Page 1

e

SERVICE MANUAL

MODEL JP E3 E2 EK K2A E1 E1K EUT

Ver. 3

Please refer to the

MODIFICATION NOTICE.

S-5BD

33 3

BLU-RAY DISC/DVD SURROUND RECEIVER

For purposes of improvement, specifi cations and design are subject to change without notice.

•

Please use this service manual with referring to the operating instructions without fail.

•

Some illustrations using in this service manual are slightly different from the actual set.

•

e

D&M Holdings Inc.

S0151V03DM/DG1009

Copyright 2010 D&M Holdings Inc. All rights reserved.

WARNING: Violators will be prosecuted to the maximum extent possible.

Page 2

SAFETY PRECAUTIONS

The following check should be performed for the continued protection of the customer and service technician.

LEAKAGE CURRENT CHECK

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis

resistance check. if the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the

power cord is less than 460 kohms, the unit is defective.

Be sure to test for leakage current with the AC plug in both polarities, in addition, in each power ON, OFF and STANDBY

mode, if applicable.

CAUTION

Please heed the points listed below during servicing and inspection.

◎Heed the cautions!

Spots requiring particular attention when servicing, such

as the cabinet, parts, chassis,etc., have cautions indicated

on l ab els. be sure to hee d the se ca usions and the

cautions indicated in the handling instructions.

◎Caution concerning electric shock!

(1) An AC voltage is impressed on this set, so touching

internal metal parts when the set is energized could

cause electric shoc k. Take care to avoid electric

shock, by for example using an isolating transformer

and gloves when servicing while the set is energized,

unplugging the power cord when replacing parts, etc.

(2) Tere are high voltage parts inside. Handle with extra

care when the set is energized.

◎ Caution concerning disassembly and

assembly!

Through great care is taken when manufacturing parts

from sheet metal, there may in some rare cases be burrs

on the edges of parts which could cause injury if ngers

are moved across them. Use gloves to protect your hands.

◎Only use designated parts!

The set's parts have spec if ic saf et y propert ie s (fire

resistance, voltage resistance, etc.). For replacement

par ts, be s u re to use par t s w hich hav e the sam e

poroperties. In particular, for the important safety parts

that are marked z on wiring diagrams and parts lists, be

sure to use the designated parts.

◎ Be sure to mount parts and arrange the wires

as they were originally!

For safety seasons, some parts use tape, tubes or other

insulating materials, and some parts are mounted away

from the surface of printed circuit boards. Care is also

taken with the positions of the wores omsode amd clamps

are used to keep wires away from heating and high

voltage parts, so be sure to set everything back as it was

originally.

◎Inspect for safety after servicing!

Ch eck that all s crews, par ts an d wires rem oved or

disconnected for servicing have been put back in their

original positions, inspect that no parts around the area

that has been serviced have been negatively affected,

con duct an i nsla tion chec k on th e e xter nal me tal

connectors and between the blades of the power plug,

and otherwise check that safety is ensured.

(Insulation check procedure)

Unplug the power cord from the power outlet, disconnect

the antenna, plugs, etc., and turn the power switch on.

Using a 500V insulation resistance tester, check that the

inplug and the externally exposed metal parts (antenna

terminal, headphones terminal, input terminal, etc.) is

1MΩ or greater. If it is less, the set must be inspected and

repaired.

CAUTION

Concerning important safety

parts

Many of the electric and structural parts used in the set

have sp ecial safety properties. In most ca ses these

properties are difficult to distinguish by sight, and using

replacement parts with higher ratings (rated power and

withstand voltage) does not necessarily guarantee that

safety performance will be poreserved. Parts with safety

properties are indicated as shown below on the wiring

diagrams and parts lists is this service manual. Be sure to

replace them with parts with the designated part number.

(1) Schematic diagrams ...... Indicated by the z mark.

(2) Parts lists ...... Indicated by the z mark.

Using parts other than the designated

parts could result in electric shock, res

or other dangerous situations.

2

Page 3

NOTE FOR SCHEMATIC DIAGRAM

NOTE FOR PARTS LIST

WARNING:

Parts marked with this symbol z have critical characteristics. Use ONLY replacement parts recommended by the manufacture

CAUTION:

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis resistance check. If the

leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the power cord is less than 460 kohms, the unit is defective.

WARNING:

DO NOT return the unit to the customer until the problem is located and corrected.

NOTICE:

ALL RESISTANCE VALUES IN OHM. k=1,000 OHM / M=1,000,000 OHM

ALL CAPACITANCE VALUES IN MICRO FARAD. P=MICRO-MICRO FARAD EACH VOLTAGE AND CURRENT ARE MEASURED AT NO SIGNAL

INPUT CONDITION. CIRCUIT AND PARTS ARE SUBJECT TO CHANGE WITHOUT PRIOR NOTICE.

r.

NOTE FOR PARTS LIST

1.

Parts for which "nsp" is indicated on this table cannot be supplied.

2.

When ordering of part, clearly indicate "1" and "I" (i) to avoid mis-supplying.

3.

Ordering part without stating its part number can not be supplied.

4.

Part indicated with the mark "★" is not illustrated in the exploded view.

5.

Not including General-purpose Carbon Film Resistor in the P.W.Board parts list. (Refer to the Schematic Diagram for those parts.)

6.

Not including General-purpose Carbon Chip Resistor in the P.W.Board parts list. (Refer to the Schematic Diagram for those parts.)

WARNING:

● Resistors

Ex.: RN

* Resistance

Capacitors

●

Ex.: CE

* Capacity (electrolyte only)

* Capacity (except electrolyte)

・ When the dielectric strength is indicated in AC,"AC" is included after the dieelectric strength value.

Parts marked with this symbol z have critical characteristics. Use ONLY replacement parts recommended by the manufacturer.

Type

RD : Carbon

RC : Composition

RS : Metal oxide film

RW: winding

RN : Metal film

RK : Metal mixture

2

Indicates number of zeros after effective number.

2-digit effective number.

1-digit effective number.

: Units: ohm

Type

CE : Aluminum foil

electrolytic

CA : Aluminium solid

electrolytic

CS : Tantalum electrolytic

CQ : Film

CK : Ceramic

CC : Ceramic

CP : Oil

CM: Mica

CF : Metallized

CH : Metallized

2

Indicates number of zeros after effective number.

・ Units:μF.

・ Units:pF

2-digit effective number.

2

14K

Shape

and performance

2-digit effective number, decimal point indicated by R.

04W

Shape

and performance

Indicates number of zeros after efective number. (More than 2)

2-digit effective number.

2E

Power

2B : 1/8 W

2E : 1/4 W

2H : 1/2 W

3A : 1 W

3D : 2 W

3F : 3 W

3H : 5 W

1800ohm=1.8kohm1 8

1.2ohm1 R 2

1H

Dielectric

strength

0J : 6.3 V

1A : 10 V

1C : 16 V

1E : 25 V

1V : 35 V

1H : 50 V

2A : 100 V

2B : 125 V

2C : 160 V

2D : 200 V

2E : 250 V

2H : 500 V

2J : 630 V

2200μF2 2

2200pF=0.0022μF2 2

182

Resistance

F : ±1%

G : ±2%

J : ±5%

K : ±10%

M : ±20%

3R2

CapacityMAllowable

G

Allowable

error

P : Pulse-resistant type

NL : Low noise type

NB : Non-burning type

FR : Fuse-resistor

F : Lead wire forming

error

F : ±1%

G : ±2%

J : ±5%

K : ±10%

M : ±20%

Z : ±80%

: - 20%

P : +100%

C : ±0.25pF

D : ±0.5pF

= : Others

FR

Others

BP

Others

HS : High stability type

BP : Non-polar type

HR : Ripple-resistant type

DL : For change and discharge

HF : For assuring high requency

U : UL part

C : CSA part

W : UL-CSA part

F : Lead wire forming

2

・ Units:μF.

1

・ Units:pF

2.2μF2 R

1-digit effective number.

2-digit effective number, decimal point indicated by R

220pF2 2

Indicates number of zeros after effective numver. (0 or 1)

2-digit effective number.

3

Page 4

m

WARNING AND LASER SAFETY INSTRUCTIONS

GB

WARNING

All ICs and many other semi-conductors are

susceptible to electrostatic discharges (ESD).

Careless handling during repair can reduce

life drastically.

When repairing, make sure that you are

connected with the same potential as the

mass of the set via a wrist wrap with

resistance.

Keep components and tools also at this

potential.

F

ATTENTION

D

WARNUNG

I

WAARSCHUWING

AVVERTIMENTO

NL

Alle IC’s en vele andere halfgeleiders zijn

gevoelig voor elektrostatische ontladingen

(ESD).

Onzorgvuldig behandelen tijdens reparatie

kan de levensduur drastisch doen

verminderen.

Zorg ervoor dat u tijdens reparatie via een

polsband met weerstand verbonden bent met

hetzelfde potentiaal als de massa van het

apparaat.

Houd componenten en hulpmiddelen ook op

ditzelfde potentiaal.

Tous les IC et beaucoup d’autres semiconducteurs sont sensibles aux décharges

statiques (ESD).

Leur longévité pourrait être considérablement

écourtée par le fait qu’aucune précaution

n’est prise a leur manipulation.

Lors de réparations, s’assurer de bien être

relié au même potentiel que la masse de

l’appareil et enfiler le bracelet serti d’une

résistance de sécurité.

Veiller a ce que les composa

outils que l’on utilise soient également a ce

potentiel.

nts ainsi que les

GB

Safety regulations require that the set be restored to its original condition

and that parts which are identical with those specified be used.

NL

Veiligheidsbepalingen vereisen, dat het apparaat in zijn oorspronkelijke

toestand wordt terug gebracht en dat onderdelen, identiek aan de

gespecifieerde worden toegepast.

Alle IC und viele andere Halbleiter sind

empfindlich gegen elektrostatische

Entladungen (ESD).

Unsorgfältige Behandlung bei der Reparatur

kann die Lebensdauer drastisch vermindern.

Sorgen sie dafür, das Sie im Reparaturfall

über ein Pulsarmband mit Widerstand mit

dem Massepotential des Gerätes verbunden

sind.

Halten Sie Bauteile und Hilfsmittel ebenfalls

auf diesem Potential.

D

Bei jeder Reparatur sind die geltenden Sicherheitsvorschriften zu beachten.

Der Originalzustand des Gerats darf nicht verandert werden

Fur Reparaturen sind Original-Ersatzteile zu verwenden.

I

Le norme di sicurezza esigono che l’apparecchio venga rimesso nelle

condizioni originali e che siano utilizzati pezzi di ricambiago idetici a quelli

specificati.

Tutti IC e parecchi semi-conduttori sono

sensibili alle scariche statiche (ESD).

La loro longevita potrebbe essere fortemente

ridatta in caso di non osservazione della piu

grande cauzione alla loro manipolazione.

Durante le riparazioni occorre quindi essere

collegato allo stesso potenziale che quello

della massa dell’apparecchio tramite un

braccialetto a resistenza.

Assicurarsi che i componenti e anche gli

utensili con quali si lavora s

questo potenziale.

iano anche a

.

F

“Pour votre sécurité, ces documents

doivent être utilisés par des

spécialistes agrées, seu ls habilités à

réparer votre appareil en panne.”

Les normes de sécurité exigent que l’appareil soit remis a l’état d’origine et

que soient utilisées les pièces de rechange identiques à celles spécifiées.

LASER SAFETY

This unit employs a laser. Only a qualified service person should remove the cover or attempt to service t

device, due to possible eye injury.

his

USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURE OTHER THAN THOSE

SPECIFIED H

EREIN MAY RESULT IN HAZARDOUS RADIATION EXPOSURE.

AVOID DIRECT EXPOSURE TO BEAM

WARNING

The use of optical instruments with this product will increase eye hazard.

Repair handling should take place as much as possible with a disc loaded inside the player

WARNING LOCATION: INSIDE ON LASER COVERSHIELD

CAUTION VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID EXPOSURE TO BEAM

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING VED ÅBNING UNDGÅ UDS

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING NÅR DEKSEL Å PNES UNNGÅ EKSPONERING FOR STRÅLEN

VARNING SYNLIG OCH OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD BETRAKTA EJ STRÅLEN

VARO! AVATT AESSA OLET ALTTIINA NÄKYVÄLLE JA NÄKYMÄTTÖMÄLLE LASER SÄ

VORSICHT SICHTBARE UND UNSICHTBARE LASERSTRAHLUNG WENN ABDECKUNG GEÖFFNET NICHT DEM STRAHL AUSSETSEN

DANGER VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID DIRECT EXPOSURE TO BEAM

ATTENTION RAYONNEMENT LASER VISIBLE ET INVISIBLE EN CAS D'OUVERTURE EXPOSITION DANGEREUSE AU FAISCEAU

Æ

TTELSE FOR STRÅLING

TEILYLLE. ÄLÄ KATSO SÄTEESEEN

030804ec

4

Page 5

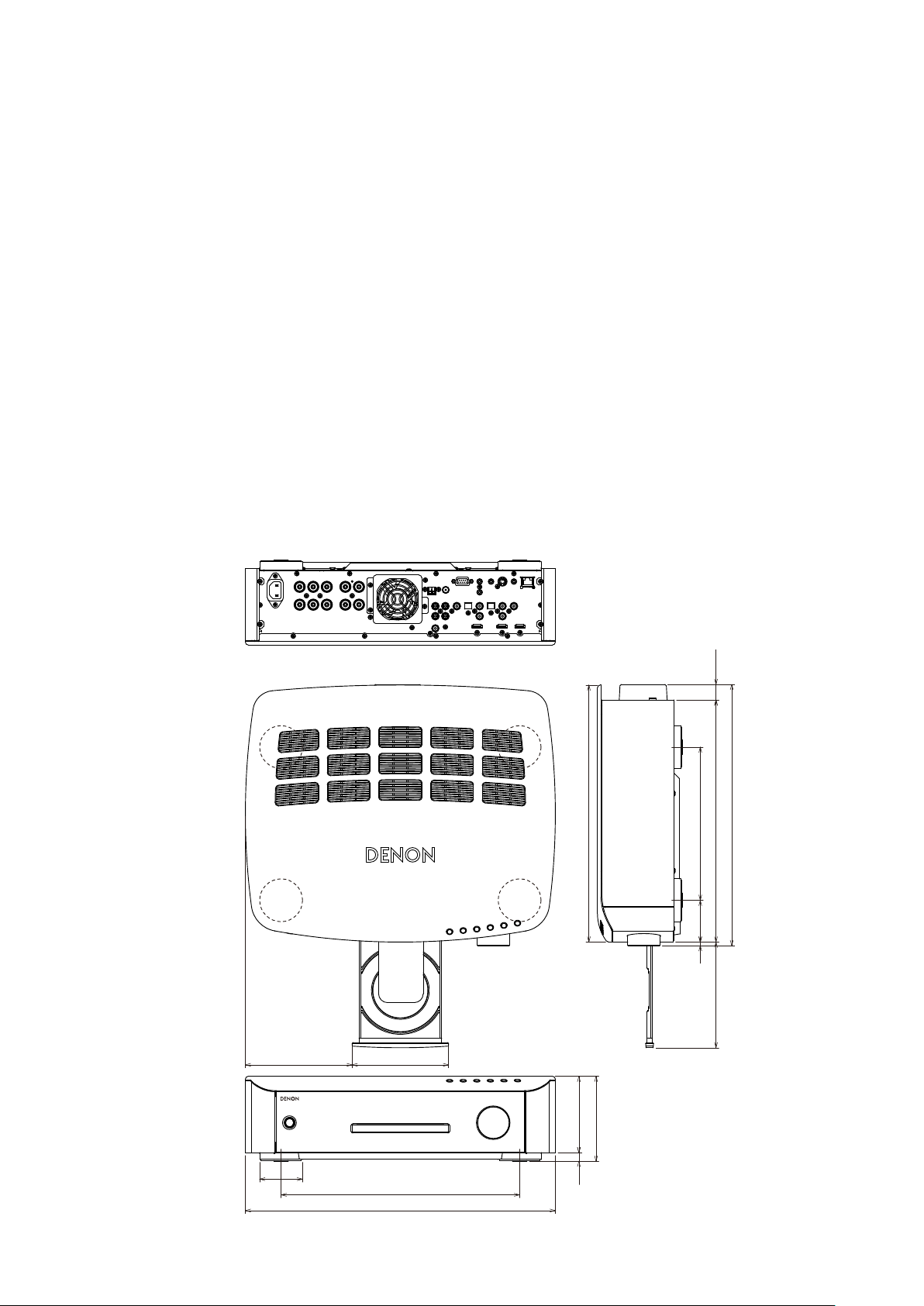

TECHNICAL SPECIFICATIONS

n Audio Section

• Power amplifier

Rated output :

Front : 75 W + 75 W (1 kHz, 4 Ω, T.H.D. 0.7 %)

Center : 75 W (1 kHz, 4 Ω, T.H.D. 0.7 %)

Surround : 75 W + 75 W (1 kHz, 4 Ω, T.H.D. 0.7 %)

Output connectors : Front, Center, Surround : 4 – 16 Ω

• Analog

Input sensitivity/Input impedance : 160 mV/47 kΩ

• Digital

Digital input : Format — Digital audio interface

n Video Section

• S-Video connectors

Input/output level and impedance :

Y (brightness) signal — 1 Vp-p, 75 Ω

C (color) signal — 0.3 (PAL)/0.286 (NTSC) Vp-p, 75 Ω

Frequency response : 5 Hz – 6 MHz — +0, –3 dB

n Tuner section

Reception frequency range :

[FM] 87.50 MHz – 108.00 MHz [AM]522 kHz – 1611 kHz

Receiving sensitivity :

[FM]1.5 μV / 75 Ω [AM]20 μV

FM stereo separation :

[FM]35 dB (1 kHz)

DIMENSION

n Applicable Discs/Memory Cards

BD-Video discs : 12 cm 1 side 1 layer, 12 cm 1 side 2 layers

DVD-Video discs :

12 cm 1 side 1 layer, 12 cm 1 side 2 layers/

12 cm 2 sides 2 layers (1 side 1 layer)

8 cm 1 side 1 layer, 8 cm 1 side 2 layers/

8 cm 2 sides 2 layers (1 side 1 layer)

Compact Discs (CD-DA) : 12 cm / 8 cm discs

Memory cards :

SD memory card/SDHC memory card/miniSD card/microSD card

n General

Power supply : AC 230 V, 50 Hz

Power consumption :

110 W

0.3 W (Normal standby)

Maximum external dimensions :

With the doors closed

434 (W) x 119 (H) x 365 (D) mm

With the doors open

445 (W) x 119 (H) x 365 (D) mm

Weight : 7.8 kg

n Remote Control Unit (RC-1122)

Batteries : R6/AA Type (two batteries)

Maximum external dimensions : 52 (W) x 243 (H) x 21 (D) mm

Weight : 175 g (including batteries)

360

135149.5

119

60

334

434

12 107

58.55 214.5

339148 21.8

365.8

5

Page 6

CAUTION IN SERVICING

Before the Digital P.W.B. are replaced

If you cannot specify the cause of the digital PWB defect, carry out "Initializing" → "Update to latest rmware".

The defect may be cleared.

• See the following for the method of initializing the μcom.

Initializing

S5BD initialization should be performed when the µcom, peripheral parts of µcom, Digital P.W.B., BE P.W.D and BD

mechanism are replaced.

1. Remove the power plug.

2. While pressing

3. Check that the entire display is ashing with an interval of about 1 second, and release your ngers from the 2

buttons and the microprocessor will be initialized.

Note: •If step 3 does not work, start over from step 1.

All user settings will be lost and this factory setting will be recovered when this initialization mode.

•

So make sure to m+emorize your setting for restoring after the initialization.

and SOURCE button simultaneously, plug the power cord into a power outlet.

9

2,3

Service tools

Measuring Disc: CD/TCD-784

DVD/VT502 or TDV-520A

BD/ABD-520 or BLX-108

Refer to "MEASURING METHOD AND WAVEFORMS".

z

Service Jigs

When you repair the printing board, you can use the following JIG (Extension cable kit). Please order to Denon Ofcial

Service Distributor in your region if necessary.

Extention cable kit

00D SPK- 562 TUCP CONN. JOINT KIT : 1 Set

6

Page 7

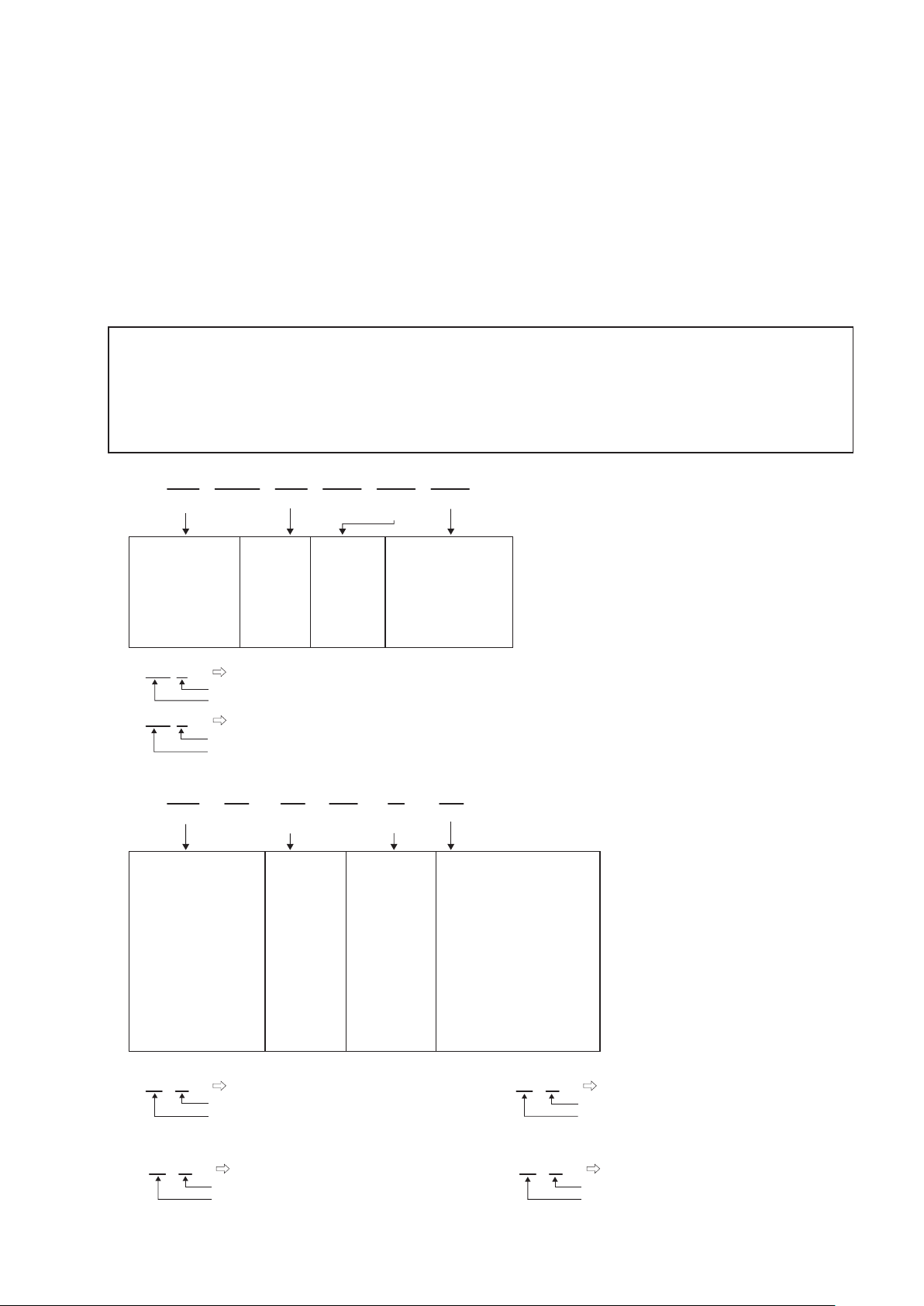

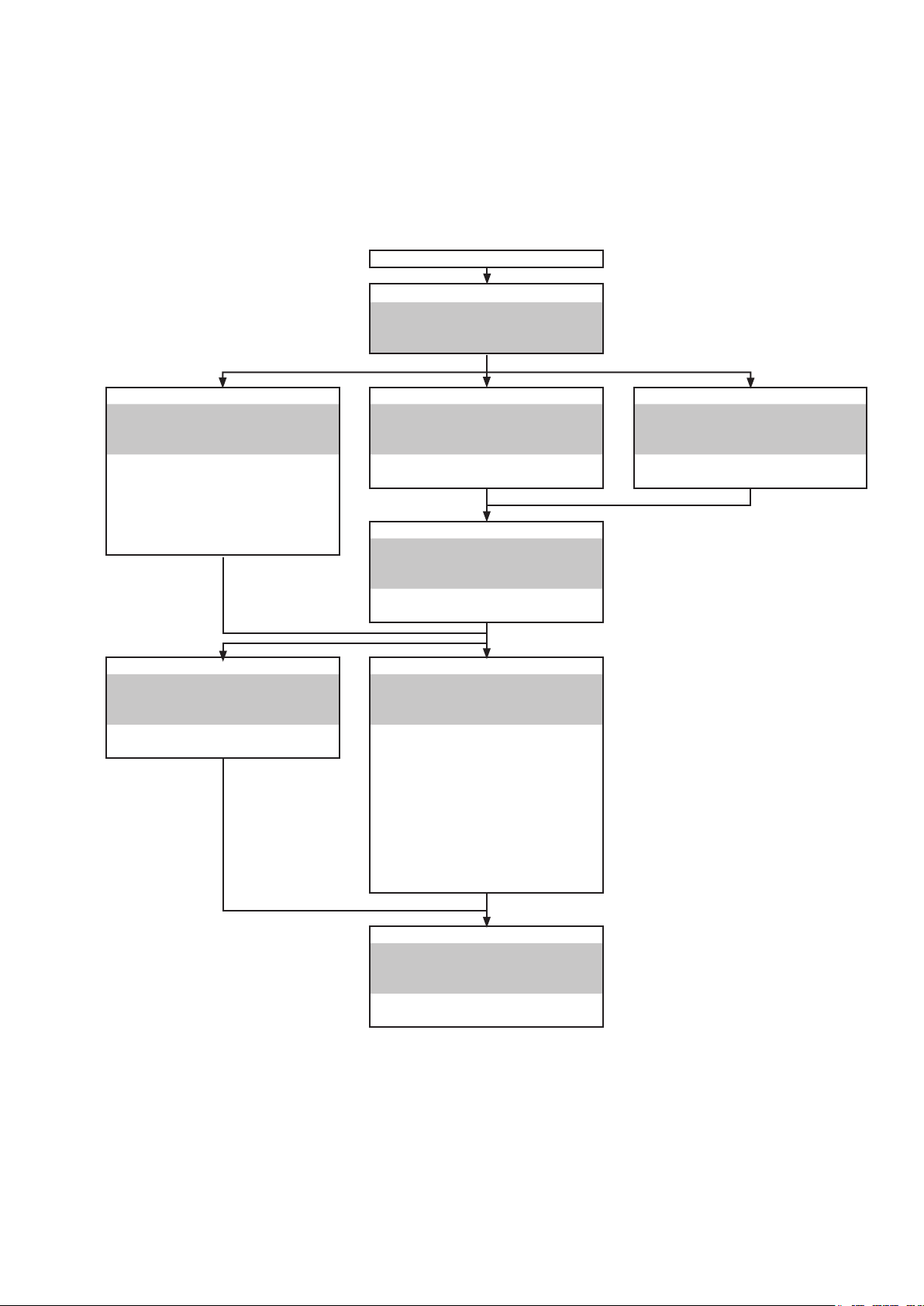

DISASSEMBLY

• Disassembleinorderofthearrowofthegureoffollowingow.

• Inthecaseofthere-assembling,assembleitinorderofthereverseofthefollowingow.

• Inthecaseofthere-assembling,observe"attentionofassembling"it.

• Ifwirebundlesareuntiedormovedtoperformadjustmentorpartsreplacementetc.,besuretorearrangethemneatly

astheywereoriginallybundledorplacedafterward.

Otherwise,incorrectarrangementcanbeacauseofnoisegeneration.

COVER SIDE-L/R

CABINET TOP ASSY

Referto "DISASSEMBLY

1.CABINET TOP ASSY"

and"EXPLODED VIEW"

FRONT PANEL ASSY BE UNIT ASSY DIGITAL AMP UNIT ASSY

Referto "DISASSEMBLY Referto "DISASSEMBLY Referto "DISASSEMBLY

2.PANEL FRONT SUB ASSY" 4. BE UNIT ASSY" 3. DIGITAL AMP UNIT ASSY"

and"EXPLODED VIEW" and"EXPLODED VIEW" and"EXPLODED VIEW"

ON/STUNIT B/EUNIT DIGITALAMPUNIT

(Ref.No.ofEXPLODEDVIEW:1-3) (Ref.No.ofEXPLODEDVIEW:5) (Ref.No.ofEXPLODEDVIEW:3-1)

FLDUNIT

(Ref.No.ofEXPLODEDVIEW:2-2)

F.USBUNIT CHASSIS MIDDLE

(Ref.No.ofEXPLODEDVIEW:3-2) Referto "DISASSEMBLY

5. CHASSIS MIDDLE"

and"EXPLODED VIEW"

CHASSISMIDDLE

(Ref.No.ofEXPLODEDVIEW:34)

MECHA ASSY CHASSIS BACK ASSY

Referto "DISASSEMBLY Referto "DISASSEMBLY

6. MECHA ASSY" 7. CHASSIS BACK ASSY"

and"EXPLODED VIEW" and"EXPLODED VIEW"

BDMECHAUNIT ANALOGAUDIOUNIT

(Ref.No.ofEXPLODEDVIEW:19) (Ref.No.ofEXPLODEDVIEW:1-2)

MAINUNIT

(Ref.No.ofEXPLODEDVIEW:2-1)

JOINTBUNIT

(Ref.No.ofEXPLODEDVIEW:2-3)

JOINTCUNIT

(Ref.No.ofEXPLODEDVIEW:3-5)

JOINTDUNIT

(Ref.No.ofEXPLODEDVIEW:3-6)

SMPS UNIT ASSY

Referto "DISASSEMBLY

8. SMPS UNIT ASSY"

and"EXPLODED VIEW"

SMPSUNIT

(Ref.No.ofEXPLODEDVIEW:1-1)

7

Page 8

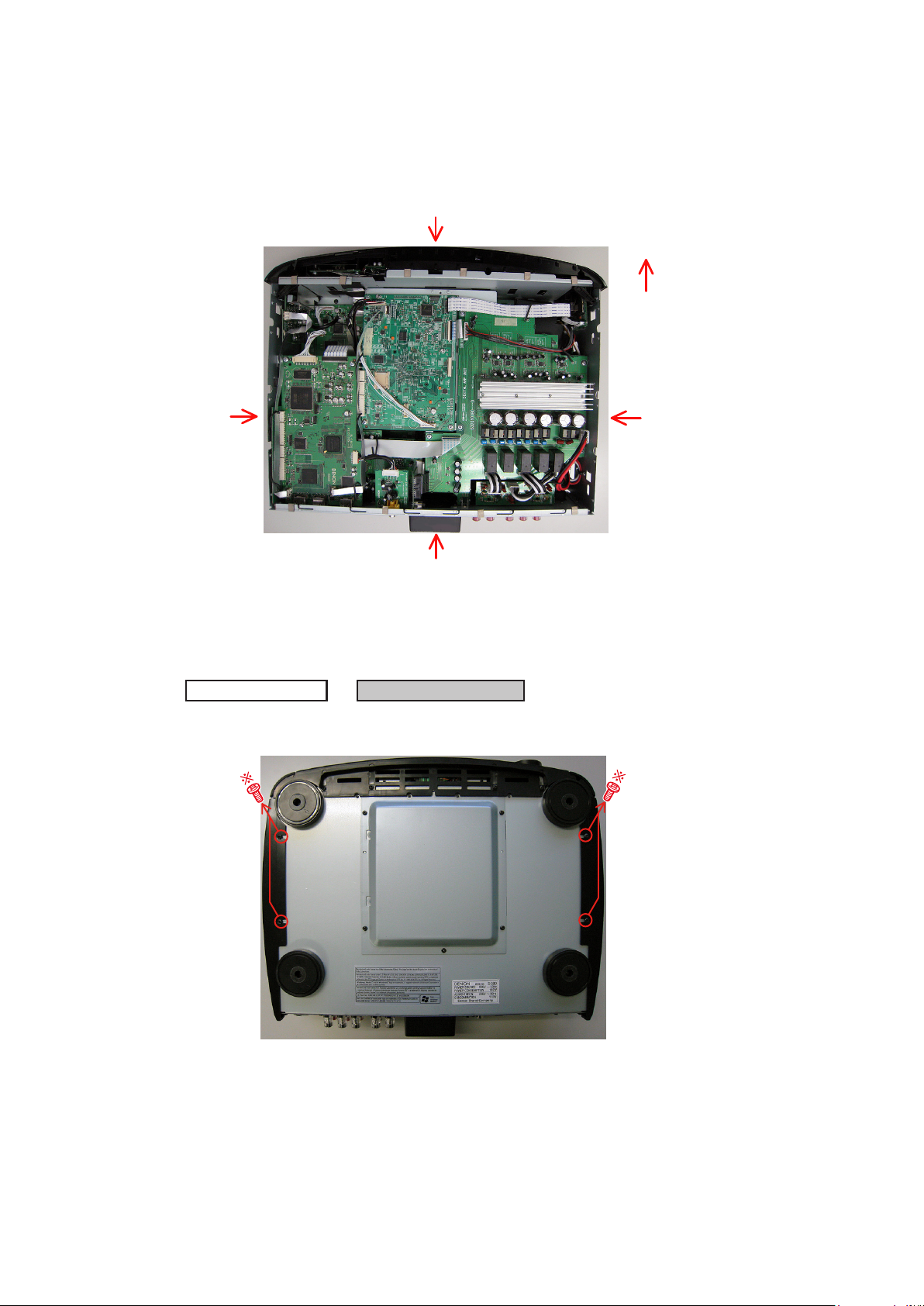

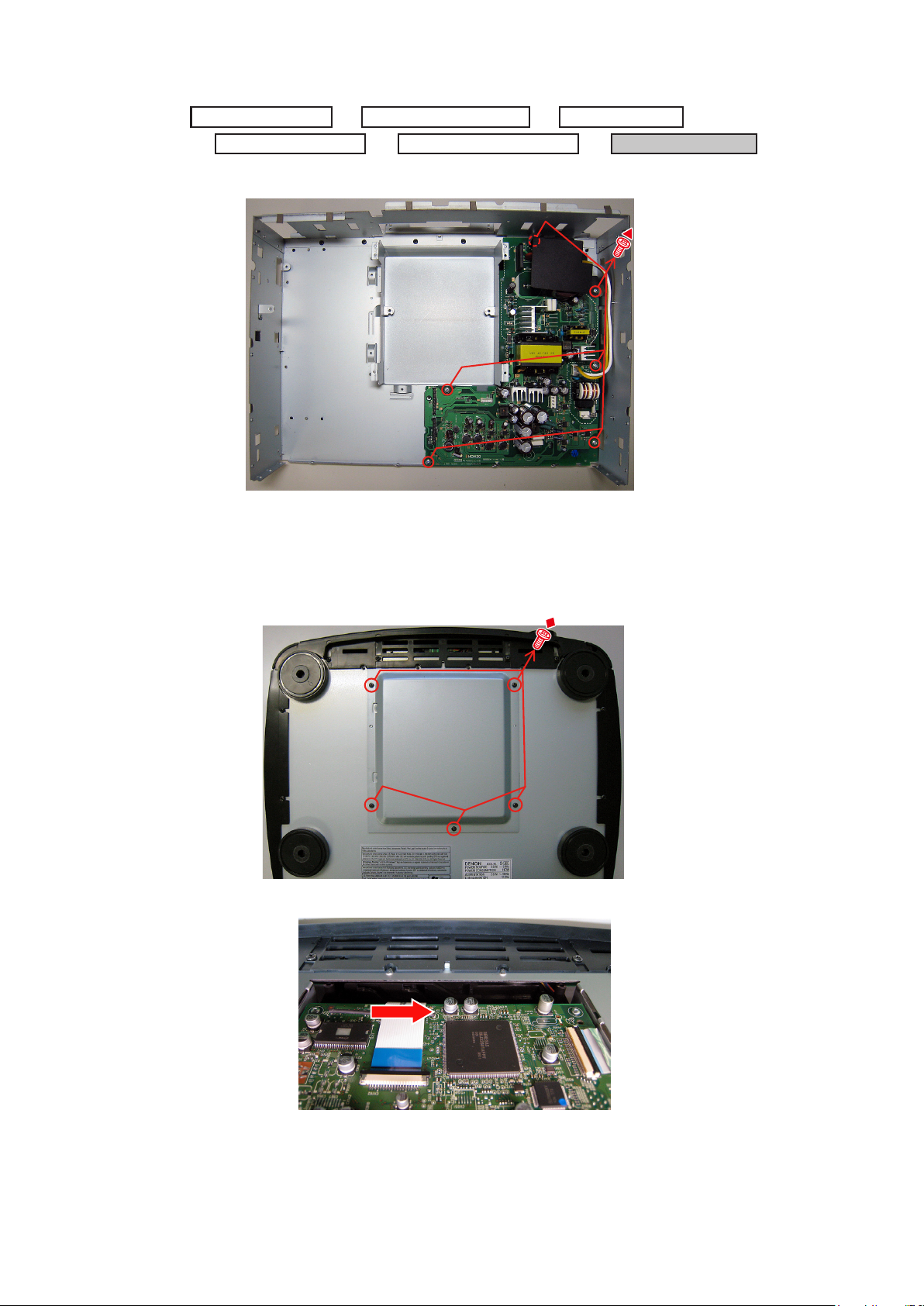

About the photos used for descriptions in the DISASSEMBLY" section.

• Thedirectionfromwhichthephotographsusedhereinwerephotographedisindicatedat"Directionofphotograph:***"

attheleftoftherespectivephotographs.

• Refertothetablebelowforadescriptionofthedirectioninwhichthephotosweretaken.

• Photographsforwhichnodirectionisindicatedweretakenfromabovetheproduct.

The viewpoint of each photograph

(Photografy direction)

[View from above]

Direction of photograph: C

Direction of photograph: B

Front side

Direction of photograph: D

Direction of photograph: A

1. CABINET TOP ASSY

Proceeding :

(1) Removethescrews.

View from bottom

COVER SIDE-L/R

CABINET TOP ASSY

→

8

Page 9

(2) RemovethescrewsandtheCoverSide.

Direction of photograph: A

(3) Removethescrews.

Direction of photograph: A

(4) Removethescrews.

Direction of photograph: C

Direction of photograph: D

Pleasereferto"EXPLODEDVIEW"forthedisassemblymethodofeachP.W.BincludedinCABINETTOPASSY.

9

Page 10

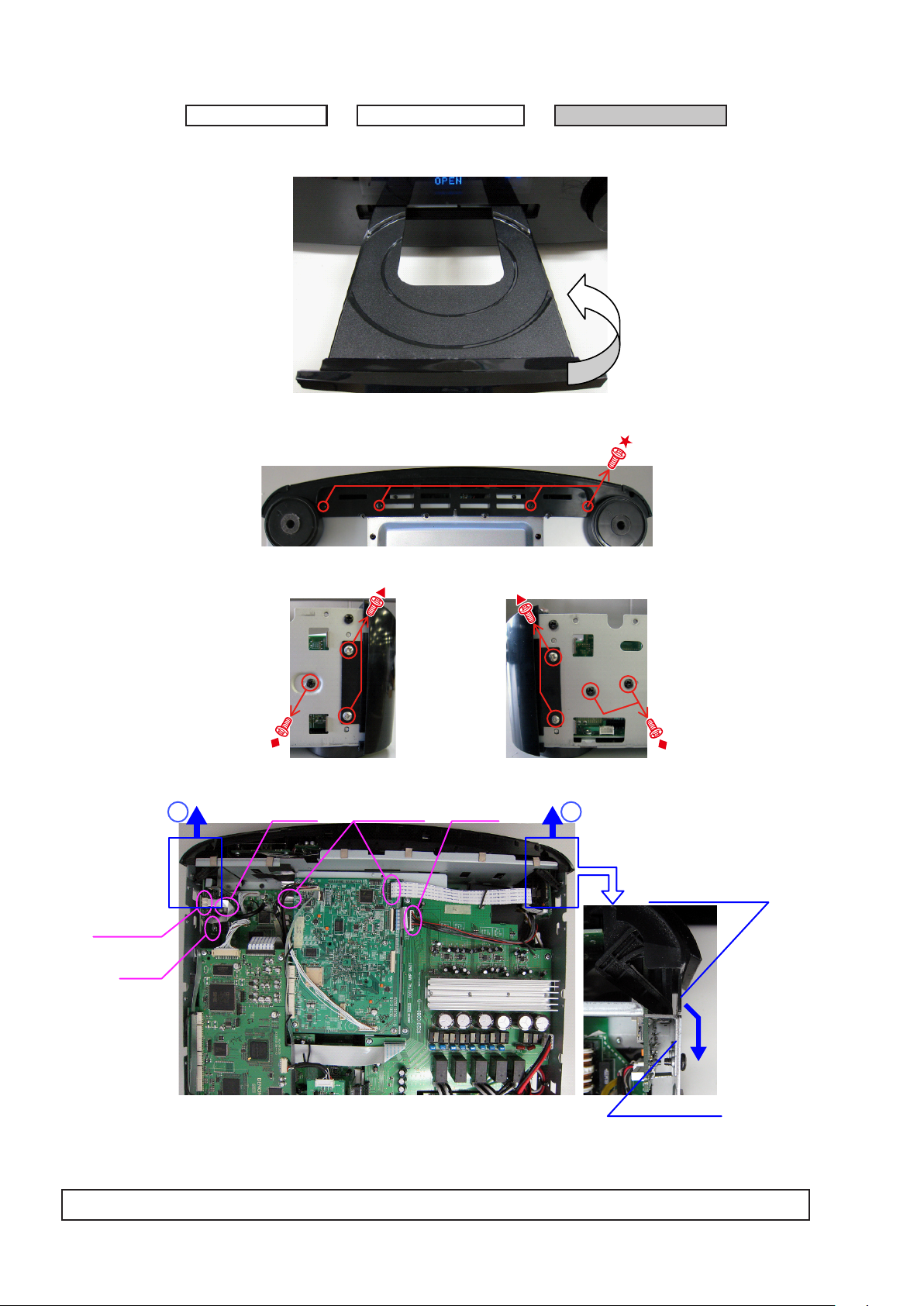

2. FRONT PANEL ASSY

Proceeding :

(1) RemovetheCoverTray.

Direction of photograph: B

(2) Removethescrews.

View from bottom

COVER SIDE-L/R

CABINET TOP ASSY

→

FRONT PANEL ASSY

→

(3) Removethescrews.

Direction of photograph: D

(4) DisconnecttheconnectorwireandFFCCable.

FFC CableCY054 CX104

FFC Cable

CY111

12

FRONT PANEL ASSY

zThe order of detaching FRONT PANEL ASSY are from q to w.

In the case of the re-assembling, install FRONT PANEL ASSY

in CHASSIS MAIN as shown in the photograph.

Pleasereferto"EXPLODEDVIEW"forthedisassemblymethodofeachP.W.BincludedinFRONTPANELASSY.

10

CHASSIS MAIN

Page 11

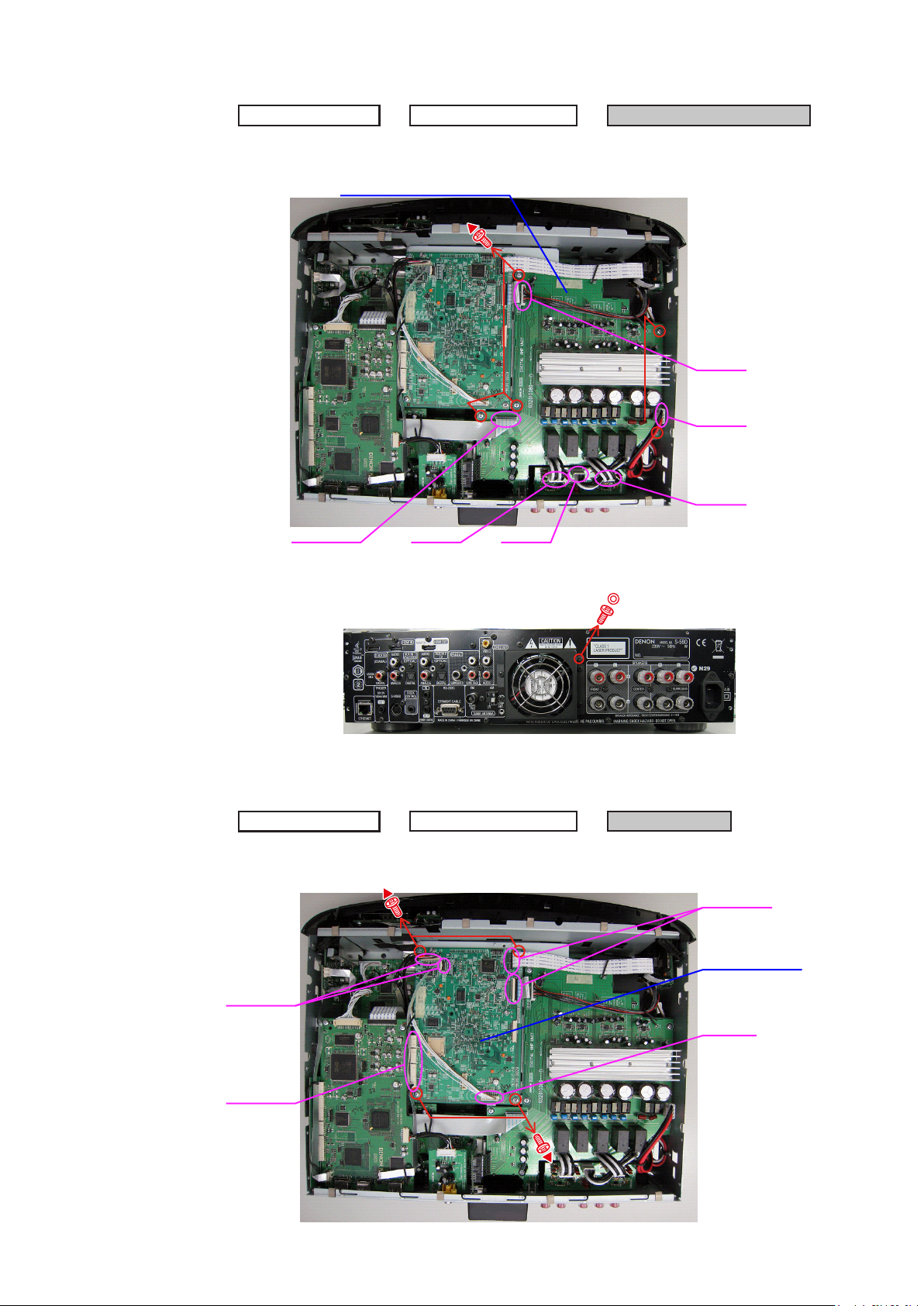

3. DIGITAL AMP UNIT ASSY

Proceeding :

(1) Removethescrews.DisconnecttheconnectorwiresandFFCCable.

COVER SIDE-L/R

DIGITAL AMP UNIT ASSY

CABINET TOP ASSY

→

DIGITAL AMP UNIT ASSY

→

CX104

CY044

CY047

FFC Cable

(2) Removethescrews.

Direction of photograph: A

CY035CY046

4. BE UNIT ASSY

Proceeding :

(1) Removethescrews.DisconnecttheconnectorwireandFFCCables.

COVER SIDE-L/R

CABINET TOP ASSY

→

BE UNIT ASSY

→

FFC Cable

BE UNIT ASSY

FFC Cable

FFC Cable

CX088

11

Page 12

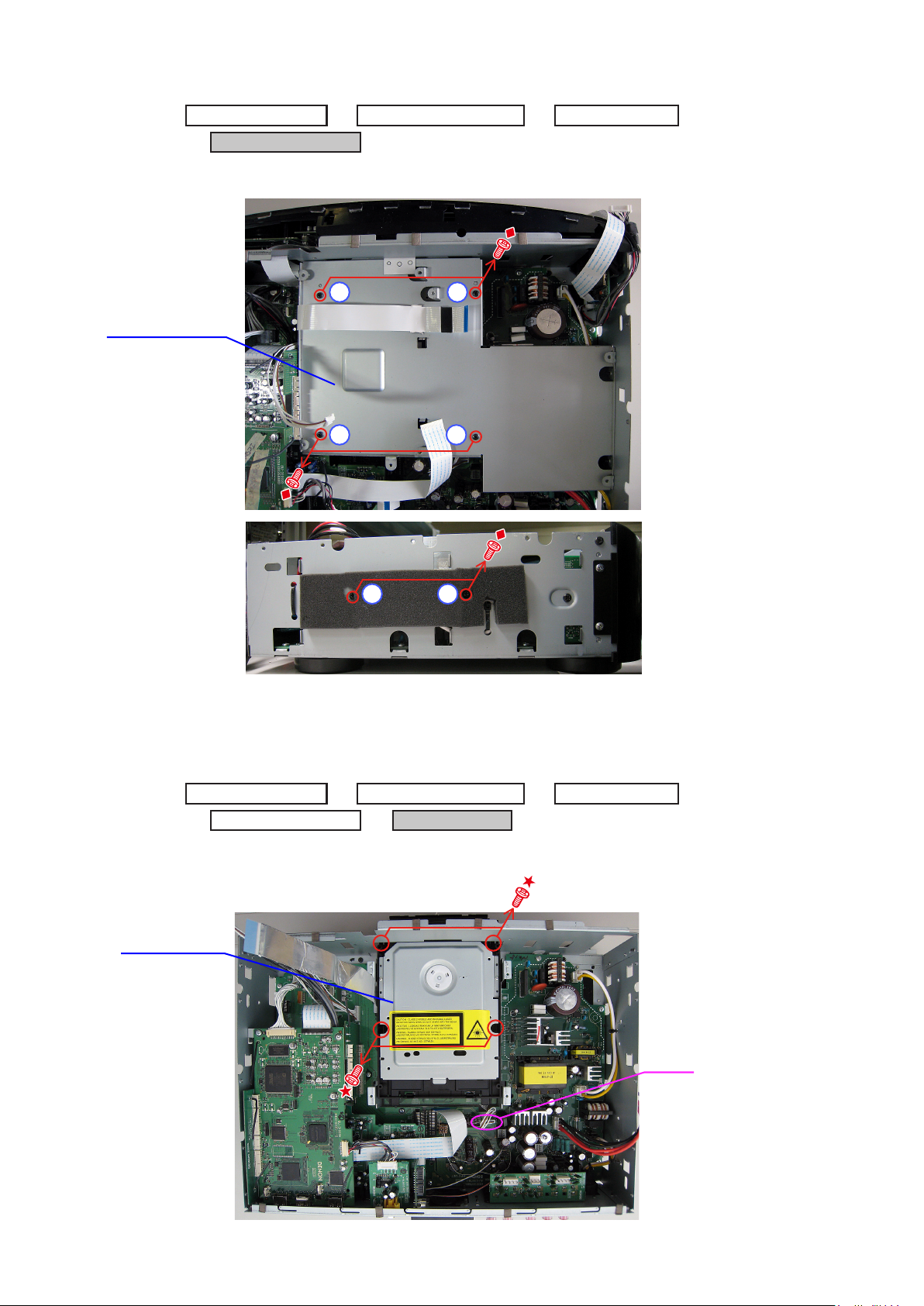

5. CHASSIS MIDDLE

→

→

Proceeding :

(1) Removethescrews.

CHASSIS MIDDLE

COVER SIDE-L/R

CHASSIS MIDDLE

→

CABINET TOP ASSY

→

1 5

4 6

BE UNIT ASSY

→

Direction of photograph: D

zIn the case of the re-assembling, assemble it in order from 1 to 6.

3 2

6. MECHA ASSY

Proceeding :

COVER SIDE-L/R

CHASSIS MIDDLE

(1) Removethescrews.Disconnecttheconnectorwire.

MECHA ASSY

CABINET TOP ASSY

→

MECHA ASSY

BE UNIT ASSY

→

CY063

12

Page 13

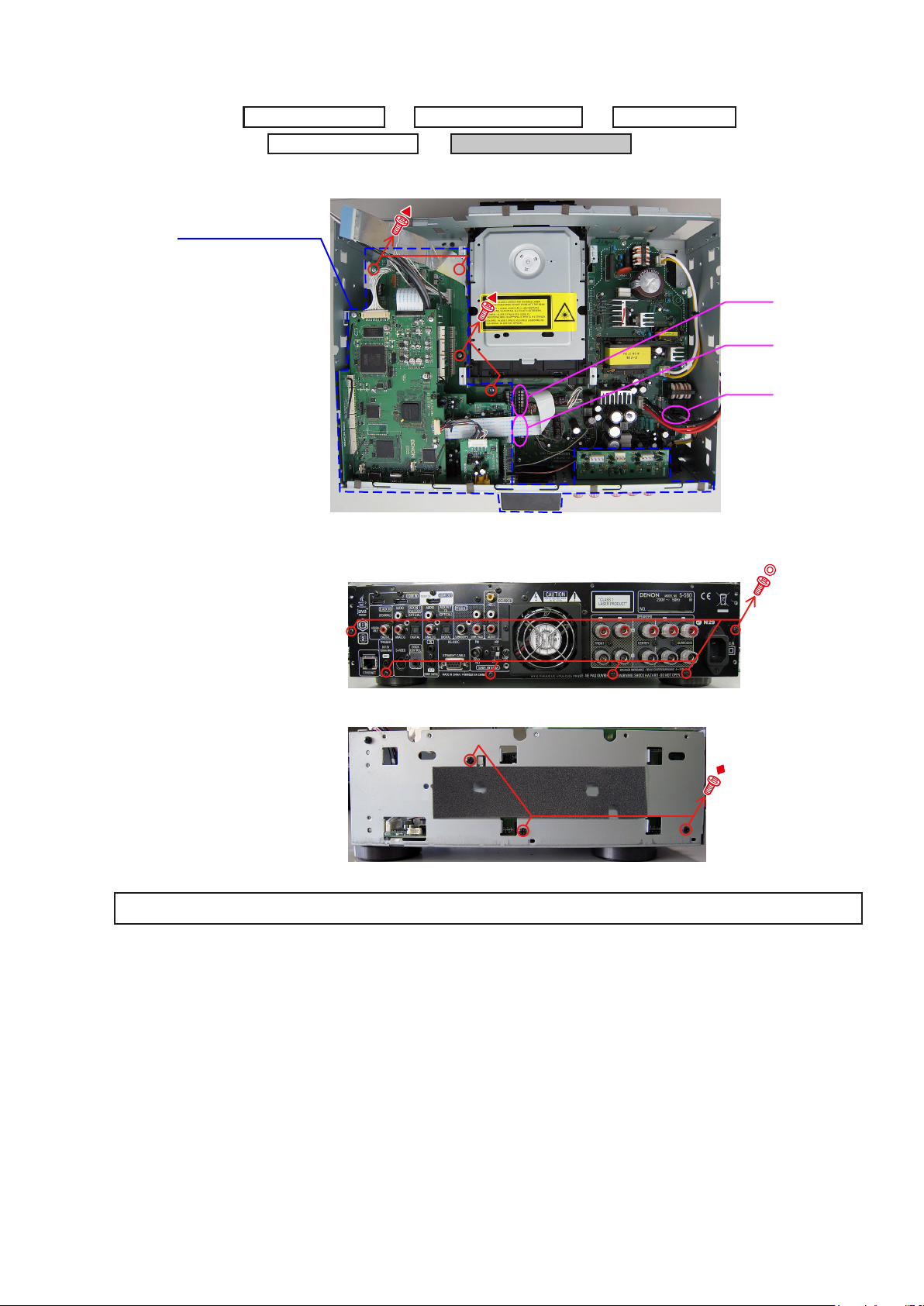

7. CHASSIS BACK ASSY

Proceeding :

(1) Removethescrews.Disconnecttheconnectorwire.

CHASSIS BACK ASSY

(2) Removethescrews.

COVER SIDE-L/R

CHASSIS MIDDLE

→

CABINET TOP ASSY

→

CHASSIS BACK ASSY

→

BE UNIT ASSY

→

CX191

CX234

CX032

Direction of photograph: A

(3) Removethescrews.

Direction of photograph: C

Pleasereferto"EXPLODEDVIEW"forthedisassemblymethodofeachP.W.BincludedinCHASSISBACKASSY.

13

Page 14

8. SMPS UNIT ASSY

Proceeding :

COVER SIDE-L/R

→

(1) Removethescrews.

→

CHASSIS MIDDLE

CABINET TOP ASSY

CHASSIS BACK ASSY

→

BE UNIT ASSY

→

→

SMPS UNIT ASSY

Removing discs

(1) Removethescrews.

View from bottom

(2) SlidetheSLIDECAMinthedirectionofthearrow.

Direction of photograph: A

(3) DrawouttheLOADERTRAY,thenremovethedisc.

14

Page 15

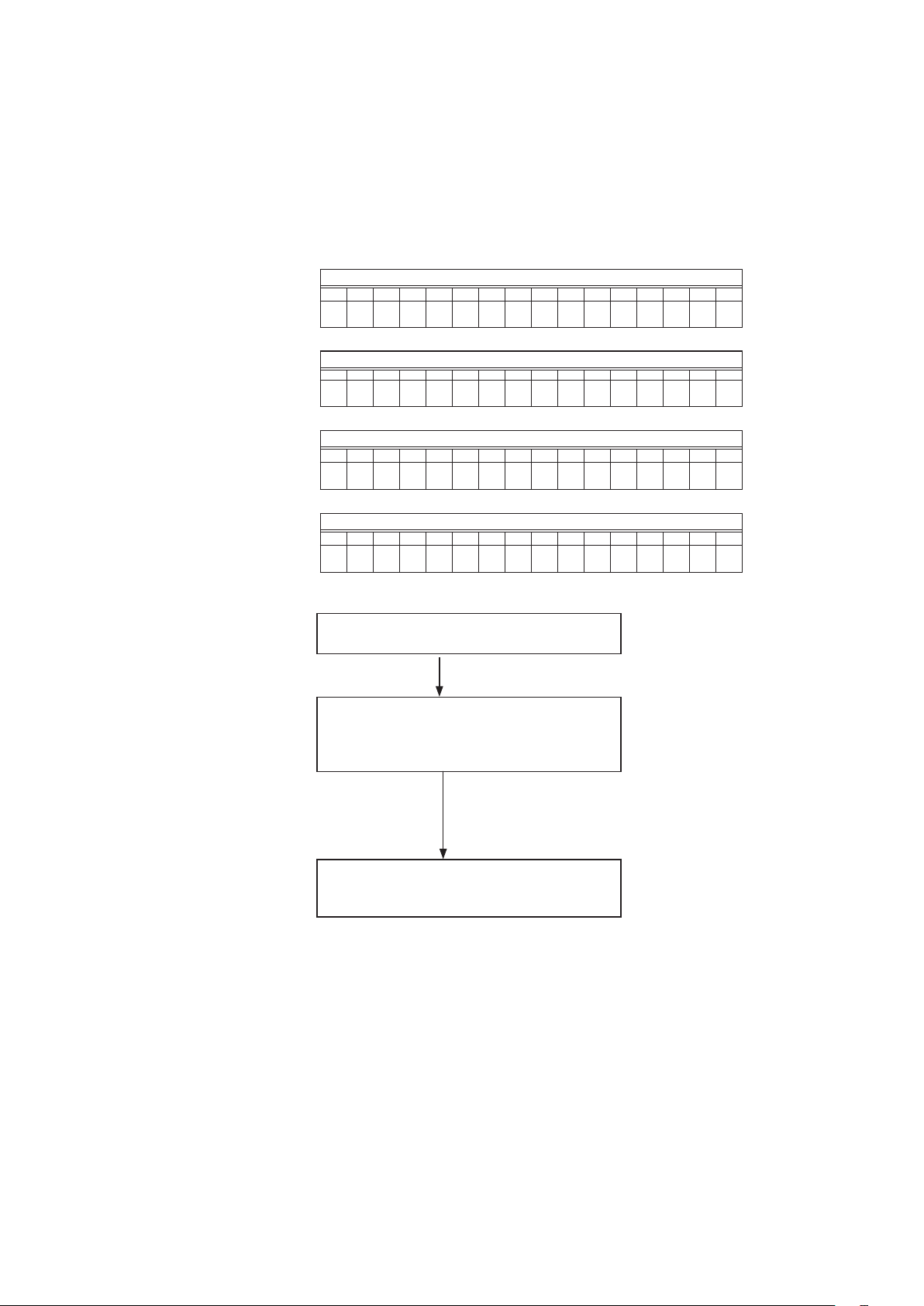

DIAGNOSTICS OF OPTICAL PICKUP AND REPLACING FE MAIN P.W.B AND BD MECHANISM UNIT ASSY

Make failure diagnostics of the Optical Pickup as follows.

If the laser drive current (Iop) becomes more than ±12[mA] of the initial value, the Optical Pickup should be replaced.

The laser drive current initial value is checked by "Iop checked Method" of next page.

In case of replacing the Pickup, change the whole part of the FE Main P.W.B and BD Mechanism Unit Assy.

No mechanical adjustment is necessary after the replacement.

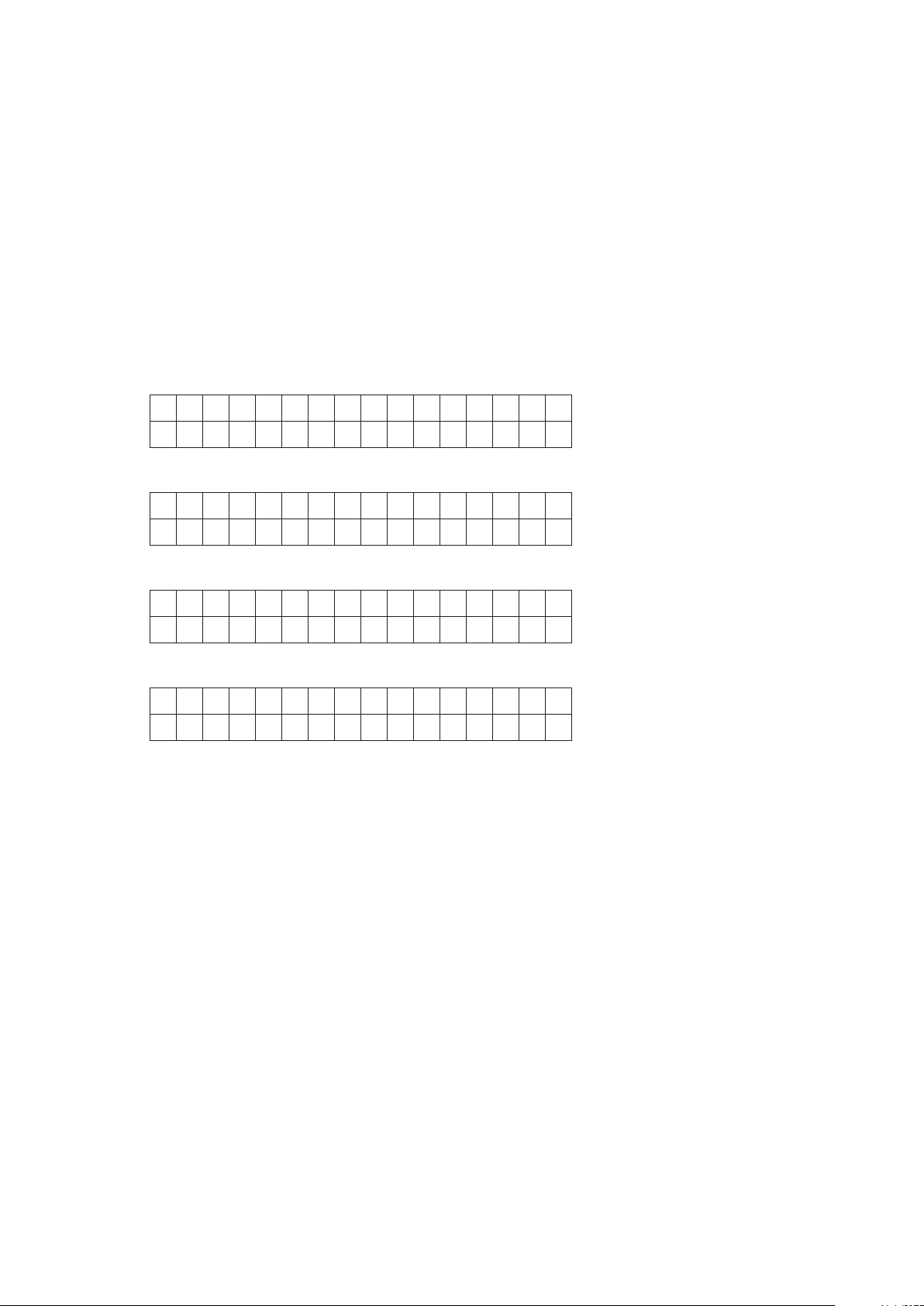

Laser drive current initial value:

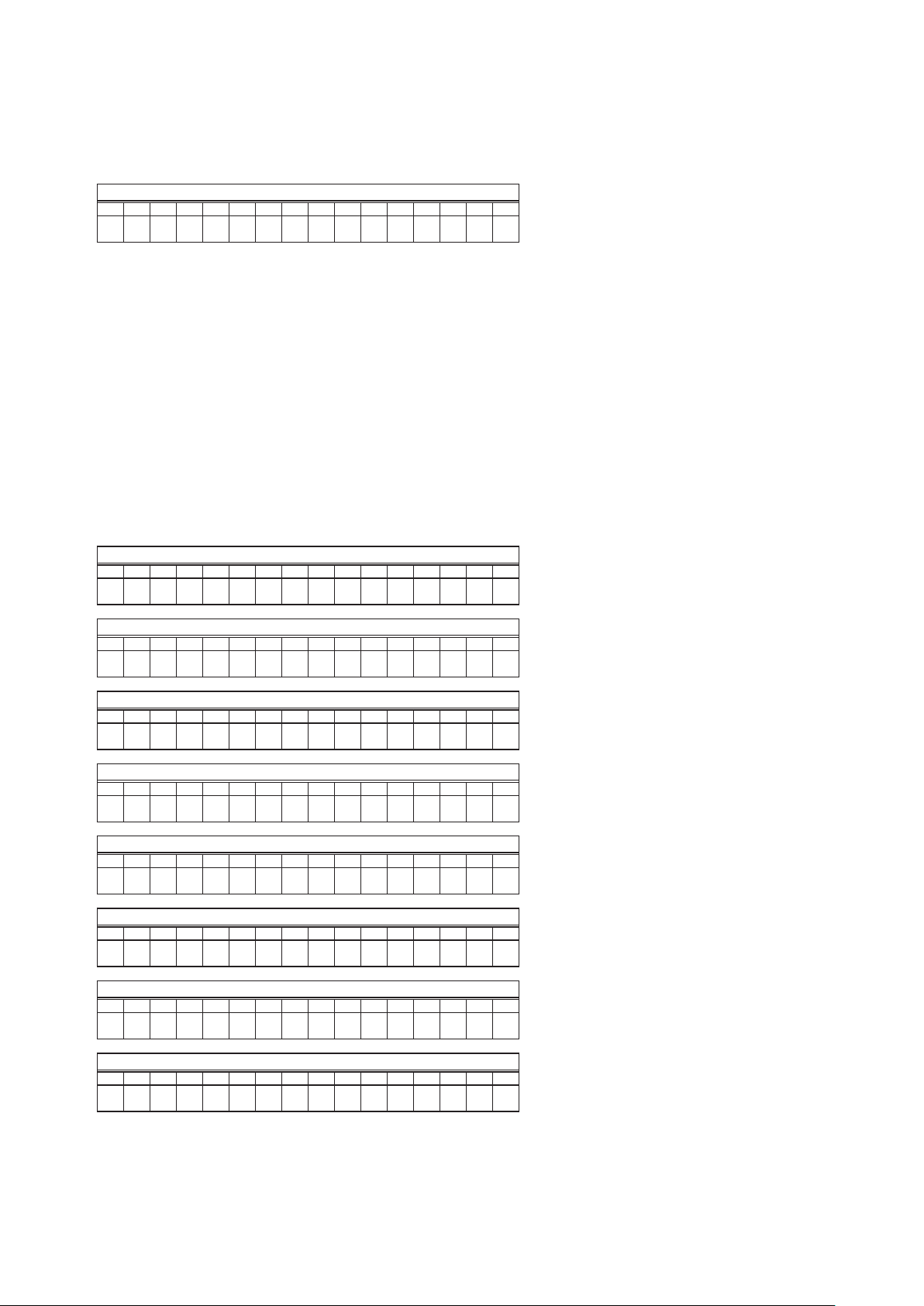

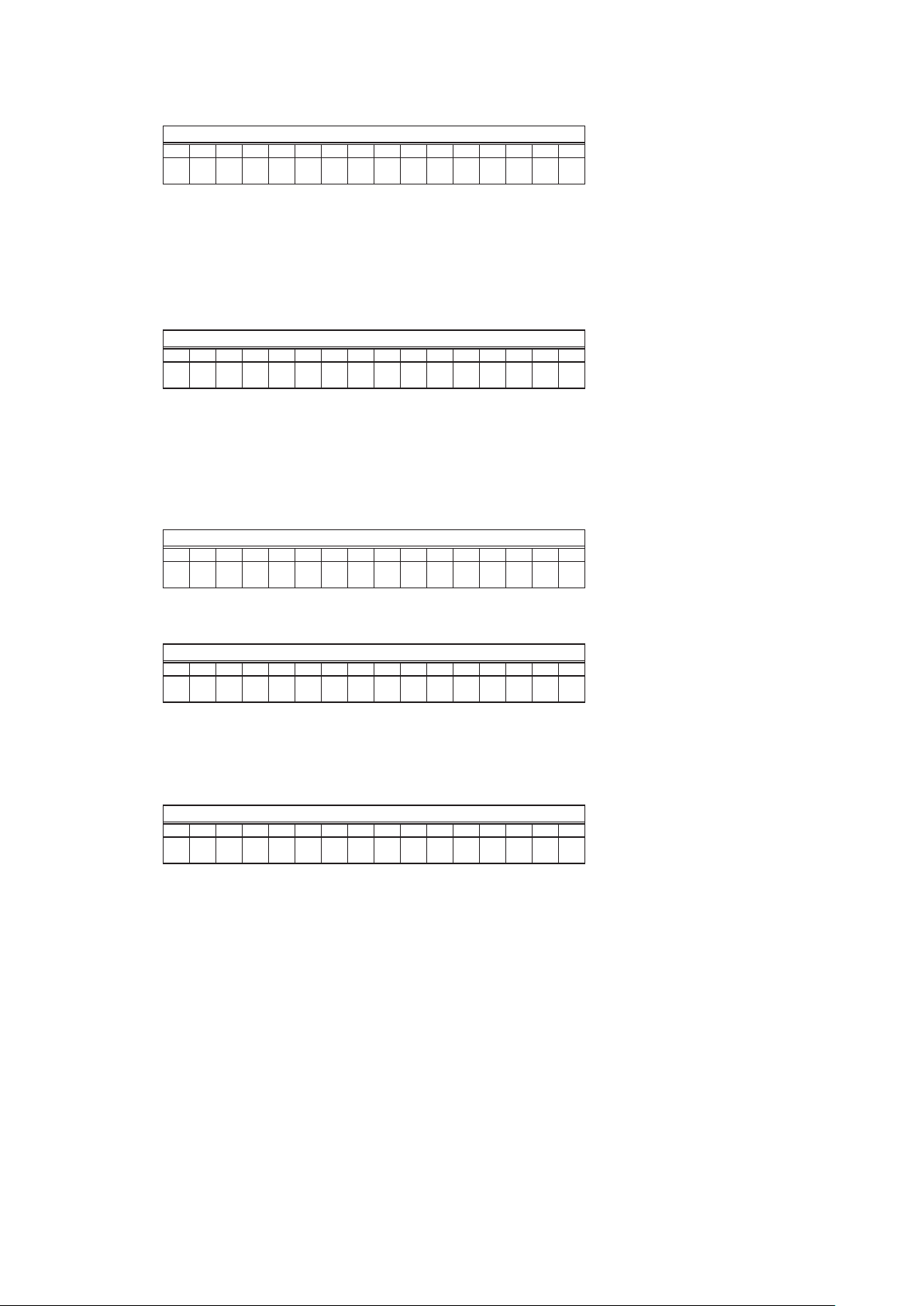

FL Display (The display part of 16 digits)

CD :

DVD :

BD(SL) :

BD(DL) :

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

T 2 1 - m m m m - n n n n

FL Display (The display part of 16 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

T 2 2 - m m m m - n n n n

FL Display (The display part of 16 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

T 2 3 - m m m m - n n n n

FL Display (The display part of 16 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

T 2 4 - m m m m - n n n n

Disc no read, unsteady playback, etc.

Laser drive current (Iop) check

HF wave form check

(Refer to WAVE FORMS)

Current value of the BD, DVD or CD IOP

is ± 12[mA] or more the initial value.

FE Main P.W.B. and BD Mechanism Unit

Assy replacing

15

Page 16

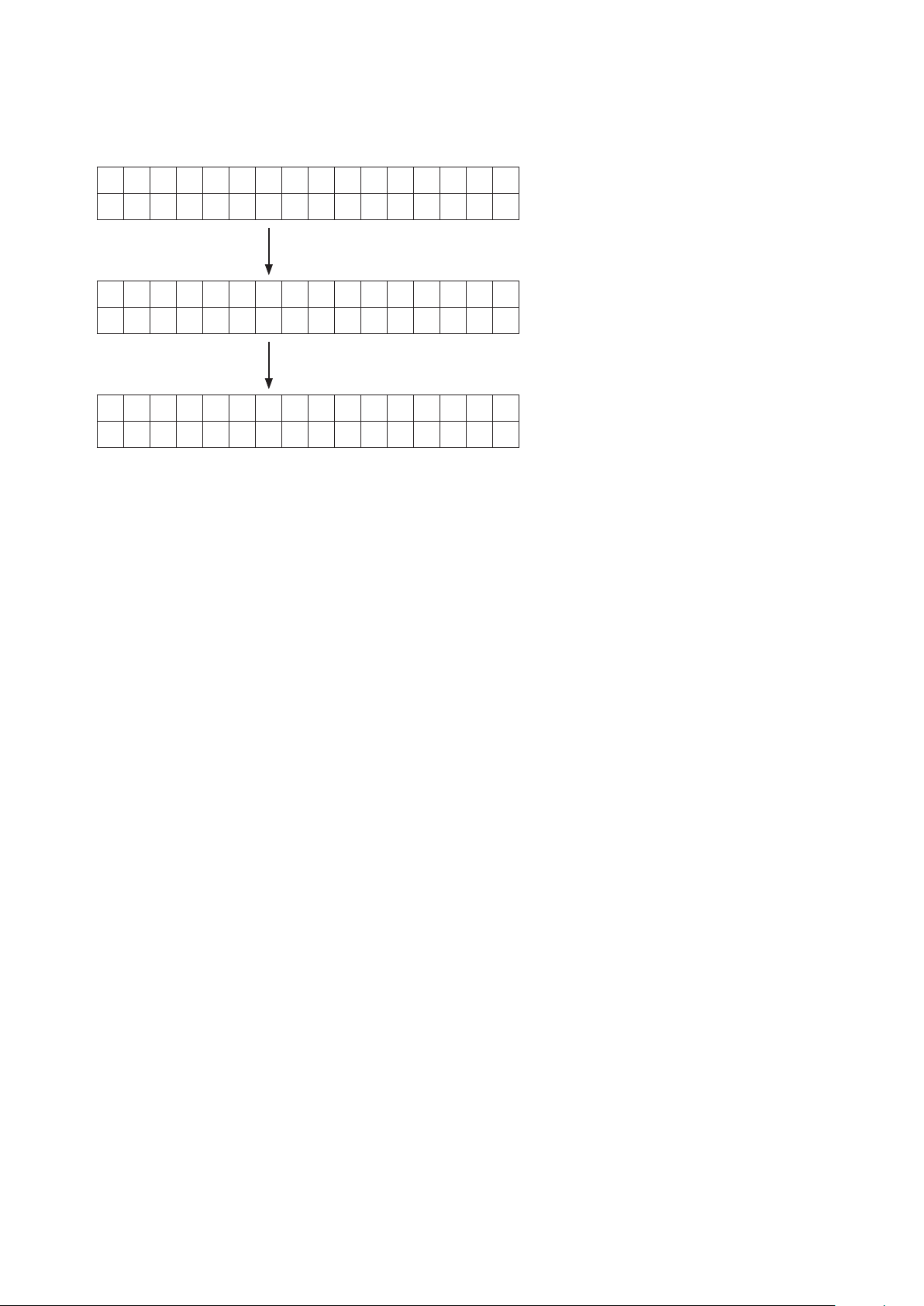

1. Iop checked Method

Select the laser ON/OFF(CD/DVD/BD)mode of the test mode, and check the IOP value of CD laser, DVD laser or BD

laser. (Refer to "6. Test mode")

FL Display (The display part of 16 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

T 2 L a s e r O n O f f

DVD laser current check

Press the 8 or 9 button to display the laser current value, and then select [X].

Check the current value of Iop (nnnn)

FL Display (The display part of 16 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

T 2 X - m m m m - n n n n

(X=1 : CD laser mode, 2 : DVD laser mode, 3 : BD(SL) laser mode, 4 : BD(DL) laser mode)

(nn.nn[mA] : Current value)

2. To clear the accumulated laser on time

Press the 1 button while the accumulated laser on time is displayed ("TC1, "TC2", "TC3" ) until "*" appears at the

fourth position. Press the 8 or 9 button to select "TC4". If the 1 button is pressed while "TC1" is displayed, the

accumulated laser on time of CD, DVD and BD is cleared

FL Display (The display part of 16 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

T C 4 * - - - - - - - - -

When "TC1", "TC2" or "TC3" is selected with the 8 or 9 button, "mmmmmm" is displayed as "0" so you can check.

FL Display (The display part of 16 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

T C V - - - m m m m m m h

(Y=1 : CD, 2 : DVD , 3 : BD, mmmmmm : Time(Fractions of hours are counted up one hour on the display.)

16

Page 17

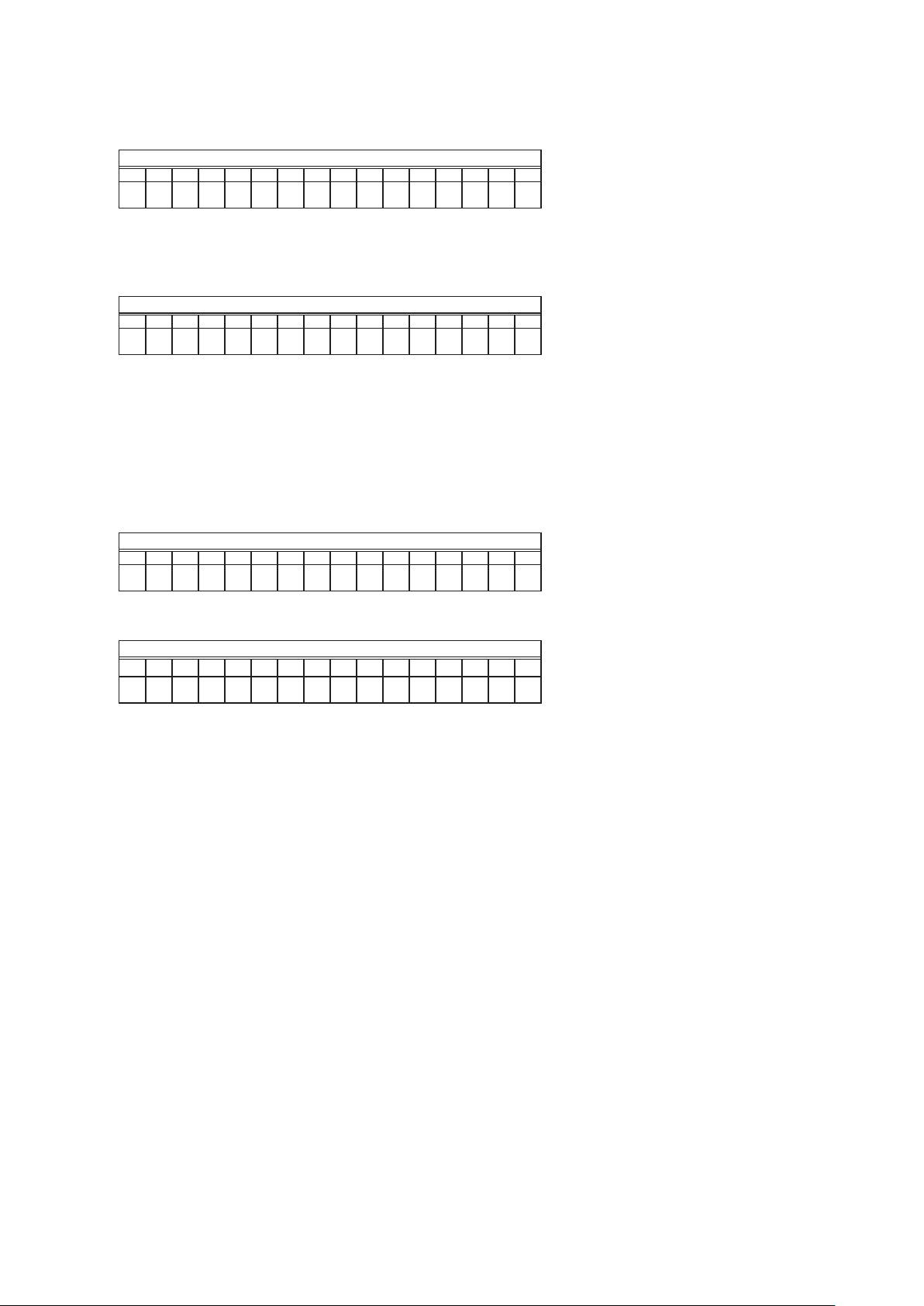

SERVICE MODE

s

Special mode setting button

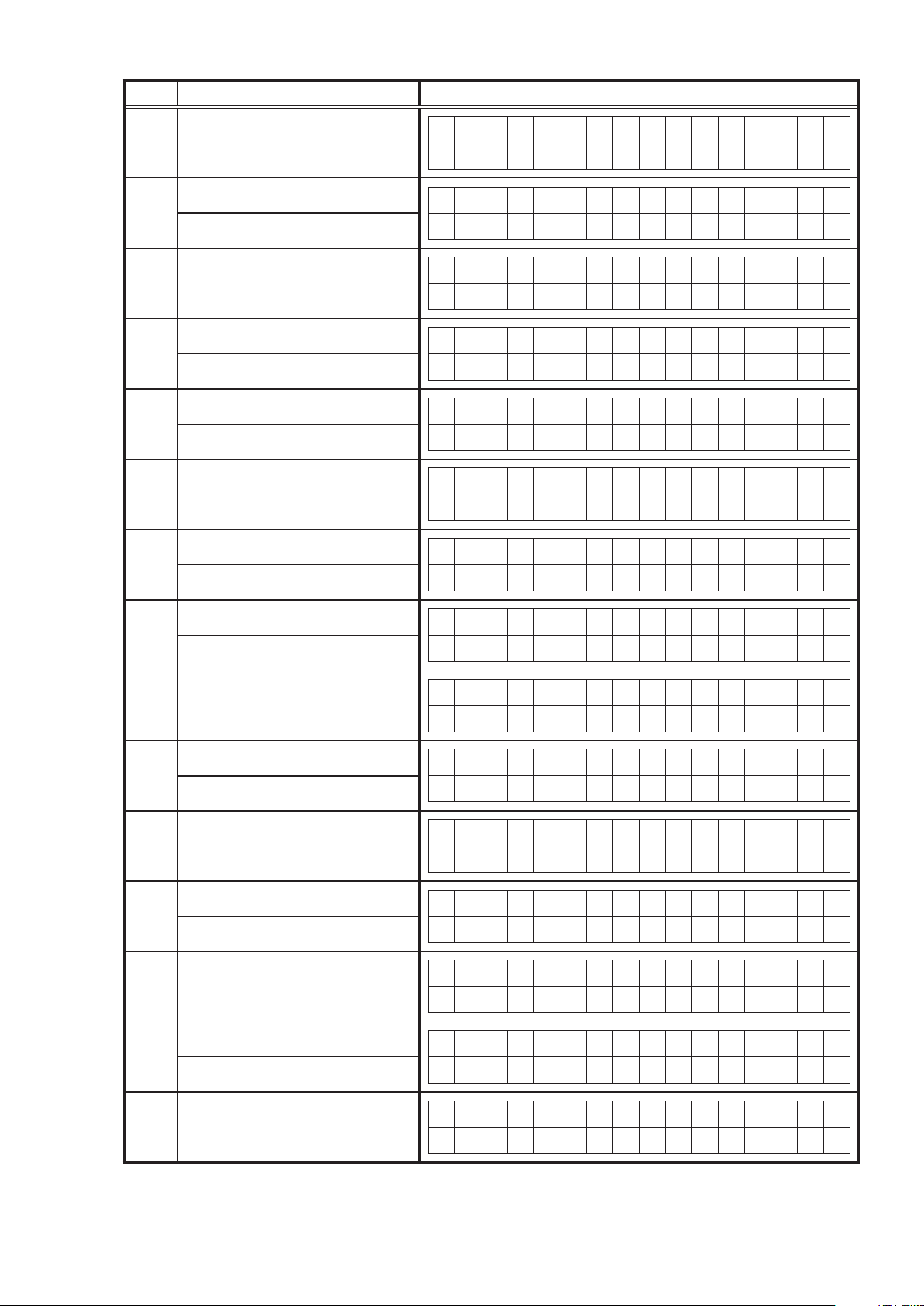

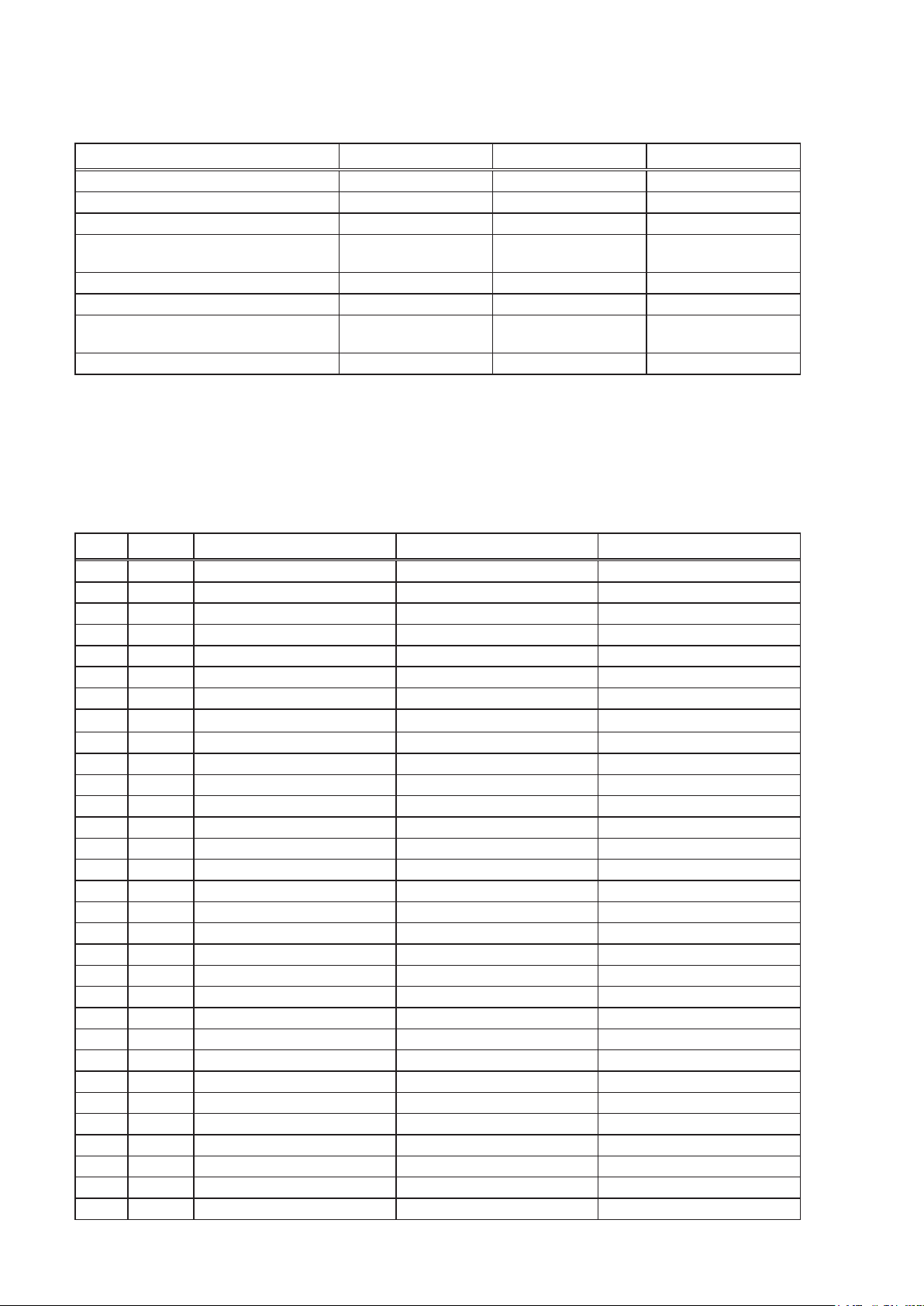

No. Mode contents

1 Initialization mode

2 Heatrun & Version display mode

3 Displaying the protection history mode Displaying the protection history

4 KEY LOCK mode

5 Test mode Pickup & Dirve Test.

Backup data initialization is carried out.

(Remove settings for Network Setup.)

Opration Heat run mode

Serial No. and rmware versions such as Main, Sub, DSP

are displayed in the FL manager.

Operations using main unit panel buttons or master volume

are rejected.

Operations using main unit panel buttons are rejected

Panel lock mode is cancelled.

Operations using remote control are rejected.

Operations using Tray open are rejected.

ON/STANDBY

Button AButton

B

SOURCE

SOURCE

9

8

5 8

2 1/3

2 9

Entering the mode

ON/STANDBY button

AC cord

ON/STANDBY button

AC cord

AC cord

1. Initial setting mode

1.1. preparation

(1) Equipment used: None

(2) Unit setting: No spec other than the following procedure.

1.2. procedure

Initialize the BD player when µcom, peripheral parts of µcom, or MAIN P.W.B. unit has been replaced in servicing.

b

All user setting will be lost and its factory setting will be restored when this initialization is made. Be sure to memorize

b

your setting for restoring again after the initialization.

(1) Plug the AC cord into a power outlet.

(2) While pressing SOURCE and 9 buttons simultaneously, press the ON/STANDBY button. FL tube all lit.

(3) Release your ngers from the SOURCE and 9 buttons.

(4) The display on the FL tube switches to "INITIALIZING" / "Please_Wait" → "BD/SD" / "INITIALIZING" →

"BD/SD" / "INITIALIZED" and initialization is completed.

Afterwards, it enters the FIRST SETUP mode.

z

17

Page 18

2. Heat run & Version display mode

2.1. preparation

(1) Equipment used : Heat run disc (This operation may not work with any discs other than the heat run discs listed

below.)

CD : CD TEST DISC (TCD-HR01)

DVD

BD

(2) Unit setting : No spec other than the following procedure.

2.2. procedure

(1) While pressing the SOURCE and 8 buttons simultaneously, plug the AC cord into a power outlet.

2.3. Heat run mode

(1) Press the

(2) Set a disc to the tray and press the

operation starts.

DVD : After playback title-1 and title-10 of the disc, the tray opens and closes automatically, then playback the

CD/BD : The disc is played through once from title 1 through the last title, the tray opens and closes automatically,

(3) This heat run operation continues automatically or it stops caused by an error. In case of some error, the following

error messages are displayed on the FL tube.

button and open a tray.

5

title-1 and title-10 again.

then the disc is played through again from title 1 through the last title.

DVD TEST DISC (TDV-HR01)

:

BD TEST DISC (TBD-HR01)

:

button once . The "1" and "3" indicators blinks alternately and heat run

1

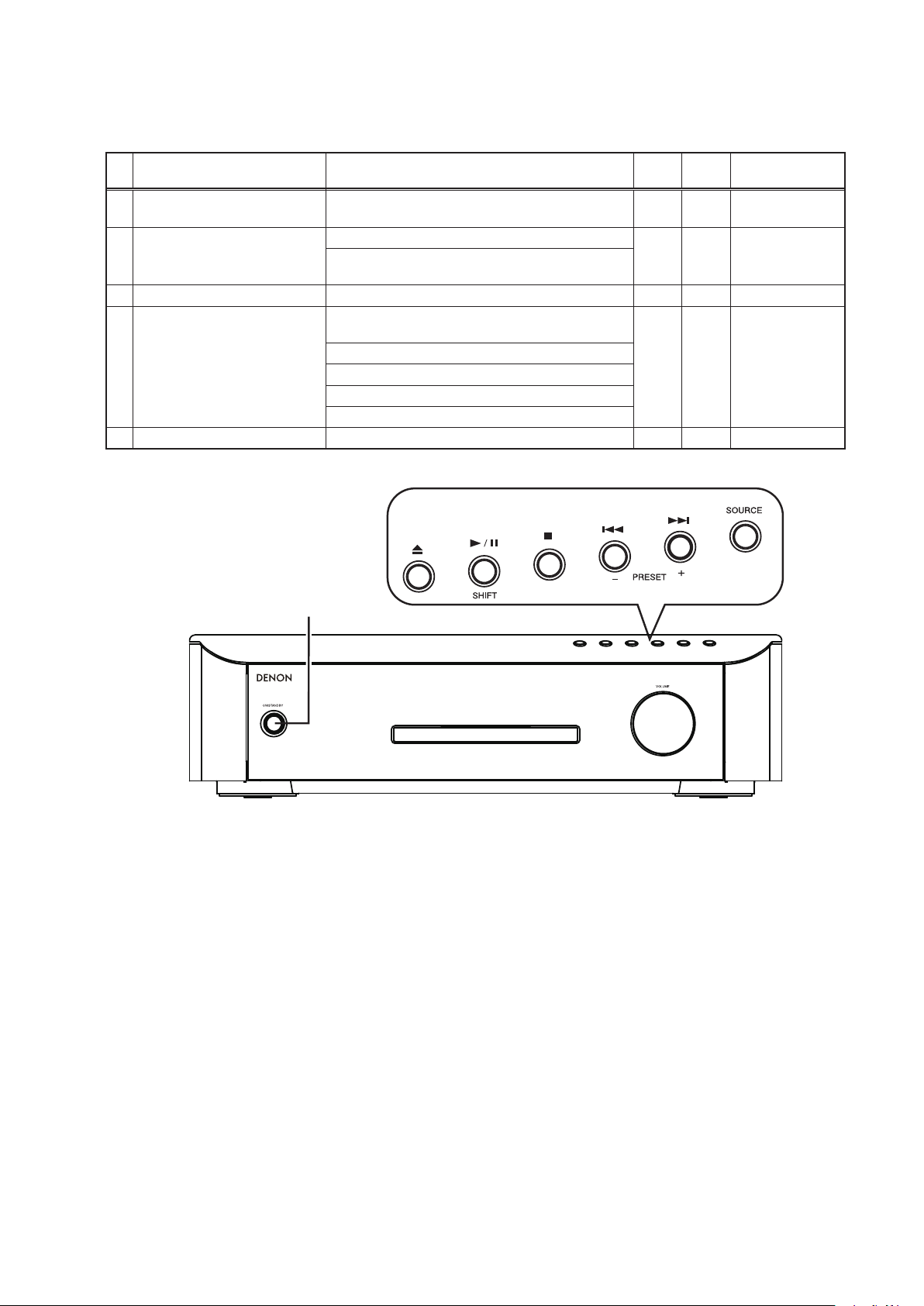

No. Error contents FL display

1 Tray Error ERROR 01

2 Bad Disc ERROR 02

3 Search Error ERROR 03

4 Read Error ERROR 04

5 Communications error ERROR 05

6 Other (Front end error) ERROR 06

2.4. Version display

When "No Disc", the FL display changes in the order given in item-2.5. Display Order each time you press the STATUS

button of remote control.

2.5. Display Order

Error information (Refer to 2.6. Error display)→q Model destination information → w Model Region information

→ e Main-μcom version information→ r Main1st Boot Loader → t DSPversion information / Audio PLD

→ y GUI FPGA Cong → u GUI Nios Program → i BD System-μcom version infomation

→ o BD System-μcom Gen number information → Q0 BD System-μcom Boot Loder → Q1 B/E version infomation

→ Q2 B/E Gen number information → Q3 B/E Boot Loder → Q4 B/E OS version information → Q5 F/E version information

→ Q6 F/E Gen number information → Q7 F/E Boot Loder → Q8 USB-μcom version information

XX : E1, E2, E3,etc X : A,B,C Y : 1, 2, 3, 4, 5, 6

No. Display item Display

q

w

e

Model destination

REGION BD

REGION DVD

Main-μcom

Main FLASH

S e r i a l N o . X X

R e g i o n B D : X

D V D : Y

M a i n : X X . X X

M a i n R O M : X X . X X

18

Page 19

No. Display item Display

Main 1st Boot Loder

r

Sub-μcom

DSP

t

Audio PLD

GUI FPGA

y

GUI Sash Nios

u

GUI Sash Font

BD System-μcom Version

i

BD System-μcom Date

BD System Gen

o

BD System-μcom Boot VersionVersion

Q0

BD System-μcom Boot Date

M a i n F B L : X X . X X

S u b : X X . X X

D S P : X X . X X

A u d i o P L D : X X X X

G U I C o n f i g :

X X X X X X X X

G U I P R G : X X X X X X X X

G U I D A T : X X X X X X X X

S y s V e r : X X X X X X

S y s D a y : X X X X X X

S y s G e n : X X X X X X

S y s B V e r : X X X X X X

S y s B D a y : X X X X X X

Q1

Q2

Q3

Q4

Q5

Q6

Q7

B/E Version

B/E Date

B/E Gen Number

B/E Boot Version

B/E Boot Date

B/E OS Version

B/E OS Date

F/E Verion

F/E Date

F/E Gen Number

F/E Boot Versoin

F/E Boot Date

B / E V e r : X X X X X X

B / E D a y : X X X X X X

B / E G e n : X X X X X X

B / E B V e r : X X X X X X

B / E B D a y : X X X X X X

B O S V e r : X X X X X X

B O S D a y : X X X X X X

F / E V e r : X X X X X X

F / E D a y : X X X X X X

F / E G e n : X X X X X X

F / E B V e r : X X X X X X

F / E B D a y : X X X X X X

USB-μcom Version

Q8

U S B : X X X

19

Page 20

2.6. Error display

See the following table for each "Error information" display and its contents (status). Display order is

Condition State Display

Sub-μcom NG No response from Sub-μcom

q

DIR NG No response from DIR

w

DSP1 NG

e

When DSP boot, executing DSP reset makes no change to DSP1 FLAGO port

"H".

No change to DSP1 FLAGO port "H" before issuing DSP command.

S U B E R R O R 0 1

D I R E R R O R 0 1

D S P 1 E R R O R 0 1

D S P 1 E R R O R 0 2

q,w,e,r,t

.

When DSP data read, executing WRITE="L" makes no change to ACK="H".

When DSP data read, executing REQ="L" makes no change to ACK="L".

When DSP data write, executing WRITE="H" makes no change to ACK="H".

When DSP data write, executing REQ="L" makes no change to ACK="L".

When DSP special code boot, executing DSP reset makes no change to DSP1

FLAGO port "H".

No change to DSP1 FLAGO port "H" before issuing DSP special read

command.

No change to DSP1 FLAGO port "H" before DSP version read.

EEPROM NG Error appeared in EEPROM checksum.(*** is a block address number.)

r

Both SUB/DSP/

t

EEPROM OK

D S P 1 E R R O R 0 3

D S P 1 E R R O R 0 4

D S P 1 E R R O R 0 5

D S P 1 E R R O R 0 6

D S P 1 E R R O R 1 1

D S P 1 E R R O R 1 2

D S P 1 E R R O R 1 3

E 2 P R O M E R R * * *

(No error display, version display only)

20

Page 21

3. Displaying the protection history mode

3.1. preparation

(1) Equipment used: None

(2) Unit setting: No spec other than the following procedure.

3.2. procedure

(1) Plug the AC cord into a power outlet.

(2) While pressing 5 and 8 buttons simultaneously, press the ON/STANDBY button to turn the power on.

The error (protection history display) mode is set.

(3) Press the STATUS button of remote control to turn on the FL display.

3.3. About the display on the FL display

When the STATUS button of remote control is pressed after setting the error (protection history display) mode, a history

like the one shown below is displayed, depending on the conditions.

(1) Normally (when there has been no protection incident)

P R O T E C T H I S T O R Y

: N O P R O T E C T

(2) For SP DC (when the last protection incident was SP DC protection)

P R O T E C T H I S T O R Y

: S P O U T _ D C

(3) For AMP SD (when the last protection incident was AMP SD protection)

P R O T E C T H I S T O R Y

: D A M P E R R

(4) For POWER DC (when the last protection incident was POWER DC protection)

P R O T E C T H I S T O R Y

: 2 n d - P o w D C

When the STATUS button of remote control. is pressed again after the above protection history is displayed, the normal

display reappears.

21

Page 22

3.4. Clearing the protection history

There are two ways to clear the protection history, as described below.

(1) Start up the error (protection history display) mode, display the error, then press and hold in the

seconds.

P R O T E C T H I S T O R Y

: S P O U T _ D C

Press and hold in the 2 button for 3 seconds.

P R O T E C T H I S T O R Y

C L E A R

The above is displayed and the protection history is cleared.

P R O T E C T H I S T O R Y

: N O P R O T E C T

button for 3

2

(2) Initialize. (See 1.Initial setting mode)

If you want to save a backup of other setting item, use the method in 3.4.(1) above.

z

s

s

Warning indication by the STANDBY LED

If the power is turned off when a protection incident has been detected, the STANDBY LED (red) ashes as follows as

warning according to the conditions in which the protection incident occurred.

(1) SP DC PROTECTION/AMP SD PROTECTION : Flashes in cycles of 2 seconds (1 second lit, 1 second off)

(2) POWER DC PROTECTION : Flashes in cycles of 0.5 seconds (0.25 seconds lit, 0.25 seconds off)

1 Accepting input from the ON/STANDBY,

b

2 Even if the AC cord is disconnected and then reconnected, the unit starts in 0.25-second interval ashing mode.

b

The accepting of input from the ON/STANDBY, 1, and 5 buttons is also prohibited in that case.

, and 5 buttons is prohibited.

1

1, b2

b

3.5. Recovering from POWER DC PROTECTION

(1) When POWER DC PROTECT is detected, press the ON/STANDBY button while pressing the

the unit simultaneously.

(2) The STANDBY LED (red) stops ashing and the unit enters the normal standby mode.

2

and

buttons on

1/3

22

Page 23

4. KEY LOCK mode

4.1. preparation

(1) Equipment used: None

(2) Unit setting: No spec other than the following procedure.

4.2. procedure

(1) While pressing 2 and

(2) "KEY_LOCK_MODE" is displayed on the FL tube. This sets the KEY LOCK mode.

buttons simultaneously, plug the AC cord into a power outlet.

1/3

K E Y L O C K M O D E

p r e s s a n y k e y

4.3. KEY LOCK mode(with Master Volume)

(1) While the indication of section 4.2 is displayed on the FL tube, press the

(2) "Key_Lock_w/_VR" is displayed on the FL tube. This sets the KEY LOCK mode (with Master Volume).

9

button.

K e y L o c k w / V R

4.4. KEY LOCK mode (without Master Volume)

(1) While the indication of section 4.2 is displayed on the FL tube, press the

(2) "Key_Lock_w/o_VR" is displayed on the FL tube. This sets the KEY LOCK mode (without Master Volume).

8

button.

K e y L o c k w / o V R

4.5. REMOTE LOCK mode

(1) While the indication of section 4.2 is displayed on the FL tube, press the

(2) "Remote_Lock" is displayed on the FL tube. This sets the REMOTE LOCK mode.

1/3

button.

R e m o t e L o c k

4.6. TRAY LOCK mode

(1) While the indication of section 4.2 is displayed on the FL tube, press the SOURCE button.

(2) "Tray_Lock" is displayed on the FL tube. This sets the REMOTE LOCK mode.

T r a y L o c k

4.7. KEY LOCK mode cansel

(1) Plug the AC cord into a power outlet.

(2) While pressing 2 and

mode.

(3) While the indication of section 4.2 is displayed on the FL tube, press the

(4) "CLEAR" is displayed on the FL tube, each mode in sections 4.3., 4.4., 4.5., and 4.6. is cancelled.

buttons simultaneously, plug the AC cord into a power outlet. This sets the KEY LOCK

1/3

button.

2

C L E A R

23

Page 24

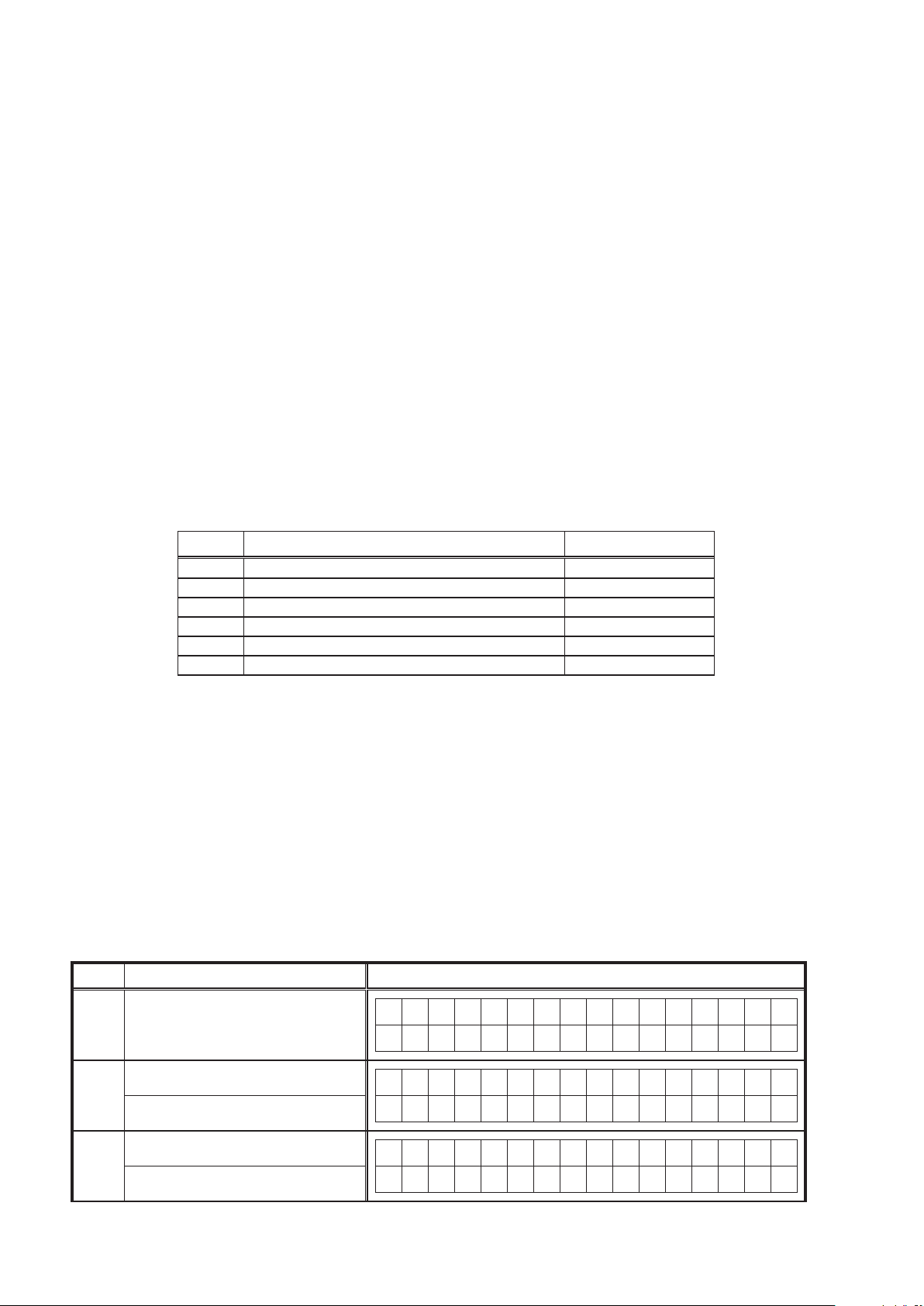

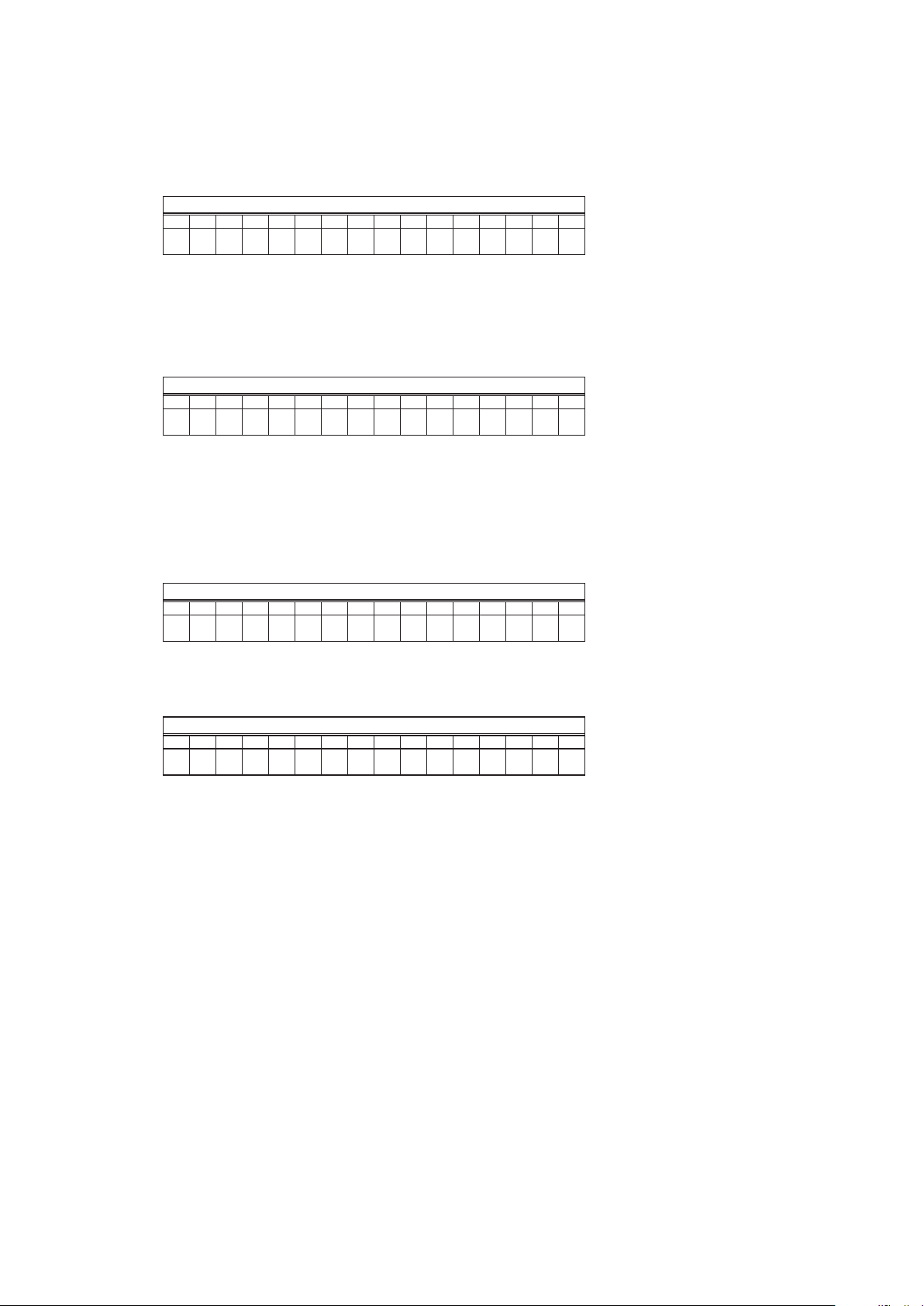

5. Test mode

5.1. Entering the test mode

The test mode is entered by pressing the 2 and 9 buttons simultaneously, plug the AC cord into a power outlet.

FL tube display when test mode entered

FL Display (The display part of 16 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

T E S T M O D E

When the test mode is set, a color bar appears on the monitor.

5.2. Selecting the mode

The following modes are available.

・

(1) Laser on/off (CD/DVD/BD) mode : T2

(2) Servo adjustment value display mode : T3

(3) Error rate (skew) measurement mode : T7

(4) Accumulated laser on time display mode : TC

(5) Track buffer output mode : TE

(6) Picking up No. display mode : TG

(7) Error log display mode : TH

(8) Test mode cancel : TI

When the

q

button is pressed after entering the test mode, the display switches in the order: "T2, T3, T7, TC, TE,

9

TG, TH, TI, T2 …"

FL Display (The display part of 16 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

T 2 L a s e r O n O f f

FL Display (The display part of 16 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

T 3 S e r v o A d j .

FL Display (The display part of 16 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

T 7 E r r o r R a t e

FL Display (The display part of 16 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

T C L a s e r O n T i m

FL Display (The display part of 16 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

T E T r a c k B u f

FL Display (The display part of 16 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

T G O P U N u m b e r

FL Display (The display part of 16 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

T H E r r o r L o g

FL Display (The display part of 16 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

T I T e s t E x i t

When the

w

position (for example, if currently at "TI", it switches as follows: "TH, TG,

button is pressed, the display switches in the opposite order fromq above, starting from the current

8

24

TE, TC, T7, T3, T2, TI, TH …").

s

Page 25

5.3. About each mode

With the mode selected, press the 1 button to set that mode.

・

(1) Laser on/off (CD/DVD/BD) mode

Press the 8 or 9 button to select [X] and press the 1 button to set it.

Laser on/off control is executed and the laser current is displayed.

FL Display (The display part of 16 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

T 2 X m m m m n n n n

(X=1 : CD laser mode, 2 : DVD laser mode, 3 : BD(SL) laser mode, 4 : BD(DL) laser mode)

(mm.mm[mA] : Stored data, nn.nn[mA] : Current value)

When the current value is more that ± 12.00[mA] of saved data, it becomes the pickup transducer's target.

b

In this case, replace the mechanism unit.

If stored value is not

FL Display (The display part of 16 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

T 2 X - - - - - - n n n n

(X=1 : CD laser mode, 2 : DVD laser mode, 3 : BD(SL) laser mode, 4 : BD(DL) laser mode)

(nn.nn[mA] : Current value)

When the 2 button is pressed, the layer above the current layer is displayed. See "5.4 Stopping the mode".

(2) Servo adjustment value display mode

Press the 8 or 9 button to select [XXX]. Refer to [Table 1 - Servo adjustment value display mode details].

FL Display (The display part of 16 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

T X X X

(XXX : Servo adjustment value

Press the 1 button to set. The contents indicated on "Table 1: Details of the servo adjustment value display mode"

are displayed.

FL Display (The display part of 16 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

)

T X X X m m m m m m n n

(XXX : Selection mode, mmmmmm : Address(HEX), nn:Data(HEX))

The rst time, the address speciciation position is the uppermost position (5th place). The address speciciation

position moves downwards each time the 1 button is pressed.

The address speciciation position ashes (at an interval of about 0.5 seconds). If the 1 button is pressed after

moving to the lowermost position (10th place), the position moves to the uppermost position

Use the 8 or 9 button to change the display at the address specication position.

When the 2 button is pressed, the layer above the current layer is displayed. See "5.4 Stopping the mode".

25

Page 26

(3) Error rate measurement mode

Press the 8 or 9 button to select [YY] .

Refer to [Table 2 - Error rate details].

FL Display (The display part of 16 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

T Y Y F F F F F F F F F F

(X : measurement mode, F : Address and error rate (When not set, "F" is displayed.)

Press the 1 button to begin error rate measurement. The address and error rate are displayed.

For a description of the displayed measurement results, see "Table 2: Error rate details".

FL Display (The display part of 16 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

T Y Y m m m m m m | | | |

(YY : selection mode [71 to 94], m : address [PBA][HEX], l : error rate [COUNT/SEC] [HEX])

(Note) CD (4x-speed) : Renewal of data is carried out for every 300 frame.

Error rate of 75 frames is displayed.

DVD (2x-speed) : Renewal of data is carried out for every 80ECC block.

Error rate of 8ECC block is displayed.

BD (2x-speed) : Renewal of data is carried out for every 136LDC clusters block.

Error rate of 8LDC clusters block is displayed.

The mode chosen when selection mode was changed into the trace execution and the 1 button was pushed is

performed from the beginning.

When the 1 button is pushed without changing selection mode, the mode under selection is performed from the

beginning.

(If the 1 button is pushed, the address corresponding to the chosen mode will be searched again.)

The pause mode is set after tracing is completed.

When the 2 button is pressed, the layer above the current layer is displayed. See "5.4 Stopping the mode".

(4) Accumulated laser on time display mode

Press the 8 or 9 button to select [Y] and press the 1 button to set it.

The accumulated laser on time is displayed.

FL Display (The display part of 16 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

T C Y m m m m m m h

(Y=1 : CD, 2 : DVD , 3 : BD, mmmmmm : Time(Fractions of hours are counted up one hour on the display.)

When the 2 button is pressed, the layer above the current layer is displayed. See "5.4 Stopping the mode".

---To clear the accumulated laser on time---

Press the 1 button while the accumulated laser on time is displayed ("TC1, "TC2", "TC3" ) until "*" appears at

the fourth position.

FL Display (The display part of 16 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

T C Y * m m m m m m

Press the 8 or 9 button to select "TC4"

FL Display (The display part of 16 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

T C 4 *

If the 1 button is pressed while "TC4" is displayed, the accumulated laser on time of CD, DVD and BD is cleared.

FL Display (The display part of 16 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

T C 1 0 0 0 0 0 0 h

When "TC1", "TC2" or "TC3" is selected with the 8 or 9 button, "mmmmmm" is displayed as "0" so you can

check.

26

Page 27

(5) Track buffer output mode

Press the 8 or 9 button to select "Y" and switch the track buffer output.

FL Display (The display part of 16 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

T E Y T r a c k B u f f

(Y=1 : Track buffer being output, 0 : Track buffer output off )

When the 2 button is pressed, the layer above the current layer is displayed. See "5.4 Stopping the mode".

(6) Picking up No. display mode

Press the 8 or 9 button to switch to the pickup number display.

The pickup number is a 14-digit number, so it is displayed in two sections.

FL Display (The display part of 16 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

T G X Y Y Y Y Y Y Y

(X (display position) = 1 : Lower digits, 2 : Upper digits. YYYYYYY: Pickup number)

When the 2 button is pressed, the layer above the current layer is displayed. See "5.4 Stopping the mode".

(7) Error log display mode

Press the 8 or 9 button to switch to the error log display.

For Error log No. and description of the displayed measurement results, see "Table 3: Error log details".

FL Display (The display part of 16 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

n T H X

(n : Error information No.(1~5), X : Error log No.)

Display when there is no error

FL Display (The display part of 16 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

n T H 1 N o E r r o r

When the 2 button is pressed, the layer above the current layer is displayed. See "5.4 Stopping the mode".

(8) Test mode cancel

A conrmation message is displayed. Press the 1 button to set, canceling the test mode.

FL Display (The display part of 16 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

T I 1 R e a l l y ?

When the 2 button is pressed, the layer above the current layer is displayed. See "5.4 Stopping the mode".

27

Page 28

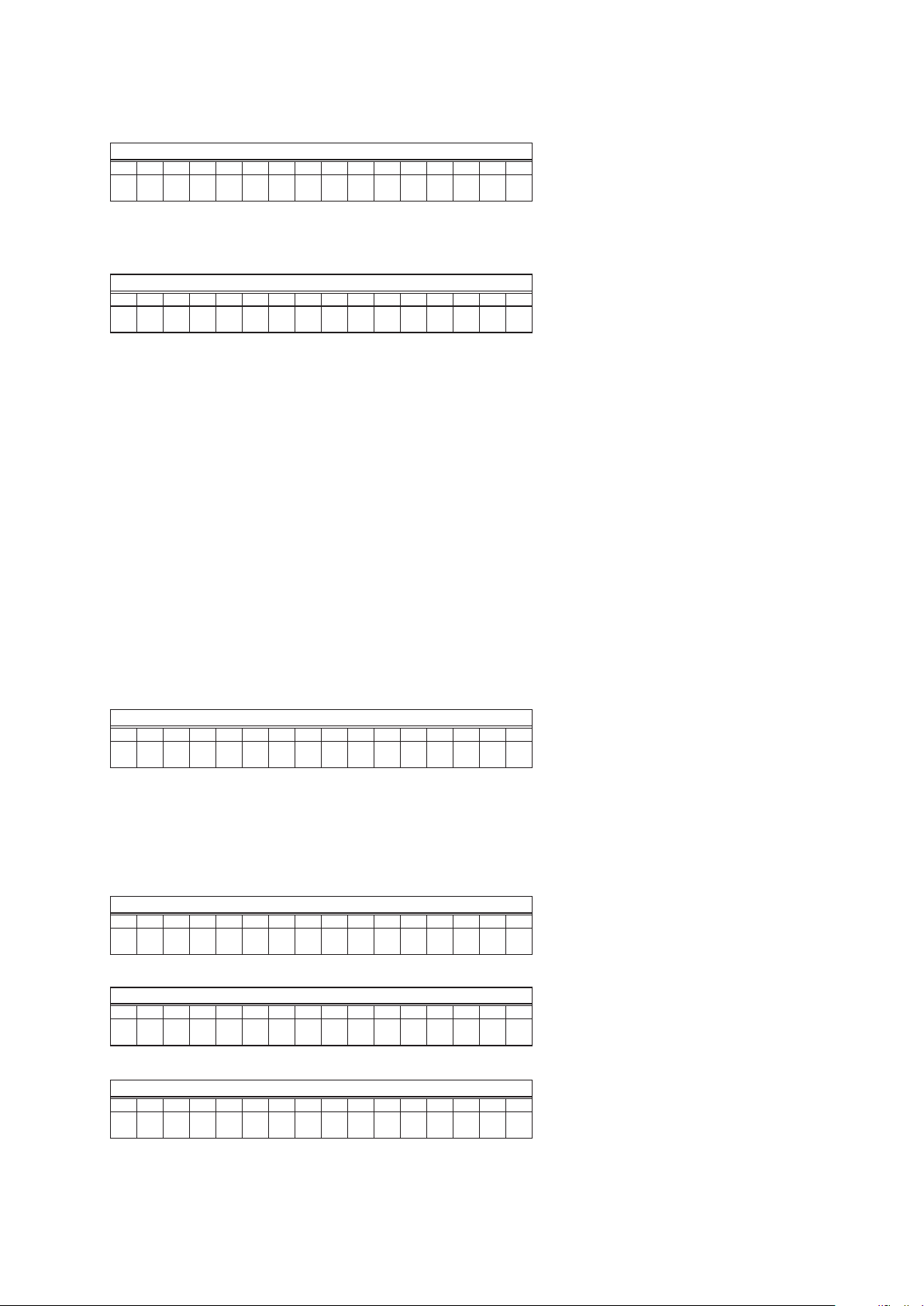

5.4. Stopping the mode

When the 2 button is pressed, the layer above the current layer is displayed. The relationship between the different

modes and the display of the different layers is shown on the table below.

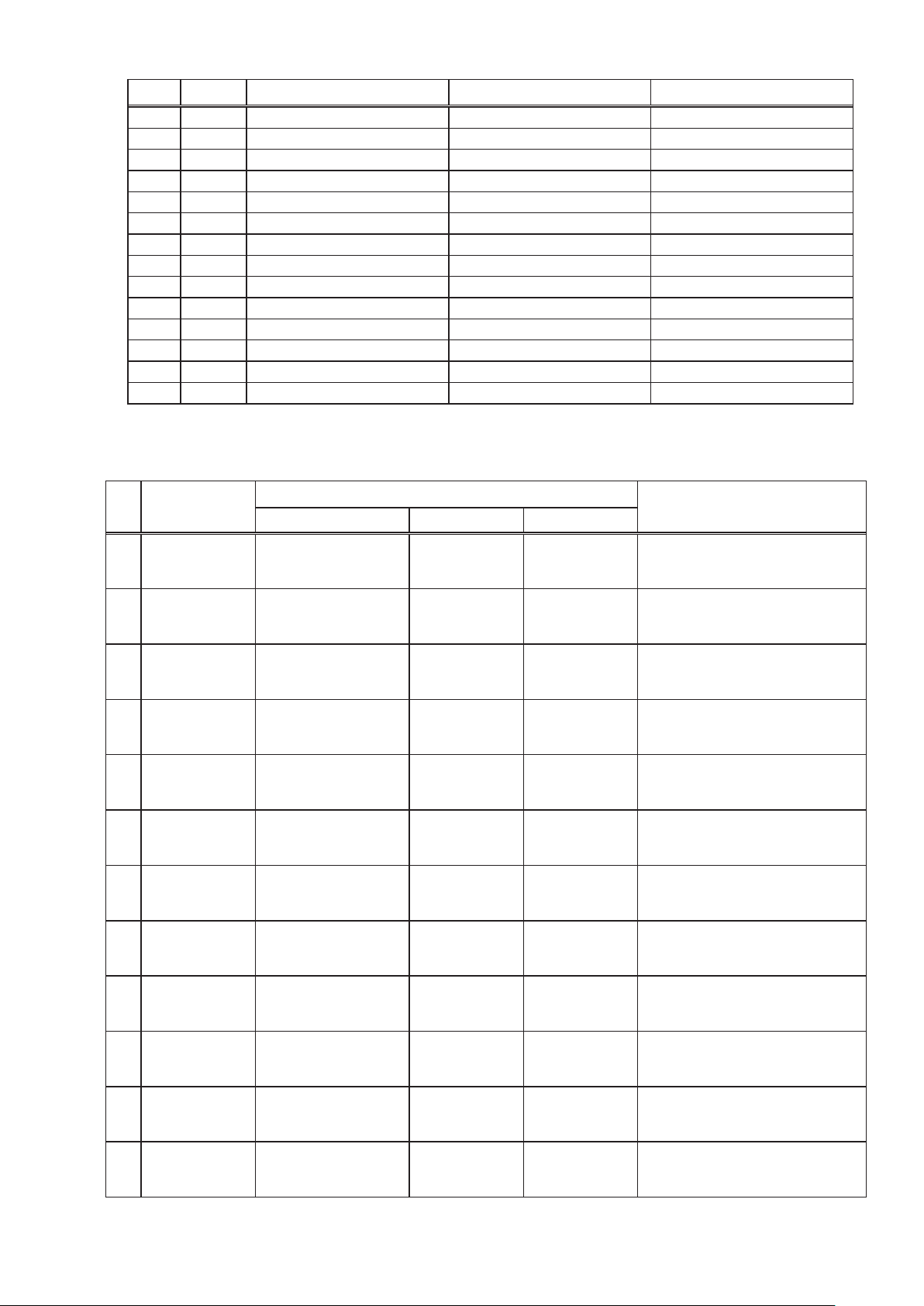

Mode 1 layer 2 layer 3 layer

Laser on/off (CD/DVD/BD) mode T2 LaserOnOff T2X mmmm nnnn Non

Servo adjustment value display mode T3 Servo Adj. TXXX TXXXmmmmmm nn

Error rate (skew) measurement mode T7 Error Rate TYYFFFFFFFFFF TYYmmmmmmllll

Accumulated laser on time display mode TC LaserOnTim TCY mmmmmmh

Track buffer output mode TE Track Buf TEYTrack Buff Non

Picking up No. display mode TG OPU Number TGX YYYYYYY Non

Error log display mode TH Error Log

Test mode cancel TI Test Exit TI1 Really? Non

nTHX

nTH1 No Error

TCY* mmmmmmh

TC4*

nTHX dddddd

nTHAyyy dddd

5.5. About the OPEN/CLOSE (

)button

5

Even during the test mode, the tray is opened and closed when the 5 button is pressed.

5.6. Test mode detailed table

Table 1: Servo adjustment value display mode details

No XXX Name Address range Meaning

0 T30 BUF_ID_SDRAM 0x000000~0x3FFFFF SDRAM

1 T31 BUF_ID_MPU_ALL 0x000000~0xBEFF3F MPU(Abs Access)

2 T32 BUF_ID_MPU_RMCR 0x000000~0x00FFFF ROMCOR

3 T33 BUF_ID_MPU_SYSCFG 0x000000~0x000FFF SystemCongration

4 T34 BUF_ID_MPU_DMAC 0x000000~0x0004FF DMAC

5 T35A BUF_ID_MPU_ITIM0 0x000000~0x0000FF ITIM 0

6 T35B BUF_ID_MPU_ITIM1 0x000000~0x0000FF ITIM 1

7 T35C BUF_ID_MPU_ITIM2 0x000000~0x0000FF ITIM 2

8 T35D BUF_ID_MPU_ITIM3 0x000000~0x0000FF ITIM 3

9 T35E BUF_ID_MPU_ITIM4 0x000000~0x0000FF ITIM 4

10 T35F BUF_ID_MPU_ITIM5 0x000000~0x0000FF ITIM 5

11 T36 BUF_ID_MPU_RSV2 0x000000~0x0079FF Reserved

12 T37 BUF_ID_MPU_WDT 0x000000~0x000FFF WDT

13 T38 BUF_ID_MPU_UART0 0x000000~0x0000FF UART 0

14 T39 BUF_ID_MPU_UART1 0x000000~0x0000FF UART 1

15 T40 BUF_ID_MPU_CSIO0 0x000000~0x0000FF CSIO 0

16 T41 BUF_ID_MPU_CSIO1 0x000000~0x0000FF CSIO 1

17 T42 BUF_ID_MPU_GPIO0 0x000000~0x0000FF GPIO 0

18 T43 BUF_ID_MPU_GPIO1

19 T44 BUF_ID_MPU_GPIO2 0x000000~0x0000FF GPIO 2

20 T45 BUF_ID_MPU_RSV5 0x000000~0x00BCFF Reserved

21 T46 BUF_ID_MPU_HEXBIU 0x000000~0x000FFF HEXBIU

22 T47 BUF_ID_MPU_HCSC 0x000000~0x000FFF HCSC

23 T48 BUF_ID_MPU_RSV6 0x000000~0x7DDFFF Reserved

24 T49 BUF_ID_MPU_RSV7 0x000000~0x3DFEFF Reserved

25 T50 BUF_ID_MPU_INT 0x000000~0x00003F INT

26 T51 BUF_ID_IRAM 0x000000~0x003FFF IRAM(internal SRAM))

27 T52 BUF_ID_DSP 0x000000~0x001FFF DSP Register

28 T53 BUF_ID_AFE 0x000000~0x0000FF AFE Register

29 T54 BUF_ID_SVO_ALL 0x000000~0x001FFF SVO REG ABS ACCESS

30 T55 BUF_ID_SVO_REG 0x000000~0x0007FF SVERVO REG

0x000000~0x0000FF GPIO 1

28

Page 29

No XXX Name Address range Meaning

31 T56 BUF_ID_SVO_SVRAM 0x000000~0x0005FF SVRAM

32 T57A BUF_ID_SVO_CRAM0 0x000000~0x0001FF CRAM0

33 T57B BUF_ID_SVO_CRAM1 0x000000~0x0001FF CRAM1

34 T57C BUF_ID_SVO_CRAM2 0x000000~0x0001FF CRAM2

35 T57D BUF_ID_SVO_CRAM3 0x000000~0x0001FF CRAM3

36 T58A BUF_ID_SVO_ZRAM0 0x000000~0x0001FF ZRAM0

37 T58B BUF_ID_SVO_ZRAM1 0x000000~0x0001FF ZRAM1

38 T58C BUF_ID_SVO_ZRAM2 0x000000~0x0001FF ZRAM2

39 T58D BUF_ID_SVO_ZRAM3 0x000000~0x0001FF ZRAM3

40 T59 BUF_ID_EPRM 0x000000~0x000FFF EEPROM

41 T60 BUF_ID_PUCONT_LDD 0x000000~0x000007 LDD

42 T61 BUF_ID_SVRESULT 0x000000~0x0002C3 SvResult

43 T62 BUF_ID_LD_TIME 0x000000~0x00000D LD ON Time Integrated value

44 T63 BUF_ID_IOP 0x000000~0x000007 IOP(Stored value)

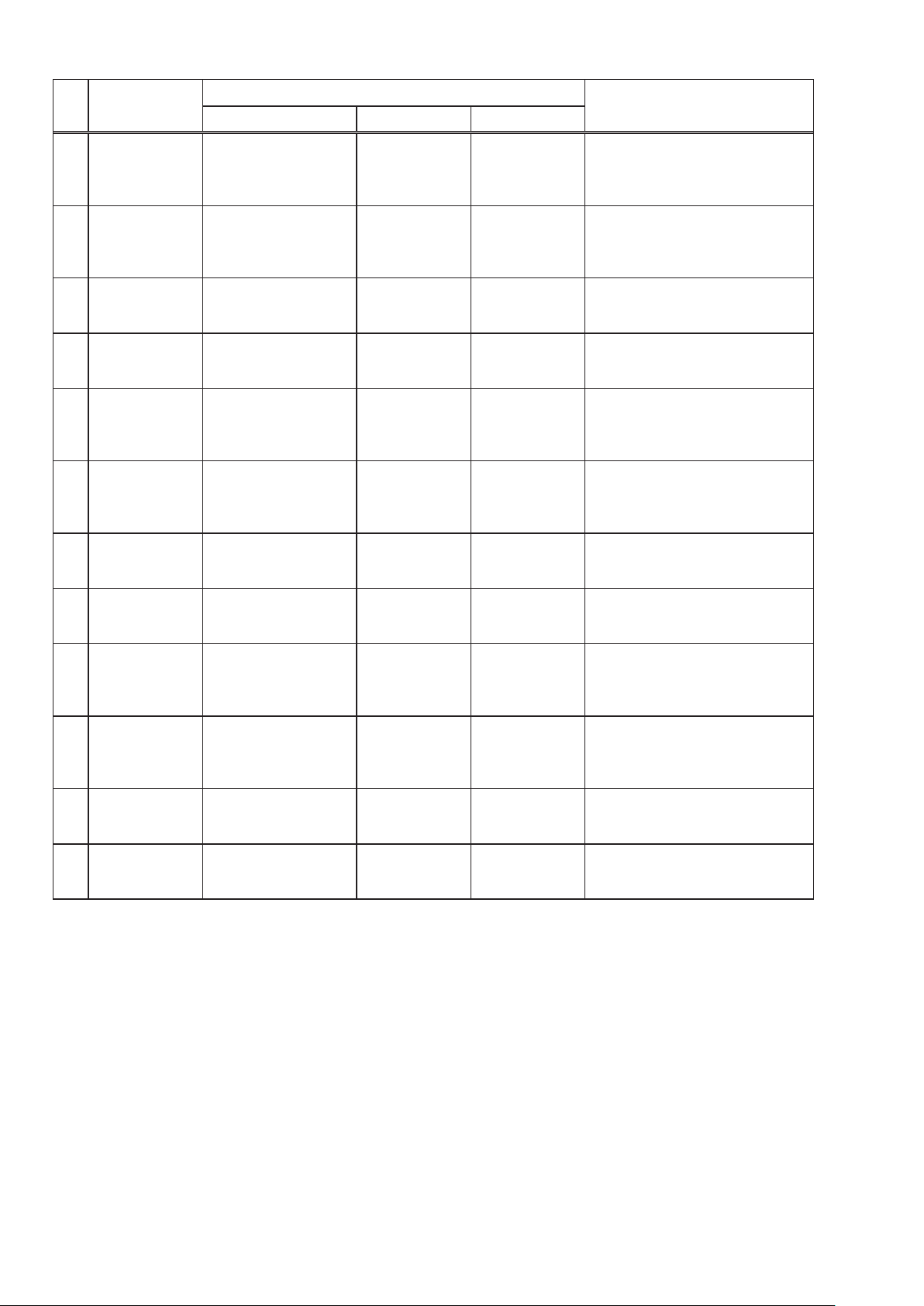

Table 2: Error rate details

Measurement

YY

The inner

71

circumference of

1-layer

The inner

72

circumference of

1-layer

The inner

73

circumference of

1-layer

The inner

74

circumference of

1-layer

The central

75

circumference of

1-layer

The central

76

circumference of

1-layer

The central

77

circumference of

1-layer

The central

78

circumference of

1-layer

The outer

79

circumference of

1-layer

The outer

80

circumference of

1-layer

The outer

81

circumference of

1-layer

The outer

82

circumference of

1-layer

position

Error rate display details for each media type

BD DVD CD

BIS error detection

signed number

BIS error uncorrectable

signed numbe

LDC error detection

signed number

LDC error uncorrectable

signed numbe

BIS error detection

signed number

BIS error uncorrectable

signed numbe

LDC error detection

signed number

LDC error uncorrectable

signed numbe

BIS error detection

signed number

BIS error uncorrectable

signed numbe

LDC error detection

signed number

LDC error uncorrectable

signed numbe

It is invalid. It is invalid.

It is invalid. It is invalid.

PI error detection

number

PO uncorrectable

error number

It is invalid. It is invalid.

It is invalid. It is invalid.

PI error detection

number

PO uncorrectable

error number

It is invalid. It is invalid.

It is invalid. It is invalid.

PI error detection

number

PO uncorrectable

error number

C1 error

detection number

C2 uncorrectable

error number

C1 error

detection number

C2 uncorrectable

error number

C1 error

detection number

C2 uncorrectable

error number

Remarks

When this is selected for DVD or CD,

it shifts to YY=73.

When this is selected for DVD or CD,

it shifts to YY=73.

When this is selected for DVD or CD,

it shifts to YY=77.

When this is selected for DVD or CD,

it shifts to YY=77.

When this is selected for DVD or CD,

it shifts to YY=81.

When this is selected for DVD or CD,

it shifts to YY=81.

29

Page 30

Measurement

YY

The inner

83

circumference of

2-layer

The inner

84

circumference of

2-layer

The inner

85

circumference of

2-layer

The inner

86

circumference of

2-layer

The central

87

circumference of

2-layer

The central

88

circumference of

2-layer

The central

89

circumference of

2-layer

The central

90

circumference of

2-layer

The outer

91

circumference of

1-layer

The outer

92

circumference of

1-layer

The outer

93

circumference of

1-layer

The outer

94

circumference of

1-layer

position

Error rate display details for each media type

BD DVD CD

BIS error detection

signed number

BIS error uncorrectable

signed number

LDC error detection

signed number

LDC error uncorrectable

signed numbe

BIS error detection

signed number

BIS error uncorrectable

signed numbe

LDC error detection

signed number

LDC error uncorrectable

signed numbe

BIS error detection

signed number

BIS error uncorrectable

signed numbe

LDC error detection

signed number

LDC error uncorrectable

signed numbe

It is invalid. It is invalid.

It is invalid. It is invalid.

PI error detection

number

PO uncorrectable

error number

It is invalid. It is invalid.

It is invalid. It is invalid.

PI error detection

number

PO uncorrectable

error number

It is invalid. It is invalid.

It is invalid. It is invalid.

PI error detection

number

PO uncorrectable

error number

It is invalid.

It is invalid.

It is invalid.

It is invalid.

It is invalid.

It is invalid.

Remarks

When this is selected for 2-layer DVD,

it shifts to YY=85.

When this is selected for 1-layer DVD

or CD, it shifts to YY=73.

When this is selected for DVD 2-layer,

it shifts to YY=85.

When this is selected for DVD 1-layer

or CD, it shifts to YY=73.

When this is selected for 1-layer DVD

or CD, it shifts to YY=73.

When this is selected for 1-layer DVD

or CD, it shifts to YY=73.

When this is selected for DVD

2-layer, it shifts to YY=89.When this

is selected for DVD 1-layer or CD, it

shifts to YY=77.

When this is selected for DVD 2-layer,

it shifts to YY=89.

When this is selected for DVD 1-layer

or CD, it shifts to YY=77.

When this is selected for DVD 1-layer

or CD, it shifts to YY=77.

When this is selected for DVD 1-layer

or CD, it shifts to YY=77.

When this is selected for DVD 2-layer,

it shifts to YY=93.

When this is selected for DVD 1-layer

or CD, it shifts to YY=81.

When this is selected for DVD 2-layer,

it shifts to YY=93.

When this is selected for DVD 1-layer

or CD, it shifts to YY=81.

When this is selected for DVD 1-layer

or CD, it shifts to YY=81.

When this is selected for DVD 1-layer

or CD, it shifts to YY=81.

* The inner circumference of the layer refers to the physical inner circumference for DVD parallel, the physical outer

circumference for the opposite case.

* The inner circumference of the layer refers to the physical outer circumference for DVD parallel, the physical inner

circumference for the opposite case.

30

Page 31

Table 3: Error log details

Error log No.

1 LD On Time (4Byte)

2 Error type (2Byte) See "Table 3-1: Error type details"

3 (31 to 34 displayed in 4-byte units) Reserve (16Byte)

4 Media type (2Byte) See "Table 3-2: Media type details"

5 Reserve (4Byte)

6 Reserve (4Byte)

7 Reserve (2Byte)

8 HyBrid Disc layer (2Byte) See "Table 3-3: HyBrid Disc current layer details"

9 (91 to 92 displayed in 7-digit units)

(Matched to TG pickup number display)

A (A000 to A161 displayed in 2-digit units) Reserve (708Byte)

B (B1 to B3 displayed in 4-digit units) Reserve (11Byte)

C Reserve (1Byte)

D (D1 to D3 displayed in 4-digit units) Reserve (12Byte)

PU# (16Byte)

Table 3-1: Error type details

Error type Error code

NoError 0x0000

Focus does not turn on. 0x0001

Tracking does not turn on. 0x0002

CLV does not turn on. 0x0003

ID cannot be read. 0x0004

Loader error 0x0005

Thread error 0x0006

Expander error 0x0007

Other error 0x0008

Error disc (Failure to recognition of disc) 0x0009

Seek error 0x0010

Lead error 0x0020

Other Reserved

Table 3-3: HyBrid Disc current layer details

HyBrid Disc current layer Current layer code

SACD layer 0x0000

CD layer 0x0001

DVD layer 0x0002

BD layer 0x0003

Other Reserved

Contents

(Error log overall layout)

DVD-ROM 0x0001

DVD-R 0x0002

DVD-RW 0x0003

DVD-PLUS-R 0x0004

DVD-PLUS-RW 0x0005

DVD-ROM DL 0x0006

DVD+R DL 0x0007

DVD-R DL 0x0008

DVD+RW DL 0x0009

DVD-RW DL 0x000A

CD-ROM 0x000B

CD-R 0x000C

CD-RW 0x000D

BD-RE SL 0x000E

BD-RE DL 0x000F

BD-R SL 0x0010

BD-R DL 0x0011

BD-R SL LTH 0x0012

BD-ROM SL 0x0013

BD-ROM DL 0x0014

BD-Hybrid 0x0015

SACD-Hybrid 0x0016

SACD DL 0x0017

SACD SL 0x0018

DVD-Hybrid 0v0019

Unknown 0xFFFF

Other Reserved

Remarks

Table 3-2: Media type details

Media type Media code

31

Page 32

ABOUT REPLACE THE MICROPROCESSOR WITH A NEW ONE

When replaced of the U-PRO (Microprocessor) or the Flash ROM, conrm contents of the following.

PWB Name Ref. No. Description

MAIN IC401 R5F64169DFD B SOFTWARE: Main

MAIN IC302 EN29LV160BB-70TIP B SOFTWARE: MainROM

MAIN IC702 MX29LV160DTTI B SOFTWARE: USB

DIGITAL IC901 R5F3650TNFD B SOFTWARE: Sub

DIGITAL IC205 EN29LV320BB B SOFTWARE: DSP

DIGITAL IC102 EPM3032ATC4410 B SOFTWARE: Audio PLD

DIGITAL IC611 EPCS16SI8N B SOFTWARE: GUI Cong

DIGITAL IC607 T5CC1(FLASH U-COM) CD6003 B SOFTWARE: GUI PRG

B/E IC110 S29GL01GP11TFCR20# B SOFTWARE: B/E

B/E IC853 R5F364VDNFB B SOFTWARE: SYS

After replaced

A : Mask ROM (With software). No need write-in of software to the microprocessor.

B : Flash ROM (With software). Usually, no need write-in of software. But, when the software was updated, you should be

write-in of the new software to the microprocessor or ash ROM. Please check the software version.

C : Empty Flash ROM (Without software). You should be write-in of the software to the microprocessor or ash ROM.

Refer to "Update procedure" or "writing procedure", when you should be write-in the software.

After

replaced

Remark

VERSION UPGRADE PROCEDURE OF FIRMWARE

You can update by downloading the latest rmware from the Internet.

1. Update from the Internet

1.1. preparation

(1) System Requirement

• Internet Connection by Broadband Circuit

• Modem

• Router

• Ethernet cable (CAT-5 or greater recommended)

(2) Setting

Internet

Computer

Router

Modem

To WAN port

To LAN port

To LAN port

LAN port/Ethernet connector

ETHERNET

connector

32

Page 33

1.2. Check for Update and Update

Check if the latest rmware exists. You can also check approximately how long it will take to complete an update.

(1) Press the SETUP button on the remote control to display the GUI menu.

(2) Use the cursor buttons to select "Other Setup" → "Firmware Update" → "Update Check".

(3) Press the ENTER buttom.

• The latest version of the rmware uploaded to the web is displayed.

• If the latest rmware version is on the web, proceed to (4).

• f the latest rmware is already installed, press the MENU button to close the menu.

(4) Use the cursor buttons to select "Update", then press the ENTER button.

• During update, the power indicator lights red and the GUI screen is shut down. And a rough remaining time is

indicated on the display.

• When updating is complete the power indicator lights green and normal status is resumed.

(5) Press the MENU button to close the menu.

--- Cautions on Firmware Update ---

• In order to use these functions, you must have the correct system requirements and settings for a broadband Internet

connection.

• Do not turn off the power until updating is completed.

Even with a broadband connection to the Internet, approximately about 1 hour is required for the updating procedure to

be completed.

Once updating starts, normal operations on the S5BD cannot be performed until updating is completed. Also, setting

items of the GUI menu of S5BD or setting items of the image adjustment may be initialized.

Make a note of the settings before updating, and set them again after updating.

1.3. About the error code

See the chart below for error codes, details of faults, and coping strategies when rmware updates are performed

through DPMS (Denon Product Management Server).

Error

Code

01

02

03

04

05

06

07

08

Details of Error code Display Coping strategies

Reset and update again.

Carry out the update in an environment

0 1

that has little network load.

Carry out the update in an environment

that has little network load.

0 2

Check the network connection.

Carry out the update in an environment

0 3

that has little network load.

Turn the power off then back on.

Updating starts automatically.

Carry out the update in an environment

0 4

that has little network load.

Turn the power off then back on.

Updating starts automatically.

Carry out the update in an environment

0 5

that has little network load.

Turn the power off then back on.

Updating starts automatically.

Carry out the update in an environment

0 6

that has little network load.

Turn the power off then back on.

Updating starts automatically.

Carry out the update in an environment

0 6

that has little network load.

Turn the power off then back on.

Updating starts automatically.

Carry out the update in an environment

0 8

that has little network load.

Log-in to DPMS has failed.

Line, etc., is busy when logging into

DPMS.

Connection to DPMS failed.

Firmware le data was requested

but error message was received.

Firmware le data was requested

but it timed out.

Error (connection failure) message

received when downloading

rmware.

Data acquisition failed (timed out)

when downloading rmware.

There was invalid data in the

rmware for rewriting that

downloaded (when a Check Sum

error).

L o g i n f a i l e d

S e r v e r i s b u s y

C o n n e c t i o n f a i l

C o n n e c t i o n f a i l

C o n n e c t i o n f a i

D o w n l o a d f a i l

D o w n l o a d f a i l

D o w n l o a d f a i l

33

Page 34

Error

Code

Error codes when rewriting B/E

Details of Error code Display Coping strategies

The rewriting of block data failed

10

when rewriting B/E.

Error codes when rewriting F/E

The rewriting of block data failed

20

when rewriting F/E.

Error codes when rewriting MAIN

MAIN CPU failed to receive MAIN

CPU rewrite command sent from BD

30

SYSTEM CPU (when timed out).

MAIN CPU failed to receive MAIN

CPU rewrite command sent from BD

31

SYSTEM CPU

MAIN CPU failed to receive

rmware for rewriting sent from BD

33

SYSTEM CPU (when timed out).

MAIN CPU failed to receive

rmware for rewriting sent from BD

34

SYSTEM CPU (when an error )

MAIN CPU failed to receive

rmware for rewriting sent from BD

35

SYSTEM CPU (when invalid data

received).

(when an error).

B E * * *

m i

U p d a t i n g f a i l 1 0

F E * * *

m i

U p d a t i n g f a i l 2 0

M a i n * * *

m i

U p d a t i n g f a i l 3 0

M a i n * * *

m i

U p d a t i n g f a i l 3 1

M a i n * * *

m i

U p d a t i n g f a i l 3 3

M a i n * * *

m i

U p d a t i n g f a i l 3 4

M a i n * * *

m i

U p d a t i n g f a i l 3 5

n

Turn the power off then back on.

Updating starts automatically.

n

Turn the power off then back on.

Updating starts automatically.

n

Turn the power off then back on.

Updating starts automatically.

n

Turn the power off then back on.

Updating starts automatically.

n

Turn the power off then back on.

Updating starts automatically.

n

Turn the power off then back on.

Updating starts automatically.

n

Turn the power off then back on.

Updating starts automatically.

MAIN CPU failed to receive

rmware for rewriting sent from BD

36

SYSTEM CPU (when timed out).

MAIN CPU failed to receive

rmware for rewriting sent from BD

37

SYSTEM CPU (when an error).

MAIN CPU failed to receive

rmware for rewriting sent from BD

38

SYSTEM CPU (when invalid data

received).

The deletion of block data failed

39

before rewriting MAIN CPU.

The rewriting of block data failed

3A

when rewriting MAIN CPU.

The data verication was invalid

3B

after rewriting MAIN CPU.

Failed to transmission for Updata

command (when a communication

3E

error).

M a i n * * *

m i

U p d a t i n g f a i l 3 6

M a i n * * *

m i

U p d a t i n g f a i l 3 7

M a i n * * *

m i

U p d a t i n g f a i l 3 8

M a i n * * *

m i

E r a s e f a i l 3 9

M a i n * * *

m i

U p d a t i n g f a i l 3 A

M a i n * * *

m i

U p d a t i n g f a i l 3 B

M a i n * * *

m i

U p d a t i n g f a i l 3 E

n

Turn the power off then back on.

Updating starts automatically.

n

Turn the power off then back on.

Updating starts automatically.

n

Turn the power off then back on.

Updating starts automatically.

n

Turn the power off then back on.

Updating starts automatically.

n

Turn the power off then back on.

Updating starts automatically.

n

Turn the power off then back on.

Updating starts automatically.

n

Turn the power off then back on.

Updating starts automatically.

Failed to receive of Updata

command (when a communication

3F

error).

M a i n * * *

m i

U p d a t i n g f a i l 3 F

34

n

Turn the power off then back on.

Updating starts automatically.

Page 35

Error

Code

General error codes when rewriting ROM other than MAIN.

40

Details of Error code Display Coping strategies

Failed to receive the rewrite starting

command sent from BD SYSTEM

CPU to MAIN CPU (when timed

out).

M a i n R O M * * *

U p d a t i n g f a i l 4 0

m i

n

Turn the power off then back on.

Updating starts automatically.

Failed to receive the rewrite starting

command sent from BD SYSTEM

41

CPU to MAIN CPU (when an error).

MAIN CPU failed to receive

rmware for serial ash rewriting

43

sent by BD SYSTEM CPU (when

timed out).

MAIN CPU failed to receive

rmware for serial ash rewriting

44

sent by BD SYSTEM CPU (when

an error ).

MAIN CPU failed to receive

rmware for serial ash rewriting

45

sent by BD SYSTEM CPU (when

invalid data received).

Failed to receive the complete

rewrite command sent from BD

46

SYSTEM CPU to MAIN CPU (when

timed out).

Failed to receive the complete

rewrite command sent from BD

44

SYSTEM CPU to MAIN CPU (when

an error).

Failed to transmission for Updata

command (when a communication

4E

error ).

M a i n R O M * * *

m i

U p d a t i n g f a i l 4 1

M a i n R O M * * *

m i

U p d a t i n g f a i l 4 3

M a i n R O M * * *

m i

U p d a t i n g f a i l 4 4

M a i n R O M * * *

m i

U p d a t i n g f a i l 4 5

M a i n R O M * * *

m i

U p d a t i n g f a i l 4 6

M a i n R O M * * *

m i

U p d a t i n g f a i l 4 7

M a i n R O M * * *

m i

U p d a t i n g f a i l 4 E

n

Turn the power off then back on.

Updating starts automatically.

n

Turn the power off then back on.

Updating starts automatically.

n

Turn the power off then back on.

Updating starts automatically.

n

Turn the power off then back on.

Updating starts automatically.

n

Turn the power off then back on.

Updating starts automatically.

n

Turn the power off then back on.

Updating starts automatically.

n

Turn the power off then back on.

Updating starts automatically.

Failed to receive of Updata

command (when a communication

4F

error ).

Error codes for when rewriting SUB system rmware

Timeout occurred when "C"

command sent to SUB CPU, DSP,

50

FPGA, PLD, etc.

NACK received when "C" command

sent to Sub CPU, DSP, FPGA, PLD

51

etc.

Timeout occurred when "L"

command sent to SUB CPU, DSP,

52

FPGA, PLD, etc.

NACK received when "L" command

sent to Sub CPU, DSP, FPGA, PLD

53

etc.

SUB CPU, DSP, FPGA, PLD failed

to receive rmware for rewriting

54

sent from BD SYSTEM CPU (when

timed out).

SUB CPU, DSP, FPGA, PLD failed

to receive rmware for rewriting

55

sent from BD SYSTEM CPU (when

a Check Sum error)

M a i n R O M * * *

U p d a t i n g f a i l 4 F

S u b * * *

U p d a t i n g f a i l 5 0

S u b * * *

U p d a t i n g f a i l 5 1

S u b * * *

U p d a t i n g f a i l 5 2

S u b * * *

U p d a t i n g f a i l 5 3

S u b * * *

U p d a t i n g f a i l 5 4

S u b * * *

U p d a t i n g f a i l 5 5

m i

m i

m i

m i

m i

m i

m i

n

Turn the power off then back on.

Updating starts automatically.

n

Turn the power off then back on.

Updating starts automatically.

n

Turn the power off then back on.

Updating starts automatically.

n

Turn the power off then back on.

Updating starts automatically.

n

Turn the power off then back on.

Updating starts automatically.

n

Turn the power off then back on.

Updating starts automatically.

n

Turn the power off then back on.

Updating starts automatically.

35

Page 36

Error

Code

56

Details of Error code Display Coping strategies

SUB CPU, DSP, FPGA, PLD failed

to receive rmware for rewriting

sent from BD SYSTEM CPU (when

a Check Sum error)

S u b * * *

m i

U p d a t i n g f a i l 5 3

n

Turn the power off then back on.

Updating starts automatically.

NACK is received or a timeout

occurred when "P" command sent

57

to SUB CPU, DSP, FPGA, PLD, etc.

NACK is received or a timeout

occurred when "I" command sent to

59

SUB CPU, DSP, FPGA, PLD, etc.

NACK received when "I" command

sent to Sub CPU, DSP, FPGA, PLD

5A

etc.

Failed to receive of Updata

command (when a communication

5F

error ).

Error codes when rewriting B/E SerialFlash/Main.ROM

Failure to acquire serial ash data

60

and before deleting serial ash.

Failure to delete data before

61

rewriting serial ash.

Failure to receive rmware for serial

ash rewriting sent by BD System

62

CPU (when timed out).

S u b * * *

U p d a t i n g f a i l 5 7

S u b * * *

U p d a t i n g f a i l 5 9

S u b * * *

U p d a t i n g f a i l 5 A

S u b * * *

U p d a t i n g f a i l 5 F

G U I

U p d a t i n g f a i l 6 0

G U I

U p d a t i n g f a i l 6 1

G U I

U p d a t i n g f a i l 6 2

F l ash

F l ash

F l ash

* * *

* * *

* * *

m i

m i

m i

m i

m i

m i

m i

n

Turn the power off then back on.

Updating starts automatically.

n

Turn the power off then back on.

Updating starts automatically.

n

Turn the power off then back on.

Updating starts automatically.

n

Turn the power off then back on.

Updating starts automatically.

n

Turn the power off then back on.

Updating starts automatically.

n

Turn the power off then back on.

Updating starts automatically.

n

Turn the power off then back on.

Updating starts automatically.

Failure to receive rmware for Main

ROM rewriting sent by BD System

63