Page 1

Programmer’s Manual DMX® Emulation

for 7106, 7206 and 7010 Series

Page 2

The Programmer's Manual is designed for the following printers:

7106, 7206, 7206-300 and 7010 Series

Copyright © August 2010, DASCOM Europe GmbH

Page 3

1-1

Chapter 1

Command Interpreter

and Command System

1.1 Outline 1-2

1.2 Outline of Command System 1-2

1.3 Outline of Interpreter 1-4

1.4 Outline of Label Format Data 1-5

1.5 Outline of Label Printing Method 1-7

1.6 Control Code Specification 1-8

1.6.1 System Level Immediate Execution Commands 1-9

1.6.2 System Level Occasional Execution Commands 1-14

1.6.3 Label Format Commands 1-51

Page 4

1-2

1.1 Outline

Generally, when labels of graphics and bar codes are printed by a

line printer, print data is converted into bit map data in the computer and

transmitted to the printer for printing. In this process the host computer

has to generate the bit map data and send it to the printer, this reduces

throughput leading to slow printing and host computer operation.

This printer incorporate many functions such as a variety of fonts, bar

code generators, and graphic commands along with high speed

processing, so high-quality labels can be printed easily at high speeds

when simple commands are transmitted from the host computer. The

computer processing in generating labels is reduced enabling it to

undertake more processing.

1.2 Outline of Command System

Commands for this printer consist of a string of ASCII characters and

end with a "CR" (decimal: 13, hex: 0D). Generally, commands are

classified into two types, that is, system level commands and label format

commands.

System level commands are used in system level operations,

including printer output, sensor selection and memory maintenance.

Label format commands are used in the definition of printing contents

such as character data, bar code data, printing speed, and print density.

System level commands start with ASCII "SOH" ($01) or ASCII "STX"

($02).

Commands that start with “SOH” are requested for the real-time

execution. When received, they are executed immediately even during

printing. Commands that start with “STX” enter the buffer area and are

executed in the order of data reception.

Label format commands follow the system level commands' "STX" +

"L" and end with a "CR."

(For details, see 1.3 Outline of Interpreter and 1.4 Outline of Label

Format Data.)

Page 5

1-3

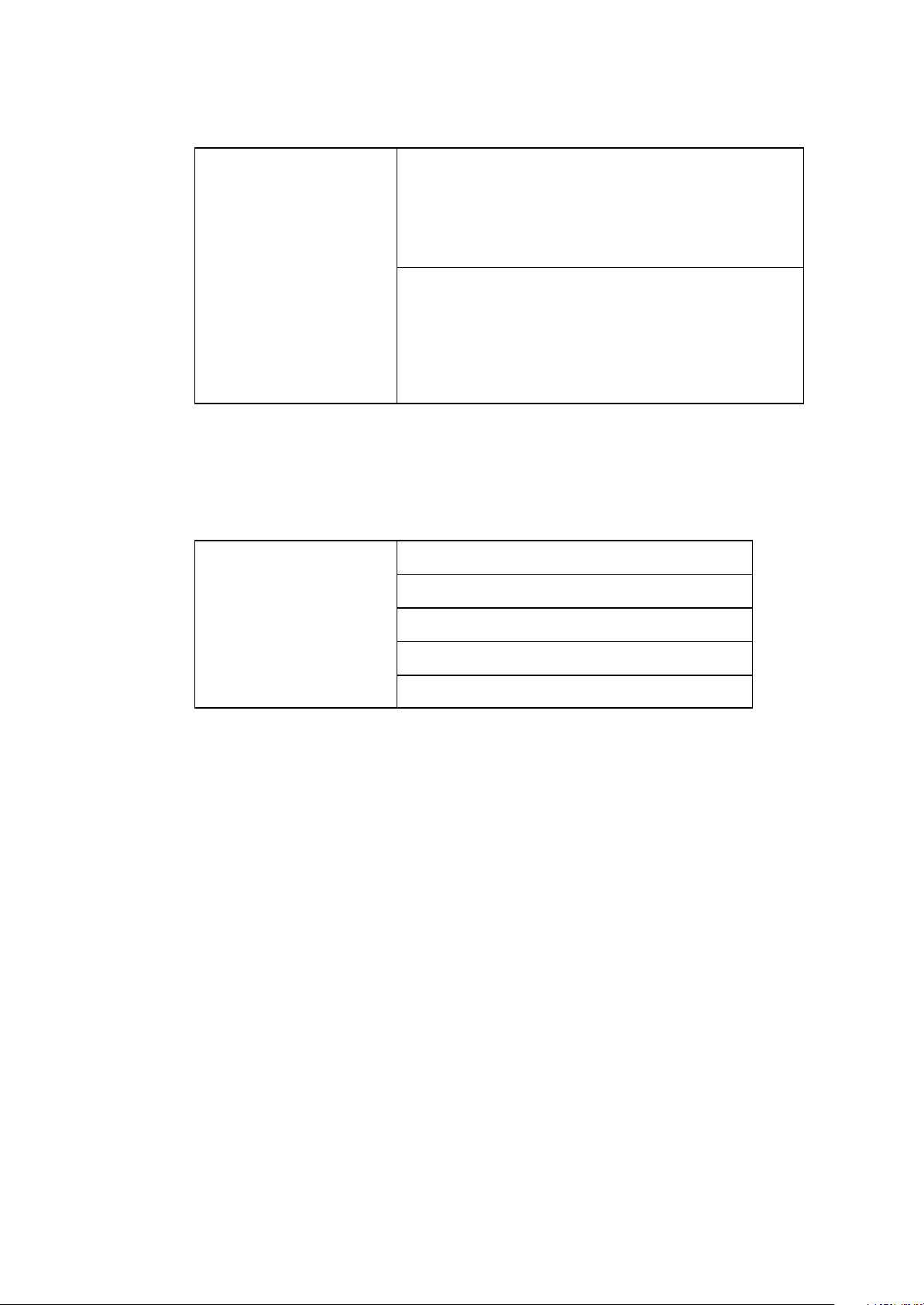

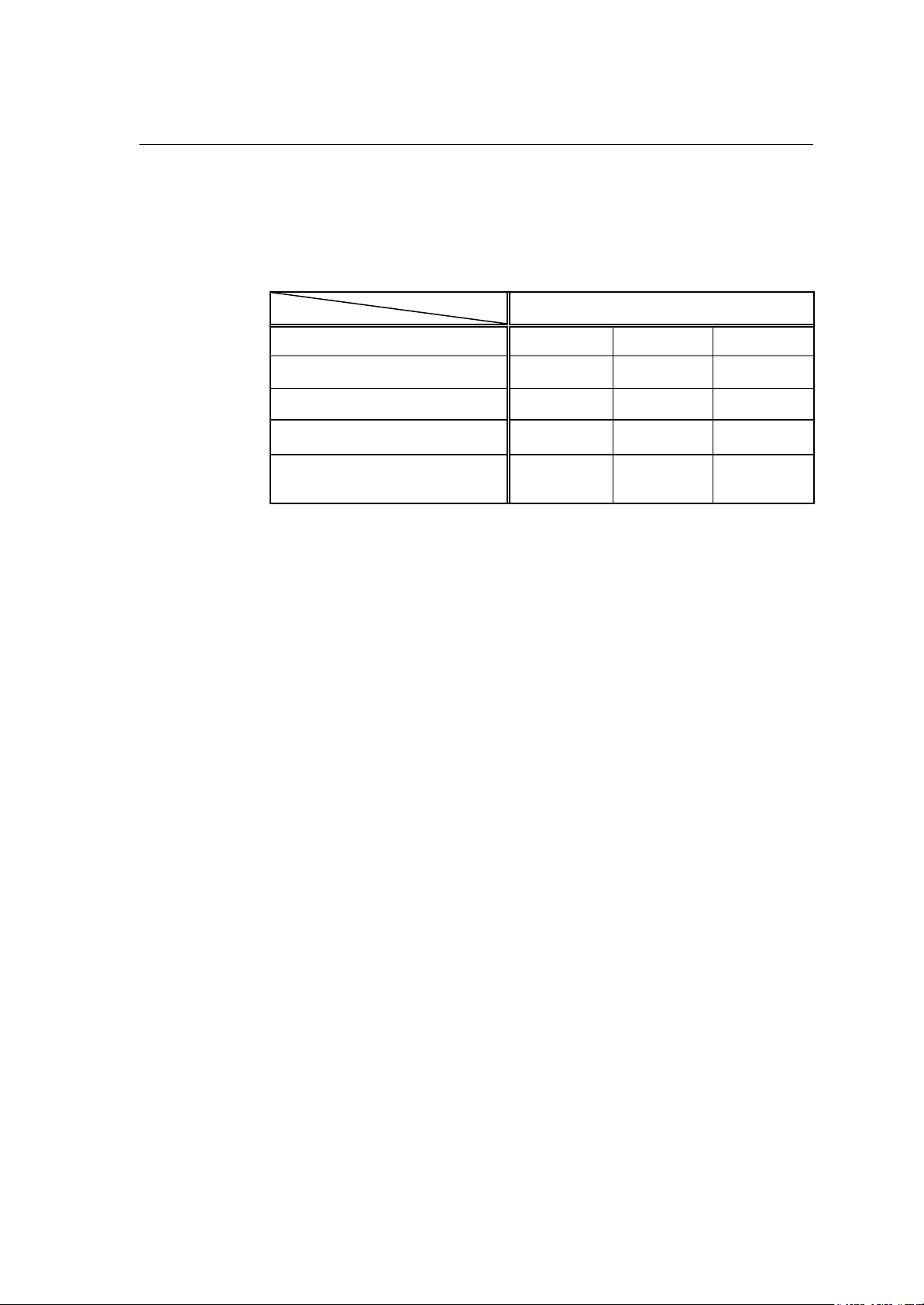

Fig. 1 Command summary

System level commands

Start with "SOH" or "STX"

and end with a “CR”

Commands which start with "SOH"

Executed as soon as they are received

(For example: printing halt, output of printer status, etc.)

Commands which start with "STX"

Executed in order after they are received into the

reception buffer

(For example: sensor switching, memory card

maintenance, etc.)

"STX" + "L" ↓ ↑ "E" (with printing)

"X" (without printing)

Label format commands Print parameter control

End with a "CR" Character data definition commands

Bar code definition commands

Graphic commands

Other commands

Page 6

1-4

1.3 Outline of Interpreter

Two types of interpreters are used for this printer; system level and

label format interpreters. When power is turned on, the system level

interpreter is selected and the data received is processed in the system

level interpreter and system level commands are executed.

Changing to the label format interpreter to start generating label data

is executed with system level commands. When the system level

interpreter receives the system level command "STX" + "L," it changes to

the label format interpreter. The commands after this are regarded as

label format commands and label format starts.

The label format interpreter does not need headers such as "SOH"

and "STX." The data for printing data format is delimited by a "CR" and

then transmitted.

The label format command “E” or “X” executes changing to the

system level interpreter from the label format interpreter. When label

format ends with "E," defined data is printed and the system level

interpreter is started. When label format ends with "X," the system level

interpreter is started without printing.

Page 7

1-5

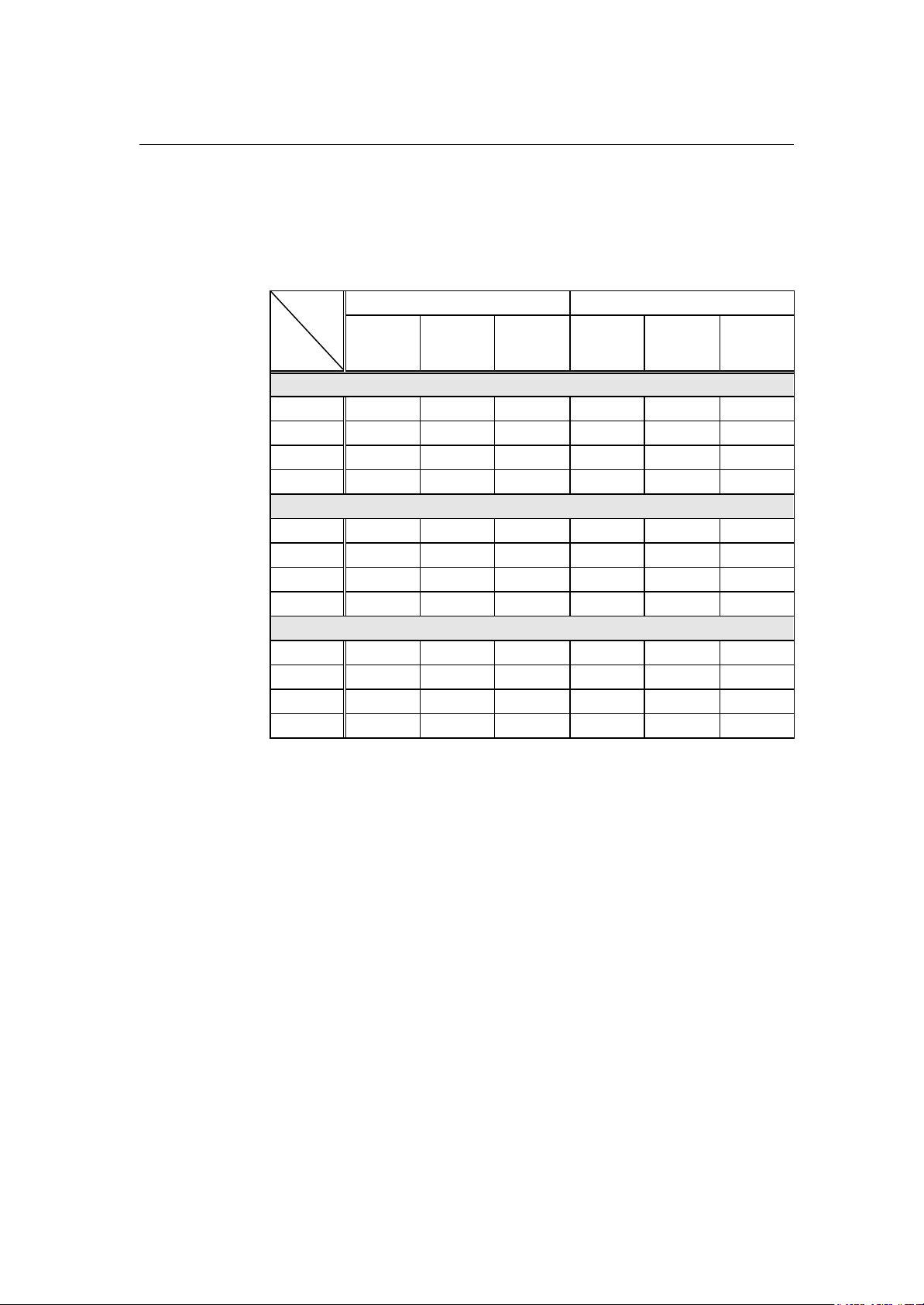

1.4 Outline of Label Format Data

This printer prints label format data by using memory space of the

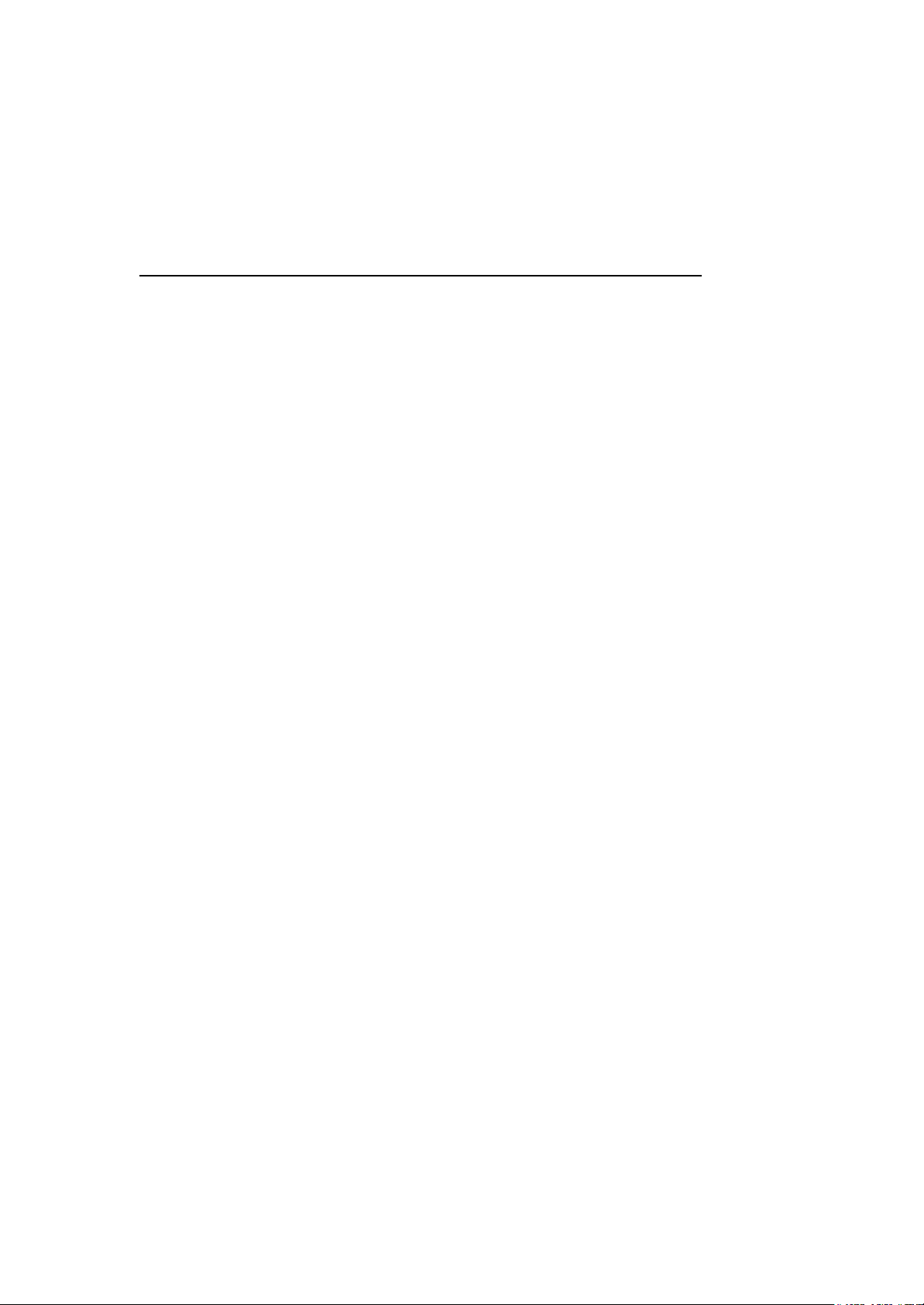

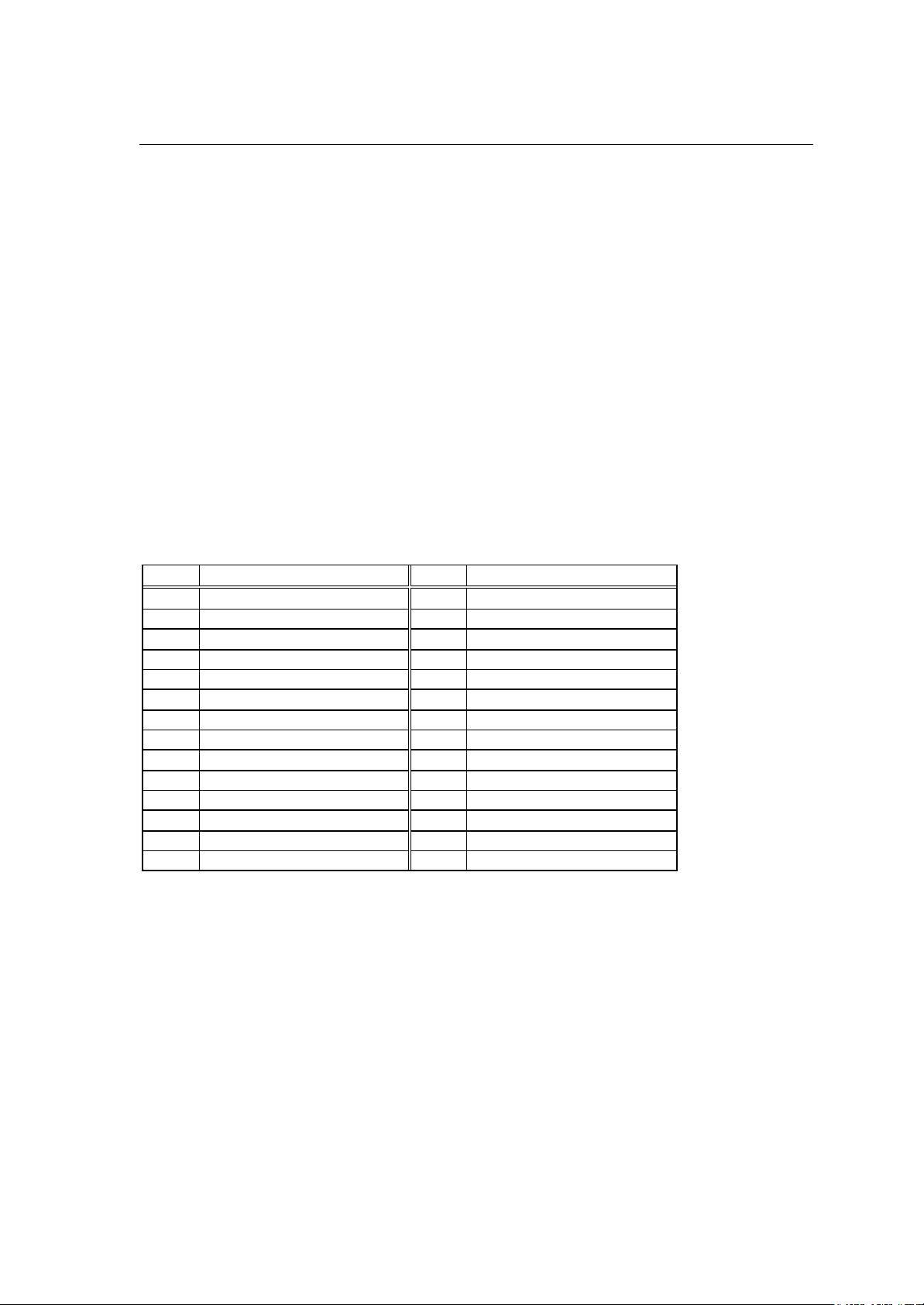

following size.

Model

area 7206 7106

7010

Reception buffer area [bytes] 16K

Field register data area [bytes] 20K

Number of maximum print fields 400

Global register area [bytes] 1K

Bit map area [bytes] 1892K

Maximum page length [inches] 32

1 Reception buffer area

The reception buffer area is a ring data buffer area (software FIFO)

under software control. Basically, all commands and data transmitted

from the host computer are buffered once into this area and then

executed in the order of buffering to complete communications from

the host computer in the shortest possible time. However, some

system level commands (such as those starting with "SOH" for print

halt) which require real-time execution are executed immediately after

being received.

2 Field register area

A string of character data and bar code data is regarded as one field

that includes information such as type, print position, and size. The

field register area is an area that encloses the label format field. The

label format interpreter analyzes the format data received, stores it

once, and then generates a bit map. If there are any problems in the

data received, the data that is being analyzed is discarded without

being stored in the field register area. The field data is given a control

number for every field (1, 2, · · 400) when the data is stored. This

printer has a field register area of 20,000 characters and can print a

maximum of 400 different types of field data per label.

3 Global register area

The global register area is an area which stores field data that is

repeatedly used. A part of the data (character string and bar code

data) in the field register is stored in the global register area and used

as requested. The data stored in the global register area is given a

control number starting with A (A, B, ----- , P). The data set in the

global register is stored while formatting for one label is performed

(until the label format interpreter returns control to the system level

interpreter) so it can be reused for data definition within the same

label.

Page 8

1-6

4 Bit map area

The bit map area is a buffering area for output data. The data in this

area is generated by a rasterizer according to the data in the field

data area and corresponds to individual dots that are generated on

the label during printing. The data of the bit map area is printed on the

label with high quality and at high speed by means of the printer

control program and exclusive thermal control circuit.

Page 9

1-7

1.5 Outline of Label Printing Method

This printer has two label printing methods, one is that all label format

data received is printed, and the other is that format data which has been

received beforehand, is printed or partially modified and printed.

1 All data received method

・ ASCII code "STX" + "L" sets the printer to label format mode.

The printer clears the field register area and control is transferred

from the system level interpreter to the label format interpreter.

At this time, use of label format commands is enabled.

・ Printing data such as characters, bar codes and graphics is

transmitted. Each data set has a special field structure that

includes information such as print position and size. The label

format interpreter, stored in the field register area checks the

printing data received, and generation of bit map data is then

started. Powerful commands such as specification of the number

of copies, characters strings and automatic increasing or

decreasing of bar code data are included in the label format

commands. In addition, the format data stored in the global

register area can be read out and used.

・ After completing label formatting, an ASCII "E" is transmitted.

The printer prints the labels specified by the data in the field

register area and control is then returned from the label format

interpreter to the system level interpreter.

2 Using forma tted data

・ In this mode, fixed format labels are printed. While label data

formatting is completed, an ASCII "X" is transmitted instead of "E."

The printer forms the field register area and completes formatting

without printing and control is returned to the system level

command processor. From this point on, the system level

command processor allows the printer to print fixed format labels

by using the format data in the field register area.

・ If ASCII "STX" + "G" is transmitted to the system level command

processor, the labels are printed according to the contents of the

specified field register.

In addition, change of data and number of copies is provided.

(Only data can be changed. Format information such as print

position and size cannot be changed.) Printing with the "STX" +

"G" command can be performed repeatedly.

Page 10

1-8

1.6 Control Code Specification

1 Outline

・ This printer is connected to the computer via a serial interface and

prints characters and bar codes at the requested print position on

the label.

・ The printer has a data area of 20,000 characters. This character

data can be stored in up to 400 different fields in single buffer

mode (200 different fields in double buffer mode) Each field stores

attributes such as print position, rotation angle, font specification,

and expansion factor (called attribute information). Machine

control commands for print density or printing speed setting are

used in addition to printing data control commands.

・ Basically, this printer prints labels by means of bi-directional

communications with the computer via the serial interface. The

printer not only prints data, but also transmits information such as

label and printer settings to the computer. The computer and

printer communicate so that the printer can receive correct data

from the computer and perform optimum printing.

Also, the printer has the parallel interface (centronics) as a

standard but in this case bi-directional communications are not

used, so data cannot be transmitted from the printer.

Page 11

1-9

1.6.1 System Level Immediate Execution Commands

These commands are executed as soon as the printer receives them.

They begin with "SOH," i.e. [01].

Command reset [01] #

Printer status transmission request

[01] A

(8-byte packet)

Pause [01] B

Stop/cancel [01] C

SOH command shutdown [01] D

Transmission of number of remaining sheets to be issued [01] E

Printer status transmission request (1-byte packet) [01] F

Error status transmission request

[01] |

(4-byte pack et)

Page 12

1-10

Command reset

250ms).

Code

Function

[01] #

Initialized equivalent to power is turned on. Buffer and on-board

memory contents are initialized. Command setting for previous

commands is initialized.

Transmission

data

Caution

(XOFF) T (XON)

R (XON) for hardware reset.

Since printer executes reset immediately after receiving this

command, it clears un-printed data in the reception buffer. When

using this command, you are recommended to check printing

completion first, then send this command. This com mand will let the

printer off, thus ensure the printer is ready mode state before sending

this command.

Printer status transmission request (8-byte packet)

Code

[01] A

Function If this command is received, printer will send data on current printer

status to the computer with the following 8 ASCII characters.

1

2

3

4

5

6

7

8

Command interpreter in action

Paper end

Ribbon end

Batch processing (printing)

Printing

Pause

Waiting for peeling

Spare

Y or N

Y or N

Y or N

Y or N

Y or N

Y or N

Y or N

N (always)

After sending 8 ASCII characters, code [0D] hex is added. Y and N

each is hex digit and [59] hex and [4E] hex.

Caution

Printer sends data on printer status to the computer as soon as it

receives this command (in a period of approx. 150ms Therefore, the computer must be ready to receive data from the

printer immediately after receiving this command.

Page 13

1-11

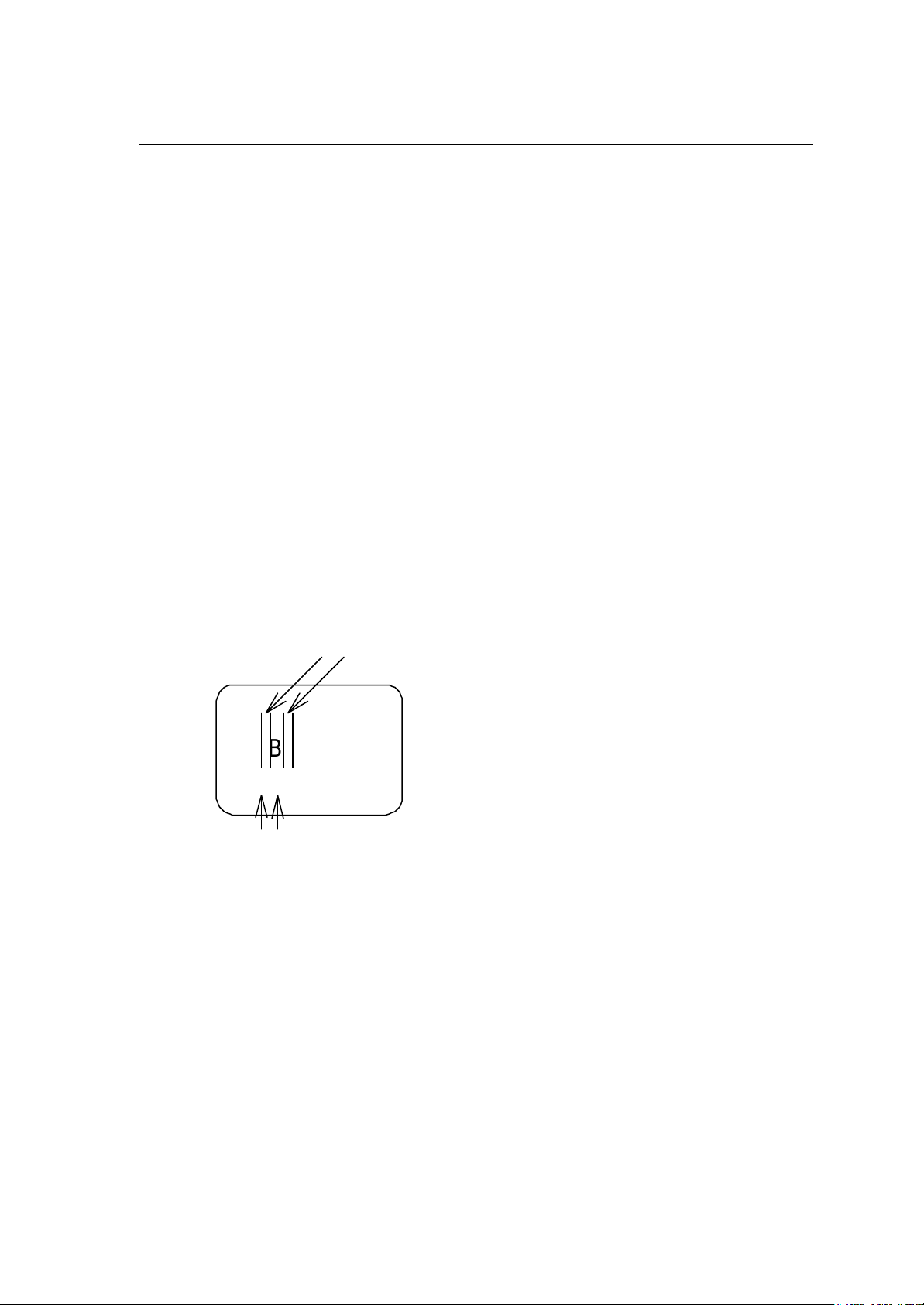

Printer status

Relationship between command interpreter, batch processing and printing

Normal label printing puts the printer in the above status. The printer, however,

operates with a double buffer, so if the next printing data is received during batch

processing, both interpreter operation and batch processing (printing) may be

performed simultaneously.

Difference between batch processing and printing

As shown in the diagram, printing start and stop may be repeated within a single

cycle of batch processing. Therefore, use the operations properly (peeling,

auto-cutter, etc.) as required.

Pause

Code

Function

[01] B

Printing temporarily stops and resumes. Toggles printer pause on and

off. Pause on and off by using this command is performed in the same

way as operated from the control panel. Pause on from the control

panel can change to pause off with this command.

Stop/cancel

Code

Function

[01] C

Printing stops. Performed in the same way as operated from the Stop

key on the control panel. With this command, printer stops on

completion of the current printing label and will clear data in the

reception buffer.

SOH command shutdown

Code

Function

[01] D

After receiving this command, printer ignores immediate execution

commands starting with control code [01] even if those commands are

received.

To send nothing for five seconds can automatically cancel the setting.

Page 14

1-12

Transmission of number of remaining sheets to be issued

Code

Function

[01] E

If this command is received, printer will send data on the number of

remaining sheets to be issued for the current printing to the computer

with 4 ASCII characters.

The [0D] hex code is added to the end of the 4-digit transmission data.

Caution

Printer sends data on the number of remaining sheets to be issued to

the computer as soon as it receives this command (in a period of

approx. 150ms - 250ms). Therefore, the computer must be ready to

receive data from the printer immediately after receiving this

command.

Printer status transmission request (1-byte packet)

Code

Function

[01] F

If this command is received, printer will send 1-byte packet data on

current printer status to the computer. The contents of 1-byte packet

data transmitting from the printer are as follows:

Caution

Bit

1

2

3

4

5

6

7

8

Description

Command interpreter in action

Paper end

Ribbon end

Batch processing (printing)

Printing

Pause

Waiting for peeling

Spare

YES NO

1 or 0

1 or 0

1 or 0

1 or 0

1 or 0

1 or 0

1 or 0

0

(always)

The [0D] hex code is added to the end of transmission data.

Printer sends data on printer status to the computer as soon as it

receives this command. Therefore, the computer must be ready to

receive data from the printer immediately after receiving this

command.

Page 15

1-13

Error status transmission request (4-byte packet)

Code

Function

[01] I

After receiving this command, printer sends 4-byte data on current

conditions inside the printer to the host PC. Shown below are contents

of the 4-byte data to be sent from the printer.

Byte

1

2 1

3 1

4 1

Bit

Description

1

Battery exhaustion (Unsupported)

2

Head at low temperature (Unsupported)

3

Main PCB at low temperature (Unsupported)

4

Wear and tear on a head

5

Spare

6

Pause

7

Fixed

8

Fixed

Spare

2

Head overheat

3

Spare

4

Spare

5

Mechanism is exposed.

6

Paper end

7

Fixed

8

Fixed

Paper out

2

Ribbon end

3

Overheating of Main PCB (Unsupported)

4

Spare

5

Abnormality in option boards (Unsupported)

6

Abnormality in auto cutter

7

Fixed

8

Fixed

Fan motor stop (Unsupported)

2

Spare

3

Spare

4

Spare

5

Spare

6

Error is occurring.

7

Fixed

8

Fixed

YES NO

1 or 0

1 or 0

1 or 0

1 or 0

0 (always)

1 or 0

1 (always)

0 (always)

0 (always)

1 or 0

0 (always)

0 (always)

1 or 0

1 or 0

1 (always)

0 (always)

1 or 0

1 or 0

1 or 0

0 (always)

1 or 0

1 or 0

1 (always)

0 (always)

1 or 0

0 (always)

0 (always)

0 (always)

0 (always)

1 or 0

1 (always)

0 (always)

The [0D] hex code is added to the end of transmission data.

Caution

Printer sends data on printer status to the computer as soon as it receives this

command. Therefore, the computer must be ready to receive data from the

printer immediately after receiving this command.

Page 16

1-14

1.6.2 System Level Occasional Execution Commands

These commands are executed as soon as the printer receives them.

They begin with "STX," i.e. [02].

Setting date and time [02] A

Setting feedback character transmission validness [02] a

Date and time transmission request [02] B

Setting paper length for continuous paper [02] c

Setting two -page edit mode (double buffer) [02] d

Changing number of prints for edited format [02] E

Setting edge sensor selection [02] e

Label one sheet feed [02] F

Setting peeling (cutting) position [02] f

Printing edited or formerly-printed format [02] G

Graphics data block input command [02] I

TrueType fonts downloading command [02] i

Pause per label printing [02] J

Extension system command (printer settings) [02] KD

Extension system command (setting peeling or cutting position) [02] Kf

Setting Y-code-transmission-to-serial-port request [02] k

Specifying printing contents setting start [02] L

Setting maximum label length [02] M

Changing units from inch to metric system [02] m

Changing units from metric to inch system [02] n

Setting printing position [02] O

Paper cut [02] o

Setting dump mode start [02] P

Pause in occasional execution [02] p

Clearing all memory module contents [02] Q

Clearing memory module contents [02] q

Setting reflective paper sensor selection [02] r

Setting paper feed speed [02] S

Setting one-page edit mode (single buffer) [02] s

Page 17

1-15

Printing quality test pattern [02] T

Rewriting specified format register contents [02] U

Setting memory switch contents [02] V

Printer version numb er transmission request [02] v

Information-in-memory-module transmission request [02] W

Testing flash memory [02] w

Default module selection [02] X

Clearing memory module contents (in file units) [02] x

TrueType fonts Symbol Set Selection [02] y

Printing printer status [02] Z

Select Command Set [02][1B] G

Setting printing methods [02][1B] M

Head disconnection detection [02][1B] T

Setting ejection (tear-off) [02][1B] t

Setting label width [02][1B] w

Page 18

1-16

Setting date and time

4

Code

Setting

[02] A, w, mm, dd, yyyy, hh, MM, j j j

w Sun. 0 Mon. 1 Tues. 2 Weds. 3 Thurs.

Fri. 5 Sat. 6

mm Month 01 - 12

dd Day 01 - 31

yyyy Year 4 digits

hh Hour (24-hour display)

MM Minute 00 - 59

j j j Spare 000 fixed

Function

Example

Input data

Sets date and time on the calendar stored in the printer.

Input data below represents 15:30 Saturday 7 July 2001.

[02]A607072001 1530000

Setting feedback character transmission validness

Code

Function

Caution

[02] a

With this command, printer transmits [1E] every one label printing to

the computer and on completion of one batch printing, [1F] is

transmitted to the computer.

After one label printing [1E]

On completion of one batch printing [1F]

When receiving invalid label format command [07]

The [0D] hex code is not added to the end of the transmission data.

Page 19

1-17

Date and time transmission request

4

(c0250)

Code

Data format

Function

Example

[02] B

w, mm, dd, yyyy, hh, MM, j j j

w Sun. 0 Mon. 1 Tues. 2 Weds. 3 Thurs.

Fri. 5 Sat. 6

mm Month 01 - 12

dd Day 01 - 31

yyyy Year 4 digits

hh Hour (24-hour display)

MM Minute 00 - 59

j j j Total number of days from the 1st of January

Data on the contents of the calendar (date and time) stored in the

printer is transmitted to the computer. Data format transmitted from

the printer is described below. The [0D] hex code is added to the end

of the transmission data.

Reception data below represents 15:30 Saturday 7 July 2001, which is

transmitted from the printer.

Reception

data

6070720011530188[0D]

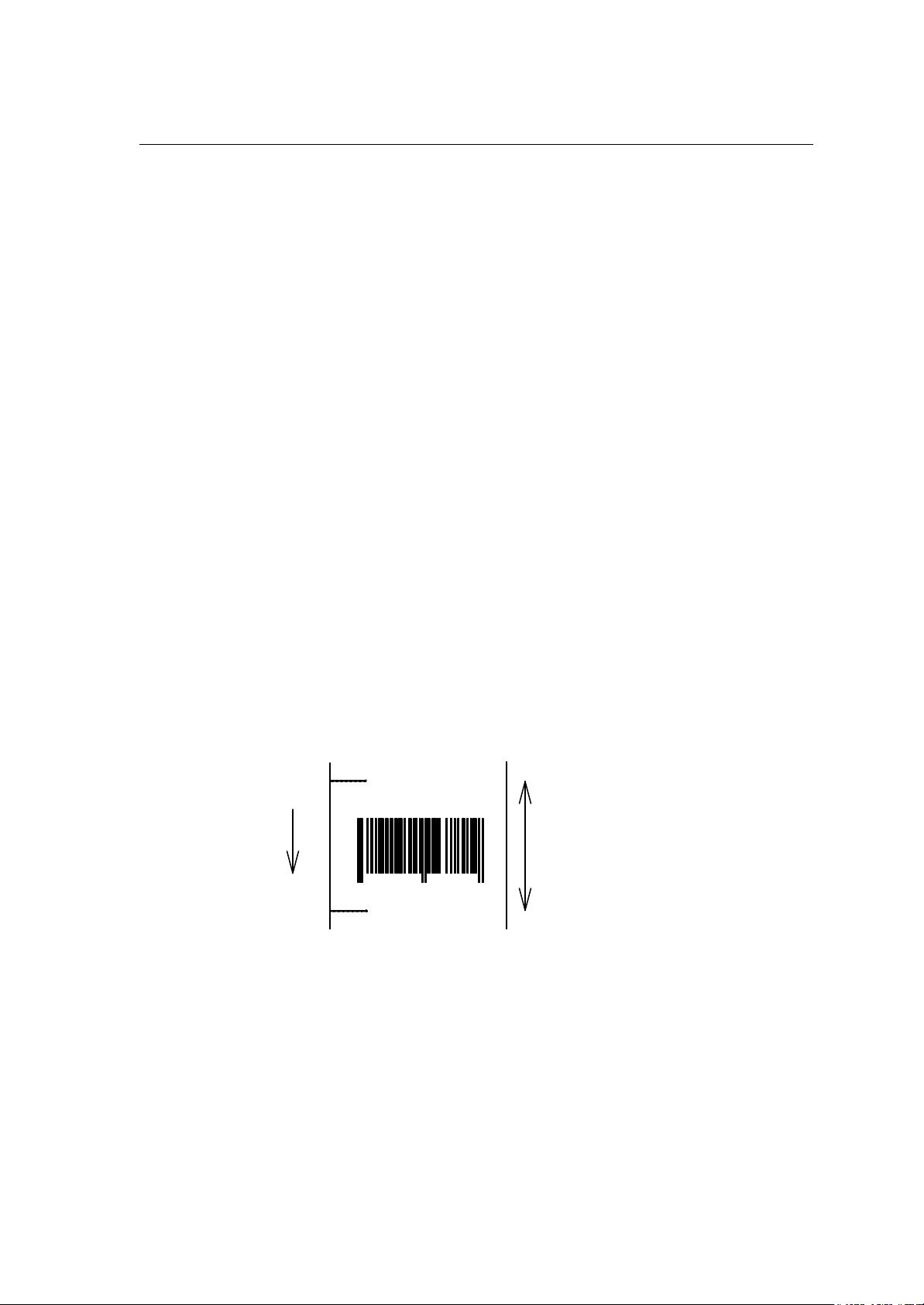

Direction of feed

901234 567894

4

Paper length

2.5 in

Page 20

1-18

Setting paper length for continuous paper

(c0250)

Code

Unit

Setting

Function

Example

Input data

[02] c nnnn

0.01 inch

nnnn 4-digit data Initialization value: 0000

Inch system 0001 – 9999 (0.01 – 99.99 inches)

Metric system 0001 – 9999 (0.1 – 999.9 mm)

Sets label length for continuous paper. Length of label format is

specified with this command. Label is cut in the length with this setting

when using auto-cutter. When using label paper, 0000 must be set.

Example of input data below represents paper length of 2.5-inch

setting.

[02] n Sets units to inch system

[02] c 0250 Sets paper length to 2.5 inches

for continuous paper

[02] L Starts label format mode

D11 Sets pixel size

1F3306000500050490123456789 Sets EAN13 bar code for data

E Ends label format mode and

Direction of feed

901234 567894

4

"490123456789"

prints

Paper length

2.5 in

Page 21

1-19

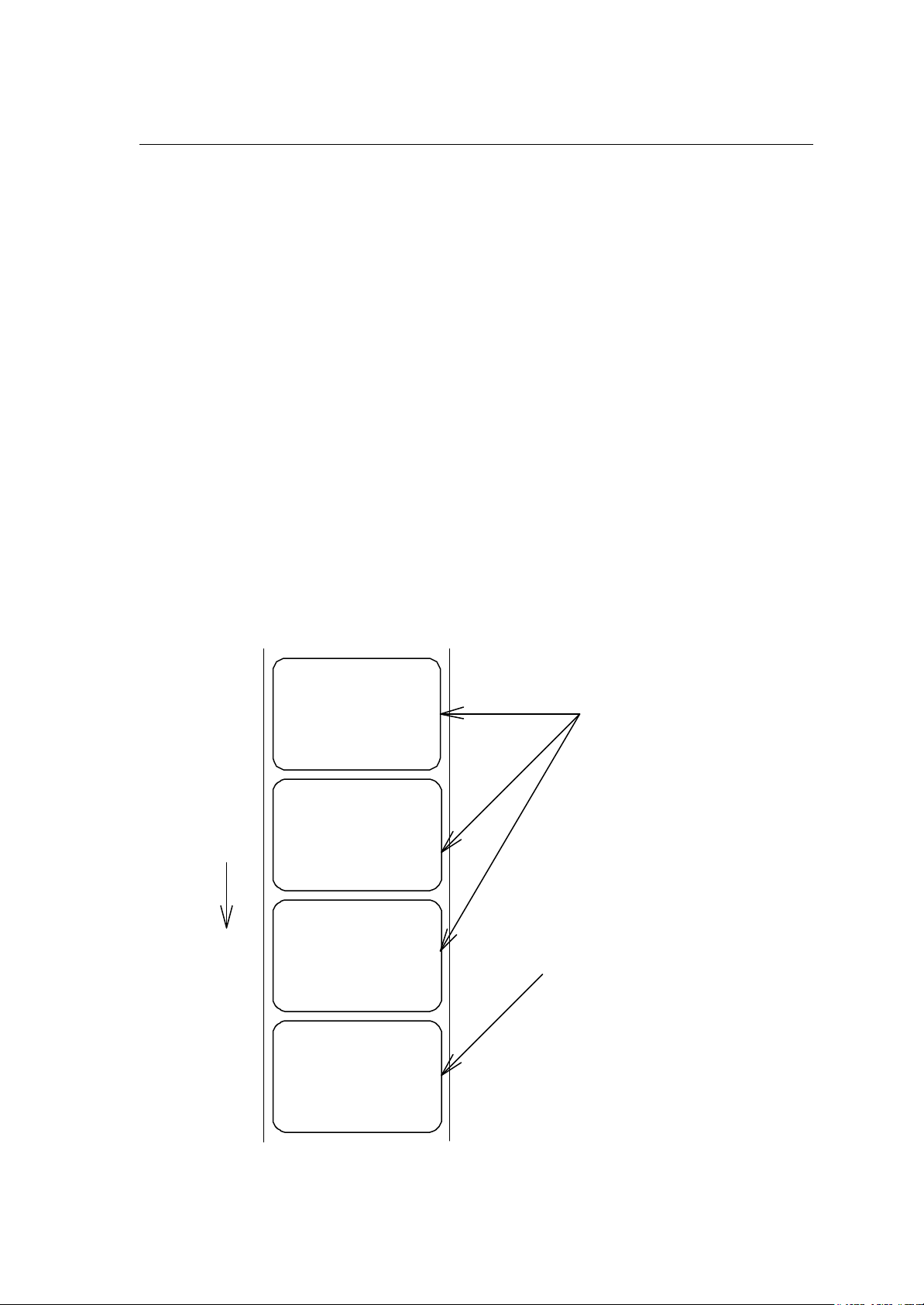

Setting two-page edit mode (double buffer)

901234

Code

Function

Caution

Direction of feed

[02] d

After receiving this command, printer divides the internal edit

buffer into 2 pages and enters the high-speed edit mode.

In the high-speed edit mode, editing the next page in advance while

the current page is being printed increases printing speed.

The printer automatically judges whether the double buffer is needed

or not, and the mode is switched accordingly, so this command does

not need to be particularly specified. Maximum printing length per

page is 40 inches, independently of the division.

Internal edit buffer

One-page mode

1st page

In one-page mode,

until printing is completed

ABCD

Two-page mode

2nd page

1st page

In two-page mode,

data on next page is edited

while printing 1st page

Page 22

1-20

Changing number of prints for edited format

three sheets are printed with

Code

Setting

Function

Example

Input data

[02] E nnnn

nnnn 4-digit numeric 0001 - 9999

Specifies changing of number of prints for formatted or formerly

printed label format.

Input data below represents that after ending label format printing data

"ABC" one sheet, the number of prints is set to 3 by using this

command and printing is executed with [02] G command. (In this case,

the number of prints is one plus three.)

[02] n Sets units to inch system

[02] L Starts label format mode

D22 Sets pixel size

190001001000050ABC Sets character data "ABC" with smooth

font 48pt

E Ends label format mode and prints

[02] E0003 Sets 3-sheet printing for edited format

[02] G Executes 3-sheet printing for edited

format

Direction of feed

After changing number of prints to 3,

ABC

ABC

ABC

One sheet is printed with "E"

"G"

ABC

Page 23

1-21

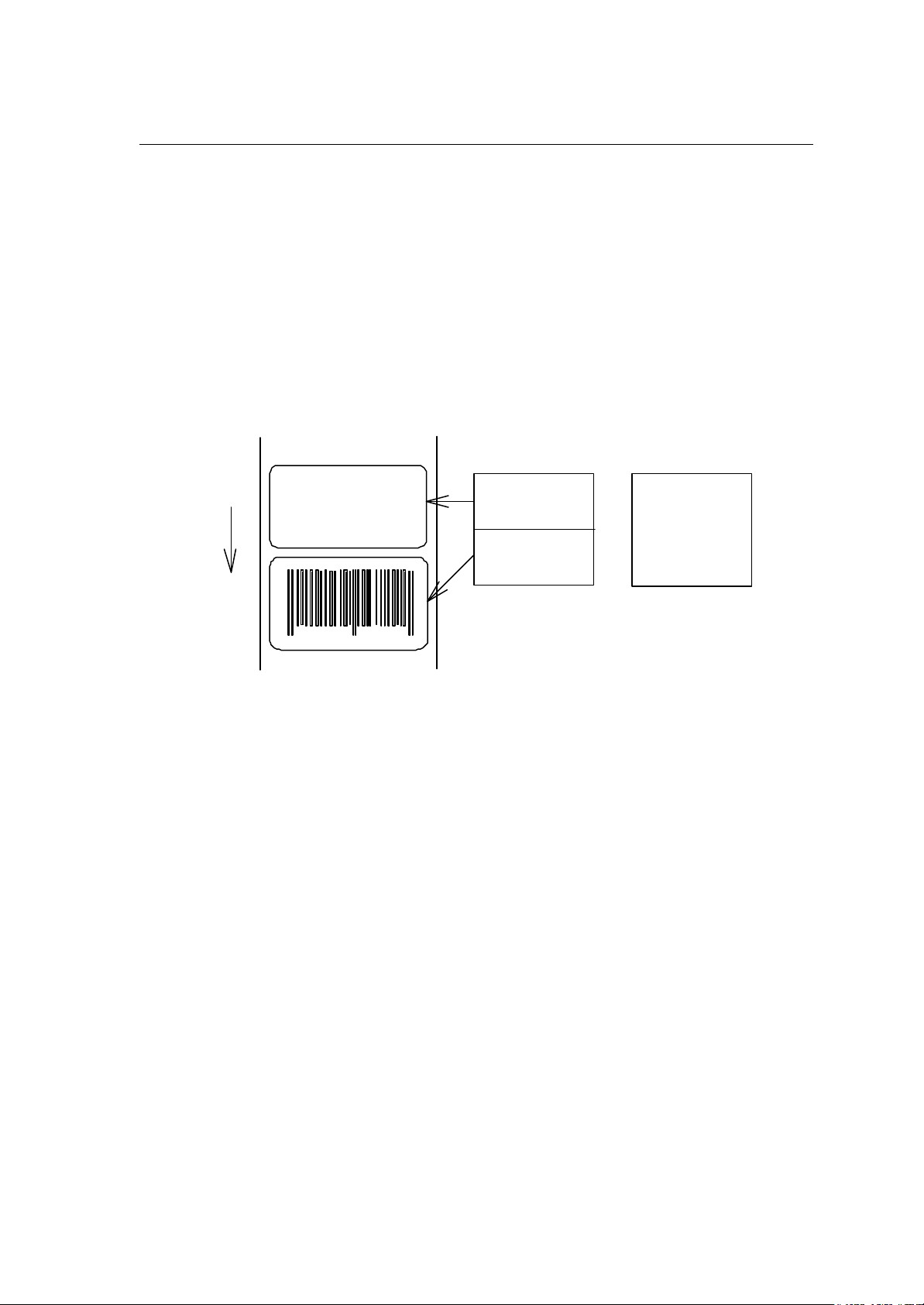

Setting edge sensor selection

ABCDEF

ABCDEF

Label paper

Code

Function

Caution

Example

[02] e

Changes paper position detection sensor to transparent-type.

Used for detecting paper gap between label papers, die-cut paper,

notch hole for tag paper, etc. This setting is used as default.

If not detected properly, check the sensor position.

Paper gap between label papers and notch holes for tag paper in Fig

below is detected.

Label paper gap

No 0001

No 0002

Tag paper notch holes

Label one sheet feed

Code

Function

[02] F

Feeds label one sheet. The amount of feed is the length from the

bottom of the label paper to the next bottom of the label paper.

When using continuous paper, feeds paper the length currently set

([02] c nnnn).

Performed in the same way as operated from the Feed key on the

control panel.

Direction of feed

Continuous paper

Amount of feed Paper length

[02] cnnnn

Page 24

1-22

Setting peeling (cutting) position

Code

Units

Setting

[02] f nnn

0.01 inch (0.1mm)

nnn 3-digit data

Initial value and its set range vary depending on the command setting.

Inch system Metric system

Initial

value

DMI / DMW

Normal

Cutter

Peel

Tear Off

DM4 / DM8

Normal

Cutter

Peel

Tear Off

DPP

Normal

Cutter

Peel

Tear Off

*In setting 4-digit value, use [02] Kf command.

000 000 200 000 000 508

100 000 200 254 000 508

050 000 150 127 000 381

070 000 170 178 000 432

220 220 420 559 559 1067*

340 240 440 864 610 1118*

270 220 370 686 559 940

290 220 390 737 559 991

110 110 310 279 279 787

230 130 330 584 330 838

146 96 246 371 244 625

166 96 266 422 244 676

Minimum

value

Max

value

Initial

value

Minimum

value

Max

value

Function

Caution

With the setting above, the distance between paper sensor and

cutter or peeler can be specified.

When nnn is small, the amount of feed is small, so printed label will

be cut.

When nnn is appropriate, the label is fed the required amount, then

cut at the paper gap.

When nnn is large, the amount of feed is large, so the next printing

label will be cut.

If value out of range is specified, the command parameter will be

ignored.

If optional functions such as cutter, peeler and ejection are turned

on from the control panel, their initialization values will be set

automatically. These initialization values, however, vary depending

on the specifications of each option. For details, see the instruction

manuals of each option.

Once this command was set, auto-setting function is stopped due to

priority for user's specification. Do not set this command if not

necessary.

Page 25

1-23

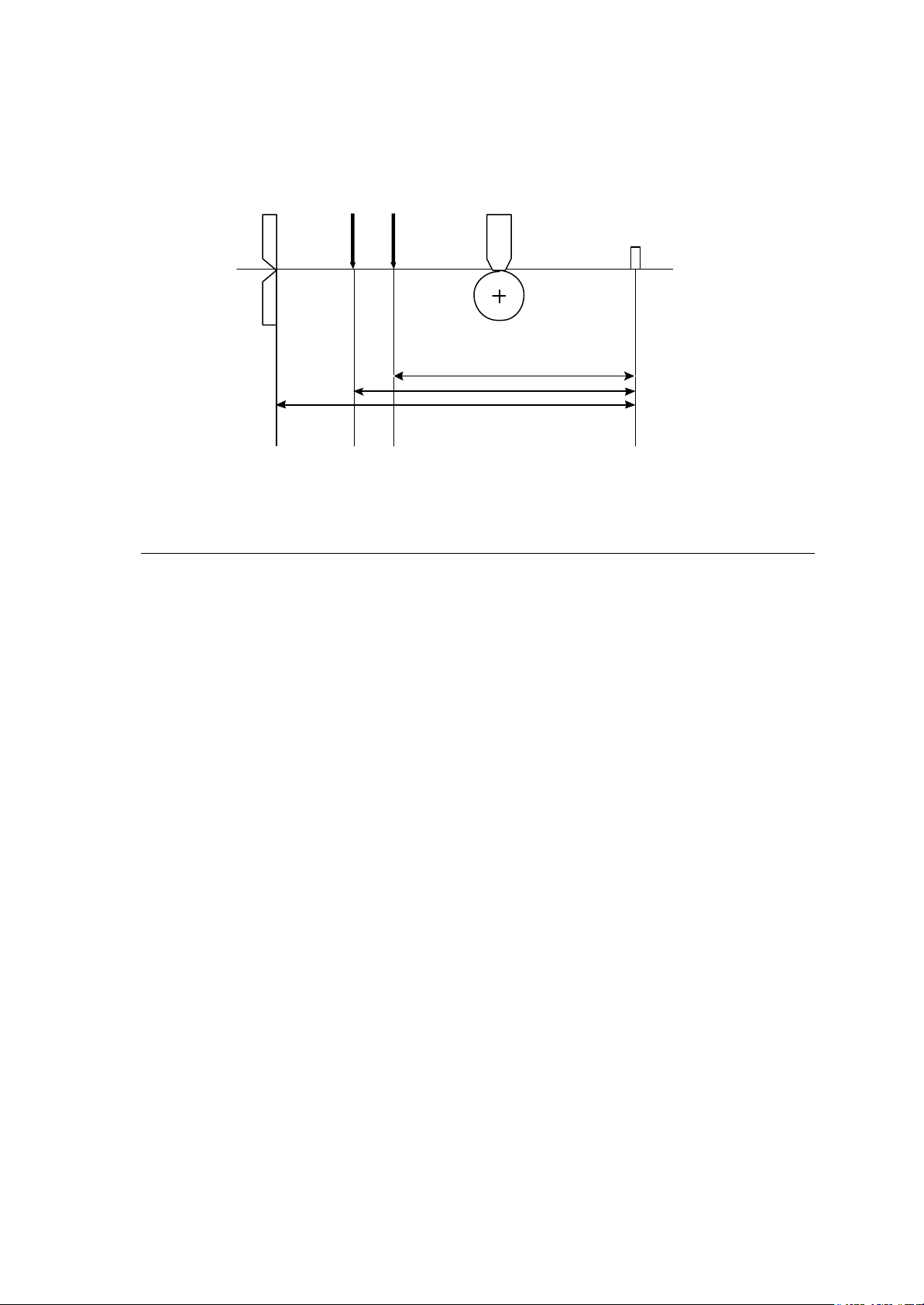

Figure

Print head

Cutter

Ejection

Note: Peeler option is not available for CLP-8301

Peeler

Printing edited or formerly-printed format

Code

Function

[02] G

Prints label data for former printing or formatting.

Paper sensor

A

B

C

Caution

Example

Input data

This command is effective only when label data for former printing or

formatting is left in the internal memory. If power is turned off or reset

is performed, data in the internal memory will be cleared, so this

command will not be effective.

Input data below represents that after ending label format printing data

"ABC" one sheet, printing for the same data is executed again with

this command [02] G.

[02] n Sets units to inch system

[02] L Starts label format mode

D22 Sets pixel size

190001001000050ABC Sets character data "ABC" with smooth

font 48pt

E Ends label format mode and prints

[02] G Executes 1-sheet printing for edited

format

Page 26

1-24

Graphics data block input command

Code

Transmission

data

[02] I m a f name, data

m Storing memory module specification

Allocation of modules varies with command settings. Refer to the table

below.

Command Set

Allocation of module DMI / DMW DM4 / DM8

on-board SD-RAM D A B

on-board flash memory G B A

PCMCIA Card (option) E or F E or F E or F

Current memory module on-board

SD-RAM

on-board

SD-RAM

DPP

on-board

SD-RAM

f Graphics data format

F 7-bit image loading file

I 8-bit image format (image saved in reverse)

i 8-bit image format (image saved in normal)

B 8-bit BMP format (saved in normal)

Function

Caution

b 8-bit BMP format (saved in reverse)

P 8-bit PCX format (saved in normal)

p 8-bit PCX format (saved in reverse)

Note: For graphics data format, refer to input data examples.

name File name for graphics data (up to 16 characters ending

with CR)

data Graphics data for each format

Stores specified format data in the specified memory module.

In the 8-bit BMP format and PCX format, data in colors other than

black-and-white (two colors) cannot be used. Color or gray-scale data

must be converted to black -and-white before use.

If the same file name as that of the current file is used for storing its

data in the memory module, the contents of the current file will be

replaced by the new image file. (Note: Working memory space is

required for new image file.) Therefore, if overwrite is repeated, the

data will not be stored due to lack of memory capacity. In this case,

packing the data with command [02] z may store the data in the

memory module.

Page 27

1-25

7-bit image loading file format

7-bit image data uses ASCII format data. In this example, 7-bit image data with the file

name of “MARK7” is stored in the memory card and printed out. Value of inside [ ] is

shown in hex format.

[02]IBFMARK7 --------------- Graphics data input command

8006000041040000 ---------- After this, 7-bit image data follows

80060000C30C0000 Top data “80” is a starting code for image data

8006000186180000 Next data “06” following “80” is the number of data in

800600030C300000 horizontal direction

800600071C700000

8006000618600000

8006000618600000

8006000618600000

8006000618600000

800600030C300000

800600030C300000

8006000186180000

80060001C71C0000

80060000C30C0000

80060000C30C0000

80060000C30C0000

80060030C30CC000

800600F18618F000

800603E186187C00

800607830C301E00

8006070F3CF00E00

80060E1E79E00700

80060C3861800300

80061C0000000380

80061C0000000380

80060C0000000300

80060E0000000700

8006070000000E00

8006078000001E00

800603E000007C00

800601F80001F800

800600FC0007F000

8006003F803FC000

8006000FFFFF0000

80060003FFFC0000

800600007FE00000

FFFF ------------------------------------ Graphics data ending code

[02] m

[02] M1500 ---------------------------- Sets maximum label length

[02] L ------------------------------------ Starts label format

D22

1Y1100001000500MARK7 -------- Develops “ MARK7” graphics data to specified position

E ----------------------------------------- Starts printing

Page 28

1-26

8-bit image format

Data on header is fixed except

After this, 8

-

bit image data follows

8-bit image data uses ASCII format data. In this example, 8-bit image data with the

file name of “MARK8” is stored in the memory card and printed out. Value of inside

[ ] is shown in hex format. (Note: Data below is described in hex.)

[01][44][0D]--------------------------- Stops immediate execution command

(Required only for 8-bit image data)

[02][49][42][69][4D][41][52][4B][38][0D]----------- Graphics

[00][01][00][08][00][01][00][02][00][7F][00][7F][00][E0][00][24] ----------┐

[80][06][00][00][41][04][00][00] -----[80][06][00][00][C3][0C][00][00]

[80][06][00][01][86][18][00][00]

[80][06][00][03][0C][30][00][00]

[80][06][00][07][1C][70][00][00]

[80][06][00][06][18][60][00][00]

[80][06][00][06][18][60][00][00]

[80][06][00][06][18][60][00][00]

[80][06][00][06][18][60][00][00]

[80][06][00][03][0C][30][00][00]

[80][06][00][03][0C][30][00][00]

[80][06][00][01][86][18][00][00]

[80][06][00][01][C7][1C][00][00]

[80][06][00][00][C3][0C][00][00]

[80][06][00][00][C3][0C][00][00]

[80][06][00][00][C3][0C][00][00]

[80][06][00][30][C3][0C][C0][00]

[80][06][00][F1][86][18][F0][00]

[80][06][03][E1][86][18][7C][00]

[80][06][07][83][0C][30][1E][00]

[80][06][07][0F][3C][F0][0E][00]

[80][06][0E][1E][79][E0][07][00]

[80][06][0C][38][61][80][03][00]

[80][06][1C][00][00][00][03][80]

[80][06][1C][00][00][00][03][80]

[80][06][0C][00][00][00][03][00]

[80][06][0E][00][00][00][07][00]

[80][06][07][00][00][00][0E][00]

[80][06][07][80][00][00][1E][00]

[80][06][03][E0][00][00][7C][00]

[80][06][01][F8][00][01][F8][00]

[80][06][00][FC][00][07][F0][00]

[80][06][00][3F][80][3F][C0][00]

[80][06][00][0F][FF][FF][00][00]

[80][06][00][03][FF][FC][00][00]

[80][06][00][00][7F][E0][00][00]

[46][46][46][46] ------------------------- Graphics data ending code

[02] m [0D]

[02] M1500 [0D]------------------------- Sets maximum label length

[02] L [0D] ------------------------------- Starts label format

1Y1100001000500MARK8[0D]----- Develops “ MARK8” graphics data to specified position

Top data “80” is a starting code for

image data

Next data “06” following “80” is the

number of data in horizontal direction

for the last 2 bytes, i.e., “00”

“24”(36 lines in this example)

E [0D] ------------------------------------- Starts printing

Page 29

1-27

Download of TrueType Font

Code

Transmission

data

[02] i m T nn name <CR> xxxxxxxx data…

m Storing memory module specification

Allocation of modules varies with command settings. Refer to

the table below.

Command Set

Allocation of module DMI / DMW DM4 / DM8

on-board SD-RAM D A B

on-board flash memory G B A

PCMCIA Card (option) E or F E or F E or F

Current memory module on-board

SD-RAM

on-board

SD-RAM

DPP

on-board

SD-RAM

T T fixed (TrueType)

nn Two-digit font ID

Valid values: 50 – 59, 5A – 5Z, 5a – 5z,

60 – 69, 6A – 6Z, 6a – 6z,

Function

Caution

Example

Input data

:

90 –99, 9A – 9Z, 9a – 9z

name Font name (Max. 16 characters followed by CR code to end)

xxxxxxxx TrueType font data size, number of bytes assigned by 8

digits hexadecimal characters.

data TrueType font data

Stores specified font data in the specified memory module.

File will be overwritten when the font data is stored in the memory

module using the same name of the existing file. Therefore, free

space for the file to write new data will be necessary.

The following command line shows the command to download 34754

bytes of TrueType font file, named “Tree Frog”, with the font ID 52 into

the memory module B:

[02] iCT52TreeFrog<CR>000087C2 data…

Page 30

1-28

Pause per label printing

Code

Function

Caution

[02] J

Performs pause each time label is printed one sheet. Used when label

peeling detection sensor is not mounted on the printer incorporating

peeling function. Pause is cancelled by pressing Pause key on the

control panel.

To clear this function, reset the printer.

Page 31

1-29

Extension system command (printer settings)

Code

Transmission

data

[02] Kdabc

Printer setting parameter

a Hex notation for the following bit settings

bit 0-2 baud rate

case bit 4 = 0

0=9600*, 1=600, 2=2400, 3=4800, 5=300,

6=1200, 7=9600 test mode

case bit 4 = 1

0=115200, 1=57600, 2= 38400, 3= none, 5=none,

6= none 7= none

bit 3 character length

0=8 bits*, 1=7 bits

bit 4 Extended baud rate

0=OFF*, 1=ON

bit 5 (not used) always 0

bit 6 (fixed) always 1

bit 7 (fixed) always 0

b Hex notation for the following bit settings

bit 0 printing method

0=thermal, 1=thermal transfer*

bit 1 peeling sensor

0=OFF*, 1=ON

bit 2 (not used) always 0

bit 3 auto-cutter

0=OFF*, 1=ON

bit 4-5 (not used) always 0

bit 6 (fixed) always 1

bit 7 (fixed) always 0

c Hex notation for the following bit settings

bit 0-1 type of paper

0=transparent*, 1=reflective, 2=continuous (3 inches)

bit 2-5 (not used) always 0

bit 6 (fixed) always 1

bit 7 (fixed) always 0

Function

Caution

Example

(*: factory setting)

Provides various printer settings.

This setting is stored even when the power is turned off.

[02]KD@A@[0D]

@: 9600 baud, 8-bit length, no parity

A: thermal, no peeling sensor, no auto-cutter

@: transparent paper

[02]KDP@B[0D]

Page 32

1-30

P: 115200 baud, 8-bit length, no parity

@: thermal transfer , no peeling sensor, no auto-cutter

B: continuous paper

Setting peeling (cutting) position

Code

Units

Setting

[02] Kf nnnn

0.01 inch (0.1mm)

nnnn 4-digit data

Inch system 0001 - 9999 (0.01 – 99.99 inches)

Metric system 0001 - 9999 (0.1 – 999.9 mm)

Function/

Command is valid only for DMI/DMW mode.

Caution

It has the same funct ion as that of [02] fnnn.

For details, refer to [02] fnnn command.

Setting Y-code-transmission-to-serial-port request

Code

Function

Caution

[02] k

After receiving this command, printer issues "Y"(59hex) code via serial

port. This allows printer and computer to synchronize each other.

[0D] hex code is not added to the end of the "Y"(59hex) code.

Page 33

1-31

Specifying printing contents setting start

Code

Function

Example

Input data

[02] L

With this command input, printer enters the label format mode and

waits for input of printing contents definition and label format

commands until it receives "E" "s" or "X" code.

Input data below represents that label format command input is

started, data "ABC" is defined as printing contents, label format

command input is completed, and label printing command "E" is

entered.

[02] n Sets units to inch

[02] L Starts label format mode

D22 Sets pixel size

190001001000050ABC Sets character data "ABC" with smooth

font 48pt

E Ends label format mode and prints

Direction of feed

ABC

Page 34

1-32

Setting maximum label length

901234

Code [02] M nnnn

Units 0.01 inch or 0.1 mm

Setting nnnn 4-digit data Initialization value: 1000 (10.00 inches)

Max. value: Inch system 9999 (99.99 inches)

Metric system 9999 (99.9 mm)

Function

Sets maximum label length for detecting label out. If printer cannot

detect the next top of the label within the maximum label length which

has been set with this command, "M" command error occurs. Set

value 2.5 to 3 times as large as the label length to be used.

Example

I f label length is 2.5 inches, the value more than double 2.5 inches

must be set for maximum label length. But if label length is 1.1 inch or

less, the value more than triple must be set for maximum label length.

Input data below is for 3.5-inch setting

Input data

[02] n Sets units to inch system

[02] M 0350 Sets 3.5 inches for maximum

label length

[02] L Starts label format mode

D11 Sets pixel size

1F3306000500050490123456789 Sets EAN13 bar code for data

"490123456789"

E Ends label format mode and

prints

Initialization value for printer maximum label length is set to 10 inches (254 mm). If

longer label length is required, using the maximum label length command must set the

value larger than the length of printing. If the length of printing is larger than the

maximum label length, set the M command as follows:

Maximum label length [02] M nnnn > length of printing

Note: If label paper mode is continuous paper, this command is ignored.

Direction of feed

Label length

Maximum label length

Page 35

1-33

Changing units from inch to metric system

When inch is specified

5 mm

(0050)

Code

Function

Example

Input data

Printing results of the same data with or without units of metric system are as follows:

Changing units from metric to inch system

[02] m

Changes units for all-distance-specified-command-parameters from

0.01 inch to 0.1 mm. With reset, units are set to metric syst em.

Input data below represents that data "ABC" is specified with units in

metric system.

[02] m Sets units to metric system

[02] L Starts label format mode

D22 Sets pixel size

190001001000050ABC Sets character data "ABC" with smooth

font 48pt

E Ends label format mode and prints

Code

Function

Example

Input data

Direction of feed

[02] n

Changes units for all-distance-specified-command-parameters from

0.1 mm to 0.01 inch. With reset, units are set to inch system.

Input data below represents that data "ABC" is specified with units of

inch.

[02] n Sets units to inch

[02] L Starts label format mode

D22 Sets pixel size

190001001000050ABC Sets character data "ABC" with smooth

font 48pt

E Ends label format mode and prints

When mm is specified

ABC

1 inch

(0100)

ABC

10 mm

(0100)

0.5 inch

(0050)

Page 36

1-34

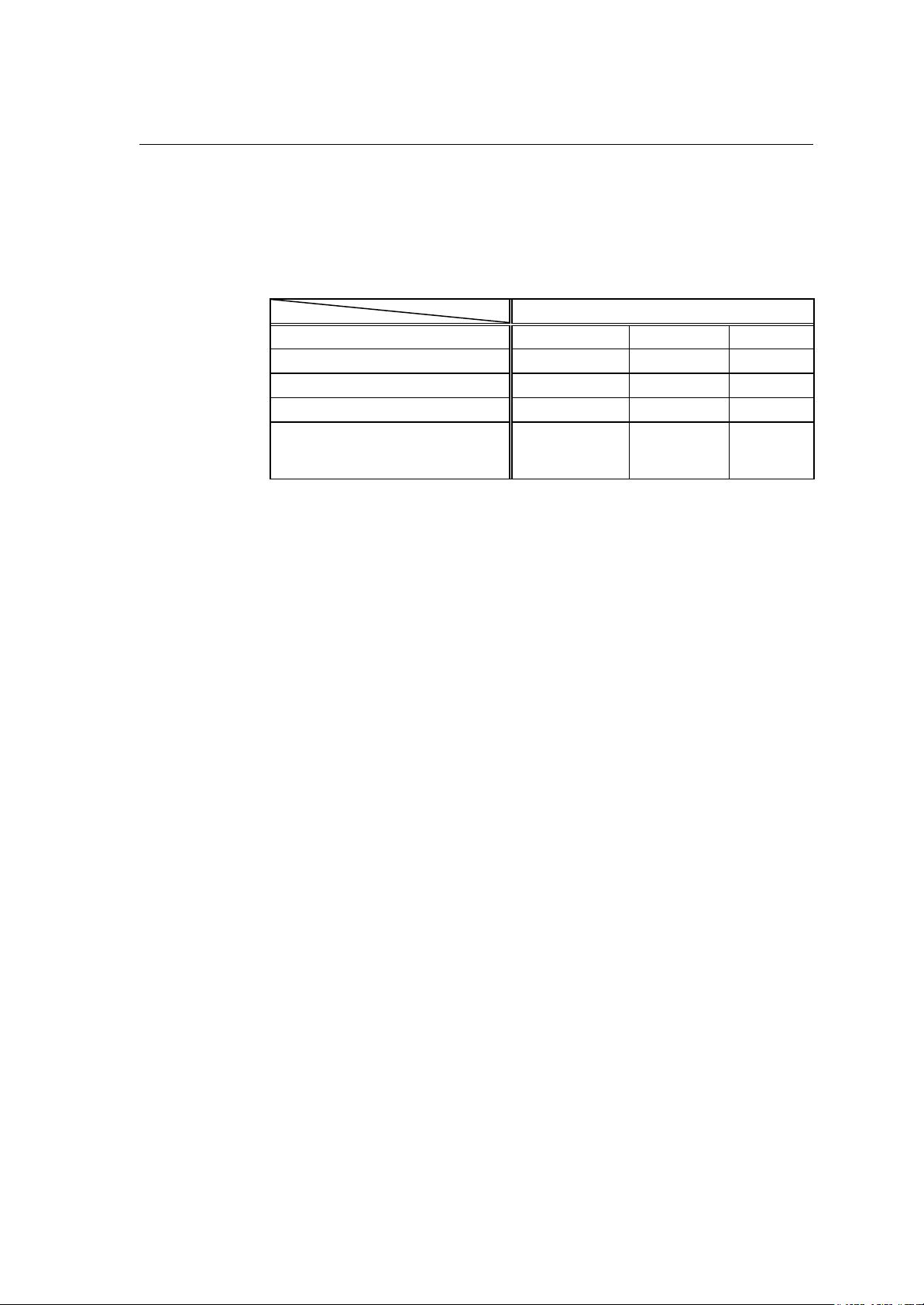

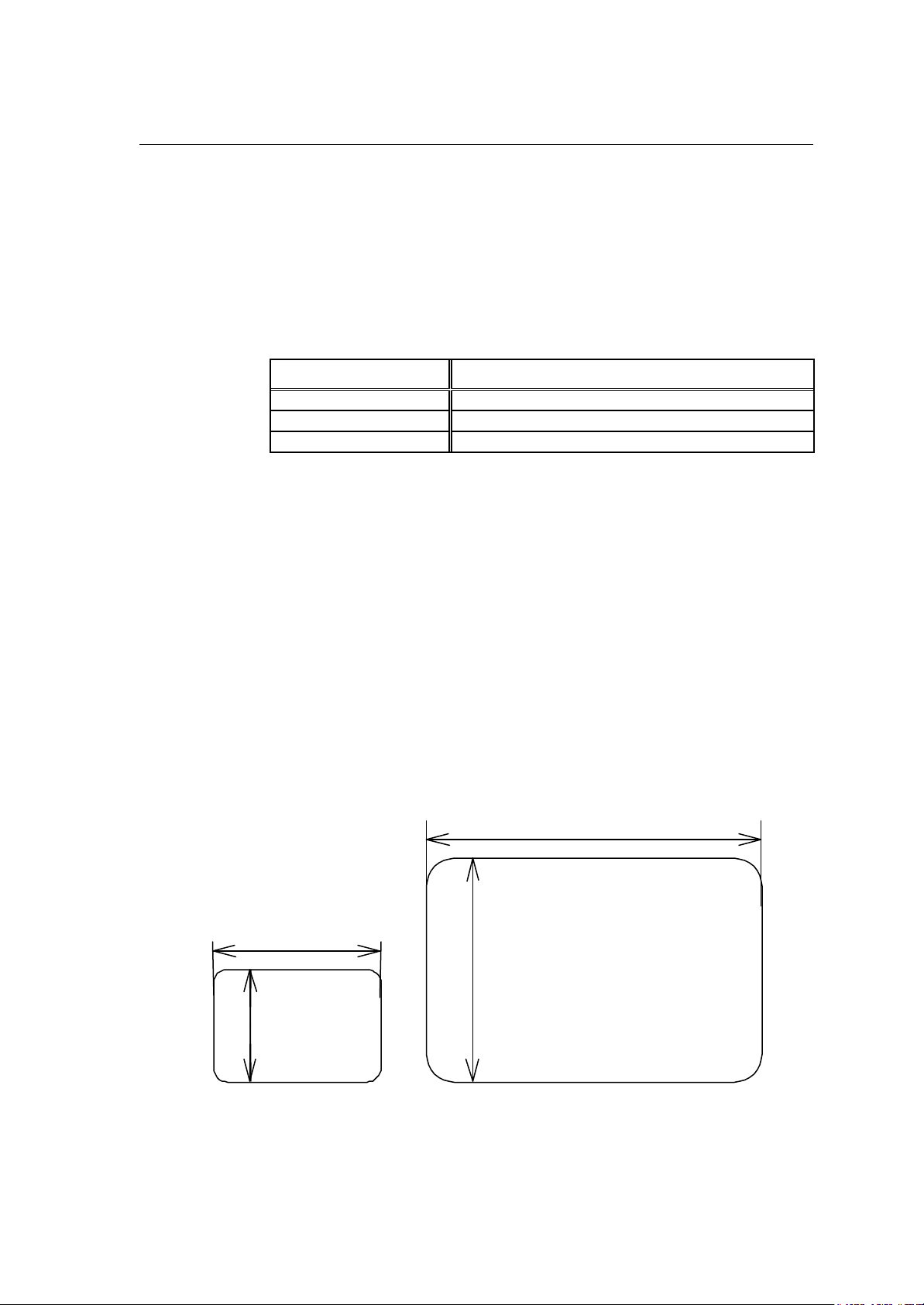

Setting printing position

Code

Units

Setting

Function

Caution

Figure

[02] O nnnn

0.01 inch or 0.1 mm

nnnn 4-digit data

I nitial value and its set range vary depending on the command set.

Inch system Metric system

Command Set

DMI / DMW 0220 0120 0320 0559 0305 0813

DM4 / DM8 0220 0120 0320 0559 0305 0813

DPP 0110 0010 0210 0279 0025 0533

Initial

value

Minimum

value

Max

value

Initial

value

Minimum

value

Max

value

Specifies the distance between paper sensor and print head. By

changing this value, a physical printing start position can be changed.

If value less than 0.5 inch (0050) is specified, the initialization value will

be set automatically. With the initialization value set, printing starts from

the bottom of the label. If the command is used after completing

printing, this command setting will not be effective to the first sheet of

the label. From the second sheet of the label, this will be effective.

Cutter

Peeler

Print head Reference point

(peeling)

Onnnn = 1.10 inch (initialization value)

Page 37

1-35

Paper cut

all data transmitted from the computer are printed out with hex code.

Code

Function

Caution

[02] o

When mounting auto-cutter, if this command is received, the label or

paper cutting will be performed once.

If auto-cutter is not turned to ON, this command will be ignored.

Set the cutting sheet number to 0 (zero) with the specified command

(cnn or :nnnn). Otherwise, each label will be cut automatically.

Setting dump mode start

Code

Function

Example

[02] P

By receiving this command, printer enters the dump mode. After that,

To escape from the dump mode, turn on and off the power or turn the

“Hex Dump” mode off by the operation panel.

Input data below represents that label format command input is

started, data "ABC" is defined as printing contents, label format

command input is completed, and label printing command "E" is

entered.

Input data

Direction of feed

[02] P Sets dump mode

[02] L Starts label format mode

190001001000050ABC Sets character data "ABC" with smooth

font 48pt

E Ends label format mode and prints

DUMP LIST

0D024C0D4431310D3139313130313030..L.D11.19110100

313030303035304142430D450D 1000050ABC.E.

Page 38

1-36

Pause in occasional execution

Clearing of all memory module contents takes about 15 seconds.

Code

Function

Caution

[02] p

Executes pause occasionally.

Pause on and off cannot be performed with this command. Cancelling

pause must be operated from the Pause key on the control panel.

Clearing all memory module contents

Code

Function

[02] Q

Clears all data in on-board flash memory and on-board SD-RAM and

option memory card modules.

Caution

For models with an LCD, "On Line" appears on the LCD as soon as

the module contents are cleared.

Page 39

1-37

Clearing memory module contents

memory module takes about 10 seconds.

Code

Setting

Function

Caution

[02] q n

n Memory module specification parameter

Allocation of modules varies with command settings. Refer to the

table below.

Allocation of

module

on-board SD-RAM

on-board flash

memory

PCMCIA Card

(option)

Current memory

module

DMI / DMW DM4 / DM8 DPP

D A B

G B A

E or F E or F E or F

on-board

SD-RAM

Command Set

on-board

SD-RAM

on-board

SD-RAM

Clears all data in memory module.

Clearing of on-board flash

For models with LCD, "On Line" appears on the LCD as soon as the

module contents are cleared.

Input data

[02] q B Sets clearance of module B (on-board SD-RAM ) contents.

Page 40

1-38

Setting reflective paper sensor selection

Detects label position automatically by reflective paper sensor.

Black line

Code

Function

Caution

Example

[02] r

Reflective paper sensor detects black lines that are printed on the

back of the label and understands the label position. In default,

reflective paper sensor is selected.

When detection is not performed properly, check the sensor position.

As shown in the figure below, label position is detected with the black

lines on the back of the label.

Black line

Label paper gap

Direction of feed

Black line

* Figure above shows the back of the paper

Page 41

1-39

Setting paper feed speed

and maximum value vary depending on the printer

*Feeds at speed of setting Sa (or previous

(or previous

(or previous paper

Paper feed area

Code

Setting

[02] Sa

a Paper feed speed specifying character

A or B or 1 2.0 inches (50.8 mm)/sec

C or D or 2 2.0 inches (50.8 mm)/sec

E or F or 3 3.0 inches (76.2 mm)/sec

G or H or 4 4.0 inches (101.6 mm)/sec

I or J or 5 5.0 inches (127.0 mm)/sec

K or L or 6 6.0 inches (152.4 mm)/sec

M or N or 7 7.0 inches (177.8 mm)/sec

O or P or 8 8.0 inches (203.2 mm)/sec

Q or R or 9 9.0 inches (228.6 mm)/sec

S or T or a 10.0 inches (254.0 mm)/sec

U or V or b 11 .0 inches (279.4 mm)/sec

W or c 12.0 inches (304.5 mm)/sec

Note: Initial value

model.

Function

Direction of feed

Sets paper feed speed.

Paper feed area

Unprintable area*

Printable area

Unprintable area*

Unprintable area

Power is turned on

Feeds at speed of setting STX+Sa

(of default value)

paper feed section when no Sa is set

Feeds at speed of setting Pa (or default value)

Feeds at speed of setting STX+Sa

unprintable section when no STX + Sa is set)

Feeds at speed of setting Sa

feed section when no Sa is set

Page 42

1-40

Setting one-page edit mode (single buffer)

Code

Function

[02] s

After receiving this command, printer makes the internal edit buffer

one page. At this time, the maximum printing length on one page is 40

inches. In initialization after turning on power, this mode is set.

Caution

The printer automatically judges whether the single buffer is needed or

not, and the mode is switched accordingly, so this command does not

need to be particularly specified. Maximum printing length per page is

40 inches.

Printing quality test pattern

Code

Function

[02] T

After receiving this command, printer prints out the quality test pattern

to check whether printer is in good condition and not involved in

troubles such as head disconnection. This test pattern is the same as

the print pattern by the se lf-test.

Page 43

1-41

Rewriting specified format register contents

0001

Code

Setting

Function

Example

Input data

[02] U nnaa..

nn 2-digit format register numbers 01 - 99

Printer sets format register numbers in sequence when label

format is executed.

aa Input character string data ending with CR code (0D hex) instead

of old data. Basically the number of characters must be the same

as the old data. But if it is small, rewriting can be executed.

Changes some part of the formerly printed label format or formatted

label contents and prints it again.

Input data below represents that data "0001" and "ABC" are set on the

fields No. 01 and No. 02 respectively and label is printed and then with

this command, the data contents of the fields No. 01 and No. 02 are

changed to "9999" and "GHIJK" and printed.

[02] n Sets units to inch

[02] L Starts label format mode

D11 Sets pixel size

1611000000000500001 Sets data "0001" on fields No. 01

161100000300050ABCDE Sets data "ABCDE" on fields No. 02

E Ends label format mode and prints

[02] U019999 Changes data on fields No. 01 to "9999"

[02] U02GHIJK Changes data on fields No. 02 to

"GHIJK"

[02] G Prints edited format

Direction of feed

GHIJK

9999

ABCDE

Page 44

1-42

Setting memory switch contents

Code

Setting

Function

Example

Input data

[02] V n

n is hex data expressing switch on and off with binary. Appropriate

ASCII codes are used for setting.

Bit 0 1 2 3 4 5 6 7

Auto-cutter 1 O O O O

Ribbon end sensor

Not care

Peeling sensor 3 O O O O

With this command, memory switch contents can be changed

temporarily.

When auto-cutter is turned to ON, n = 1 (binary 0001), i.e., 1 for hex,

so ASCII code 31hex is set. When peeling sensor is turned to ON, n =

4 (binary 0100), i.e., 4 for hex, so ASCII code 34hex is set.

When auto-cutter is turned to ON: [02] V 1

When peeling sensor is turned to ON: [02] V 4

Printer version number transmission request

Code

Function

[02] v

After receiving this command, printer transmits the control ROM

version number and date to the computer in ASCII code.

Caution

Printer sends data on printer status to the computer as soon as it

receives this command. Therefore, the computer must be ready to

receive data from the printer immediately after receiving this

command.

The [0D] hex code is added to the end of the transmission data.

Page 45

1-43

Information-in-memory-module transmission request

Code

Setting

Function

Caution

Example

Input data

Reception

data

[02] W n

n F, G, L

F Transmits downloading font information.

G Transmits graphic image file information.

L Transmits format (label printing contents) information.

Transmits file name and memory remaining capacity in the currently

installed memory module to the computer in ASCII code.

The [0D] hex is added to the end of the transmission code.

Reception data below represents that file nam e "ABC.DAT" is set on

the module A and transmitted by printer.

[02] WG

MODULE: A [0D]

ABCDAT[0D]

AVAILABLE BYTES IN MODULE: 00496720[0D]

MODULE: B [0D]

AVALIABLE BYTES IN MODULE: 00524288 [0D]

Testing flash memory

Code

Function

Caution

Reception

data

[02] w

After receiving this command, printer tests flash memory module and

transmits capacity and test results (GOOD or BAD).

The [0D] hex is added to the end of the transmission data. Also,

memory card is initialized with this command.

If no flash memory card is installed, nothing will be returned. And if the

write-protect switch of the flash memory card is turned to ON, the test

results are always BAD.

MODULE B: xxxxK Flash Tested Good [0D]

Page 46

1-44

Default module selection

Code

Setting

Function

Example

[02] X a

a Default module selection

Allocation of modules varies with command settings. Refer to the table

below.

Allocation of module

on-board SD-RAM

on-board flash

memory

PCMCIA Card

(option)

Current memory

module

DMI / DMW DM4 / DM8 DPP

D A B

G B A

E or F E or F E or F

on-board

SD-RAM

Command Set

on-board

SD-RAM

on-board

SD-RAM

Selects default module. If default is set with other command module

parameter, the module selected with this command is used. (E.g., [02]

Imfaa, [02] qn, snaa..a, etc.)

Input data below represents that default module A is selected and

default module is cleared.

Input data

[02] X A Selects default module A.

[02] q C Clears default module.

Page 47

1-45

Clearing memory module contents (in file units)

Code

Transmission

data

[02] xntname

m Memory module specification parameter

Allocation of modules varies with command settings. Refer to the table

below.

Allocation of module

on-board SD-RAM D A B

on-board flash

memory

PCMCIA Card

(option)

Current memory

module

DMI / DMW DM4 / DM8 DPP

G B A

E or F E or F E or F

on-board

SD-RAM

Command Set

on-board

SD-RAM

on-board

SD-RAM

T File format

F Download font

G Graphics data

L Label format

S TrueType font

Name File name (up to 16 characters ending with CR)

Function

Example

Input data

Bit mapped download font ID is three digits and TrueType

download font ID is two digits.

The data in a memory module is cleared per file.

The graphic image file "MARK8" which exists in Module B is cleared.

[02] xBGMARK8 [0D]

Page 48

1-46

TrueType font symbol set selection

Code

Setting

[02] ySxx

S S fixed

xx Specification of a symbol set

The character sequence of 2 figures

(Refer to the following table for a setting value.)

Function

Caution

Selection of a TrueType font symbol set

It depends on each TrueType font file for the symbol set which

becomes actually effective.

Example

Input data

PC-850 multilingual is chosen.

[02] ySPM

Table

XX Font name XX Font name

US ISO 6: ASCII (standard) PE PC-852 Latin 2

DN ISO 60: Danish/Norwegian W1 Windows 3.1 Latin 1

IT ISO 15: Italian PD PC-8 D/N, Code Page 437N

GR ISO 21: German PC PC-8 Code Page 437

FR ISO 69: French MC Macintosh

E5 ISO 8859/5 Latin 5 SW ISO 11: Swedish

E2 ISO 8859/2 Latin 2 SP ISO 17: Spanish

E1 ISO 8859/1 Latin 1 UK ISO 4: United Kingdom

DT DeskTop TS PS Text

LG Legal WE Windows 3.1 Latin 2

R8 Roman-8 WO Windows 3.0 Latin 1

PT PC-8 TK, Code Page 437T PI PI font

PM PC-850 Multilingual

WT Windows 3.1 Latin 5

Page 49

1-47

Printing printer status

Code

Function

[02] Z

Performs test printing for indicating printer status.

Select Command Set

Code

Setting

Function

Caution

[02] [1B] G n

n 0, 1,2

0 : DMI or DMW

1 : DM4 or DM8

2 : DPP

Selects proper command set for your application.

Switching command sets will change the designated destination of

memory module and paper position. Check the command set if

something is wrong with the destination and location of files.

Example

Input data

Shown below are examples of input data when command set is DMI

(DMW) or DPP.

[02][1B]G0 When command set DMI(DMW)is specified.

[02][1B]G2 When command set DPP is specified.

Page 50

1-48

Setting Printing Method

Code

Setting

Function

Example

Input data

[02] [1B] Mn

n T , D

T : Thermal transfer

D : Heat-sensitive

Designates the printing method to be set; thermal transfer mode

where a ribbon is used, or heat-sensitive mode where heat-sensitive

paper is used.

Shown below are examples of input data when printing in thermal

transfer mode.

[02] n Sets units to inch

[02][1B] MT Sets printing method to thermal transfer

mode.

[02] L Starts label format mode

D22 Sets pixel size

191101001000050ABC Sets character data "ABC" with smooth

font 48pt

E Ends label format mode and prints

Direction of feed

ABC

Head disconnection detection

Code

Function

Caution

[02] [1B] T

Measures resistance value per dot on head heat-generation part and

checks whether head heat-generation part (resistance value) is

normal. If it is normal, [01] is transmitted to the computer and if it is

abnormal, [00] is transmitted to the computer.

The [0D] hex code is not added to the end of the transmission data.

Page 51

1-49

Setting ejection (tear-off)

Code

Setting

Function

Caution

Example

Input data

[02] [1B] tn

n 0 , 1

0 : Ejection is turned to OFF

1 : Ejection is turned to ON

Switches ejection ON and OFF. The contents with this command are

stored in the backup memory and kept valid even if the power is

turned off.

When the auto-cutter and peeling sensor are turned to ON, any

ejection is not performed even if ejection is turned to ON because the

auto-cutter and peeling sensor have priority. Setting of ejection,

however, is kept valid because it is stored in the backup memory, so

ejection will be performed when both auto-cutter and peeling sensor

are turned to OFF.

Examples of input data when Ejection ON and OFF are shown below.

[02][1B] t1 When specifying Ejection ON

[02][1B] t0 When specifying Ejection OFF

Page 52

1-50

Setting label width

of label format is specified with this command.

Code

Unit

Setting

Function

[02] [1B]w nnnn

In inch unit mode, nnnn is defined as nn.nn inch, in metric unit, nnnn

is defined as nnn.n mm

0.01 inch or 0.1 mm

nnnn 4-digit data Initialization value: depending on the printer

Inch system 0000 – 9999 (0 inch - 99.99 inches)

Metric system 0000 – 9999 (0 mm - 999.9 mm)

Note: Maximum setting value will be different depending on the

the printer model .

Sets label width. Width

When receiving this command, the printer will be operated as follows.

The label width set by the operation panel will be ignored.

The print buffer will be cleared and repeat operation will be cancelled.

Maximum label length will be set automatically depending on the

selected paper width.

Example

Input data

Caution

Example of input data below represents paper width of 4 inch setting.

[02] n Sets units to inch system

[02] [1B]w0400 Sets paper width to 4 inches

When the parameter number is out of specified range will be

ignored.

Page 53

1-51

1.6.3 Label Format Commands

The following commands will be valid if the label format command

interpreter is turned on with "STX" + "L," i.e. [02] L.

Set format attribute A

Set format attribute [1B]B

Setting offset in direction of column C

Setting number of cuts (2-digit) c

Setting pixel size in horizontal and vertical direction D

Completion of setting printing contents (field preparation) and

printing labels

Entering previous-defined field character string into global table G

Setting print density (head heat factor) H

Changing units from inch to metric system m

Changing units from metric to inch system n

Setting printable area speed P

Setting backfeed speed p

Specifying space between characters [1B]P

Setting number of prints Q

Setting offset in direction of row R

Calling label format r

Setting unprintable area speed S

Storing label format s

Specifying ending code T

E

Setting previous field to character-string-replacement-mode

field

Completion of setting printing contents (field preparation) X

TrueType font symbol setting y

Setting slash zero z

Setting addition of previous-defined printing contents (field

data) 1

Setting subtraction of previous-defined printing contents (field

data) 1

Setting addition of previous-defined printing contents (field

data) 2

Setting subtraction of previous-defined printing contents (field

data) 2

U

+

-

>

<

Page 54

1-52

Setting number of prints for same label ^

Setting number of cuts (4-digit) :

Character field definition 1n..

Bar code field definition

Ruled line definition 1X..L

Box definition 1X..B

Polygon definition 1X..P

Circle definition 1X..C

Graphics printing definition 1Y..

Reading out from global register 1n.. [02]S

Date and time printing definition 1n.. [02]T

Page 55

1-53

Set format attribute

In this mode, the area where text strings, images or barcodes

In this mode, first text format is covered by the text formatted

Code

Setting

An

n 1, 2, 3, 5

1 : All data should be formed by XOR processing

In this mode, the area where text strings, images or barcodes

intersect will not be printed.

2 : All data should be formed by OR processing.

intersect will be printed.

3 : Following data should be formed by overlay processing

* Human readable character and barcode

* Image and drawing data

last.

5 : Following data should be printed in reverse.

* Human readable character and barcode

* Image data

Note: Reversed data should be formed by XOR processing.

Other data should be formed by XOR processing.

Function

Specifies development method for character and bar code.

Set format attribute

Code

Setting

Function

[1B] B n 1B is hex code.

n 0, 1 Initialization value: 0

0 Specifies XOR development and character and bar code overlaid

are reversed out of black.

1 Specifies OR development and character and bar code are

overlaid.

Specifies development method for character and bar code.

Page 56

1-54

Setting offset in direction of column

4

901234

567894

Code

Units

Setting

Function

Example

Input data

C nnnn

0.01 inch or 0.1 mm

nnnn 4-digit data Initialization value: 0000

Inch system 0000 - 9999 (0.00 inch - 99.99 inches)

Metric system 0000 - 9999 (0.0 mm - 99.9 mm)

Sets offset value for printing start position in direction of column (paper

left and right) to adjust the position of the total printing contents.

Shifts label printing position 1.0 inch (C0100) rightward and prints.

[02] n Sets units to inch

[02] L Starts label format mode

D11 Sets pixel size

C0100 Sets column offset to 1.0 inch

190000501150090ABC Sets character data "ABC" with

smooth font 14pt

1F3306000500050490123456789 Sets EAN13 bar code for data

"490123456789"

E Ends label format mode and

prints

Normal printing starting position

Direction of feed

ABC

Printing starting position after setting offset

Page 57

1-55

Setting number of cuts (2-digit)

Cut

Code

Setting

Function

Caution

Example

Input data

c nn

nn 00 - 99 Initialization value: 01

After printing specified number of labels, cuts paper.

This command is invalid unless the auto-cutter is installed and it is

turned to ON. Since the initialization value is 01 (one sheet), if the

auto-cutter is ON, each label sheet will be cut automatically. When the

label is cut by using the paper cut command (o), this must be set to 0

(zero) sheet.

Input data below represents that the same contents of the labels are

printed ten sheets and cut out every two sheets.

[02] n Sets units to inch

[02] L Starts label format mode

D22 Sets pixel size

Q0010 Sets 10 sheets for same label printing

190000700500050ABC Sets character data "ABC" with smooth

font 24pt

c 02 Sets 2 sheets for cutting

E Ends label format mode and prints

Direction of feed

5th sheet

4th sheet

3rd sheet

2nd sheet

1st sheet

Cut

10th sheet

Cut

9th sheet

8th sheet

Cut

7th sheet

Cut

6th sheet

Page 58

1-56

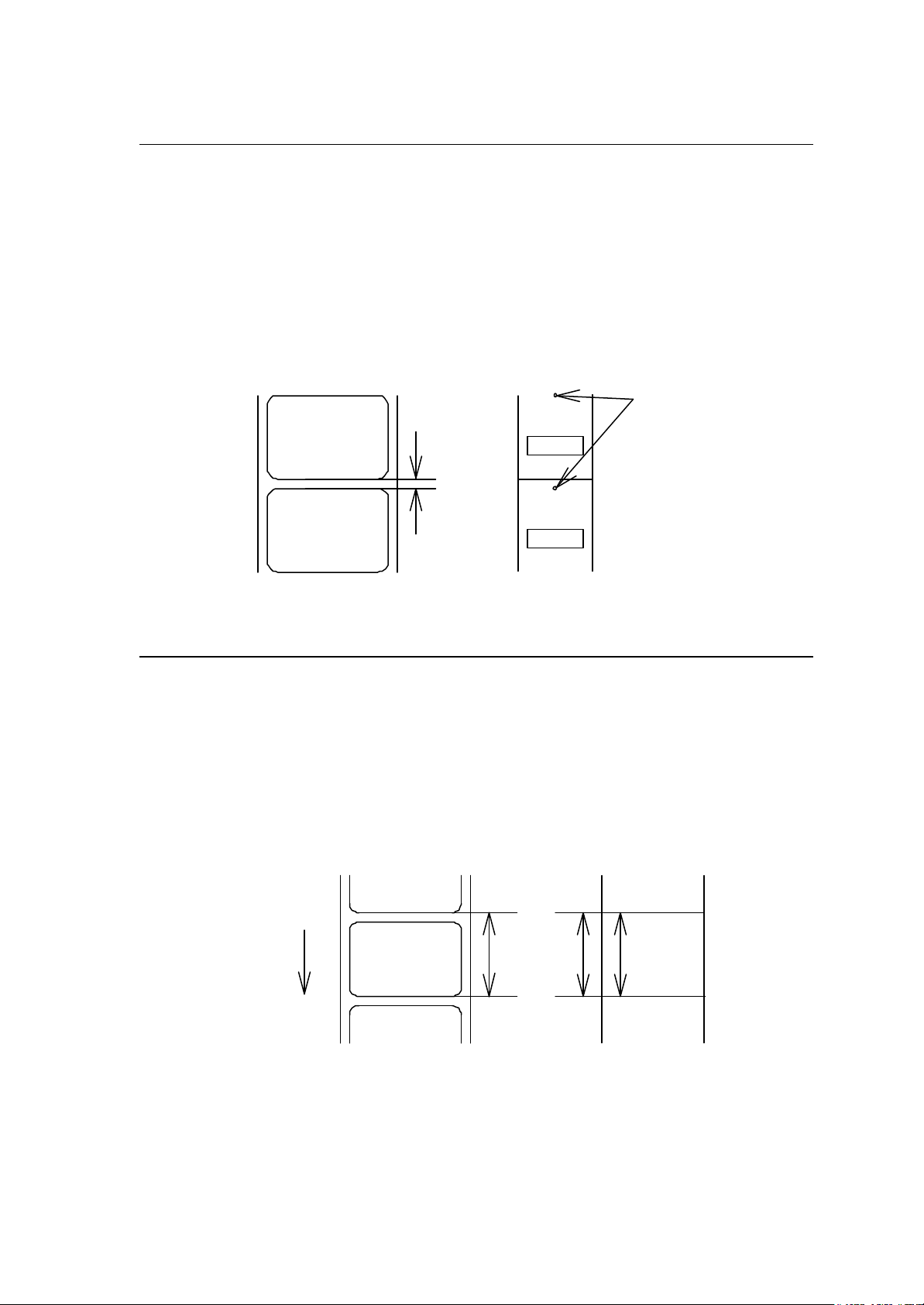

Setting pixel size in horizontal and vertical direction

alization value will be varied by the Print Res. DPI

h=2

Code

Units

Setting

Function

Example

Input data

D hv

One dot 0.127 mm or 0.005 inch

h Dot size in horizontal direction 1, 2

v Dot size in vertical direction 1, 2, 3

Note: Initi

(DP mm) set by the operation panel.

Command Set Initialization value

DMI / DMW 11

DM4 / DM8 22

DPP 11

Specifies pixel size (dot formation units) in the range of 1 dot x 1 dot to

2 dots x 3 dots. If dot size in vertical direction is doubled or tripled, the

maximum printing length (printing range) will be doubled or tripled.

The following is that dot size in horizontal direction is set to 1 and dot

size in vertical direction is set to 1.

[02] n Sets units to inch

[02] L Starts label format mode

D11 Sets pixel size

1F3306000500050490123456789 Sets EAN13 bar code for data

"490123456789"

E Ends label format mode and

prints

Pixel size 2 x 2

Pixel size 1 x 1

h=1

v=2

v=1

Page 59

1-57

Completion of setting printing contents (field preparation) and printing labels

table, allocating one character in alphabetical order from A to P.

Code

Function

E

Completes printing contents setting and prints labels. On completion

of printing, command interpreter is switched to system level interpreter

and syst em level commands are valid.

Caution

If label format commands are used again, use the system level "STX"

+ "L" command.

Entering previous-defined field character string into global table

Code

Function

Example

G

Enters a previous-defined label format character string into global

Reading of character string stored in the global table is executed with

command " Reading out from global register "

Input data below represents that data of character string "ABC" is

stored in the global table with font 9 and fonts 9 and 5 are printed.

Input data

[02] n Sets units to inch

[02] L Starts label format mode

D22 Sets pixel size

190000500800120ABC Sets character data "ABC" with

G Stores character string "ABC" in

151100002800120[02]SA

E Ends label format mode and prints

Setting print density (head heat factor)

Code

Setting

H nn

nn 00 – 20 in DPP

00 – 30 in DM4/DM8/DMI/DMW

Initialization value: 10

smooth font 14pt

global table

Function

Sets print density (heat energy is applied to print head).

Page 60

1-58

Changing units from inch to metric system

Code

Function

m

Changes units temporarily for all-distance-specified-command-parameters

from 0.01 inch to 0.1 mm.

Example

Input data below represents that data "ABC" is specified with units in metric

system.

Changing units from metric to inch system

Code

Function

n

Changes units temporarily for all-distance-specified-command-parameters

from 0.1 mm to 0.01 inch. Operation is same as [02] n command.

Page 61

1-59

Setting printable area speed

and maximum value vary depending on the printer

901234

Code

Setting

P a

a One alphanumeric character.

A or B or 1 2.0 inches (50.8 mm)/sec

C or D or 2 2.0 inches (50.8 mm)/sec

E or F or 3 3.0 inches (76.2 mm)/sec

G or H or 4 4.0 inches (101.6 mm)/sec

I or J or 5 5.0 inches (127.0 mm)/sec

K or L or 6 6.0 inches (152.4 mm)/sec

M or N or 7 7.0 inches (177.8 mm)/sec

O or P or 8 8.0 inches (203.2 mm)/sec

Q or R or 9 9.0 inches (228.6 mm)/sec

S or T or a 10 .0 inches (254.0 mm)/sec

U or V or b 11.0 inches (279.4 mm)/sec

W or c 12.0 inches (304.5 mm)/sec

Note: Initial value

model.

Function

Sets printable area speed.

Unprintable area Sa

Direction of feed

Printable area Pa

Unprintable area Sa

Printable area Pa

Page 62

1-60

Setting backfeed speed

and maximum value vary depending on the printer

Code

Setting

p a

a One alphanumeric character.

A or B or 1 2.0 inches (50.8 mm)/sec

C or D or 2 2.0 inches (50.8 mm)/sec

E or F or 3 3.0 inches (76.2 mm)/sec

G or H or 4 4.0 inches (101.6 mm)/sec

I or J or 5 5.0 inches (127.0 mm)/sec

K or L or 6 6.0 inches (152.4 mm)/sec

M or N or 7 7.0 inches (177.8 mm)/sec

O or P or 8 8.0 inches (203.2 mm)/sec

Q or R or 9 9.0 inches (228.6 mm)/sec

S or T or a 10 .0 inches (254.0 mm)/sec

U or V or b 11.0 inches (279.4 mm)/sec

W or c 12.0 inches (304.5 mm)/sec

Note: Initial value

model.

Function

Sets backfeed speed.

Page 63

1-61

Specifying space between characters

Code

Setting

Function

Example

Input data

[1b] P nn Data in [ ] is hex.

nn Amount of space between characters 00 - 99

Initialization value: 00

Adds specified space between characters to all characters.

Input data below represents that data without specification of space

between characters and data with specification of 10 to space

between characters are set and printed.

[02] n Sets units to inch

[02] L Starts label format mode

D11 Sets pixel size

190000700500050ABC Sets character data "ABC" with smooth

font 24pt

[1b] P10 Sets 10 for space between characters

190000700800050ABC Sets character data "ABC" with smooth

font 24pt

E Ends label format mode and prints

Spaces between characters nn=13

A B C

ABC

Spaces between characters

nn=0

Page 64

1-62

Setting number of prints

Code

Setting

Function

Example

Input data

Q nnnn

nnnn 0001 – 9999 Initialization value: 0001

Sets number of sheets to be printed.

Input data below represents that the same contents of labels are

printed ten sheets.

[02] n Sets units to inch

[02] L Starts label format mode

D11 Sets pixel size

Q0010 Setting 10 sheets for same label

printing

1F3306000500050490123456789 Sets EAN13 bar code for data

"490123456789"

E Ends label format mode and

prints

Page 65

1-63

Setting offset in direction of row

ABC

Code

Units

Setting

Function

Example

Input data

R nnnn

0.01 inch or 0.1 mm

nnnn 4-digit data Initialization value: 0000

Inch system 0000 - 9999 (0.00 inch - 99.99 inches)

Metric system 0000 - 9999 (0.0 mm - 99.9 mm)

Sets offset value for printing start position in direction of row (paper

top and bottom) to adjust the position of the total printi ng contents.

Shifts label printing position 1.0 inch (R0100) upwards and prints.

[02] n Sets units to inch

[02] L Starts label format mode

D11 Sets pixel size

R0100 Sets row offset to 1.0 inch

190000501150090ABC Sets character data "ABC" with

smooth font 14pt

1F3306000500050490123456789 Sets EAN13 bar code for data

"490123456789"

Direction

of feed

E Ends label format mode and

prints

Printing starting position after setting

4 901234 567894

Normal printing starting position

Page 66

1-64

Calling label format

Code

Setting

Function

Caution

Example

Input data

r aa..a

aa..a Maximum 16 characters of format name ending with CR

code

Calls label format stored in the memory module. Storing of label

format into memory module is executed with "s" command.

Priority for calling module

(1) Default (module C) or STX + Xa setting module

(2) Modules other than above

Input data below represents that label format data is stored in the

RAM by using "NAME" and label format is ended once, then put in

again and file name "NAME" in the RAM is called and those data

together with the current label format data are printed.

[02] n Sets units to inch

[02] L Starts label format mode

D11 Sets pixel size

190000700500050PRINTER Sets data "PRINTER" with

smooth font 24pt

sANAME Stores label format name