is of f. Exposed turbocharger could cause se vere injury to personnel and major internal engine damage could

occur should an y foreign matter be dra wn

into the engine.

DDFP

The air, entering the blower from the air cleaner , is pick ed

up by the blo wer rotor lobes and carried to the dischar ge

side of the blower as indicated by the arro ws in Figure 1 &

2, Page 1. The continuous dischar ge of fresh air from the

blower enters the air chamber of the c ylinder block and

sweeps through the intake ports of the cylinder liners.

The angle of the ports in the c ylinder liners creates a uniform swirling motion to the intak e air as it enters the c ylinders. This motion persists throughout the compr ession

The air cleaner manufacturer recommends the following:

1. On engines using dry elements, replace the air cleaner

element.

2. On engines with pre-oiled elements, service with a special oil. These elements can be serviced or replaced. Part

number is shown in the parts section of this manual.

3. When servicing the element is not practical, you can improve filter efficiency by re-spraying with oil.

NOTE: Do not attempt this while engine is running.

NOTE: Do not over oil.

Page 16

Page 22

SECTION 3.2 DDFP

AIR FILTER SERVICE INSTRUCTIONS

Figure 1 - Air Filter Service Instructions

Page 17

Page 23

SECTION 3.2

AIR BOX DRAINS

DDFP

During normal engine operation, water v apor from the

intake air, as well as a slight amount of fuel and lubricating

oil fumes, condenses and settles on the bottom of the air

box. This condensation is remo ved by the air box pressure

through air box drain tubes mounted on the side of the cylinder block.

CRANKCASE VENTILATION

Harmful vapors which may form within the engine are removed from the crankcase, gear train, and injector compart-

Liquid accumulation in the air box will result if a drain tube

becomes plugged. Remo ve the drain tubes and connectors

from the c ylinder block and clean them thoroughly when

necessary.

ments by a continuous, pressurized ventilation system.

I-53 V71 or V-92I-71

Figure 2 - Crankcase Ventilation

A slight pressure is maintained within the engine crankcase

and injector compartment. This crankcase pressure and resulting ventilation is accomplished by the air seepage past

the piston rings sweeping up through the flywheel housing

and/or the balance weight co ver into the v alve and injector

rocker arm compartment. Here it is e xpelled through a vent

pipe attached to the rock er cover breather assembly . Turbo

charged I-71 engines additionally use a breather attached to

the front left side of the c ylinder block. Figure 2 sho ws the

vent system for each engine series.

Page 18

Page 24

SECTION 3.2 DDFP

EXHAUST OPERATION

Internal comb ustion engines con vert fuel ener gy into both

useful w ork and w asted heat. The useful w ork is the flywheel rotation that dri ves the pump. The w asted heat

involves the engine water cooling system, radiated heat and

the exhaust gases. Approximately 2/

3 of the fuel ener gy is

wasted. Critical re view must be made of these systems to

assure that the engine delivers the useful power required and

maintains the engine within the operating parameters established by the engine manufacturer.

The exhaust system is critical to the proper engine performance. When initially installed, consideration must be gi ven

to the exhaust gas flow requirements, the exhaust temperatures and the e xhaust back-pressure limitations of the specific engine. Generally , N engines can tolerate a higher

exhaust pressure than T engines. Refer to Section 5 for specific engine model and operating speed back-pressure limitations. All the components in an exhaust system contribute

to the back-pressure determination including the fle x

exhaust section, muffler, exhaust piping and its conf iguration. In addition to providing engine exhaust data and backpressure limitations, Clarke of fers a service to installers,

through the local Pump OEM Dealer , for making recommendations on e xhaust system sizing for specif ic installations.

MAINTENANCE AND SERVICE PROCEDURES

Weekly

Prior to each maintenance run mak e a visual check of the

exhaust system to v erify condition of piping and muf fler (if

used). Investigate thoroughly any areas that w ould appear to

have rusty conditions such as rain w ater running do wn pipe

and getting inside the engine. Se vere internal engine damage

could occur.

Inspect the engine air cleaner for dirt b uildup or damage.

During actual maintenance run check engine crankcase ventilation tube for excessive blow-by or pressure.

If the exhaust system should become restricted, the hot exhaust gases cannot escape from the engine. This condition

would cause a loss of po wer, extreme internal engine heat,

and v ery high e xhaust gas temperatures. These conditions

can and will cause internal cylinder damage and a reduction

of engine life.

Some engines are turbocharged (T). Turbochargers increase

the air flo w into the engine c ylinder and permit increased

horsepower by burning more fuel than is possible in a naturally aspirated (N) engine. Turbochargers enhance the ef ficiencies of engines and add power to a similar displacement

(N) engine.

Basically, turbochargers are maintenance free. Ho wever,

should any exhaust manifold studs or bolts break or come

loose, engine exhaust gases can start leaking into the pump

room. Under these conditions, the engine should be attended to immediately . First indications of an e xhaust leak

would be the smell of diesel exhaust and possible eye irritation. Unless f ire pump maintenance personnel are well

versed in a repair of turbochar gers and e xhaust systems,

contact your local Distributor/Dealer for assistance.

NOTE: Exhaust back pressure, air inlet restriction and

crankcase pressure limits are listed for each

DDFP Model in Technical Data Section 5. These

limits are not to be e xceeded. To properly check

these limits, the engine must be producing maximum required horsepower.

While the engine is running inspect e xhaust pipe outlet outside of the pump room itself for en vironmental hazards such

as excessive smoke conditions. The following could be used

as a guide for general engine operating conditions.

1. Blue Smoke — Possible engine oil consumption - too

many areas to list for possibilities.

2. White Smoke — Possibility of water in cylinders

Source — Possible w ater in fuel or internal engine prob-

lem.

6 Months

Inspect exhaust system for leaks or plugging,if any are found,

repair immediately. Inspect and tighten if necessary e xhaust

manifold, turbo mount (if equipped) and piping bolts/n uts.

NFPA 37 requirements are to ha ve the e xhaust system co vered with high temperature insulation for personnel protection. Inspect the insulations condition for any deterioration or

looseness, repair as necessary.

Exhaust system back pressure limits are not to be e xceeded.

Should any of these or any other conditions be found, contact

your local DDC Distrib utor/Dealer for assistance. Check

condition of the air inlet system ducting, clamp tightness hose

condition.

Yearly

Clean and re-oil the air cleaner element per the manufacturers

directions. Each engine is shipped with the cleaning instructions. Refer to Figure 1, page 17.

Check crankcase v entilation tube for proper operation by

making a visual inspection while engine is running.

Page 19

Page 25

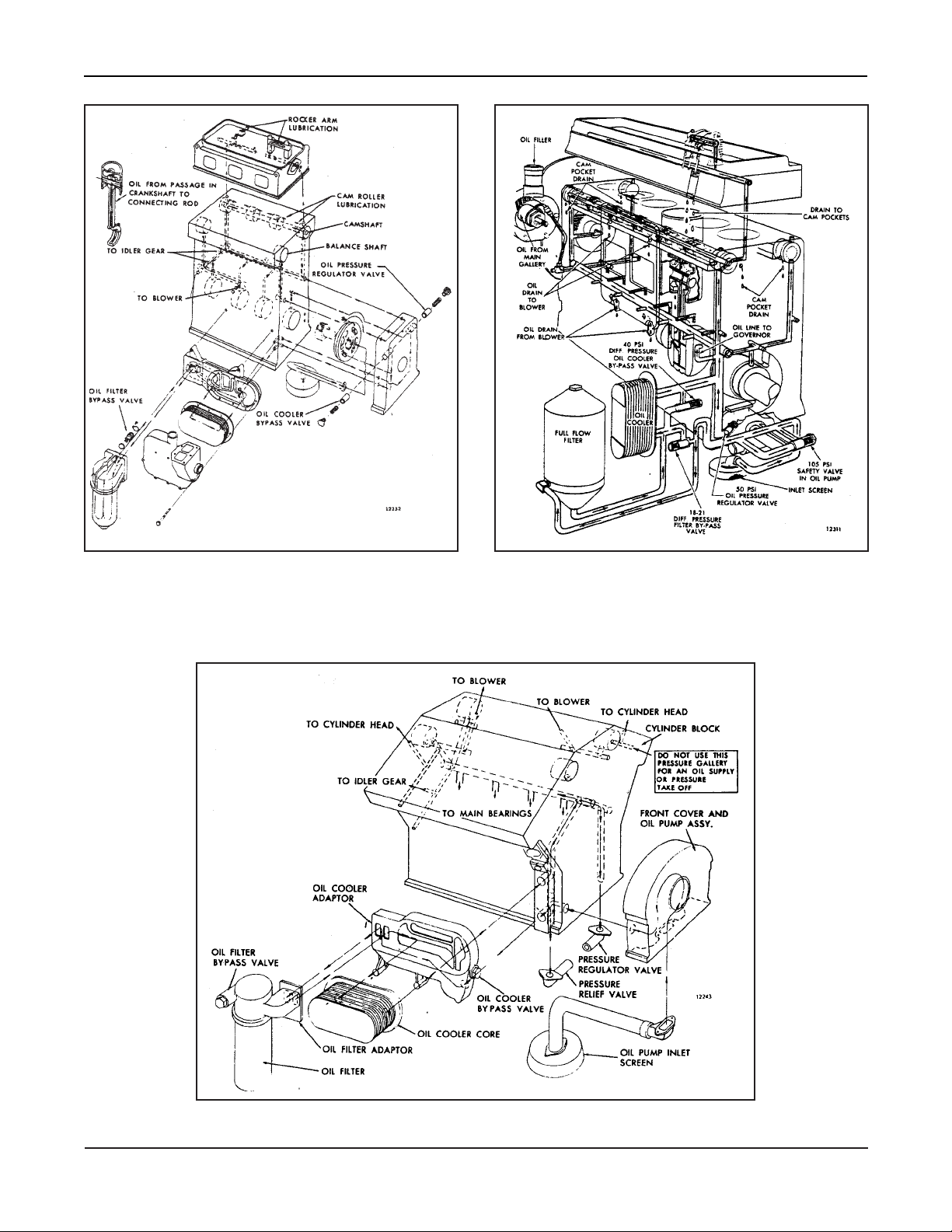

LUBRICATION SYSTEM

DDFPSECTION 3.3

OPERATION

The lubricating oil system is schematically illustrated in

Figures 1, 2 and 3 for the Inline and VEE engines. The system consists of an oil pump, oil cooler, a full-flow oil filter,

by-pass valves at the oil cooler and filter, and pressure regulator valves at the pump and in the c ylinder block main oil

gallery. Positive lubrication is ensured at all times by this

system.

Oil for lubricating the connecting rod bearings, piston pins,

and for cooling the piston head, is pro vided through the

drilled hole in the crankshaft from the adjacent forw ard

main bearings. The gear train is lubricated by the o verflow

of the oil from the camshaft pock et through a connecting

passage into the flywheel housing from the camshaft, balance shaft, and idler gear bearings. The blower drive gear

bearing is lubricated through an e xternal pipe from the rear

horizontal oil passage of the cylinder block.

On the Inline engines the oil from the cam pocket enters the

blower and overflows through two holes, one at each end of

the blo wer housing, providing lubrication for the blo wer

drive gears at the rear end and for the go vernor mechanism

at the front. On the VEE engines, the blower drive gear is

lubricated from the rear of the blower.

OIL COOLER

All engines use a plate type oil cooler. Between each engine

model, the major difference lies in the number of plates in

each cooler. The number of plates required is determined by

engine horsepo wer de veloped. All the oil cooler systems

incorporate oil bypass valves in the event of plate core plugging.

It should be understood that improper engine maintenance

could adversely effect the ef ficiency of the oil cooler system. Please refer to the technical data Section 5, for specific lube oil temperature and engine coolant temperature

ranges for each engine model.

LUBE OIL FILL

On I-71 engines, the oil f ill is located on the right rear . On

the VEE engines, it is found in the right bank v alve rocker

cover. On the 53 Series engine, the oil fill is also located on

the rocker cover. See technical data, Section 5 for oil v olumes and specif ications on each engine model. A typical

oil fill location is shown in Figure 5, Page 24.

LUBE OIL PUMP

The positive displacement gear type pump is mounted to the

main bearing caps on I-71 and dri ven from the front end of

the crankshaft. On the I-53,V-71 and V-92 engines the pump

is found in the lower front cover and driven by the front end

of the crankshaft. The I-71, V-71 and V-92 have a pressure

relief located on the dischar ge side of the pump, which

maintains pressure being delivered to the oil filter and cooler. The I-53 engine does not use a pressure relief v alve but

does incorporate the use of the f ilter and oil cooler bypass

valve to maintain pressure.

All four engines use an oil pressure regulator valve to maintain oil g alley minimum pressures. See technical data

Section 5 for specifics per engine model.

OIL LEVEL DIPSTICK

On most DDFP engines, the dipstick is located on the lower

left side. Exceptions are the I-71 and 12V92 models where

the dipstick is located on the right. Oil level can be checked

only when the engine is at rest (not running). Oil levels must

be maintained between the low and full marks.

NOTE: Due to the basic engine design, DDC engines

retain large volumes of oil in the block while

running. For this reason, proper oil level cannot

be checked immediately after engine shut of f.

Wait approximately 10 minutes before checking oil le vel. Do not add oil to a running

engine; overfilling can occur!

Page 20

Page 26

SECTION 3.3 DDFP

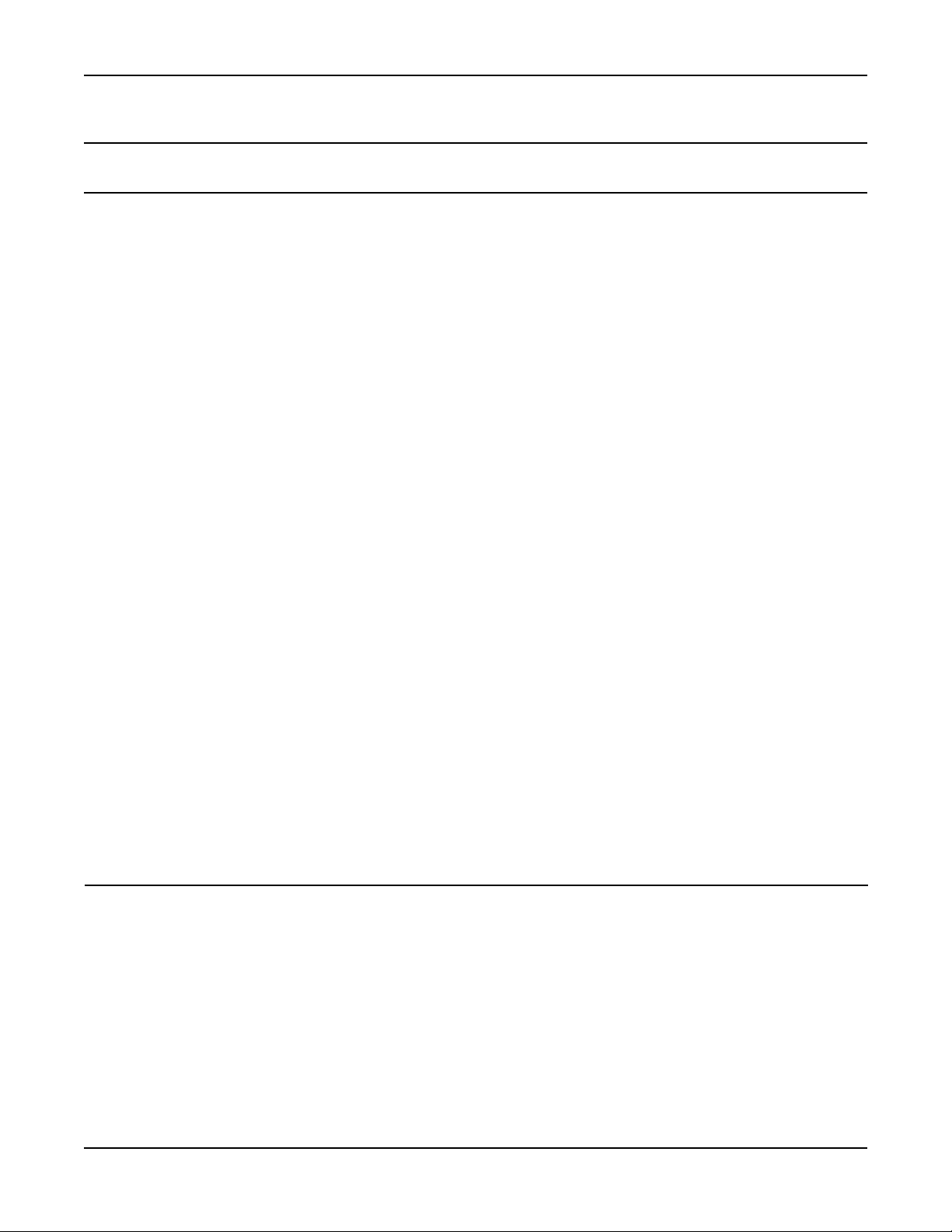

Fig. 1 - I-53 Lubricating System Schematic

Fig. 2 - I-71 Lubricating System Schematic

Fig. 3 - V-71 & 92 Lubricating System Schematic

Page 21

Page 27

SECTION 3.3

DDFP

LUBE OIL FILTER

All engines use full flow oil filters of the "spin on" type element. They have a non-replaceable pleated paper cartridge.

Each filter has an integral bypass valve in the event of plugging or for cold start purposes.

NOTE: Use only appro ved f ilters with the recom-

mended filtration micron rating. See parts list

Section 6 for proper service part numbers.

Replacing Spin on Oil Filter(s)

1. Obtain the Detroit Diesel recommended replacement

lube oil filter. See Chart, Page 44.

2. Use a properly sized oil f ilter wrench, such as

Kentmoore P/N J24783, and remove filter(s).

3. Discard used filter(s) as recommended by EPA.

4. Clean the f ilter base mounting surf ace with a lint free

cloth.

5. Lightly coat the oil filter seal with clean engine oil.

specify a Mil-L-2104F type oil. Because the y may display

different viscosity grades, it is necessary to use a SAE 40

grade only.

TWO-CYCLE ENGINES

DETROIT DIESEL SERIES 53, 71, 92

LUBRICANT REQUIREMENTS

API Symbol:

*

SAE Viscosity Grade: 40

API Classification: CDII or CF2

*CF-2 when available

This is the only oil recommended for Detroit Diesel Engines

used in DDFP service. Lubricants meeting these criteria

have provided maximum engine life when used in conjunction with recommended oil drain and f ilter maintenance

schedules.

Sulfated Ash: less than 1.0%

6. Start threading the ne w replacement f ilter onto the

threaded portion of the base and hand tighted until the

seal contacts the filter head. With the filter wrench, continue to tighten two-thirds of a turn.

7. Start engine and check for leaks. If any are found do not

put engine into service until corrections are made.

LUBRICATING OIL REQUIREMENTS

Hundreds of commercial oils are marketed today, but labeling terminology differs among suppliers and can be confusing. Some mark eters may claim that their lubricant is suitable for all mak es of diesel engines and may list engine

makes and types, including Detroit Diesel, on their containers. Such claims, by themselves, are insufficient as a method

of lubricant selection for DDFP engines.

The proper lubricating oil for all DDFP engines is selected,

based on SAE Viscosity Grade and API (American

Petroleum Institute) Service Designation. Both of these

properties are displayed in the API Symbol, which is illustrated within the specif ic requirements. For DDFP engines,

the proper lubricant must also possess a sulfated ash content

below 1.0% mass.

Lubricating oils for Non-T actical Military usage currently

Certain engines operating conditions may require e xceptions to this recommendation. They are as follows:

1. For continuous high temperature operation (o ver 100° F

38° C Ambient), the use of SAE 50 grade lubricant in all

DDFP engines is recommended.

2. The API Performance Cate gory CF2 represents an enhanced level of lubricant performance o ver CD-II category which it replaces. Lubricants meeting this new performance level may not be readily available. During this

interim period oils labeled as API CD-II may be used.

3. When the use of High Sulfur Diesel Fuel (greater than

0.5% mass) is una voidable, the use of lubricants with

higher Total Base Numbers (alkalinity) are recommended. Refer to Fig. 4 for minimum TBN numbers to be

used for normal service.

MAINTENANCE AND SERVICE PROCEDURE

Weekly

1). Check oil le vel with the engine stopped. Please refer to

"note" listed in Section 3 under oil le vel dipstick for

proper oil level check.

Page 22

Page 28

SECTION 3.3 DDFP

2). During and after weekly maintenance run, check o ver

entire engine for signs of oil leaks. Repair immediately

if found or call your authorized DDC Distributor/Dealer

for service.

NOTE: If oil is observed coming from the air box drain

tubes while running, review maintenance procedure on page 19.

Yearly

Stationary diesel engines collect condensation in the engine

oil pan while at rest. When in use, lubricating oil undergoes

deterioration from combustion by-products and contamination. For these reasons, regardless of the appearance of the

oil, change oil and filter(s) annually.

TWO CYCLE ENGINES ONLY

ASTM

Designation

Pentane Insolubles

D 893

% Max.

Carbon (Soot) Content,

E-1131

TGA Mass % Max.

CAUTION: Use only recommended lube oil and oil f ilters. Internal engine damage and/or excessive wear could

occur using unauthorized materials.

LUBRICATING OIL ANALYSIS

Oil Analysis kits are available through the DDC Distributor

Network for ef ficient monitoring of the lubricating oil in a

DDFP engine. Refer to Parts Information Section 6 to order.

Oil Analysis consists of a series of laboratory tests conducted on the engines lubricant. Some tests sho w the condition

of the engine and others show the condition of the lubricant.

Refer to Fig. 4 for warning limits.

Condition

Measured

Engine

53, 71, 92

1.0

Combust.

Engine

0.8

Combust.

Viscosity at 40°C cS

% Max. Increase

% Max. Decrease

Total Base Number (TBN)

Min.

Min.

Water Content (dilution)

Vol. % Max.

Flash Point °C

Reduction Max.

Fuel Dilution Vol. % Max.

Glycol Dilution

PPM Max.

Iron Content

PPM Fe Max.

Copper Content

PPM Cu Max.

Sodium Content PPM NA

Over Baseline Max.

Boron Content PPM B

Over Baseline Max.

D 445 & D 2161

D 664 or D4739

D 2896

D 95

D 92

*

D 2982

**

**

**

**

Engine & Oil

Oil

Engine

Engine

Fuel Dil.

Engine

Engine

Engine

Wear

Engine

Wear

Engine

Coolant

Engine

Coolant

40.0

15.0

1.0

2.0

0.30

20.0

2.5

1000

150

25

50

20

** Various Methods

** Elemental Analyses are conducted using either emission or atomic absorption spectroscop y. Neither method has an ASTM designation.

Fig. 4 - Oil Analysis Warning Limits

Page 23

Page 29

SECTION 3.3

OIL VOLUME

For specific oil quantities please refer to Technical Data Section 5 for each engine model listing.

DDFP

▼

Fig. 5 - Typical Oil Fill Location

Page 24

Page 30

SECTION 3.4 DDFP

COOLING SYSTEM

The Engine Cooling System Includes:

Coolant Pump

Heat Exchanger with Overflow Pipe

Oil Cooler

Pressure Cap-Fill Cap

Thermostat & Water Bypass

Raw Water Inlet and Discharge

Zinc Electrode

OPERATION

The heat resulting from combustion in the engine cannot be

fully converted into kinetic ener gy. A major portion of that

heat is absorbed by the coolant from the c ylinder walls and

cylinder heads and must be carried away from the engine. It

is the function of the Heat Exchanger to transfer w aste

engine heat to the raw cooling water.

Inside the heat e xchanger tank Fig. 1 is a heat e xchanger

core, somewhat similar to a miniature radiator . Engine

coolant circulates around the heat exchanger core while cool

raw water, from a tap on the pressure side of the f ire pump,

is circulated inside the core carrying a way the heat. The installing contractor mak es the ra w water discharge connection at time of system installation.

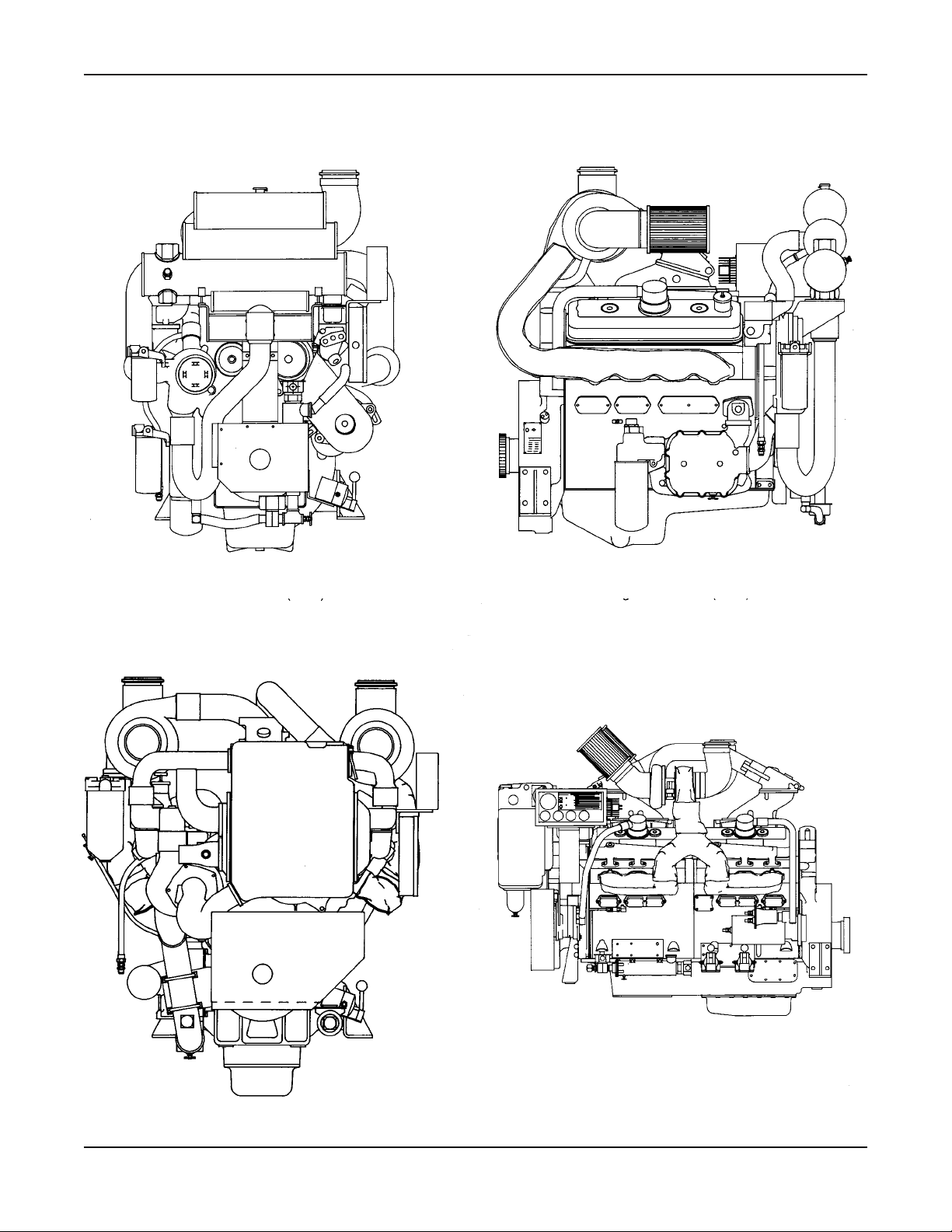

V-71

I-53

Fig. 1 - Heat Exchanger Cooling System

V-92

I-71

Page 25

Page 31

SECTION 3.4

DDFP

Engine coolant is circulated by the engine coolant pump.

Engine coolant enters the side of the block upon dischar ge

from the oil cooler and coolant pump. Under lo w pressure,

the coolant flo ws past the c ylinders, up through the heads,

and then through the open thermostat into the heat exchanger tank. After passing o ver the heat e xchanger core, the

coolant then re-enters the coolant pump and starts the c ycle

over. If the thermostat is closed, coolant would flow down a

bypass tube, back to the coolant pump. Under that condition,

the coolant bypasses the heat exchanger core and allows the

engine to retain some of the heat so it can quickly reach optimum operating temperature.

ENGINE COOLANT

The following information is provided as a guide for Detroit

Diesel engine users in the selection of a suitable coolant.

The water/ethylene glycol/inhibitor coolant mixture used in

DDFP engines must meet the following basic requirements:

• Provide for adequate heat transfer.

• Provide protection from cavitation damage.

• Provide a corrosion/erosion resistant environment within

the cooling system.

• Prevent formation of scale or sludge deposits in the cooling system.

• Be compatible with engine hose and seal materials.

• Provide adequate freeze and boil over protection.

WARNING

A 50% water and 50% anti-freeze solution is

required for pump installations. Premixing

this solution prior to installing is required.

This prevents possible pure anti-freeze chemical reactions to block heater elements which

can burn out the element. Please see the technical data Section 5 for proper cooling system capacities of each model.

tory as an engine coolant when properly inhibited. Use of

distilled water is ideal.

GRAINS PER

Chlorides (Maximum)

Sulfates (Maximum)

Total Dissolved Solids (Maximum)

Total Hardness (Maximum)

GALLON

40

100

340

170

PA RTS PER

MILLION

2.5

5.8

20

10

Fig. 2 Satisfactory Water Limits

ANTIFREEZE

Use an eth ylene glycol coolant (lo w silicate formulation)

that meets or exceeds the standard of either the GM 6038-M

formulation (GM 1899-M performance) or ASTM D 4985

requirements.

A 50% coolant/water solution is normally used. Concentrations over 70% are not recommended because of poor heat

transfer capability , adverse freeze protection and possible

silicate dropout. Concentrations belo w 30% of fer little

freeze, boil over or corrosion protection.

COOLANT INHIBITOR

The importance of a properly inhibited coolant cannot be

over-emphasized. A coolant which has insuf ficient or no

inhibitors at all, invites the formation of rust, scale, sludge

and mineral deposits. These deposits can greatly reduce the

cooling systems efficiency and protection capabilities.

DDC-recommended supplemental coolant inhibitors are a

combination of chemical compounds which pro vide corrosion protection, cavitation suppression, pH controls and prevent scale. These inhibitors are a vailable in v arious forms,

such as liquid packages or integral parts of anti-freeze.

WATER

Water can produce a corrosi ve en vironment in the cooling

system, and the mineral content may permit scale deposits to

form on internal cooling surfaces. Therefore, inhibitors must

be added to control corrosion, cavitation, and scale deposits.

Chlorides, sulfates, magnesium and calcium are among the

materials which mak e up dissolv ed solids that may cause

scale deposits, sludge deposits, corrosion or a combination

of these. Chlorides and/or sulf ates tend to accelerate corrosion, while hardness (percentage of magnesium and calcium

salts broadly classif ied as carbonates) causes deposits of

scale. Water within the limits specif ied in Fig. 2 is satisfac-

It is imperative that supplemental inhibitors be added to all

DDFP engine systems. A pre-charge dosage must be used at

the initial fill and the maintenance dosage used at each service interv al. Serious damage will occur unless inhibitors

are used. Some of the more common corrosion inhibitors

are borates, nitrates and silicates.

Inhibitors become depleted through normal operation, additional inhibitors must be added to the coolant as required to

maintain original strength levels. Refer to Fig. 3 for proper

concentrations of inhibitors.

Do not use soluble oils or chromate inhibitors in DDFP

engines. Detrimental effects will occur.

Page 26

Page 32

SECTION 3.4 DDFP

Max.

PPM

1500

2400

2000

250

500

10.5

Boron (B)

Nitrite (NO2)

Nitrates (NO3)

Silicon (Si)

Phosphorous (P)

pH

Min.

PPM

1000

800

1000

50

300

8.5

Fig. 3 - Proper Concentrations Of Inhibitors

To properly check inhibitor concentrations it may be necessary to contact your local DDC Distributor/Dealer for assistance. Refer to P arts Information Section 6, Page 45, to

obtain the DDC part number for the F actory Coolant

Analysis Kit. This kit can be purchased for nominal fee for

analyzing the condition of the engine's coolant.

PROCEDURE FOR FILLING ENGINE

During filling of the cooling system, air pockets may form.

The system must be pur ged of air prior to being put in service. This is best accomplished by f illing with a pre-mix

solution, to the top of f iller neck. Install the pressure cap,

start and run engine until the temperature staabilizes at

approximately 170° - 190° F (77° - 91° C). During this

warming process, you may

To verify that the coolant is at a safe operating level, it's best

to wait until the engine temperature drops to approximately

120°F (49°C), or lo wer, before removing the pressure cap.

After the cap is removed, the level should be within 2 inches (51mm) of the filler neck.

NOTE: I-71 engines have incorporated the use of a coolant

recovery bottle (white plastic bottle) Fig 4. During

initial filling of the cooling system, it will be necessary to f ill the Reco very Bottle to the Cold Full

line with the pre-mix solution. Start and run the

engine as indicated abo ve. After reaching normal

operating temperature check the coolant le vel in

the recovery bottle to v erify that the le vel is at the

Hot Full line, if not add coolant to the bottle.

Following the same instructions as abo ve, wait for

the engine coolant temperature to drop before

removing the pressure cap. The coolant le vel

should be at the pre viously mention height. The

coolant level must remain between Hot and Cold

run lines on the recovery bottle.

CAUTION: Do not remove pressure cap while coolant is at

normal operating temperatures. Possible personal injury could result from the expulsion of

hot coolant.

PRESSURE CAP

Like most cooling systems, the Heat Exchanger type operates under pressure. A typical cap shown in Fig. 5 maintains

system pressure to raise the coolant boiling point and permits a some what higher operating temperature without

coolant loss. Pressure cap values can vary in different engine

series. Refer to Section 5 for your engine type.

Fig. 4 - Coolant Recovery Bottle

see coolant coming from the o verflow tube attached at the

pressure cap location. This is a normal condition since the

coolant expands as it heats up. When the o verflow ceases,

stop the engine.

NOTE: Air entrapment in I-53 engines is v ery lik ely to

occur due to cooling system design. Upon initial

fill with a pre-mix solution. It is recommended that

the coolant be allowed to stand for a four hour period prior to starting.

All pressure caps include a vacuum valve which opens during cool down. This prevents an internal vacuum from being

formed which could contrib ute to leaking seals and hoses

collapsing.

NOTE: I-71 engines use a coolant reco very bottle. The

pressure cap includes a rubber ring-type seat.

When the cap installed this ring forms a positi ve

seal between the filler neck and cap. During engine

cool down, if the wrong type cap is used, coolant

cannot transfer back into the heat e xchanger from

the recovery bottle. This can progress into an overheated engine and possible damage.

Fig. 5 - Typical Coolant Cap

Page 27

Page 33

SECTION 3.4

DDFP

COOLANT PUMP

The engine water pump is a centrifugal impeller type pump.

It is gear dri ven on the I-71, V-71 and V-92 Series engines

and belt driven on the I-53 Series engines. The rebuildable

pump utilizes a shaft and sealed bearing assembly. The V-71

and V-92 incorporate an oil seal and tw o splash lubricated ball type bearings. Each pump also included a w ater

pump seal weep hole. Should a coolant leak occur at this

location, the pump seal must be replaced. Contact your local

DDC Distrib utor/Dealer for assistance. Should a replacement pump be required for repair , use only the e xact same

type of pump.

THERMOSTAT

Each pump engine is equipped with a temperature controlling thermostat(s). Normal operating ranges will vary due to

engine horsepower and operating speed. The thermostat(s)

are located at the front of the c ylinder heads. Refer to

Section 5 for specif ic operating temperatures for each

engine.

ENGINE COOLANT HEATER

CAUTION: Do not acti vate the AC circuit unless the

engine cooling system has been filled.

A pre-mix solution must be used. Chemical

reactions will occur if pure Ethylene Glycol

anti-freeze is allo wed to f ill the heater ca vity

with AC circuit is activated.

HEAT EXCHANGER COOLING

The heat e xchanger cooling system is illustrated in Fig. 1,

Page 25.

Raw water from the f ire pump passes through the heat e xchanger core where it lowers the engine coolant temperature

10-15° F (-12° – -9° C). Typical raw water connection points

on the heat exchanger are shown in Fig. 7, Page 29.

HOSES