Daikin RXYSA4A7V1B, RXYSA5A7V1B, RXYSA6A7V1B, RXYSA4A7Y1B, RXYSA5A7Y1B Installer reference guide

...

Installer and user reference guide

VRV 5-S system air conditioner

RXYSA4A7V1B

RXYSA5A7V1B

RXYSA6A7V1B

RXYSA4A7Y1B

RXYSA5A7Y1B

RXYSA6A7Y1B

Table of contents

Table of contents

1 About the documentation 6

1.1 About this document ...................................................................................................................................................... 6

1.2 Meaning of warnings and symbols................................................................................................................................. 6

2 General safety precautions 8

2.1 For the installer............................................................................................................................................................... 8

2.1.1 General ........................................................................................................................................................... 8

2.1.2 Installation site ............................................................................................................................................... 9

2.1.3 Refrigerant — in case of R410A or R32.......................................................................................................... 9

2.1.4 Electrical ......................................................................................................................................................... 11

3 Specific installer safety instructions 14

3.1 Instructions for equipment using R32 refrigerant ......................................................................................................... 17

3.1.1 Installation space requirements..................................................................................................................... 18

3.1.2 System layout requirements .......................................................................................................................... 19

3.1.3 To determine the charge limitations ............................................................................................................. 22

For the user 28

4 User safety instructions 29

4.1 General............................................................................................................................................................................ 29

4.2 Instructions for safe operation ....................................................................................................................................... 30

5 About the system 32

5.1 System layout.................................................................................................................................................................. 32

6 User interface 34

7 Before operation 35

8 Operation 36

8.1 Operation range.............................................................................................................................................................. 36

8.2 Operating the system ..................................................................................................................................................... 36

8.2.1 About operating the system........................................................................................................................... 36

8.2.2 About cooling, heating, fan only, and automatic operation ......................................................................... 36

8.2.3 About the heating operation.......................................................................................................................... 37

8.2.4 To operate the system (WITHOUT cool/heat changeover remote control switch)...................................... 37

8.2.5 To operate the system (WITH cool/heat changeover remote control switch) ............................................. 38

8.3 Using the dry program.................................................................................................................................................... 39

8.3.1 About the dry program................................................................................................................................... 39

8.3.2 To use the dry program (WITHOUT cool/heat changeover remote control switch) .................................... 39

8.3.3 To use the dry program (WITH cool/heat changeover remote control switch) ........................................... 39

8.4 Adjusting the air flow direction ...................................................................................................................................... 40

8.4.1 About the air flow flap.................................................................................................................................... 40

8.5 Setting the master user interface................................................................................................................................... 41

8.5.1 About setting the master user interface........................................................................................................ 41

8.5.2 To designate the master user interface ......................................................................................................... 41

9 Energy saving and optimum operation 42

9.1 Available main operation methods ................................................................................................................................ 43

9.2 Available comfort settings .............................................................................................................................................. 43

10 Maintenance and service 44

10.1 Maintenance after a long stop period............................................................................................................................ 45

10.2 Maintenance before a long stop period......................................................................................................................... 45

10.3 About the refrigerant...................................................................................................................................................... 45

10.4 After-sales service and warranty .................................................................................................................................... 46

10.4.1 Warranty period............................................................................................................................................. 46

10.4.2 Recommended maintenance and inspection................................................................................................ 46

10.4.3 Recommended maintenance and inspection cycles ..................................................................................... 47

10.4.4 Shortened maintenance and replacement cycles......................................................................................... 47

Installer and user reference guide

2

11 Troubleshooting 49

11.1 Error codes: Overview .................................................................................................................................................... 51

11.2 Symptoms that are NOT system malfunctions............................................................................................................... 53

11.2.1 Symptom: The system does not operate....................................................................................................... 53

RXYSA4~6A7V/Y1B

VRV 5-S system air conditioner

4P600330-1B – 2020.10

Table of contents

11.2.2 Symptom: Cool/Heat cannot be changed over ............................................................................................. 53

11.2.3 Symptom: Fan operation is possible, but cooling and heating do not work ................................................ 53

11.2.4 Symptom: The fan speed does not correspond to the setting...................................................................... 53

11.2.5 Symptom: The fan direction does not correspond to the setting................................................................. 54

11.2.6 Symptom: White mist comes out of a unit (Indoor unit) .............................................................................. 54

11.2.7 Symptom: White mist comes out of a unit (Indoor unit, outdoor unit)........................................................ 54

11.2.8 Symptom: The user interface reads "U4" or "U5" and stops, but then restarts after a few minutes.......... 54

11.2.9 Symptom: Noise of air conditioners (Indoor unit)......................................................................................... 54

11.2.10 Symptom: Noise of air conditioners (Indoor unit, outdoor unit) .................................................................. 54

11.2.11 Symptom: Noise of air conditioners (Outdoor unit)...................................................................................... 55

11.2.12 Symptom: Dust comes out of the unit........................................................................................................... 55

11.2.13 Symptom: The units can give off odours ....................................................................................................... 55

11.2.14 Symptom: The outdoor unit fan does not spin.............................................................................................. 55

11.2.15 Symptom: The compressor in the outdoor unit does not stop after a short heating operation ................. 55

11.2.16 Symptom: The inside of an outdoor unit is warm even when the unit has stopped.................................... 55

11.2.17 Symptom: Hot air can be felt when the indoor unit is stopped.................................................................... 55

12 Relocation 56

13 Disposal 57

14 Technical data 58

14.1 Information requirements for Eco Design...................................................................................................................... 58

For the installer 59

15 About the box 60

15.1 Overview: About the box ................................................................................................................................................ 60

15.2 Outdoor unit ................................................................................................................................................................... 60

15.2.1 To unpack the outdoor unit ........................................................................................................................... 60

15.2.2 To handle the outdoor unit............................................................................................................................ 61

15.2.3 To remove the accessories from the outdoor unit........................................................................................ 61

16 About the units and options 63

16.1 Identification ................................................................................................................................................................... 63

16.1.1 Identification label: Outdoor unit .................................................................................................................. 63

16.2 About the outdoor unit................................................................................................................................................... 63

16.3 System layout .................................................................................................................................................................. 64

16.4 Combining units and options .......................................................................................................................................... 64

16.4.1 About combining units and options............................................................................................................... 64

16.4.2 Possible combinations of indoor units........................................................................................................... 65

16.4.3 Possible options for the outdoor unit............................................................................................................ 65

17 Unit installation 66

17.1 Preparing the installation site......................................................................................................................................... 66

17.1.1 Installation site requirements of the outdoor unit........................................................................................ 66

17.1.2 Additional installation site requirements of the outdoor unit in cold climates............................................ 69

17.2 Opening and closing the unit .......................................................................................................................................... 69

17.2.1 About opening the units................................................................................................................................. 69

17.2.2 To open the outdoor unit............................................................................................................................... 70

17.2.3 To close the outdoor unit............................................................................................................................... 70

17.3 Mounting the outdoor unit............................................................................................................................................. 71

17.3.1 About mounting the outdoor unit ................................................................................................................. 71

17.3.2 Precautions when mounting the outdoor unit.............................................................................................. 71

17.3.3 To provide the installation structure ............................................................................................................. 71

17.3.4 To install the outdoor unit ............................................................................................................................. 72

17.3.5 To provide drainage........................................................................................................................................ 72

17.3.6 To prevent the outdoor unit from falling over .............................................................................................. 73

RXYSA4~6A7V/Y1B

VRV 5-S system air conditioner

4P600330-1B – 2020.10

18 Piping installation 75

18.1 Preparing refrigerant piping ........................................................................................................................................... 75

18.1.1 Refrigerant piping requirements.................................................................................................................... 75

18.1.2 Refrigerant piping material ............................................................................................................................ 75

18.1.3 To select the piping size ................................................................................................................................. 76

18.1.4 To select refrigerant branch kits.................................................................................................................... 77

18.1.5 Refrigerant piping length and height difference ........................................................................................... 78

18.2 Connecting the refrigerant piping .................................................................................................................................. 79

18.2.1 About connecting the refrigerant piping....................................................................................................... 79

18.2.2 Precautions when connecting the refrigerant piping.................................................................................... 79

18.2.3 Pipe bending guidelines ................................................................................................................................. 80

Installer and user reference guide

3

Table of contents

18.2.4 To braze the pipe end..................................................................................................................................... 80

18.2.5 Using the stop valve and service port............................................................................................................ 81

18.2.6 To remove the spun pipes.............................................................................................................................. 82

18.2.7 To connect the refrigerant piping to the outdoor unit ................................................................................. 83

18.2.8 To connect the refrigerant branching kit....................................................................................................... 85

18.3 Checking the refrigerant piping ...................................................................................................................................... 86

18.3.1 About checking the refrigerant piping........................................................................................................... 86

18.3.2 Checking refrigerant piping: General guidelines ........................................................................................... 87

18.3.3 Checking refrigerant piping: Setup ................................................................................................................ 88

18.3.4 To perform a leak test.................................................................................................................................... 88

18.3.5 To perform vacuum drying............................................................................................................................. 89

19 Charging refrigerant 90

19.1 About charging refrigerant ............................................................................................................................................. 90

19.2 About the refrigerant...................................................................................................................................................... 90

19.3 Precautions when charging refrigerant .......................................................................................................................... 91

19.4 To determine the additional refrigerant amount .......................................................................................................... 93

19.5 To charge refrigerant ...................................................................................................................................................... 94

19.6 Error codes when charging refrigerant .......................................................................................................................... 96

19.7 To fix the fluorinated greenhouse gases label ............................................................................................................... 96

19.8 To check for refrigerant leaks after charging ................................................................................................................. 97

19.9 To insulate the refrigerant piping ................................................................................................................................... 97

20 Electrical installation 100

20.1 About connecting the electrical wiring .......................................................................................................................... 100

20.1.1 Precautions when connecting the electrical wiring....................................................................................... 100

20.1.2 Field wiring: Overview.................................................................................................................................... 101

20.1.3 Guidelines when knocking out knockout holes............................................................................................. 102

20.1.4 Guidelines when connecting the electrical wiring......................................................................................... 103

20.1.5 About electrical compliance........................................................................................................................... 104

20.1.6 Safety device requirements ........................................................................................................................... 104

20.2 To connect the electrical wiring to the outdoor unit..................................................................................................... 105

20.3 To connect the external outputs .................................................................................................................................... 108

20.4 To connect the cool/heat selector switch option .......................................................................................................... 109

20.5 To check the insulation resistance of the compressor .................................................................................................. 110

21 Configuration 112

21.1 Overview: Configuration ................................................................................................................................................. 112

21.2 Making field settings ....................................................................................................................................................... 113

21.2.1 About making field settings............................................................................................................................ 113

21.2.2 To access the field setting components......................................................................................................... 114

21.2.3 Field setting components............................................................................................................................... 114

21.2.4 To access mode 1 or 2.................................................................................................................................... 115

21.2.5 To use mode 1................................................................................................................................................ 116

21.2.6 To use mode 2................................................................................................................................................ 117

21.2.7 Mode 1: Monitoring settings ......................................................................................................................... 118

21.2.8 Mode 2: Field settings.................................................................................................................................... 119

21.3 Energy saving and optimum operation .......................................................................................................................... 124

21.3.1 Available main operation methods................................................................................................................ 124

21.3.2 Available comfort settings.............................................................................................................................. 125

21.3.3 Example: Automatic mode during cooling..................................................................................................... 127

21.3.4 Example: Automatic mode during heating.................................................................................................... 128

22 Commissioning 130

22.1 Precautions when commissioning .................................................................................................................................. 130

22.2 Checklist before commissioning ..................................................................................................................................... 131

22.3 Checklist during commissioning ..................................................................................................................................... 132

22.4 About the test run........................................................................................................................................................... 132

22.5 To perform a test run (7-segment display) .................................................................................................................... 132

22.6 Correcting after abnormal completion of the test run .................................................................................................. 133

23 Hand-over to the user 134

24 Maintenance and service 135

24.1 Maintenance safety precautions .................................................................................................................................... 135

24.1.1 To prevent electrical hazards......................................................................................................................... 136

24.2 Checklist for yearly maintenance of the outdoor unit ................................................................................................... 137

24.3 About service mode operation ....................................................................................................................................... 137

24.3.1 To use vacuum mode ..................................................................................................................................... 137

24.3.2 To recover refrigerant.................................................................................................................................... 137

Installer and user reference guide

4

VRV 5-S system air conditioner

RXYSA4~6A7V/Y1B

4P600330-1B – 2020.10

Table of contents

25 Troubleshooting 138

25.1 Overview: Troubleshooting ............................................................................................................................................ 138

25.2 Precautions when troubleshooting ................................................................................................................................ 138

25.3 Solving problems based on error codes ......................................................................................................................... 138

25.3.1 Error codes: Overview.................................................................................................................................... 139

25.4 Refrigerant leak detection system.................................................................................................................................. 141

26 Disposal 144

27 Technical data 145

27.1 Service space: Outdoor unit ........................................................................................................................................... 146

27.2 Piping diagram: Outdoor unit ......................................................................................................................................... 148

27.3 Wiring diagram: Outdoor unit ........................................................................................................................................ 149

28 Glossary 153

RXYSA4~6A7V/Y1B

VRV 5-S system air conditioner

4P600330-1B – 2020.10

Installer and user reference guide

5

1 | About the documentation

1 About the documentation

In this chapter

1.1 About this document.............................................................................................................................................................. 6

1.2 Meaning of warnings and symbols......................................................................................................................................... 6

1.1 About this document

Target audience

Authorised installers + end users

Documentation set

This document is part of a documentation set. The complete set consists of:

INFORMATION

This appliance is intended to be used by expert or trained users in shops, in light

industry and on farms, or for commercial use by lay persons.

▪ General safety precautions:

- Safety instructions that you must read before installing

- Format: Paper (in the box of the outdoor unit)

▪ Outdoor unit installation and operation manual:

- Installation and operation instructions

- Format: Paper (in the box of the outdoor unit)

▪ Installer and user reference guide:

- Preparation of the installation, reference data,…

- Detailed step-by-step instructions and background information for basic and

advanced usage

- Format: Digital files on http://www.daikineurope.com/support-and-manuals/

product-information/

Latest revisions of the supplied documentation may be available on the regional

Daikin website or via your dealer.

The original documentation is written in English. All other languages are

translations.

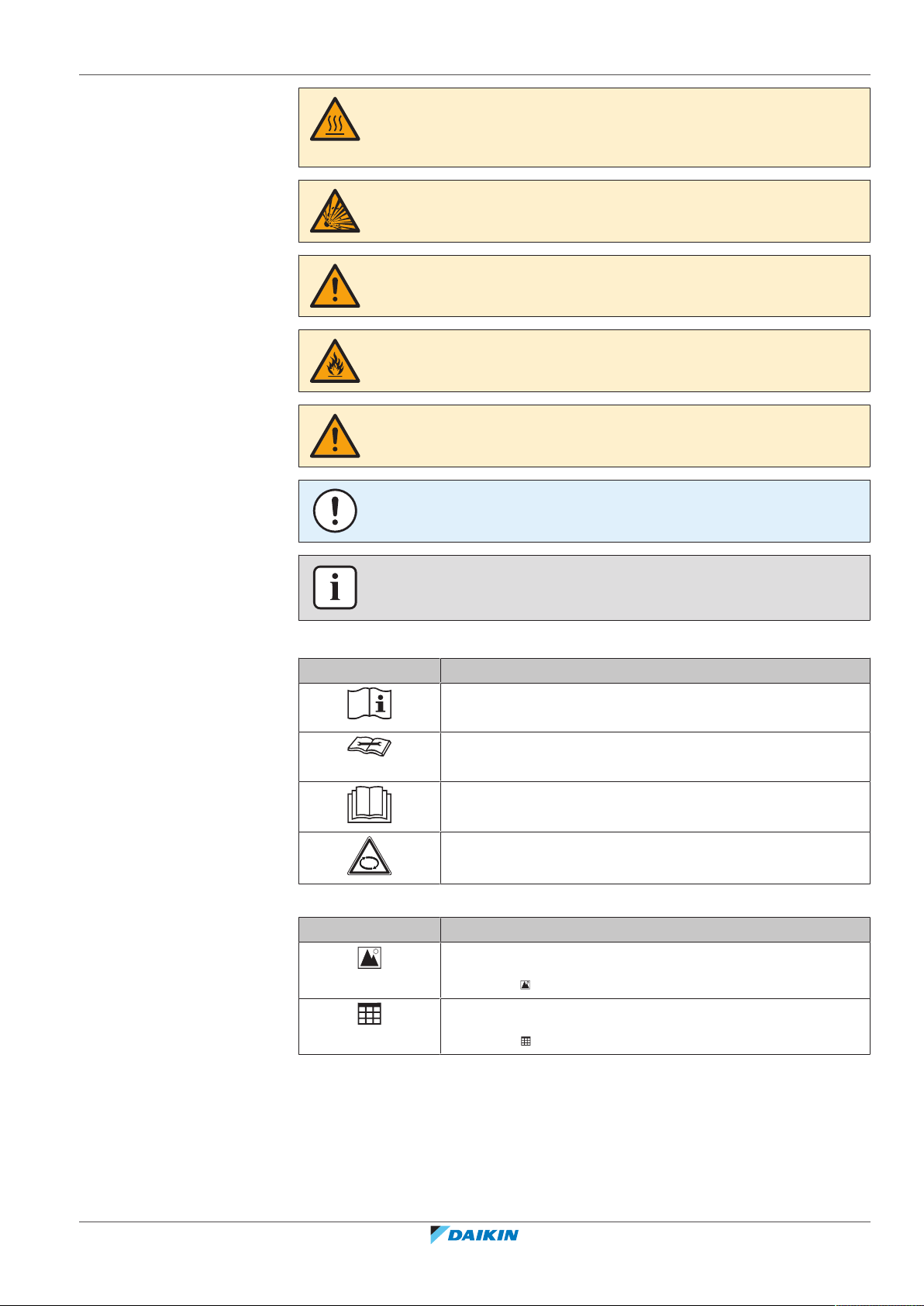

1.2 Meaning of warnings and symbols

Installer and user reference guide

6

DANGER

Indicates a situation that results in death or serious injury.

DANGER: RISK OF ELECTROCUTION

Indicates a situation that could result in electrocution.

RXYSA4~6A7V/Y1B

VRV 5-S system air conditioner

4P600330-1B – 2020.10

1 | About the documentation

DANGER: RISK OF BURNING/SCALDING

Indicates a situation that could result in burning/scalding because of extreme hot or

cold temperatures.

DANGER: RISK OF EXPLOSION

Indicates a situation that could result in explosion.

WARNING

Indicates a situation that could result in death or serious injury.

WARNING: FLAMMABLE MATERIAL

CAUTION

Indicates a situation that could result in minor or moderate injury.

NOTICE

Indicates a situation that could result in equipment or property damage.

INFORMATION

Indicates useful tips or additional information.

Symbols used on the unit:

Symbol Explanation

Before installation, read the installation and operation

manual, and the wiring instruction sheet.

Before performing maintenance and service tasks, read the

service manual.

For more information, see the installer and user reference

guide.

The unit contains rotating parts. Be careful when servicing or

inspecting the unit.

Symbols used in the documentation:

Symbol Explanation

Indicates a figure title or a reference to it.

Example: " 1–3 Figure title" means "Figure 3 in chapter 1".

Indicates a table title or a reference to it.

RXYSA4~6A7V/Y1B

VRV 5-S system air conditioner

4P600330-1B – 2020.10

Example: " 1–3 Table title" means "Table 3 in chapter 1".

Installer and user reference guide

7

2 | General safety precautions

2 General safety precautions

In this chapter

2.1 For the installer....................................................................................................................................................................... 8

2.1 For the installer

2.1.1 General

If you are NOT sure how to install or operate the unit, contact your dealer.

2.1.1 General ................................................................................................................................................................... 8

2.1.2 Installation site ....................................................................................................................................................... 9

2.1.3 Refrigerant — in case of R410A or R32 ................................................................................................................. 9

2.1.4 Electrical ................................................................................................................................................................. 11

DANGER: RISK OF BURNING/SCALDING

▪ Do NOT touch the refrigerant piping, water piping or internal parts during and

immediately after operation. It could be too hot or too cold. Give it time to return

to normal temperature. If you must touch it, wear protective gloves.

▪ Do NOT touch any accidental leaking refrigerant.

WARNING

Improper installation or attachment of equipment or accessories could result in

electrical shock, short-circuit, leaks, fire or other damage to the equipment. Only use

accessories, optional equipment and spare parts made or approved by Daikin.

WARNING

Make sure installation, testing and applied materials comply with applicable

legislation (on top of the instructions described in the Daikin documentation).

CAUTION

Wear adequate personal protective equipment (protective gloves, safety glasses,…)

when installing, maintaining or servicing the system.

WARNING

Tear apart and throw away plastic packaging bags so that nobody, especially

children, can play with them. Possible risk: suffocation.

WARNING

Provide adequate measures to prevent that the unit can be used as a shelter by small

animals. Small animals that make contact with electrical parts can cause

malfunctions, smoke or fire.

Installer and user reference guide

8

CAUTION

Do NOT touch the air inlet or aluminium fins of the unit.

RXYSA4~6A7V/Y1B

VRV 5-S system air conditioner

4P600330-1B – 2020.10

2 | General safety precautions

CAUTION

▪ Do NOT place any objects or equipment on top of the unit.

▪ Do NOT sit, climb or stand on the unit.

NOTICE

Works executed on the outdoor unit are best done under dry weather conditions to

avoid water ingress.

In accordance with the applicable legislation, it might be necessary to provide a

logbook with the product containing at least: information on maintenance, repair

work, results of tests, stand-by periods,…

Also, at least, following information MUST be provided at an accessible place at the

product:

▪ Instructions for shutting down the system in case of an emergency

▪ Name and address of fire department, police and hospital

▪ Name, address and day and night telephone numbers for obtaining service

In Europe, EN378 provides the necessary guidance for this logbook.

2.1.2 Installation site

▪ Provide sufficient space around the unit for servicing and air circulation.

▪ Make sure the installation site withstands the weight and vibration of the unit.

▪ Make sure the area is well ventilated. Do NOT block any ventilation openings.

▪ Make sure the unit is level.

Do NOT install the unit in the following places:

▪ In potentially explosive atmospheres.

▪ In places where there is machinery that emits electromagnetic waves.

Electromagnetic waves may disturb the control system, and cause malfunction of

the equipment.

▪ In places where there is a risk of fire due to the leakage of flammable gases

(example: thinner or gasoline), carbon fibre, ignitable dust.

▪ In places where corrosive gas (example: sulphurous acid gas) is produced.

Corrosion of copper pipes or soldered parts may cause the refrigerant to leak.

2.1.3 Refrigerant — in case of R410A or R32

If applicable. See the installation manual or installer reference guide of your

application for more information.

RXYSA4~6A7V/Y1B

VRV 5-S system air conditioner

4P600330-1B – 2020.10

NOTICE

Make sure refrigerant piping installation complies with applicable legislation. In

Europe, EN378 is the applicable standard.

NOTICE

Make sure the field piping and connections are NOT subjected to stress.

Installer and user reference guide

9

2 | General safety precautions

WARNING

During tests, NEVER pressurize the product with a pressure higher than the

maximum allowable pressure (as indicated on the nameplate of the unit).

WARNING

Take sufficient precautions in case of refrigerant leakage. If refrigerant gas leaks,

ventilate the area immediately. Possible risks:

▪ Excessive refrigerant concentrations in a closed room can lead to oxygen

deficiency.

▪ Toxic gas might be produced if refrigerant gas comes into contact with fire.

DANGER: RISK OF EXPLOSION

Pump down – Refrigerant leakage. If you want to pump down the system, and there

is a leak in the refrigerant circuit:

▪ Do NOT use the unit's automatic pump down function, with which you can collect

all refrigerant from the system into the outdoor unit. Possible consequence: Selfcombustion and explosion of the compressor because of air going into the

operating compressor.

▪ Use a separate recovery system so that the unit's compressor does NOT have to

operate.

WARNING

ALWAYS recover the refrigerant. Do NOT release them directly into the environment.

Use a vacuum pump to evacuate the installation.

NOTICE

After all the piping has been connected, make sure there is no gas leak. Use nitrogen

to perform a gas leak detection.

NOTICE

▪ To avoid compressor breakdown, do NOT charge more than the specified amount

of refrigerant.

▪ When the refrigerant system is to be opened, refrigerant MUST be treated

according to the applicable legislation.

WARNING

Make sure there is no oxygen in the system. Refrigerant may only be charged after

performing the leak test and the vacuum drying.

Possible consequence: Self-combustion and explosion of the compressor because of

oxygen going into the operating compressor.

▪ In case recharge is required, see the nameplate of the unit. It states the type of

refrigerant and necessary amount.

Installer and user reference guide

10

▪ The unit is factory charged with refrigerant and depending on pipe sizes and pipe

lengths some systems require additional charging of refrigerant.

▪ Only use tools exclusively for the refrigerant type used in the system, this to

ensure pressure resistance and prevent foreign materials from entering into the

system.

▪ Charge the liquid refrigerant as follows:

RXYSA4~6A7V/Y1B

VRV 5-S system air conditioner

4P600330-1B – 2020.10

2 | General safety precautions

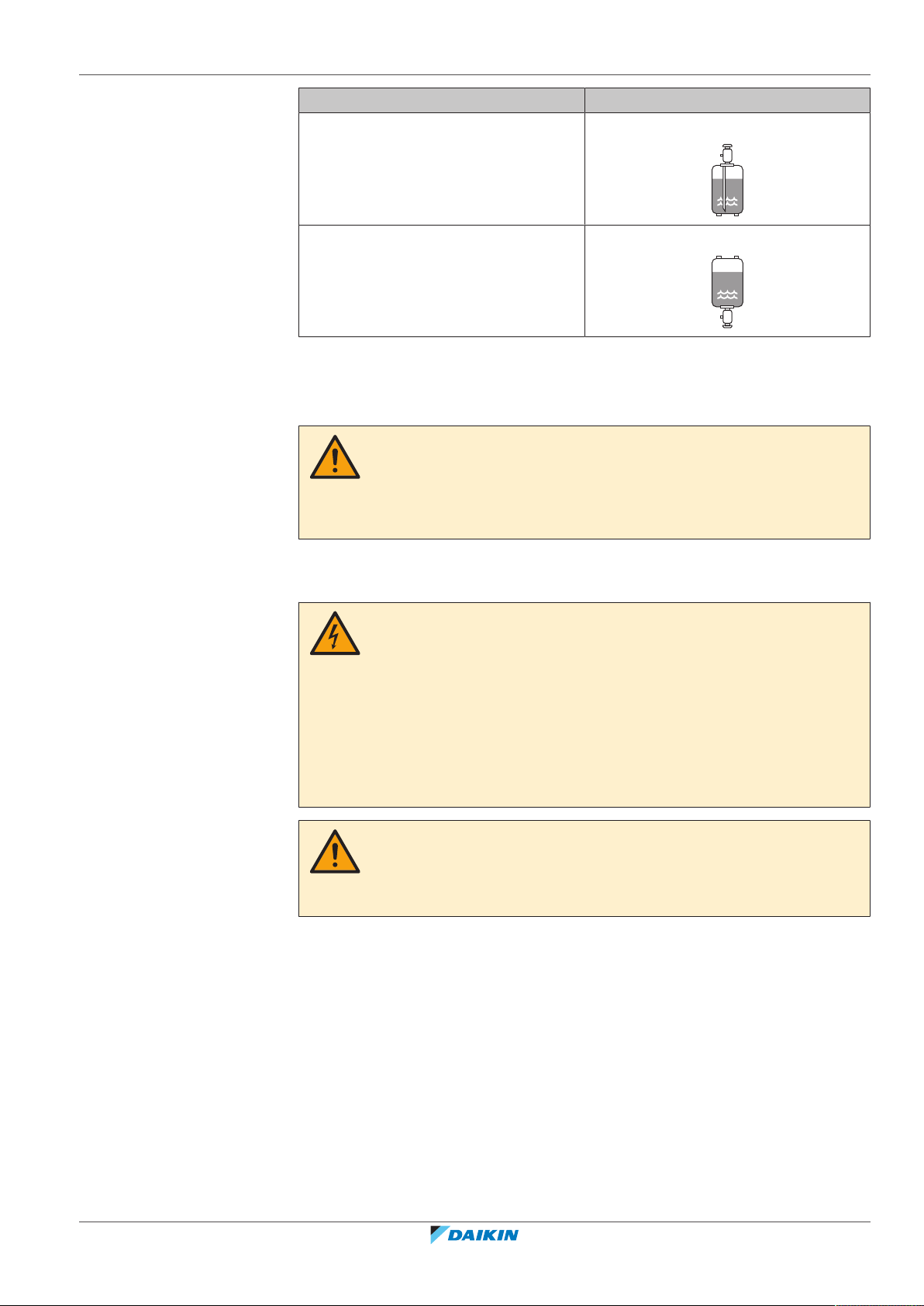

If Then

A siphon tube is present

Charge with the cylinder upright.

(i.e., the cylinder is marked with "Liquid

filling siphon attached")

A siphon tube is NOT present Charge with the cylinder upside down.

▪ Open refrigerant cylinders slowly.

▪ Charge the refrigerant in liquid form. Adding it in gas form may prevent normal

operation.

CAUTION

When the refrigerant charging procedure is done or when pausing, close the valve of

the refrigerant tank immediately. If the valve is NOT closed immediately, remaining

pressure might charge additional refrigerant. Possible consequence: Incorrect

refrigerant amount.

2.1.4 Electrical

DANGER: RISK OF ELECTROCUTION

▪ Turn OFF all power supply before removing the switch box cover, connecting

electrical wiring or touching electrical parts.

▪ Disconnect the power supply for more than 10minutes, and measure the voltage

at the terminals of main circuit capacitors or electrical components before

servicing. The voltage MUST be less than 50VDC before you can touch electrical

components. For the location of the terminals, see the wiring diagram.

▪ Do NOT touch electrical components with wet hands.

▪ Do NOT leave the unit unattended when the service cover is removed.

WARNING

If NOT factory installed, a main switch or other means for disconnection, having a

contact separation in all poles providing full disconnection under overvoltage

categoryIII condition, MUST be installed in the fixed wiring.

RXYSA4~6A7V/Y1B

VRV 5-S system air conditioner

4P600330-1B – 2020.10

Installer and user reference guide

11

2 | General safety precautions

WARNING

▪ ONLY use copper wires.

▪ Make sure the field wiring complies with the applicable legislation.

▪ All field wiring MUST be performed in accordance with the wiring diagram

supplied with the product.

▪ NEVER squeeze bundled cables and make sure they do NOT come in contact with

the piping and sharp edges. Make sure no external pressure is applied to the

terminal connections.

▪ Make sure to install earth wiring. Do NOT earth the unit to a utility pipe, surge

absorber, or telephone earth. Incomplete earth may cause electrical shock.

▪ Make sure to use a dedicated power circuit. NEVER use a power supply shared by

another appliance.

▪ Make sure to install the required fuses or circuit breakers.

▪ Make sure to install an earth leakage protector. Failure to do so may cause

electrical shock or fire.

▪ When installing the earth leakage protector, make sure it is compatible with the

inverter (resistant to high frequency electric noise) to avoid unnecessary opening

of the earth leakage protector.

CAUTION

▪ When connecting the power supply: connect the earth cable first, before making

the current-carrying connections.

▪ When disconnecting the power supply: disconnect the current-carrying cables

first, before separating the earth connection.

▪ The length of the conductors between the power supply stress relief and the

terminal block itself must be as such that the current-carrying wires are tautened

before the earth wire is in case the power supply is pulled loose from the stress

relief.

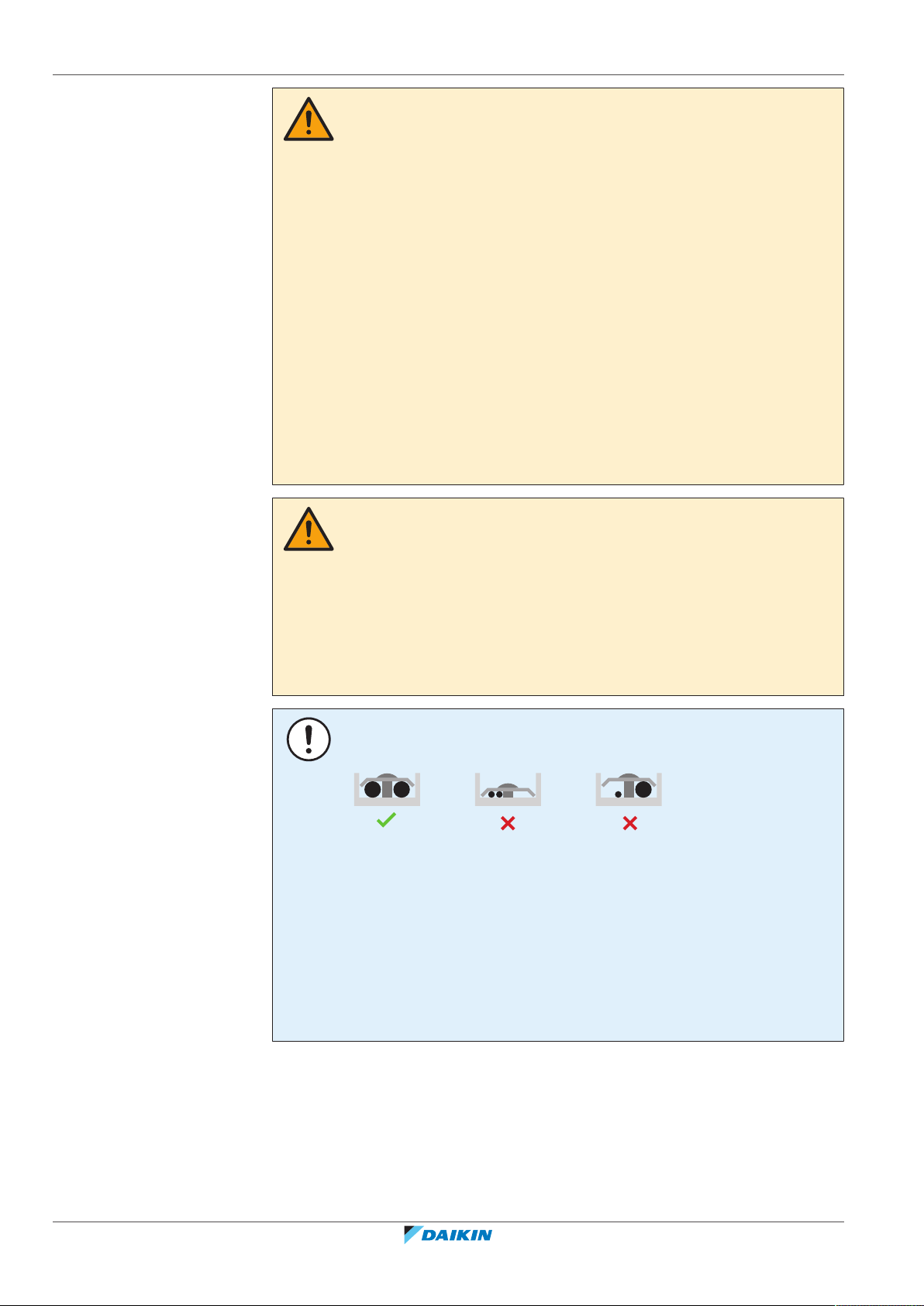

NOTICE

Precautions when laying power wiring:

▪ Do NOT connect wiring of different thicknesses to the power terminal block (slack

in the power wiring may cause abnormal heat).

▪ When connecting wiring which is the same thickness, do as shown in the figure

above.

▪ For wiring, use the designated power wire and connect firmly, then secure to

prevent outside pressure being exerted on the terminal board.

▪ Use an appropriate screwdriver for tightening the terminal screws. A screwdriver

with a small head will damage the head and make proper tightening impossible.

▪ Over-tightening the terminal screws may break them.

Installer and user reference guide

12

Install power cables at least 1 m away from televisions or radios to prevent

interference. Depending on the radio waves, a distance of 1 m may not be

sufficient.

RXYSA4~6A7V/Y1B

VRV 5-S system air conditioner

4P600330-1B – 2020.10

2 | General safety precautions

WARNING

▪ After finishing the electrical work, confirm that each electrical component and

terminal inside the electrical components box is connected securely.

▪ Make sure all covers are closed before starting up the unit.

NOTICE

Only applicable if the power supply is three‑phase, and the compressor has an ON/

OFF starting method.

If there exists the possibility of reversed phase after a momentary black out and the

power goes on and off while the product is operating, attach a reversed phase

protection circuit locally. Running the product in reversed phase can break the

compressor and other parts.

RXYSA4~6A7V/Y1B

VRV 5-S system air conditioner

4P600330-1B – 2020.10

Installer and user reference guide

13

3 | Specific installer safety instructions

3 Specific installer safety instructions

Always observe the following safety instructions and regulations.

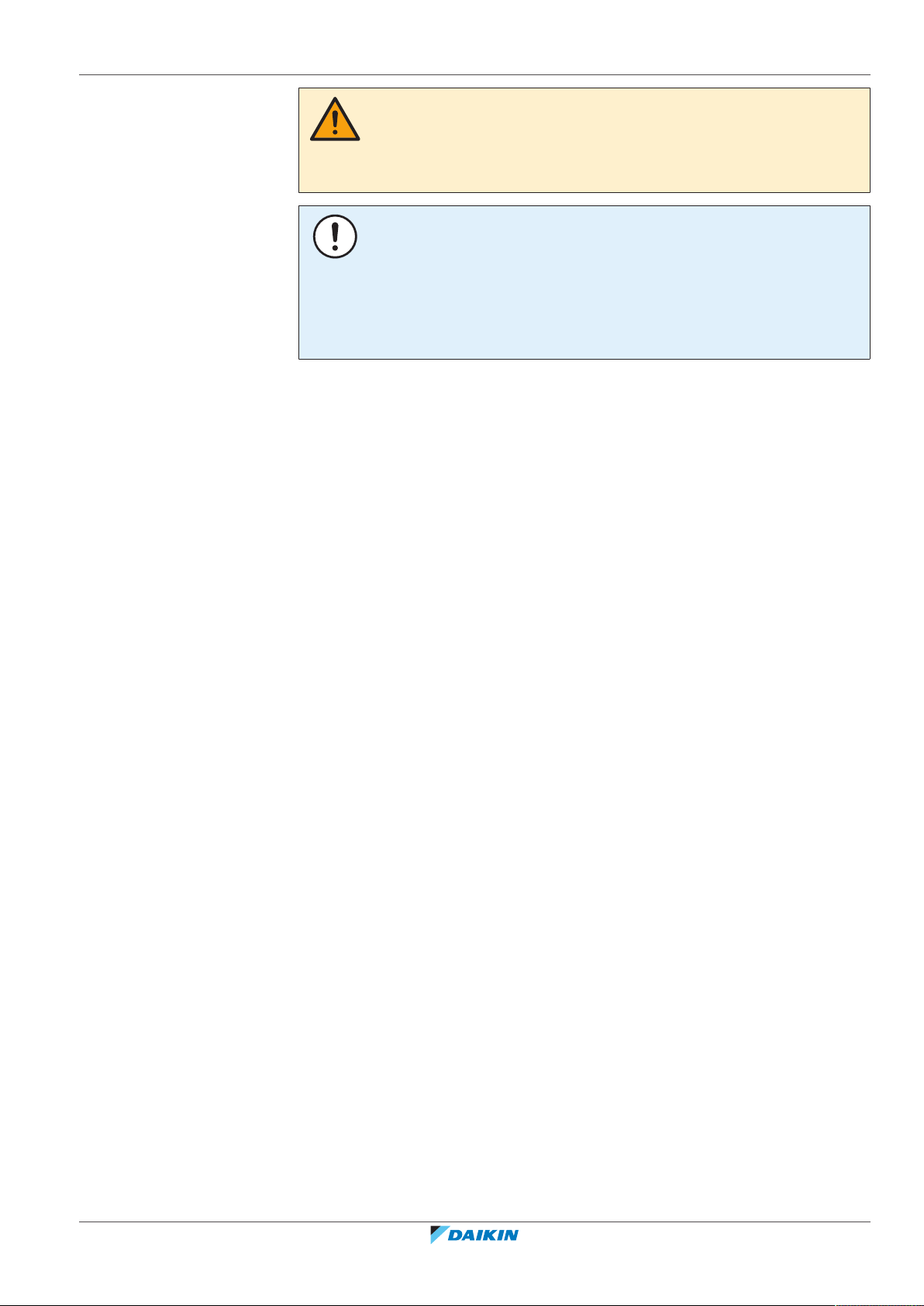

CAUTION

The cloth inside the left handle is intended to protect the hand from being cut by the

aluminium fins of the unit.

Remove the cloth after the unit is completely mounted.

Installation site (see

"17.1Preparing the installation site"[466]

WARNING

Follow the service space dimensions in this manual for correct installation of the unit.

See Service space: Outdoor unit.

WARNING

The appliance shall be stored in a room without continuously operating ignition

sources (example: open flames, an operating gas appliance or an operating electric

heater).

CAUTION

Appliance not accessible to the general public, install it in a secured area, protected

from easy access.

This unit, both indoor and outdoor, is suitable for installation in a commercial and

light industrial environment.

Opening and closing the unit (see

DANGER: RISK OF BURNING/SCALDING

)

"17.2Opening and closing the unit"[469]

)

Installer and user reference guide

14

DANGER: RISK OF ELECTROCUTION

Mounting the outdoor unit (see

WARNING

Fixing method of the outdoor unit MUST be in accordance with the instructions from

this manual. See "17.3Mounting the outdoor unit"[471].

"17.3Mounting the outdoor unit"[471]

RXYSA4~6A7V/Y1B

VRV 5-S system air conditioner

4P600330-1B – 2020.10

)

3 | Specific installer safety instructions

Connecting the refrigerant piping (see

piping"[479]

)

WARNING

Any gas or oil remaining inside the stop valve may blow off the spun piping.

If these instructions are NOT followed correctly it may result in property damage or

personal injury, which may be serious depending on the circumstances.

WARNING

NEVER remove the spun piping by brazing.

Any gas or oil remaining inside the stop valve may blow off the spun piping.

CAUTION

Do not vent gases into the atmosphere.

WARNING

Provide adequate measures to prevent that the unit can be used as a shelter by small

animals. Small animals that make contact with electrical parts can cause

malfunctions, smoke or fire.

"18.2Connecting the refrigerant

CAUTION

NEVER install a drier to this unit to guarantee its lifetime. The drying material may

dissolve and damage the system.

Charging refrigerant (see

WARNING

The refrigerant inside the unit is mildly flammable, but normally does NOT leak. If the

refrigerant leaks in the room and comes in contact with fire from a burner, a heater,

or a cooker, this may result in fire, or the formation of a harmful gas.

Turn off any combustible heating devices, ventilate the room, and contact the dealer

where you purchased the unit.

Do NOT use the unit until a service person confirms that the part from which the

refrigerant leaked has been repaired.

WARNING

Charging of refrigerant MUST be in accordance with the instructions from this

manual. See "19Charging refrigerant"[490].

WARNING

▪ Only use R32 as refrigerant. Other substances may cause explosions and

accidents.

▪ R32 contains fluorinated greenhouse gases. Its global warming potential (GWP)

value is 675. Do NOT vent these gases into the atmosphere.

▪ When charging refrigerant, ALWAYS use protective gloves and safety glasses.

"19Charging refrigerant"[490]

)

RXYSA4~6A7V/Y1B

VRV 5-S system air conditioner

4P600330-1B – 2020.10

Installer and user reference guide

15

3 | Specific installer safety instructions

Electrical installation (see

WARNING

▪ All wiring MUST be performed by an authorised electrician and MUST comply

with the applicable legislation.

▪ Make electrical connections to the fixed wiring.

▪ All components procured on-site and all electrical construction MUST comply

with the applicable legislation.

WARNING

Electrical wiring connection method MUST be in accordance with the instructions

from this manual. See "20Electrical installation"[4100].

WARNING

ALWAYS use multicore cable for power supply cables.

WARNING

▪ If the power supply has a missing or wrong N-phase, equipment might break

down.

▪ Establish proper earthing. Do NOT earth the unit to a utility pipe, surge absorber,

or telephone earth. Incomplete earthing may cause electrical shock.

▪ Install the required fuses or circuit breakers.

▪ Secure the electrical wiring with cable ties so that the cables do NOT come in

contact with sharp edges or piping, particularly on the high-pressure side.

▪ Do NOT use taped wires, stranded conductor wires, extension cords, or

connections from a star system. They can cause overheating, electrical shock or

fire.

▪ Do NOT install a phase advancing capacitor, because this unit is equipped with an

inverter. A phase advancing capacitor will reduce performance and may cause

accidents.

"20Electrical installation"[4100]

)

Installer and user reference guide

16

CAUTION

Do NOT push or place redundant cable length in the unit.

Commissioning (see

CAUTION

Do NOT perform the test operation while working on the indoor units.

When performing the test operation, NOT only the outdoor unit, but the connected

indoor unit will operate as well. Working on an indoor unit while performing a test

operation is dangerous.

CAUTION

Do NOT insert fingers, rods or other objects into the air inlet or outlet. Do NOT

remove the fan guard. When the fan is rotating at high speed, it will cause injury.

"22Commissioning"[4130]

)

RXYSA4~6A7V/Y1B

VRV 5-S system air conditioner

4P600330-1B – 2020.10

3 | Specific installer safety instructions

Troubleshooting (see

In this chapter

3.1 Instructions for equipment using R32 refrigerant ................................................................................................................. 17

"25Troubleshooting"[4138]

)

WARNING

▪ When carrying out an inspection on the switch box of the unit, ALWAYS make

sure that the unit is disconnected from the mains. Turn off the respective circuit

breaker.

▪ When a safety device was activated, stop the unit and find out why the safety

device was activated before resetting it. NEVER shunt safety devices or change

their values to a value other than the factory default setting. If you are unable to

find the cause of the problem, call your dealer.

WARNING

Prevent hazards due to inadvertent resetting of the thermal cut-out: power to this

appliance MUST NOT be supplied through an external switching device, such as a

timer, or connected to a circuit that is regularly turned ON and OFF by the utility.

3.1.1 Installation space requirements ............................................................................................................................ 18

3.1.2 System layout requirements .................................................................................................................................. 19

3.1.3 To determine the charge limitations ..................................................................................................................... 22

3.1 Instructions for equipment using R32 refrigerant

WARNING: MILDLY FLAMMABLE MATERIAL

The refrigerant inside this unit is mildly flammable.

WARNING

▪ Do NOT pierce or burn.

▪ Do NOT use means to accelerate the defrosting process or to clean the

equipment, other than those recommended by the manufacturer.

▪ Be aware that R32 refrigerant does NOT contain an odour.

WARNING

The appliance shall be stored so as to prevent mechanical damage and in a wellventilated room without continuously operating ignition sources (example: open

flames, an operating gas appliance or an operating electric heater) and have a room

size as specified below.

See "To determine the charge limitations" [4 22] to check if your system meets

the requirement for charge limitation.

WARNING

Make sure installation, servicing, maintenance and repair comply with instructions

from Daikin and with applicable legislation (for example national gas regulation) and

are executed only by authorised persons.

RXYSA4~6A7V/Y1B

VRV 5-S system air conditioner

4P600330-1B – 2020.10

Installer and user reference guide

17

3 | Specific installer safety instructions

WARNING

If one or more rooms are connected to the unit using a duct system, make sure:

▪ there are no operating ignition sources (example: open flames, an operating gas

appliance or an operating electric heater) in case the floor area is less than the

minimum floor area A (m²).

▪ no auxiliary devices, which may be a potential ignition source, are installed in the

duct work (example: hot surfaces with a temperature exceeding 700°C and

electric switching device);

▪ only auxiliary devices approved by the manufacturer are used in the duct work;

▪ air inlet AND outlet are connected directly to the same room by ducting. Do NOT

use spaces such as a false ceiling as a duct for the air inlet or outlet.

See "To determine the charge limitations" [4 22] to check if your system meets

the requirement for charge limitation.

NOTICE

▪ Precautions shall be taken to avoid excessive vibration or pulsation to

refrigeration piping.

▪ Protection devices, piping and fittings shall be protected as far as possible against

adverse environmental effects.

▪ Provision shall be made for expansion and contraction of long runs of piping.

▪ Piping in refrigerating systems shall be designed and installed such as to minimise

the likelihood of hydraulic shock damaging the system.

▪ The indoor equipment and pipes shall be securely mounted and guarded such

that accidental rupture of equipment or pipes cannot occur from events such as

moving furniture or reconstruction activities.

CAUTION

Do NOT use potential sources of ignition in searching for or detection of refrigerant

leaks.

NOTICE

▪ Do NOT re-use joints and copper gaskets which have been used already.

▪ Joints made in installation between parts of refrigerant system shall be accessible

for maintenance purposes.

3.1.1 Installation space requirements

WARNING

If the appliance contains R32 refrigerant, the floor area of the room in which the

appliance is stored shall be at least 98.3m².

NOTICE

▪ Pipework shall be protected from physical damage.

▪ Installation of pipework shall be kept to a minimum.

Installer and user reference guide

18

VRV 5-S system air conditioner

RXYSA4~6A7V/Y1B

4P600330-1B – 2020.10

3.1.2 System layout requirements

The VRV 5-S uses R32 refrigerant which is rated as A2L and is mildly flammable.

To comply with the requirements of enhanced tightness refrigerating systems of

the IEC 60335-2-40, this system is equipped with shut-off valves in the outdoor

unit and an alarm in the remote controller. In case the requirements of this manual

are followed, no additional safety measures are needed.

A big range of charge and room area combinations is allowed thanks to the

countermeasures that are implemented in the unit by default.

Follow the installation requirements below to ensure that the complete system is

compliant to legislation.

Outdoor unit installation

The outdoor unit has to be installed outside. For indoor installation of the outdoor

unit, additional measures can be necessary to comply with the applicable

legislation.

A terminal for external output is available in the outdoor unit. This SVS output can

be used when additional countermeasures are needed. The SVS output is a contact

on terminal X2M that closes in case a leak is detected, failure or disconnection of

the R32 sensor (located in the indoor unit).

3 | Specific installer safety instructions

For more information about the SVS output, see "20.3 To connect the external

outputs"[4108].

Indoor unit installation

For installation of the indoor unit, refer to the installation and operation manual

delivered with the indoor unit. For compatibility of indoor units refer to the latest

version of the technical data book of this unit.

The total amount of refrigerant in the system shall be less than or equal to the

maximum allowed total refrigerant amount. The maximum allowed total

refrigerant amount depends on the area of the rooms being served by the system

and the rooms in the lowest underground floor.

See "To determine the charge limitations" [4 22] to check if your system meets

the requirement for charge limitation.

An optional output PCB for the indoor unit can be added to provide output for

external device. The output PCB will trigger in case a leak is detected, the R32

sensor fails or when the sensor is disconnected. For exact model name see option

list of the indoor unit. For more information about this option, refer to the

installation manual of the optional output PCB.

Piping requirements

Piping must be installed according to instructions given in "18 Piping

installation"[4 75]. Only mechanical joints (e.g. braze+flare connections) that are

compliant with the latest version of ISO14903 can be used.

RXYSA4~6A7V/Y1B

VRV 5-S system air conditioner

4P600330-1B – 2020.10

For piping installed in the occupied space, please make sure that the piping is

protected against accidental damage. Piping should be checked according to

procedure as mentioned in "18.3Checking the refrigerant piping"[486].

Installer and user reference guide

19

3 | Specific installer safety instructions

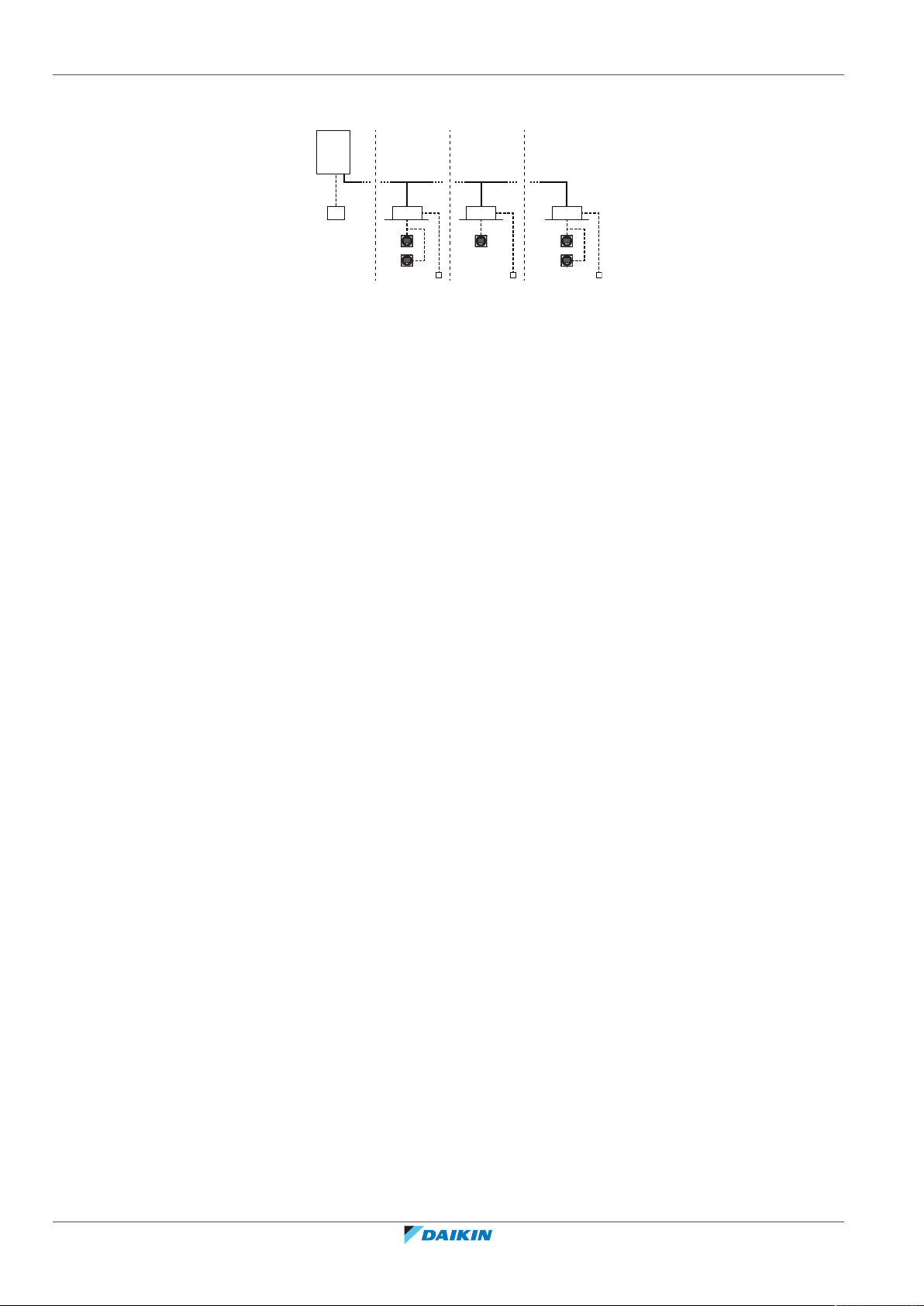

b

a

c

d

f

h

e

d

c

b b

c

d

g

h h

Remote controller requirements

a Heat pump outdoor unit

b Refrigerant piping

c VRV direct expansion (DX) indoor unit

d Remote controller in normal mode

e Remote controller in alarm only mode

f Remote controller in supervisor mode (mandatory in some situations)

g iTM (optional)

h Option PCB (optional)

For installation of the remote controller, please refer to the installation and

operation manual delivered with the remote controller. Each indoor unit has to be

connected with a R32 safety system compatible remote controller (e.g.

BRC1H52/82* or later type). These remote controllers have implemented safety

measures that will warn the user visually and audibly in case of a leak.

For installation of the remote controller it is mandatory to follow the requirements.

1 Only a safety system compatible remote controller can be used. See technical

data sheet for remote controller compatibility (e.g. BRC1H52/82*).

2 Each indoor unit has to be connected to a separate remote controller.

3 Even if multiple indoors are in the same room, they should all have a separate

remote controller.

4 The remote controller put in the same room as the indoor unit has to be in

fully functional mode or alarm only mode. For details about the different

remote controller modes and how to set up, please check the note below or

refer to the installation and operation manual delivered with the remote

controller.

5 Group control is not allowed.

6 For buildings where sleeping facilities are offered (e.g. hotel), where persons

are restricted in their movements (e.g. hospitals), an uncontrolled number of

persons is present or buildings where people are not aware of the safety

precautions it is mandatory to install one of the following devices at a location

with 24-hour monitoring:

▪ a supervisor remote controller

▪ or an iTM with external alarm via WAGO module.

Note: The remote controller will generate a visible and audible warning. E.g. the

BRC1H52/82* remote controllers can generate an alarm of 65dB (sound pressure,

measured at 1m distance of the alarm). Sound data is available in the technical

data sheet of the remote controller. The alarm should always be 15dB louder than

the background noise of the room. In case of higher background noise in a certain

room, we recommend to use an external alarm (field supply) in that room. This

alarm can be connected to the SVS output channel of the outdoor unit or to the

optional output PCB of the indoor unit of that specific room.

For more information on the SVS output signal, see "20.2To connect the electrical

wiring to the outdoor unit"[4105].

Installer and user reference guide

20

VRV 5-S system air conditioner

RXYSA4~6A7V/Y1B

4P600330-1B – 2020.10

3 | Specific installer safety instructions

a

c

b

a

d

b

a

b

c

b

b

a

b

d

b

d

b

d

a

d

b

a

d

b

Note: Depending on configuration, the remote controller is operable in three

possible modes. Each mode offers different controller functionality. For detailed

information about setting the operation mode of the remote controller and its

function, please refer to the installer and user reference guide of the remote

controller.

Mode Function

Fully functional The controller is fully functional. All normal

functionality is available. This controller can be master

or slave.

Alarm only The controller only acts as leak detection alarm (for a

single indoor unit). No functionality is available. The

remote controller should always be put in the same

room as the indoor unit. This controller can be master

or slave.

Supervisor The controller only acts as leak detection alarm (for

the whole system, i.e. multiple indoor units and their

respective controllers). No other functionality is

available. The remote controller should be placed at a

supervised location. This remote controller can only

be the slave.

Note: In order to add a supervisor remote controller to

the system, a field setting should be set on both

remote controller and outdoor unit.

Note: Incorrect use of remote controllers can result in occurrence of error codes,

non-operating system or system that is not compliant to applicable legislation.

Note: iTM in combination with a WAGO module can also be used as supervisor

remote controller. For further details on installation, please refer to installation

manual of the iTM.

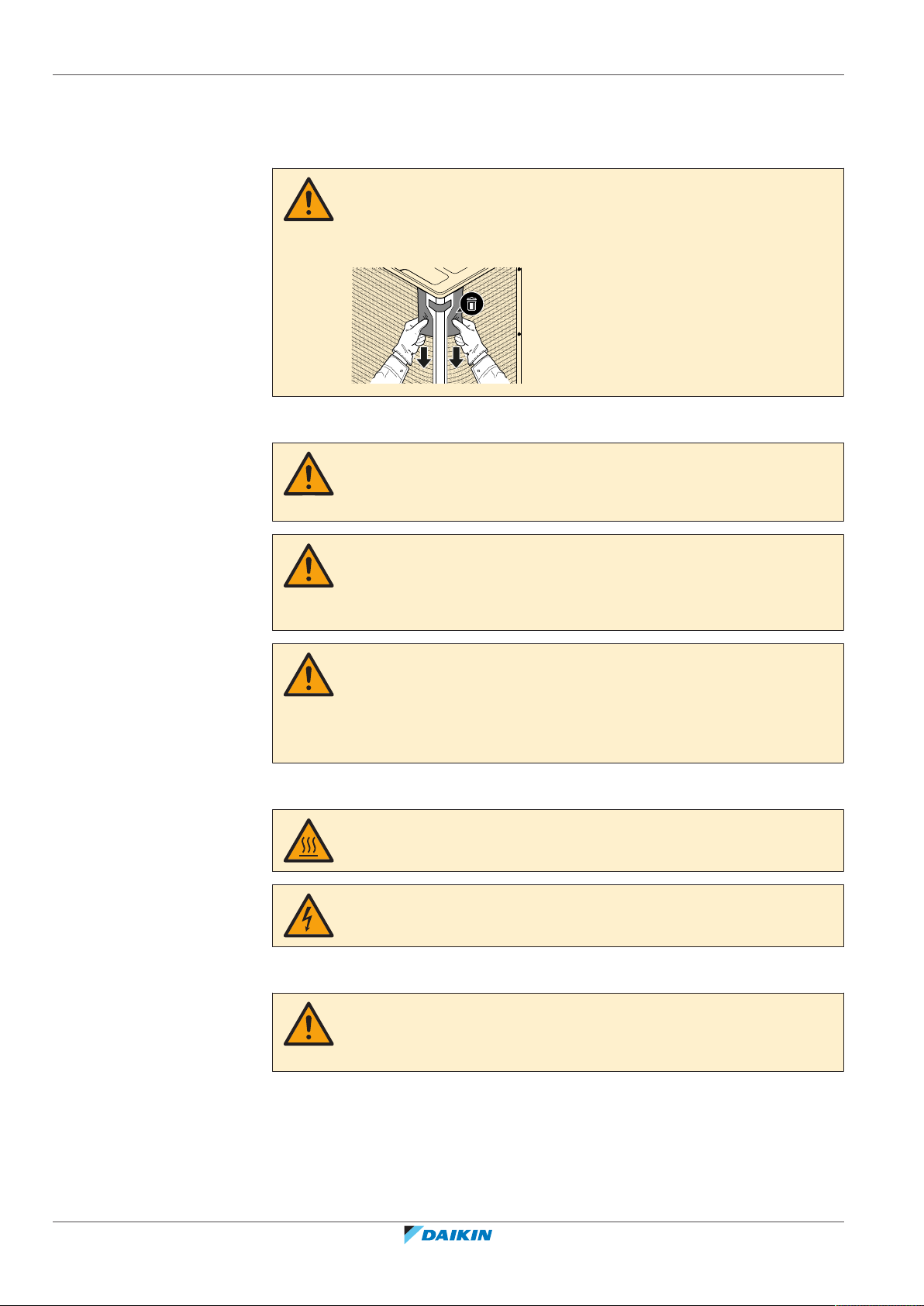

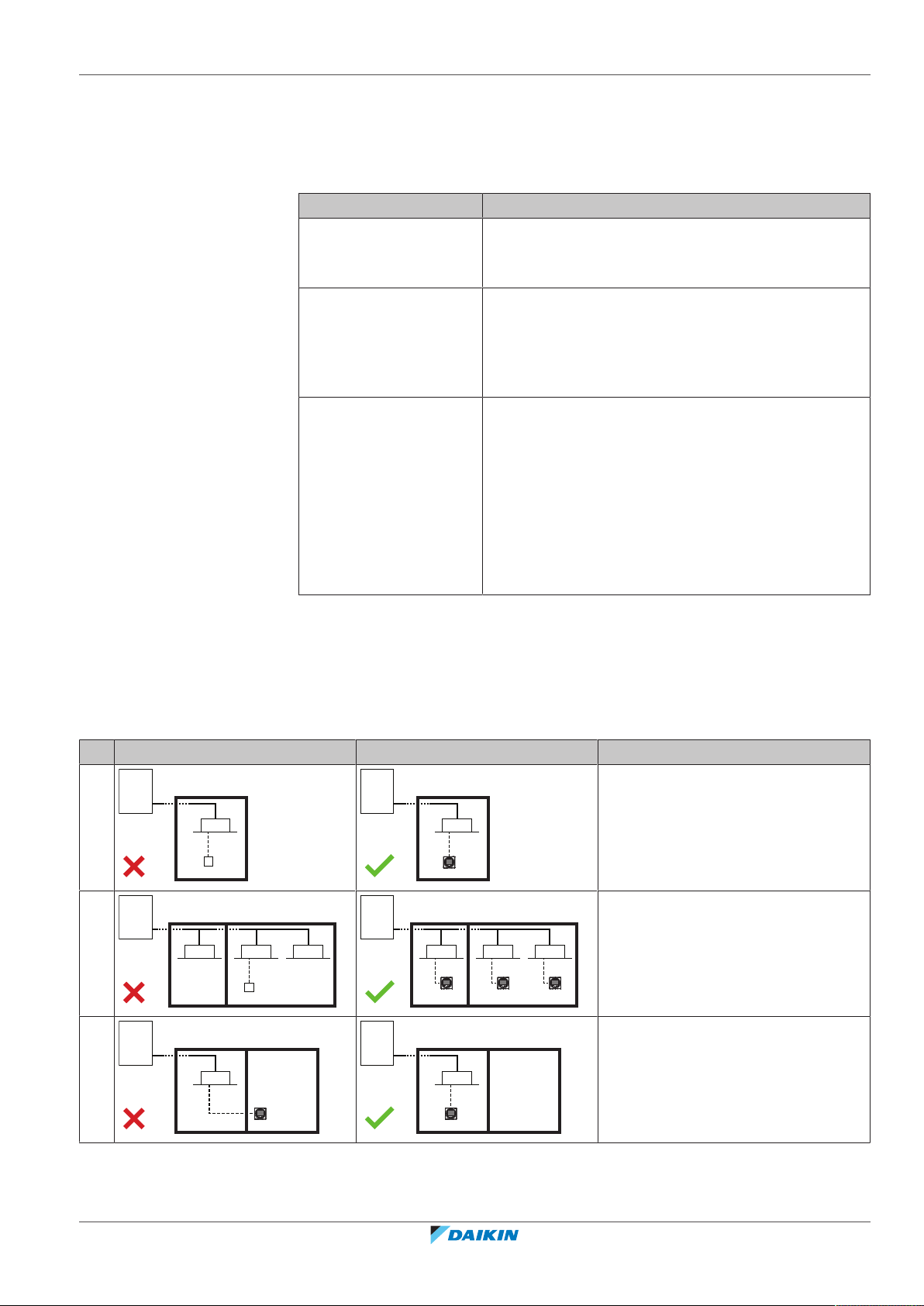

Examples

NOT OK OK Case

1

2

Remote controller is not R32 safety

system compatible

Indoor units without remote

controller are not allowed

3

In case of one R32 safety system

compatible remote controller, it

should be the master and in the same

room of the indoor unit.

RXYSA4~6A7V/Y1B

VRV 5-S system air conditioner

4P600330-1B – 2020.10

Installer and user reference guide

21

3 | Specific installer safety instructions

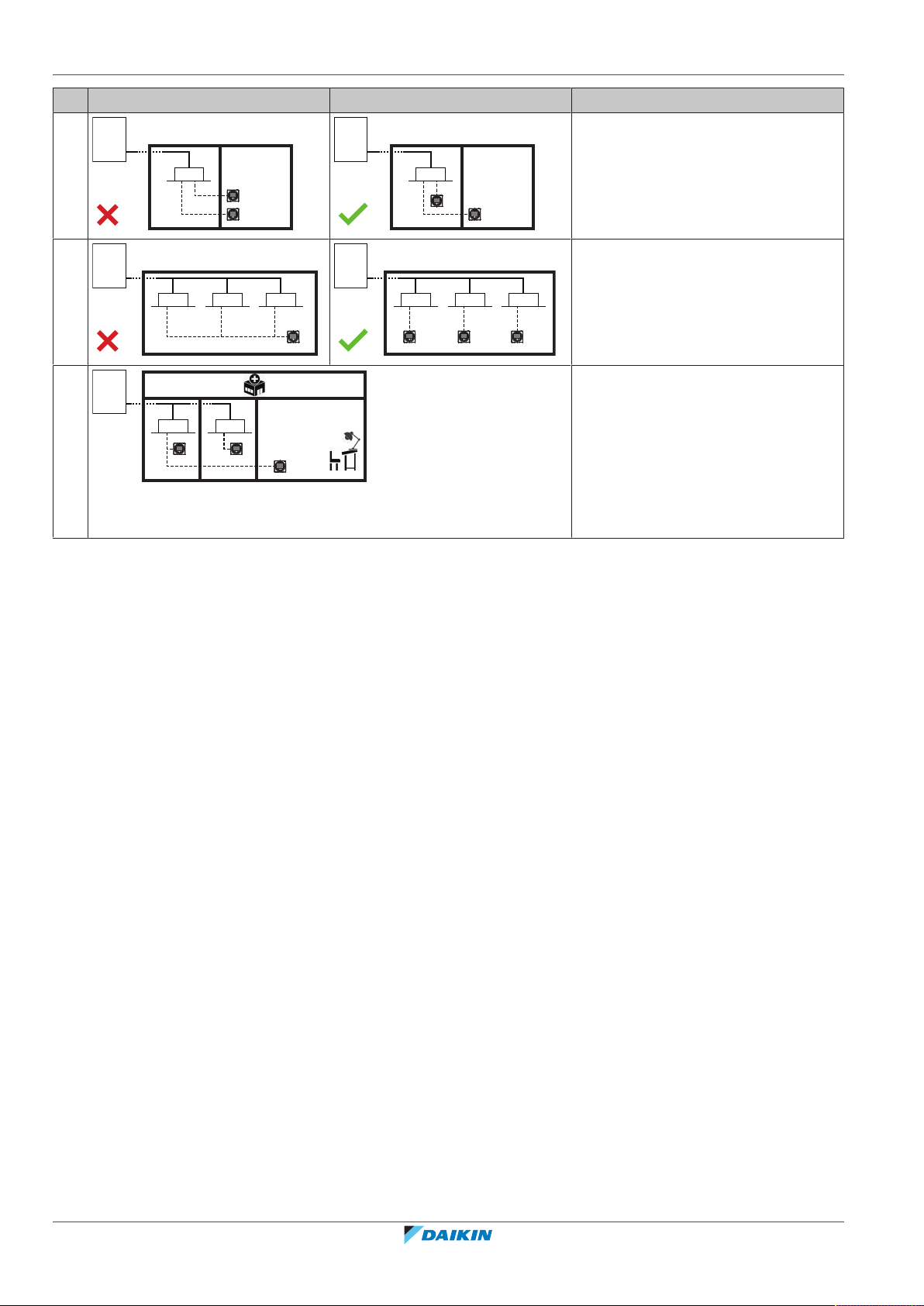

a

d

d

b

a

d

d

b

a

b b b

d

a

b b b

d d d

a

b

d

b

d

e

f

NOT OK OK Case

4

5

6

In room: master remote controller in fully functional OR alarm only.

In supervisor room: supervisor remote controller

a Outdoor unit

b Indoor unit

c Remote controller NOT compatible with R32 safety system

d Remote controller compatible with R32 safety system

e Remote controller in supervisor mode

f Supervisor room

In case of two R32 safety system

compatible remote controllers, at

least one remote controller should be

in the room of the indoor.

Group control system is not allowed.

Each indoor unit should be connected

to a separate remote controller

In particular situations it is mandatory

to install a remote controller at a

supervised location

3.1.3 To determine the charge limitations

1 Determine the area of the smallest room in order to derive the total

refrigerant charge limit in the system:

The room area can be determined by projecting the walls, doors and

partitions to the floor and calculate the enclosed area. The area of the

smallest room being served by the system is used in the next step to

determine the maximum allowable total charge of the system.

Spaces connected by only false ceilings, ductwork, or similar connections

shall not be considered a single space.

If the partition between 2 rooms on the same floor meets certain

requirements then the rooms are considered as one room and the areas of

the rooms may be added up. In this way it is possible to increase the A

value used to calculate the maximum allowed charge.

One of the following 2 requirements must be met in order to add up room

areas.

1 Rooms on the same floor that are connected with a permanent opening

that extends to the floor and is intended for people to walk through can

be considered as one room.

min

Installer and user reference guide

22

VRV 5-S system air conditioner

RXYSA4~6A7V/Y1B

4P600330-1B – 2020.10

3 | Specific installer safety instructions

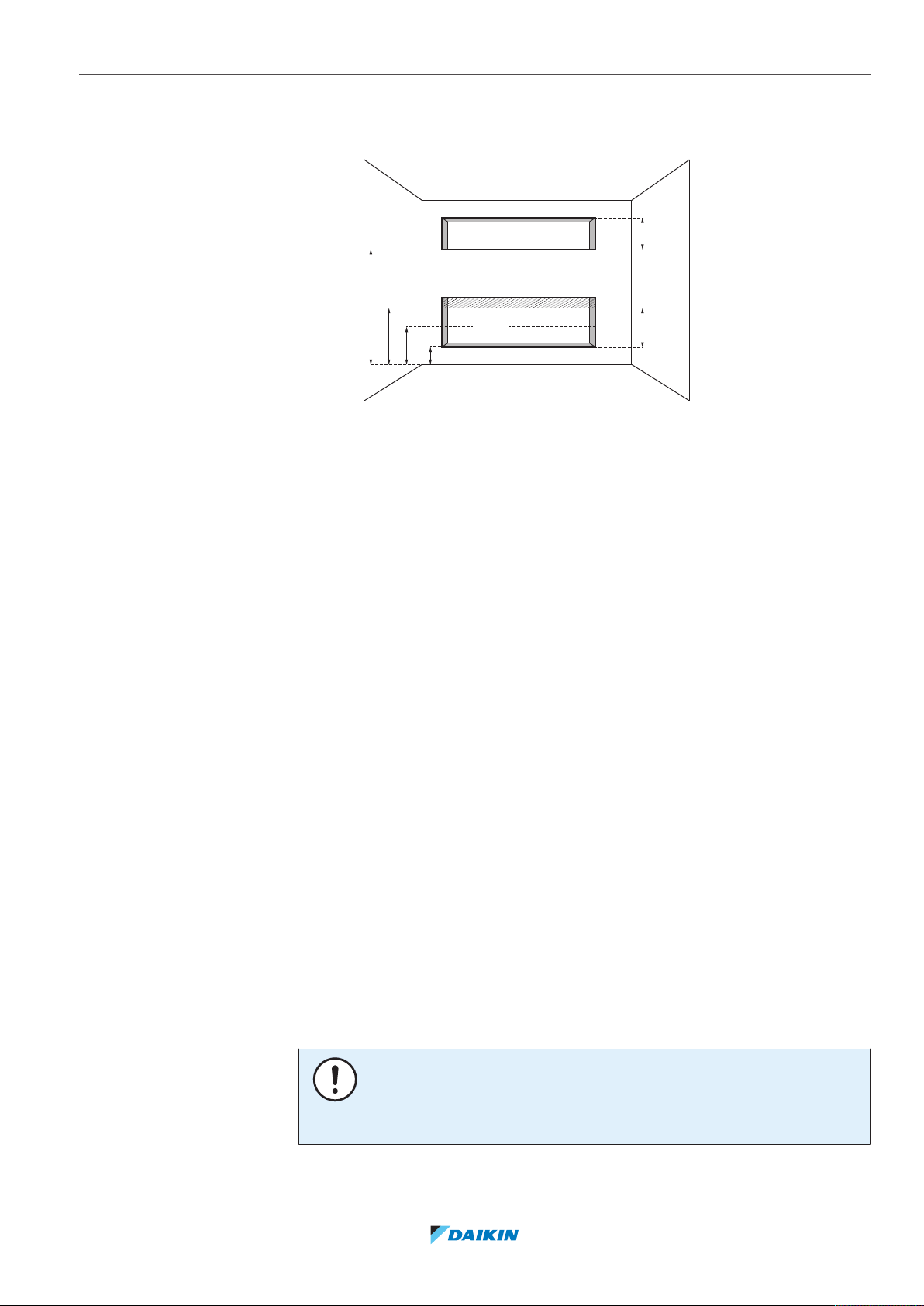

A

nvmin

≥ 20 mm

≥ 50% A

nvmin

≤ 100 mm

1500

mm

300

mm

200

mm

≥ 20 mm

2 Rooms on the same floor connected with openings that fulfil following

requirements can be considered as a single room. The opening must

consist out of 2 parts to allow for air circulation.

For the lower opening:

- The opening cannot go outdoors

- The opening cannot be closed

- The lower opening must be ≥0.012m² (A

nvmin

)

- The area of any openings above 300 mm from the floor does not

count when determining A

- At least 50% of A

nvmin

nvmin

is less than 200mm above the floor

- The bottom of the lower opening is ≤100mm from the floor

- The height of the openings is ≥20mm

For the upper opening:

- The opening cannot go outdoors

- The opening cannot be closed

- The upper opening must be ≥0.006m² (50% of A

nvmin

)

- The bottom of the upper opening must be ≥1500 mm above the

floor

- The height of the opening is ≥20mm

Note: The requirement for the upper opening can be met by drop

ceilings, ventilation ducts or similar arrangements that provide an airflow

path between the connected rooms.

2 Depending on the installation height of the indoor units, different values may

be used in the next step IF:

RXYSA4~6A7V/Y1B

VRV 5-S system air conditioner

4P600330-1B – 2020.10

▪ installation height is1.8≤x<2.2m, then use the charge limit of the graph for

wall-mounted units.

▪ installation height is ≥2.2 m, then use the charge limit of the graph for

ceiling-mounted units.

NOTICE

Wall mounted units cannot be installed lower than 1,8 m from the lowest point of

the floor. Ceiling mounted units cannot be installed lower than 2,2m from the lowest

point of the floor.

3 Use the graph or table below to determine the total refrigerant charge limit in

the system.

Installer and user reference guide

23

3 | Specific installer safety instructions

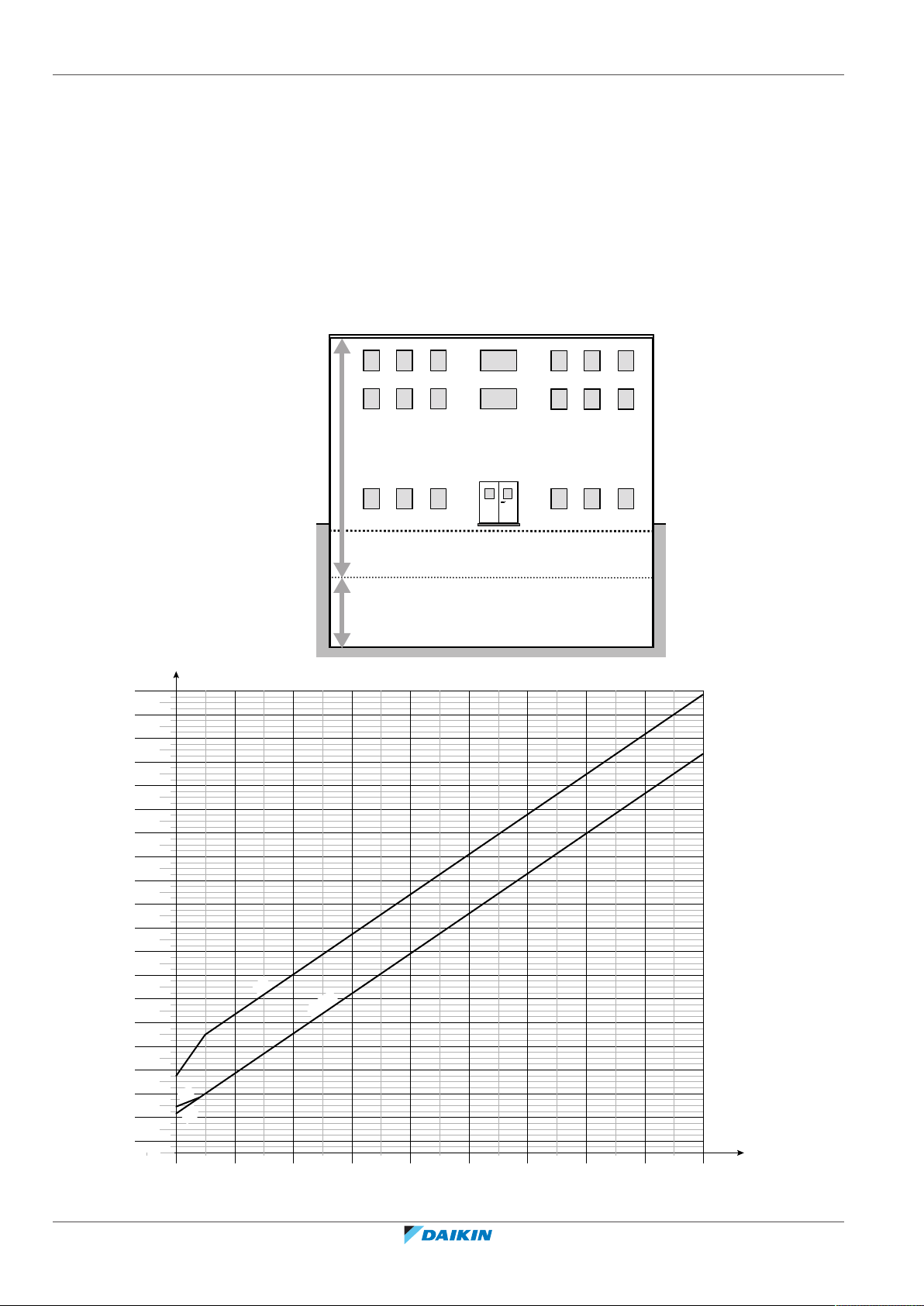

OTHER FLOORS

Curve (c) = room area ≥10 m²

Curve (a) OR (b) = room area <15 m²

Curve (a)(b) = room area ≥15 m²

LOWEST UNDERGROUND FLOOR

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

10 20 30 40 50 60 70 80 90

15 25 35 45 55 65 75 85 95

100

m (kg)

A

min

(m2)

(b)

(a)

(a)(b)

(c)

In case there are any underground floors in the building, there are special

requirements for the maximum allowable charge.

The maximum allowable charge is determined by using graph "(a)" or "(b)"

and "(a)(b)" for the room with the smallest area on the lowest underground

floor.

The maximum allowable charge has to be assessed for the room with the

smallest room area in both the lowest underground floor and the other

floors.

The lowest maximum allowable charge of both MUST be used.

Note: The derived charge value should be rounded down.

Installer and user reference guide

24

VRV 5-S system air conditioner

RXYSA4~6A7V/Y1B

4P600330-1B – 2020.10

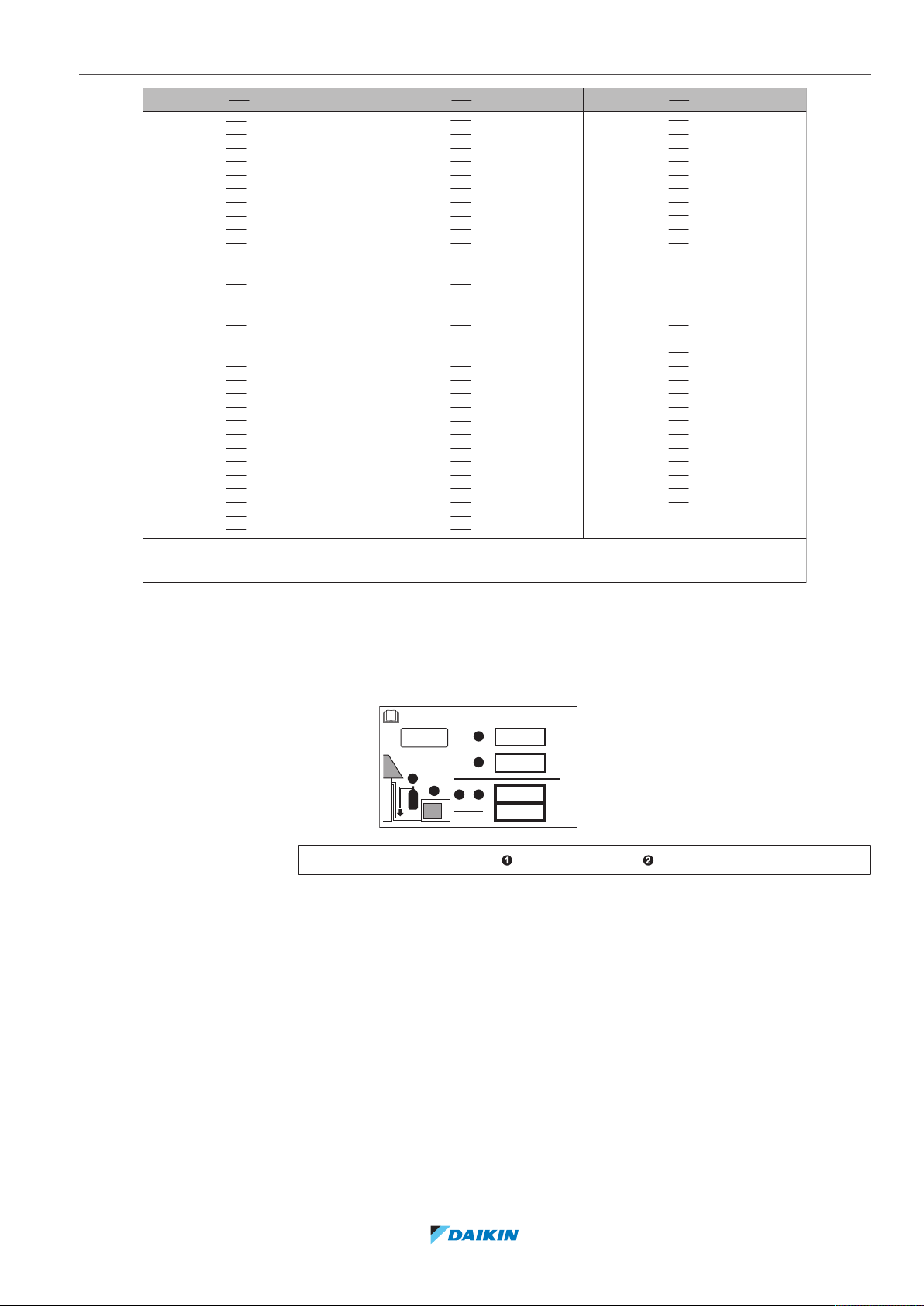

3 | Specific installer safety instructions

m (kg)

A

min

(m2)

m (kg)

A

min

(m2)

m (kg)

A

min

(m2)

(a)

Lowest underground floor (ceiling-mounted units)

(b)

Lowest underground floor (wall-mounted units)

(c)

Smallest room on other oors (all units)

23 7.7

(a)(b)

/ 12.7

(c)

24 8.1

(a)(b)

/ 13.1

(c)

25 8.4

(a)(b)

/ 13.4

(c)

26 8.7

(a)(b)

/ 13.7

(c)

27 9.1

(a)(b)

/ 14.1

(c)

10 3.9

(a)

/ 3.3

(b)

/ 6.5

(c)

28 9.4

(a)(b)

/ 14.4

(c)

11 4.1

(a)

/ 3.7

(b)

/ 7.2

(c)

29 9.7

(a)(b)

/ 14.7

(c)

12 4.3

(a)

/ 4.0

(b)

/ 7.9

(c)

30 10.1

(a)(b)

/ 15.1

(c)

13 4.5

(a)

/ 4.3

(b)

/ 8.6

(c)

31 10.4

(a)(b)

/ 15.4

(c)

14 4.7

(a)(b)

/ 9.3

(c)

32 10.8

(a)(b)

/ 15.8

(c)

15 5.0

(a)(b)

/ 10.0

(c)

33 11.1

(a)(b)

/ 16.1

(c)

16 5.4

(a)(b)

/ 10.4

(c)

34 11.4

(a)(b)

/ 16.4

(c)

17 5.7

(a)(b)

/ 10.7

(c)

35 11.8

(a)(b)

/ 16.8

(c)

18 6

(a)(b)

/ 11.0

(c)

36 12.1

(a)(b)

/ 17.1

(c)

19 6.4

(a)(b)

/ 11.4

(c)

37 12.4

(a)(b)

/ 17.4

(c)

20 6.7

(a)(b)

/ 11.7

(c)

38 12.8

(a)(b)

/ 17.8

(c)

21 7

(a)(b)

/ 12.0

(c)

22 7.4

(a)(b)

/ 12.4

(c)

90 30.3

(a)(b)

/ 35.3

(c)

91 30.7

(a)(b)

/ 35.7

(c)

92 31.0

(a)(b)

/ 36.0

(c)

93 31.4

(a)(b)

/ 36.4

(c)

94 31.7

(a)(b)

/ 36.7

(c)

95 32.0

(a)(b)

/ 37.0

(c)

96 32.4

(a)(b)

/ 37.4

(c)

97 32.7

(a)(b)

/ 37.7

(c)

98 33.0

(a)(b)

/ 38.0

(c)

99 33.4

(a)(b)

/ 38.4

(c)

100 33.7

(a)(b)

/ 38.7

(c)

63 21.2

(a)(b)

/ 26.2

(c)

64 21.6

(a)(b)

/ 26.6

(c)

65 21.9

(a)(b)

/ 26.9

(c)

66 22.2

(a)(b)

/ 27.2

(c)

67 22.6

(a)(b)

/ 27.6

(c)

68 22.9

(a)(b)

/ 27.9

(c)

69 23.3

(a)(b)

/ 28.3

(c)

72 24.3

(a)(b)

/ 29.3

(c)

55 18.5

(a)(b)

/ 23.5

(c)

73 24.6

(a)(b)

/ 29.6

(c)

56 18.9

(a)(b)

/ 23.9

(c)

74 24.9

(a)(b)

/ 29.9

(c)

57 19.2

(a)(b)

/ 24.2

(c)

75 25.3

(a)(b)

/ 30.3

(c)

58 19.5

(a)(b)

/ 24.5

(c)

76 25.6

(a)(b)

/ 30.6

(c)

59 19.9

(a)(b)

/ 24.9

(c)

77 26.0

(a)(b)

/ 31.0

(c)

60 20.2

(a)(b)

/ 25.2

(c)

78 26.3

(a)(b)

/ 31.3

(c)

61 20.5

(a)(b)

/ 25.5

(c)

79 26.6

(a)(b)

/ 31.6

(c)

62 20.9

(a)(b)

/ 25.9

(c)

80 27.0

(a)(b)

/ 32.0

(c)

70

23.6

(a)(b)

/ 28.6

(c)

71 23.9

(a)(b)

/ 28.9

(c)

81 27.3

(a)(b)

/ 32.3

(c)

82 27.6

(a)(b)

/ 32.6

(c)

83 28.0

(a)(b)

/ 33.0

(c)

84 28.3

(a)(b)

/ 33.3

(c)

85 28.7

(a)(b)

/ 33.7

(c)

86 29.0

(a)(b)

/ 34.0

(c)

87 29.3

(a)(b)

/ 34.3

(c)

88 29.7

(a)(b)

/ 34.7

(c)

89 30.0

(a)(b)

/ 35.0

(c)

51 17.2

(a)(b)

/ 22.2

(c)

52 17.5

(a)(b)

/ 22.5

(c)

53 17.8

(a)(b)

/ 22.8

(c)

54 18.2

(a)(b)

/ 23.2

(c)

39 13.1

(a)(b)

/ 18.1

(c)

40 13.5

(a)(b)

/ 18.5

(c)

41 13.8

(a)(b)

/ 18.8

(c)

42 14.1

(a)(b)

/ 19.1

(c)

43 14.5

(a)(b)

/ 19.5

(c)

44 14.8

(a)(b)

/ 19.8

(c)

45 15.1

(a)(b)

/ 20.1

(c)

46 15.5

(a)(b)

/ 20.5

(c)

47 15.8

(a)(b)

/ 20.8

(c)

48 16.2

(a)(b)

/ 21.2

(c)

49 16.5

(a)(b)

/ 21.5

(c)

50 16.8

(a)(b)

/ 21.8

(c)

Contains fluorinated greenhouse gases

2

1

1

1

2

2

kg

tCO2eq

1000

GWP × kg

=

=

+

kg

=

kg

=

GWP: xxx

R32

m Total refrigerant charge limit in the system

A

Smallest room area

min

(a) Lowest underground floor (ceiling-mounted units) (=Lowest underground floor (ceiling-mounted units))

(b) Lowest underground floor (wall-mounted units) (=Lowest underground floor (wall-mounted units))

(c) Smallest room on other floors (all units) (=Smallest room on other floors (all units))

RXYSA4~6A7V/Y1B

VRV 5-S system air conditioner

4P600330-1B – 2020.10

4 Determine the total amount of refrigerant in the system:

Total charge=Factory charge +additional charge =3.4kg+R

(a)

The R value is calculated in "19.4To determine the additional refrigerant amount"[493].

5 The total refrigerant charge in the system MUST be less than the total

refrigerant charge limit value that is derived from the graph. If NOT, change

the installation (see choices below) and repeat all of the above steps.

1. Increase the area of smallest room.

OR

2. Decrease the piping length by changing the system layout.

OR

3. Add additional countermeasures as described in applicable legislation.

SVS output or optional output PCB for indoor unit can be used to

connect and activate the additional countermeasures (e.g. mechanical

ventilation). For more information, see "20.3To connect the external

outputs"[4108].

(a)

Installer and user reference guide

25

3 | Specific installer safety instructions

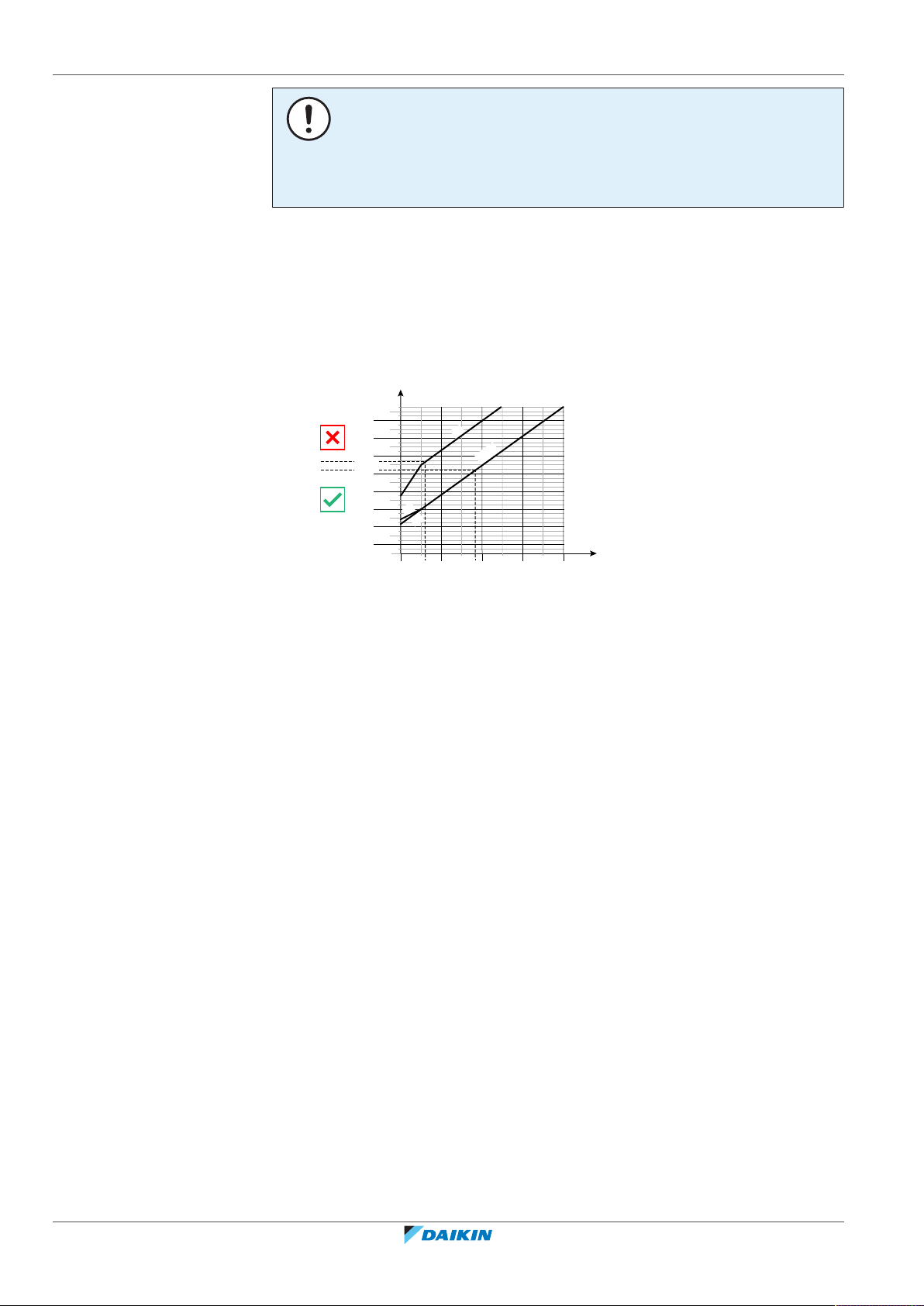

0

1

2

3

4

5

6

7

8

10.4

9.4

12

13

14

15

16

10 20 40 50

16 28

25 35 45

m (kg)

A

min

(m2)

(b)

(a)(b)

(a)

(c)

NOTICE

The total refrigerant charge amount in the system MUST always be lower than the

number of connected indoor units x15.96 [kg], with a maximum of 63.84kg.

E.g. In a system with 1 indoor unit, the maximum refrigerant charge amount is:

1x15.96=15.96kg.

Example1:

VRV system serving 6 rooms. The biggest room has an area of 60m², the smallest

room has an area of 16m². No underground floor in the building.

Use graph "(c)" to check the maximum allowed charge for a room of 16m² with a

ceiling mounted unit: 10.4kg