Page 1

PROGRAMMABLE

DELAY CHIP

ClockWorks™

SY10E195

SY100E195

FEATURES

■ Up to 2ns delay range

■ Extended 100E V

EE range of –4.2V to –5.5V

■ ≈20ps/digital step resolution

■ >1GHz bandwidth

■ On-chip cascade circuitry

■ 75KkΩ input pulldown resistor

■ Fully compatible with Motorola MC10E/100E195

■ Available in 28-pin PLCC package

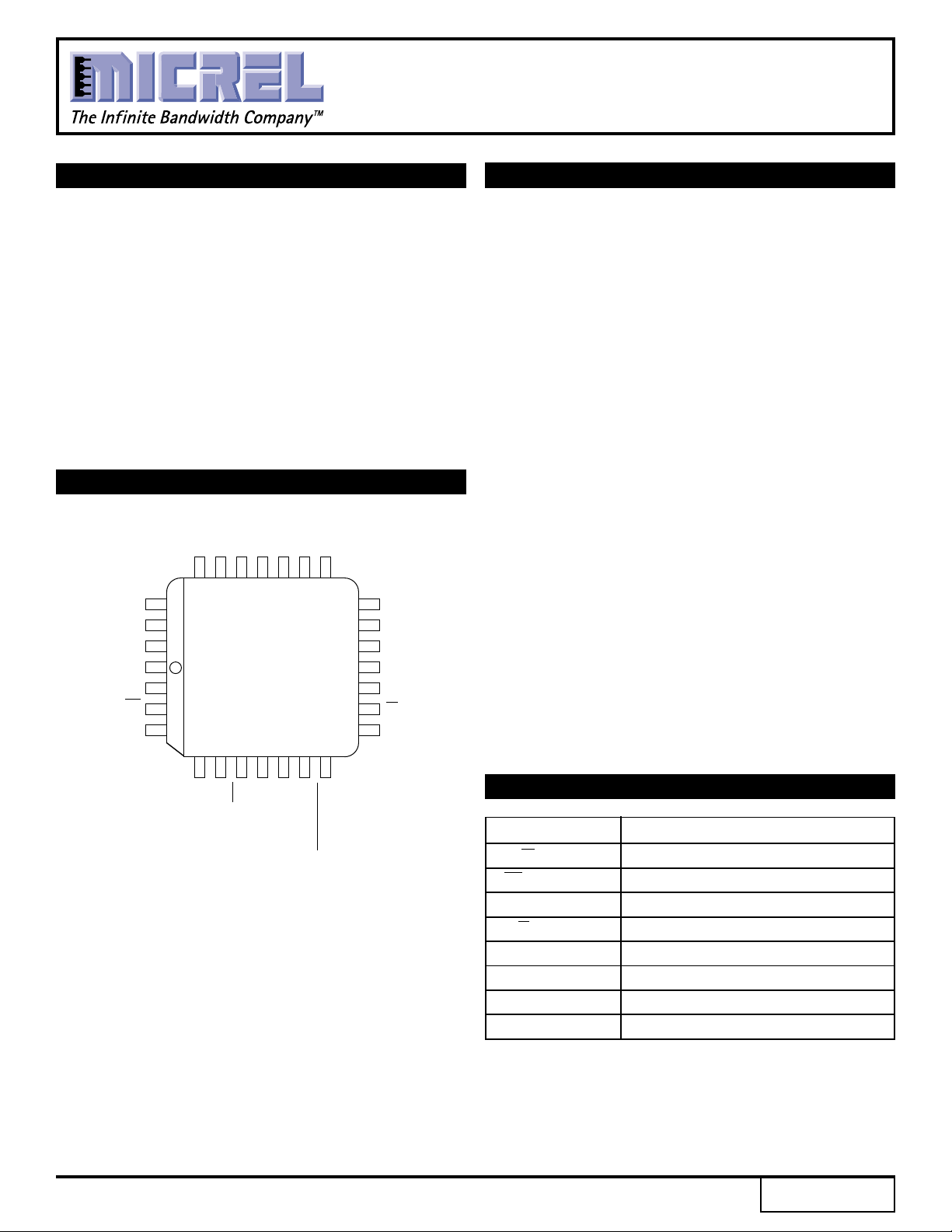

PIN CONFIGURATION

D4

D5

PLCC

J28-1

D6

D7

NC

18

NC

17

NC

16

VCC

15

VCCO

14

Q

13

Q

12

VCCO

D1

D0

LEN

VEE

IN

IN

VBB

D2

D3

25

24 23 22 21 20 19

26

27

28

1

2

3

4

TOP VIEW

567891011

DESCRIPTION

The SY10/100E195 are programmable delay chips

(PDCs) designed primarily for clock de-skewing and timing

adjustment. They provide variable delay of a differential

ECL input transition.

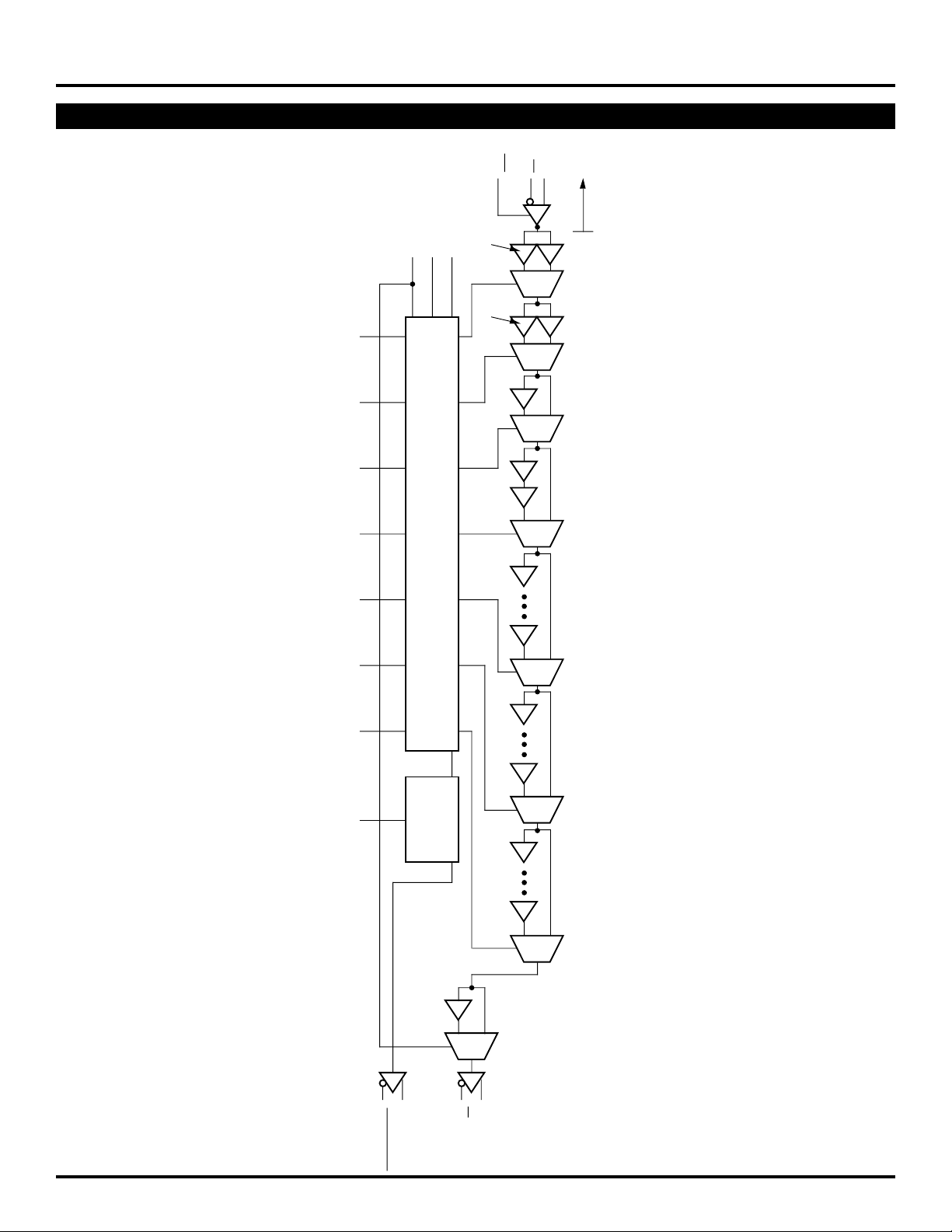

The delay section consists of a chain of gates

organized as shown in the logic diagram. The first two

delay elements feature gates that have been modified to

have delays 1.25 and 1.5 times the basic gate delay of

approximately 80ps. These two elements provide the

E195 with a digitally-selectable resolution of

approximately 20ps. The required device delay is selected

by the seven address inputs D[0:6], which are latched

on-chip by a high signal on the latch enable (LEN) control.

If the LEN signal is either LOW or left floating, then the

latch is transparent.

Because the delay programmability of the E195 is

achieved by purely differential ECL gate delays, the

device will operate at frequencies of >1GHz, while

maintaining over 600mV of output swing.

The E195 thus offers very fine resolution, at very high

frequencies, selectable entirely from a digital input,

allowing for very accurate system clock timing.

An eighth latched input, D7, is provided for cascading

multiple PDCs for increased programmable range. The

cascade logic allows full control of multiple PDCs, at the

expense of only a single added line to the data bus for

each additional PDC, without the need for any external

gating.

NC

NC

EN

SET MIN

SET MAX

CASCADE

CASCADE

PIN NAMES

Pin Function

IN/IN Signal Input

EN Input Enable

D[0:7] Mux Select Inputs

Q/Q Signal Output

LEN Latch Enable

SET MIN Minimum Delay Set

SET MAX Maximum Delay Set

CASCADE Cascade Signal

1

Rev.: E Amendment: /0

Issue Date: October, 1998

Page 2

Micrel

BLOCK DIAGRAM

ClockWorks™

SY10E195

SY100E195

IN

V

BB

SET MAX

SET MIN

EN

IN

LEN

*1.25

*1.5

D

0

D

1

D

2

1

1

0

1

1

0

1

1

0

1

1

7-Bit Latch

1

D

3

0

4 gates

D

4

*Delays are 25% or 50% longer than

standard (standard = 80ps).

D

5

D

6

D

7

D

CASCADE

CASCADE

LEN

Latch

Q

Cascade

1

1

Q

1

0

8 gates

1

0

16 gates

1

0

0

Q

2

Page 3

ClockWorks™

SY10E195

Micrel

SY100E195

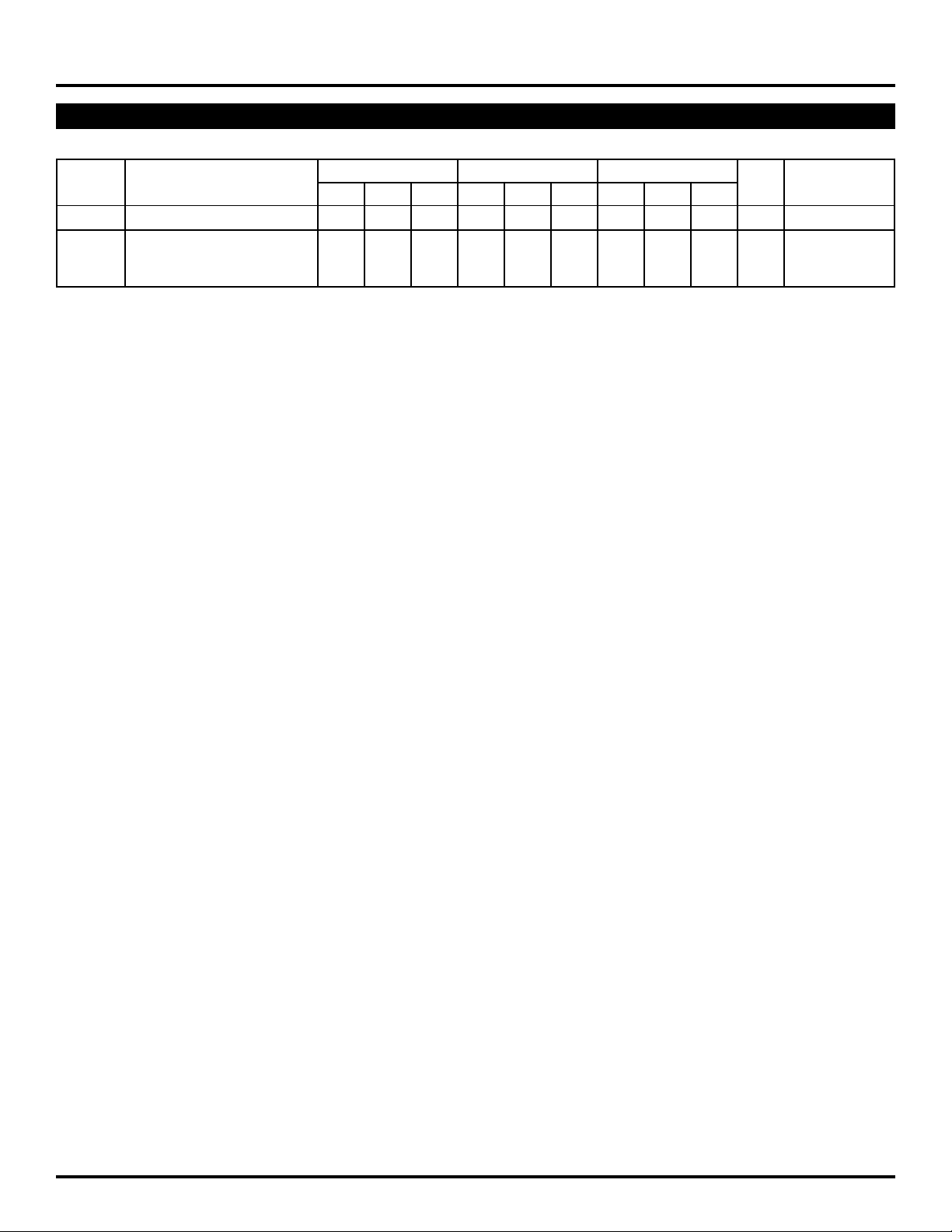

DC ELECTRICAL CHARACTERISTICS

VEE = VEE (Min.) to VEE (Max.); VCC = GND

T

A = 0°CTA = +25°CTA = +85°C

Symbol Parameter Min. Typ. Max. Min. Typ. Max. Min. Typ. Max. Unit Condition

IIH Input HIGH Current — — 150 — — 150 — — 150 µA—

EE Power Supply Current mA —

I

10E — 130 156 — 130 156 — 130 156

100E — 130 156 — 130 156 — 150 179

3

Page 4

ClockWorks™

SY10E195

Micrel

SY100E195

AC ELECTRICAL CHARACTERISTICS

VEE = VEE (Min.) to VEE (Max.); VCC = GND

TA = 0°CTA = +25°CTA = +85°C

Symbol Parameter Min. Typ. Max. Min. Typ. Max. Min. Typ. Max. Unit Condition

PLH Propagation Delay to Output ps —

t

tPHL IN to Q; Tap = 0 1210 1360 1510 1240 1390 1540 1440 1590 1765

IN to Q; Tap = 127 3320 3570 3820 3380 3630 3880 3920 4270 4720

EN to Q; Tap = 0 1250 1450 1650 1275 1475 1675 1350 1650 1950

D7 to CASCADE 300 450 700 300 450 700 300 450 700

RANGE Programmable Range 2000 2175 — 2050 2240 — 2375 2580 — ps —

t

tPD (max.) – tPD (min.)

∆t Step Delay ps 6

D

0 High — 17 — — 17.5 — — 21 —

D1 High — 34 — — 35 — — 42 —

D2 High 55 68 105 55 70 105 65 84 120

D3 High 115 136 180 115 140 180 140 168 205

D4 High 250 272 325 250 280 325 305 336 380

D5 High 505 544 620 515 560 620 620 672 740

D6 High 1000 1088 1190 1030 1120 1220 1240 1344 1450

Lin Linearity D1 D0 —D1 D0 —D1 D0 —— 7

tskew Duty Cycle Skew, tPHL–tPLH — ±30 — — ±30 — — ±30 — ps 1

S Set-up Time ps

t

D to LEN 200 0 — 200 0 — 200 0 —

D to IN 800 — — 800 — — 800 — — 2

EN to IN 200 — — 200 — — 200 — — 3

H Hold Time ps

t

LEN to D 500 250 — 500 250 — 500 250 —

IN to EN 0 — — 0 — — 0 — — 4

R Release Time ps

t

EN to IN 300 — — 300 — — 300 — — 5

SET MAX to LEN 800 — — 800 — — 800 — —

SET MIN to LEN 800 — — 800 — — 800 — —

tjit Jitter — <5 — — <5 — — <5 — ps 8

r Rise/Fall Times ps —

t

tf 20–80% (Q) 125 225 325 125 225 325 125 225 325

20–80% (CASCADE) 300 450 650 300 450 650 300 450 650

NOTES:

2. Duty cycle skew guaranteed only for differential operation measured from the cross point of the input to the cross point of the output.

3. This set-up time defines the amount of time prior to the input signal the delay tap of the device must be set.

4. This set-up time is the minimum time that EN must be asserted prior to the next transition of IN/IN to prevent an output response greater than ±75mV to

that IN/IN transition.

5. This hold time is the minimum time that EN must remain asserted after a negative going IN or positive going IN to prevent an output response greater than

±75mV to that IN/IN transition.

6. This release time is the minimum time that EN must be deasserted prior to the next IN/IN transition to ensure an output response that meets the specified

IN to Q propagation delay and transition times.

7. Specification limits represent the amount of delay added with the assertion of each individual delay control pin. The various combinations of asserted delay

control inputs will typically realize D0 resolution steps across the specified programmable range.

8. The linearity specification guarantees to which delay control input the programmable steps will be monotonic (i.e. increasing delay steps for increasing

binary counts on the control inputs Dn). Typically, the device will be monotonic to the D0 input, however, under worst case conditions and process variation,

delays could decrease slightly with increasing binary counts when the D0 input is the LSB. With the D1 input as the LSB, the device is guaranteed to be

monotonic over all specified environmental conditions and process variation.

9. The jitter of the device is less than what can be measured without resorting to very tedious and specialized measurement techniques.

4

Page 5

Micrel

APPLICATIONS INFORMATION

7

A

ClockWorks™

SY10E195

SY100E195

ADDRESS BUS (A0 – A6)

6

5

4

D

E196

Chip #1

EN

7

D

D

D

VCC

VCCO

Q

Q

VCCO

SET MAX

CASCADE

SET MIN

Figure 1. Cascading Interconnect Architecture

CASCADE

Input

D

1

D

0

LEN

VEE

IN

IN

VBB

2

3

D

D

Cascading Multiple E195s

To increase the programmable range of the E195,

internal cascade circuitry has been included. This circuitry

allows for the cascading of multiple E195s without the

need for any external gating. Furthermore, this capability

requires only one more address line per added E195.

Obviously, cascading multiple PDCs will result in a larger

programmable range; however, this increase is at the

expense of a longer minimum delay.

Figure 1 illustrates the interconnect scheme for

cascading two E195s. As can be seen, this scheme can

easily be expanded for larger E195 chains. The D7 input

of the E195 is the cascade control pin. With the

interconnect scheme of Figure 1, when D7 is asserted, it

signals the need for a larger programmable range than

is achievable with a single device.

An expansion of the latch section of the block diagram

is pictured below. Use of this diagram will simplify the

explanation of how the cascade circuitry works. When

D7 of chip #1 above is low, the cascade output will also

be low, while the cascade bar output will be a logical

high. In this condition, the SET MIN pin of chip #2 will

be asserted and, thus, all of the latches of chip #2 will

be reset and the device will be set at its minimum delay.

Since the RESET and SET inputs of the latches are

overriding, any changes on the A0–A6 address bus will

not affect the operation of chip #2.

D

1

D

0

LEN

VEE

IN

IN

VBB

4

3

2

D

D

D

E196

Chip #2

EN

6

5

D

D

SET MIN

SET MAX

7

D

VCC

VCCO

VCCO

CASCADE

CASCADE

Q

Q

Output

Chip #1, on the other hand, will have both SET MIN

and SET MAX de-asserted so that its delay will be

controlled entirely by the address bus A0–A6. If the delay

needed is greater than can be achieved with 31.75 gate

delays (1111111 on the A0–A6 address bus), D7 will be

asserted to signal the need to cascade the delay to the

next E195 device. When D7 is asserted, the SET MIN

pin of chip #2 will be de-asserted and the delay will be

controlled by the A0–A6 address bus. Chip #1, on the

other hand, will have its SET MAX pin asserted, resulting

in the device delay to be independent of the A0–A6

address bus.

When the SET MAX pin of chip #1 is asserted, the D0

and D1 latches will be reset while the rest of the latches

will be set. In addition, to maintain monotonicity, an

additional gate delay is selected in the cascade circuitry.

As a result, when D7 of chip #1 is asserted, the delay

increases from 31.75 gates to 32 gates. A 32-gate delay

is the maximum delay setting for the E195.

To expand this cascading scheme to more devices,

one simply needs to connect the D7 input and CASCADE

outputs of the current most significant E195 to the new

most significant E195 in the same manner as pictured in

Figure 1. The only addition to the logic is the increase

of one line to the address bus for cascade control of the

second PDC.

5

Page 6

Micrel

SET MAX

SET MIN

Reset

Reset

Reset

Set

Reset

Reset

LEN

LEN

LEN

ClockWorks™

SY10E195

SY100E195

D

0

Bit 0

Q

0

D

1

Bit 1

Q

1

D

2

Bit 2

Q

2

Set

Reset

Set

Reset

Set

Reset

Set

Reset

LEN

LEN

LEN

LEN

D

3

Bit 3

Q

3

D

4

Bit 4

Q

4

D

5

Bit 5

Q

5

D

6

Bit 6

Q

6

To Select Multiplexers

Figure 2. Expansion of the

Latch Section of the E195

Block Diagram

LEN

CASCADE

D

7

Bit 7

Q

7

CASCADE

PRODUCT ORDERING CODE

Ordering Package Operating

Code Type Range

SY10E195JC J28-1 Commercial

SY10E195JCTR J28-1 Commercial

SY100E195JC J28-1 Commercial

SY100E195JCTR J28-1 Commercial

6

Page 7

Micrel

28 LEAD PLCC (J28-1)

ClockWorks™

SY10E195

SY100E195

Rev. 03

7

Page 8

Micrel

ClockWorks™

SY10E195

SY100E195

MICREL-SYNERGY 3250 SCOTT BOULEVARD SANTA CLARA CA 95054 USA

TEL + 1 (408) 980-9191 FAX + 1 (408) 914-7878 WEB http://www.micrel.com

This information is believed to be accurate and reliable, however no responsibility is assumed by Micrel for its use nor for any infringement of patents or

other rights of third parties resulting from its use. No license is granted by implication or otherwise under any patent or patent right of Micrel Inc.

© 2000 Micrel Incorporated

8

Loading...

Loading...