Page 1

For U.S.A., Canada,

Europe & Japan model

Ver. 6

SERVICE MANUAL

Please refer to the

MODIFICATION NOTICE.

MODEL S-301

DVD HOME THEATER SYSTEM

HOME THEATER SYSTEM (S-301) consists of DVD SURROUND RECEIVER (ADV-S301),

SUB WOOFER (DSW-S301) and SPEAKER SYSTEM (SC-S301)

注 意

サービスをおこなう前に、このサービスマニュアルを

必ずお読みください。本機は、火災、感電、けがなど

に対する安全性を確保するために、さまざまな配慮を

おこなっており、また法的には「電気用品安全法」に

もとづき、所定の許可を得て製造されております。

従ってサービスをおこなう際は、これらの安全性が維

持されるよう、このサービスマニュアルに記載されて

いる注意事項を必ずお守りください。

●

For purposes of improvement, specifications and

design are subject to change without notice.

●

Please use this service manual with referring to the

operating instructions without fail.

●

Some illustrations using in this service manual are

slightly different from the actual set.

Denon Brand Company, D&M Holdings Inc.

●

●

●

●

TOKYO, JAPAN

本機の仕様は性能改良のため、予告なく変更すること

があります。

補修用性能部品の保有期間は、製造打切後8年です。

修理の際は、必ず取扱説明書を参照の上、作業を行っ

てください。

本文中に使用しているイラストは、説明の都合上現物

と多少異なる場合があります。

X0245 V.06 DE/CDM 0612

Page 2

SAFETY PRECAUTIONS

The following check should be performed for the continued protection of the customer and service technician.

LEAKAGE CURRENT CHECK

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis

resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the power

cord is less than 460 kohms, the unit is defective.

LASER RADIATION

Do not stare into beam or view directly with optical instruments, class 3A laser product.

S-301

CAUTION

Please heed the points listed below during servicing and inspection.

◎ Heed the cautions!

Spots requiring particular attention when servicing, such as

the cabinet, parts, chassis, etc., have cautions indicated on

labels or seals. Be sure to heed these cautions and the cautions indicated in the handling instructions.

◎ Caution concerning electric shock!

(1) An AC voltage is impressed on this set, so touching inter-

nal metal parts when the set is energized could cause

electric shock. Take care to avoid electric shock, by for example using an isolating transformer and gloves when

servicing while the set is energized, unplugging the power

cord when replacing parts, etc.

(2)There are high voltage parts inside. Handle with extra care

when the set is energized.

◎

Caution concerning disassembly and assembly!

Though great care is taken when manufacturing parts from

sheet metal, there may in some rare cases be burrs on the

edges of parts which could cause injury if fingers are moved

across them. Use gloves to protect your hands.

◎ Only use designated parts!

The set's parts have specific safety properties (fire resistance, voltage resistance, etc.). For replacement parts, be

sure to use parts which have the same properties. In particular, for the important safety parts that are marked ! on wiring

diagrams and parts lists, be sure to use the designated parts.

◎ Be sure to mount parts and arrange the

wires as they were originally!

For safety reasons, some parts use tape, tubes or other insulating materials, and some parts are mounted away from the

surface of printed circuit boards. Care is also taken with the

positions of the wires inside and clamps are used to keep

wires away from heating and high voltage parts, so be sure to

set everything back as it was originally.

◎ Inspect for safety after servicing!

Check that all screws, parts and wires removed or disconnected for servicing have been put back in their original positions, inspect that no parts around the area that has been

serviced have been negatively affected, conduct an insulation

check on the external metal connectors and between the

blades of the power plug, and otherwise check that safety is

ensured.

(Insulation check procedure)

Unplug the power cord from the power outlet, disconnect the

antenna, plugs, etc., and turn the power switch on. Using a

500V insulation resistance tester, check that the insulation resistance between the terminals of the power plug and the externally exposed metal parts (antenna terminal, headphones

terminal, microphone terminal, input terminal, etc.) is 1MΩ or

greater. If it is less, the set must be inspected and repaired.

CAUTION

Many of the electric and structural parts used in the set have

special safety properties. In most cases these properties are

difficult to distinguish by sight, and using replacement parts

with higher ratings (rated power and withstand voltage) does

not necessarily guarantee that safety performance will be preserved. Parts with safety properties are indicated as shown

below on the wiring diagrams and parts lists is this service

manual. Be sure to replace them with parts with the designated part number.

(1) Schematic diagrams ... Indicated by the ! mark.

(2) Parts lists ... Indicated by the ! mark.

Concerning important safety parts

Using parts other than the designated parts

could result in electric shock, fires or other

dangerous situations.

注 意

サービス、点検時にはつぎのことにご注意願います。

◎注意事項をお守りください!

サービスのとき特に注意を必要とする個所についてはキャ

ビネット、部品、シャーシなどにラベルや捺印で注意事項を

表示しています。これらの注意書きおよび取扱説明書などの

注意事項を必ずお守りください。

◎感電に注意!

(1) このセットは、交流電圧が印加されていますので通電時

に内部金属部に触れると感電することがあります。従っ

て通電サービス時には、絶縁トランスの使用や手袋の着

用、部品交換には、電源プラグを抜くなどして感電にご

注意ください。

(2) 内部には高電圧の部分がありますので、通電時の取扱に

は十分ご注意ください。

◎分解、組み立て作業時のご注意!

板金部品の端面の『バリ』は、部品製造時に充分管理をして

おりますが、板金端面は鋭利となっている箇所が有りますの

で、部品端面に触れたまま指を動かすとまれに怪我をする場

合がありますので十分注意して作業して下さい。手の保護の

ために手袋を着用してください。

◎指定部品の使用!

セットの部品は難燃性や耐電圧など安全上の特性を持った

ものとなっています。従って交換部品は、使用されていたも

のと同じ特性の部品を使用してください。特に配線図、部品

表に!印で指定されている安全上重要な部品は必ず指定の

ものをご使用ください。

◎部品の取付けや配線の引きまわしは、

元どおりに!

安全上、テープやチューブなどの絶縁材料を使用したり、プ

リント基板から浮かして取付けた部品があります。また内部

配線は引きまわしやクランパーによって発熱部品や高圧部

品に接近しないように配慮されていますので、これらは必ず

元どおりにしてください。

◎サービス後は安全点検を!

サービスのために取り外したねじ、部品、配線などが元どお

りになっているか、またサービスした個所の周辺を劣化させ

てしまったところがないかなどを点検し、外部金属端子部

と、電源プラグの刃の間の絶縁チェックをおこなうなど、安

全性が確保されていることを確認してください。

(絶縁チェックの方法)

電源コンセントから電源プラグを抜き、アンテナやプラグな

どを外し、電源スイッチを入れます。500V 絶縁抵抗計を用

いて、電源プラグのそれぞれの端子と外部露出金属部[アン

テナ端子、ヘッドホン端子マイク端子、入力端子など]との

間で、絶縁抵抗値が1 MΩ 以上であること、この値以下の

ときはセットの点検修理が必要です。

注 意

本機に使用している多くの電気部品、および機構部品は安全

上、特別な特性を持っています。この特性はほとんどの場合、

外観では判別つきにくく、またもとの部品より高い定格(定

格電力、耐圧)を持ったものを使用しても安全性が維持され

るとは、限りません。安全上の特性を持った部品は、この

サービスマニュアルの配線図、部品表につぎのように表示し

ていますので必ず指定されている部品番号のものを使用願

います。

(1) 配線図…!マークで表示しています。

(2) 部品表…!マークで表示しています。

安全上重要な部品について

指定された部品と異なるものを使用した場合に

は、感電、火災などの危険を生じる恐れがあり

ます。

2

Page 3

S-301

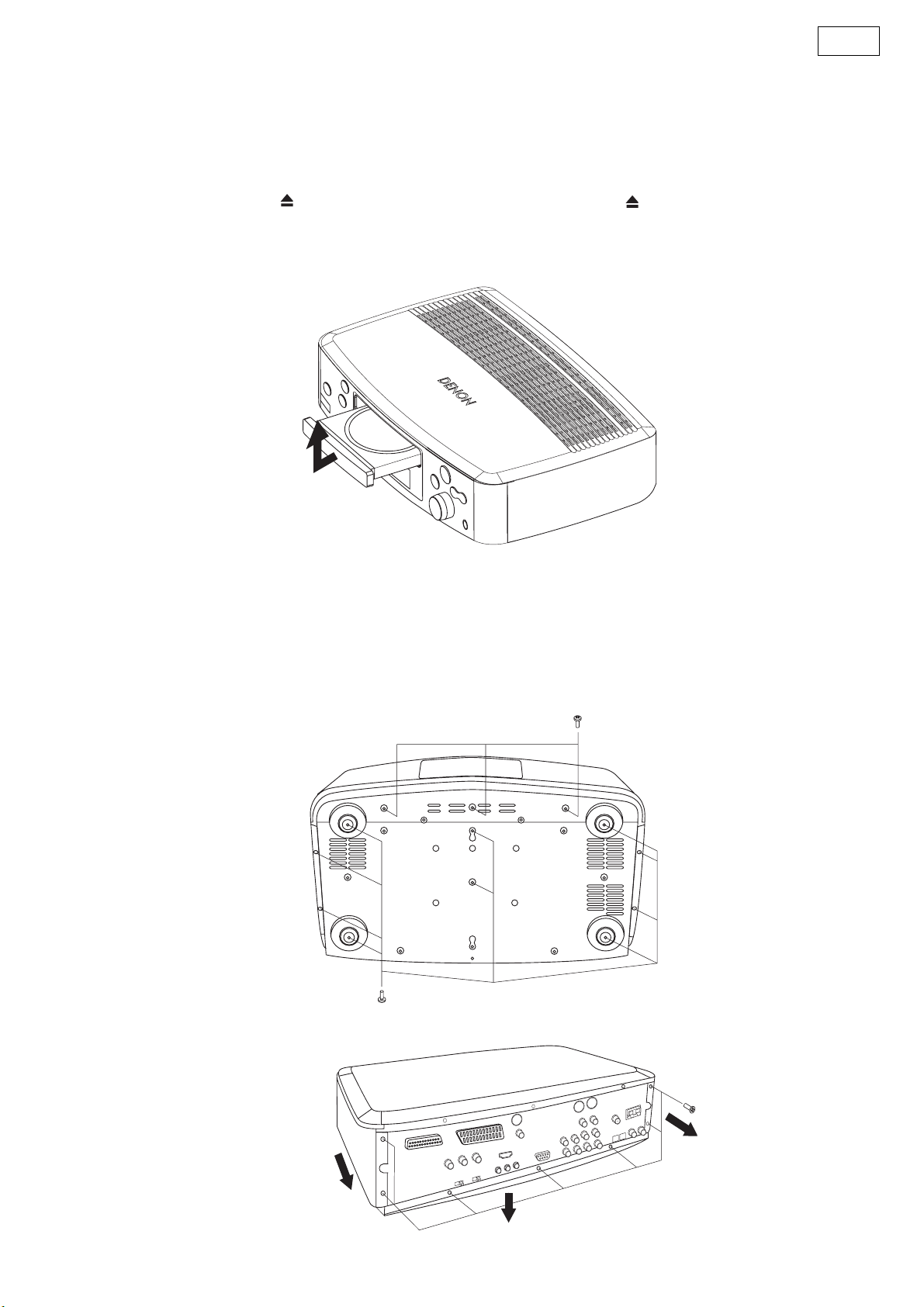

DISASSEMBLY

(Follow the procedure below in reverse order when

reassembling.)

1. Loader Panel

(1) Switch on, and press [ (OPEN/CLOSE)] button

to open the Disc tray.

(2) Detach the Loader Panel by lifting.

各部のはずしかた

(組み立てるときは、逆の順序でおこなってください。)

1. ローダーパネルのはずしかた

(1) 電源を入れ「 (OPEN/CLOSE)」ボタンを押して、

ディスクトレイを開きます。

(2) ローダーパネルを持ち上げてはずします。

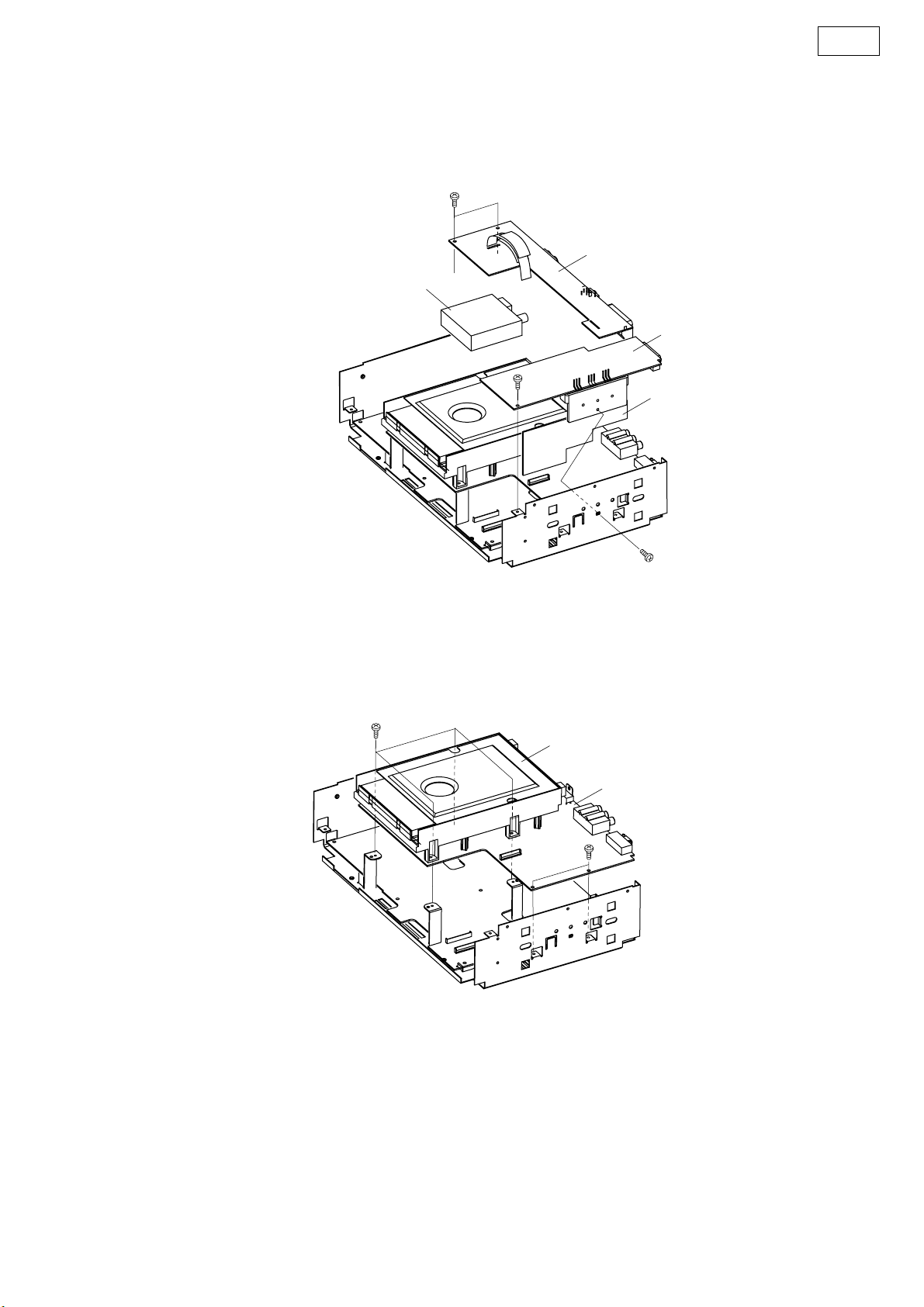

2. Side Panel, Bottom Cover

(1) Remove 13 bottom screws.

(2) Remove 7 rear screws, then detach Side Panel and

Bottom Cover.

2. サイドパネル、ボトムカバーのはずしかた

(1) 底面よりネジを 13 本はずします。

(2) 裏面よりネジを 7 本はずし、サイドパネル、ボト

ムカバーをそれぞれ矢印の方向へはずします。

3

Page 4

S-301

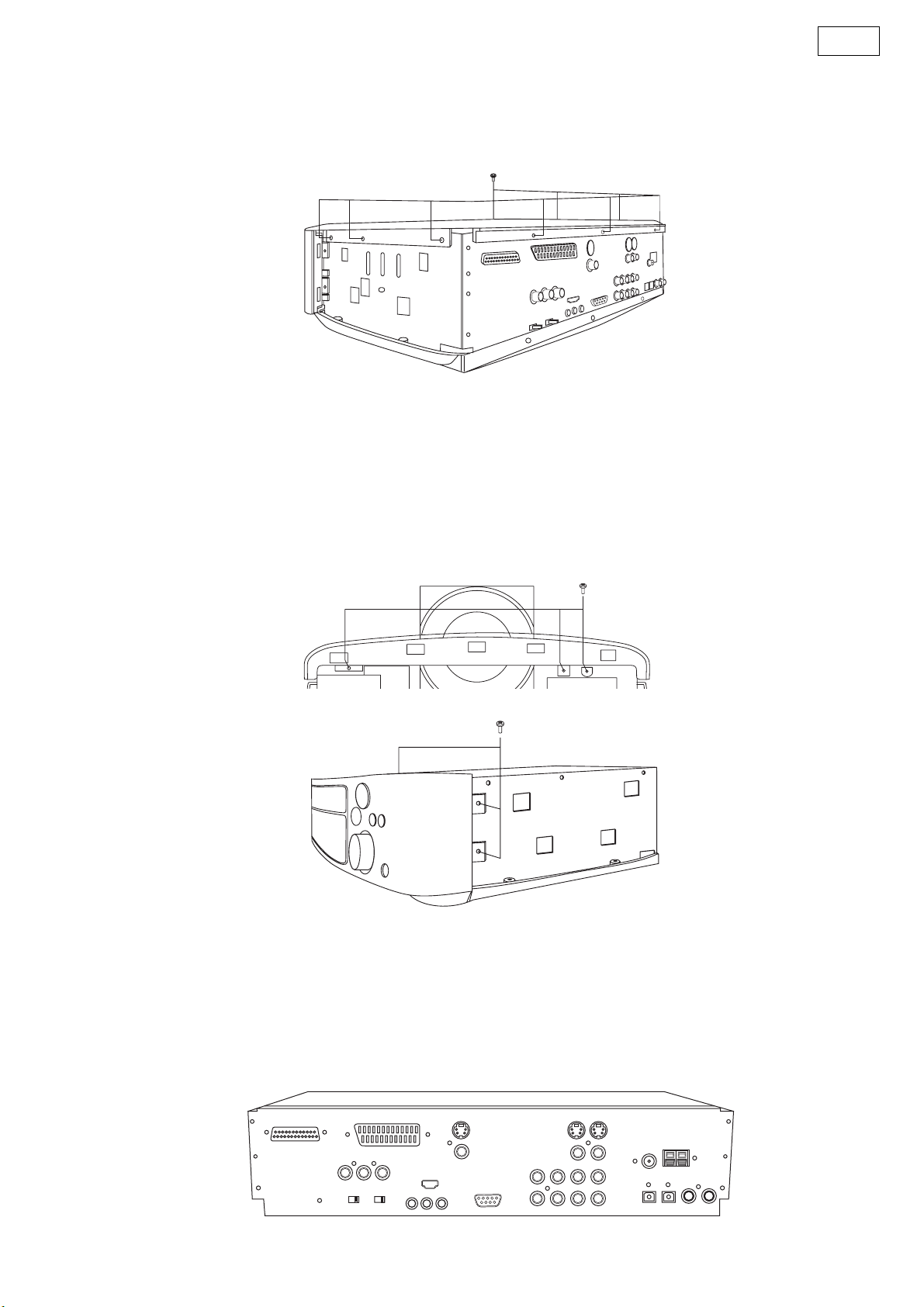

3. Top Cover

(1) Remove 9 top screws, then detach Top Cover.

4. Front Panel Ass’y

(1) Remove 3 Front panel screws, then detach P.W.B.

and chassis.

(2) Remove 4 Front panel side screws, then detach the

Front Panel Ass’y.

3. トップカバーのはずしかた

(1) トップカバーを止めている上部のネジ 9 本をはず

し、トップカバーを矢印の方向へはずします。

4. フロントパネルのはずしかた

(1) フロントパネルからの基板とシャーシを止めてい

るネジを 3 本はずします。

(2) フロントパネル側面を止めているネジ 4 本(左右

各 2 本)をはずし、フロントパネルを矢印の方向

へはずします。

5. Front Panel Ass’y

(1) Remove each terminal screws, Back Panel screws

and Chassis screws, then detach the Back Panel.

5. バックパネルのはずしかた

(1) 各端子を止めているネジおよびバックパネルと

シャーシを止めているネジをはずし、バックパネ

ルをはずします。

4

Page 5

S-301

6. DVD Mecha

(1) Remove 4 screws, then detach P.W.B.(1U-3695-1,

1U-3695-2, 1U-3695-3) and TUNER PACK.

TUNER PACK

6. DVD メカの取りはずしかた

(1) ネジを 4 本はずし、1U-3695-1 基板と 1U-3695-2

基板と 1U-3695-3 基板と TUNERPACK をはずしま

す。

1U-3695-3

1U-3695-1

1U-3695-2

(2) Remove 6 screws, then detach 1uU-3692 P.W.B.

with DVD mecha from bottom chassis.

(2) ネジを 6 本はずし、1U-3692 基板と DVD メカを

一体でシャーシよりはずします。

D

VD mecha

1U-3692

5

Page 6

S-301

7. Traverse Unit Disassembly

Caution: The optical pickup can be damaged easily

by static electricity charged on human body. Take

necessary anti-static measures when repairing

around the optical pickup.

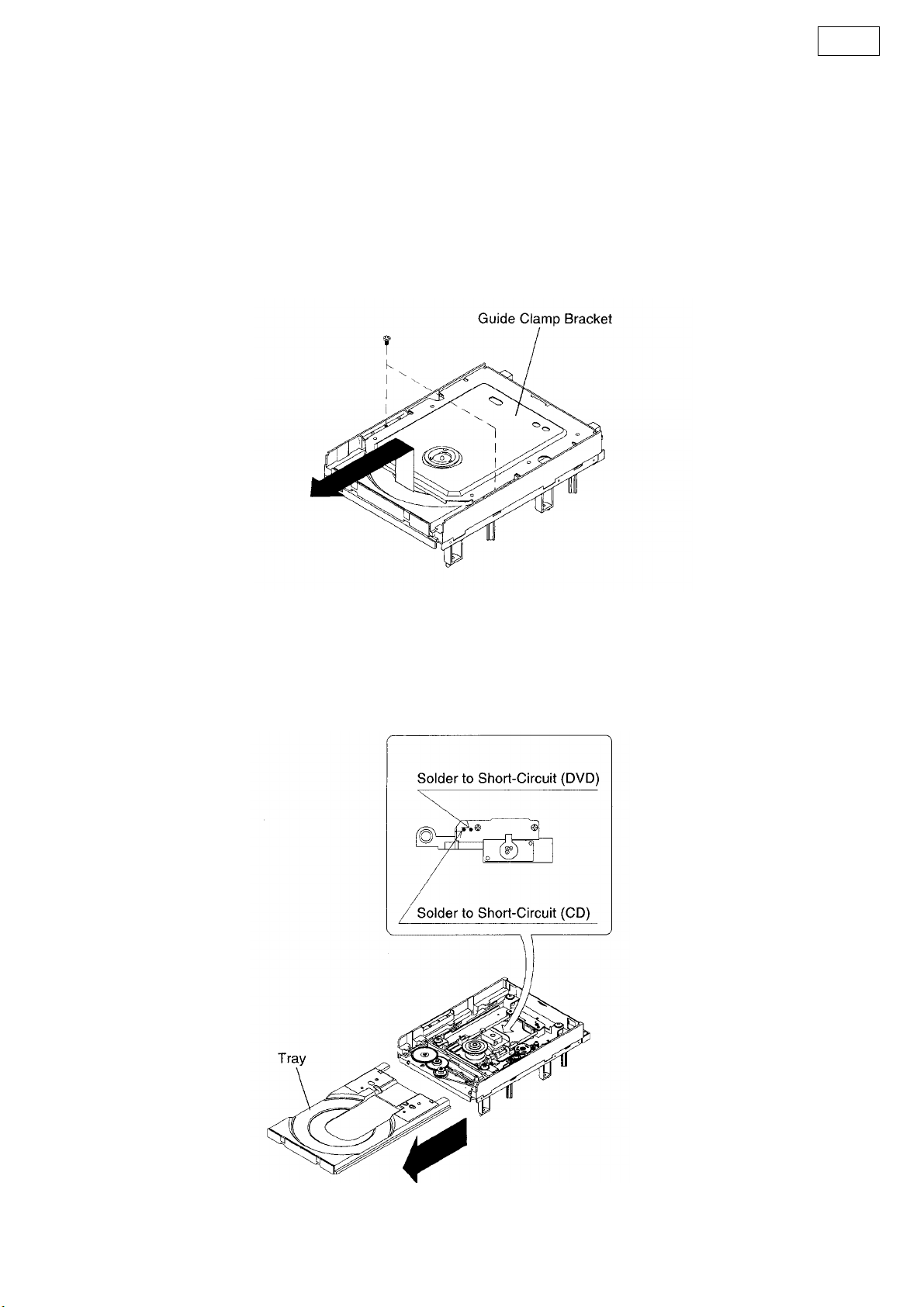

7.1. Guide Clamp Bracket disassembly

(1) Remove 2 screws.

(2) Remove Guide Clamp Bracket to arrow direction.

7. トラバースユニットのはずしかた

注意:光ピックアップは、人体に帯電した静電気等で

静電破壊することがあります。光ピックアップ周辺を

修理する際は、必要な静電対策を行ってください。

7.1. ガイドクランプブラケットのはずしかた

(1) ねじ 2本をはずします。

(2) ガイドクランプブラケットを矢印の方向にとりは

ずします。

7.2. Tray disassembly

(1) Remove to arrow direction.

(2) Solder the short-circuit (see in the frame).

7.2. トレイのはずし方

(1) 矢印の方向にとりはずします。

(2) 半田付けショートを行います。(枠内図参照 )

6

Page 7

S-301

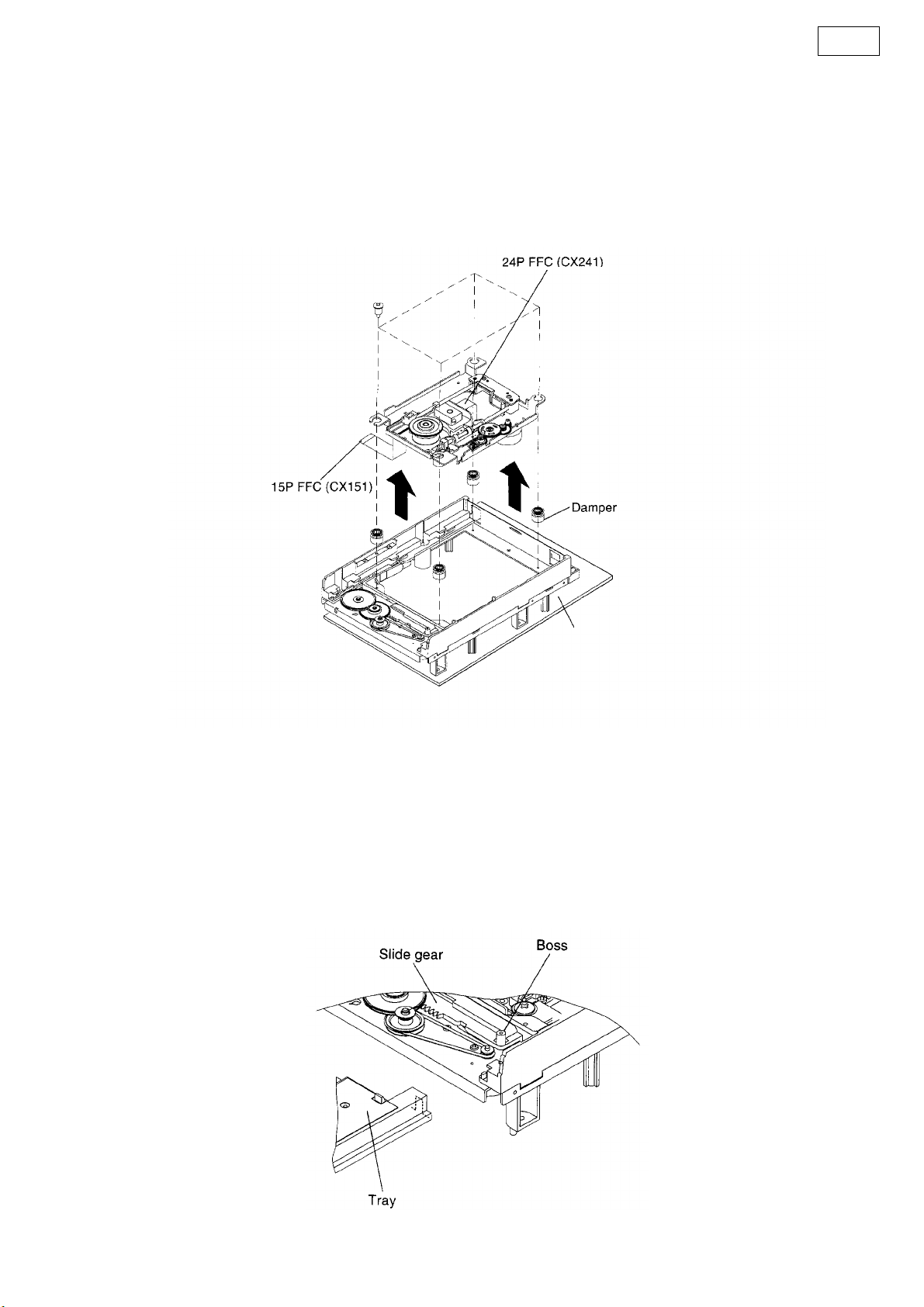

7.3. Traverse Unit disassembly

(1) Remove 24P FFC (CX241), 15P FFC (CX151), 5P

PH WIRE (CX051) connecting with from 1U-3692

P.W.B.

(2) Remove 4 screws fixing Damper.

(3) Remove Traverse Unit to arrow direction.

7.3. トラバースユニットのはずしかた

(1) 1U-3692 基板に接続している 24PFFC(CX241)、

15PFFC(CX151)、5PPHワイヤ(CX051) をはずし

ます。

(2) ダンパーを固定しているねじ 4本をはずします。

(3) トラバースユニットを矢印の方向にとりはずしま

す。

Note for disassembly Traverse Unit

(1) When assembling, reverse the order of the above.

(2) When inserting Tray, confirm boss on Slide Cam

set to ditch of the Tray (Compare with below drawing).

1U-3692 P.W.B.

トラバースユニット分解の注意

(1) 組み立てるときは、上記の逆の順序で行ってくだ

さい。

(2) トレイ組込み時、スライドカムのボスがトレイの

溝に合っているか確認してください。(下図参照)

7

Page 8

S-301

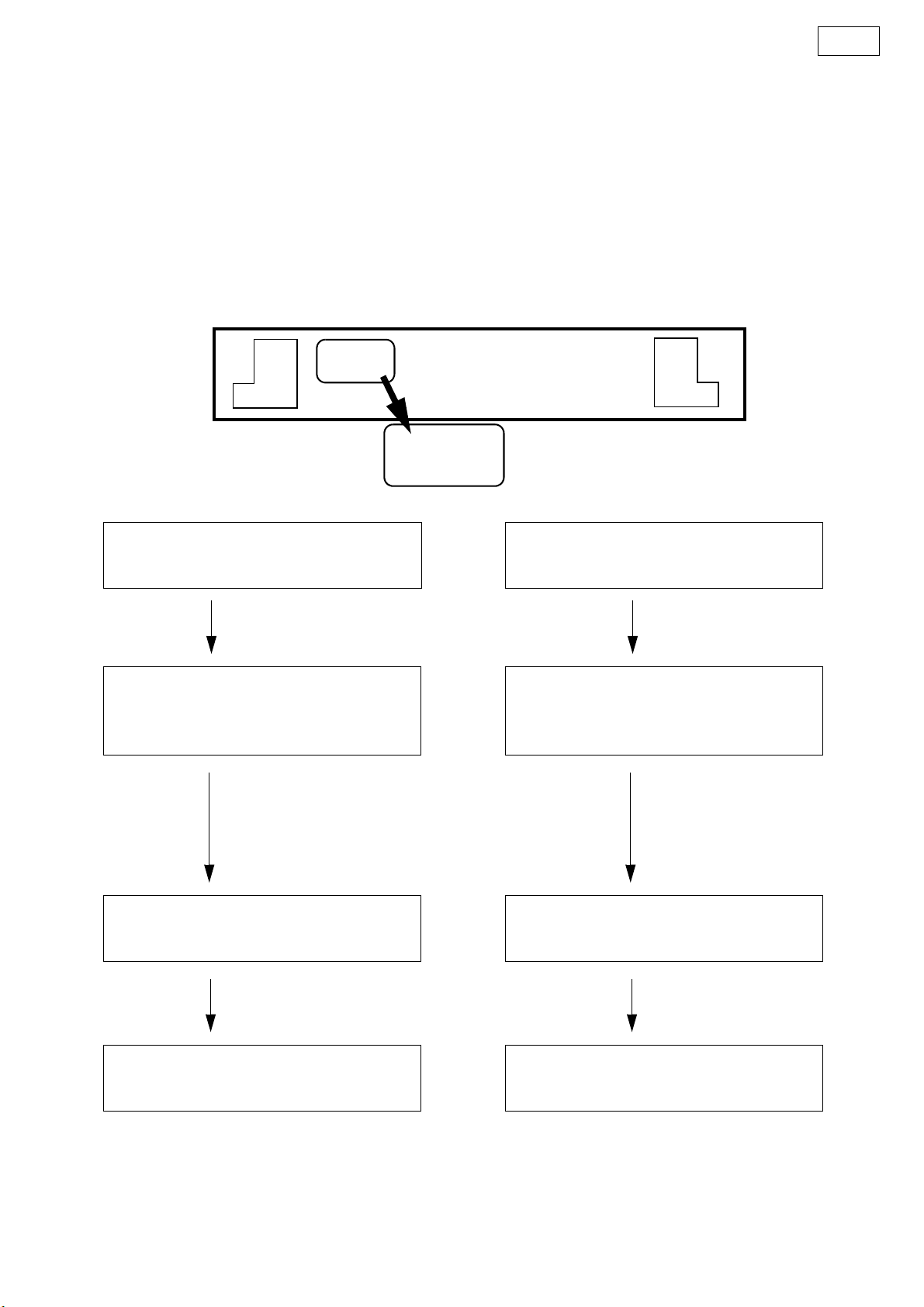

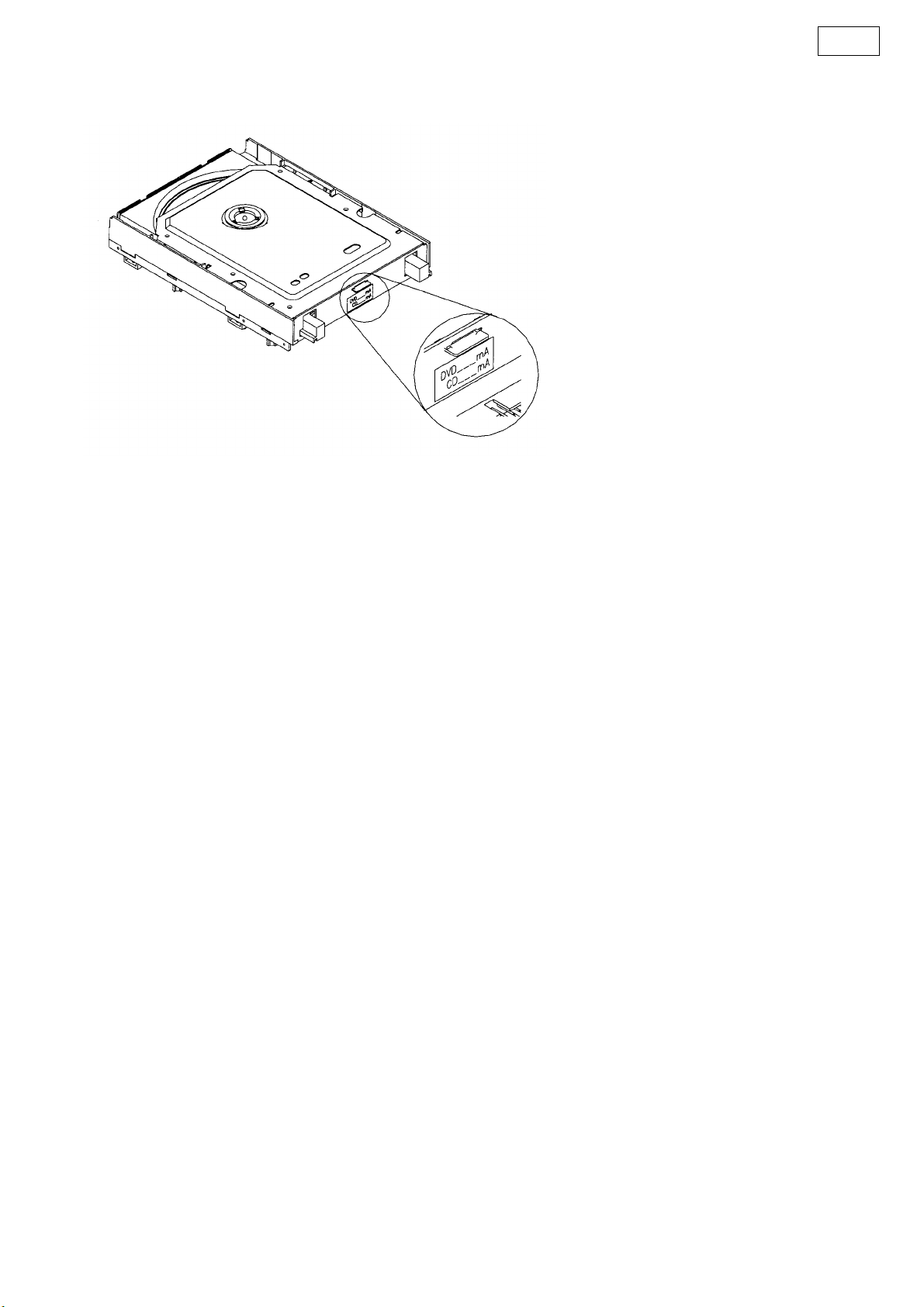

DIAGNOSTICS OF OPTICAL PICKUP AND REPLACING TRAVERSE UNIT

Make failure diagnostics of the Optical Pickup as follows.

If the laser drive current (Iop) becomes more than 1.5 times of

the initial value, the Optical Pickup should be replaced.

The laser drive current is registered on the seal attached to the

rear of the Mecha.Unit.

In case of replacing the Pickup, change the whole part of the

Traverse Unit.

No mechanical adjustment is necessary after the replacement.

Example:

例:

DVD 30mA

CD 30mA

光ピックアップの故障診断とトラバース

ユニットの交換

次の順序で故障診断を行ってください。

レーザー駆動電流 Iop 値が初期値の 1.5 倍以上になっている

場合は光ピックアップ交換の目安となります。

レーザー駆動電流初期値は、メカの後部のシール上に記入さ

れています。

ピックアップ交換の場合は、トラバースユニット単位での交

換となります。メカの調整は不要です。

Disc no read, unsteady playback, etc.

Laser drive current (Iop) check

HF wave form check

(Refer to WAVE FORMS)

Present value exceeds the initial value by 1.5 times

Traverse Unit replacing

(See page 6, 7 for details)

ディスクを読み込まない

スムーズに再生しない、等

レーザー駆動電流 Iop 値の確認

HF 波形の確認

(WAVEFORMS参照)

現在値が初期値の

1.5 倍になっている

トラバースユニット交換

(詳細は 6,7 ページ)

Laser current registering after replacement.

Step: Disc playback

Write the measured value on the seal attached to the

Mecha. Unit

* As to the measuring method, refer to page 9, 10.

交換後のレーザー電流記入

手順:ディスクを再生

その時の Iop 値をメカ後方のシールの上に重ねて貼る

等で更新する。

*Iop の測定方法は、9,10 ページ参照。

8

Page 9

S-301

1. Label Indication of SACD Mechanism.

2. Note for Handling the Laser Pick-Up

The protection for the damage of laser diode.

If you want to change the optical device unit from any other

units, you must keep the following.

(1) It should be done at the desk already took measures the

static electricity in care of removing the OPU's (Optical

device unit) connector cable.

(2) Workers should be put on the "Earth Band".

(3) It should be done to add the solder to the short land to

prevent the broken Laser diode before removing the 24P

FFC cable.

(4) Don't touch OPU's connector parts carelessly.

1. SACD メカのラベル表示

Laser current consumption value

DVD

㧖㧖㧖

㧖㧖㧖

mA, CD

mA, CD

ex) DVD

ࠩ㚟േ㔚ᵹ୯

㧕

㧖㧖㧖

㧖㧖㧖

mA

mA

2. レーザーピックアップの取扱注意

レーザーダイオードの破壊防止。

光素子ユニットを交換するときは、以下を遵守してくださ

い。

(1) 光素子ユニットの接続ケーブルをはずすときは、静電対

策を行ったデスク上で作業してください。

(2) 作業者は、リストストラップを使用してください。

(3) レーザーダイオードの破壊防止のため、24PFFC ケーブ

ルをはずす前にランドを半田付けショートしてくださ

い。

(4) 光素子ユニットのコネクタ部に触れないでください。

3. Replacement of the Laser Pick-up

(Traverse Unit)

Check the Iop (Laser drive current)

If the present Iop (current) value exceeds.+150% of the initial value, replace the Traverse unit (Laser Pick-up) with a

new one.

4. Iop Measurement Method

When measuring Laser drive current (Iop), playback the

discs (CD,DVD) described below, measure Iop for CD Laser

and DVD Laser by the test point (+5V-A2~ LD (CD), LD

(DVD))on the Main P.W.B.

Test Disc : DVD/DVDT-S01 or commercially available

discs.

: CD/TCD-784 (manufactured by ALMEDIO

INC) or commercially available discs.

3. レーザーピックアップ ( トラバースユニッ

ト ) の交換

Iop( レーザー駆動電流)をチェックします。

現在の Iop値が初期値の 150%を越えている場合、トラバー

スユニット(レーザーピックアップ)を交換してください。

4. Iop の測定方法

レーザー駆動電流を測定する場合、下記のディスク

(CD,DVD) を再生します。

Main 基板上のテストポイント(+5V-A2 〜LD(CD),LD(DVD))

にて、CD レーザーと DVD レーザーの Iop を測定してくだ

さい。

テストディスク: DVD/DVDT-S01または市販同等ディスク

: CD/TCD-784(ALMEDIO社製)または市販

同等ディスク

9

Page 10

S-301

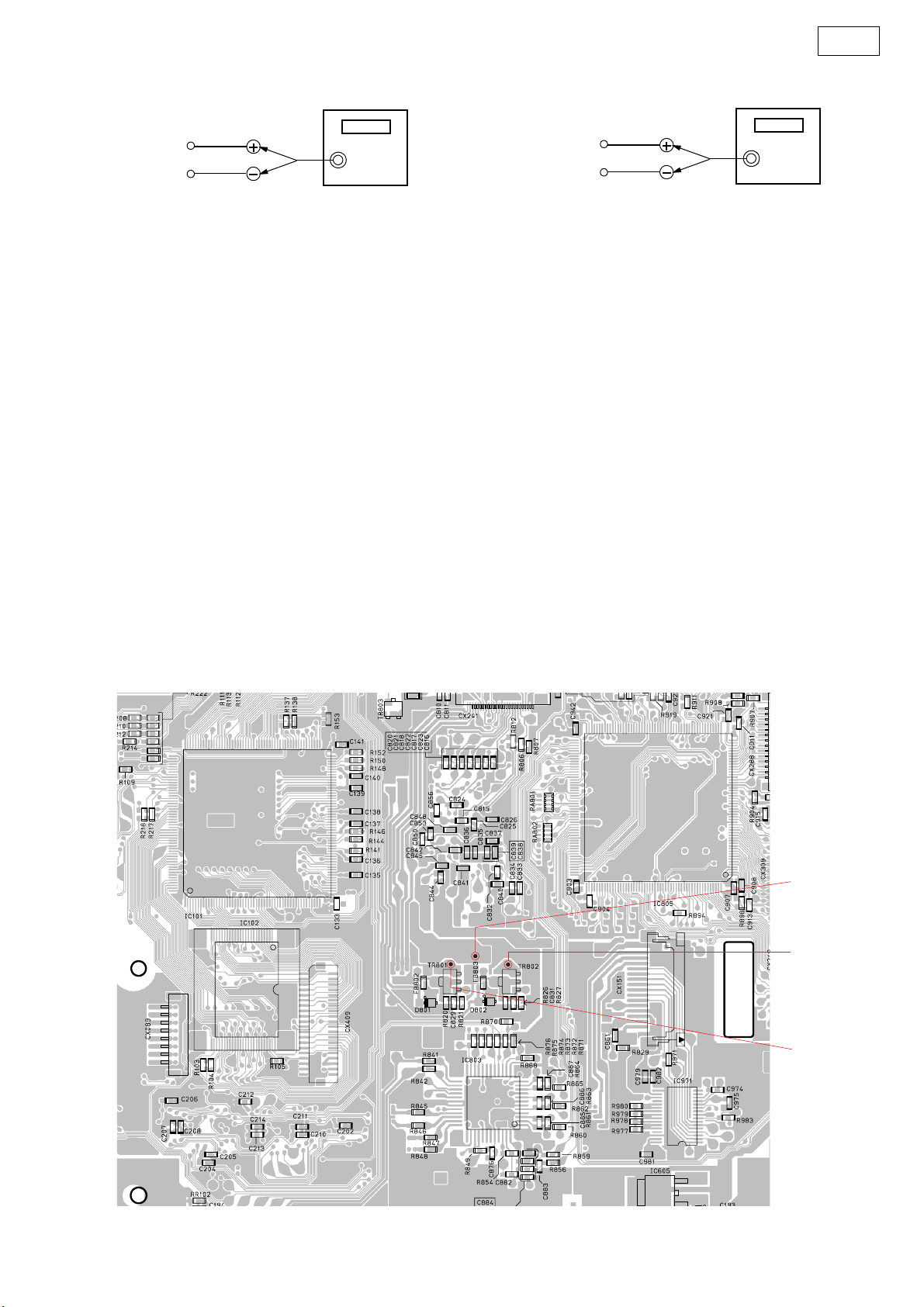

4.1. DVD Laser current measurement

LD (DVD)

+5V-A2

Oscilloscope

(1) Connect the oscilloscope to +5V-A2 of test point for

GND side and LD (DVD) of test point for signal side.

(2) Playback the multi layer track 1 of the DVD Test Disc.

(3) Measure the voltage between +5V-A2 and LD (DVD),

calculate Iop by the formula as shown below.

Iop

Measurement Voltage Value

-----------------------------------------------------------------------------=

14 (Resistance value)

4.2. CD Laser current measurement

(1) Connect the oscilloscope to +5V-A2 of test point for

GND side and LD (CD) of test point for signal side.

(2) Playback the track 1 of the CD Test Disc.

(3) Measure the voltage between +5V-A2 and LD (CD), cal-

culate Iop by the formula as shown below.

4.1. DVD レーザー電流測定

LD (DVD)

+5V-A2

Oscilloscope

(1) オシロスコープをテストポイント +5V-A2(GND) と

LD(DVD)( 信号 ) へ接続します。

(2) DVDテストディスクのマルチレイヤートラック 1 を再生

します。

(3) +5V-A2 と LD(DVD) 間の電圧を測定し、次式により Iop

を算出します。

Iop

測定電圧値

-----------------------------=

14(抵抗値)

4.2. CD レーザー電流測定

(1) オシロスコープをテストポイント +5V-A2(GND) と

LD(CD)( 信号 ) へ接続します。

(2) CD テストディスクのトラック 1 を再生します。

(3) +5V-A2 と LD(CD) 間の電圧を測定し、次式より Iop を

算出します。

Iop

Measurement Voltage Value

-----------------------------------------------------------------------------=

11.75 (Resistance value)

Iop

測定電圧値

------------------------------------=

11.75(抵抗値)

+5V_A2

LD(CD)

1u-3692 foil side

10

LD(DVD)

Page 11

S-301

Special operating procedures

1. Initialization

※ This initializes the data for the function, volume,

DVD mechanism (RL-874), etc.

(1) Check that the AC cord is disconnected from the

power outlet. (AC OFF)

(2) While pressing the FUNCTION and OPEN/CLOSE

( ) buttons on the main unit, plug the AC cord into

the power outlet. (AC ON)

(3) Check that the entire display and all the LEDs light,

then release the FUNCTION and OPEN/CLOSE

() buttons.

(4) After about 3 seconds, "INITIALIZE" appears on the

display.

(5) After initialization is complete (when "INITIALIZE"

turns off), the function is set to "DVD" and the volume level is set to -∞ ("-dB" is displayed).

2. System check mode

※ Use this to display the version information, etc.

(1) In the standby mode, while pressing the STOP ( )

and A.FWD ( ) buttons on the main unit, press

the ON/STANDBY button.

(2) Press the STATUS button on the remote control

unit (RC-1005 or RC-1006) to display the following

information, in this order: Time (TIME) → System

microprocessor version (SYS Ver) → Date of system microprocessor version updating (SYS Date)

→ DSP version (DSP Ver) → Date of DSP version

updating (DSP Date) → Date of drive microprocessor version updating (Dr Date) → ESS version (Ess

Ver) → Date of ESS version updating (Ess Date) →

Region number (Region No.)

(3) To cancel, unplug the AC cord. (AC OFF)

NOTE 1: The DVD mechanism driver version and

ESS version are not displayed unless the

function is once set to DVD.

特殊操作方法

1. 初期化

※ ファンクション、VOL 及び DVD メカ (RL-874) 等の

データを初期化します。

(1) ACコードがコンセントより外れていることを確認

します。(ACOFF)

(2) 本体の FUNCTION ボタンと OPEN/CLOSE( ) ボタ

ンを押しながら、AC コードをコンセントに接続

(ACON) します。

(3) ディスプレイと LED の全点灯を確認したら、本体

の FUNCTION ボタンと OPEN/CLOSE( ) ボタンを

離します。

(4) 約 3 秒後、ディスプレイに "INITIALIZE" が表示され

ます。

(5) 初期化完了 ("INITIALIZE" 消灯 ) 後、FUNCTION は

"DVD"、VOL位置は- ∞ ( 表示は "---dB") となります。

2. システムチェックモード

※ バージョン表示等をおこないます。

(1) STANDBY 時、本体の STOP( )ボタンと A.FWD

( )ボタンを押しながら、ON/STANDBY ボタ

ンを押します。

(2) リモコン(RC-1005orRC-1006)の STATUS ボタン

を押すことにより

時間(TIME)→システムマイコンのバージョン(SYS

Ver) →システムマイコンのバージョンアップ日

(SYSDate)→DSP のバージョン (DSPVer) → DSP

のバージョンアップ日(DSPDate)→ドライブマイ

コンのバージョンアップ日 (DrDate) →ESS のバー

ジョン (EssVer) → Ess のバージョンアップ日 (Ess

Date) →地域番号 (RegionNo.)

の順に表示されます。

(3) 解除するにはAC コードを抜きます。(ACOFF)

( 注 1) DVD メカのドライブバージョン表示、ESS

のバージョン表示については、1 度ファン

クッションを DVD にしないと表示されま

せん。

11

Page 12

S-301

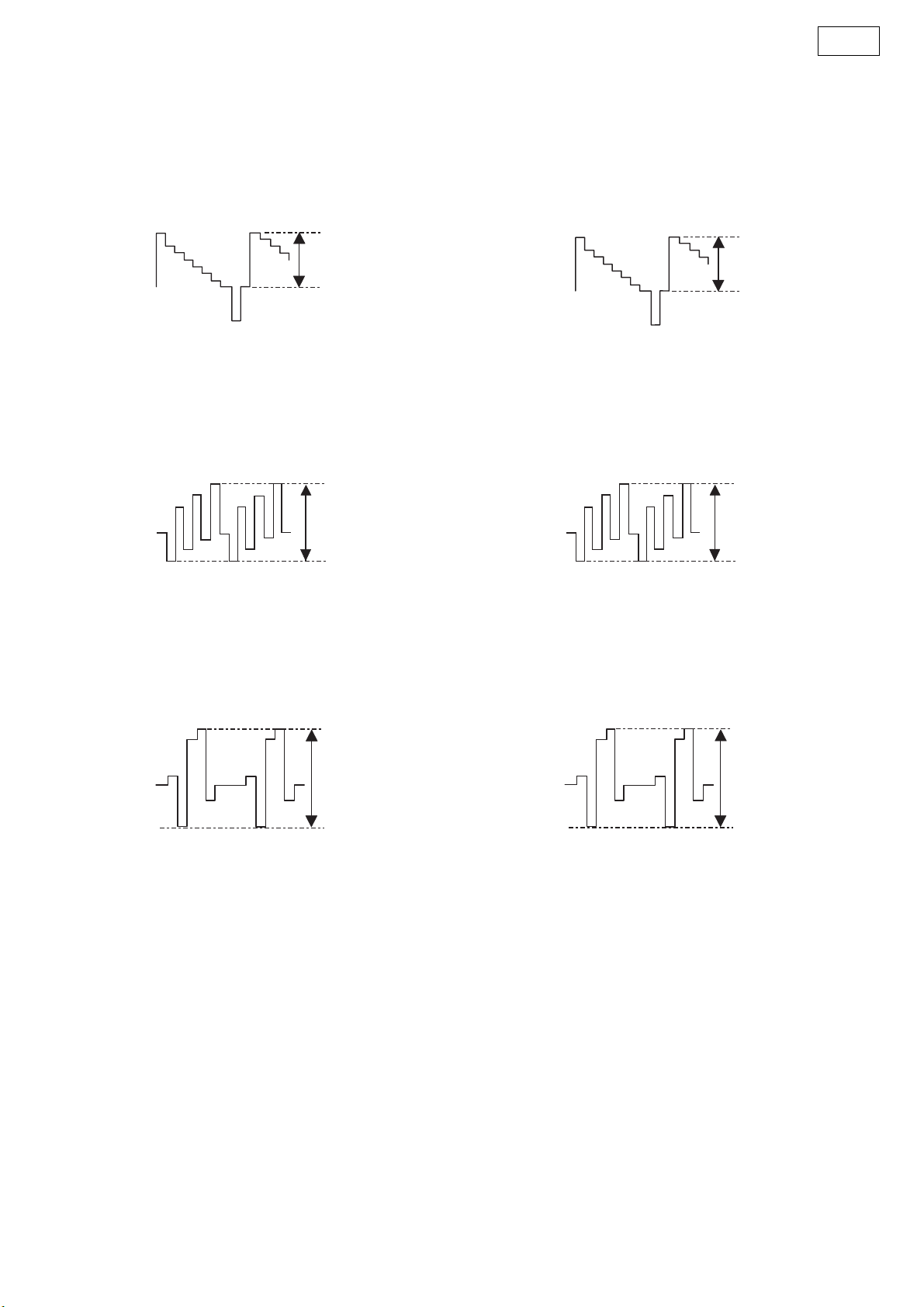

ADJUSTMENT

1. SETTING

(1) Connect the oscilloscope to the Y-signal, PB-signal and

C

B-signal, PR-signal and CR-signal of ZONE2 COMPO-

NENT OUT terminal and each terminate at 75 Ohms.

※ Use the 75 Ohms resistance must be 1%

(2) DVD test disc : DVDT-S01

(3) S OUT of DVD player is connected to AUX1 S IN.

2. Before Adjustment

2.1. Setting the Oscilloscope as below.

(1) PB/CB, PR/CR

(a) TIME/DIV : 10μs

(b) VOLT/DIV : 100mV

(Use the probe : x10 )

(2) Y

(a) TIME/DIV : 10μs

(b) VOLT/DIV : 200mV

(Use the probe : x10 )

Power on. Power Supply

USA & Canada : 120V

Europe : 230V

Japan : 100V

China & Korea : 220V

調整

1. セッティング手順

(1) セットの ZONE2COMPONENTOUT の端子(Y,PB/CB,

PR/CR)をそれぞれオシロスコープ(終端抵抗:75Ω)

に接続します。

※ 75Ω 抵抗は 1%品を使用する事。

(2) DVD テストディスク:DVDT-S01 を用意します。

(3) DVD プレーヤーの SOUT を AUX1SIN に接続します。

2. 調整のまえに

2.1. オシロスコープを下記に設定

(1) PB/CB,PR/CR

(a) TIME/DIV : 10μs

(b) VOLT/DIV : 100mV

(プローブ x10 使用)

(2) Y

(a) TIME/DIV : 10μs

(b) VOLT/DIV : 200mV

(プローブ x10 使用)

電源電圧 : 100V

2.2. Setup the DVD player and confirmation of the

stators

(1) Set to "INTERLACED" mode at the COMPONENT OUT.

(2) Confirm the DVD player’s out put level is equal as the

item 2.4. in following.

2.3. Preparation

(1) Push the FUNCTION knob to select "AUX1" input.

(2) Push [OPEN/CLOSE] button of DVD player, then open

the Disc Tray.

Set DVD test disc (DVDT-S01) on the Disc Tray, and

then push [CLOSE] button.

(3) DVD player FL display appear "STOP", push [PLAY] but-

ton to playback DVD.

(4) Push the [DISPLAY] button of remote control of DVD

player unit and then appear the ON-Screen Display (GUI)

on the monitor TV.

(5) Push the [+10] and [2] button, select Title 12 of DVD.

(6) Push the [ENTER] button, playback Title 12.

(color bar 75%)

2.2. DVD プレーヤの設定と確認

(1) COMPONENTOUTの設定を"インターレース "にします。

(2) DVD プレーヤーの出力が以下 2.4. に合っていることを

確認します。

2.3. 準備手順

(1) FUNCTION ノブを押し、入力を "AUX1" に切り替えます。

(2) DVD プレーヤーの「OPEN/CLOSE」ボタンを押しトレイ

を開き、トレイ上に DVD テストディスク(DVDT-S01)

をセット後、「CLOSE」ボタンを押します。

(3) DVD プレーヤーの表示管上に "STOP" が表示されてか

ら、「PLAY」ボタンを押し、ディスクを再生します。

(4) DVD プレーヤーのリモコンの「DISPLAY」ボタンを押

しグラフィカル・ユーザー・インターフェイス (GUI) 画

面を出します。

(5) 番号ボタンの「 +10 」 , 「 2 」ボタンを押し、Title12 を選択

します。

(6) 「ENTER」ボタンを押し、Title12 を再生します。

(75%カラーバー信号)。

12

Page 13

S-301

2.4. Procedure

(1) Adjust the signal of COMPONENT OUT by the wave of

oscilloscope.

(a) Target, Y-signal

Point : 1U-3695-3 VR601

Adjustment Value : 714 ± 35mV

Waveform

Y

Y-signal COMPONENT OUT

(b) Target, P

Point : 1U-3695-3 VR602

Adjustment Value : *525 ± 25mV

Waveform

B/CB-signal

PB

2.4. 手順

(1) COMPONENTOUTの信号レベルをオシロスコープ上の

波高値で調整します。

(a) Y 信号レベル

調整個所 : 1U-3695-3VR601

調整値 : 714 ± 35mV

波形

Y

COMPONENTOUT の Y 信号レベル

B/CB 信号レベル

(b) P

調整個所 : 1U-3695-3VR602

調整値 : 525 ± 25mV

波形

PB/CB

PB/CB-signal COMPONENT OUT

(c) Target, PR/CR-signal

Point : 1U-3695-3 VR603

Adjustment Value : *525 ± 25mV

Waveform

PR/CR

PR/CR-signal COMPONENT OUT

* : 486 ± 10mV for U.S.A. & Canada model

COMPONENTOUT の PB/CB 信号レベル

(c) PR/CR 信号レベル

調整個所 : 1U-3695-3VR603

調整値 : 525 ± 25mV

波形

PR/CR

COMPONENTOUT の PR/CR 信号レベル

13

Page 14

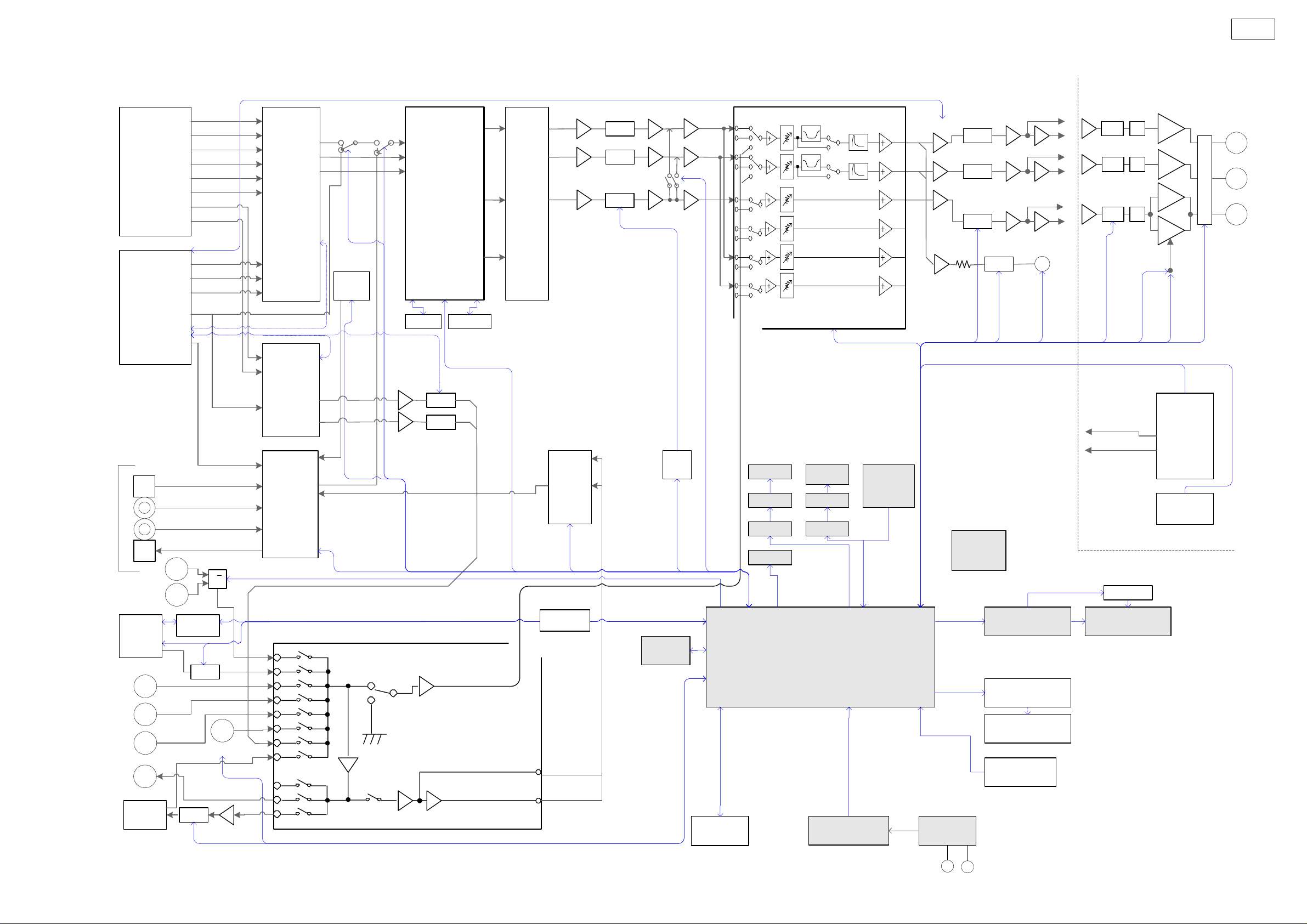

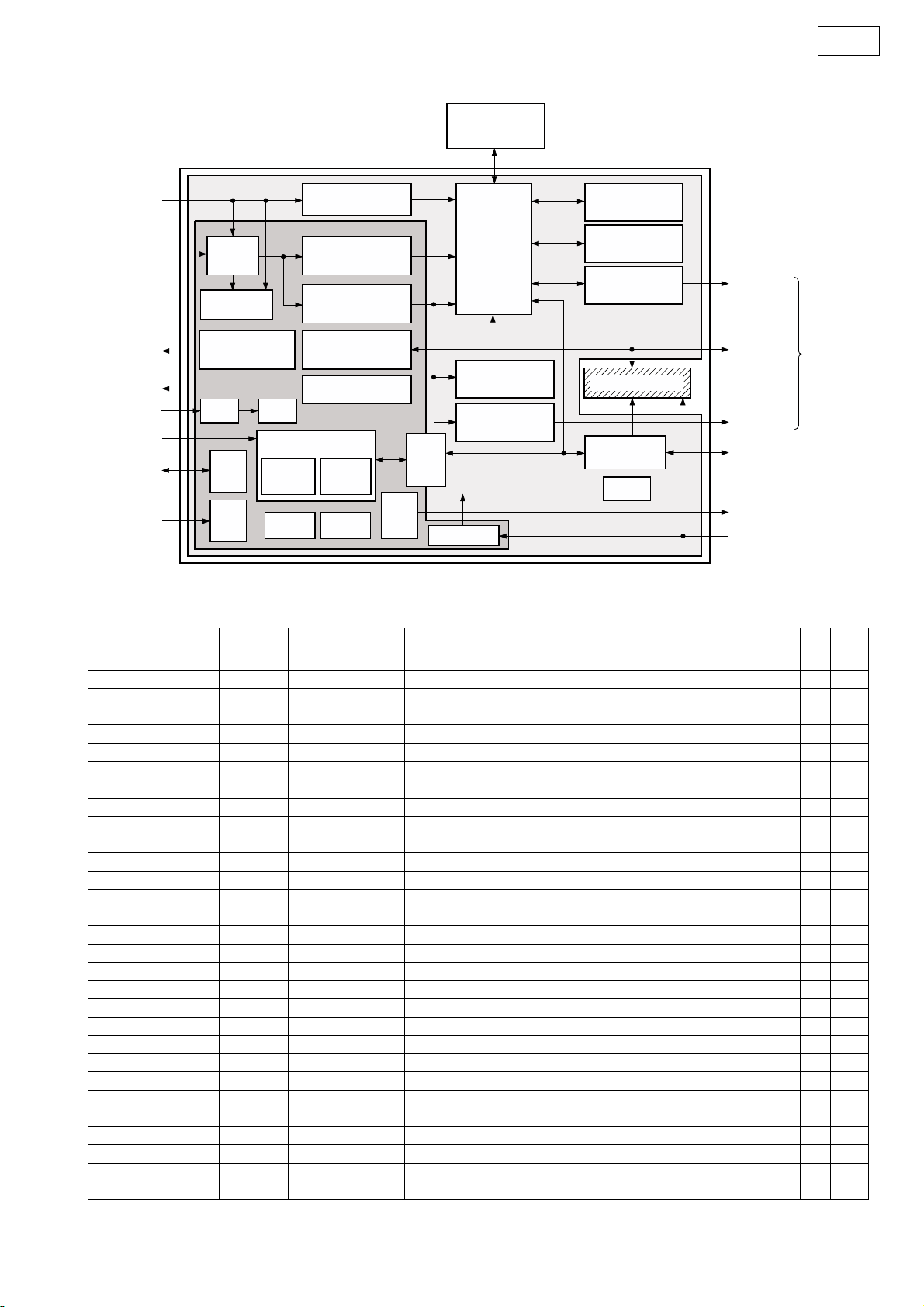

BLOCK DIAGRAM

S-301

㪜㫏㫋㪅

㪛㫀㪾㫀㫋㪸㫃㩷㪠㫅

㫏㪊

㪜㫏㫋㪅

㪘㫅㪸㫃㫆㪾㩷㪠㫅

㫏㪊

㪪㪘㪚㪛

㪛㪜㪚㪦㪛㪜㪩

㪚㪯㪛㪉㪎㪌㪊㪩

㪠㪉㪪㩷㪦㪬㪫

㪛㪭㪛

㪛㪜㪚㪦㪛㪜㪩

㪧㪅㪧㪚㪤㪆㪤㪧㪊㪆㪮㪤㪘

㪛㪜㪚㪦㪛㪜

㪜㪪㪍㪈㪊㪏

㪪㪧㪛㪠㪝㩷㪦㪬㪫

㪦㪧㪫

㪠㪥㪈

㪚㪦㪘

㪠㪥

㪚㪦㪘

㪠㪥

㪦㪧㪫

㪦㪬㪫

㫀㪧㫆㪻

㫀㫅

㪬㪪㪙

㫀㫅

㪫㪬㪥㪜㪩

㪫㪬㪥㪜㪩

㪧㪘㪚㪢

㪧㪘㪚㪢

㪣㪚㪎㪉㪈㪊㪈

㪣㪚㪎㪉㪈㪊㪈

㪘㪥㪘

㪘㪥㪘

㪘㪥㪘

㪘㪥㪘

㪦㪬㪫

㪣㪆㪩

㪣㪆㪩

㪠㪥

㪣㪆㪩

㪠㪥

㪣㪆㪩

㪠㪥

㪣㪆㪩

㪪㪚㪘㪩㪫

㪦㪬㪫

㩿㪜㪉㩷㫆㫅㫃㫐㪀

㪛㪪㪛㩷㪦㪬㪫

㪛㪪㪛㩷㪝㪣

㪛㪪㪛㩷㪝㪩

㪛㪪㪛㩷㪪㪣

㪛㪪㪛㩷㪪㪩

㪛㪪㪛㩷㪚

㪛㪪㪛㩷㪪㪮

㪛㪪㪛㩷㪤㪠㪯㩷㪣

㪛㪪㪛㩷㪤㪠㪯㩷㪩

㪧㪚㪤㩷㪝㪣㪆㪝㪩

㪧㪚㪤㩷㪪㪣㪆㪪㪩

㪧㪚㪤㩷㪚㩷㪆㪪㪮

㪧㪚㪤㩷㪤㪠㪯㩷㪣㪆㪩

㪩㪯㪇㪄㪍䉕㪪㪜㪣㪜㪚㪫䈚䈩ജ

㪪㪮

㪩㪛㪪

㪣㪚㪎㪉㪎㪉㪇

㪤㪬㪫㪜

㪘㪥㪘

㪠㪥

㪧㫆㫉㫋㪸㪹㫃㪼㩷㪠㫅

㩿㪽㫉㫆㫅㫋㩷㫇㪸㫅㪼㫃㪀

㪪㪚㪘㪩㪫㩷㪠㪥

㪣㪆㪩

㪤㪬㪫㪜

㪝㪩㪠㪥㩷㪪㪮

㪩㪜㪚㩷㪦㪬㪫㪈

㪂

㪪㪚㪘㪩㪫㪶㪤㪬㪫㪜

㪛㪪㪛㩷㪠㪥

㪧㪚㪤㩷㪠㪥

㪩㪯㪈

㪪㪘㪥㪶㪛㪦

㪪㪘㪥㪶㪛㪠

㪪㪘㪥㪶㪚㪢

㪪㪘㪥㪶㪚㪜

㪧㪚㪤㩷㪝㪣㪆㪝㪩

㪧㪚㪤㩷㪚㪆㪪㪮

㪛㪪㪛

㪧㪚㪤㩷㪪㪣㪆㪪㪩

㪛㪸㫋㪸㩷㪪㪼㫃㪼㪺㫋㫆㫉

㪛㪪㪛㪄㪧㪚㪤㩷㪚㫆㫅㫍㪼㫉㫋

㪛㪪㪛㪆㪜㪯㪫

㪪㪜㪣㪶㪝㫊㪈

㪠㪥㪠㪫

㪜㪯㪫

㪛㪪㪛㪆㪧㪚㪤

㪛㪘㪚

㪛㪪㪛㪈㪎㪐㪈

㩿㪩㪼㪺㫆㫌㫋㪆

㪪㪚㪘㪩㪫㪀

㪩㪯

㪩㪯

㪛㪠㪩

㪩㪯

㪣㪚㪏㪐㪇㪌㪎

㪆㪫㪶㪤㪬㪫㪜

㪆㪪㪰㪩

㪆㪫㪬㪥㪜㪛

㪪㪫㪜㪩㪜㪦

㪩㪜㪚㩷㪦㪬㪫

㪤㪠㪯

㪛㪘㪫㪘

㪚㪣㪢

㪩㪜㪪㪜㪫

㪚㪜

㪬㪪㪙

㪪㪧㪛㪠㪝

㪛㪠㪩

㪘㪛

㪠㪥

㪤㫌㫃㫋㫀 㪤㫌㫃㫋㫀

㪛㪠㪩

㪤㪠㪯㪆㪤㪬㪣㪫㪠

㪠㪉㪪㩷㪛㪘㪫㪘

㪦㪬㪫

㪬㪪㪙

㪤㪦㪛㪬㪣㪜

㪬㪪㪙㪶㪫㪯㪛

㪬㪪㪙㪶㪩㪯㪛

㪬㪪㪙㪶㪚㪣㪢

㪬㪪㪙㪶㪩㪪㪫

㪬㪪㪙㪶㪚㪜

㪬㪪㪙㪶㪩㪜㪨

㪬㪪㪙㪶㪤㪦㪛㪜

㪬㪪㪙㪶㪧㪦㪮㪶㪦㪥

㪩㪜㪚㩷㩷㪣㪆㪩

㪛㪠㪩㪆㪚㪦㪛㪜㪚㪶㪚㪣㪢

㪛㪠㪩㪶㪚㪜

㪛㪠㪩㪆㪚㪦㪛㪜㪚㪶㪛㪠㪥

㪛㪠㪩㪶㪛㪦㪬㪫

㪛㪠㪩㪶㪩㪪㪫

㪆㪠㪥㪫㪈

㪠㪥㪧㪬㪫

㪪㪜㪣㪜㪚㪫㪦㪩

㪂

㪤㪬㪣㪫㪠㪆㪛㪠㪩

㪠㫅㫇㫌㫋㩷㪘㪫㪫

㪇㪆㪄㪍㪆㪄㪐㪆㪄㪈㪉㪻㪙

㪄

㪛㪪㪧

㪪㪿㪸㫉㪺㩷㪜㪯㩿㪨㪝㪧㪀

IN

DATP20:FL/FR

DAIP19:C/SW

DAIP18:SL/SR

OUT

DAIP16:FL/FR

DAIP16:0/SW

DAIP15:0/0

DAIP14:RECL/RECR

㪍㪋㪤

㪪㪛㪩㪘㪤

㪘㪤㪬㪫㪜

㪤㪬㪫㪜

㪤㪬㪫㪜

㪂

㪄

㪣㪆㪩

㪪㪮

㪩㪜㪚㩷㪣㪆㪩

㪈㪍㪤㩷㪩㪦㪤

㪝㪣㪘㪞㪊㪘

㪙㪬㪪㪰㪈

㪘㪚㪢㪈

㪩㪦㪤㪶㪩㪪㪫

㪛㪪㪧㪶㪩㪪㪫

㪭㪧㪧

㪩㪆㪮

㪙㪬㪪㪰㪶㪜㪧㪩㪦㪤

㪘㪥㪘㪣㪦㪞

㪛㪠㪩㪜㪚㪫

㪜㪣㪜㪚㪅㪭㪩㩷㩷㪙㪛㪊㪏㪈㪈

㩿㪉㪆㪉㪀

㪘㪆㪛㩷㪦㪬㪫㩷㪄

㪘㪆㪛㩷㪦㪬㪫㩷㪂

㪘㪛㪈㪏㪊㪎

㪏㪺㪿

㪚㪦㪛㪜㪚

㪈㪆㪉

㩿㪛㪘㪚㪀

㪛㪪㪧㪶㪠㪦㪶㪧㪦㪮

㪛㪪㪧㪶㪚㪦㪩㪜㪶㪧㪦㪮

㪛㪪㪧㪶㪦㪪㪚㪶㪦㪥

㪛㪪㪧㪤㪠㪪㪦

㪛㪪㪧㪤㪦㪪㪠

㪛㪪㪧㪪㪧㪠㪚㪣㪢

㪛㪪㪧㪪㪧㪠㪚㪪

㩿㪛㪠㪩㪆㪚㪦㪛㪜㪚㪶㪚㪣㪢㪀

㩿㪛㪠㪩㪆㪚㪦㪛㪜㪚㪶㪛㪠㪥㪀

㪚㪣㪘㪫㪚㪟

㪚㪦㪛㪜㪚㪶㪩㪪㪫

㪂㪌㪭㪆㪂㪊㪅㪊㪭

㪘㪛㪈㪏㪊㪎

㪏㪺㪿

㪚㪦㪛㪜㪚

㪉㪆㪉

㩿㪘㪛㪚㪀

㪚㫆㫅㫍㪅

㪝㫀㫃㫋㪼㫉

㪣㪆㪩

㪪㪮

㪛㪘㪚㪶㪤㪬㪫㪜

㪤㪬㪫㪜

㪤㪬㪫㪜

㪤㪬㪫㪜

㪪㪬㪙㪶㪪㪬㪤

㪜㪉㪧㪶㪛㪠

㪜㪉㪧㪶㪛㪦

㪜㪉㪧㪶㪚㪪

㪜㪉㪧㪶㪚㪢

㪄

㪄

㪄

㪣㪦㪞㪠㪚

㪜㪜㪧㪩㪦㪤

㪙㪩㪐㪊㪣㪏㪍

㩿㪈㪍㫂㪀

㪄

㪄

㪄

㪙㪪㪜

㪜㪩㪩㪤㪬㪫㪜

㪪㪜㪣㪚㪣㪢

㪦㪧㪶㪚㪣㪢

㪦㪧㪶㪚㪜

㪦㪧㪶㪛㪦

㪦㪧㪶㪛㪠

㪙㪜㪶㪦㪥

㪛㪝㪩㪪㪫

㪧㪣㪣㪶㪩㪪㪫

㪛㪭㪛㪶㪩㪪㪫

㫋㫆㩷㪛㪭㪛㩷㪛㫉㫀㫍㪼㪆

㪭㫀㪻㪼㫆㩷㪙㪣㪦㪚㪢

㪘㪥㪘㪣㪦㪞

㪛㪠㪩㪜㪚㪫

㪚㪣㪪㪶㪪㪮

㪦㪧㪥㪶㪪㪮

㪦㪧㪥㪶㪛㪩㪭

㪚㪣㪪㪶㪛㪩㪭

㪭㪶㪚㪦㪥㪫

㪣㪛㪶㪚㪦㪥㪫

㪧㪩㪦㪞㪆㪫㪥㪫㪜㪩

㪭㪛㪜㪫㪈

㪭㪛㪜㪫㪉

㪇㩷㫋㫆㩷㪄㪈㪇㪊㪻㪙

㪠㫅㫇㫌㫋㩷㪞㪸㫀㫅㩷㪘㫄㫇㪑

㩷㪇㪆㪂㪍㪻㪙

㪉㪊㪉㪚

㪣㪤㪪㪉㪇㪉

㪎㪋㪣㪭㪇㪏

㪫㪩㪠㪞㪞㪜㪩

㪫㪩㪠㪞㪞㪜㪩

㪭㪠㪛㪜㪦㪶㪘

㪭㪠㪛㪜㪦㪶㪙

㪭㪠㪛㪜㪦㪶㪚

㪭㪠㪛㪜㪦㪶㪛

㪭㪤㪬㪫㪜㪈

㪭㪤㪬㪫㪜㪉

㪤㪸㫀㫅㩷㪭㫆㫃

㪈㪻㪙㩷㫊㫋㪼㫇

㪜㪣㪜㪚㪅㪭㪩㩷㩷㪙㪛㪊㪏㪈㪈

㩿㪈㪆㪉㪀

㪊㪏㪈㪈㪚㪣㪢

㪊㪏㪈㪈㪛㪘㪫㪘

㪩㪜㪤㪦㪫㪜

㪚㪯㪘㪈㪌㪈㪈

㪎㪋㪣㪭㪇㪏

㪪㪰㪪㪫㪜㪤㩷㫌㪚㪦㪤

㪤㪊㪇㪍㪉㪎㪝㪟㪧㪞㪧

㩿㪈㪉㪏㫇㫀㫅㩷㪊㪏㪋㫂㪆㪊㪈㫂㪀

㩷㪠㪆㪦

㪫㪯㪛㪉㪊㪉㪚

㪩㪯㪛㪉㪊㪉㪚

㪢㪜㪰㪇

㪢㪜㪰㪈

㪡㪦㪞㪶㪘

㪡㪦㪞㪶㪙

㪫㪘㪚㪫㩷㪪㪮㩷㪆

㪩㪦㪫㪅㪜㪥㪚㪦㪛㪜㪩

㪦㫌㫋㫇㫌㫋㩷㪞㪸㫀㫅㩷㪘㫄㫇㪑

㩷㪇㪆㪂㪉㪆㪂㪋㪆㪂㪍㪆㪂㪏㪆

㪂㪈㪇㪆㪂㪈㪉㪻㪙

㪩㪜㪤㪦㪚㪦㪥

㪩㪜㪚㪠㪜㪭㪜㪩

㪞㪧㪈㪬㪜㪉㪎㪈㪯

㪩㪜㪤㪦㪚㪦㪥

㪟㪞㪘㪠㪥

㪣

㪩

㪪㪮

㪟㪆㪧㪄㪈

㪘㪆㪛

㪛㪠㪤㪤㪜㪩㪶㪠㪥

㪧㪣㪘㪰㩷㪢㪜㪰

㪧㫉㪼㩷㪘㫄㫇

㪥㪡㪤㪉㪇㪍㪏

㪟㪆㪧㩷㪘㫄㫇㪄㪈

㪘㪺㫋㫀㫍㪼㩷㪙㫃㫆㪺㫂

㪜㪯㪫㪶㪛㪘㪫㪘

㪜㪯㪫㪶㪚㪣㪢

㪝㪣㪶㪛㪘

㪝㪣㪶㪚㪪

㪝㪣㪶㪚㪢

㪝㪣㪶㪩㪪㪫

㪫㪦㪬㪚㪟

㪪㪜㪥㪪㪦㪩㩷㪠㪚

㪤㪬㪫㪜

㪤㪬㪫㪜

㪤㪬㪫㪜

㪧㪩㪜㪶㪤㪬㪫㪜

㪪㫋㪸㫅㪻㪹㫐

㪪㪫㪦㪧㩷㪢㪜㪰

㪘㪛㪭㪄㪪㪊㪇㪈

㪛㫀㪽㪽㪅㩷㪦㫌㫋㫇㫌㫋

㪄 㪄

㪄 㪄

㪄 㪄

㪤㪬㪫㪜

㪟㪆㪧㩷㪤㪬㪫㪜

㪪㪜㪩㪠㪄㪧㪘㪩㪘

㪚㪦㪥㪭㪜㪩㪫㩷㪠㪚

㪙㪬㪉㪇㪐㪇㪝

㪝㪣㩷㪛㪩㪠㪭㪜㪩

㪤㪍㪍㪇㪇㪌㪘㪟㪧

㪝㪣㪛

㪛㪠㪤㪤㪜㪩

㪪㪜㪥㪪㪦㪩㩷㪠㪚

㪟㪆㪧

㪟㪧㩷㪪㪮

㪉㪌㪧㩷㪛㪄㪪㫌㪹

㪣㪦㪞㪠㪚㩷㪘㪆㪙㪆㪚

㪛㫀㪽㪽㪅㩷㪠㫅㫇㫌㫋

㪚㫌㫉㫉㪅㪣㫀㫄㫀㫋㫋㪼㫉

㪝㪣㪂

㪝㪣㪄

㪝㪩㪂

㪝㪩㪄

㪪㪮㪂

㪪㪮㪄

㪤㪬㪫㪜

㪤㪬㪫㪜 㪘㪆㪛

㪘㪣㪚㪆

㪧㪼㪸㫂㫀㫅㪾㪆

㪚㫌㫉㫉㪅㪣㫀㫄㫀㫋㫋㪼㫉

㪤㪬㪫㪜

㪧㪩㪜㪶㪤㪬㪫㪜

㪌㪇㪆㪍㪇

㪧㪅㪦㪥㪆㪦㪝㪝

㪂㪊㪈㪭

㪂㪌㪅㪇㪭㪶㪥㪪㪮

㪧㪚㪤㪄㪈㪏㪇㪊

㪭㫆㫃㫋㪸㪾㪼㩷㪸㪻㫁㫌㫊㫋

㪢㪜㪰㩷㪣㪜㪛

㪪㪫㪘㪥㪛㪙㪰㩷㪣㪜㪛

㪪㪊㪇㪈㩷㪘㪬㪛㪠㪦㩷㪙㪣㪦㪚㪢㩷㪛㪠㪘

㪧㪚㪤㪄㪈㪏㪇㪉

㪘㪆㪛

㪧㪚㪤㪄㪈㪏㪇㪉

㪘㪆㪛

㪘㪤㪧㩷㪤㪬㪫㪜

㪏㫊㫋㪼㫇

㪛㪪㪮㪄㪪㪊㪇㪈

㪧㫆㫎㪼㫉㩷㪘㫄㫇

㪫㪘㪪㪌㪇㪍㪍㪆㪫㪘㪪㪌㪈㪉㪈

㪙㪫㪣

㪙㪫㪣

㪙㪫㪣㪙㪫㪣

㪧㪩㪦㪫㪜㪚㪫

㪚㪦㪥㪥㪜㪚㪫㪶㪪㪧㪈

㪪㪤㪧㪪㩷㪬㪥㪠㪫

㪝㫉㫆㫅㫋㩷㪪㪧

㪚㫆㫅㫅㪼㪺㫋㩷㪛㪼㫋㪼㪺㫋

㪣㪦㪞㪠㪚

㪪㪧

㪫㪼㫉㫄㫀㫅㪸㫃

㪣

㪩

㪩㪜㪣㪘㪰

㪪

㪮

㪩㪣㪶㪪㪧

14

Page 15

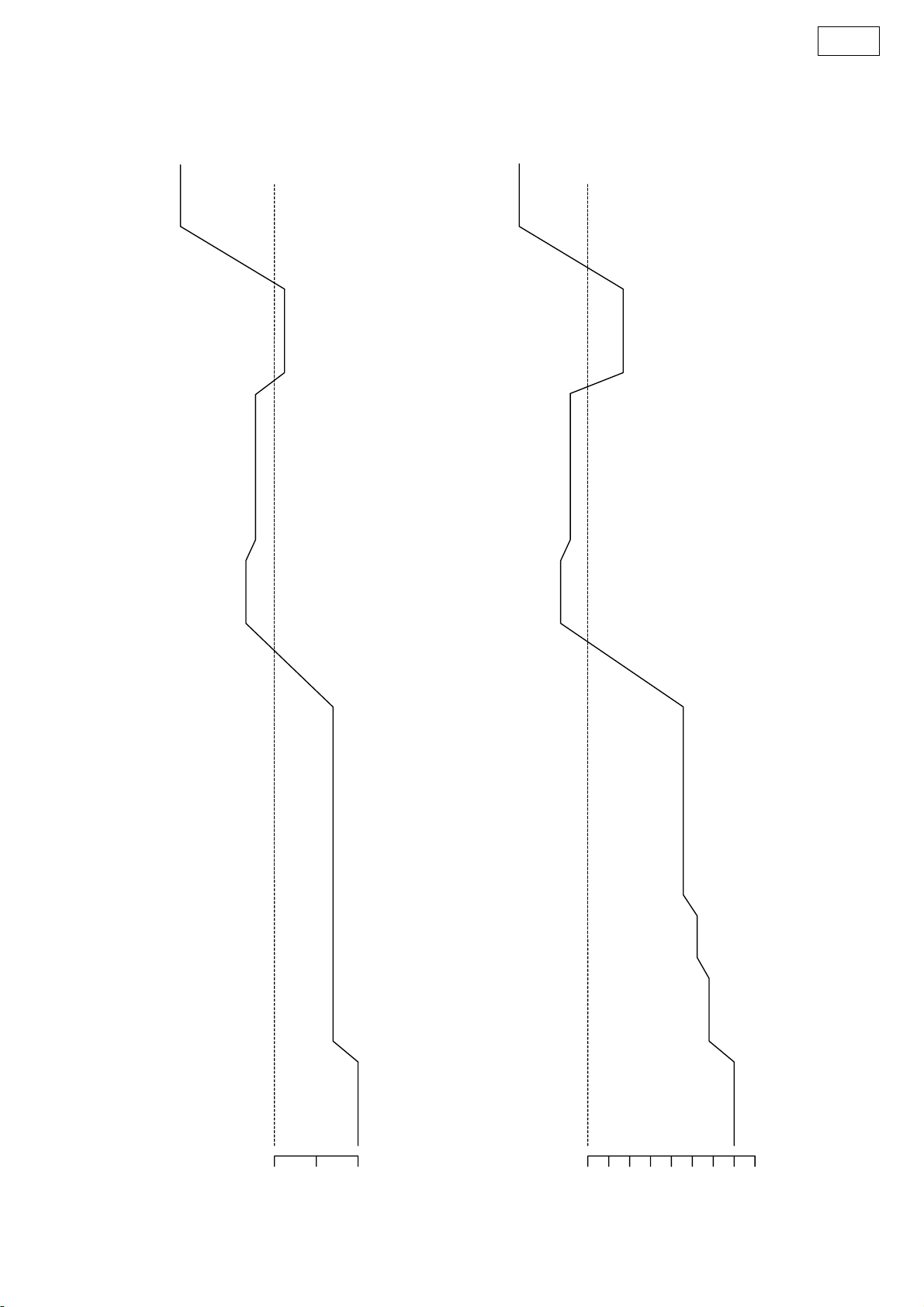

LEVEL DIAGRAM

S-301

㪂㪉㪋㪅㪐㪻㪙

㪄㪍㪅㪐㪻㪙

㪄㪉㪅㪊㪻㪙

㪂㪉㪇㪅㪏㪊㪻㪙

㪂㪉㪋㪅㪐㪻㪙

㪄㪈㪉㪅㪍㪻㪙

㪄㪉㪅㪊㪻㪙

㪂㪉㪐㪅㪊㪌㪻㪙

㪂㪊㪅㪊㪈㪻㪙

㪂㪉㪅㪏㪌㪻㪙

㪫㫆㫋㪸㫃㩷㪂㪊㪍㪅㪌㪉㪻㪙

㪂㪍㪻㪙

㪇㪻㪙㪝㫊

㪄㪈㪇㪻㪙㪝㫊

㪝㫉㫆㫅㫋㪄㪺㪿

㪄㪉㪇㪻㪙㪝㫊

㪇㪻㪙㪝㫊

㪄㪈㪇㪻㪙㪝㫊

㪪㪮㪄㪺㪿

㪄㪉㪇㪻㪙㪝㫊

㪂㪍㪻㪙

㪄㪊㪇㪻㪙㪝㫊

㪄㪋㪇㪻㪙㪝㫊

15

Page 16

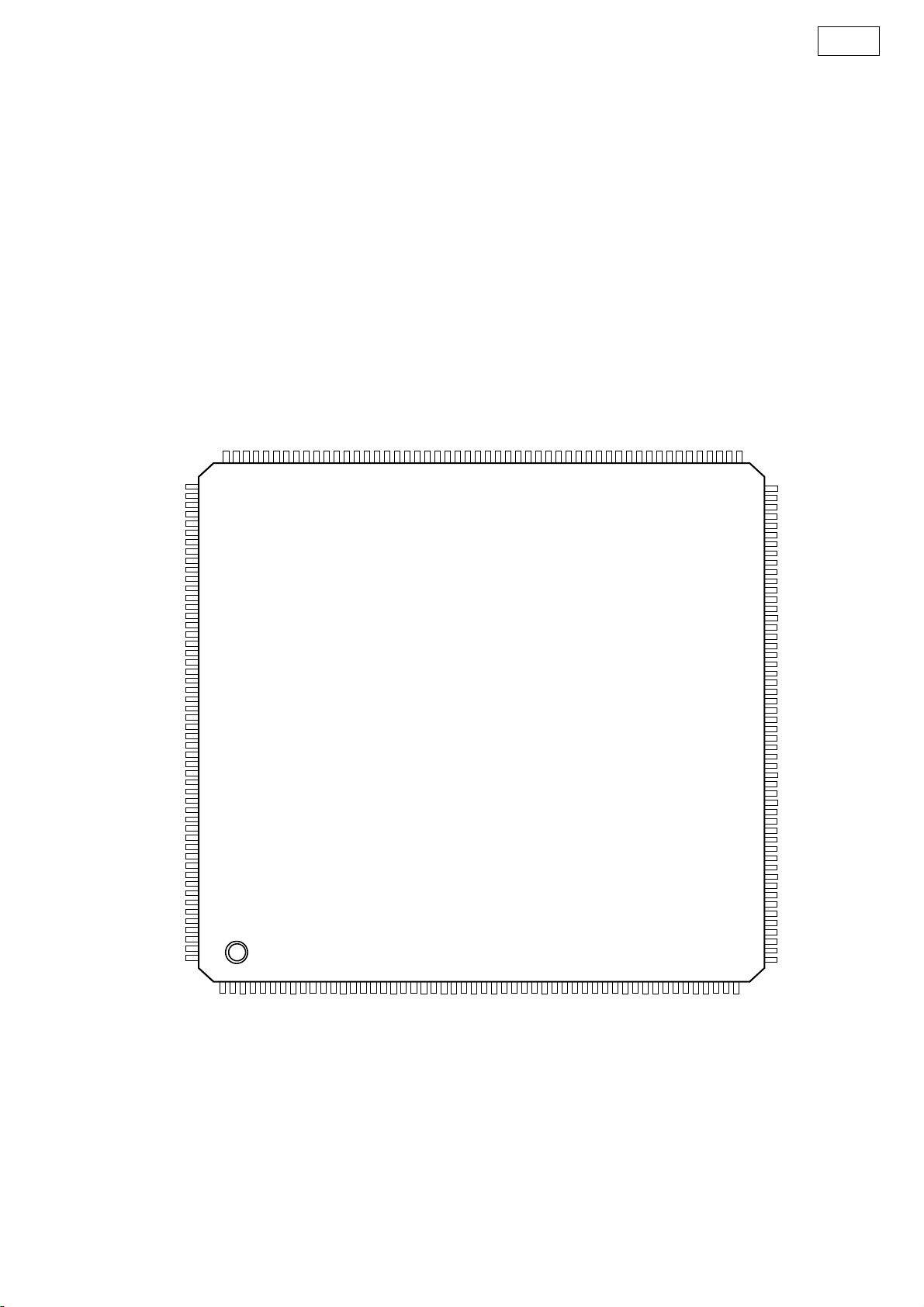

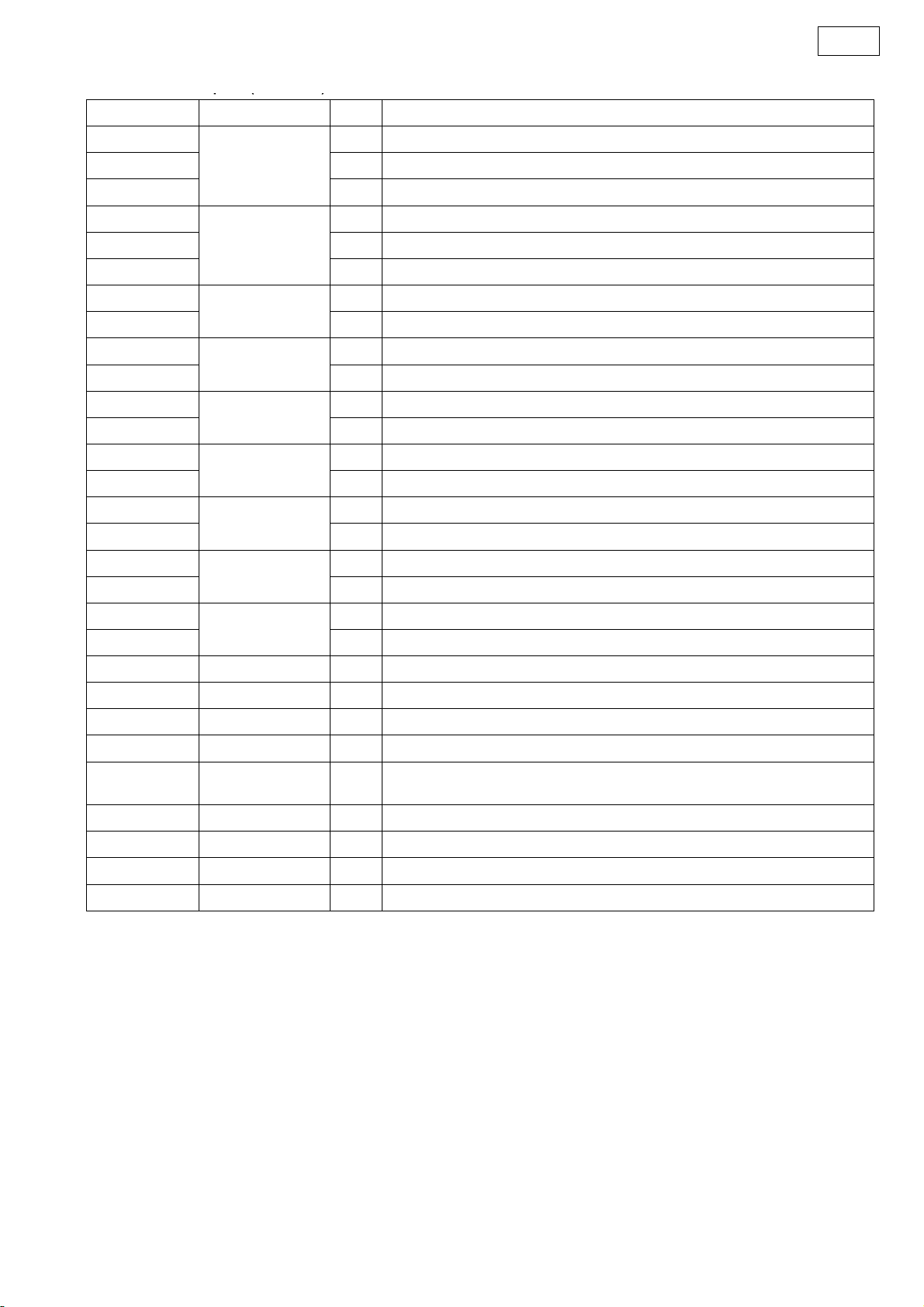

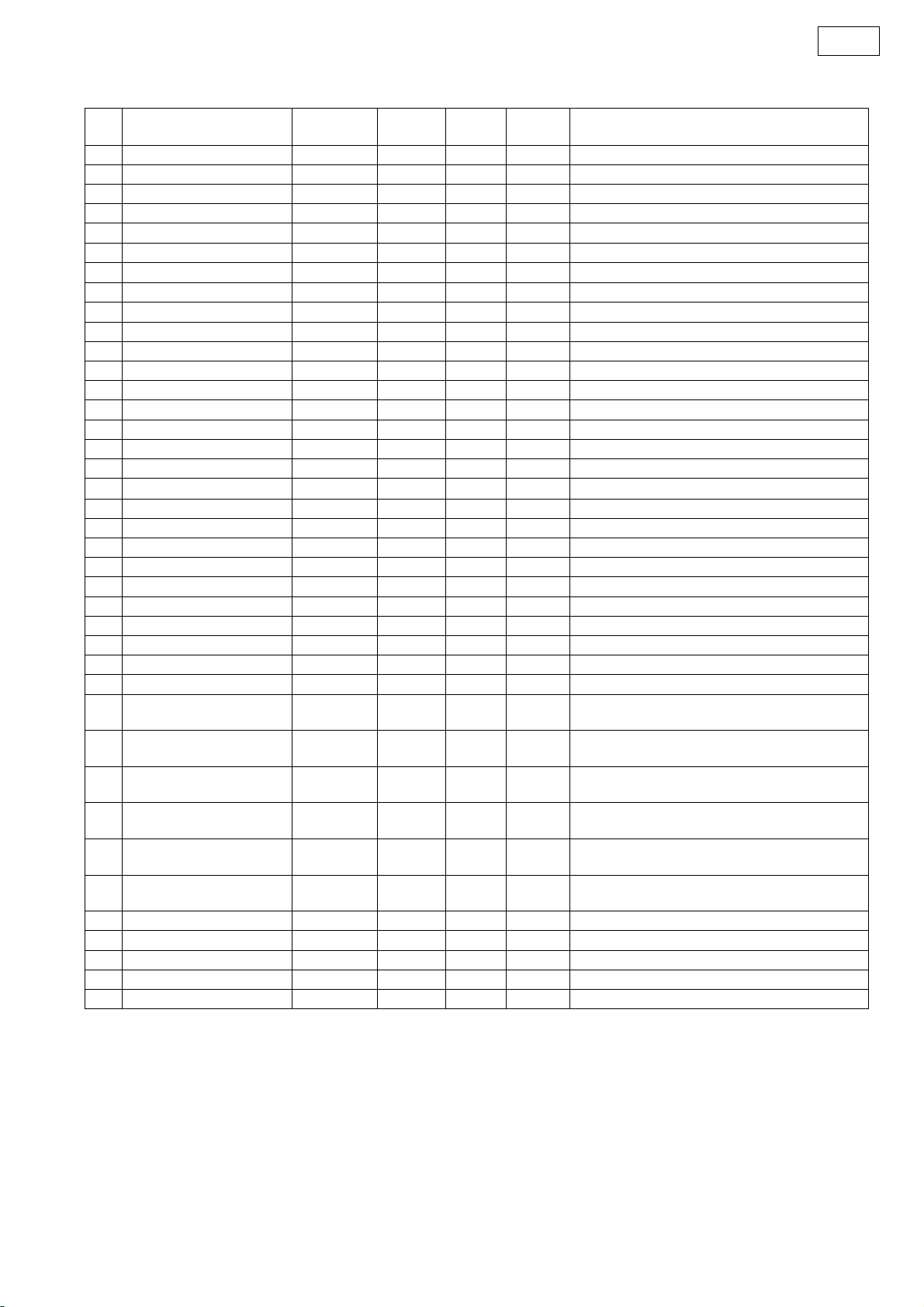

SEMICONDUCTORS / 半導体一覧表

Only major semiconductors are shown, general semiconductors etc. are omitted to list.

主な半導体を記載しています。汎用の半導体は記載を省略しています。

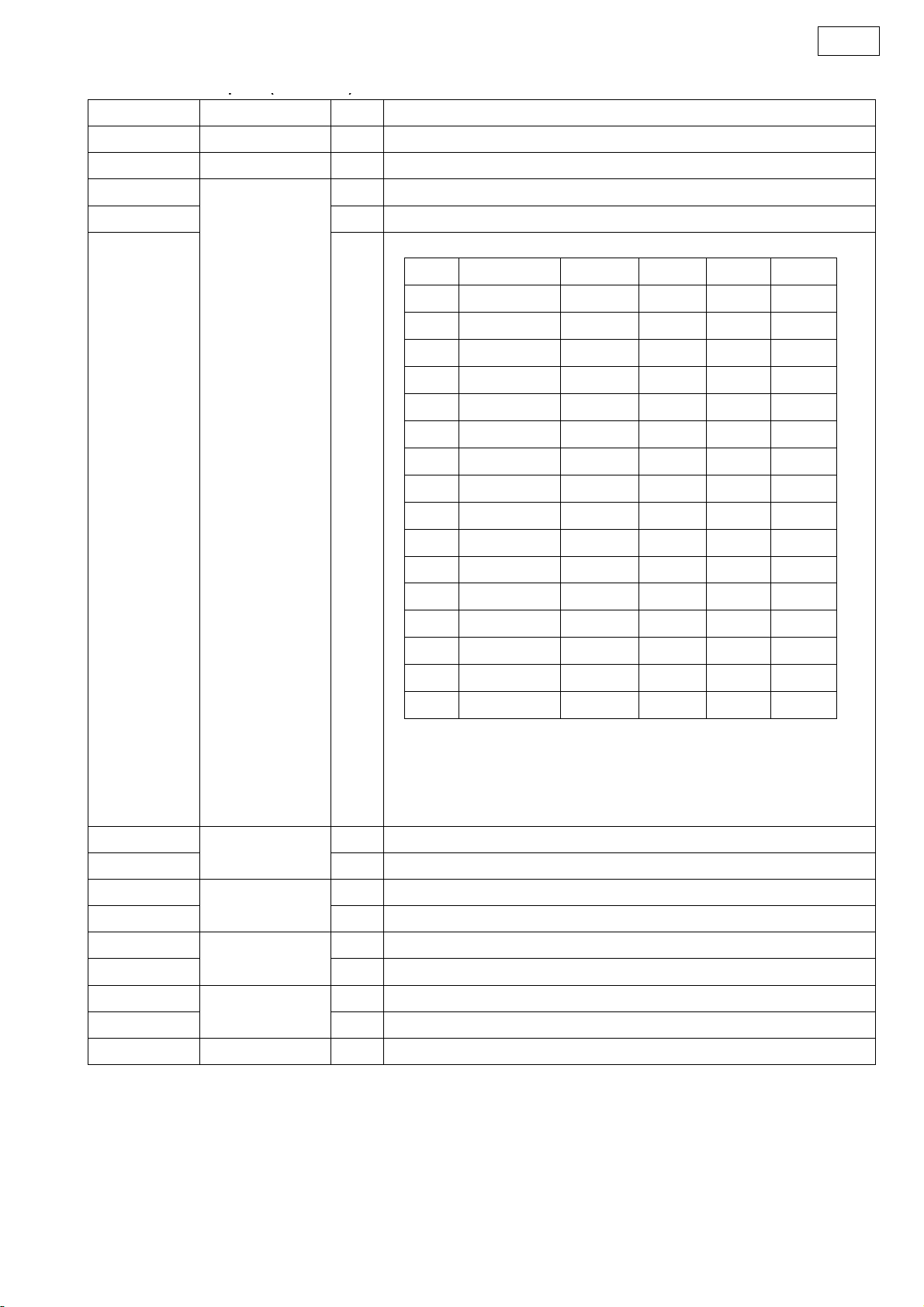

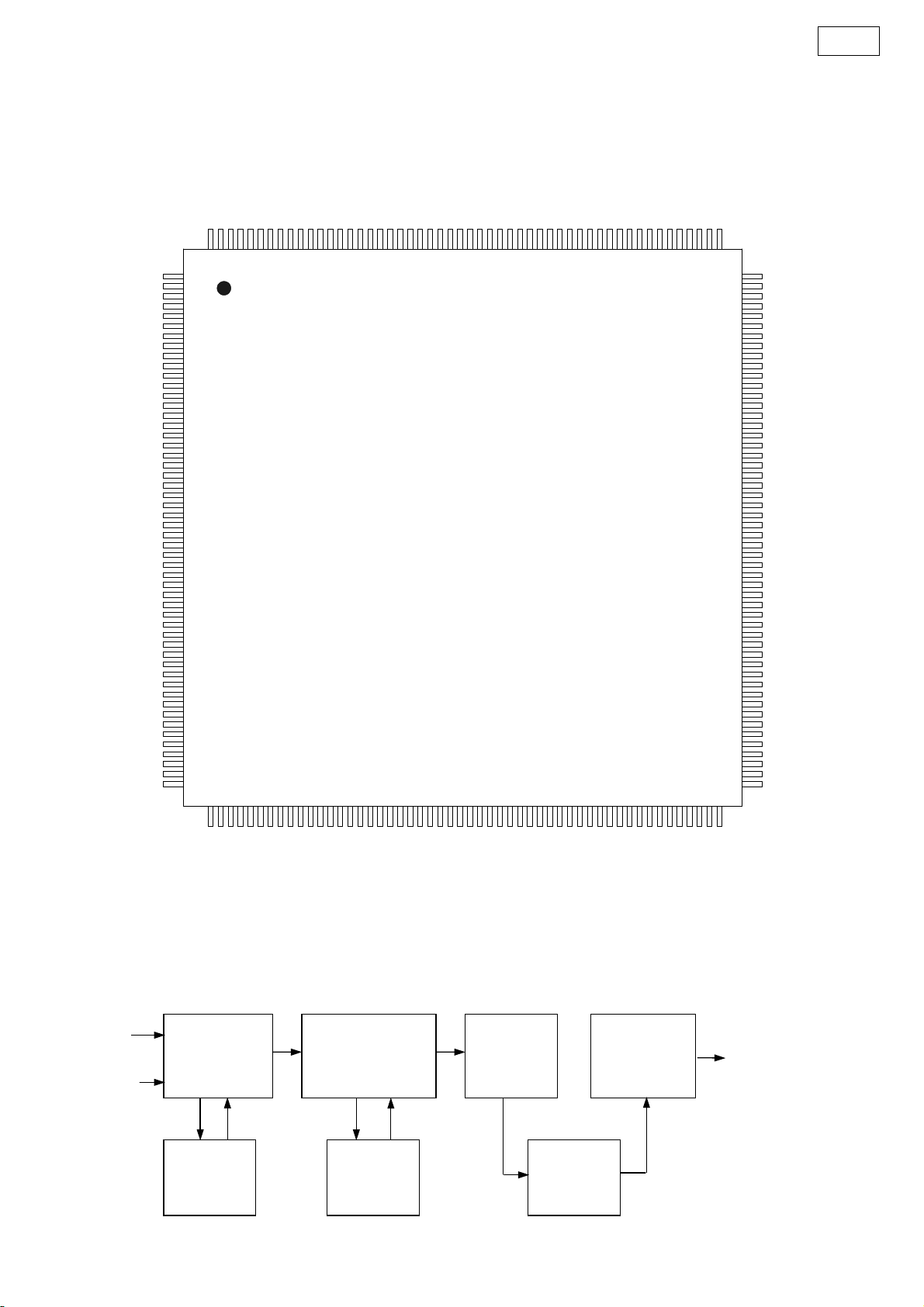

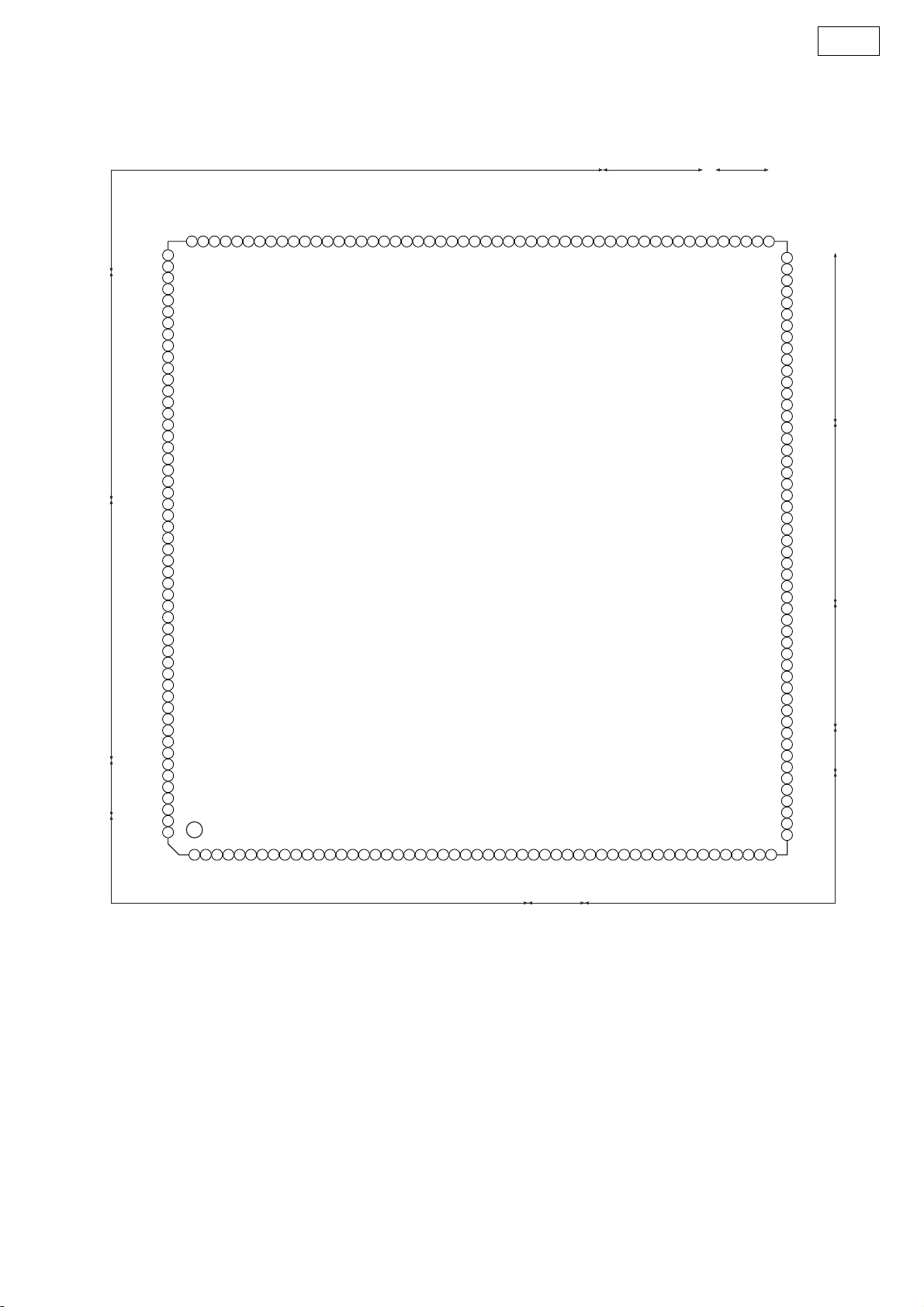

1. IC’s

ES6138F (IC101: 1U-3692)

PINOUT DIAGRAM

HCS3FX#/AUX3[6]

VEE

/AUX4[4]

HA2

I2CDATA/AUX[0]

I2C_CLK/AUX[1]

VEE

AUX[2]/IOW#

VSS

VEE

AUX[3]/IOR#

AUX[4]

AUX[5]

AUX[6]

AUX[7]

LOE#

VSS

VCC

LCS0#

LCS1#

LCS2#

LCS3#

VSS

LD0

LD1

LD2

LD3

LD4

VEE

VSS

LD5

LD6

LD7

LD8

LD9

LD10

LD11

VSS

VEE

LD12

LD13

LD14

LD15

LWRLL#

LWR HL#

VSS

VEE

CAMIN0

CAMIN1

LA0

LA1

LA2

LA3

VSS

HCS1FX#/AUX3[7]

HA1/AUX4[3]

VSS

HA0/AUX4[2]

152

153

154

155

156

157

158

159

160

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

177

178

179

180

181

182

183

184

185

186

187

188

189

190

191

192

193

194

195

196

197

198

199

200

201

202

203

204

205

206

207

208

1

2 3 4 5 6 7 8 910111213141516171819202122232425262728293031323334353637383940414243444546474849505152

VSS

HIORDY/AUX3[3]

HIOCS16#/CAMCLK/AUX3[4]

HRD#/DCI_ACK#/AUX4[6]

150

151

HRST#/AUX3[5]

HWR#/DCI_CLK/AUX4[5]

VEE

145

146

147

148

149

HIRQ/DCI_ERR#/AUX4[7]

144

HRRQ#/AUX4[0]

143

HWRQ#/DCI_REQ#/AUX4[1]

142

HD15/AUX2[7]/IR

HD14/AUX2[6]

VCC

139

140

141

VSS

HD13/AUX2[5]/SP

HD12/AUX2[4]/C2PO

HD11/AUX2[3]//IRQ

135

136

137

138

ES6138F

HD10/AUX2[2]

HD9/AUX2[1]

HD8/DCI_FDS#/AUX2[0]/VFD_CLK

HD7/DCI7/AUX1[7]/VFD_DIN

131

132

133

134

VEE

130

VSS

129

HD6/DCI6/AUX1[6]/VFD_DOUT

128

HD5/DCI5/AUX1[5]

127

HD4/DCI4/AUX1[4]

126

HD3/DCI3/AUX1[3]

125

HD2/DCI2/AUX1[2]

124

HD1/DCI1/AUX1[1]

123

HD0/DCI0/AUX1[0]

122

VCC

121

VSS

120

HSYNC#/CAMIN7/AUX3[0]

119

VSYNC#/CAMIN6/AUX3[1]

118

PCLKQSCN/CAMIN5/AUX3[2]

117

PCLK2XSCN/CAMIN4

116

YUV7/FDAC/CAMIN3

YUV6/VDAC

YUV5/YDAC

ADVSS

112

113

114

115

ADVEE

YUV4/RSET

YUV3/COMP

YUV2/CDAC

108

109

110

111

YUV1/VREF

YUV0/CAMIN2/UDAC

DCLK

105

106

107

104

VEE

103

VSS

102

DSCK

101

DQM

100

DCS0#

99

VEE

98

VSS

97

DCS1#

96

DB15

95

DB14

94

DB13

93

DB12

92

VEE

91

VSS

90

DB11

89

DB10

88

DB9

87

DB8

86

DB7

85

DB6

84

VSS

83

VCC

82

DB5

81

DB4

80

DB3

79

DB2

78

DB1

77

DB0

76

VSS

75

VEE

74

DMBS1

73

DMBS0

72

DRAS#

71

DWE#

70

DOE#/DSCK_EN

69

DCAS#

68

VEE

67

VSS

66

DMA11

65

DMA10

64

DMA9

63

DMA8

62

DMA7

61

DMA6

60

VSS

59

VEE

58

DMA5

57

DMA4

56

DMA3

55

DMA2

54

DMA1

53

DMA0

S-301

NC

LA4

LA5

LA6

LA7

LA8

VEE

LA9

VSS

VCC

LA11

LA10

LA12

VSS

VEE

LA13

LA14

LA15

LA16

LA20

LA17

LA18

LA19

LA21

RESET#

TDMDX/RSEL

VEE

VSS

TDMDR

TDMCLK

VSS

VCC

TSD3

TDMFS

TDMTSC#

TWS/SEL_PLL2

TSD2

TSD0/SEL_PLL0

TSD1/SEL_PLL1

TBCK

MCLK

SPDIF_IN

SEL_PLL3/SPDIF_OUT

VSS

VCC

RSD

RWS

RBCK

XIN

AVE E

XOUT

AVS S

16

Page 17

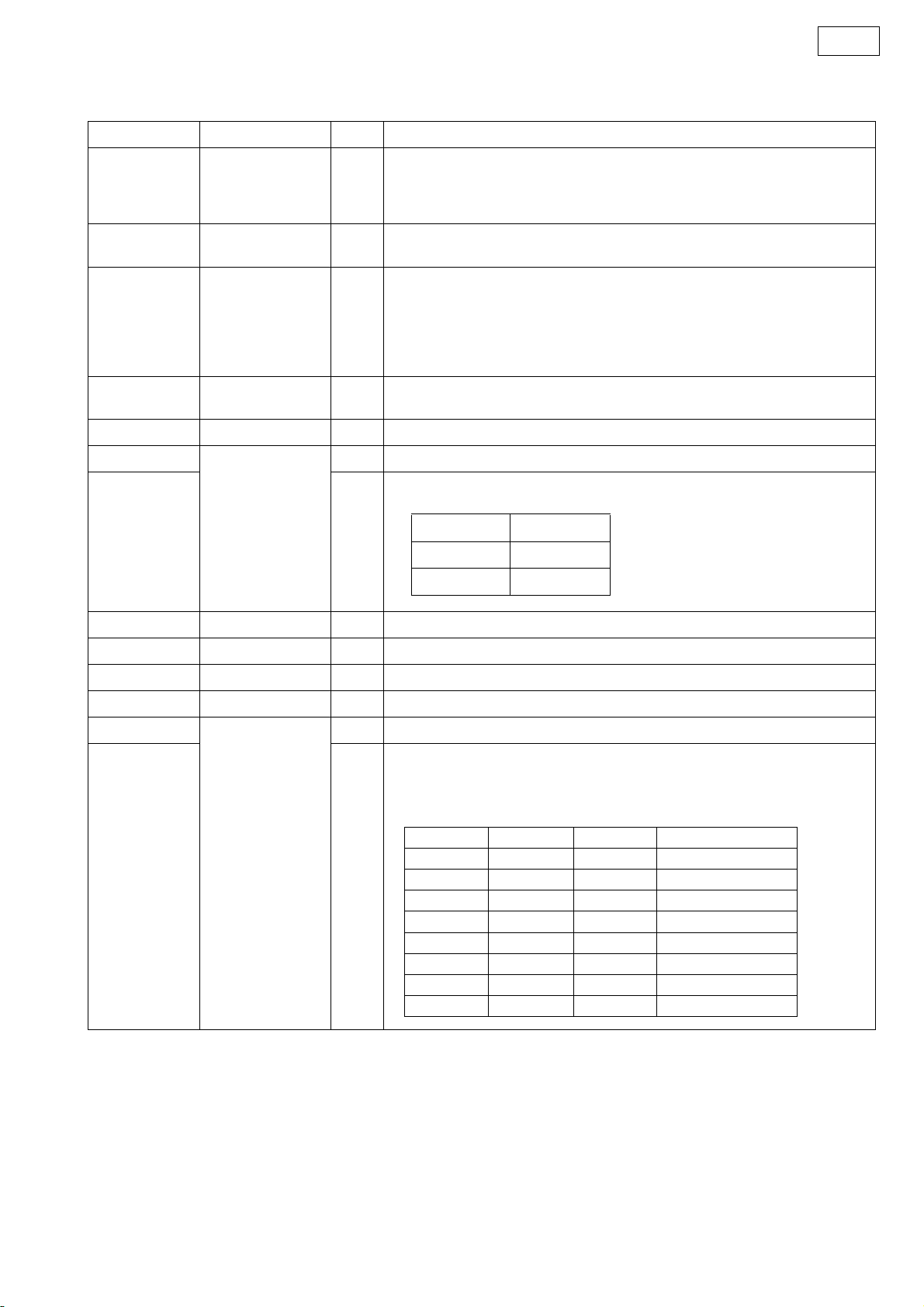

ES6138F Pin Description

Name Pin Numbers I/O Definition

VEE 1,18, 27, 59, 68, 75,

92, 99, 104, 130,

148, 157, 159, 164,

183, 193, 201

P I/O power supply.

S-301

LA[21:0]

VSS 8, 17, 26, 34, 43,

VCC

RESET# 24 I Reset input (active-low).

TDMDX

RSEL I LCS3 ROM Boot Data Width Select. Strapped to VCC or ground via 4.7-kΩ

TDMDR 28 I TDM receive data input.

TDMCLK 29 I TDM clock input.

TDMFS 30 I TDM frame sync input.

2:7, 10:16, 19:23,

204:207

60, 67, 76, 84, 91,

98, 103, 120, 129,

138, 147, 156, 163,

171, 177, 184, 192,

200, 208

9, 35, 44, 83, 121,

139, 172

25

O RISC port address bus.

G Ground.

P Core power supply.

O TDM transmit data output.

resistor; read only during reset.

RSEL Selection

0 16-bit ROM

1 8-bit ROM

TDMTSC# 31 O TDM output enable (active-low).

TWS

SEL_PLL2 I System and DSCK output clock frequency selection is made at the rising edge of

32

O Audio transmit frame sync output.

RESET#. The matrix below lists the available clock frequencies and their

respective PLL bit settings. Strapped to VCC or ground via 4.7-kΩ resistor; read

only during reset.

SEL_PLL2 SEL_PLL1 SEL_PLL0 PLL Settings

0 0 0 DCLK × 4.5

001DCLK × 5.0

0 1 0 Bypass

011DCLK × 4.0

1 0 0 DCLK × 4.25

1 0 1 DCLK × 4.75

110DCLK × 5.5

111DCLK × 6.0

17

Page 18

p( )

Name Pin Numbers I/O Definition

S-301

TSD0

SEL_PLL0 I Refer to the description and matrix for SEL_PLL2 pin 32.

TSD1

SEL_PLL1 I Refer to the description and matrix for SEL_PLL2 pin 32.

TSD2 37 O Audio transmit serial data output 2.

TSD3 38 O Audio transmit serial data output 3.

NC 48 — No connect pins. Leave open.

MCLK 39 I/O Audio master clock for audio DAC.

TBCK 40 O Audio transmit bit clock.

SEL_PLL3

SPDIF_OUT O S/PDIF output.

SPDIF_IN 42 I S/PDIF input.

33

36

41

O Audio transmit serial data port 0.

O Audio transmit serial data port 1.

I Clock source select. Strapped to VCC or ground via 4.7-kΩ resistor; read only

during reset.

SEL_PLL3 Clock Source

0 Crystal oscillator

1 DCLK input

RSD 45 I Audio receive serial data.

RWS 46 I Audio receive frame sync.

RBCK 47 I Audio receive bit clock.

XIN 49 I 27-MHz crystal input.

XOUT 50 O 27-MHz crystal output.

AVEE 51 P Analog power for PLL.

AVSS 52 G Analog ground for PLL.

DMA[11:0] 53:58, 61:66 O DRAM address bus.

DCAS# 69 O DRAM column address strobe.

DOE#

70

DSCK_EN O DRAM clock enable.

DWE# 71 O DRAM write enable (active-low).

DRAS# 72 O DRAM row address strobe (active-low).

DMBS0 73 O DRAM bank select 0.

DMBS1 74 O DRAM bank select 1.

DB[15:0] 77:82, 85:90, 93:96 I/O DRAM data bus.

DCS[1:0]# 97,100 O DRAM chip select (active-low).

O DRAM output enable (active-low).

DQM 101 O Data input/output mask.

18

Page 19

p( )

Name Pin Numbers I/O Definition

DSCK 102 O Output clock to DRAM.

DCLK 105 I Clock input to PLL.

S-301

YUV0

CAMIN2 I Camera YUV 2.

UDAC O Video DAC output.

106

O YUV pixel 2 output data.

Pin 115 114 11 3 108 106

Value F DAC V DAC Y DAC C DAC U DAC

0 CVBS/Chroma CVBS1 Y C N/A

1 CVBS/Chroma CVBS1 Y C CVBS2

2 CVBS/Chroma N/A Y C N/A

3 CVBS/Chroma CVBS1 N/A N/A CVBS2

4 CVBS/Chroma CVBS1 N/A N/A N/A

5 CVBS/Chroma CVBS1 Y Pb Pr

6 CVBS/Chroma N/A Y Pb Pr

7 N/A SYNC G B R

8 CVBS/Chroma Chroma Y Pb Pr

9 CVBS CVBS1 G B R

10 CVBS CVBS1 G R B

11 N/A SYNC G R B

12 CVBS/Chroma N/A Y Pr Pb

13 CVBS/Chroma CVBS1 Y Pr Pb

14 Chroma Y G R B

F: CVBS/chroma signal for simultaneous mode.

Y: Luma component for YUV and Y/C processing.

C: Chrominance signal for Y/C processing.

U: Chrominance component signal for YUV mode.

V: Chrominance component signal for YUV mode.

YUV1

107

VREF I Internal voltage reference to video DAC. Bypass to ground with 0.1-µF capacitor.

YUV2

108

CDAC O Video DAC output. Refer to description and matrix for UDAC pin 106.

YUV3

109

COMP I Compensation input. Bypass to ADVEE with 0.1-µF capacitor.

YUV4

110

RSET I DAC current adjustment resistor input.

ADVEE 111 P Analog power for video DAC.

O YUV pixel 1 output data.

O YUV pixel 2 output data.

O YUV pixel 3 output data.

O YUV pixel 4 output data.

19

Page 20

p( )

Name Pin Numbers I/O Definition

ADVSS 112 G Analog ground for video DAC.

S-301

YUV5

YDAC O Video DAC output. Refer to description and matrix for UDAC pin 106.

YUV6

VDAC O Video DAC output. Refer to description and matrix for UDAC pin 106.

YUV7

FDAC O Video DAC output. Refer to description and matrix for UDAC pin 106.

CAMIN3 I Camera YUV 3.

PCLK2XSCN

CAMIN4 I Camera YUV 4.

PCLKQSCN

CAMIN5 I Camera YUV 5.

AUX3[2] I/O Aux3 data I/O.

VSYNC#

CAMIN6 I Camera YUV 6.

AUX3[1] I/O Aux3 data I/O.

HSYNC#

CAMIN7 I Camera YUV 7.

113

114

115

116

117

118

119

O YUV pixel 5 output data.

O YUV pixel 6 output data.

O YUV pixel 7 output data.

I/O 27-MHz video output pixel clock.

O 13.5-MHz video output pixel clock.

I/O Vertical sync (active-low).

I/O Horizontal sync (active-low).

AUX3[0] I/O Aux3 data I/O.

HD[5:0]

DCI[5:0] I/O DVD channel data I/O.

AUX1[5:0] I/O Aux1 data I/O.

HD6

DCI6 I/O DVD channel data I/O.

AUX1[6] I/O Aux1 data I/O.

VFD_DOUT I VFD data output.

HD7

DCI7 I/O DVD channel data I/O.

AUX1[7] I/O Aux1 data I/O.

VFD_DIN I VFD data input.

HD8

DCI_FDS# I/O DVD input sector start (active-low).

AUX2[0] I/O Aux2 data I/O.

VFD_CLK I VFD clock input.

122:127

128

131

132

I/O Host data bus lines 5:0.

I/O Host data bus line 6.

I/O Host data bus line 7.

I/O Host data bus line 8.

20

Page 21

p( )

Name Pin Numbers I/O Definition

S-301

HD9

AUX2[1] I/O Aux2 data I/O.

HD10

AUX2[2] I/O Aux2 data I/O.

HD11

AUX2[3] I/O Aux2 data I/O.

IRQ O IRQ.

HD12

AUX2[4] I/O Aux2 data I/O.

C2PO I C2PO error correction flag from CD-ROM.

HD13

AUX2[5] I/O Aux2 data I/O.

SP I 16550 UART serial port input.

HD14

AUX2[6] I/O Aux2 data I/O.

HD15

AUX2[7] I/O Aux2 data I/O.

133

134

135

136

137

140

141

I/O Host data bus line 9.

I/O Host data bus line 10.

I/O Host data bus line 11.

I/O Host data bus line 12.

I/O Host data bus line 13.

I/O Host data bus line 14.

I/O Host data bus line 15.

IR I IR remote control input.

HWRQ#

DCI_REQ# O DVD control interface request (active-low).

AUX4[1] I/O Aux4 data I/O.

HRRQ#

AUX4[0] I/O Aux4 data I/O.

HIRQ

DCI_ERR# I/O DVD channel data error (active-low).

AUX4[7] I/O Aux4 data I/O.

HRST#

AUX3[5] I/O Aux3 data I/O.

HIORDY

AUX3[3] I/O Aux3 data I/O.

HWR#

DCI_CLK I/O DVD channel data clock.

AUX4[5] I/O Aux4 data I/O.

142

143

144

145

146

149

O Host write request (active-low).

O Host read request (active-low).

I/O Host interrupt.

O Host reset (active-low).

I Host I/O ready.

I/O Host write (active-low).

21

Page 22

p( )

Name Pin Numbers I/O Definition

S-301

HRD#

DCI_ACK# O DVD channel data valid (active-low).

150

O Host read (active-low).

AUX4[6] I/O Aux4 data I/O.

HIOCS16#

CAMCLK I Camera port pixel clock input.

151

I Device 16-bit data transfer (active-low).

AUX3[4] I/O Aux3 data I/O.

HCS1FX#

O Host select 1 (active-low).

152

AUX3[7] I/O Aux3 data I/O.

HCS3FX#

O Host select 3 (active-low).

153

AUX3[6] I/O Aux3 data I/O.

HA[2:0]

I/O Host address bus.

154, 155, 158

AUX4[4:2] I/O Aux4 data I/Os.

AUX[0]

160

I2CDATA I/O I

AUX[1]

161

I2C_CLK I/O I

AUX[2]

I/O Auxiliary port 0 (open collector).

2

C data I/O.

I/O Auxiliary port 1 (open collector).

2

C clock I/O.

I/O Auxiliary port.

162

IOW# O I/O write strobe (LCS1) (active-low).

AUX[3]

I/O Auxiliary port.

165

IOR# O I/O read strobe (LCS1) (active-low).

AUX[6:4] 166:168 I/O Auxiliary ports.

AUX[7] 169 I/O Auxiliary port.

LOE# 170 O RISC port output enable (active-low).

LCS[3:0]# 173:176 O RISC port chip select (active-low).

LD[15:0]

178:182,

185:191,194:197

I/O RISC port data bus.

LWRLL# 198 O RISC port low-byte write enable (active-low).

LWRHL# 199 O RISC port high-byte write enable (active-low).

CAMIN0 202 I Camera YUV 0.

CAMIN1 203 I Camera YUV 1.

22

Page 23

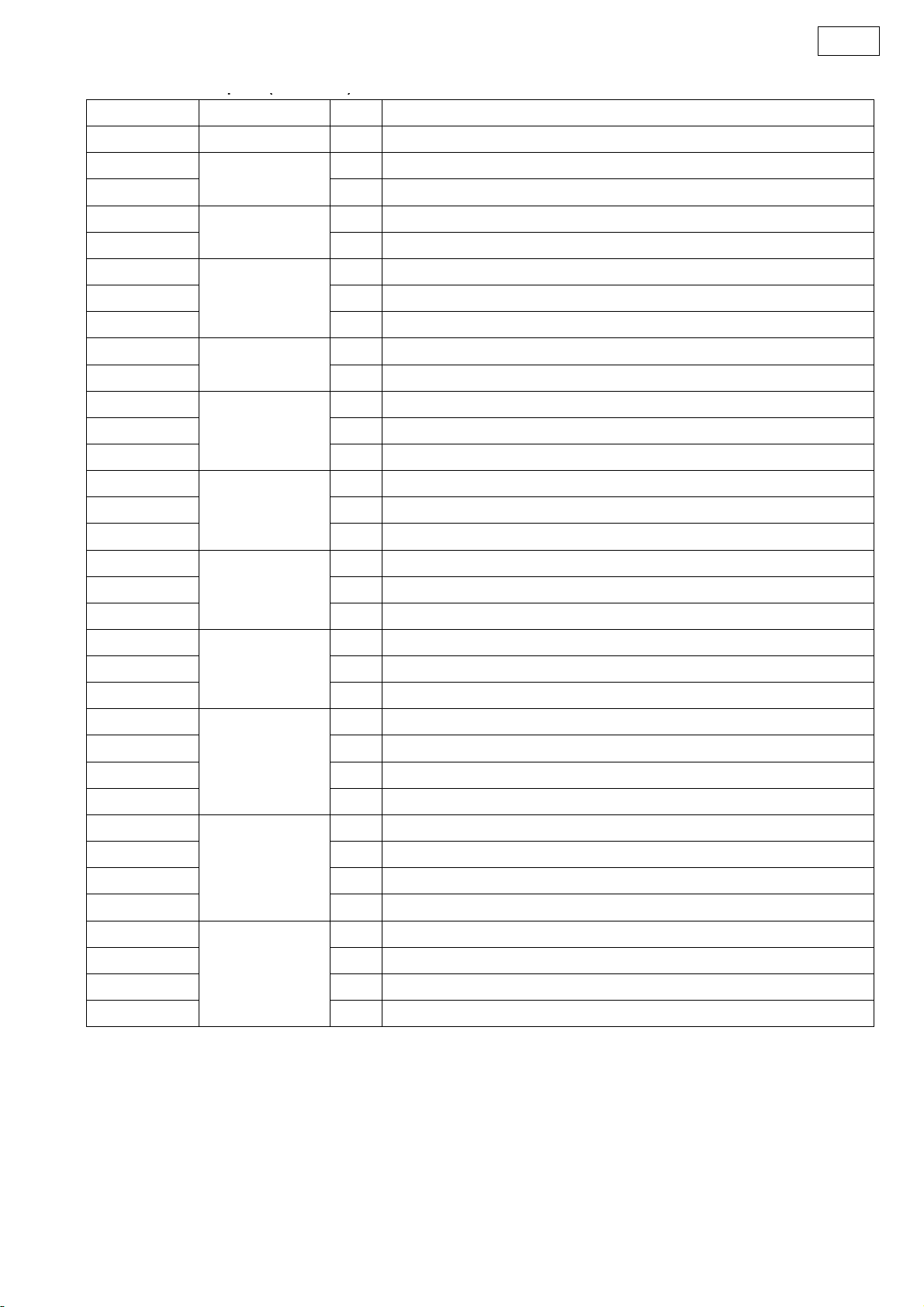

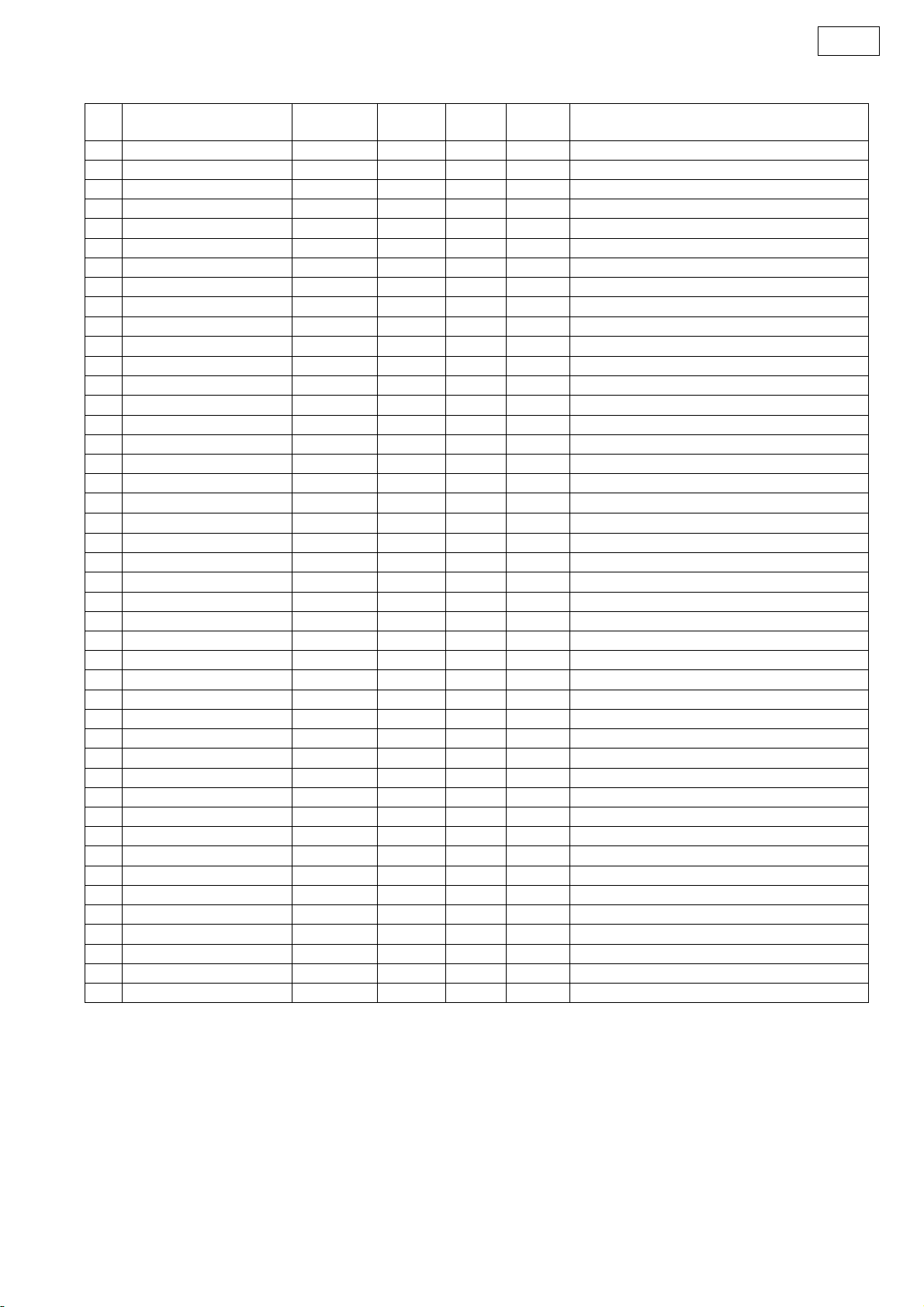

FLI2310 (IC403: 1U-3692)

t

Pin Diagram

FIELD ID_PORT2

HSYNC_PORT2

VSYNC_PORT2

D1_IN_7

D1_IN_6

D1_IN_5

S-301

R_VDD

IN_CLK_PORT2

XTAL IN

XTAL OUT

VDD9

VSS

D1_IN_4

D1_IN_3

D1_IN_0

D1_IN_2

D1_IN_1

VDDcore8

VSScore

TEST0

TEST1

TEST2

R_VDD

R_VSS

R_VSS

R_VDD

R_VSS

R_VDD

R_VDD

R_VSS

Reserved

Reserved

Reserved

R_VSS

R_VSS

Reserved

Reserved

R_VSS

AVDD_PLL_FE

R_VDD1.8

AVDD_PLL_SDI

AVSS_PLL_BE2

AVSS_PLL_FE

AVSS_PLL_SDI

PLL_PVDD

AVDD_PLL_BE2

PLL_PVSS

AVSS_PLL_BE1

AVDD_PLL_BE1

R_VSS

R_VDD

Reserved

HSYNC1_PORT1

VSYNC1_PORT1

FIELD ID1_PORT1

IN_CLK1_PORT1

HSYNC2_PORT1

VSYNC2_PORT1

FIELD ID2_PORT1

VDD1

VSS

IN_CLK2_PORT1

B/Cb/D1_0

B/Cb/D1_1

B/Cb/D1_2

B/Cb/D1_3

B/Cb/D1_4

VDDcore1

VSScore

B/Cb/D1_5

B/Cb/D1_6

B/Cb/D1_7

R/Cr/Cb Cr_0

R/Cr/Cb Cr_1

R/Cr/Cb Cr_2

R/Cr/Cb Cr_3

R/Cr/Cb Cr_4

R/Cr/Cb Cr_5

R/Cr/Cb Cr_6

R/Cr/Cb Cr_7

G/Y/Y_0

VDD2

VSS

G/Y/Y_1

G/Y/Y_2

G/Y/Y_3

G/Y/Y_4

VDDcore2

VSScore

G/Y/Y_5

G/Y/Y_6

G/Y/Y_7

IN_SEL

TEST

DEV_ADDR1

DEV_ADDR0

SCLK

SDATA

RESET_N

VDD3

SDRAM DATA(0)

SDRAM DATA(1)

SDRAM DATA(2)

VSS

1 0 0

1 6 0

1 5 5

1 5 0

1 4 5

1 4 0

1 3 5

1 3 0

1 2 5

1 2 0

1 1 5

1 1 0

1 0 5

OE

G/Y/Y_OUT_7

G/Y/Y_OUT_6

G/Y/Y_OUT_5

G/Y/Y_OUT_4

G/Y/Y_OUT_3

G/Y/Y_OUT_2

G/Y/Y_OUT_1

G/Y/Y_OUT_0

VSS

VDD8

R/V/Pr_OUT_7

R/V/Pr_OUT_6

R/V/Pr_OUT_5

R/V/Pr_OUT_4

R/V/Pr_OUT_3

R/V/Pr_OUT_2

VSScore

VDDcore7

R/V/Pr_OUT_1

R/V/Pr_OUT_0

B/U/Pb_OUT_7

B/U/Pb_OUT_6

B/U/Pb_OUT_5

B/U/Pb_OUT_4

B/U/Pb_OUT_3

B/U/Pb_OUT_2

VSS

VDD7

B/U/Pb_OUT_1

B/U/Pb_OUT_0

CLKOUT

VSScore

VDDcore6

CTLOUT4

CTLOUT3

CTLOUT2

CTLOUT1

CTLOUT0

TEST OUT1

TEST OUT0

TEST3

SDRAM CLKIN

VSS

VDD6

SDRAM CLKOUT

SDRAM DQM

SDRAM CSN

SDRAM BA0

SDRAM BA1

SDRAM CASN

SDRAM RASN

2 0 5

1

2 0 0

1 9 5

1 9 0

1 8 5

1 8 0

1 7 5

1 7 0

1 6 5

5

1 0

1 5

2 0

2 5

3 0

3 5

4 0

4 5

5 0

5 5

6 0

6 5

7 0

7 5

8 0

8 5

9 0

9 5

Block Diagrams

Port 2

8-bit

656 Input

Port 1

8/16/24-bit

RGB/YCrCb

Input

Input Processor

with Auto Sync

and auto Adjust

Generation

SDRAM DATA(3)

Clock

PLLs

VSS

VDD4

SDRAM DATA(5)

SDRAM DATA(4)

SDRAM DATA(8)

SDRAM DATA(7)

SDRAM DATA(6)

SDRAM DATA(9)

SDRAM DATA(10)

SDRAM DATA(12)

SDRAM DATA(11)

Noise Reducer,

Deinterlacer, Frame

Rate Converter and

SDRAM interface

VSScore

VDDcore3

SDRAM DATA(21)

SDRAM DATA(17)

SDRAM DATA(16)

SDRAM DATA(14)

SDRAM DATA(13)

SDRAM DATA(15)

SDRAM DATA(18)

SDRAM DATA(22)

SDRAM DATA(20)

SDRAM DATA(19)

SDRAM DATA(24)

SDRAM DATA(23)

SDRAM DATA(25)

VSScore

VDDcore4

SDRAM DATA(28)

SDRAM DATA(26)

SDRAM DATA(27)

Vertical and

Horizontal

Scalers

VSS

VDD5

TEST IN

SDRAM DATA(31)

SDRAM DATA(30)

SDRAM DATA(29)

SDRAM ADDR(9)

SDRAM ADDR(10)

SDRAM ADDR(7)

SDRAM ADDR(8)

SDRAM ADDR(6)

VSScore

VDDcore5

SDRAM ADDR(5)

SDRAM ADDR(4)

SDRAM ADDR(3)

SDRAM ADDR(2)

SDRAM ADDR(0)

SDRAM ADDR(1)

SDRAM WEN

Output

Processor

16/20/24-bi

RBG/YCrCb

Digital Outputs

2Mx32

SDRAM

(external)

Vertical and

Horizontal

Enhancers

23

Page 24

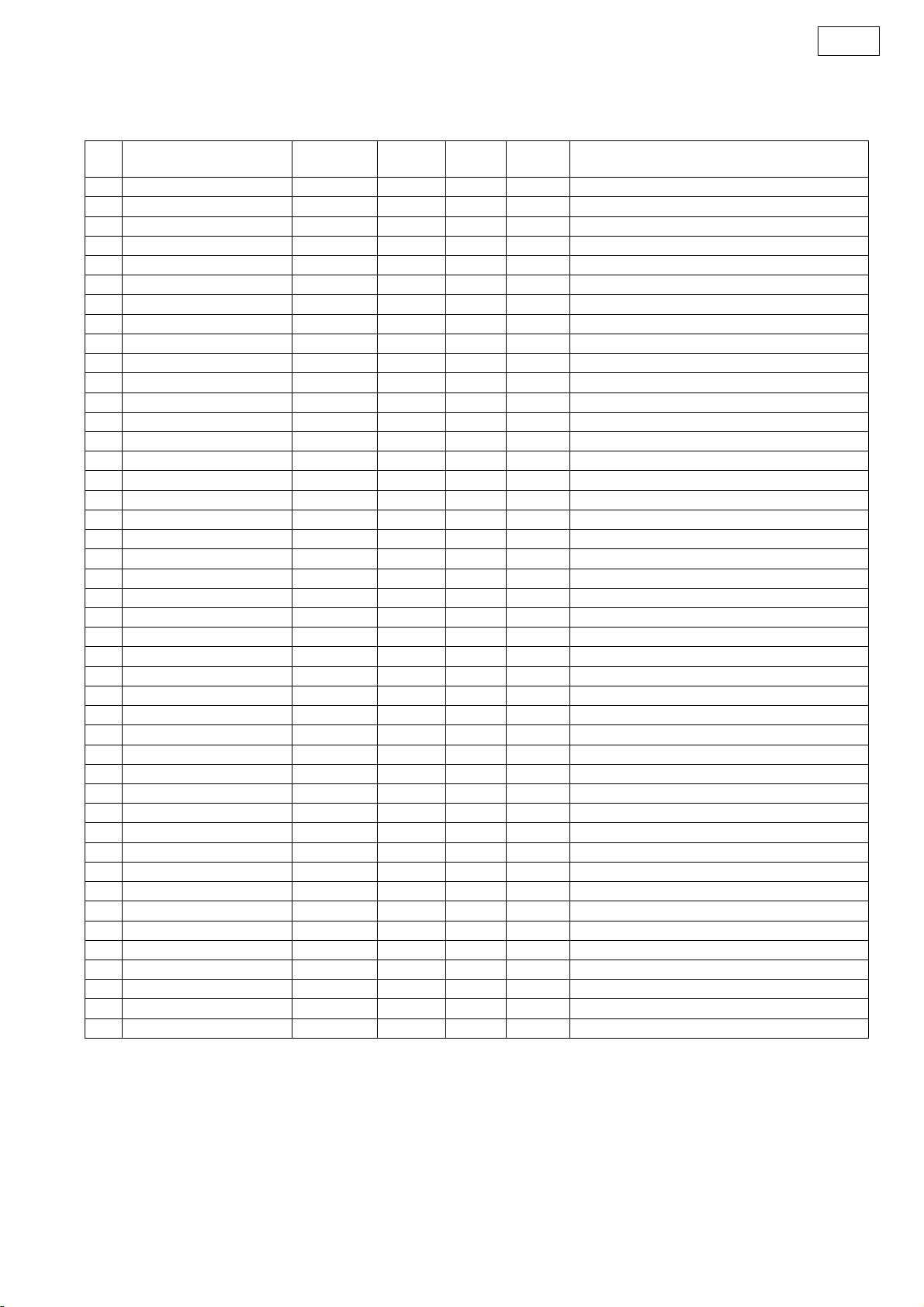

Pin details

S-301

Pin

No Pin Name I/O Type

1

HSYNC1_PORT1 Input 5v

2

VSYNC1_PORT1 Input 5v

FIELD ID1_PORT1

3

IN_CLK1_PORT1

4

5

HSYNC2_PORT1 Input 5v

6

VSYNC2_PORT1 Input 5v

FIELD ID2_PORT1

7

VDD1

8

VSS

9

IN_CLK2_PORT1

10

B/Cb/D1_0

11

B/Cb/D1_1

12

B/Cb/D1_2

13

B/Cb/D1_3

14

B/Cb/D1_4

15

VDDcore1

16

VSScore

17

B/Cb/D1_5

18

B/Cb/D1_6

19

B/Cb/D1_7

20

R/Cr/Cb Cr_0

21

R/Cr/Cb Cr_1

22

R/Cr/Cb Cr_2

23

R/Cr/Cb Cr_3

24

R/Cr/Cb Cr_4

25

R/Cr/Cb Cr_5

26

R/Cr/Cb Cr_6

27

R/Cr/Cb Cr_7

28

G/Y/Y_0

29

VDD2

30

VSS

31

G/Y/Y_1

32

G/Y/Y_2

33

G/Y/Y_3

34

G/Y/Y_4

35

VDDcore2

36

VSScore

37

G/Y/Y_5

38

G/Y/Y_6

39

G/Y/Y_7

40

41

IN_SEL Output 5v 8 mA

42 TEST Input 5v

43

DEV_ADDR1 Input 5v

44

DEV_ADDR0 Input 5v

Input 5v

Input 5v

Input 5v

Power 3.3 V - Power pin for IO

Ground Ground

Input 5v

Input 5v

Input 5v

Input 5v

Input 5v

Input 5v

Power 1.8 V - Power pin for core

Ground Ground

Input 5v

Input 5v

Input 5v

Input 5v

Input 5v

Input 5v

Input 5v

Input 5v

Input 5v

Input 5v

Input 5v

Input 5v

Power 3.3 V - Power pin for IO

Ground Ground

Input 5v

Input 5v

Input 5v

Input 5v

Power 1.8 V - Power pin for core

Ground Ground

Input 5v

Input 5v

Input 5v

Voltage

Tolerance Drive

Pull up/

Pulldown Description

Horizontal sync or reference -CTL1 of Port 1

Vertical sync or reference -CTL1 of Port 1

Odd/Even Field identification -CTL1 of Port 1

Data Clock input -CTL1 of Port 1

Horizontal sync or reference –CTL2 of Port 1

Vertical sync or reference –CTL2 of Port 1

Odd/Even Field identification –CTL2 of Port 1

Data Clock input –CTL2 of Port 1

Port 1 – Digital video input (Blue/Cb/D1)

Port 1 – Digital video input (Blue/Cb/D1)

Port 1 – Digital video input (Blue/Cb/D1)

Port 1 – Digital video input (Blue/Cb/D1)

Port 1 – Digital video input (Blue/Cb/D1)

Port 1 – Digital video input (Blue/Cb/D1)

Port 1 – Digital video input (Blue/Cb/D1)

Port 1 – Digital video input (Blue/Cb/D1)

Port 1 – Digital video input (Red/Cr/CrCb)

Port 1 – Digital video input (Red/Cr/CrCb)

Port 1 – Digital video input (Red/Cr/CrCb)

Port 1 – Digital video input (Red/Cr/CrCb)

Port 1 – Digital video input (Red/Cr/CrCb)

Port 1 – Digital video input (Red/Cr/CrCb)

Port 1 – Digital video input (Red/Cr/CrCb)

Port 1 – Digital video input (Red/Cr/CrCb)

Port 1 – Digital video input (Green/Y)

Port 1 – Digital video input (Green/Y)

Port 1 – Digital video input (Green/Y)

Port 1 – Digital video input (Green/Y)

Port 1 – Digital video input (Green/Y)

Port 1 – Digital video input (Green/Y)

Port 1 – Digital video input (Green/Y)

Port 1 – Digital video input (Green/Y)

Output to select external video mux

Connect to Ground

Device address setting 1

Device address setting 0

24

Page 25

S-301

Pin

No Pin Name I/O Type

45 SCLK

46 SDATA

47 RESET_N

48 VDD3

49 VSScore

50 SDRAM DATA(0)

51 SDRAM DATA(1)

52 SDRAM DATA(2)

53 SDRAM DATA(3)

54 SDRAM DATA(4)

55 SDRAM DATA(5)

56 SDRAM DATA(6)

57 SDRAM DATA(7)

58 SDRAM DATA(8)

59 SDRAM DATA(9)

60 SDRAM DATA(10)

61 SDRAM DATA(11)

62 VDD4

63 VSS

64 SDRAM DATA(12)

65 SDRAM DATA(13)

66 SDRAM DATA(14)

67 SDRAM DATA(15)

68 VDDcore3

69 VSScore

70 SDRAM DATA(16)

71 SDRAM DATA(17)

72 SDRAM DATA(18)

73 SDRAM DATA(19)

74 SDRAM DATA(20)

75 SDRAM DATA(21)

76 SDRAM DATA(22)

77 SDRAM DATA(23)

78 SDRAM DATA(24)

79 SDRAM DATA(25)

80 VDDcore4

81 VSScore

82 SDRAM DATA(26)

83 SDRAM DATA(27)

84 SDRAM DATA(28)

85 SDRAM DATA(29)

86 SDRAM DATA(30)

87 SDRAM DATA(31)

88 VDD5

I/O

I/O

Input

Power

Ground

Tristate I/O

Tristate I/O

Tristate I/O

Tristate I/O

Tristate I/O

Tristate I/O

Tristate I/O

Tristate I/O

Tristate I/O

Tristate I/O

Tristate I/O

Tristate I/O

Power

Ground

Tristate I/O

Tristate I/O

Tristate I/O

Tristate I/O

Power

Ground

Tristate I/O

Tristate I/O

Tristate I/O

Tristate I/O

Tristate I/O

Tristate I/O

Tristate I/O

Tristate I/O

Tristate I/O

Tristate I/O

Power

Ground

Tristate I/O

Tristate I/O

Tristate I/O

Tristate I/O

Tristate I/O

Tristate I/O

Power

Voltage

Tolerance Drive

5v 8 mA 2-wire serial control bus clock

5v 8 mA 2-wire serial control bus data

5v PU Reset

3.3 V – Power pin for IO

Ground

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

3.3 V – Power pin for IO

Ground

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

1.8 V - Power pin for core

Ground

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

1.8 V – Power pin for core

Ground

5v 4 mA PD SDRAM data bus *

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

3.3 V – Power pin for IO

Pull up/

Pulldown Description

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

25

Page 26

S-301

Pin

No Pin Name I/O Type

89 VSS

90 TEST IN

91 SDRAM ADDR(10)

92 SDRAM ADDR(9)

93 SDRAM ADDR(8)

94 SDRAM ADDR(7)

95 SDRAM ADDR(6)

96 VDDcore5

97 VSScore

98 SDRAM ADDR(5)

99 SDRAM ADDR(4)

100 SDRAM ADDR(3)

101 SDRAM ADDR(2)

102 SDRAM ADDR(1)

103 SDRAM ADDR(0)

104 SDRAM WEN

105 SDRAM RASN

106 SDRAM CASN

107 SDRAM BA1

108 SDRAM BA0

109 SDRAM CSN

110 SDRAM DQM

111 SDRAM CLKOUT

112 VDD6

113 VSS

114 SDRAM CLKIN

115 TEST3

116 TEST OUT0

TEST OUT1 / Interrupt

117

Out Output

118 CTLOUT0

119 CTLOUT1

120 CTLOUT2

121 CTLOUT3

122 CTLOUT4

123 VDDcore6

124 VSScore

125 CLKOUT

126 B/U/Pb_OUT_0

127 B/U/Pb_OUT_1

Ground

Input

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Power

Ground

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Output

Power

Ground

Input

Input

Output

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Power

Ground

Tristate O/P

Tristate O/P

Tristate O/P

Voltage

Tolerance Drive

Ground

5V Test input-Connect to ground

5v 8 mA SDRAM address bus *

5v 8 mA SDRAM address bus *

5v 8 mA SDRAM address bus *

5v 8 mA SDRAM address bus *

5v 8 mA SDRAM address bus *

1.8 V – Power pin for core

Ground

5v 8 mA SDRAM address bus *

5v 8 mA SDRAM address bus *

5v 8 mA SDRAM address bus *

5v 8 mA SDRAM address bus *

5v 8 mA SDRAM address bus *

5v 8 mA SDRAM address bus *

5v 8 mA SDRAM write enable *

5v 8 mA SDRAM row address select *

5v 8 mA SDRAM column address select *

5v 8 mA SDRAM bank select 1*

5v 8 mA SDRAM bank select 0*

5v 4 mA SDRAM CS *

5v 8 mA SDRAM DQM *

5v 12 mA Clock out to SDRAM *

3.3 V - Power pin for IO

Ground

5v Trace delayed SDRAM Clock in

Test input – Connect to ground

Test output – leave open

Interrupt Output

5v 8 mA

5v 8 mA

5v 8 mA

5v 8 mA

5v 8 mA

1.8 V - Power pin for core

Ground

5v 12 mA Output data rate clock

5v 8 mA

5v 8 mA

Pull up/

Pulldown Description

Control signal output selectable as HSync1/

CSync/HRef/Monitor coast

Control signal output selectable as

VSync1/CRef/VRef/Film Indicator

Control signal output selectable as Monitor

coast/HRef/VDD_en / HSync2

Control signal output selectable as Film

Indicator/VRef/backlight_en/VSync2

Control signal output selectable as CRef/Field

ID/CSync/Monitor coast

Digital video output – Blue/U/Pb

Digital video output – Blue/U/Pb

26

Page 27

S-301

Pin

No

Pin Name I/O Type

128 VDD7

129 VSS

130 B/U/Pb_OUT_2

131 B/U/Pb_OUT_3

132 B/U/Pb_OUT_4

133 B/U/Pb_OUT_5

134 B/U/Pb_OUT_6

135 B/U/Pb_OUT_7

136 R/V/Pr_OUT_0

137 R/V/Pr_OUT_1

138 VDDcore7

139 VSScore

140 R/V/Pr_OUT_2

141 R/V/Pr_OUT_3

142 R/V/Pr_OUT_4

143 R/V/Pr_OUT_5

144 R/V/Pr_OUT_6

145 R/V/Pr_OUT_7

146 VDD8

147 VSS

148 G/Y/Y_OUT_0

G/Y/Y_OUT_1

149

G/Y/Y_OUT_2

150

G/Y/Y_OUT_3

151

G/Y/Y_OUT_4

152

G/Y/Y_OUT_5

153

G/Y/Y_OUT_6

154

G/Y/Y_OUT_7

155

156 OE

157 PLL_PVDD

158 PLL_PVSS

159 AVSS_PLL_BE1

160 AVDD_PLL_BE1

161 AVDD_PLL_BE2

162 AVSS_PLL_BE2

163 AVSS_PLL_SDI

164 AVDD_PLL_SDI

165 AVDD_PLL_FE

166 AVSS_PLL_FE

167 DAC_PVSS

168 DAC_VDD

169 DAC_VSS

170 DAC_BOUT

171

DAC_AVDDB

Power

Ground

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Power

Ground

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Power

Ground

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Input

Power

Ground

Ground

Power

Power

Ground

Ground

Power

Power

Ground

Ground

Power

Ground

Output

Power

Voltage

Tolerance

3.3 V – Power pin for IO

Ground

5v 8 mA Digital video output – Blue/U/Pb

5v 8 mA

5v 8 mA

5v 8 mA

5v 8 mA

5v 8 mA

5v 8 mA Digital video output – Red/V/Pr

5v 8 mA Digital video output – Red/V/Pr

1.8 V – Power pin for core

Ground

5v 8 mA

5v 8 mA

5v 8 mA

5v 8 mA

5v 8 mA

5v 8 mA

3.3 V – Power pin for IO

Ground

5v 8 mA Digital video output – Green/Y

5v 8 mA

5v 8 mA

5v 8 mA

5v 8 mA

5v 8 mA

5v 8 mA

5v 8 mA

5v Output data enable for Digital video output

1.8 V – Power pin for PLL pads

Ground for PLL pads

PLL Ground

1.8 V – Power pin for PLL

1.8 V – Power pin for PLL

PLL Ground

PLL Ground

1.8 V – Power pin for PLL

1.8 V – Power pin for PLL

PLL Ground

Ground for DAC pads

1.8 V – Digital power pin for DAC

DAC digital Ground

34 mA Analog B/U output

3.3 V – Analog power pin for B channel

Drive

Pull up/

Pulldown

Description

Digital video output – Blue/U/Pb

Digital video output – Blue/U/Pb

Digital video output – Blue/U/Pb

Digital video output – Blue/U/Pb

Digital video output – Blue/U/Pb

Digital video output – Red/V/Pr

Digital video output – Red/V/Pr

Digital video output – Red/V/Pr

Digital video output – Red/V/Pr

Digital video output – Red/V/Pr

Digital video output – Red/V/Pr

Digital video output – Green/Y

Digital video output – Green/Y

Digital video output – Green/Y

Digital video output – Green/Y

Digital video output – Green/Y

Digital video output – Green/Y

Digital video output – Green/Y

27

Page 28

S-301

Pin

No

Pin Name I/O Type

172 DAC_AVSSB

173 DAC_GOUT

174 DAC_AVDDG

175 DAC_AVSSG

176 DAC_ROUT

177 DAC_AVDDR

178 DAC_AVSSR

179 DAC_COMP

180 DAC_RSET

181 DAC_VREFOUT

182 DAC_VREFIN

183 DAC_AVDD

184 DAC_AVSS

185 DAC_GR_AVSS

186 DAC_GR_AVDD

187 DAC_PVDD

188 TEST0

189 TEST1

190 TEST2

191 XTAL IN

192 XTAL OUT

193 VDD9

194 VSS

195 IN_CLK_PORT 2

196 D1_IN_0

197 VDDcore8

198 VSScore Ground Ground

199 D1_IN_1 Input 5v 4 mA Port 2 - ITU-R BT656 digital data input

200 D1_IN_2 Input 5v 4 mA Port 2 - ITU-R BT656 digital data input

201 D1_IN_3 Input 5v 4 mA Port 2 - ITU-R BT656 digital data input

202 D1_IN_4 Input 5v 4 mA Port 2 - ITU-R BT656 digital data input

203 D1_IN_5 Input 5v 4 mA Port 2 - ITU-R BT656 digital data input

204 D1_IN_6 Input 5v 4 mA Port 2 - ITU-R BT656 digital data input

205 D1_IN_7 Input 5v 4 mA Port 2 - ITU-R BT656 digital data input

206 FIELD ID_PORT 2

207 VSYNC_ PORT 2

208 HSYNC_PORT 2

Ground

Output

Power

Ground

Output

Power

Ground

Output

Output

Output

Input

Power

Ground

Ground

Power

Power

Input

Input

Input

Input

Output

Power

Ground

Input

Input

Power

Input

Input

Input

Voltage

Tolerance

Analog Ground for B channel

34 mA Analog G/Y output

3.3 V – Analog power pin for G channel

Analog Ground for G channel

34 mA Analog R/V output

3.3 V – Analog power pin for R channel

Analog Ground for R channel

Compensation for video DACs

Current setting resistor for video DACs

External Voltage reference for video DACs

3.3 V – Analog power pin for DAC

Analog Ground for DAC

Ground for DAC Guard ring

3.3 V – Power pin for DAC Guard ring

3.3 V –Power pin for DAC pads

5v Test pin – connect to ground

5v Test pin – connect to ground

5v Test pin – connect to ground

External parallel crystal oscillator

External parallel crystal oscillator

3.3 V - Power pin for IO

Ground

5v 4 mA Port 2 - Data Clock input

5v 4 mA Port 2 - ITU-R BT656 digital data input

1.8 V – Power pin for core

5v 4 mA Port 2 - Odd/Even Field identification

5v 4 mA Port 2 - Vertical sync or reference

5v 4 mA Port 2 - Horizontal sync or reference

Drive

Pull up/

Pulldown

Description

1.28 V Internally generated voltage reference for

video DACs

Note: * - The connection of these pins depends on the type of external SDRAM used.

28

Page 29

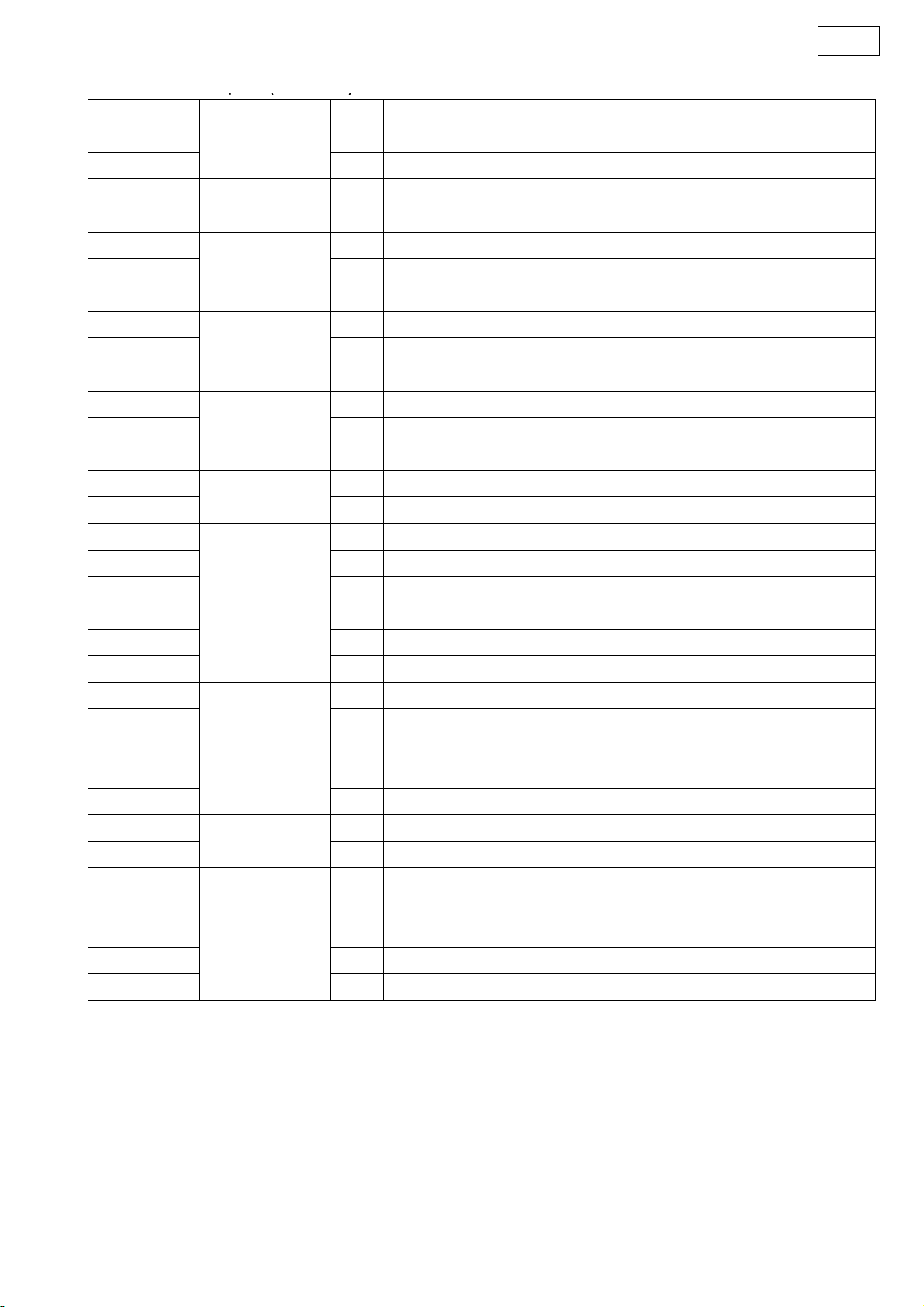

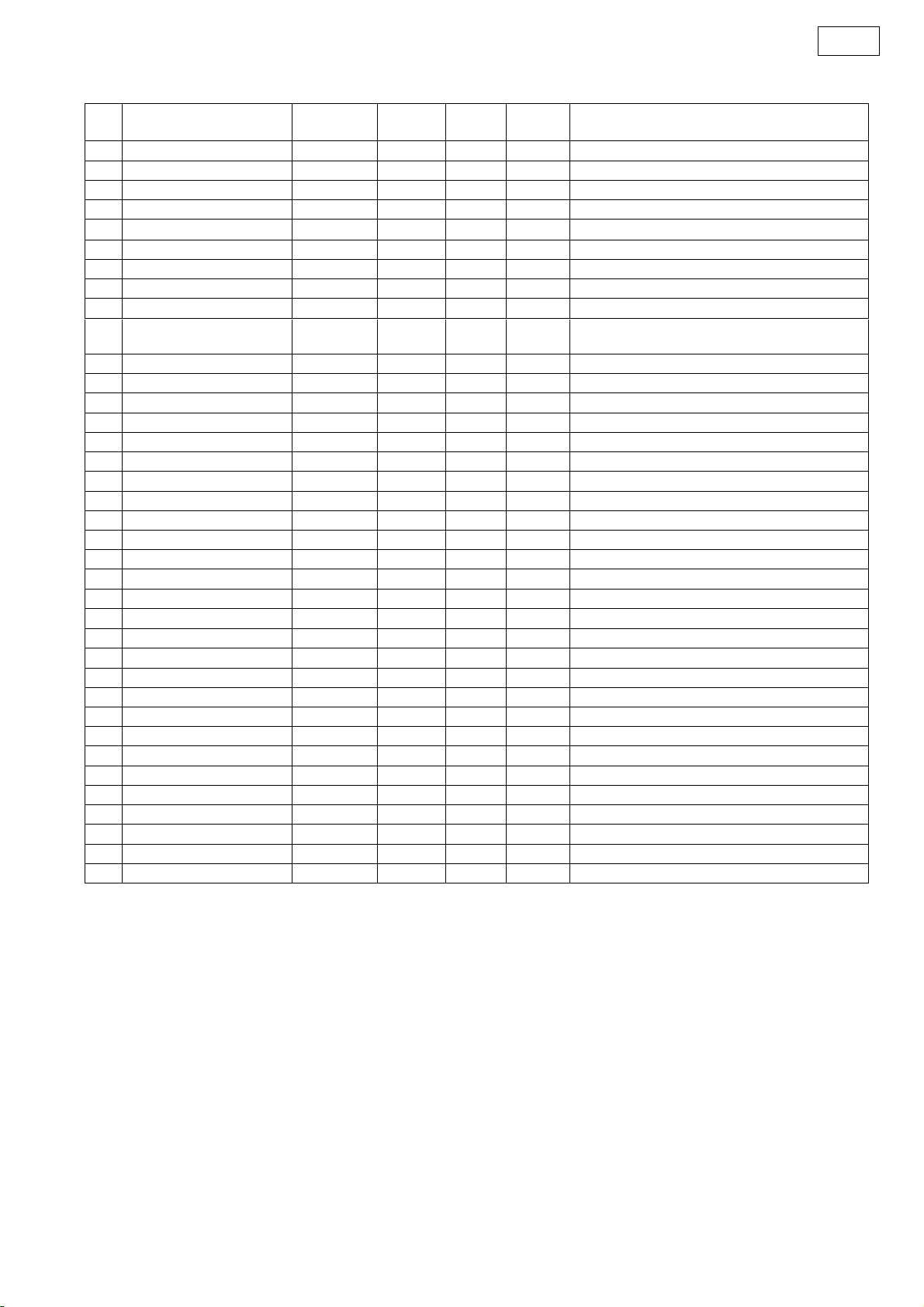

CXD1885Q (IC805: 1U-3692)

S-301

DRAM I/F PWM.FG D/A

DV

TEST10

TEST11

TEST12

TEST13

TEST14

TEST15

MODSEL0

MODSEL1

MODSEL2

DV

DV

General Port

JTAG Test/Monitor Pin

VMCHG

DVDD18

DD33

RD8

TEST0

TEST1

TEST2

TEST3

TEST4

TEST5

TEST6

TEST7

TEST8

TEST9

DV

GIO0

GIO1

GIO2

GIO3

DD33

GIO4

GIO5

GIO6

GIO7

DD18

GIO8

GIO9

GIO10

GIO11

GIO12

DV

GIO13

GIO14

GIO15

GIO16

GIO17

GIO18

GIO19

TRST

TMS

TCK

TDO

18

DD

DV

RD9

RD10

RD11

RD12

RD13

RD14

RD15

RD0

RD1

157

158

159

160

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

177

SS

178

179

180

181

182

183

184

185

186

187

188

189

190

191

192

193

194

SS

195

196

197

198

199

200

201

202

203

204

TDI

205

206

207

208

RD2

RD3

RD4

RD5

SS

RD6

DV

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52

33

MA0

MA1

MA2

MA3

MA4

MA5

MA6

MA7

MA8

MD0

DD

ALCR

MSEL0

MSEL1

DV

MD1

TESTSEL

RD7

MD2

XMWR

MD3

XRAS

MD4

RA0

MD5

18

DD

DV

SS

DV

RA1

MD6

RA2

MD7

RA3

MALE

RA4

MCS

33

DD

DV

MWR

RA5

33

DD

DV

RA6

MRD

RA7

SS

RA10

RA11

XMOE

XUCAS

XLCAS

GPWM5

GPWM4

GPWM3

GPWM2

GPWM1

VDT5

VDT4

VDT3

VDT2

GPWM0

VDT1

RA8

RA9

DV

XI

SS

18

DD

MINT

MRDY

SYSCK

DV

SS

XO

DV

DV

VDT7

VDT6

SPWM2

SPWM1FGAVSSDA3 (SLED2_TILT)

VDT0

HDRQ

VSTEM I/FClockB/E MCU I/F

33

DD

DA2 (FSCON)

DA1 (SLED)

DA0 (TSCON)

AV

105106107108109110111112113114115116117118119120121122123124125126127128129130131132133134135136137138139140141142143144145146147148149150151152153154155156

AV

DD18

104

VREFL

103

VREFH

102

AD9

101

AD8

100

AD7

99

AD6

98

AD5

97

AD4

96

AD3

95

AV

94

AD2

93

AD1

92

AD0

91

AVSS

90

AV

89

RC

88

LPF2

87

LPF1

86

VCOI

85

AV

84

VFBC

83

CHG

82

JMOUT

81

JMREF

80

AV

79

IREF

78

TLC1

77

TLC0

76

HF

75

ATC

74

AV

73

DTC

72

MIRRORH

71

HFD

70

RFOKGH

69

SCLKH

68

SO

67

SI

66

CSL

65

EXPLDT

64

EXVCO

63

BCK

62

LRCK

61

DOTK

60

DADT

59

C2PO

58

DRVRDY

57

DRVCLK

56

DRVRX

55

DRVTX

54

DV

53

18

DCK

XSHD

DRVIRQ

DRVRST

DD

DV

VEFG

XHAC

A/DData PLL/Data SlicerASP S-I/O, Defect etcAudio D/AVSTEM I/F

DD33

SS

DD18

DD33

SS

DD33

29

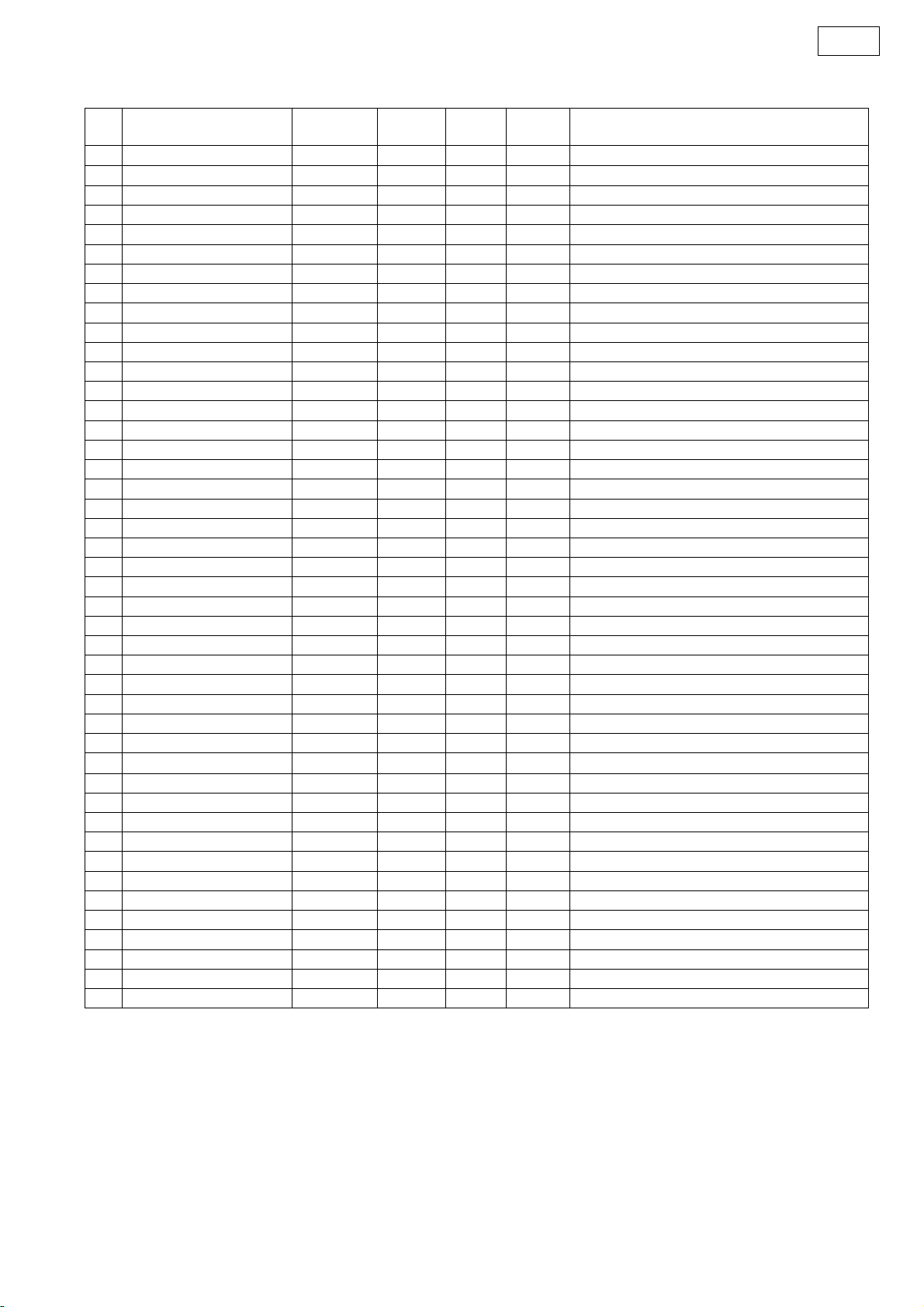

Page 30

16/4M DRAM

S-301

HFD

HF

ASP

PWM

AT C

JTAG

Mecha

control

Servo

singnal

Data

Slicer

Data-PLL

ASP Serial I/F

TZC

GIO

A/D

TC

Direction

ROM/RAM

ICU Timer

BCA

DVD

Demodulation

CD-DSP (DDCD)

VSTEM

Serial I/F

Spindle

DSP

Data

RAM

D/A

PWM

CMD/

RSP

reg.

Memory

manager

CD-ROM

Header Dec.

Peri. CLK

Audio I/F

ECC Core

EDC

MPEG I/F

DSP CLK/Mode

MCU I/F

ICU

Video

Serial

Command

Audio

MCU

Servo

control

X'tal

VSTEM

Functions (A/D : Analog/Digital, PU : Pull-up, PD : Pull-down, SMT=Schumitt )

No. Terminal Name I/O A/D Classification Function PU PD SMT

DD33 P VDD & GND Digital 3.3V Power for I/O.

1DV

2 ALCR I D MCU I/F Chip select input. (L: Reset) * *

3 MSEL0 I D MCU I/F MCU I/F mode select 0. *

4 MSEL1 I D MCU I/F MCU I/F mode select 1. *

5 MA0 I/O D MCU I/F MCU Adress input 0 / data I/O 0 <LSB>. *

6 MA1 I/O D MCU I/F MCU Adress input 1 / data I/O 1. *

7 MA2 I/O D MCU I/F MCU Adress input 2 / data I/O 2. *

8 MA3 I/O D MCU I/F MCU Adress input 3 / data I/O 3. *

9 MA4 I/O D MCU I/F MCU Adress input 4 / data I/O 4. *

10 MA5 I/O D MCU I/F MCU Adress input 5 / data I/O 5. *

11 MA6 I/O D MCU I/F MCU Adress input 6 / data I/O 6. *

12 MA7 I/O D MCU I/F MCU Adress input 7 / data I/O 7. *

13 MA8 I D MCU I/F MCU Adress input 8 <MSB>. *

14 TESTSEL I D MCU I/F TEST Select input. *

15 MD0 I/O D MCU I/F MCU data I/O 0 <LSB>. *

16 MD1 I/O D MCU I/F MCU data I/O 1. *

17 MD2 I/O D MCU I/F MCU data I/O 2. *

18 MD3 I/O D MCU I/F MCU data I/O 3. *

19 MD4 I/O D MCU I/F MCU data I/O 4. *

20 MD5 I/O D MCU I/F MCU data I/O 5. *

SS PVDD & GND Digital Ground.

21 DV

22 MD6 I/O D MCU I/F MCU data I/O 6. *

23 MD7 I/O D MCU I/F MCU data I/O 7 <MSB>. *

24 MALE I D MCU I/F MCU Adress latch signal input. *

25 MCS I D MCU I/F MCU Chip Select signal input. *

26 MWR I D MCU I/F MCU Write strobe signal. *

DD

27 DV

28 MRD I D MCU I/F MCU Read Strobe signal. *

29 MRDY O D MCU I/F MCU Ready signal. (L: Wait)

30 MINT O D MCU I/F MCU Interrupt signal. (L: Interrupt request)

33 P VDD & GND digital 3.3V Power. (for I/O )

30

Page 31

S-301

No. Terminal Name I/O A/D Classification Function PU PD SMT

31 SYSCK O D Clock Clock Monitor output.

DD

32 DV

33 XI I D Clock Crystal oscillation input.

34 XO O D Clock Crystal oscillation output.

35 DV

36 VDT7 O D VSTEM A/V MPEG data output 7.

37 VTD6 O D VSTEM A/V MPEG data output 6.

38 DV

39 VDT5 O D VSTEM A/V MPEG data output 5.

40 VDT4 O D VSTEM A/V MPEG data output 4.

41 VDT3 O D VSTEM A/V MPEG data output 3.

42 VDT2 O D VSTEM A/V MPEG data output 2.

43 VDT1 O D VSTEM A/V MPEG data output 1.

44 VDT0 O D VSTEM A/V MPEG data output 0.

45 HDRQ I D VSTEM A/V MPEG data Request input. *

46 XHAC O D VSTEM A/V Data Valid output.

47 VEFG O D VSTEM A/V ECC Error-sector Flag output. (L: error sector)

48 XSHD O D VSTEM A/V DVD Sector Head Flag output.

49 DCK O D VSTEM A/V Data Strobe output.

50 DRVIRQ O D VSTEM Command Interrupt Request output for Host. (L: interruption is demanded)

51 DRVRST I D VSTEM Command Drive H/W Reset input. (L: reset) * *

52 DV

53 DV

54 DRVTX O D VSTEM Command Transmitting serial data output to Host.

55 DRVRX I D VSTEM Command Reception serial data input from Host.

56 DRVCLK I D VSTEM Command Clock input from Host. *

57 DRVRDY O D VSTEM Command Drive Ready signal output. (L: ready)

58 C2PO O D Audio I/F CD-DSP C2 Pointer output.

59 DADT O D Audio I/F Audio serial data output.

60 DOTX O D Audio I/F Digital audio output.

61 LRCK O D Audio I/F L/R Clock output.

62 BCK O D Audio I/F Audio Bit Clock output.

63 EXVCO I D TEST/Monitor External Channel clock input.

64 EXPLDT I D TEST/Monitor External RF data input. (Logic level)

65 CSL O D ASP I/F SIO for RF signal processing LSI control. Latch signal output.

66 SI I D ASP I/F SIO for RF signal processing LSI control. Serial data input.

67 SO O D ASP I/F SIO for RF signal processing LSI control. Serial data output.

68 SCLKH O D ASP I/F SIO for RF signal processing LSI control. Serial clock output.

69 RFOKGH I D ASP I/F RF O.K. Signal input. *

70 HFD I D ASP I/F RF lack Signal input. *

71 MIRRORH I D ASP I/F Mirror detected signal input.(H: Mirror detected) *

72 DTC I D ASP I/F Track cross signal input. (Logic level input) *

73 AV

74 ATC I A Data PLL Track Cross signal input. (Analog level input)

75 HF I A Data PLL RF signal input.

76 TLC0 O A Data PLL Asymmetry Charge-pump output 0.

77 TLC1 O A Data PLL Asymmetry Charge-pump output 1

78 IREF I A Data PLL Reference current setting terminal for Asymmetry Circuit.

79 AV

80 JMREF I A Data PLL Reference current setting terminal for Jitter Monitor

81 JMOUT O A Data PLL Jitter Monitor output.

82 CHG I A Data PLL Reference current setting terminal for data PLL.

83 VFBC I A Data PLL VCO offset frequency setting terminal for data PLL.

84 AV

85 VCOI I A Data PLL VCO Control voltage input terminal for data PLL.

86 LPF1 O A Data PLL VCO Loop-filter connection terminal 1 for data PLL.

87 LPF2 O A Data PLL VCO Loop-filter connection terminal 2 for data PLL

88 RC I A Data PLL VCO gain setting terminal for data PLL.

89 AV

90 AV

91 AD0 I A ADC AD0 Input.

18 P VDD & GND Digital 1.8V Power. (Internal logic system power)

SS

SS

DD

18 P VDD & GND Digital 1.8V power for Internal logic system.

DD

33 P VDD & GND Digital 3.3V Power for I/O.

SS

DD33 P VDD & GND Analog 3.3V Power.

DD18 P VDD & GND Analog 1.8V Power.

SS

SS

PV

PV

PV

PV

PV

DD

& GND Digital Ground.

DD

& GND Digital Ground.

DD

& GND Analog Ground.

DD

& GND Analog Ground.

DD

& GND Analog Ground.

31

Page 32

S-301

No. Terminal Name I/O A/D Classification Function PU PD SMT

92 AD1 I A ADC AD1 Input.

93 AD2 I A ADC AD2 Input.

DD

94 AV

95 AD3 I A ADC AD3 Input.

96 AD4 I A ADC AD4 Input.

97 AD5 I A ADC AD5 Input.

98 AD6 I A ADC AD6 Input.

99 AD7 I A ADC AD7 Input.

100 AD8 I A ADC AD8 Input.

101 AD9 I A ADC AD9 Input.

102 VREFH I/O A ADC Max Reference Voltage input for ADC.

103 VREFL I/O A ADC Min Reference Voltage input for ADC.

104 AV

105 AV

106 DA0 (TSCON) O A DAC DA0 output. (Track Servo output)

107 DA1 (SLED) O A DAC DA1 output. (Sled Servo output)

108 DA2 (FSCON) O A DAC DA2 output. (Forcus Servo output)

109 DA3 (SLED2_

110 AV

111 FG I D SPM FG signal input. *

112 SPWM1 O D SPM Spindle motor PWM output 1.

113 SPWM2 O D SPM Spindle motor PWM output 2.

114 GPWM0 O D General PWM Multi-purpose PWM output 0.

115 GPWM1 O D General PWM Multi-purpose PWM output 1.

116 GPWM2 O D General PWM Multi-purpose PWM output 2.

117 GPWM3 O D General PWM Multi-purpose PWM output 3.

118 GPWM4 O D General PWM Multi-purpose PWM output 4.

119 GPWM5 O D General PWM Multi-purpose PWM output 5.

120 XLCAS O D DRAM I/F DRAM LCAS output. (Low-Byte row address strobe output)

121 XUCAS O D DRAM I/F DRAM UCAS output. (Upper-Byte row address strobe output)

122 XMOE O D DRAM I/F DRAM output enable.

123 RA11 O D DRAM I/F DRAM address output terminal 11.

124 RA10 O D DRAM I/F DRAM address output terminal 10.

125 DV

126 RA9 O D DRAM I/F DRAM address output terminal 9.

127 RA8 O D DRAM I/F DRAM address output terminal 8.

128 RA7 O D DRAM I/F DRAM address output terminal 7.

129 RA6 O D DRAM I/F DRAM address output terminal 6.

130 RA5 O D DRAM I/F DRAM address output terminal 5.

131 DV

132 RA4 O D DRAM I/F DRAM address output terminal 4.

133 RA3 O D DRAM I/F DRAM address output terminal 3.

134 RA2 O D DRAM I/F DRAM address output terminal 2.

135 RA1 O D DRAM I/F DRAM address output terminal 1.

136 DV

137 RA0 O D DRAM I/F DRAM address output terminal 0.

138 XRAS O D DRAM I/F DRAM RAS output. (Column address strobe output)

139 XMWR O D DRAM I/F DRAM Write enable.

140 RD7 I/O D DRAM I/F DRAM data input/output terminal 7. *

141 RD6 I/O D DRAM I/F DRAM data input/output terminal 6. *

142 DV

143 RD5 I/O D DRAM I/F DRAM data input/output terminal 5. *