SERIES 92 SERVIC

EMANUAL

Diesel engine exhaust and some of its constituents are

known to the State of California to cause cancer, birth

defects, and other reproductive harm.

Always start and operate an engine in a well ventilated

area.

If operating an engine in an enclosed area, vent the

exhaust to the outside.

Do not modify or tamper with the exhaust system or

emission control system.

ABSTRACT

This manual pr ovides instruction for servicing on-highway, industrial, generator set, and marine

applications of the Detroit Diesel Series 92 Engines.

Specifically a ba sic overview of each major component and system along with recommendations

for removal, cleaning, inspection, criteria for replacement, repair and installation and mechanical

troubleshooting are contained in this manual.

®

DDEC

III/IV troubleshooting concerns are contained in the DDEC III/IV Single ECM

Troubleshooting Guide, 6SE497.

3M Super Tack™ is a trademark of Minnesota Mining and Manuf ac tu rin g Company. Aeroshell®is a registered trademark of Shell Oil Company.

Allison®is a registeredtrademark of General Motors Corporation. Alvania®is a registered trademark of Shell Oil Company. Barber-Colman

is a registered trademark of Barber-Colman Company. Biobor®is a registered trademark of United States Borax and ChemicalC orporation.

Cindol®is a registered trademark of E.F.Houghton & Co. DDEC®is a registered trademark of Detroit Diesel Corporation. D elco R emy®is

a re gi ste red trademark of Delco Remy America, Inc. Donaldson®is a registered trademark of Donaldson Company, Inc. Dow Corning®is a

registered trademark of Dow Corning Corporation. Endurion

of Davco Manufacturing, L.L.C. Jabsco®is a registered trademark of ITT Industries. Jake Brake®is a registered t rademark of Diesel Engine

®

Retarders, Inc. Kent-Moore

®

Loctite

is a registered tra demark of Loctite Corporation. Lubripla te®is a registered trademark of Fiske Brothers Refining Company. Lubrite

is a registered trademark of Henkel Corporation. Mobilgrease®is a registered tr ademark of Mobil Oil Corporation. Permatex®is a registered

trademark of Loctite Corporation. Power Cool

Detroit Diesel Corporation. Red-Jaket

Diesel Corporation. Rockfo rd

®

L.L.C. Shell

registered trademark of First Brand Corporation. Teflon

registered trademark of Texaco, Inc. Twin Disc

ElastomersL.L.C. Volvo

Woodward

is a registered trademark of Shell Oil Corporatio n. Sta rrett®is a registered trademark of L.S. Starrett Company. STP®is a

®

is a registered trademark of Woodward Governor Company.

is a registered trademark of SPX Corporation. Leece-Neville®is a registered tradema rk of Leece-N ev ille Company.

®

is a registered trademark of Detroit Diesel Corporation. Power Trac®is a registered trademark of

®

is a registered trademark o f INCOM International, Inc. reliabilt®is a registered trademark of Detroit

®

is a registered trademark of Rockford Powertrain, Inc. Sea Pro®is a registered trademark of DavcoManufacturing,

®

is a registered trademark of Twin Disc, Inc. Viton®is a registered trademark of Dupont Dow

®

is a registered trademark of Volvo Trademark Holding AB. WD-40®is a registered trademark of WD-40 Company.

®

is a registered trademark of Jason Incorporated. Fuel Pro®is a registered trademark

®

is a registered trademark of E.I. DuPont de Nemours and Company, Inc. Texaco®is a

®

®

All information subject to change without notice.

6SE379 0303 Copyright © 2003 DETROIT DI ES EL CORPORATION i

SERIES 92 SERVICE MANUAL

REVISION NOTIFICATION

Modifications to this manual are announced in the form of Service Information

Bulletins. The bulletins include attachment pages and are posted on the World Wide Web

(www.detroitdiesel.com/svc/sibindex.htm).

Revisions to this manual will be sent marked with a revision bar (see Example 2). Sections

containing revisions will have a third line in the page footer (compare Examples 1 and 2).

ii 6

SE379 0303 Copyright © 2003 DETROIT DIES EL CORPORATION

All information subject to change without notice.

TABLE OF CONTENTS

GENERAL INFORMATION ...................................................................... 1

SCOPE AND USE OF THIS MANUAL ..................................................... 3

SAFETY PRECAUTIONS ........................................................................ 3

FLUOROELASTOMER (VITON) CAUTION ............................................. 10

SERVICE PARTS AVAILABILITY ............................................................. 11

CLEARANCE AND TORQUE SPECIFICATIONS .................................... 11

THE TWO CYCLE PRINCIPLE FOR DIESEL ENGINES ........................ 12

GENERAL DESCRIPTION ..................................................................... 13

DDEC DIAGNOSTIC READER CAUTION ............................................... 15

DDEC I ..................................................................................................... 16

DDEC II .................................................................................................... 17

DDEC III .................................................................................................. 17

GENERAL S PECIFICATIONS ................................................................ 18

ENGINE MO DEL, SERIAL NUMBER AND O PTION LABEL ................... 21

REPAIR AND R EPLACE .......................................................................... 24

DISASSEMBLY ....................................................................................... 25

CLEANING ............................................................................................... 25

INSPECTION .......................................................................................... 26

ASSEMBLY .............................................................................................. 27

FABRICATING, ALTERING, REMOVING AND DISPOSING OF

GASKETS ................................................................................................ 27

ENGLISH TO METRIC CO NVERSION .................................................... 28

DECIMAL AND METRIC EQUIVALENTS ................................................ 30

SPECIFICATIONS ................................................................................... 30

SERIES 92 SERVICE MANUAL

1ENGINE

1.1 CYLINDER BLOCK ................................................................................. 1-3

1.2 CYLINDER BLOCK END PLATES ........................................................... 1-38

1.3 CYLINDER HEAD ................................................................................... 1-47

1.4 VALVE AND INJECTOR OPERATING MECHANISM .............................. 1-74

1.5 EXHAUST VALVES ................................................................................. 1-102

1.6 VALVE ROCKER COVERS ...................................................................... 1-126

1.7 CRANKSHAFT ........................................................................................ 1-132

1.8 CRANKSHAFT O IL SEALS (FRONT AND REAR) .................................. 1-166

1.9 CRANKSHAFT CAP ................................................................................ 1-176

1.10 CRANKSHAFT MAIN BEARING SHELLS ............................................... 1-180

1.11 ENGINE FRONT COVER ........................................................................ 1-197

1.12 CRANKSHAFT OUTBOARD BEARING SUPPORT (TRUNNION) .......... 1-202

1.13 CRANKSHAFT REAR OUTBOARD BEARING SUPPORT ..................... 1-210

1.14 CRANKSHAFT VIBRATION DAMPER ..................................................... 1-223

1.15 CRANKSHAFT PULLEY .......................................................................... 1-238

1.16 FLYWHEEL ............................................................................................. 1-243

All information subject to change without notice.

6SE379 0303 Copyright © 2003 DETROIT DIESEL CORPORAT ION iii

SERIES 92 SERVICE MANUAL

1.17 CLUTCH PILOT BEARING ...................................................................... 1-251

1.18 ENGINE DRIVE SHAFT FLEXIBLE COUPLING ..................................... 1-256

1.19 FLYWHEEL HOUSING ............................................................................ 1-264

1.20 PISTON AND PISTON RINGS ................................................................. 1-284

1.21 CONNECTING ROD ................................................................................ 1-308

1.22 CONNECTING ROD BEARINGS ............................................................. 1-326

1.23 CYLINDER LINER .................................................................................. 1-333

1.24 ENGINE BALANCE AND BALANCE WEIGHTS ..................................... 1-347

1.25 GEAR TRAIN AND ENGINE TIMING ...................................................... 1-348

1.26 CAMSHAFTS AND BEARINGS ............................................................... 1-356

1.27 CAMSHAFT GEARS ............................................................................... 1-385

1.28 IDLER GEAR AND BEARING ASSEMBLY .............................................. 1-393

1.29 CRANKSHAFT TIMING GEAR ................................................................ 1-416

1.30 BLOWER DRIVE G E AR AND SUPPORT ASSEMBLY ............................ 1-427

1.31 ACCESSORY DRIVE ............................................................................... 1-445

1.32 BALANCE W EIGHT COVER ................................................................... 1-468

1.A ADDITIONAL INFORMATION .................................................................. 1-473

2 FUEL SYSTEM

2.1 FUEL SYSTEM ....................................................................................... 2-3

2.2 MECHANICAL UNIT INJECTOR ............................................................. 2-7

2.3 ELECTRONIC UNIT INJECTOR .............................................................. 2-55

2.4 FUEL INJECTOR TUBE ........................................................................... 2-66

2.5 ELECTRONIC ENGINE CONTROLS ...................................................... 2-77

2.6 DDEC II .................................................................................................... 2-83

2.7 DDEC III .................................................................................................. 2-89

2.8 DDEC IV .................................................................................................. 2-95

2.9 ELECTRONIC FOOT PEDAL ASSEMBLY ............................................... 2-102

2.10 TURBO BOO ST SENSOR ...................................................................... 2-103

2.11 OIL PR ESSURE SENSOR ..................................................................... 2-106

2.12 OIL TEM PERATURE SENSOR ............................................................... 2-109

2.13 PULSE WHEEL DDEC III AND II (6V AND 8V EN GINES) ...................... 2-112

2.14 SYNCHRONOUS REFERENCE SENSOR (6V AND 8V) ........................ 2-119

2.15 TIMING REFERENCE SENSOR ............................................................. 2-123

2.16 COOLANT LEVEL SENSOR ................................................................... 2-135

2.17 COOLANT TEMPERATURE SENSOR .................................................... 2-141

2.18 COOLANT PRESSURE SENSOR (12V AND 16V) ................................. 2-143

2.19 FUEL PRESSURE SENSOR ................................................................... 2-145

2.20 FUEL TEMPERATURE SENSOR ............................................................ 2-148

2.21 FUEL PUMP ............................................................................................ 2-151

2.22 FUEL STRAINER AND FUEL FILTER ..................................................... 2-176

2.23 FUEL COOLER ....................................................................................... 2-184

2.24 LIMITING SPEED MECHANICAL GOVERNOR ...................................... 2-187

2.25 LIMITING SPEED MECHANICAL GOVERNOR (VARIABLE

LOW-SPEED) ........................................................................................... 2-252

2.26 LIMITING SPEED MECHANICAL GOVERNOR (VARIABLE HIGH

SPEED) .................................................................................................... 2-266

iv 6

SE379 0303 Copyright © 2003 DETROIT DI ES EL CORPORATION

All information subject to change without notice.

SERIES 92 SERVICE MANUAL

2.27 VARIABLE SPEED MECHANICAL GOVERNOR .................................... 2-275

2.28 SG HYDRAULIC GOVERNORS .............................................................. 2-328

2.29 PSG HYDR AULIC GOVERNOR .............................................................. 2-367

2.30 HYDRAULIC GOVERNOR DRIVE ........................................................... 2-376

2.31 HYDRAULIC GOVERNOR SYNCHRONIZING MOTOR .......................... 2-413

2.32 ELECTRONIC GOVERNOR .................................................................... 2-416

2.33 FUEL INJEC TOR CONTROL TUBE (NON-DDEC ENGINES) ................ 2-417

2.A ADDITIONAL INFORM ATION .................................................................. 2-431

3 LUBRICATING SYSTEM

3.1 LUBRICATION SYSTEM .......................................................................... 3-3

3.2 LUBRICATING O IL PUMP (6V AND 8V ENGINES) ................................ 3-11

3.3 LUBRICATING O IL PUMP (12V AND 16V EN GINES) ............................ 3-35

3.4 LUBRICATING OIL PRESSURE REGULATOR VALVE ........................... 3-49

3.5 LUBRICATING O IL PRESSURE RELIEF VALVE .................................... 3-58

3.6 LUBRICATING OIL F ILTERS ................................................................... 3-67

3.7 LUBRICATING OIL COO LER (PLATE TYPE) .......................................... 3-79

3.8 LUBRICATING OIL COOLER (TUBE TYPE) ........................................... 3-93

3.9 LUBRICATING O IL COOLER BYPASS VALVE ........................................ 3-112

3.10 OIL LEVEL DIPSTICK .............................................................................. 3-117

3.11 OIL PAN ................................................................................................... 3-120

3.12 VENTILATING SYSTEM .......................................................................... 3-126

3.A ADDITIONAL INFORM ATION .................................................................. 3-131

4 COOLING SYSTEM

4.1 COOLING SYSTEM ................................................................................ 4-3

4.2 WATER PUMP (6V AND 8V ENGINES) .................................................. 4-5

4.3 WATER PUMP (12V AND 16V ENGINES) .............................................. 4-23

4.4 WATER MANIFOLD ................................................................................ 4-35

4.5 THERMOSTAT ........................................................................................ 4-40

4.6 RADIATOR .............................................................................................. 4-50

4.7 COOLANT PRESSURE CON TROL CAP ................................................ 4-63

4.8 ENGINE COOLING FAN .......................................................................... 4-66

4.9 HEAT EXCHANGER ............................................................................... 4-94

4.10 RAW WATER PUMP ................................................................................ 4-102

4.11 COOLANT FILTER AND CONDITIONER ................................................ 4-116

4.A ADDITIONAL INFORM ATION .................................................................. 4-123

5 FUEL, LUBRICATING OIL, AND COOLANT

5.1 FUEL ........................................................................................................ 5-3

5.2 LUBRICATING OIL REQUIREMENTS ..................................................... 5-19

5.3 COOLANT ................................................................................................ 5-28

6 AIR INTAKE SYSTEM

6.1 AIR INTAKE SYSTEM ............................................................................. 6-3

6.2 AIR CLEANER ........................................................................................ 6-5

6.3 AIR SEPARATOR FILTER ELEMENT ...................................................... 6-13

6.4 AIR SHUTDOWN HOUSING ................................................................... 6-15

6.5 BLOWER .................................................................................................. 6-27

All information subject to change without notice.

379 0303 Copyright © 2003 DETROIT DIES EL CORPORATION

6SE

v

SERIES 92 SERVICE MANUAL

6.6 TURBOCHARGER (AIRESEARCH) ........................................................ 6-89

6.7 TURBOCHARGER INTERCOOLER ........................................................ 6-120

6.8 TURBOCHARGER AFTERCO O L ER ....................................................... 6-128

6.A ADDITIONAL INFORMATION .................................................................. 6-139

7 EXHAUST SYSTEM

7.1 EXHAUST SYSTEM ................................................................................ 7-3

7.2 EXHAUST MANIFOLD ............................................................................ 7-5

7.3 EXHAUST MANIFOLD (WATER-COOLED) ............................................. 7-11

8 ELECTRICAL EQUIPMENT

8.1 BATTERY-CHARGING ALTERNATOR .................................................... 8-3

8.2 STARTING MOTOR ................................................................................. 8-12

8.3 TACHOMETER DRIVE ............................................................................. 8-15

8.4 INSTRUMENTS ...................................................................................... 8-20

8.5 ENGINE P ROTECTIVE SYSTEMS ......................................................... 8-24

8.6 ALARM SYSTEM .................................................................................... 8-45

8.7 OVERSPEED GOVERNOR ..................................................................... 8-52

8.A ADDITIONAL INFORMATION .................................................................. 8-59

9POWERTAKE-OFF

9.1 POWER TAKE-OFF TORQMATIC CONVERTER .................................... 9-3

10 SPECIAL EQUIPMENT

10.1 AIR COMPRESSOR ............................................................................... 10-3

10.2 ENGINE BLOCK HEATER ....................................................................... 10-9

10.3 TRANSMISSIONS .................................................................................. 10-10

11 OPERATION AND VERIFICATION

11.1 PREPARATION FOR A FIRST TIME START ........................................... 11-3

11.2 STARTING ............................................................................................... 11-8

11.3 RUNNING ................................................................................................. 11-11

11.4 STOPPING .............................................................................................. 11-16

11.5 OPERATING CONDITIONS ..................................................................... 11-18

11.6 ENGINE RUN-IN PROCEDURES ............................................................ 11-52

12 ENGINE TUNE-UP

12.1 ENGINE TUNE-UP ................................................................................. 12-3

12.2 EXHAUST VALVE CLEARANCE ADJUSTMENT .................................... 12-28

12.3 FUEL INJECTOR TIMING ........................................................................ 12-32

12.4 LIMITING SPEED MECHANICAL GOVERNOR INJECTOR RACK

CONTROL ADJUSTMENT (6V AND 8V ENGINES) ............................... 12-35

12.5 LIMITING SPEED MECHANICAL GOVERNOR AND INJECTOR RACK

CONTROL ADJUSTMENT (12V AND 16V ENGINES) ............................ 12-86

12.6 STATIC DOUBLE WEIGHT LIMITING SPEED GOVERNOR GAP

CHECKING AND SETTING PROCEDURE ............................................. 12-118

12.7 LIMITING SPEED MECHANICAL GOVERNOR ADJUSTMENT

(VAR IABLE LOW-SPEED) ....................................................................... 12-129

12.8 LIMITING SPEED MECHANICAL GOVERNOR FAST IDLE CYLINDER 12-139

12.9 GOVERNOR SETTINGS FOR "TT" EN GINES ........................................ 12-143

vi 6

SE379 0303 Copyright © 2003 DETROIT DI ES EL CORPORATION

All information subject to change without notice.

SERIES 92 SERVICE MANUAL

12.10 VARIABLE SPEED MECHANICAL GOVERNOR INJECTOR RACK

CONTROL ADJUSTMENT (6V AND 8V ENGINES) ............................... 12-173

12.11 VARIABLE SPEED MECHANICAL GOVERNOR AND INJECTOR RACK

CONTROL ADJUSTMENT (12V AND 1 6V ENGINES) ............................ 12-186

12.12 SG VARIABLE SPEED HYDRAULIC GOVERNOR INJECTOR RACK

CONTROL ADJUSTMENT (6V AND 8V ENGINES) ............................... 12-204

12.13 SG VARIABLE SPEED HYDRAULIC GOVERNOR INJECTOR RACK

CONTROL ADJUSTMENT (12V AND 16V) ............................................. 12-223

12.14 GOVERNORS WITH SYNCHRONIZING MOTOR ................................... 12-243

12.15 SUPPLEMENTARY GOVERNING DEVICE ADJUSTMENT .................... 12-244

12.16 POWER CONTROL DEVICE ................................................................... 12-248

12.17 THROTTLE DELAY MECHANISM ADJUSTMENT .................................. 12-251

12.18 FUEL MODULATOR ................................................................................ 12-264

13 PREVENTIVE MAINTENANCE

13.1 PREVENTIVE MAINTENANCE ITEMS DESCRIPTION .......................... 13-5

13.2 MAINTENANCE O F VEHICLE ENGINE .................................................. 13-6

13.3 MAINTENANCE OF STATIONARY AND INDUSTRIAL ENGINE ............ 13-12

13.4 MAINTENANCE OF PLEASURE CRAFT MARINE ENGINES ................ 13-16

13.5 LUBRICATING O IL ................................................................................... 13-19

13.6 OIL PRESSURE ...................................................................................... 13-26

13.7 LUBRICATING O IL FILTER ...................................................................... 13-27

13.8 FUEL ST RAINER AND FILTER ............................................................... 13-29

13.9 FUEL TANK ............................................................................................. 13-32

13.10 FUEL CONTAMINATION .......................................................................... 13-33

13.11 FUEL LINES AND FLEXIBLE HOSES ..................................................... 13-34

13.12 COOLING SYSTEM ................................................................................ 13-36

13.13 WATER PUMP ........................................................................................ 13-49

13.14 COOLANT FILTER .................................................................................. 13-50

13.15 COOLANT FILTER/INHIBITOR PRECHARGE E LEMEN T ...................... 13-51

13.16 RADIATOR .............................................................................................. 13-53

13.17 TURBOCHARGER AND EXHAUST CONNECTIONS ............................. 13-54

13.18 DRIVE BELTS ......................................................................................... 13-58

13.19 BATTERY ................................................................................................. 13-65

13.20 BATTERY CHARGING ALTERNATOR ..................................................... 13-68

13.21 ENGINE AND TRAN SMISSION MOUNTS .............................................. 13-70

13.22 ENGINE TUNE-UP ................................................................................. 13-71

13.23 BLOWER BYPASS VALVE ....................................................................... 13-72

13.24 TACHOMETER DR IVE ............................................................................. 13-73

13.25 AIR COMPRESSOR ............................................................................... 13-74

13.26 THROTTLE AND CLUTCH CONTROLS ................................................. 13-75

13.27 AIR BOX DRAIN TUBE ............................................................................ 13-76

13.28 AIR BOX CHECK VALVES ....................................................................... 13-77

13.29 SHUTTER O PERATION ......................................................................... 13-78

13.30 GOVERNOR, OVERSPEED GOVERNOR .............................................. 13-79

13.31 THROTTLE DELAY FUEL MODULATOR ................................................ 13-80

13.32 FA N HUB .................................................................................................. 13-81

All information subject to change without notice.

6SE379 0303 Copyright © 2003 DETROIT DIESEL CORPORAT ION vii

SERIES 92 SERVICE MANUAL

13.33 FAN (THERMO -M OUNTED) ................................................................... 13-83

13.34 THERMOSTATS AND SEALS .................................................................. 13-84

13.35 BLOWER SCREEN ................................................................................. 13-85

13.36 FUEL INJECTORS AND VALVE CLEARANCE ....................................... 13-87

13.37 VIBRATION DAMPER .............................................................................. 13-88

13.38 STARTING MOTOR ................................................................................. 13-89

13.39 EXHAUST SYSTEM ................................................................................ 13-91

13.40 CRANKCASE BR EATHER (EXTERNALLY MOUNTED) ......................... 13-92

13.41 CRANKCASE BREATHER (INTERNALLY MOUNTED) .......................... 13-93

13.42 ENGINE (STEAM C LEAN) ....................................................................... 13-94

13.43 POWER TAKE-OFF ................................................................................ 13-95

13.44 TORQMATIC CONVERTER ..................................................................... 13-97

13.45 REDUCTION GEAR ................................................................................. 13-99

13.46 TRANSIT COACH CONVERTER MUFFLER ........................................... 13-101

13.47 AIR CLEANER ........................................................................................ 13-103

13.48 AIR SYSTEM .......................................................................................... 13-106

13.49 AIR SEPARATOR FILTER ELEMENT ...................................................... 13-107

13.50 AIR SHUTDOWN VALVE ......................................................................... 13-111

13.51 COOLING SYSTEM (MARINE) ............................................................... 13-112

13.52 HEAT EXCHANGER CHANGEOUT INTERVAL ...................................... 13-113

13.53 HEAT EXCHANGER ELECTRODES AND CORE (RAW WATER

SYSTEM ZINCS) ..................................................................................... 13-116

13.54 RAW WATER PUMP ................................................................................ 13-118

13.55 FUEL AND BOOST COOLERS ............................................................... 13-121

13.56 TORQMATIC MAR INE GEAR (6V AND 8V) ............................................ 13-122

13.57 MARINE GEAR (TWIN DISC 16V) .......................................................... 13-124

13.58 CLUTCH ACTUATOR (DDEC MARINE) .................................................. 13-126

14 STORAGE

14.1 PREPARING ENGINE FOR STORAGE ................................................... 14-3

14.2 TEMPORARY ENGINE STORAGE (30 DAYS OR LESS) ....................... 14-4

14.3 RESTORING A TEMPORARILY STORED ENGINE (30 DAYS OR

LESS) ....................................................................................................... 14-6

14.4 EXTENDED E NG INE STORAGE (MOR E THAN 30 DAYS) .................... 14-7

14.5 RESTORING AN EXTENDED STORAGE ENGINE (MORE THAN 30

DAYS) ....................................................................................................... 14-13

14.6 STORAGE OF B ATTERY ......................................................................... 14-16

INDEX ................................................................................................. Index-1

vii

i

6SE379 0303 Copyright © 2003 DETROIT DIESEL CORPORAT ION

All information subject to change without notice.

ENGINE EXHAUST

Consider the following before servicing e ngines:

Diesel engine exhaust and some of its constituents are

known to the State of California to cause cancer, birth

defects, and other reproductive harm.

Always start and operate an engine in a well ventilated

area.

If operating an engine in an enclosed area, vent the

exhaust to the outside.

Do not modify or tamper with the exhaust system or

emission control system.

Please note this caution and remember:

SERIES 92 SERVICE MANUAL

Always start and operate the engine in a well ventilated area.

If in an enclosed area, vent the exhaust to the outside.

Do not modify or tamper with the exhaust system.For accurate dynamometer readings

during a engine run-in, the cha ssis dynamometer room must be properly ventilated.

Diesel engine exhaust and some of its constituents are

known to the State of California to cause cancer, birth

defects, and other reproductive harm.

Always start and operate an engine in a well ventilated

area.

If operating an engine in an enclosed area, vent the

exhaust to the outside.

Do not modify or tamper with the exhaust system or

emission control system.

All information subject to change without notice.

6SE379 0303 Copyright © 2003 DETROIT DIESEL CORPORAT ION ix

SERIES 92 SERVICE MANUAL

x 6S

E379 0303 Copyright © 2003 DETROIT DIES EL CORPORATION

All information subject to change without notice.

GENERAL INFORMATION

Section Page

SCOPE AND USE OF THIS MANUAL ....................................................... 3

SAFETY PRECAUTIONS ........................................................................... 3

FLUOROELASTOMER (VITON) CAUTION ................................................ 10

SERVICE PARTS AVAILABILITY ................................................................ 11

CLEARANCE AND TORQUE SPECIFICATIONS ....................................... 11

THE TWO CYCLE PRINCIPLE FOR DIESEL ENGINES ........................... 12

GENERAL DESCRIPTION ........................................................................ 13

DDEC DIAGNOSTIC READER CAUTION .................................................. 15

DDEC I ........................................................................................................ 16

DDEC II ....................................................................................................... 17

DDEC III ..................................................................................................... 17

GENERAL S PECIFICATIONS ................................................................... 18

ENGINE MODEL, SER

REPAIR AND R EPLACE ............................................................................. 24

DISASSEMBLY .......................................................................................... 25

CLEANING .................................................................................................. 25

INSPECTION ............................................................................................. 26

ASSEMBLY ................................................................................................. 27

FABRICATI

GASKETS ............................................................................................ 2 7

ENGLISH TO METRIC CO NVERSION ...................................................... 28

NG, ALTERING, REMOVING AND DISPOSING OF

IAL NUMBER AND OPTION LABEL .....................

21

SERIES 92 SERVICE MANUAL

DECIMAL AND METRIC EQUIVALENTS ................................................... 30

SPECIFICATIONS ..................................................................................... 30

2 6S

E379 0303 Copyright © 2003 DETROIT DIES EL CORPORATION

All information subject to change without notice.

SERIES 92 SERVICE MANUAL

SCOPE AND USE OF THIS MANUAL

This manual covers the ba s ic V-92 diesel engines built by the Detroit Diesel Corporation.

Complete instructions on operation, adjustment (tune-up), preventive maintenance, and

lubrication and repair (including complete overhaul) are covered. Basic maintenance and overhaul

procedures are common to all V-92 engines and apply to all engine models.

The manual is divided into numbered sections. The first section covers the engine (less major

assemblies). The following sections cove r a complete system such as the fuel system, lubrication

system or air system. Each section is divided into subsections containing complete maintenance

and operating instructions for a specific subassembly on the engine. Each section begins with a

table of contents. Pages and illustrations are numbered consecutively within each se ction.

Information can be located using the table of contents at the front of the manual or the table of

contents at the beginning of each section. Information on specific subassemblies within the major

section is listed immediately following the section title.

SAFETY PRECAUTIONS

The following safety measures are essential when working on the Series 92 engine.

Please note this caution and remember:

Always start and operate the engine in a well ventilated area.

If in an enclosed area, vent the e xhaust outside.

Do not modify or tamper with the exhaust system.

Diesel engine exhaust and some of its constituents are

known to the State of California to cause cancer, birth

defects, and other reproductive harm.

Always start and operate an engine in a well ventilated

area.

If operating an engine in an enclosed area, vent the

exhaust to the outside.

Do not modify or tamper with the exhaust system or

emission control system.

Stands

Safety stands are required in conjunction with hydraulic jacks or hoists. Do not rely on either

the jack or the hoist t o carry the load. When lifting an engine, ensure lifting device is fastened

securely. Ensure that the item to be lifted does not exceed the c apacity of the lifting device.

Glasses

Select appropriate safety glasses for the job. It is especially important to wear safety glasses w hen

using tools such as hamm e rs, chisels, pullers, or punches.

All information subject to change without notice.

379 0303 Copyright © 2003 DETROIT DIES EL CORPORATION

6SE

3

SERIES 92 SERVICE MANUAL

Welding

Wear welding goggles and gloves when welding or using an acetylene torch. Ensure that a metal

shield separates the acetylene and oxygen that must be chained to a cart.

4 6S

E379 0303 Copyright © 2003 DETROIT DIES EL CORPORATION

All information subject to change without notice.

SERIES 92 SERVICE MANUAL

To avoid injury from arc welding, gas welding, or cutting,

wear required safety equipment such as an arc welder ’s

face plate or gas welder’s goggles, welding gloves,

protective apron, long sleeve shirt, head protection,

and safety shoes. Always perform welding or cutting

operations in a well-ventilated area. The gas in

oxygen/acetylene cylinders used in gas welding and

cutting is under high pressure. If a cylinder should fall

due to careless handling, the gage end could strike an

obstruction and fracture, resulting in a gas leak leading to

fire or an explosion. If a cylinder should fall resulting in

the gage end breaking off, the sudden release of cylinder

pressure will turn the cylinder into a dangerous projectile.

Observe the following precautions when using

oxygen/acetylene gas cylinders:

Always wear required safety shoes.

Do not handle tanks in a careless manner or with greasy

gloves or slippery hands.

Use a chain, bracket, or other restraining device at all

times to prevent gas cylinders from falling.

Do not place gas cylinders o n their sides, but stand

them upright when in use.

Do not drop, drag, roll, or strike a cylinder forcefully.

Always close valves completely when finished welding

or cutting.

To avoid injury from fire, keep all potential ignition sources

away from diesel fuel, open flames, sparks, and electrical

resistanceheating elements. Do not smokewhen refueling.

Work Place

Organize your work area, and keep it clean. A fall could result i n a serious injury. E liminate

the possibility of a fall by:

Wiping up oil spills.

Keeping tools and parts off the floor.

After servicing or a djusting the engine:

Install all safety devices, guards, or shields.

Ensure that all tools a nd service equipment are removed from the engine.

All information subject to change without notice.

379 0303 Copyright © 2003 DETROIT DIES EL CORPORATION

6SE

5

SERIES 92 SERVICE MANUAL

Clothing

Wear safe work clothes that fit and are in good condition. Work shoes are sturdy and rough-soled.

Bare feet, sandals, or sneakers are not acceptable foot wear when adjusting and/or servicing an

engine. Do not we ar the following when working on an engine:

To avoid injury when working near or on an operating

engine equipped with electric fans, remove loose items of

clothing, jewelry; tie back or contain long hair that could

be caught in any moving part causing injury. Electric fans

may start without warning.

Rings

Wrist watches

Loose fitting clothing

Any of these items could catch on moving parts causing serious injury.

Power Tools

Do not use defective portable power tools. Check for frayed cords prior to using the tool. Ensure

that all electric tools are grounded. Defective electrical equipment and improper use of ele ctrica l

equipment can cause severe injury.

To avoid injury from electrical shock, follow OEM furnished

operating instructions prior to usage.

Air

Recommendations regarding the use of c ompressed air are indicated throughout the manual

with the following:

6 6S

E379 0303 Copyright © 2003 DETROIT DIES EL CORPORATION

All information subject to change without notice.

SERIES 92 SERVICE MANUAL

To avoid injury from flying debris when using compressed

air, wear adequate eye protection (face shield or safety

goggles) and do not exceed 40 psi (276 kPa) air pressure.

Too much air can rupture or in some other way damage a component and create a hazardous

situation that can lead to personal injury. Use only approved air blow guns that do not exceed

276 kPa (40 lb/in.

2

). Wea r safety glasses or goggles. Use proper shielding to protect everyone in

the work area.

Fluids and Pressure

Be extremely careful when dealing with fluids under pressure.

To avoid injury from penetrating fluids, do not put your

hands in front of fluid under pressure. Fluids under

pressure can penetrate skin and clothing.

Fluids under pressure can penetrate the skin. These fluids can infect a minor cut or opening in

the skin. If injured, see a doctor immediately.

Fuel

Keep the hose a nd nozzle or the funnel and container in contact with the metal of the f uel tank

when refueling to avoid the possibility of an electric spar k igniting the fuel.

The following cautions should be followed when filling a fuel tank:

All information subject to change without notice.

379 0303 Copyright © 2003 DETROIT DIES EL CORPORATION

6SE

7

SERIES 92 SERVICE MANUAL

To avoid injury from fire, do not overfill the fuel tank.

To avoid injury from fire, keep all potential ignition sources

away from diesel fuel, o pen flames, sparks, and electrical

resistanceheatingelements. Do not smokewhen refueling.

To avoid injury from fire, keep all potential ignition sources

away from diesel fuel, o pen flames, sparks, and electrical

resistanceheatingelements. Do not smokewhen refueling.

Batteries

Electrical storage batteries emit highly flammable hydrogen gas when charging and continue to

do so for some time after receiving a steady charge.

To avoid injury from battery explosion or contact w ith

battery acid, work in a well-ventilated area, wear protective

clothing, and avoid sparks or flames near the battery.

Always establish correct polarity before c onnecting cables

to the battery or battery circuit. If you c ome in contact w ith

battery acid:

Flush your skin with water.

Apply baking soda or lime to help neutralize the acid.

Flush your eyes with water.

Get medical attention immediately.

Always disconnect the battery cable before working on the electrical system.

8 6S

E379 0303 Copyright © 2003 DETROIT DIES EL CORPORATION

All information subject to change without notice.

SERIES 92 SERVICE MANUAL

To avoid injury from accidental engine startup while

servicing the engine, disconnect/disable the starting

system.

Disconnect the batteries or disable an air starter w hen working on the engine to prevent accidental

starting.

Fire

Keep a charged fire extinguisher within reach. Ensure the correct type of extinguisher is used

for the situation.

Cleaning Agent

Avoid the use of carbon tetrachloride as a cleaning agent because of the harmful vapors that it

releases. Ensure work area is adequately ventilated. Use protective gloves, goggles or face

shield, and apron.

Working on a Running Engine

When working on a running engine, accidental contact with the hot exhaust manifold ca n cause

severe burns. Remain alert to the location of the rotating fan, pulleys and belts. Avoid making

contact across thetwo terminals of a battery which can resultin severe arcing, or battery explosion.

To avoid injury from hot surfaces, a llow engine to cool

before removing any component. Wear protective gloves.

To avoidinjury,use carewhen workingaround movingbelts

and rotating parts on the engine.

Start Attempts

Observe the following caution when working with mineral spirits or mineral spirit-based solvents.

All information subject to change without notice.

379 0303 Copyright © 2003 DETROIT DIES EL CORPORATION

6SE

9

SERIES 92 SERVICE MANUAL

To avoid injury from flames, explosion, and toxicants when

using ether, the following precautions must be taken:

Do not smoke when servicing ether system.

Work in well-ventilated area.

Do not work near open flames, pilot flames (gas or oil

heaters), o r sparks.

Do not weld or carry an open flame near the ether

system if you smell ether or otherwise suspect a leak.

Always wear goggles when testing.

If fluid enters the eyes or if fumes irritate the eyes, wash

eyes with large quantities of clean water for 15 minutes.

A physician, preferably an eye specialist, should be

contacted.

Contents of cylinder are under pressure. Store

cylinders in a cool dry area. Do not incinerate, pu ncture

or attempt to remove cores from cylinders.

Avoid excessive injection of ether into the engine during start attempts. Follow the instructions on

the container or by the manufacturer of the star ting aid.

FLUOROELASTOMER (VITON) CAUTION

Observe the following caution when handling fluoroelastomer.

10 6

SE379 0303 Copyright © 2003 DETROIT DI ES EL CORPORATION

All information subject to change without notice.

SERIES 92 SERVICE MANUAL

To avoid injury from chemical burns, wear a face

shield and neoprene or PVC gloves when handling

fluoroelastomer O-rings or seals that have been degraded

by excessive heat. Discard gloves after handling degraded

fluoroelastomer parts.

Under normal design conditions, fluoroelastomer (Viton®) parts, such as O-rings and seals,

are perfec tly safe to handle. They may become hazardous, however, if t hese components are

subjected to temperatures above 316

At temperatures above 316

C(600F), f luoroelastomer will decompose (indicated by charring

C (600 F), such as during a cylinder failure or engine fire.

or the appearance of a black, sticky mass) and produce hydrofluoric acid. This is extremely

corrosive and, if it contacts bare skin, it may cause severe burns, sometimes with symptoms

delayed for several hours.

SERVICE PARTS AVAILABILITY

Genuine Detroit Diesel service parts are available from authorized Detroit Diesel distributors a nd

service dealers throughout the world. A complete list of all distributors and dealers is available

in the World Wide Parts and Serv ice Directory, 6SE280. This publication can be ordered from

any authorized distributor.

CLEARANCE AND TORQUE SPECIFICATIONS

Refer to section ADDITIONAL INF ORM ATION for a listing of new part clearances and used

part wear limits. The appropriate use of information from the limits column requires service

personnel to exercise good judgment. The wear limits recorded, i n general, apply only to those

parts most fre quently replaced during engine overhaul. For additional information, refer to repair

or replace in this chapter.

All information subject to change without notice.

379 0303 Copyright © 2003 DETROIT DIES EL CORPORATION

6SE

11

SERIES 92 SERVICE MANUAL

THE TWO CYCLE PRINCIPLE FOR DIESEL ENGINES

In the two-cycle engine, intake and exhaust take place dur ing part of the compression and power

strokes respe ctively. See Figure 1.

Figure 1 The Two-Stroke Cylinder Engine

Scavenging

A blower forces air into the cylinders to expel the exhaust gases and to supply the cylinders with

fresh air for combustion. The cylinder wall contains a row of ports which are above the piston

when it is at the bottom of its stroke. These ports a dmit air from the blower into the cylinder as

soon as the rim of the piston uncovers the ports.

The unidirectional air flow toward the exhaust valves produces a scavenging e ffect, leaving the

cylinders full of clean air when the piston again covers the inlet ports.

12 6

SE379 0303 Copyright © 2003 DETROIT DI ES EL CORPORATION

All information subject to change without notice.

SERIES 92 SERVICE MANUAL

Compression

As the piston c ontinues on the upward stroke, the exhaust valves close, and the charge of fresh air

is compressed.

Power

Shortly before the piston reaches its highest position, the unit fuel injector sprays the required

amount of fuel into the combustion chamber. The intense heat generated during the high air

compression immediately ignites the fine fuel spray. The combustion continues until the injected

fuel has been burned.

Exhaust

The resulting pressure forces the piston downward on its power stroke. The exhaust valves are

again opened when the piston is about half way down, allowing the burned gases to escape into

the exhaust manifold. Shortly thereafter, the downward moving piston uncovers the inlet ports

and the cylinder is once again swept with clean scavenging air. This entire combustion cycle is

completed in each cylinder for each crankshaft revolution, in other words, in two strokes. Hence,

it is a " two-stroke cycle".

GENERAL DESCRIPTION

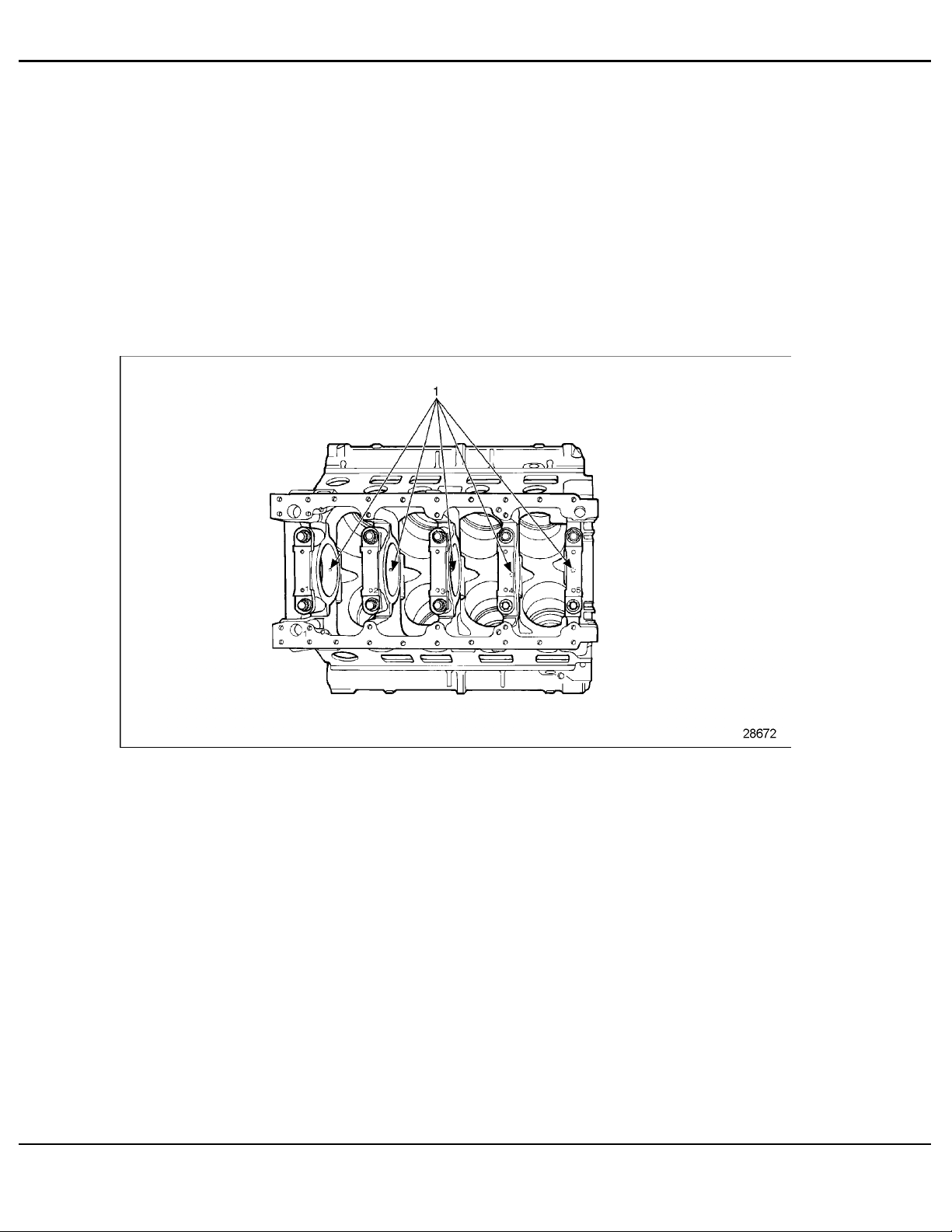

The two-cycle diesel engines c overed in this manual are produced in 6, 8, 12, and 16 cylinder

models. Each model shares the same bore and stroke and many of the ma jor working parts such

as injectors, pistons, connecting rods, cylinder liners and other interchangeable parts.

All information subject to change without notice.

379 0303 Copyright © 2003 DETROIT DIES EL CORPORATION

6SE

13

SERIES 92 SERVICE MANUAL

The engines are built with right-hand or left-hand crankshaft rotation. See Figure 2. The oil cooler

can be mounted only on the right side of the engine. On 6V and 8V engines the starter can be

mounted on either the right or left side of the engine, and the 12V and 16V engines have a starter

on both the right and left side of the engine.

Figure 2 Views From R ear of Engine

See Figure 2 for the meaning of each digit in the model numbering system. The letter L or R

indicates left or right-hand engine rotation as viewed from the front of the engine. The letter A, B,

C, or D designates the location of the starter and oil cooler as viewed from the rear of the engine.

Each engine is equipped with oil coolers, lubricating oil filters, fuel oil stra iner, fuel oil filter, air

cleaners, governor, heat exchanger and raw w ater pump or fan and radiator, and starting motor.

14 6

SE379 0303 Copyright © 2003 DETROIT DI ES EL CORPORATION

All information subject to change without notice.

SERIES 92 SERVICE MANUAL

Full pressure lubrication is supplied to all main, connecting rod and cam shaft bearings, and to

other moving parts within the engine. A gear-type pump draws oil from the oil pan through an

intake screen, through the oil filter, and then to the oil cooler. From the oil cooler, the oil flows

through passages that connect with the oil galleries in the cylinder block and cylinder heads for

distribution to the bearings, rocker arm mechanism and other functional parts.

Coolant is circulated through the engine by a centrifugal-type water pump. Heat is r emoved

from the coolant, which circulates in a closed system, by the radiator or heat exchanger. Engine

temperature is controlled by t he rmostats that regulate the flow of the coolant within the cooling

system.

Fuel is drawn from the supply tank through the fuel filter by a gear-type fuel pump. It is then

forced through a filter and into the fuel inlet m anifolds in the cylinder heads and to the injectors.

Excess fuel is returned to the supply tank through the fuel outlet manifolds and connecting lines.

Since the fuel is constantly circulating through the injectors, it serves to cool the injectors and also

carries off any air in the fuel system.

A blower that pumps air into the engine cylinders via the air box and cylinder liner ports supplies

air for scavenging and combustion. All air entering the blower passes through an air cleaner.

An electric starting system starts the engine. A storage battery e n ergizes the electric starting

motor. A battery-charging generator, with a suitable voltage regulator or an alternator keeps

the battery charged.

Engine speed is regulated by a mechanical or hydraulic type engine governor, depe nding upon

the engine application.

DDEC DIAGNOSTIC READER CAUTION

To avoid injury from loss of vehicle/vessel control, the

operator of a DDEC equipped engine must not attempt

to use or read the Diagnostic Data Reader when the

vehicle/vessel is moving.

Diagnosis of the engine or electronics system of a DDEC-equipped vehicle, vessel, or wheeled

machine, must be done by someone other than the driver or operator. The operator must maintain

control o f the moving vehicle, vessel, or wheeled machine while the assistant performs the

diagnosis.

All information subject to change without notice.

379 0303 Copyright © 2003 DETROIT DIES EL CORPORATION

6SE

15

SERIES 92 SERVICE MANUAL

DDEC I

DDEC I controls the timing and amount of fuel injected into each cylinder. The system also

monitors several engine functions using various sensors that send electrical signals to the main

Electronic Control Module (ECM). See Figure 3. The ECM uses this information to send a

command pulse to the Electronic Distributor Unit (EDU). The EDU functions as the high current

switching unit for actuation of the Electronic Unit Injector (EUI) solenoids. The ECM also has the

ability to limit or shut down the engine completely (de pending on option selection) in the case of

damaging engine conditions, such as low oil pressure, low coolant level, or high oil temperature.

Figure 3 DECC I

16 6

SE379 0303 Copyright © 2003 DETROIT DI ES EL CORPORATION

All information subject to change without notice.

SERIES 92 SERVICE MANUAL

DDEC II

DDEC II also controls the timing and amount of fuel injected into each cylinder. The system also

monitors several engine sensors that send electrical signals to the main ECM. See Figure 4.

Unlike DDEC I, the DDEC II ECM uses this information to actuate the EUI solenoids. DDEC I I

incorporates all control electronics into one engine mounted ECM instead of the ECM and EDU

that are required in DDEC I. The ECM also has the ability to limit or shut down the engine

completely (depending on option selection) in the case of damaging engine conditions, such as

low oil pressure, low coolant level, or high oil temperature.

Figure 4 DECC II

DDEC III

The DDEC III ECM receives electronic inputs from sensors on the engine and v e h icle and uses

the information to contr ol engine operation. It computes fuel timing and fuel quantity based upon

predeterm

All information subject to change without notice.

379 0303 Copyright © 2003 DETROIT DIES EL CORPORATION

6SE

ined calibration tables in its memory.

17

SERIES 92 SERVICE MANUAL

Fuel is delivered to the cylinders by the EUI solenoids, which are cam-driven to provide the

mechanical input for pressurization of the fuel. The ECM controls solenoid operated v alve s in the

EUIs to provide precise fuel delivery. See Figure 5.

Figure 5 DECC III

Portable equipment facilitates access to DDEC III's diagnostic capabilities. The Diagnostic Data

Reader (DDR) requests and receives engine data and diagnostic codes. This equipment provide s

many unique cap

abilities including cylinder cutout, parameter vs. engine speed (or time), printer

output, and data snapshot. The DDR also provides limited programming capability.

GENERAL SPECIFICATIONS

The general sp

cylinder designation and firing order.

18 6

ecifications for the Series 92 Engine are listed in Table 1. See Figure 6 for the

SE379 0303 Copyright © 2003 DETROIT DI ES EL CORPORATION

All information subject to change without notice.

SERIES 92 SERVICE MANUAL

Engine 2Cycle 2Cycle 2Cycle 2Cycle

Number of Cylinders 6 8 12 16

Bore (inches) 4.84 4.84 4.84 4.84

Bore (mm) 123 123 123 123

Stroke (inches) 5 5 5 5

Stroke (mm) 127 127 127 127

Comp. Ratio

(Nominal)

(Turbo. Engines)

Comp. Ratio

(Nominal)

(N/A Engines)

Comp. Ratio

(Nominal)

(High Output-DDEC)

Comp. Ratio

(Nominal)

(Special-DDEC)

Total Displacement

- (cubic inches)

Total Displacement

- (liters)

Number of

Main Bearings

17 to 1 17 to 1 17 to 1 17 to 1

19 to 1 19 to 1 19 to 1 19 to 1

15 to 1 15 to 1 15 to 1 15 to 1

18 to 1 18 to 1 - -

552 736 1104 1472

9.05 12.07 18.10 24.14

4 5 7 10

Ta ble 1 General Specifications for the Series 92 Engine

All information subject to change without notice.

379 0303 Copyright © 2003 DETROIT DIES EL CORPORATION

6SE

19

SERIES 92 SERVICE MANUAL

Figure 6 V-92 Engine Cylinder Designation and Firing Order

20 6

SE379 0303 Copyright © 2003 DETROIT DI ES EL CORPORATION

All information subject to change without notice.

SERIES 92 SERVICE MANUAL

ENGINE MODEL, SERIAL NUMBER AND OPTION LABEL

The engine ser ial number and model number are stamped on the c ylinder block in the following

locations (as view ed from the flywheel end): the right side, upper front corne r of current 6V and

8V cylinder blocks. See Figure 7.

Figure 7 Location of Engine Model Number and Serial Number

All information subject to change without notice.

379 0303 Copyright © 2003 DETROIT DIES EL CORPORATION

6SE

21

SERIES 92 SERVICE MANUAL

On former 6V and 8V bloc k s and current 12V a nd 16V blocks the e ngine serial number and

model number is stamped on the right side, upper rear corner. See Figure 8.

1. Serial Number 2. Model Number

Figure 8 Typical Engine Serial Number and Model Number as Stamped on

Cylinder Block

22 6

SE379 0303 Copyright © 2003 DETROIT DI ES EL CORPORATION

All information subject to change without notice.

SERIES 92 SERVICE MANUAL

Option Plate (Metal Labels)

An option plate, attached to one of the valve rocker covers, carries the engine serial number and

model number and lists any optional equipment u sed on the engine. See Figure 9.

1. Rocker Cover 3. Option Plate

2. Hold Down Bolt 4. Smoke Emission Plate

Figure 9 Location of Option Plates

On-highway vehicle engines also carry an exhaust emission certification la bel next to the option

plate. It is separate from the option plate and is mounted permanently in the option plate retainer.

The current label includes information relating to an engine family for the maximum fuel injector

size and maximum speed. Due to Federa l regulations, the exhaust emission plate should not

be removed from the rocker cover. Refer to section 12.1.3 for further information regarding

emission regulations.

With any order for parts, the engine model number and serial number must be given. If a type

number is shown on the option plate covering the equipment required, it should be included on

the parts order.

All parts used on a unit are standard for the engine model unless otherwise listed on the option

plate.

Power takeoff assemblies, torque converters, marine gears, etc., may also carry name plates. The

information on these name plates is useful when ordering replacement parts for these assemblies.

All information subject to change without notice.

379 0303 Copyright © 2003 DETROIT DIES EL CORPORATION

6SE

23

SERIES 92 SERVICE MANUAL

Option Plate (Paper Labels)

A new paper/laminate engine option label has replaced the metal option plate. In conjunction with

the new option label, the following pape r/laminate labels are also being used: bar code labels

for engine serial number and customer specification number, emissions label (when applicable)

and disclaimer label.

Distributors will provide their own label(s) in order to notify the customer of any distributor-made

changes to Detroit Diesel-manufactured engines. Distributor-typed label(s) will indicate the

distributor name, address and the group/type revisions that reflect their changes to engines as

originally manufactured by Detroit Diesel.

NOTICE:

Extreme heat from components such as turbocharger exhaust

piping can cause the labels to darken, discolor or deteriorate

over a period of time. Therefore, labels should be installed at

alternate rocker cover locations.

Labels must be placed on rocker covers. Labels are designed to fit in the same space provided

for the former stamped or current cast rocker cover option plate holder. Replacement option

labels can be placed directly over existing option labels. Ensure labels are applied to clean,

dry, oil-free surfaces to ensure adhesion and retention. Lam inate should completely cover the

label to provide a good seal.

The option plate holder on cast covers is held to the cover by rivets in blind holes. Therefor e,

the option plate holder can be remove d and the labels applied directly to the rocker covers. The

option plate holder on stamped rocker covers is retained by spot welding. This option plate holder

should not be removed, since it can leave open holes that will allow lube oil to leak.

REPAIR AND REPLACE

In many cases, a service technician is justified in replacing parts with new material rather than

attempting repair. However, there are times when a slight amount of reworking or reconditioning

may save a customer added expense. Crankshafts, cylinder liners and other parts are in this

category. For example, if a cylinder liner is only slightly worn and within usable limits, a honing

operation to remove the glaze may make it suitable for reuse, thereby saving the expense of a

new part. Exchange assemblies, such as injectors, fuel pumps, water pumps and blow ers, are

also desirable service items.

Various factors, such as the type of engine operation, hours in service and next overh aul

period, must be considered when determining whether new parts are installed or used parts are

reconditioned to provide trouble-free operation.

For convenience and logical order in disassembly and assembly, the various subassemblies and

other related par ts mounted on the cylinder block will be treated as separate items in the various

sections of this manual.

24 6

SE379 0303 Copyright © 2003 DETROIT DI ES EL CORPORATION

All information subject to change without notice.

SERIES 92 SERVICE MANUAL

DISASSEMBLY

Before any major disassembly, the engine must be drained of lubricating oil, water and fuel. On

engines cooled by a heat exchanger, the fresh water system and raw water system must both be

drained. Lubricating oil should also be drained from any transmission attached to the engine.

To avoid injury from accidental engine startup while

servicing the engine, disconnect/disable the starting

system.

To perform a major overhaul or other extensive repairs, the complete engine assembly, after

removal from the engine base and drive mec h anism, should be mounted on an engine overhaul

stand. The various subassemblies should be removed from the engine. When only a few items

need replacement, it is not always necessary to mount the engine on an overhaul stand.

Parts removed from an individual engine should be kept together so they will be available for

inspection and assembly. Those items having machined faces, which might be easily damaged by

steel or c oncrete, should be stored on suitable wooden racks, blocks, or parts dollies.

CLEANING

Before removing any of the subassemblies from the engine (but after removal of the electrical

equipment), the exterior of the engine should be thoroughly cleaned. After each subassembly is

removed and disassembled, the individual parts should be cleaned. Thorough cleaning of each

part is necessary before it can be satisfactorily inspected.

The cleaning procedure used for all ordinary cast iron p arts is outlined under Clean Cylinder

Block. Refer to section 1.1. Any special cleaning procedures will be mentioned in the text,

wherever required.

Steam Cleaning

A steam cleaner isa necessary item in a largeshop and is useful forremoving heavy accumulations

of grease and dirt from the exterior of the engine and its subassemblies.

Tank Cleaning

A tank o f sufficient size to accommodate the largest par t requiring cleaning (usually the cylinder

block) should be provided and provisions made for heating the cleaning solution to 82-90

(180-200

F).

C

All information subject to change without notice.

379 0303 Copyright © 2003 DETROIT DIES EL CORPORATION

6SE

25

SERIES 92 SERVICE MANUAL

NOTICE:

The Series 92 engine is equipped with various sensors and

other electronic components that may be damaged if subjected

to the high temperatures in a solvent tank. Do NOT immerse

any electrical components in a solvent tank. Care should be

taken to ensure that all electronic components are removed

from the various engine assemblies before they are immersed

in a solvent tank.

Fill the tank with a comm ercial heavy-duty alkaline cleaner heated to 82-90 C (180-200 F).

Lower large parts directly into the tank with a hoist. Place small parts in a wire mesh basket, and

lower them i nto the tank. Immerse the parts long enough to loosen all grease and dirt.

Rinsing Bath

Provide another tank of similar size containing hot water for rinsing the parts.

Drying

Parts may be dried with compressed air. The heat from the hot tanks will frequently completely

dry the parts without using compressed air.

Rust Preventive

If parts are not to be used immediately after cleaning, dip them in a suitable rust preventive

compound. The rust preventive compound should be removed before installing the parts in

the engine.

INSPECTION

Parts inspection is used to determine whether p a rts should be reused or replaced. Although the

engine overhaul specifications given throughout this manual will help determine which parts

should be replace d, considerable judgment must be exercised by the inspector.

The factors determining whether worn parts (in good condition otherwise) may be reused are the

clearance be tween the mating parts and the wear r ate on each of the parts. If the current wear

rate will ma intain clearances within the specified maximum limit until the next engine overhaul,

the used parts may be reinstalled. Wear rate is determined by dividing the wear amount by the

hours operated.

Many service replacement parts are available in various undersize, oversize, or standard sizes.

Service kits for reconditioning certain parts, and service se ts, which include all parts necessary to

complete a particular repair job, are also available.

A thorough discussion of proper measurement and inspection procedures lies outside the scope

of this manual. Nonetheless, every shop should be equipped with standard gages, such as dial

bore gages, dial indicators, and inside and outside micrometers.

26 6

SE379 0303 Copyright © 2003 DETROIT DI ES EL CORPORATION

All information subject to change without notice.

SERIES 92 SERVICE MANUAL

In addition to measuring the used parts after cleaning, the parts should also be inspected for

cracks, scoring, chipping, and other defe cts.

ASSEMBLY

After cleaning and inspection, the engine should be reassembled using new parts when necessary.

Using proper equipment and tools mak es the job progress faster a nd produces better results.

Likewise, a suitable working space with adequate lighting must be provided.

Keep the working space, equipment, tools, engine assemblies, and parts clean at all times. If

possible, the assembly area should be located away from the d isassembly and cleaning areas.

After removal and cleaning, store parts and subassemblies where they will be kept clean. If there

is any question about the cleanliness of such parts, they should be recleaned.

During assembly, consult the "Torque Specification Table" at the end of each section for proper

bolt, nut, and stud torques.

To ensure a clean e ngine at time of rebuild, any plug, fitting or fastener (including studs) tha t

intersects w ith a through hole a n d contacts oil, fuel or c oolant must have a sealer applied to

the threads.

Many universal sealers are commercially available. Detroit Diesel Corporation recomme nds

®

that Loctite

567 pipe sealer with Teflon®, or equivalent, be used in some instances. Certain

plugs, fittings and fa stener s available from the Parts Distribution C enter already have a sealer

applied to the threads. This precoating will not be adversely affected when pipe sealer with

Teflon is also applied.

NOTE:

Loctite 567 must not be confused with International Compound No. 2, which is used as a

lubricant before tightening certain bolts. Use International Compound No. 2 only when

the manual specifically instructs.

FABRICATING, ALTERING, REMOVING AND DISPOSING OF GASKETS

Many gasket materials contain bonded asbestos. Asbestos, in itself, presents no health haz ard

when handled properly. A health hazard may exist, however, if the asbestos becomes airborne.

This may occur if gaskets are fabricated or altered using the following methods: drilling, grinding,

saw cutting, or using practically all types o f power operated machines and hand tools.

Gasket manufacture rs and industrial hygienists prescribe specific methods for handling gasket

material. The following guidelines are based on their recommendations. Detroit Diesel

recommends that these guidelines be f ollowedwhenfabricatingoralteringanygasket:

1. Unless it is known otherwise, treat all gasket material as though it contains asbestos.

2. When cutting strips or blocks from sheets (blanking), hand cut with scissors, knife, or

paper cutter. Avoid creating dust.

3. Form outside dimensions with a punch die, or hand cut with scissors, knife or compass.

4. For internal hubs, use a punc h die, hand cut with scissors, knife or compass, or punch by

hand w ith a ball-peen hammer or ball bearing.

All information subject to change without notice.

379 0303 Copyright © 2003 DETROIT DIES EL CORPORATION

6SE

27

SERIES 92 SERVICE MANUAL

5. When stripping gaskets from parts, do not grind or f ile off the material or abrade it off

with a wire brush or wheel. Use a putty knife to remove the gasket after it has been

wetted with water or oil.

6. After fabricating or altering a gasket, clean the area to remove any particles that may have

been generated. This should be done by wiping the area with a rag wetted with water or a

water-based detergent. If large areas need to be cleaned, remove gasket dust and debris

using an "HEPA" (High Efficiency Particulate Arrestor) vacuum cleaner. Do not clean the

area by blowing with compressed air or brushing.

Place the rags containing the waste and any scrap gasket material in an impervious container

labeled with the OSHA (Occupational H ealth and Safety Administration) designated caution, and

dispose of it in a solid waste disposal facility (land fill) that will accept asbestos material. Heavy

plastic garbage bags (6 mils thick), each seal ed separately, or other closed and impermeable

container may be used.

ENGLISH TO METRIC CONVERSION

Listed in Table 2 are the English to metric conversions.

Multiply Length By To get equivalent number of:

Inch (in.) 25.4 Millimeters (mm)

Foot (ft) 0.3048 Meters (m)

Yard (yd) 0.9144 Meters (m)

Mile (mile) 1.609 Kilometers (km)

Multiply Area By To get equivalent number of:

Inch2(in.2) 6452 Millimeters2(mm2)

Inch2(in.2) 6.45 Centimeters2(cm2)

Foot2(ft2) 0.0929 Meters2(m2)

Yard2(yd2) 0.8361 Meters2(m2)

Multiply Volume By To get equivalent number of:

Inch3(in.3) 16387 Millimeters3(mm3)

Inch3(in.3) 16.387 Centimeters3(cm3)

Inch3(in.3) 0.0164 Liters (L)

Quart (qt) 0.9464 Liters (L)

Gallon (gal) 3.785 Liters (L)

Yard3(yd3) 0.7646 Meters3(m3)

Multiply Mass By To get equivalent number of:

Pound (lb) 0.4536 Kilograms (kg)

Ton (ton) 907.18 Kilograms (kg)

Ton (ton) 0.907 Tonne (t)

Multiply Force By To get equivalent number of:

Kilogram (kg) 9.807 Newtons (N)

Ounce (oz) 0.2780 Newtons (N)

Pound (lb) 4.448 Newtons (N)

28 6

SE379 0303 Copyright © 2003 DETROIT DI ES EL CORPORATION

All information subject to change without notice.

SERIES 92 SERVICE MANUAL

Multiply Temperature By To get equivalent number of:

Degree Fahrenheit ( F) ( F-32) ÷ 1.8 Degree C elsius C)

Multiply Acceleration By To get equivalent number of:

Foot/second2(ft/sec2) 0.3048 Meter/second2(m/s2)

Inch/second2(in./sec2) 0.0254 Meter/second2(m/s2)

Multiply Torque By To get equivalent number of:

Pound-inch (lb·in.) 0.11298 Newton-meters (N·m)

Pound-foot (lb·ft) 1.3558 Newton-meters (N·m)

Multiply Power By To get equivalent number of:

Horsepower (hp) 0.746 Kilowatts (kW)

Multiply Pressure or Stress By To get equivalent number of:

Inches of water (in. H2O) 0.2491 Kilopascals (kPa)

Pounds/square in. (lb/in.2) 6.895 Kilopascals (kPa)

Multiply Energy or Work By To get equivalent number of:

British Thermal Unit (Btu) 1055 Joules (J)

Foot-pound (ft·lb) 1.3558 Joules (J)

kilowatt-hour (kW·hr)

Multiply Light By To get equivalent number of:

Foot candle (fc) 1.0764 Lumens/meter2(lm/m2)

Multiply Fuel Performance By To get equivalent number of:

Miles/gal (mile/gal) 0.4251 Kilometers/liter (km/L)

Gallons/mile (gal/mile) 2.3527 Liter/kilometer (L/km)

Multiply Velocity By To get equivalent number of:

Miles/hour (mile/hr) 1.6093 Kilometers/hour (km/hr)

3,600,000. or

3.6 x 10

6

Joules (J = one W/s)

Table 2 English to Metric Conversion Table

All information subject to change without notice.

379 0303 Copyright © 2003 DETROIT DIES EL CORPORATION

6SE

29

SERIES 92 SERVICE MANUAL

DECIMAL AND METRIC EQUIVALENTS

Listed in Table 3 are the decimal to metric equivalents.

Fractions of

an inch

1/64 0.015625 0.39688 33/64 0.515625 13.09687

1/32 0.03125 0.79375 17/32 0.53125 13.49375

3/64 0.046875 1.19062 35/64 0.546875 13.89062

1/16 0.0625 1.58750 9/16 0.5625 14.28750

5/64 0.078125 1.98437 37/64 0.578125 14.68437

3/32 0.09375 2.38125 19/32 0.59375 15.08125

7/64 0.109375 2.77812 39/64 0.609375 15.47812

1/8 0.125 3.175 5/8 0.625 15.87500

9/64 0.140625 3.57187 41/64 0.640625 16.27187

5/32 0.15625 3.96875 21/32 0.65625 16.66875

11/64 0.171875 4.36562 43/64 0.671875 17.06562

3/16 0.1875 4.76250 11/16 0.6875 17.46250

13/64 0.203125 5.15937 45/64 0.703125 17.85937

7/32 0.21875 5.55625 23/32 0.71875 18.25625

15/64 0.234375 5.95312 47/64 0.734375 18.65312

1/4 0.250 6.35000 3/4 0.750 19.05000

17/64 0.265625 6.74687 49/64 0.765625 19.44687

9/32 0.28125 7.14375 25/32 0.78125 19.84375

19/64 0.296875 7.54062 51/64 0.796875 20.24062

5/16 0.3125 7.93750 13/16 0.8125 20.63750

21/64 0.328125 8.33437 53/64 0.828125 21.03437

11/32 0.34375 8.73125 27/32 0.84375 21.43125

23/64 0.359375 9.12812 55/64 0.859375 21.82812

3/8 0.375 9.52500 7/8 0.875 22.22500

25/64 0.390625 9.92187 57/64 0.890625 22.62187

13/32 0.40625 10.31875 29/32 0.90625 23.01875

27/64 0.421875 10.71562 59/64 0.921875 23.41562

7/16 0.4375 11.11250 15/16 0.9375 23.81250

29/64 0.453125 11.50937 61/64 0.953125 24.20937

15/32 0.46875 11.90625 31/32 0.96875 24.60625

31/64 0.484375 12.30312 63/64 0.984375 25.00312

1/2 0.500 12.70000 1 1.00 25.40000

Decimal (in.) Metric (mm)

Fractions of

an inch

Decimal (in.) Metric (mm)

Table 3 Conversion Chart - Customary and Metric Units

SPECIFICATIONS

This section contains fastener torque specifications and pipe plug torque specifications.

30 6

SE379 0303 Copyright © 2003 DETROIT DI ES EL CORPORATION

All information subject to change without notice.

SERIES 92 SERVICE MANUAL

Torque Specifications - Fasteners

The proper bolt and nut torque is dependent on its size. Standard (customary) nut and bolt torque

specifications are listed i n Table 4. The proper torque specifications for metric nuts and bolts

arelistedinTable5.

Nut and Bolt Size, in. 260M or Better Torque 280M or Better Torque

10-24 5-7 N·m (4-5 lb·ft) 1/4 in.-20 7-9 N·m (5-7 lb·ft) 10-12 N·m (7-9 lb·ft)

1/4 in.-28 8-11 N·m (6-8 lb·ft) 11-14 N·m (8-10 l b·ft)