查询FAN5099供应商

FAN5099 Wide Frequency Synchronous Buck

PWM & LDO Controller

FAN5099 Wide Frequency Synchronous Buck PWM & LDO Controller

Decemeber 2006

Features

■ General Purpose PWM Regulator and LDO Controller

■ Input Voltage Range: 3V to 24V

■ Output Voltage Range: 0.8V to 15V

■ V

CC

– 5V

– Shunt Regulator for 12V Operation

■ Support for Ceramic Cap on PWM Output

■ Programmable Current Limit for PWM Output

■ Wide Programmable Switching Frequency Range

(50kHz to 600kHz)

■ R

■ Internal Synchronous Boot Diode

■ Soft-Start for both PWM and LDO

■ Multi-Fault Protection with Optional Auto-restart

■ 16-Pin TSSOP Package

Current Sensing

DS(ON)

Applications

■ High-Efficiency (80+) Computer Power Supplies

■ PC/Server Motherboard Peripherals

– V

_MCH (1.5V), V

CC

V

■ Power Supply for

– FPGA, DSP, Embedded Controllers, Graphic Card

Processor, and Communication Processors

■ High-Power DC-to-DC Converters

TT_GTL

(1.25V)

(1.5V) and

DDQ

Related Application Notes

■ AN-6020 FAN5099 Component Calculation and

Simulation Tools

■ AN-6005 Synchronous Buck MOSFET Loss

Calculations with Excel Model

Description

The FAN5099 combines a high-efficiency pulse-width

modulated (PWM) controller and an LDO (Low DropOut)

linear regulator controller. The PWM controller is

designed to operate over a wide frequency range (50kHz

to 600kHz) to accommodate a variety of applications.

Synchronous rectification provides high efficiency over a

wide range of load currents. Efficiency is further

enhanced by using the low-side MOSFET’s R

sense current. In addition, the capability to operate at low

switching frequencies provides opportunities to boost

power supply efficiency by reducing switching losses and

gain cost savings using low-cost materials, such as powdered iron cores, on the output inductor.

Both the linear and PWM regulator soft-start are controlled by a single external capacitor, to limit in rush current from the supply when the regulators are first

enabled. Current limit for PWM is also programmable.

The FAN5099’s ability to handle wide input voltage

ranges makes this controller suitable for power solutions

in a wide range of applications involving conversion input

voltages from Silver box, battery, and adapters. The

PWM regulator employs a summing-current-mode control with external compensation to achieve fast load transient response and provide system design optimization.

FAN5099 is offered in both industrial temperature grade

(-40°C to +85°C) as well as commercial temperature

grade (-10°C to +85°C).

DS(ON)

to

Ordering Information

Part Number Operating Temp. Range Pb-Free Package Packing Method Qty/Reel

FAN5099MTCX -10°C to +85°C Yes 16-Lead TSSOP Tape and Reel 2500

FAN5099EMTCX -40°C to +85°C Yes 16-Lead TSSOP Tape and Reel 2500

FAN5099MX -10°C to +85°C Yes 16-Lead SOIC Tape and Reel 2500

FAN5099EMX -40°C to +85°C Yes 16-Lead SOIC Tape and Reel 2500

Note: Contact Fairchild sales for availability of other package options.

© 2006 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN5099 Rev. 1.1.3

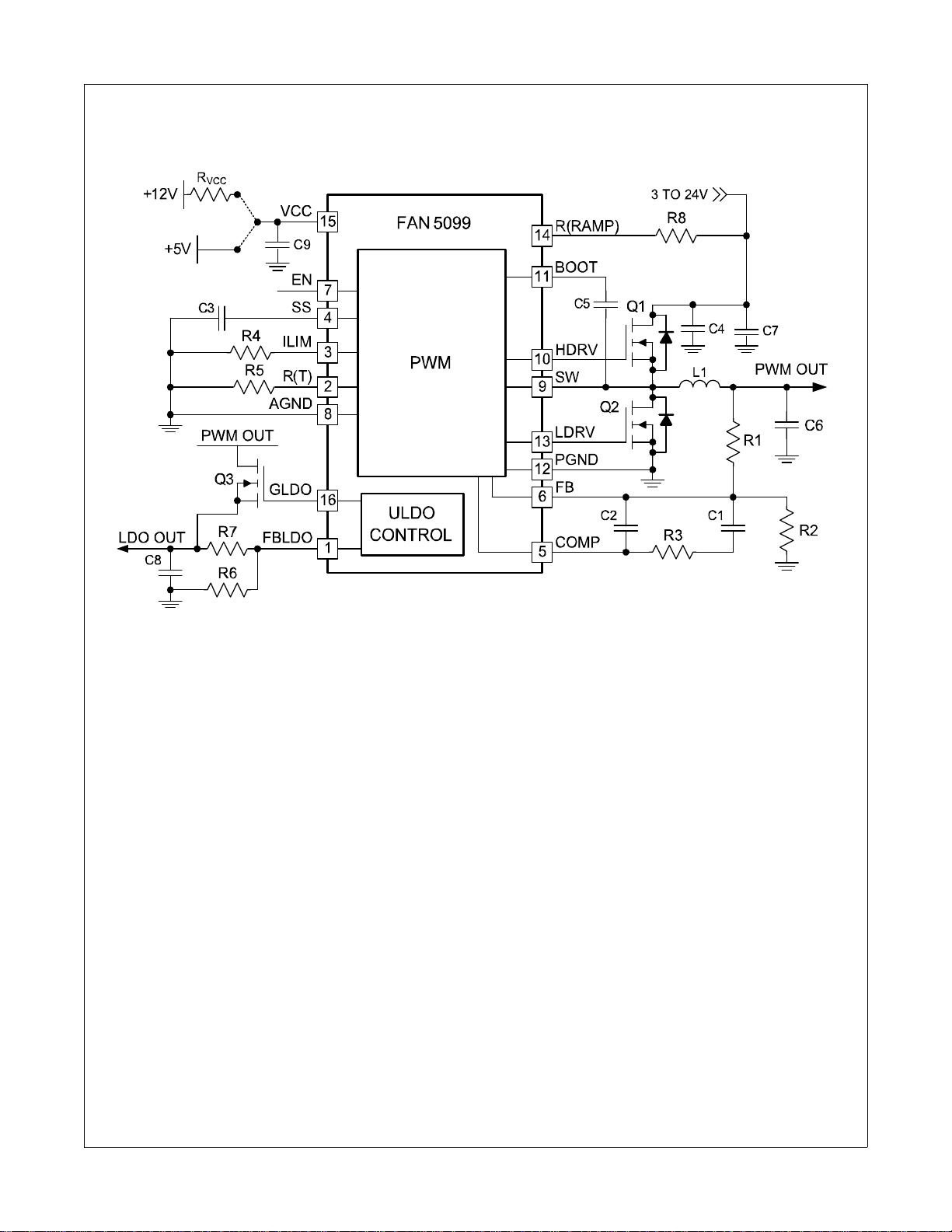

Typical Application

FAN5099 Wide Frequency Synchronous Buck PWM & LDO Controller

Figure 1. Typical Application Diagram

© 2006 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN5099 Rev. 1.1.3 2

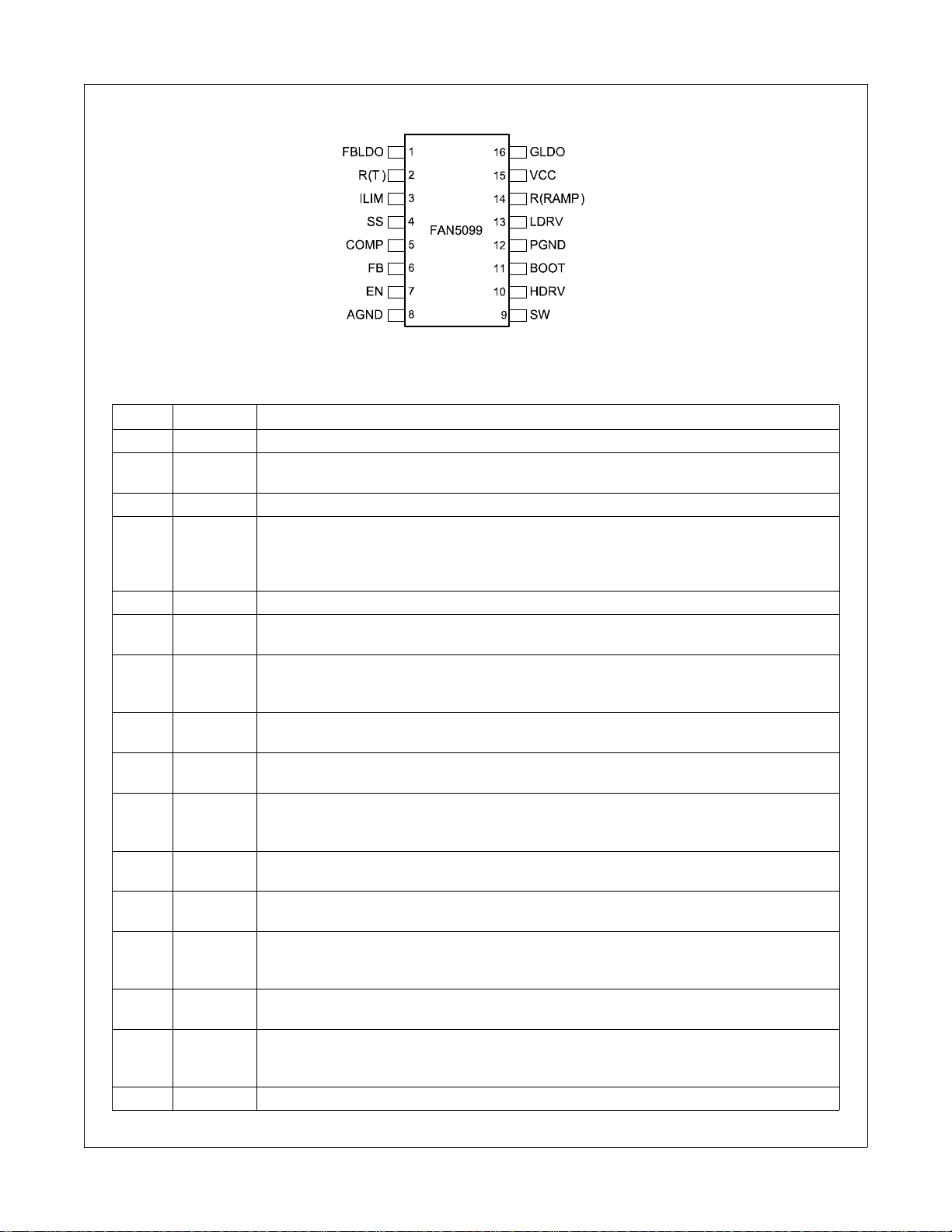

Pin Assignment

Figure 2. Pin Assignment

Pin Description

Pin No. Pin Name Pin Description

1FBLDOLDO Feedback. This node is regulated to V

2R(T)Oscillator Set Resistor. This pin provides oscillator switching frequency adjustment. By plac-

ing a resistor (RT) from this pin to GND, the nominal 50kHz switching frequency is increased.

3ILIMCurrent Limit. A resistor from this pin to GND sets the current limit.

4 SS Soft-Start. A capacitor from this pin to GND programs the slew rate of the converter and the

LDO during initialization. It also sets the time by which the converter delays when restarting

after a fault occurs. SS has to reach 1.2V before fault shutdown feature is enabled. The LDO

is enabled when SS reaches 2.2V.

5COMPCOMP. The output of the error amplifier drives this pin.

6FBFeedback. This pin is the inverting input of the internal error amplifier. Use this pin, in combi-

nation with the COMP pin, to compensate the feedback loop of the converter.

7ENEnable. Enables operation when pulled to logic high. Toggling EN resets the regulator after a

latched fault condition. This is a CMOS input whose state is indeterminate if left open and

needs to be properly biased at all times.

8AGND

9SWSwitching Node. Return for the high-side MOSFET driver and a current sense input. Connect

10 HDRV High-Side Gate Drive Output. Connect to the gate of the high-side power MOSFETs. This

11 BOO T Bootstrap Supply Input. Provides a boosted voltage to the high-side MOSFET driver.

12 PGND Power Ground. The return for the low-side MOSFET driver. Connect to source of low-side

13 LDRV Low-Side Gate Drive Output. Connect to the gate of the low-side power MOSFETs. This pin

14 R(RAMP) Ramp Resistor. A resistor from this pin to VIN sets the ramp amplitude and provides voltage

15 VCC V

16 GLDO Gate Drive for the LDO. Turned off (low) until SS is greater than 2.2V.

Analog Ground.

pin. Tie this pin to the ground island/plane through the lowest impedance connection available.

to source of high-side MOSFET and drain of low-side MOSFET.

pin is also monitored by the adaptive shoot-through protection circuitry to determine when the

high-side MOSFET is turned off.

Connect to bootstrap capacitor as shown in Figure 1.

MOSFET.

is also monitored by the adaptive shoot-through protection circuitry to determine when the

lower MOSFET is turned off.

feed-forward.

. Provides bias power to the IC and the drive voltage for LDRV. Bypass with a ceramic

CC

capacitor as close to this pin as possible. This pin has a shunt regulator which draws current

when the input voltage is above 5.6V.

The signal ground for the IC. All internal control voltages are referred to this

REF

.

FAN5099 Wide Frequency Synchronous Buck PWM & LDO Controller

© 2006 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN5099 Rev. 1.1.3 3

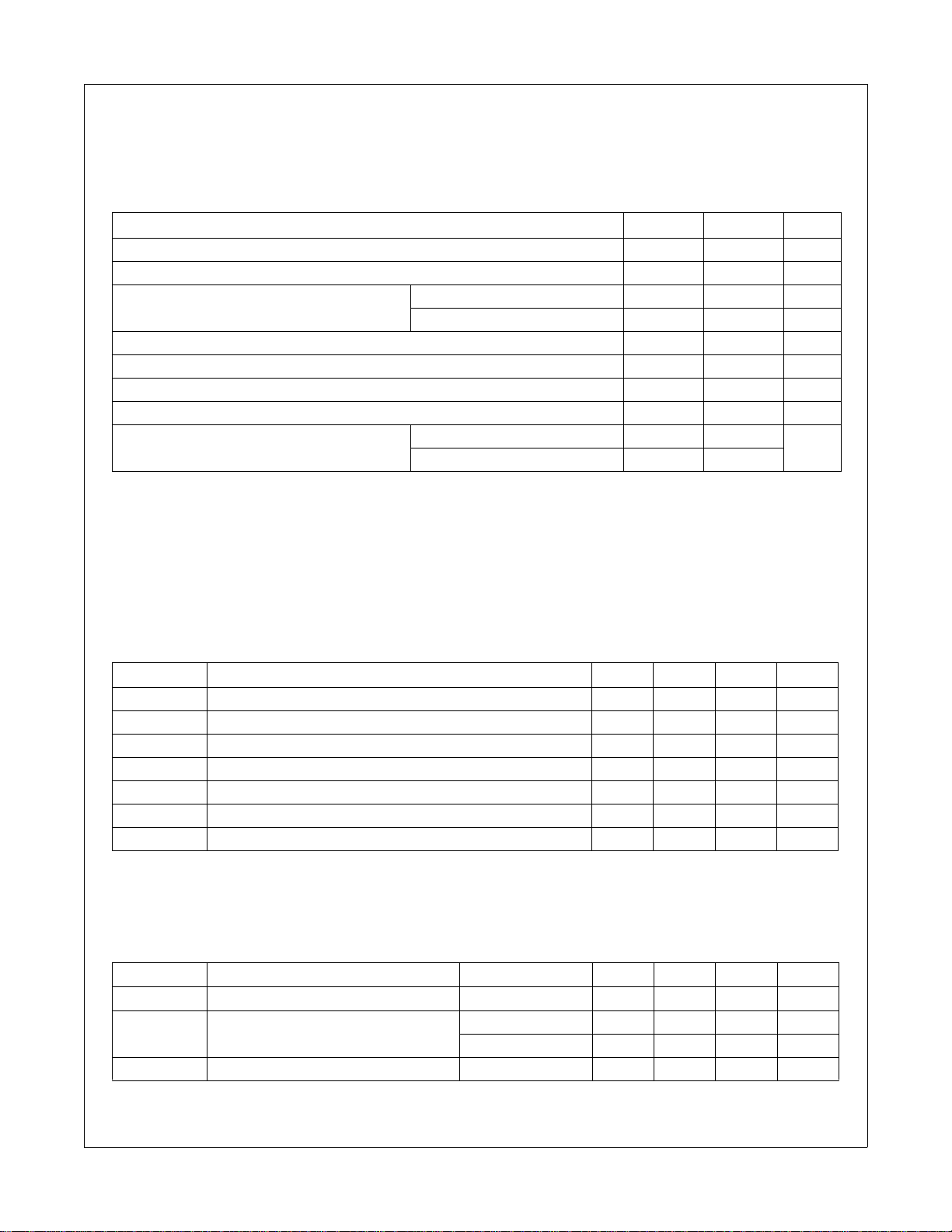

Absolute Maximum Ratings

The “Absolute Maximum Ratings” are those values beyond which the safety of the device cannot be guaranteed. The

device should not be operated at these limits. The parametric values defined in the Electrical Characteristics tables

are not guaranteed at the absolute maximum ratings. The “Recommended Operating Conditions” table defines the

conditions for actual device operation.

VCC to PGND 6.0 V

BOOT to PGND 33.0 V

SW to PGND Continuous -0.5 33.0 V

HDRV (V

– VSW) 6.0 V

BOOT

LDRV -0.5 6.0 V

All Other Pins -0.3 V

Maximum Shunt Current for V

Electrostatic Discharge (ESD) Protection

(2)

Level

Notes:

1. Stresses above those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. This

is a stress rating only; functional operation of the device at these or any conditions above those indicated in the

operational section of this specification is not implied. Exposure to absolute maximum rating conditions for extended

periods may affect device reliability. Absolute maximum ratings apply individually only, not in combination. Unless

otherwise specified, all other voltages are referenced to AGND.

2. Using Mil Std. 883E, method 3015.7 (Human Body Model) and EIA/JESD22C101-A (Charge Device Model).

(1)

Parameter Min. Max. Unit

Transient (t < 50ns, f < 500kHz) -3.0 33.0 V

+ 0.3 V

CC

CC

HBM 3.5 kV

CDM 1.8

150 mA

FAN5099 Wide Frequency Synchronous Buck PWM & LDO Controller

Thermal Information

Symbols Parameter Min. Typ. Max. Unit

T

STG

T

L

P

D

θ

JC

θ

JA

3. Junction-to-ambient thermal resistance, θJA, is a strong function of PCB material, board thickness, thickness and

number of copper planes, number of vias used, diameter of vias used, available copper surface, and attached heat

sink characteristics.

Storage Temperature -65 150 °C

Lead Soldering Temperature, 10 Seconds 300 °C

Vapor Phase, 60 Seconds 215 °C

Infrared, 15 Seconds 220 °C

Power Dissipation, TA = 25°C 715 mW

Thermal Resistance – Junction-to-Case 37 °C/W

Thermal Resistance – Junction-to-Ambient

(3)

100 °C/W

Recommended Operating Conditions

Symbols Parameter Conditions Min. Typ. Max. Unit

V

CC

T

A

T

J

Supply Voltage VCC to GND 4.5 5.0 5.5 V

Ambient Temperature

Commercial -10 85 °C

Industrial -40 85 °C

Junction Temperature 125 °C

© 2006 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN5099 Rev. 1.1.3 4

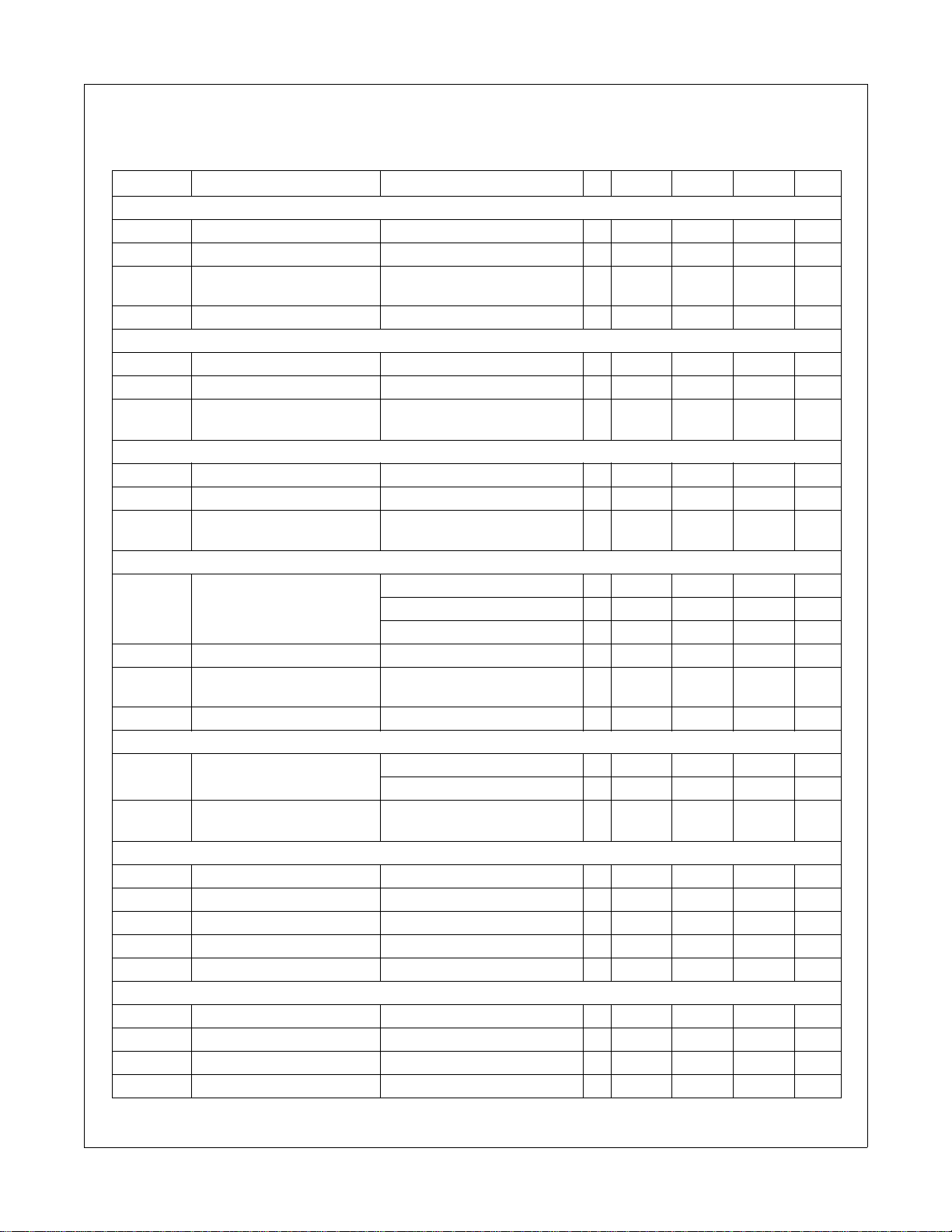

Electrical Characteristics

Unless otherwise noted, VCC = 5V, TA = 25°C, using the circuit in Figure 1. The ‘•’ denotes that the specifications apply

to the full ambient operating temperature range.

Symbol Parameter Conditions Min. Typ. Max. Unit

Supply Current

I

VCC

I

VCC(SD)VCC

I

VCC(OP)VCC

V

SHUNTVCC

Under-Voltage Lockout (UVLO)

UVLO(H) Rising V

UVLO(L) Falling V

Soft-Start

I

SS

V

LDOSTART

V

SSOK

Oscillator

F

OSC

ΔV

RAMP

Reference

V

REF

Error Amplifier

GBWP Gain-BW Product 25 MHz

S/R Slew Rate 10pF across COMP to GND 8 V/μS

I

FB

Gate Drive

R

HUP

R

HDN

R

LUP

R

LDN

VCC Current (Quiescent) HDRV, LDRV Open

Current (Shutdown) EN = 0V, VCC = 5.5V

Current (Operating)

Volta ge

UVLO Threshold

V

CC

(6)

UVLO Threshold

CC

UVLO Threshold

CC

Hysteresis

Current 10 μA

LDO Start Threshold 2.2 V

PWM Protection Enable

Threshold

Frequency

Operating Frequency Range 40 600 kHz

Ramp Amplitude

(Peak-to-Peak)

Minimum On Time f = 200kHz 200 ns

Reference Voltage

(Measured at FB Pin)

Current Amplifier Reference

(at SW node)

DC Gain 80 dB

Output Voltage Swing No Load

FB Pin Source Current μA

HDRV Pull-up Resistor Sourcing

HDRV Pull-down Resistor Sinking

LDRV Pull-up Resistor Sourcing

LDRV Pull-down Resistor Sinking

(4,5)

•

2.6 3.2 3.8 mA

EN = 5V, V

Q

= 20nC, FSW = 200kHz

FET

= 5.0V,

CC

Sinking 1mA to 100mA at VCC Pin

•

5.4 5.9 V

•

4.00 4.25 4.50 V

•

3.60 3.75 4.00 V

200 400 μA

10 15 mA

0.5 V

1.2 V

R(T) = 25.5KΩ ± 1% 240 300 360 kHz

R(T) = 199KΩ ± 1% 60 80 100 kHz

R(T) = Open 50 kHz

R(RAMP) = 330KΩ 0.4 V

TA = 0°C to 70°C

= -40°C to 85°C

T

A

•

790 800 810 mV

•

788 800 812 mV

160 mV

•

0.5 4.0 V

•

•

•

•

1.8 3.0 Ω

1.8 3.0 Ω

1.8 3.0 Ω

1.2 2.0 Ω

FAN5099 Wide Frequency Synchronous Buck PWM & LDO Controller

© 2006 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN5099 Rev. 1.1.3 5

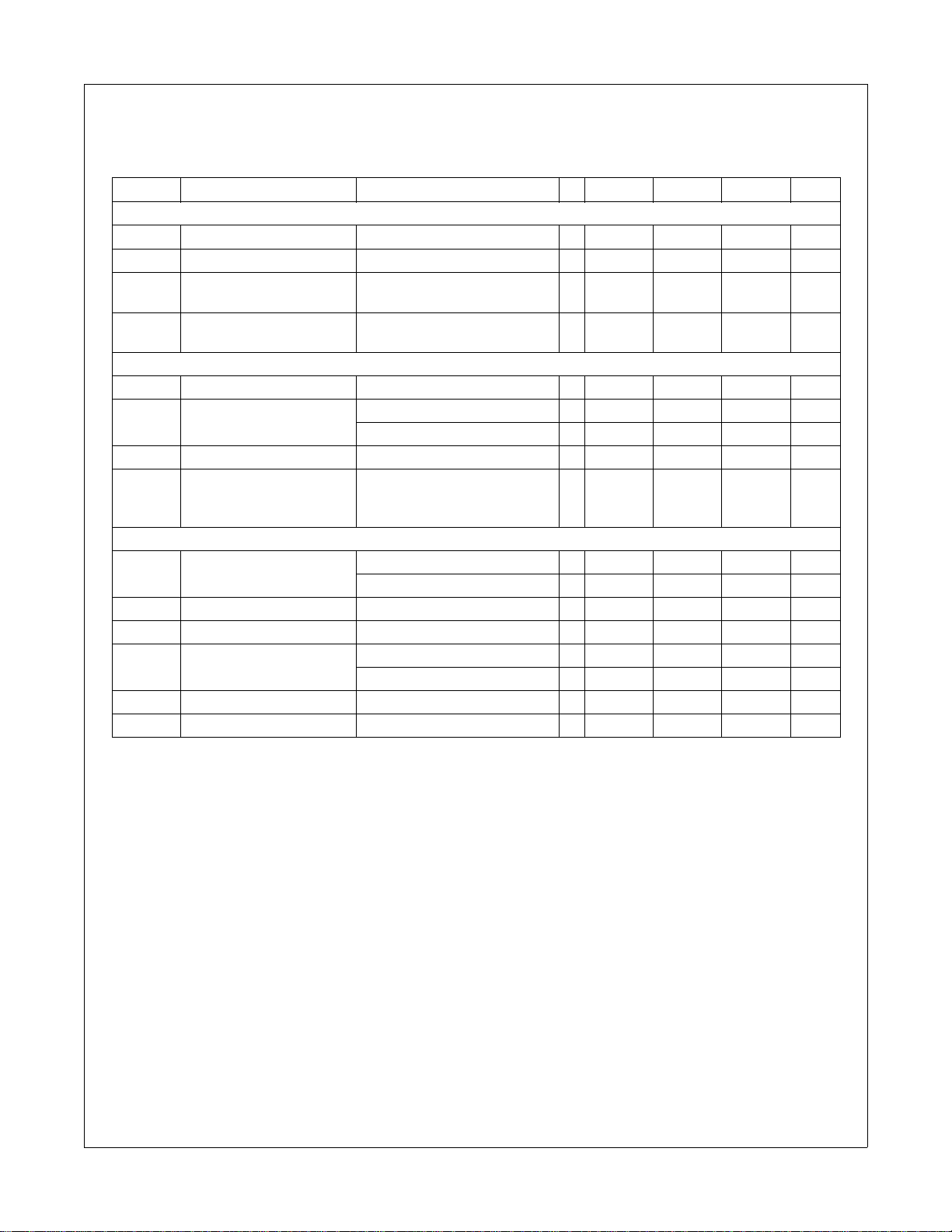

Electrical Characteristics (Continued)

Unless otherwise noted, V

= 5V, T

CC

to the full ambient operating temperature range.

Symbol Parameter Conditions Min. Typ. Max. Unit

Protection/Disable

I

I

SWPD

V

V

Supply Current

TSD Thermal Shutdown 160 °C

V

Low Drop-Out (LDO)

V

LDOREF

V

LDO_DO

ILIMIT Source Current 9 10 11 μA

LIM

SW Pull-down Current SW = 1V, EN = 0V mA

Under-Voltage Threshold

UV

Over-Voltage Threshold

OV

Enable Threshold Voltage

EN

Enable Source Current V

Enable Sink Current

(7)

Reference Voltage

(measured at FBLDO pin)

Regulation 0A ≤ I

Drop-out Voltage I

External Gate Drive

Gate Drive Source Current 1.2 mA

Gate Drive Sink Current 400 μA

= 25°C, using the circuit in Figure 1. The ‘•’ denotes that the specifications apply

A

As % of set point;

2μS noise filter

As % of set point;

2μS noise filter

Enable Condition

Disable Condition

V

(4, 5)

65 75 80 %

•

110 115 120 %

•

•

2.0 V

•

= 5V 50 μA

CC

= 5V and fault conditions

CC

10 μA

0.8 V

(overload, short-circuit,

over-voltage, under-voltage)

TA = 0°C to 70°C

= -40°C to 85°C

T

A

≤ 5A

LOAD

≤ 5A and R

LOAD

= 4.75V

V

CC

= 5.6V

V

CC

< 50mΩ 0.3 V

DS-ON

•

775 800 825 mV

•

770 800 830 mV

•

1.17 1.20 1.23 V

•

•

4.5 V

5.3 V

FAN5099 Wide Frequency Synchronous Buck PWM & LDO Controller

Notes:

4. All limits at operating temperature extremes are guaranteed by design, characterization, and statistical quality control.

5. AC specifications guaranteed by design/characterization (not production tested).

6. For a case when V

is sinking current to keep voltage on V

7. Test Conditions: V

© 2006 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN5099 Rev. 1.1.3 6

is higher than the typical 5V V

CC

LDO_IN

= 1.5V and V

pin constant.

CC

LDO_OUT

voltage observed at VCC pin when the internal shunt regulator

CC,

= 1.2V.

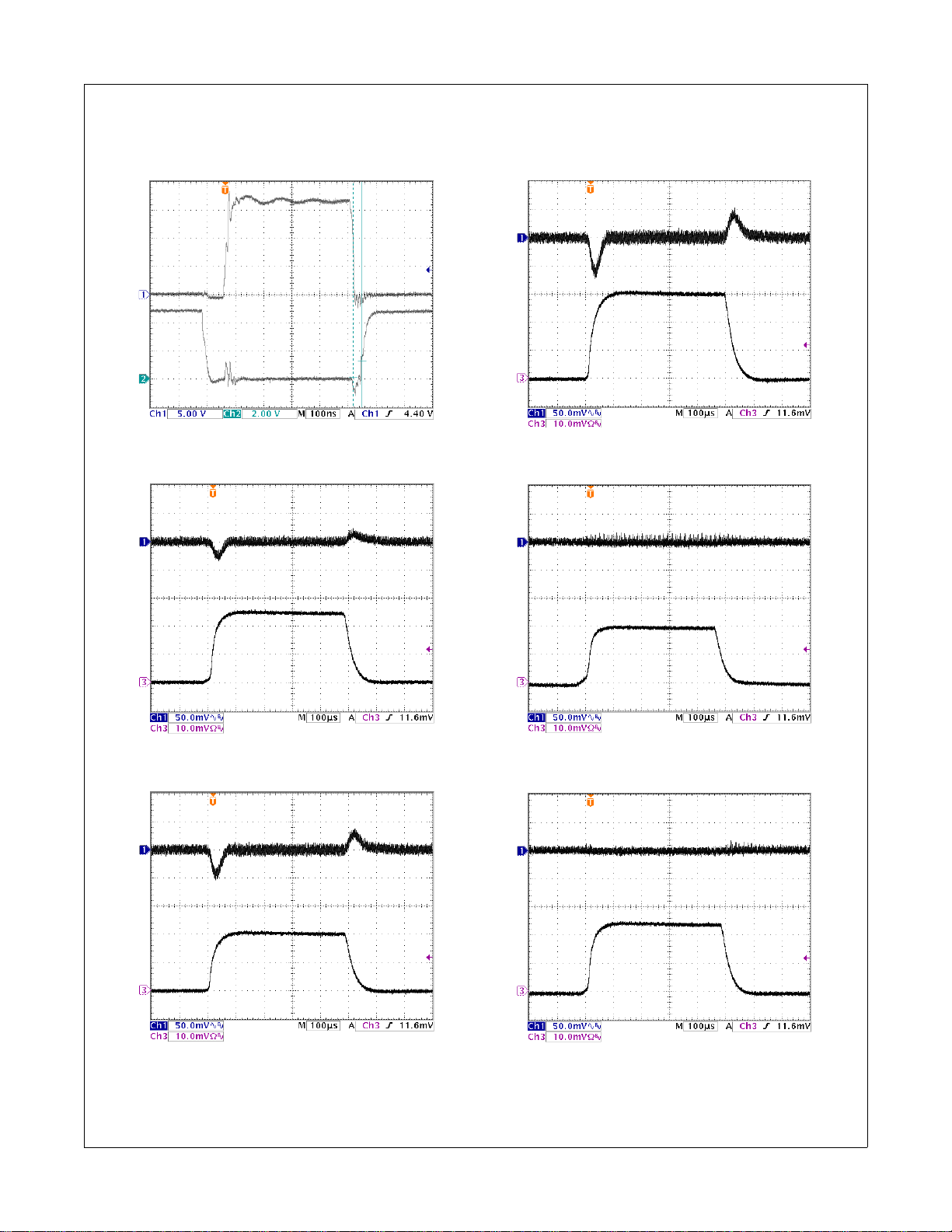

Typical Performance Characteristics

VIN=12V, Vdd=5V, V

OUT

=1.5V, V

=1.2V, I

ldo

load

=5A, I

ldo

=2A, F

= 300kHz, unless otherwise noted.

osc

FAN5099 Wide Frequency Synchronous Buck PWM & LDO Controller

Ch1: HDRV; Ch2: LDRV. Dead times: 62ns, 32ns

Figure 3. Dead Time Waveform

Ch1: V

; Ch3: IL, 2.5A/div

OUT

Figure 4. PWM Load Transient (0 to 5A)

Ch1: V

; Ch3: IL, 5A/div

OUT

Figure 6. PWM Load Transient (0 to 15A)

Ch1: V

OUT_LDO

; Ch3: I

LDO

, 1A/div

Figure 7. LDO Load Transient (0 to 2A)

Ch1: V

; Ch3: IL, 5A/div

OUT

Figure 5. PWM Load Transient (0 to 10A)

© 2006 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN5099 Rev. 1.1.3 7

Ch1: V

Figure 8. LDO Load Transient (0 to 5A)

OUT_LDO

; Ch3: I

LDO

, 2.5A/div

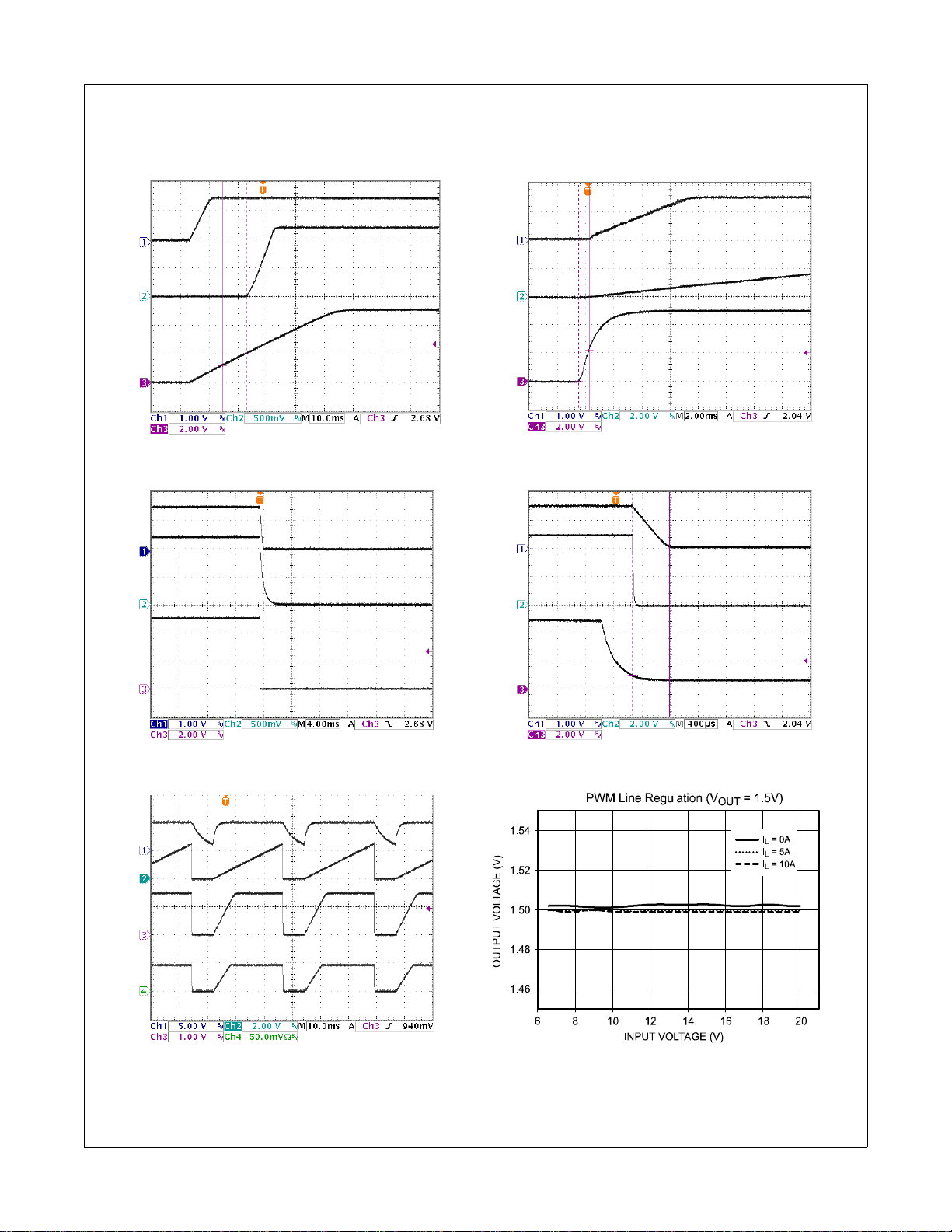

Typical Performance Characteristics (Continued)

VIN=12V, Vdd=5V, V

Ch1: V

; Ch2:V

OUT

OUT

OUT_LDO

=1.5V, V

; Ch3: SS

=1.2V, I

ldo

load

=5A, I

ldo

=2A, F

osc

= 300kHz, unless otherwise noted.

Ch1: V

; Ch2: SS; Ch3: EN

OUT

FAN5099 Wide Frequency Synchronous Buck PWM & LDO Controller

Figure 9. PWM/LDO Power Up

Ch1: V

OUT

; Ch2: V

OUT_LDO

; Ch3: SS

Figure 10. PWM/LDO Power Down

Figure 12. Enable On (I

Ch1: V

; Ch2: SS; Ch3: EN

OUT

Figure 13. Enable Off (I

PWM

PWM

= 5A)

= 5A)

Ch1: EN; Ch2: SS; Ch3: V

Figure 11. Auto Restart

© 2006 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN5099 Rev. 1.1.3 8

; Ch4: IL, 25A/div

OUT

Figure 14. PWM Line Regulation

Typical Performance Characteristics (Continued)

VIN=12V, Vdd=5V, V

OUT

=1.5V, V

=1.2V, I

ldo

load

=5A, I

ldo

=2A, F

osc

FAN5099 Wide Frequency Synchronous Buck PWM & LDO Controller

= 300kHz, unless otherwise noted.

Figure 15. LDO Load Regulation

Figure 16. PWM Load Regulation

Figure 18. R

vs. Frequency

T

Figure 19. 1.5V PWM Efficiency

Figure 17. LDO Load Regulation

© 2006 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN5099 Rev. 1.1.3 9

Figure 20. Efficiency Comparison at V

IN

=12V

Block Diagram

Vcc

R

ILIM

ILIM

Shunt Reg

InternalVcc5.6V Max.

10μA

CurrentLimit

Comparator

Internal

Boot Diode

BO OT

C

V

FAN5099 Wide Frequency Synchronous Buck PWM & LDO Controller

BOOT

IN

V

IN

COMP

FB

SS

R

RAMP

R(RAMP)

EN

Vref

Ramp

Generator

10μA

Enable

Error

Amplifier

Vcc

Summing

Amplifier

PWM

Comparator

OSC

Figure 21. Block Diagram

Detailed Operation Description

FAN5099 combines a high-efficiency, fixed-frequency

PWM controller designed for single-phase synchronous

buck Point-Of-Load converters with an integrated LDO

controller to support GTL-type loads. This controller is

ideally suited to deliver low-voltage, high-current power

supplies needed in desktop computers, notebooks,

workstations, and servers. The controller comes with an

integrated boot diode which helps reduce component

cost and increase space savings. With this controller, the

input to the power supply can be varied from 3V to 24V

and the output voltage can be set to regulate at 0.8V to

15V on the switcher output. The LDO output can be configured to regulate between 0.8V to 3V and the input to

the LDO can be from 1.5V to 5V, respectively. An internal

shunt regulator at the V

operation from either a 5V or 12V power source.

VCC Bias Supply

FAN5099 can be configured to operate from 5V or 12V

for V

. When 5V supply is used for VCC, no resistor is

CC

required to be connected between the supply and the

. When the 12V supply is used, a resistor R

V

CC

connected between the 12V supply and the V

shown in Figure 1. The internal shunt regulator at the V

pin is capable of sinking 150mA of current to ensure the

controller’s internal V

Choose a resistor such that:

■ It is rated to handle the power dissipation.

■ Current sunk within the controller is minimized to

prevent IC temperature rise.

pin facilitates the controller

CC

is maintained at 5.6V maximum.

CC

VCC

CC,

is

as

CC

PWM

RSQ

Current

Sense

Amplifier

R

Selection (IC)

VCC

The selection of R

Adaptive

GateDrive

Circuit

HDR V

SW

LDRV

PGND

is dependent on:

VCC

L

O

■ Variation of the 12V supply

■ Sum of gate charges of top and bottom FETs (Q

■ Switching frequency (F

SW

)

■ Shunt regulator minimum current (1mA)

■ Quiescent Current of the IC (I

Calculate R

R

VCC

CC

:

the V

based on the minimum input voltage for

VCC

VIN

------------------------------------------------------------------------------------------=

I

110•

Q

MIN

3–

Q

)

Q

5.6–

FETFSW

1.2••++()

For a typical example, where:

= 11.5V, IQ = 3mA, Q

V

MIN

IN

R

is calculated to be 398.65Ω.

VCC

= 30nC, F

FET

SW

PWM Section

The FAN5099’s PWM controller combines the conventional voltage mode control and current sensing through

lower MOSFET R

This method of current sensing is loss-less and cost

effective. For more accurate current sense requirements,

an optional external resistor can be connected with the

bottom MOSFET in series.

to generate the PWM signals.

DS_ON

Vout

C

O

)

FET

= 300kHz,

© 2006 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN5099 Rev. 1.1.3 10

FAN5099 Wide Frequency Synchronous Buck PWM & LDO Controller

PWM Operation

Refer to Figure 21 for the PWM control mechanism. The

FAN5099 uses the summing mode method of control to

generate the PWM pulses. The amplified output of the

current-sense amplifier is summed with an internally

generated ramp and the combined signal is amplified

and compared with the output of the error amplifier to get

the pulse width to drive the high-side MOSFET. The

sensed current from the previous cycle is used to modulate the output of the summing block. The output of the

summing block is also compared against the voltage

threshold set by the R

resistor to limit the inductor cur-

LIM

rent on a cycle-by-cycle basis. The controller facilitates

external compensation for enhanced flexibility.

Initialization

When the PWM is disabled, the SW node is connected

to GND through an internal 500Ω MOSFET to slowly discharge the output. As long as the PWM controller is

enabled, this internal MOSFET remains OFF.

Soft-Start (PWM and LDO)

When VCC exceeds the UVLO threshold and EN is high,

the circuit releases SS and enables the PWM regulator.

The capacitor connected to the SS pin and GND is

charged by a 10µA internal current source, causing the

voltage on the capacitor to rise. When this voltage

exceeds 1.2V, all protection circuits are enabled. When

this voltage exceeds 2.2V, the LDO output is enabled.

The input to the error amplifier at the non-inverting pin is

clamped by the voltage on the SS pin until it crosses the

reference voltage.

The time it takes the PWM output to reach regulation

) is calculated using the following equation:

(T

T

Rise

RISE

810

× CSS×=

2–

(C

is in μf) (EQ. 1)

SS

tively changes the slope of the internal ramp, minimizing

the variation of the PWM modulator gain when input voltage varies. The R

explained in later sections. The R

effect on the current limit is

RAMP

value can be

RAMP

approximated using the following equation:

R

RAMP

where F

OSC

VIN = 12V, R

V

IN nom,()

--------------------------------------------K Ω=

6.3

×10 F

is in Hz. For example, for F

RAMP

8–

×

= 2MΩ.

1.8–

OSC

= 80kHz and

OSC

(EQ. 3)

Gate Drive Section

The adaptive gate control logic translates the internal

PWM control signal into the MOSFET gate drive signals

and provides necessary amplification, level shifting, and

shoot-through protection. It also has functions that help

optimize the IC performance over a wide range of operating conditions. Since the MOSFET switching time can

vary dramatically from device to device and with the

input voltage, the gate control logic provides adaptive

dead time by monitoring the gate-to-source voltages of

both upper and lower MOSFETs. The lower MOSFET

drive is not turned on until the gate-to-source voltage of

the upper MOSFET has decreased to less than approximately 1V. Similarly, the upper MOSFET is not turned on

until the gate-to-source voltage of the lower MOSFET

has decreased to less than approximately 1V. This

allows a wide variety of upper and lower MOSFETs to be

used without a concern for simultaneous conduction, or

shoot-through.

A low impedance path between the driver pin and the

MOSFET gate is recommended for the adaptive deadtime circuit to work properly. Any delay along this path

reduces the delay generated by the adaptive dead-time

circuit, thereby increasing the chances for shoot-through.

Oscillator Clock Frequency (PWM)

The clock frequency on the oscillator is set using an

external resistor, connected between R(T) pin and

ground. The frequency follows the graph, as shown in

Figure 18. The minimum clock frequency is 50kHz,

which is when R(T) pin is left open. Select the value of

R(T) as shown in the equation below. This equation is

valid for all F

Rt()

------------------------------------------------------------------kΩ=

6.25 F

where, F

OSC

For example, for F

> 50kHz:

OSC

410

×

× 2.99 105×–

OSC

is in Hz.

OSC

7

(EQ. 2)

= 80kHz, R(t) = 199kΩ.

Protection

In the FAN5099, the converter is protected against overload, short-circuit, over-voltage, and under-voltage conditions. All of these extreme conditions generate an

internal “fault latch” which shuts down the converter. For

all fault conditions, both the high-side and the low-side

drives are off, except in the case of OVP, where the lowside MOSFET is turned on until the voltage on the FB pin

goes below 0.4V. The fault latch can be reset either by

toggling the EN pin or recycling V

to the chip.

CC

Over-Current Limit (PWM)

The PWM converter is protected against overloading

through a cycle-by-cycle current limit set by selecting

resistor. An internal 10µA current source sets the

R

ILIM

threshold voltage for the output of the summing amplifier.

R

Selection and Feedforward Operation

RAMP

The FAN5099 provides for input voltage feedforward

compensation through R

© 2006 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN5099 Rev. 1.1.3 11

. The value of R

RAMP

RAMP

effec-

When the summing amplifier output exceeds this threshold level, the current limit comparator trips and the PWM

starts skipping pulses. If the current limit tripping occurs

for 16 continuous clock cycles, a fault latch is set and the

FAN5099 Wide Frequency Synchronous Buck PWM & LDO Controller

controller shuts down the converter. This shutdown feature is disabled during the start-up until the voltage on

the SS capacitor crosses 1.2V.

To achieve current limit, the FAN5099 monitors the

inductor current during the OFF time by monitoring and

holding the voltage across the lower MOSFET. The voltage across the lower MOSFET is sensed between the

PGND and the SW pins.

The output of the summing amplifier is a function of the

inductor current, R

of the current sense amplifier. With the R

of the bottom FET and the gain

DS_ON

DS_ON

method

of current sensing, the current limit can vary widely from

unit to unit. R

not only varies from unit to unit, but

DS_ON

also has a typical junction temperature coefficient of

about 0.4%/°C (consult the MOSFET datasheet for

actual values). The set point of the actual current limit

decreases in proportion to increase in MOSFET die temperature. A factor of 1.6 in the current limit set point typically compensates for all MOSFET R

DS_ON

variations,

assuming the MOSFET's heat sinking keeps its operating die temperature below 125°C.

For more accurate current limit setting, use resistor

sensing. In a resistor sensing scheme, an appropriate

current sense resistor is connected between the source

terminal of the bottom MOSFET and PGND.

Set the current limit by choosing R

K1 I

MAXRDSON

R

ILIM

------------------------------------------------------------------ 1

128

=

1.43

103•••

+

as follows:

ILIM

•

11

••

(EQ. 4)

( )

Vin

F

SWRRAMP

Vout 33.32 10

1.8

----------------------------------------------------

---------

•+

( - )

where:

R

is in KΩ.

ILIM

I

is the maximum load current.

MAX

K1 is a constant to accommodate for the variation of

MOSFET R

With K

V

= 1.6, I

1

= 1.5V, FSW = 300 kHz, R

OUT

DS(ON)

MAX

(typically 1.6).

= 20A, R

DS(ON)

= 7mΩ, VIN = 24V,

= 400 KΩ, R

RAMP

ILIM

calculates to be 323.17KΩ.

Auto Restart (PWM)

The FAN5099 supports two modes of response when the

internal fault latch is set. The user can configure it to

keep the power supply latched in the OFF state OR in

the auto restart mode. When the EN pin is tied to V

the power supply is latched OFF. When the EN pin is terminated with a 100nF to GND, the power supply is in

auto restart mode. The table below describes the relationship between PWM restart and setting on EN pin. Do

not leave the EN pin open without any capacitor.

CC

EN Pin PWM/Restart

Pull to GND OFF

V

CC

No restart after fault

Cap to GND Restart after

(Sec.) = 0.85 x C

t

DELAY

where C is in μF

The fault latch can also be reset by recycling the V

the controller.

Under Voltage Protection (PWM)

The PWM converter output is monitored constantly for

under voltage at the FB pin. If the voltage on the FB pin

stays lower than 75% of internal V

for 16 clock

REF

cycles, the fault latch is set and the converter shuts

down. This shutdown feature is disabled during startup

until the voltage on the SS capacitor reaches 1.2V.

Over-Voltage Protection (PWM)

The PWM converter output voltage is monitored constantly at the FB pin for over voltage. If the voltage on the

FB pin stays higher than 115% of internal V

clock cycles, the controller turns OFF the upper MOSFET and turns ON the lower MOSFET. This crowbar

action stops when the voltage on the FB pin comes down

to 0.4V to prevent the output voltage from becoming negative. This over-voltage protection (OVP) feature is

active when the voltage on the EN pin becomes HIGH.

Turning ON the low-side MOSFETs on an OVP condition

pulls down the output, resulting in a reverse current,

which starts to build up in the inductor. If the output overvoltage is due to failure of the high-side MOSFET, this

crowbar action pulls down the input supply or blows its

fuse, protecting the system, which is very critical.

During soft-start, if the output overshoots beyond 115%

of V

, the output voltage is brought down by the low-

REF

side MOSFET until the voltage on the FB pin goes below

0.4V. The fault latch is NOT set until the voltage on the

SS pin reaches 1.2V. Once the fault latch is set, the converter shuts down.

115 % V ref

FB

0.4V

,

Figure 22. Over-Voltage Protection

ILIM

UV

Delay

2 Clks

OV

S

>1.2V

V

SS

S

Q

R

EN

R

Thermal Fault Protection

The FAN5099 features thermal protection where the IC

temperature is monitored. When the IC junction temperature exceeds +160°C, the controller shuts down and

when the junction temperature gets down to +125°C, the

converter restarts.

REF

Q

CC

for two-

Fault

Latch

LS Drive

to

© 2006 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN5099 Rev. 1.1.3 12

LDO Section

The LDO controller is designed to provide ultra low voltages, as low as 0.8V for GTL-type loads. The regulating

loop employs a very fast response feedback loop and

small capacitors can be used to keep track of the changing output voltage during transients. For stable operation, the minimum capacitance on the output needs to be

100µF and the typical ESR needs to be around 100mΩ.

The maximum voltage at the gate drive for the MOSFET

can reach close to 0.5V below the V

of the controller.

CC

For example, for a 1.2V output, the minimum enhancement voltage required with 4.75V on VCC is 3.05V

(4.75V-0.5V-1.2V = 3.05V). The dropout voltage for the

LDO is dependent on the load current and the MOSFET

chosen. It is recommended to use low enhancement

voltage MOSFETs for the LDO. In an application where

LDO is not needed, pull up the FBLDO pin (Pin 1) higher

than 1V to disable the LDO.

The soft-start on the LDO output (ramp) is controlled by

the capacitor on the SS pin to GND. The LDO output is

enabled only when the voltage on the SS pin reaches

2.2V. Refer to Figure 9 for startup waveform.

Design Section

General Design Guidelines

Establishing the input voltage range and the maximum

current loading on the converter before choosing the

switching frequency and the inductor ripple current is

highly recommended. There are design tradeoffs choosing optimum switching frequency and ripple current.

The input voltage range should accommodate the worstcase input voltage with which the converter may ever

operate. This voltage needs to account for the cable drop

encountered from the source to the converter. Typically,

the converter efficiency tends to be higher at lower input

voltage conditions.

When selecting maximum loading conditions, consider

the transient and steady-state (continuous) loading separately. The transient loading affects the selection of the

inductor and the output capacitors. Steady-state loading

affects the selection of MOSFETs, input capacitors, and

other critical heat-generating components.

The selection of switching frequency is challenging.

While higher switching frequency results in smaller components, it also results in lower efficiency. Ideal selection

of switching frequency takes into account the maximum

operating voltage. The MOSFET switching losses are

directly proportional to F

the input voltage.

When selecting the inductor, consider the minimum and

maximum load conditions. Lower inductor values produce better transient response, but result in higher ripple

and lower efficiency due to high RMS currents. Optimum

minimum inductance value enables the converter to

and the square function of

SW

operate at the boundary of continuous and discontinuous

conduction modes.

Setting the Output Voltage (PWM)

The internal reference for the PWM controller is at 0.8V.

The output voltage of the PWM regulator can be set in

the range of 0.8V to 90% of its power input by an external resistor divider. The output is divided down by an

external voltage divider to the FB pin (for example, R1

and R

as in Figure 25). The output voltage is given

BIAS

by the following equation:

R1

V

OUT

⎛⎞

0.8V 1

----------------+

×=

⎝⎠

R

BIAS

(EQ. 5)

To minimize noise pickup on this node, keep the resistor

to GND (R

) below 10KΩ.

BIAS

Inductor Selection (PWM)

When the ripple current, switching frequency of the converter, and the input-output voltages are established,

select the inductor using the following equation:

2

V

OUT

--------------

–

V

IN

×

is the ripple current.

(EQ. 6)

L

MIN

where I

⎛⎞

V

OUT

⎝⎠

--------------------------------------------=

I

RippleFSW

Ripple

This number typically varies between 20% to 50% of the

maximum steady-state load on the converter.

When selecting an inductor from the vendors, select the

inductance value which is close to the value calculated at

the rated current (including half the ripple current).

Input Capacitor Selection (PWM)

The input capacitors must have an adequate RMS current rating to withstand the temperature rise caused by

the internal power dissipation. The combined RMS current rating for the input capacitor should be greater than

the value calculated using the following equation:

I

INPUT RMS()ILOAD MAX()

=

×

V

⎛⎞

OUT

V

IN

⎛⎞

–

⎝⎠

--------------

⎜⎟

⎝⎠

V

OUT

--------------

V

IN

2

(EQ. 7)

Common capacitor types used for such application

include aluminum, ceramic, POS CAP, and OSCON.

Output Capacitor Selection (PWM)

The output capacitors chosen must have low enough

ESR to meet the output ripple and load transient requirements. The ESR of the output capacitor should be lower

than both of the values calculated below to satisfy both

the transient loading and steady-state ripple conditions

as given by the following equation:

V

ESR

STEP

----------------------------------≤ and ESR

ΔI

LOAD MAX()

V

Ripple

-------------------≤

I

Ripple

(EQ. 8)

FAN5099 Wide Frequency Synchronous Buck PWM & LDO Controller

© 2006 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN5099 Rev. 1.1.3 13

In the case of aluminum and polymer-based capacitors,

the output capacitance is typically higher than normally

required to meet these requirements. While selecting the

ceramic capacitors for the output; although lower ESR

can be achieved easily, higher capacitance values are

required to meet the V

OUT(MIN)

restrictions during a load

transient. From the stability point of view, the zero

caused by the ESR of the output capacitor plays an

important role in the stability of the converter.

FAN5099 Wide Frequency Synchronous Buck PWM & LDO Controller

Output Capacitor Selection (LDO)

For stable operation, the minimum capacitance of 100µF

with ESR around 100mΩ is recommended. For other values, contact the factory.

Power MOSFET Selection (PWM)

The FAN5099 is capable of driving N-Channel MOSFETs

as circuit switch elements. For better performance,

FET selection should address these key parameters

■

The maximum Drain-to-Source Voltage (VDS) should be

MOS-

:

at least 25% higher than the worst-case input voltage.

■

The MOSFETs should have low QG, Q

■

The R

of the MOSFETs should be as low as possible.

DS_ON

GD

and Q

,

GS

.

In typical applications for a buck converter, the duty

cycles are lower than 20%. To optimize the selection of

MOSFETs for both the high-side and low-side, follow different selection criteria. Select the high-side MOSFET to

minimize the switching losses and the low-side MOSFET

to minimize the conduction losses due to the channel

and the body diode losses. Note that the gate drive

losses also affect the temperature rise on the controller.

For loss calculation, refer to Fairchild's Application Note

AN-6005 and the associated spreadsheet.

High-Side Losses

To understand losses in the MOSFET, follow the MOSFET switching interval shown in Figure 23. The MOSFET

gate drive equivalent circuit is shown in Figure 24

.

Figure 24. Drive Equivalent Circuit

The upper graph in Figure 23 represents Drain-toSource Voltage (V

) and Drain Current (ID) waveforms.

DS

The lower graph details Gate-to-Source Voltage (VGS)

versus time with a constant current charging the gate.

The x-axis is representative of Gate Charge (Q

CGD + CGS and controls t1, t2, and t4 timing. C

G

). C

ISS

GD

receives current from the gate driver during t3 (as VDS is

falling). Obtain the gate charge (Q

) parameters shown

G

on the lower graph from the MOSFET datasheets.

Assuming switching losses are about the same for both

the rising edge and falling edge, Q1's switching losses

occur during the shaded time when the MOSFET has

voltage across it and current through it.

Losses are given by Equations 9-11:

= P

P

UPPER

P

=

SW

P

COND

where P

PSW and P

+ P

SW

COND

VDSIL×

⎛⎞

--------------------- 2t

⎝⎠

2

V

OUT

⎛⎞

--------------

⎝⎠

V

IN

is the upper MOSFET's total losses and

UPPER

are the switching and conduction losses

COND

for a given MOSFET R

temperature (T

) and tS is the switching period (rise or

J

××

2

I

OUT

DS(ON)

F

s

SW

R

××=

DS ON()

is at the maximum junction

(EQ. 9)

(EQ. 10)

(EQ. 11)

fall time) and equals t2+t3, as shown in Figure 23.

The driver's impedance and C

period is controlled by the driver's impedance and Q

Since most of tS occurs when VGS = V

determine t2 while t3's

ISS

assume a con-

SP,

GD

stant current for the driver to simplify the calculation of t

with the following equation:

t

s

Q

GSW()

--------------------

I

Driver

Q

GSW()

----------------------------------------------≈=

VCCVSP–

⎛⎞

----------------------------------------

⎝⎠

R

+

DriverRGate

(EQ. 12)

=

.

S

Most MOSFET vendors specify QGD and QGS. Q

G(SW)

can be determined as:

Q

= QGD + QGS – QTH where QTH is the gate

G(SW)

charge required to reach the MOSFET threshold (V

Note that for the high-side MOSFET, V

equals VIN,

DS

TH

).

which can be as high as 20V in a typical portable application. Include the power delivered to the MOSFET's

) in calculating the power dissipation required for

(P

Figure 23. Switching Losses and Q

© 2006 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN5099 Rev. 1.1.3 14

g

GATE

the FAN5099.

P

is determined by the following equation:

GATE

P

Gate

QGV

××=

CCFSW

(EQ. 13)

where QG is the total gate charge to reach VCC.

Low-Side Losses

Q2 switches on or off with its parallel Schottky diode

simultaneously conducting, so the V

is proportional to VDS, Q2's switching losses are

P

SW

negligible and Q2 is selected based on R

≈ 0.5V. Since

DS

alone.

DS(ON)

Conduction losses for Q2 are given by the equation:

P

COND

where R

1D–()I

DS(ON)

highest operating junction temperature and D=V

2

× R

OUT

is the R

×=

DS ON()

of the MOSFET at the

DS(ON)

(EQ. 14)

OUT/VIN

is the minimum duty cycle for the converter.

Since D

< 20% for portable computers, (1-D) ≈ 1 pro-

MIN

duces a conservative result, simplifying the calculation.

The maximum power dissipation (P

D(MAX)

) is a function

of the maximum allowable die temperature of the lowside MOSFET, the θ

ambient temperature rise. P

and the maximum allowable

JA,

is calculated using

D(MAX)

the following equation:

P

DMAX()

T

-------------------------------------------------=

–

JMAX()TAMAX()

θ

JA

(EQ. 15)

θJA depends primarily on the amount of PCB area

devoted to heat sinking.

Selection of MOSFET Snubber Circuit

The switch node (SW) ringing is caused by fast switching

transitions due to energy stored in parasitic elements.

This ringing on the SW node couples to other circuits

around the converter if they are not handled properly. To

dampen ringing, an R-C snubber is connected across

the SW node and the source of the low-side MOSFET.

R-C components for the snubber are selected as follows:

a) Measure the SW node ringing frequency (F

ring

) with a

low capacitance scope probe.

b) Connect a capacitor (C

) from SW node to GND

SNUB

so that it reduces this ringing by half.

c) Place a resistor (R

is calculated using the following equation:

R

SNUB

R

SNUB

-----------------------------------------------=

π F

2

ringCSNUB

) in series with this capacitor.

SNUB

××

(EQ. 16)

d) Calculate the power dissipated in the snubber resisto-

ras shown in the following equation:

P

R SNUB()CSNUBVIN MAX()

where, V

is the maximum input voltage and FSW

IN(MAX)

2

(EQ. 17)

FSW××=

is the converter switching frequency.

The snubber resistor chosen should be de-rated to handle the worst-case power dissipation. Do not use wire-

wound resistors for R

SNUB

.

Loop Compensation

Typically, the closed-loop crossover frequency (F

where the overall gain is unity, should be selected to

achieve optimal transient and steady-state response to

disturbances in line and load conditions. It is recommended to keep F

below one-fifth of the switching

cross

frequency of the converter. Higher phase margin tends to

have a more stable system with more sluggish response

to load transients. Optimum phase margin is about 60°, a

good compromise between steady-state and transient

responses. A typical design should address variations

over a wide range of load conditions and over a large

sample of devices.

cross

FAN5099 Wide Frequency Synchronous Buck PWM & LDO Controller

),

V

IN

Current

Sense

V

IN

R

RAMP

Ramp

Generator

Amplifier

Summing

Amplifier

PWM

&

DRIVER

C1 R2

R

Referen c e

BIAS

C2

Q2

L

Q1

R

DC

C

R

C3

R1

V

OUT

R

L

ES

R3

Figure 25. Closed-Loop System with Type-3 Network

© 2006 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN5099 Rev. 1.1.3 15

FAN5099 Wide Frequency Synchronous Buck PWM & LDO Controller

FAN5099 has a high gain error amplifier around which

the loop is closed. Figure 25 shows a type-3 compensation network. For type-2 compensation, R3 and C3 are

not used. Since the FAN5099 architecture employs summing current mode, type-2 compensation can be used

for most applications. For for further information about

type-2 compensation networks, refer to the following:

■ Venable, H. Dean, "The K factor: A new mathematical

tool for stability analysis and synthesis," Proceedings

of Powercon, March 1983.

Type-3 Feedback Component Calculations

Use these steps to calculate feedback components:

Notation:

C0Net Output Filter Capacitance=

Gps() Net Gain of Plant = control-to-output transfer function=

L Inductor Value=

R

DSON

R

es

RLLoad Resistance=

On-State Drain-to Source Resistance of Low-side MOSFET=

Net ESR of the output filter capacitors=

Note: For critical applications requiring wide loop bandwidth using very low ESR output capacitors, use type-3

compensation.

Switching Period=

T

s

ViInput Voltage=

SW

Switching Frequency=

F

Equations:

Effective current sense resistance = (EQ. 18)

V

||

MvM

M

m

M

i

i

v

MvMi×

--------------------==

M

Current modulator DC gain = (EQ. 19)

Effective ramp amplitude =

Voltage modulator DC gain = (EQ. 21)

Plant DC gain = (EQ. 22)

M

o

Sampling gain natural frequency = (EQ. 23)

M

O

-------- L

×=

M

v

||

×()R

⎛⎞

⎝⎠

Effective inductance = (EQ. 24)

MvRiRL××

R

==

--------------------------------- M

p

M

+×

vRiRL

L

e

vRi

R

i

R

L

-------=

R

i

3.33 10

V

i

--------=

V

m

+

vMi

π

ω

------=

n

T

M

vRi

--------------------+

ω

nQz

L

7R

×=

DSON

10

s

×

×

Vi1.8–()Ts×

-------------------------------------××=

R

ramp

(EQ. 20)

(EQ. 25)

© 2006 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN5099 Rev. 1.1.3 16

Poles and Zeros of Plant Transfer Function:

Plant zero frequency = (EQ. 26)

f

z

------------------------------------------=

2 π C

1

×××

oRes

FAN5099 Wide Frequency Synchronous Buck PWM & LDO Controller

Plant 1st pole frequency = (EQ. 27)

f

-----------------------------------------------------------=

p1

2 π C

Plant 2nd pole frequency = (EQ. 28)

Plant 3rd pole frequency = (EQ. 29)

f

f

p3

p2

1

------------

2 π×

ω

--------------------------=

2 π R

1

L

⎛⎞

××

oRp

⎝⎠

1

⎛⎞

×=

--------------------

⎝⎠

CoRL×

2

Le×

n

××

p

e

-------+×

R

L

R

p

-------+

L

e

Plant gain (magnitude) response:

2

f

⎛⎞

----

+

1

⎝⎠

f

G

(f) 20 M

p

log 10

0

----------------------------------------------------------------------------------------------------------log×+×=

f

⎛⎞

-------

+ 1

1

⎝⎠

f

p1

2

z

2

f

⎛⎞

-------

+ 1

⎝⎠

f

p2

⎛⎞

-------

+××

⎝⎠

f

p3

2

f

(EQ. 30)

Plant phase response:

1– f

GP(f)∠ tan

Choose R1, R

loop. Typically F

⎛⎞

⎝⎠

BIAS

cross

----

f

z

be between 60° to 90°.

Calculate plant gain at F

vide to get the required crossover is given by:

G

AMP

--------------------------------=

Gp(F

1

cross

1– f

⎛⎞

tan

– tan

-------

⎝⎠

f

p1

to set the output voltage using EQ.5. Choose the zero crossover frequency F

1– f

⎛⎞

– tan

-------

⎝⎠

f

p2

––=

1– f

⎛⎞

-------

⎝⎠

f

p3

of the overall

cross

(EQ. 31)

should be less than 1/5th of Fsw. Choose the desired phase margin. Typically this number should

using EQ.30 by substituting F

cross

)

in place of f. The gain that the amplifier needs to pro-

cross

(EQ. 32)

The phase boost required is calculated as given in (EQ. 33).

Phase Bo ost M GP∠ (F

cross

)– 90°–=

(EQ. 33)

where M is the desired phase margin in degrees.

The feedback component values are now calculated as given in equations below:

⎧⎫

KTan

=

⎨⎬

⎩⎭

C2

Boost

⎛⎞

----------------

⎝⎠

------------------------------------------------------------------------=

2 π F

4

1

crossGAMP

C1 C2 K 1–()×=

C3

----------------------------------------------------------------=

2 π F

R2

--------------------------------------------------=

2 π F

R3

© 2006 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN5099 Rev. 1.1.3 17

R1

------------------=

K1–()

1

cross

K

×× C1×

cross

45+

K××× R3×

2

(EQ. 34)

R1××××

(EQ. 35)

(EQ. 36)

(EQ. 37)

(EQ. 38)

(EQ. 39)

FAN5099 Wide Frequency Synchronous Buck PWM & LDO Controller

Design Tools

Fairchild application note AN-6020 provides a PSPICE

model and spreadsheet calculator for the PWM regulator, simplifying external component selections and verifying loop stability. The topics covered in the datasheet

provide an understanding behind the calculations in the

spreadsheet.

The spreadsheet calculator, which is part of AN-6020

can be used to calculate all external component values

for designing around FAN5099. The spreadsheet provides optimized compensation components and generates a Bode plot to ensure loop stability.

Based on the input values entered, AN-6020’s PSPICE

model can be used to simulate Bode plots (for loop stability) as well as transient analysis that help customize

the design for a wide range of applications.

Use Fairchild application note AN-6005 for prediction of

the losses and die temperatures for the power semiconductors used in the circuit.

Both AN-6020 and AN-6005 can be downloaded from

www.fairchildsemi.com/apnotes/

.

Layout Considerations

The switching power converter layout needs careful

attention and is critical to achieving low losses and clean

and stable operation. Below are specific recommendations for a good board layout:

■ Keep the high current traces and load connections as

short as possible.

■ Use thick copper boards whenever possible to

achieve higher efficiency.

■ Keep the loop area between the SW node, low-side

MOSFET, inductor, and the output capacitor as small

as possible.

■ Route high dV/dt signals, such as SW node, away

from the error amplifier input/output pins. Keep components connected to these pins close to the pins.

■ Place ceramic de-coupling capacitors very close to

VCC pin.

■ All input signals are referenced with respect to AGND

pin. Dedicate one layer of the PCB for a GND plane.

Use at least four layers for the PCB.

■ Minimize GND loops in the layout to avoid EMI-related

issues.

■ Use wide traces for the lower gate drive to keep the

drive impedances low.

■ Connect PGND directly to the lower MOSFET source

pin.

■ Use wide land areas with appropriate thermal vias to

effectively remove heat from the MOSFETs.

■ Use snubber circuits to minimize high-frequency

ringing at the SW nodes.

■ Place the output capacitor for the LDO close to the

source of the LDO MOSFET.

© 2006 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN5099 Rev. 1.1.3 18

Application Board Schematic

VIN = 3 to 24V; V

=1.5V at 20A; F

OUT

OSC

FAN5099 Wide Frequency Synchronous Buck PWM & LDO Controller

= 300kHz.

Figure 26. Application Board Schematic

Bill of Materials

Vendor Part

Part Description Quantity Designator Vendor

Capacitor, 1500pF, 10%, 50V, 0603, X7R 1 C1 Panasonic ECJ1VB1H152K

Capacitor, 220pF, 5%, 50V, 0603, NPO 1 C2 Panasonic ECJ1VC1H221J

Capacitor, 3300pF, 10%, 50V, 0603, X7R 1 C3 Panasonic ECJ1VB1H332K

Capacitor, 0.1µF, 10%, 25V, 0603, X7R 4 C4, C5, C6, C15 Panasonic ECJ1VB1E104K

Capacitor, 0.22µF, 20%, 25V, 0603, X7R 2 C7, C8 TDK C1608JB1E224K

Capacitor, 0.01µF, 10%, 50V, 0603, X7R 1 C9 Panasonic ECJ1VB1H103K

Capacitor, 820µF, 20%, 10X20, 25V, 20mΩ, 1.96A 2 C10, C11 Nippon-Chemicon KZH25VB820MHJ20

Capacitor, 820µF, 20%, 8X8, 2.5V, 7mΩ, 6.1A 1 C17 Nippon-Chemicon PSC2.5VB820MH08

Capacitor, 560µF, 20%, 8X11.5, 4V, 7mΩ, 5.58A 3 C12, C13, C14 Nippon-Chemicon PSA4VB560MH11

Capacitor, 3300pF, 10%, 50V, 0805, X7R 1 C16 Panasonic ECJ2VB1H332K

Connector Header 0.100 Vertical, Tin – 2 Pin 1 J1 Molex 22-28-4360

Terminal Quickfit Male .052"Dia.187" Tab 6 J2–J7 Keystone 1212

Inductor, 1.8µH, 20%, 26Amps Max, 3.24mΩ 1 L1 Inter-Technical SC5018-1R8M

MOSFET N-CH, 32mΩ, 20V, 21A, D-PAK, FSID: FDD6530A 1 Q1 Fairchild Semiconductor FDD6530A

MOSFET N-CH, 8.8mΩ, 30V, 50A, D-PAK, FSID: FDD6296 1 Q2 Fairchild Semiconductor FDD6296

MOSFET N-CH, 6mΩ, 30V, 75A, D-PAK, FSID: FDD6606 2 Q3, Q4 Fairchild Semiconductor FDD6606

Resistor, 5.11k, 1%, 1/16W 1 R1 Panasonic ERJ3EKF5111V

Resistor, 12.7k, 1%, 1/16W 1 R2 Panasonic ERJ3EKF1272V

Resistor, 825, 1%, 1/16W 1 R3 Panasonic ERJ3EKF8250V

Resistor, 25.5k, 1%, 1/16W 1 R4 Panasonic ERJ3EKF2552V

Resistor, 210k, 1%, 1/16W 1 R5 Panasonic ERJ3EKF2103V

Resistor, 453k, 1%, 1/16W 1 R6 Panasonic ERJ3EKF453V

Resistor, 10k, 1%, 1/16W 1 R7 Panasonic ERJ3EKF1002V

Resistor, 4.99k, 1%, 1/16W 1 R8 Panasonic ERJ3EKF4991V

Resistor, 200, 1%, 1/4W 1 R9 Panasonic ERJ8ENF2000V

Resistor, 5.90k, 1%, 1/16W 1 R10 Panasonic ERJ3EKF5901V

Resistor, 2.2, 1%, 1/4W 1 R11 Panasonic ERJ8RQF2R2V

Connector Header 0.100 Vertical, Tin – 1 Pin 3 TP1, TP2, Vcc Molex 22-28-4360

IC, System Regulator, TSSOP16, FSID: FAN5099 1 U1 Fairchild Semiconductor FAN5099

Number

© 2006 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN5099 Rev. 1.1.3 19

Application Board Schematic

VIN = 3 to 24V; V

=1.5V at 20A; F

OUT

OSC

Figure 27. Application Board Schematic

FAN5099 Wide Frequency Synchronous Buck PWM & LDO Controller

= 80kHz.

Bill of Materials

Vendor Part

Part Description Quantity Designator Vendor

Capacitor, 3900pF, 10%, 50V, 0603, X7R 1 C1 Panasonic ECJ1VB1H392K

Capacitor, 680pF, 5%, 50V, 0603, NPO 1 C2 Panasonic ECJ1VC1H681J

Capacitor, 6800pF, 10%, 50V, 0603, X7R 1 C3 Panasonic ECJ1VB1H682K

Capacitor, 0.1µF, 10%, 25V, 0603, X7R 4 C4, C5, C6, C15 Panasonic ECJ1VB1E104K

Capacitor, 0.22µF, 20%, 25V, 0603, X7R 2 C7, C8 TDK C1608JB1E224K

Capacitor, 0.01µF, 10%, 50V, 0603, X7R 1 C9 Panasonic ECJ1VB1H103K

Capacitor, 820µF, 20%, 10X20, 25V, 20mΩ, 1.96A 2 C10, C11 Nippon-Chemicon KZH25VB820MHJ20

Capacitor, 820µF, 20%, 8X8, 2.5V, 7mΩ, 6.1A 1 C17 Nippon-Chemicon PSC2.5VB820MH08

Capacitor, 560µF, 20%, 8X11.5, 4V, 7mΩ, 5.58A 3 C12, C13, C14 Nippon-Chemicon PSA4VB560MH11

Capacitor, 3300pF, 10%, 50V, 0805, X7R 1 C16 Panasonic ECJ2VB1H332K

Connector Header 0.100 Vertical, Tin – 2 Pin 1 J1 Molex 22-28-4360

Terminal Quickfit Male .052"Dia.187" Tab 6 J2–J7 Keystone 1212

Inductor, 4.0µH@25A, 9.0µH@0A, 25A max, 4.4mΩ, wound

on T80-52B core (Micrometals), 12 turns, 14 AWG wire

MOSFET N-CH, 32mΩ, 20V, 21A, D-PAK, FSID: FDD6530A 1 Q1 Fairchild Semiconductor FDD6530A

MOSFET N-CH, 8.8mΩ, 30V, 50A, D-PAK, FSID: FDD6296 1 Q2 Fairchild Semiconductor FDD6296

MOSFET N-CH, 6mΩ, 30V, 75A, D-PAK, FSID: FDD6606 2 Q3, Q4 Fairchild Semiconductor FDD6606

Resistor, 5.11k, 1%, 1/16W 1 R1 Panasonic ERJ3EKF5111V

Resistor, 10.5k, 1%, 1/16W 1 R2 Panasonic ERJ3EKF1052V

Resistor, 845, 1%, 1/16W 1 R3 Panasonic ERJ3EKF8450V

Resistor, 200k, 1%, 1/16W 1 R4 Panasonic ERJ3EKF2003V

Resistor, 287k, 1%, 1/16W 1 R5 Panasonic ERJ3EKF2873V

Resistor, 453k, 1%, 1/16W 1 R6 Panasonic ERJ3EKF453V

Resistor, 10k, 1%, 1/16W 1 R7 Panasonic ERJ3EKF1002V

Resistor, 4.99k, 1%, 1/16W 1 R8 Panasonic ERJ3EKF4991V

Resistor, 200, 1%, 1/4W 1 R9 Panasonic ERJ8ENF2000V

Resistor, 5.90k, 1%, 1/16W 1 R10 Panasonic ERJ3EKF5901V

Resistor, 2.2, 1%, 1/4W 1 R11 Panasonic ERJ8RQF2R2V

Connector Header 0.100 Vertical, Tin – 1 Pin 3 TP1, TP2, Vcc Molex 22-28-4360

IC, System Regulator, TSSOP16, FSID: FAN5099 1 U1 Fairchild Semiconductor FAN5099

1 L1 Custom made

Number

© 2006 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN5099 Rev. 1.1.3 20

Typical Application Board Layout

FAN5099 Wide Frequency Synchronous Buck PWM & LDO Controller

Figure 28. Assembly Diagram

Figure 29. Top Layer

Figure 31. Mid Layer 2

Figure 32. Bottom Layer

Figure 30. Mid Layer 1

© 2006 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN5099 Rev. 1.1.3 21

Mechanical Dimensions

16-Lead TSSOP

All dimensions are in millimeters unless otherwise specified.

FAN5099 Wide Frequency Synchronous Buck PWM & LDO Controller

Figure 33. 16-Lead Thin Shrink Small Outline Package

© 2006 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN5099 Rev. 1.1.3 22

Mechanical Dimensions (continued)

16-Lead SOIC

All dimensions are in millimeters unless otherwise specified.

FAN5099 Wide Frequency Synchronous Buck PWM & LDO Controller

Figure 34. 16-Lead Molded Small Outline Package

© 2006 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN5099 Rev. 1.1.3 23

FAN5099 Wide Frequency Synchronous Buck PWM & LDO Controller

© 2006 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN5099 Rev. 1.1.3 24

Loading...

Loading...