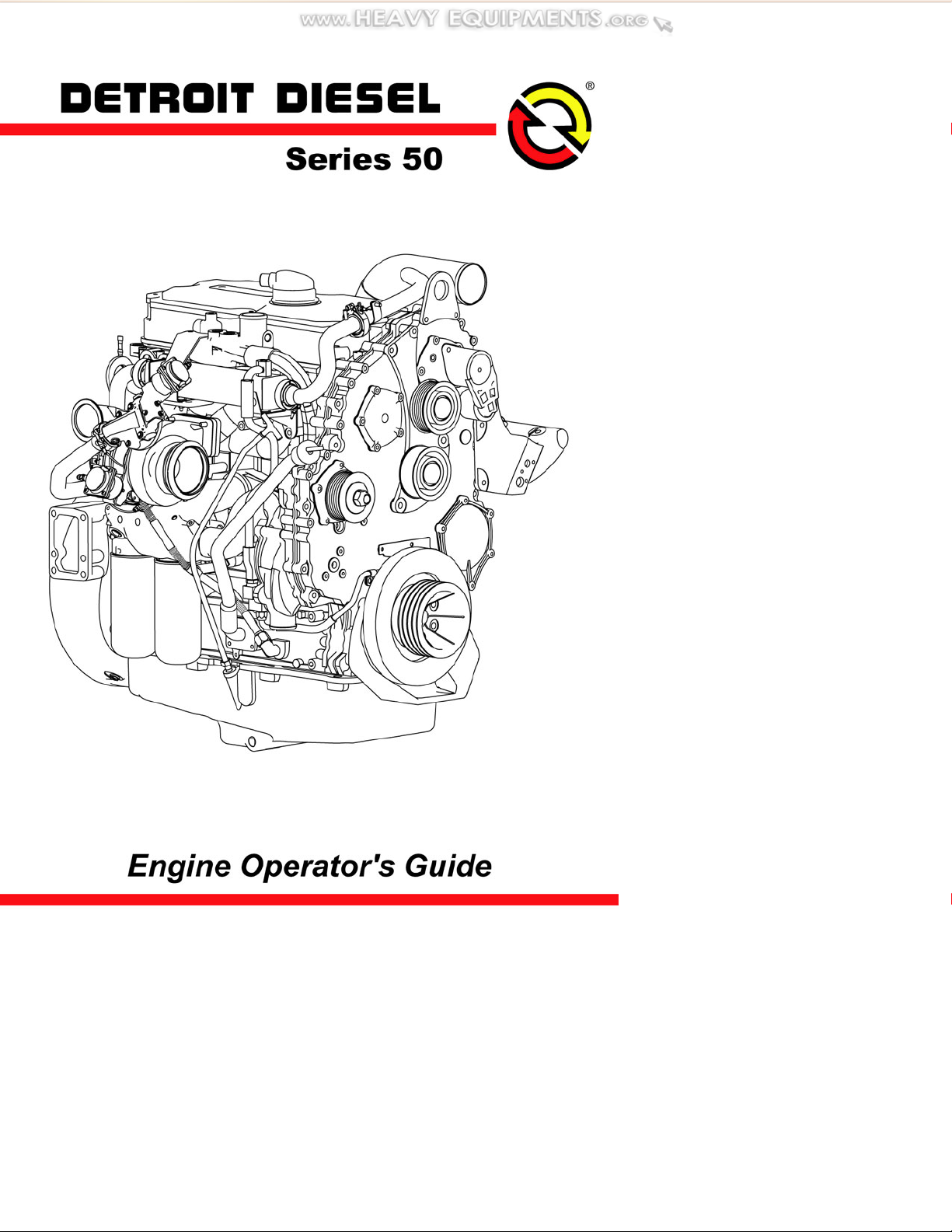

SERIES 50 OPERATOR'S GUIDE

To the Operator

This guide contains instructions on

the safe operation and preventive

maintenance of your Detroit Diesel

Series 50

stationary, construction/industrial,

agricultural, generator set or fire

fighting apparatus applications.

Maintenance instructions cov er

routine engine services such as lube

oil and filter changes in enough detail

to permit self-servicing, if desired.

The operator should become familiar

with the con tents of this guide before

operating the engine or carrying out

maintenance procedures.

Power-driven equipment is only

as safe as the person operating the

controls. You are urged, as the

operator of this diesel engine, to keep

fingers and clothing away from the

revolving belts, drive shafts, pulleys,

etc. on the engine installation.

®

engine used in vehicle,

Whenever possible, it will benefit

youtorelyonanauthorized Detroit

Diesel service outlet for all your

service needs from maintenance to

major parts replacement. Authorized

service outlets worldwide stock

factory-original parts and have

the specialized equipment and

experienced, trained personnel

to provide prompt preventive

maintenance and skilled engine

repairs.

The information and specifications

in this publication are based on the

information in effect at the time of

approval for printing. Contact an

authorized Detroit Diesel service

outlet fo r information on the latest

revision. The right is reserved to

make changes at any time without

obligation.

Throughout this guide CAUTION S

regarding personal safety and

NOTICES regarding engine

performance or service life will

appear. To avoid personal injury and

ensure long engine service life, always

heed these instructions.

All information subject to change without not ice. (Rev. 01/ 04) i

6SE550 0401 Copyright © 2004 DETROIT DIE

SEL CORPORATION

NOTICE:

Trademark Information

Failure to check and maintain

SCA (supplemental coolant

additive) levels at required

concentrations will result in

severe damage (corrosion) to

the engine cooling system and

related components.Coolant must

be inhibited with the recommended

SCAslistedinthisengineoperator's

guide.Refer to section How to Select

Coolant. In addition, the engine

can be equipped with a coolant

filter/inhibitor system as an installed

option or as an after-sale item.

WARRANTY

The limited warranties for each

engine application are covered in

the Limited Warranty pages of this

guide and in the booklet, “Warranty

Information for Series 50 Engines,”

available f rom authorized Detroit

Diesel service outlets.

Detroit Diesel®,DDC®,DDEC®,

Series 50

ProManager

Trac

Guard

®

, Optimized Idle®,

®

®

, Power Cool®,andPower

, reliabilt®, Power

®

are registered t radem a rks of

DetroitDieselCorporation. Delco

®

Remy

Delco Remy America, Inc. Bosch

is a registered trademark of

®

is a registered trademark of Ro bert

Bosch Company N.A. Fuel Pro

®

Pro

and Mega Filter®are registered

®

,Sea

trademarks of Davco Manufacturing,

L.L.C. The PowerBand

®

is a

registered trademark of Gates Rubber

Company. Tectyl

®

is a reg ister e d

trademark of Daubert Chemical

Company, Inc. Biobor

®

is a registered

trademark of United States Borax and

Chemical Corporation. DuPont

®

is a

registered trademark of E.I. DuPont

de Nemours and Company, Inc. All

other trad emarks used are the property

of their respective owners.

p this Operator's Guide

Kee

ith the engine installation at

w

all times. It contains important

operating, maintenance, and safety

instructions.

ii All information subject to change without notic e . (Rev. 01/ 04)

6SE550 0401 Copyright © 2004 DETROIT DIE

SEL CORPORATION

SERIES 50 OPERATOR'S GUIDE

TABLE OF CONTENTS

INTRODUCTION .................................................................................. 1

NON-GENUINE AND REBUILT COMPONENT QUALITY ALERT .. 1

CAUTION SUMMARY .......................................................................... 3

ENGINE OPERATION ............................. ....................................... .. 3

PREVENTIVE MAINTENANCE ....................................................... 4

ELECTRICAL SYSTEM ................................................................... 7

COOLING SYSTEM ...................................... ................................... 8

AIR INTAKE SYSTEM ...................................................................... 8

FUEL SYSTEM ................................................................................ 9

STARTING AIDS .............................................................................. 1 0

COMPRESSED AIR ......................................................................... 11

LUBRICATING OIL AND FILTERS ................................................... 11

ENGINE MODEL AND SERIAL NUMBER DESIGNATION ................ 12

OPTION LABELS ....................................... ...................................... 13

CERTIFICATION LABELS ............................................................... 14

OPERATING INSTRUCTIONS FOR A FIRST TIME START .............. 15

PREPARATIONS FOR S TARTING THE ENGINE THE FIRST

TIME ................................................................................................. 15

COOLING SYSTEM CHECKS ........... ......................................... 15

LUBRICATION SYSTEM CHECKS ............................................. 16

EXTENDED STORAGE ................................................... ........ 16

FUEL SYSTEM CHECKS ............................................................ 17

OTHER CHECKS ........................................................................ 18

STARTING THE ENGINE ................................................................ 18

INITIAL ENGINE START .............................................................. 19

ELECTRIC STARTER ............................................................. 19

AIR STARTER ......................................................................... 20

RUNNING THE ENGINE ............... .................................................. 20

OIL PRESSURE ............................................................... ........... 20

WARM-UP ................................................................................... 20

INSPECTION ................. ....................................... ....................... 20

AVOID UNNECESSARY IDLING ................................................. 21

All information subject to change without not ice. (Rev. 01/ 04) iii

6SE550 0401 Copyright © 2004 DETROIT DIE

SEL CORPORATION

TABLEOFCONTENTS

STOPPING THE ENGINE ................................... ............................. 21

EMERGENCY JUMP STARTING .................................................... 22

DDEC IV SYSTEM ............................................ ................................... 23

DDEC SYSTEM .............................................................................. 23

ENGINE PROTECTION ............................................................... 24

IDLE SHUT DOWN TIMER ................................................... ........ 2 4

CRUISE CONTROL .................................................... ................. 24

ENGINE BRAKES ....................................................................... 26

DATA RECORDING C APABILITY ....... ... ...................................... 27

DDEC IV OPERATION .......................................................... ........... 27

IMMEDIATE SPEED RE DUC TION OPTION ............................... 28

STOP ENGINE LIGHT ................................................................. 28

DIAGNOSTIC DATA READER ..................................................... 28

DIAGNOSTIC CODE LIST ........................................................... 30

DDEC IV ENGINE DRIVING TIPS ....................................................... 37

ACCELERATING THE VEHICLE ..................................................... 37

CRUISE CONTROL .............................................................. ........... 37

ENGINE BRAKES AND CRUISE CONTROL ................. ... .............. 39

SHIFTING ........................................................................................ 39

IDLING .................................. ........................................................... 40

WINTER F RONTS ............................................................ ........... 40

ENGINE BRAKE SYSTEM .................................................................. 41

DRIVER CONTROL SWITCHES ..................................................... 41

LOW/HIGH SWITCH ................................. ................................... 41

LOW/MED/HIGH SWITCH ................................. .......................... 41

CLUTCH PEDAL AND THROTTLE POSITION CONTROLS .......... 41

ENGINE BRAKE OPERATION .................................... .................... 42

ANTI-LOCK BRAKING SYSTEMS ................................................... 43

DRIVING ON FLAT, DRY PAVEMENT ............................................. 43

DESCENDING A LONG, STEEP GRADE ....................................... 43

DRIVING ON WET OR SLIPPERY PAVEMENT .............................. 45

ENGINE SYSTEMS .................. .................................... ....................... 46

FUEL SYSTEM ................................................................................ 46

LUBRICATION SYSTEM ............. ..................................................... 46

AIR SYSTEM ................................................................................... 46

COOLING SYSTEM ...................................... ................................... 46

iv All information subject to change without notice. (Rev. 01/ 04)

6SE550 0401 Copyright © 2004 DETROIT DIE

SEL CORPORATION

SERIES 50 OPERATOR'S GUIDE

ELECTRICAL SYSTEM ................................................................... 46

EXHAUST SYSTEM ......................................................................... 46

EXHAUST GAS RECIRCULATION SYSTEM .................................. 46

MAINTENANCE ................................................................................... 47

PREVENTIVE MAINTEN A NCE INTERVALS ................................... 63

ITEM 1 – LUBRICATING OIL ...................................... ................. 63

ITEM 2 – FUEL AND FUEL TANK ............................................... 65

ITEM 3 – FUEL LINES, F LEXIBLE HOSES ................................ 66

LEAKS ..................................................... ................................ 66

HOSES AND FITT INGS .............. ............................................ 67

HOSE SERVICE LIFE ............................................... .............. 67

ITEM 4 – COOLING SYSTEM ..................................................... 67

COOLANT LEVEL ........................................................ ........... 67

COOLANT INHIBITORS .......................................................... 68

COOLANT DRAIN INTERVAL ............................. .................... 68

ITEM 5 – TURBOCHARGER, AIR-TO-AIR CHARGE COOLER . 70

WASTEGATE D TURBOCHARGERS ......... ... .......................... 70

ITEM 6 – B ATTERY ....................................................... .............. 71

ITEM 7 – TACHOMETER DRIVE ........ ....................................... .. 72

ITEM 8 – DRIVE BELTS ............................................. ................. 72

V-BELTS ........................................................ .......................... 73

2-GROOVE POWERBAND ........................ ............................. 73

12–RIB POLY-V BELT ............................................................. 74

BELT REPLACEMENT ..................................... ....................... 74

ITEM 9 – AIR COMPRESSOR ................................ ... ................. 74

ITEM 10 – AIR CLEANER ........................................................... 75

ITEM 11 – LUBRICATING OIL FILTERS ........ ... .......................... 75

ITEM 12 – FUEL FILTERS ........................................................... 76

FUEL PRO

®

382 FILTERS ...................................................... 76

SPIN-ON FILTERS .................................................................. 76

ITEM 13 – WATER PUMP AND COOLANT INHIBITOR

ELEMENT .......................................................... .......................... 77

WATER PUMP DRAIN HOLE .................................................. 77

COOLANT INHIBITOR ELEMENT .................................. ........ 7 7

ITEM 14 – CRANKING MOTOR .................................................. 78

ITEM 15 – AIR SYSTEM ............................................................. 78

ITEM 16 – EXHAUST SYSTEM ................................................... 78

ITEM 17 – ENGINE (STE AM CLEAN) .................................... ..... 78

All information subject to change without not ice. (Rev. 01/ 04) v

6SE550 0401 Copyright © 2004 DETROIT DIE

SEL CORPORATION

TABLEOFCONTENTS

ITEM 18 – RADIATOR ................................................................. 78

ITEM 19 – O IL PRESSURE ........................................ ................. 79

ITEM 20 – B ATTERY-CHARGING ALTERNATOR ................. ..... 79

BOSCH

GENERAL SERVICE REQUIREMENTS – BOSCH

DELCO REMY

®

T1 ALTERNATOR SERVICE REQUIREMENTS ...... 80

®

ALTERNATORS .......................................... .. 80

®

AND

ITEM 21 – ENGINE AND TRANSMISSION MOUNTS ................ 80

ITEM 22 – CRANKCASE PRESSURE ........................................ 80

ITEM 23 – FAN HUB .................................................................... 81

ITEM 24 – THERMOSTATS AND SEALS . ... ................................ 81

ITEM 25 – CRANKCASE BREATHER ......................................... 81

ITEM 26 – ENGINE TUNE -UP ........ .......................................... .. 82

ITEM 27 – VIBRATION DAMPER ................................................ 82

HOW-TO SECTION .............................................................................. 83

HOW TO SELECT LUBRICATING OIL ............................................ 83

LUBRICANT REQUIREMENTS .................................................. 83

EGR-EQUIPPED ENGINES .................................................... 83

NON-EGR ENGINES ...... ........................................................ 83

ENGINES BU ILT PRIOR TO 1 998 .......................................... 83

COLD WEATHER STARTING ...................................................... 84

SYNTHETIC OILS ........................ ............................................... 84

THE USE OF SUPPLEMENTAL ADD IT IVES .............................. 85

WHEN TO CHANGE OIL ................................................................. 85

DISPOSING OF WASTE OIL ...................... ................................ 86

HOW TO REPLACE THE LUBE OIL FILTERS ................................ 86

REPLACE SPIN-ON TYPE OIL FILTER ...................................... 86

HOW TO SELECT FUEL OIL ..................... ...................................... 88

QUALITY .................................... .................................................. 88

FUEL CONTAMINATION ................................... .......................... 88

PROHIBITED ADDITIVES ........................................................... 88

USED LUBRI CATING OIL ....................................................... 89

GASOLINE ............................................................................. 89

HOW TO REPLACE THE FUE L FILTERS ....................................... 89

REPLACE SPIN-ON FILTER EL EMENTS ................................... 89

REPLACE FUEL/WATER SEPARATOR ELEMENT .................... 91

REPLACE FUEL PRO FILTER ELEMENT .................................. 92

ENGINE OUT OF FUEL — HOW TO RESTART ............................. 94

ENGINES W ITH SPIN-ON FILTERS ........................................... 95

vi All information subjec t to change without notice. (Rev. 01/ 04)

6SE550 0401 Copyright © 2004 DETROIT DIE

SEL CORPORATION

SERIES 50 OPERATOR'S GUIDE

ENGINES WITH FUEL PRO FILTERS ........... ............................. 95

HOW TO SELECT COOLANT .... ....................................... .............. 96

DEFINITIONS ......................................................................... ..... 96

ANTIFREEZE .......................................................................... 96

COOLANT ............................................................................... 96

DROP-OUT ........................................................................... .. 96

FULLY FORMULATED ANT IFREEZE ..................................... 96

INITIAL–FILL COOLANT ......................................................... 96

OAT .... ...................................................................................... 96

SCA ......................................................................................... 96

APPROVED COOLANTS ........................................... ................. 97

EG OR PG & WATER + S CA INHIBITOR ............................... 98

MIXING EG OR PG ANTIFREEZ E AND WATER ......... ... ... ... .. 98

RECYCLED ANTIFREEZE ...................................... .............. 100

EG OR PG & WATER + OAT INHIBITOR ............... ................. 100

WATER ONLY + SCA OR WATER ONLY + OAT INHIBITOR . 101

WATER REQUIREMENTS ..................................................... 102

COOLANTS NOT RECOMMENDED ................................... ........ 102

ALL ANTIFREEZES AND COOLANTS CONTAINING

PHOSPHATE . .......................................................................... 102

AUTOMOTIVE TYPE COOLANTS .......................................... 102

METHYL ALCOHOL-BASED ANTIFREEZE ........................... 103

METHOXY PROPANOL-BASED ANTIFR EEZE .................... .. 103

GLYCOL-BASED COOLANTS FORMULATED FOR HVAC .... 103

ADDITIVES NOT RECOMMENDED .......................... ................. 103

SOLUBLE OIL ADDITIVES ..................................................... 103

CHROMATE ADDITIVES ....................................... ................. 103

COOLANT MAINTENANCE .................. ...................................... 103

COOLANT I NHI BITOR TEST INT E RVALS ............................ 103

SUPPLEMENTAL ADDITIVES ................................................ 104

COOLANT M AI NTENANCE INTERVALS ............................... 105

SCA TES T PROCEDURES ........................................ ................. 107

NEED-RELEASE F ILTERS (NON-OAT SYSTEMS) .................... 108

DROPOUT ................................................................................... 108

EXTENDER ADDITIVE FOR OAT COOLANT ............................. 109

OAT COOLANT DRAIN INTERVAL ............... .......................... 109

CHRONIC COOLANT SYSTEM PROBLEMS ............................. 109

MAINTENANCE PRODUCTS ........................ ............................. 109

All information subject to change without not ice. (Rev. 01/ 04) vii

6SE550 0401 Copyright © 2004 DETROIT DIE

SEL CORPORATION

TABLEOFCONTENTS

POWER COOL SCAS ..... ....................................... ................. 109

POWER COOL COOLANT FILTER ELEMENTS .................... 110

POWER COOL CL EANERS ................................................... 110

SUMMARY OF COOLANT RECOMMENDATIONS .................... 110

HOW TO DRAIN AN D FLUSH THE COOLING SYSTEM ............... 112

WHEN TO SERVICE TH E DRY TYPE AIR CLEANER .................... 114

BASIC TROUBLESHOOTING ................................ ............................. 115

ENGINE STORAGE ............................................................................. 120

PREPARING THE ENGINE FOR STORAGE .................................. 120

TEMPORARY STORAGE (30 DAYS OR LESS) .......................... 120

EXTENDED STORAGE (MORE THAN 30 DAYS) ...... ... .............. 121

RESTORING ENGINE TO SERVICE .......................................... 124

SERIES 50 SERVICE PUBLICATIONS ......... .................................... .. 126

CUSTOMER ASSISTANCE ................................................................. 127

IN U.S. AND CANADA CALL 1–800–445–1980 .............................. 130

WORKING WITH DDC SERVICE OUTLETS .................................. 130

ON-HIGHWAY VEHICLE ENGINE WARRANTY ................................. 133

TERMS OF COVERAGE: ON-HIGHWAY VEHICLE ENGINE

APPLICATIONS ................ .............................................................. 133

USES ...................................... ..................................................... 133

DEFECTS ........................................... ......................................... 133

REPAIRS ..................................................................................... 133

WARRANTY PERIOD ........................................... ....................... 133

LIKE REPLACEMENT ENGINE .................................................. 134

SERVICE SUPPLIES ................................................................... 134

ENGINE REM OVAL AND REINSTALLATION ...................... ... ... .. 135

THIS WARRANTY DOES NOT COVER: ......................................... 135

REPAIRS DUE TO ACCIDENTS, MISUSE, STORAGE DAMAGE,

NEGLIGENCE OR CERTAIN MODIFICATIONS ......................... 135

BRAKING DEVICES .................................................................... 135

FUEL INJECTORS AFTER 100,000 MILES/160,000

KILOMETERS .............................................................................. 135

MAINTENANCE ........................................................................... 135

INCIDENTAL OR CONSEQUENTIAL DAMAGE ......................... 1 3 5

OTHER LIMITATIONS .................................................................. 136

viii All information subject to change without notic e . (Rev. 01/ 04)

6SE550 0401 Copyright © 2004 DETROIT DIE

SEL CORPORATION

SERIES 50 OPERATOR'S GUIDE

URBAN BUS, MOTOR COACH OR MOTOR HOME ENGINE

WARRANTY ....................................... .................................................. 137

TERMS OF COVERAGE: URBAN BUS, MOTOR COACH OR

MOTOR HOME ENGINE APPLICATIONS ...................................... 137

USES ...................................... ..................................................... 137

DEFECTS ........................................... ......................................... 137

REPAIRS ..................................................................................... 137

WARRANTY PERIOD ........................................... ....................... 137

SERVICE SUPPLIES ................................................................... 138

LIKE REPLACEMENT ENGINE .................................................. 138

ENGINE REM OVAL AND REINSTALLATION ...................... ... ... .. 139

THIS WARRANTY DOES NOT COVER: ......................................... 139

REPAIRS DUE TO ACCIDENTS, MISUSE, ALTERATION,

STORAGE DAMAGE, NEGLIGENCE OR CERTAIN

MODIFICATIONS .. ....................................................................... 139

BRAKING DEVICES .................................................................... 139

FUEL INJECTORS AFTER 200,000 MILES/320,000

KILOMETERS .............................................................................. 139

MAINTENANCE ........................................................................... 139

INCIDENTAL OR CONSEQUENTIAL DAMAGE ......................... 1 3 9

OTHER LIMITATIONS .................................................................. 139

CONSTRUCTION/ INDUSTRIAL ENGINE WARRANTY .................... 141

TERMS OF COVERAGE: CONSTRUCTION/INDUSTRIAL ENGINE

APPLICATIONS ......................................... ...................................... 141

USES ...................................... ..................................................... 141

DEFECTS ........................................... ......................................... 141

REPAIRS ..................................................................................... 141

WARRANTY PERIOD ........................................... ....................... 141

SERVICE SUPPLIES ................................................................... 141

ENGINE REMOVAL AND REINSTALLATION –

CONSTRUCTION/INDUSTRIAL APPLICATIONS ....................... 142

MECHANIC'S TRAVEL EXPENSES ........................................... 142

LIKE REPLACEMENT ENGINE .................................................. 142

THIS WARRANTY DOES NOT COVER: ......................................... 143

REPAIRS DUE TO ACCIDENTS, MISUSE, STORAGE DAMAGE,

NEGLIGENCE OR CERTAIN MODIFICATIONS ......................... 143

ENGINE REMOVAL AND REINSTALLATION – AGRICULTU RAL

MACHINERY AND STAND-BY PUMP APPLICATIONS .............. 143

All information subject to change without not ice. (Rev. 01/ 04) ix

6SE550 0401 Copyright © 2004 DETROIT DIE

SEL CORPORATION

TABLEOFCONTENTS

NON-DDC SUPPLIED/MANUFACTURED C OMPONEN T S ....... 143

MAINTENANCE ........................................................................... 143

INCIDENTAL OR CONSEQUENTIAL DAMAGE ......................... 1 4 3

OTHER LIMITATIONS .................................................................. 144

AGRICULTURAL MACHINERY ENGINE WARRANTY ...................... 145

TERMS OF COVERAGE: AGRICULTURAL MACHINERY ENGINE

APPLICATIONS ......................................... ...................................... 145

USES ...................................... ..................................................... 145

DEFECTS ........................................... ......................................... 145

REPAIRS ..................................................................................... 145

WARRANTY PERIOD ........................................... ....................... 146

THIS WARRANTY DOES NOT COVER: ......................................... 146

REPAIRS DUE TO ACCIDENTS, MISUSE, STORAGE DAMAGE,

NEGLIGENCE OR CERTAIN MODIFICATIONS ......................... 146

ENGINE REM OVAL AND REINSTALLATION ...................... ... ... .. 146

NON-DDC SUPPLIED/MANUFACTURED C OMPONEN T S ....... 146

MAINTENANCE ........................................................................... 146

INCIDENTAL OR CONSEQUENTIAL DAMAGE ......................... 1 4 7

OTHER LIMITATIONS .................................................................. 147

PRIME POWER GENERATOR SET ENGINE WARRANTY ............... 148

TERMS OF COVERAGE: PRIME POWER GENERATOR SET

ENGINE APPLICATIONS ................................................................. 148

USES ...................................... ..................................................... 148

DEFECTS ........................................... ......................................... 148

REPAIRS ..................................................................................... 148

WARRANTY PERIOD ........................................... ....................... 148

LIKE REPLACEMENT ENGINE .................................................. 148

SERVICE SUPPLIES ................................................................... 149

MECHANIC'S TRAVEL EXPENSES ........................................... 149

THIS WARRANTY DOES NOT COVER: ......................................... 149

REPAIRS DUE TO ACCIDENTS, MISUSE, STORAGE DAMAGE,

NEGLIGENCE OR CERTAIN MODIFICATIONS ......................... 149

ENGINE REM OVAL AND REINSTALLATION ...................... ... ... .. 149

NON-DDC SUPPLIED/MANUFACTURED C OMPONEN T S ....... 150

MAINTENANCE ........................................................................... 150

INCIDENTAL OR CONSEQUENTIAL DAMAGE ......................... 1 5 0

OTHER LIMITATIONS .................................................................. 150

x All information subject to change without notice. (Rev. 01/ 04)

6SE550 0401 Copyright © 2004 DETROIT DIE

SEL CORPORATION

SERIES 50 OPERATOR'S GUIDE

STAND-BY GENERATOR SET ENGINE WARRANTY ....................... 151

TERMS OF COVERAGE: STAND-BY GENERATOR SET ENGINE

APPLICATIONS ......................................... ...................................... 151

USES ...................................... ..................................................... 151

DEFECTS ........................................... ......................................... 151

REPAIRS ..................................................................................... 151

WARRANTY PERIOD ........................................... ....................... 152

LIKE REPLACEMENT ENGINE .................................................. 152

SERVICE SUPPLIES ................................................................... 152

MECHANIC'S TRAVEL EXPENSES ........................................... 152

THIS WARRANTY DOES NOT COVER: ......................................... 152

REPAIRS DUE TO ACCIDENTS, MISUSE, STORAGE DAMAGE,

NEGLIGENCE OR CERTAIN MODIFICATIONS ......................... 152

ENGINE REM OVAL AND REINSTALLATION ...................... ... ... .. 152

NON-DDC SUPPLIED/MANUFACTURED C OMPONEN T S ....... 152

MAINTENANCE ........................................................................... 153

INCIDENTAL OR CONSEQUENTIAL DAMAGE ......................... 1 5 3

OTHER LIMITATIONS .................................................................. 153

SPECIFICATIONS ................................................................................ 154

FUEL AND LUBRICATING OIL FILTER REQUIREMENTS ............. 154

OIL PAN ...................................................................... ................. 154

OIL PAN CAPACITY ............................................ .................... 154

TOTAL OI L CAPACITY OF THE ENGINE ............................... 154

POWER COOL ENGINE PRODUCTS ............................................. 155

FULLY FORMULATED IEG COOLANT ....................................... 155

LATIN AMERICAN COOLANT ..................................................... 155

2000 SUPPLEM ENTAL COOLANT ADDITIVE .... ... ... ... ... ........... 156

3000 SUPPLEM ENTAL COOLANT ADDITIVE .... ... ... ... ... ........... 156

3000 SUPPLEMENTAL ADDITIVE COOLANT FILTERS ............ 157

SUPPLEMENTAL ADDITIVE NEED RELEASE FILTERS ........... 157

PLUS EXTENDED LIFE OAT COOLANT .................................... 158

PLUS EXTENDER FOR USE WITH POWER COOL PLUS OAT

COOLANT .................................................................. ................. 158

PLUS 6000 OAT INHIBITOR FOR WATER-O NLY SYSTEMS ..... 159

COOLING SYSTEM CLEANERS ............................ .................... 159

COOLANT TESTING AND ANALYSIS PRODUCTS ................... 160

All information subject to change without not ice. (Rev. 01/ 04) xi

6SE550 0401 Copyright © 2004 DETROIT DIE

SEL CORPORATION

TABLEOFCONTENTS

xii All information subject to change without notice . (Rev. 01/ 04)

6SE550 0401 Copyright © 2004 DETROIT DIE

SEL CORPORATION

INTRODUCTION

SERIES 50 OPERATOR'S GUIDE

This guide is intended for use by the

operator of a Detroit Diesel Series

®

50

engine used in the f ollow ing

applications:

On-Highway Vehicles

Construction/Industrial

Agricultural Machinery

Generator Drive Engines

Operators of Series 50 engines used

in prime power or stand-by generator

set applications should also refer

to the Detroit Diesel Generator Set

Operator's Guide, 6SE513. Guides

are available from authorized Detroit

Diesel distributors.

NON-GENUINE AND

REBUILT COMPONENT

QUALITY ALERT

In recent years, electronic engine

controls have been instrumental

in aid ing engine manufacturers in

meeting the stringent emission

requirements of the U.S.

Environmental P rotection Agency

(U.S. E PA) and the California Air

Resources Board (CARB) and

also in meeting the ever-increasing

performance demands of the customer.

Maintenance procedures are to

be followed in order to continue

satisfactory performance and

durability and to ensure coverage of

the engine under th e manufacturer's

warranty. M any of these main tenance

procedures also ensure that the engine

continues to comply with applicable

emissions standards. The U.S. E PA

specifically defines an engine's

“useful emission life” — currently

established as 290,000 miles (464,000

kilometers) for on-highway engines.

Proper maintenance procedures, using

specific components engineered to

comply with emissions regulations,

may be performed by an authorized

Detroit Diesel distributor or dealer,

an independent o utlet or the operator

or owner. The owner is responsible

for determining the suitability of

components to maint a in emissions

compliance during the engine's useful

emission life.

Electronic controls and components

have significantly increased in

sophistication, but the fundamental

objective remains the same — precise

timing and delivery of fuel. The very

heart of the Detroit Diesel electro nic

controls is the electronic unit injector

(EUI). The pro per functioning of the

EUI is absolutely paramount if the

benefits of electronic controls are to be

realized. Detroit Diesel Corporation

has built over 650,000 engines with

electronic unit injectors — more than

anyone else in the business.

All information subject to change without not ice. (Rev. 01/ 04) 1

6SE550 0401 Copyright © 2004 DETROIT DIE

SEL CORPORATION

INTRODUCTION

Detroit Diesel cauti ons that the

indiscriminate rebuilding of precision

components, without the benefit of

specifications, specialized equipment,

and knowledge of the electronic

operating system, will jeopardize

performance or lead to more serious

problems, and can take the engine

outside of compliance with U.S. EPA

or CARB emissions standards.

There are other components in

an engine, such as turbocharger,

camshaft, piston, etc., which

are specifically designed and

manufactured to exacting standards

for emissions compliance. It is

important that these components, if

replaced, modified or substituted, can

be verified to ensure that the engine

remains in compliance with emissions

standards. The use of inadequately

engineered, manufactured or tested

components in repair or rebuild of

the engine may be in violation of the

federal Clean Air Act and applicable

U.S. EPA or CARB regulations.

Furthermore, modern engines exhibit

operating parameters which require

the use of proper fluids, such as

fuel, coolant and lubricating oil, to

maintain long engine life. The use of

fluids that do not meet Detroit D iesel

Corporation specifications may result

in early wear out or engine failure.

2 All information subject to change without notice. (Rev. 01/ 04)

6SE550 0401 Copyright © 2004 DETROIT DIE

SEL CORPORATION

CAUTION SUMMARY

The following cautions must be

observed by the operator of the

vehicle or equipment in which th is

engine is installed an d/ or by those

performing basic engine preventive

maintenance. Failure to read and

heed these cautions and exercise

reasonable care for personal safety

and the safety of others when

operating the vehicle/equipment

or performing basic engine

preventive maintenance may result

in personal injury and engine

and/or vehicle/equipment damage.

Engine Operation

Observe the fo llowing cautions when

operating the engine.

SERIES 50 OPERATOR'S GUIDE

Diesel engine exhaust and some

of its constituents are known to

the State of California to cause

cancer, birth d efects, and other

reproductive harm.

Always start and operate an

engine in a well ventilated

area.

If operating an engine in

an enclosed area, vent the

exhaust to the outside.

Do not modify or tamper

with the exhaust system or

emission control system.

To avoid injury from loss of

vehicle/vessel control, the

operator of a DDEC equipped

engine must not attempt to use

or read the Diagnostic Data

Reader when the vehicle/vessel

is moving.

All information subject to change without not ice. (Rev. 01/ 04) 3

6SE550 0401 Copyright © 2004 DETROIT DIE

To avoid injury from engine

shutdown in an unsafe situation,

ensure the operator knows how

to override the stop engine

condition on a DDEC-equipped

unit.

SEL CORPORATION

CAUTION SUMMARY

To avoid injury from loss of

vehicle control, do not activate

the Engine Brake system under

the following conditions:

On wet or slippery pavement,

unless the vehicle is equipped

with ABS (anti-lock braking

system) and you have had

prior experience driving

under these conditions.

When driving without a trailer

(bobtailing) or pulling and

empty trailer.

If the tractor drive wheels

begin to lock or there is

fishtail motion after the

Engine Br ake is activated.

Deactivate the brake system

immediately, if this occurs.

Failure to observe these

precautions may result in

loss of vehicle control and/or

personal injury.

To avoid injury from the loss of

vehicle control, do not use cruise

control under these conditions:

When it is not possible to

keep the vehicle at a con stant

speed (on winding roads, in

heavy traffic, in traffic that

varies in speed, etc.).

On slippery roads

(wet pavement, ice-or

snow-covered roads, loose

gravel, etc.).

Preventive Maintenance

Observe the following cautions when

performing preventative maintenance.

To avoid injury when working

near or on an operating engine,

remove loose items of clothing,

jewelry, tie back or contain long

hair that could be caught in any

moving part causing injury.

4 All information subject to change without notice. (Rev. 01/ 04)

6SE550 0401 Copyright © 2004 DETROIT DIE

SEL CORPORATION

SERIES 50 OPERATOR'S GUIDE

To avoid injury when working

on or near an operating engine,

wear protective clothing,

eye protection, and hearing

protection.

To avoid injury from hot oil, do

not operate the engine with the

rocker cover(s) removed.

To avoid injury from fire, contain

and eliminate leaks o f flammable

fluids as they occur. Failure to

eliminate lea ks could result in

fire.

To avoid injury from slipping and

falling, immediately clean up any

spilled liquids.

To avoid injury from the expulsion

of hot coolant, never remove the

cooling system pressure cap

whiletheengineisatoperating

temperature. Remove the cap

slowly to reliev e pressure. Wear

adequate protective clothing

(face shield or safety goggles,

rubber gloves, apron, and boots).

To avoid injury from hot surfaces,

allow engine to c ool before

removing any component. Wear

protective gloves.

To avoid injury from contact with

the contaminants in used engine

oil, wear protective gloves and

apron.

All information subject to change without not ice. (Rev. 01/ 04) 5

6SE550 0401 Copyright © 2004 DETROIT DIE

SEL CORPORATION

CAUTION SUMMARY

To avoid injury, use care when

working around moving belts and

rotating parts on the engine.

To avoid injury from fire caused

by heated lubricating-oil vapors:

Keep those people who

are not directly involved

in servicing away from the

engine.

Stop the engine immediately

if an oil leak is detected.

Do not allow open flames or

smoke whe n working on an

operating engine.

Wear adequate protective

clothing (face shield,

insulated gloves, ap ron, etc.)

to avoid burns.

To prevent a b uildup of

potentially volatile vapors,

keep the engine area well

ventilated during operation.

To avoid injury from rotating belts

and fans, do not remove and

discard safety guards.

To avoid injury from contact

with rotating parts when an

engine is operating with the air

inlet piping removed, install an

air inlet screen shield over the

turbocharger air inlet. The shield

prevents contact with rotating

parts.

To avoid injury when using

caustic cleaning agents, follow

the chemical manufacturers

usage, disposal, and safety

instructions.

Lubricating oil is relatively

harmless at ambient

temperatures.

6 All information subject to change without notice. (Rev. 01/ 04)

6SE550 0401 Copyright © 2004 DETROIT DIE

SEL CORPORATION

Electrical System

Observe the fo llowing cautions when

jump starting an engine, charging

a battery, or working with the

vehicle/application electrical system.

To avoid injury from accidental

engine startup while servicing

the engine, disconnect/disable

the starting system.

To avoid injury from electrical

shock, do not touch battery

terminals, alternator terminals, or

wiring cables while the engine is

operating.

SERIES 50 OPERATOR'S GUIDE

To avoid injury from battery

explosion or contact with battery

acid, w ork in a well-ventilated

area, wear pr otective clothing,

and avoid sparks or flames

near th e battery. Always

establish correct polarity before

connecting cables to the battery

or battery circuit. If you come in

contact with battery acid:

Flush your skin with water.

Applybakingsodaorlimeto

help neutralize the acid.

Flush your eyes with water.

Get medical attention

immediately.

All information subject to change without not ice. (Rev. 01/ 04) 7

6SE550 0401 Copyright © 2004 DETROIT DIE

SEL CORPORATION

CAUTION SUMMARY

Cooling System

Observe the fo llowing cautions when

servicing the coolin g system.

To avoid injury from the expulsion

of hot coolant, never remove the

cooling system pressure cap

while the engine is at operating

temperature. Remove the c ap

slowly to relieve pressure. Wear

adequate protective clothing

(face shield or safety goggles,

rubber gloves, apron, and boots).

To avoid injury from slipping and

falling, immediately clean up any

spilled liquids.

Air Intake System

Observe the following cautions when

working on the air intake system.

To avoid injury from hot surfaces,

allow engine to c ool before

removing any component. Wear

protective gloves.

To avoid injury from contact

with rotating parts when an

engine is operating with the air

inlet piping removed, install an

air inlet screen shield over the

turbocharger air inlet. The shield

prevents contact with rotating

parts.

8 All information subject to change without notice. (Rev. 01/ 04)

6SE550 0401 Copyright © 2004 DETROIT DIE

SEL CORPORATION

Fuel System

Observe the fo llowing cautions when

fueling the vehicle or working with

the fuel system.

To avoid injury from fire, keep all

potential ignition sources away

from diesel fuel, open flames,

sparks, and electrical resistance

heating elements. Do not smoke

when refueling .

To avoid injury from fire, contain

and eliminate leaks o f flammable

fluids as they occur. Failure to

eliminate lea ks could result in

fire.

SERIES 50 OPERATOR'S GUIDE

To avoid injury from fire caused

by heated diesel-fuel vapors:

Keep those people who

are not directly involved

in servicing away from the

engine.

Stop the engine immediately

ifafuelleakisdetected.

Do not allow open flames or

smoke when working on an

operating engine.

Wear adequate protective

clothing (face shield,

insulated gloves and apron,

etc.).

To prevent a buildup of

potentially volatile vapors,

keeptheengineareawell

ventilated during operation.

Diesel fuel is relatively harmle ss

at ambient temperatures.

To avoid increased risk of a fuel

fire, do not mix gasoline and

diesel fuel.

All information subject to change without not ice. (Rev. 01/ 04) 9

6SE550 0401 Copyright © 2004 DETROIT DIE

SEL CORPORATION

CAUTION SUMMARY

Starting Aids

Observe the fo llowing cautions when

using starting aids.

To avoid injury from flames,

explosion, and toxicants when

using ether, the following

precautions must be taken:

To avoid injury from flames,

explosion, and toxicants when

using ether, the following

precautions must be taken:

Always wear goggles when

testing.

If fluid enters the eyes or if

fumes irritate the eyes, wash

eyes with large quantities of

clean water for 15 minutes.

A physician, preferably an

eye specialist, should be

contacted.

Contents of cylinder are

under pressure. Store

cylinders in a co ol dry area.

Do not incinerate, puncture

or attempt to remove cores

from cylinders.

Do not smoke when servicing

ether system.

Work in well-ventilated area.

Do not work near open

flames, pilot flames (gas or

oil heaters), or sparks.

Do not weld or carry an open

flame near the ether system if

you smell ether or otherwise

suspect a leak.

10 All information subject to change without notice. (Rev. 01/ 04)

6SE550 0401 Copyright © 2004 DETROIT DIE

SEL CORPORATION

Compressed Air

Observe the fo llowing cautions when

using compressed air.

To avoid injury from flying debris

when using compressed air, wear

adequate eye protection (face

shield or safety goggles) and do

not exceed 40 psi (276 k Pa) air

pressure.

Lubricating Oil and Filters

Observe the fo llowing cautions when

replacing the engine lubricating oil

and filters.

SERIES 50 OPERATOR'S GUIDE

To avoid injury from fire caused

by heated lubricating-oil vapors:

Keep those people who

are not directly involved

in servicing away from the

engine.

Stop the engine immediately

if an oil lea k is detected.

Do not allow open flames or

smoke when working on an

operating engine.

Wear adequate protective

clothing (face shield,

insulated gloves, apron, etc.)

to avoid burns.

To prevent a buildup of

potentially volatile vapors,

keeptheengineareawell

ventilated during operation.

To avoid injury from slipping and

falling, immediately clean up any

spilled liquids.

All information subject to change without not ice. (Rev. 01/ 04) 11

6SE550 0401 Copyright © 2004 DETROIT DIE

Lubricating oil is relatively

harmless at ambient

temperatures.

SEL CORPORATION

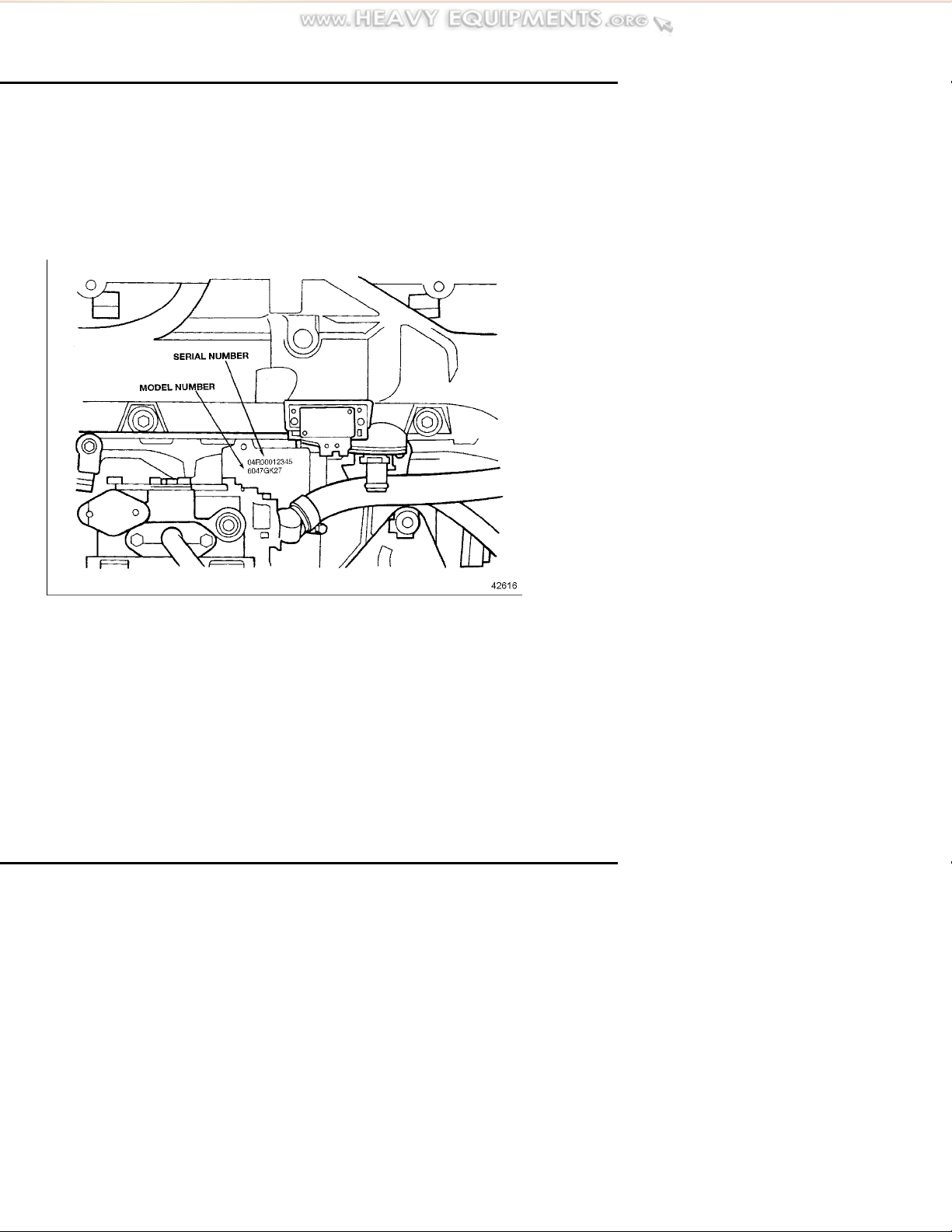

ENGINE MODEL AND SERIAL NUMBER DESIGNATION

ENGINE MODEL AND SERIAL NUMBER DESIGNATION

The engine serial number and model

number are laser etched on the

cylinder block on the left side just

the cast- in Detroit Diesel logo (as

viewed from the flywheel end).

SeeFigure1

below the intake manifold and above

Figure 1 Location of Engine Serial and Model Numbers

12 All information subject to change without notice. (Rev. 01/ 04)

6SE550 0401 Copyright © 2004 DETROIT DIE

SEL CORPORATION

SERIES 50 OPERATOR'S GUIDE

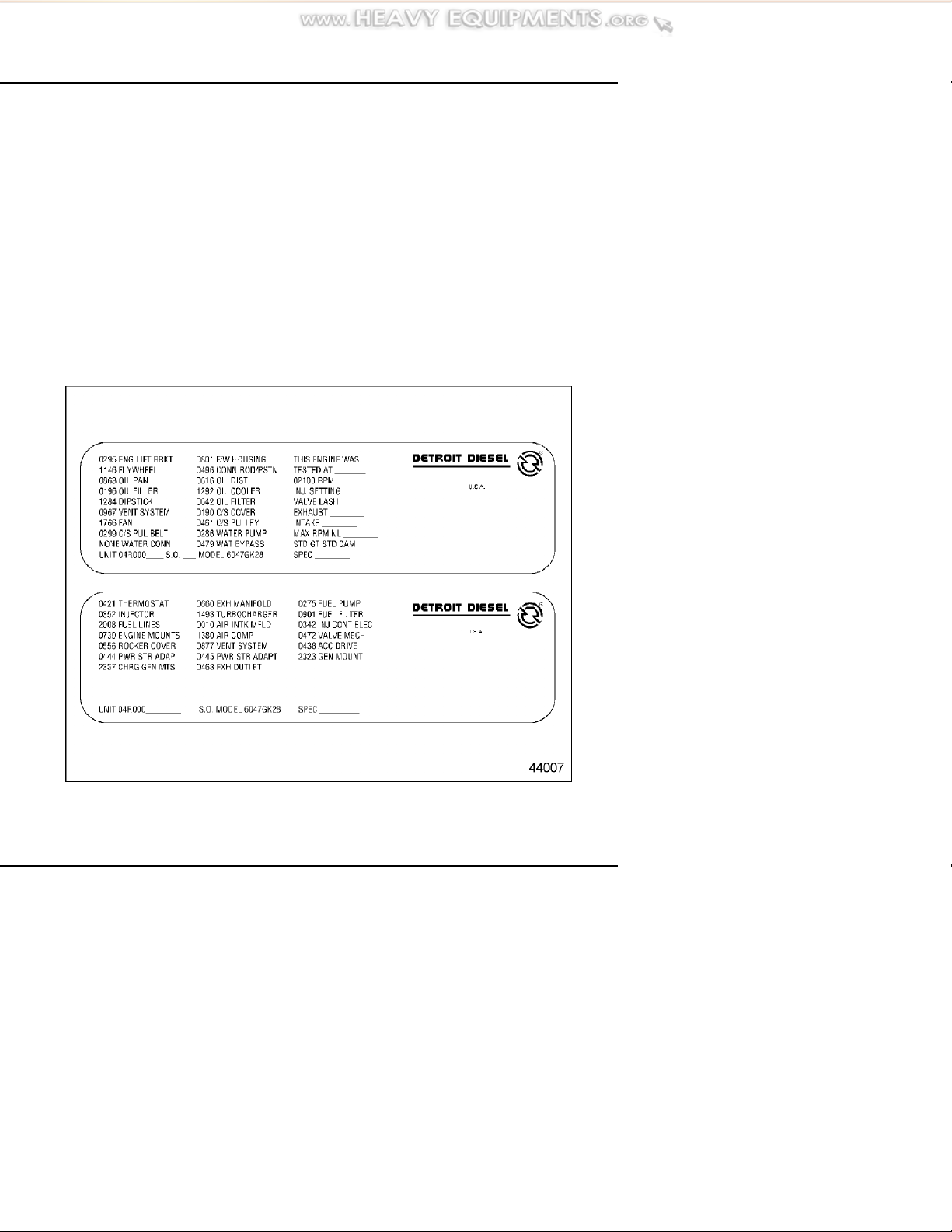

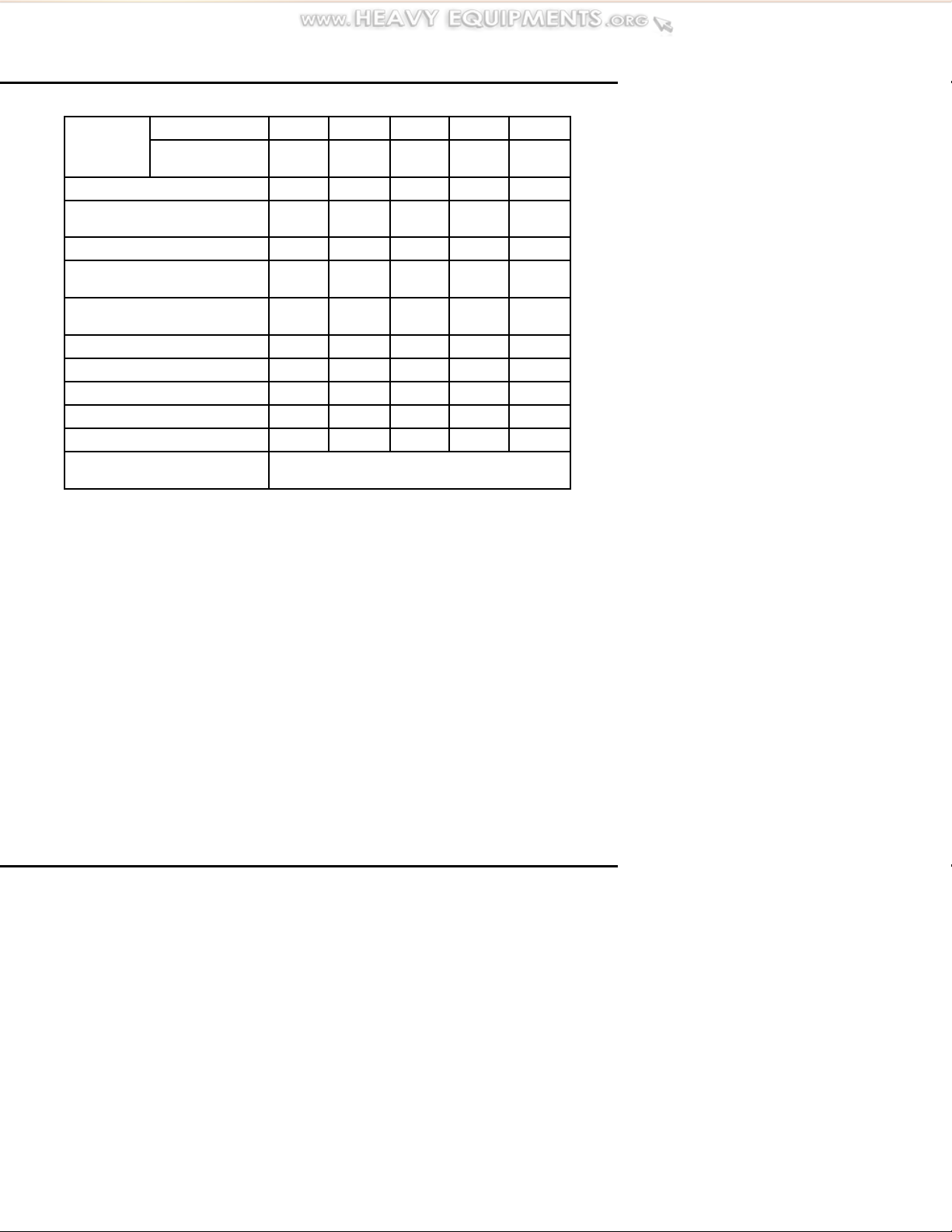

Option Labels

Computerized en gin e option labels

are attached to the valve rocker

cover. These labels contain the engine

serial number and model number

and, in addition, list any optional

equipment used on the engine.

Labels also include required tune-up

information (injection timin g, valve

lash, maximum no-load rpm, etc.).

With any order for parts, the engine

model and serial num ber m ust be

given. If a type number is shown

on the option label covering the

equipment required, this number

should also be included on the parts

order. See Figure 2.

Transmissions and power take-o ffs

generally carry their own name

plates. The model a n d serial number

information on these plates is

useful when ordering parts for these

assemblies.

Figure 2 Typical Option Labels

All information subject to change without not ice. (Rev. 01/ 04) 13

6SE550 0401 Copyright © 2004 DETROIT DIE

SEL CORPORATION

ENGINE MODEL AND SERIAL NUMBER DESIGNATION

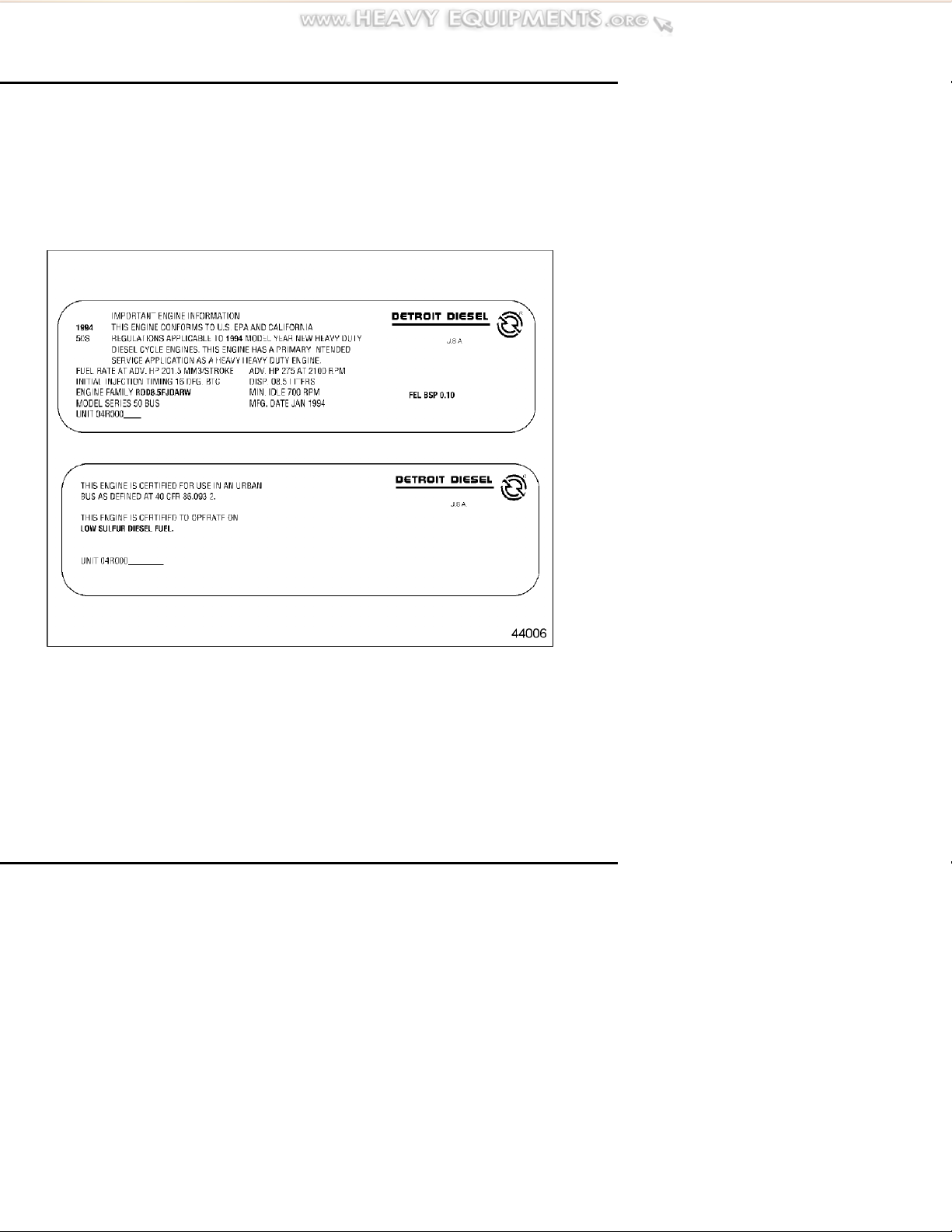

Certification Labels

If required, a certification label is

attached to the valve rocker cover.

This label certifi es that the engine

conforms to federal and certain state

emissions regulations for its particular

application. It also gives the operating

conditions under which certification

was made. See Figure 3.

Figure 3 Typical Engine Certification Labels

14 All information subject to change without notice. (Rev. 01/ 04)

6SE550 0401 Copyright © 2004 DETROIT DIE

SEL CORPORATION

SERIES 50 OPERATOR'S GUIDE

OPERATING INSTRUCTIONS FOR A FIRST TIME START

When preparing to start a new or newly

overhauled engine which has been in

storage, perform a ll of the operations

listed below. Failure to follow these

instructions may result in serious

engine damage. Before a routine start,

see the “Daily” checks for your engine

in the MAINTENANCE section.

To avoid injury when working

near or on an operating engine,

remove loose items of clothing,

jewelry, tie back or contain long

hair that could be caught in any

moving part causing injury.

System Checks

Diesel engine exhaust and some

of its constituents are known to

the State of California to cause

cancer, birth defects, and other

reproductive harm.

Always start and operate an

engine in a well ventilated

area.

If operating an engine in

an enclosed area, vent the

exhaust to the outside.

Do not modify or tamper

with the exhaust system or

emission control system.

Perform the following system checks

before starting for the first time.

Cooling System Checks

Check the cooling system as follows:

1. Make sure all drain cocks in

the cooling system are installed

(drain cocks are often removed

for shipping) and are closed

tightly.

2. Remove the radiator pressure

control cap and fill with genuine

Detroit Diesel Power Cool

antifreeze or an equivalent quality

ethylene glycol or propylene

glycol-base antifreeze solution

in the required concentration.

In extremely hot environments,

properly inhibited water may

be used in the summer. Keep

the coolant level at the bo ttom

of the fill er neck to allow for

All information subject to change without not ice. (Rev. 01/ 04) 15

6SE550 0401 Copyright © 2004 DETROIT DIE

SEL CORPORATION

OPERATING INSTRUCTIONS FOR A FIRST TIME START

expansion of the coolant. For

more detailed reco mmendations,

refer to the How to Select Coolant

section in this guide.

3. Entrapped air m ust be purged

after filling the cool ing system.

To do this, allow the engine to

warm up with the pressure cap

removed. With the transmission

in neutral, increase engine speed

above 1,000 rpm and add coolant

to the radiator as required.

4. Check to make sure the front

of the radiator and air-to -air

charge cooler (if equipped) are

unblocked and free of debris.

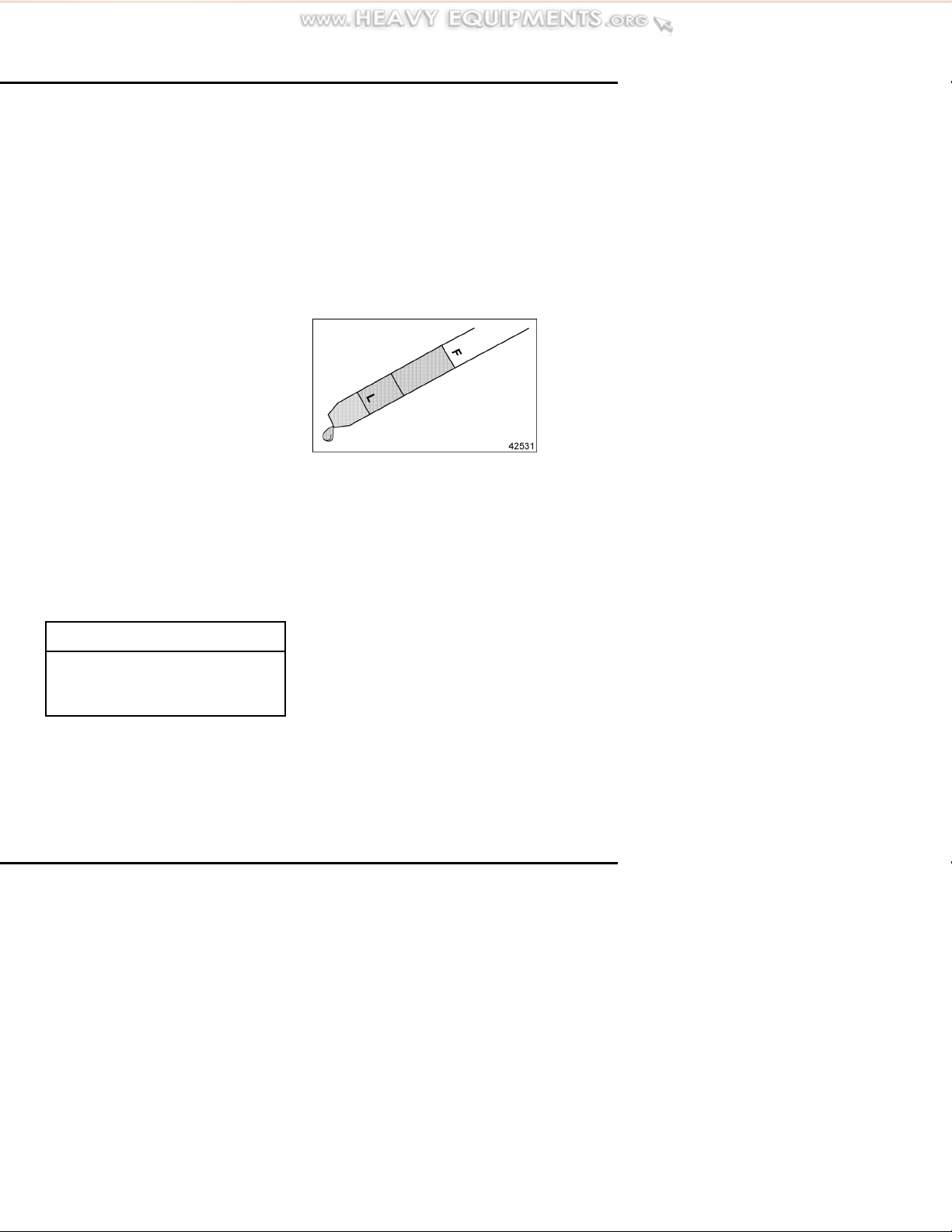

Lubrication System C hecks

The lubricating oil film on the rotating

parts and bearings of a new or newly

overhauled engine, or one which has

been in storage for six months or

more, may be insufficient when the

engine is started for the first time.

NOTICE:

Insufficient lubrication at startup can

cause serious damage to engine

components.

To insure an immediate flow of

oil to all bearing surfaces at initial

engine startup, the engine lubrication

system should be charged with a

commercially available pressure

pre-lubricator. If this is impractical,

rocker covers should be removed and

clean lubricating oil should be poured

over the rocker arms. The oil should

be the same weight and viscosity

as that used in the crankcase. After

pre-lubricating, add additional oil to

bring the level to the proper mark on

the dipstick. See Figure 4.

Figure 4 Check Lube Oil Level

Before Starting

For lubricant recomm endation ,

refer to the How to Select Lubricating

Oil section in this guide.

Extended Storage — An engine

in storage for an extended period

of time (over winter, for example)

may accumulate water in the oil

pan through normal condensation of

moisture (always present in the air)

on the cold, internal surfaces of the

engine. Lube oil diluted by water

cannot provide adequate bearing

protection at engine startup. For this

reason, Detroit Diesel recommends

16 All information subject to change without notice. (Rev. 01/ 04)

6SE550 0401 Copyright © 2004 DETROIT DIE

SEL CORPORATION

SERIES 50 OPERATOR'S GUIDE

replacing the engine lubricating oil

and filters after extended storage.

NOTICE:

Failure to eliminate water-diluted

lubricating oil may lead to serious

engine damage at startup.

Fuel System Checks

Fill the tanks with the recommended

fuel. Keeping tanks full reduces water

condensation and helps keep fuel

cool, which is important to engine

performance. Full tanks also reduce

the chance for microbe (black slime)

growth. For fuel recommendations,

refer to the How to Select Fuel Oil

section in this guide. Make sure the

fuel shutoff valve (if used) is open.

To insure prompt starting and even

running, the fuel system must

be primed if air has entered the fuel

system. Priming is done by connecting

a manual or electric priming pump

to the secondary fuel filter adaptor.

Authorized Detroit Diesel service

outlets are properly eq uip ped and have

the trained technicians to perform this

service.

NOTICE:

Prolonged use of the starting motor

andenginefuelpumptoprimethe

fuel system can result in damage to

the starter, fuel pump and injectors

and may cause erratic engine

operation due to the amount of air

in the line s and filters from the fuel

supply tank to the cylinder head.

Engines equipped with starting

devices dependent on compressed

air or gas reservoirs should always

be primed before initial startup.

Otherwise, reserve pressure can

be exhausted and injectors may be

damaged from lack of lubrication

and cooling.

Under no circumstances should

a starting aid such as ether be

used to run the engine until the

fuel system is primed. Injector

damage will result if this method

is used. The heat generated by the

external fuel source will cause the

injector tips to be damaged when

the fuel cools them. The injector

plunger and bushing can be scored

from running without lubrication.

Priming is not normally required if

the filter elements are filled with clean

fuel when installed and the manifolds

are not drained of fuel.

All information subject to change without not ice. (Rev. 01/ 04) 17

6SE550 0401 Copyright © 2004 DETROIT DIE

SEL CORPORATION

OPERATING INSTRUCTIONS FOR A FIRST TIME START

If the engine is equipped with a

fuel/water separator, drain off any

water that has accumulated. Water

in fuel can seriously affect engine

performance and may cause engine

damage. Detroit Diesel recommends

installation of a fuel/water separator

wherever water contamina tio n is a

concern.

Other Checks

Make sure the transmission is

filled to the proper level with the

fluid recommended by the gear

manufacturer. Do not ov erfill.

Make sure cable connections to

the storage batteries are clean and

tight. Check the hydrometer “eye” of

maintenance-free batteries for charge.

SeeFigure5.

Check drive belts to m ake sure they

are in good condition (not cracked,

torn, worn or glazed) and are properly

adjusted.

If lead-acid or low-maintenance

batteries are used, make sure battery

electrolyte level is normal.

Check the turbocharger for signs of

oil or exhaust leaks. Leaks should be

corrected before starting the engine.

Check engine mounting bolts for

tightness. Bolts should be retightened,

if necessary.

Starting the Engine

Before starting the engine the first

time, refer to the System Checks

section and perform the operations

listed.

NOTICE:

The turbocharger may be seriously

damaged if the engine is cranked

with the air shutdown in the closed

position.

If the engine has an emergency manual

or automatic shutdown system, make

sure the control is set in th e open

position before starting.

Figure 5 Check “Eye” of

Maintenance-Free

Batteries

18 All information subject to change without notice. (Rev. 01/ 04)

6SE550 0401 Copyright © 2004 DETROIT DIE

Theenginemayrequiretheuseofa

cold weather star ting aid if the ambient

temperature is below 40

F(4 C).

SEL CORPORATION

To avoid injury from flames,

explosion, and toxicants when

using ether, the following

precautions must be taken:

SERIES 50 OPERATOR'S GUIDE

warning lights. If everything is

OK, both lights will go out in

approximately five seconds.

Start the engine after the lights go

out. If starting a vehicle, start the

engine with foot off the foot pedal.

Do not smoke when servicing

ether system.

Work in well-ventilated area.

Do not work near open

flames, pilot flames (gas or

oil heaters), or sparks.

Do not weld or carry an open

flame near the ether system if

you smell ether or otherwise

suspect a leak.

Initial Engine Start

To start a Series 50 engine, make sure

the transmission is in neutral and turn

the ignition key on.

You will notice t hat both t he yellow

Check Engin Light (CEL) and the red

Stop Engine Light (SEL) will come

on.

This is the result of theDetroit

Diesel Electronic Control (DDEC

®

)

computer diagnosing the system

to ensure everything is functional,

including the light bulbs for the

NOTICE:

If the operating lights stay on,

consult with DDC Technical Service.

Operating the engine under these

circumstances may result in engine

damage.

Electric Starter — Start an engine

equipped with an electric starting

motor as follows:

1. With foot OFF the foot pedal,

press the starter switch firmly.

NOTICE:

To prevent serious starting motor

damage, d o not press the starter

switch again after the engine has

started.

2. If the engine fails to start within

15 seconds, release the starter

switch and allow the starter to

cool for 15 seconds before trying

again. If the engine fails to start

after four attempts, an inspection

should be m a de to determine the

cause.

All information subject to change without not ice. (Rev. 01/ 04) 19

6SE550 0401 Copyright © 2004 DETROIT DIE

SEL CORPORATION

OPERATING INSTRUCTIONS FOR A FIRST TIME START

Air Starter — Because of the limited

volume of most compressed air

storage tanks and the relatively short

duration of the cranking cycle, it is

important to make sure the engine is

ready to start before acti vati ng the air

starter. Start an en gin e equipped with

an air starter as follows:

1. Check the pressure in the air

storage tank. If necessary, add

air to b ri ng the pressure up to at

least the recommended minimum

for starting.

2. With foot OFF the foot pedal,

press the starter button firmly and

hold until the engine starts.

Running the Engine

While the engine is operating, monitor

the battery charge indicator light,

the oil pressure and avoid excessive

idling.

operating pressure should be higher. If

oil pressure does not fall within these

guidelines, it should be checked with

a manual gage.

To avoid injury from hot oil, do

not operate the engine with the

rocker cover(s) removed.

Warm-up

Run the engine at part throttle for

about five minutes to allow it to warm

up before applying a loa d.

Inspection

While the engine is idling, inspect the

transmission, check for fluid leaks,

check the crankcase and turbocharger.

Oil Pressure

Observe the oil pressure gage

immediately after starting the engine.

A good indicator that all m oving parts

are getting lubrication is when the

oil pressure gage registers pressure

(5 psi or 35 kPa at idle speed). If

no pressure is indicated within 10

is idling, check the automatic

transmission (if equipp e d) for proper

oil level and add oil as required.

Fluid Leaks – Lo ok for coolant,

fuel or lubricating oil leaks. If any

are found, shut down the engine

immediately and have the leaks

repaired after the engine has cooled.

to 15 seconds, stop the engine and

check the lubrication system. The

pressure should not drop below 28 psi

or 193 kPa at 1800 rpm, an d normal

Transmission – While the engine

20 All information subject to change without notice. (Rev. 01/ 04)

6SE550 0401 Copyright © 2004 DETROIT DIE

SEL CORPORATION

SERIES 50 OPERATOR'S GUIDE

Crankcase – Iftheengineoilwas

replaced, stop the engine after normal

operating temperature has been

reached. Allow the oil to drain

back into the crankcase for about

twenty minutes, then check the oil

level. If necessary, add oil to bring

the level to the proper mark on the

dipstick. Use only the heavy-duty oils

recommended. Refer to the How to

Select Lubricating Oil section in this

guide.

Turbocharger – Makeavisual

inspection of the turb ocharger for

oil leaks, exhaust leaks, excessive

noise or vibration. Stop the engine

immediately if a leak or unusual noise

or vibration is noted. Do not restart

the engine until the cause of the

concern has been investigated and

corrected. Autho rized Detroit Diesel

service outlets are properly equipped

to perform this service.

sludge in the engine. When prolonged

idling is necessary, maintain at least

850 rpm spring/summer and 1200 rpm

fall/winter.

Stopping the Engine

Stop an engine under normal operating

conditions as follows:

1. Reduce engine speed to idle and

put all shift levers in the n e utr al

position.

NOTICE:

Stopping a turbocha rged engine

immediately after high-speed

operation without allowing a

sufficient cool-down peri od may

cause damage to the turbocharger,

as it will continue to turn without an

oil supply to the bearings.

Avoid Unnecessary Idling

Whenever possible, avoid unnecessary

idling.

During long engine idling periods

with the transmission in neutral, the

engine coolant temperature may fall

2. Allow the engine to run between

idle and 1000 rpm with no load

for four or five minutes. This

allows the engine to cool and

permits the turbo charger to slow

down. After four or five minutes,

shut down th e engine.

below the normal operating range.

The incomplete combustion of fuel

in a cold engine will cause crankcase

oil dilution, formation of lacquer or

gummy deposits on the valves, pistons,

and rings, and rapid accumulation of

All information subject to change without not ice. (Rev. 01/ 04) 21

6SE550 0401 Copyright © 2004 DETROIT DIE

SEL CORPORATION

OPERATING INSTRUCTIONS FOR A FIRST TIME START

Emergency Jump Starting

The DDEC IV system operates on

12 or 24 volts DC. If an engine with

an electric starting motor requires

emergency jump starting, do not

exceed 32 volts DC.

NOTICE:

Jump starting with voltages greater

than those indicated or reversing

battery polarity may damage the

Electronic Control Module.

To avoid injury from battery

explosion when jump starting the

engine, do not attach the cable

end to the negative terminal of

the disabled battery.

and in the proper sequence (negative

to negative g ro und last).

To avoid injury from battery

explosion or contact with battery

acid, w ork in a well-ventilated

area, wear pr otective clothing,

and avoid sparks or flames

near th e battery. Always

establish correct polarity before

connecting cables to the battery

or battery circuit. If you come in

contact with battery acid:

Flush your skin with water.

Applybakingsodaorlimeto

help neutralize the acid.

Flush your eyes with water.

Get medical attention

immediately.

NOTICE:

Failure to connect jumper cables

in the proper sequence can result

in alternator and/or equipment

damage.

Before att e mpting to jump start the

engine, make sure the jumper cables

are connected properly (positive to

positive, negative to negative ground)

22 All information subject to change without notice. (Rev. 01/ 04)

6SE550 0401 Copyright © 2004 DETROIT DIE

SEL CORPORATION

DDEC IV SYSTEM

SERIES 50 OPERATOR'S GUIDE

The DDEC sytem's engine-mounted

Electronic Control Module (ECM)

includes control logic to provide

overall engine m anagement. The

ECM co ntinuo usly performs

self-diagnostic checks and monitors

other system components. System

diagnostic checks are made at

ignition-on and continue throughout

all engine-operating modes.

Detroit Diesel Series 50 engines

equipped with DDEC IV are identified

by the letter “K” in the sixth position

of the model number. Example:

6047GK27.

The DDEC engine is equipped

with an electronically controlled

fuel injection system. There are no

control racks or mechanical linkages

to adjust. This system not only helps

to improve fuel economy and vehicle

performance, it also helps to reduce

cold starting time and increase initial

idle speed for fast engine wa rm-up

and virtual elimination of cold smoke.

The DDEC engine has no

mechanical governor. Engine

horsepower, torque, idle, and engine

speed are contained in the internal

electronics. Therefore, there are

no mechanical governor spring

adjustments for idle and high-speed

control.

There is no need for a throttle delay.

Emission control is performed through

the electronic control module (ECM).

The Electronic Foot Pedal Assembly

(EFPA) eliminates the need for any

throttle linkage.

DDEC Features

DDEC offers a variety of options

designed to warn the operator of an

engine malfunction. Options can

range from the CEL and SEL panel

lightstoautomaticreductioninengine

power followed by automatic engine

shutdown.

The pow er-down/shutdown option

may be activated by a low coolant

level, low oil pressure or high engine

oil or coolant temperature.

The DDEC engine has the ability to

perform diagnostics for self-checks

and continuous monitoring of other

system components. Depending

on the application, DDEC can also

monitor oil temperature, coolant

temperature, oil pressure, fuel

pressure, coolant level and remote

sensors (if used). This diagnostic

system is connected to the CEL and

the SEL to provide a visual warning

of a system malfunction.

All information subject to change without not ice. (Rev. 01/ 04) 23

6SE550 0401 Copyright © 2004 DETROIT DIE

SEL CORPORATION

DDEC IV SYSTEM

Engine Protection

The DDE C engine protection

system monitors all engine sensors

and electronic components, and

recognizes system malfunctions. If

a critical fault is detected, the CEL

and SEL illumin ate. The malfunction

codes are logged into the ECM's

memory.

The standard parameters which are

monitored for engine protection

are: low coolant level, high coolant

temperature, low oil pressure, and

high oil temperature

This system features a 30-second,

stepped-power shutdown sequence

or an immediate speed reduction

without shutdown in the event a major

engine malfunction occurs, such as

low oil pressure, high oil or coolant

temperature, or low coolant level.

NOTICE:

Engines equipped w ith the

power-down/shutdown option have

a system override button or switch

to allow engine operation for a

short period of time. Using the

override button so the engine does

not shutdown in 30 seconds but

operates for an extended period

may result in engine damage

Idle Shutdown Timer

The DDEC engine may also have

an optional 1 to 100 minute idle

shutdown system. The purpose of

this system is to conserve fuel by

eliminating excessive idling and to

allow for a turbocharger cool-down

period. To activate the shutdown, the

transmission must be in neutral with

the vehicle parking brakes set and the

engine in idle or fast-idle mode.

Cruise Control

To avoid injury from engine

shutdown in an unsafe situation,

ensure the operator knows how

to override the stop engine

condition on a DDEC-equipped

unit.

Cruise Control is available with

any DDEC engine. Cruise Control

maintains a set vehicle or engine

speed settin g. The driver/operator

has switches to set, activate and

deactivate the system . See Figure 6.

A slight pressure on the brake or

clutch deactivates the system, as well.

The minimum speed at which cruise

control can be used is programmable.

24 All information subject to change without notice. (Rev. 01/ 04)

6SE550 0401 Copyright © 2004 DETROIT DIE

SEL CORPORATION

Figure 6 Typical Cruise Control

Switches

SERIES 50 OPERATOR'S GUIDE

To avoid injury from the loss of

vehicle control, do not use cruise

control under these conditions:

When it is not possible to

keep the vehicle at a con stant

speed (on winding roads, in

heavy traffic, in traffic that

varies in speed, etc.).

On slippery roads

(wet pavement, ice-or

snow-covered roads, loose

gravel, etc.).

Cruise Control may a lso be

programmed to permit fast idle

using the cruise control switches.

With the engine at normal idle,

transmission in neutral and service

brakes on, turn on the cruise control

“ON/OFF” switch, and use the

“Resume” switch. The engine rpm

should increase to a pre-defined

When descending a hill with

cruise control OFF, do not allow

the eng ine to exceed 2,500 rpm

under any conditions. Failure to

observe this precaution can result

in overspeeding and serious engine

damage.

NOTICE:

speed. The engine rpm can be raised

or lowered from this point using the

“Set” and “Resume” switches.

Cruise Control will main tain the set

speed under normal road and load

conditions.

Cruise Control cannot limit vehicle

speeds on down grades if available

engine braking effort is exceeded, nor

can it maintain speed on upgrades if

power requirements exceed engine

power capability.

All information subject to change without not ice. (Rev. 01/ 04) 25

6SE550 0401 Copyright © 2004 DETROIT DIE

SEL CORPORATION

DDEC IV SYSTEM

When the Cruise Control switch

is in the O N position, cruise

control is engaged by momentarily

contacting the “Set/Coast” switch

to the ON position. Holding the

switch in the ON position allows the

vehicle to slow to a lower speed.

Toggling t he switch will result in a

one mile-per-hour (1.6 kph) decrease

in vehicle speed. If cruise control

has been disabled, toggling the

“Resume/Accel” switch restores the

vehicle to the previously set cruise

speed.

Using either the brake or the clutch

will disable cruise control.

To avoid injury from loss of

vehicle control, do not activate

the Engine Brake system under

the following conditions:

On wet or slippery pavement,

unless the vehicle is equipped

with ABS (anti-lock braking

system) and you have had

prior experience driving

under these conditions.

When driving without a trailer

(bobtailing) or pulling and

empty trailer.

Engine Brakes

Engine brakes are enabled by an

ON/OFF switch mounted on the dash.

A separate intensity switch is used to

select low, medium or high braking

power. Th e engine brakes will only

operate when the electronic foot pedal

assembly (EFPA) is fully released.

Disengaging the clutch will prevent

the engine brakes from operating.

Ifthetractordrivewheels

begin to lock or there is

fishtail motion after the

EngineBrakeisactivated.

Deactivate the brake system