Page 1

ModEva RA

ModEva RA is an evolution of Cybelec’s ModEva range. Its programming console has both a large touchscreen and a

traditional keypad and operates with full 3D simulation software.

ModEva RA is composed of 2 main elements:

• The programming console: located within the operator's reach, generally fixed to a pendant arm.

• The CNC rack: placed inside the electric cabinet.

ModEva RA can control up to 18 axes, of which 2 are synchronized hydraulic axes especially int ended for press-brakes.

ModEva RA system software gives manufacturers the ability to configure axes, inputs/outputs and auxiliary functions

according to their needs.

Since ModEva RA is the continuation of the ModEva range, it benefits from the exact same compatibilities as the previous

ModEva numerical controls in terms of hardware:

• Same wiring.

• Same signals.

• Same electronic interface.

• Same commissioning procedures.

To work with programs prepared on older machines, the classic ModEva interface is still accessible (ModEva 15S mode).

ModEva RA is available in two software versions

• ModEva RA

• ModEva RA Premium

For the preparation of work in the office, Cybelec offers PC-RA, an off-line software with the same features as in ModEva

RA Premium.

CDS_modeva_RA_EN_V4.2.doc / sept 2013 Modification rights reserved 1/8

Page 2

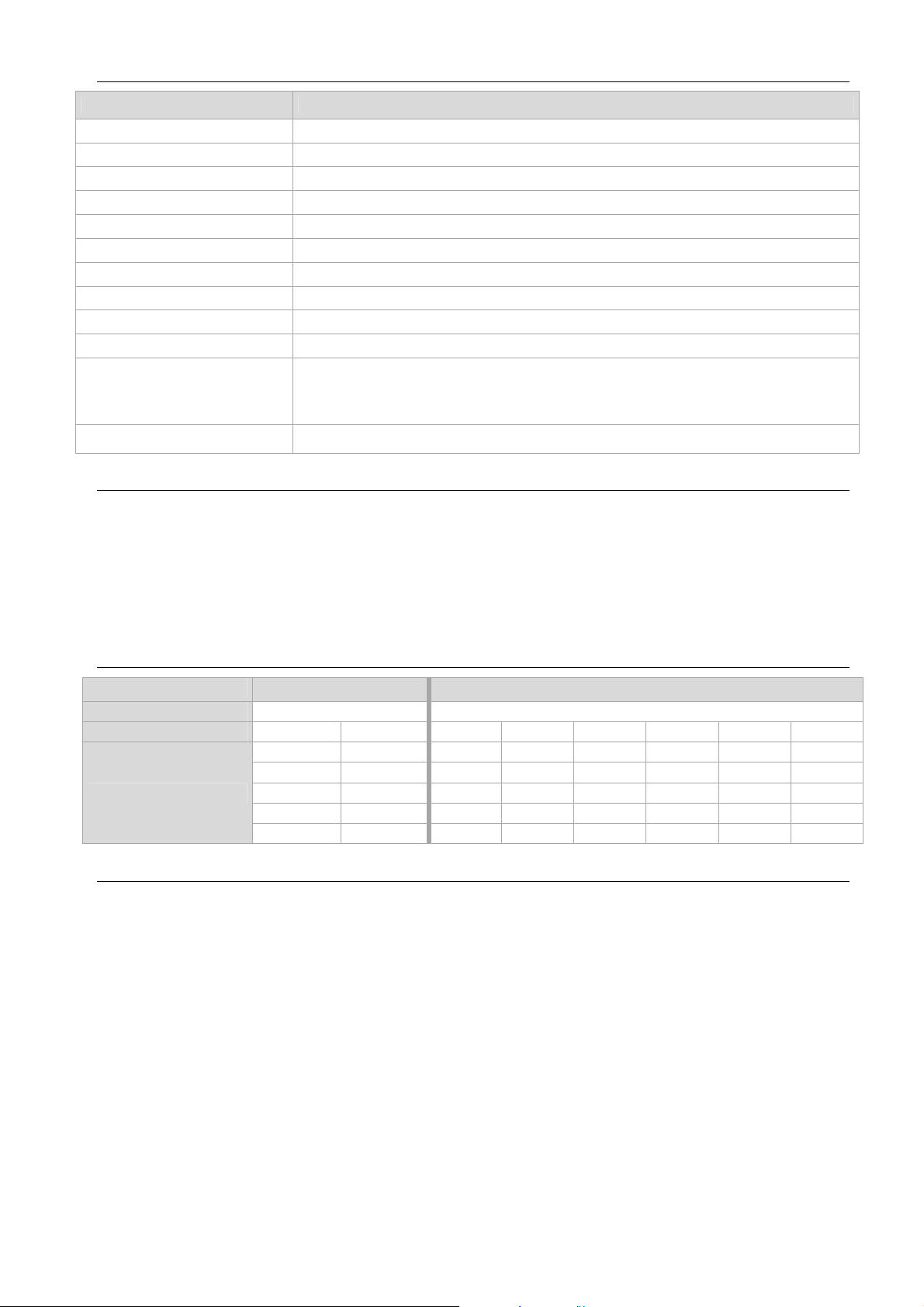

Console Hardware

Console

TFT screen

Keypad

Resolution

Touch screen

USB port

Power

Seal

P-Link

Auxiliary panel for machine buttons

Handle

Temperature, pollution level,

relative humidity, during work.

Weight

CNC Hardware

The CNC is available in 3 rack sizes depending on the configuration:

ModEva RA CNC/C

CNC rack version "C" (Compact): can control 2, 4 or 6 axes, and up to 10 axes with CANopen axes*.

15"

41 keys

1024x768

Yes

1

Through the panel link.

IP 54.

2 cables RJ 45 twisted pair category 6. Cables 5 m or 10 m. Dist. > 5 m with CYBELEC repeater.

Option

Inclusive

Min. 5° Celsius, max. 40° Celsius.*

Relative humidity (10 to 85% non-condensing).

* If the ambient temperature approaches or exceeds 40° Celsius, it would be advisable to install

special ventilation, or even air-conditioning.

Approximately 5 kg.

S-MOD-RA

ModEva RA CNC/M

CNC rack version "M" (Medium): can control 4, 6, 8, 10, 12 or 14 axes, and up to 18 axes

with CANopen axes*.

ModEva RA CNC/L

CNC rack version "L" (Large): a special large rack version available upon request.

CNC Axes Configuration

Rack version

No. of axis boards

Axis position (slot N°)

Most common configurations

CNC / C (Compact) CNC / M (Maxi)

2 5

0 1 0 1 2 3 4 5

NMX - NMX NSX NSX

NMX NSX NMX NSX NSX NSX

NMX NLR NMX NSX NSX NLR

NCX - NMX NSX NSX NLR NMX

NCX NLR NCX NLR NMX NSX

Definitions

Hydraulic axes: Analog axes especially intended for controlling the beams (Y1-Y2), controlled by the NPU board.

Analog axes: An NMX/NSX board provides a speed command to the axis drive as a +-10VDC voltage as well as

a small number of digital signals. Axis position is provided to the NMX/NSX board b y an

incremental encoder as a quadrature signal.

CANopen axes: An NCX board provides motion commands and receives position information from the axis drives

via a CAN bus abiding to CANOpen conventions. One NCX board can control up to 8 axes

depending on the options. A ModEva CNC can be equipped with a maximum of 2 NCX boards.

Please contact Cybelec before ordering if you consider CAN for your axes.

NMX: A master board for 2 analog axes. In addition, an NMX can control up to 3 NSX slave boards.

NSX: A slave board for 2 additional analog axes. An NSX in all cases requires an NMX board.

NCX: CANopen board for up to 8 CANopen axes. This board can handle various protocols according to

the type of servo-amplifier used. It is possible to combine NCX and NMX/NSX boards, in order to

combine CANopen and analog axes. ModEva RA accepts up to 2 NCX boards

CDS_modeva_RA_EN_V4.2.doc Modification rights reserved 2/8

Page 3

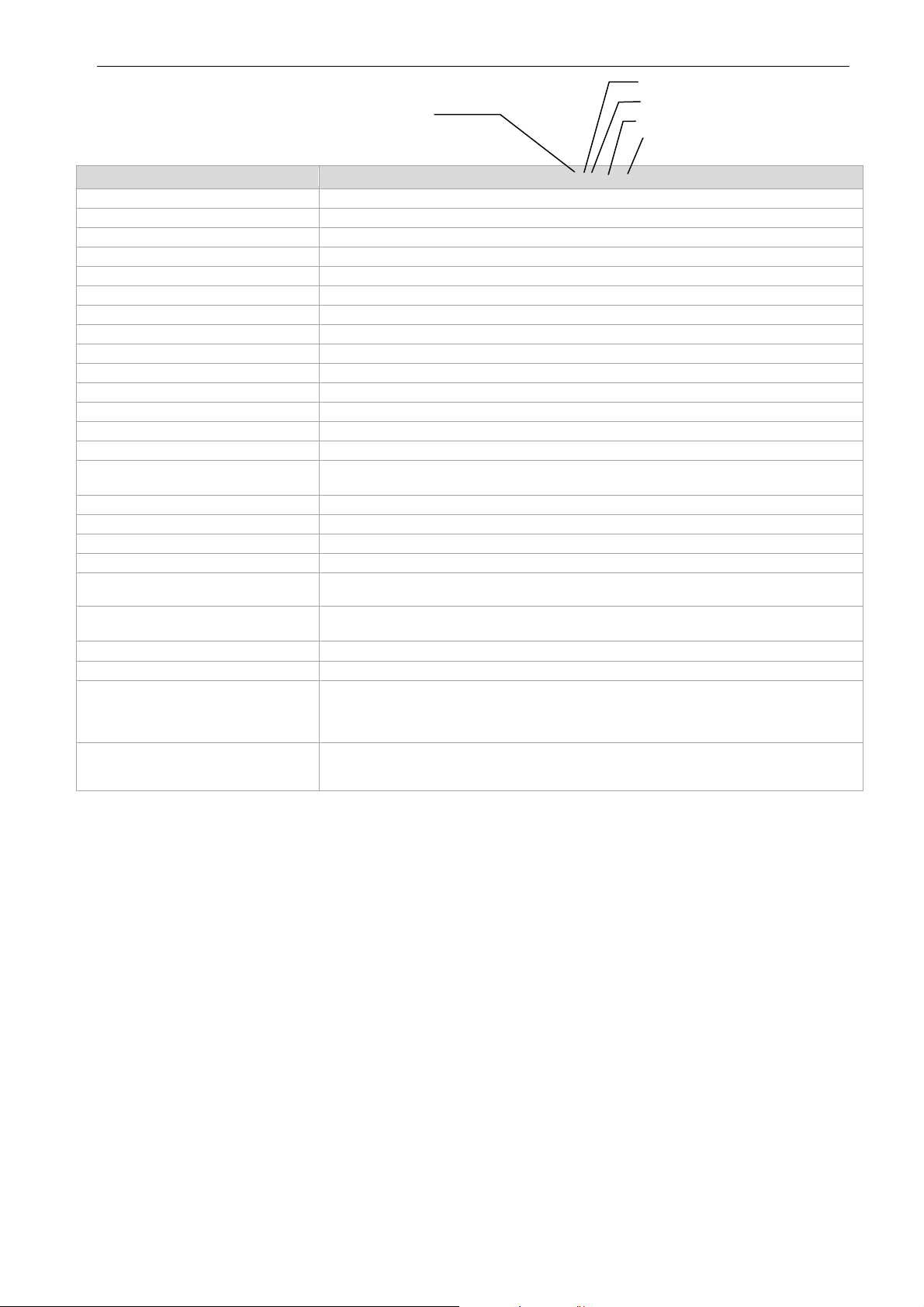

CNC Configuration

±

Reference

3D Software

System

CPU

RAM

Disk

Network

USB 2.0

Printer port

Keyboard input

Mouse input

Screen output

Y1, Y2

RS 232 port

Serial port for PLC

Analog axes

CAN axes

Incremental encoders

Digital inputs

Digital outputs

Analog inputs

Analog outputs FA

Power supply

Seal

Temperature, pollution level, relative

humidity during work.

Weight

Electrical axes configuration (analogue: A, Can: C, Mixed: M)

Rack version C or M or L

Number of axes 02 to 18

Type of machine, PS, PC

NLR board, ex: angle measurement device

S-CNC-xxxxPxxxRA

ModEva RA.

Windows XP Pro Compact.

AMD Fusion T40R, 1GHz

2 GB.

16 GB flash.

Yes, Ethernet RJ45.

2, with RJ45 extensions (10 m)

Yes.

Yes, PS/2 or USB

Yes, PS/2 or USB

Yes, STD VGA.

NPU board.

Yes, 2 of which 1 configurable to RS 422 (LazerSafe).

Yes, on NPU board. RS232 configurable to RS 422 (Pilz).

NMX, NSX boards, 2 axes per board, according to configuration and rack version.

Zout output impedance < 100 Ω , Zl load ≥ 10 kΩ.

NCX boards, depending on configuration and rack version.

5V DC line driver, complementary signals are obligatory.

NIN boards, 32 inputs 24 VDC opto-coupled.

NOT boards, 32 outputs, 24 VDC "sources", max 2.5 A / output (NOT 204). Max 6 A / board.

NIN boards, 6 analog inputs.

Depending on configuration 0-10, 0-24 VDC A/D 8 bits.

NOT boards, 4 outputs, 0-10 VDC (8 bits) for the auxiliary functions,

Zout output impedance < 100 Ω , Zl load ≥ 10 kΩ.

24 VDC / max 4A

Must be installed in an approved electric cabinet.

Min. 5° Celsius, max. 40° Celsius.*

Relative humidity (10 to 85% non-condensing).

If the ambient temperature approaches or exceeds 40° C, it would be advisable to install special

ventilation, or even air-conditioning.

Rack version C: approx. 5 kg.

Rack version M: approx. 6 kg. Depending on equipment.

Rack version L: approx. 7 kg. Depending on equipment.

15%.

CDS_modeva_RA_EN_V4.2.doc Modification rights reserved 3/8

Page 4

ModEva RA and ModEva RA Premium Overall Features

The below table compares features in ModEva RA and ModEva RA Premium.

+ The feature is present

– The feature is not possible

Option The feature is available as an option

Hardware platform RA Premium RA

Rack Same Same

Terminal with handle Same Same

Auxiliary panel Option Option

Keyboard support Option Option

Part data management RA Premium RA

Direct programming + +

Extruded 2D profile + +

Import 3D MetaCAM format + +

Import 3D IGES + Import DXF flat pattern + Option RA01

Export DXF flat pattern + Import/Export jobs in ModEva RA format + +

Execute 3D, 2D and direct jobs. + +

Organize job list in sub-directories + +

Job list with thumbnail images + +

Tool lists, catalogs, materials, etc. RA Premium RA

Parametric tools and tool holders + +

Transfer tools defined on other ModEva RA machines or off-line + +

Display and use any free-profile tool in the inventory + +

Tool catalogs + -

More than one catalog active + -

Multiple tool valencies (tool grip types) + +

Explicit treatment of punch-holders and die-holders + +

Automatic solution: bending sequence, gauging and tooling RA Premium RA

Find adequate tool profiles + Option RA02

User can suggest or enforce which tools to use + +

Find a solution for extruded 2D profiles + +

Find a solution for (transferred) generic 3D parts + +

Check if tool segments fit, compute segmentation + Option RA02

Bend deduction: K-based, empirical table or user’s entry + +

Find a solution for step bending + +

Find a solution for hemming (punch- or die-hemming) + +

Find solutions with slanted or out-of-axis gauging + +

3D scenes display RA Premium RA

3D machine and part models + +

Selectable display of machine components + +

Selectable points of view + +

Rotate , Pan and Zoom with touch-screen or buttons + +

Edit environment RA Premium RA

Video-like 3D bend simulation + Still-image-only 3D bend simulation + +

User can change bending sequence, gauging and tooling + +

User can insert directly programmed operations + +

Step bend: change number of steps + +

CDS_modeva_RA_EN_V4.2.doc Modification rights reserved 4/8

Page 5

Run environment: setup sheet RA Premium RA

Jogs, manual moves + +

Drawing of part before/after + +

Tool station position and width + +

Tool station segmentation + Option RA02

Run environment: running, correcting RA Premium RA

Auto/SemiAuto selector + +

Correction of BDC and crowning after measuring 1, 2 or 3 angles + +

Direct corrections of any axis + +

Modifying cycle properties (TDC, PP, speed, force, etc.) + +

Thickness variation measure: thick sheet, manual or die-displacer + +

Machine, options RA Premium RA

Synchronized Y1-Y2 press-brake + +

P/PC press: Y, Y+Y0 + +

Upstroking P/PC press. + +

Independent column for each BG finger: (X,R,Z), (X2,R2,Z2) + +

Backgauge beam moved by one X axis: X, (X,R), (X,Z1,Z2),

+ +

(X,R,Z1,Z2), (X,R,Z1,Z2,X1), (X,R,Z1,Z2,X1,X2rel)

Backgauge beam moved by two X axes at the extremities + +

Additional backgauge axes (X5,X6,R5,R6,Z5,Z6) as directly

+ +

programmable axes (no 3D treatment, no collision checking).

Crowning: mechanical, hydraulic static, hydraulic adaptive + +

OEM-configured digital and analog auxiliary functions + +

(*) Rear sheet supports (H, H2) Option 38 (*) Front sheet supports (H3, H4, H7, H8, H11) Option 52 (*) Front and rear bending aids (AP1, AP2, AP3, AP4) Option 42 (*) Combined bending aids and sheet supports ( H+AP, etc…) Option 90 (*) Die displacer (M1, M2) Option 51 Die displacer (auxiliary digital function) + +

Free axes, as directly programmable axes (no 3D treatment) + +

Slave axes Option 91 (*) Front gauges Option 33, 34 CANOpen axis drives Option 74, 75,

76, 78

(*) In-process angle measurement (NLR board) Option 30, 60,

Option 74, 75,

76, 78

-

66, 65

Thickness variation compensation: strain gauge Option 86 PCSS interface Option 84 Option 84

(*) Available soon

Languages

Chinese (simplified and traditional), Croatian, Sloveni an,

+ +

Hungarian, Czech, Danish, English (reference language), French,

German, Italian, Polish, Spanish, Russian, Turkish.

Language translation modifiable by manufacturer or end-user + +

CDS_modeva_RA_EN_V4.2.doc Modification rights reserved 5/8

Page 6

Other Software Options

The following features work only when ModEva RA is used in ModEva 15S mode.

Angle protractor

Message interpreter

Other Hardware Options

Fixing adapter

S-series

Earthing kit

CybVA 6

MVP 100

MSV

After the bend, the resulting angle is measured using an angle protractor. The value is transmitted

via wireless, USB or RS232 link to the NC and automatically generates the correction.

Option 8 allows remote control of the CNC via network or RS 232.

Reading/writing of variables, corrections, part loading, mode changing, etc.

Ideal for automation and/or applications with robot(s).

Only for communication in ModEva 15S mode.

Same mounting flange as for the ModEva 10S, 12S, 15S, allowing the installation of a ModEva RA

on a pendant arm previously used for ModEva 10S, 12S or 15S.

Rail and bridles for earthing the earthing for the ModEva CNC rack. See photo belo w.

Interface board for proportional Hoerbiger (or similar) valves.

Voltage / current conversion module (0-10V Î 0,25-0,5 / 0-2 A) for pressure and crowning valves, to

be fitted in the electric cabinet. Not required with CybVA 6.

Voltage / current conversion module (0-10V Î 0-50 mA, 0-300 mA) for servo-valves.

CDS_modeva_RA_EN_V4.2.doc Modification rights reserved 6/8

Page 7

EC Directives

Directives

Console Dimensions

Our numerical control units comply with directives

EC61131-2 type 1-3.

CDS_modeva_RA_EN_V4.2.doc Modification rights reserved 7/8

Page 8

CNC Dimensions – Rack C - M

CNC Dimensions – Rack L

CDS_modeva_RA_EN_V4.2.doc Modification rights reserved 8/8

Loading...

Loading...