Page 1

Ver. 2

Please refer to the

MODIFICATION NOTICE.

SERVICE MANUAL

MODEL JP E3 E2 EK E2A E1C E1K EUT

S-102

333

DVD HOME ENTERTAINMENT SYSTEM

HOME ENTERTAINMENT SYSTEM (S-102) consists of DVD SURROUND RECEIVER

(ADV-S102), SUB WOOFER (DSW-S102) and SPEAKER SYSTEM (SC-S102)

注 意

サービスをおこなう前に、このサービスマニュアルを

必ずお読みください。本機は、火災、感電、けがなど

に対する安全性を確保するために、さまざまな配慮を

おこなっており、また法的には「電気用品安全法」に

もとづき、所定の許可を得て製造されております。

従ってサービスをおこなう際は、これらの安全性が維

持されるよう、このサービスマニュアルに記載されて

いる注意事項を必ずお守りください。

●

For purposes of improvement, specifications and

design are subject to change without notice.

●

Please use this service manual with referring to the

operating instructions without fail.

●

Some illustrations using in this service manual are

slightly different from the actual set.

Denon Brand Company, D&M Holdings lnc.

●

本機の仕様は性能改良のため、予告なく変更すること

があります。

●

補修用性能部品の保有期間は、製造打切後 8 年です。

●

修理の際は、必ず取扱説明書を参照の上、作業を行っ

てください。

●

本文中に使用しているイラストは、説明の都合上現物

と多少異なる場合があります。

TOKYO, JAPAN

X0341 V.02 DE/CDM 0710

Page 2

SAFETY PRECAUTIONS

The following check should be performed for the continued protection of the customer and service technician.

LEAKAGE CURRENT CHECK

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis

resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the power

cord is less than 460 kohms, the unit is defective.

LASER RADIATION

Do not stare into beam or view directly with optical instruments, class 3A laser product.

S-102

CAUTION

Please heed the points listed below during servicing and inspection.

◎ Heed the cautions!

Spots requiring particular attention when servicing, such as

the cabinet, parts, chassis, etc., have cautions indicated on

labels or seals. Be sure to heed these cautions and the cautions indicated in the handling instructions.

◎ Caution concerning electric shock!

(1) An AC voltage is impressed on this set, so touching inter-

nal metal parts when the set is energized could cause

electric shock. Take care to avoid electric shock, by for example using an isolating transformer and gloves when

servicing while the set is energized, unplugging the power

cord when replacing parts, etc.

(2)There are high voltage parts inside. Handle with extra care

when the set is energized.

◎

Caution concerning disassembly and assembly!

Though great care is taken when manufacturing parts from

sheet metal, there may in some rare cases be burrs on the

edges of parts which could cause injury if fingers are moved

across them. Use gloves to protect your hands.

◎ Only use designated parts!

The set's parts have specific safety properties (fire resistance, voltage resistance, etc.). For replacement parts, be

sure to use parts which have the same properties. In particular, for the important safety parts that are marked ! on wiring

diagrams and parts lists, be sure to use the designated parts.

◎ Be sure to mount parts and arrange the

wires as they were originally!

For safety reasons, some parts use tape, tubes or other insulating materials, and some parts are mounted away from the

surface of printed circuit boards. Care is also taken with the

positions of the wires inside and clamps are used to keep

wires away from heating and high voltage parts, so be sure to

set everything back as it was originally.

◎ Inspect for safety after servicing!

Check that all screws, parts and wires removed or di sconnected for servicing have been put back in their original positions, inspect that no parts around the area that has been

serviced have been negatively affected, conduct an insulation

check on the external metal connectors and between the

blades of the power plug, and otherwise check that safety is

ensured.

(Insulation check procedure)

Unplug the power cord from the power outlet, disconnect the

antenna, plugs, etc., and turn the power switch on. Using a

500V insulation resistance tester, check that the insulation resistance between the terminals of the power plug and the externally exposed metal parts (antenna terminal, h eadphones

terminal, microphone terminal, input terminal, etc.) is 1MΩ or

greater. If it is less, the set must be inspected and repaired.

CAUTION

Many of the electric and structural parts used in the set have

special safety properties. In most cases these properties are

difficult to distinguish by sigh t, and using replacement parts

with higher ratings (rated power and withstand voltage) does

not necessarily guarantee that safety performance will be preserved. Parts with safety properties are indicated as shown

below on the wiring diagrams and parts lists is this service

manual. Be sure to replace them with parts with the designated part number.

(1) Schematic diagrams ... Indicated by the ! mark.

(2) Parts lists ... Indicated by the ! mark.

Concerning important safety parts

Using parts other than the designated parts

could result in electric shock, fires or other

dangerous situations.

注 意

サービス、点検時にはつぎのことにご注意願います。

◎注意事項をお守りください!

サービスのとき特に注意を必要とする個所についてはキャ

ビネット、部品、シャーシなどにラベルや捺印で注意事項を

表示しています。これらの注意書きおよび取扱説明書などの

注意事項を必ずお守りください。

◎感電に注意!

(1) このセットは、交流電圧が印加されていますので通電時

に内部金属部に触れると感電することがあります。従っ

て通電サービス時には、絶縁トランスの使用や手袋の着

用、部品交換には、電源プラグを抜くなどして感電にご

注意ください。

(2) 内部には高電圧の部分がありますので、通電時の取扱に

は十分ご注意ください。

◎分解、組み立て作業時のご注意!

板金部品の端面の『バリ』は、部品製造時に充分管理をして

おりますが、板金端面は鋭利となっている箇所が有りますの

で、部品端面に触れたまま指を動かすとまれに怪我をする場

合がありますので十分注意して作業して下さい。手の保護の

ために手袋を着用してください。

◎指定部品の使用!

セットの部品は難燃性や耐電圧など安全上の特性を持った

ものとなっています。従って交換部品は、使用されていたも

のと同じ特性の部品を使用してください。特に配線図、部品

表に!印で指定されている安全上重要な部品は必ず指定の

ものをご使用ください。

◎部品の取付けや配線の引きまわしは、

元どおりに!

安全上、テープやチューブなどの絶縁材料を使用したり、プ

リント基板から浮かして取付けた部品があります。また内部

配線は引きまわしやクランパーによって発熱部品や高圧部

品に接近しないように配慮されていますので、これらは必ず

元どおりにしてください。

◎サービス後は安全点検を!

サービスのために取り外したねじ、部品、配線などが元どお

りになっているか、またサービスした個所の周辺を劣化させ

てしまったところがないかなどを点検し、外部金属端子部

と、電源プラグの刃の間の絶縁チェックをおこなうなど、安

全性が確保されていることを確認してください。

(絶縁チェックの方法)

電源コンセントから電源プラグを抜き、アンテナやプラグな

どを外し、電源スイッチを入れます。500V 絶縁抵抗計を用

いて、電源プラグのそれぞれの端子と外部露出金属部[アン

テナ端子、ヘッドホン端子マイク端子、入力端子など]との

間で、絶縁抵抗値が1 MΩ 以上であること、この値以下の

ときはセットの点検修理が必要です。

注 意

本機に使用している多くの電気部品、および機構部品は安全

上、特別な特性を持っています。この特性はほとんどの場合、

外観では判別つきにくく、またもとの部品より高い定格(定

格電力、耐圧)を持ったものを使用しても安全性が維持され

るとは、限りません。安全上の特性を持った部品は、この

サービスマニュアルの配線図、部品表につぎのように表示し

ていますので必ず指定されている部品番号のものを使用願

います。

(1) 配線図…!マークで表示しています。

(2) 部品表…!マークで表示しています。

安全上重要な部品について

指定された部品と異なるものを使用した場合に

は、感電、火災などの危険を生じる恐れがあり

ます。

2

Page 3

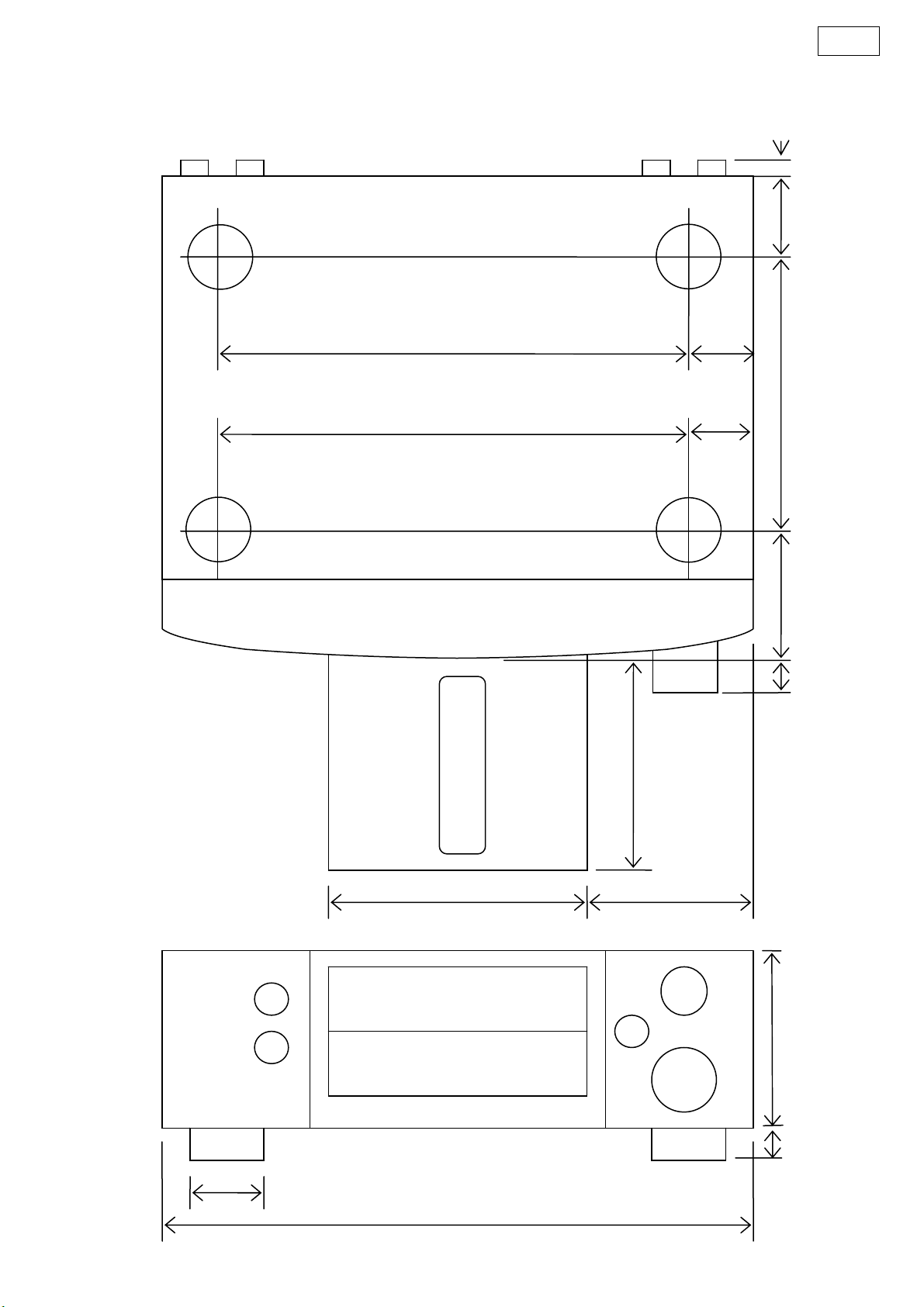

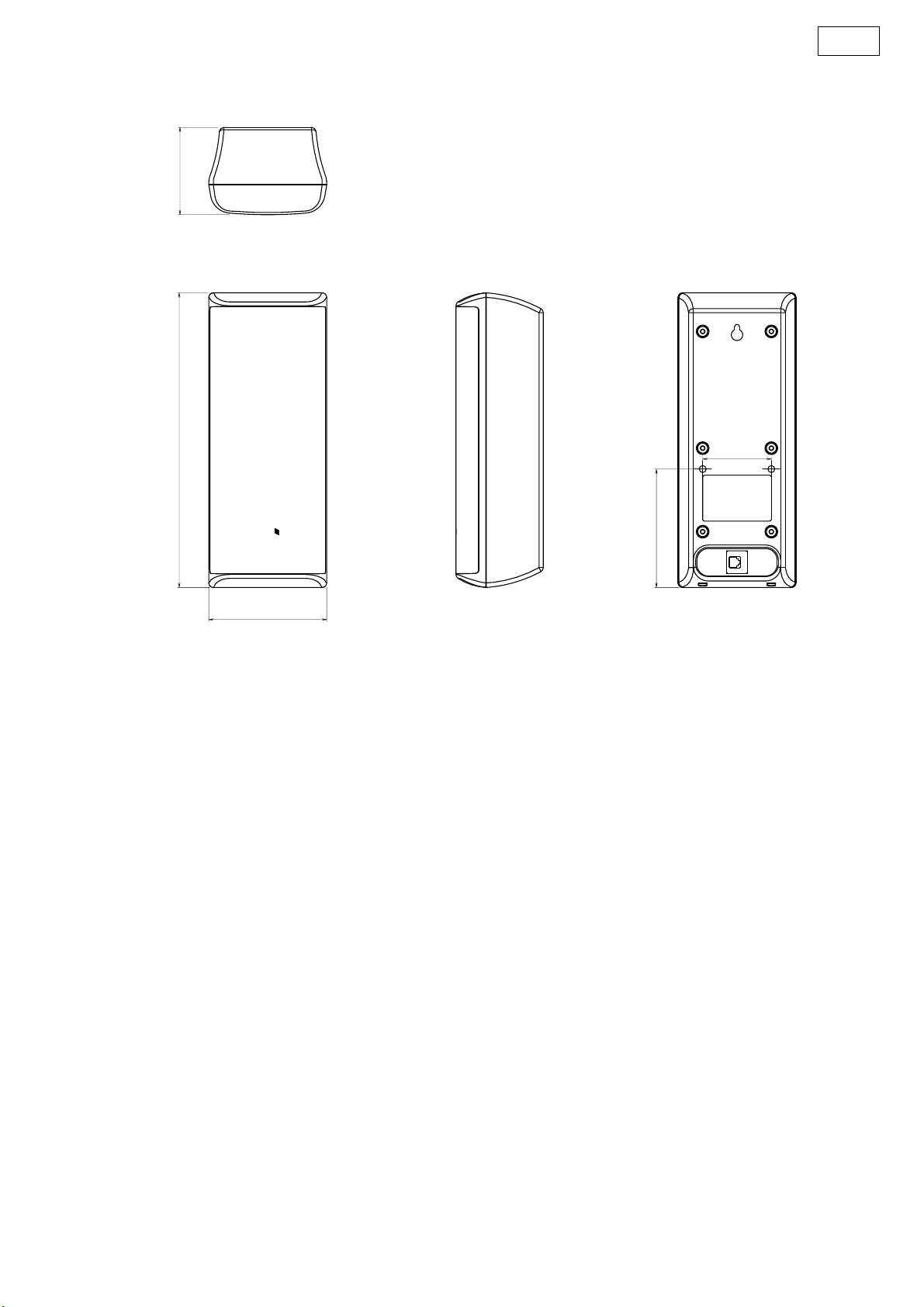

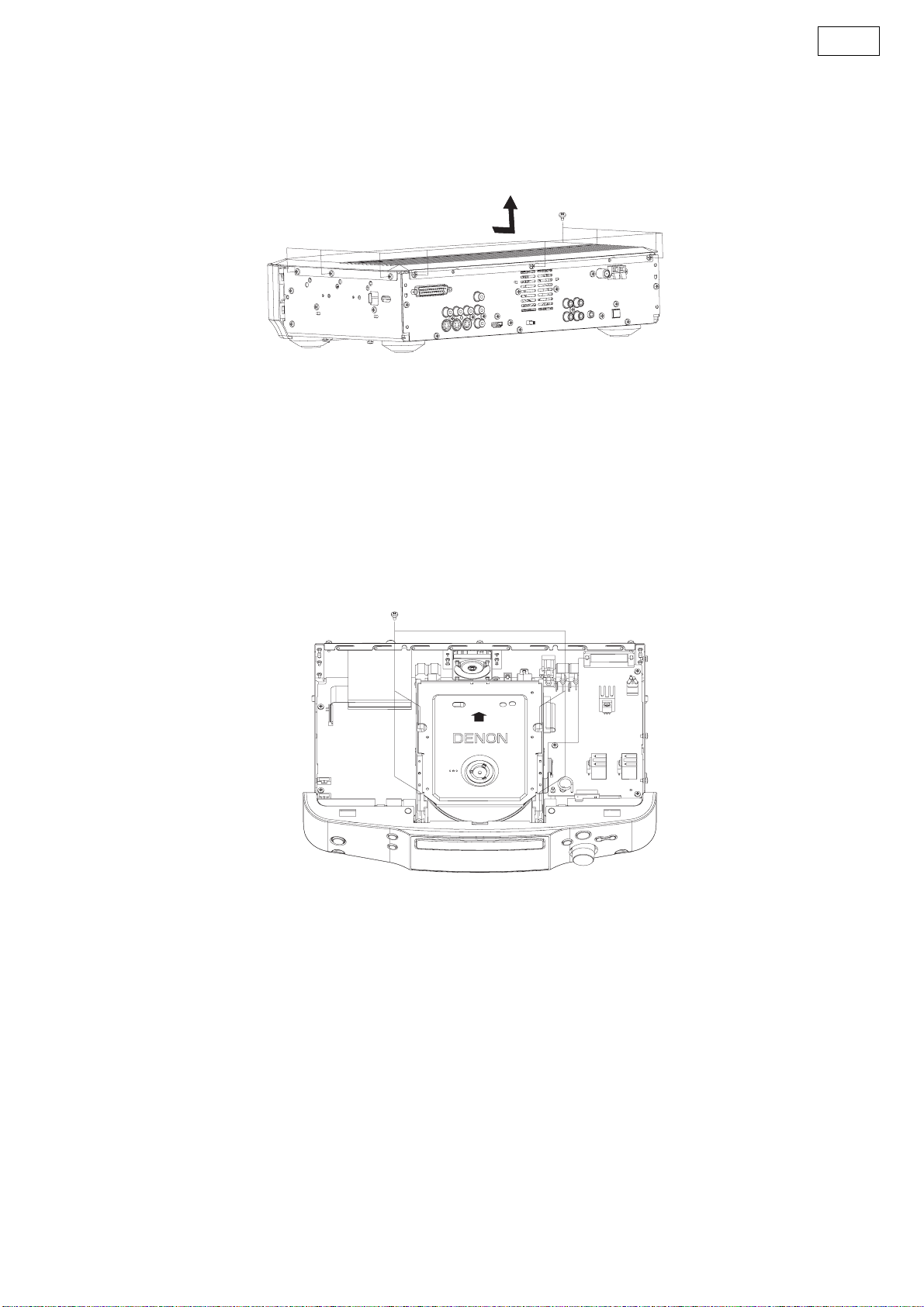

DIMENSION

ADV-S102

S-102

0.5 max.

294

294

43

43

152

58

1.5 45

149

45

135

380

122.5

83

10

3

Page 4

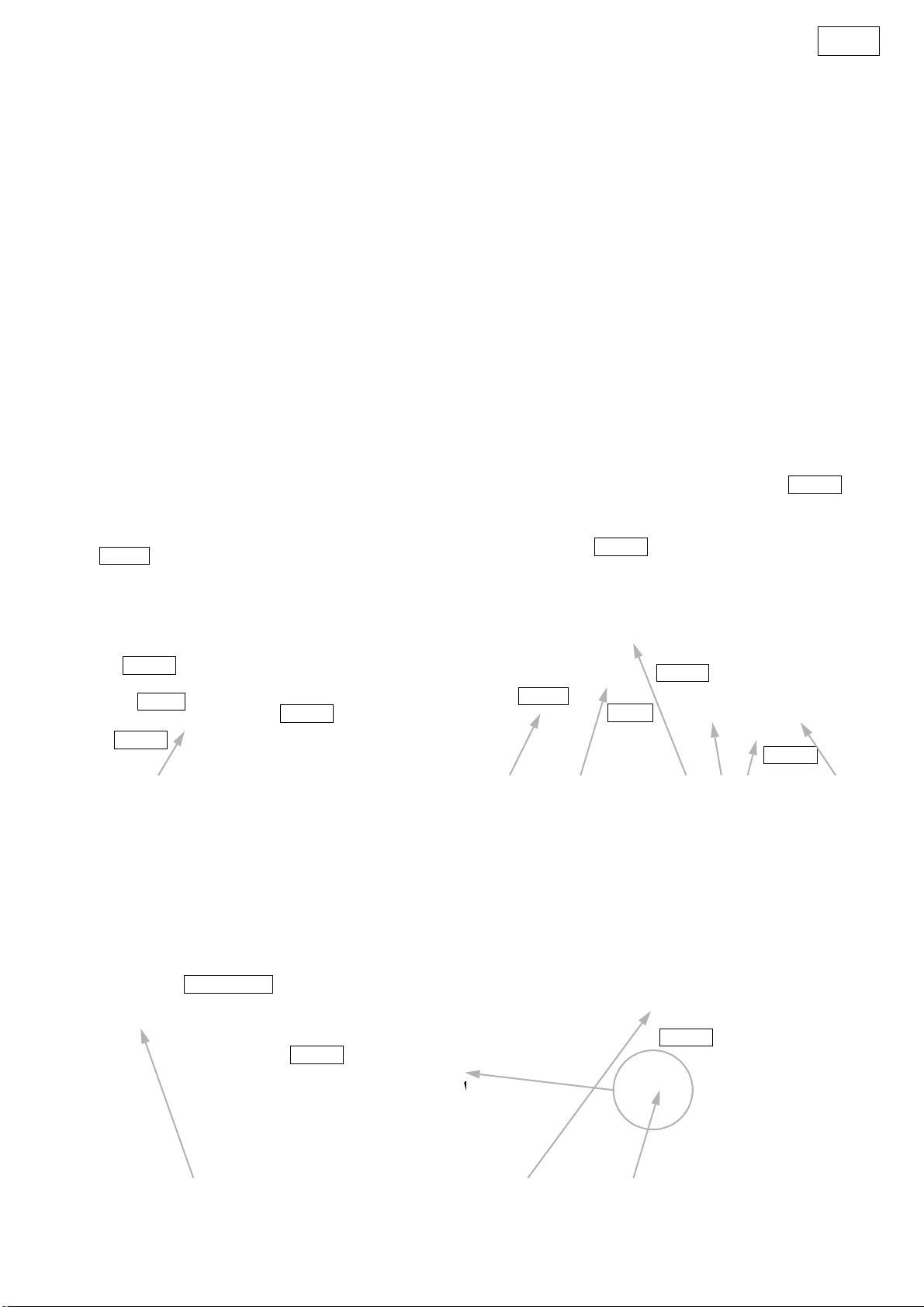

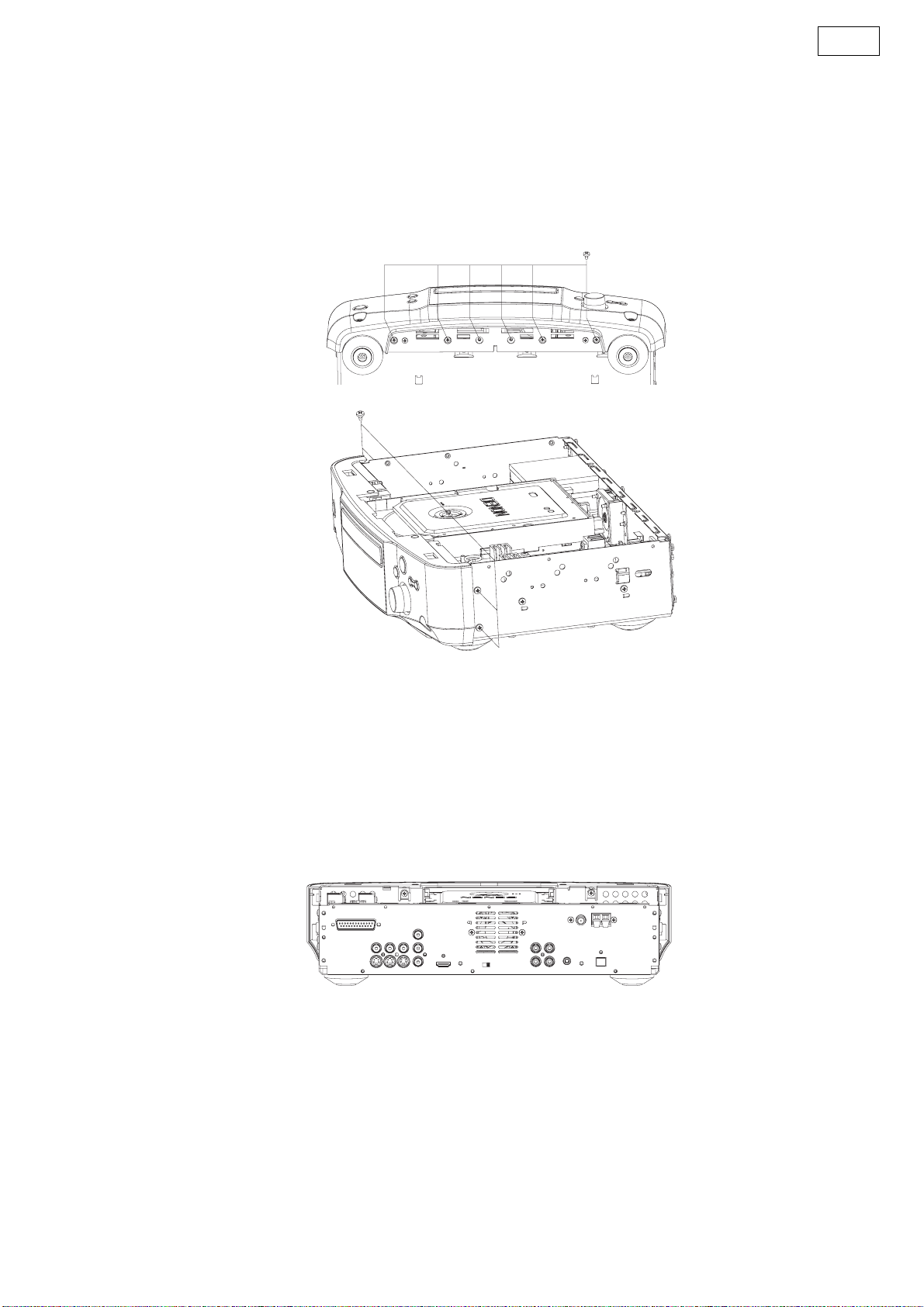

DSW-S102

336.541

S-102

0.5

167.5

213

287 6556

212

140

141

4

Page 5

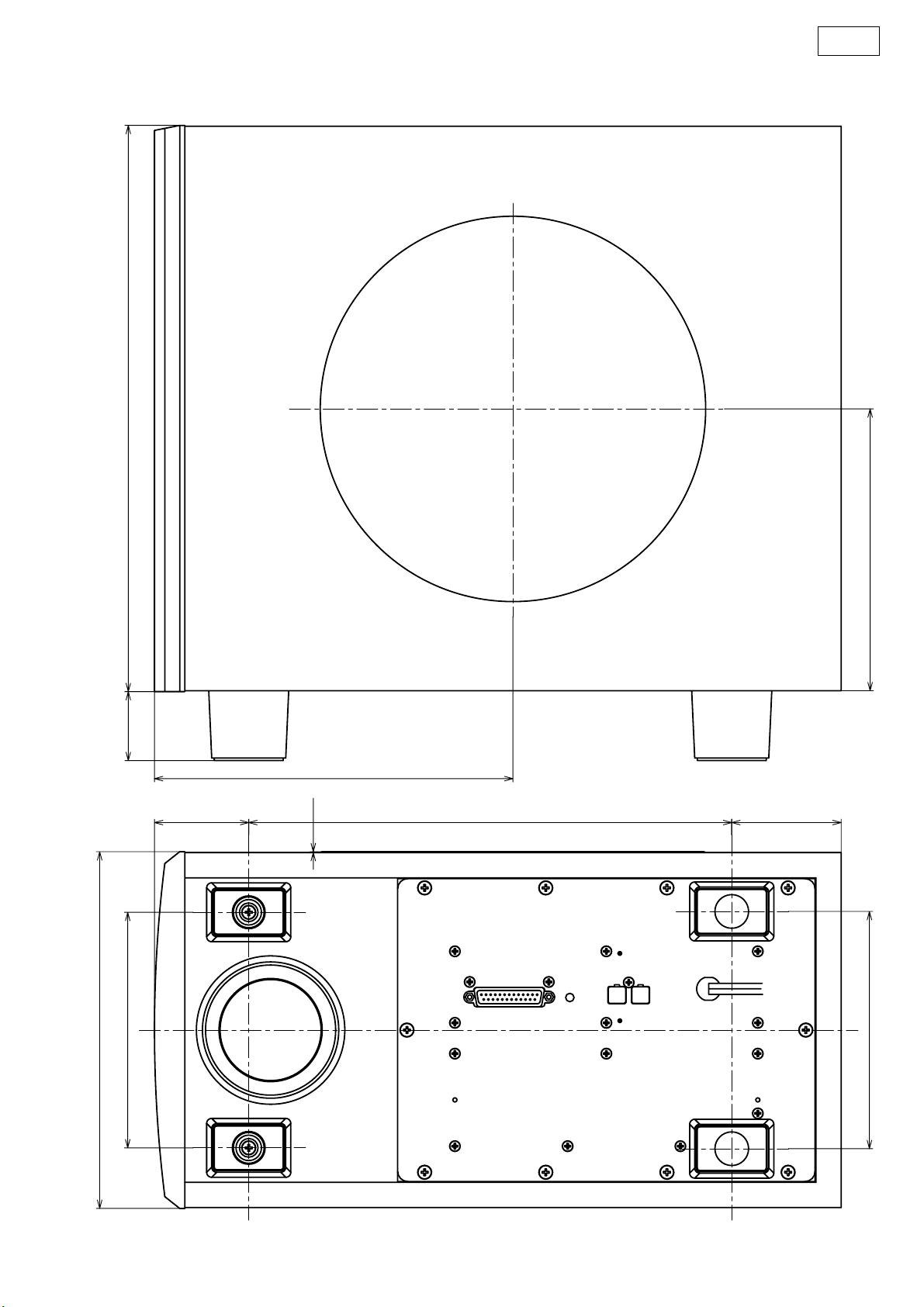

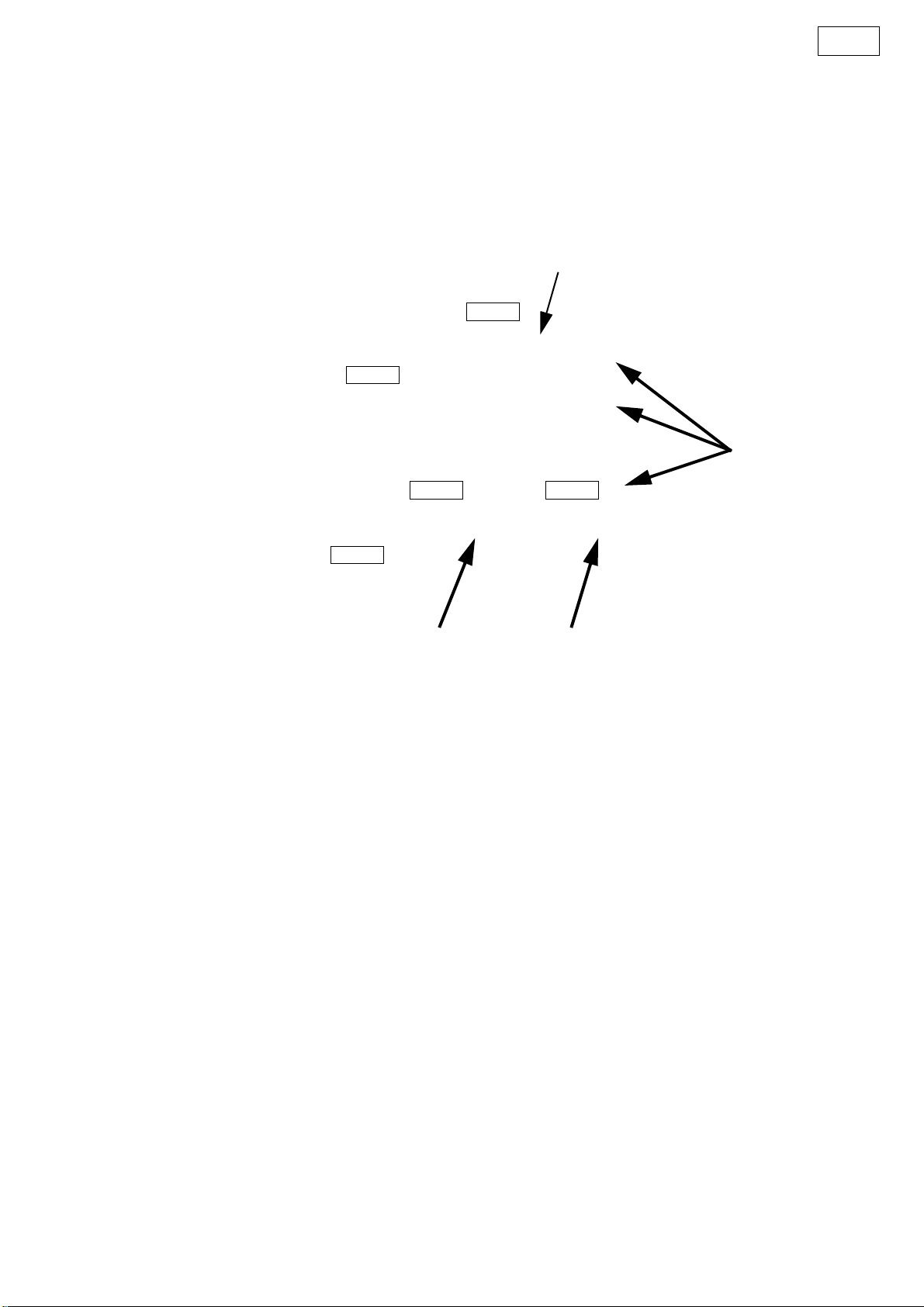

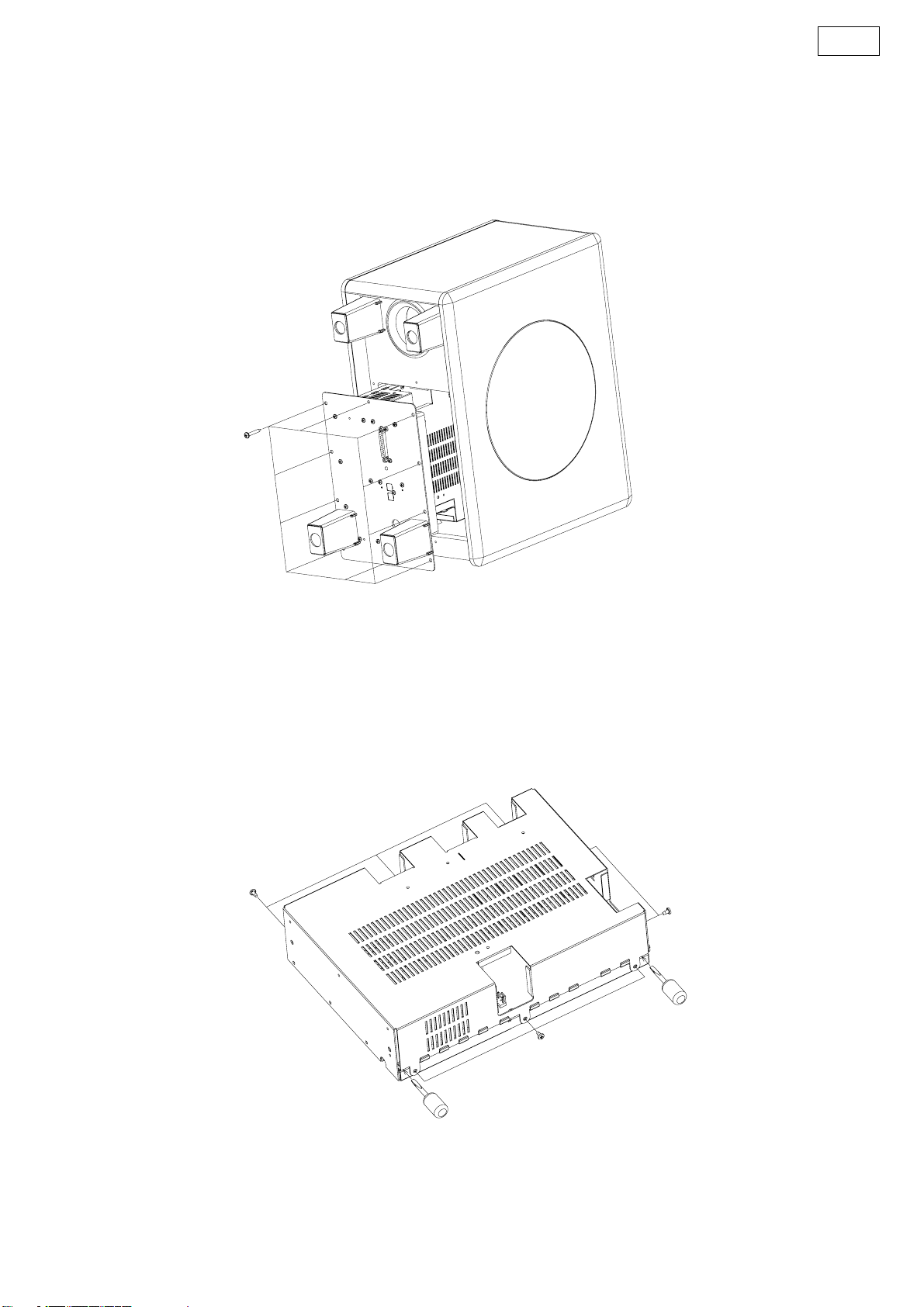

SC-S102

S-102

76.3

257.5

60

103.5

103

5

Page 6

S-102

WIRE ARRANGEMENT

If wire bundles are untied or moved to perform adjustment or

parts replacement etc., be sure to rearrange them neatly as

they were originally bundled or placed afterward.

Otherwise, incorrect arrangement can be a cause of noise

generation.

1. ADV-S102

① Fasten the CW051 5P connector cord to the front chassis

with a clamp band.

② Fasten the CW052 5P connector cord to the front chassis

with a clamp band.

③ Fasten the CX31 3P connector cord to the circuit board with

a style pin.

④ Fasten the CW52 5P connector cord to the circuit board with

a style pin.

⑤ Press the CX211 FFC in with a style pin.

⑥ Twist the CX021 2P connector cord several times and

fasten it twice with a style pin.

ワイヤー整形図

調整や部品の交換等により、ワイヤー類の結束をはずしたり移

動させた場合には、それらの作業が完了した時点でワイヤーの

整形をおこなってください。正しく整形されてないとノイズ発

生の原因となることがあります。

1. ADV-S102

① CW051 5P コネクターコードをフロントシャーシにクラン

プバンドで結束する。

② CW052 5P コネクターコードをフロントシャーシにクラン

プバンドで結束する。

③ CX031 3P コネクターコードをスタイルピンで基板に固定

する。

④ CW052 5P コネクターコードをスタイルピンで基板に固定

する。

⑤ CX211 の FFC をスタイルピンで押さえこむ。

⑥ CX021 2P コネクターコードを数回捩ってスタイルピンで

2 箇所を固定する。

CX021

CX151

CX052

CX051

CX051

CX061

①⑤④③②

⑥ Fasten the CX061 6P connector with a cord holder.

⑦ Float the CX061 6P connector code to the circuit board with

a style pin and fasten.

Ferrite Cramp

CX301

CX171

CX211

CX031

CW052

⑥

⑥ CX061 6P コネクターコードをコードホルダーで固定す

る。

⑦ CX061 6P コネクターコードをスタイルピンで基板より浮

かせて固定する。

⑥

CX061

⑦⑦⑧

6

CX061

Page 7

S-102

2. DSW-S102

① Fasten the CX041 4P connector cord to the chassis with a

clamp band.

② Fasten the CX041 4P connector cord and CX081 8P con-

nector cord to the chassis with a clamp band.

③ Fasten with a clamp band.

④ Fasten the CX021 2P connector cord to the chassis with a

clamp band.

CX151

CX041 CX081

2. DSW-S102

① CX041 4P コネクターコードをクランプバンドでシャーシ

に固定。

② CX041 4P コネクターコードと CX0818P コネクターコー

ドをクランプバンドでシャーシに固定。

③ クランプバンドで結束。

④ CX021 2P コネクターコードをクランプバンドでシャーシ

に固定。

④

CX021

③

CX022

①②

7

Page 8

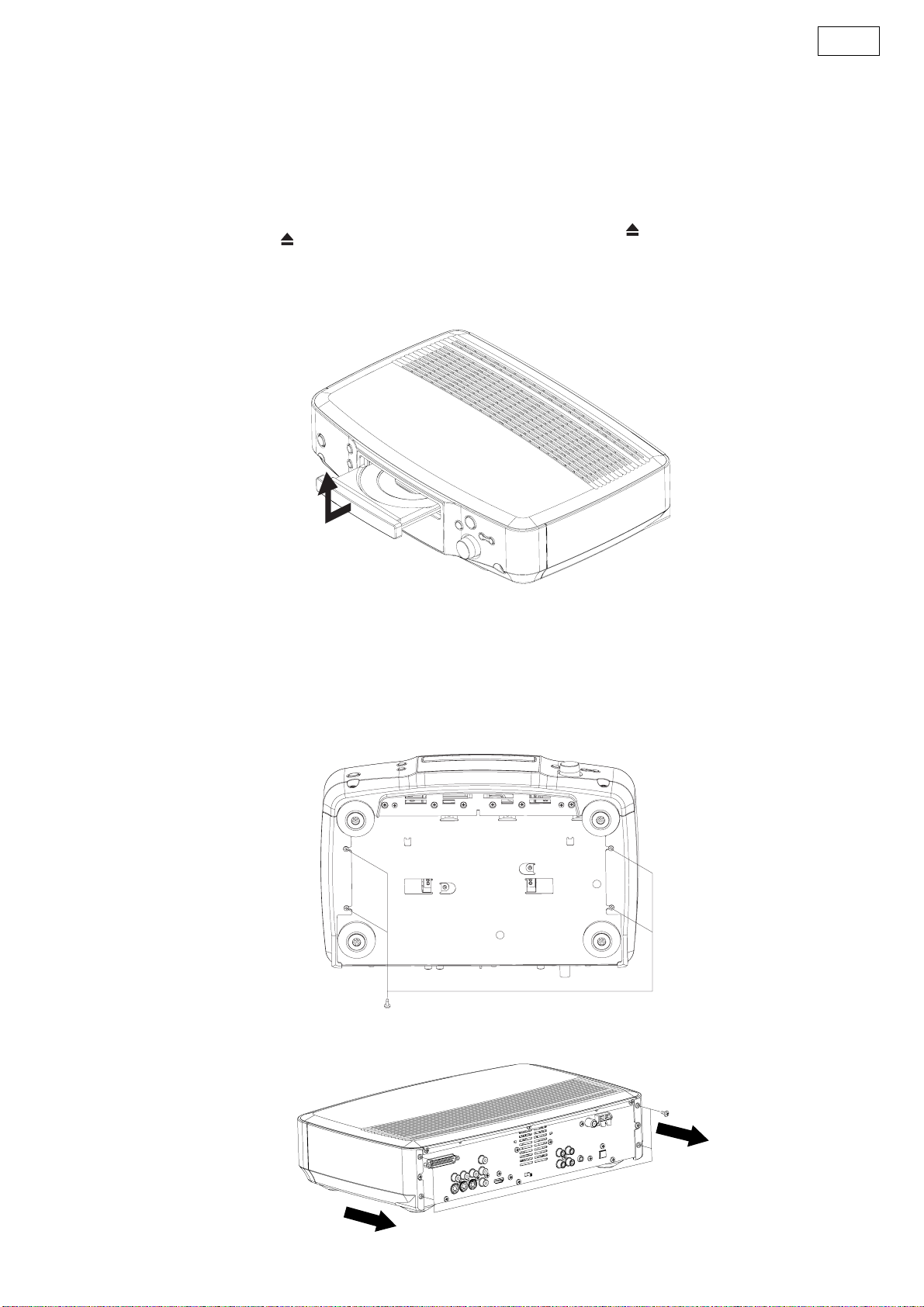

S-102

DISASSEMBLY

(Follow the procedure below in reverse order when

reassembling.)

● ADV-S102

1. Loader Panel

(1) Switch on, and press [ (OPEN/CLOSE)] button

to open the Disc tray.

(2) Detach the Loader Panel by lifting.

各部のはずしかた

(組み立てるときは、逆の順序でおこなってください。)

● ADV-S102

1. ローダーパネルのはずしかた

(1) 電源を入れ「 (OPEN/CLOSE)」ボタンを押して、

ディスクトレイを開きます。

(2) ローダーパネルを持ち上げてはずします。

2. Side Panel

(1) Remove 4 bottom screws.

(2) Remove 4 rear screws, then detach Side Panel.

2. サイドパネルのはずしかた

(1) 底面よりネジを 4 本はずします。

(2) 裏面よりネジを 4 本はずし、サイドパネルを矢印

の方向へはずします。

8

Page 9

S-102

3. Top Cover

(1) Remove 9 screws, then detach Top Cover.

4. DVD Mecha. Unit

(1) Remove 4 screws fixing the DVD Mecha.

(2) Detach the DVD Mecha. to the arrow direction.

(3) Lift the DVD Mecha. and disconnect FFC and con-

nectors.

3. トップカバーのはずしかた

(1) トップカバーを止めているネジ 9 本をはずし、

トップカバーを矢印の方向へはずします。

4. DVD メカユニットのはずしかた

(1) メカユニットを止めているネジ 4 本をはずしま

す。

(2) メカユニットを矢印の方向にはずします。

(3) DVD メカユニットを持ち上げ、コネクタと FFC

をはずします。

9

Page 10

S-102

5. Front Panel Ass’y

(1) Remove 6 Front panel screws, then detach P.W.B.

and chassis.

(2) Remove 4 Front panel side screws, then detach the

Front Panel Ass’y.

5. フロントパネルのはずしかた

(1) フロントパネルからの基板とシャーシを止めてい

るネジを 6 本はずします。

(2) フロントパネル側面を止めているネジ 4 本(左右

各 2 本)をはずし、フロントパネルをはずしま

す。

6. Back Panel Ass’y

(1) Remove each terminal screws, Back Panel screws

and Chassis screws, then detach the Back Panel.

6. バックパネルのはずしかた

(1) 各端子を止めているネジおよびバックパネルと

シャーシを止めているネジをはずし、バックパネ

ルをはずします。

10

Page 11

S-102

● DSW-S102

1. Rear panel

(1) Remove 10 screws 101 on the bottom side.

(2) Detach the Rear panel.

101

● DSW-S102

1. Rearpanel

(1) 底面側から 101 のねじ 10 本をはずします。

(2) Rearpanelをはずします。

2. SHIELD COVER

(1) Remove 8 screws 103 on the Side.

(2) Lift the shield cover using a flat-headed screwdriver and

remove it. When doing this, be careful not to deform the

main bracket's hook.

103

2. SHIELDCOVER

(1) 側面側から 103 のねじ 8 本をはずします。

(2) マイナスドライバーでシールドカバーを持ち上げては

ずします。このとき、メインブラケットのつめを変形

させないように注意してください。

103

103

11

Page 12

S-102

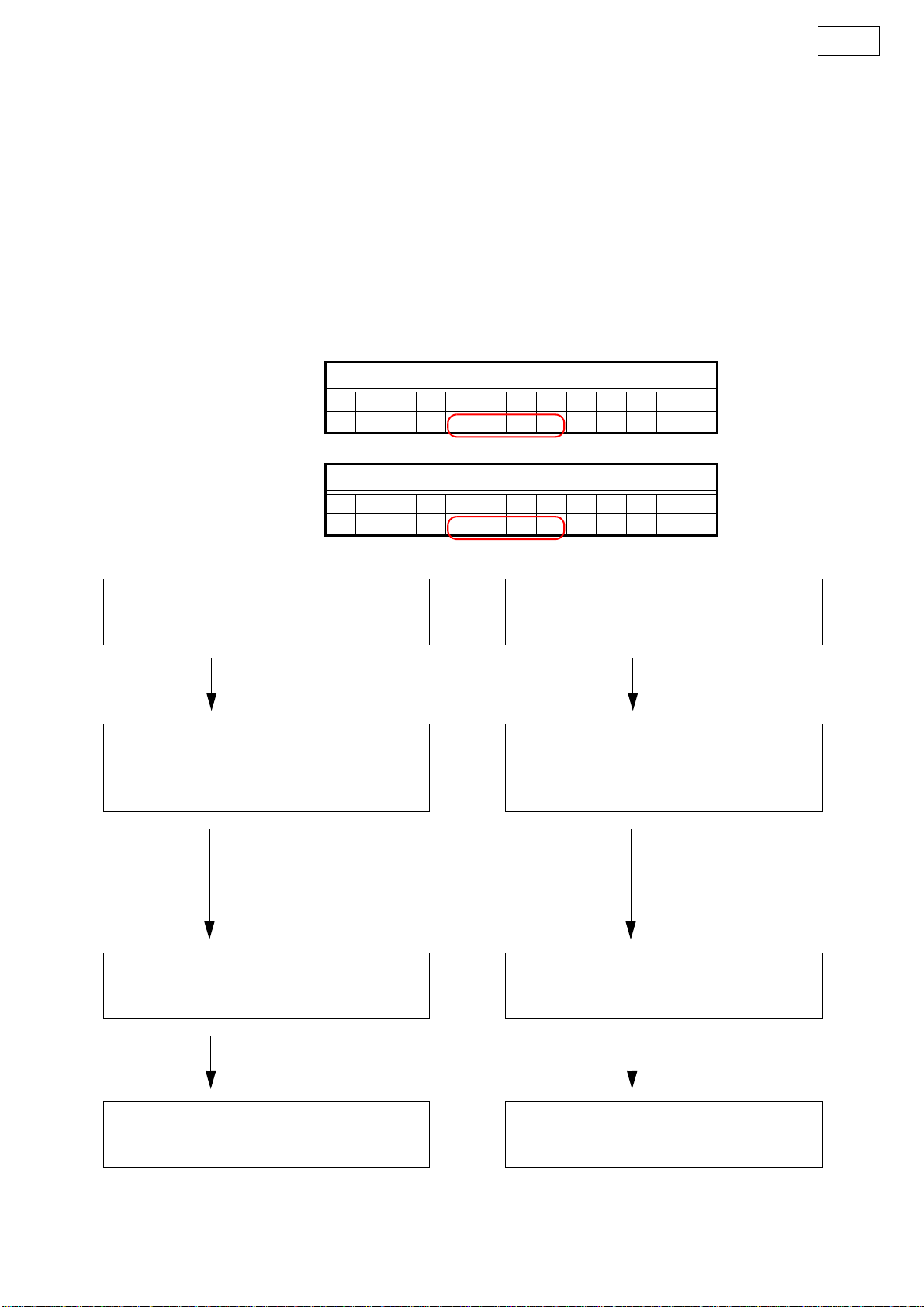

DIAGNOSTICS OF OPTICAL PICKUP

AND REPLACING TRAVERSE UNIT

Make failure diagnostics of the Optical Pickup as follows.

If the laser drive current (Iop) becomes more than 1.5 times of

the initial value, the Optical Pickup should be replaced.

The laser drive current initial value is checked by "Iop checked

Method" of next page.

In case of replacing the Pickup, change the whole part of the

Traverse Unit.

No mechanical adjustment is necessary after the replacement.

レーザー駆動電流初期値 :

Laser drive current initial value:

DVD:

CD:

FLDisplay(Thedisplaypartof13digits)

12345678910111213

T22―mmmm―nnnn

FLDisplay(Thedisplaypartof13digits)

12345678910111213

T2 1 ―mmmm―nnnn

光ピックアップの故障診断とトラバース

ユニットの交換

次の順序で故障診断を行ってください。

レーザー駆動電流 Iop 値が初期値の 1.5 倍以上になっている

場合は光ピックアップ交換の目安となります。

レーザー駆動電流初期値は、次ページ "Iop 値の確認方法 " で

確認できます。

ピックアップ交換の場合は、トラバースユニット単位での交

換となります。メカの調整は不要です。

Disc no read, unsteady playback, etc.

Laser drive current (Iop) check

HF wave form check

(Refer to WAVE FORMS)

Present value exceeds the initial value by 1.5 times

Traverse Unit replacing

ディスクを読み込まない

スムーズに再生しない、等

レーザー駆動電流 Iop 値の確認

HF 波形の確認

(WAVEFORMS参照)

現在値が初期値の

1.5 倍になっている

トラバースユニット交換

Laser current (Iop) memorizing after replacement

交換後にレーザー電流値の記憶

12

Page 13

S-102

1. Iop checked Method

Select the laser ON/OFF (CD/DVD) mode of the test mode,

and check the lop value of DVD laser or CD laser.

(See page 13 for test mode.)

FLDisplay(Thedisplaypartof13digits)

12345678910111213

T2 L a s e r O n O f f

1.1. DVD laser current check

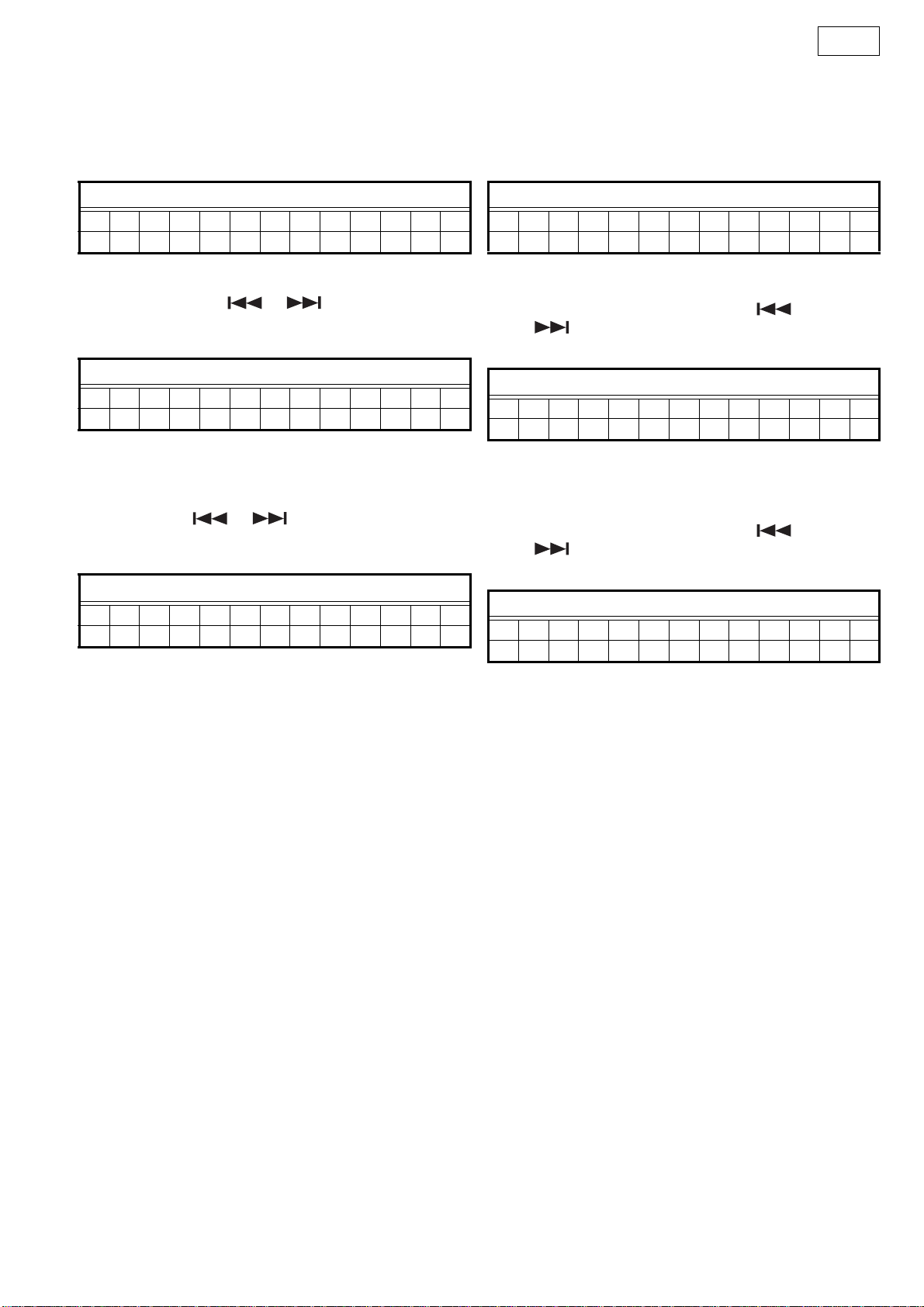

(1) Press the SKIP or button to display the la-

ser current value, and then select T22.

(2) Check the current value of Iop (nnnn).

FLDisplay(Thedisplaypartof13digits)

12345678910111213

T22―mmmm―nnnn

( − : Off, DVD laser, Initial value: mm.mm [mA],

Current value: nn.nn [mA])

1.2. CD Laser current check

(1) Press the or button to display the laser

current value, and then select T21.

(2) Check the current value of Iop (nnnn).

FLDisplay(Thedisplaypartof13digits)

12345678910111213

T2 1 ―mmmm―nnnn

( − : Off, CD laser, Initial value: mm.mm [mA],

Current value: nn.nn [mA])

1. Iop 値の確認方法

レーザー駆動電流を確認する場合は、テストモードのレー

ザー ON/OFF(CD/DVD) モードを選択して、DVD レーザー

または CD レーザーの lop 値を確認します。

(詳細は 13 ページ、テストモード参照)

FL 管の表示 (13 桁の表示部 )

12345678910111213

T2 L a s e r O n O f f

1.1. DVD レーザー電流確認

(1) レーザー電流値を表示する場合は、 ボタンまたは

ボタンを押し、T22 を選択します。

(2) 現在の lop 値 (nnnn) を確認します。

FL 管の表示 (13 桁の表示部 )

12345678910111213

T22―mmmm―nnnn

( −:消灯、DVD レーザー、初期値:mm.mm[mA],

現在値:nn.nn[mA])

1.2. CD レーザー電流確認

(1) レーザー電流値を表示する場合は、 ボタンまたは

ボタンを押し、T21 を選択します。

(2) 現在の lop 値 (nnnn) を確認します。

FL 管の表示 (13 桁の表示部 )

12345678910111213

T2 1 ―mmmm―nnnn

( −:消灯、CD レーザー、初期値:mm.mm[mA],

現在値:nn.nn[mA])

2. Note for Handling the Laser Pick-Up

The protection for the damage of laser diode.

If you want to change the optical device unit from any other

units, you must keep the following.

(1) It should be done at the desk already took measures the

static electricity in care of removing the OPU's (Optical

device unit) connector cable.

(2) Workers should be put on the "Earth Band".

(3) It should be done to add the solde r to the short land to

prevent the broken Laser diode before removing the 24P

FFC cable.

(4) Don't touch OPU's connector parts carelessly.

3. Replacement of the Laser Pick-up

(Traverse Unit)

Check the Iop (Laser drive current)

If the present Iop (current) value exceeds.+150% of the initial value, replace the Traverse unit (Laser Pick-up) with a

new one.

2. レーザーピックアップの取扱注意

レーザーダイオードの破壊防止。

光素子ユニットを交換するときは、以下を遵守してくださ

い。

(1) 光素子ユニットの接続ケーブルをはずすときは、静電対

策を行ったデスク上で作業してください。

(2) 作業者は、リストストラップを使用してください。

(3) レーザーダイオードの破壊防止のため、24PFFC ケーブ

ルをはずす前にランドを半田付けショートしてくださ

い。

(4) 光素子ユニットのコネクタ部に触れないでください。

3. レーザーピックアップ ( トラバースユニッ

ト ) の交換

Iop( レーザー駆動電流)をチェックします。

現在の Iop 値が初期値の 150%を越えている場合、トラバー

スユニット(レーザーピックアップ)を交換してください。

13

Page 14

S-102

4. Rewriting the default value of the laser

current

To rewrite the default value of the laser current, press the

button for at least 5 seconds while the CD or DVD laser

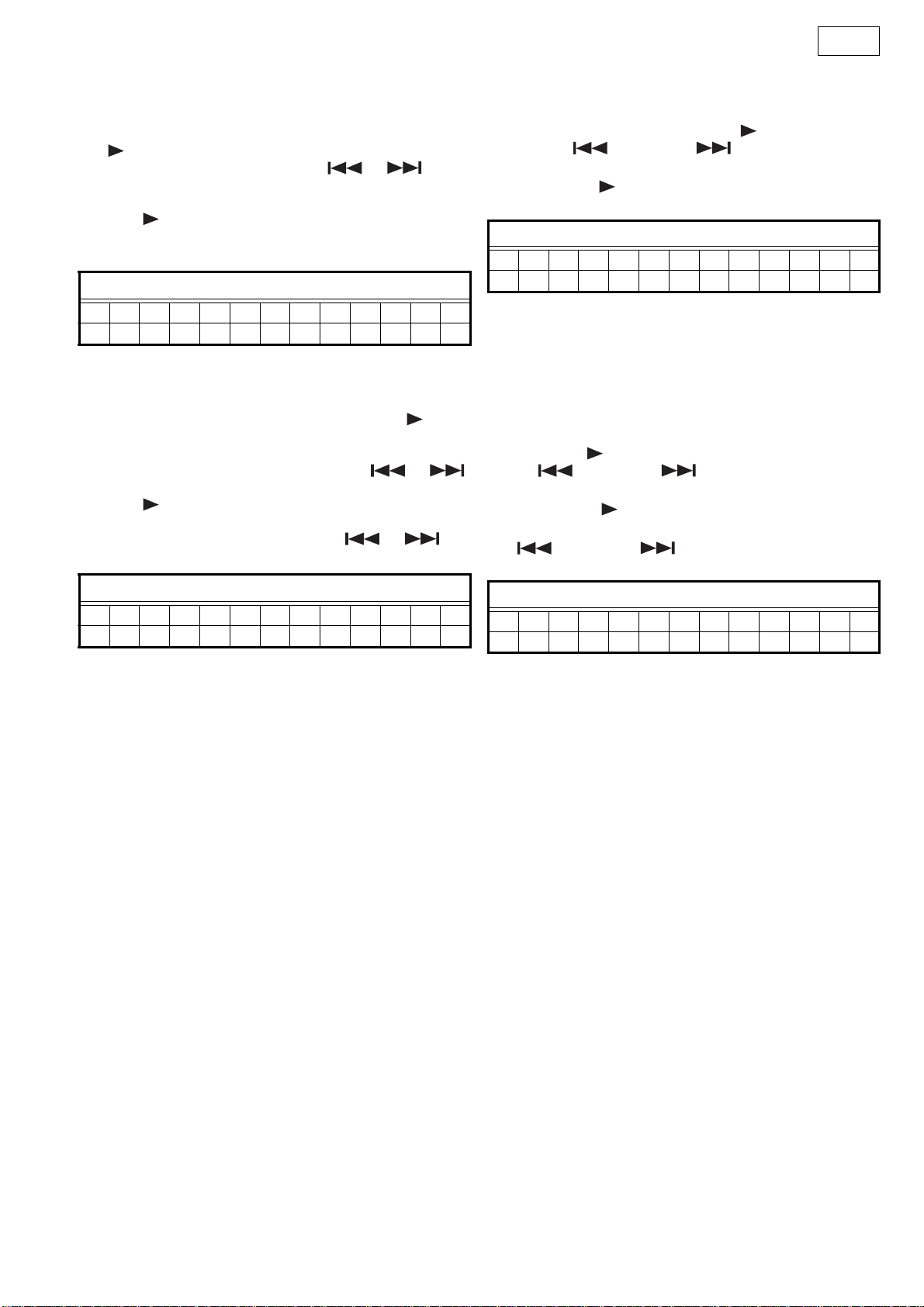

current is displayed, then press the or button

to select T23. (For details, see "Iop checked Method" on

page 22.)

If the button is pressed while T23 is displayed, the current value is displayed at "mmmm" and stored in the EEPROM.

FLDisplay(Thedisplaypartof13digits)

12345678910111213

T23 ―mmmm―――――

5. Resetting the accumulated laser on time

To clear the accumulated laser on time, press the button

while the accumulated laser on time is displayed (TB1, TB2

: For details, see "Test Mode" on page 22.) until " * " appears at the fourth position, then press the or

button to select TB3.

If the button is pressed while TB3 is displayed, the accumulated laser on time of CD and DVD is cleared.

When TB1 or TB2 is selected with the or button, "nnnnnnn" is displayed as 0 so you can check.

FLDisplay(Thedisplaypartof13digits)

12345678910111213

TBY―――nnnnnnn

( − : Off, Y:1: CD, 2: DVD, nnnnnnn: Hour [h])

4. レーザー電流初期値の書き換え方法

レーザー電流の初期値を書き換えるには、CD または DVD

レーザー電流が表示されている時に ボタンを5秒以上押

し、次に ボタンまたは ボタンを押して T23 を

選択します。(詳細は 22 ページ、Iop 値の確認方法参照)

T23 表示時に ボタンを押と、mmmm 部に現在値を表示

し、EEPROM に保存します。

FL 管の表示 (13 桁の表示部 )

12345678910111213

T23 ―mmmm―――――

5. レーザー ON 累積時間のリセット方法

レーザーON 累積時間をクリアするには、レーザーON 累

積時間表示 (TB1,TB2) の時(詳細は 22 ページ、テストモー

ド参照)に ボタンを 4 桁目に ' * ' が表示されるまで押

し、 ボタンまたは ボタンを押しTB3 を表示させ

ます。

TB3 表示時に ボタンを押すと、CD 及び DVD レーザー

ON 累積時間をクリアします。

ボタンまたは ボタンで TB1 または TB2 を選択

すると、nnnnnnn 部が 0 表示となり確認できます。

FL 管の表示 (13 桁の表示部 )

12345678910111213

TBY―――nnnnnnn

( −:消灯、Y:1:CD,2:DVD、nnnnnnn:時間 [h])

14

Page 15

S-102

HOW TO REPLACE TRAVERSE UNIT

Caution: The optical pickup can be dama ge d e as ily by

static electricity charged on human body.

T ake necessary anti-static measures when

repairing around the optical pickup.

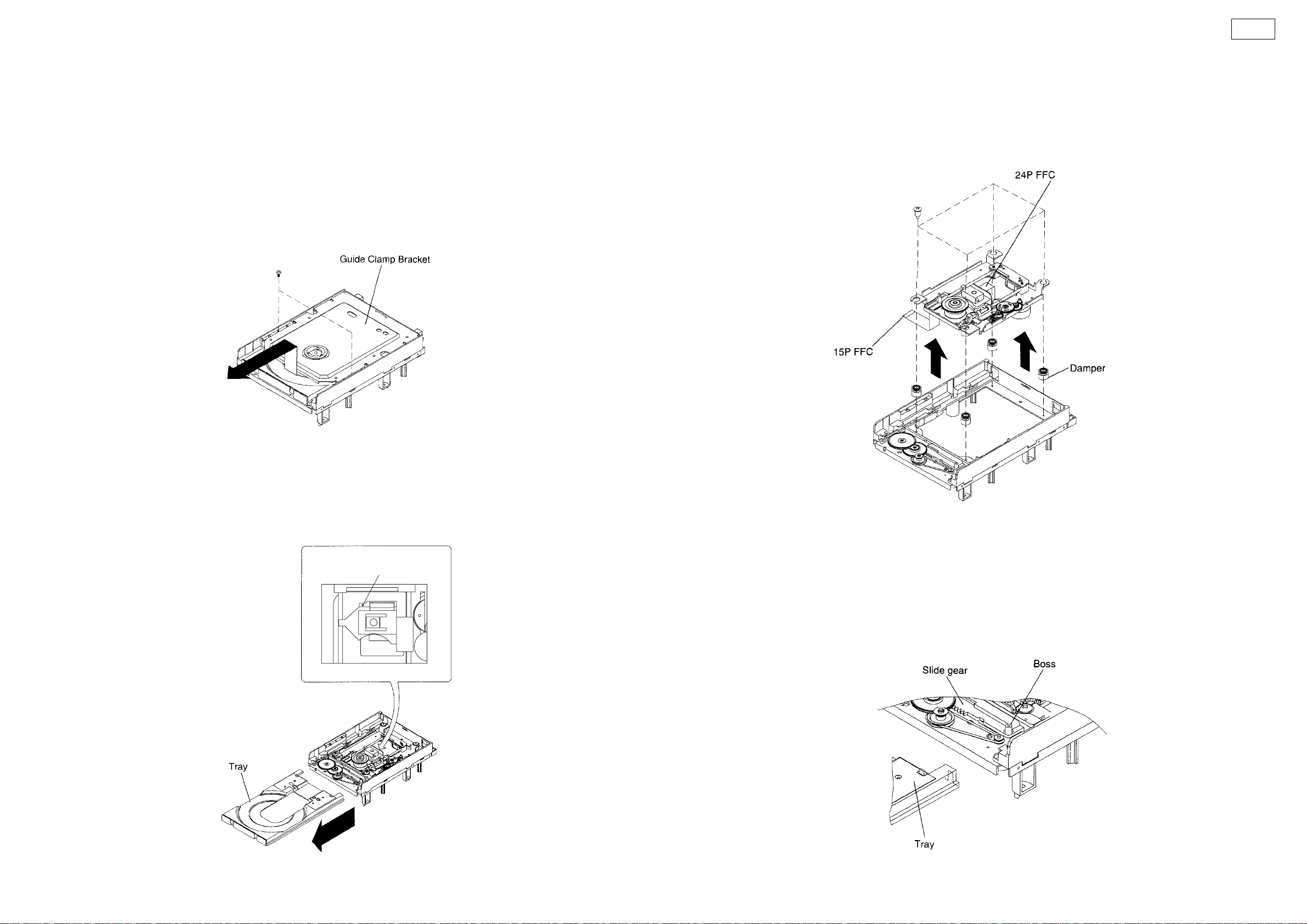

1. Guide Clamp Bracket disassembly

(1) Remove 2 screws.

(2) Remove Guide Clamp Bracket to arrow direction.

トラバースユニットの交換方法

注意 : 光ピックアップは、人体に帯電した静電気等で静電

破壊することがあります。光ピックアップ周辺を修

理する際は、必要な静電対策を行ってください。

1. ガイドクランプブラケットのはずしかた

(1) ねじ 2 本をはずします。

(2) ガイドクランプブラケットを矢印方向にとりはずしま

す。

3. T raverse Unit disassembly

(1) Remove 24P FFC, 15P FFC and 5P PH WIRE connect-

ing with from the Main P.W.B.

(2) Remove 4 screws fixing Damper.

(3) Remove Traverse Unit to arrow direction.

3. トラバースユニットのはずしかた

(1) メイン基板に接続している 24PFFC、15PFFC、5PPH

ワイヤをはずします。

(2) ダンパーを固定しているねじ 4 本をはずします。

(3) トラバースユニットを矢印方向にとりはずします。

2. T r ay disassembly

(1) Remove to arrow direction.

(2) Solder the short-circuit (see in the frame).

2. トレイのはずしかた

(1) 矢印方向にとりはずします。

(2) 半田付けショートを行います。(枠内図参照 )

半田ショート

Solder to short-circuit

Short-circuit with Solder

半田ショート拡大図

Note for disassembly Traverse Unit

(1) When assembling, reverse the order of the above.

(2) When inserting Tray, confirm boss on Slide Cam set to

ditch of the Tray (Compare with below dra w ing).

トラバースユニット分解の注意

(1) 組み立てるときは、上記の逆の順序で行ってください。

(2) トレイ組込み時、スライドカムのボスがトレイの溝に

合っているか確認してください。(下図参照)

15

Page 16

S-102

SERVICE MODE

1. Aging Mode

1.1. preparation0

(1) Equipment used: Any one of DVD Karaoke Disc (containing more than 10 titles).

(ex : Heat run disc TDV-HR01)

(2) Unit setting : No spec other than the following procedure.

1.2. procedure

※ Perform aging of the DVD.

(1) Pressing the and buttons simultaneously, plug the AC cord into a power outlet, then press the ON/STANDBY button

to turn the power on. This sets the aging mode.

• Once the aging mode is set, press the FUNCTION button to switch the mode.

(After the display is put out at the switch, it selects.)

(a) To select the normal aging mode ... Start from (2)

(b) To select the error rate display mode ... Start from (8)

(2) Press the button and play all the tracks recorded on the disc.

(3) Both the " " and " " indicators light on the fluorescent display tube.

(4) When the button is pressed once with the tray open, titles 1 and 10 recorded on the disc are played.

(5) The " " indicator flashes and the " " indicator lights on the fluorescent display tube.

(6) Once playback is completed, open and close the tray and repeat the operation in step (3) or (4).

(7) If there is an error while in the aging mode, the error is displayed and the stop mode is set with the status at that time.

NOTE)・The FUNCTION button on the main unit and the FUNCTION selector button on the remote control unit will not work

during the aging mode.

(If the function is switched, the DVD stops and the aging mode is canceled.)

・The ON/STANDBY buttons on the main unit and the remote control unit will not work during the aging mode.

(If the set's power is turned off, the DVD stops and the aging mode is canceled.

(8) When the error rate display mode is set, the final error rate information is displayed on the fluorescent display tube.

サービスモードについて

1. エージングモード

1.1. 準備

(1) 使用機器:DVD カラオケディスク (10 タイトル以上のもの)

(例:ヒートランディスク TDV-HR01)

(2) 本体設定:下記設定以外規定無。

1.2. 手順

※ DVD のエージングをおこなう。

(1) 本体の ボタンと ボタンを同時に押しながら、AC コードをコンセントへ接続し、ON/STANDBY ボタンを押してセット

の電源を入れると、エージングモードが設定される。

・ エージングモード設定後、FUNCTION ボタンを押して、モードを切り替える。

(切り替え時に表示を出してから選択する。)

(a) 通常のエージングモードを選択・・・(2) から開始

(b) エラーレート表示モードを選択・・・(8) から開始

(2) ボタンを押し、ディスクに収録されている全ての曲を再生する。

(3) FL 管の インジケーターと インジケーターが両方とも点灯する。

(4) トレイを開いた状態で ボタンを 1 回押して、ディスクに収録されているタイトル 1 とタイトル 10 を再生する。

(5) FL 管の インジケーターが点滅し、 インジケーターが点灯する。

(6) 再生終了後、トレイを開閉させ (3) または (4) の動作をする。

(7) エージングモード中にエラーが発生すると、エラーを表示し、その時の状態で停止する。

注 )・ エージングモード中は、本体の FUNCTION ボタンおよび、リモコンの FUNCTION 切替ボタンは動作しない。

(ファンクッションを変えると DVD が停止し、エージングモードが解除される。)

・ エージングモード中は本体およびリモコンの ON/STANDBY ボタンを動作しない。

(セットの電源を OFF にすると DVD が停止し、エージングモードが解除される。)

(8) エラーレート表示モードに入ると、最終エラーレート情報を FL 管に表示する。

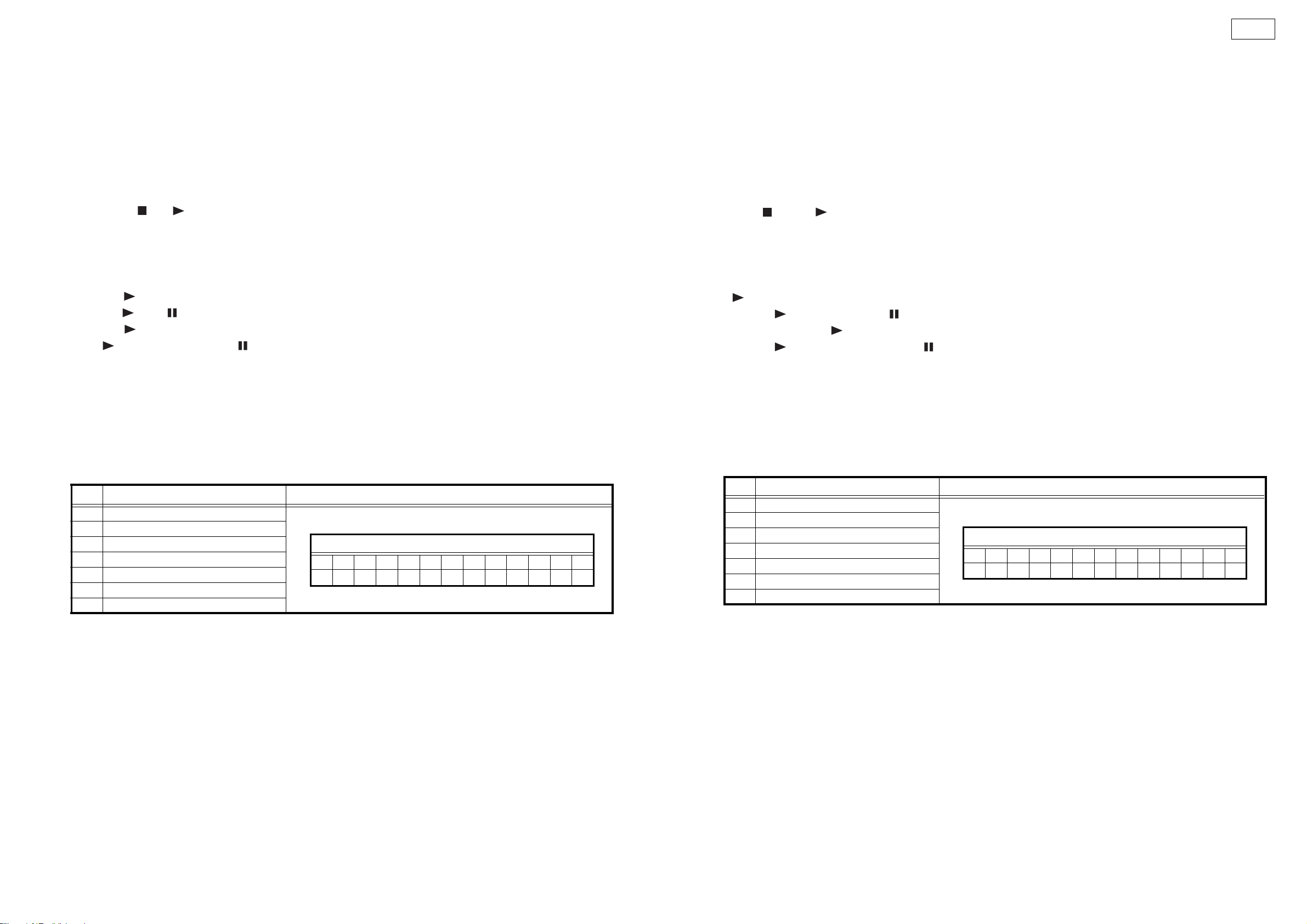

No. Error contents FL display

1 Bad DIsc

2 Forcus Error

3 Read Error

4 Tracking Error

5Tray Error

6 Navigation Pack Read Error

7 Cmmunication Error

FLDisplay(Thedisplaypartof13digits)

12345678910111213

E7 XX XX XX

No. エラー内容 FL 管表示

1 不良ディスク

2 フォーカスエラー

3 リードエラー

4 トラッキングエラー

5 トレイエラー

6 ナビゲーションパックエラー

7 コマンド通信エラー

FL 管の表示 (13 桁の表示部 )

12345678910111213

E7 XX XX XX

16

Page 17

S-102

2. Initial Setting Mode

2.1. Preparation

(1) Equipment used: None

(2) Unit setting: No spec other than the following procedure.

2.2. Procedure

● SYSTEM

※ This initializes th e data for the function, volume, DVD mechanism, etc.

(1) When the ON/STANDBY button is pressed to turn the set on while pressing the main unit's FUNCTION and buttons

simultaneously, the initialization mode is set.

(2) The standby indicator lights yellow and "INITIALIZE" is displayed on the fluorescent display tube.

(3) Once the entire initialization procedure has been completed, the set is in the normal mode with the power turned on.

● DVD

※ This initializes th e data for the DVD mechanism.

(1) With the power on, set the function to DVD, and in the playback stopped mode, press the and buttons simultaneously

for at least 2 seconds to set the DVD initialization mode.

(2) "INITIALIZE" is displayed on the fluorescent display tube.

3. µcom Firm Check Mode

3.1. Preparation

(1) Equipment used: None

(2) Unit setting: No spec other than the following procedure.

3.2. Procedure

※ Use this to display the version info rmation, etc.

(1) When, in the standby mode, the ON/STANDBY button is pressed to turn the set on while pressing the main unit's FUNCTION

and buttons simultaneously, the system check mode is set.

(2) Press the STATUS button on the remote control unit to display the following information, in this order: System microprocessor

version → Date of system microprocessor version updating → DSP version → Date of DSP version updating → Drive micropro-

cessor version of DVD mechanism → ESS version → Date of ESS version updating.

(3) Unplug AC cord to clear this mode.

NOTE) The DVD mechanism driver version and ESS version are not displayed un less the function is once set to DVD.

2. イニシャルモード

2.1. 準備

(1) 使用機器:無

(2) 本体設定:下記手順以外規定無。

2.2. 手順

● システム

※ ファンクション、VOL 等および DVD メカのバックアップデータの初期化をおこなう。

(1) 本体 FUNCTION ボタンと ボタンを同時に押しながら、ON/STANDY ボタンを押してセットの電源を入れるとイニシャ

ルモードが設定される。

(2) スタンバイ LED が黄色に点灯し、FL 管にINITIALIZEが表示される。

(3) 全ての初期化完了後、通常モードの電源 ON の状態になる。

●DVD

※ DVD のみのバックアップデータの初期化をおこなう。

(1) 電源 ON 時にファンクッションを DVD にし再生停止状態で、 ボタンと ボタンを 2 秒以上同時に押し続けると、

DVD 初期化モードが設定される。

(2) FL 管にINITIALIZEが表示される。

3. マイコンファームチェックモード

3.1. 準備

(1) 使用機器:無

(2) 本体設定:下記手順以外規定無。

3.2. 手順

※ バージョン表示等をおこなう。

(1) STANDBY 時に本体 FUNCTION ボタンと ボタンを同時に押しながら、ON/STANDBY ボタンを押してセットの電源を入

れると、システムチェックモードが設定される。

(2) リモコンの STATUS ボタンを押すと、システムマイコンのバージョン→システムマイコンのバージョンアップ日→ DSP の

バージョン→ DSP のバージョンアップ日→ DVD メカのドライブマイコンのバージョン→ ESS のバージョン→ ESS のバー

ジョンアップ日の順に表示される。

(3) AC コードを抜くことにより、システムチェックモードを解除する。

注 ) DVD メカのドライブバージョン、ESS のバージョンの表示については、一度ファンクッションを DVD にしないと表示

されない。

17

Page 18

S-102

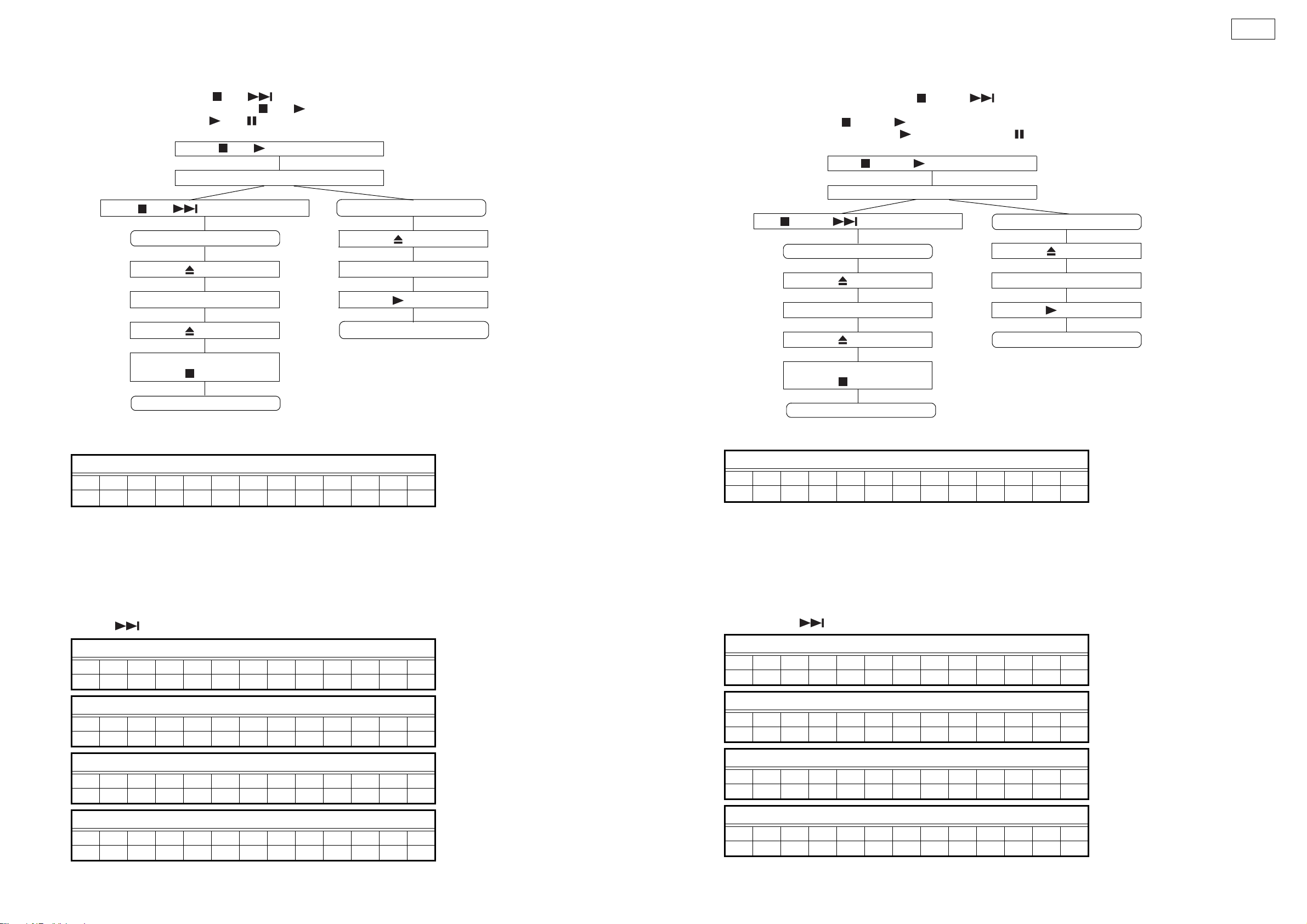

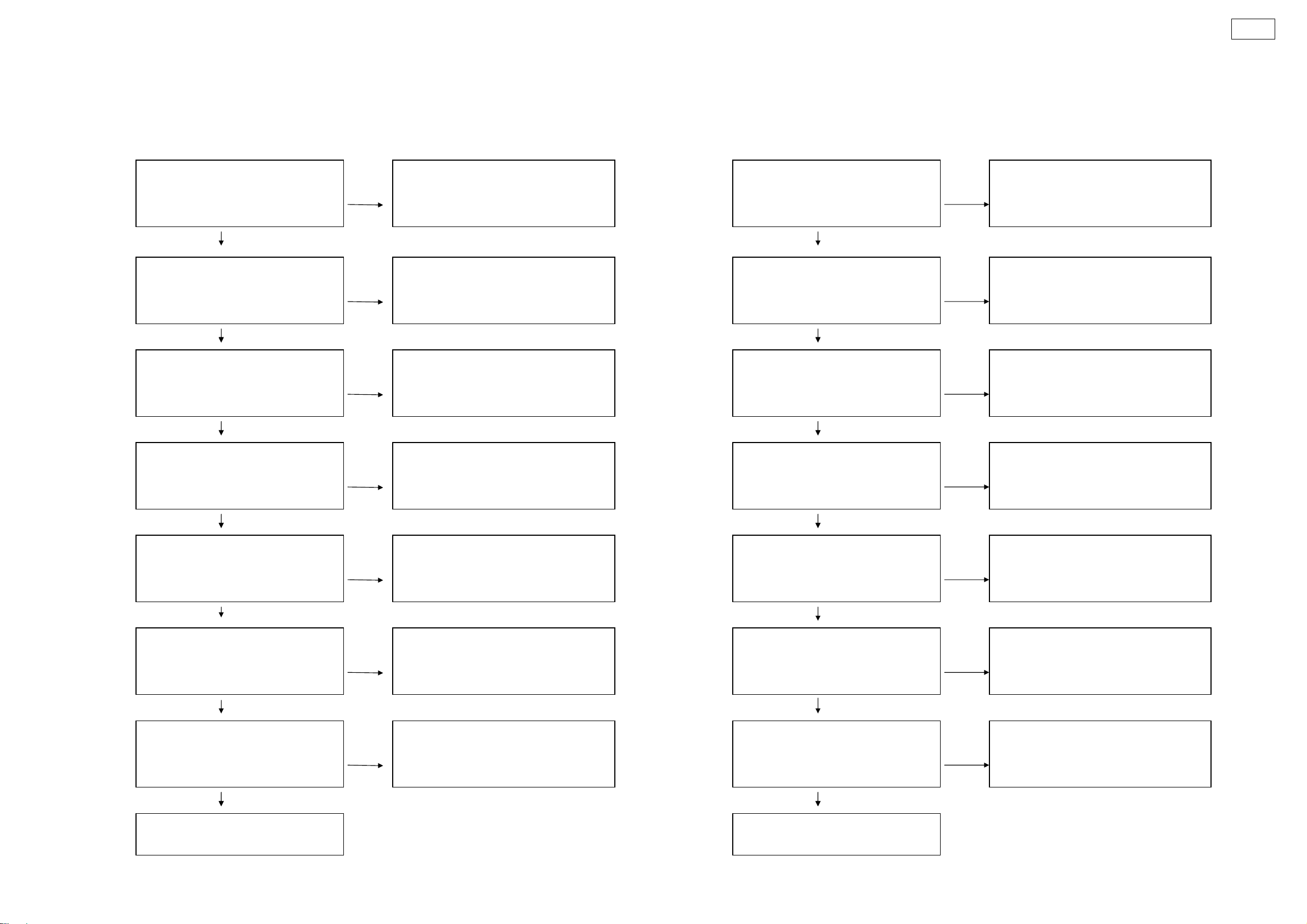

4. Test mode

4.1. Entering the test mode

To enter the test mode, press the and buttons simultaneously while in the Aging mode. Not insert the disc.

(The Aging mode is entered by pressing the and buttons simultaneously to turn on the AC power.

When the Aging mode is set, the and indicators light.)

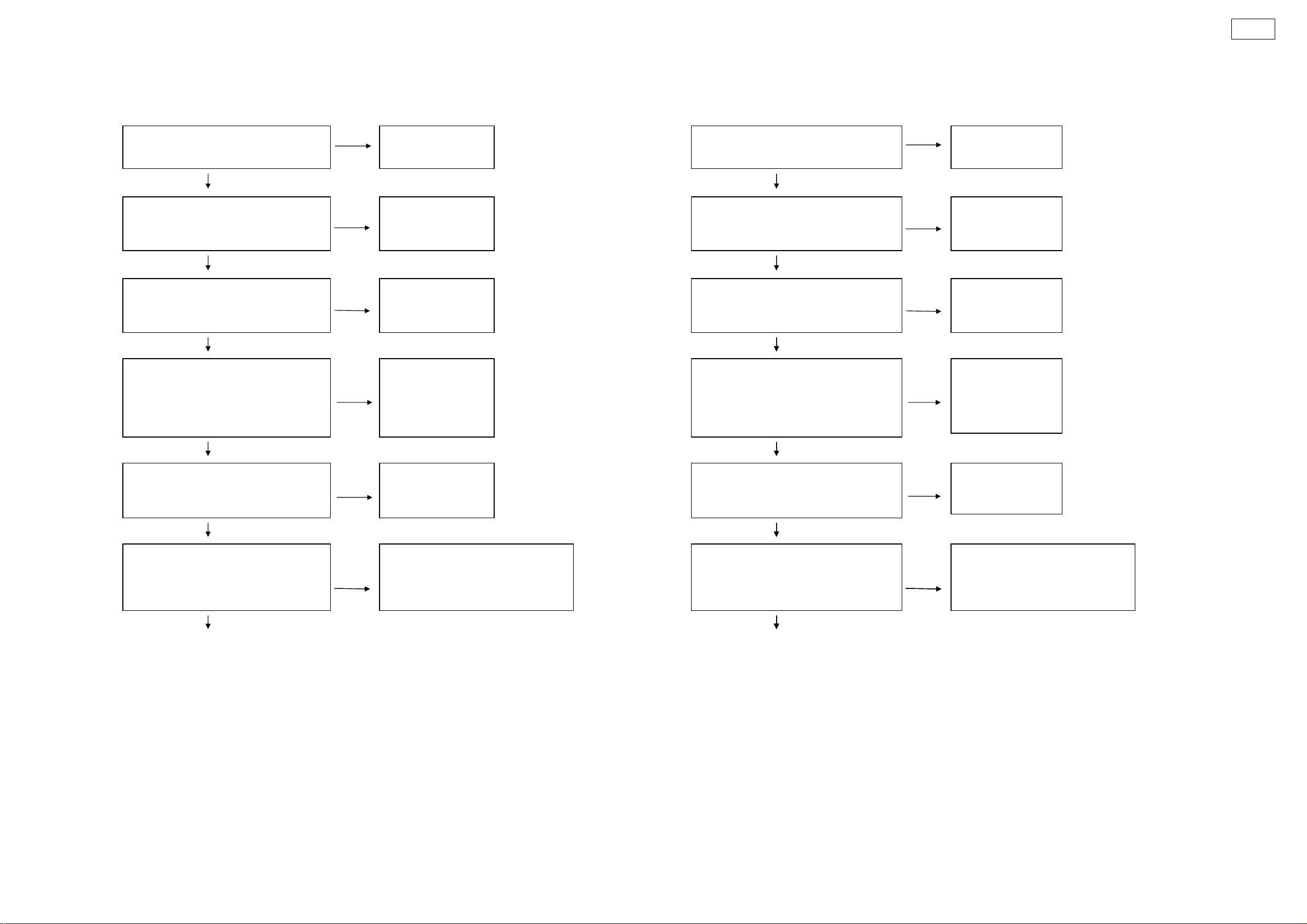

Press and buttons simultaneously

Power turns on

Press and buttons simultaneously

Test mode

button

Set the disc

button

After the TOC reading

button

Aging mode

button

Set the disc

button

Aging mode start

4. テストモード

4.1. テストモードの設定

テストモードの設定はエージングモード時に ボタンと ボタンを同時に押すことでおこなう。ディスクは挿入していな

いこと。

( エージングモードの設定は ボタンと ボタンを同時に押しながら、AC コードをコンセントへ接続し、セットの電源を入れ

る。エージングモードになると FL 管の インジケーターと インジケーターが点灯する。)

ボタンと ボタンの同時押し

電源 ON

ボタンと ボタンの同時押し

テストモード

ボタン

ディスクを載せる

ボタン

TOC リード後

ボタン

エージングモード

ボタン

ディスクを載せる

ボタン

エージング開始

Test mode start

FL tube display when test mode entered

FLDisplay(Thedisplaypartof13digits)

12345678910111213

TEST MODE

4.2. Selecting the mode

The following modes are available.

(1) Laser on/off (CD/DVD) mode : T2

(2) Servo adjustment value display mode : T3

(3) Trace mode (error rate display) : T7

(4) Accumulated laser on time : TB

① When the button is pressed after ente ring the test mode, the display switches in the order: T2, T3, T7, TB, T2 …

FLDisplay(Thedisplaypartof13digits)

12345678910111213

T2 L a s e r O n O f f

FLDisplay(Thedisplaypartof13digits)

12345678910111213

T3 S e r v o A d j

テストモード開始

テストモード設定時の FL 管表示

FL 管の表示 (13 桁の表示部 )

12345678910111213

TEST MODE

4.2. モードの選択

モードには、次のモードがある。

(1) レーザー ON/OFF(CD/DVD) モード : T2

(2) サーボ調整値表示モード : T3

(3) トレースモード ( エラーレート表示 ) : T7

(4) レーザー ON 累積時間 : TB

①テストモード中に ボタンを押すと、T2,T3,T7,TB,T2…の順に表示される。

FL 管の表示 (13 桁の表示部 )

12345678910111213

T2 L a s e r O n O f f

FL 管の表示 (13 桁の表示部 )

12345678910111213

T3 S e r v o A d j

FLDisplay(Thedisplaypartof13digits)

12345678910111213

T7 T r a c e M o d e

FLDisplay(Thedisplaypartof13digits)

12345678910111213

TB L a s e r O n T i m

FL 管の表示 (13 桁の表示部 )

12345678910111213

T7 T r a c e M o d e

FL 管の表示 (13 桁の表示部 )

12345678910111213

TB L a s e r O n T i m

18

Page 19

S-102

4.3. Setting the mode

With the mode selected, press the button to set that mode.

① In the laser on/off (CD/DVD) mode, laser on/off control is executed and the laser current is displayed.

Press the or button to switch the CD/DVD (T21, T22, T21. .).

To save the current laser current value, press and hold in the button for at least 5 seconds to turn off the "mmmm" section

of the display, then press the or button and select T23. When the button is pressed while T23 is displayed, the

data is displayed in the "mmmm" section.

For the CD laser

FLDisplay(Thedisplaypartof13digits)

12345678910111213

T21―mmmm―nnnn

( − : Off, CD laser, Stored data: mm.mm [mA], Current value: nn.nn [mA])

For the DVD laser

FLDisplay(Thedisplaypartof13digits)

12345678910111213

T22―mmmm―nnnn

( − : Off, DVD laser, Stored data: mm.mm [mA], Current value: nn.nn [mA])

② In the servo adjustment value display mode (See "Table 1 - Servo adjustment value display mode de tails")

FLDisplay(Thedisplaypartof13digits)

12345678910111213

T X X −−−−−−nnnn

(XX : Selection mode, n : Adjustment value (HEX))

③ In the trace mode (error rate display), select the trace of the innermost circumference of 1 layer.

FLDisplay(Thedisplaypartof13digits)

12345678910111213

T71FFFFFFFFFF

(F : When address and error rate not set, F is displayed.)

④ Displaying the accumulated laser on time (stored in the EEPROM)

FLDisplay(Thedisplaypartof13digits)

12345678910111213

T B Y―――nnnnnnn

(Y : 1:CD, 2:DVD, nnnnn: Time [h])

※ Fractions of hours are counted up one hour on the display.

4.3. モードの確定

モードを選択してある状態で ボタンを押すとモードを確定する。

①レーザーON/OFF(CD/DVD) モードの場合、レーザーのON/OFF 制御を実行し、レーザー電流を表示する。CD/DVD の切り替

えは、 ボタンまたは ボタンを押す (T21、T22、T21..)。

現在のレーザー電流値を保存する場合、 ボタンを 5 秒以上押し続け、mmmm 部を非表示にし、 ボタンまたは

ボタンを押して、T23 を選択する。T23 を表示時に ボタンを押すと、mmmm 部にデータが表示される。

CD レーザーの場合

FL 管の表示 (13 桁の表示部 )

12345678910111213

T21―mmmm―nnnn

( −:消灯、CD レーザー、保存データ:mm.mm[mA],現在値:nn.nn[mA])

DVD レーザーの場合

FL 管の表示 (13 桁の表示部 )

12345678910111213

T22―mmmm―nnnn

( −:消灯、DVD レーザー、保存データ:mm.mm[mA],現在値:nn.nn[mA])

②サーボ調整値表示モードの場合 (表 1 サーボ調整値表示モード詳細参照)

FL 管の表示 (13 桁の表示部 )

12345678910111213

TXX――――――nnnn

(XX: 選択モード、n: 調整値 (HEX))

③トレースモード ( エラーレート表示 ) の場合は、1層内周のトレースを選択する。

FL 管の表示 (13 桁の表示部 )

12345678910111213

T71FFFFFFFFFF

(F: アドレス及びエラーレートは未確定時、F を表示する。)

④レーザー ON 累積時間 (EEPROM に記憶 ) を表示する。

FL 管の表示 (13 桁の表示部 )

12345678910111213

T B Y―――nnnnnnn

(Y:1:CD、2:DVD、nnnnn: 時間 [h])

※ 1 時間未満は切り上げて表示する。

19

Page 20

S-102

4.4. Change within the mode

Changes within modes are made by pressing the and buttons while the mode is set.

① In the laser on/off (CD/DVD) mode, laser on/off control is executed and the laser current is displ ayed.

For the CD laser

FLDisplay(Thedisplaypartof13digits)

12345678910111213

T21―mmmm―nnnn

( − : Off, CD laser, Stored data: mm.mm [mA], Current value: nn.nn [mA])

For the DVD laser

FLDisplay(Thedisplaypartof13digits)

12345678910111213

T22―mmmm―nnnn

( − : Off, DVD laser, mm.mm [mA], nn.nn [mA])

When there is no saved data (for the DVD laser)

FLDisplay(Thedisplaypartof13digits)

12345678910111213

T2 2 ――――――nnnn

( − : Off, DVD laser, nn.nn [mA])

To store the current value, press the button for at least 5 seconds, then press the or button to select T23.

If the button is pressed while T23 is displayed, the current value is displayed at "mmmm" and stored in the EEPROM.

4.4. モード内での変更

モードを確定してある状態で ボタンまたは ボタンを押すとモード内での変更をおこなう。

①レーザーON/OFF(CD/DVD) モードの場合、レーザーのON/OFF 制御を実行し、レーザー電流を表示する。

CD レーザーの場合

FL 管の表示 (13 桁の表示部 )

12345678910111213

T21―mmmm―nnnn

( −:消灯、CD レーザー、保存データ:mm.mm[mA],現在値:nn.nn[mA])

DVD レーザーの場合

FL 管の表示 (13 桁の表示部 )

12345678910111213

T22―mmmm―nnnn

( −:消灯、DVD レーザー、mm.mm[mA],nn.nn[mA])

保存データなしの場合 (DVD レーザーの場合 )

FL 管の表示 (13 桁の表示部 )

12345678910111213

T22――――――nnnn

( −:消灯、DVD レーザー、nn.nn[mA])

現在地を保存するには、 ボタンを 5 秒以上押し、次に ボタンまたは ボタンを押して、T23 を選択する。T23 表

示時に、 ボタンを押すと、mmmm 部に現在値を表示し、EEPROM に保存される。

FLDisplay(Thedisplaypartof13digits)

12345678910111213

T2 3 ―mmmm―nnnn

( − : Off, DVD laser, nn.nn [mA])

If the current value is over 100 mA, the 4th and 9th digit sections are used.

② In the servo adjustment value display mode (See "Table 1 - Servo adjustment value display mode de tails")

FLDisplay(Thedisplaypartof13digits)

12345678910111213

TXX――nnnnnnnn

(XX : Selection mode, n: Adjustment value (HEX))

For the adjustment values, 0's are added in front of the effective number of bytes.

(Ex.: If the value is 0x123 for 4-byte data, "00 00 01 23" is displayed.)

⑤ In the trace mode (error rate display) (See "Table 2 - Trace mode details")

FLDisplay(Thedisplaypartof13digits)

12345678910111213

TYYFFFFFFFFFF

(YY : Selection mode [71 to 94], F: When address and error rate not set, F is displayed.)

⑥ In the accumulated laser on time display

FL 管の表示 (13 桁の表示部 )

12345678910111213

T2 3 ―mmmm―――――

( −:消灯、DVD レーザー、mm.mm[mA])

電流値が 100mA 以上の場合は、4 桁、9 桁部分を使用。

②サーボ調整値表示モードの場合 (表 1 サーボ調整値表示モード詳細参照)

FL 管の表示 (13 桁の表示部 )

12345678910111213

TXX――nnnnnnnn

(XX: 選択モード、n: 調整値 (HEX))

調整値は、有効バイト数分先頭に 0 をつける。

(例:4 バイトデータで値が 0x123 の場合は00000123)

③トレースモード ( エラーレート表示 ) の場合(表 2 トレースモード詳細参照)

FL 管の表示 (13 桁の表示部 )

12345678910111213

TYYFFFFFFFFFF

(YY: 選択モード [71 〜 94]、F: アドレス及びエラーレートは未確定時、F を表示する。)

⑥レーザー ON 累積時間を表示場合

FLDisplay(Thedisplaypartof13digits)

12345678910111213

T B Y―――nnnnnnn

(Y : 1: CD, 2: DVD, nnnnnnn: Time [h]) ※ If the current value is over 100 mA, the 4th and 9th digit sections are used.

To clear the accumulated laser on time, press the button while the accumulated laser on time is displayed (TB1, TB2) until

" * " appears at the fourth position, then press the or button to select TB3.

If the PLAY button is pressed while TB3 is displayed, the accumulated laser on time of CD and DVD is cleared.

When TB1 or TB2 is selected with the or button, "nnnnnnn" is displa yed as 0 so you can check.

FL 管の表示 (13 桁の表示部 )

12345678910111213

T B Y―――nnnnnnn

(Y:1:CD,2:DVD、nnnnnn: 時間 [h]) ※ 1 時間未満は切り上げて表示する。

レーザー ON 累積時間をクリアする場合、レーザー ON 累積時間表示時 (TB1、TB2) のとき、 ボタンを 4 桁目に*が表

示されるまで押し、 ボタンまたは ボタンを押し、TB3 を表示させる。TB3 表示時に ボタンを押すと CD および

DVD レーザー ON 累積時間をクリアする。 ボタンまたは ボタンを押して、TB1 または TB2 を選択すると、

nnnnnn 部が 0 表示になり確認できる。

20

Page 21

S-102

4.5. Execution of trace mode (error rate display) (See "Table 2 - Trace mode details")

Trace will be performed if the button is pushed after choosing operation.

FLDisplay(Thedisplaypartof13digits)

12345678910111213

TYYmmmmmmllll

(YY : selection mode [71 to 94], m : address [PBA][HEX], l : error rate [COUNT/SEC] [HEX])

Note) CD : Error rate of 75 frames is displayed (1 second).

DVD : Error rate of 8ECC block is displayed.

The mode chosen when selection mode was changed into the trace execution and the button was pushed is performed

from the beginning.

When the button is pushed without changing selection mode, the mode under selection is performed from the beginning.

(If the button is pushed, the address corresponding to the chosen mode will be searched again.)

The pause mode is set after tracing is completed.

4.6. Other operations

① When the button is pressed, the mode returns to the previously selected mode.

4.5. トレースモード ( エラーレート表示 ) の実行(表 2 トレースモード詳細参照)

動作を選択した後、 ボタンを押すとトレースを実行する。

FL 管の表示 (13 桁の表示部 )

12345678910111213

TYYmmmmmmllll

(YY: 選択モード [71 〜 94]、m: アドレス [PBA][HEX]、l: エラーレート [COUNT][DEC])

注 ) CD : 表示するエラーレートは、75 フレーム分の値 (1 秒 )。

DVD : 表示するエラーレートは、8ECC ブロック分の値。

トレース実行中に選択モードを変更し、 ボタンを押すと選択したモードを最初から実行する。

選択モードを変更せずに ボタンを押した場合も、選択中のモードを最初から実行する。

( ボタンを押すと、選択しているモードに対応したアドレスを再度サーチする。)

トレース終了時は、PAUSE 状態になります。

4.6. その他の動作

① ボタンを押すと、前の選択モードに戻る。

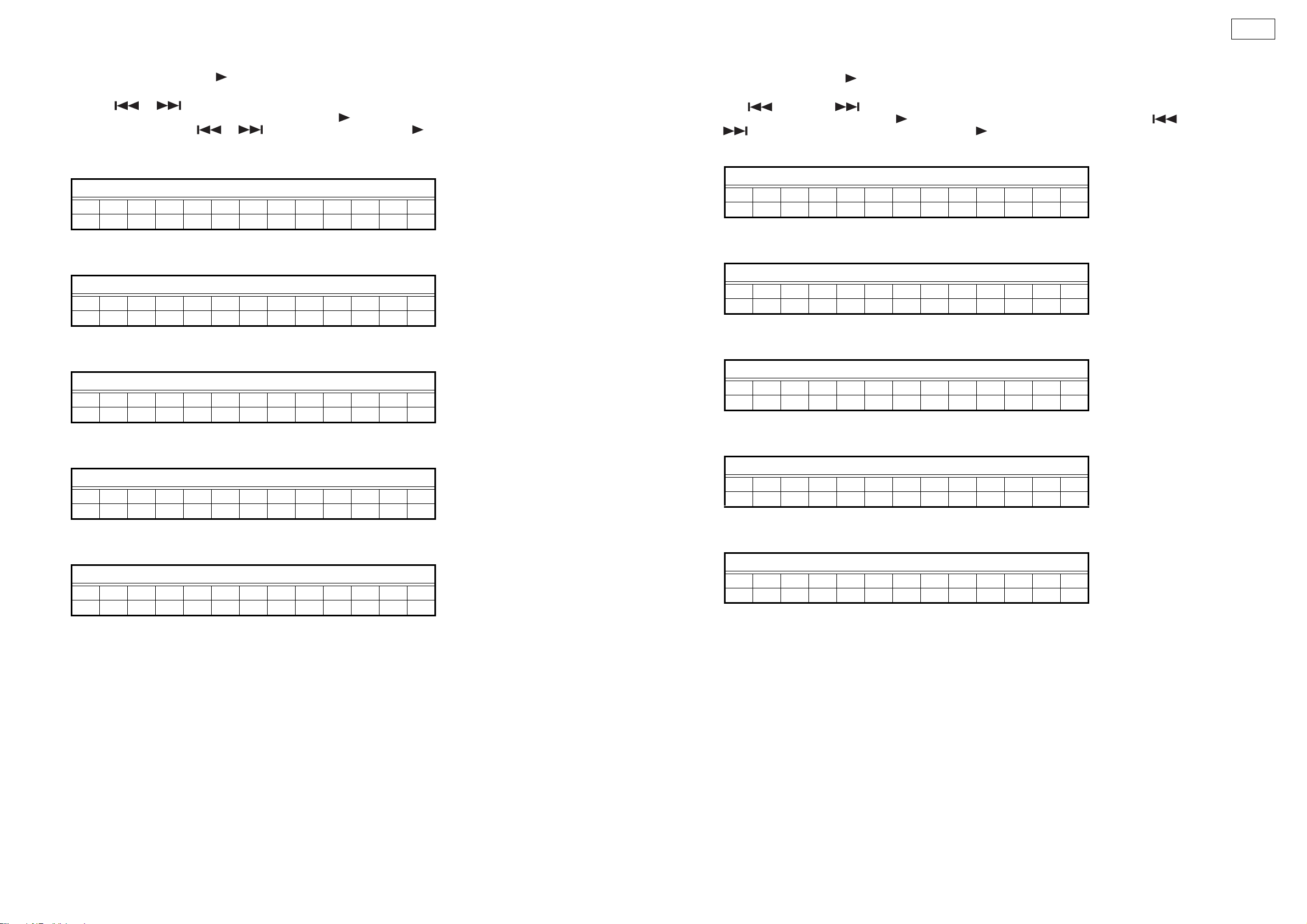

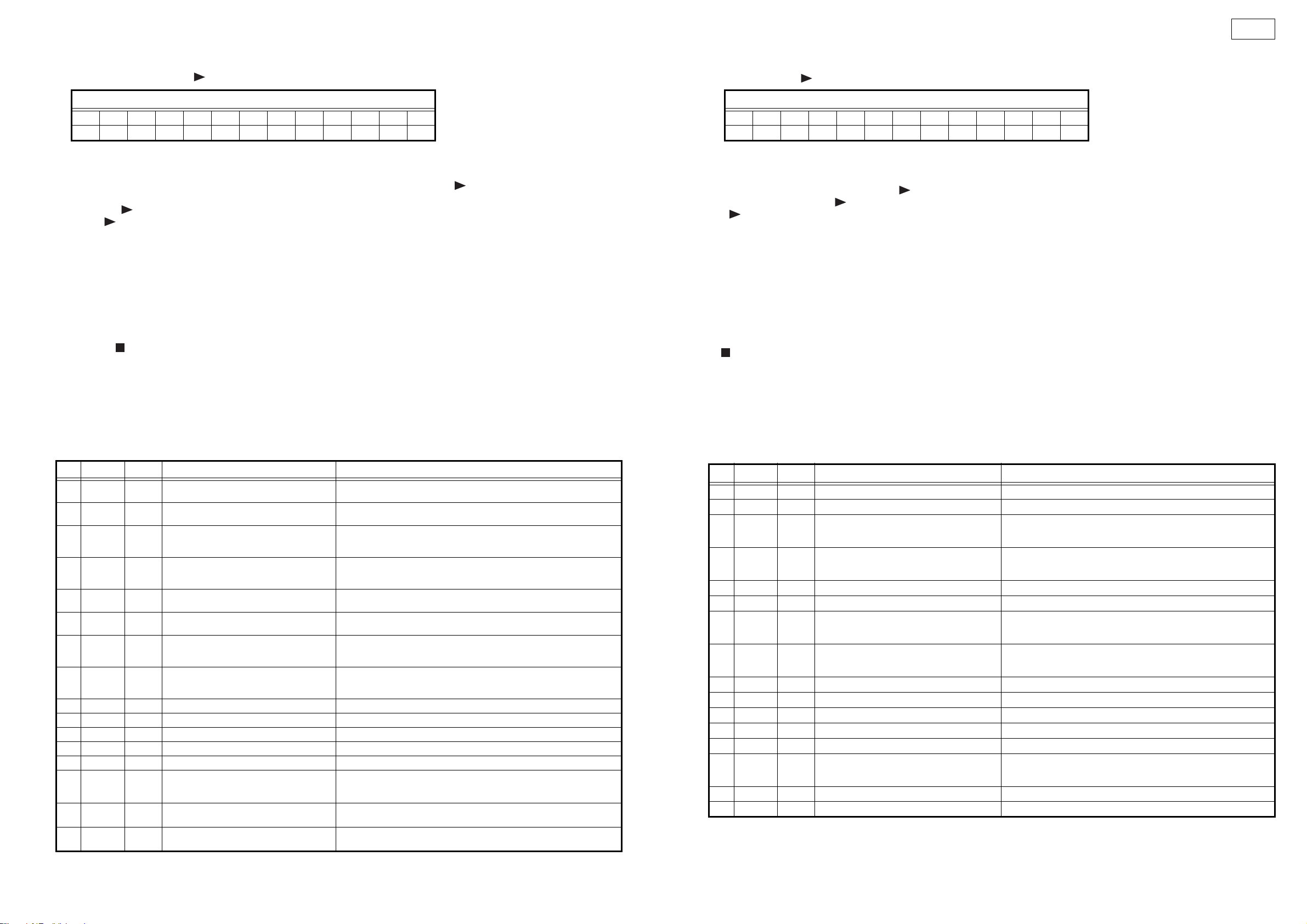

(1) Test mode detailed table

Table 1: Servo adjustment value display mode details

XXX

Name Size Meaning Remarks

T31 fbal0 16bits CD/DVD L0 layer focus balance adjust-

T32 tbal0 16bits CD/DVD L0 layer tracking balance adjust-

T33 fcga0 16bits CD/DVD L0 layer focus Loop Gain adjust-

T34 tkga0 16bits CD/DVD L0 layer tracking Loop Gain

T35 Fbal1 16bits DVD L1 layer focus balance adjustment

T36 Tbal1 16bits DVD L1 layer tracking balance adjustment

T37 Fcga1 16b its DVD L1 layer focus Loop Gain adjustment

T38 Tkga1 16b its DVD L1 layer tracking Loop Gain adjust-

T39 Asoffs 16bits AS signal Offset value Upper 10 bit is valid

T40 Envoffse 16bits ENV signal Offset adjustment value Upper 10 bit is valid

T41 Foffse 16bits FE signal Offset adjustment value Upper 10 bit is valid

T42 Teoffse 16bits TE signal Offset adjustment value Upper 10 bit is valid

T43 RFfc 8bits RF signal frequency adjustment value

T44 RFbst 8bits RF signal Boost adjustment value

T45 RFgdl 8bits

T46 RFgdh 8bits

ment value

ment value

ment value

adjustment value

value

value

value

ment value

RF signal low range group delay adjust-

ment value

RF signal high range group delay adjust-

ment value

FBAL range: 0x8000 < FBAL < 0x7FC0(Center:0x0000)

TBAL range: 0x0000 < TBAL < 0x003F

1x for 0x100 [0x200 (2x) set to Typ.

(1x for 0x100, 2x for 0x200. Y/0x100 ratio calculation.)

Adjustment value 0x200 sets so that gain crossover reaches target.

1x for 0x100 [0x200 (2x) set to Typ.

(1x for 0x100, 2x for 0x200. Y/0x100 ratio calculation.)

Adjustment value 0x202 sets so that gain crossover reaches target.

FBAL range: 0x8000 < FBAL < 0x7FC0(Center:0x0000)

TBAL range: 0x0000 < TBAL < 0x003F

1x for 0x100 [0x200 (2x) set to Typ.

(1x for 0x100, 2x for 0x200. Y/0x100 ratio calculation.)

Adjustment value 0x200 sets so that gain crossover reaches target.

1x for 0x100 [0x200 (2x) set to Typ.

(1x for 0x100, 2x for 0x200. Y/0x100 ratio calculation.)

Adjustment value 0x202 sets so that gain crossover reaches target.

Adjustment range : 0x0000 〜 0x001F

0x0000 : 0dB

0x001F : 14dB

(1) テストモード詳細一覧表

表 1サーボ調整値表示モード詳細

XXX 名称 サイズ 意味 備考

T31 fbal0 16 ビット CD/DVDL0 層フォーカスバランス調整値

T32 tbal0 16 ビット CD/DVDL0 層トラッキングバランス調整値

T33 fcga0 16 ビット CD/DVDL0 層フォーカス LoopGain 調整値 0x100 で 1 倍[0x200(2 倍 ) を Typ に設定する ]

T34 tkga0 16 ビット

T35 Fbal1 16 ビット DVDL1 層フォーカスバランス調整値

T36 Tbal1 16 ビット DVDL1 層トラッキングバランス調整値

T37 Fcga1 16 ビット DVDL1 層フォーカス LoopGain 調整値 0x100 で 1 倍[0x200(2 倍 ) を Typ に設定する ]

T38 Tkga1 16 ビット DVDL1 層トラッキング LoopGain 調整値 0x100 で 1 倍[0x200(2 倍 ) を Typ に設定する ]

T39 Asoffs 16 ビット AS 信号の Offset 値 上位 10bit が有効

T40 Envoffse 16 ビット ENV 信号の Offset 調整値 上位 10bit が有効

T41 Foffse 16 ビット FE 信号の Offset 調整値 上位 10bit が有効

T42 Teoffse 16 ビット TE 信号の Offset 調整値 上位 10bit が有効

T43 RFfc 8 ビット RF 信号の周波数調整値

T44 RFbst 8 ビット RF 信号の Boost 調整値 調整範囲: 0x0000 〜 0x001F

T45 RFgdl 8 ビット RF 信号の低域群遅延調整値

T46 RFgdh 8 ビット RF 信号の高域群遅延調整値

CD/DVDL0 層トラッキング LoopGain 調整値

FBAL の範囲は 0x8000<FBAL<0x7FC0。( センター :0x0000)

TBALの範囲は 0x0000<TBAL<0x003F。

(0x100 で 1 倍、0x200 で 2 倍。Y/0x100 の比率計算)

調整値 0x200 で Gain 交点が目標ターゲットになる様設定している。

0x100 で 1 倍[0x200(2 倍 ) を Typ に設定する。]

(0x100 で 1 倍、0x200 で 2 倍。Y/0x100 の比率計算)

調整値 0x202 で Gain 交点が目標ターゲットになる様設定している。

FBAL の範囲は 0x8000<FBAL<0x7FC0。( センター :0x0000)

TBAL の範囲は 0x0000<TBAL<0x003F。

(0x100 で 1 倍、0x200 で 2 倍。Y/0x100 の比率計算)

調整値 0x200 で Gain 交点が目標ターゲットになる様設定している。

(0x100 で 1 倍、0x200 で 2 倍。Y/0x100 の比率計算)

調整値 0x202 で Gain 交点が目標ターゲットになる様設定している。

0x0000:0dB

0x001F:14dB

21

Page 22

S-102

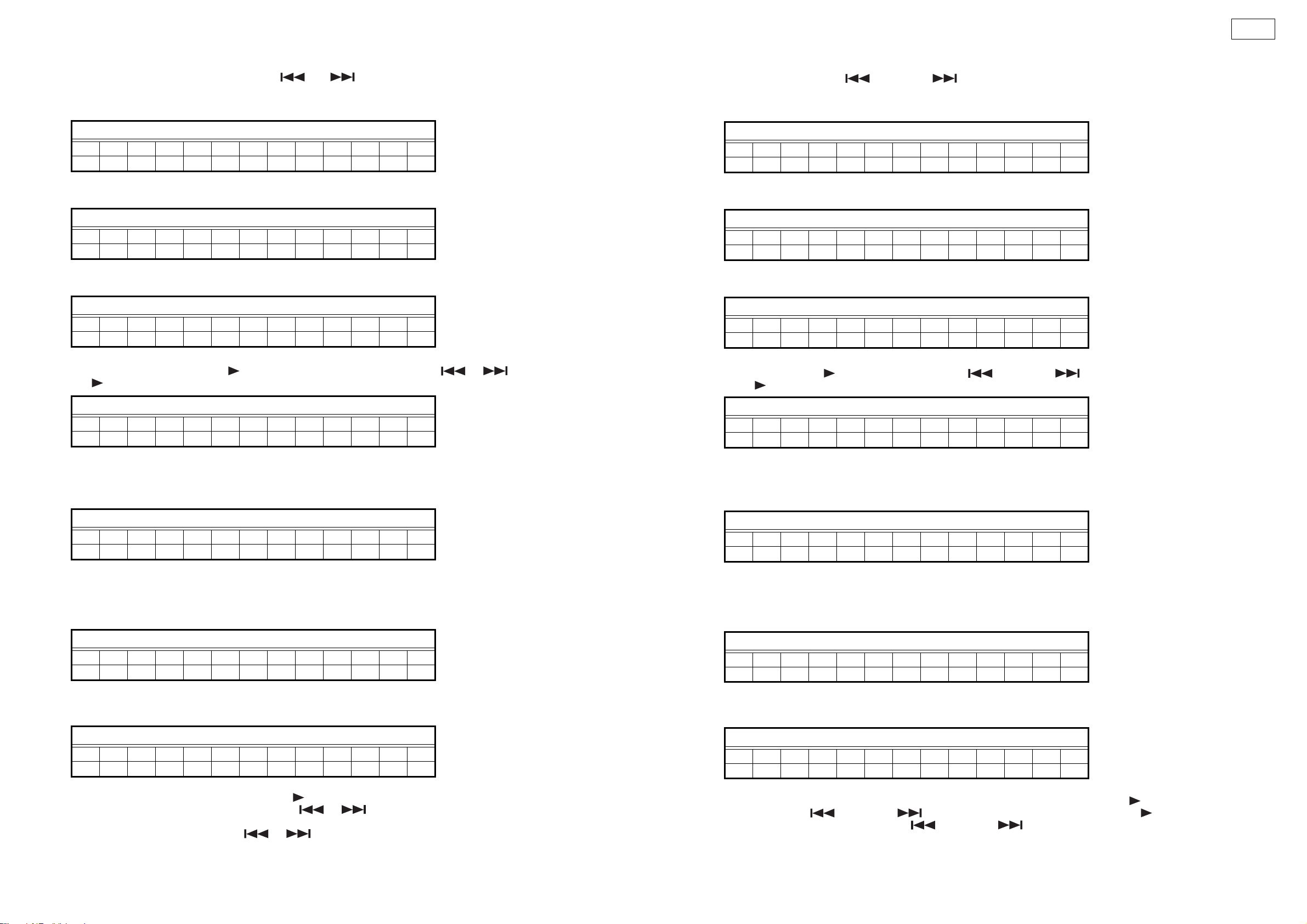

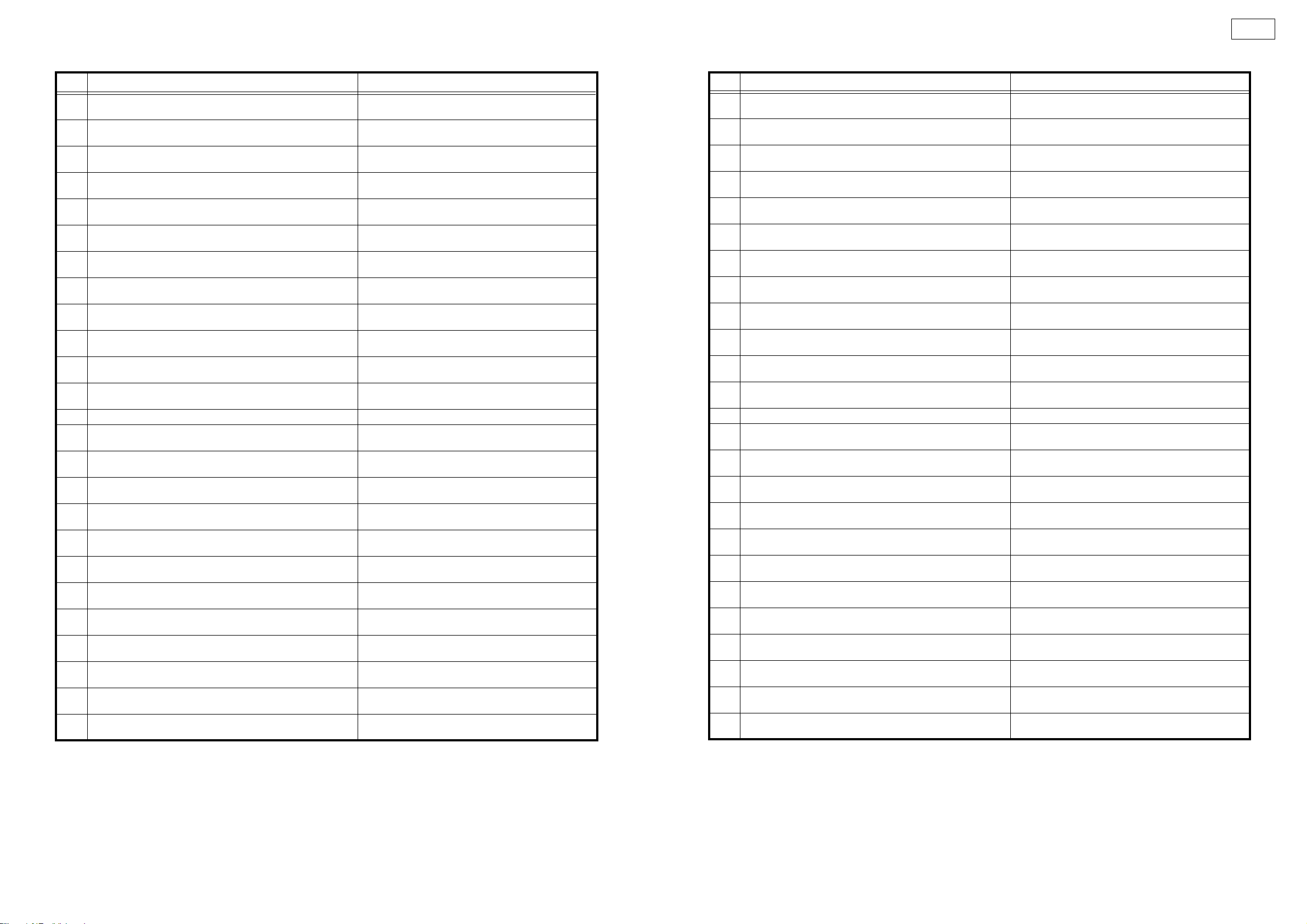

Table 2: Trace mode details

YY Contents Contents supplement

71 A display of PO error detection number of the inner circumference

of 1-layer and an address.

72 A display of PO uncorrectable number of the inner circumference of

1-layer and an address.

73 A display of PI error detection number of the inner circumference of

1-layer and an address.

74 A display of PI uncorrectable number of the inner circumference of

1-layer and an address.

75 A display of PO error detection number of the central circumfer-

ence of 1-layer and an address.

76 A display of PO uncorrectable number of the central circumference

of 1-layer and an address.

77 A display of PI error detection number of the central circumference

of 1-layer and an address.

78 A display of PI uncorrectable number of the central circumference

of 1-layer and an address.

79 A display of PO error detection number of the outer circumference

of 1-layer and an address.

80 A display of PO uncorrectable number of the outer circumference

of 1-layer and an address.

81 A display of PI error detection number of the outer circumference of

1-layer and an address.

82 A display of PI uncorrectable number of the outer circumference of

1-layer and an address.

It is invalid at the time of CD operation.

It is invalid at the time of CD operation.

CD : C1 error detection number (x3)

It is invalid at the time of CD operation.

It is invalid at the time of CD operation.

It is invalid at the time of CD operation.

CD : C1 error detection number (x3)

It is invalid at the time of CD operation.

It is invalid at the time of CD operation.

It is invalid at the time of CD operation.

CD : C1 error detection number (x3)

It is invalid at the time of CD operation.

表 2トレースモード詳細

YY 内容 補足説明

71 1 層内周の PO 誤り検出数とアドレスの表示 CD 時は無効。

72 1 層内周の PO 訂正不可数とアドレスの表示 CD 時は無効。

73 1 層内周の PI 誤り検出数とアドレスの表示 CD 時は C1 誤り検出数。(x3)

74 1 層内周の PI 訂正不可数とアドレスの表示 CD 時は無効。

75 1 層中周の PO 誤り検出数とアドレスの表示 CD 時は無効。

76 1 層中周の PO 訂正不可数とアドレスの表示 CD 時は無効。

77 1 層中周の PI 誤り検出数とアドレスの表示 CD 時は C1 誤り検出数。(x3)

78 1 層中周の PI 訂正不可数とアドレスの表示 CD 時は無効。

79 1 層外周の PO 誤り検出数とアドレスの表示 CD 時は無効。

80 1 層外周の PO 訂正不可数とアドレスの表示 CD 時は無効。

81 1 層外周の PI 誤り検出数とアドレスの表示 CD 時は C1 誤り検出数。(x3)

82 1 層外周の PI 訂正不可数とアドレスの表示 CD 時は無効。

83 A display of PO error detection number of the inner circumference

of 2-layer and an address.

84 A display of PO uncorrectable number of the inner circumference of

2-layer and an address.

85 A display of PI error detection number of the inner circumference of

2-layer and an address.

86 A display of PI uncorrectable number of the inner circumference of

2-layer and an address.

87 A display of PO error detection number of the central circumfer-

ence of 2-layer and an address.

88 A display of PO uncorrectable number of the central circumference

of 2-layer and an address.

89 A display of PI error detection number of the central circumference

of 2-layer and an address.

90 A display of PI uncorrectable number of the central circumference

of 2-layer and an address.

91 A display of PO error detection number of the outer circumference

of 2-layer and an address.

92 A display of PO uncorrectable number of the outer circumference

of 2-layer and an address.

93 A display of PI error detection number of the outer circumference of

2-layer and an address.

94 A display of PI uncorrectable number of the outer circumference of

2-layer and an address.

In the case of 1-layer DVD and CD disc, it is invalid.

In the case of 1-layer DVD and CD disc, it is invalid.

In the case of 1-layer DVD disc, it is invalid.

CD : C1 error detection number (x6)

In the case of 1-layer DVD and CD disc, it is invalid.

In the case of 1-layer DVD and CD disc, it is invalid.

In the case of 1-layer DVD and CD disc, it is invalid.

In the case of 1-layer DVD disc, it is invalid.

CD : C1 error detection number (x6)

In the case of 1-layer DVD and CD disc, it is invalid.

In the case of 1-layer DVD and CD disc, it is invalid.

In the case of 1-layer DVD and CD disc, it is invalid.

In the case of 1-layer DVD disc, it is invalid.

CD : C1 error detection number (x6)

In the case of 1-layer DVD and CD disc, it is invalid.

83 2 層内周の PO 誤り検出数とアドレスの表示 DVD1 層ディスクの場合、無効。

CD 時は無効。

84 2 層内周の PO 訂正不可数とアドレスの表示 DVD1 層ディスクの場合、無効。

CD 時は無効。

85 2 層内周の PI 誤り検出数とアドレスの表示 DVD1 層ディスクの場合、無効。

CD 時は C1 誤り検出数。(x6)

86 2 層内周の PI 訂正不可数とアドレスの表示 DVD1 層ディスクの場合、無効。

CD 時は無効。

87 2 層中周の PO 誤り検出数とアドレスの表示 DVD1 層ディスクの場合、無効。

CD 時は無効。

88 2 層中周の PO 訂正不可数とアドレスの表示 DVD1 層ディスクの場合、無効。

CD 時は無効。

89 2 層中周の PI 誤り検出数とアドレスの表示 DVD1 層ディスクの場合、無効。

CD 時は C1 誤り検出数。(x6)

90 2 層中周の PI 訂正不可数とアドレスの表示 DVD1 層ディスクの場合、無効。

CD 時は無効。

91 2 層外周の PO 誤り検出数とアドレスの表示 DVD1 層ディスクの場合、無効。

CD 時は無効。

92 2 層外周の PO 訂正不可数とアドレスの表示 DVD1 層ディスクの場合、無効。

CD 時は無効。

93 2 層外周の PI 誤り検出数とアドレスの表示 DVD1 層ディスクの場合、無効。

CD 時は C1 誤り検出数。(x6)

94 2 層外周の PI 訂正不可数とアドレスの表示 DVD1 層ディスクの場合、無効。

CD 時は無効。

22

Page 23

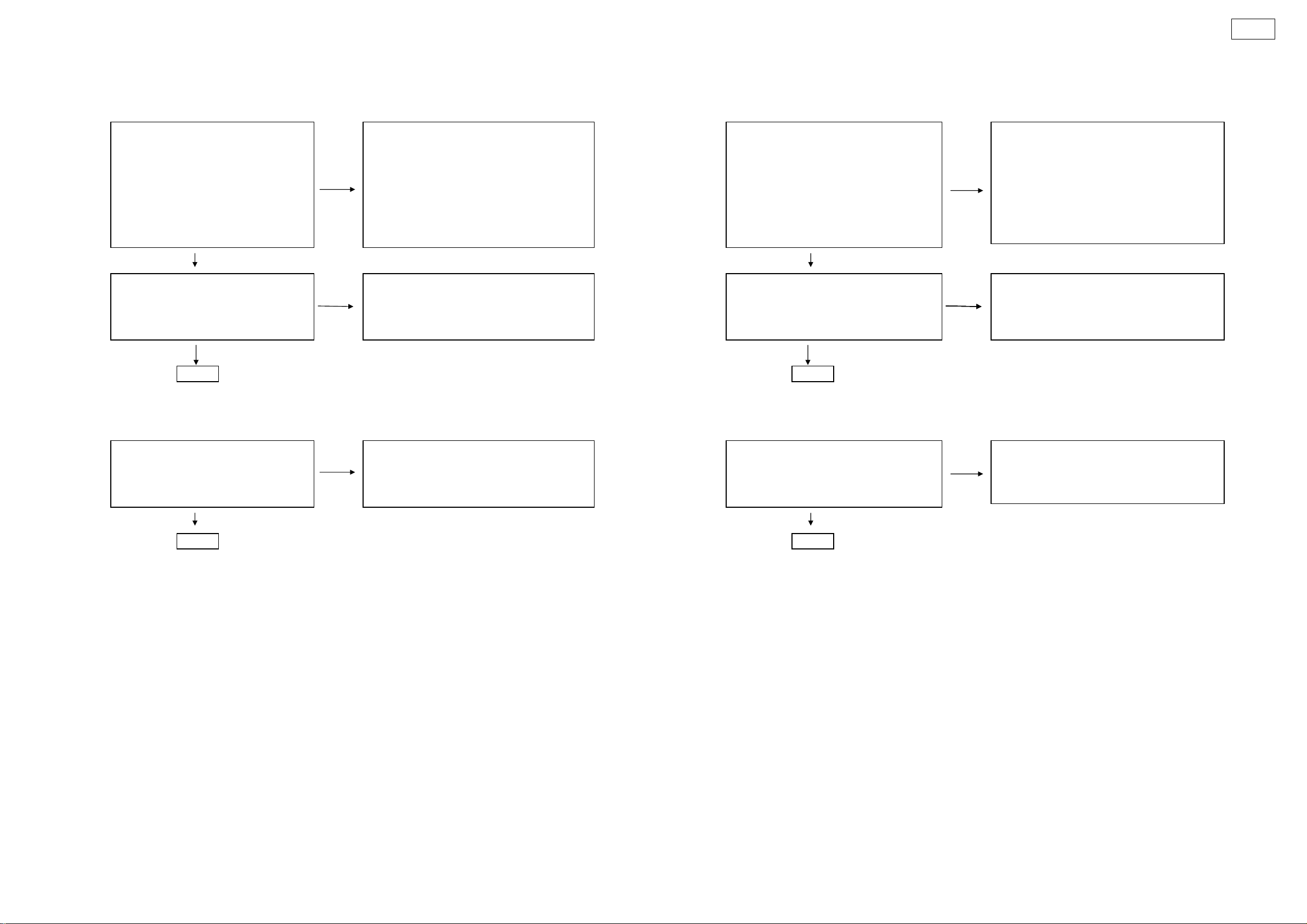

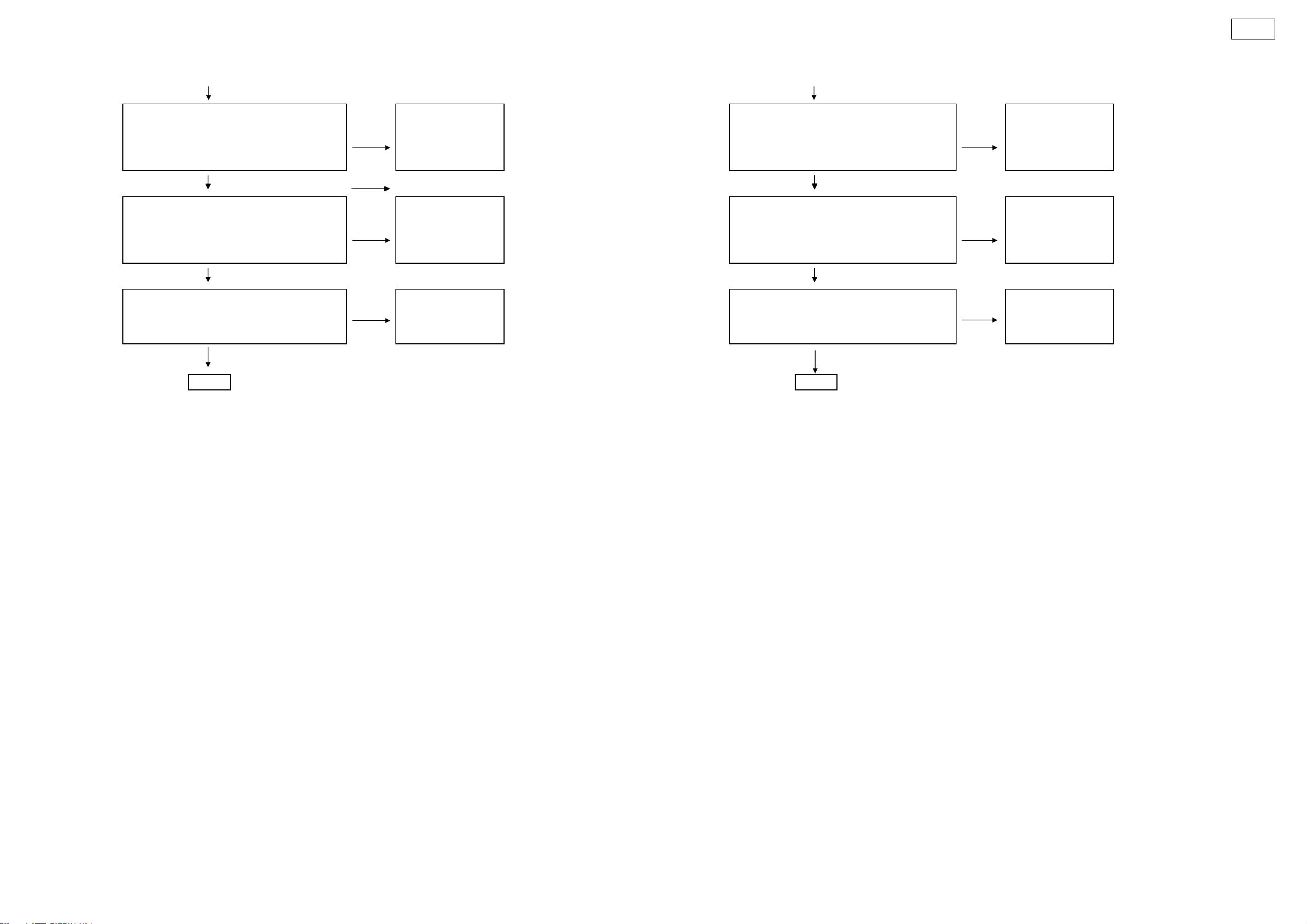

TROUBLE SHOOTING トラブルシューティング

トラブルシュー

1. 1U-3836(MAINUNIT)

1.1. FL

管点灯

せ

ず

立ち上

が

程

半田付

けを

確

T

O.K

源電圧確

半田付

けを

確

T

O.K

発振波形確

半田付

けを

確

T

O.K

源電圧確

半田付

けを

確

T

O.K

源電圧確

半田付

けを

確

T

O.K

源電圧確

半田付

けを

確

T

O.K

データバ

T

付

けを

確

良

O.K

次

/

立ち上

げ

● ADV-S102 ● ADV-S102

1. 1U-3836 (MAIN UNIT)

1.1. FL TUBE dosen't light

(1) Check the Set-up process of System μ-COM (1) システムμ-COM

Check Power Supply Voltages. 電源電圧確認

1U-3836-1(MAIN UNIT) 1U-3836-1(MAINUNIT)

䊶 [IC303]: N.G Check Soldering. ・ [IC303]: N.G

+9V_DNS 䊶 CX142 on MAIN UNIT. +9VDNS ・ MAINUNI

S-102

りチェック工

認

のCX142

O.K.

Check Power Supply Voltages. 電

1U-3836-1(MAIN UNIT) 1U-3836-1(MAINUNIT)

䊶 [IC301]: N.G Check Soldering. ・ [IC301]: N.G

+3.3V_DNS 䊶 IC303 on MAIN UNIT. +3.3VDNS ・ MAINUNI

O.K.

Check Oscillation waveform.

1U-3836-1(MAIN UNIT) 1U-3836-1(MAINUNIT)

䊶 [IC301]: N.G Check Soldering. ・ [IC301]: N.G

16MHz at 18pin. 䊶 X301 on MAIN UNIT. 16MHzat18pin. ・ MAINUNI

O.K.

Check Power Supply Voltages. 電

1U-3836-1(MAIN UNIT) 1U-3836-1(MAINUNIT)

䊶 [IC301]: N.G Check Soldering. ・ [IC301]: N.G

"H"level at [ON/STBY]15pin 䊶 IC301 on MAIN UNIT. "H"levelat[ON/STBY]15pin ・ MAINUNI

and "L"LEVEL at [CHOP_ON]48pin? and"L"LEVELat[CHOPON]48pin?

O.K.

Check Power Supply Voltages. 電

1U-3836-1(MAIN UNIT) 1U-3836-1(MAINUNIT)

䊶 [IC306]: N.G Check Soldering. ・ [IC306]: N.G

+12V_M1 䊶 IC306 on MAIN UNIT. +12VM1 ・ MAINUNI

認

認

認

認

.

.

.

.

認

のIC303

認

のX301

認

のIC301

認

のIC306

O.K.

Check Power Supply Voltages. 電

1U-3836-1(MAIN UNIT) 1U-3836-1(MAINUNIT)

䊶 [CX211]:19pin N.G Check Soldering. ・ [CX211]:19pin N.G

-HB -35V±3䌖䊶T201 on MAIN UNIT. -HB=-35V±3V ・ MAINUNI

O.K.

Check Data Bus between

1U-3831-1(DISPLAY CENTER UNIT) 1U-3831-1(DISPLAYCENTERUNIT)

FLD Driver(1U-3831-1[IC241]) N.G (1) Check soldering of CX211 on MAIN UNIT. FLDDriver(1U-3831-1[IC241]) N.G (1) MAINUNI

䊶 [FL_RST]:"H"level? (2) 1U-3831-1 is N.G.(No Good). ・ [FLRST]:"H"level? (2) 1U-3831-1 の不

O.K.

Continue to next step.

Check the Set-up process of B/E μ-COM. (2)B

のステップへ

認

スの確認

Eμ-COM

.

.

.

チェック工程へ

認

のT201

のCX211の半田

認

23

Page 24

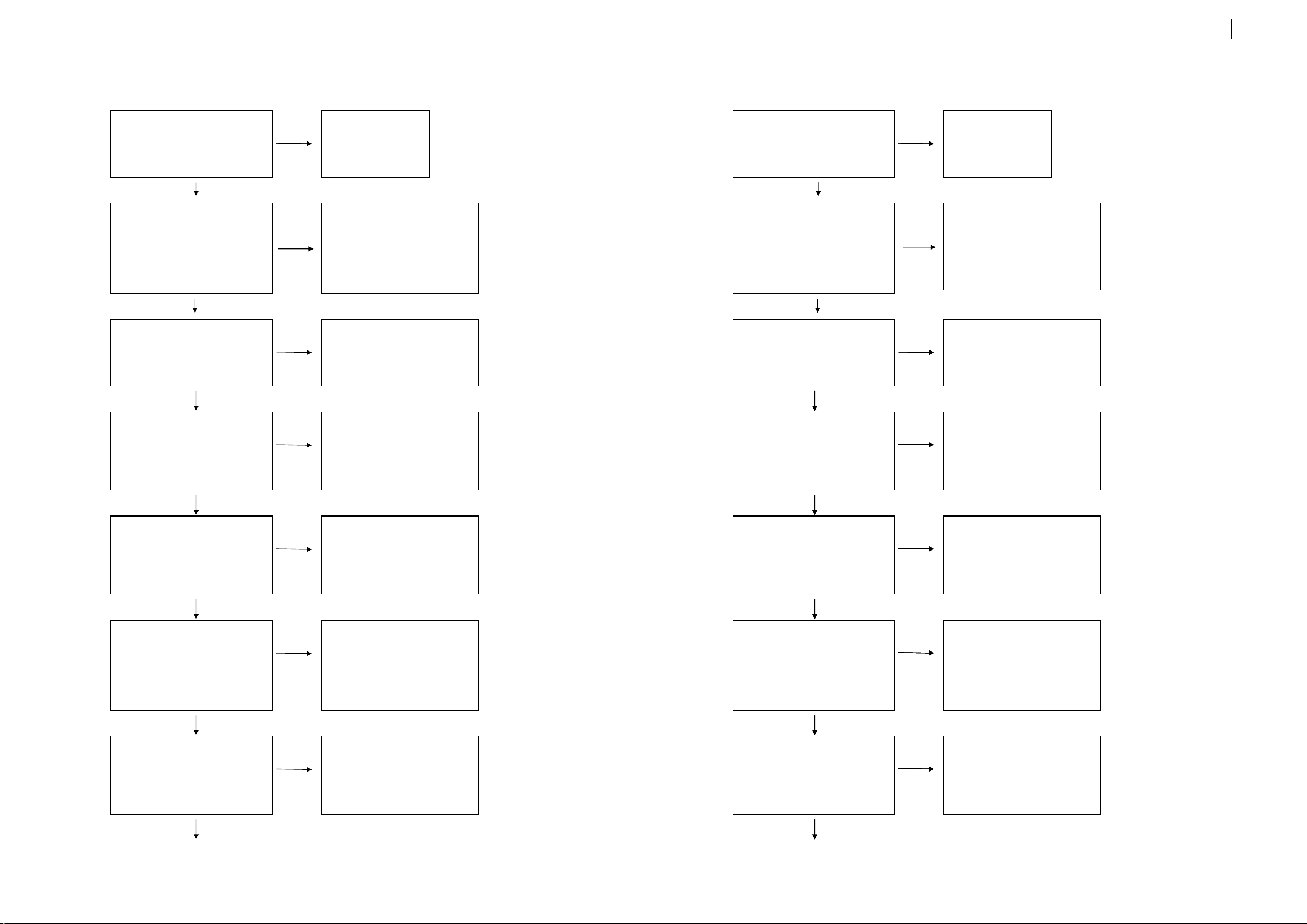

(2) Check the Set-up process of B/E μ-COM (2) B/Eμ-COM 立ち上がりチェック工程

源電圧確

半田付

けを

確

O.K

クク

波形確

クク

波形確

を

確

半田付

けを

確

R202

O.K

T

信号の確

半田付

けを

確

O.K

O.K

半田付

けを

確

と

ドデ

確

タバ

O.K

制御信

半田付

けを

確

終

S-102

Check Power Supply Voltages. 電

1U-3836-1(MAIN UNIT) N.G Check Soldering. 1U-3836-1(MAINUNIT) N.G

・ [IC101]: ・ [IC304] ・ [IC101]: ・ [IC304]

+3.3V_D2,+2.0V_ESS O.K.? ・ [IC111] +3.3VD2,+2.0VESSO.K.? ・ [IC111]

O.K.

Check Clock waveform. Check 27MHz(3.3V)at (1) Check Soldering. of X101.

1U-3836-1(MAIN UNIT) N.G 4pin of IC109. N.G (2) Check Soldering. of IC109 1U-3836-1(MAINUNIT) ・ [IC109]:4pin (2)

・ [IC101]:49,105,116pin and ・ [IC101]:49,105,116pinand ・ [IC109]

117pin. 117pin.

27MHz(3.3V),O.K.? O.K.

O.K.

Check Reset signal. RESE

1U-3836-1(MAIN UNIT) N.G Check Soldering. 1U-3836-1(MAINUNIT) N.G

・ [IC101]:[BE_RST]24 pin. ・ IC301,R112 ・ [IC101]:[BERST]24pin. ・ IC301,R112

"H"level O.K.? "H"levelO.K.?

O.K.

䋲

Check I

1U-3836-1(MAIN UNIT) 1U-3836-1(MAIN UNIT) 1U-3836-1(MAINUNIT) 1U-3836-1(MAINUNIT)

C Signal. Check Soldering. I2C信号の確認 半田付けを確認

・ [IC101]: N.G ・ [IC104] ・ [IC101]: N.G ・ [IC104]

"H"level at 160pin and 161pin. "H"levelat160pinand161pin.

Check Soldering. Of

・ R202 ・

認

認

.

の認ロッ

27MHz(3.3V),O.K.? O.K.

.

認

.

N.G

の認ロッ

認

N.G (1) [X101]

半田付けを確認

認

認

O.K.

1U-3836-1(MAIN UNIT) Check Soldering at Address,Data Bus,Control Signal. 1U-3836-1(MAINUNIT)

Check Address,Data Bus between 1U-3836-1(MAIN UNIT) [IC101]

[IC101],[1C102]and[IC103] N.G ・ [LD0-LD7],[LCS3,LOE] ア

O.K.

Check controll signal. Check Soldering.

1U-3836-1(MAIN UNIT) N.G ・ IC105 1U-3836-1(MAINUNIT) N.G ・ IC105

・ [IC105]:[BE_ON]19 pin. ・ [IC105]:[BEON]19pin.

"H"level O.K.? "H"levelO.K.?

END

[1C102]と[IC103]間の 1U-3836-1(MAINUNIT)

ー

スの N.G ・ [LD0-LD7],[LCS3,LOE]

号の確認

了

.

認レス、

.

認

認

24

Page 25

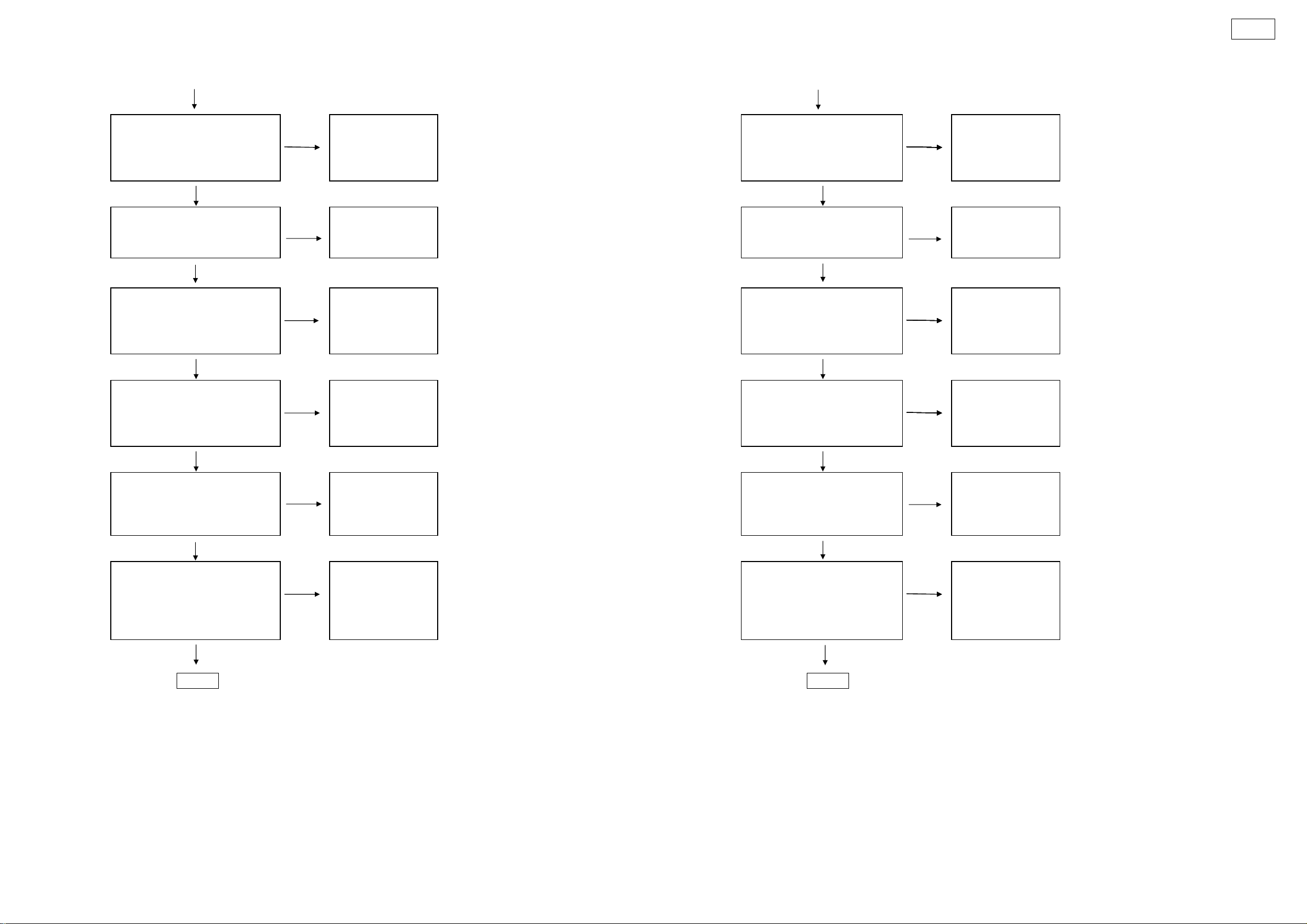

1.2. No Sound,Noise generated

1.2.ディスク読め

ず

[NoPlay],[0000]等の表示

Y

ず

半

ド

を

確

kを確

発光

付

けを

確

ネクタ

接続を確

ザ

K

発光

トドT

ザ

流

付

けを

確

とその周辺の半田付

けを

確

O.K

ピンドルドブ

信

確

付

けを

確

信

付

けを

確

とその周辺の半田付

けを

確

O.K

終

ク

程

半田付

けを

確

トポイント

T

約

差動出力

付

けを

確

O.K

終

[No Play], [00 00] displayed etc.

(1) CD,DVD PLA

S-102

(1)ディスク回転せ

(1) Check Soldering of P.U.

・ short-circuit?

Check the Emission of Pick-up. (2) Check the circumference soldering of TR603 (1) P.U.の

IU-3807(FEP UNIT) and TR604. Pic

・ Emission of P.U. laser O.K.? N.G (3) Check connector insertion. IU-3807(FEPUNIT) N.G (3) コ

・ The test mode "T2" is executed. ・ [P.U.]-[IU-3807] FFC(CX241) ・ P.U.レー

Laser current O.K.? (4) Check the soldering [IC601] and circumference ・テス

soldering of [IC601] (5) [IC101],[IC102]

(5) Check the soldering [IC101] ,[IC102]and

circumference soldering of [IC101] ,[IC102]

O.K.

(1) Check soldering of [IC101]:56, 75pin

Check Spindle drive. N.G (2) Check the circumference soldering of ス

IU-3807(FEP UNIT) [SPDRV], [FG] signal. IU-3807(FEPUNIT) (2) [SPDRV][FG]

・ [SPDRV]: "H" level? (3) Check the soldering [IC151] and circumference ・ [SPDRV]:"H"level? (3) [IC151]

soldering of [IC151]

O.K.

END

(2) CD or DVD check process (2) CDorDVDチェッ

田ショートラン

認-upの

ー

O. .? ・ [P.U.]-[IU-3807]FFC(CX241)

モー 2実行レー ー電 OK? (4) [IC601]とその周辺の半田

.

認ライ 号の N.G (1) [IC101]56,75pinの半田

.

了

工

(2)TR603,TR604周辺の半田

認

号ライン周辺の半田

認

認

認

認

認

認

認

Check the RF signal. RF信号の確認

IU-3807(FEP UNIT) N.G Check Soldering. IU-3807(FEPUNIT) N.G

・ Check the voltage of Test-Point (TP) 㪠㪬 㪊㪏㪇㪎㩿㪝㪜㪧 㪬㪥㪠㪫㪀 ・テス

・ TP[mAMON1] [AMON2]: differential output ・ Check the circumference soldering of [IC101], ・

about1.0Vp-p [IC601]

O.K.

END

P[A

MON1][AMON2]:

(TP)の電圧確認 IU-3807-1(FEPUNIT)

1.0Vp-p ・ [IC101],[IC601]とその周辺の半田

.

了

認

認

25

Page 26

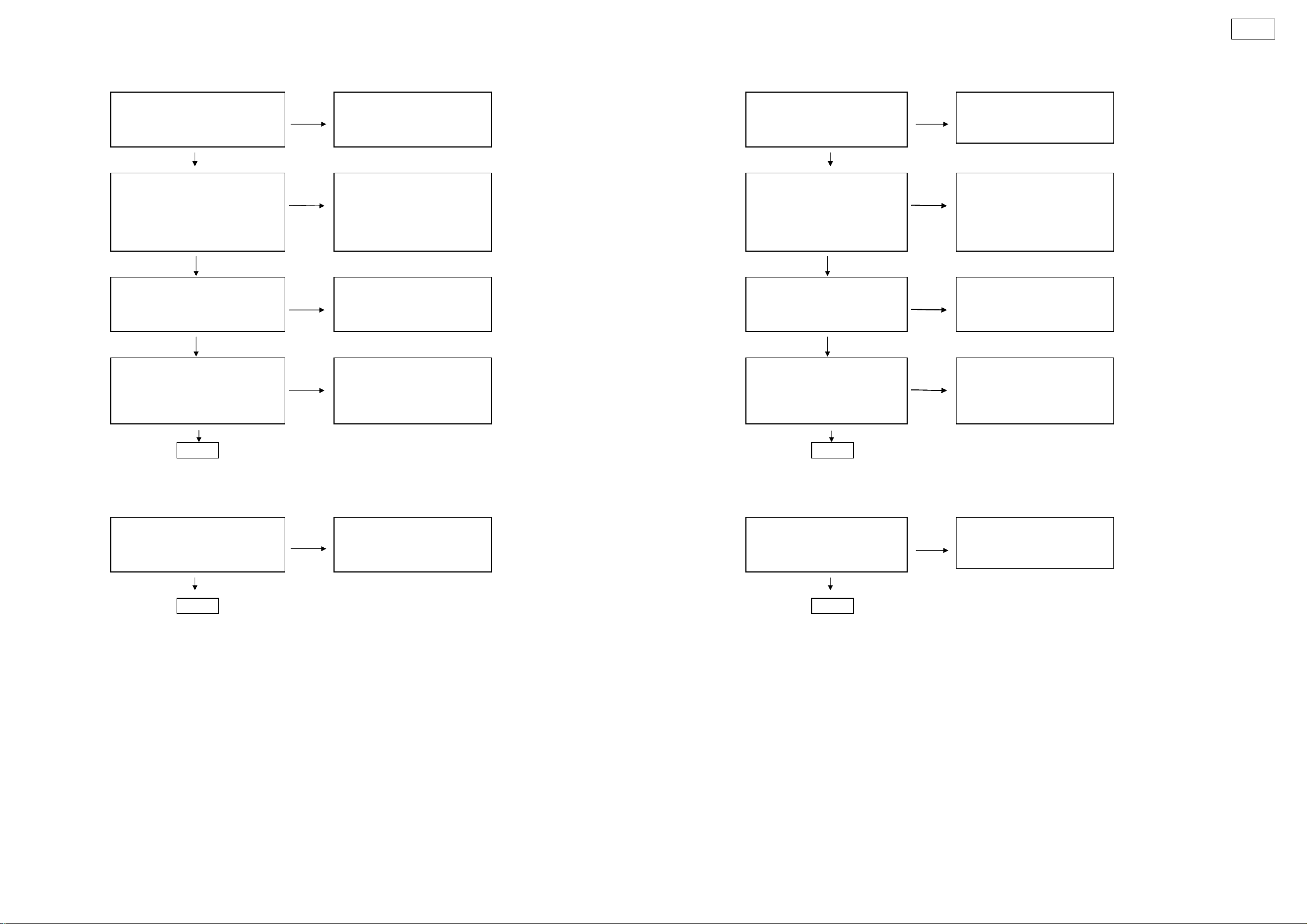

1.3. No Sound,Noise generated

1.3. 音声出力せず、ノイズ発生

源電圧確

半田付

けを

確

f

f

O.K

T

信号の確

半田付

けを

確

O.K

/Eから

デジタルオーディオ

半田付

けを

確

データ

出力確

/

力:出力

O.K

から

デジタルオーディオ

データ

出力確

半田付

けを

確

/

力:出力

O.K

から

デジタ

オーデ

オデ

出力確

半田付

けを

確

/

力:出力

O.K

から

デジタ

半田付

けを

確

オーデ

オデ

出力確

/

力:出力

/

力:出力

O.K

から

デジタ

オーデ

オデ

出力確

半田付

けを

確

/

力:出力

O.K

(1) CD,DVD PLAY (1) CD,DVD再生時

S-102

Check Power Supply Voltages. 電

1U-3836(MAIN UNIT) N.G Check Soldering. 1U-3836(MAINUNIT) N.G

・ +12V_A1,-12V_A1 ・ IC602,IC603 ・ +12VA1,-12VA1 ・ IC602,IC603

・ +7V,-7V of [IC601] ・ IC404 ・ +7V,-7Vo

・ +1.2V_DSP of [IC401] ・ +1.2VDSPo

O.K.

Check Reset signal of [IC401], RESE

[IC501],[IC502]. Check Soldering. [IC401].[IC501],[IC502]

1U-3836(MAIN UNIT) N.G ・ [IC301]:115,82,109 pin 1U-3836(MAINUNIT) N.G ・ [IC301]:115,82,109pin

・ [IC401]:[DSP_RST]202pin ・ IC401,RR210 ・ [IC401]:[DSPRST]202pin ・ IC401,RR210

・ [IC501]:[CODEC_RST]10 pin. ・ IC501,R603 ・ [IC501]:[CODECRST]10pin. ・ IC501,R603

・ [IC502]:[DIR_RST]41 pin. ・ IC502,R661 ・ [IC502]:[DIRRST]41pin. ・ IC502,R661

"H"level O.K.? "H"levelO.K.?

O.K.

Check Digital Audio Data output Check Soldering. B

from B/E to DIR N.G ・ [IC101]:41pin

1U-3836(MAIN UNIT) ・ R119 1U-3836(MAINUNIT) ・ R119

・ [IC101]output and [IC502]input: ・ [IC502]:2pin ・ [IC101]

[BE_SPDIF] ・ R685 [BESPDIF] ・ R685

O.K.

Check Digital Audio Data output DIR

from DIR to PLD N.G Check Soldering.

1U-3836(MAIN UNIT) ・ [IC502]:22,23,21pin 1U-3836(MAINUNIT) ・ [IC502]:22,23,21pin

・ [IC502]output and [IC503]input: ・ R670-672 ・ [IC502]

[DIR_S_64FS],[DIR_S_FS], ・ [IC503]:71,72,70pin [DIRS64FS],[DIRSFS], ・ [IC503]:71,72,70pin

[DIR_DA] ・ R737-739 [DIRDA] ・ R737-739

認

[IC601] ・ IC404

[IC401]

.

認

.

DIRへの

認

[IC502]入 ・ [IC502]:2pin

.

PLDへの

認

[IC503]入 ・ R670-672

N.G ・ [IC101]:41pin

N.G

認

認

認

認

ル

ル

.

N.G

.

ル

N.G ・ [IC401]:137,143,133,135pin

.

N.G

認

認

認

O.K.

Check Digital Audio Data output PLD

from PLD to DSP N.G Check Soldering.

1U-3836(MAIN UNIT) ・ [IC503]:60,59,55pin 1U-3836(MAINUNIT) ・ [IC503]:60,59,55pin

・ [IC503]output and [IC401]input: ・ R719,722,723 ・ [IC503]

[DSPI_64FS],[DSPI_FS], ・ [IC401]:146,144,125pin [DSPI64FS],[DSPIFS], ・ [IC401]:146,144,125pin

[DSPI_FDA] ・ RR165,167 [DSPIFDA] ・ RR165,167

O.K.

Check Digital Audio Data output Check Soldering. DSP

from DSP to PLD/CODEC N.G ・ [IC401]:137,143,133,135pin

1U-3836(MAIN UNIT) ・ RR169,168,173,171 1U-3836(MAINUNIT) ・ RR169,168,173,171

・ [IC401]output and [IC503]input: ・ [IC503]:64,61pin ・ [IC401]

[DSPO_64FS],[DSPO_FS] ・ R725,724 [DSPO64FS],[DSPOFS] ・ R725,724

・ [IC401]output and [IC501]input: ・ [IC501]:16,15pin ・ [IC401]

[DSPO_FDA],[DSPO_CWDA] ・ R656,655 [DSPOFDA],[DSPOCWDA] ・ R656,655

O.K.

Check Digital Audio Data output PLD

from PLD to CODEC N.G Check Soldering.

1U-3836(MAIN UNIT) ・ [IC503]:79,80pin 1U-3836(MAINUNIT) ・ [IC503]:79,80pin

・ [IC503]output and [IC501]input: ・ R728,727 ・ [IC503]

[DSC_64FS],[DAC_FS], ・ [IC501]:17,18pin [DSC64FS],[DACFS], ・ [IC501]:17,18pin

・ R657,658 ・ R657,658

DSPへの

ィータ認

[IC401]入 ・ R719,722,723

PLD/CODECへの

ィータ認

[IC503]入 ・ [IC503]:64,61pin

[IC501]入 ・ [IC501]:16,15pin

CODECへの

ィータ認

[IC501]入 ・ R728,727

O.K.

.

26

Page 27

Check Analog Audio Data output CODECからAMPへのアナロ

グ

オーデ

オデ

出力確

半田付

けを

確

/

力:出力

O.K

オーディオ

ト

信号の確認半田付

けを

確

T

O.K

から

グ

オーデ

オデ

出力確

半田付

けを

確

出力

/

O.K

から

差動

グ

オーデ

オデ

出力確

半田付

けを

確

/

力:出力

差動

O.K

オーディオ

ト

信号の確認半田付

けを

確

T

O.K

差動

オ

データ

出力確

半田付

けを

確

出力

O.K

終

from CODEC to AMP. N.G Check Soldering.

1U-3836(MAIN UNIT) ・ [IC501]:28,29,31pin 1U-3836(MAINUNIT) ・ [IC501]:28,29,31pin

・ [IC501]output and [IC506],[IC507] ・ [IC506],[IC507] ・ [IC501]

[FL],[FR],[SW] [FL],[FR],[SW]

ィータ認

[IC506],[IC507]入 ・ [IC506],[IC507]

N.G

認

S-102

O.K.

Check audio mute signal. Check Soldering.

1U-3836(MAIN UNIT) N.G ・ [IC503]:86pin 1U-3836(MAINUNIT) N.G ・ [IC503]:86pin

・ [DAC_MUTE] ・ TR501-505 ・ [DACMUTE] ・

"L"level O.K.? "L"levelO.K.?

O.K.

Check Analog Audio Data output AMP

from AMP to FUNC.VR. N.G Check Soldering.

1U-3836(MAIN UNIT) ・ [IC601]:11,12,8pin 1U-3836(MAINUNIT) ・ [IC601]:11,12,8pin

・ AMPoutput and [IC601]input: ・AMP

[DSP_FL],[DSP_FR],[DSP_LFE] [DSPFL],[DSPFR],[DSPLFE]

O.K.

Check Analog Audio Data output FUNC.VR.

from FUNC.VR. to Diff.AMP. N.G Check Soldering.

1U-3836(MAIN UNIT) ・ [IC601]:54,47,35pin 1U-3836(MAINUNIT) ・ [IC601]:54,47,35pin

・ [IC601]output and Diff.AMP.input: ・ IC609,610 ・ [IC601]

[IC601]:54,47,35pin [IC601]:54,47,35pin

O.K.

Check audio mute signal. Check Soldering.

1U-3836(MAIN UNIT) N.G ・ [IC301]:100,83pin 1U-3836(MAINUNIT) N.G ・ [IC301]:100,83pin

・ [PRE_MUTE_MAIN], ・ TR609-615 ・ [PREMUTEMAIN], ・

[PRE_MUTE_SUB] [PREMUTESUB]

"L"level O.K.? "L"levelO.K.?

ミュー

FUNC.VR.へのアナロ

ィータ認

[IC601]入力:

AMPへのアナロ

ィータ認

AMP入 ・ IC609,610

ミュー

.

認

R501-505

.

N.G

.

N.G

.

認

認

認

R609-615

O.K.

Check Analog Audio Data output

from Diff.AMP. N.G Check Soldering.

1U-3836(MAIN UNIT) ・ IC609,610 1U-3836(MAINUNIT) ・ IC609,610

・ [IC609],[IC610]output: ・ CX171 ・[ :IC609],[IC610]

[FL+],[FL-],[FR+],[FR-], [FL+],[FL-],[FR+],[FR-],

[SW+],[SW-] [SW+],[SW-]

O.K.

END

AMPのアナログオーディ

認

了

.

N.G

・ CX171

.

認

27

Page 28

S-102

から

グ

オーデ

オデ

力確

半田付

けを

確

O.K

から

グ

オーデ

オデ

力確

半田付

けを

確

/力出力

O.K

から

グ

半田付

けを

確

オーデ

オデ

力確

/

出力

/

力

O.K

から

デジタ

オーデ

オデ

出力確

半田付

けを

確

/

力:出力

O.K

終

デジタルオーディオ

力時

デジタ

オーデ

オデ

力確

半田付

けを

確

O.K

終

(2) Analog audio in(AUX1,AUX2) (2) アナログオーディオ入力時(AUX1,AUX2)

Check Analog Audio Data input AUX1-2

from AUX1-2 to FUNC.VR. N.G Check Soldering.

1U-3836(MAIN UNIT) ・ JK601 1U-3836(MAINUNIT) ・ JK601

Check Analog Audio Data input FUNC.VR.

from FUNC.VR. to AMP N.G Check Soldering.

1U-3836(MAIN UNIT) ・ [IC601]14,17pin 1U-3836(MAINUNIT) ・ [IC601]14,17pin

・ [AUX1-2 IN]-L/R ・ [IC601]74-77pin ・ [AUX1-2IN]-L/R ・ [IC601]74-77pin

O.K.

・ [IC601]output and [IC504] ・ IC504,505 ・ [IC601]

/[IC505]input: [A/DL],[A/DR]

[A/D_L],[A/D_R]

O.K.

FUNC.VR.へのアナロ

ィータ入認

AMPへのアナロ

ィータ入認

[IC504],[IC505]入 ・ IC504,505

Check Analog Audio Data input Check Soldering. AMP

from AMP to CODEC N.G ・ IC504,505

1U-3836(MAIN UNIT) ・ [IC501]39-42pin 1U-3836(MAINUNIT) ・ [IC501]39-42pin

・ [IC504/505]output and [IC501]input: ・ [IC504

Check Digital Audio Data output CODEC

from CODEC to DIR N.G Check Soldering.

1U-3836(MAIN UNIT) ・ [IC501]:20pin 1U-3836(MAINUNIT) ・ [IC501]:20pin

・ [IC501]output and [IC502]input: ・ [IC502]:24pin ・ [IC501]

[AD_FDA] [ADFDA]

O.K.

CODECへのアナロ

ィータ入認

505]

DIRへの

ィータ認

[IC501]入

ル

[IC502]入 ・ [IC502]:24pin

N.G

.

N.G

.

N.G ・ IC504,505

.

N.G

認

認

認

認

O.K.

END

(3) Digital audio in (3)

Check Digital Audio Data input Dig-INからDIRへの

from Dig-IN to DIR N.G Check Soldering.

1U-3836(MAIN UNIT) ・ IC511 1U-3836(MAINUNIT) ・ IC511

・ [DIN] ・ [IC502]9pin ・ [DIN] ・ [IC502]9pin

O.K.

END

了

入

ル

ィータ入認

了

.

N.G

.

認

28

Page 29

S-102

3. 1U-3836-1(MAINUNIT)

3-1.DVD再

生時

源確

半田付

けを

確

O.K

CheckP

電源電圧確認

半田付

けを

確

O.K

クロック

波形確

半田付

けを

確

O.K

T

信号の確

半田付

けを

確

O.K

ビデオ

ト

信号の確

半田付

けを

確

O.K

/Eから

デジタ

映像

データ

出力

半田付

けを

確

確

/力出力

O.K

3. 1U-3836-1 (MAIN UNIT)

3-1.DVD PLAY

(1) INTERLACE output does not outputed. (1) インターレース映像出力せず

Check Power Supply Voltages. N.G Check Soldering. 電

1U-3836-1(MAIN UNIT) ・ IC304 1U-3836-1(MAINUNIT) ・ IC304

1U-3836-1(MAIN UNIT) N.G Check Soldering. 1U-3836-1(MAINUNIT) N.G

Check Clock waveform.

1U-3836-1(MAIN UNIT) N.G Check Soldering. 1U-3836-1(MAINUNIT) N.G

Check Reset signal. RESE

1U-3836-1(MAIN UNIT) Check Soldering. 1U-3836-1(MAINUNIT)

・ +3.3V_D1,±5V_V1 ・ +3.3VD1,±5VV1

owerSupplyVoltages.

・ [IC701]:+1.8V ・ IC706,707 ・ [IC701]:+1.8V ・ IC706,707

・ [IC801]:+2.5V_DE,+2.5V_A ・ IC806,807 ・ [IC801]:+2.5VDE,+2.5VA ・ IC806,807

O.K.

O.K.

・ [IC701]192pin ・ X701 ・ [IC701]192pin ・ X701

13.5MHz OK? 13.5MHzOK?

・ [IC703]:[VPLD_RST] N.G ・ [IC301]57pin,RR838 ・ [IC703]:[VPLDRST] N.G ・ [IC301]57pin,RR838

・ [IC701]:[FLI_RST] ・ [IC301]12pin,RR701 ・ [IC701]:[FLIRST] ・ [IC301]12pin,RR701

・ [IC801]:[ENC_RST] ・ [IC301]50pin,RR355 ・ [IC801]:[ENCRST] ・ [IC301]50pin,RR355

"H"level O.K.? "H"levelO.K.?

O.K.

認電圧 N.G

.

.

の

認

.

認

認

認

認

認

Check video mute signal.

1U-3836-1(MAIN UNIT) N.G Check Soldering. 1U-3836-1(MAINUNIT) N.G

・ [IC802]:[S/V_MUTE],[COMP_MUTE] ・ IC802 ・ [IC802]:[S/VMUTE],[COMPMUTE] ・ IC802

"H"level O.K.? "H"levelO.K.?

Check Digital Video DATA output Check Soldering. B

from B/E to ENCODER の

1U-3836-1(MAIN UNIT) N.G ・ [IC101]:106-110,113-115,118,119pin 1U-3836-1(MAINUNIT) N.G ・ [IC101]:106-110,113-115,118,119pin

・ [IC101]output/[IC801]input ・ IC109,IC803 ・ [IC101]

[BE_ID0-7.],[BE_HS],[BE_VS],[PXCLK] ・ RR326-349 [BEID0-7.],[BEHS],[BEVS],[PXCLK] ・ RR326-349

O.K.

ミュー

O.K.

ENCODERへの

認

[IC801]入 ・ IC109,IC803

O.K.

認

ル

.

認

.

認

.

29

Page 30

S-102

から

ビデオドライバ

グ

半田付

けを

確

映像

データ

出力の確

出力

/

T

O.K

から

ビデオセレクタ

グ

半田付

けを

確

映像

データ

出力の確

出力

/

T

O.K

ビデオセレクタ

から

ビデオドライバ

グ

半田付

けを

確

映像

データ

出力の確

出力

/

O.K

終

Check analog signal for Video Check Soldering. ENCODER

from ENCODER to Video driver(COMPONENT) ・ [IC801]37-39pin

1U-3836-1(MAIN UNIT) N.G ・ VR803-805 1U-3836-1(MAINUNIT) N.G ・ VR803-805

・ [IC801]output and [IC802]input: ・ TR803-805 ・ [IC801]

[Py],[Pb],[Pr] ・ [IC802]11,13,15pin [Py],[Pb],[Pr] ・ [IC802]11,13,15pin

O.K.

Check analog signal for Video Check Soldering. ENCODER

from ENCODER to Video selector(CVBS/YC) ・ [IC801]43,42pin

1U-3836-1(MAIN UNIT) N.G ・ VR801,802 1U-3836-1(MAINUNIT) N.G ・ VR801,802

・ [IC801]output and [IC804]input: ・ IC801,802 ・ [IC801]

[Y],[C] ・ [IC804]1,12pin [Y],[C] ・ [IC804]1,12pin

O.K.

Check analog signal for Video Check Soldering.

from selector to Video driver(CVBS/YC) N.G ・ [IC804]3,13pin

1U-3836-1(MAIN UNIT) ・ [IC802]8,4pin 1U-3836-1(MAINUNIT) ・ [IC802]8,4pin

・ [IC804]output and [IC802]input: ・ [IC804]

O.K.

END

認(COMPONENT) ・ [IC801]37-39pin

[IC802]入力:・

認(CVBS/YC) ・ [IC801]43,42pin

[IC804]入力:・

認(CVBS/YC) N.G ・ [IC804]3,13pin

[IC802]入力:

了

ーへのアナロ

.

へのアナロ

.

ーへのアナロ

.

認

R803-805

認

R801,802

認

30

Page 31

(2) PROGRESSIVE output does not outputed. (2) プログレッシブ映像出力せず

/EからI/

デジタ

映像

データ

出力

半田付

けを

確

/

力:出力

O.K

/Pから

デジタ

映像

データ

出力

半田付

けを

確

/

力:出力

O.K

から

デジタ

映像

データ

出力

半田付

けを

確

/

力:出力

O.K

から

ビデオドライバ

グ

半田付

けを

確

映像

データ

出力

/

力:出力

O.K

終

Check Digital signal for Video B

from B/E to I/P Check Soldering. の確認

1U-3836-1(MAIN UNIT) N.G ・ [IC101]106-119pin 1U-3836-1(MAINUNIT) N.G ・ [IC101]106-119pin

・ [IC101]output and [IC701]input: ・ RR743-765 ・ [IC101]

[B/E_ID0-7],[BE_HS],[BE_VS],[PXCLK] [B/EID0-7],[BEHS],[BEVS],[PXCLK]

Pへの

[IC701]入 ・ RR743-765

S-102

ル

認

O.K.

.

Check Digital signal for Video I

from I/P to FPGA Check Soldering. の確認

1U-3836-1(MAIN UNIT) N.G ・ [IC701]118-156pin 1U-3836-1(MAINUNIT) N.G ・ [IC701]118-156pin

・ [IC701]output and [IC703]input: ・ RR803-830 ・ [IC701]

[IP_R6/Y0-9],[IP_BO/C0-9],[IP_HS],[IP_VS], [IPR6/Y0-9],[IPBO/C0-9],[IPHS],[IPVS],

[IP_DE],[IP_PXCLK] [IPDE],[IPPXCLK]

Check Digital signal for Video FPGA

from FPGA to ENCODER Check Soldering. の確認

1U-3836-1(MAIN UNIT) N.G ・ [IC703]105-138pin 1U-3836-1(MAINUNIT) N.G ・ [IC703]105-138pin

Check analog signal for Video Check Soldering. ENCODER

from ENCODER to Video driver ・ [IC801]37-39pin

1U-3836-1(MAIN UNIT) N.G ・ VR803-805 1U-3836-1(MAINUNIT) N.G ・ VR803-805

・ [IC703]output and [IC801]input: ・ RR308-349 ・ [IC703]

[ENC_Y0-9],[ENC_C0-9],[ENC_HS],[ENC_VS], [ENCY0-9],[ENCC0-9],[ENCHS],[ENCVS],

[ENC_DE],[ENC_CLK] [ENCDE],[ENCCLK]

・ [IC801]output and [IC802]input: ・ TR803-805 ・ [IC801]

[Py],[Pb],[Pr] ・ [IC802]11,13,15pin [Py],[Pb],[Pr] ・ [IC802]11,13,15pin

O.K.

O.K.

O.K.

END

FPGAへの

[IC703]入 ・ RR803-830

ENCODERへの

[IC801]入 ・ RR308-349

の確認

[IC802]入 ・TR803-805

了

ル

.

ル

.

ーへのアナロ

.

認

認

認

・ [IC801]37-39pin

31

Page 32

S-102

源電圧確

半田付

けを

確

O.K

T

信号の確

半田付

けを

確

O.K

から

T

デジタ

映像

データ

出力の確認半田付

けを

確

/

力:出力

O.K

T

ネクタ

デジタ

半田付

けを

確

映像

データ

出力

T

出力

O.K

終

(3) HDMI output does not outputed. (3) HDMI映像出力せず

Check Power Supply Voltages. 電

1U-3836-1(MAIN UNIT) N.G Check Soldering. 1U-3836-1(MAINUNIT) N.G

Check Reset signal. RESE

1U-3836-1(MAIN UNIT) N.G Check Soldering. 1U-3836-1(MAINUNIT) N.G

Check Digital signal for Video FPGA

from FPGA to TRANSMITTER Check Soldering.

1U-3836-1(MAIN UNIT) N.G ・ RR856-886 1U-3836-1(MAINUNIT) N.G ・ RR856-886

Check Digital signal for Video Check Soldering.

from TRANSMITTER to HDMI_CON. N.G ・ [IC704]26-36pin

1U-3836-1(MAIN UNIT) ・ TR701 1U-3836-1(MAINUNIT) ・

・ [IC704]:+1.8V ・ IC708 ・ [IC704]:+1.8V ・ IC708

O.K.

・ [IC704]:[HDMI_RST] ・ [IC105]15pin ・ [IC704]:[HDMIRST] ・ [IC105]15pin

"H"level O.K.? ・ RR853 "H"levelO.K.? ・ RR853

O.K.

・ [IC703]output and [IC704]input: ・ [IC704]49-80,1,2pin ・ [IC703]

[HDMTY0-9],[HDMTC0-9],[HDMTHS], [HDMTY0-9],[HDMTC0-9],[HDMTHS],

[HDMTVS],[HDMTDE],[HDMTCLK] [HDMTVS],[HDMTDE],[HDMTCLK]

O.K.

RANSMITTERからHDMIコ

・ [IC704]output ・ JK701 ・ [IC704]

END

O.K.

認

.

認

.

RANSMITTERへの

[IC704]入 ・ [IC704]49-80,1,2pin

の確認

了

ル

.

への

.

ル

N.G ・ [IC704]26-36pin

R701

・ JK701

認

認

認

認

32

Page 33

3-2.AUX IN

3-2.

外部入力時

力

半田付

けを

確

O.K

ネクタ

から

ビデオセレクタ

グ

半田付

けを

確

映像出力

力

O.K

ビデオセレクタ

から

ビデオドライバ

半田付

けを

確

ナログ

映像出力

出力

/

O.K

ビデオドライバ

ネクタ

グ

半田付

けを

確

映像出力

出力

O.K

終

(1) Conposite INPUT (1) コンポジット入

Check Power Supply Voltages. N.G Check Soldering. 電源電圧確認 N.G

1U-3836-1(MAIN UNIT) ・ CX142 1U-3836-1(MAINUNIT) ・ CX142

・ ±5V_V1 ・ ±5VV1

S-102

認

O.K.

Check analog signal for Video N.G Check Soldering. コ

from connector to Video selector ・ JK301

1U-3836-1(MAIN UNIT) ・ RR411,413 1U-3836-1(MAINUNIT) ・ RR411,413

・ [IC805]input: ・ [IC805]1,5pin ・ [IC805]入

[CVBS1],[CVBS2] [CVBS1],[CVBS2]

O.K.

Check analog signal for Video Check Soldering.

from Video selector to Video driver ・ [IC805]3pin ア

1U-3836-1(MAIN UNIT) N.G ・ CC145 1U-3836-1(MAINUNIT) N.G ・ CC145

・ [IC805]output/[IC802]input: ・ [IC802]5pin ・ [IC805]

[SEL_CVBS] [SELCVBS]

O.K.

Check analog signal for Video Check Soldering.

from Video driver to connector ・ [IC802]30pin

1U-3836-1(MAIN UNIT) N.G ・ CC161 1U-3836-1(MAINUNIT) N.G ・ CC161

・ [IC802]output ・ RR420 ・ [IC802]

・ JK801 ・ JK801

O.K.

END

の確認 ・ JK301

: ・ [IC805]1,5pin

の確認 ・ [IC805]3pin

[IC802]入力: ・ [IC802]5pin

ーからコ

の確認 ・ [IC802]30pin

了

.

へのアナロ

.

ーへの

.

へのアナロ

.

N.G

・ RR420

認

認

認

33

Page 34

(2) Y/C INPUT (2) S端子入

力

Ch k P S l V

N.G

CheckSolderi

電源電圧確認

N.G

半田付

けを

確認

O.K

ナログ

ネクタ

から

ビデオセレクタ

半田付

けを

確

映像出力

力

O.K

ビデオセレクタ

から

ビデオドライバ

半田付

けを

確

ナログ

映像出力

/

力:出力

O.K

ビデオドライバ

ネクタ

グ

半田付

けを

確

映像出力

出力

O.K

終

oec ower upp y ltages.

1U-3836-1(MAIN UNIT) ・ CX142 1U-3836-1(MAINUNIT) ・ CX142

・ ±5V_V1 ・ ±5VV1

ng.

S-102

O.K.

Check analog signal for Video N.G Check Soldering. コ

from connector to Video selector ・ JK301

1U-3836-1(MAIN UNIT) ・ RR402,403,408,409 1U-3836-1(MAINUNIT) ・ RR402,403,408,409

・ [IC804]input: ・ [IC804]2,5,14,15pin ・ [IC804]入

[Y1],[Y2],[C1],[C2] [Y1],[Y2],[C1],[C2]

O.K.

Check analog signal for Video Check Soldering.

from Video selector to Video driver ・ [IC804]3,13pin ア

1U-3836-1(MAIN UNIT) N.G ・ CC145,147 1U-3836-1(MAINUNIT) N.G ・ CC145,147

・ [IC804]output/[IC802]input: ・ [IC802]4,8pin ・ [IC804]

[SELY],[SELC] [SELY],[SELC]

O.K.

Check analog signal for Video Check Soldering.

from Video driver to connector

1U-3836-1(MAIN UNIT) N.G ・ [IC802]27,32pin 1U-3836-1(MAINUNIT) N.G ・ [IC802]27,32pin

・ [IC802]output ・ CC160,163 ・ [IC802]

・ JK801 ・ JK801

O.K.

END

の確認 ・ JK301

: ・ [IC804]2,5,14,15pin

の確認

[IC802]入 ・ [IC802]4,8pin

ーからコ

の確認

了

.

へのア N.G

.

ーへの

.

へのアナロ

.

認

認

・ [IC804]3,13pin

認

・ CC160,163

34

Page 35

S-102

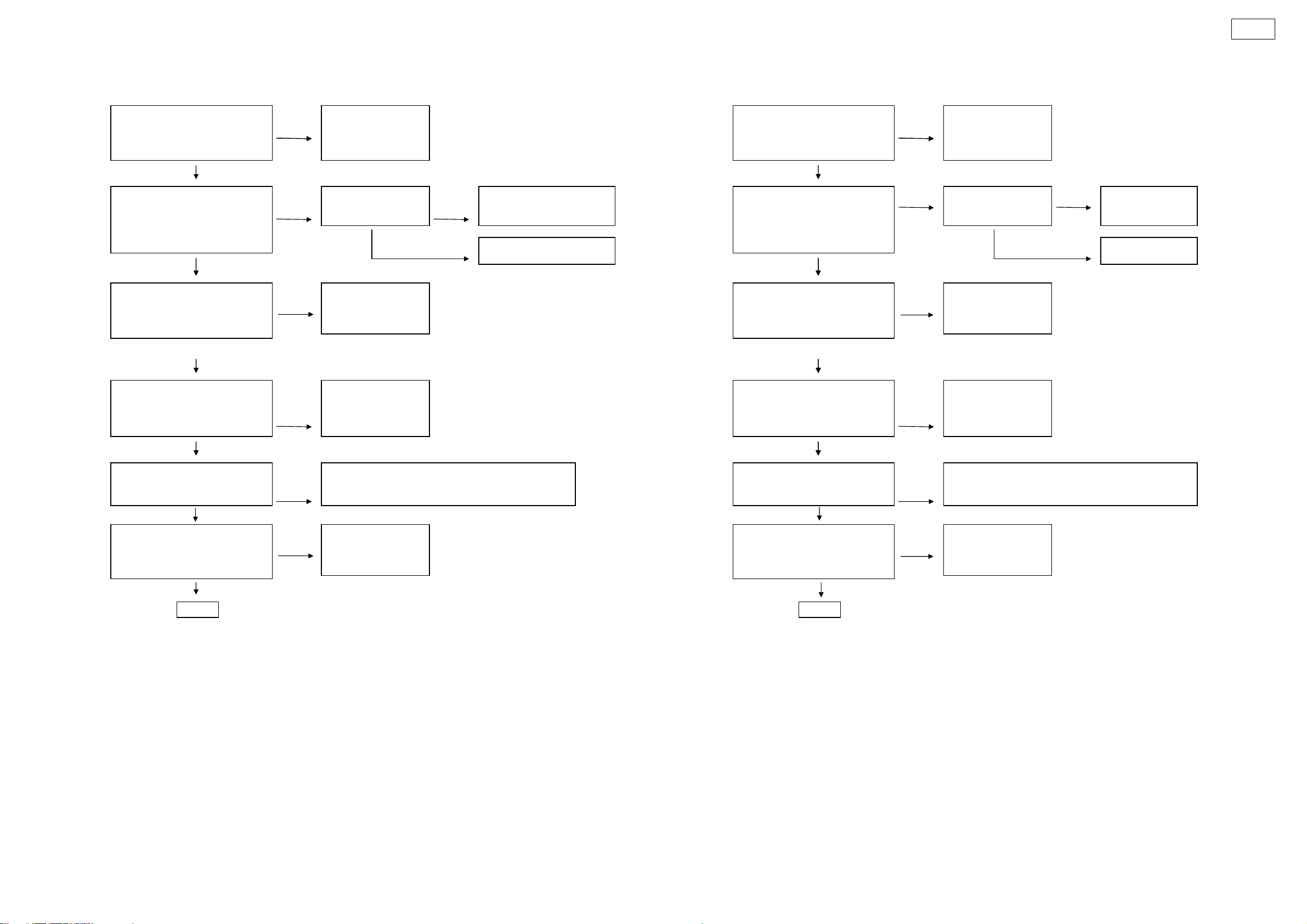

● DSW-S102

1. 1U-3811 (D.AMP/SMPS UNIT)

(1) AMPLIFER

Check Reset signal.

(IC208 4pin)

"H" level (About 3.3V)

O.K.

Check Clock waveform.

• (IC201 2pin)

• (IC203 15pin)

• (IC204 15pin)

Refer (waveform 1)

O.K.

Check PWM sginal waveform.

• (IC206 4,5,6pin)

• (IC206 14,15,16pin)

• (IC207 2,4,17pin)

Refer (waveform 2)

N.G.

N.G.

N.G.

Check the following parts (and surrounding area) and

their soldering.

• [IC208] (BD4730)

• [IC201] circumference of 9pin(TAS5066PAGRG4)

Also circuits connected to this part

Check the following parts (and surrounding area) and

their soldering.

• [X201] (X-TAL)

• [IC202] (SN74HCU04APWR)

• [IC201] circumference of 2pin(TAS5066PAGRG4)

• [IC203] circumference of 15pin(PCM1803DBR)

• [IC204] circumference of 15pin(PCM1803DBR)

Also circuits connected to this part

Check the following parts (and surrounding area) and

their soldering.

• [IC201] ALL pin (TA S5066PAGRG4)

Also circuits connected to this part

● DSW-S102

1. 1U-3811 (D.AMP/SMPS UNIT)

(1) アンプ

リセット信号の確認

・ (IC208 4pin)

"H" レベル ( 約 3.3V)

O.K.

クロック波形の確認?

・ (IC201 2pin)

・ (IC203 15pin)

・ (IC204 15pin)

( 波形 1」を参照

O.K.

PWM 信号波形の確認

・ (IC206 4,5,6pin)

・ (IC206 14,15,16pin)

・ (IC207 2,4,17pin)

「波形2」を参照

O.K.

N.G.

N.G.

N.G.

以下部品(周辺)の状態・半田付けチェック

・ [IC208] (BD4730)

・ [IC201] 9pin 周辺 (TAS5066PAGRG4)

その他この部品につながる回路

以下部品(周辺)の状態・半田付けチェック

・ [X201] (X-TAL)

・ [IC202] (SN74HCU04APWR)

・ [IC201] 2pin 周辺 (TAS5066PAGRG4)

・ [IC203] 15pin 周辺 (PCM1803DBR)

・ [IC204] 15pin 周辺 (PCM1803DBR)

その他この部品につながる回路

以下部品(周辺)の状態・半田付けチェック

・ [IC201] 全てのピン (TAS5066PAGRG4)

その他この部品につながる回路

O.K.

Check Digital amp carrier waveform.

• (IC206 33,30pin)

• (IC206 26,22pin)

• (IC207 29,25pin)

Refer (waveform 3)

O.K.

Check Speaker relay.

• Is (RL201,RL202) switched?

O.K.

Check A/D signal waveform.

• (IC201 24,23,21,19)