Dell™ C5765dn

Color Laser Multifunction Printer

Administrator Guide

Regulatory Model: C5765dn

Information in this document is subject to change without notice.

© 2013 Dell Inc. All rights reserved.

als in an

Reproduction of these materi

Trademarks used in this text:

Windows Vista, Microsoft Network, and Internet Explorer

United States and/or other countries;

Macintosh, and Mac OS

registered trademarks or trademarks of Adobe Systems Incorporated in the United States and/or other countries;

are registered trademarks of Hewlett-Packard Corporation;

countries;

RSA and BSAFE

are trademarks of Apple Inc., registered in the U.S. and other countries.

are either registered trademarks or trademarks of EMC Corporation in the United States and/or other countries.

XML Paper Specification (XPS)

conditions upon which Microsoft is licensing such intellectual property may be found at http://go.microsoft.com/fwlink/?LinkId=52369;

DES

: This product includes software developed by Eric Young (eay@mincom.oz.au);

Worcester, UK. All rights reserved. This product uses published AES software provided by Dr Brian Gladman under BSD licensing terms;

TIFF (libtiff)

(c) 1998-2004 Marti Maria.

Nuance

Other trademarks and trade names may be used in this document to refer to either the entities claiming the marks and names or their

products. Dell Inc. disclaims any proprietary interest in trademarks and trade names other than its own.

The printer software uses some of the codes defined by the Independent JPEG Group.

WSD stands for Web Services on Devices.

: Copyright (c) 1988-1997 Sam Leffler and Copyright (c) 1991-1997 Silicon Graphics, Inc.;

TM

OCR © 1994-2013 Nuance Communications. All Rights Reserved.

SD Logo is a trademark of SD-3C, LLC.

y manner whatsoever without the written permission of Dell Inc. is strictly forbidden.

Dell

and the

DELL

NetWare

logo are trademarks of Dell Inc.;

are either trademarks or registered trademarks of Microsoft Corporation in the

is a registered trademark of Novell, Inc. in the United States and other countries;

Microsoft, Windows, Windows NT, Windows Server,

Adobe, Acrobat, and PostScript

PCL, HP-GL, and HP-GL/2

ThinPrint

: This product may incorporate intellectual property owned by Microsoft Corporation. The terms and

is a registered trademark of ThinPrint GmbH in Germany and other

AES

: Copyright (c) 2003, Dr Brian Gladman,

ICC Profile (Little cms)

EtherTalk,

are either

: Copyright

As for RSA BSAFE

This printer includes RSA® BSAFE® Cryptographic software from EMC Corporation.

____________________

UNITED STATES GOVERNMENT RESTRICTED RIGHTS

This software and documentation are provided with RESTRICTED RIGHTS. Use, duplication or disclosure by the Government is subject

to restrictions as set forth in subparagraph (c)(1)(ii) of the Rights in Technical Data and Computer Software clause at DFARS 252.227-7013

and in applicable FAR provisions: Dell Inc., One Dell Way, Round Rock, Texas, 78682, USA.

August 2013 Rev. A00

Table of Contents

1 Before Using the Machine .................................................................................................................... 13

Table of Contents

Preface.........................................................................................................................................

Types of Manuals.............................................................................................................................

Using This Guide..............................................................................................................................

Organization of This Guide......................

Conventions................................................................................................................................

Interface Cables............................................................................................................................

Using the USB Interface ................................................................................................................... 19

Using the Ethernet Interface

Power Saver Mode............................................................................................................................

Changing the Interval for Entering Power Saver Mode........

Customizing the Control Panel ............................................

Changing the Default Screen........................................................................................................... 24

Setting the Screen

Customizing the Button Layout

Assigning Services to the Custom Buttons...

Adjusting the Screen Brightness.................................................................................................... 31

Entering Text

2 Paper and Other Media.......................................................................................................................... 33

...............................................................................................................................

After Auto Clear............................................................................................... 25

............................................................................................................

........................................................................................................ 26

......................................................................................... 16

...................................................... 21

.................................................................. 24

.........

....................................................................... 30

.............. 14

........ 15

........ 16

......... 17

........... 19

19

...... 21

.............. 32

Print Media G

Paper ............................................................................................................................................

Transparencies.............................................................................................................................

Envelopes .................................................................................................................................

Labels ........................................................................................................................................

Storing Print Media ........................................................................................................................

Identifying Print Media and Specifications.................................................................................. 39

Loading P

Loading Paper in Trays 1 to 4..................

Loading an Envelope in Trays 1 to 4 ................................

Loading Paper in Tray 5 (Bypass Tray)...............................

Loading an Envelope in Tray 5 (Bypass Tray) ......................

Changing the Paper Settings .................................................................................................................

3 Maintenance............................................................................................................................................

Replacing Consumables......................................................................................................................

Replacing Toner Cartridges ............................................................................................................. 53

Replacing Waste Toner Container

Replacing Drum Cartridges C, M, Y, or K ...

Replacing Staple Cartridge (for Finisher-AB1).......................

Replacing Fusing Unit ......................................................................................................................

Replacing Transfer Belt Unit ............................................

Replacing Transfer Roller ............................................................................................................... 68

Replacing Separator Rollers

uidelines.....................................................................................................................

aper...................................................................................................................................

......................................................................................... 41

............................................................... 43

............................................................45

......................................................... 46

.................................................................................................. 55

.......................

.............................................

............................................................ 57

...................................................... 61

............................................................... 64

............................................................... 70

...... 34

........ 34

...... 36

........... 37

........... 38

........ 41

... 38

48

51

... 52

62

3

Cleaning the Machine .............................................................................................................................74

Cleaning the Exterior .........................................................................................................................74

Cleaning the Interior (Laser Scanners) ..........................................................................................74

Cleaning the

Cleaning the Touch Screen ..............................................................................................................7

Cleaning Document Cover and Document Glass ......................

Cleaning the White Chute and Constant Velocity Transport Glass...........

Cleaning Document Feeder Rollers ................................................................................................81

Conductivity Temperature Depth (CTD) Sensor...........

....................................................80

.........................................76

9

................................80

Executing Calibration.....

Adjusting Color Registration.................................................................................................................

Auto Color Registration ....................................................................................................................

Side Color Registration ....................................................................................................................

Printing a Report/List......................................................................................................................

Deleting a Private Charge Print Job with an Invalid User ID ...

Setting Restore Tool........................................................................................................................

4 Machine Status ........................................................................................................................................

Overview of Machine Status.................................................................................................................

Machine Information

General Information

Paper Tray Status

Print Reports

Automatically Printed Reports/Lists ...........

Overwrite Hard Disk

Print Mode

Fax Receiving Mode

Faults

.........................................................................................................................................................107

........................................................................................................................................95

..........................................................................................................................................104

..........................

...............................................................................................................................93

...........................................................................................................................93

................................................................................................................................94

.........................................................................................................................103

........................................................................................................................106

...............................................................................................82

.........88

.......................................................89

.........90

..................................................................................102

.85

.85

.86

91

.92

Supplies

Billing Information

5 Tools.........................................................................................................................................................

System Settings Procedure ..................................................................................................................

Tools Menu List....

Common Service Settings.....................................................................................................................

....................................................................................................................................................108

.................................................................................................................................109

Billing Information

User Account Billing Information

Step 1 Entering System Administration Mode ...........

Step 2 Entering the System Administrator User ID and Passcode......

Step 3 Selecting [Tools] .................................................

Step 4 Selecting a Tab on the [Tools] Screen.....................

Step 5 Setting a Feature ..................................................................................................................

Step 6 Exiting System Administration Mode...............................................................................117

Machine Clock/Timers ....................................................................................................................129

Audio Tones

Screen/Button Settings ...................................................................................................................133

Paper Tray

Image Quality Adjustment..........................

Settings........................................................................................................................

...........................................................................................................................109

..................................................................................................110

.................................................................114

....................................114

.................................................................115

........................................................115

.........................................................................................................................

.....................................................................................................................................

.....................................................................................138

..........118

113

114

117

129

..132

..135

4

Table of Contents

Reports ............................................................................................................................................... 140

Maintenance..................................................................................................................................... 141

Notify Job Completion by E-mail................................................................................................... 142

Plug-in Settings...............................................

Other Settings ...............................................................................................................................

.............................................................................

.... 142

.... 143

Copy Service Settings.......................................................................................................................

Copy Tab - Features Allocation..................................................................................................... 150

Preset Buttons ......

Copy Defaults................................................................................................................................

Copy Control..................................................................................................................................

Original Size Defaults .....................................................................................................................

Reduce/Enlarge Presets ................................................................................................................. 157

Custom Col

Connectivity & Network Setup............................................................................................................ 158

Port

Settings..................................................................................................................................

Protocol Settings..........................................................................................................................

Machine's E-mail Address/Host Name....................................

Proxy Server Settings......................................................................................................................

Outgoing/Incoming E-mail Settings.............................................................................................. 167

Remote Authentication/Directory Service....

Security Settings..........................................................................................................................

Other Settings ...............................................................................................................................

Print Service Settings .......................................................................................................................

Allocate Memory.............................................................................................................................

Delete Form ................................................................................................................................

Other Settings ...............................................................................................................................

ors...............................................................................................................................

........................................................................................................................

.................................................... 165

..........................

.................................................... 169

.... 150

.... 151

.... 151

.... 155

157

.... 157

.... 158

.... 162

166

.... 174

.... 178

.... 179

. 179

....... 181

.... 181

Scan Service Settings.......................................................................................................................

First Tab .................................................................................................................................

Scan Defaults................................................................................................................................

Scan to PC Defaults ........................................................................................................................

Original Size Defaults .....................................................................................................................

Output Size Defaults .......................................................................................................................

Reduce/Enlarge Presets ................................................................................................................. 190

Other Settings

Fax Service Settings .........................................................................................................................

Screen Defaults............................................................................................................................

Fax Defaults ..................................................................................................................................

Fax Control ..................................................................................................................................

Fax Received Options......................................................................................................................

Reduce/Enlarge Presets ................................................................................................................. 200

Original

Local Terminal Information............................................................................................................

E-mail Service Settings ....................................................................................................................

E-mail Control ...............................................................................................................................

Folder Service Settings ....................................................................................................................

...............................................................................................................................

Size Defaults .....................................................................................................................

............ 186

.... 186

.... 187

. 189

189

. 190

.... 190

.... 193

.... 193

.... 194

...... 194

199

200

200

.... 202

.... 202

.... 205

Job Flow Service Settings ..................................................................................................................

Media Print Service Settings .....................................................................................................

......... 207

. 206

5

Stored File Settings................................................................................................................................208

Web Applications Service Setup ........................................................................................................210

Server Setup ................................................................................................................................

Other Settings...............................................................................................................................

......210

.....212

Web Browser Setup..........................................................................................................................

Setup ......................................................................................................................................

Create Folder ................................................................................................................................

Stored Programming ........................................................................................................................

Create Job Flow Sheet ....................................................................................................................217

Create

Add Address Book Entry......

Create Fax Group Recipients..........................................................................................................231

Add Fax Comment...

Paper Tray Attributes.......................................................................................................................

Accounting..................................................................................................................................

Create/View User Accounts ...........................................................................................................233

View Accounts.....

Reset User Accounts........................................................................................................................

System Administrator's Meter (Copy Jobs)............................

Accounting Type.............................................................................................................................

Accounting Login Screen Settings................................................................................................238

Fax Billing Data.....................................................

Accounting/Billing Device Settings .............................................................................................240

Job Flow Sheet Keyword ...................................................................................................224

..............................................

..........................................................................................................................

...........................................................................................................................

.......................................................................

..............................................................224

.....................................................237

...................215

.............233

.....213

.....215

217

232

232

..236

236

..237

.....239

Authentication/Security Settings......................................................................................................

System Administrator Settings ......................................................................................................242

Authentication......

Job Status Default ..........................................................................................................................

Overwrite Hard Disk.........................................................................................................................

6 Dell Printer Configuration Web Tool Settings.....................

Installation of Dell Printer Configuration Web Tool................

Preparations ................................................................................................................................

Configuration on the Machine .......................................................................................................255

Starting Dell Printer Configuration Web Tool

Configuring Machine Settings Using Dell Printer Configuration Web Tool ...............................

7 Printer Environment Settings...............................................................................................................261

Print Overview

Installation When Using USB Port......................................................................................................265

Step 1 Preparations...

Step 2 Configuration on the Machine............

Step 3 Configuration on the Computer..................................

Dell Printer Configuration Web Tool Setting Items ...................................................................266

........................................................................................................................

.............................................................253

........................................................254

..........

.........................................................................256

..............................................................................................................................

.....................................................................................................................

...............................................................................265

........................................................266

..242

.....243

..250

250

......254

257

..........262

..265

Installation When Using TCP/IP (LPD/Port 9100)..............................................................................267

Step 1 Preparations.............................................................................................................

Step 2 Configuration on the Machine............

Step 3 Configuration on the Computer..................................

...............................................................................267

........................................................268

...........

..267

6

Table of Contents

Dell Printer Configuration Web Tool Setting Items................................................................... 268

Installation When Using NetWare ..................................................................................................... 270

Step 1 Preparations ........................................................................................................................

Step 2 Configuration on the Machine........................................................................................... 270

Step 3 Configuration on the Computer ......................................................................................... 271

Dell Printer Configuration Web Tool Setting Items...............

.................................................... 272

. 270

Installation When Using Microsoft Network (SMB).......

Step 1 Preparations ........................................................................................................................

Step 2 Configuration on the Machine........................................................................................... 273

Step 3 Configuration on the Computer ......................................................................................... 274

Dell Printer Configuration Web Tool Setting Items...............

Installation When Using Internet Printing Protocol (IPP).......

Step 1 Preparations ........................................................................................................................

Step 2 Configuration on the Machine........................................................................................... 275

Step 3 Configuration on the Computer ......................................................................................... 276

Dell Printer Configuration Web Tool Setting Items...............

Installation When Using EtherTalk .............

Step 1 Preparations ........................................................................................................................

Step 2 Configuration on the Machine .......................................................................................... 277

Step 3 Configuration on the Computer ......................................................................................... 278

Dell Printer Configuration Web Tool Setting Items...............

8 E-mail Environment Settings............................................................................................................... 279

E-mail Overview...

Preparations ..................................................................................................................................

............................................................................................................................

....................................................................................... 277

................................................................ 273

. 273

.................................................... 274

....................................................... 275

. 275

.................................................... 276

. 277

.................................................... 278

...... 280

......... 281

Installation Procedures ............................

Step 1 Enabling Port and Setting up TCP/IP................................................................................ 283

Step 2 Conf

Dell Printer Configuration Web Tool Setting Items...............

9 Scanner Environment Settings ........................................................................................................... 287

Scan Service Overview ..

Configuration of Store to Folder.......................................

Step 1 Enabling Port and Setting up TCP/IP................................................................................ 289

Step 2 Regi

Step 3 C

Configuration of Scan to PC...

Step 1 Preparations ........................................................................................................................

Step 2 Enabling Port and Setting up TCP/IP................................................................................ 292

Step 3 Conf

Configuration of Store to USB .............................................................................................................

Step 1 Available USB Memory Devices....................................................................................... 294

Step 2 Dell Printer Configuration Web Tool Setting Items....................................................... 294

Configuration of Job Flow Sheets .

Step 1 Enabling Ports and Setting up TCP/IP.............................................................................. 295

Step 2 Configuring the SNMP Port.

Step 3 Configuration on the Computer

iguring E-mail Environment....................................................................................... 284

...................................................

stering a Folder ............................................................................................................ 290

onfiguring a Computer...................................................................................................... 290

...............

iguration on the Computer ......................................................................................... 293

............................................................................................ 283

.................................................... 285

................................................................... 288

................................................................... 289

............................................................................................... 291

.....................................

............................................................................................... 296

......................................................................................... 296

................................................................ 295

. 291

294

7

Configuration of Store & Send Link.....................................................................................................297

Step 1 Configuring E-mail ...............................................................................................................297

Step 2 Enabling Authentication .....................................................................................................297

Step 3 Other Settings

Step 4 Dell Printer Configuration Web Tool Setting Items .......................................................298

.......................................................................................................................

297

10 Encryption and Digital Signature Settings.....................

Encryption and Digital Signature Overview..............................

Types of Certificate ........................................................................................................................

Encryption Features for Communication..........

Encryption and Digital-Signature Features for Scan Files ..........

Configuration of HTTP Communications Encryption ..................

Installation Overview ......................................................................................................................

Step1 Configuration on the Machine..........

Step2 Configuration on the Computer............

Configuration of Encryption using IPSec................................

Installation Overview ......................................................................................................................

Step1 Import and Configuration of a Certificate .........................................................................

Step2 Configuration on the Machine (Configuration of IPSec)............

Step3 Configuration on the Computer............

Configuration of E-mail Encryption/Digital Signature................

Installation Overview ......................................................................................................................

Step1 Configuration on the Machine..........

Step2 Configuration on Sender and Recipient.......................

Configuration of PDF/XPS Signature...................................................................................................311

Installation O

Step1 Configuration on the Machine..........

Step2 Configuration on the Computer............

verview ......................................................................................................................

..................................................................................302

..................................................................................307

..................................................................................311

...................................................................

........................................................300

............................................................................300

.............................................301

.....................................................302

...............................................................................303

...........................................................304

....................................305

...............................................................................306

.....................................................307

.....................................................309

...............................................................................312

299

..300

302

304

304

307

311

11 Authentication and Accounting Features .........................................................................................313

Overview of Authe

Overview of Authentication Feature...........

Overview of Accounting Feature.................

Authentication...............................................................................................................................

User Types Managed by Authentication Feature.....................

User Roles and Authorization Groups......................................

Types of Authentication ..........................

Types of Account Administration ..................................................................................................318

Authentication and Accounting Relationship.........

Services Controlled by Authentication .........

Overview .....................................................................................................................................

Services Restricted by User ID Authentication .........

Services Restricted by the Combined Use of

Smart Card Authentication and User ID Authentication ...........

Authentication for Job Flow Sheets and Folders.....................

Overview .....................................................................................................................................

When the Authentication Feature is Disabled.......................

When the Authentication Feature is Enabled .........

ntication and Accounting Feature................

..................................................................................314

..................................................................................315

........................................................................................317

....................................................................319

.....................................................................................320

.................................................................320

....................................................................331

.....................................................314

..........316

..................................................316

.....................................................316

.......320

................................................322

........................................................325

.......325

.....................................................328

8

Table of Contents

Jobs Manageable by Account Administration................................................................................. 334

Configuration for Authentication ........................................................................................................ 337

Installation Overview......................................................................................................................

Enabling Authentication ....................................................

Changing the Default Authorization Group Settings ................

Creating an Authorization Group..................

................................................................................. 340

............................................................. 337

................................................. 339

337

Configuration for Account Administration..........

Step 1 Selecting an Accounting Type.......................................................................................... 341

Step 2 Registering User Information ............................................................................................341

User Authentication Operations .......

Authenticating Login Users........................

Changing Passcode .........................................................................................................................

12 Problem Solving .................................................................................................................................... 345

oubleshooting ...............................................................................................................................

Tr

Machine Trouble..............................................................................................................................

Image Quality Trouble.......................................................................................................................

Trouble during Copying ............................

Unable to Copy..............................................................................................................................

The Copy Result is Not What was Expected............................................................................... 359

Trouble during Printing....................................................

Unable to Print..............................................................................................................................

The Print Result is Not What was Expected............................................................................... 363

Trouble during Faxing.......................................................................................................................

Sending Problems...........................................................................................................................

Receiving Problems.........................................................................................................................

...........

............................................................................................ 358

.............................................................................. 341

....................................................................................... 343

.................................................................................... 343

344

...... 346

...... 347

.... 352

.... 358

..................................................................... 362

.... 362

.... 365

. 365

367

Trouble during Scanning.................

Unable to Scan with the Machine.........

Unable to Import Scanned Documents to the Computer............

Unable to Send a Scanned Document over the Network (FTP/SMB) .......

Unable to Send E-mail...........................

The Image is not What was Expected.......................................................................................... 372

Network-related Problems ..................................................................................................................

When using SMB .............................................................................................................................

When using NetWare...................................................................................................................... 376

When using

When using EtherTalk.....................................................................................................................

Dell Printer Configuration Web Tool Problems..........

E-mail Features Problems ..............................................................................................................

Internet/Intranet Connection Problems ....................................................................................... 384

IPv4

and IPv6 Connection Problems............................................................................................. 385

Media Print - Text Trouble..................................................................................................................

Media Print - Photos Trouble ..............................................................................................................

Status Code ................................................................................................................................

Other Errors ................................................................................................................................

TCP/IP ..........................................................................................................................

..................................................................................................... 369

....................................................................................... 369

............................................... 370

............................. 371

.......................................................................................... 372

................................................................ 382

............. 390

....... 452

374

374

380

381

383

. 388

389

Paper Jams .................................................................................................................................

............ 454

9

Paper Jams in Trays 1 to 4 ..............................................................................................................454

Paper Jams in Tray 5 (Bypass).......................................................................................................456

Paper Jams in Fusing Unit ..............................................................................................................

Paper Jams in Duplex Module.......................................................................................................458

Paper Jams in Finisher-AB1.....

Paper Jams in H

Transport Unit.....................................................................................................460

......................................................................................................459

457

Document Jams ......

Duplex Automatic Document Feeder B1-C............

Stapler Faults ...................................................................................................................................

Staple Jams in Staple Cartridge (for Finisher-AB1)..............

13 Appendix ................................................................................................................................................

Specifications...............................................................................................................................

Printable Area...............................................................................................................................

Standard Printable Area..................................................................................................................476

Extended Pri

Int

ernal Fonts..............................................................................................................................

Optional Components........................................................................................................................

ESC/P-K Emulation ............................................................................................................................

Emulation.....................................................................................................................................

Fonts....................................................................................................................................

Output Feature..............................................................................................................................

ESC/P-K Emulation Print Features.................................................................................................482

ESC/P-K Emulation Settings ......................................................................................................

Magnification Table

Paper Size and Number of Printable Characters........................................................................492

.........................................................................................................................

......................................................................461

.....................................................464

ntable Area .................................................................................................................476

.........................................................................................................................

.......461

.......463

..........468

..........476

.............477

.....479

.....480

.......480

................481

.....481

.....483

.467

488

PDF Direct Print ............................................................................................................................

PDF Direct Print Settings ................................................................................................................494

PCL Emulation

Emulation.....................................................................................................................................

Fonts....................................................................................................................................

Output Feature..............................................................................................................................

PCL Emulation Settings ...................................................................................................................498

HP-GL/2 Emulati

Emulation.....................................................................................................................................

Fonts....................................................................................................................................

Output Feature..............................................................................................................................

Factory Default Settings..................................................................................................................

HP-GL/2 Emulation Settings............................................................................................................505

Hard Clip Area...

Printable Area ..............................................................................................................................

Auto Layout ................................................................................................................................

Notes and Restrictions.....................................................................................................................

Notes and Restrictions on the Use of the Machine ..............

Notes and Restrictions on the Use of the Copy Feature.......

Notes and Restrictions on the Use of the Print Feature..........

Notes and Restrictions on the Use of the Scan Features..........

...............................................................................................................................

on...........................................................................................................................

...........................................................................................................................

.....................................................520

.....................................................522

..................................................522

................................................524

..........494

..........496

................497

................503

.......496

.....498

.......503

.......503

.....504

504

.....510

.....511

........513

.....520

10

Table of Contents

Notes and Restrictions on the Use of the Fax Feature.............................................................. 527

Notes and Restrictions on the Use of the E-mail Feature......................................................... 528

Notes and Restrictions when Connecting with Internet Service Provider............

Notes and Restrictions on the Interrupt Mode.......................

Notes and Restrictions on Folders......................................

Notes and Restrictions when Connecting to Internet or Intranet.....

Notes and Restrictions when Operating from Computers............

Notes and Restrictions on Job Flows ......................................

Notes and Restrictions on the Security Features ..................

Notes and Restrictions on the Authentication and Accounting..............

Notes and Restrictions for Using SMB........................................................................................ 536

Notes and Restrictions for Using TCP/IP..............................

Notes and Restrictions for Using EtherTalk.........................

Notes and Restrictions for Using Bonjour............................

Notes and Restrictions for IPv6 Connection...........................

Notes and Restrictions for Print E-mail....................................................................................... 541

.................................................... 531

.......................................................... 533

...................................... 533

............................................ 533

.................................................... 534

.................................................... 535

................................ 535

....................................................... 537

....................................................... 538

....................................................... 539

.................................................... 539

............... 530

Using the Telephone .........................................................................................................................

Placing a Call..............................................................................................................................

Activity Report...............................................................................................................................

Index....................................................................................................................................................

.... 542

...... 542

......... 544

............ 547

11

12

1 Before Using the Machine

This chapter describes the organization of this guide and conventions used in this guide.

• Preface ....................................................................................................................................

• Types of Manuals ..................................................................................................................15

• Using This Guide.....

• Interface Cables......

• Power Saver Mode.

• Customizing the Control Pa

• Entering Text ..........................................................................................................................32

...............................................................................................................16

...............................................................................................................19

...............................................................................................................21

nel............................................................................................24

14

1 Before Using the Machine

Preface

Thank you for selecting the Dell C5765dn Color Laser Multifunction Printer (hereafter

referred to as "the machine").

This guide is intended for system administrators, and provides maintenance information

such as how to replace consumables, how to configure network, and troubleshooting

procedures.

The guide assumes that you are familiar with a personal computer

knowledgeable of computer networks. When you need

manuals provided with the personal computer, operating system, and network products.

After reading this guide, be sure to keep it handy for quick reference. It will be useful in case

you forget how to perform operations or if a problem occurs

For more information on how to copy, print, scan, and fax, refer to the User Guide. For

information about optional components for the

with each optional component.

and that are

additional information, refer to the

with the machine.

Print feature, refer to the guide provided

14

Types of Manuals

The following guides are provided with the machine.

Accompanying Manuals

User's Guide (PDF)

Types of Manuals

The guide describes the basic operations of the machine, as well

maintenance. This guide is included in the Documentation CD-ROM.

PostScript User Guide (PDF)

The guide describes how to install the print driver and configure the functions in order to

use the machine as a PostScript

Library" CD-ROM.

Driver CD Kit Documentation (HTML)

The documentation describes installation and configuration procedures for print drivers and

the printe

r environment. This documentation is included in the Driver CD Kit.

Guides for Optional Components

Optional components are available for the machine. Some of them come with user guides.

The guides for optional components describe all the necessary steps for using the optional

components and installing the software.

as daily management and

printer. This guide is included in the "PostScript Driver

15

1 Before Using the Machine

Using This Guide

This guide is intended for system administrators, and provides maintenance information

such as how to replace consumables, how to configure network, and troubleshooting

procedures.

Organization of This Guide

This guide consists of the following chapters.

1 Before Using the Machine

Describes the organization of this guide and conventions.

2 Paper and Other Media

Describes the types of paper and other media that you can use on the machine and how to

load media in a

3 Maintenance

tray.

Describes how to replace consumables and to clean the machine.

4 Machine

Describes how to check the faults that occurred on the machine and to print various reports/

lists.

5

Tools

Describes the procedures to set up the system.

6 Dell Printer Configuration Web Tool Settings

Describes how to use Dell Printer Configuration Web Tool.

7 Printer Environment Settings

Describes the settings to use the Print feature on the machine.

8 E-

9 Scanner Environment Settings

10 Encryptio

mail Environment Settings

Describes the settings to use various services via e-mail on the machine.

Describes the settings to use the Scan services on the machine.

Status

n and Digital Signature Settings

16

Describes how to configure the machine to use the Encryption and the Digital Signature

features with your co

11 Authentication and Accounting Features

The machine has the Authentication feature to restrict the availability of services for each

feature and the Accounting feature to manage the use of each feature

Type selected.

12 Problem Solving

Describes troubleshooting procedures to solve the problems with the machine.

mmunications and documents.

based on the Login

13 Appendix

Conventions

Using This Guide

Describes the specifications of the machine, optional accessories, and cautions/restrictions.

• The screen shots and illustrations used in this guide vary depending on the machine

configuration and optional components installed. Some of the items in the screen shots

may not be displayed or available depending on your machine configuration.

• The procedures in this guide may vary depending on the

used due to the upgrades.

• In this guide, "Computer" refers to

• The following term is used in this g

Note : Additional information on operations or features.

• The following symbols are used in this guide:

" " : • A cross-reference included in this guide.

• Names of CD-ROM, features, and

input text.

[

< > button : Hardware buttons on the control panel.

< > key : Keys on the keyboard of the computer.

> : • Path to a certain item within a procedure on the control panel.

] : • Folders, files, applications, button or menu names displayed on

the touch screen.

• Names of menus, commands, windows, or dialog boxes

displayed on the computer screen and their buttons and menu

names

a personal computer or workstation.

uide:

.

driver and utility software being

touch screen messages and

For example: When you see the procedure "select [Tools] >

[Setup] > [Create Folder]", this means that you need to

[Tools], select [Setup], and then select [Create Folder].

• Path to a certain item within a procedure on a computer.

For example: When you see the procedure "to search for files

and folders, click [Start] > [Search] > [For Files or Folders]",

this

means that you need to click

then click [For Files or Folders] to search for files and folders.

• Cross-reference

For example: "Refer to "5 Tools" > "Common Service Settings"

> "Audio Tones" in the Administrator Guide."

The sentence above m

the section "Audio Tones" in "Common Service Settings" in

chapter 5 "Tools" of the Administrator Guide.

eans that it is recommended to refer to

[Start], click [Search], and

select

17

1 Before Using the Machine

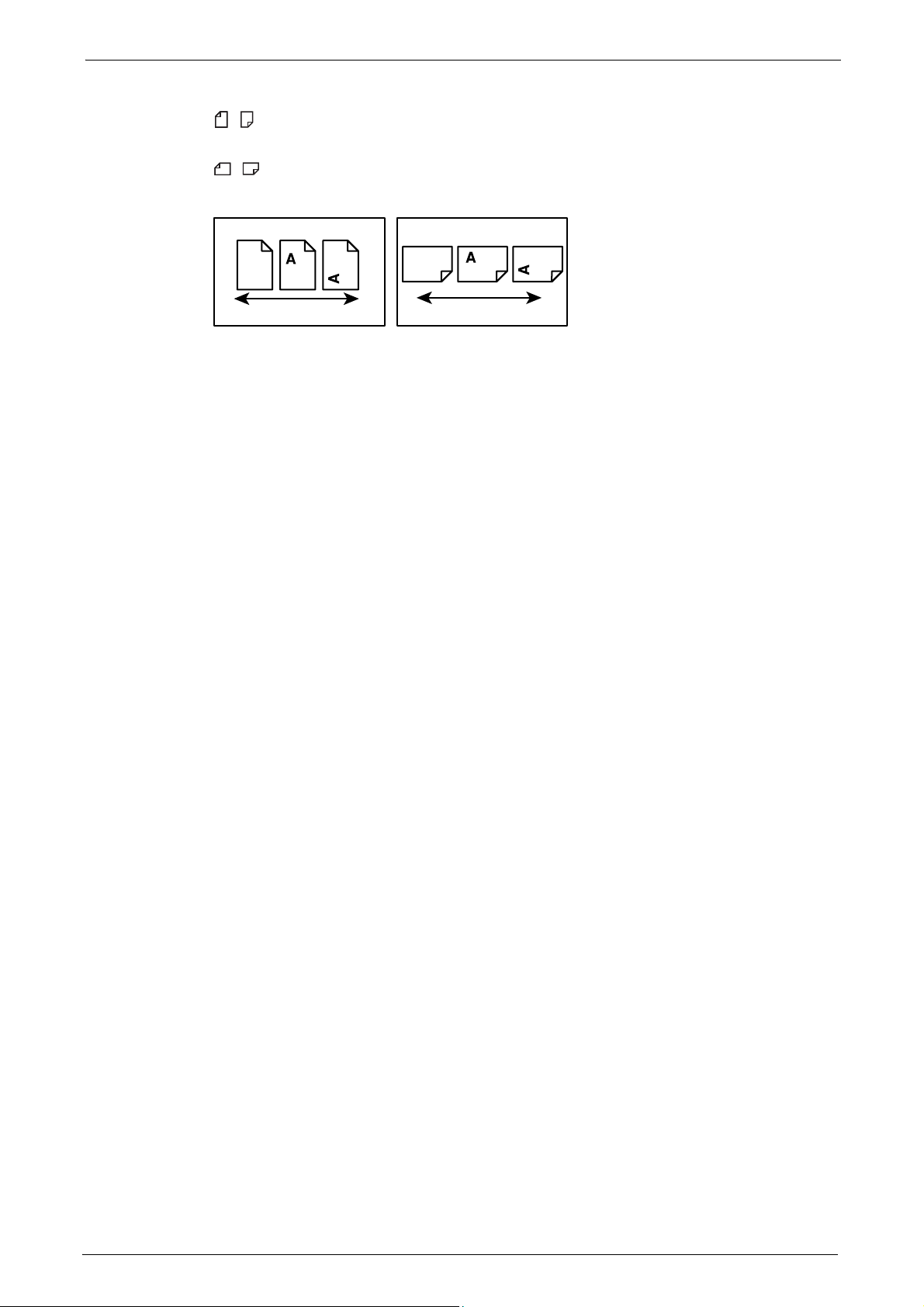

LEF Orientation

Paper feed direction

SEF Orientation

Paper feed direction

• Orientation of documents or paper is described in this guide as follows:

, , Long Edge Feed (LEF):Loading the document or paper in portrait orientation

when viewed from the front of the machine.

, , Short Edge Feed (SEF):Loading the document or paper in landscape orientation

when viewed from the front of the machine.

18

Interface Cables

When you connect the machine directly to your computer, use the USB interface. When you

connect the machine to a network, use the Ethernet interface.

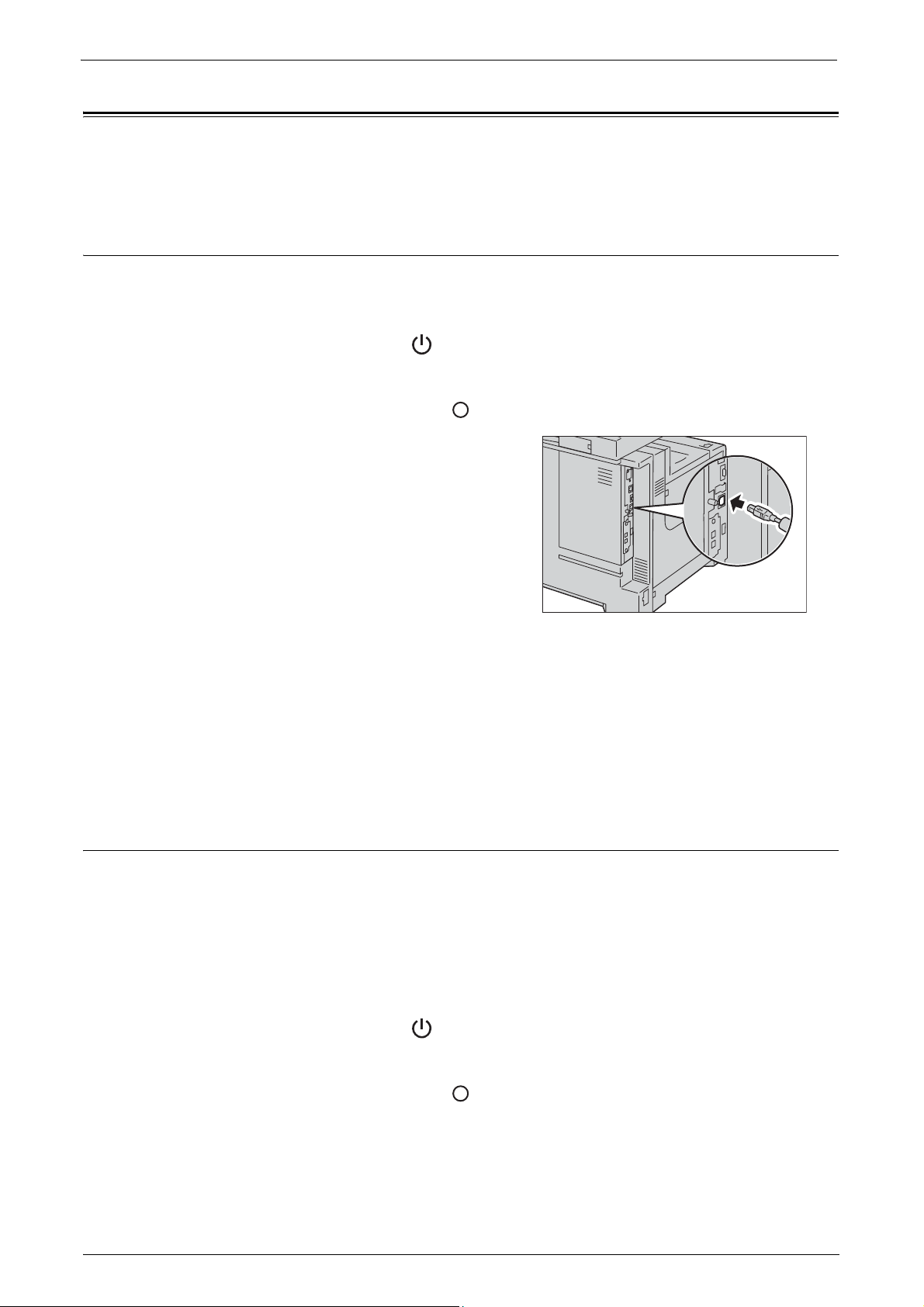

Using the USB Interface

The USB interface of the machine supports USB 2.0.

This section describes the installation procedures for the USB interface.

1

Press the power switch to the [ ] position to switch off the power.

2

Make sure that the touch screen is blank and the <Power Saver> button is not lit.

3

Press the main power switch to the [ ] position to switch off the main power.

4

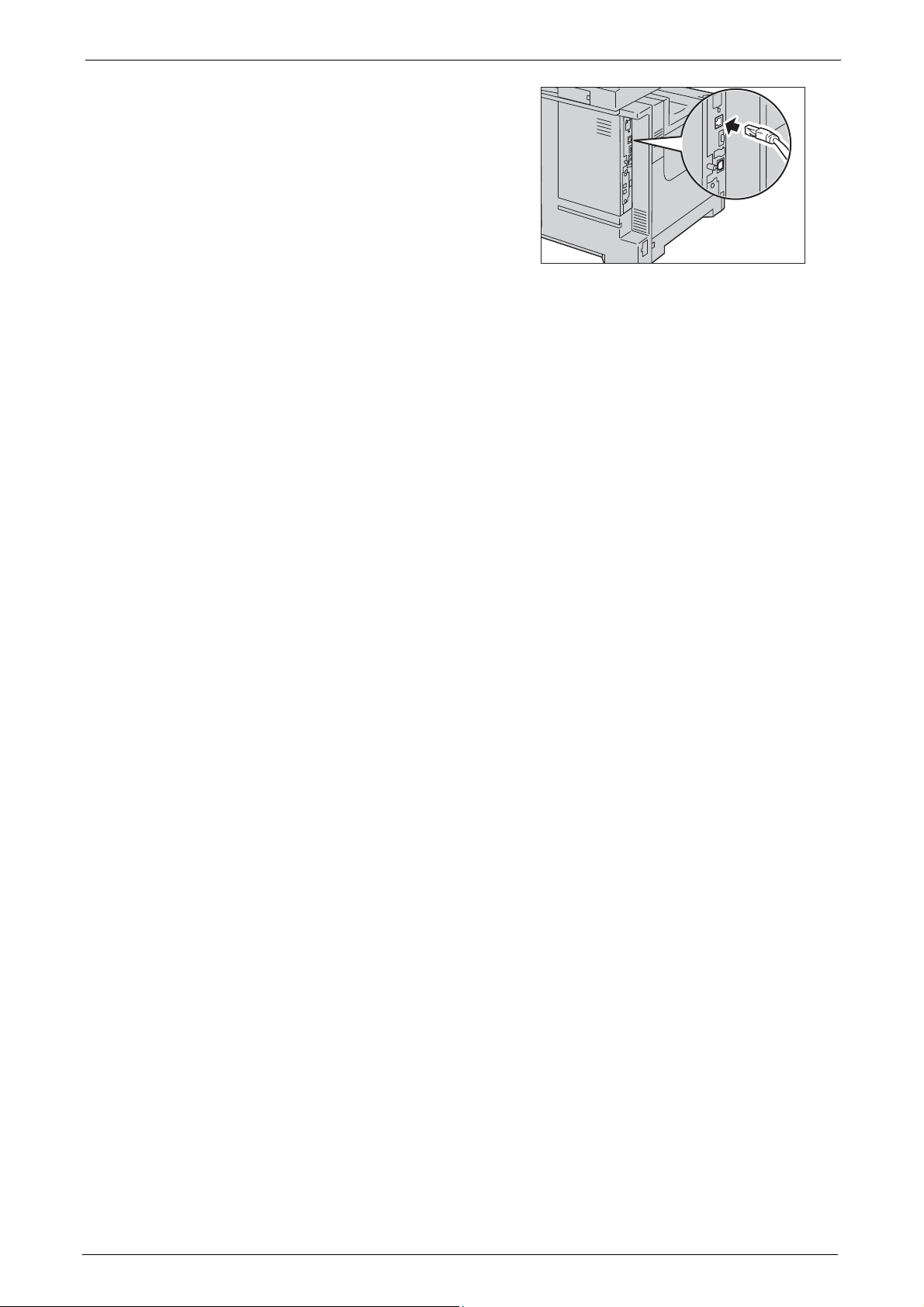

Connect the USB cable to the USB 2.0

interface connector.

Interface Cables

5

Connect the other end of the USB cable to the computer.

6

Press the main power switch to the [ | ] position to switch on the main power.

7

Press the power switch to the [ | ] position to switch on the power.

8

Restart the computer.

For more information on setting items, refer to "Printer Environment Settings" (P.261).

Using the Ethernet Interface

The Ethernet interface of the machine supports the following three types.

• 1000BASE-T

•100BASE-TX

•10BASE-T

This section describes the installation proced

1

Press the power switch to the [ ] position to switch off the power.

2

Make sure that the touch screen is blank and the <Power Saver> button is not lit.

3

Press the main power switch to the [ ] position to switch off the main power.

ures for the Ethernet interface.

19

1 Before Using the Machine

4

Connect the network cable to the Ethernet

interface connector.

Note • Always use the correct network cable with

5

Press the main power switch to the [ | ] position to switch on the main power.

6

Press the power switch to the [ | ] position to switch on the power.

For more information on setting items, refer to "Printer Environment Settings" (P.261).

your network connection. When you replace

the cable, contact Customer Support at

dell.com/contactdell.

20

Power Saver Mode

<Log In/Out> button

The machine is equipped with the Power Saver mode that reduces the power consumption

by saving the electricity to the machine when no copy or print data is received for a specified

time.

There are two types of Power Saver modes: the Low Power mode and the Sleep mode.

When you press the <Power Saver> button or do not use the machine for a specified period

of time, the machine

When time exceeds the time specified in the Low Power mode, the machine then enters the

Sleep mode.

Press the <Power Saver> button on the control panel to make the machine enter the

Saver mode.

Note • When the following device is connected to the machine and a user operates the device, the Low

• When the machine is in the Authentication mode, the Authentication mode is exited once the machine

Power Saver Mode

enters the Low Power mode.

Power

Power mode can be deactivated without pressing the <Power Saver> button. If the machine is in the

Sleep mode, however, the Sleep mode will not be deactivated by the following operation. Set the time

long to elapse until the machine enters the Sleep mode from the Low Power mode. For information on

how to change the interval to enter the Low Power mode and Sleep mode, refer to "Changing the

Interval for Entering Power Saver Mode" (P.21).

- Placing a smart card on the smart card reader

enters the Low Power mode.

Low Power Mode

The Low Power mode reduces the power to the control panel and the fusing unit.

Note • While the machine is in the Low Power mode, the power supply to the fusing unit is also reduced.

Sleep Mode

The Sleep mode reduces the power to the machine even more than the Low Power mode.

It takes longer time than the Low Power mode to deactivate the Sleep mode and enable to

use the machine.

Changing the Interval for Entering Power Saver Mode

This section describes the procedures for setting the Power Saver mode.

To activate the Power Saver, set the time to elapse until the machine enters the Low Power

mode as well as the time to elapse until the machine enters the Sleep mode.

1

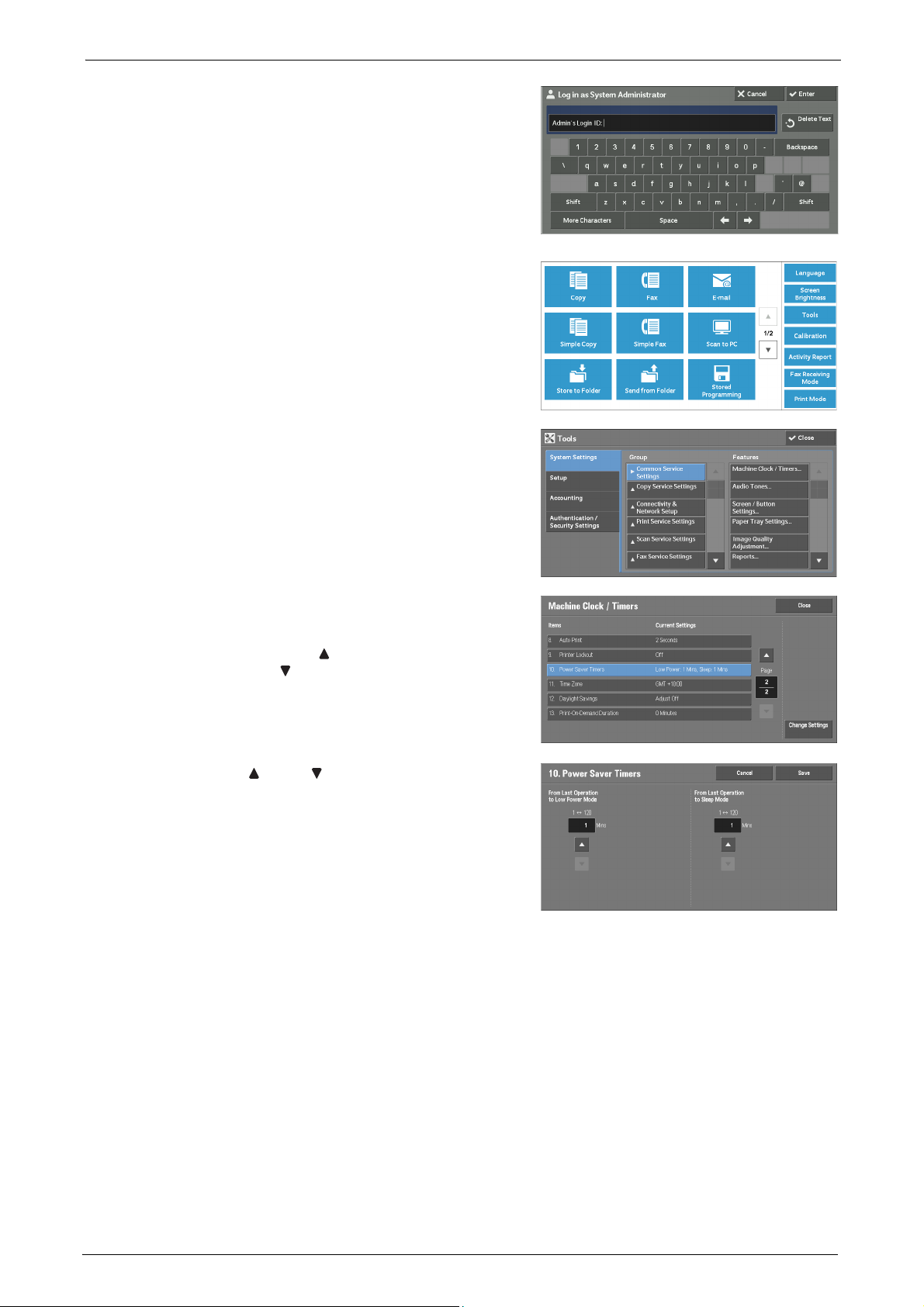

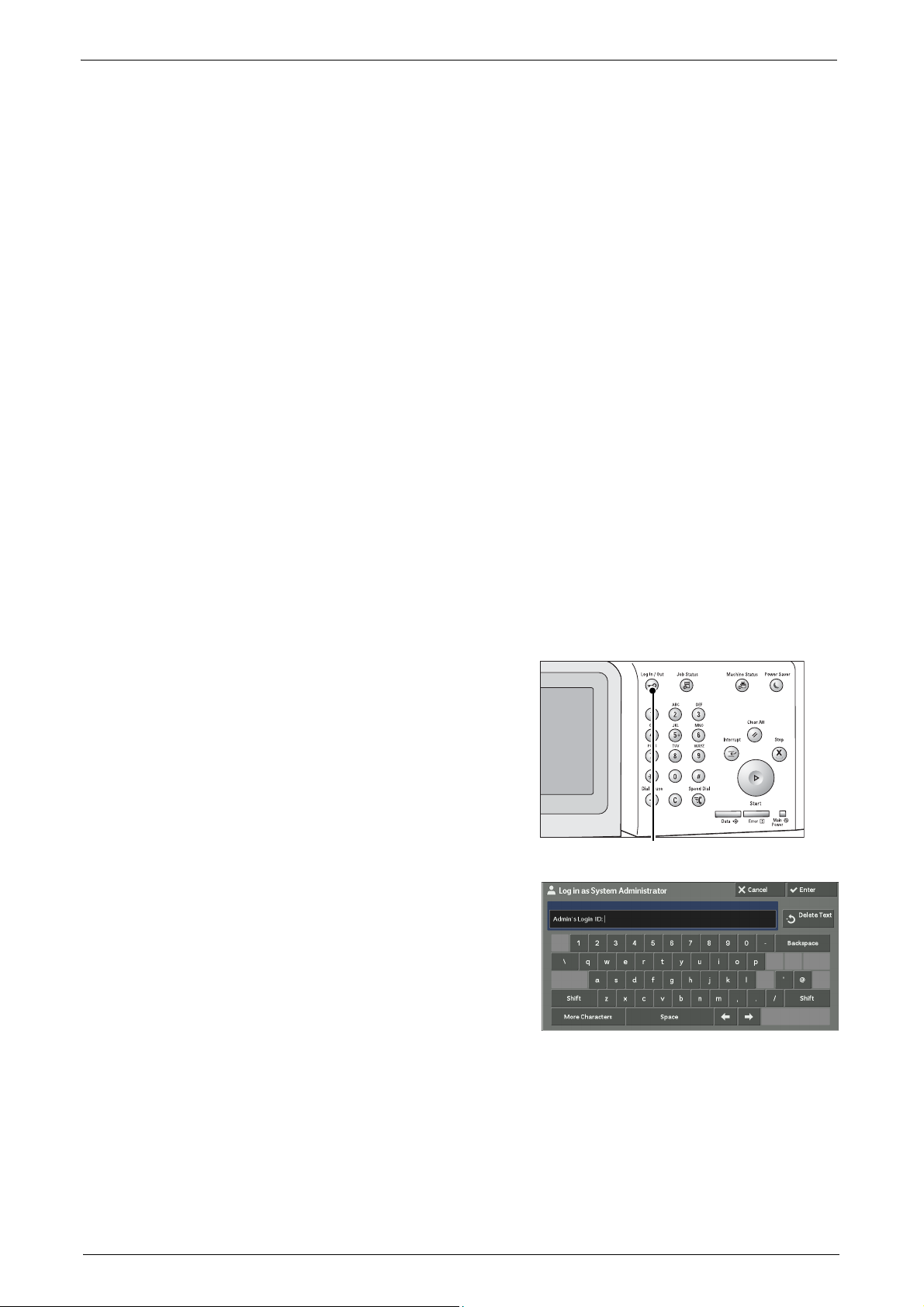

Press the <Log In/Out> button.

21

1 Before Using the Machine

2

Enter the system administrator's user ID with

the numeric keypad or the keyboard displayed

on the screen, and select [Enter].

When a passcode is required, select [Next] and

enter the system administrator's passcode, and

select [Enter].

Note • The default user ID is "admin".

3

Select [Tools] on the [Home] screen.

Note • When the [Home] screen is not displayed on

4

Select [System Settings] > [Common Service

Settings] > [Machine Clock/Timers].

• The default passcode is "1111".

the touch screen, press the <Home> button.

5

Select [Power Saver Timers], and then select

[Change Settings].

Note • Select [ ] to display the previous screen or

[ ] to display the next screen.

6

Using [ ] and [ ], set the time to elapse until

entering the Power Saver mode, in 1 minute

increments.

From Last Operation to Low Power Mode

Set the time to elapse from the last operation until the machine enters the

Note • The default value for [From Last Operation to Low Power Mode] is [10] minutes. You cannot disable the

Low Power mode.

Low Power mode.

22

From Last Operation to Sleep Mode

Set the time to elapse from the last operation until the machine enters the Sleep mode.

Note • The default value for [From Last Operation to Sleep Mode] is [10] minutes. To make the machine enter

the Low Power mode, set a longer period of time for [From Last Operation to Sleep Mode] than for

[From Last Operation to Low Power Mode].

7

Select [Save].

8

Select [Close] repeatedly until the [Tools] screen is displayed.

9

Select [Close].

Power Saver Mode

23

1 Before Using the Machine

<Log In/Out> button

Customizing the Control Panel

You can change the services displayed on the touch screen or the features assigned to the

buttons to make best use of the machine.

This section describes how to change the screen default, the services displayed after Auto

Clear, the services displayed on the [Home] screen, and the services

buttons, and how to adjust the screen brightness.

For information on how to change the other settings of the control panel, refer to "Screen/Button

Settings" (P.133).

Changing the Default Screen

You can specify what screen to display when the machine is turned on or the Power Saver

mode is deactivated.

The [Home] screen is displayed by factory default.

1

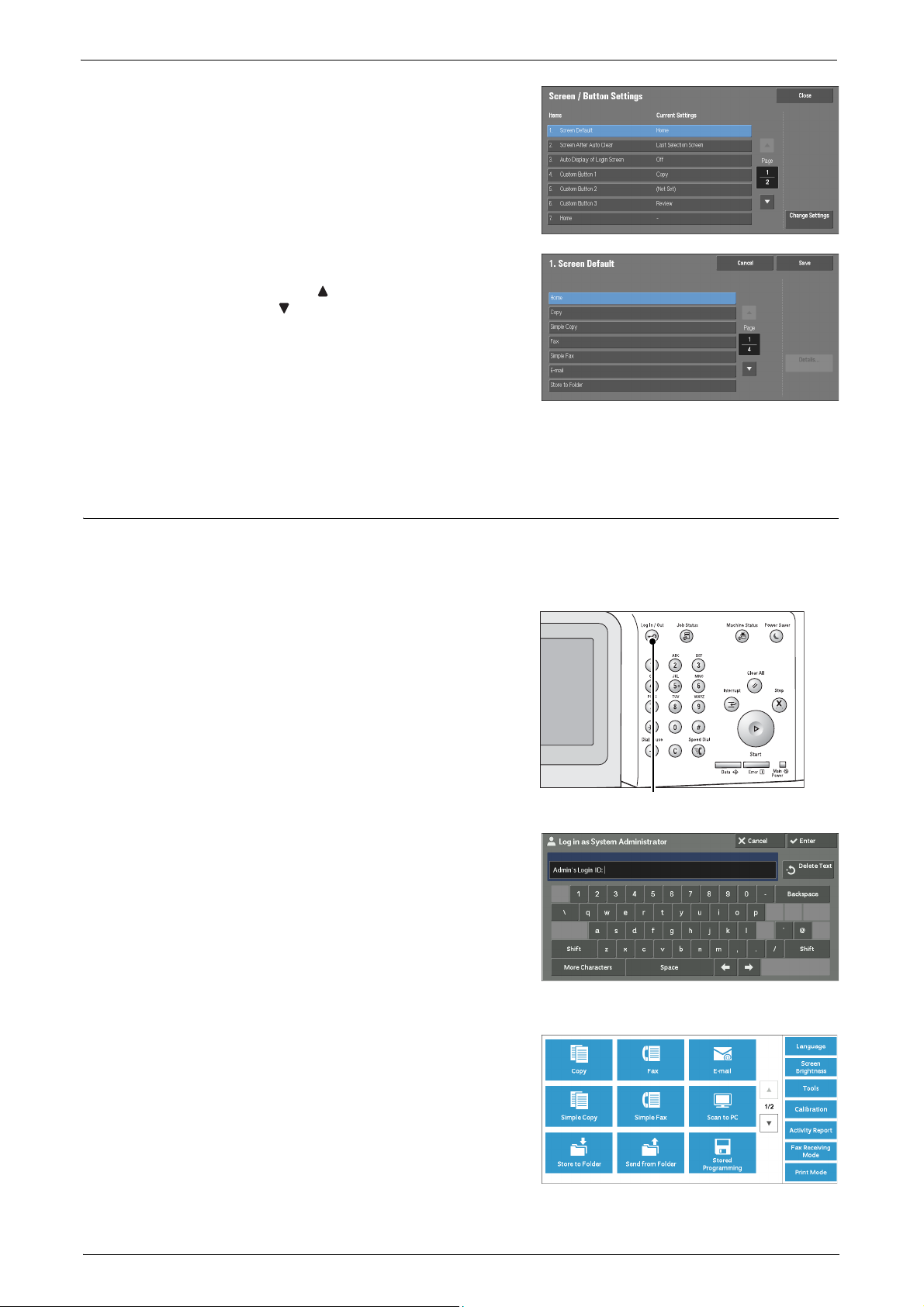

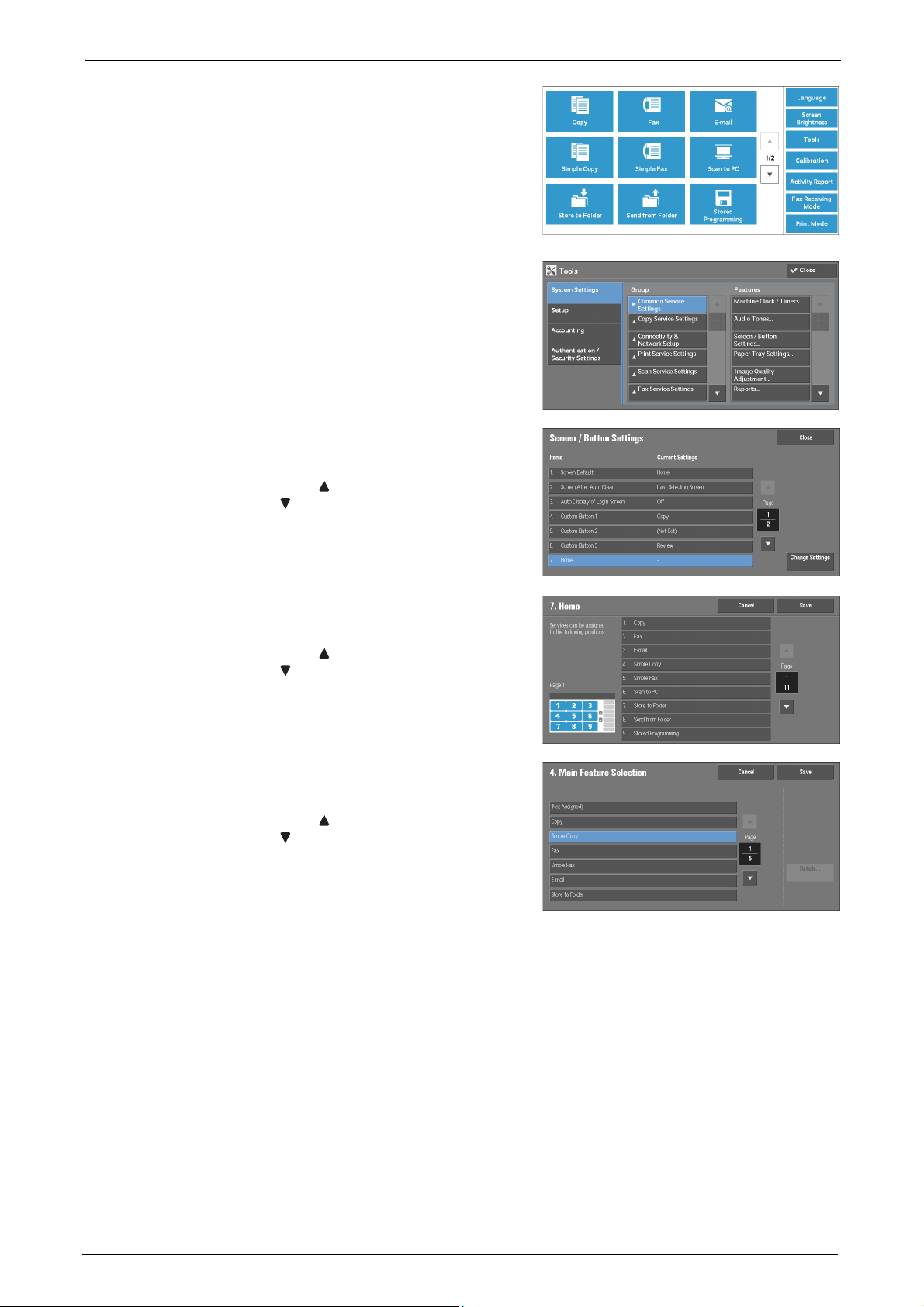

Press the <Log In/Out> button.

assigned to the custom

2

Enter the system administrator's user ID with

the numeric keypad or the keyboard displayed

on the screen, and select [Enter].

When a passcode is required, select [Next] and

enter the system administrator's passcode, and

select [Enter].

Note • The default user ID is "admin".

• The default passcode is "1111".

3

Select [Tools] on the [Home] screen.

Note • When the [Home] screen is not displayed on

the touch screen, press the <Home> button.

4

Select [System Settings] > [Common Service

Settings] > [Screen/Button Settings].

24

5

<Log In/Out> button

Select [Screen Default], and then select

[Change Settings].

6

Select a service you want to display.

Note • Select [ ] to display the previous screen or

] to display the next screen.

[

7

Select [Save].

Customizing the Control Panel

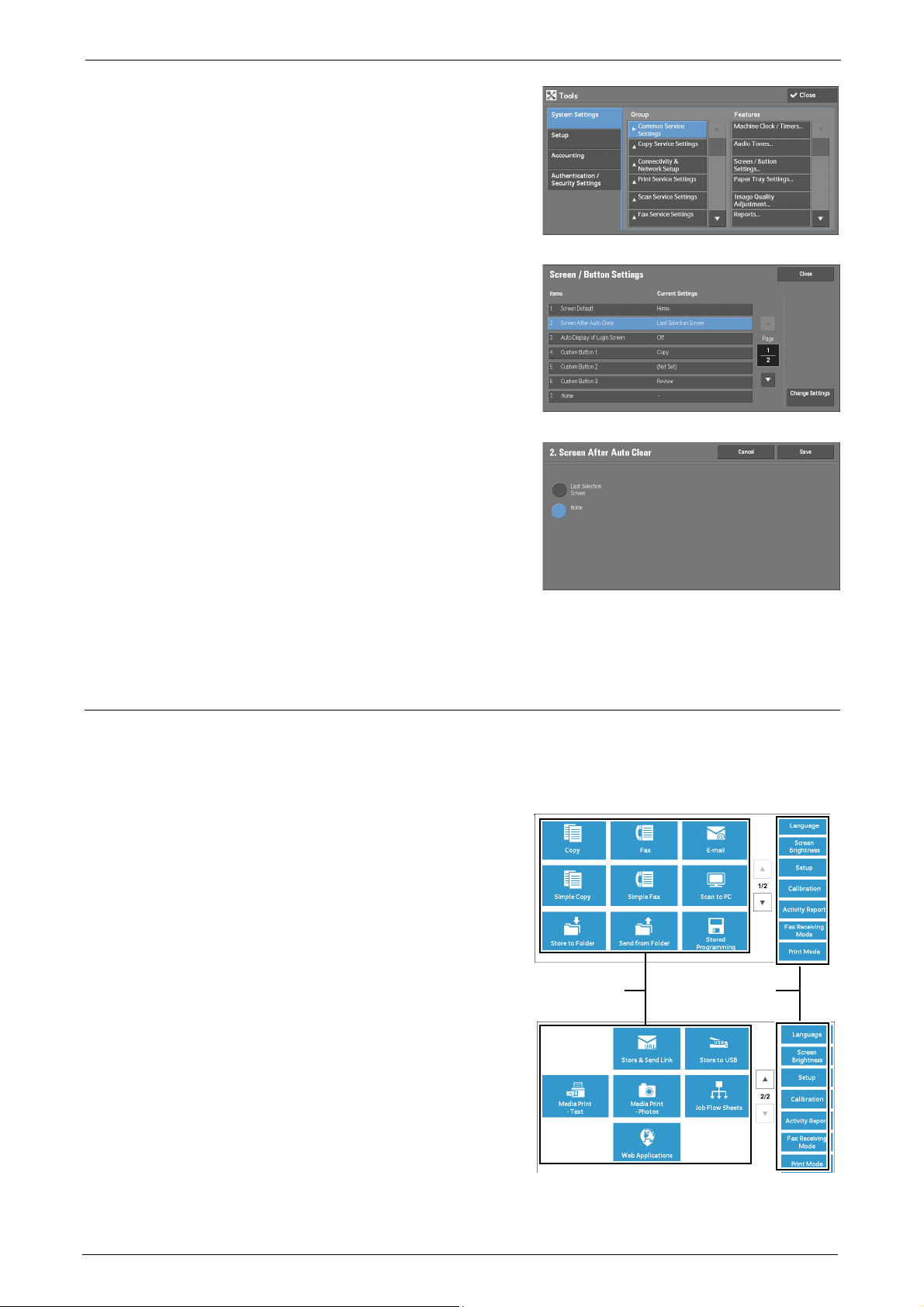

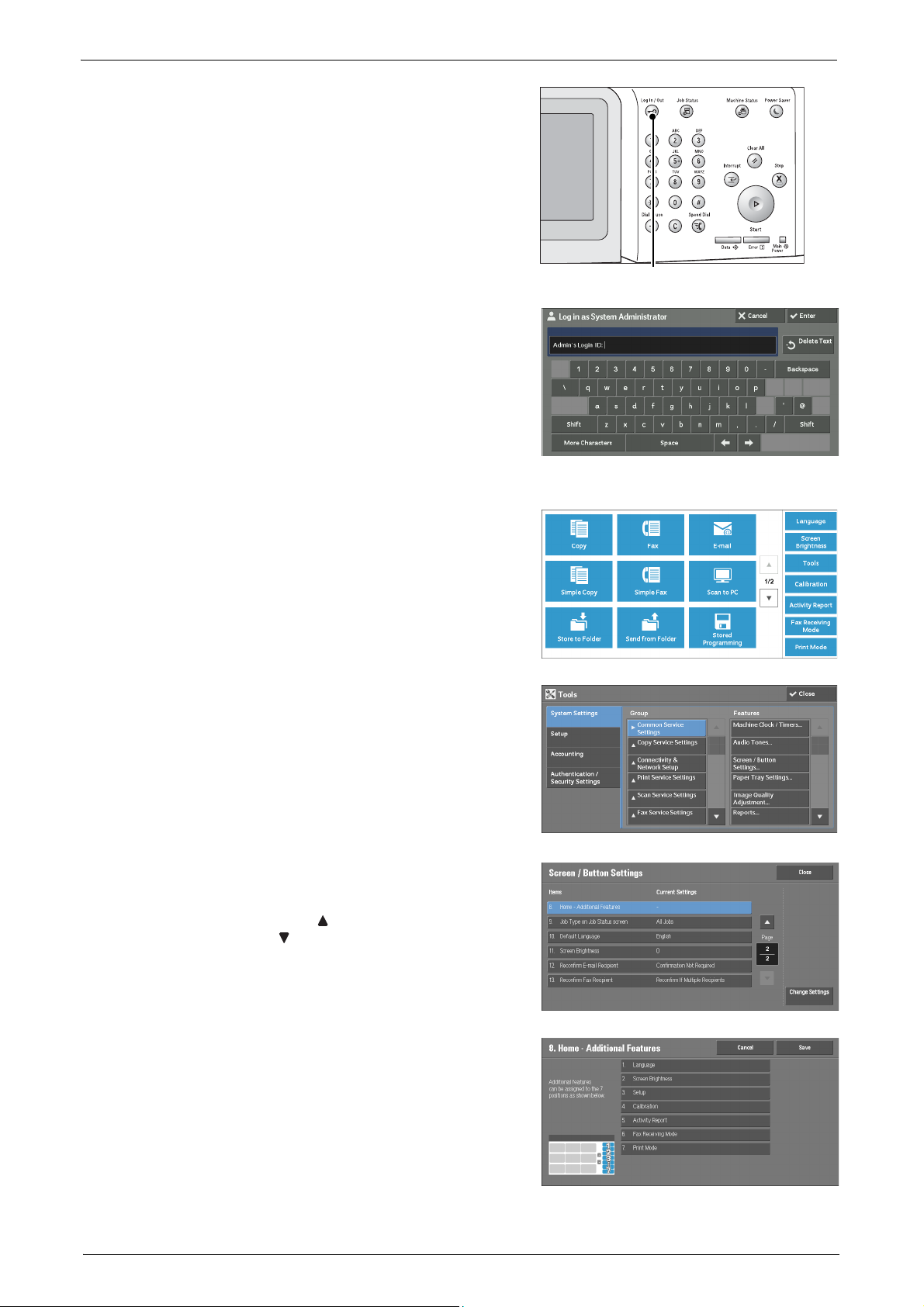

Setting the Screen After Auto Clear

You can specify what screen to display when the settings are reset with Auto Clear. [Last

Selection Screen] or [Home] can be selected.

For information on Auto Clear, refer to "Auto Clear" (P.130).

1

Press the <Log In/Out> button.

2

Enter the system administrator’s user ID with

the numeric keypad or the keyboard displayed

on the screen, and select [Enter].

When a passcode is required, select [Next] and

enter the system administrator's passcode, and

select [Enter].

Note • The default user ID is "admin".

• The default passcode is "1111".

3

Select [Tools] on the [Home] screen.

Note • When the [Home] screen is not displayed on

the touch screen, press the <Home> button.

25

1 Before Using the Machine

Service buttons

Additional feature

buttons

4

Select [System Settings] > [Common Service

Settings] > [Screen/Button Settings].

5

Select [Screen After Auto Clear], and then

select [Change Settings].

6

Select [Last Selection Screen] or [Home].

7

Select [Save].

Customizing the Button Layout

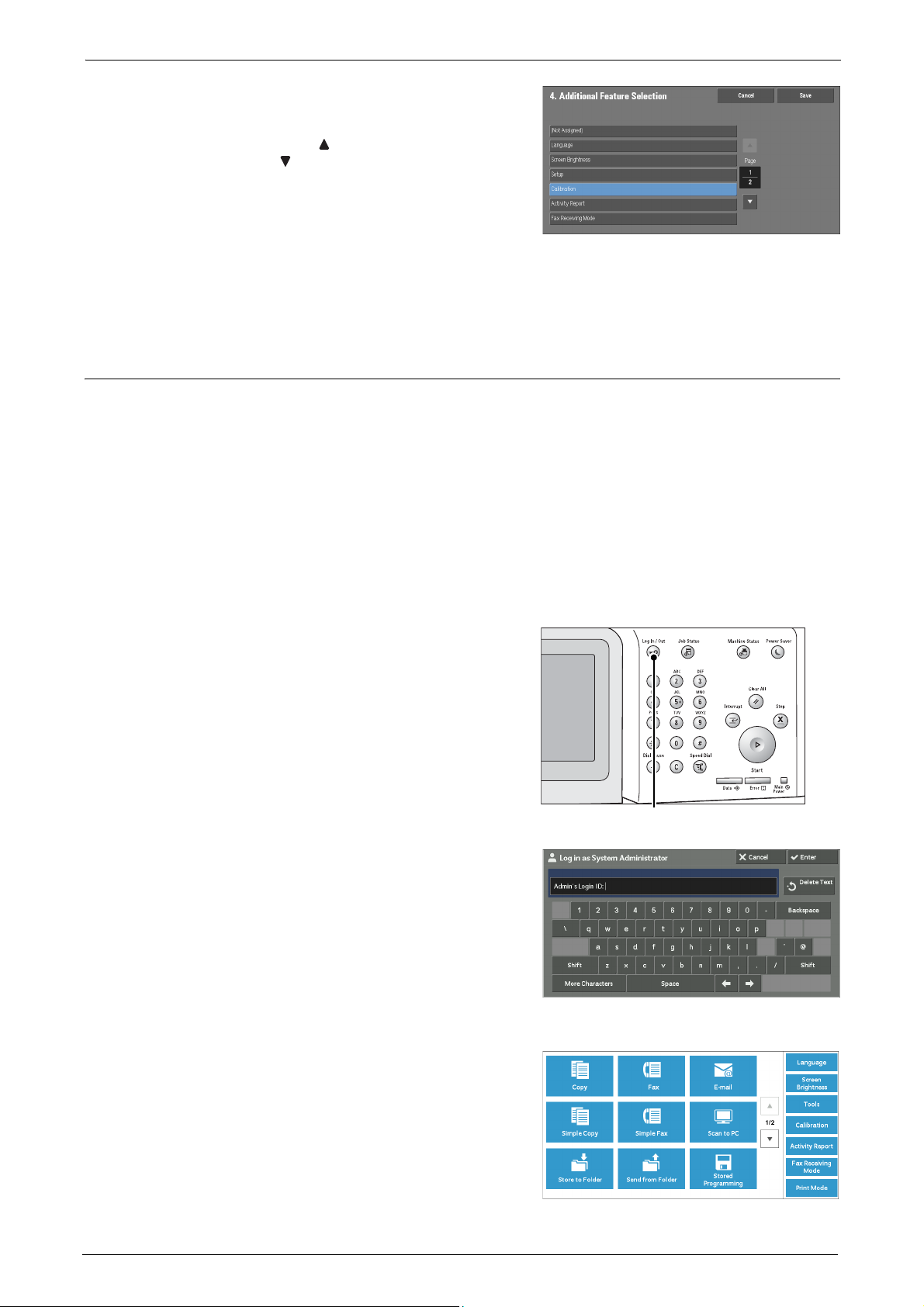

You can specify the button layout and what buttons to display on the [Home] screen, which

can be displayed by pressing the <Home> button on the control panel.

Note • The feature unsupported by the machine will not be displayed, and the feature unavailable due to a

failure will be grayed out.

•Copy

•Fax

•E-mail

• Simple Copy

• Simple Fax

•Scan to PC

• Store to Folder

• Send from Folder

26

• Stored Programming

•Store & Send Link

Note • This service is displayed when the User

• Store to USB

• Media Print - Text

Authentication feature is used.

Customizing the Control Panel

<Log In/Out> button

• Media Print - Photos

• Job Flow Sheets

• Web Applications

•Custom Services

Note • This service is for service representative use. For more information, contact Customer Support at

dell.com/contactdell.

• Language

• Screen Brightness

•Setup

•Calibration

• Activity Report

• Fax Receiving Mode

•Print Mode