Denon AVR-487, AVR-687, AVR-587, AVR-1707, AVR-1507 User Manual

For U.S.A. , Canada, Europe,

& Taiwan R.O.C. model

SERVICE MANUAL

Ver. 1

MODEL

AV SURROUND RECEIVER

AVR-1707

AVR-1507

AVR-687

AVR-587

AVR-487

注 意

サービスをおこなう前に、このサービスマニュアルを

必ずお読みください。本機は、火災、感電、けがなど

に対する安全性を確保するために、さまざまな配慮を

おこなっており、また法的には「電気用品安全法」に

もとづき、所定の許可を得て製造されております。

従ってサービスをおこなう際は、これらの安全性が維

持されるよう、このサービスマニュアルに記載されて

いる注意事項を必ずお守りください。

●

For purposes of improvement, specifications and

design are subject to change without notice.

●

Please use this service manual with referring to the

operating instructions without fail.

●

Some illustrations using in this service manual are

slightly different from the actual set.

Denon Brand Company, D&M Holdings Inc.

●

●

●

●

TOKYO, JAPAN

本機の仕様は性能改良のため、予告なく変更すること

があります。

補修用性能部品の保有期間は、製造打切後8年です。

修理の際は、必ず取扱説明書を参照の上、作業を行っ

てください。

本文中に使用しているイラストは、説明の都合上現物

と多少異なる場合があります。

X0282V.01 DE/CDM 0605

SAFETY PRECAUTIONS

The following check should be performed for the continued protection of the customer and service technician.

LEAKAGE CURRENT CHECK

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis

resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the power

cord is less than 460 kohms, the unit is defective.

AVR-1707/1507/687/587/487

CAUTION

Please heed the points listed below during servicing and inspection.

◎ Heed the cautions!

Spots requiring particular attention when servicing, such as

the cabinet, parts, chassis, etc., have cautions indicated on

labels or seals. Be sure to heed these cautions and the cautions indicated in the handling instructions.

◎ Caution concerning electric shock!

(1) An AC voltage is impressed on this set, so touching inter-

nal metal parts when the set is energized could cause

electric shock. Take care to avoid electric shock, by for example using an isolating transformer and gloves when

servicing while the set is energized, unplugging the power

cord when replacing parts, etc.

(2)There are high voltage parts inside. Handle with extra care

when the set is energized.

◎

Caution concerning disassembly and assembly!

Though great care is taken when manufacturing parts from

sheet metal, there may in some rare cases be burrs on the

edges of parts which could cause injury if fingers are moved

across them. Use gloves to protect your hands.

◎ Only use designated parts!

The set's parts have specific safety properties (fire resistance, voltage resistance, etc.). For replacement parts, be

sure to use parts which have the same properties. In particular, for the important safety parts that are marked ! on wiring

diagrams and parts lists, be sure to use the designated parts.

◎ Be sure to mount parts and arrange the

wires as they were originally!

For safety reasons, some parts use tape, tubes or other insulating materials, and some parts are mounted away from the

surface of printed circuit boards. Care is also taken with the

positions of the wires inside and clamps are used to keep

wires away from heating and high voltage parts, so be sure to

set everything back as it was originally.

◎ Inspect for safety after servicing!

Check that all screws, parts and wires removed or disconnected for servicing have been put back in their original positions, inspect that no parts around the area that has been

serviced have been negatively affected, conduct an insulation

check on the external metal connectors and between the

blades of the power plug, and otherwise check that safety is

ensured.

(Insulation check procedure)

Unplug the power cord from the power outlet, disconnect the

antenna, plugs, etc., and turn the power switch on. Using a

500V insulation resistance tester, check that the insulation resistance between the terminals of the power plug and the externally exposed metal parts (antenna terminal, headphones

terminal, microphone terminal, input terminal, etc.) is 1MΩ or

greater. If it is less, the set must be inspected and repaired.

CAUTION

Many of the electric and structural parts used in the set have

special safety properties. In most cases these properties are

difficult to distinguish by sight, and using replacement parts

with higher ratings (rated power and withstand voltage) does

not necessarily guarantee that safety performance will be preserved. Parts with safety properties are indicated as shown

below on the wiring diagrams and parts lists is this service

manual. Be sure to replace them with parts with the designated part number.

(1) Schematic diagrams ... Indicated by the ! mark.

(2) Parts lists ... Indicated by the ! mark.

Concerning important safety parts

Using parts other than the designated parts

could result in electric shock, fires or other

dangerous situations.

注 意

サービス、点検時にはつぎのことにご注意願います。

◎注意事項をお守りください!

サービスのとき特に注意を必要とする個所についてはキャ

ビネット、部品、シャーシなどにラベルや捺印で注意事項を

表示しています。これらの注意書きおよび取扱説明書などの

注意事項を必ずお守りください。

◎感電に注意!

(1) このセットは、交流電圧が印加されていますので通電時

に内部金属部に触れると感電することがあります。従っ

て通電サービス時には、絶縁トランスの使用や手袋の着

用、部品交換には、電源プラグを抜くなどして感電にご

注意ください。

(2) 内部には高電圧の部分がありますので、通電時の取扱に

は十分ご注意ください。

◎分解、組み立て作業時のご注意!

板金部品の端面の『バリ』は、部品製造時に充分管理をして

おりますが、板金端面は鋭利となっている箇所が有りますの

で、部品端面に触れたまま指を動かすとまれに怪我をする場

合がありますので十分注意して作業して下さい。手の保護の

ために手袋を着用してください。

◎指定部品の使用!

セットの部品は難燃性や耐電圧など安全上の特性を持った

ものとなっています。従って交換部品は、使用されていたも

のと同じ特性の部品を使用してください。特に配線図、部品

表に!印で指定されている安全上重要な部品は必ず指定の

ものをご使用ください。

◎部品の取付けや配線の引きまわしは、

元どおりに!

安全上、テープやチューブなどの絶縁材料を使用したり、プ

リント基板から浮かして取付けた部品があります。また内部

配線は引きまわしやクランパーによって発熱部品や高圧部

品に接近しないように配慮されていますので、これらは必ず

元どおりにしてください。

◎サービス後は安全点検を!

サービスのために取り外したねじ、部品、配線などが元どお

りになっているか、またサービスした個所の周辺を劣化させ

てしまったところがないかなどを点検し、外部金属端子部

と、電源プラグの刃の間の絶縁チェックをおこなうなど、安

全性が確保されていることを確認してください。

(絶縁チェックの方法)

電源コンセントから電源プラグを抜き、アンテナやプラグな

どを外し、電源スイッチを入れます。500V 絶縁抵抗計を用

いて、電源プラグのそれぞれの端子と外部露出金属部[アン

テナ端子、ヘッドホン端子マイク端子、入力端子など]との

間で、絶縁抵抗値が1 MΩ 以上であること、この値以下の

ときはセットの点検修理が必要です。

注 意

本機に使用している多くの電気部品、および機構部品は安全

上、特別な特性を持っています。この特性はほとんどの場合、

外観では判別つきにくく、またもとの部品より高い定格(定

格電力、耐圧)を持ったものを使用しても安全性が維持され

るとは、限りません。安全上の特性を持った部品は、この

サービスマニュアルの配線図、部品表につぎのように表示し

ていますので必ず指定されている部品番号のものを使用願

います。

(1) 配線図…

(2) 部品表…

安全上重要な部品について

!マークで表示しています。

!マークで表示しています。

指定された部品と異なるものを使用した場合に

は、感電、火災などの危険を生じる恐れがあり

ます。

2

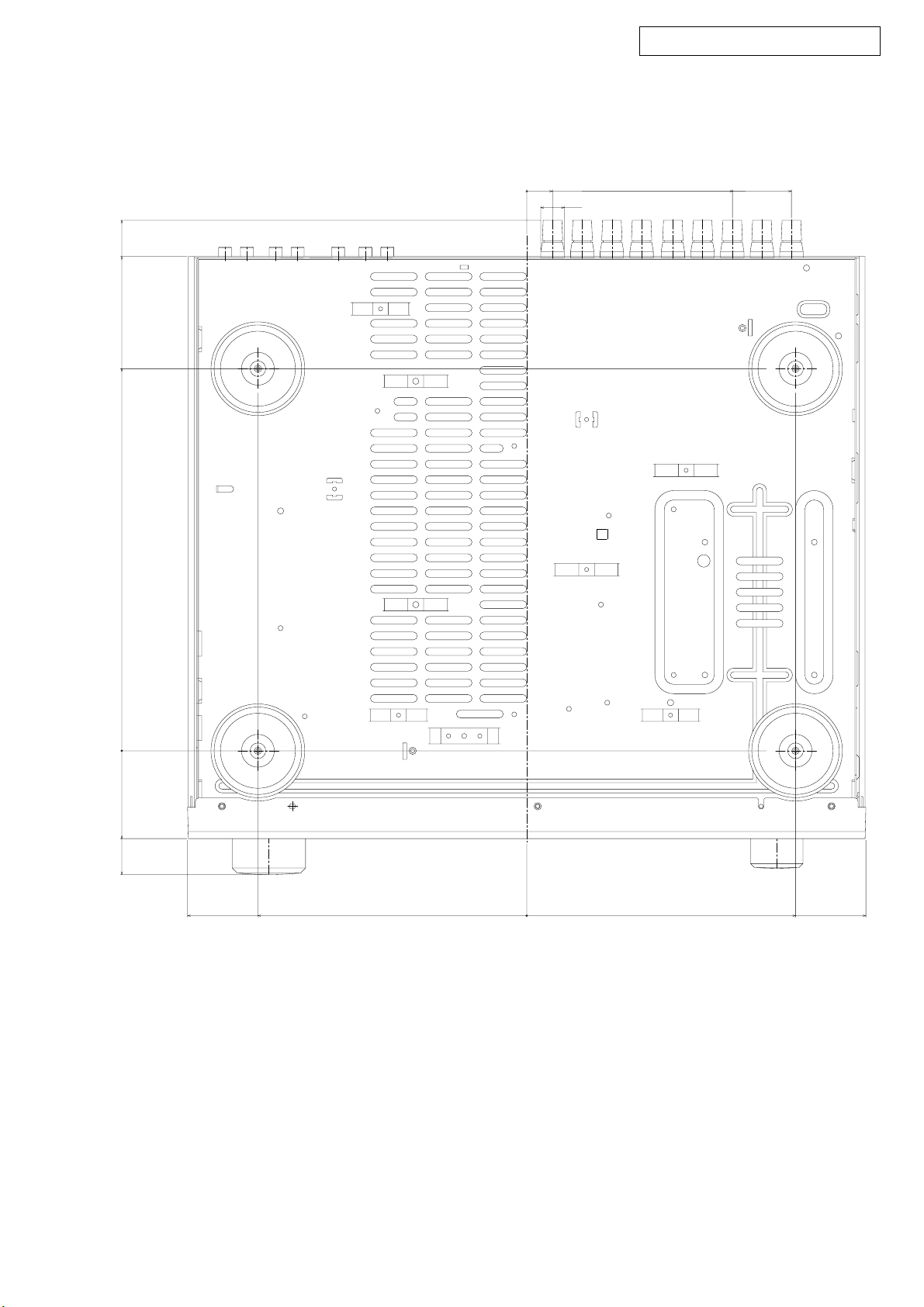

DIMENSION

AVR-1707/1507/687/587/487

339.5

316.3

244.5

16.5

0

15

131.5

170.5

56.2

79.3

0

217

172

0

172

217

3

AVR-1707/1507/687/587/487

CAUTION IN SERVICING

Initializing AV SURROUND RECEIVER

AV SURROUND RECEIVER initialization should be performed

when the µcom, peripheral parts of µcom, and Digital P.W.B. are

replaced.

1. Switch off the unit.

2. Hold the following SPEAKERS-A button and SPEAKERS-B

button, and switch on the unit.

3. Check that the entire display is flashing with an interval of

about 1 second, and release your fingers from the 2 buttons

and the microprocessor will be initialized.

Note:・If step 3 does not work, start over from step 1.

・ All user settings will be lost and this factory setting will

be recovered when this initialization mode.

So make sure to memorize your setting for restoring

after the initialization.

サービス時の注意事項

AVサラウンドアンプの初期化について

マイコンやマイコン周辺部品、Digital 基板等を交換した場合

は、AV サラウンドアンプの初期化を行って下さい。

1. オン/オフボタンを OFF にします。

2. SPEAKERS-A ボタンと SPEAKERS-B ボタンを同時に押しな

がら、オン/オフボタンを押して ON にします。

3. ディスプレイ表示が約 1秒間隔で点滅するのを確認後、2

つのボタンから指を離します。

*マイコンが初期化されます。

注意 :・上記 3 の状態にならない場合は、もう一度操作 1 か

らやり直してください。

・初期化を行うとお客様が設定した内容が工場出荷状

態に戻りますので、あらかじめ設定内容を控えてお

き初期化後再設定してください。

4

AVR-1707/1507/687/587/487

ADJUSTMENT

Audio Section

Idling Current

Required measurement equipment: DC Voltmeter

1. Preparation

(1) Avoid direct blow from an air conditioner or an electric

fan, and adjust the unit at normal room temperature 15 °C

~ 30 °C (59 °F ~ 86 °F).

(2) Presetting

• POWER (Power source switch) OFF

• SPEAKER (Speaker terminal) No load

(Do not connect speaker, dummy resistor, etc.)

2. Adjustment

(1) Remove top cover and set VR101, VR102, VR103,

VR104, VR105, on Amp. Unit, VR107SBL,107SBR on

SURR.-BACK ch Amp. Unit at fully counterclockwise

( ) position.

(2) Connect DC Voltmeter to test points (FRONT-Lch:

TP104, FRONT-Rch: TP105, CENTER ch: TP103, SURROUND-Lch: TP101, SURROUND-Rch: TP102, SURROUND-BACK Lch: TP106, SURROUND-BACK Rch:

TP107).

(3) Connect power cord to AC Line, and turn power switch

"ON".

(4) Presetting.

MASTER VOLUME : "---" counterclockwise ( min.)

MODE : 7CH STEREO

FUNCTION : CD

(5) Within 2 minutes after the power on, turn VR101 clock-

wise ( ) to adjust the TEST POINT voltage to 1.5 mV

± 0.5 mV DC.

(6) After 10 minutes from the preset above, turn VR101 to

set the voltage to 2.0 mV ± 0.5 mV DC.

(7) Adjust the Variable Resistors of other channels in the

same way.

調整

オーディオセクション

アイドリング電流の調整

調整に必要な測定器 : DCVoltmeter

1. 準備

(1) セットをクーラ、扇風機のそばなど風通しの良い場所

を避け、通常の使用状態に置きます。セットの周囲温

度は 15〜30 ℃、湿度は常湿とします。

(2) プリセット

・電源スイッチ OFF

・スピーカ端子 無負荷

( スピーカ・ダミー抵抗器などを接続しない。)

2. 調整

(1) 上カバーをはずし、パワーアンプ基板の VR101,VR102,

VR103,VR104,VR105 及び SURR.-BACK アンプ基板の

VR107SBL,107SBR を反時計方向 ( )に回し切った状

態にセットします。

(2) テストポイント (FRONT-Lch:TP104,FRONT-Rch:

TP105,CENTERch:TP103,SURROUND-Lch:TP101,

SURROUND-Rch:TP102,SURROUND-BACKLch:TP106,

SURROUND-BACKRch:TP107) に DCVoltmeterを接続

します。

(3) 電源コードを AC100V(95〜105Vの範囲でも可)に接

続し、電源スイッチを "ON"にします。

(4) ON後、次のようにセットします。

・MASTERVOLUME(音量調節つまみ)→反時計方向

( )に回す、最小の状態にする。

・SPEAKER(スピーカ端子)→無負荷(スピーカ、

ダミー抵抗器などを接続しない。)

MODE:7CHSTEREO

FUNCTION:CD

(5) 2分以内に VR101を時計方向 ( ) に回しテストポイ

ントの電圧を次のように調整します。

1.5mV ±0.5mVDC

(6) 予備調整から 10分後 VR101を回し、次のように電圧を

設定します。

2.0mV± 0.5mVDC

(7) 同じ方法で各チャネルの可変抵抗を調整します。

DC Voltmeter

F Lch

S Lch

S Back Rch

C ch

S Back Lch

S Rch

F Rch

5

VR104

TP104

VR101

TP101

TP107

VR107

VR103,TP103

TP106

VR106

VR102,TP102

VR105

TP105

AVR-1707/1507/687/587/487

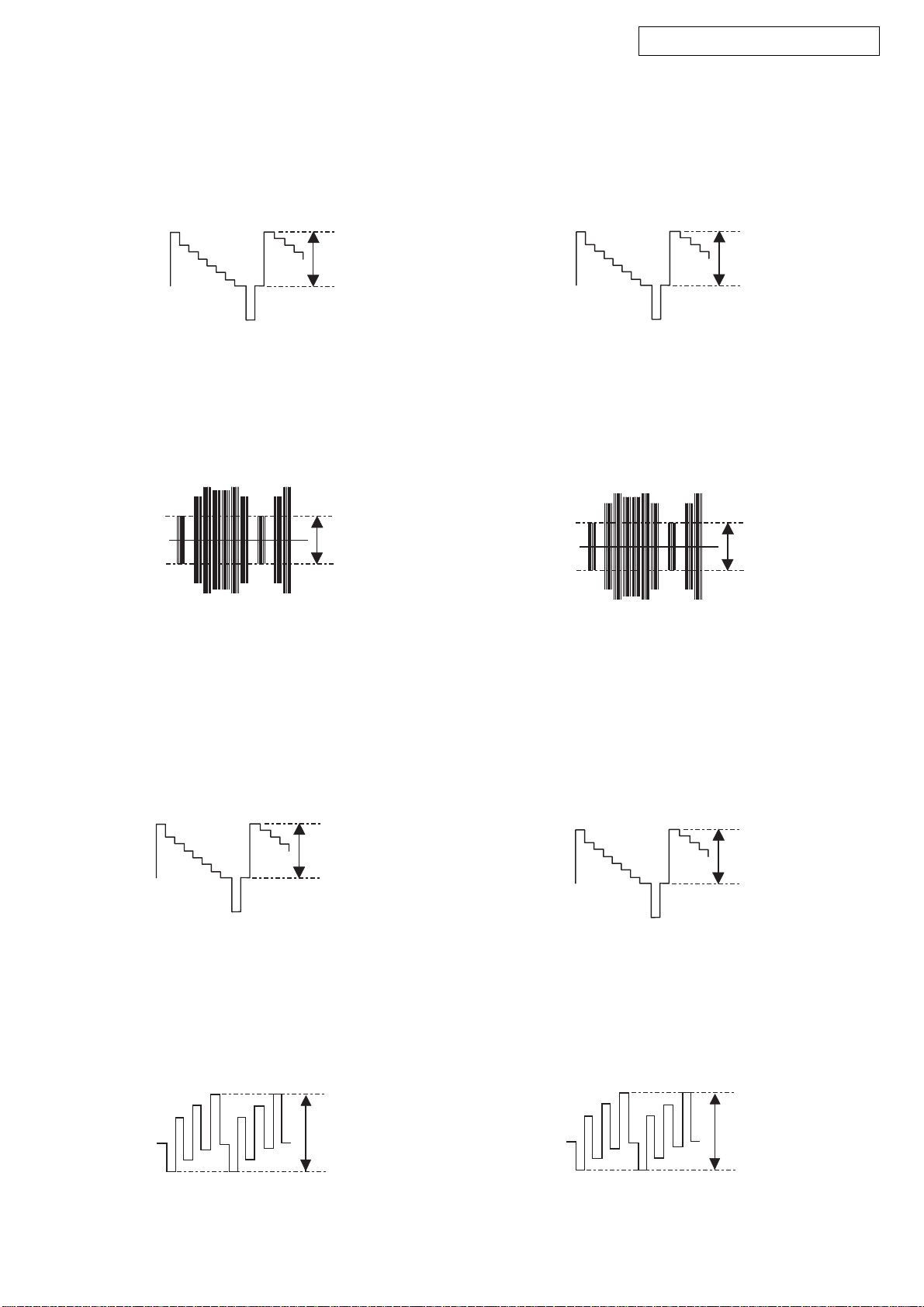

VIDEO Section (AVR-1707/687 ONLY)

1. SETTING

(1) Connect the oscilloscope to the Y-signal and C-signal of

S MONITOR OUT terminal and each terminate at 75

Ohms.

(2) Connect the oscilloscope to the Y-signal, P

B-signal, PR-signal and CR-signal of COMPONENT

C

MONITOR OUT terminal and each terminate at 75

Ohms.

※ Use the 75 Ohms resistance must be 1%

(3) DVD test disc : DVDT-S01

(4) COMPOSITE VIDEO OUT of DVD player is connected

to COMPOSITE : DVD.

2. BEFORE ADJUSTMENT

2.1. Setting the Oscilloscope as below.

(1) PB/CB, PR/CR, C

(a) TIME/DIV : 10μs

(b) VOLT/DIV : 100mV

(Use the probe : x10 )

(2) Y (Py)

(a) TIME/DIV : 10μs

(b) VOLT/DIV : 200mV

(Use the probe : x10 )

B-signal and

ビデオセクション(AVR-1707/687 のみ )

1. セッティング手順

(1) セットの SMONITOROUT 端子から Y 信号と C 信号を

それぞれオシロスコープ(終端抵抗:75Ω)に接続し

ます。

(2) セットのCOMPONENTMONITOROUTの端子

B/CB,PR/CR)をそれぞれオシロスコープ

(Y,P

(終端抵抗:75Ω)に接続します。

※ 75Ω 抵抗は 1%品を使用する事。

(3) DVD テストディスク:DVDT-S01 を用意します。

(4) DVD プレーヤーの COMPOSITEVIDEOOUT を

COMPOSITE:DVD に接続します。

(5)

2. 調整のまえに

2.1. オシロスコープを下記に設定

(1) PB/CB,PR/CR,C

(a) TIME/DIV : 10μs

(b) VOLT/DIV : 100mV

(プローブ x10 使用)

(2) Y(Py)

(a) TIME/DIV : 10μs

(b) VOLT/DIV : 200mV

(プローブ x10 使用)

Power on. Power Supply

U.S.A. , Canada & Taiwan R.O.C. : 120V

Europe : 230V

Japan : 100V

China & Korea : 220V

2.2. Setup the DVD player and confirmation of the

stators

(1) Set to "INTERLACED" mode at the COMPONENT OUT.

(2) Confirm the DVD player’s out put level is equal as the

item 2.4. in following.

2.3. Preparation

(1) Turn the FUNCTION knob to select "DVD" input.

(2) Push [OPEN/CLOSE] button of DVD player, then open

the Disc Tray.

Set DVD test disc (DVDT-S01) on the Disc Tray, and

then push [CLOSE] button.

(3) DVD player FL display appear "STOP", push [PLAY] but-

ton to playback DVD.

(4) Push the [DISPLAY] button of remote control of DVD

player unit and then appear the ON-Screen Display (GUI)

on the monitor TV.

(5) Push the [+10] and [2] button, select Title 12 of DVD.

(6) Push the [ENTER] button, playback Title 12.

(color bar 75%)

電源電圧

U.S.A. , Canada & Taiwan R.O.C. : 120V

Europe : 230V

Japan : 100V

China & Korea : 220V

2.2. DVD プレーヤの設定と確認

(1) COMPONENTOUT の設定を " インターレース " にしま

す。

(2) DVD プレーヤーの出力が以下 2.4. に合っていることを

確認します。

2.3. 準備手順

(1) FUNCTION ノブを回し、入力を "DVD" に切り替えます。

(2) DVD プレーヤーの「OPEN/CLOSE」ボタンを押しトレ

イを開き、トレイ上に DVD テストディスク(DVDTS01)をセット後、「CLOSE」ボタンを押します。

(3) DVD プレーヤーの表示管上に "STOP" が表示されてか

ら、「PLAY」ボタンを押し、ディスクを再生します。

(4) DVD プレーヤーのリモコンの「DISPLAY」ボタンを押

しグラフィカル・ユーザー・インターフェイス (GUI) 画

面を出します。

(5) 番号ボタンの「 +10 」 , 「 2 」ボタンを押し、Title12 を選択

します。

(6) 「ENTER」ボタンを押し、Title12 を再生します。

(75%カラーバー信号)

6

AVR-1707/1507/687/587/487

2.4. Procedure

(1) Adjust the signal of S MONITOR OUT by the wave of os-

cilloscope.

(a) Target, Y-signal

Point : C-S VIDEO 1 VR604

Adjustment Value : 714 ± 14mV

Waveform

Y

Y-signal of S MONITOR OUT

(b) Target, C-signal

Point : C-S VIDEO 1 VR605

Adjustment Value : 286 ± 5mV

Waveform

2.4. 手順

(1) セットの SMONITOROUT の信号レベルをオシロスコー

プ上の波高値で調整します。

(a) Y 信号レベル

調整個所 : C-SVIDEO1VR604

調整値 : 714 ± 14mV

波形

Y

SMONITOROUT の Y 信号レベル

(b) C 信号レベル

調整個所 : C-SVIDEO1VR605

調整値 : 286 ± 5mV

波形

C

C-signal of S-MONITOR OUT

(2) Adjust the signal of COMPONENT OUT by the wave of

oscilloscope.

(a) Target, Y-signal

Point : C-S VIDEO 1 VR601

Adjustment Value : 714 ± 14mV

Waveform

Y

Y-signal COMPONENT OUT

C

S-MONITOROUT の C 信号レベル

(2) COMPONENTOUTの信号レベルをオシロスコープ上の

波高値で調整します。

(a) Y 信号レベル

調整個所 : C-SVIDEO1VR601

調整値 : 714 ± 14mV

波形

Y

COMPONENTOUT の Y 信号レベル

(b) Target, P

Point : C-S VIDEO 1 VR602

Adjustment Value : *525 ± 10mV

Waveform

* : 486 ± 10mV for U.S.A. & Canada model

B/CB-signal

PB/CB

PB/CB-signal COMPONENT OUT

B/CB 信号レベル

(b) P

調整個所 : C-SVIDEO1VR602

調整値 : 525 ± 10mV

波形

PB/CB

COMPONENTOUT の PB/CB 信号レベル

7

AVR-1707/1507/687/587/487

(c) Target, P

R/CR-signal

Point : C-S VIDEO 1 VR603

Adjustment Value : *525 ± 10mV

Waveform

PR/CR-signal COMPONENT OUT

* : 486 ± 10mV for U.S.A. & Canada model

C-S VIDEO 1 UNIT

Oscilloscope

PR/CR

(c) PR/CR 信号レベル

調整個所 : C-SVIDEO1VR603

調整値 : 525 ± 10mV

波形

PR/CR

COMPONENTOUT の PR/CR 信号レベル

COMPONENT VIDEO

(Y,P

Pb

VR602

Py

VR601

C

VR605

VR603

VR604

MONITOR OUT

B/CB,PR/CR

Pr

Y

S-VIDEO

)

MONITOR OUT

(Y,C)

Video Section

8

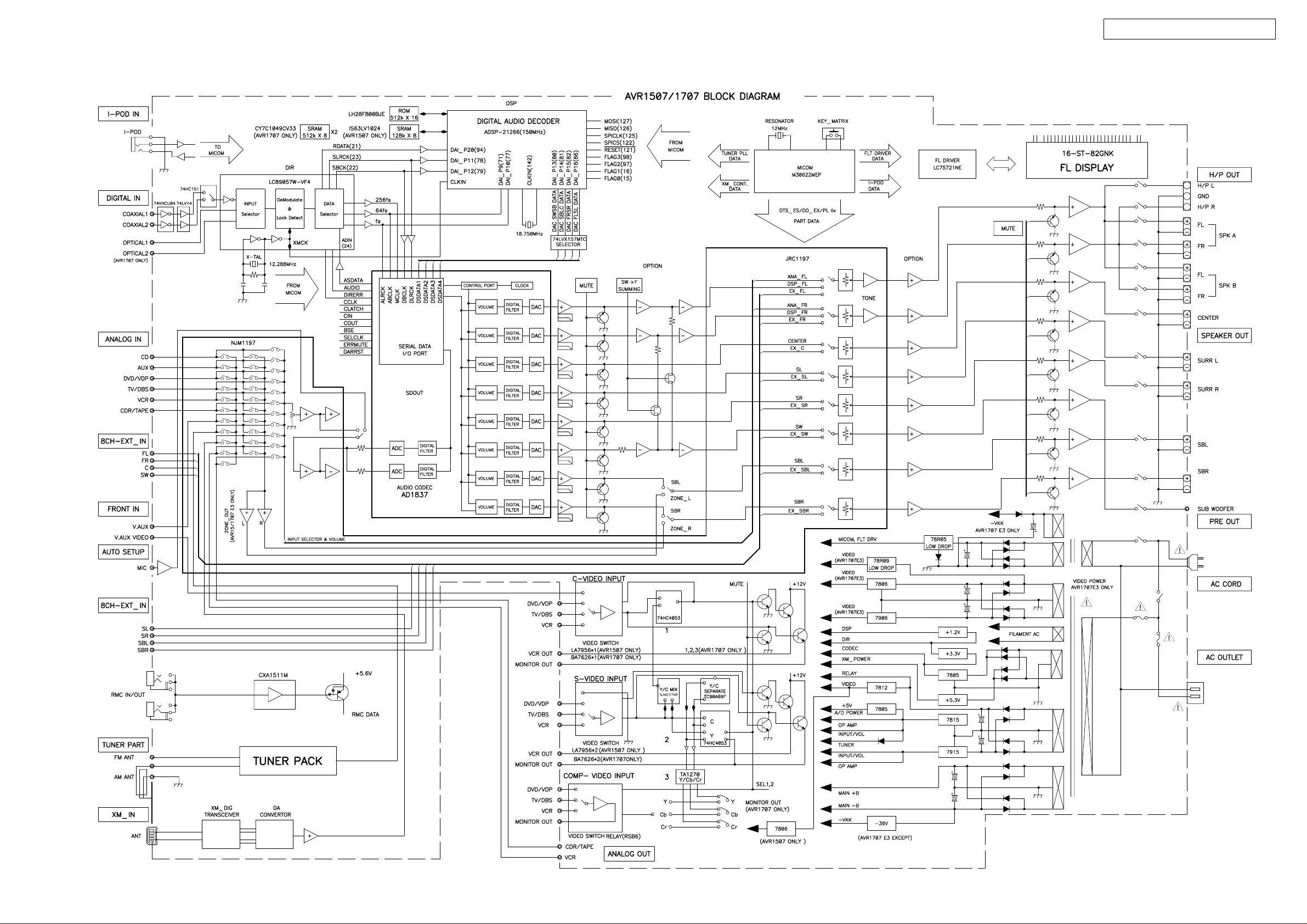

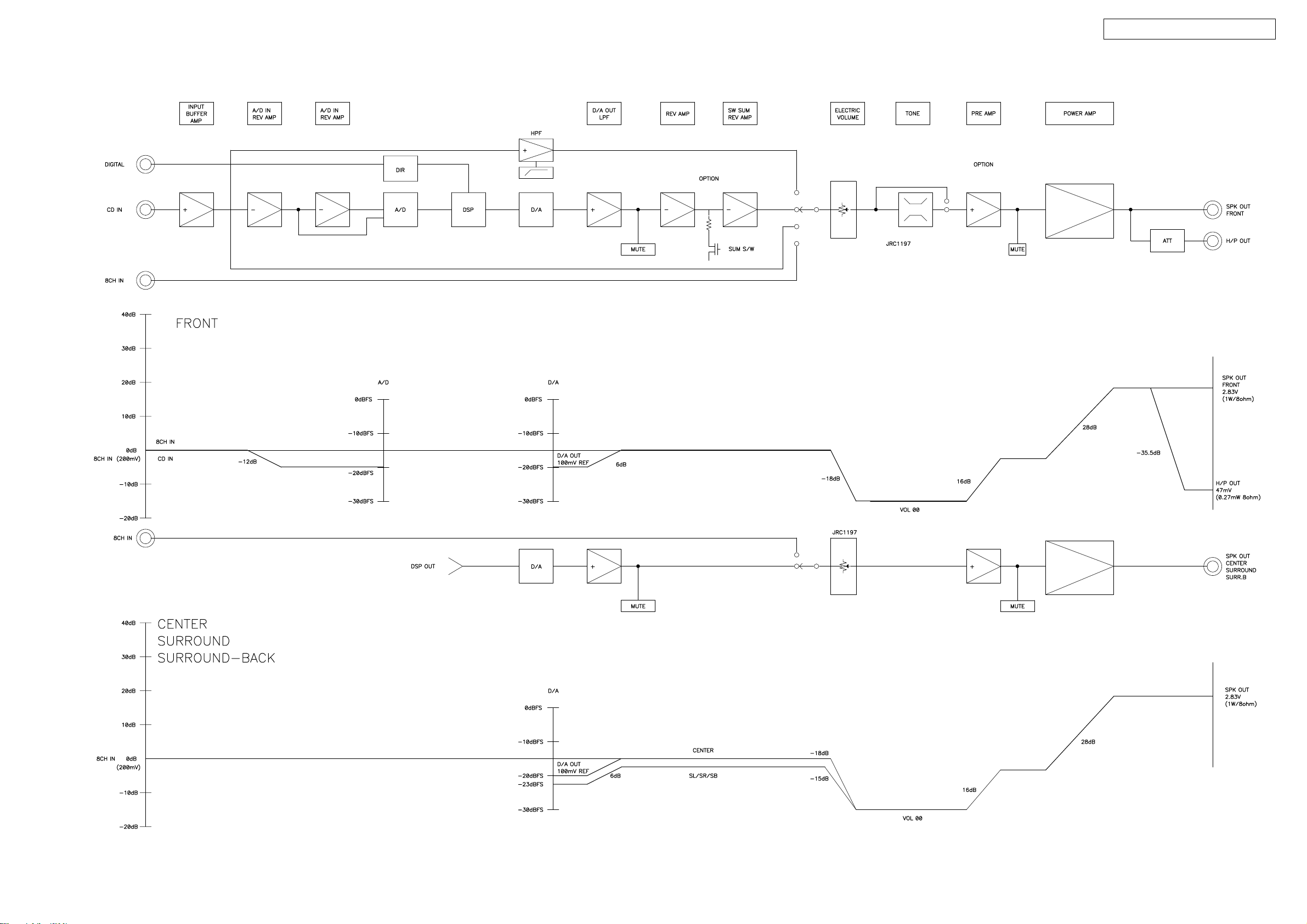

BLOCK DIAGRAM

AVR-1707/1507/687/587/487

9

LEVEL DIAGRAMS (1/2)

AVR-1707/1507/687/587/487

10

LEVEL DIAGRAMS (2/2)

AVR-1707/1507/687/587/487

11

AVR-1707/1507/687/587/487

A

SEMICONDUCTORS

Only major semiconductors are shown, general semiconductors etc. are omitted to list.

主な半導体を記載しています。汎用の半導体は記載を省略しています。

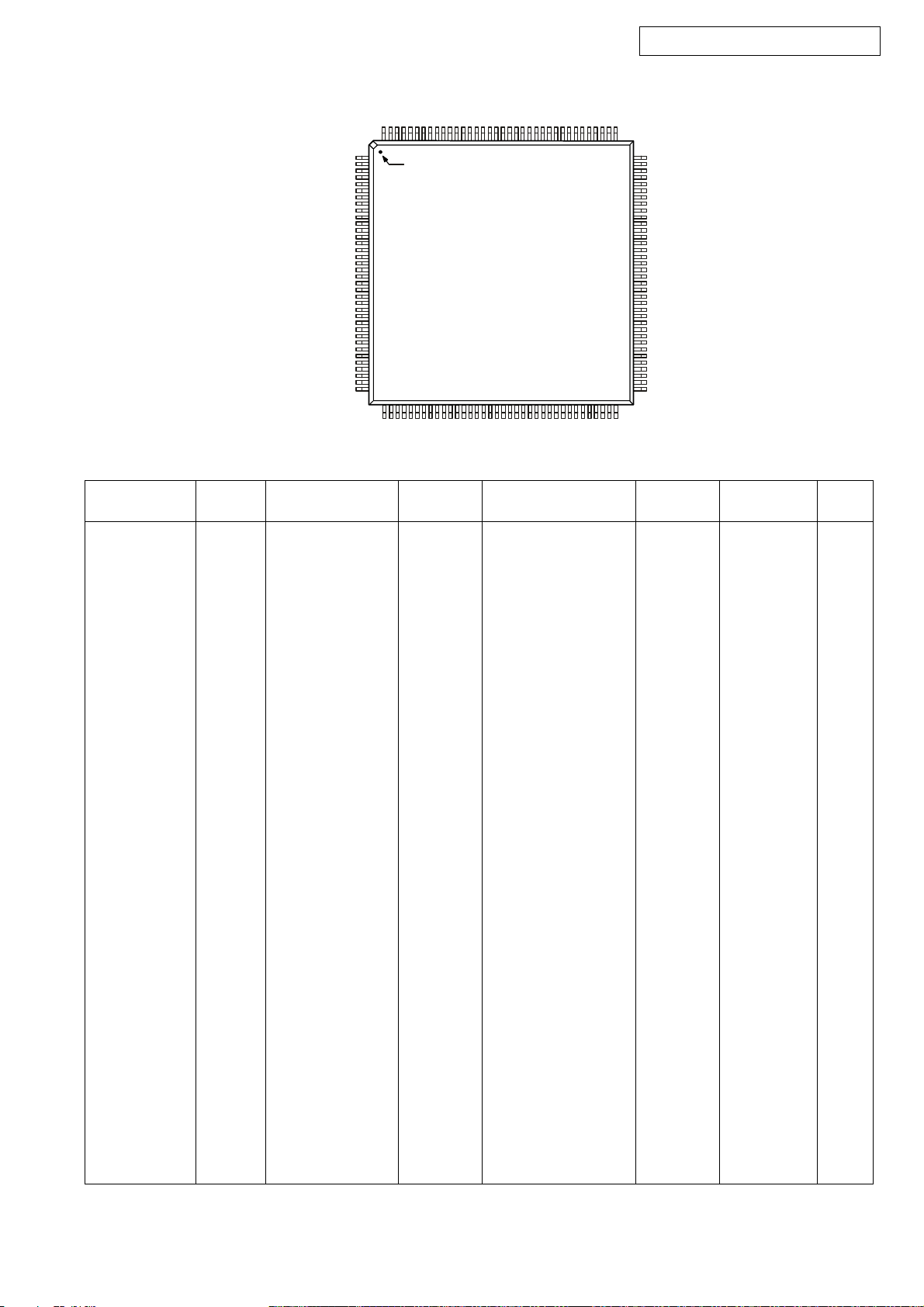

1. IC’s

M30622MEP (IC201)

LC74781_CS

AVCC(+5V)

Vref(+5V)

XM_DAC_MDI

AVSSNCBAND_OPTION

100 99 98 97 96 95 94 93 92 91 90 89 88 87 86 85 84 83 82 81

P9_7

AVCC

Vref

AVSS

P10_0

SW_SUM 1 P9_6 P1_0 80 NJW1197_DATA

2090_CLK(VIDEO)/SEL2/G 3 P9_4 P1_2 78 NJW1197_LATCH

2090_DATA2/VIDEO_MUTE 5 P9_2 P1_4 76 POWER_RELAY

AD1837_SDIN(OverLoad) 7 P9_0 (INT4) P1_6 74 BU4094_STB(XM)

BU4094_BU2090_Data(Front) 10 P8_7 P2_1 71 FUNC_UP

FLD_RESET_BU4094_ENABLE 11 P8_6 P2_2 70 H/P_DET

I-POD_DET 2 P9_5 P1_1 79 NJW1197_CLK

2090_DATA/SEL1/F 4 P9_3 P1_3 77 STBY_RED(LED)

REMOCON 6 P9_1(TB1IN) (INT3)P1_5 75 MIC_DETECT

BYTE 8 BYTE (INT5)P1_7 73 RDS_CLK

CNVSS 9 CNVSS (UP_GRADE) P2_0 72 FUNC_DOWN

RESET 12 RESET P2_3 69 FLAG1

XOUT 13 XOUT P2_4 68 FLAG2

VSS 14 VSS P2_5 67 FLAG3

XIN 15 XIN P2_6 66 AD1837_CE

VCC1(+5V) 16 VCC1 P2_7 65 SHARC_RESET

NMI 17 P8_5 VSS 64 VSS

FLAG0 18 P8_4(INT2) P3_0 63 SHARC_SCLK

LC89057_INT 19 P8_3(INT1) VCC2 62 VCC2(+5V)

PROTECTION 20 P8_2(INT0) P3_1 61 AD1837_RESET

FLD_BU2090_CLK 21 P8_1 P3_2 60 LC89057W_AD1837_SCLK

FLD_DATA 22 P8_0 P3_3 59 LC89057W_AD1837_SDOUT

FLD_CE 23 P7_7 P3_4 58 LC89057W_CE

I-POD 24 P7_6 P3_5 57 SHARC_SDOUT

7180/7172_DATA 25 P7_5 P3_6 56 SHARC_CE

9164_CLK 26 P7_4 P3_7 55 LC89057W_RESET

7180/7172_CLK 27 P7_3 P4_0 54 EEPROM_RESET

NC 28 P7_2 P4_1 53 LC89057W_SDIN

I-POD_RX 29 P7_1

I-POD_TX 30 P7_0

M30622MxP-xxxFP

(RXD)

(TXD)

(UP_GR)

(UP_GR)

P6_7

P6_6

P6_5

P6_4

31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50

P6_3

SEL_OPTION

KEY_IN3

KEY_IN2

(KI0) P10_4

(AN3) P10_3

P6_0

P5_7

(KI1) P10_5

P5_6

(AN1) P10_1

(AN2) P10_2

(Flash =M30624FGPFP)

P6_2

P6_1

KEY_IN1

PWR_DOWN

(KI2) P10_6

(KI3) P10_7

P5_5 (UP_GR)

P5_4

S-VIDEO_DET

C_VIDEO_DET

COMP_VIDEO_DET

P0_0

P0_1

P0_2

P5_3

P5_2

P5_1

S-MONITOR_DET/J

BU4094_STB(MUTE)

BU4094_STB(RELAY&MUTE)

BU4094_STB(RLY)

MUTE_POWER

P0_3

P0_4

P0_5

P0_6

P0_7

P4_2 52 SHARC_SDIN

P4_3 51 LC89057_EMPHASIS

P5_0 (UP_GR)

P4-7

P4-6

P4-5

P4-4

TUNED

PLL_CE

STEREO

XM_UART_TX

PLL_IF_COUNT

RS232C_TX(Crestron)

RS232C_RX(Crestron)

XM_UART_RX

PLL/XM/4094_CLK

PLL_DATA_OUT/XM_DAC_D

EPM(UP_GRADE)

SEL_UP

SEL_DOWN

CE(UP_GRADE)

VOL_ENCODER_UP

VOL_ENCODER_DOWN

RS232C_SW

BSE

RDS_DATA

ERR_MUTE

12

M30622MEP Terminal Function

Pin No. Pin Name I/O/T Pin Function

1 P9_6 O SW_SUM

2 P9_5 O I-POD DET

3 P9_4 O BU209CLK(VIDEO)/SEL2/G

4 P9_3 O BU2090Data/SEL1/F

5 P9_2 O BU2090DATA2/VIDEO_MUTE

6 P9_1(TB1IN) I REMOCON

7 P9_0 I AD1837_SDIN(OverLoad)

8 BYTE I BYTE

9 CNVSS(UP_GRADE) I CNVSS

10 P8_7 O BU4094_BU2090_Data(Front)

11 P8_6 O FLD_RESET_BU4094_ENABLE

12 RESET I RESET

13 XOUT O XOUT

14 VSS I VSS

15 XIN I XIN

16 VCC1 I VCC1(+5V)

17 P8_5 I NMI

18 P8_4(INT2) I FLAG0

19 P8_3(INT1) I LC89057_INT

20 P8_2(INT0) I PROTECTION

21 P8_1 O FLD_BU2090_CLK

22 P8_0 O FLD_DATA

23 P7_7 O FLD_CE

24 P7_6 O I-POD ??PIN

25 P7_5 O 7180/7172_DATA

26 P7_4 O TC9273/9164_CLK

27 P7_3 O 7180/7172_CLK

28 P7_2 O NC

29 P7_1(RXD) I I-POD RX

30 P7_0(TXD) O I-POD TX

31 P6_7(UP_GRADE) O RS232C_TX(Crestron)

32 P6_6(UP_GRADE) I RS232C_RX(Crestron)

33 P6_5 I PLL_IF_COUNT

34 P6_4 O PLL_DATA OUT/XM_DAC_DATA

35 P6_3 O XM_UART_TX

36 P6_2 I XM_UART_RX

37 P6_1 O PLL_CLK/XM_DAC_CLK/BU4094_CLK

38 P6_0 O PLL_CE

39 P5_7 I TUNED

40 P5_6 I STEREO

41 P5_5(UP_GRADE)

42 P5_4 I VOL_ENCODER_UP

43 P5_3 I VOL_ENCODER_DOWN

44 P5_2 I SEL_UP

45 P5_1 I SEL_DOWN

46 P5_0(UP_GRADE)

47 P4-7 O RS232C_SW

48 P4-6 I RDS_DATA

49 P4-5 O ERR_MUTE

50 P4-4 O BSE

51 P4_3 I LC89057_EMPHASIS

52 P4_2 I SHARC_SDIN

53 P4_1 I LC89057W_SDIN

54 P4_0 O EEPROM_RESET

55 P3_7 O LC89057W_RESET

AVR-1707/1507/687/587/487

13

Pin No. Pin Name I/O/T Pin Function

56 P3_6 O SHARC_CE

57 P3_5 O SHARC_SDOUT

58 P3_4 O LC89057W_CE

59 P3_3 O LC89057W_AD1837_SDOUT

60 P3_2 O LC89057W_AD1837_SCLK

61 P3_1 O AD1837_RESET

62 VCC2 I VCC2(+5V)

63 P3_0 O SHARC_SCLK

64 VSS I VSS

65 P2_7 O SHARC_RESET

66 P2_6 O AD1837_CE

67 P2_5 I FLAG3

68 P2_4 I FLAG2

69 P2_3 I FLAG1

70 P2_2 I H/P_DET

71 P2_1 I FUNC_ENCODER_UP

72 P2_0 I FUNC_ENCODER_DOWN

73 (INT5)P1_7 I RDS_CLOCK

74 (INT4)P1_6 O 4094_STB(XM)

75 (INT3)P1_5 I MIC_DETECT

76 P1_4 O POWER_RELAY

77 P1_3 O STBY_RED_LED

78 P1_2 O 1197_LATCH

79 P1_1 O 1197_CLK

80 P1_0 O 1197_DATA

81 P0_7 O MUTE_POWER

82 P0_6 O 4094_STB(RLY)

83 P0_5 O 4094_STB(RLY/MUTE)

84 P0_4 O 4094_STB(MUTE)

85 P0_3 I S-MONITOR_DET

86 P0_2 I COMPONENT_DET

87 P0_1 I COMPOSITE_DET

88 P0_0 I S-VIDEO_DET

89 (KI3)P10_7 I POWER_DOWN

90 (KI2)P10_6 I KEY_IN1

91 (KI1)P10_5 I KEY_IN2

92 (KI0)P10_4 I KEY_IN3

93 (AN3)P10_3 I SET_OPTION

94 (AN2)P10_2 I BAND_OPTION

95 (AN1)P10_1 O NC

96 AVSS I AVSS

97 P10_0 O XM_DAC_MDI

98 Vref I Vref(+5V)

99 AVCC I AVCC(+5V)

100 P9_7 O 74781_CS

AVR-1707/1507/687/587/487

14

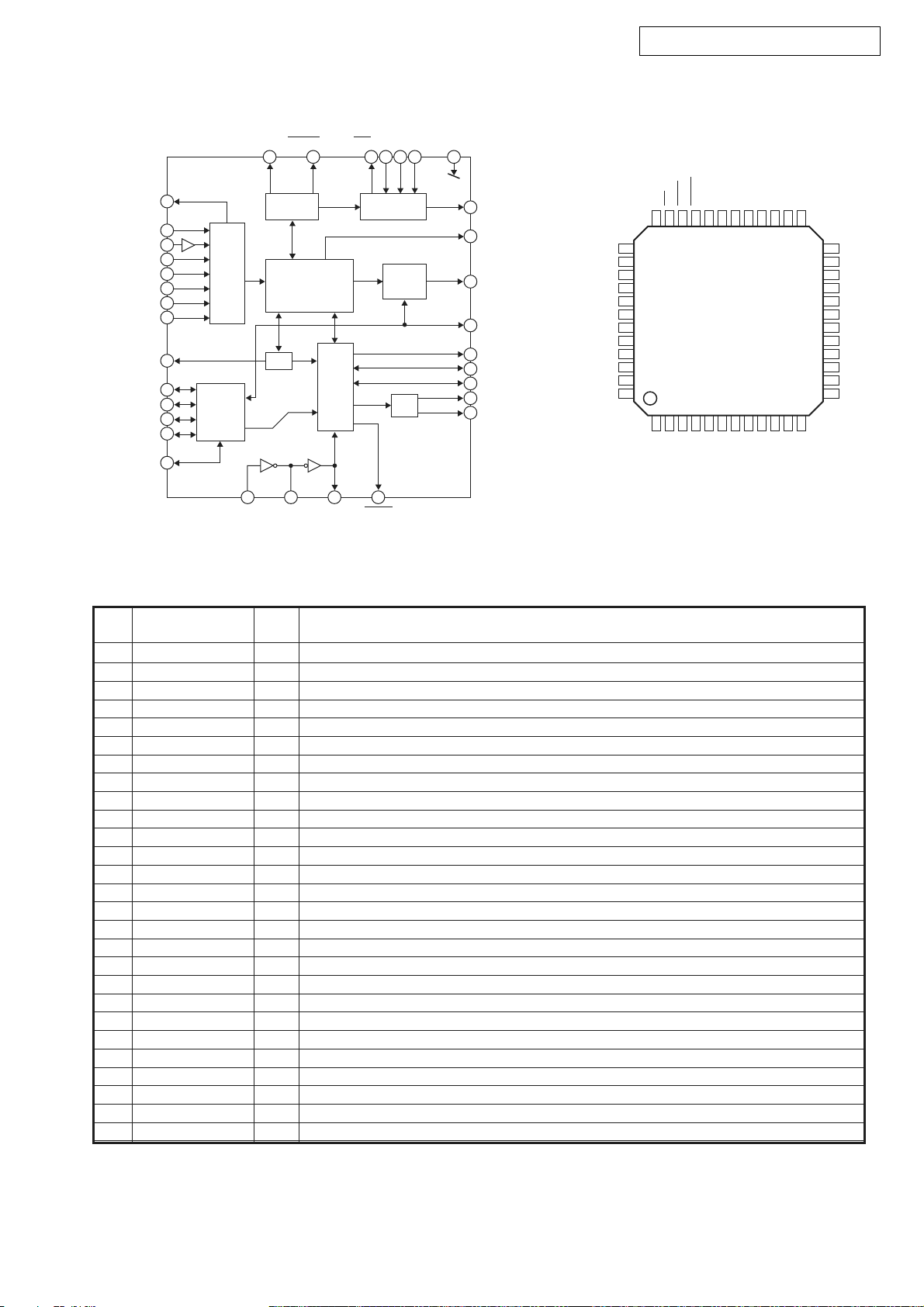

NJW1197 (IC701)

AVR-1707/1507/687/587/487

81

100

80

51

50

31

1

30

15

AVR-1707/1507/687/587/487

NJW1197 Terminal Function

No. SYMBOL FUNCTION No. SYMBOL FUNCTION

1 ROUT Rch output 51 DCR_IN Multi-channel selector Rch input

2 COUT Cch output 52 DCR_OUT Input selector Rch output

3 LSOUT LSch output 53 GND Ground

4 RSOUT RSch output 54 DC L_IN Multi-channel selector Lch input

5 LBOUT LBch output 55 DCL_OUT Input selector Lch output

6 RBOUT RBch output 56 GND Ground

7 SWOUT SWch output 57 REC_B1R Input selector Rch REC output B1

8 GND Ground 58 REC _B1L Input selector Lch REC output B1

9 FIL_BL2 Lch Bass filter terminal 2 59 REC_A4R Input selector Rch REC output A4

10 FIL_BL1 Lch Bass filter terminal 1 60 REC_A4L Input selector Lch REC output A4

11 FIL_TL Lch Treble filter terminal 61 REC_A3R Input selector Rch REC output A3

12 TCAP Switching noise rejection capacitor 62 REC_A3L Input selector Lch REC output A3

13 FIL_BR2 Rch Bass filter terminal 2 63 REC_A2R Input selector Rch REC output A2

14 FIL_BR1 Rch Bass filter terminal 1 64 REC_A2L Input selector Lch REC output A2

15 FIL_TR Rch Treble filter terminal 65 REC_A1R Input selector Rch REC output A1

16 V+ + Power supply voltage input 66 REC_A1L Input selector Lch REC output A1

17 ADR Chip address select input 67 VDD OUT Internal Digital +Power Supply Output

18 V- - Power supply voltage input 68 DATA Control data signal input

19 L1IN Input selector Lch input 1 69 CLOCK Clock signal input

20 DCCAP_SW Switching noise rejection capacitor 70 LATCH Latch signal input

21 R 1IN Input selector Rch input 1 71 MUTE External Mute control

22 DCCAP_RB Switching noise rejection capacitor 72 FL+ Input selector gain control Lch no-inverted output

23 L2IN Input selector Lch input 2 73 FL- Input selector gain control Lch inverted output

24 DCCAP_LB Switching noise rejection capacitor 74 FR+ Input selector gain control Rch no-inverted output

25 R2IN Input selector Rch input 2 75 FR- Input selector gain control Rch inverted output

26 DCCAP_RS Switching noise rejection capacitor 76 GND Ground

27 L3IN Input selector Lch input 3 77 LSCIN Multi-channel LSch input C

28 DCCAP_LS Switching noise rejection capacitor 78 RSCIN Multi-channel RSch input C

29 R3IN Input selector Rch input 3 79 LBCIN Multi-channel LBch input C

30 DCCAP_C Switching noise rejection capacitor 80 RBCIN Multi-channel RBch input C

31 L4 IN Input selector Lch input 4 81 GND Ground

32 DCCAP_R Switching noise rejection capacitor 82 LAIN Multi-channel Lch input A

33 R4IN Input selector Rch input 4 83 RAIN Multi-channel Rch input A

34 DCCAP_L Switching noise rejection capacitor 84 CAIN Multi-channel Cch input A

35 L5 IN Input selector Lch input 5 85 LSAIN Multi-channel LSch input A

36 GND Ground 86 RSAIN Multi-channel RSch input A

37 R 5IN Input selector Rch input 5 87 LBAIN Multi-channel LBch input A

38 GND Ground 88 RBAIN Multi-channel RBch input A

39 L6 IN Input selector Lch input 6 89 SWAIN Multi-channel SWch input A

40 L9 IN Input selector Lch input 9 90 GND Ground

41 R6IN Input selector Rch input 6 91 LBIN Multi-channel Lch input B

42 R9IN Input selector Rch input 9 92 RBIN Multi-channel Rch input B

43 L7IN Input selector Lch input 7 93 CBIN Multi-channel Cch input B

44 L1 0IN Input selector Lch input 10 94 LSBIN Multi-channel LSch input B

45 R7IN Input selector Rch input 7 95 RSBIN Multi-channel RSch input B

46 R10IN Input selector Rch input 10 96 LBBIN Multi-channel LBch input B

47 L8IN Input selector Lch input 8 97 RBBIN Multi-channel RBch input B

48 L11IN Input selector Lch input 11 98 SWBIN Multi-channel SWch input B

49 R8IN Input selector Rch input 8 99 GND Ground

50 R11IN Input selector Rch input 11 100 LOUT Lch output

16

ADSP21266SKSTZ-1B (IC804)

AVR-1707/1507/687/587/487

144

1

PIN 1 INDICATOR

109

108

TOP VIEW

36

37

73

72

ADSP21266SKSTZ-1B Terminal Function

LQFP

Pin Name

V

DDINT

Pin # Pin Name

1V

DDINT

CLKCFG0 2 GND 38 GND 74 V

CLKCFG1 3 RD 39 V

BOOTCFG0 4 ALE 40 GND 76 V

LQFP

Pin # Pin Name

37 V

DDEXT

DDINT

LQFP

Pin # Pin Name

73 GND 109

DDINT

75 GND 111

DDINT

BOOTCFG1 5 AD15 41 DAI_P10 (SD2B) 77 GND 113

GND 6 AD14 42 DAI_P11 (SD3A) 78 V

V

DDEXT

7 AD13 43 DAI_P12 (SD3B) 79 GND 115

GND 8 GND 44 DAI_P13 (SCLK23) 80 V

V

DDINT

9V

DDEXT

45 DAI_P14 (SFS23) 81 GND 117

GND 10 AD12 46 DAI_P15 (SD4A) 82 V

V

DDINT

11 V

DDINT

47 V

DDINT

83 GND 119

GND 12 GND 48 GND 84 V

V

DDINT

13 AD11 49 GND 85 RESET 121

DDINT

DDEXT

DDINT

DDINT

GND 14 AD10 50 DAI_P16 (SD4B) 86 SPIDS 122

FLAG0 15 AD9 51 DAI_P17 (SD5A) 87 GND 123

FLAG1 16 AD8 52 DAI_P18 (SD5B) 88 V

DDINT

AD7 17 DAI_P1 (SD0A) 53 DAI_P19 (SCLK45) 89 SPICLK 125

GND 18 V

V

DDINT

19 GND 55 GND 91 MOSI 127

DDINT

54 V

DDINT

90 MISO 126

GND 20 DAI_P2 (SD0B) 56 GND 92 GND 128

V

DDEXT

GND 22 GND 58 DAI_P20 (SFS45) 94 V

V

DDINT

AD6 24 V

21 DAI_P3 (SCLK0) 57 V

23 V

DDEXT

DDINT

59 GND 95 A

60 V

DDEXT

DDINT

93 V

96 A

DDINT

DDEXT

VDD

VSS

AD5 25 GND 61 FLAG2 97 GND 133

AD4 26 DAI_P4 (SFS0) 62 FLAG3 98 CLKOUT 134

V

DDINT

27 DAI_P5 (SD1A) 63 V

DDINT

99 EMU 135

GND 28 DAI_P6 (SD1B) 64 GND 100 TDO 136

AD3 29 DAI_P7 (SCLK1) 65 V

AD2 30 V

V

DDEXT

31 GND 67 V

GND 32 V

DDINT

DDINT

66 GND 102 TRST 138

68 GND 104 TMS 140

AD1 33 GND 69 V

DDINT

DDINT

DDINT

101 TDI 137

103 TCK 139

105 GND 141

AD0 34 DAI_P8 (SFS1) 70 GND 106 CLKIN 142

WR 35 DAI_P9 (SD2A) 71 V

V

DDINT

36 V

DDINT

72 V

DDINT

DDINT

107 XTAL 143

108 V

DDEXT

LQFP

Pin #

110

112

114

116

118

120

124

129

130

131

132

144

17

LC89057W (IC807)

AVR-1707/1507/687/587/487

RXOUT

RX0

RX1

RX2

RX3

RX4

RX5/VI

RX6/UI

LPF

TMCK/PIO0

TBCK/PIO1

TLRCK/PIO2

TDATA/PIO3

TXO/PIOEN

1

2

3

4

5

8

9

10

13

44

45

46

47

48

EMPHA/UO33AUDIO/VO35INT40CL39CE38DI

32

Clock

Selector

27

Microcontroller

Input

Selector

Modulation

or

Parallel Port

29

XIN

C bit, U bit

Demodulation

&

Lock Detect

PLL

28

XOUT

XMCK34CKST

I/F

Data

Selector

I/N

XMODE

41

37

36

21

24

16

17

20

22

23

DO

RERR

RD ATA

SDIN

RMCK

RBCK

RLRCK

SBCK

SLRCK

36 RERR1RXOUT

35 INT2RX0

34 CKST3RX1

TOP VIEW

33 AUDIO/VO4RX2

32 EMPHA/UO5RX3

31 DGND6DGND

30 DVDD7DVDD

29 XIN8RX4

28 XOUT9RX5/VI

27 XMCK10RX6/UI

26 DVDD11DVDD

25 DGND12DGND

24 SDIN37DO

23 SLRCK38DI

22 SBCK39CE

21 RDATA40CL

20 RLRCK41XMODE

19 DVDD42DGND

18 DGND43DVDD

17 RBCK44TMCK/PIO0

16 RMCK45TBCK/PIO1

15 AGND46TLRCK/PIO2

14 AVDD47TDATA/PIO3

13 LPF48TXO/PIOEN

LC89057W Terminal Function

Pin

No.

1 RXOUT O Input bi-phase select data output terminal

2 RX0 I TTL compatible digital data input terminal

3 RX1 I Coaxial compatible amp built-in digital data input terminal

4 RX2 I TTL compatible digital data input terminal

5 RX3 I TTL compatible digital data input terminal

6 DGND — Digital GND

7 DVDD — Digital power

8 RX4 I TTL compatible digital data input terminal

9 RX5/VI I TTL compatible digital data/Validity flag input terminal for modulation

10 RX6/UI I TTL compatible digital data/User data input terminal for modulation

11 DVDD — Digital power for PLL

12 DGND — Digital GND for PLL

13 LPF O PLL loop filter connecting terminal

14 AVDD — Analog power for PLL

15 AGND — Analog GND for PLL

16 RMCK O RMCK clock output terminal (256fs, 512fs, XIN, VCO)

17 RBCK O/I RBCK clock in/output terminal (64fs)

18 DGND — Digital GND

19 DVDD — Digital power

20 RLRCK O/I RLRCK clock in/output terminal (fs)

21 RDATA O Serial audio data output terminal

22 SBCK O SBCK clock output terminal (32fs, 64fs, 128fs)

23 SLRCK O SLRCK clock output terminal (fs/2, fs, 2fs)

24 SDIN I Serial audio data input terminal

25 DGND — Digital GND

26 DVDD — Digital power

27 XMCK O Osc. amp output terminal

Pin Name

I/O

Function

18

AVR-1707/1507/687/587/487

Pin

No.

Pin Name I/O

Function

28 XOUT O X’tal osc. connecting output terminal

29 XIN I X’tal osc. connection, external clock input terminal (24.576MHz or 12.288MHz)

30 DVDD — Digital power

31 DGND — Digital GND

32 EMPHA/UO I/O Emphasis information/U-data output/Chip address setting terminal

33 AUDIO/VO I/O Non-PCM detect/V-flag output/ Chip address setting terminal

34 CKST I/O Clock switch transition period output/Demodulation master or slave function switching terminal

35 INT I/O Interrupt output for µcom (Interrupt factor selectable)/Modulation or general I/O switching terminal

36 RERR O PLL lock error, data error flag output

37 DO O µcom I/F, read out data output terminal (3-state)

38 DI I µcom I/F, write data input terminal

39 CE I µcom I/F, chip enable input terminal

40 CL I µcom I/F, clock input terminal

41 XMODE I System reset input terminal

42 DGND — Digital GND

43 DVDD — Digital power

44 TMCK/PIO0 I/O 256fs system clock input for modulation/General I/O in/output terminal

45 TBCK/PIO1 I/O 64fs bit clock input for modulation/General I/O in/output terminal

46 TLRCK/PIO2 I/O fs clock input for modulation/General I/O in/output terminal

47 TDATA/PIO3 I/O Serial audio data input for modulation/General I/O in/output terminal

48 TXO/PIOEN O/I Modulation data output/ General I/O enable input terminal

* For latch-up countermeasure, perform each power supply ON/OFF in the same timing.

LC75721E (IC301) BU2090F (IC302,1005,1008)

G7 G8G9

48 33

49

DI

CL

CE

RES

DD

V

OSCI

OSCO

Vss

TEST

FL

V

G1

G2

G3

G4

G5

G6

64

AM 1

AM 2

AM 3

G10

G11

AA8/G12

AA7/G13

AA6/G14

AA5/G15

AA4/G16

AA3

AA2

AA1

AM35

AM34

AM33

161

AM 4

AM 5

AM 6

AM 7

AM 8

AM 9

AM 10

AM 11

AM 12

AM 13

AM 14

AM 15

AM 16

LC75721E Terminal Function

Symbol

32

17

V

DD

Vss

AM 17

V

FL

AM 18

AM 19

AM 20

DI

AM 21

CL

AM 22

AM 23

CE

AM 24

AM 25

AM 26

OSCI

AM 27

OSCO

AM 28

AM 29

RES

AM 30

AM 31

AM1~AM35

AM 32

AA1~AA3

AA4/G16

AA5/G15

AA6/G14

AA7/G13

AA8/G12

G1~G11 Grid output terminal

TEST LSI test terminal

Power terminal +5V

Power terminal GND

Power terminal FL drive

Serial data transfer terminal

DI: Data

CL: Clock

CE: Chip enable

External CR connecting terminal

System reset terminal

Anode output terminal

Anode/Grid output terminal

Function

VSS

DATA

CLOCK

LCK

1

CONTROL CIRCUIT

2

12-bi t SHIFT REGI STER

3

4

5

6

7

8

9

12- bit STRAGE REGI STER

OUTPUT BUFF ER (OPE N DRAI N)

Q0

Q1

Q2

Q4

18

17

16

15

14

13

12

11Q3

10

MM74LCX244 (IC809-811)

TOP VIEW

1

OE

2

I0

3

O4

4

I1

5

O5

6

I2

7

O6

8

I3

912

O7 O3

10 11

GND

20

VCC

19

OE2

18

O0

17

I4

16

O1

15

I5

14

O2

13

I6

I7

VDD

OE

Q11

Q10

Q9

Q8

Q7

Q6

Q5

19

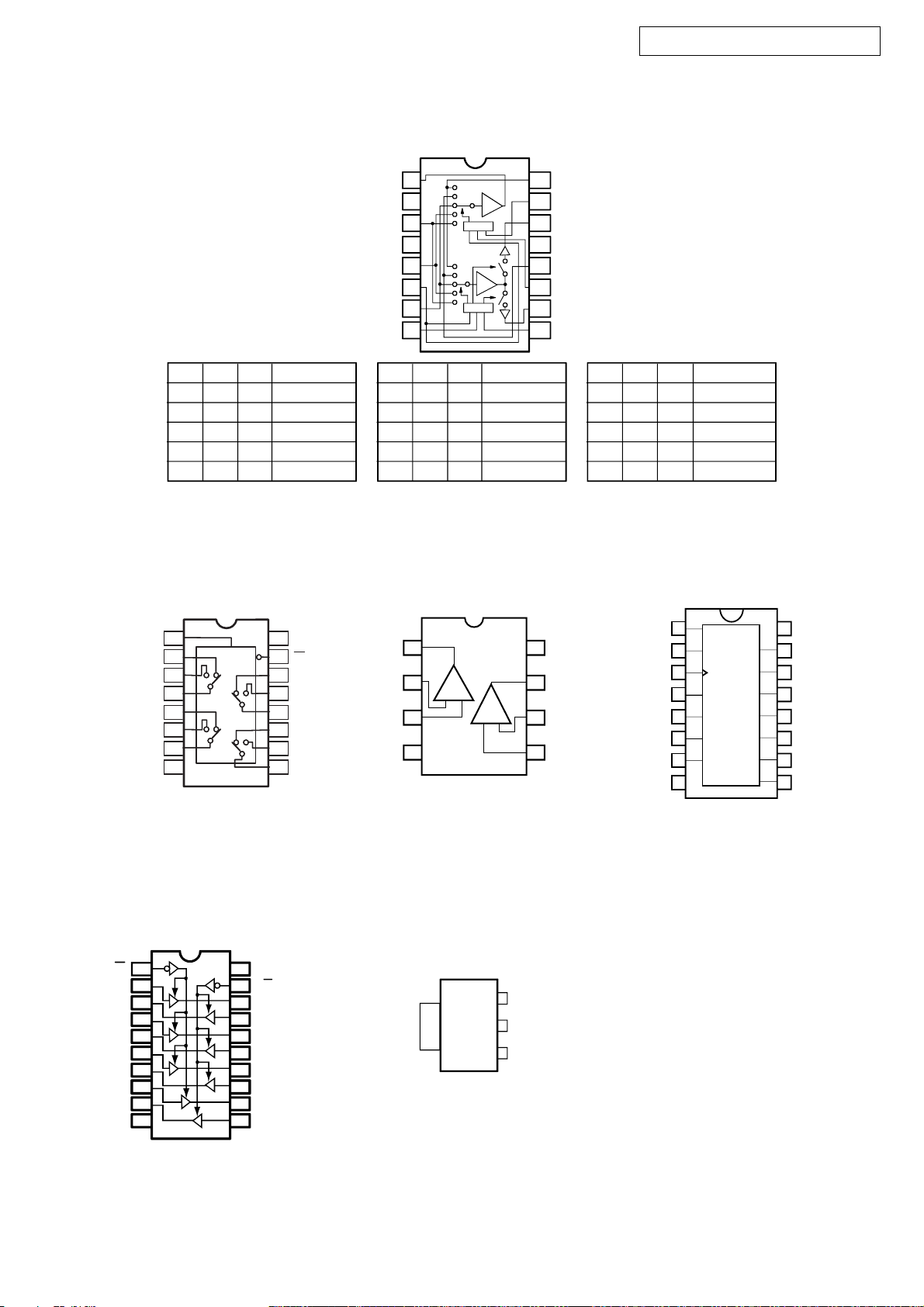

AD1837AAS (IC808)

AVR-1707/1507/687/587/487

DSDATA2

DSDATA1

NC

AGND

CLOCK

DIGITAL

FILTER

DIGITAL

FILTER

DIGITAL

FILTER

DIGITAL

FILTER

DGND

DVDD

39

38

DBCLK

37

DLRCLK

M/S

36

AGND

35

34

OUTR4

33

NC

32

OUTL4

31

NC

30

AGND

29

AVDD

28

OUTR3

NC

27

OUTL3

MCLKASDATAABCLKALRCLKODVDDDVDD DVDD

PD/RST M/S AVDD AVDD

DescriptionPin No.

V

Σ-∆

DAC

Σ-∆

DAC

Σ-∆

DAC

Σ-∆

DAC

REF

OUTL1

OUTR1

OUTL2

OUTR2

OUTL3

OUTR3

OUTL4

OUTR4

FILTD

FILTR

DLRCLK

DBCLK

DSDATA1

DSDATA2

DSDATA3

DSDATA4

ADCLP

ADCLN

ADCRP

ADCRN

AD1837 Terminal Function

Pin Name

CLATCH

Σ-∆

ADC

Σ-∆

ADC

AD1837

Input/

Output

DVDD

CIN

PD/RST

AGND

NC

OUTL1

NC

OUTR1

AGND

AVDD

NC

OUTL2

DGND

CCLK

COUT

ASDATA

ODVDD

MCLK

ALRCLK

ABCLK

50 494847 46 45 44 43 42 41 40

51

52

1

2

3

4

5

6

7

8

9

10

11

12

13

14 15 16 17 18 19 20 21 22 23 24 25 26

NC

OUTR2

SERIAL DATA

I/O PORT

DIGITAL

FILTER

DIGITAL

FILTER

TOP VIEW

FILTD

FILTR

AGND

DGND AGND AGND AGND AGNDDGND

AVDD

DSDATA4

ADCLP

ADCLN

ADCRN

CONTROL PORT

VOLUME

VOLUME

VOLUME

VOLUME

VOLUME

VOLUME

VOLUME

VOLUME

DSDATA3

ADCRP

CINCLATCHCCLK COUT

1,39 DVDD Digital Power Supply. Connect to digital 5V supply.

2 CLATCH I Latch Input for Control Data

33 CIN I Serial Control Input

4 PD/RST I Power-Down/Reset

5,10,16,24,30,35 AGND Analog Ground

6,12,25,31 NC Not connected

7,13,26,32 OUTLx O DACx Left Channel Output

8,14,27,33 NC Not connected

9,15,28,34 OUTRx O DACx Right Channel Output

11,19,29 AVDD Analog Power Supply. Connect to analog 5V supply.

17 FILTD Filter Capacitor Connection. Recommend 10µF/100nF.

18 FILTR Reference Filter Capacitor Connection. Recommended 10µF/100nF.

20 ADCLN I ADC Left Channel Negative Input

21 ADCLP I ADC Left Channel Positive Input

22 ADCRN I ADC Right Channel Negative Input

23 ADCRP I ADC Right Channel Positive Input

36 M/S I ADC Master/Slave Select

37 DLRCLK I/O DAC LR Clock

38 DBCLK I/O DAC Bit Clock

40,52 DGND Digital Ground

41-44 DSDATAx I DACx Input Data (Left and Right Supply)

45 ABCLK I/O ADC Bit Clock

46 ALRCLK I/O ADC LR Clock

47 MCLK I Master Clock Input

48 ADVDD Digital Output Driver Power Supply

49 ASDATA O ADC Serial Data Output

50 COUT O Output for Control Data

51 CCLK I Control Clock Input for Control Data

20

BA7626 (IC1004,1016,1019 : for AVR1707/687 model)

2

SERIAL

IN

STROBE

Q

1

Q2

Q3

Q4

CLOCK

3

4

5

6

7

8

15

14

13

12

11

10

9

V

SS

1

OUTPUT

ENABLE

V

DD

Q6

Q7

Q8

Q'S

Q5

QS

16

(IC652,653 : for AVR1507/487 model)

BA7625 (IC651 : for AVR1507/487 model)

AVR-1707/1507/687/587/487

Monitor OUT

ABE

MONITOR OUT

LL* IN 1 LL*

H L * IN 2 H L * IN 2 H L *

GND

IN5

GND

IN4

CTL E

IN3

CTL D

1

2

3

6dB

LOGIC

4

5

6

7

6dB

LOGIC

8

16

15

14

13

12

11

10

9

IN1

CTL A

V OUT1

Vcc

IN2

CTL B

V OUT2

CTL C

C D E V OUT 1 C D E V OUT 2

⎯

LL* IN 1

⎯

L H * IN 3 L H * IN 3 L H * IN 3

H H L IN 4 H H L IN 4 H H L IN 4

HHH IN 5 HHH IN 5 HHH IN 5

Note 1: * mark means that feasible for either H or L.

Note 2: Each input terminal is provided with sink chip clamp (BA7625).

Each input terminal takes 20kohm at the end (BA7626).

74LVX157MTC (IC816) BA4510F (IC815A,816A) BU4094BCF (IC551,552)

SE

LECT

1A

1B

1Y

2A

2B

2Y

GND

1

2

SEL

3

4

5

5

6

7

8

16

15

14

13

12

11

10

Vcc

OUT1

1

ST

4A

4B

4Y

– IN1

+ IN1

2

1ch

+

–

3

3A

3B

9

3Y

EE

V

4

MM74HCT244 (IC812) FAN1117-1.2 (IC824)

RC1117-33 (IC823)

OUT

FRONT VIEW

2

21

20 1

V

1G

0

1A

0

2Y

1

1A

1

2Y

2

1A

2

2Y

3

1A

3

2Y

GND

CC

19 2

2G

0

18 3

1Y

0

17 4

2A

1

16 5

1Y

1

15 6

2A

2

14 7

1Y

2

13 8

2A

3

12 9

1Y

3

11 10

2A

V

+

2ch

3

2

1

–

IN

OUT

ADJ/GND

VCC

8

OUT2

7

– IN2

6

+ IN2

5

LH28F800BJE (IC805)

SN74LV573APWR (IC818,819)

1

OE

2

D0

3

D1

4

D2

D3

5

6

D4

7

D5

8

D6

9

D7

GND

10

AVR-1707/1507/687/587/487

Vcc

20

Q0

19

Q1

18

Q2

17

Q3

16

Q4

15

Q5

14

13

Q6

12

Q7

11

LE

OE

11

E

1

D1 D2

D0

234

D

D

D

Q

L

Q0 Q1

L

Q

Q

L

L

1819

17

Q2

D3 D4 D5 D6

567

D

D

Q

Q

L

L

16

Q3

89

D

Q

L

Q4 Q5 Q6 Q7

D7

D

D

Q

Q

L

L

12131415

SN74LVC139APWR (IC820)

FUNCTION TABLE

(each decoder/demultiplexer)

1G

1A

1B

1Y0

1Y1

1Y2

1Y3

GND

1

16

V

2

3

4

5

6

7

8

CC

15

2G

14

2A

13

2B

12

2Y0

11

2Y1

10

2Y2

9

2Y3

INPUTS

SELECT

G

G

B A Y3 Y2 Y1 Y0

L L L H H H L

L L HHHLH

L H LHLHH

L H HLHHH

H X X H H H H

OUTPUTS

OUTPUTS

SN74LV14APWR (IC829) MM74HCT00MTCX (IC814,815)

1

1A

1B

1Y

2A

2B

2Y

GND

Vcc

14

2

3

4

5

6

7

4B

13

4A

12

4Y

11

3B

10

9

3A

3Y

8

GND

1

1A

2

1Y

2A

3

4

2Y

5

3A

3Y

6

7

Vcc

14

13

6A

6Y

12

5A

11

5Y

10

9

4A

4Y

8

22

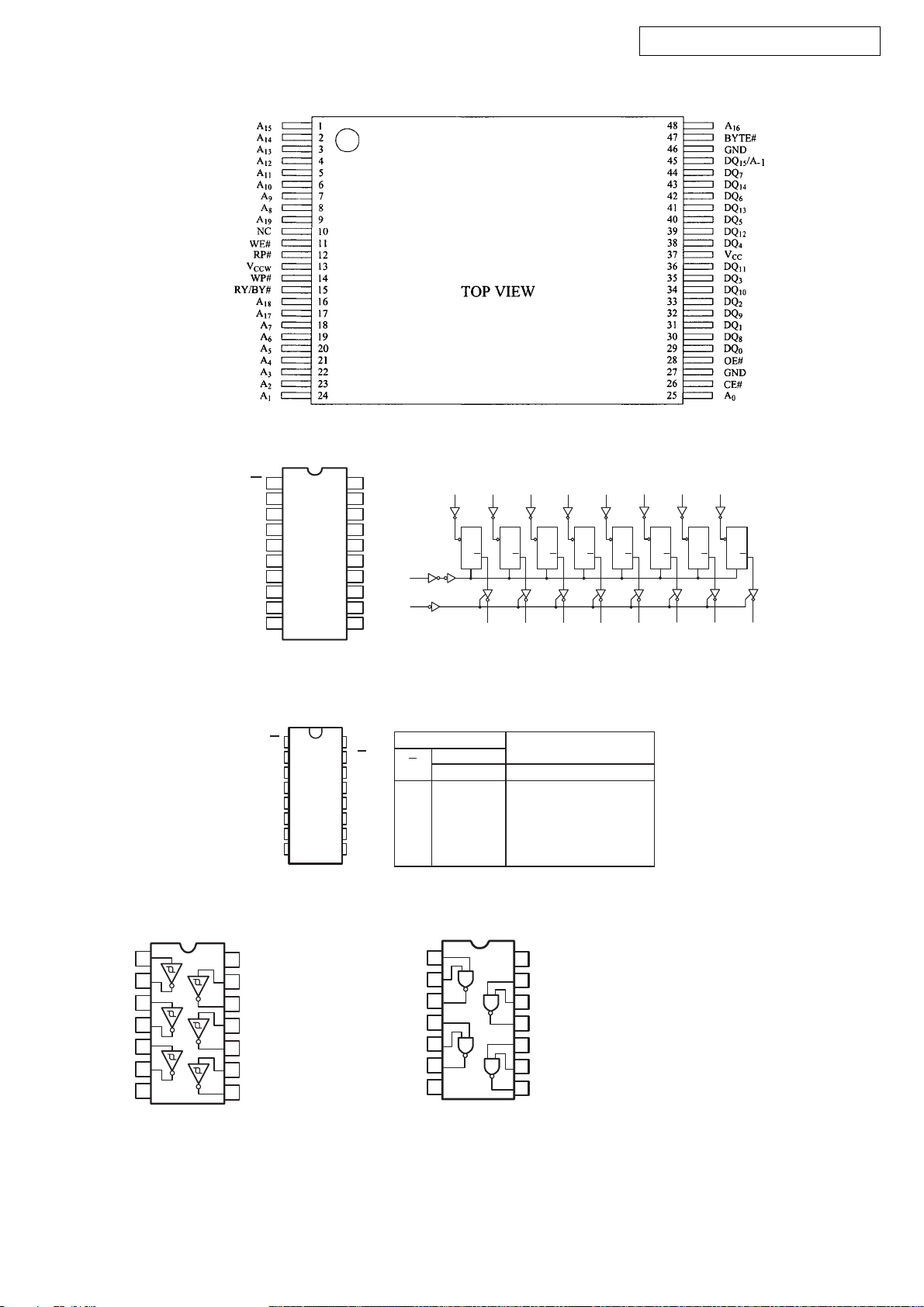

AS7C34096A-10TCN (IC806,817 : for AVR-1707/687 model)

(IC817 : for AVR-1507 E2 model)

Top View

1

44

NC

43

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

NC

42

NC

A

41

18

A

40

17

A

39

16

A

38

15

37

OE

I/O

36

7

I/O

35

6

V

34

SS

V

33

CC

I/O

32

5

I/O

31

4

A

30

14

A

29

13

A

28

12

A

27

11

A

26

10

25

NC

24

NC

23

NC

WE

OE

A

0

A

1

A

2

A

3

A

4

A

5

A

6

A

7

A

A

A

ROW DECODER

8

9

10

INPUT BUFFER

512K x 8

ARRAY

COLUMN

DECODER

11

12

A

A13A

I/O

I/O

V

V

I/O

I/O

WE

NC

NC

CE

NC

NC

A

0

A

1

A

2

A

3

A

4

0

1

CC

SS

2

3

A

5

A

6

A

7

A

8

A

9

14

ACEA

AVR-1707/1507/687/587/487

I/O

0

I/O

1

I/O

2

I/O

3

I/O

I/O

I/O

I/O

4

5

6

7

SENSE AMPS

POWER

DOWN

15

16

17

18

A

A

A

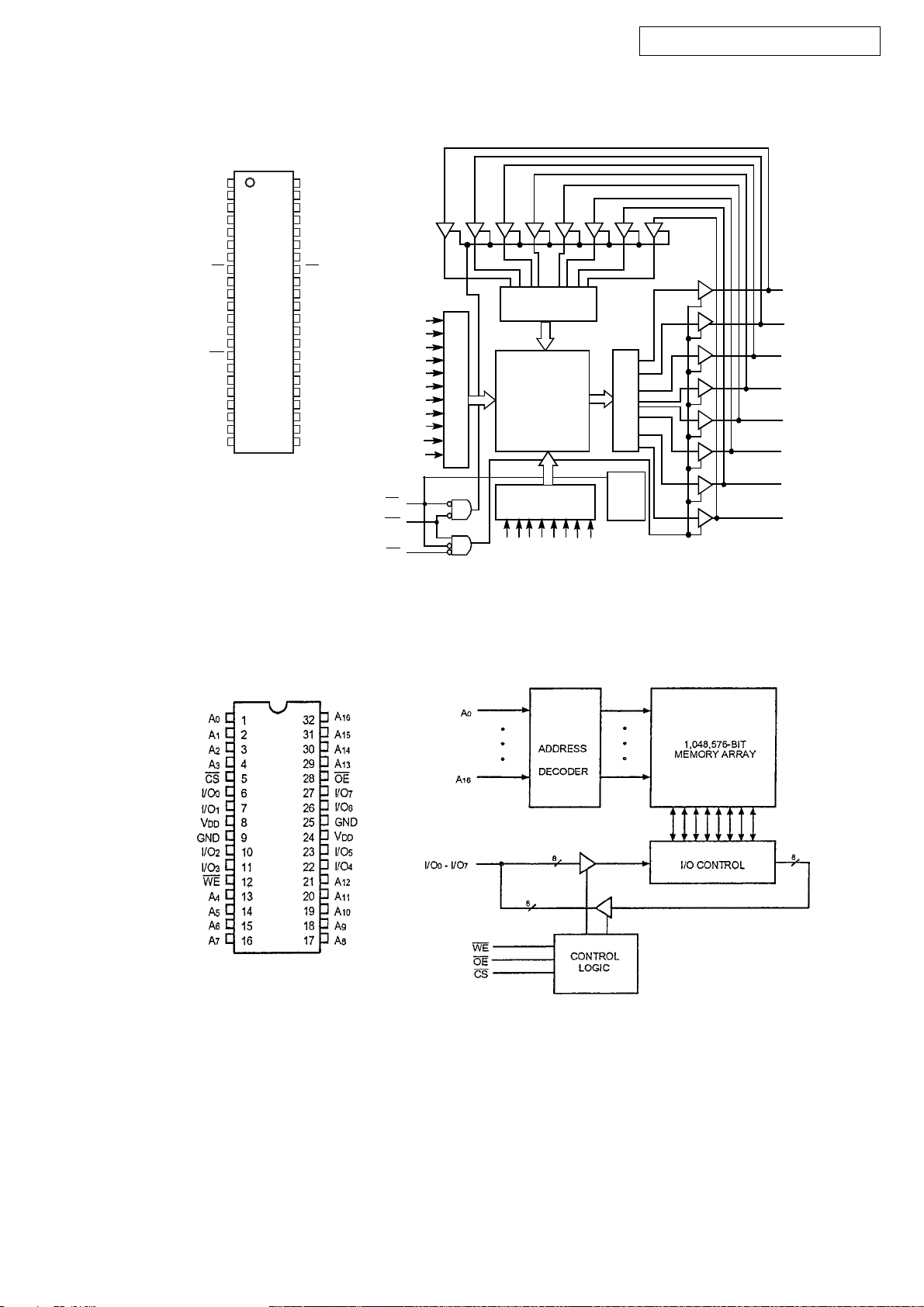

IC63LV1024-10T (IC817 : for AVR1507/587/487 E3 model)

23

ADV7180BSTZ (IC601 : for AVR1707/687 model)

AVR-1707/1507/687/587/487

24

AVR-1707/1507/687/587/487

25

ADV7172KSTZ (IC602 : for AVR1707/687 model)

AVR-1707/1507/687/587/487

26

PIN FUNCTION DESCRIPTION

AVR-1707/1507/687/587/487

27

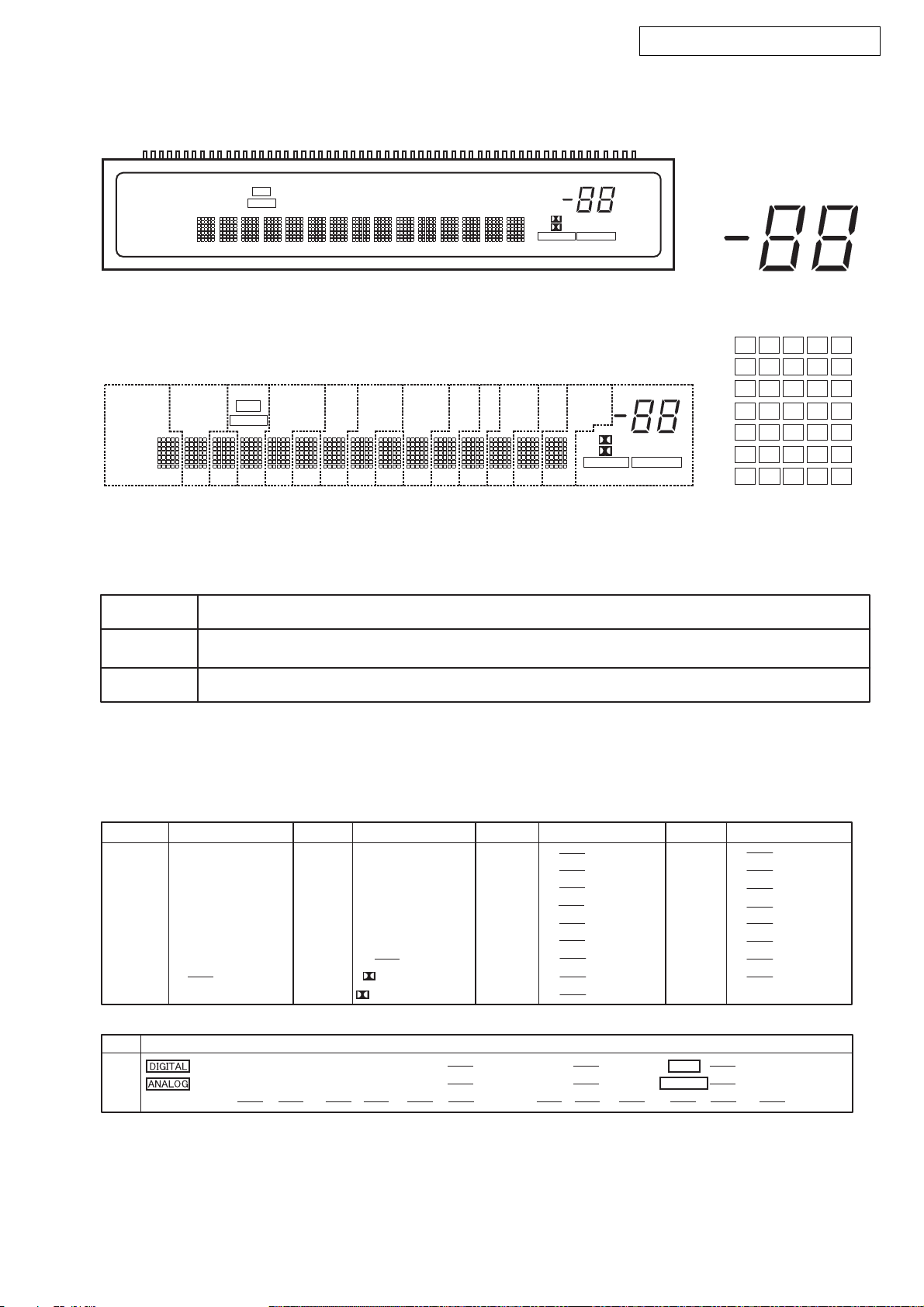

2. FL DISPLAY

2

7

P

t

A

HNA-16SM13T (FL301)

AVR-1707/1507/687/587/487

59

TUNED

STEREO

RDS

CH

G16

TUNED

RDS

CH

G15 G13

STEREO

AUTO

in Assignment

AUTO

G14

ZONE2

REC

ZONE2

REC

PHONO

VCR

G12

PHONO

VCR

G11

CD

-

1

G10

CD

-

TUNER

-2-

TUNER

-2-

1

AUX

3 V.AUX

G9

3

G8

DVD /

CDR

G7

AUX

V.AUX

VDP TV

TAPE

/

G6

DVD /

CDR

G5

/

-1-

G4

VDP

TAPE

/

2

DBS

DIGITAL

G3

TV

-1-

PRO LOGICII

DIGITAL

ANALOG

G2

DBS

/

2

DIGITAL

1

G1

PRO LOGIC

DIGITAL

ANALOG

G1

S38

S13

S14

S15

S11

S12

S9

S10

S1

S6

S

S7

S5

S3

S4

G2~G16

S3

S8

S13

S18

S23

S28

S33

S4

S9

S14

S19

S24

S29

S34

S5

S10

S15

S20

S25

S30

S35

S2

S1

S7

S6

S12

S11

S17

S16

S22

II

S21

S26

S31

S27

S32

PIN NO.

CONNECTION

PIN NO.

CONNECTION

PIN NO.

CONNECTION

12345

NP

F1 F1

21 22

S18

S19 S20 S21 S22 S23 S24 S25 S26 S27 S28 S29 S30 S31 S32 S33 S34 S35 S36 S3

S1 S2 S3

23 24 25

41 42 43 44 45

S38

G16 G15 G14 G13 G12 G11 G10 G9 G8 G7 G6 G5 G4 G3 G2 G1 F2 F2

7 8 9 10 11 12 13 14 15 16 17 18 19

6

S5 S6 S7 S8 S9 S10 S11 S12 S13 S14 S15

S4

27 28 29 30 31 32 33 34

26

47 48 49 50 51 52 53 54 55 56 57

46

35 36 37 38

58 59

20

S16 S17

39 40

F1, F2 : Filamen

G1~G16 : Grid

S1~S38 : Anode

node & Grid Assignment

G2~G16

G1

G2~G16

S1

S2

S3

S4

S5

S6

S7

S1

S2

S3

S4

S5

S6

S7

S8

S9

S9

S1

S2

S3

S4

S5

S6

S7

S8

S9

S10

S11

S12

S13

S14

S15

S16

S17

S18

G1

S10

S11

S12

S13

S14

S15

DIGITAL

PRO LOGICII

S10

S11

S12

S13

S14

S15

S16

S17

S18

S19

S20

S21

S22

S23

S24

S25

S26

S27

G1

G2~G16

S19

S20

S21

S22

S23

S24

S25

S26

S27

S28

S29

S30

S31

S32

S33

S34

S35

G1 G2 G3 G4 G5 G6 G7 G8 G9 G10 G11 G12 G13 G14 G15

S36

S37

S38

S38

/

-

2

DBS

TV

-

1

VDP

TAPE

/(DVD)

/(CDR)

CDR

AUXDVD

V.AUX

TUNER

-

2

-

3

CD

-

PHONO

1

VCR

REC

ZONE2

G1

STEREO

AUTO

G2~G16

S28

S29

S30

S31

S32

S33

S34

S35

G16

TUNED

RDS

CH

28

PRINTED WIRING BOARDS

MAIN P.W.B. UNIT (1/2)

AVR-1707/1507/687/587/487

DENON

DENON

DENON

DENON

29

DENON

COMPONENT SIDE

PRINTED WIRING BOARDS

MAIN P.W.B. UNIT (2/2)

AVR-1707/1507/687/587/487

30

FOIL SIDE

Loading...

Loading...