Page 1

/

PS

Version for synchronized press-brakes.

encoder.

ModEva CNC /C

ModEva CNC version "C" (Compact): can control up to 4/6 axes or even 18 with CAN axes*.

ModEva CNC /M

ModEva CNC version "M" (Medium): controls up to 12/14 axes or even 18 with CAN axes*.

ModEva™ 15T

ModEva is a range of numerical control units intended specifically for sheet metal working.

Depending on the software installed, ModEva can be used on synchronized or non-synchronized press-brakes of the upstroking or down-stroking type.

ModEva numerical control units can control up to 18 axes of which 2 are synchronized hydraulic axes especially intended for

press-brakes.

The numerical control is composed of 2 main elements:

• The programming console.

• The CNC (Computerized Numerical Control).

The programming console is located within the operator's reach, generally fixed to a swiveling arm; the CNC is placed inside

the electric cabinet.

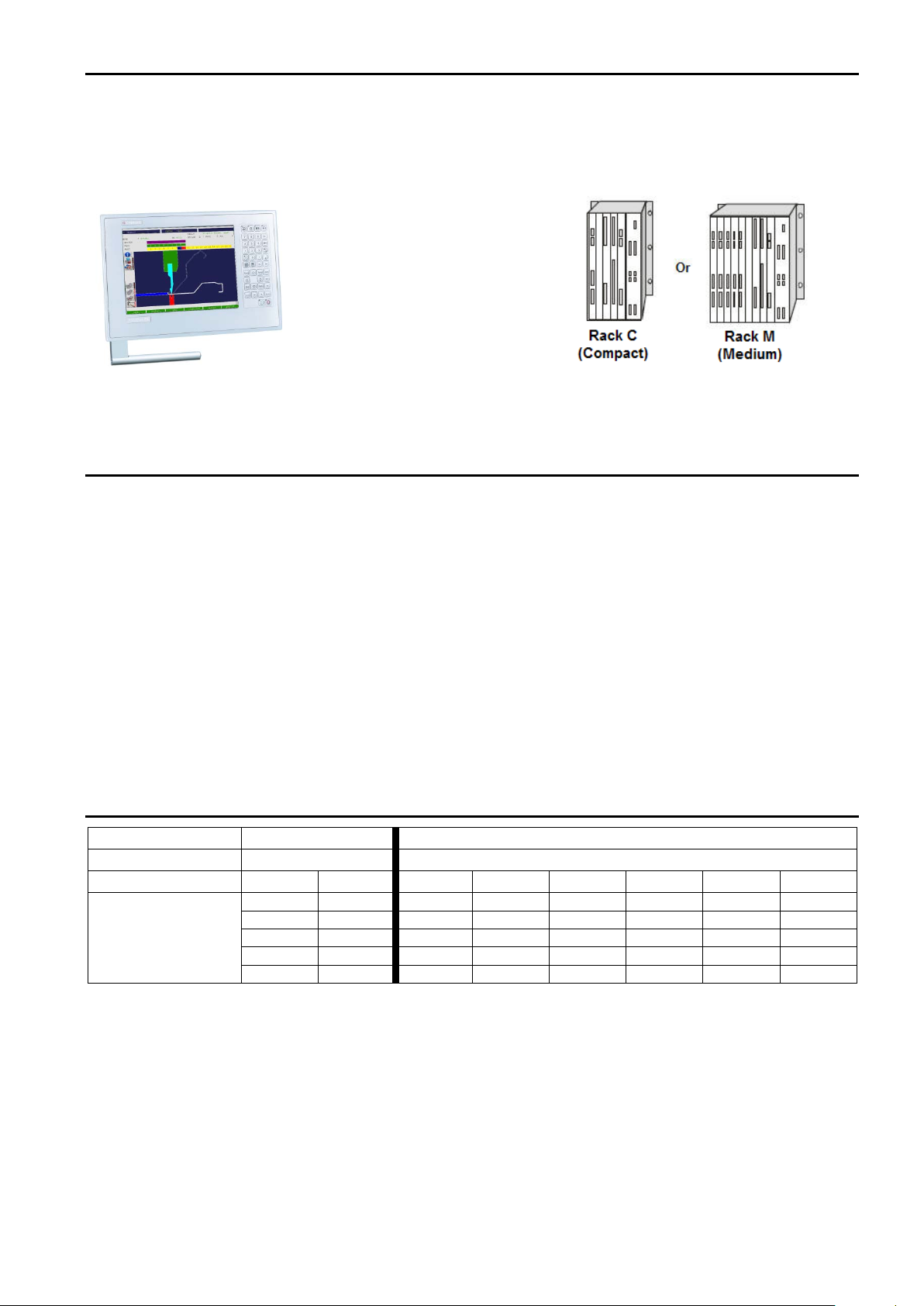

The CNC is available in 2 rack formats.

• Rack version C (Compact): This is a small, very compact rack, convenient for many situations.

• Rack version M (Medium): This is a bigger rack permitting a varied combination of configurations.

The software enables manufacturers to configure the axes, the inputs/outputs and the auxiliary functions according to their

needs.

Versions

PC

* see definitions of the axes and configurations further on in the document.

CDS_ModEva_15T_EN_V2.5.docx5 Aug 2014 1

Like the PS but for press-brakes with mechanical (or hydraulic) stops and beam control with a linear

Page 2

ModEva Range

CNC / C (Compact)

CNC / M (Medium)

2

5

Axis position (slot No)

0 1 0 1 2 3 4

5

NMX

NSX

NMX

NSX

NSX

NSX

NMX

NLR

NMX

NSX

NSX

NLR

NCX

-

NMX

NSX

NSX

NLR

NMX

ModEva is a modular range with a choice of:

• 1 programming console 15” touchscreen.

• 2 programs (2D or 3D) an d 1 Windows XP emb. operational system.

• 2 different rack sizes depending on the number of axes and the desired technology (analog or CAN).

Definitions:

Hydraulic axes: An analog axis especially intended for controlling the beams (Y1-Y2). These two axes are on the

NPU.

Analogical axes: Axes for which position is given by an incremental sensor and instructions are provided by the CNC

via a ±10V DC analog voltage. One also corresponds to an analog interface axis. These axes are

controlled by boards called NMX / NSX. Each of these boards controls 2 axes.

CAN axes: Axes for which positioning information is handled through a CAN bus.

These axes require an NCX board on the CNC side and a CAN interface on the servo-amplifier side.

An NCX board can control up to 8 axes. The number of CAN axes is controlled as an option.

The ModEva CNC can be equipped with a maximum of 2 NCX axis boards.

NMX: A master board for 2 analog ax es. A master board controls up to 3 NSX slave boards.

NSX: A slave board for 2 analog axes. A slave board in all case s requires an NMX board.

NCX: CAN board for a maximum of 8 CAN ax es. This board can handle various protocols according to the

type of servo-amplifier used. It is possible to combine CAN and analog axes.

Configurations of CNC axes

Rack version

No. of axis boards

NMX - NMX NSX NSX

The most common

configurations

NCX NLR NCX NLR NMX NSX

CDS_ModEva_15T_EN_V2.5.docx5 Modification rights reserved 2/6

Page 3

Configuration of the consoles

TFT screen

15"

Touchscreen

Yes

Resolution

1024 x 768

Ext. keyboard socket

Yes, PS2

Ext. mouse socket

Yes, serial mouse with mini DIN socket

Power

Through the panel link

Seal

IP 54

2 cables RJ 45 twisted pair category 6. Cables 5 m or 10 m.

Dist. > 10 m with CYBELEC repeater.

Temperature,

Min. 5° Celsius, max. 40° Celsius.*

conditioning.

Weight

Approximately 9.6 kg

Reference

S-CNC-xxxxPxxxx

Software

2D or 3D

System

Windows XP embedded, XP pro optional**

CPU

500 MHz

RAM

256 MB, 512 MB optional**

Disk

4 GB flash**

Network

Yes, Ethernet RJ45

USB 1.1

Yes

Printer port

Yes

Keyboard input

Yes, PS2

Mouse input

Yes, PS2

Screen output

Yes, std VGA

Y1, Y2

NPU board

RS 232 port

Yes, 2 (of which 1 configurable to RS 422)

Serial port for PLC

Yes, RS232 configurable to RS 422

Analog axes

NMX, NSX boards, according to configuration and rack version

CAN axes

NCX boards, dependi ng on conf i guration and rack version

Sensor inputs

5V DC line driver, obligatory complementary signals

Digital inputs

NIN boards, 32 24 VDC opto-coupled inputs

Digital outputs

NOT boards, 32 outputs, 24 VDC "sources", max 2.5 A / output (NOT

204). Max 6 A / board

Depending on configuration 0-10, 0-24 VDC A/D 8 bits

FA

Z

out

output impedance < 100 Ω , Zl load ≥ 10 kΩ

Power supply

24 VDC / max 4A ± 15%

Seal

Must be installed in an approved electric cabinet.

Temperature, pollution

Min. 5° Celsius, max. 40° Celsius.*

be advisable to install special ventilation, or even air-conditioning.

Rack version M: approx. 6 kg. Depending on equipment

Rack version C or M

Number of axes 02 to 18

Type of machine, PS, PC

Electrical axes configuration (analogue: A, Can: C, Mixed: M)

NLR board, ex: angle measurement device

Software/OS: XP embedded 2D (12), 3D (E)

Console

Link CNC

pollution level,

relative humidity,

during work.

Configuration of the CNCs

S-MOD-15T

Pollution level 2.

Relative humidity (10 to 85% non-condensing).

* If the ambient temperature approaches or exceeds 40° Celsius, it

would be advisable to install special ventilation, or even air-

Analog inputs NIN boards, 6 analog inputs

Analog outputs Axes and

level, relative humidity

during work.

Weight Rack version C: approx. 5 kg.

** Data may be modified without notice for the proper operation of the numeric control.

Other configurations available on request.

CDS_ModEva_15T_EN_V2.5.docx5 Modification rights reserved 3/6

NOT boards, 4 outputs, 0-10 VDC (8 bits) for the auxiliary functions,

Pollution level 2.

Relative humidity (10 to 85% non-condensing).

* If the ambient temperature approaches or exceeds 40° C, it would

Page 4

Auxiliary axes and functions of the standard software

(within the number of available axes).

Y1 - Y2

Synchronized axes for the beam (servo-valv es, proportional valves).

X, X1, X2, X5, X6

Main rear backgauge axes (X5, X6 generally for gauges external to the frame).

X1 ABS, X2 REL

Secondary gauge axes in absolute or relative mode.

R, R2, R5, R6

Backgauge height-adjustment axes (R5, R6 generally for gauges external to the frame).

Z, Z2, Z5, Z6

Axes for left/right movement of the backgauge.

M1, M2

Axes for the adjustment / movement of the die.

Conical folds

Comfortable programming for conical folds (requires X, X2 and adapted stop fingers).

Free 1, 2, 3, 4

Independent axes without any particular control.

be fitted in the electric cabinet, would be necessary (see the MVP 100 data sheet).

crowning (Wila type).

Configurable auxiliary functions (possibly, the number of AFs may be limited according to the type of

Special controls for gauge fingers, bend ing aid s, die movem e nts.

Polish, Czech, Slovene, Russian, T urkish, Chinese, Taiwanese. Other languages available on request.

Mitutoyo or other compatible systems.

M1 M2 mounting

Axes for the adjustment / movement of the die in relation with the choice of tool mounting.

X3, X4, X7, X8

Front gauge axes (not calculated).

Z3, Z4, Z7, Z8

Front gauge axes (not calculated).

H, H2

Rear sheet support axes (not calculated).

H3, H4

Calculated front sheet support axes.

AP1–AP4

Calculated front / rear folding assistance axes.

CAN axes

The number of CAN axes is optionally controlled.

Angle measurement

Option permitting the adaptation of an angle-measuring system during the folding.

measurement

thickness measuring equipment connected by RS 232.

encoders.

external program.

Other options can be developed according to needs.

The elements listed below are available and can be configured in all numerical controls supplied with standard software

Pressure

Crowning

F1 to F10

Languages

Angle measurement

Voltage output for pressure valve control.

Should current control be wanted, the MVP 100 accessory, which is an external amplifier module to

Voltage output for adjusting the hydraulic crowning.

Should current control be wanted, the MVP 100 accessory, which is an external amplifier module to

be fitted in the electric cabinet, would be necessary (see the MVP 100 data sheet).

or

24 VDC (SP, SN) outputs and potentiometric position transducer for adjusting the mechanical

function and management). 24VDC voltage or logical order outputs, with or without position control

by means of a potentiometric transducer.

French, German, English, Italian, Spanish, Portugues e, Swedish, Danish, Finnish, Dutch, Hungarian,

Automatic correction by means of the angle measurement in serial link with digital angle protractor

Optional auxiliary axes and functions and other options (at extra cost)

Thickness

Axis thickness

measurement

Message interpreter

Other

CDS_ModEva_15T_EN_V2.5.docx5 Modification rights reserved 4/6

Option permitting the automatic correction of the depth calculation by using external sheet-metal

Option permitting the automatic correction of the depth calculation by using external thickness

measuring equipment connected to an axis board. The measurement is taken using conventional

Option for the complete remote control of the CNC via network or RS 232.

Reading/writing of variables, corrections, part loading, mode changing, etc.

Ideal for automation and/or applications with robot. Possibility of connecting the results of an

Various options exist and are specific to each OEM.

Page 5

Hardware options

Designation

Description

Ordering number

Auxiliary panel

Auxiliary panel for Lazer Safe commands, virgin or

customized auxiliary panels

S-OPT-BTAUX-S/E

Keyboard support

Support for external USB keyboard (the keyboard is not

provided).

S-OPT-KBSUP15

Earthing kit

Rail and bridles for earthing the sheathing for the ModEva

CNC rack. See illustrations below.

S-OPT-EARTHKITC for size C rack

S-OPT-EARTHKITM for size M rack

CybVA 6

Interface board for proportional Hoerbiger valves and pressure + crowning valves.

S-CAH-CybVA6

MVP 100

Voltage / current conversion module (0-10V 0,25-0,5 / 0electric cabinet.

S-MVP-100/A

MSV 402

Voltage / current conversion module (0-10V 0-50 mA, 0300 mA) for servo-valves.

S-MSV-402/A

Directives

Our numerical control units comply with Directives EN 61000-6-4 / EN 61000-6-2.

Earthing kit

CNC / C

CNC / M

EC Directives

Overall dimensions

2 A) for pressure and crowning valves, to be fitted in the

CDS_ModEva_15T_EN_V2.5.docx5 Modification rights reserved 5/6

Page 6

ModEva 15T

CDS_ModEva_15T_EN_V2.5.docx5 Modification rights reserved 6/6

Loading...

Loading...