Page 1

53-1003990-01

16 December 2015

Brocade G620

Hardware Installation Guide

Page 2

©

2015, Brocade Communications Systems, Inc. All Rights Reserved.

ADX, Brocade, Brocade Assurance, the B-wing symbol, DCX, Fabric OS, HyperEdge, ICX, MLX, MyBrocade, OpenScript, The Effortless

Network, VCS, VDX, Vplane, and Vyatta are registered trademarks, and Fabric Vision and vADX are trademarks of Brocade

Communications Systems, Inc., in the United States and/or in other countries. Other brands, products, or service names mentioned may be

trademarks of others.

Notice: This document is for informational purposes only and does not set forth any warranty, expressed or implied, concerning any

equipment, equipment feature, or service offered or to be offered by Brocade. Brocade reserves the right to make changes to this document

at any time, without notice, and assumes no responsibility for its use. This informational document describes features that may not be

currently available. Contact a Brocade sales office for information on feature and product availability. Export of technical data contained in

this document may require an export license from the United States government.

The authors and Brocade Communications Systems, Inc. assume no liability or responsibility to any person or entity with respect to the

accuracy of this document or any loss, cost, liability, or damages arising from the information contained herein or the computer programs that

accompany it.

The product described by this document may contain open source software covered by the GNU General Public License or other open

source license agreements. To find out which open source software is included in Brocade products, view the licensing terms applicable to

the open source software, and obtain a copy of the programming source code, please visit http://www.brocade.com/support/oscd.

Page 3

Contents

Preface.....................................................................................................................................7

Document conventions......................................................................................7

Text formatting conventions.................................................................. 7

Command syntax conventions.............................................................. 7

Notes, cautions, and warnings.............................................................. 8

Brocade resources............................................................................................ 9

Contacting Brocade Technical Support.............................................................9

Document feedback........................................................................................ 10

About This Document.............................................................................................................. 11

Supported hardware and software.................................................................. 11

What's new in this document...........................................................................11

Device Overview......................................................................................................................13

Hardware features...........................................................................................13

License options............................................................................................... 14

Port-side view..................................................................................................14

Nonport-side view........................................................................................... 15

Device management options...........................................................................15

Preparing for Installation.........................................................................................................17

Safety precautions.......................................................................................... 17

General precautions............................................................................17

ESD precautions................................................................................. 18

Power precautions.............................................................................. 18

Lifting and weight-related precautions................................................ 19

Laser precautions................................................................................20

Facility requirements....................................................................................... 20

Quick installation checklist.............................................................................. 21

Shipping carton contents.................................................................................23

Mounting the Device............................................................................................................... 25

Mounting options.............................................................................................25

Precautions specific to mounting.................................................................... 25

Standalone installation ................................................................................... 26

Installing the Universal Four-Post Rack Kit (XBR-R000296).......................... 26

Installation requirements..................................................................... 27

Time and items required..................................................................... 28

Flush-front mounting........................................................................... 30

Flush-rear (recessed) mounting.......................................................... 35

Installing the Universal Two-Post Rack kit (XBR-R000294)........................... 40

Installation requirements..................................................................... 41

Time and items required..................................................................... 41

Flush-front mounting........................................................................... 42

Mid-mounting...................................................................................... 46

Brocade G620 Hardware Installation Guide

53-1003990-01

3

Page 4

Initial Setup and Verification.................................................................................................51

Items required............................................................................................... 51

Providing power to the device.......................................................................51

Establishing a first-time serial connection.....................................................52

Configuring the IP address............................................................................53

Using DHCP to set the IP address....................................................53

Setting a static IP address................................................................ 53

Setting the date and time.............................................................................. 53

Setting the time zone........................................................................ 54

Synchronizing local time with an external source............................. 55

Customizing the chassis name and switch name......................................... 55

Establishing an Ethernet connection.............................................................56

Setting the domain ID....................................................................................56

Verifying correct operation............................................................................ 56

Backing up the configuration.........................................................................57

Powering down the device............................................................................ 58

Installing Transceivers and Cables.........................................................................................59

Time and items required............................................................................... 59

Precautions specific to transceivers and cables........................................... 60

Cleaning the fiber-optic connectors.............................................................. 60

Managing cables...........................................................................................60

Installing an SFP+ transceiver...................................................................... 61

Replacing an SFP+ transceiver.................................................................... 62

Installing a QSFP transceiver........................................................................63

Replacing a QSFP transceiver......................................................................64

Verifying the operation of new transceivers.................................................. 65

Monitoring the Device........................................................................................................... 67

Interpreting port-side LEDs........................................................................... 67

System power LED........................................................................... 67

System status LED............................................................................68

FC port status LED............................................................................69

QSFP port status LED.......................................................................69

Interpreting nonport-side LEDs..................................................................... 70

Power supply and fan assembly status LED.....................................71

Interpreting the POST results........................................................................71

Interpreting the BOOT results....................................................................... 72

Running diagnostic tests...............................................................................72

Power Supply and Fan Assembly............................................................................................75

Power supply and fan assembly overview.................................................... 75

Precautions specific to the power supply and fan assemblies......................76

Identifying the airflow direction......................................................................77

Power supply and fan assembly status LED.................................................78

Power supply and fan assembly unit fault indicators.................................... 78

Power supply and fan assembly task guide..................................................78

Time and items required............................................................................... 79

Recording power supply and fan assembly critical information.................... 79

Removing a power supply and fan assembly............................................... 80

Inserting a new power supply and fan assembly.......................................... 81

Verifying the operation of the power supply and fan assemblies..................82

4

Brocade G620 Hardware Installation Guide

53-1003990-01

Page 5

Brocade G620 Technical Specifications.................................................................................. 83

Regulatory Statements............................................................................................................91

BSMI statement (Taiwan)................................................................................91

Canadian requirements...................................................................................91

CE statement.................................................................................................. 91

China CC statement........................................................................................92

China ROHS................................................................................................... 93

FCC warning (US only)................................................................................... 93

Germany statement.........................................................................................93

KCC statement (Republic of Korea)................................................................93

VCCI statement...............................................................................................93

Cautions and Danger Notices.................................................................................................. 95

Danger Notices............................................................................................... 95

Cautions.......................................................................................................... 98

Brocade G620 Hardware Installation Guide 5

53-1003990-01

Page 6

6 Brocade G620 Hardware Installation Guide

53-1003990-01

Page 7

Preface

● Document conventions......................................................................................................7

● Brocade resources............................................................................................................ 9

● Contacting Brocade Technical Support.............................................................................9

● Document feedback........................................................................................................ 10

Document conventions

The document conventions describe text formatting conventions, command syntax conventions, and

important notice formats used in Brocade technical documentation.

Text formatting conventions

Text formatting conventions such as boldface, italic, or Courier font may be used in the flow of the text

to highlight specific words or phrases.

Format

bold text

italic text

Courier font

Description

Identifies command names

Identifies keywords and operands

Identifies the names of user-manipulated GUI elements

Identifies text to enter at the GUI

Identifies emphasis

Identifies variables

Identifies document titles

Identifies CLI output

Identifies command syntax examples

Command syntax conventions

Bold and italic text identify command syntax components. Delimiters and operators define groupings of

parameters and their logical relationships.

Convention

bold text Identifies command names, keywords, and command options.

italic text Identifies a variable.

value In Fibre Channel products, a fixed value provided as input to a command

Description

option is printed in plain text, for example, --show WWN.

Brocade G620 Hardware Installation Guide 7

53-1003990-01

Page 8

Notes, cautions, and warnings

Convention Description

[ ] Syntax components displayed within square brackets are optional.

Default responses to system prompts are enclosed in square brackets.

{ x | y | z } A choice of required parameters is enclosed in curly brackets separated by

x | y A vertical bar separates mutually exclusive elements.

< > Nonprinting characters, for example, passwords, are enclosed in angle

...

\

vertical bars. You must select one of the options.

In Fibre Channel products, square brackets may be used instead for this

purpose.

brackets.

Repeat the previous element, for example, member[member...].

Indicates a “soft” line break in command examples. If a backslash separates

two lines of a command input, enter the entire command at the prompt without

the backslash.

Notes, cautions, and warnings

Notes, cautions, and warning statements may be used in this document. They are listed in the order of

increasing severity of potential hazards.

NOTE

A Note provides a tip, guidance, or advice, emphasizes important information, or provides a reference

to related information.

ATTENTION

An Attention statement indicates a stronger note, for example, to alert you when traffic might be

interrupted or the device might reboot.

CAUTION

A Caution statement alerts you to situations that can be potentially hazardous to you or cause

damage to hardware, firmware, software, or data.

DANGER

A Danger statement indicates conditions or situations that can be potentially lethal or

extremely hazardous to you. Safety labels are also attached directly to products to warn of

these conditions or situations.

8 Brocade G620 Hardware Installation Guide

53-1003990-01

Page 9

Brocade resources

Visit the Brocade website to locate related documentation for your product and additional Brocade

resources.

You can download additional publications supporting your product at www.brocade.com. Select the

Brocade Products tab to locate your product, then click the Brocade product name or image to open the

individual product page. The user manuals are available in the resources module at the bottom of the

page under the Documentation category.

To get up-to-the-minute information on Brocade products and resources, go to MyBrocade. You can

register at no cost to obtain a user ID and password.

Release notes are available on MyBrocade under Product Downloads.

White papers, online demonstrations, and data sheets are available through the Brocade website.

Contacting Brocade Technical Support

Brocade resources

As a Brocade customer, you can contact Brocade Technical Support 24x7 online, by telephone, or by email. Brocade OEM customers contact their OEM/Solutions provider.

Brocade customers

For product support information and the latest information on contacting the Technical Assistance

Center, go to http://www.brocade.com/services-support/index.html.

If you have purchased Brocade product support directly from Brocade, use one of the following methods

to contact the Brocade Technical Assistance Center 24x7.

Online Telephone E-mail

Preferred method of contact for nonurgent issues:

• My Cases through MyBrocade

• Software downloads and licensing

tools

• Knowledge Base

Required for Sev 1-Critical and Sev

2-High issues:

• Continental US: 1-800-752-8061

• Europe, Middle East, Africa, and

Asia Pacific: +800-AT FIBREE

(+800 28 34 27 33)

• For areas unable to access toll

free number: +1-408-333-6061

• Toll-free numbers are available in

many countries.

support@brocade.com

Please include:

• Problem summary

• Serial number

• Installation details

• Environment description

Brocade OEM customers

If you have purchased Brocade product support from a Brocade OEM/Solution Provider, contact your

OEM/Solution Provider for all of your product support needs.

• OEM/Solution Providers are trained and certified by Brocade to support Brocade® products.

• Brocade provides backline support for issues that cannot be resolved by the OEM/Solution Provider.

Brocade G620 Hardware Installation Guide 9

53-1003990-01

Page 10

Document feedback

• Brocade Supplemental Support augments your existing OEM support contract, providing direct

access to Brocade expertise. For more information, contact Brocade or your OEM.

• For questions regarding service levels and response times, contact your OEM/Solution Provider.

Document feedback

To send feedback and report errors in the documentation you can use the feedback form posted with

the document or you can e-mail the documentation team.

Quality is our first concern at Brocade and we have made every effort to ensure the accuracy and

completeness of this document. However, if you find an error or an omission, or you think that a topic

needs further development, we want to hear from you. You can provide feedback in two ways:

• Through the online feedback form in the HTML documents posted on www.brocade.com.

• By sending your feedback to documentation@brocade.com.

Provide the publication title, part number, and as much detail as possible, including the topic heading

and page number if applicable, as well as your suggestions for improvement.

10 Brocade G620 Hardware Installation Guide

53-1003990-01

Page 11

About This Document

● Supported hardware and software.................................................................................. 11

● What's new in this document...........................................................................................11

Supported hardware and software

The following tables list the power supply and fan assemblies, and rack mount kits supported on the

Brocade G620 FC switch running Fabric OS 8.0.0 or later.

Power supply and fan assembliesTABLE 1

Part number Description Introduced (OS) Currently

supported (OS)

XBR-G250WPSAC-F 250W AC power supply with nonport-side

exhaust airflow

XBR-G250WPSAC-R 250W AC power supply with nonport-side

intake airflow

Rack mount kitsTABLE 2

Part number Description

XBR-R000294 Universal two-post mid-mount or flush-mount rack kit

XBR-R000296 Universal four-post fixed rack mount kit

What's new in this document

This is a new document.

Fabric OS 8.0.0 Yes

Fabric OS 8.0.0 Yes

Brocade G620 Hardware Installation Guide

53-1003990-01

11

Page 12

What's new in this document

12 Brocade G620 Hardware Installation Guide

53-1003990-01

Page 13

Device Overview

● Hardware features...........................................................................................................13

● License options............................................................................................................... 14

● Port-side view..................................................................................................................14

● Nonport-side view........................................................................................................... 15

● Device management options...........................................................................................15

Hardware features

The Brocade G620 offers the following features and capabilities:

• Up to 48 auto-sensing ports supporting high-performance 32-Gbps SFP+ ports technology in a single

domain.

• Up to four 128-Gbps (4 x 32-Gbps) QSFP ports to connect to the QSFP ports of another Brocade

G620 device.

• Dynamic Ports on Demand (Dynamic-POD) scaling from a base configuration of 24 ports to 64 ports

(two 12-port SFP+ PODs and one 16-port QSFP POD).

• 4-, 8-, 16-, and 32-Gbps auto-sensing Fibre Channel switch and router ports.

‐ A 32-Gbps optical transceiver can auto-negotiate to 32 Gbps, 16 Gbps, or 8 Gbps.

‐ A 16-Gbps optical transceiver can auto-negotiate to 16 Gbps, 8 Gbps, or 4 Gbps.

NOTE

The port speed is determined by the maximum speed supported by the optical transceiver at the

other end of the link.

• 10-Gbps manually set capability on FC ports (requires the optional 10-Gigabit FCIP/Fibre Channel

license).

‐ 10-Gbps performance is enabled by 10-Gbps SFP+ transceivers.

‐ Ports can be configured for 10-Gbps for metro connectivity.

• Universal ports self-configure as a E_Ports, F_Ports, M_Ports, or D_Ports. EX_Ports can be

activated on a per-port basis with the optional Integrated Routing license.

‐ A Diagnostic Port (D_Port) provides diagnostics, troubleshooting, and verification services for the

physical media.

• Support for port-side exhaust or nonport-side exhaust airflow for cooling.

• Brocade small form-factor pluggable plus (SFP+) optical transceivers support any combination of

Short Wavelength (SWL), Long Wavelength (LWL) or Extended Long Wavelength (ELWL) optical

media among the switch ports.

• Extended distance Fibre Channel to support long distance native FC connectivity.

• 10-Gbps Fibre Channel integration on any selected port provides DWDM metro connectivity on the

same switch.

• Port-to-port latency is minimized to 700 nanoseconds by using cut-through frame switching at 32

Gbps.

• High performance T1022 processor with two cores operating at 1.2 GHz delivers high performance,

scalability, and advanced Fabric Vision functionality.

Brocade G620 Hardware Installation Guide

53-1003990-01

13

Page 14

License options

• One 10BASE-T / 100BASE-TX / 1000BASE-T RJ45 connector Ethernet port for management

connection. In conjunction with EZSwitchSetup, this port supports switch IP address discovery and

configuration, eliminating the need to attach a serial cable to configure the switch IP address.

• One RS-232 3-wire (Tx, Rx, and Gnd) universal asynchronous receiver/transmitter (UART) serial

port to BMC with RJ-45 connector for debugging initial switch setup (if not using EZSwitch Setup)

and factory default restoration. Integral LEDs remain unlit at all times.

• One internal e-USB module provides 2 GB of persistent storage, increased serviceability, and error

logging functionality by facilitating easier firmware upgrades and downloads of the system log files.

• One external USB connector.

• Two hot-swappable redundant integrated power supply and fan assembly field-replaceable units.

• 48 hot-pluggable SFP+ optical transceiver slots and 4 hot-pluggable QSFP optical transceiver slots.

• 64 bicolor (green/amber) LEDs to indicate the status for each port.

• One green LED to indicate valid system power.

• One bicolor (green/amber) LED to indicate the system status.

• Two Ethernet LEDs: one bicolor (green/amber) LED to indicate link at 1000/100/10 Mbps and one

green LED to indicate activity.

• SEEPROM for switch identification.

• Real-time power monitoring.

• Real-time voltage monitoring.

• Real-time fan monitoring including airflow direction.

• Real-time digital thermometers for temperature monitoring.

• Real-time clock (RTC) with battery.

License options

The Brocade G620 uses a capacity-based Ports on Demand (POD) license method. Refer to the

Brocade Fabric OS Software Licensing Guide for more details.

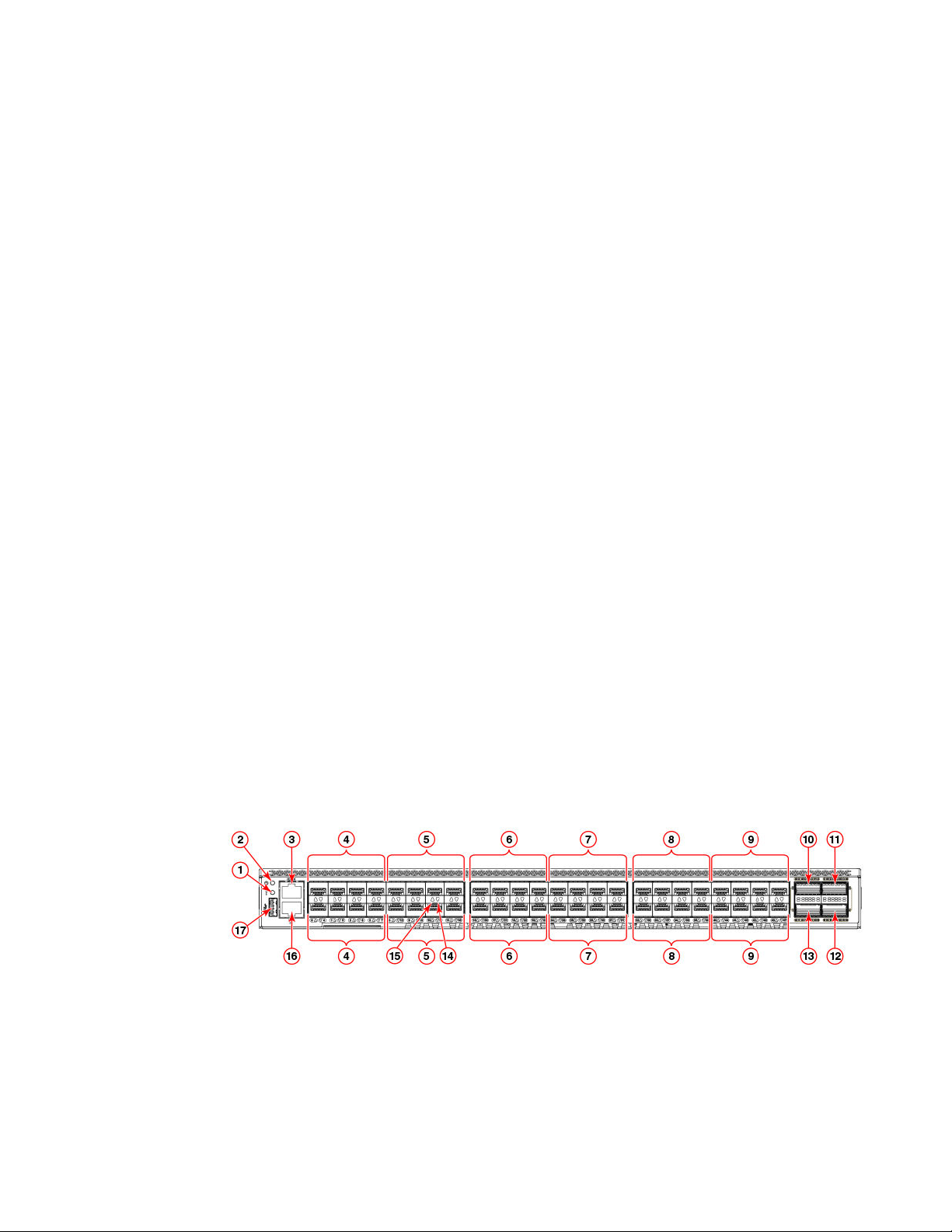

Port-side view

The following illustration shows the port-side view of the Brocade G620 Fibre Channel switch.

1 System status LED

2 System power LED

3 UART RJ-45 serial console port

4 SFP+ FC (four upper and four lower)

ports 0-7

5 SFP+ FC (four upper and four lower)

ports 8-15

6 SFP+ FC (four upper and four lower)

ports 16-23

7 SFP+ FC (four upper and four lower)

ports 24-31

14 Brocade G620 Hardware Installation Guide

53-1003990-01

Page 15

Nonport-side view

8 SFP+ FC (four upper and four lower)

ports 32-39

9 SFP+ FC (four upper and four lower)

ports 40-47

10 QSFP port 0 (FC ports 48-51)

11 QSFP port 2 (FC ports 56-59)

12 QSFP port 3 (FC ports 60-63)

FIGURE 1 Port-side view

NOTE

All the ports are connected to a single ASIC.

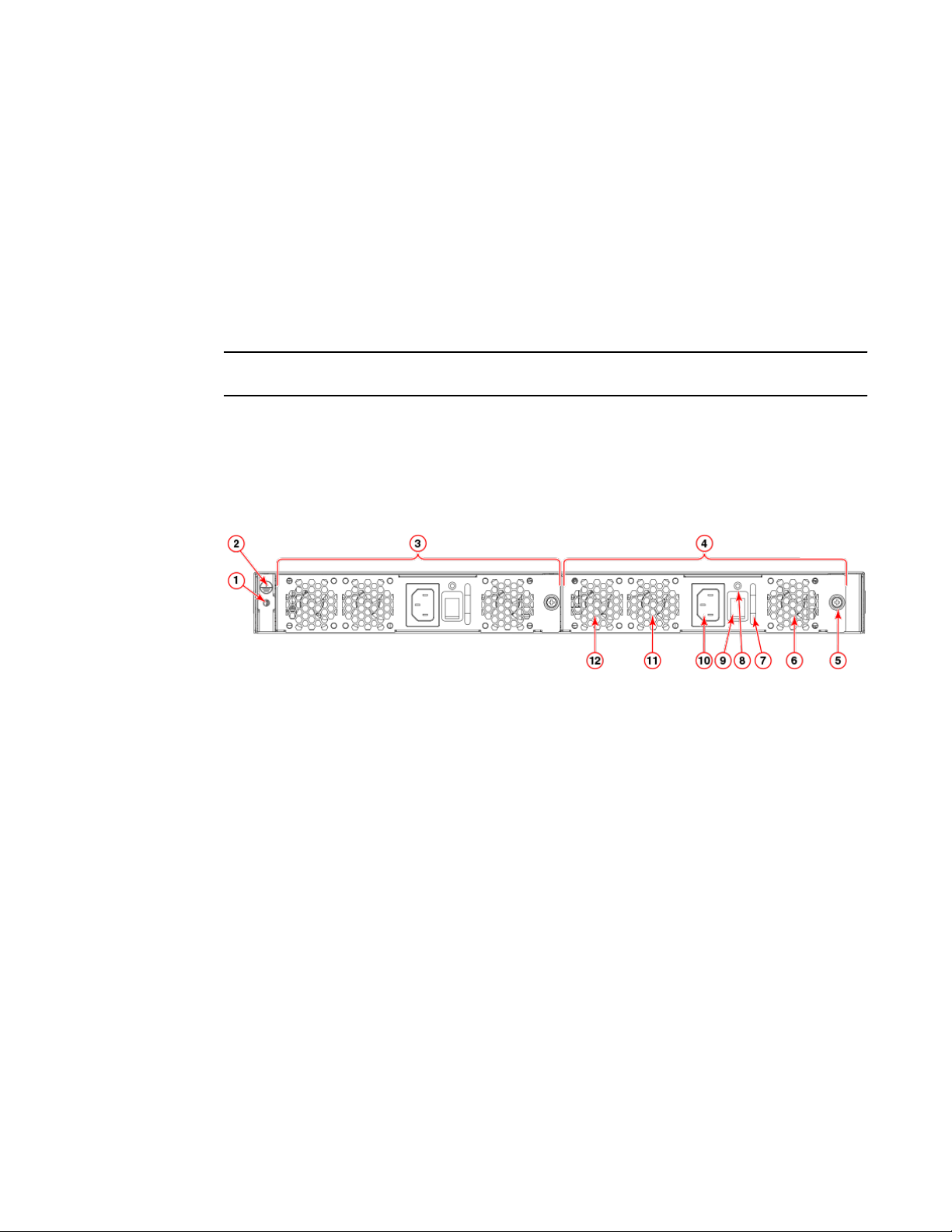

Nonport-side view

The following illustration shows the nonport-side view of the Brocade G620 FC switch.

13 QSFP port 1 (FC ports 52-55)

14 SFP+ (lower) port 14 status LED

15 SFP+ (upper) port 10 status LED

16 1000Base-T/100Base-TX/10Base-T

RJ-45 Ethernet management port

17 USB port

1 Ground sticker

2 Ground cable connector

3 Power supply and fan assembly 2

4 Power supply and fan assembly 1

5 Captive screw

6 Fan 1

7 Handle

FIGURE 2 Nonport-side view with AC power supply and fan assembly units

Device management options

You can use the management functions built into the device to monitor the fabric topology, port status,

physical status, and other information to help you analyze switch performance and to accelerate system

debugging. The device automatically performs power-on self-test (POST) each time it is turned on. Any

errors are recorded in the RASlog messages.

You can manage the device using any of the management options listed in the following table.

8 Power supply and fan assembly status

LED

9 Power-on switch

10 Power supply receptacle

11 Fan 2

12 Fan 3

Brocade G620 Hardware Installation Guide 15

53-1003990-01

Page 16

Device Overview

Management options for the deviceTABLE 3

Management tool Out-of-band

support

Command line interface

(CLI)

Up to two admin sessions

and four user sessions

simultaneously.

Brocade EZSwitchSetup

EZSwitchSetup helps to

complete the basic

configuration for singleswitch setup.

Brocade Web Tools Ethernet or serial

Standard SNMP

applications

Management Server Ethernet or serial

Ethernet or serial

connection

Ethernet or serial

connection

connection

Ethernet or serial

connection

connection

In-band support Reference documents

IP over Fibre Channel Fabric OS Administrator's Guide

Fabric OS Command Reference

IP over Fibre Channel Brocade G620 EZSwitchSetup

QuickStart Guide

Brocade EZSwitchSetup

Administrator's Guide

IP over Fibre Channel Web Tools Administrator's Guide

IP over Fibre Channel Fabric OS MIB Reference

Native in-band interface

(over HBA only)

Fabric OS Administrator's Guide

Fabric OS Command Reference

Brocade Network Advisor

(BNA)

BNA must be purchased

separately.

Ethernet or serial

connection

IP over Fibre Channel Brocade Network Advisor

documentation set

16 Brocade G620 Hardware Installation Guide

53-1003990-01

Page 17

Preparing for Installation

● Safety precautions.......................................................................................................... 17

● Facility requirements....................................................................................................... 20

● Quick installation checklist.............................................................................................. 21

● Shipping carton contents.................................................................................................23

Safety precautions

When using this product, observe all danger, caution, and attention notices in this manual. The safety

notices are accompanied by symbols that represent the severity of the safety condition

Refer to Cautions and Danger Notices at the end of this guide for translations of safety notices for this

product.

General precautions

DANGER

The procedures in this manual are for qualified service personnel.

DANGER

Before beginning the installation, see the precautions in “Power precautions.”

DANGER

Be careful not to accidently insert your fingers into the fan tray while removing it from the

chassis. The fan may still be spinning at a high speed.

CAUTION

Changes or modifications made to this device that are not expressly approved by the party

responsible for compliance could void the user's authority to operate the equipment.

CAUTION

Disassembling any part of the power supply and fan assembly voids the warranty and regulatory

certifications. There are no user-serviceable parts inside the power supply and fan assembly.

CAUTION

Make sure the airflow around the front, sides, and back of the device is not restricted.

CAUTION

Ensure that the airflow direction of the power supply unit matches that of the installed fan tray.

The power supplies and fan trays are clearly labeled with either a green arrow with an "E", or an

orange arrow with an "I."

Brocade G620 Hardware Installation Guide 17

53-1003990-01

Page 18

ESD precautions

CAUTION

Never leave tools inside the chassis.

CAUTION

To protect the serial port from damage, keep the cover on the port when not in use.

CAUTION

If you do not install a module or a power supply in a slot, you must keep the slot filler panel in

place. If you run the chassis with an uncovered slot, the system will overheat.

CAUTION

Do not install the device in an environment where the operating ambient temperature might

exceed 40°C (104°F).

ESD precautions

DANGER

For safety reasons, the ESD wrist strap should contain a series 1 megaohm resistor.

CAUTION

Before plugging a cable into any port, be sure to discharge the voltage stored on the cable by

touching the electrical contacts to ground surface.

CAUTION

Static electricity can damage the chassis and other electronic devices. To avoid damage, keep

static-sensitive devices in their static-protective packages until you are ready to install them.

NOTE

Wear a wrist grounding strap connected to the chassis ground (if the device is plugged in) or to a

bench ground.

Power precautions

DANGER

Make sure that the power source circuits are properly grounded, then use the power cord

supplied with the device to connect it to the power source.

DANGER

If the installation requires a different power cord than the one supplied with the device, make

sure you use a power cord displaying the mark of the safety agency that defines the

regulations for power cords in your country. The mark is your assurance that the power cord

can be used safely with the device.

18 Brocade G620 Hardware Installation Guide

53-1003990-01

Page 19

Lifting and weight-related precautions

DANGER

This device might have more than one power cord. To reduce the risk of electric shock,

disconnect all power cords before servicing.

DANGER

Remove both power cords before servicing.

DANGER

Disconnect the power cord from all power sources to completely remove power from the device.

DANGER

To avoid high voltage shock, do not open the device while the power is on.

DANGER

Risk of explosion if battery is replaced by an incorrect type. Dispose of used batteries according

to the instructions.

CAUTION

Use a separate branch circuit for each power cord, which provides redundancy in case one of

the circuits fails.

CAUTION

Ensure that the device does not overload the power circuits, wiring, and over-current protection.

To determine the possibility of overloading the supply circuits, add the ampere (amp) ratings of

all devices installed on the same circuit as the device. Compare this total with the rating limit for

the circuit. The maximum ampere ratings are usually printed on the devices near the input

power connectors.

CAUTION

The power supply switch must be in the off position when you insert the power supply into the

chassis. Damage to the switch can result if a live power supply is installed.

CAUTION

Carefully follow the mechanical guides on each side of the power supply slot and make sure the

power supply is properly inserted in the guides. Never insert the power supply upside down.

Lifting and weight-related precautions

DANGER

Use safe lifting practices when moving the product.

DANGER

Mount the devices you install in a rack as low as possible. Place the heaviest device at the

bottom and progressively place lighter devices above.

Brocade G620 Hardware Installation Guide 19

53-1003990-01

Page 20

Laser precautions

DANGER

Make sure the rack housing the device is adequately secured to prevent it from becoming

unstable or falling over.

CAUTION

Do not use the port cover tabs to lift the module. They are not designed to support the weight

of the module, which can fall and be damaged.

CAUTION

To prevent damage to the chassis and components, never attempt to lift the chassis using the

fan or power supply handles. These handles were not designed to support the weight of the

chassis.

Laser precautions

DANGER

All fiber-optic interfaces use Class 1 lasers.

DANGER

Use only optical transceivers that are qualified by Brocade Communications Systems, Inc. and

comply with the FDA Class 1 radiation performance requirements defined in 21 CFR

Subchapter I, and with IEC 825 and EN60825. Optical products that do not comply with these

standards might emit light that is hazardous to the eyes.

Facility requirements

Before installing the device, be sure the following facilities requirements are met.

Facility requirements TABLE 4

Type Requirements

Electrical • Adequate supply circuit, line fusing, and wire size, as specified by the electrical

rating on the switch nameplate

• Circuit protected by a circuit breaker and grounded in accordance with local

electrical codes

Refer to the Technical Specifications at the end of this guide for complete power

supply specifications.

20 Brocade G620 Hardware Installation Guide

53-1003990-01

Page 21

Quick installation checklist

Facility requirements (Continued)TABLE 4

Type Requirements

Thermal • A minimum airflow of 79.8 cubic meters/hour (47 cubic ft/min.) available in the

immediate vicinity of the switch

NOTE

Although this airflow may exceed the airflow maximum listed in the device

Technical Specifications, the additional airflow is recommended to pressurize the

inlet (cool isle) side of rack installations relative to the exhaust side to minimize

recirculation of hot air back to the inlet side.

• Ambient air temperature not exceeding 40°C (104°F) while the switch is operating

Rack (when rack-mounted) • One rack unit (1U) in a 48.3 cm (19-inch) rack

• All equipment in the rack grounded through a reliable branch circuit connection

• Additional weight of switch not to exceed the rack’s weight limits

• Rack secured to ensure stability in case of unexpected movement

Quick installation checklist

This checklist provides a high-level overview of the basic installation process from the planning stage to

the point where the device comes online and is ready to be deployed. Completing all the tasks in the

suggested order ensures successful installation. Brocade recommends that you print this checklist and

take it to the installation site.

Pre-installation tasks

Review all installation requirements ahead of time as part of your site preparation. Careful planning and

site preparation ensures seamless installation, especially when installing multiple devices.

Installation prerequisitesTABLE 5

Task Task details or additional information Completed

Unpack the device. Take an inventory of the hardware components included in your shipment. Refer to

Shipping carton contents on page 23.

Gather necessary components and

required tools.

Review the time and items required information at the beginning of each chapter to

ensure you have gathered all necessary components required for the following

installation tasks:

• Mounting the Device on page 25

• Power Supply and Fan Assembly on page 75

• Installing Transceivers and Cables on page 59

Review the safety precautions. Refer to Safety precautions on page 17. For translations, refer to Cautions and

Danger Notices on page 95 at the end of this guide.

Brocade G620 Hardware Installation Guide 21

53-1003990-01

Page 22

Preparing for Installation

Installation prerequisites (Continued)TABLE 5

Task Task details or additional information Completed

Plan the installation. Decide whether you want to install the unit on a flat surface or in a rack. For rack

installation, obtain the appropriate rack mount kit. Refer to Mounting options on

page 25.

Review and verify installation

requirements.

Gather network configuration

parameters.

Verify that the following requirements are met. Refer to Facility requirements on

page 20.

• Power requirements

• Environmental requirements

• Clearance for standalone or rack installation

• IP address:

• Subnet mask:

• Default gateway:

• Domain ID:

• Time zone:

Installation and initial configuration

The initial setup includes mounting the device on a flat surface or in a rack and completing the

configuration tasks necessary to bring the device online and verify the operation.

Installation and basic system configuration TABLE 6

Task Task details or additional information Completed

Mount the device. Choose one of the following mounting options:

• Mount the device as a standalone unit. Refer to Standalone installation on page

26.

• Mount the device in a four-post rack. Refer to Installing the Universal Four-Post

Rack Kit (XBR-R000296) on page 26.

• Mount the device in a two-post rack. Refer to Installing the Universal Two-Post

Rack kit (XBR-R000294) on page 40.

Check the airflow of the power supply

and fan assembly

Gather all components required for the

initial setup.

Provide power to the device. Refer to Providing power to the device on page 51.

Attach a management station, establish

a serial connection, and change the

default passwords (optional).

Set the IP address, subnet mask, and

the default gateway IP address.

22 Brocade G620 Hardware Installation Guide

The airflow direction of the power supply and fan should match. The power

supplies and fan trays are clearly labeled with either a green arrow with an "E", or

an orange arrow with an "I." For more details, refer to Identifying the airflow

direction on page 77.

Refer to Items required on page 51.

Refer to Establishing a first-time serial connection on page 52. After completing

this task, log in to the serial port to configure the device.

Use the ipaddrset command to configure a static device IP address, subnet mask,

and gateway IP address, or you can use a DHCP server to obtain the information

dynamically. Refer to Configuring the IP address on page 53.

53-1003990-01

Page 23

Shipping carton contents

Installation and basic system configuration (Continued)TABLE 6

Task Task details or additional information Completed

Set the date and time.

Customize the switch name and chassis

name.

Establish an Ethernet connection. By establishing an Ethernet connection, you can complete the device configuration

Optional: Configure the DNS service. Use the dnsconfig command to create DNS server entries. Refer to the Fabric OS

Optional: Customize the domain ID. Use the configure command to change the domain ID (default ID is 1). Refer to

Verify that the device operates correctly.

• Use the date command to display and set the date and time.

• Use the tstimezone command to display and set the time zone.

• Use the tsclockserver command to synchronize the time with an external NTP

server.

Refer to Setting the date and time on page 53 for more information.

• Use the swicthname command to change the default switch name.

• Use the chassisname command to change the default chassis name.

Refer to Customizing the chassis name and switch name on page 55 for more

information.

using a serial session, Telnet, or management application, such as Brocade

Network Advisor. Refer to Establishing an Ethernet connection on page 56.

Administrator's Guide.

Setting the domain ID on page 56 for more information.

• Check the LEDs to verify operation of functional parts. Refer to Interpreting

port-side LEDs on page 67 and Interpreting nonport-side LEDs on page 70.

• The following commands can be useful to establish an operational baseline for

the device. Refer to the Fabric OS Command Reference for more information

on these commands.

‐ psshow

‐ fanshow

‐ tempshow

‐ historyshow

‐ errdump

Back up the configuration. Use the interactive configupload command to back up the configuration. Refer to

Verifying correct operation on page 56 for more information.

Optional: Power off the devices. Enter the shutdown command and wait for the device to power down, and then

unplug the power cords. Refer to Powering down the device on page 58 for more

information.

Shipping carton contents

When unpacking the device, verify that the contents of the shipping carton is complete. Save the

shipping carton and packaging in the event you need to return the shipment.

• The Brocade G620 device

• An accessory kit containing the following items:

‐ A serial cable

‐ Two 6-ft. power cords

Brocade G620 Hardware Installation Guide 23

53-1003990-01

Page 24

Preparing for Installation

• Inner foam

‐ Power cord retainer clips

‐ Rubber feet.

‐ China-RoHS Hazardous/Toxic Substance statement

‐ Network Advisor web pointer card.

‐ EZSwitch web pointer card

‐ Brocade documentation web pointer card

24 Brocade G620 Hardware Installation Guide

53-1003990-01

Page 25

Mounting the Device

● Mounting options.............................................................................................................25

● Precautions specific to mounting.................................................................................... 25

● Standalone installation ................................................................................................... 26

● Installing the Universal Four-Post Rack Kit (XBR-R000296).......................................... 26

● Installing the Universal Two-Post Rack kit (XBR-R000294)........................................... 40

Mounting options

You can install the device in several ways:

• As a standalone unit on a flat surface, for example, a table top. Use the rubber feet included with the

shipment to secure the device on the surface. No other equipment is required for desktop installation.

• In a four-post EIA rack: You will need a Universal Four-Post Rack Kit (XBR-R000296) to install

devices in EIA racks that are between L-13.7 to 81.28 cm deep (L-5.0 to 32.0 in.), where L is the

chassis depth.

• In a two-post Telco rack: You will need a Universal Two-Post Rack Kit (XBR-R000294) to install 1U

and 2U devices in a two-post telecommunications (Telco) rack.

NOTE

Review the Safety Precautions before mounting the device.

Precautions specific to mounting

The following precautions specifically apply to mounting the device.

DANGER

Use safe lifting practices when moving the product.

DANGER

Mount the devices you install in a rack as low as possible. Place the heaviest device at the

bottom and progressively place lighter devices above.

CAUTION

Make sure the airflow around the front, sides, and back of the device is not restricted.

CAUTION

Never leave tools inside the chassis.

Brocade G620 Hardware Installation Guide 25

53-1003990-01

Page 26

Standalone installation

CAUTION

Do not use the port cover tabs to lift the module. They are not designed to support the weight

of the module, which can fall and be damaged.

CAUTION

To prevent damage to the chassis and components, never attempt to lift the chassis using the

fan or power supply handles. These handles were not designed to support the weight of the

chassis.

Standalone installation

Complete the following steps to install the device as a standalone unit on a table.

1. Unpack the device and verify the items listed under Shipping carton contents on page 23 are

present and undamaged.

2. Apply the adhesive rubber feet to the underside of the device. The rubber feet help prevent the

device from sliding off the supporting surface.

a) Clean the indentations at each corner of the bottom of the device to ensure that they are free of

dust or other debris that might lessen the adhesion of the feet.

b) With the adhesive side against the chassis, place one rubber foot in each indentation and press

into place.

3. Place the device on a sturdy flat surface.

4. Provide power to the device as described in Providing power to the device on page 51.

NOTE

Do not connect the device to the network until the IP address is set correctly. For instructions on

how to set the IP address, refer to Configuring the IP address on page 53.

Installing the Universal Four-Post Rack Kit (XBR-R000296)

Use the following instructions to install a device in EIA racks that are between L-12.7 to 81.28 cm deep

(L-5.0 to 32.0 in.), where L is the chassis depth, using the Universal Four-Post Rack Kit (XBR-

R000296).

There are two ways you can mount the device in a four-post rack:

• With the port side flush with the front posts

• With the nonport side flush with the rear posts in a recessed position

A recessed position allows a more gradual bend in the fiber-optic cables connected to the switch and

less interference in the aisle at the front of the rack.

NOTE

Although this document describes how to install both single height (1U) and double height (2U)

switches, the illustrations show a 1U switch as a typical installation.

26 Brocade G620 Hardware Installation Guide

53-1003990-01

Page 27

Installation requirements

NOTE

Hardware devices illustrated in these procedures are only for reference and may not depict the device

you are installing into the rack.

Installation requirements

Provide space in an EIA rack with the following minimum and maximum distances between the front

and back posts.

NOTE

For 1U and 2U devices, two people are required to install the device in a rack. One person holds the

device, while the other screws in the front and rear "L" brackets.

Space requirementsTABLE 7

Chassis with

port-side side

vents

No Applicable to port-side and nonport-

Yes Applicable to port-side flush mounts. L L-12.7 cm (L-5

Yes Applicable to nonport-side flush

Notes Chassis depth Minimum rack

L L-12.7 cm (L-5

side flush mounts.

L L 81.28 cm (32 in.)

mounts.

depth

in.)

in.)

Maximum rack

depth

81.28 cm (32 in.)

81.28 cm (32 in.)

Note that if chassis depth (L) is less than 40.64 cm (16 in.), the chassis will not fit into a rack with a

maximum depth of 81.28 cm (32 in.) using the universal four-post rack kit. The maximum rack depth for

a chassis less than 40.64 cm (16 in.) is 81.28 cm (32 in.) minus the difference between the chassis

depth and 40.64 cm (16 in.). For example, a chassis with a depth (L) of 35.56 cm (14 in.) is 5.08 cm (2

in.) smaller than 40.64 cm (16 in.), so it will install into a rack with a maximum depth of 81.28 cm (32 in.)

- 5.08 cm (2 in.) = 76.2 cm (30 in.).

• Verify that the additional weight of the device does not exceed the rack weight limits.

• Ensure that an electrical branch circuit with the following characteristics is available:

‐ Required voltage and frequency as indicated in the Technical Specifications (200-240 VAC is

always preferred).

‐ Protection by a circuit breaker in accordance with local electrical codes.

‐ Supply circuit, line fusing, and wire size that conform to the electrical rating on the device

nameplate.

‐ Grounded outlet compatible with the power cord and installed by a licensed electrician.

• Ensure that all equipment installed in the rack is grounded through a reliable branch circuit

connection. Do not rely on a secondary connection to a branch circuit, such as a power strip.

• Ensure that the rack is mechanically secured to ensure stability.

• Ensure that the air temperature at the fan inlet is less than 40oC (104oF) during device operation.

• Ensure that the airflow available at the air vents meets the minimum requirements for the device.

Brocade G620 Hardware Installation Guide 27

53-1003990-01

Page 28

Time and items required

NOTE

Install the device with the airflow aligned with any other devices in the rack. Some devices have airflow

running from port side to fan side and others have the opposite arrangement. Make sure that the

airflow for all devices moves in the same direction to maximize cooling.

Time and items required

Allow 15 to 30 minutes to complete the installation.

The following items are required to install the device using the Universal Four-Post Rack Kit:

• #2 Phillips torque screwdriver

• 1/4-inch slotted-blade torque screwdriver

28 Brocade G620 Hardware Installation Guide

53-1003990-01

Page 29

Mounting the Device

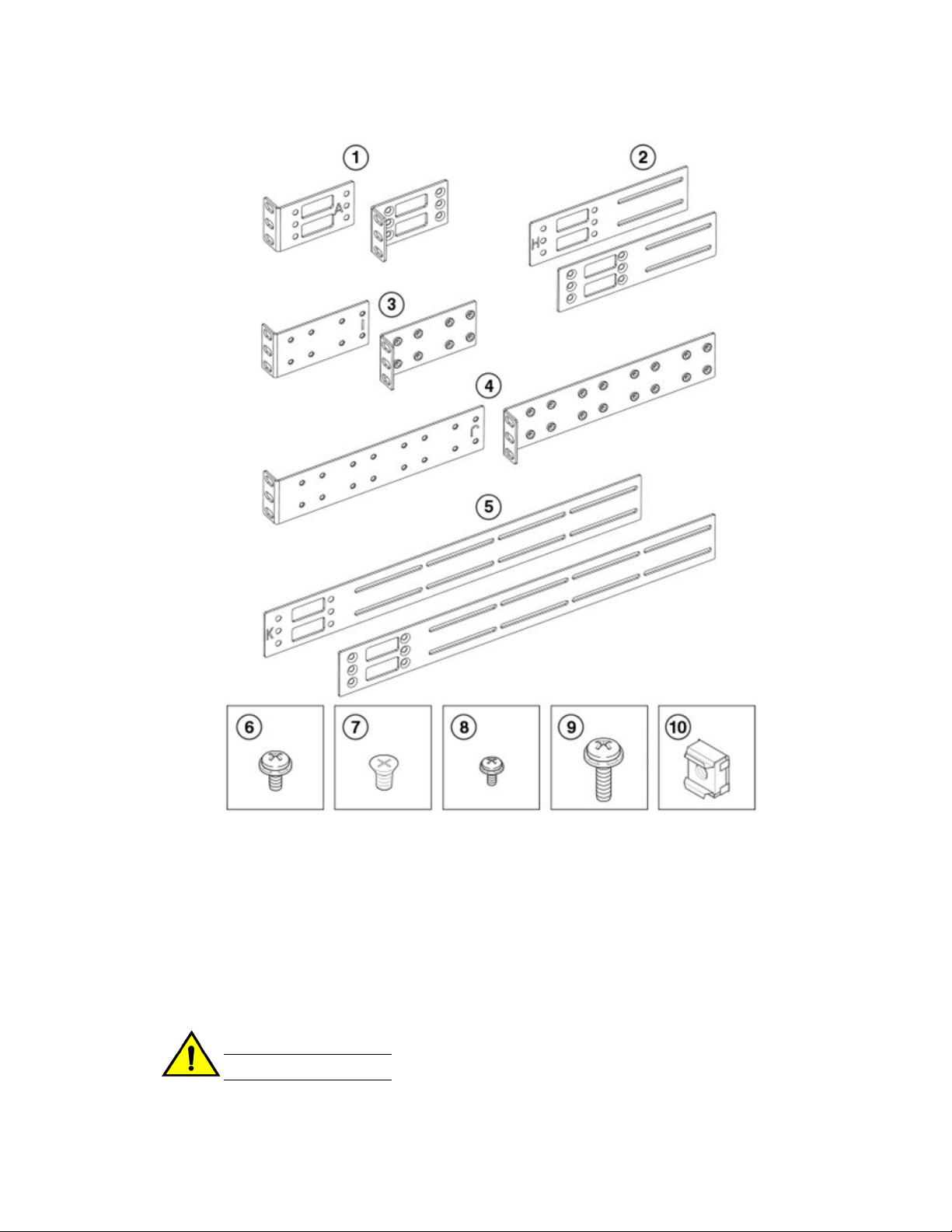

1 Front brackets (2)

2 Extension brackets, medium (2)

3 Rear brackets, short (2)

4 Rear brackets, long (2)

5 Extension brackets, long (2)

6 Screw, 8-32 x 5/16-in., panhead Phillips

(8)

7 Screw, 8-32 x 5/16-in., flathead Phillips

(16)

8 Screw, 6-32 x 1/4-in., panhead Phillips

(8)

9 Screw, 10-32 x 5/8-in., panhead Phillips

(8)

10 Retainer nut, 10-32 (8)

FIGURE 3 Items in the Universal Four-Post Rack Kit

Ensure that the items listed and illustrated in Figure 3 are included in the kit. Note that not all parts may

be used with certain installations depending on the device type.

CAUTION

Use the screws specified in the procedure. Using longer screws can damage the device.

Brocade G620 Hardware Installation Guide 29

53-1003990-01

Page 30

Flush-front mounting

Flush-front mounting

CAUTION

The device must be turned off and disconnected from the fabric during this procedure.

NOTE

The illustrations in the rack installation procedures show a 1U device, but the instructions are the

same for a 2U device. The illustrations in the rack installation procedures are for reference only and

may not show the actual device.

Complete the following tasks to install the device in a four-post rack:

1. Attaching the front brackets on page 30

2. Attaching the extension brackets to the device on page 31

3. Installing the device in the rack on page 32

4. Attaching the rear brackets to the extensions on page 33

5. Attaching the rear brackets to the rack posts on page 34

Attaching the front brackets

Complete the following steps to attach the front brackets to the device.

1. Position the right front bracket with the flat side against the right side of the device at the front of the

device, as shown in Figure 4 .

2. Insert four 8-32 x 5/16-in. flathead screws through the vertically aligned holes in the bracket and

then into the holes on the side of the device. Use the upper and lower screw holes, leaving the

center holes empty.

3. Repeat step 1 and step 2 to attach the left front bracket to the left side of the device.

4. Tighten all the 8-32 x 5/16-in. screws to a torque of 15 in-lb (17 cm-kg).

30 Brocade G620 Hardware Installation Guide

53-1003990-01

Page 31

Attaching the extension brackets to the device

1 The Brocade device

2 Front brackets

3 Screws, 8-32 x 5/16-in., flathead

Phillips

FIGURE 4 Attaching the front brackets

Attaching the extension brackets to the device

Complete the following steps to attach the extension brackets to the device. There are medium and long

extension brackets that you can use for this step. Choose the correct extension bracket for the depth of

your rack.

1. Select the proper length extension bracket for your rack depth.

2. Position the right extension bracket along the side of the device as shown in Figure 5 .

3. Insert four 8-32 x 5/16-in. flathead screws through the vertically aligned holes in the extension

bracket and then into the holes on the side of the device. Use the upper and lower screw holes,

leaving the center holes empty.

4. Repeat step 1 and step 2 to attach the left extension bracket to the left side of the device.

5. Tighten all the 8-32 x 5/16-in. screws to a torque of 15 in-lb (17 cm-kg).

Brocade G620 Hardware Installation Guide 31

53-1003990-01

Page 32

Installing the device in the rack

1 Extension brackets

2 Screws, 8-32 x 5/16-in., flathead

Phillips

FIGURE 5 Attaching the extension brackets to the device

Installing the device in the rack

Complete the following steps to install the device in the rack.

1. Position the device in the rack, as shown in Figure 6 , providing temporary support under the device

until the rail kit is secured to the rack.

2. Attach the right front bracket to the right front rack post using two 10-32 x 5/8-in. panhead screws

and two retainer nuts. Use the upper and lower holes in the bracket.

3. Attach the left front bracket to the left front rack post using two 10-32 x 5/8-in. panhead screws and

two retainer nuts. Use the upper and lower holes in the bracket.

4. Tighten all the 10-32 x 5/8-in. screws to a torque of 25 in-lb (29 cm-kg).

32 Brocade G620 Hardware Installation Guide

53-1003990-01

Page 33

Attaching the rear brackets to the extensions

1 Screws, 10-32 x 5/8-in., panhead

Phillips

2 Retainer nuts, 10-32

FIGURE 6 Positioning the device in the rack

Attaching the rear brackets to the extensions

Complete the following steps to attach the rear brackets to the extensions. There are short and long

rear brackets that you can use for this step. Choose the correct bracket for the depth of your rack.

1. Select the proper length rear bracket for your rack depth.

2. Slide the right rear bracket onto the right extension and attach to the extension by inserting four 6-32

x 1/4-in. panhead screws through the bracket holes. If possible, leave at least one empty vertical pair

of holes between the screws for better support.

3. Repeat step 2 to attach the left rear bracket to the left extension.

4. Adjust the brackets to the rack depth and tighten all the 6-32 x 1/4-in. screws to a torque of 9 in-lb

(10 cm-kg).

Brocade G620 Hardware Installation Guide 33

53-1003990-01

Page 34

Attaching the rear brackets to the rack posts

1 Rear brackets

2 Screws, 6-32 x 1/4-in., panhead Phillips

FIGURE 7 Attaching the rear brackets to the extensions

Attaching the rear brackets to the rack posts

Complete the following steps to attach the rear brackets to the rack posts.

1. Attach the right rear bracket to the right rear rack post using two 10-32 x 5/8-in. panhead screws

and two retainer nuts, as shown in Figure 8 . Use the upper and lower holes in the bracket.

2. Attach the left rear bracket to the left rear rack post using two 10-32 x 5/8-in. panhead screws and

two retainer nuts. Use the upper and lower holes in the bracket.

3. Tighten all the 10-32 x 5/8-in. screws to a torque of 25 in-lb (29 cm-kg).

34 Brocade G620 Hardware Installation Guide

53-1003990-01

Page 35

Flush-rear (recessed) mounting

1 Screws, 10-32 x 5/8-in., panhead

Phillips

2 Retainer nuts, 10-32

FIGURE 8 Attaching the rear brackets to the rack posts

Flush-rear (recessed) mounting

The flush-rear (recessed) mounting is similar to the flush-front mounting except that the brackets are

reversed on the device.

CAUTION

The device must be turned off and disconnected from the fabric during this procedure.

NOTE

The illustrations in the rack installation procedures show a 1U device, but the instructions are the same

for a 2U device. The illustrations in the rack installation procedures are for reference only and may not

show the actual device.

Complete the following tasks to install the device in a four-post rack:

1. Attaching the front brackets to the rear of the device on page 36

2. Attaching the extensions to the front of the device on page 36

3. Installing the device in the rack on page 37

4. Attaching the rear brackets to the extensions at the front of the device on page 38

5. Attaching the rear brackets to the front rack posts on page 40

Brocade G620 Hardware Installation Guide 35

53-1003990-01

Page 36

Attaching the front brackets to the rear of the device

Attaching the front brackets to the rear of the device

NOTE

In this installation, the brackets are named as listed in the parts list even though the installation of the

brackets is reversed from the flush-front installation.

Complete the following steps to attach the front brackets to the rear of the device.

1. Position the right front bracket with the flat side against the right rear side of the device, as shown in

Figure 9 .

2. Insert four 8-32 x 5/16-in. flathead screws through the vertically aligned holes in the bracket and

then into the holes on the side of the device. Use the upper and lower screw holes, leaving the

center holes empty.

3. Repeat step 1 and step 2 to attach the left rear bracket to the left side of the device.

4. Tighten all the 8-32 x 5/16-in. screws to a torque of 15 in-lb (17 cm-kg).

1 The Brocade device

2 Screws, 8-32 x 5/16-in., flathead

Phillips

3 Front brackets

FIGURE 9 Attaching the front brackets to the rear of the device

Attaching the extensions to the front of the device

Complete the following steps to attach the extension brackets to the front of the device. There are

medium and long extension brackets that you can use for this step. Choose the correct extension for

the depth of your rack.

1. Select the proper length extension bracket for your rack depth.

2. Position the right extension along the side of the device as shown in Figure 10 .

36 Brocade G620 Hardware Installation Guide

53-1003990-01

Page 37

Installing the device in the rack

3. Attach the bracket using four 8-32 x 5/16-in. flathead screws.

4. Repeat step 1 and step 2 to attach the left front extension to the left side of the device.

5. Tighten all the 8-32 x 5/16-in. screws to a torque of 15 in-lb (17 cm-kg).

1 Extension brackets

2 Screws, 8-32 x 5/16-in., flathead

Phillips

FIGURE 10 Attaching the bracket extensions to the device

Installing the device in the rack

Complete the following steps to install the device in the rack.

1. Position the device in the rack, as shown in Figure 11 , providing temporary support under the device

until the rail kit is secured to the rack.

2. Attach the right front bracket to the right rear rack post using two 10-32 x 5/8-in. panhead screws and

two retainer nuts. Use the upper and lower holes in the bracket.

3. Attach the left front bracket to the left rear rack post using two 10-32 x 5/8-in. panhead screws and

two retainer nuts. Use the upper and lower holes in the bracket.

4. Tighten all the 10-32 x 5/8-in. screws to a torque of 25 in-lb (29 cm-kg).

Brocade G620 Hardware Installation Guide 37

53-1003990-01

Page 38

Attaching the rear brackets to the extensions at the front of the device

1 Screws, 10-32 x 5/8-in., panhead

Phillips

2 Retainer nuts, 10-32

FIGURE 11 Positioning the device in the rack

Attaching the rear brackets to the extensions at the front of the device

Complete the following steps to attach the rear brackets to the extensions. There are short and long

front brackets that you can use for this step. Choose the correct bracket for the depth of your rack.

1. Select the proper length rear bracket for your rack depth.

2. Slide the right rear bracket onto the right extension, as shown in Figure 12 .

The short rear brackets are shown. Use the first and third vertical pairs of holes for the screws.

Refer to Figure 13 for the positioning of the short or long brackets and screws.

3. Attach the brackets using four 6-32 x 1/4-in. screws.

4. Repeat step 2 and step 3 to attach the left rear bracket to the left extension.

5. Adjust the brackets to the rack depth and tighten all the 6-32 x 1/4-in. screws to a torque of 9 in-lb

(10 cm-kg).

38 Brocade G620 Hardware Installation Guide

53-1003990-01

Page 39

Mounting the Device

1 Rear brackets, short

2 Screws, 6-32 x 1/4-in., panhead Phillips

FIGURE 12 Attaching the rear brackets to the extensions at the front of the device

1 Rear bracket, short or long

2 Screws, 6-32 x 1/4-in., panhead Phillips

Brocade G620 Hardware Installation Guide 39

53-1003990-01

Page 40

Attaching the rear brackets to the front rack posts

FIGURE 13 Attaching the short or long rear brackets to the extensions

Attaching the rear brackets to the front rack posts

Complete the following steps to attach the rear brackets to the front rack posts.

1. Attach the right rear bracket to the right front rack post using two 10-32 x 5/8-in. screws and two

retainer nuts, as shown in Figure 14 . Use the upper and lower holes in the bracket.

2. Attach the left rear bracket to the left front rack post using two 10-32 x 5/8-in. screws and two

retainer nuts. Use the upper and lower holes in the bracket.

3. Tighten all the 10-32 x 5/8-in. screws to a torque of 25 in-lb (29 cm-kg).

1 Screws, 10-32 x 5/8-in., panhead

Phillips

2 Retainer nuts, 10-32

FIGURE 14 Attaching the rear brackets to the front rack posts

Installing the Universal Two-Post Rack kit (XBR-R000294)

Use the following instructions to install a Brocade 1U or 2U switch in a two-post telecommunications

(Telco) rack using the Universal Two-Post Rack Kit (XBR-R000294).

There are two ways you can mount the device in a two-post rack:

• With the port side flush with the front posts

• With the posts mounted to the midsection of the device

40 Brocade G620 Hardware Installation Guide

53-1003990-01

Page 41

Installation requirements

NOTE

Hardware devices illustrated in these procedures are only for reference and may not depict the device

you are installing into the rack.

Installation requirements

Note the following requirements to ensure correct installation and operation:

• Verify that the additional weight of the device does not exceed the rack’s weight limits.

• Ensure that an electrical branch circuit with the following characteristics is available:

‐ Required voltage and frequency as indicated in the Technical Specifications (200-240 VAC is

always preferred).

‐ Protection by a circuit breaker in accordance with local electrical codes.

‐ Supply circuit, line fusing, and wire size that conform to the electrical rating on the device

nameplate.

‐ Grounded outlet compatible with the power cord and installed by a licensed electrician.

• Ensure that all equipment installed in the rack is grounded through a reliable branch circuit

connection. Do not rely on a secondary connection to a branch circuit, such as a power strip.

• Ensure that the rack is mechanically secured to ensure stability.

• Ensure that the air temperature at the fan inlet is less than 40oC (104oF) during device operation.

• Ensure that the airflow available at the air vents meets the minimum requirements for the device.

NOTE

Install the device with the airflow aligned with any other devices in the rack. Some devices have airflow

running from port side to fan side and others have the opposite arrangement. Make sure that the airflow

for all devices moves in the same direction to maximize cooling.

Lifting requirements

For 1U and 2U devices, two people are required to install the device in a rack. One person holds the

device, while the other screws in the front and rear "L" brackets.

Time and items required

Allow 15 to 30 minutes to complete the installation.

The following items are required to install the device using the Universal Two-Post Rack Kit:

• #2 Phillips torque screwdriver

• 1/4-inch slotted-blade torque screwdriver

Brocade G620 Hardware Installation Guide 41

53-1003990-01

Page 42

Flush-front mounting

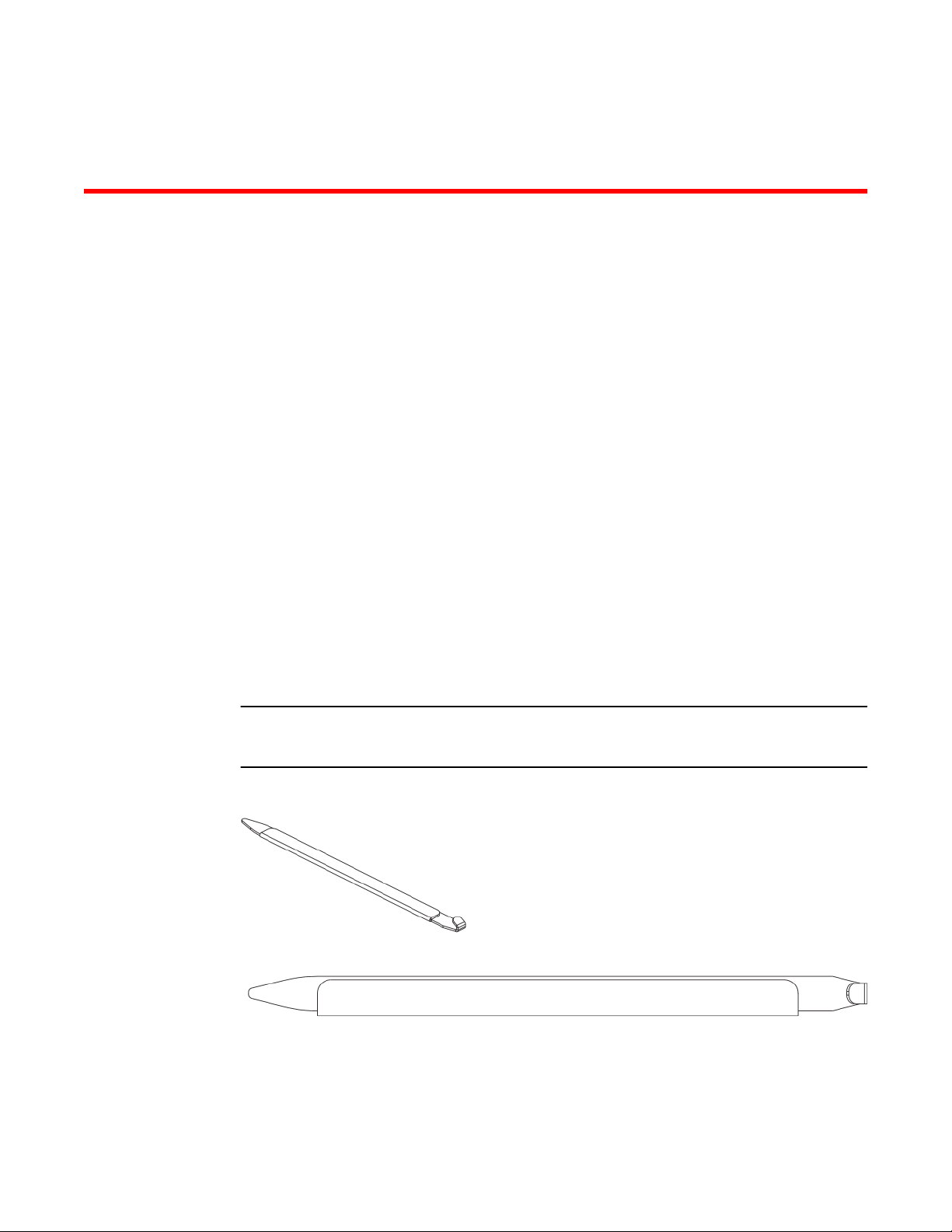

1 Front brackets (2)

2 Rear brackets, 3-5 inch post (2)

3 Rear brackets, 5-6 inch post (2)

4 Screw, 8-32 x 5/16-in., panhead Phillips

(8)

5 Screw, 8-32 x 5/16-in., flathead Phillips

(16)

FIGURE 15

Items in the Universal Two-Post Rack Kit

6 Screw, 6-32 x 1/4-in., panhead Phillips

(8)

7 Screw, 10-32 x 5/8-in., panhead Phillips

(8)

8 Retainer nut, 10-32 (8)

CAUTION

Use the screws specified in the procedure. Using longer screws can damage the device.

Ensure that the items listed and illustrated in Figure 15 are included in the kit. Note that not all parts

may be used with certain installations depending on the device type.

Flush-front mounting

Observe the following notes when using this procedure:

• The device must be turned off and disconnected from the fabric during this procedure.

• The illustrations in this document show a 1U device, but the instructions are the same for a 2U

device.

• The illustrations for this procedure show a two-post rack with narrow posts (3- to 5-inch) as an

example.

• The illustrations in the rack installation procedures are for reference only and may not show the

actual device.

Complete the following tasks to install the device in a rack:

42 Brocade G620 Hardware Installation Guide

53-1003990-01

Page 43

Attaching the front brackets to the device

1. Attaching the front brackets to the device on page 43

2. Attaching the front brackets to the rack on page 43

3. Attaching the rear brackets to the rack on page 44

4. Attaching the rear brackets to the device on page 45

Attaching the front brackets to the device

Complete the following steps to attach the front brackets to the device.

1. Position the right front bracket with the flat side against the right side of the device, as shown in

Figure 16 .

2. Insert four 8-32 x 5/16-in. flathead screws through the vertically aligned holes in the bracket and then

into the holes on the side of the device. Use the upper and lower screw holes, leaving the center

holes empty.

3. Repeat step 1 and step 2 to attach the left front bracket to the left side of the device.

4. Tighten all the 8-32 x 5/16-in. screws to a torque of 15 in-lb (17 cm-kg).

1 The Brocade device

2 Front brackets, right and left

3 Screws, 8-32 x 5/16-in., flathead

Phillips

FIGURE 16 Attaching the front brackets

Attaching the front brackets to the rack

Complete the following steps to install the device in the rack.

Brocade G620 Hardware Installation Guide 43

53-1003990-01

Page 44

Attaching the rear brackets to the rack

1. Position the device in the rack, as shown in (Figure 17 ), providing temporary support under the

device until the rack kit is fully secured to the rack.

2. Attach the right front bracket to the right rack upright using two 10-32 x 5/8-in. panhead screws and

two retainer nuts. Use the upper and lower holes in the bracket.

3. Attach the left front bracket to the left rack upright using two 10-32 x 5/8-in. panhead screws and

two retainer nuts.

4. Use the upper and lower holes in the bracket. Tighten all the 10-32 x 5/8-in. screws to a torque of

25 in-lb. (29 cm-kg).

1 Screws, 10-32 x 5/8-in., panhead

Phillips

2 Retainer nuts, 10-32

FIGURE 17 Attaching front brackets to a rack

Attaching the rear brackets to the rack

Complete the following steps to attach the rear brackets to the rack.

1. Select the proper length bracket for your post width. If your posts are three to five inches wide, use

the brackets marked 3-5 INCH. If your posts are five to six inches wide, use the brackets marked

5-6 INCH.

2. Position the right rear bracket in the right rear of the device, as shown in Figure 18 .

3. Attach the bracket to the right rack upright using two 10-32 x 5/8-in. panhead screws and two

retainer nuts. Use the upper and lower holes in the bracket.

4. Repeat step 2 and step 3 to attach the left rear bracket to the left rack upright.

5. Tighten all the 10-32 x 5/8-in. screws to a torque of 25 in-lb. (29 cm-kg).

44 Brocade G620 Hardware Installation Guide

53-1003990-01

Page 45

Attaching the rear brackets to the device

1 Retainer nuts, 10-32

2 Rear brackets

3 Screws, 10-32 x 5/8-in., panhead

Phillips

FIGURE 18 Attaching the rear brackets to a rack

Attaching the rear brackets to the device

Complete the following steps to attach the rear brackets to the device.

1. Align the right rear bracket to the right rear of the device and use four 8-32 x 5/16-in. panhead

screws to attach the bracket to the device, as shown in Figure 19 . Be sure to insert the screws

through the upper and lower slots in the bracket.

2. Align the left rear bracket to the left rear of the device and use four 8-32 x 5/16-in. panhead screws to

attach the bracket to the device. Again, use the upper and lower slots in the bracket.

3. Tighten all the 8-32 x 5/16-in. screws to a torque of 15 in-lb (17 cm-kg).

Brocade G620 Hardware Installation Guide 45

53-1003990-01

Page 46

Mid-mounting

1 Screws, 8-32 x 5/16-in., panhead

Phillips

FIGURE 19 Attaching the rear brackets to the device

Mid-mounting

Observe the following notes when using this procedure:

• The device must be turned off and disconnected from the fabric during this procedure.

• The illustrations in this document show a 1U device, but the instructions are the same for a 2U

device.

• The illustrations in the rack installation procedures are for reference only and may not show the

actual device.

Complete the following tasks to install the device in a rack:

1. Attaching the front brackets to the device on page 46

2. Attaching the front brackets to the rack on page 47

3. Attaching the rear brackets to the rack on page 48

4. Attaching the rear brackets to the device on page 49

Attaching the front brackets to the device

Complete the following steps to attach the front brackets to the device.

1. Position the right front bracket with the flat side against the right side of the device, as shown in

Figure 20 .

2. Insert four 8-32 x 5/16-in. flathead screws through the vertically aligned holes in the bracket and

then into the holes on the side of the device. Use the upper and lower screw holes, leaving the

center holes empty.

46 Brocade G620 Hardware Installation Guide

53-1003990-01

Page 47

Attaching the front brackets to the rack

3. Repeat step 1 and step 2 to attach the left front bracket to the left side of the device.

4. Tighten all the 8-32 x 5/16-in. screws to a torque of 15 in-lb (17 cm-kg).

1 The Brocade device

2 Front brackets, right and left

3 Screws, 8-32 x 5/16-in., flathead

Phillips

FIGURE 20 Attaching the front brackets

Attaching the front brackets to the rack

Complete the following steps to install the device in the rack.

1. Position the device in the rack, as shown in Figure 21 , providing temporary support under the device

until the rack kit is fully secured to the rack.

2. Attach the right front bracket to the right rack upright using two 10-32 x 5/8-in. screws and two

retainer nuts. Use the upper and lower holes in the bracket.

3. Attach the left front bracket to the left rack upright using two 10-32 x 5/8-in. screws and two retainer

nuts. Use the upper and lower holes in the bracket.

4. Tighten all the 10-32 x 5/8-in. screws to a torque of 25 in-lb (29 cm-kg).

Brocade G620 Hardware Installation Guide 47

53-1003990-01

Page 48

Attaching the rear brackets to the rack

1 Screws, 10-32 x 5/8-in., panhead

Phillips

2 Retainer nuts, 10-32