Page 1

PRODUCT DATA SHEET

cy

ng)

ng

ACTUATOR

LA30

Features:

• 12/24V DC permanent magnet motor

• Max. thrust up to 6000 N (LA30LK)

• Stainless steel piston rod

• Elegant and compact construction with small

installation dimensions

• Protection class: IP51 / IP66

• Colour: black

• Speed max. 65 mm/s (LA30 S-motor with 12 mm

pitch)

• Low noise level

• Steel construction for all bearing parts

• Acme thread spindle for optimum efficiency

Options:

• Extra powerful motor (S-motor)

• L-motor for system actuator

• IP66 (by ordering LA30 with plastic housing)

• Double-acting brake - increased self-locking

ability (LA30 with 6 or 9 mm pitch + LA30 S-motor

with 6 or 9 mm pitch and LA30L) which ensures

that all these types are fully self-locking

• Potentiometer for positioning the actuator. 0-1 K

ohm, 0-5 K ohm or 0-10 K ohm

• Optical encoder for positioning the actuator. 10

pulses pr. spindle revolution

• Reed switch (only LA30 L-motor versions): 8 pulses

pr. spindle revolution

• Mechanical spline function. Safety feature by

using the mechnical spline, the actuator

can only push

• Safety nut (only in push)

• Terminal cover (only LA30 L-motor versions)

• Ball screw (K) (only LA30 L-motor versions)

• Ball screw and safety nut (KAS) (only LA30 L-motor

versions)

• Ball screw, safety nut and splines (KSM) (only LA30

L-motor versions)

Usage:

• Duty cycle: Max. 10% or 6 min/hour at continuous

use

• Ambient temperature +5° to +40°C

• Storage temperature -40° to +70°C

• Compatible with control boxes CB8, CB12, CB14,

CB18

• Should LA30 be used with a non LINAK control

unit, please ask the nearest Linak representative

for further details.

all

12 mm

-motor

nsures

r. 0-1 K

tor. 10

pulses

e by

LA30 is a powerful actuator yet small enough to

fit to most applications.

The actuator can be supplied with options such

as built-in potentiometer for servo operation or

an extra powerful motor for increased speed

and strength (S-motor).

In addition to industrial and agricultural applications, the actuator is also ideal for positioning

satellite dishes.

The system actuator LA30L (option) can be combined with LINAK control boxes and it is perfet

for a variety of furniture applications.

Page 2

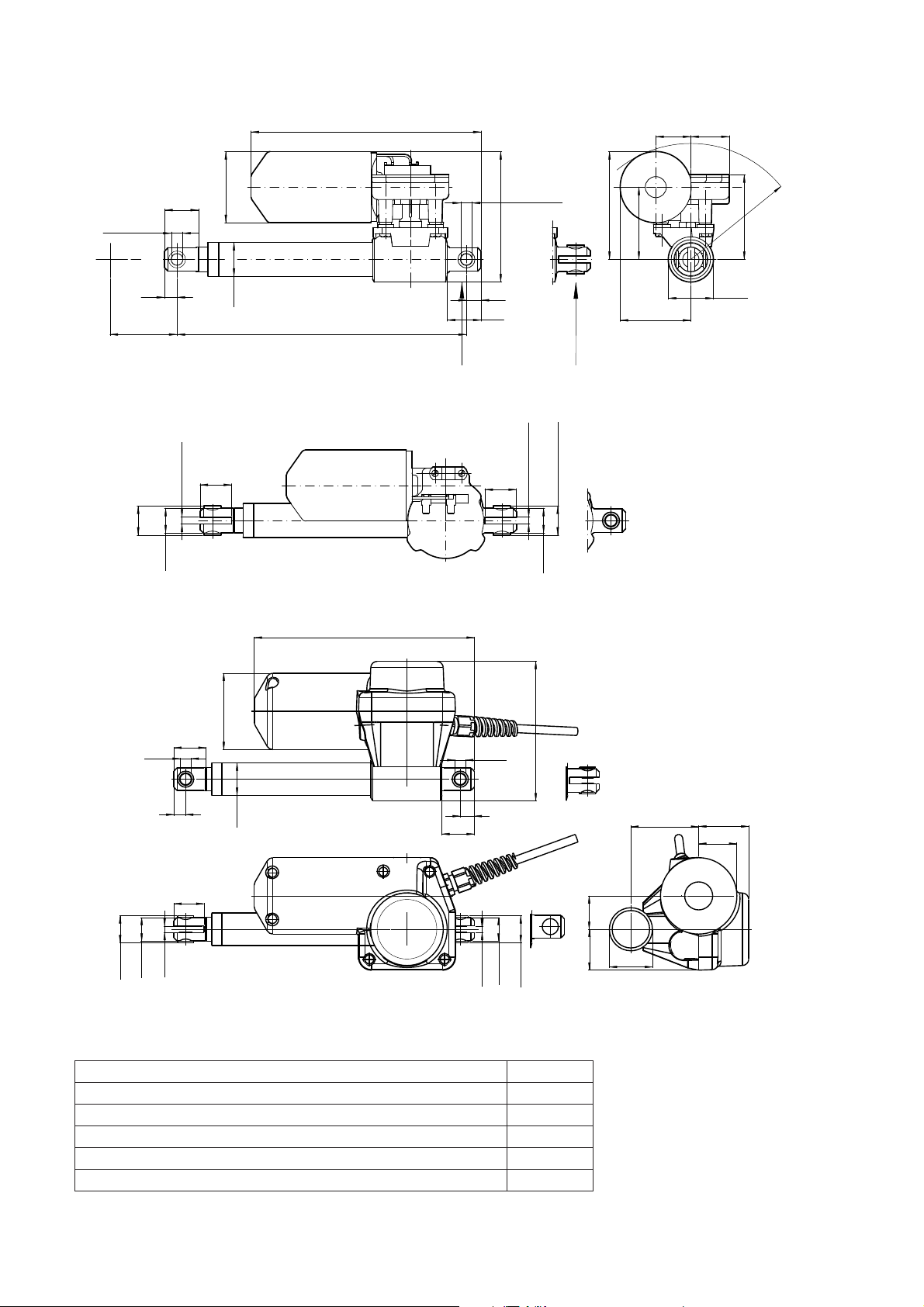

Dimensions:

203.5

31 34

115.5

13

Ø

+0.2

10.1

0

6.1

+0.2

0

95

02 = turned 90

0

-0.2

25.9

3

75

10

64

R

40Ø

63

o

LINAK A/S

LA30002A

63Ø

30

+0.2

Ø

10.1

0

11

30Ø

30

S

S+156

01 = standard

+0.2

0

6.1

28

0

-0.2

28

25.9

21.9Ø

204.5

21.9Ø

71Ø

30

10.1Ø

11

28

+0.2

-0.2

0

21.9Ø

6.1

0

25

LINAK A/S

LA30001B

30Ø

13

30

+0.2

0

6.1

129.5

10.1Ø

0

-0.2

21.9Ø

25

Installation dimension:

LA30 L-motor + LA30 + LA30 S-motor with 3 or 6 mm pitch S + 156 mm

LA30 with spline + LA30 S-motor with 9 mm pitch S + 167 mm

LA30 with brake + LA30 S-motor with 3 or 6 mm pitch with brake S + 189 mm

LA30 with ball screw and L-motor / LA30 ball screw and safety nut S + 194 mm

LA30 L-motor with brake + LA30 S-motor 9 or 12 mm pitch with brake S + 199 mm

LA30 L-motor with ball screw, safety nut and spline S + 251 mm

63

31

38

40

46.5

35.5

Page 3

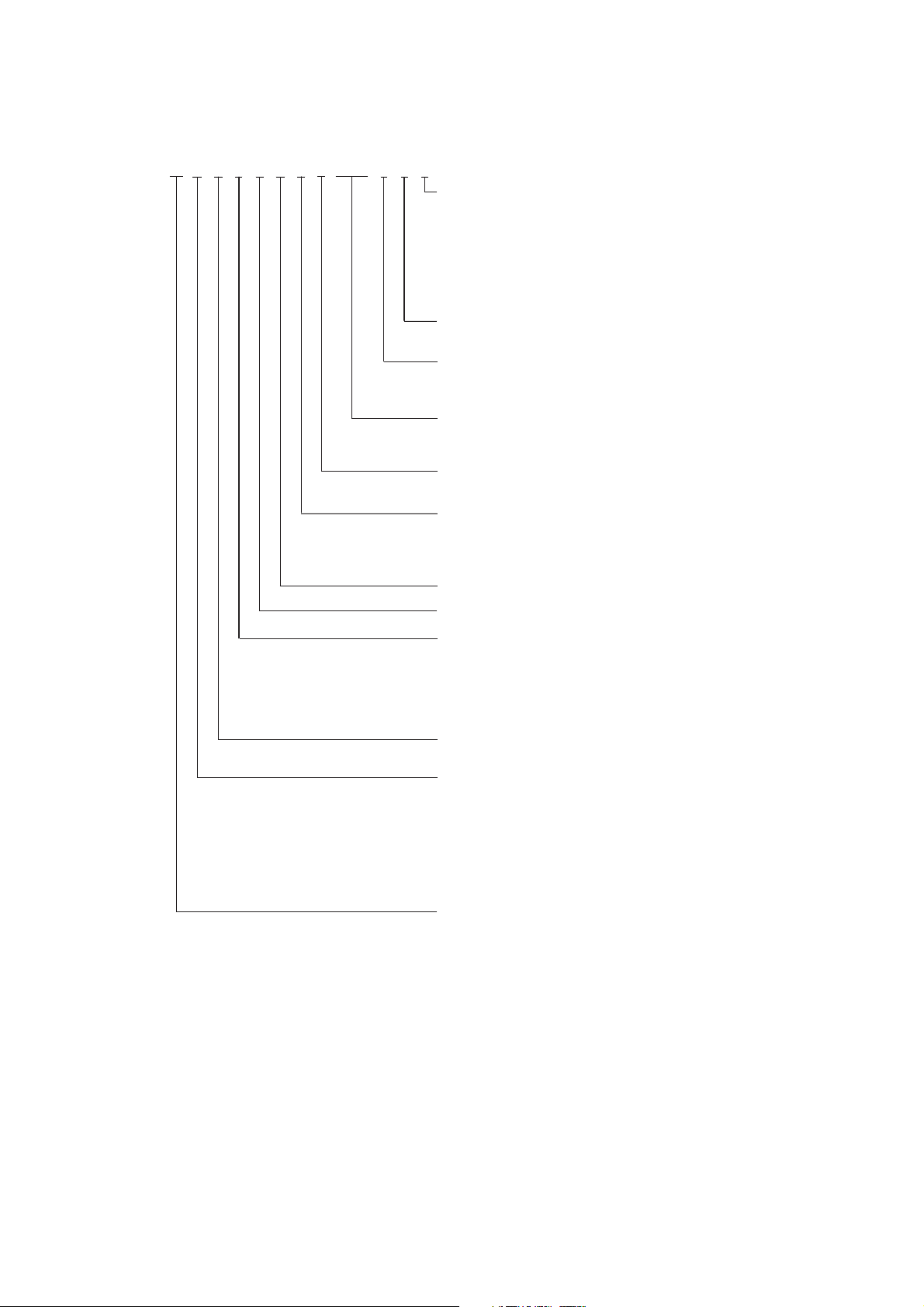

LA30

Ordering example:

30

1

1

-

0

0

0

5

0

0

2

0

0

0

Cables:

Protection class:

Motor:

Stroke length:

Install. dim.:

N = No cable when IP51 (except reed)

0 = Straight with jack plug 2300 mm

1 = Straight with jack plug 1050 mm

2 = Coiled with jack plug 400 mm

3 = Coiled with jack plug 200 mm

4 = Straight without plug 500 mm (Potentiometer)

5 = Straight without plug 1200 mm (with IP66 housing)

X = Other cable/length

0 = IP51

2 = IP66 with plastic house

0 = 24 V DC

1 = 24 V S-motor

2 = 12 V S-motor

XXX = mm

0 = Standard

X =Other installation dimension

4 = 24 V L-motor for LINAK control boxes

5 = 12 V motor

Max. with 3 & 6 mm pitch 400 mm

Max. with 9 & 12 mm pitch 500 mm

Min. 50 mm

7 = 36 V motor

Option:

Colour:

Option:

Option:

Back fixture:

Spindle type:

Actuator type:

0 = None

1 = Safety nut

2 = Steel spline

3 = Steel spline with safety nut

- = Black

0 = None

0 = None

P = Potentiometer 1 Kohm

L = Potentiometer 5 Kohm

T = Potentiometer 10 Kohm

R = Reedswitch

D = Optical encoder

1 = Standard (01)

2 = Turned 90

1 = 3 mm

2 = 6 mm

3 = 9 mm

4 = 4 mm

5 = 2.5 mm

6 = 2 mm

7 = 12 mm

K = Ball spindel

LA30

4 = Brake

5 = Brake with safety nut

o

(02)

(1-tread)

(2-tread)

(3-tread)

(2-tread)

(1-tread)

(1-tread)

(4-tread)

Old type no.

LA30.1

LA30.2

LA30.3

LA30.40

LA30.25

LA30.20

LA30.4

LA30K

Page 4

Speed and current graphs:

LA30 24V motor

8

7

6

5

4

3

Ampere

2

1

0

0 500 1000 1500 2000 2500 3000 3500

12mm

9mm

Load (N)

6mm

3mm

LA30 24V S-motor

12

10

8

6

Ampere

4

2

0

0 500 1000 1500 2000 2500 3000 3500

12mm 9mm

Load (N)

6mm

3mm

LA30 24V L-motor

5

4

3

2

Ampere

1

0

0 1000 2000 3000 4000 5000 6000 7000

9mm

12mm

6 mm

Load (N)

4mm

Ball screw

3mm

60

50

40

30

20

Speed mm/s

10

12mm

9mm pitch

6mm pitch

9mm

6mm

0

0 500 1000 1500 2000 2500 3000 3500

Load (N)

70

60

9mm pitch

12mm pitch

12mm

6mm pitch

50

40

30

20

Speed mm/s

10

9mm

6mm

3mm

0

0 500 1000 1500 2000 2500 3000 3500 4000

Load (N)

30

30

25

25

20

20

15

15

10

10

Speed mm/s

Speed (mm/s)

5

5

0

0

9mm pitch

12mm pitch

12mm

12mm

9mm

9mm

6mm

6mm

6mm pitch

4mm

Ball screw

3mm

3mm

0 1000 2000 3000 4000 5000

0 1000 2000 3000 4000 5000 6000 7000

Load (N)

Load (N)

3mm pitch

3mm

3mm pitch

3mm pitch

LA30 12V motor

16

14

12mm pitch

12

10

8

Amp.

6

4

2

0

0 500 1000 1500 2000 2500 3000 3500 4000

9mm pitch

Thrust (Nm)

6mm pitch

3mm pitch

LA30 12V S-motor

25

12mm pitch

20

15

Amp.

10

5

0

0 500 1000 1500 2000 2500 3000 3500 4000

9mm pitch

Thrust (Nm)

6mm pitch

3mm pitch

60

50

40

30

20

Speed mm/s

10

9mm pitch

12mm

6mm pitch

9mm

6mm

0

0 500 1000 1500 2000 2500 3000 3500

Load (N)

70

60

9mm pitch

12mm pitch

12mm

6mm pitch

50

40

30

20

Speed mm/s

10

9mm

6mm

3mm

0

0 500 1000 1500 2000 2500 3000 3500 4000

Load (N)

3mm pitch

3mm

3mm pitch

Page 5

Technical specifications:

New type Old Spindle Thrust *Self-lock Typical Stroke length Typical

type pitch max. max. With/ speed amp.

without 0/full at full

brake load load

(mm) (N) (N) (mm/s) (mm) 12V 24V

307xx0-4xxxx0/5xx LA30.4B 12 1000 1000/0 48/24 50 100 150 200 250 300 350 400 14 7

303xx0-4xxxx0/5xx LA30.3B 9 1500 1500/400 42/20 50 100 150 200 250 300 350 400 14 6.9

302xx0-4xxxx0/5xx LA30.2B 6 2000 2000/500 18.5/14 50 100 150 200 250 300 350 400 14 7

301xx0-xxxxx0/5xx LA30.1 3 3000 3000/3000 16/9 50 100 150 200 250 300 350 400 14 6.4

307xx0-4xxxx1/2xx LA30.7SB 12 1000 1000/0 65/35 50 100 150 200 250 300 350 400 20 10

303xx0-4xxxx1/2xx LA30.3SB 9 1800 1800/0 52/25 50 100 150 200 250 300 350 400 20 10

302xx0-4xxxx1/2xx LA30.2SB 6 2400 2400/500 34/20.3 50 100 150 200 250 300 350 400 18 9.1

301xx0-xxxxx1/2xx LA30.1S 3 3500 3500/3500 17/9.5 50 100 150 200 250 300 350 400 18 9.3

307xx0-4xxxx4xx LA30.4LB 12 1000 1000/0 26/20 50 100 150 200 250 300 350 400 - 2.5

303xx0-4xxxx4xx LA30.3LB 9 2000 2000/0 20/13 50 100 150 200 250 300 350 400 - 4.4

302xx0-4xxxx4xx LA30.2L 6 3000 3000/2000 13.8/7 50 100 150 200 250 300 350 400 - 4

301xx0-xxxxx4xx LA30.1L 3 4000 4000/4000 7/4.5 50 100 150 200 250 300 350 400 - 3.5

30Kxx0-0xxxx4xx LA30.LK 4 6000 6000/n/a 8.7/5.5 - - 150 200 250 300 350 400 - 4.7

30Kxx0-1xxxx4xx LA30.KAS 4 6000 6000/n/a 8.7/5.5 - - 150 200 250 300 350 400 - 4.7

30Kxxo-3xxxx4xx LA30.LKSM 4 6000 6000/n/a 8.7/5.5 - 100 150 200 250 300 350 400 - 4.7

The above measurements are made with the actuators connected to a stable power supply, LA30 L-motor versions with a CB12.

S = Strong motor

L = Slow motor

K = Ball screw

KAS = Ball screw, safety nut

KSM = Ball screw, safety nut, spline

All stroke lengths marked with background shading give full resolution with the standard potentiometer (1; 5 or 10 K ohm).

A potentiometer may be used with other stroke lengths but will not give full resolution.

LA30 Actuator with potentiometer

+

Black

Blue

Brown

Red /

Yellow

Green /

White

LA30 Actuator with optical encoder

Green

+

Yellow

Pulses

Black

Earth

Red

+5V DC

Optical encoder

Red / Yellow Green / White

+

+

Out going

In going

LA30 Actuator with reed ( only possible with 24V L-motor )

3.9 k

Brown

Black

+

+

Out going

In going

Pulse

Blue

Blue

Black

Brown

Please note that the voltage level og feedback signal depends on the actuator load.

Page 6

Thrust v’s Duty cycles for LA30 3 mm pitch Thrust v’s Average cycles for LA30 3 mm pitch

Duty Cycle v's Load - LA30 L-motor, 3 mm pitch (24 V)

4500

4000

3500

3000

2500

2000

Load (N)

1500

1000

500

0

0% 20% 40% 60% 80% 100%

Duty Cycle (%)

Duty Cycle v's Load - LA30 S-motor, 3 mm pitch (24 V)

4000

3500

3000

2500

2000

Load (N)

1500

1000

500

0

0% 30% 60% 90%

Duty Cycle (%)

Average Cycles v's Load - LA30 L-motor, 3 mm pitch

4500

4000

3500

3000

2500

2000

Load (N)

1500

1000

500

0

10 30 50 70 90 110

Average Cycles v's Load - LA30 S-motor, 3 mm pitch

4000

3500

3000

2500

2000

Load (N)

1500

1000

500

0

20 40 60 80 100 120 140

(24 V)

Average Cycles (X 1.000)

(24 V)

Average Cycles (X 1.000)

Thrust v’s Duty cycles for LA30 6 mm pitch Thrust v’s Average cycles for LA30 6 mm pitch

Duty Cycle versus Load - LA30.2L - 6 mm pitch (24 V)

3500

3000

2500

2000

1500

Load (N)

1000

500

0

0% 20% 40% 60% 80% 100%

Duty Cycle (%)

Duty Cycle versus Load - LA30.2S - 6 mm pitch (24 V)

3000

2500

2000

1500

Load (N)

1000

500

0

0% 20% 40% 60% 80% 100%

Duty Cycle (%)

Average Cycles versus Load - LA30.2L - 6 mm pitch (24 V)

4500

4000

3500

3000

2500

2000

Load (N)

1500

1000

500

0

20 40 60 80 100 120 140 160 180 200

Average Cycles (X 1.000)

Average Cycles versus Load - LA30.2S - 6 mm pitch (24 V)

4000

3500

3000

2500

2000

Load (N)

1500

1000

500

0

30 80 130 180 230

Average Cycles (X 1.000)

Page 7

Thrust v’s Duty cycles for LA30 9 mm pitch Thrust v’s Average cycles for LA30 9 mm pitch

Duty Cycle versus Load - LA30.3L - 9 mm pitch (24 V)

2500

2000

1500

Load (N)

1000

500

0

0% 20% 40% 60% 80% 100%

Duty Cycle (%)

Duty Cycle versus Load - LA30.3S - 9 mm pitch (24 V)

2000

1800

1600

1400

1200

1000

Load (N)

800

600

400

200

0

0% 20% 40% 60% 80% 100%

Duty Cycle (%)

Average Cycles versus Load - LA30.3L - 9 mm pitch (24 V)

2500

2000

1500

1000

Load (N)

500

0

30 80 130 180 230 280 330

Average Cycles (X 1.000)

Average Cycles versus Load - LA30.3S - 9 mm pitch (24 V)

2000

1800

1600

1400

1200

1000

Load (N)

800

600

400

200

0

60 110 160 210 260 310 360 410 460

Average Cycles (X 1.000)

Thrust v’s Duty cycles for LA30 12 mm pitch Thrust v’s Average cycles for LA30 12 mm pitch

Duty Cycle versus Load - LA30.4L - 12 mm pitch (24 V)

1200

1000

800

600

Load (N)

400

200

0

0% 20% 40% 60% 80% 100%

Duty Cycle (%)

Duty Cycle versus Load - LA30.4S - 12 mm pitch (24 V)

1200

1000

800

600

Load (N)

400

200

0

0% 20% 40% 60% 80% 100%

Duty Cycle (%)

Average Cycles versus Load - LA30.4L - 12 mm pitch (24 V)

1200

1000

800

600

Load (N)

400

200

0

45 145 245 345 445 545

Average Cycles (X 1.000)

Average Cycles versus Load - LA30.4S - 12 mm pitch (24 V)

1200

1000

800

600

Load (N)

400

200

0

75 175 275 375 475 575 675 775

Average Cycles (X 1.000)

Page 8

Accessories for LA30:

Control card

Limit Switch

The CS16 electronic limit switch is connected between the LINAK®

actuator and a non-LINAK power supply, where it cuts out the

current to the actuator in end position or if an obstacle is encountered. The PCB contains a variable current limit setting and is

available in different versions, depending on which actuator it is

to be used with.

Above mentioned guarantees the maintenance of the long life of

the LINAK actuator. The CS16 is an important component which

ensures a long life for the actuator.

There are two types of LINAK® limit switches, for LA30, LS and LSD.

The LSD type controls the stroke length of the actuator between

two fixed end positions by cutting off the current to the motor.

The LS type gives signal in two fixed end positions, but requires

a control unit to stop the actuator when the micro switches are

activated.

Bellows

• Give a better protection and therefore give a higher liftetime

of the actuator

• Protects inner tube against dust and dirt

• Can be used for actuators: LA30

• Does not change the IP rating

• Available in black colour

• Ask for special folder

Please contact your nearest LINAK dealer for further details or read more on www.linak.com.

It is the responsibility of the product user to determine the suitability

of LINAK A/S products for a specific application. LINAK will at point of

delivery replace/repair defective products covered by the warranty

if promptly returned to the factory. No liability is assumed beyond

such replacement/repair.

Specifications subject to change without prior notice.

Copyright © LINAK 07.01 MA M9-02-050-J . Chapter 5.7

Loading...

Loading...