Page 1

User Manual

for Synchronized Press Brakes

Febr.’15

V2.0

Page 2

© 2015 Cybelec S.A.

All Rights Reserved

Copying, reproduction, modification, distribution, display or transmission of any of the contents of

this manual for any purpose without the prior consent of Cybelec S.A. is strictly prohibited.

Page 3

The Intuitive Programming

Table of conTenT

Safety ......................................................................................................................1

General Safety ............................................................................................................................... 1

ModEva with Windows Operating System .................................................................................. 2

Signs and Icons appearing in this Manual .................................................................................. 3

General warning ............................................................................................................................. 3

Information.................................................................................................................................... 3

Settings .......................................................................................................................................... 3

Navigation .................................................................................................................................... 3

Getting started with ModEva 15T ............................................................................ 4

Screen Cleaning .............................................................................................................................. 4

General navigation ....................................................................................................................... 5

Menu Button ................................................................................................................................ 5

List of Products ................................................................................................................................................. 5

Graphical List of Products ...............................................................................................................................5

Search of Product/Criteria .............................................................................................................................. 6

List of Punches ..................................................................................................................................................6

Programming of Punches ................................................................................................................................6

Transfer .............................................................................................................................................................6

List of Dies ........................................................................................................................................................6

Programming of Dies .......................................................................................................................................6

Welcome ............................................................................................................................................................7

Machine Parameters ......................................................................................................................................... 7

Machine Initialization DNC/ENC ................................................................................................................... 7

Control .............................................................................................................................................................. 7

Product Button ............................................................................................................................... 8

TouchProfile .....................................................................................................................................................8

Product 3D ........................................................................................................................................................ 8

Comment ..........................................................................................................................................................8

Page 4

The Intuitive Programming

Product Numerical ........................................................................................................................................... 8

Tools Position .................................................................................................................................................... 8

Bend Button ................................................................................................................................... 9

Bend Numerical ................................................................................................................................................9

Bend 3D ............................................................................................................................................................9

Bend 2D ............................................................................................................................................................9

Image Bend ....................................................................................................................................................... 9

Correction Button ...........................................................................................................................10

Bend Function ................................................................................................................................................ 10

Corrections .....................................................................................................................................................10

Tools Bend ......................................................................................................................................................10

Actions Button ..............................................................................................................................11

Language .....................................................................................................................................11

Tools Position .......................................................................................................12

Punch Adjustment ...................................................................................................................... 12

Die Adjustment ........................................................................................................................... 13

Adding Working Stations ........................................................................................................... 14

Creating a Part Program ........................................................................................15

TouchProfile Programming ....................................................................................................... 16

Special functions for a bend .............................................................................................................17

L-Alpha Programming ............................................................................................................... 18

3D Programming (optional) ..................................................................................................... 19

Bend 2D Page ............................................................................................................................. 21

Bend Numerical Page (Direct Programming) ......................................................................... 22

Position of axes and other functions ..................................................................................................23

Bending, Tests and Corrections................................................................................................. 24

Memorize or Search a Program .............................................................................26

Memorize a Program .................................................................................................................. 26

From the List of Product page ...........................................................................................................26

Page 5

The Intuitive Programming

Search a Product ........................................................................................................................ 27

Standard Method ...........................................................................................................................27

Rapid method ................................................................................................................................27

Graphic Method .............................................................................................................................28

Sorting Products ............................................................................................................................................. 28

Searching a product .......................................................................................................................................28

Protection of the Access Levels .............................................................................29

General Information .................................................................................................................. 29

Levels ...........................................................................................................................................29

Access ...........................................................................................................................................29

Password ......................................................................................................................................29

Characteristics ...............................................................................................................................29

Loss of the password .......................................................................................................................29

Users ............................................................................................................................................ 30

Access by Password ..................................................................................................................... 31

Access to Levels Superior to 3 ................................................................................................... 31

Change Passwords ...................................................................................................................... 32

Forgotten Passwords ................................................................................................................... 33

Cybelec Software ...................................................................................................34

Installing the Software ............................................................................................................... 34

Leaving the Software .................................................................................................................. 34

Page 6

The Intuitive Programming

Page 7

ModEva 15T User Manual

Safety

General SafeTy

The users must have Read and UndeRstood, but most of all must Respect the

directives described in this manual.

All people coming into contact with the machine on which the numerical

control is installed, whatever their function or whatever state the machine is in

(assembly, disassembly, start-up, production, maintenance, repairs) must have

read and understood the requirements concerning the security and the entirety

of the directives of operation described in the manuals delivered with the

machine.

The operator must be properly trained to work with the machine

on which the numerical control is installed. Improper use of the

numerical control can cause heavy damage on equipment and/or

injuries to people.

Modification of machine parameters can cause important material damage or

lead to irregular product quality.

Do not expose the numerical control to excessive humidity so as to avoid any

risk of electrocution and any deterioration of the equipment.

Make sure the numerical control is disconnected from the mains power before

carrying out any cleaning. Do not use liquids based on alcohol or ammoniac.

In case of malfunction of the numerical control, call a technician.

Do not expose the numerical control to direct sun rays or any other heat source.

Do not place the numerical control in the neighborhood of magnetic equipment

such as transformers, motors or devices which generate interference (welding

machines, etc.)

Feb.

2015

V2.0

1/34

Page 8

Modeva wiTh windowS operaTinG SySTeM

The CYBELEC ModEva’s equipped with Windows have been installed at the factory with a

configuration especially made for the numerical control.

This configuration ensures that a minimum of files are present on the ModEva, offering

in this way a maximum speed to execute the programs. This configuration also ensures

that the drivers are correct and that the whole guarantees an optimal functioning of the

numerical control.

As Windows is a very open system, it is advised not to modify the

Windows installation or to install other programs. You risk disturbing

the functioning of the numerical control.

If you wish to install a network or a printer, please call a specialist.

Remember that the ModEva is equipped with USB ports and that it is very easy or even

tempting to install external software, utilities or games coming from the Internet or

specialized magazines.

ModEva 15T User Manual

CYBELEC accepts no responsibility in case of malfunctioning of the

numerical control if other programs have been installed or if the

original configuration has been modified.

We also remind you that the Windows environment is infested with viruses and

utmost caution is to be taken when using data or software coming from the

outside. A regular back-up enables you to get your data in safety.

We certify that our numerical controls are delivered virus free.

2/34

Feb.

2015

V2.0

Page 9

ModEva 15T User Manual

SiGnS and iconS appearinG in ThiS Manual

While using this manual, you will come across the signs and icons represented here

below: they are directly related to the safety and security of persons. Carefully follow this

advice and inform others about it.

General warning

Information

Settings

This warning sign appears in the manual whenever it is necessary to pay attention to

rules, instructions or advice. The correct sequence of operations is to be followed in order

to avoid damage to the machine.

Symbolizes a serious personnel danger

This warning sign appears in this manual whenever an important information needs to be

taken into consideration. Pay attention to this sign and follow the instructions given.

This sign appears in this manual whenever setting instructions are given. Pay attention to

this sign and follow the sequence of instructions given.

Navigation

This icon appears in this manual to give navigation information, to give the path to the

subject treated in the chapter.

Feb.

2015

V2.0

3/34

Page 10

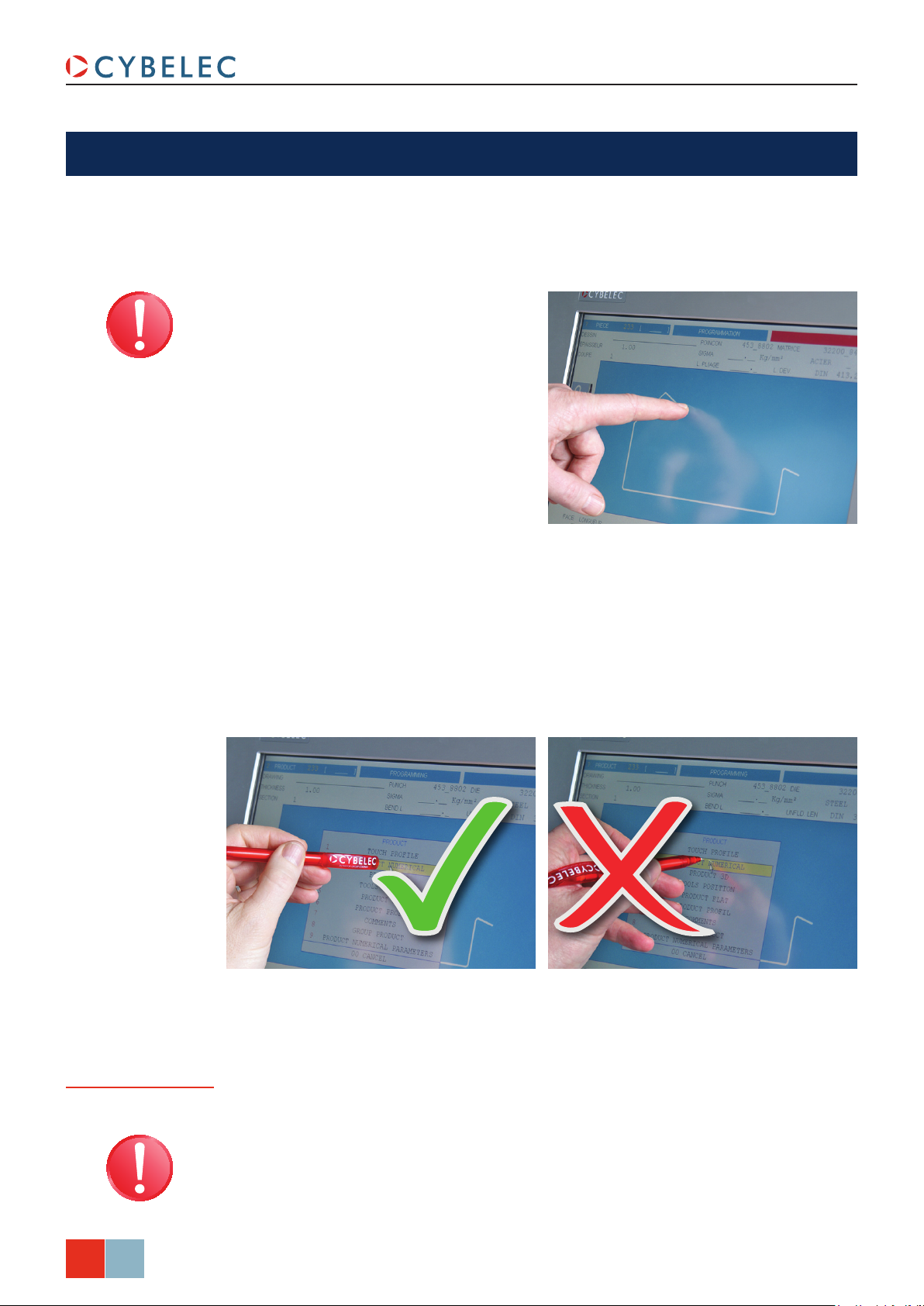

GettinG Started with Modeva 15t

Depending on software evolutions and the press brake controlled by the ModEva

(configuration/capabilities), the present manual may not fully correspond to the ModEva

that you currently have. However, differences are only minor.

Touchscreens are pressure

sensitive.

Do not press down hard on the

screen.

Pressing hard on the screen will

damage the display. Such damage

is not covered by manufacturer

warranty!

ModEva 15T User Manual

Do not use sharp and/or pointed objects (sheet metal, screwdriver, metal pen ball, etc.) to

touch the screen; only use your fingers (with or without gloves on) or a plastic pen. Make

sure that your gloves do not have metal particles encrusted in the finger tips as they may

also damage the screen.

Take a few minutes to practice pressing gently on the screen, you will find that the screen

is very reactive and it is pleasant to use.

Screen Cleaning

Feb.

4/34

2015

V2.0

Turn off the ModEva to clean its screen. Use only a damp and smooth cloth with soap or a

neutral detergent.

NEVER use solvent, petrol, benzene, alcohols, etc.

Page 11

ModEva 15T User Manual

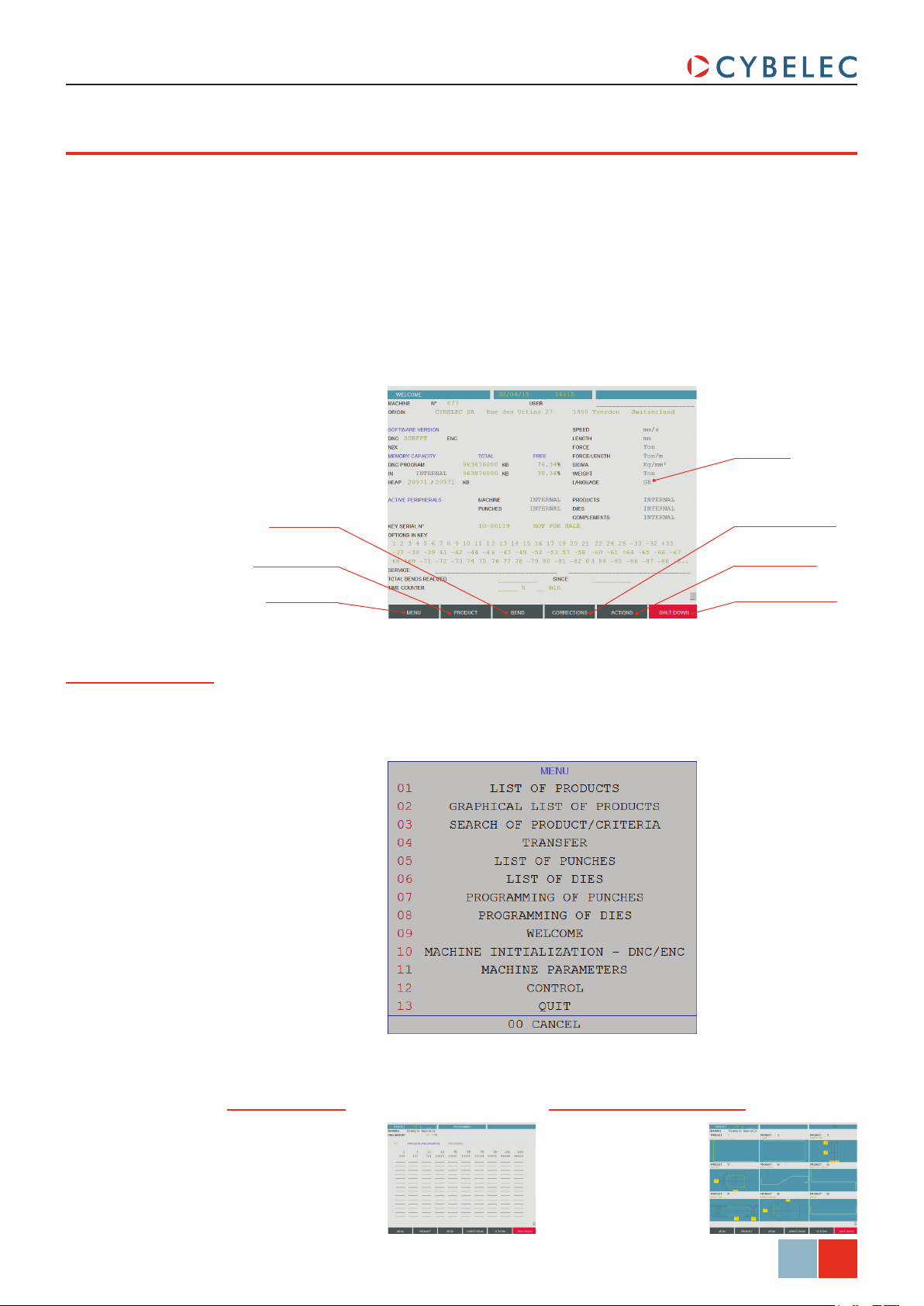

General naviGaTion

The main navigation through the many different pages of the ModEva software is done by

mean of the buttons at the bottom of the screen.

The pages contain fields of different colors:

• The blues fields are fixed texts, such as category titles or headings.

• The gray fields, when touched, open a pop-up window with a list a choices.

• The black fields are those where data is to be entered.

• The khaki fields are information data fields, like real position of axes or actual value of

a variable.

Language

Menu Button

Bend Button

Product Button

Menu Button

Correction Button

Actions Button

Shut Down Button

The Menu button allows you to access programming pages, whether they are related

to products, tools or general machine parameters. When touching the Menu button, the

following pop-up window is displayed.

List of Products

Graphical List of Products

Search of Product/Criteria

Transfer

List of Punches

List of Dies

Programming of Punches

Programming of Dies

Welcome

Machine Initialization DNC/ENC

Machine Parameters

List of Products Graphical List of Products

Allows extracting

products stored in

the NC, in numerical

increasing order.

Allows extracting

products stored in

the NC, in numerical

order, and with the

graphic associated

to them.

Feb.

2015

V2.0

5/34

Page 12

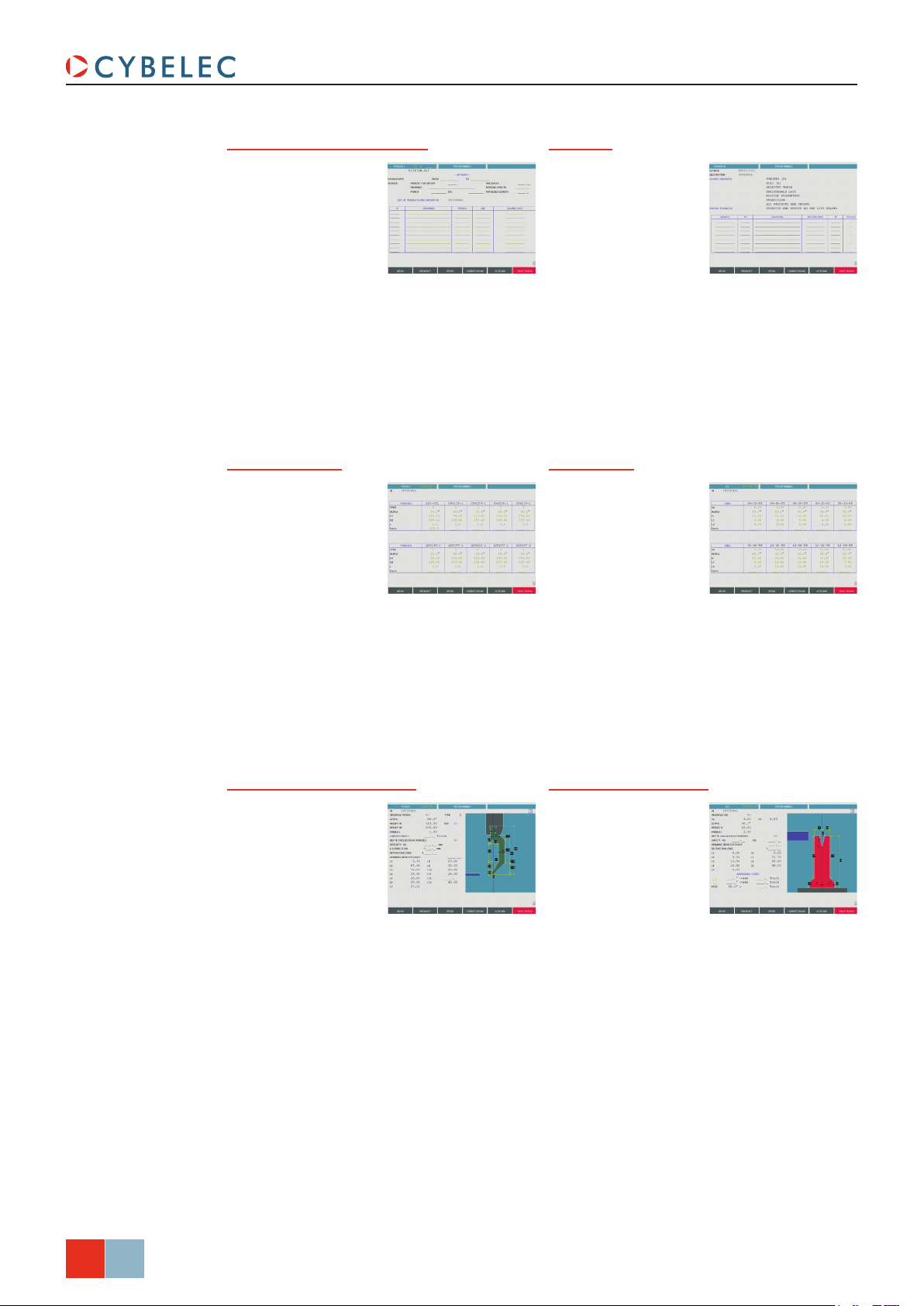

Search of Product/Criteria Transfer

ModEva 15T User Manual

Allows searching for

different products

stored in the

numerical control

according to certain

criteria.

List of Punches

Gives a quick

glimpse at the main

parameters of the

punches stored

in the numerical

control. From this

list, you can see the

complete description of the tool by simply

touching its name. The Programming of

Punches page is then displayed.

Allows making data

transfers from one

memory to another

(USB, network,

etc...).

List of Dies

Gives a quick

glimpse at the

main parameters

of the dies stored

in the numerical

control. From this

list, you can see the

complete description of the tool by simply

touching its name. The Programming of

Dies page is then displayed.

Programming of Punches

Programming of all

punches is done

from this page.

All the dimensions

relative to the tool

are introduced here.

A drawing representing the tool is displayed

on the right of the screen.

Programming of Dies

Programming of all

dies is done from

this page.

All the dimensions

relative to the tool

are introduced here.

A drawing representing the tool is displayed

on the right of the screen.

6/34

Feb.

2015

V2.0

Page 13

ModEva 15T User Manual

Welcome Machine Initialization DNC/ENC

Main data for the

machine and the

numerical control.

Gray color fields

are multiple choice

fields which can

be modified (see

General navigation, page 5).

This page is reserved

for the technical

maintenance of the

numerical control or

the machine.

It allows clearing the

ModEva data and to

modify the physical indexes of the machine.

The level 3 password (see Access by

Password, page 31) is necessary to

intervene on this page.

Machine Parameters Control

This page is the first

of the pages which

constitute the list of

all the parameters

which condition the

functioning of the

numerical control.

Displays eventual

messages related to

specially configured

inputs Control 1 to 8.

This data can only be modified with a

level 3 password (see Access by Password,

page 31).

This data may be modified only with the

help of competent technical support.

Feb.

2015

V2.0

7/34

Page 14

ModEva 15T User Manual

Product Button

The Product button allows you to access all the different pages necessary to create

products. When touching the Product button, the following pop-up widow is displayed.

TouchProle

Product Numerical

Product 3D

Tools Position

Comment

TouchProfile Product Numerical

Allows the operator

to create a product

by intuitively drawing

a profile directly on

the screen.

Allows the operator

to construct and

calculate a product

and to visualize the

profile in real time.

See TouchProfile

Programming, page

16 for more information.

Product 3D

Allows the operator

to create a product

in 3 dimensions. See

also 3D Program-

ming (optional), page

19.

See L-Alpha

Programming, page

18 for more information.

Tools Position

Allows defining

several work

stations. See also

Tools Position, page

12.

8/34

Feb.

2015

V2.0

Comment

Allows completing

the product data

with a series of commentaries. These

commentaries are

programmed using a

PC software.

Page 15

ModEva 15T User Manual

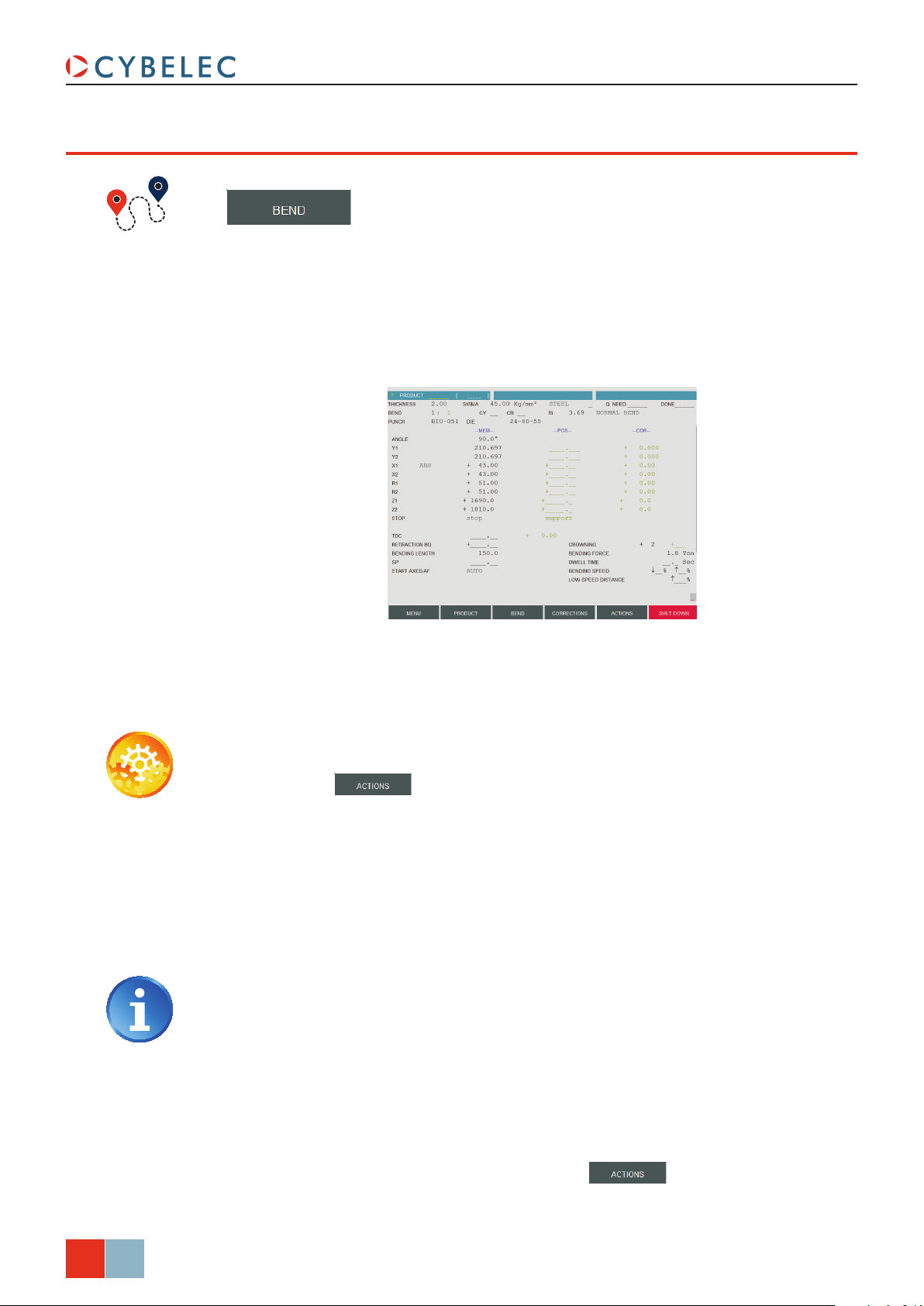

Bend Button

The Bend button allows you to access the different work pages, from which the created

products can be produced. When touching the Bend button, the following pop-up window

is displayed.

Bend Numerical

Bend 2D

Bend 3D

Image Bend

Bend Function

Tools Bend

Bend Numerical Bend 2D

Recapitulates all the

data for the current

sequence.

See Bend Numerical

Page (Direct Programming), page

22.

Allows simulating

the feasibility of

the product and

correcting the

bending order if

necessary.

See Bend 2D Page,

page 21.

Bend 3D Image Bend

Allows the operator

to simulate the feasibility of the product

and to correct, if

necessary, the stop

position as well as

the position of the

product relating to the tools.

This page is optional.

Allows the operator

to visualize the part

in 3D, while at the

same time getting

instruction on how

to handle the part.

Is only available if

the part was created on a CAD software

able to generate a Cybelec compatible

program with images.

Feb.

2015

V2.0

9/34

Page 16

Bend Function Tools Bend

ModEva 15T User Manual

Allows programming

any possible auxiliary functions of the

machine.

Allows modifying

the position and the

width of the tools

mounted on the

machine. Certain

safety factors can

also be modified

here.

Correction Button

The correction button allows you to access the corrections page, where the individual

bends of a part can be fine-tuned. When touching the correction button, the following

pop-up window is displayed.

Corrections

Corrections

Allows applying the

corrections to the

different machine

axes as a function of

the results obtained

during bending.

See Bending, Tests

and Corrections, page 24.

10/34

Feb.

2015

V2.0

Page 17

ModEva 15T User Manual

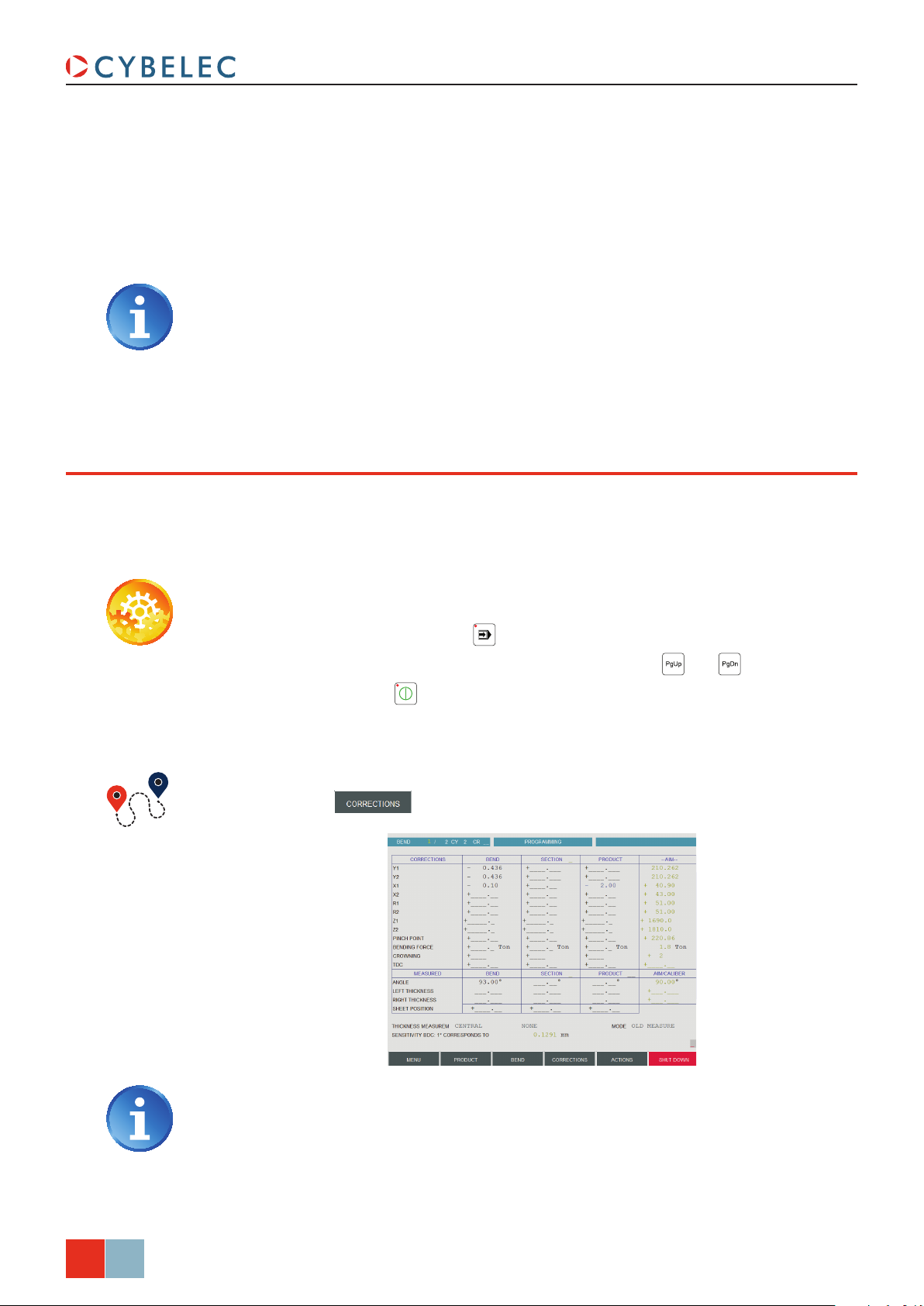

Actions Button

The actions button allows you to choose from a list of action available on the page where

you currently are. The content of the list changes contextually. Here below are examples

of the pop-up windows being displayed when touching the actions button.

Language

To browse through the available languages, simply touch Language field on the screen.

Available languages are:

• CH 中文.

• CZ Český.

• DE Deutsch.

• DK Dansk.

• ES Español.

• FI Suomi.

• FR Français.

• GB English.

• GR Ελληνικά.

• HU Magyar.

• IT Italiano.

• KO 한국의.

• NL Nederlands.

• PL Polski.

• PT Português.

• RU Русский.

• SE Svenska.

• SI Slovenski.

• TR Türkçe.

• TW 台灣.

The list of available languages is subject to change and may

increase over time.

Feb.

2015

V2.0

11/34

Page 18

toolS PoSition

The Tools Position page allows defining several places of work and hence allows the

operator to visualize the tools assembly.

punch adjuSTMenT

middle of the machine

ModEva 15T User Manual

→ Tools position

Punch placed in the

Punch name

Punch position

Setting inStructionS:

1. Touch the beam (it will turn blue)

to select the punch. The letter P is

displayed next to the punch name’s

selection field.

2. Touch the P field. The window to the

right is displayed.

3. Touch the desired punch. Touch it a

second time to select it, or simply

confirM.

touch

4. Enter the tools desired position in the

field.

Introducing a value equal to the half

of the beam’s width minus the half of

the tool length will place the tool in the

center of the machine (in our example:

3500/2 – 195/2 = 1652.5 mm).

Punch length

12/34

Feb.

2015

V2.0

5. Modify the L field by introducing

the value (here 195.00) which

corresponds to the required tool

length. In the front view the selected

tool appears in dark blue.

Page 19

ModEva 15T User Manual

die adjuSTMenT

Proceed in the same manner as for Punch Adjustment.

→ Tools position

Die placed in the middle

of the machine

Die name

Die position

Die length

Setting inStructionS:

1. Touch the table (it will turn blue) to

select the die. The letter D is displayed

next to the die name’s selection field.

2. Touch the D field. The window to the

right is displayed.

3. Touch the desired die. Touch it a

second time to select it, or simply

confirM.

touch

4. Enter the tools desired position in the

field.

Introducing a value equal to the half

of the table’s width minus the half of

the tool length will place the tool in the

center of the machine (in our example:

3500/2 – 195/2 = 1652.5 mm).

5. Modify the L field by introducing

the value (here 195.00) which

corresponds to the required tool

length. In the front view the selected

tool appears in dark blue.

Feb.

2015

V2.0

13/34

Page 20

addinG workinG STaTionS

Most parts require different sets of tools to be bent. It is therefore possible to define

several working stations in the tooLs Position page.

Double horned punch Right horned punch

ModEva 15T User Manual

→ Tools position

Inverted tool

Horned punch

Setting inStructionS:

1. Once the first working station is defined, a touch on either the beam or the table will

allow adding another tool.

2. The procedure to select, define and position the tool is the same as the one

explained before (see Punch Adjustment, page 12 and Die Adjustment, page

13).

14/34

Feb.

2015

V2.0

Page 21

ModEva 15T User Manual

CreatinG a Part ProGraM

This chapter describes, by means of a concrete example, diverse ways of using your

ModEva.: with the TouchProfile Programming, with the L-Alpha Programming (see

page 18), with the Bend Numerical Page (Direct Programming) (see page 22) and with

the 3D Programming (optional) (see page 19).

We assume in this part that all the necessary tools have already been

programmed as well as the machine parameters.

The product being used as an example is composed of 2 sections (profiles), but the

procedure is identical for one or several sections.

30.0

Section 1

45.0

40.0

150.0

200.0

Section 2

20.0

45°

The side flaps with the oblong holes, which are included in section 1, will be made first,

so that a punch of identical length as that for section 2 can be used.

We presume that the operator knows how to reach level 1. Should this not be

the case, see chapter Protection of the Access Levels, page 29.

These procedures indicate to the operator a programming method

recommended by CYBELEC, enabling to assimilate by the example the

functioning of the software.

For additional information, please consult the 2D Reference Manual and/or the

3D Reference Manual, which each contains a table of contents and a detailed index

facilitating the search for information.

Feb.

15/34

2015

V2.0

Page 22

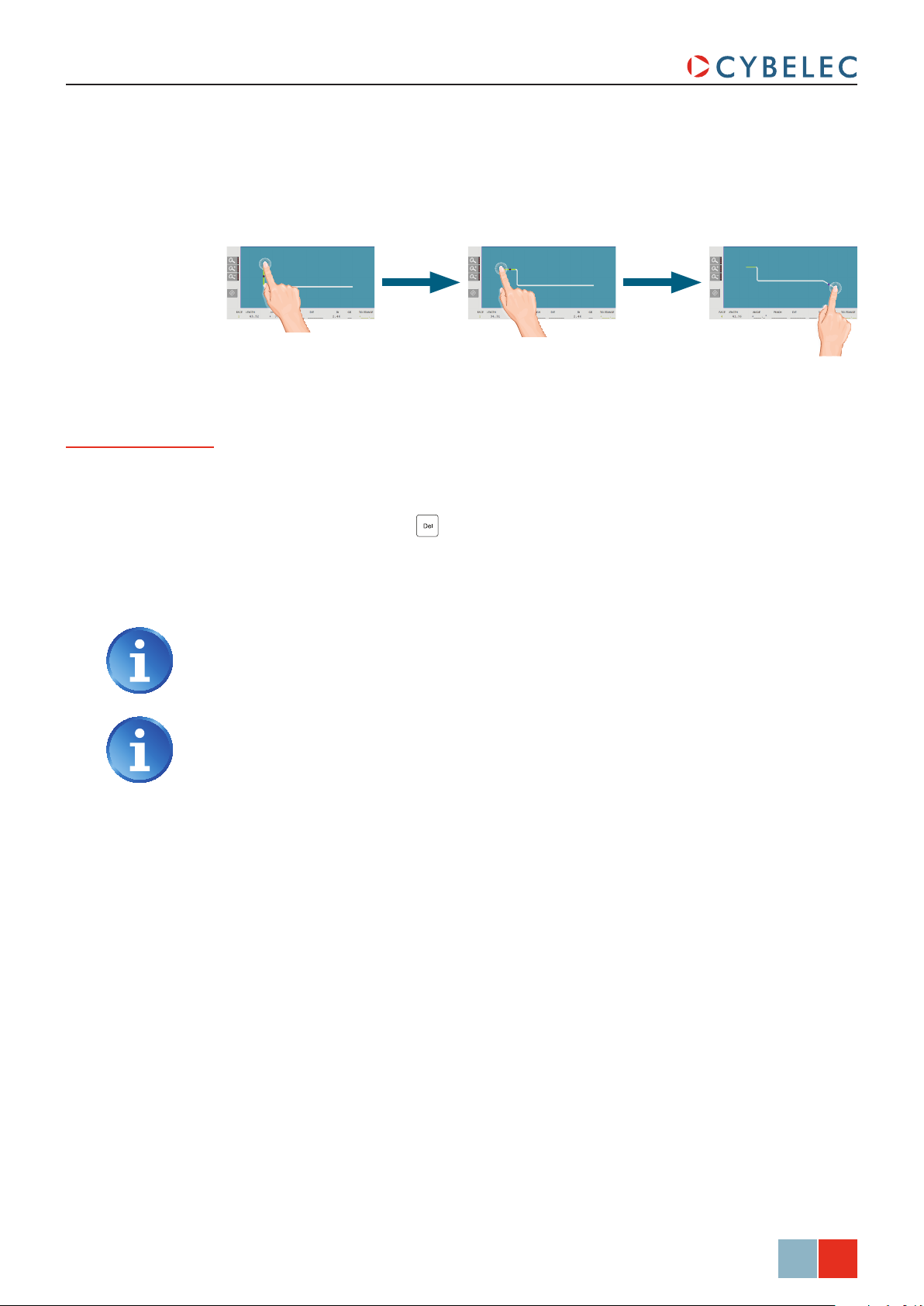

Touchprofile proGraMMinG

Product number

Material thickness

ModEva 15T User Manual

→ TouchProfile

Tools selection

Material

Material Sigma

Zoom buttons

Delete selected segment

Selected bend data

Bending length

In this mode, the operator can very intuitively draw a profile directly on the screen.

Setting inStructionS:

1. Touch the button and select New product in the list.

2. First select the material, enter its thickness and Sigma, enter the bending length, and

select the tools to be used for the part by touching their respective fields.

Selecting tools directly from the TouchProfile page places them automatically

in the middle of the machine. To change their position, see Tools Position, page

12.

16/34

Feb.

2015

V2.0

3. Draw the profile of section 1 (see

Creating a Part Program, page 15) by

touching the screen where you want

to add a segment.

4. Touch on the middle of a segment

or on an angle to modify its value.

A purple dot indicates the selected

segment, and its value is highlighted in

the bend information line.

Touching this icon allows erasing

the selected segment.

5. Proceed in the same manner to adjust

all segments and angles.

Page 23

ModEva 15T User Manual

6. Touch the SECTION field, enter the value of 2 and leave the field. This automatically

initializes a new page for programming section 2.

7. Draw the profile of section 2 (see Creating a Part Program, page 15) by touching

the screen where you want to add a segment.

8. Proceed in the same manner as for section 1 to adjust lengths and angles values.

Special functions for a bend

9. If a bend needs special parameters (large radius, special tool), it can all be

programmed on the bend data line of the corresponding sequence.

• Activate a special tool by touching the corresponding field, and select it from a list

(deactivate with the

• Change the value of the radius (Ri field) and define how many steps the NC will

make to execute it (CR field).

button).

Programming 99 in the CR field will automatically calculate the maximum

possible step bends. The resulting value may be reduced. However, if it is

increased over the maximum calculated value, the resulting radius and angle

will be drastically affected.

A special punch or /and die means there must be an additional working station.

10. Once all the segments and angles adjusted, go to the Bend 2D Page (see

page 21).

Feb.

2015

V2.0

17/34

Page 24

l-alpha proGraMMinG

In this mode, the operator can define each step (length and angle) of a profile in a table.

In the bottom section of the page, the operator can see the profile being automatically

drawn as a function of the introduced data. The value of the internal radius is

automatically calculated as a function of the selected tools.

ModEva 15T User Manual

→ Product Numerical

Tools selectionMaterial Sigma

Product number

Material thickness

Bend data table

Graphic representation

of the prole

Material

Bending length

When introducing data in L-Alpha mode, simply begin from one of the

extremities of the profile and fill in the values of each face and angle one after

another, with the last face having no corresponding angle.

Setting inStructionS:

1. Touch the button and select New product in the list.

2. First select the material, enter its thickness and Sigma, enter the bending length, and

select the tools to be used for the part by touching their respective fields.

18/34

Feb.

2015

V2.0

Selecting tools directly from the L-Alpha page places them automatically in the

middle of the machine. To change their position, see Tools Position, page 12.

3. Touch the first field of the

corresponds to the first length.

4. Touch the first field of the

corresponds to the first angle to be bent.

5. Proceed in the same manner for all steps and angles of the profile of section 1 (see

Creating a Part Program, page 15).

6. Touch the

section field, enter the value of 2 and leave the field. This automatically

initializes a new page for programming section 2.

7. Proceed in the same manner as for section 1 to define lengths and angles values.

8. If a bend needs special functions, see Special functions for a bend, page 17.

9. Once all the segments and angles defines, go to the Bend 2D Page (see page 21).

Length column and introduce the value of 45.00 which

angLe column and introduce the value of 90° which

Page 25

ModEva 15T User Manual

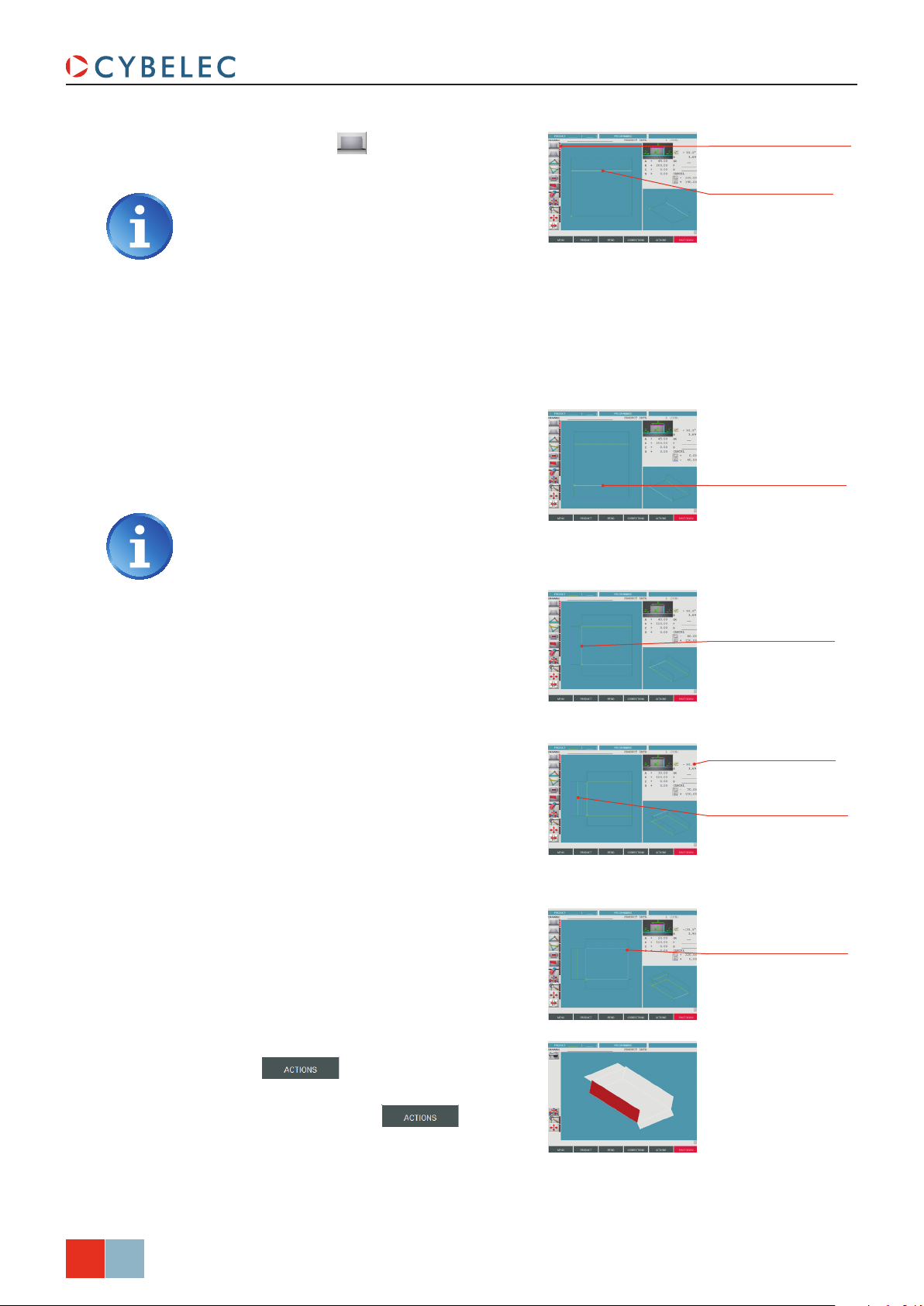

3d proGraMMinG (opTional)

In this mode (available only on the ModEva software with 3D option), the operator can

conceive a part directly in 3 dimensions. The definitions of the different icons you will

encounter through these pages are described in the 3D Reference Manual, in chapter

Definition of the Icons.

→ Product 3D

Product data eld

Tool window

(here showing add

rectangular face)

Working window

(here showing

two-dimensional view)

Display window

(here showing

axonometric view)

Touching the display window inverts the two-dimensional and the axonometric

views, allowing the operator to create his part in two or three dimensions.

Setting inStructionS:

1. Touch the button and select new Product in the list.

2. Touch the

Product data field and select the material, enter its thickness and Sigma,

enter the bending length, and select the tools to be used for the part by touching

their respective fields.

Selecting tools directly from this window places them automatically in the

middle of the machine. To change their position, see Tools Position, page 12.

3. Touch Quit to confirm the chosen values.

4. Touch the

button and select Modify 1f or Modify 2f. The difference

between the two functions is:

Modify 1f: Shows the product in plan mode (2D).

•

Modify 2f: Shows the product in plan mode and in axonometric mode (3D).

•

5. Touch this button to add a

rectangular face. The base rectangle

Base rectangle

dimensions

appears in plan mode in the work

window as well as in axonometric

mode. The tool window is adapted.

6. Introduce the dimensions for A and B

(in our example: 150.00 and 200.00).

Feb.

2015

V2.0

19/34

Page 26

ModEva 15T User Manual

7. Touch this button again to add a

rectangular face.

The red rectangle to the right of the

icons lights up and indicates that the

function is active.

8. Touch the segment of the outline to

which the side is to be added.

9. In the tool window, adjust the height

of the side (field A, here 45.00). The

angle value is 90° by default. The

internal radius is already calculated.

10. Add a second side. The same function

still being active, simply touch on the

lower segment where the side is to be

added.

The value A has been memorized and

is automatically attributed to the new

side.

Function active indicator

Touching this segment

will attach the new face

here

Touching this segment to

add the second side here

11. Add a third side. Touch the left

segment where the side is to be added

(the function remains active until

deactivated).

12. Enter 40.00 in the A field in place of

the previous memorized value (45.00).

13. Add a fourth side by touching the

left segment where the side is to be

added.

14. Enter 30.00 in the A field in place of

the previous memorized value (40.00),

and change the direction of the side by

entering -90.0° for the angle value.

15. Add the last side by touching the right

segment.

16. Change field A value to 20.00, and

angle value to -135.0°.

Touching this segment to

add the third side here

Enter a negative angle

value

Touching this segment to

add the fourth side here

Touching this segment to

add the last side here

20/34

Feb.

2015

V2.0

17. To check the construction, touch the

button and select VisuaLize.

18. To come back to the construction

mode, touch the

button

and select Modify 1f or Modify 2f.

19. The product is now finished, go to the

Bend 2D Page (see page 21).

Page 27

ModEva 15T User Manual

bend 2d paGe

→ Bend 2D

Setting inStructionS:

1. At this point, a product must have been programmed, using one of the modes

previously explained.

2. In the

3. Touch the

4. The message

5. The succession of sequences can then be visualized using the

siMuLat. field, choose the option without Progr. Bends.

button and select search Bending range in the list.

siMuLating runs…, then caLcuLating... appears in the interactive field

on the top right-hand corner of the screen.

and keys.

The operator has the possibility to modify the bending range (see the

corresponding chapter in the 2D Reference Manual) or to ask the software to

respect specific criteria like minimum of swings or returns. For that, please refer

to the 2D Reference Manual, section Simulation criteria.

In case where the software program does not find any solution, the bending

range must be imposed manually. See Bending order in the 2D Reference Manual.

Feb.

2015

V2.0

21/34

Page 28

bend nuMerical paGe (direcT proGraMMinG)

→ Bend Numerical

This type of programming is often used for simple products or by operators having

worked on conventional press brakes without numerical controls.

This page is very user-friendly, for the operator has on one single screen all the

information and fields necessary for the programming of his product.

ModEva 15T User Manual

The bending order is chosen by the operator, since he programs directly each bend.

In this example, we will program the part described in Creating a Part Program (see

page 15).

Setting inStructionS:

1. Touch the button and select new Product in the list.

2. On the top of the screen, select the material, enter its thickness and Sigma, and

select the tools to be used for the part by touching their respective fields.

3. Program the required

the tools and the material already programmed. It is also possible to directly enter

the Y1 / Y2 values without programming the angle.

4. Program the real position of the back gauge X1 (here 43.00). X2 can be individually

modified if different from X1.

angLe (here 90.0°). The Y depth will be calculated according to

The programming of the real position of the back gauge requires of the operator

to subtract (approximately) the steel thickness from the external dimension of

the product.

5. If necessary, program the specific data for the current sequence (see Position of axes

and other functions, page 23)

6. The two bends of section 1 (see Creating a Part Program, page 15) being identical,

enter 2 in the CY field (CY stands for cycle, meaning this sequence is repeated twice

in the program).

22/34

Feb.

2015

V2.0

7. To create the subsequent sequence, press the

Bend in the list. It can be seen that all the data has been copied into the second

sequence.

button and select coPy

Page 29

ModEva 15T User Manual

There is another way to program on this page, which has however some

limitations depending on the product and the chosen bending order. It consists

of entering the external flange dimension in the X field of the back gauge, and

then programming a constant negative correction (see Bending, Tests and

Corrections, page 24) corresponding to (approximately, according to your

experience with the tools and the material) the material thickness.

8. Proceed in the same manner as for section 1 to define lengths and angles values.

Position of axes and other functions

The bottom section of the Bend Numerical page contains all the extra parameters for a

bend. Some, like the bending force, are calculated automatically. But all these values can

be modified by the operator.

→ Bend Numerical

According to his needs, the operator can modify the following items:

• TDC, for Top Dead Center. If not programmed, the beam will rise to the maximum

TDC.

retraction Bg, for the back gauge retraction.

•

Bending Length, defines the length of the part being bent, this parameter must already

•

have been defined during the part programming phase.

• SP, for Switch Point. The point where the beam switches from High Speed to Bending

Speed.

start axes/af, setting this parameter to externaL gives manual control over the back

•

gauge movement. This means the operator must personally give the start to the back

gauge movement, using for example the foot switch or the start button.

crowning, if available, is automatically calculated.

•

dweLL tiMe, defines the amount of time during which the pressure is maintained.

•

Feb.

23/34

2015

V2.0

Page 30

•

Bending sPeed, defines the downward bending speed and the upward moving speed

from BDC to Pinch Point point.

Low sPeed distance, defines the portion (expressed in %) of the upward movement

•

between the TDC and the Pinch Point which will be carried out at low speed; the

continuation of the upward movement is made at high speed.

Complementary explications are found in the 2D Reference Manual.

bendinG, TeSTS and correcTionS

This chapter explains how to proceed in order to execute a product. This way of doing is

destined only to demonstrate how to use the numerical control.

ModEva 15T User Manual

The testing and adjusting operations can be carried out in the order decided by the

operator.

Setting inStructionS:

1. Go into semi-automatic mode .

2. If necessary, move to the first sequence by means of the

3. Press the start key

4. Carry out the bend with a trial product.

5. Measure the flap and the obtained angle.

6. Touch the

in order to position the axes on the first sequence.

button and select corrections in the list.

and keys.

24/34

Feb.

2015

V2.0

In the screen above, the correction of -2.00 mm corresponds to the material

thickness when programming section 2 in Bend Numerical Page (Direct

Programming), page 22.

7. If necessary, correct the flap (in this example, a correction of X = - 0.10 is assumed)

for the current bend.

Page 31

ModEva 15T User Manual

See also the Corrections section in the 2D Reference Manual.

Depending on the material, the machine adjustment and the exactness of the

data introduced, 2 or 3 corrections can be necessary for a bend. This can be

considered as being a normal situation.

10. Proceed in the same manner for all the bends by navigating through the bends by

8. Touch the angLe field, Bend column, and enter the measured angle (93.0 in this

case). The software automatically calculates the necessary correction (-0.436, which

can be seen in the Y1, Y2 fields, in the Bend column).

9. Carry out a second test bend (on the same sequence, with a second test product). If

necessary, make a new correction.

means of the

and keys.

11. When all the bends of the product turn out as expected, go into automatic mode

and choose the work page you like:

• Bend Numerical (see page 9),

• Bend 2D Page (see page 21),

• Bend 3D (see page 9) for 3D software.

Feb.

2015

V2.0

25/34

Page 32

MeMorize or SearCh a ProGraM

MeMorize a proGraM

The memorizing of a product can be carried out from all pages containing the Product

field at the top of the screen.

Setting inStructionS:

1. Set the ModEva in programming mode .

ModEva 15T User Manual

From the List of Product page

2. Enter a number in the

3. Touch the

4. If the message

Select:

canceL to choose another number,

•

confirM to overwrite the existing product.

• or

exists appears, it indicates that the number selected is already in use.

Product field.

button and select MeMorize Product in the list.

Selecting MeMorize Product in fiLe allows giving the product an alphanumerical

name, and also select its location.

If you wish to do this memorizing by having a global view of the existing products, it can

be done from the List of Product page.

→ List of products

Select where the le will

be saved here

Insert a description

of the part here

26/34

Feb.

2015

V2.0

Setting inStructionS:

1. In the drawing field, introduce a reference, if needed.

2. If you want to memorize the product elsewhere than in the internal memory, touch

Products and grouPs in field and make your choice.

the

3. Touch the

4. Touch the

5. The message

the screen.

6. The number of the product recorded will then appear in the list.

Product field and introduce the storage number (1 to 89.999).

button and select MeMorize in the list.

saVing... appears in the interactive field on the top right-hand corner of

Page 33

ModEva 15T User Manual

Search a producT

Standard Method

If you know the number of the product (provided that it is in the active peripheral), you

can search for it from all pages displaying the Product field on the top left corner of the

screen.

To this end:

1. Introduce the product number in the

2. Touch the

button and select search Product in the list.

Product field.

If you don’t know the product number, you can search for it in the list of products’ page.

Rapid method

1. Touch the button and select List of Products in the list.

2. If you want to search for the product in a location other than the internal memory,

touch the

3. Simply touch the desired product and press the

4. The product is now in the work memory (its number is displayed in the

Products and grouPs in field and make your choice.

key.

Product field).

From any page displaying the Product field:

1. Touch the

Product field and press the key.

2. The following window is displayed:

Use these arrows to

browse through the

available products

3. The products are initially listed in increasing order by product number.

4. Touch the product you want and select

confirM to load it.

Touching the product twice will also open it.

Feb.

2015

V2.0

27/34

Page 34

ModEva 15T User Manual

Sorting Products

Each column can be listed in an increasing or decreasing order by simply touching its title.

The red arrow (▲ or

▼) indicates the sorting

direction

Searching a product

Touch the table in the desired column and enter there the product number, the drawing

name or the searched date.

Graphic Method

The search criteria you

enter are displayed here

Your entry is displayed on the last line (in white), and the cursor positions itself on the first

line of the table. The names are sorted in increasing order, the first corresponding to your

entry being on the first line.

Procedure:

1. Touch the

2. Use the

and keys to scroll the list of graphical products.

3. Simply touch the desired product and press the

4. The product is now in the work memory (its number is displayed in the

button and select graPhicaL List of Products in the list.

key.

Product field).

28/34

Feb.

2015

V2.0

Touch the product number

and press to select it

Page 35

ModEva 15T User Manual

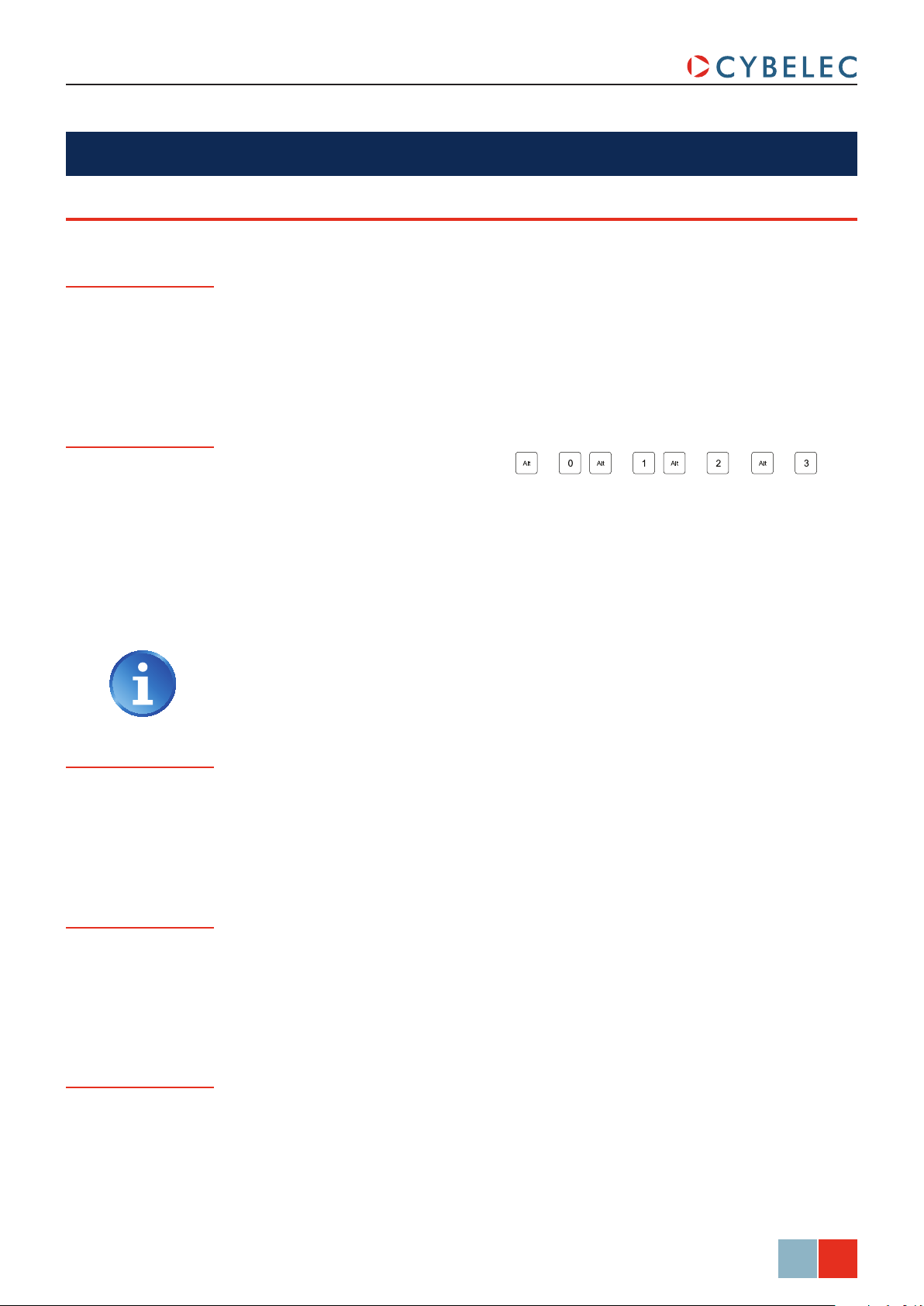

ProteCtion of the aCCeSS levelS

General inforMaTion

In this manual we will always speak of a (virtual) key position like e.g.: «Key in position 3».

Levels

Access

There are 4 access levels, 0 to 3.

0 = Programming prohibited.

1 = Creation, correction, modification, saving, deleting, transfer of one (or more)

product(s).

2 = Creation, correction, modification, saving, deleting, transfer of the tools.

3 = Programming, modification and transfer of the machine parameters.

These levels are reached by pressing the

The key position is displayed as a small pictograph at the right bottom of the screen.

When passing to non-authorized level, a password modification will be requested.

When the password has been introduced, you can «navigate» in the levels inferior and

equal to the authorized one without reintroducing the password.

+ , + , + or + keys.

Release the numerical key before the Alt key. Switching to level 0 reinitializes

the password request.

Password

Characteristics

Loss of the password

Certain users can modify their own password. For the others, the password can only be

changed by a user having a superior access.

The password can be composed of alphanumerical characters if such a keyboard is

available and if not only of numerical characters.

In case of loss of the password, a user with a superior level has to reprogram it.

Feb.

2015

V2.0

29/34

Page 36

uSerS

ModEva 15T User Manual

A number of different users is predefined. A predefined user is just a role and not

a physical person in particular. It can be for example all the operators having the

authorization to work on the machine.

Each predefined user possesses its own password and a maximum level which he can

reach.

level

PerSonal

PaSSword

ChanGinG of

defi ned uSe rS

naM eS of Pre-

ChanGinG of th e

1 EUL1 NO NO 1 111 Operators having level 1 access authorization

2 EUL2 NO NO 2 222 Operators having level 2 access authorization

3 EUL3 NO NO 3 333 Operators having level 3 access authorization

4 WSSUPER OK OK 3 817 Workshop supervisor

5 MACHMAN NO OK 3 Machine manufacturer's Service technicians

6 MACHMAN0 OK OK 3

SubordinateS

PaSSwordS of the

key

Pa SSword

by default

level v irtua l

uSer Generally attributed to

Responsible of the technicians at the machine

manufacturer's

After installing the machine, it is advised to modify the level 4 (WSSUPER =

Workshop supervisor) and level 3 (EUL3 = Operators with authorization level 3)

default passwords, because they are in this manual.

30/34

Feb.

2015

V2.0

Page 37

ModEva 15T User Manual

acceSS by paSSword

At the software’s startup, the virtual key is always positioned at 0.

When the operator selects one of the combinations

following message appears:

+ , + or + , the

Or 1 or 2 according to the

keys combination

Setting inStructionS:

1. Enter the password.

2. Press

3. The authorized level is shown in a box at the bottom right of the screen.

.

If the password is not correct, the message wrong Password is displayed,

indicating that the user is not authorized.

Once the authorization granted, the level remains accessible as long as another

password is not entered. Cybelec recommends accessing level 0 after your

intervention, in order to avoid making undesired changes by inadvertence.

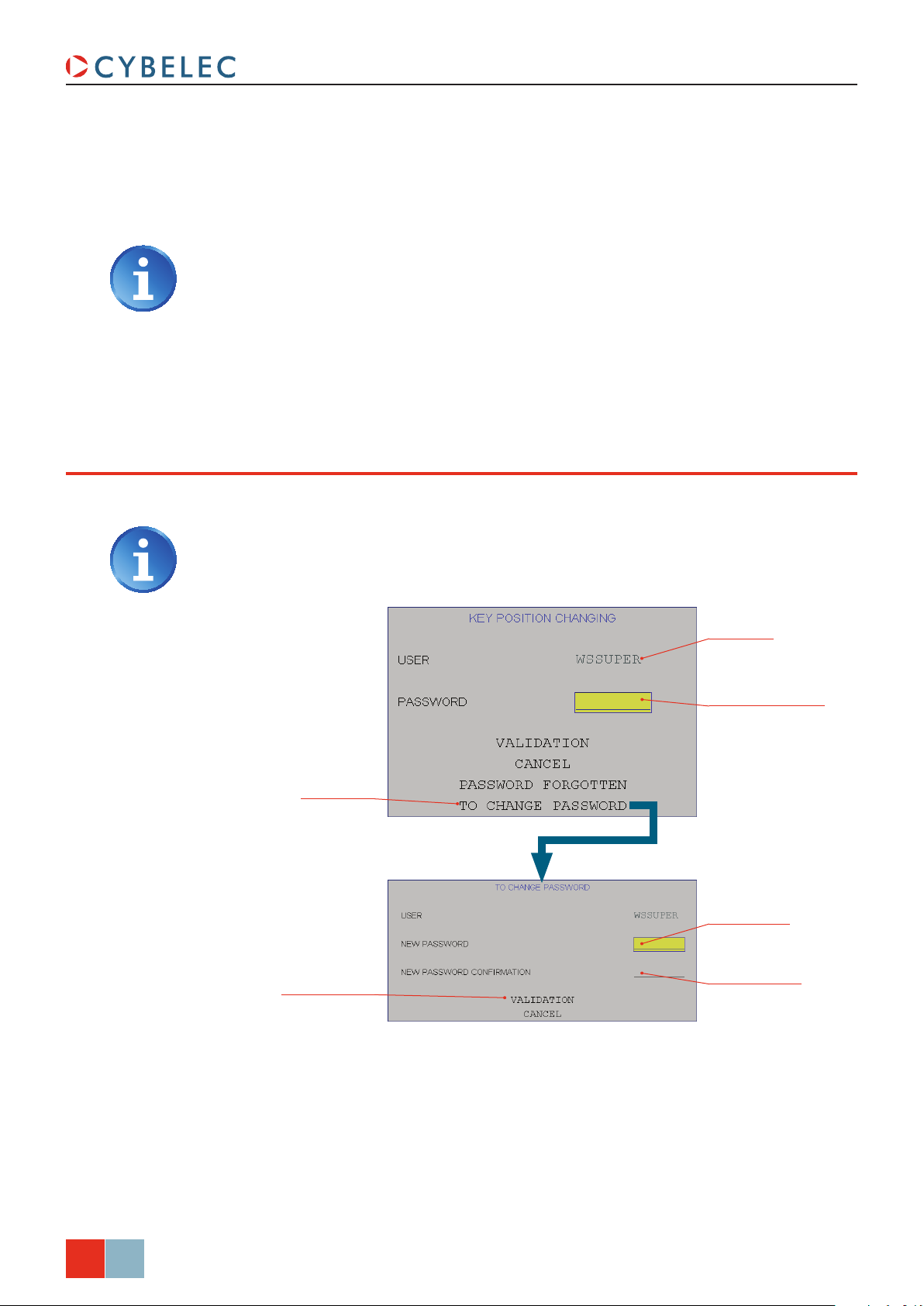

acceSS To levelS Superior To 3

Certain users can access levels superior to 3, which enables them, among other things,

to modify the passwords. To do that, one must press the combination

following message appears:

Setting inStructionS:

1. Touch the user field and select the desired user level (see Users, page 30).

2. Touch the

and validate with the

Password field, enter the password corresponding to the requested level

+ . The

Touch here to select the

desired user level

.

Feb.

2015

V2.0

31/34

Page 38

chanGe paSSwordS

ModEva 15T User Manual

3. The ModEva switches to level 3. The operator can «navigate» between levels 1 and 3

without reintroducing his password.

4. If his access level enables him, he can call the procedure to Change Passwords.

At the end of the intervention, don’t forget to pass to level 0 in order to leave the

current level.

It is possible to modify the passwords attributed by default. Certain users can do it for

themselves, others not.

In order to know the authorizations, see the table in Users, page 30.

Log in as at least

WSSUPER

Enter corresponding

password here

Touch here to change

the password

Enter the new

password here

Validate the modication

by touching here

Conrm the new

password here

32/34

Feb.

2015

V2.0

Page 39

ModEva 15T User Manual

forGoTTen paSSwordS

If a user has lost / forgotten his password, he can, if he is authorized, change it himself

(see Change Passwords, page 32).

If he is not authorized to change his password himself, he can either:

• Ask a higher user to modify the password (see Change Passwords), or

• Use the method described below, after pressing the combination

+ .

In order to know the authorizations, see the table in Users, page 30.

Choose the user whose

password is forgotten

Touch here to recover

the password

Write the heLP code

down

Contact your provider with the heLP code in order to recover the lost password.

Feb.

2015

V2.0

33/34

Page 40

CybeleC Software

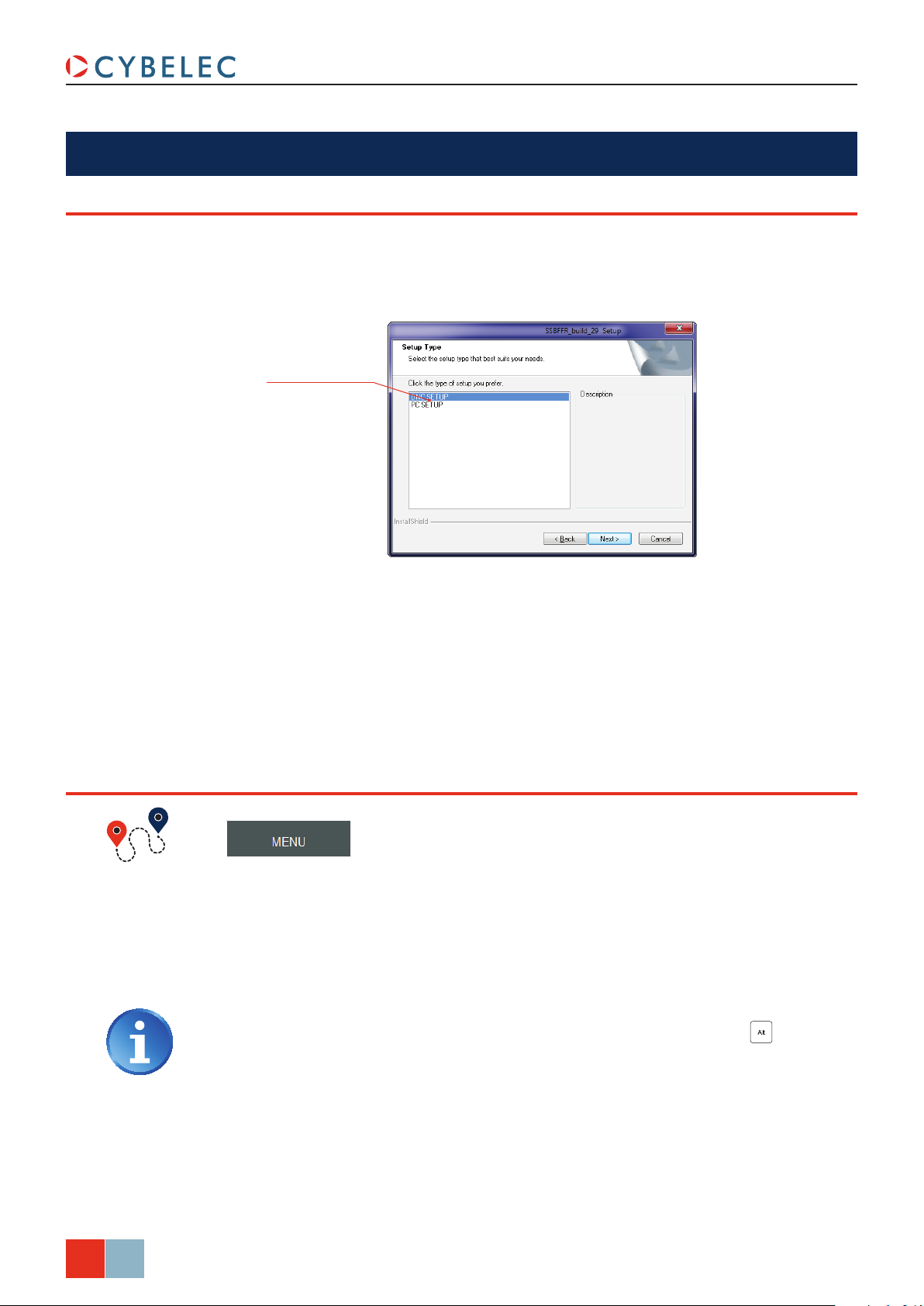

inSTallinG The SofTware

The software delivered with the ModEva can be installed on the numerical control itself of

course, but also on a PC. When running the software’s installation program, the choice is

given in a window as shown below.

Select here the type of

installation desired

ModEva 15T User Manual

leavinG The SofTware

It is possible at any time to quit the task after having memorized the current state.

However it is important to leave the software in the correct way by using the

function.

This procedure will close the PC-ModEva software and bring you to the Windows

environment.

The same procedure can be used on the PC software, or press the + Menu

keys on any page.

→ Quit → Confirm

Quit

34/34

Feb.

2015

V2.0

Loading...

Loading...