Page 1

Failure diagnosis tool for ZEAS_A type

Digital Pressure Gauge Kit

BHGP26A1(E)(H)

RDUH11-063

Connected model

ZEAS (A type)

LRLEQ5AY1(E), LRLEQ6AY1(E), LRLEQ8AY1(E), LRLEQ10AY1(E),

LRLEQ12AY1(E), LRLEQ15AY1(E), LRLEQ20AY1(E)

LRMEQ5AY1(E), LRMEQ6AY1(E), LRMEQ8AY1(E), LRMEQ10AY1(E),

LRMEQ12AY1(E), LRMEQ15AY1(E), LRMEQ20AY1(E)

Page 2

Contents

1. Preparation before Connection of

Digital Pressure Gauge Kit............................................2

2. Overview of Product ......................................................2

3. Connection Drawing ......................................................4

4. Display Item and Method of Operation ........................7

4.1 Normal ............................................................................ 7

4.2 Abnormal......................................................................... 7

4.3 Manual Operation Display 1............................................ 8

4.4 Manual Operation Display 2.......................................... 13

5. Service Diagnosis ........................................................15

6. The Entire Flow ............................................................16

1

Page 3

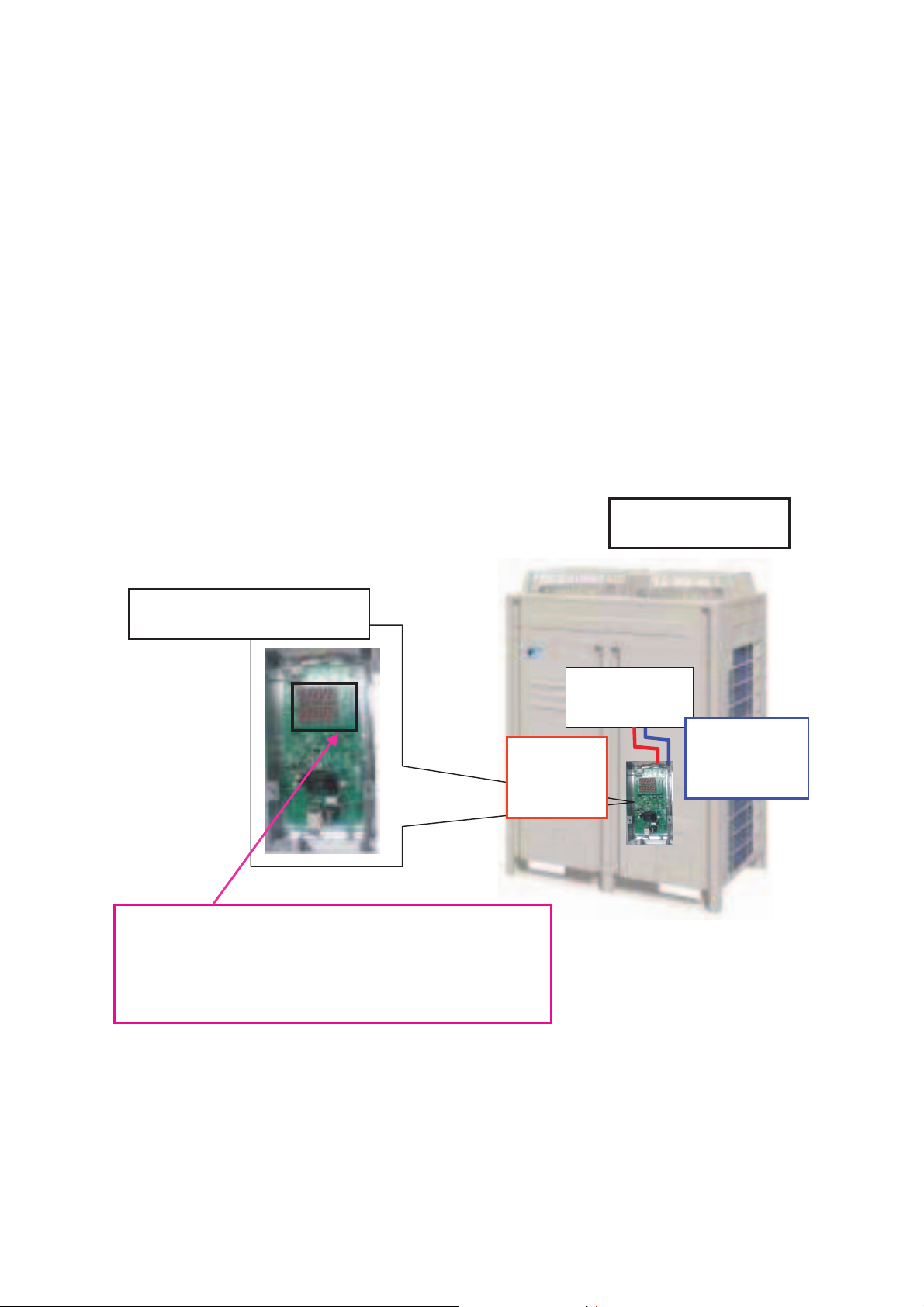

1. Preparation before Connection of Digital Pressure Gauge Kit

When the Digital Pressure Gauge Kit is connected to the outdoor unit, please confirm the software version of

control PCB of ZEAS and you need to change the software if necessary.

∗ Please refer to the manual of software writing delivered.

Check the Software of Condensing Unit

z

Condensing unit: If ver. 91 or earlier, please update the software ver. 93 or later.

z

Condensing unit: ver. 93 and later...You do not need to change the software.

2. Overview of Product

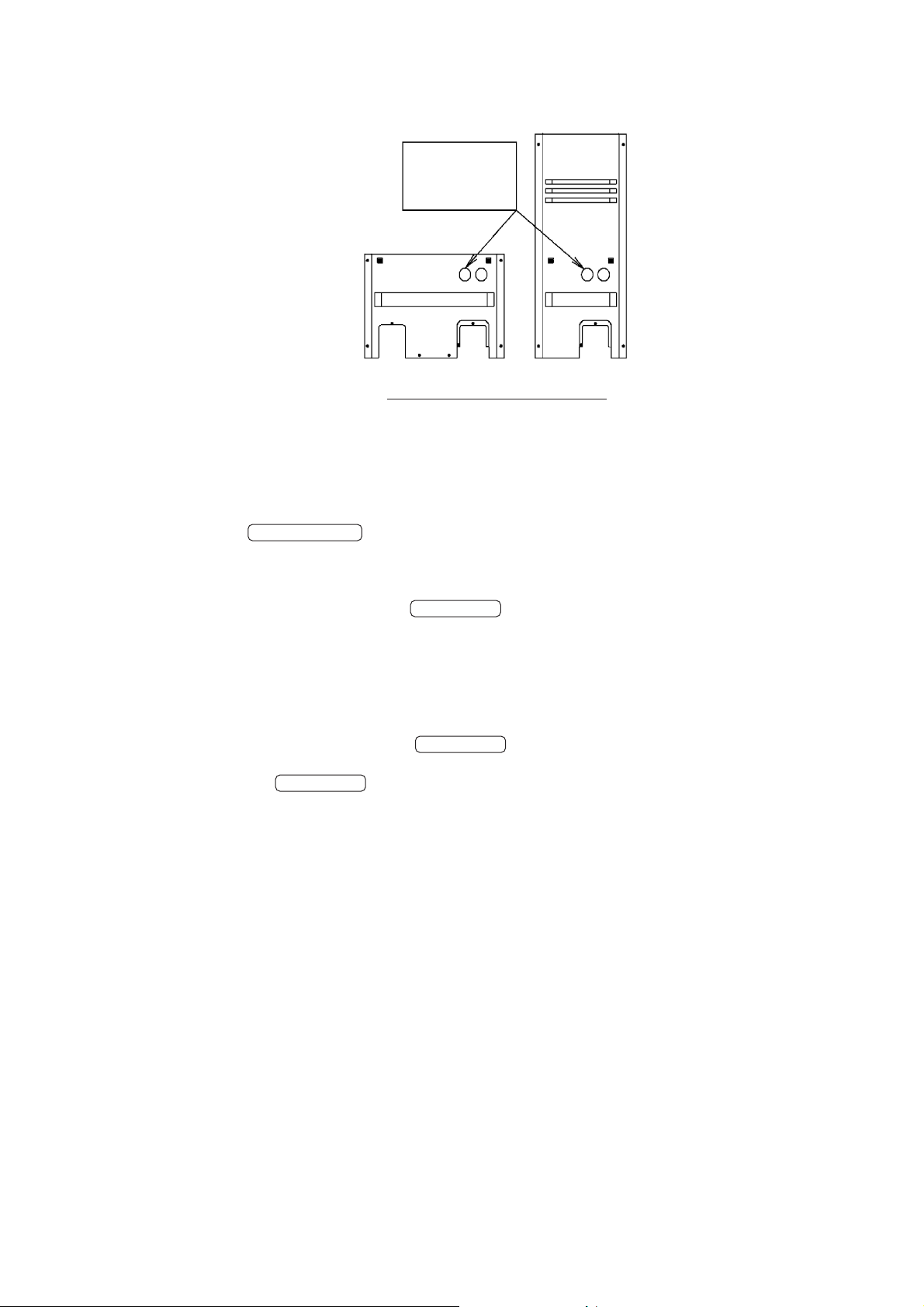

Communicated image

Condensing Unit

Digital Pressure Gauge Kit

7 segment display

Pressure and temperature, detail of running data,

Error code of outdoor unit, software version.

Power

supply line

Control PCB

Communication

line

∗ Power supply line and communication line are included with BHGP26A1.

2

Page 4

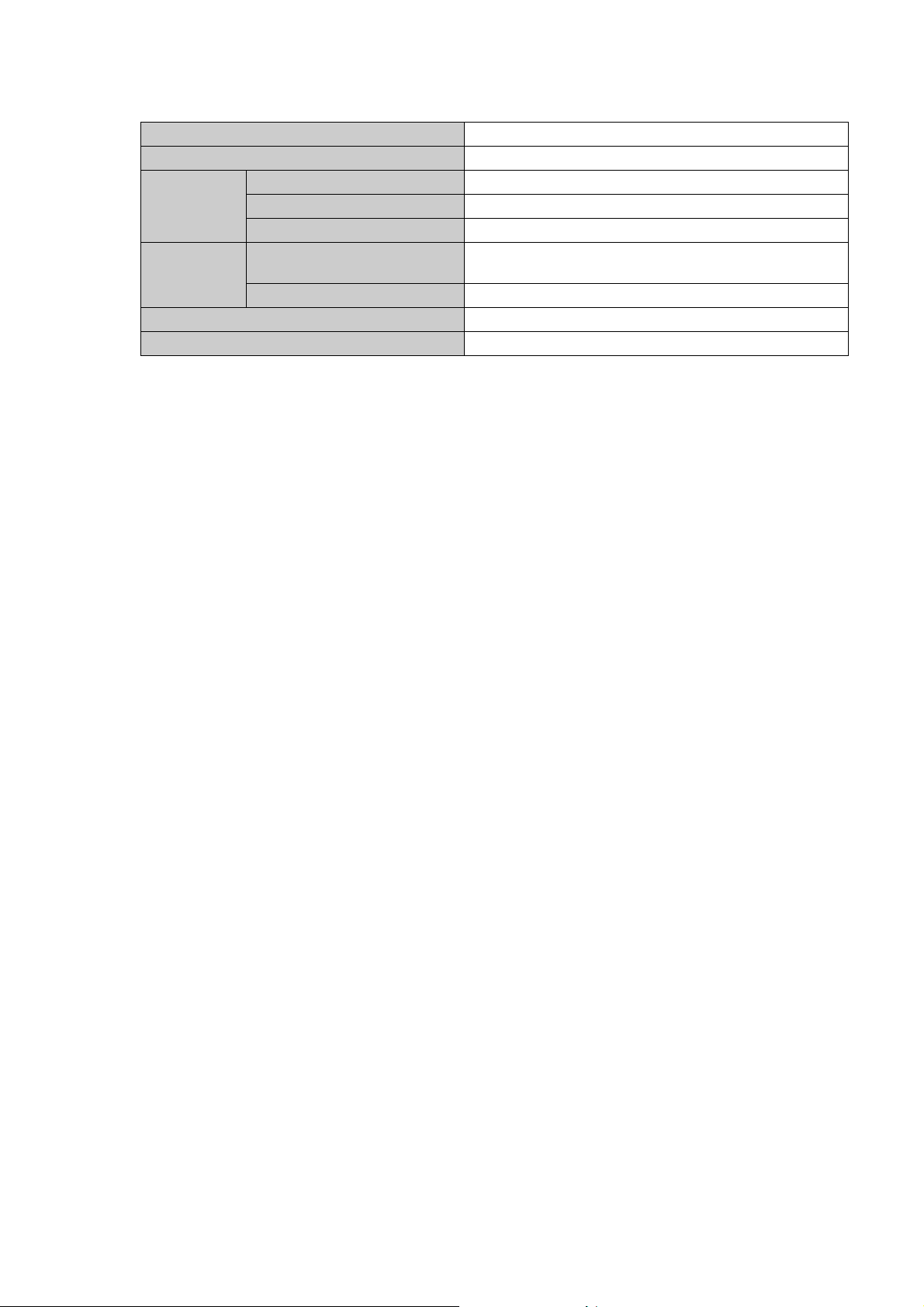

Specification of Digital Pressure Gauge Kit

Outdoor Temp. range –20°C~65°C

Power supply AC200-240V (+10%, –15%) 50/60Hz

Dimensions Height (mm) 268

Width (mm) 286

Depth (mm) 47.5

Casing Pressure gauge box main

body

Hot-dip zinc-coated steel sheets

Pressure gauge (cover) Metacrylate resin

Mass 1.8kg

Location Inside casing of outdoor unit

3

Page 5

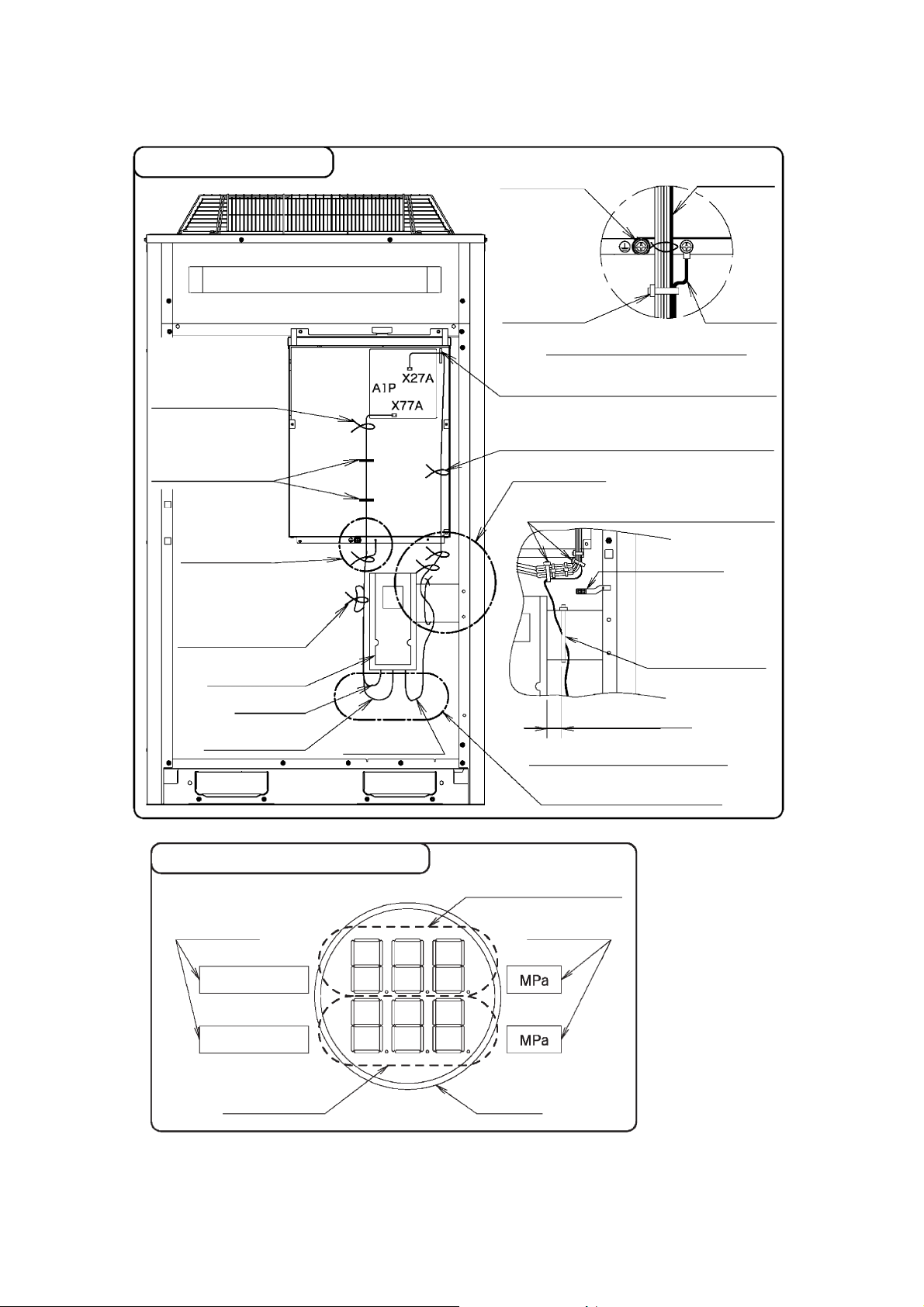

3. Connection Drawing

Wiring drawing

Bind the power supply line

with a clamp together with

the line connected to the

outdoor unit.

Insert the power supply line

into a wire clip together with

the line connected to the

outdoor unit.

Section B

Bundle the redundant length

portion so that the power

supply line or ground wire

will not come in contact with

the conduit.

Digital Pressure

Gauge Assembly

On-site ground

terminal

Bind the power

supply line and

ground wire with

a clamp together

with the line

connected to the

outdoor unit.

Power supply

line

Ground wire

Section B detail view

Insert the communication line into a wire clip

together with the line connected to the outdoor unit.

Bind the communication line with a clamp together

with the line connected to the outdoor unit.

Section A

Bind the communication line with a clamp together

with the line connected to the outdoor unit.

Thermistor

Bind the internal wires

with the large-sized

clamp so that the wires

will not come in contact

with the thermistor.

Ground wire

Power supply line

Communication

line

Label pasting drawing

Gauge window

label

DISCHARGE

SUCTION

Suction pressure

display

20 mm max.

Section A detail view

Be careful not to tense the wire.

Discharge pressure display

Gauge window

label

Resin bush

C: 2P190979

4

Page 6

Punch out the

knock hole on the

left-hand side.

Knock hole on the front panel

Connection drawing

1. Turn the outdoor unit power OFF.

2. Remove the front panel. (If the model has two front panels (i.e., one each on the left-hand side and righthand side), remove the panel on the right-hand side only.)

3. Remove the lid of the electrical box.

4. Refer to the and mount the Digital Pressure Gauge Assembly to the panel on the righthand side.

[Parts used: Digital Pressure Gauge Assembly: 1, M5×12 screw: 2]

5. Secure the ground wire to the electrical box with a screw.

Refer to section B (detail view) in the for the screwing position.

[Parts used: M4×12 screw: 1]

6. Connect the power supply line and communication line of the Digital Pressure Gauge

Assembly to the control PCB (A1P) in the electrical box.

• Power supply line: Connector (white) • X77A

• Communication line: Connector (blue) • X27A

At that time, wire the communication line behind the Digital Pressure Gauge Assembly.

(Refer to section A (detail view) in the .)

7. After connecting the power supply line, communication line, and ground wire, secure the wiring path

according to the .

[Parts used: Clamps: small 6, large 1]

8. Mount the lid of the electrical box.

9. Punch out the knock hole with a diameter of 70 mm on the front panel. (Refer to the mounting dimensions

on the upper right-hand side.)

10.Attach the resin bush to the knock hole on the front panel. [Parts used: Resin bush: 1]

11.Mount the front panel.

12.On completion of installation, turn the outdoor unit power ON and make sure that pressures are displayed

normally.

When figures appear in the discharge pressure display and suction pressure indicate, the product is

working normally.

(Pressure is indicated in the operation switch "OFF or ON" of outdoor unit.)

Abnormal upper section: Error code, Abnormal lower section: LP

Abnormal display case: Please refer to the service diagnosis P.15

Installation drawing

Wiring drawing

Wiring drawing

Wiring drawing

C: 2P190979

5

Page 7

Attention in the display.

Digital Pressure Gauge Kit and RAM-monitor can not be used at the same time for communication line is

connected to X27A of control PCB of outdoor unit.

Installation drawing

Communications line: Connector (blue)

Ground wire

Power supply line: Connector (white)

Right-hand-side

panel

M5×12 screws

Digital Pressure Gauge Assembly

2P190979

6

Page 8

4. Display Item and Method of Operation

Display item

There are four major display items as follows:

4.1: Normal; Displays high pressure and low pressure in MPa

4.2: Abnormal; Error code is blinking, which should be seven-segment blinking display for attention

seeking.

4.3: Manual Operation Display 1; Check the individual operation data. (compressor operation

frequency, target evaporation temperature, etc.)

4.4: Manual Operation Display 2; Check error history for the preceding 3 times.

4.1 Normal

High pressure is displayed in the upper section, and low pressure is displayed in the lower section with

lighting display for both.

Display examples are shown below:

4.2 Abnormal

If error occurs, error code blinks in the upper section automatically. The low pressure is kept displayed in the

lower section.

Both upper and lower section are blinking.

After reset the error, "4.1 Normal" is automatically displayed again.

Note:

If the low pressure sensor is abnormal (error code:

zDisplay example

Upper section

High pressure (HP)

Lower section

Low pressure (LP)

Lighting LED : Upper section and lower section

Unit: MPa

Unit: MPa

JC

), correct low pressure is not displayed.

zDisplay example

Upper section

Error code E9

Lower section

Low pressure (LP)

Blinking LED : Upper section and lower section

7

Page 9

4.3 Manual Operation Display 1

On the Manual Operation Display 1, you can check the individual operation data. (compressor operation

frequency, target evaporation temperature, etc.)

z

Table 1 on P. 9 shows how to set Manual Operation Display 1.

z

Table 2 on P. 10,11 shows which operation data you can check.

∗ Cautions for Manual Operation Display 1

1. Each display item is displayed by automatic scroll (interval of 3 sec.) in the order of display No.

2. After display No. 32 displayed, automatically returns to display No. 1

3. After 120 minutes of continuous displaying, the display is automatically returned to the initial display so

that it will not be lost.

4. Display items and values are fixed by pressing the RETURN (BS3).

Display is returned to automatic scroll by pressing the RETURN (BS3) again.

Note 1: Once display item is fixed, the fixed value is maintained.

Note 2: Display is fixed for up to 2 minutes. After 2 minutes, returns automatically to scroll display

5. Display digit number

Pressure and temperature data are displayed in the top 3 digits. The 4th digit is cut out.

If the displayed value is below 0, it is displayed in the top 2 digits with negative sign "-". The third digit is

cut out.

Display examples are shown below:

zDisplay example

(1) When the suction pipe temperature of INV.

compressor is 20.89 ˚C, 20.8 ˚C is displayed.

(2) When the suction pipe temperature of INV.

compressor is -20.9 ˚C, -20 ˚C is displayed.

Upper section

ti

Lower section

20.8

Upper section

ti

Lower section

-20

6. Display in case horsepower is different

As for the outdoor unit with 5 to 12 HP, discharge pipe temperature, operation data of STD compressor,

and so on, are not displayed, as those data are produced from the equipment which is not equipped to the

outdoor unit.

In such case, "-" is displayed in the lower section.

zDisplay example

Display when LRLEQ5AY1 is connected

Upper section “td2”

Lower section “– – – ”

8

Page 10

Table1. Operation method of manual operation display 1

No.

Operation

LED display of outdoor unit

H1P H2P H3P H4P H5P H6P H7P

h

: OFF / k: ON / l: Blinking

Display example Remarks

Initial display

(Normally of connected

outdoor unit and Digital

Pressure Gauge Kit)

1

Initial display

(Abnormally of

connected outdoor unit)

2

Selection

Press the

TEST (BS4)

of manual

operation

display

3

Decision

of manual

4

operation

display

Display of

5

operation

data

Press the SET

(BS2)

Press the

RETURN

(BS3)

Press the

RETURN

(BS3)

Press the

RETURN

(BS3)

Fixed

display of

6

7 segment

Press the

RETURN

(BS3)

hhkhhhh

hkkhhhh

lhhlhhh

lhlhhhh

lhkhhhl

lhkhhhk

lhkhhhk

lhkhhhk

Upper section HP

Lower section LP

Upper section

Lower section LP

Upper section tE0

Lower section

value of tE0

Upper section tE0

Lower section

value of tE0

Upper section tE0

Lower section

value of tE0

Error code

∗1

∗1

∗1

∗1

∗1

∗1

Automatic scroll

indication (Interval of 3

sec.)

Display item refer to the

next page

Press the RETURN

(BS3): Fixed display of

7 segment

Fix display items and

value when pressed.

Example is shown left.

One more press the

RETURN (BS3):

Cancel of fixed display

of 7 segment

After cancel of fixed

display of 7 segment:

Return automatic scroll

(Interval of 3 sec.)

∗1 For a display example, “tE0” is displayed. Refer to the detailed information of display items on the

following page onward.

9

Page 11

Table2. Display items of manual operation display 1

After 3 sec.

Display

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Display item

Target evaporation temperature

LP

HP

INV. compressor frequency

Point of contact output/CCU

INV. compressor (M1C)/K1M

STD1 compressor (M2C)/K2M

STD2 compressor (M3C)/K3M

Operating output/K10R

Solenoid valve (Y2S)/K4R

Solenoid valve (Y5S)/K11R

Four way valve (Y3S)/K5R

Discharge pipe temperature

(INV. compressor)

Discharge pipe temperature

(STD1 compressor)

Discharge pipe temperature

(STD2 compressor)

Suction pipe temperature

Subcooling heat exchanger

inlet temperature

Subcooling heat exchanger

outlet temperature

Outdoor air temperature

Condensation pressure equivalent

saturation temperature

Evaporation pressure equivalent

saturation temperature

Outdoor unit heat exchanger

temperature (R6T)

LED display (7 segment)

Unit

Upper section

tE0

˚C

LP

MPa

HP

MPa

inV

rps

Point of contact

output “ON”: Lighting LED

–

–

–

–

–

–

–

td1

˚C

∗2

∗2

∗2

td2

˚C

td3

˚C

ti

˚C

∗2

∗2

tL

˚C

tg

˚C

∗2

tA

˚C

∗2

tC

˚C

∗2

tE

˚C

∗2

tCE

˚C

∗2

Connection unit (

Lower section

LRLEQ5 · 6AY1(E)

LRMEQ5 · 6AY1(E)

Value of display item

Value of display item

Value of display item

Value of display item

Value of display item

Value of display item

Value of display item

Value of display item

Value of display item

Value of display item

Value of display item

Value of display item

Value of display item

Value of display item

{: display target ∗: different HP)

LRLEQ8 · 10 · 12AY1(E)

LRMEQ8 · 10 · 12AY1(E)

LRLEQ15 · 20AY1(E)

LRMEQ15 · 20AY1(E)

{{ {

{{ {

{{ {

{{ {

{{ {

∗1

∗1

{{

∗1

{

{{ {

∗1

∗1

{{

∗1

{

{{ {

{{ {

∗1

∗1 ∗1

{{

{

{{ {

{{ {

{{ {

{{ {

{{ {

{{ {

{{ {

10

Automatic return from display item No.32 to item No.1.

∗1 No display is available as target equipments are not present.

∗2 In case each sensor is abnormal, correct value can not be displayed. Before checking the sensor

measurement, please check if there is an abnormal report.

Page 12

Display

No.

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

Display item

Suction air superheated

Discharge pipe superheated

(INV. compressor)

Discharge pipe superheated

(STD1 compressor)

Discharge pipe superheated

(STD2 compressor)

Secondary current valve of

INV. compressor

Current value of STD1

compressor

Current value of STD2

compressor

Current value of outdoor

unit FAN1

Current value of outdoor

unit FAN2

Radiation fin temperature

Total operation

compressor frequency

Outdoor unit fan tap

Opening degree of electronic

expansion valve 1

Opening degree of electronic

expansion valve 2

Opening degree of

electronic expansion valve 3

Operation state

Software version of PCB

Unit

K

∗2

K

∗2

K

∗2

K

∗2

A

∗2

A

∗2

A

∗2

A

∗2

A

∗2

˚C

∗2

Hz

–

pls

pls

pls

–

–

LED display (7 segment)

Upper section

SH

Lower section

Value of display item

tS1

Value of display itemValue of display item

tS2

Value of display item

tS3

Value of display item

AdC

Value of display item

An1

Value of display item

An2

Value of display item

AF1

Value of display item

AF2

Value of display item

tF

Value of display item

HzA

Value of display item

FtP

Value of display item

EV1

Value of display item

EV2

Value of display item

EV3

Value of display item

StA

Value of display item

Ver

Value of display item

Connection unit (

LRLEQ5 · 6AY1(E)

LRMEQ5 · 6AY1(E)

{: display target ∗: different HP)

LRLEQ8 · 10 · 12AY1(E)

LRMEQ8 · 10 · 12AY1(E)

LRLEQ15 · 20AY1(E)

LRMEQ15 · 20AY1(E)

{{ {

{{ {

∗1

∗1 ∗1

{{

{

{{ {

∗1

∗1 ∗1

{{

{

{{ {

∗1

∗1

{

{{ {

{{ {

{{ {

{{ {

{{ {

∗1

{{

{{ {

{{ {

∗1 No display is available as target equipments are not present.

∗2 In case each sensor is abnormal, correct value can not be displayed. Before checking the sensor

measurement, please check if there is an abnormal report.

11

Page 13

Note

{

Display No. 1: Target Evaporation Temperature

Displays target evaporation temperature which is set by using the target evaporation

temperature set with DIP switch of the outdoor unit and correction value of target

evaporation temperature by pressing BS button.

{

Display No. 13: Condensation pressure equivalent saturated temperature f (HP)

The value of saturated temperature calculated from the high pressure of display No. 3

{

Display No. 14: Evaporation pressure equivalent saturated temperature f (LP)

The value of saturated temperature calculated from the low pressure of display No. 2

{

Display No. 16: Suction air SH

The difference between the suction pipe temperature Ti of display No. 9 and the saturated

temperature at the low pressure of display No. 2.

{

Display No. 17: INV. compressor discharge pipe SH

The difference between the INV. compressor discharge pipe temperature Td1 of display

No. 6 and the saturated temperature at the high pressure of display No. 3.

{

Display No. 18: STD1 compressor discharge pipe SH

The difference between the STD1 compressor discharge pipe temperature Td2 of display

No. 7 and the saturated temperature at the high pressure of display No. 3.

{

Display No. 19: STD2 compressor discharge pipe SH

The difference between the STD2 compressor discharge pipe temperature Td3 of display

No. 8 and the saturated temperature at the high pressure of display No. 3.

{

Display No. 26: Value of operating compressor total frequency

The total frequency is calculated by the equation below.

Total frequency = frequency of INV. compressor + (frequency of STD compressor

number of STD compressor)

*1 The frequency of STD compressor is fixed to 166 Hz.

∗1

×

12

Page 14

4.4 Manual Operation Display 2

On the manual operation display 2, you can check error history for the preceding 3 times.

In this case, both upper and lower sections show lighting display.

The upper section indicates how many times error occurred in the history.

The lower section displays error code.

z

Table 3 on P. 14 shows how to set manual operation display 2.

Display example

z

Showing how many times error occurred in the history.

Upper section

1n1

Lower section

E4

The latest history of error

Display error code

After 3 sec.

After 3 sec.

Upper section

2n1

Lower section

F4

The last but one history of error

After 3 sec.

Upper section

3n1

Lower section

E3

The last but two histories of error

In case no error is present

z

Lighting LED : Upper section and Lower section

Upper section

“000”

Lower section

“000”

∗ Cautions for manual operation display 2

1. Each display item is displayed by automatic scroll (interval of 3 sec.) in the order of display No.

2. After display No. 3 displayed, automatically returns to display No. 1

3. After 120 minutes of automatic scroll, the display is automatically returned to the initial display so that it will

not be lost.

4. If booster unit is abnormal, a batch of error codes from outdoor units such as

EJ, EF

, etc. are displayed.

13

Page 15

Table3. Operation procedure of manual operation display 2

No.

Operation

LED display of outdoor unit

H1P H2P H3P H4P H5P H6P H7P

h

: OFF / k: ON / l: Blinking

Display example Remarks

Initial display

(Normally of connected

outdoor unit and Digital

Pressure Gauge Kit)

1

Initial display

(Abnormally of

connected outdoor unit

or Digital Pressure

Gauge Kit)

2

Press the

TEST (BS4)

Selection

of manual

operation

display

3

Press the SET

(BS2)

Press the

4 Display

RETURN

(BS3)

hhkhhhh

hkkhhhh

lhhlhhh

lhllhhh

lhkkhhh

Upper section HP

Lower section LP

Upper section

Lower section LP

Upper section

1n1

Lower section

The last error history

(Error code)

Error code

History of error :

automatic scroll

indicate (Interval of 3

sec.)

14

Page 16

5. Service Diagnosis

On completion of installation (P.4 3. Connection Drawing), turn the outdoor unit power ON and make sure that

pressures are displayed normally.

Abnormal display: Refer to “Service Diagnosis” below and take necessary remedies if no figures are

displayed. If the trouble do not fall under any of the items described, change the Digital Pressure Gauge Kit.

Error display and measurements

Error display Cause Remedy

The LED indicator is not lit

Power supply is not provided

to the outdoor unit.

Provide power supply to the outdoor unit.

1

All LEDs blink

2

blinks

The connector of the power

supply line is unplugged.

The power supply line is

disconnected or damaged.

Others

The connector of the

communications line is

unplugged.

The communications line is

disconnected or damaged.

The outdoor unit is not

compatible with the Digital

Pressure Gauge Kit.

Others

There is a high-voltage line

generating noise around the

communications line.

Insert the connector of the power supply

line.

Replace the power supply line.

Please change the Digital Pressure

Gauge Kit.

Plug in the connector of the

communications line.

Replace the communications line.

Check with a this service manual if the

outdoor unit is compatible with the Digital

Pressure Gauge Kit.

If the outdoor unit is not compatible, this

Digital Pressure Gauge Kit cannot be

used.

Please change the Digital Pressure

Gauge Kit.

Noise may be imposed on the

communications line. Separate the highvoltage line.

3

The outdoor unit has a defect.

Others

Refer to the Service Guide and remedy

the problem.

Please change the Digital Pressure

Gauge Kit.

15

Page 17

6. The Entire Flow

Outdoor unit data

Indicate start of 7 segment

Press the

RETURN

(BS3) once

Decide of error

operation display

operation display

Decide of manual

Press the

RETURN

(BS3) once

Select of manual

operation display

Manual operation display 1

Manual operation display 2

Press the

SET(BS2) once

Press the

Automatic scroll

indicate (new error

Indicate start of 7 segment

Press the RETURN

(BS3) once

SET(BS2) twice

of before 2 times)

history ~ error history

display mode

Manual operation

Indicate of manual

operation display 1

Indicate of manual

operation display 2

Error State

Error state of

before 1 time

Non-error State

Indicate start of 7 segment

operation display

Decide of manual

Indicate start of 7 segment

lhlhhhh lhkhhhl lhkhhhk

Select of manual

operation display 1

Select of manual

operation display 2

lhllhhh lhkkhhh

The entire flow

16

Press the TEST(BS4) once

communication line of Digital Pressure Gauge Kit.

· Press the MODE(BS1) once.

Initial display

(HP/LP or error code/LP)

· Abnormal state of power supply line or

OR

120 minutes have passed since display of manual operation display

of Digital Pressure Gauge Kit.

· Press the MODE(BS1) once.

· Error state of power supply line or communication line

·

OR

7 segment flow (Manual operation display 1)

HP/LP or error code/LP

7 segment flow (Manual operation display 2)

HP/LP or error code/LP

LED of outdoor unit flow

Manual operation display mode

hhkhhhh lhhlhhh

Initial display

hkkhhhh

h: OFF

k: ON

Error state (Lighting H2P of LED)

l: Blinking

Loading...

Loading...