Page 1

User Manual

for Synchronized Press Brakes

Sept14

V3.1

Page 2

© 2014 Cybelec S.A.

All Rights Reserved

Copying, reproduction, modification, distribution, display or transmission of any of the contents of

this manual for any purpose without the prior consent of Cybelec S.A. is strictly prohibited.

Page 3

The Intuitive Programming

Table of conTenT

Safety ......................................................................................................................1

General Safety ............................................................................................................................... 1

Signs and Icons appearing in this Manual .................................................................................. 2

General warning ............................................................................................................................. 2

Information.................................................................................................................................... 2

Settings .......................................................................................................................................... 2

Navigation .................................................................................................................................... 2

Getting started with CybTouch 12 ..........................................................................3

General navigation ....................................................................................................................... 4

Menu Button ................................................................................................................................ 4

Status Pages Zone ........................................................................................................................... 4

Screen Cleaning .............................................................................................................................. 4

Status page .................................................................................................................................... 5

User Preferences .......................................................................................................................... 5

Language ...................................................................................................................................... 6

Length Units .................................................................................................................................. 6

Show Y1-Y2 position values .............................................................................................................. 6

Show page L-alpha num .................................................................................................................. 6

Show bent part ................................................................................................................................ 6

Materials ....................................................................................................................................... 7

BDC correction ............................................................................................................................... 7

Clear indexation ............................................................................................................................. 8

USB Explorer .................................................................................................................................. 8

Default retraction ............................................................................................................................ 8

Set Clock ........................................................................................................................................ 8

Touchscreen Calibration ................................................................................................................... 8

Brightness xx% Eco xx% ................................................................................................................ 9

Page 4

The Intuitive Programming

Manual Axes Movement ............................................................................................................... 9

Desynchronized Beam ....................................................................................................................... 9

Service Page ................................................................................................................................ 10

Set Axis ........................................................................................................................................10

Maintenance .................................................................................................................................10

Defrag .............................................................................................................................................................. 11

Format ............................................................................................................................................................. 11

Internal backup ..............................................................................................................................................11

Information...................................................................................................................................11

Configuration options .....................................................................................................................12

Serial number .................................................................................................................................................12

Computer ID ................................................................................................................................................... 12

Option list .......................................................................................................................................................12

New option code .............................................................................................................................................12

USB Transfer ............................................................................................................................... 13

Importing parts from other Cybelec NCs .............................................................................................13

Basic Page Description .......................................................................................... 14

Bend Numerical Page ................................................................................................................ 14

More Page ................................................................................................................................... 14

Available functions on the More page ................................................................................................15

Material ...........................................................................................................................................................15

Material thickness ........................................................................................................................................... 15

Material sigma .................................................................................................................................................15

Back gauge retraction ....................................................................................................................................15

Speed change threshold and bending speed ...............................................................................................15

Bending length ............................................................................................................................................... 15

Step bending ................................................................................................................................................... 16

Slow speed return ........................................................................................................................................... 16

Dwell time .......................................................................................................................................................16

Force ................................................................................................................................................................ 16

Page 5

The Intuitive Programming

Opening (TDC) .............................................................................................................................................. 17

Crowning ......................................................................................................................................................... 17

Back gauge finger type ................................................................................................................................... 17

Number of parts .............................................................................................................................................17

Back gauge manual control ...........................................................................................................................17

Tools Management ................................................................................................ 18

Punches ....................................................................................................................................... 18

How to create or modify a punch? .....................................................................................................19

Dies .............................................................................................................................................. 20

How to create or modify a die? ..........................................................................................................21

Naming Tools .............................................................................................................................. 22

Punches ........................................................................................................................................22

Dies ..............................................................................................................................................22

Creating a Part Program ........................................................................................23

TouchProfile Mode .................................................................................................................... 23

Automatic Bend Sequencing (optional)................................................................................... 24

Numerical Mode ......................................................................................................................... 26

L-Alpha Mode ............................................................................................................................. 27

Bend Correction ......................................................................................................................... 28

Angle Correction (Y axis) ................................................................................................................28

Crowning ......................................................................................................................................29

Back gauge (X & R axes) Correction ................................................................................................29

Saving and Loading a Program .............................................................................. 30

Saving a Program ........................................................................................................................ 30

Loading a Program..................................................................................................................... 30

Deleting a Program .................................................................................................................... 30

EasyBend Page ...................................................................................................... 31

Making a bend on the EasyBend Page ...................................................................................... 31

Page 6

The Intuitive Programming

Error and Warning Messages ................................................................................. 32

Warning Messages ...................................................................................................................... 32

Error Messages ............................................................................................................................ 35

Page 7

The Intuitive Programming

Page 8

The Intuitive Programming

Page 9

CybTouch 12 PS User Manual

Safety

General SafeTy

The users must have Read and UndeRstood, but most of all must Respect the

directives described in this manual.

All people coming into contact with the machine on which the numerical

control is installed, whatever their function or whatever state the machine is in

(assembly, disassembly, start-up, production, maintenance, repairs) must have

read and understood the requirements concerning the security and the entirety

of the directives of operation described in the manuals delivered with the

machine.

The operator must be properly trained to work with the machine

on which the numerical control is installed. Improper use of the

numerical control can cause heavy damage on equipment and/or

injuries to people.

Modification of machine parameters can cause important material damage or

lead to irregular product quality.

Do not expose the numerical control to excessive humidity so as to avoid any

risk of electrocution and any deterioration of the equipment.

Make sure the numerical control is disconnected from the mains power before

carrying out any cleaning. Do not use liquids based on alcohol or ammoniac.

In case of malfunction of the numerical control, call a technician.

Do not expose the numerical control to direct sun rays or any other heat source.

Do not place the numerical control in the neighborhood of magnetic equipment

such as transformers, motors or devices which generate interference (welding

machines, etc.)

Sept.

2014

V3.1

1/38

Page 10

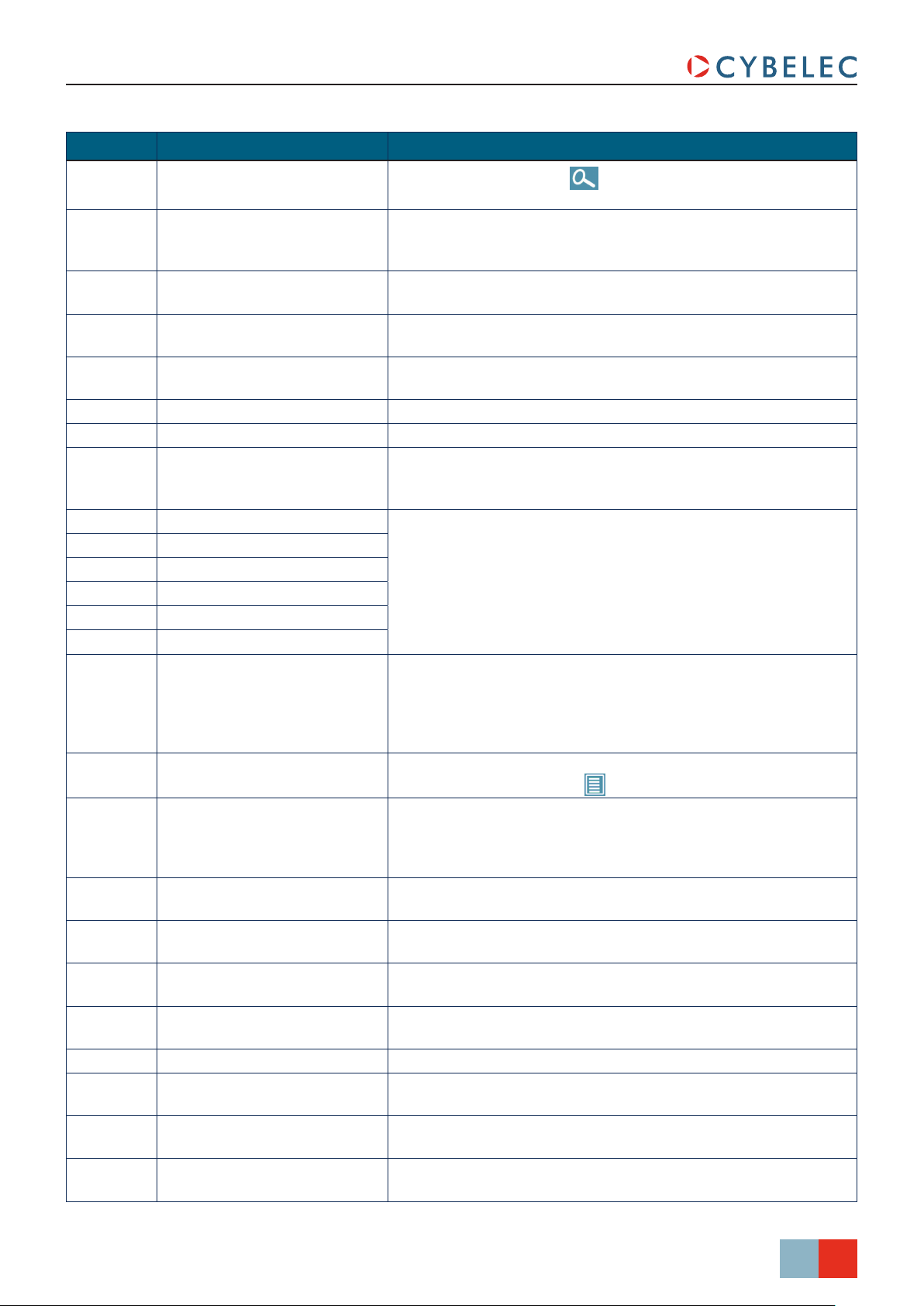

SiGnS and iconS appearinG in ThiS Manual

While using this manual, you will come across the signs and icons represented here

below: they are directly related to the safety and security of persons. Carefully follow this

advice and inform others about it.

CybTouch 12 PS User Manual

General warning

Information

Settings

This warning sign appears in the manual whenever it is necessary to pay attention to

rules, instructions or advice. The correct sequence of operations is to be followed in order

to avoid damage to the machine.

Symbolizes a serious personnel danger

This warning sign appears in this manual whenever an important information needs to be

taken into consideration. Pay attention to this sign and follow the instructions given.

This sign appears in this manual whenever setting instructions are given. Pay attention to

this sign and follow the sequence of instructions given.

Navigation

This icon appears in this manual to give navigation information, to give the path to the

subject treated in the chapter.

2/38

Sept.

2014

V3.1

Page 11

CybTouch 12 PS User Manual

GettinG Started with CybtouCh 12

Depending on software evolutions and the press brake controlled by the CybTouch

(configuration/capabilities), the present manual may not fully correspond to the CybTouch

that you currently have. However, differences are only minor.

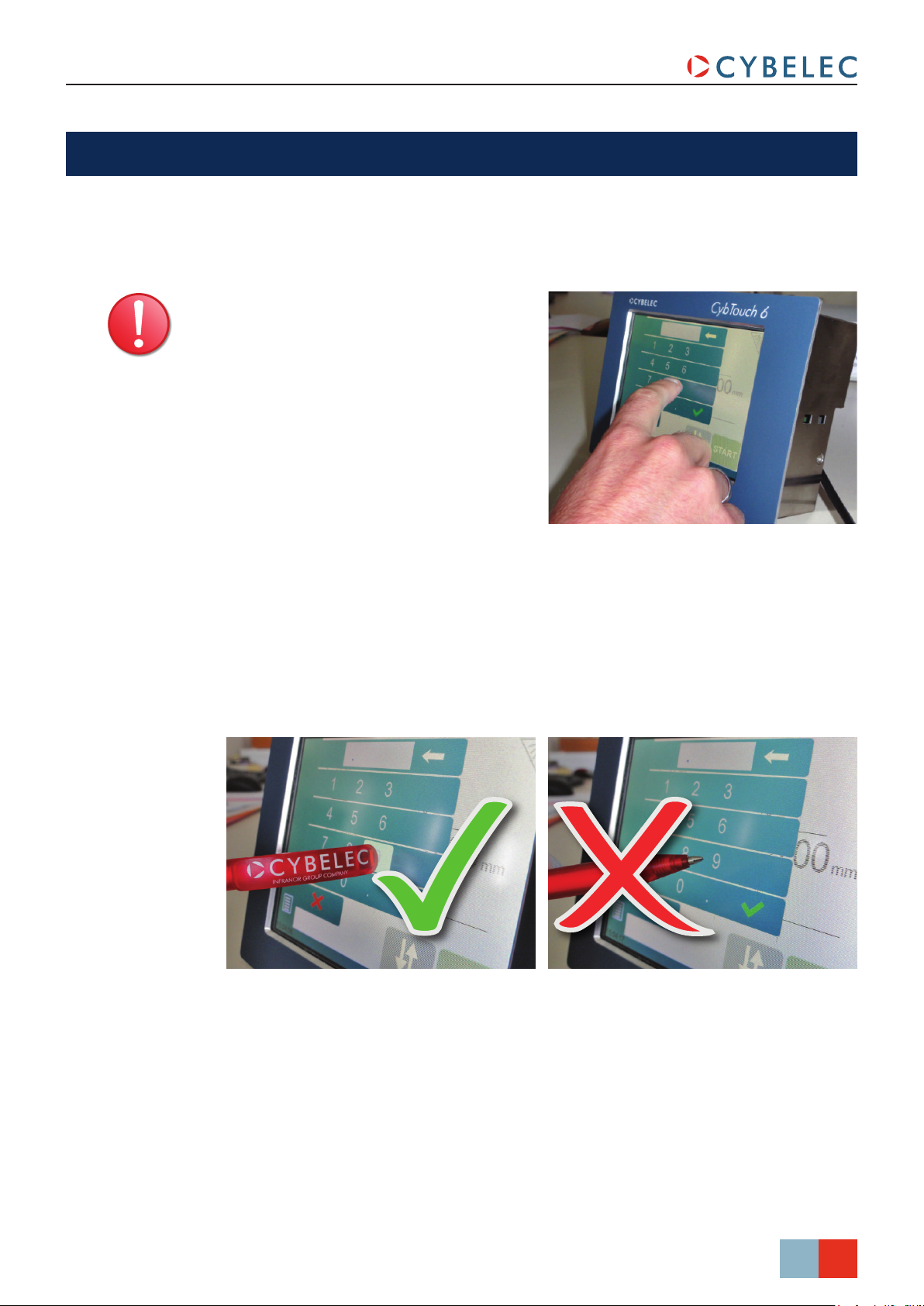

Touchscreens are pressure

sensitive.

Do not press down hard on the

screen.

Pressing hard on the screen will

damage the display. Such damage

is not covered by manufacturer

warranty!

Do not use sharp and/or pointed objects (sheet metal, screwdriver, metal pen ball, etc.) to

touch the screen; only use your fingers (with or without gloves on) or a plastic pen. Make

sure that your gloves do not have metal particles encrusted in the finger tips as they may

also damage the screen.

Take a few minutes to practice pressing gently on the screen, you will find that the screen

is very reactive and it is pleasant to use.

Sept.

2014

V3.1

3/38

Page 12

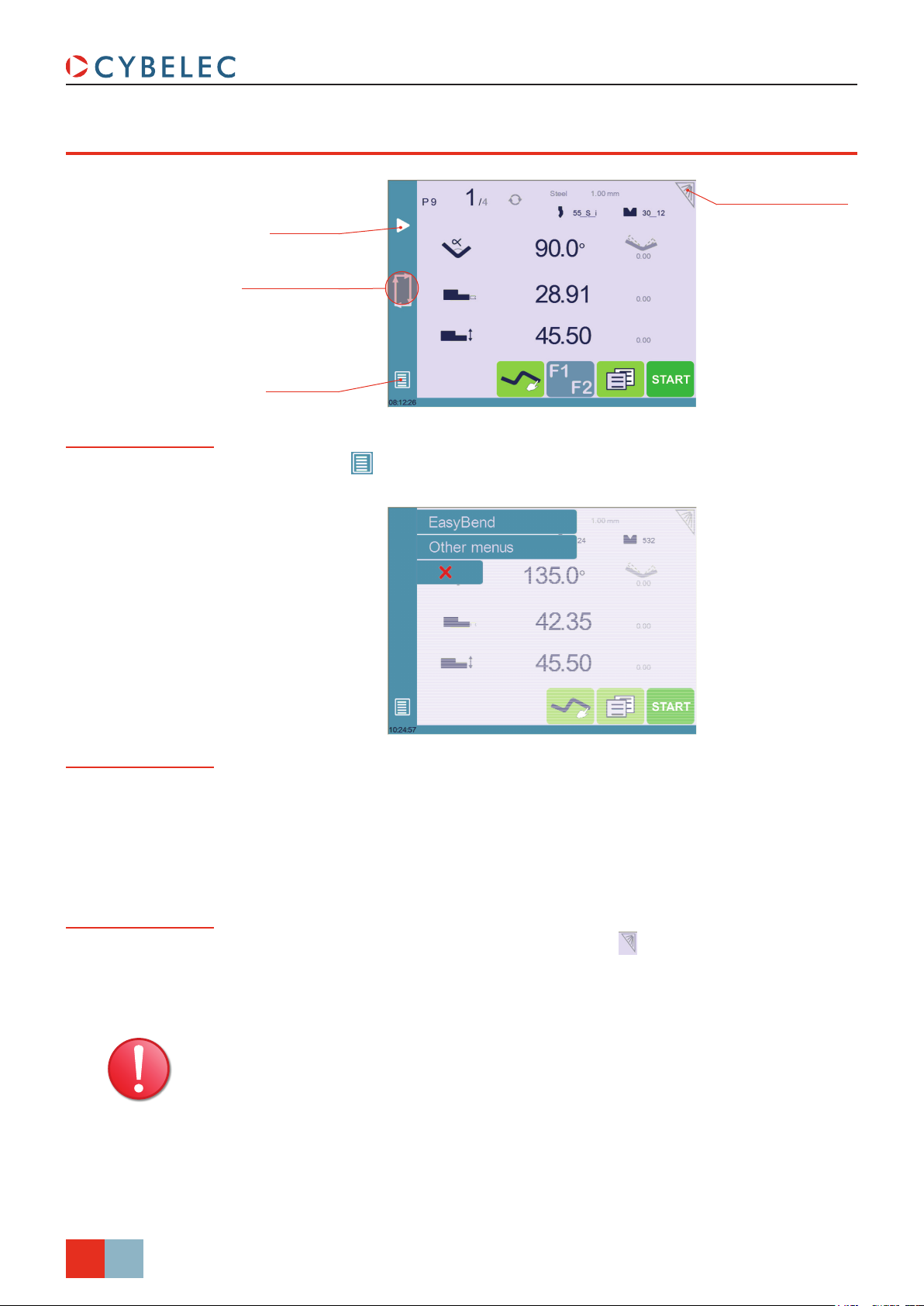

General naviGaTion

CybTouch 12 PS User Manual

Menu Button

Add step

or next step

Status Pages Zone

Menu Button

Screen Cleaning button

The Menu button allows you to directly select (jump to) the desired screen. The

content of the menu changes contextually.

Status Pages Zone

Screen Cleaning

The Status pages zone gives access to the Status page (see page 5). This is really a

zone that is active at any moment from any page (except the wizard’s).

To clean the screen while the CybTouch is on, touch the button.

Use only a damp and smooth cloth with soap or a neutral detergent.

NEVER use solvent, petrol, benzene, alcohols, etc.

4/38

Sept.

2014

V3.1

Page 13

CybTouch 12 PS User Manual

STaTuS paGe

The Status page shows the status of all inputs and outputs and axes positions of the NC.

This feature is very useful during setup or during phone service with a machine installed in

the field.

This page is accessed from anywhere by pressing the Status Pages Zone (see page 4).

To exit the Status page, press on the arrow on the left.

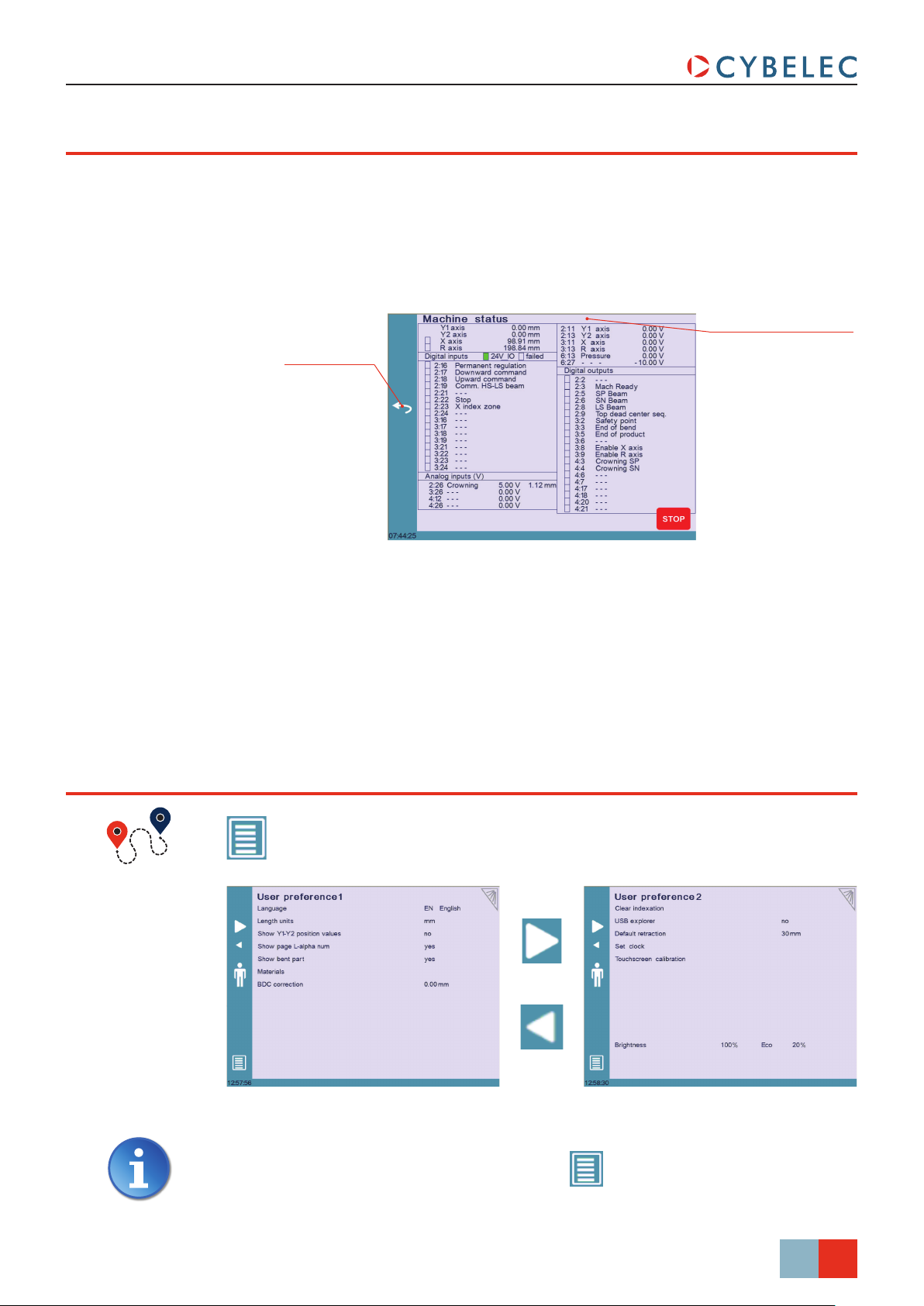

uSer preferenceS

Press arrow to

exit Status Page

On the upper line, a cycle

message may appear

indicating the cycle phase

the machine is executing

(Menu Button) → Other menus → User preference

To exit the User Preference page, touch the button.

Sept.

2014

V3.1

5/38

Page 14

CybTouch 12 PS User Manual

Language

Length Units

To browse through the available languages, simply touch Language on the screen.

Available languages are:

• EN English.

• BR Brazil.

• CN 中文.

• CZ Český.

• DE Deutsch.

• ES Español.

• FR Français.

• IT Italiano.

• NL Nederlands.

• TR Türkçe.

• TW 台灣.

The list of available languages is subject to change and may increase over time.

This parameter allows choosing between mm, inch and none for the length unit to be

used in the CybTouch.

When none is selected, the units are millimeters.

Show Y1-Y2 position values

Show page L-alpha num

This function will display the Y1 and Y2 axes positions on the Bend Numerical Page (see

page 14).

• When set to no, the position of axis Y1 is displayed during the beam’s movements.

• When set to yes1, the positions of the beam’s axes are displayed during the beam’s

movements.

• When set to yes2, the positions of the beam’s axes are constantly displayed under the

angle/beam’s position line.

When set to yes, this parameter gives access to the L-Alpha Mode (see page 27). This

button

is then displayed on the TouchProfile Mode page.

Show bent part

Sept.

6/38

2014

V3.1

This parameter, when activated, lets the operator see the state of the part before and after

the bend in the Automatic Bend Sequencing (optional) page.

Page 15

CybTouch 12 PS User Manual

Materials

Touching Materials opens the Materials page, where the default characteristics for each

material can be changed, or a new material can be configured.

This page may not be available, depending on the machine parameters’

configuration. To be allowed to access the Materials page, a level 2 password is

required.

The Materials page displays:

• Material: Selected material (here Steel).

• Default thickness for the material.

• Default sigma: Default sigma for the material (here 45).

• Displayed: If the material will be available to be selected for use (here yes).

• Thickness min/max: determines the maximum and minimum accepted thickness for

the selected material.

Three predefined default materials are available (steel, stainless steel, aluminum), but

others can be added.

To add a material:

1. Touch Material and select a non-configured material (Mater X) from the list.

2. Enter the new material’s characteristics.

3. Touch the name (Mater X) to display the keyboard and enter the name of the new

material.

BDC correction

This parameter allows the operator to apply a permanent correction to the Bottom Dead

Center position.

Please note that this correction is always applied and is NOT shown in the

correction page. If you experience big differences from what you expect to get,

maybe check the value of this parameter.

Sept.

7/38

2014

V3.1

Page 16

CybTouch 12 PS User Manual

Clear indexation

USB Explorer

Default retraction

When activated, this function clears the index and the machine will search for them, as

it does when turning the power on, allowing the operator to re-index its machine without

turning it off.

When this parameter is set to yes, it is possible to browse the USB key from the USB

transfer screen.

This parameter allows defining the default value displayed in the More Page (see

page 14) when activating the back gauge retraction function.

Set Clock

Touchscreen Calibration

Allows the user to set the time and date on the CybTouch.

Touch the eld you

want to modify

As a tall operator will tend to touch higher than a smaller one on the screen, this function

allows the calibration of the touch screen, and also makes sure that it is operating

correctly.

Use the up and down

arrows to modify the

selected eld

Setting inStructionS:

Simply follow the instructions on the page to calibrate the touchscreen.

8/38

Sept.

2014

V3.1

Use your finger or the plastic tip of a pen to calibrate the

Touchscreen. Never use sharp objects as this will damage the screen.

Page 17

CybTouch 12 PS User Manual

Brightness xx% Eco xx%

Here the brightness of the screen for normal mode and Eco mode can be defined:

1. Touch the mode for which you want to modify the brightness.

2. Use the

Manual axeS MoveMenT

In the course of setting up a machine, it is sometimes necessary to be able to move the

axes manually, for example when changing the tooling. This can be done on this page.

(Menu Button) → Other menus → Manual movement

movement not allowed)

Move beam up

(button hidden if

buttons to set the brightness.

Set here the bending force

that will be applied to the

manual movement

Desynchronized Beam

Menu Button

Setting inStructionS:

1. Select the axis that you want to move:

•

•

•

2. Touch the buttons to move the selected axis.

3. Use the foot switch (Low Speed Down movement) and this button

Up) to move the beam.

When the padlock is open

movement) Y1 or Y2 only. This is an easy way to return an unsynchronized beam back to

parallel to the table.

for the back gauge X axis.

for the back gauge R axis.

for the crowning axis.

(High Speed

, it is possible to select and move (Low Speed Down

Sept.

2014

V3.1

9/38

Page 18

Service paGe

CybTouch 12 PS User Manual

(Menu Button) → Other menus → Service → Service

Set Axis

Maintenance

Allows the operator to manually adjust the position of the back gauge (axes X and R) and

the beam (axes Y1 and Y2).

This function must be used with utter care and only by experienced

personnel. Wrong settings may mechanically damage the machine.

Settings are lost after indexing the machine.

The Maintenance page displays the hardware status of the CybTouch and lets the

operator perform different maintenance actions.

(Menu Button) → Other menus → Service → Service → Maintenance

10/38

Sept.

2014

V3.1

All the following actions require codes and should only be performed by

technicians or upon request of a technician.

Page 19

CybTouch 12 PS User Manual

Defrag

This function will rearrange the memory space of the CybTouch. Simply touch it and

follow the instructions given in the yellow pop-up window.

Format

This function will erase all data in the CybTouch. Only use this with the help of a

technician.

Internal backup

This function is specially designed for OEM and support.

Usually a machine parameters’ backup is made by the machine manufacturer or the

company who services the machine. This backup allows a maintenance technician to

restore original working parameters if necessary.

Should there be a need to restore parameters, call on a maintenance technician and

follow his instructions.

Information

Do not try to use this function unless you are in dire need.

Before using this last function, make sure that all your files have been

transfered outside the CybTouch (see USB Transfer, page 13).

The Information page displays the names and versions of the softwares installed on the

CybTouch. Pressing the Advanced button shows more detailed information.

(Menu Button) → Other menus → Service → Service → Information

To Advanced information

Sept.

11/38

2014

V3.1

Page 20

CybTouch 12 PS User Manual

Configuration

options

Touching this menu opens the following page, where one can find the computer’s

identification and manage the machine’s options.

(Menu Button) → Other menus → Service → Service → Configuration options

Serial number

This is the serial number of the CybTouch. It is entered at the factory at the end of the

machine’s initial setup and is related to the machine’s option list.

Changing the serial number means that all the options installed on the

machine can be lost.

Computer ID

This line displays an identification code that is unique to each CybTouch and guarantees,

together with the serial number, a correct identification of the machine.

Option list

This function opens a yellow pop-up window where all the options installed on the

CybTouch are displayed.

New option code

The function opens an alphanumerical pad where the code of the new option must be

entered. The format of an option code is: ABC-DEF-GHI-JKLM

12/38

Sept.

2014

V3.1

Page 21

CybTouch 12 PS User Manual

uSb Tr anSfer

This function opens the USB transfer screen, which allows the operator to transfer data

between the CybTouch and a USB key.

(Menu Button) → Other menus → USB transfer

Select the les you

want to transfer by

touching their name

Machine les listDie list

Punch list

Direction of transfer

Program list

Importing parts from other Cybelec NCs

Return to User Preferences Transfer button

CybTouch 12 is delivered with Cybelec’s off-line software PC1200, which controls most of

the other numerical controls produced by Cybelec.

From version S1, PC1200 includes CybTouchConverter, which allows you to convert parts

to the CybTouch format, and import them into your machine with the above mentioned

function.

Sept.

2014

V3.1

13/38

Page 22

baSiC PaGe deSCriPtion

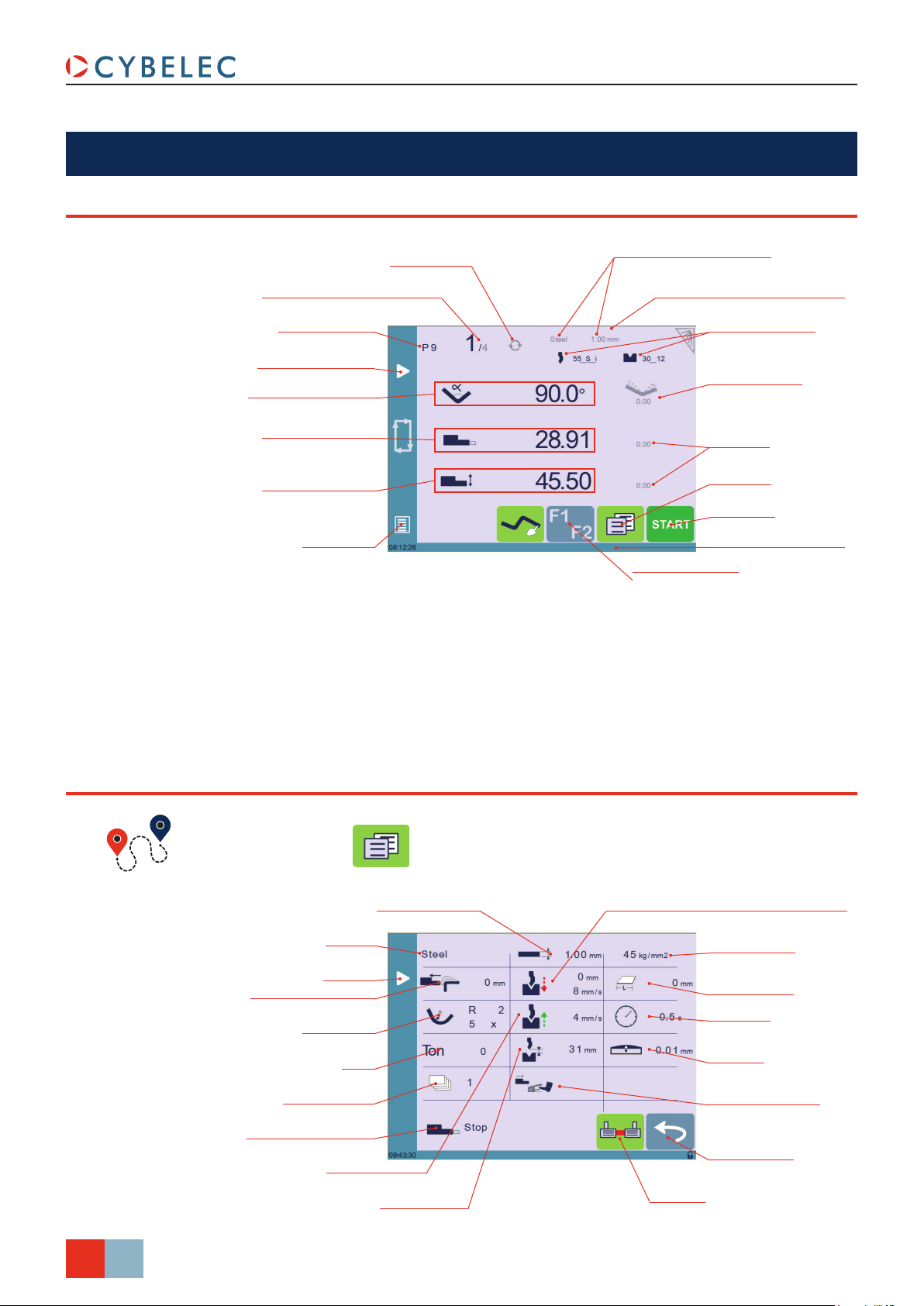

bend nuMerical paGe

CybTouch 12 PS User Manual

Repeat sequence button

Current step (sequence) number

Program number

Add step or next step

Beam (Y axis) position

value / bend angle

Back gauge (X axis)

position / ange length

Back gauge (R axis)

position value (optional)

Menu Button

(inactive here)

Material used and thickness

Current cycle activity information

Tools Management

Bend Correction

Back gauge (X & R axes)

Correction

More Page

Start – Stop

Interactive message line

TouchProle Mode

More paGe

Bend Numerical Page →

Material thickness

Material

Next step

Back gauge retraction

Step bending

Force

Number of parts

Back gauge nger type

Slow speed return

Opening (TDC)

Speed change threshold and bending speed

Material sigma

Bending length

Dwell time

Crowning

Back gauge manual

control

Return to Bend

Numerical Page

LazerSafe

14/38

Sept.

2014

V3.1

Page 23

CybTouch 12 PS User Manual

Available functions on the More page

The More page displays parameters related to the part, and depending on the CybTouch

configuration and the type of action performed, it also displays various settings for the

current bend.

Material

This is not a sequence parameter, but of course a part parameter. Each touch on the

material’s name selects the next available from the list of Materials (see page 7).

Material thickness

The default thickness, defined in Materials (see page 7), is automatically displayed

when changing material. It is however possible to change it simply by touching this icon.

This is also of course a part parameter.

Material sigma

The default sigma, defined in Materials (see page 7), is automatically displayed when

changing material. It is however possible to change it simply by touching this icon. This is

also of course a part parameter.

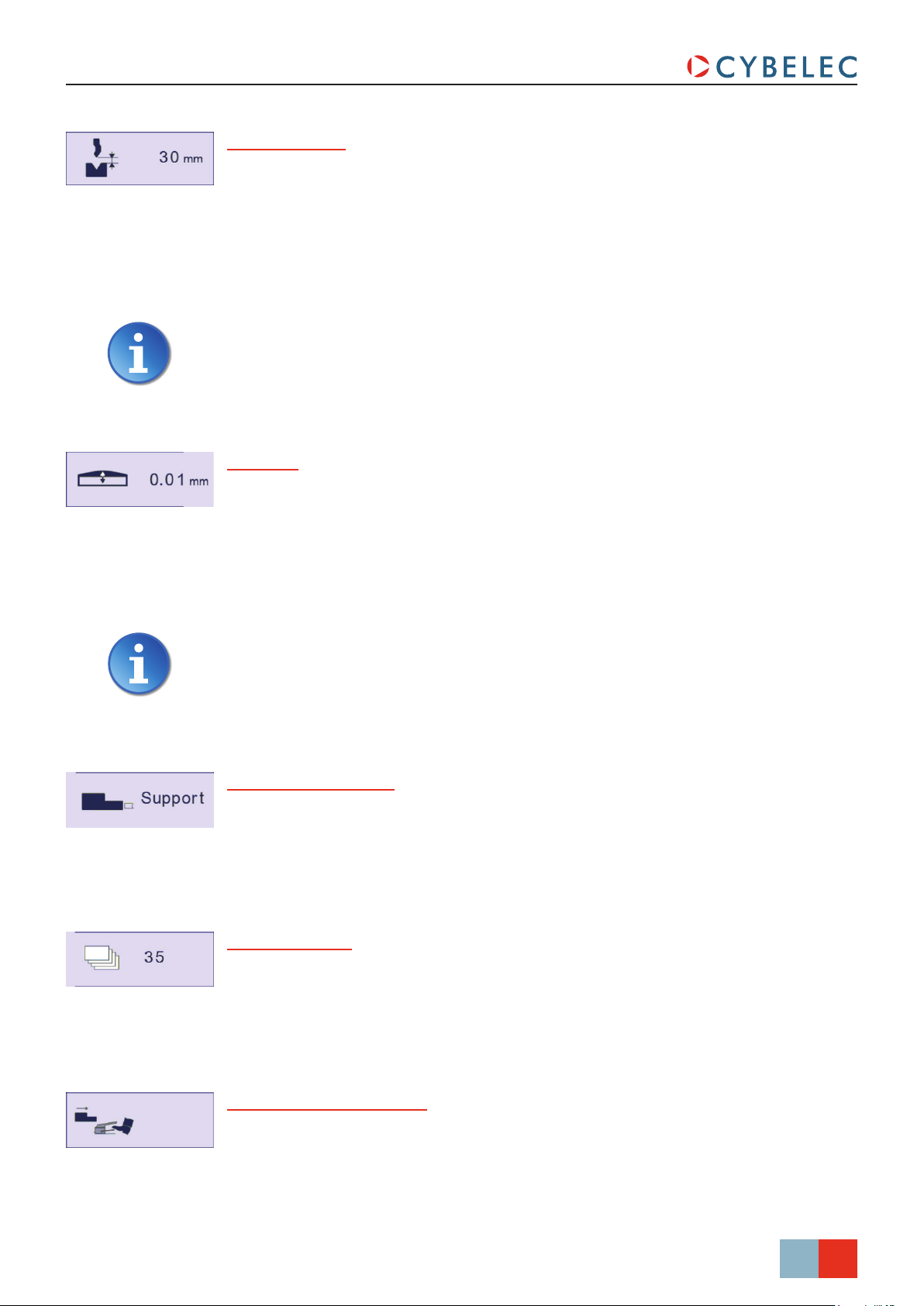

Back gauge retraction

The back gauge retraction can be activated/deactivated at its Default retraction (see

page 8) value using this icon. It is possible to modify the value by touching it. This is a

sequence parameter, meaning it can be modified with each step of the program.

Speed change threshold and bending speed

The distance parameter allows the operator to increase the height of the speed change

point. The speed parameter allows decreasing the bending speed from its maximum value

defined in the machine parameters.

Bending length

This parameter defines the width of the sheet metal part that will be pinched between the

tools. It is used to calculate the bending pressure.

If this parameter is not activated (gray), the CybTouch will not calculate the

bending Force and the Crowning.

Sept.

15/38

2014

V3.1

Page 24

CybTouch 12 PS User Manual

Step bending

When a large radius bend has been programmed (see L-Alpha Mode, page 27), its

parameters are displayed here. It is possible to modify them directly here.

Programming 99 x will automatically calculate the maximum possible step bends. The

resulting value may be reduced. However, if it is increased over the maximum calculated

value, the resulting radius and angle will be drastically affected.

The large radius bending function is deactivated when this field is grayed.

Slow speed return

This parameter allows slowing down the speed of the beam after the bend, and is

generally used when the part has a long flange and the operator tries not to let it “fall

down too fast”.

The beam will return at low speed up while the operator holds the foot pedal. It switches

to high speed up when either the pedal is released or Pinch Point is reached, whichever

comes first.

When this field is deactivated (grayed), the beam moves back up directly at HSU

(High Speed Up).

Dwell time

Allows defining the duration of the dwell time, meaning the time during which the punch

remains at BDC before coming back up.

When this field is deactivated (grayed), the default Dwell Time value defined in

the machine parameters is applied.

16/38

Sept.

2014

V3.1

Force

The force is automatically calculated by the CybTouch, according to the Material, the

Material thickness, the Material sigma and the Bending length. The value can also be

manually modified here.

Page 25

CybTouch 12 PS User Manual

Opening (TDC)

For parts created with a profile (see TouchProfile Mode or L-Alpha Mode), this value is

automatically calculated to allow the operator enough room to extract its bent part from

between the tools. It is however possible to change it manually.

For part created manually (see Numerical Mode), this parameter uses the default

minimum value defined in the machine parameters. It can however be programmed here.

Creating a “New part” reinitializes it to its default value.

When this field is deactivated (grayed), the beam moves back all the way up to

its maximum limit switch.

Crowning

The crowning function is activated here. It is automatically calculated, according to

the Material, the Material thickness, the Material sigma and the Bending length. If the

crowning needs correction, use the Crowning (see page 29) function in the correction

page.

The value can be manually changed by operator. It will however be automatically

recalculated if any of the values used for its calculation is changed.

When the crowning function is deactivated (gray icon), the crowning system

physically remains to its last position and does not automatically return to

0.0 mm. Keep that in mind when using this function – or not – between one

sequence and the following.

Back gauge finger type

The back gauge dimensions are defined in the machine parameters. This function allows

browsing through the available support and stop positions of the back gauge. This

function may be available, or not, according to the machine configuration.

Number of parts

The operator can enter here the total amount of parts to be produced. Every time all

the sequences of the program are executed, hence a part is completed, this counter is

decreased of one unit. When the amount of parts is reached, a yellow pop-up window

signals it to the operator.

Back gauge manual control

Activating this parameter gives manual control over the back gauge movement. This

means the operator must personally give the start to the back gauge movement, using for

example the foot switch or the start button.

Sept.

17/38

2014

V3.1

Page 26

toolS ManaGeMent

Tools management allows the creation and configuration on the CybTouch of the tools to

be used on the machine. These tools are then taken into account in bend calculations.

Once a punch and die are created and selected, you can select the bend angle you require

as well as the flange length (L). The CybTouch then calculates the positions for axes X and

Y for the bend.

puncheS

Bend Numerical Page →

Punch name

Browsing through

existing punches

CybTouch 12 PS User Manual

Punch mounting direction

Basic punch data

Bottoming

Basic shapes of the punch

Punch more specic data

Return to Bend

Numerical Page

Touch the punch to

display its default shape,

allowing an easier

identication of the

various dimensions

18/38

Sept.

2014

V3.1

Setting inStructionS:

To select a punch, simply browse through the existing punches in your library using the

arrows buttons, and then return to Bend Numerical Page.

Page 27

CybTouch 12 PS User Manual

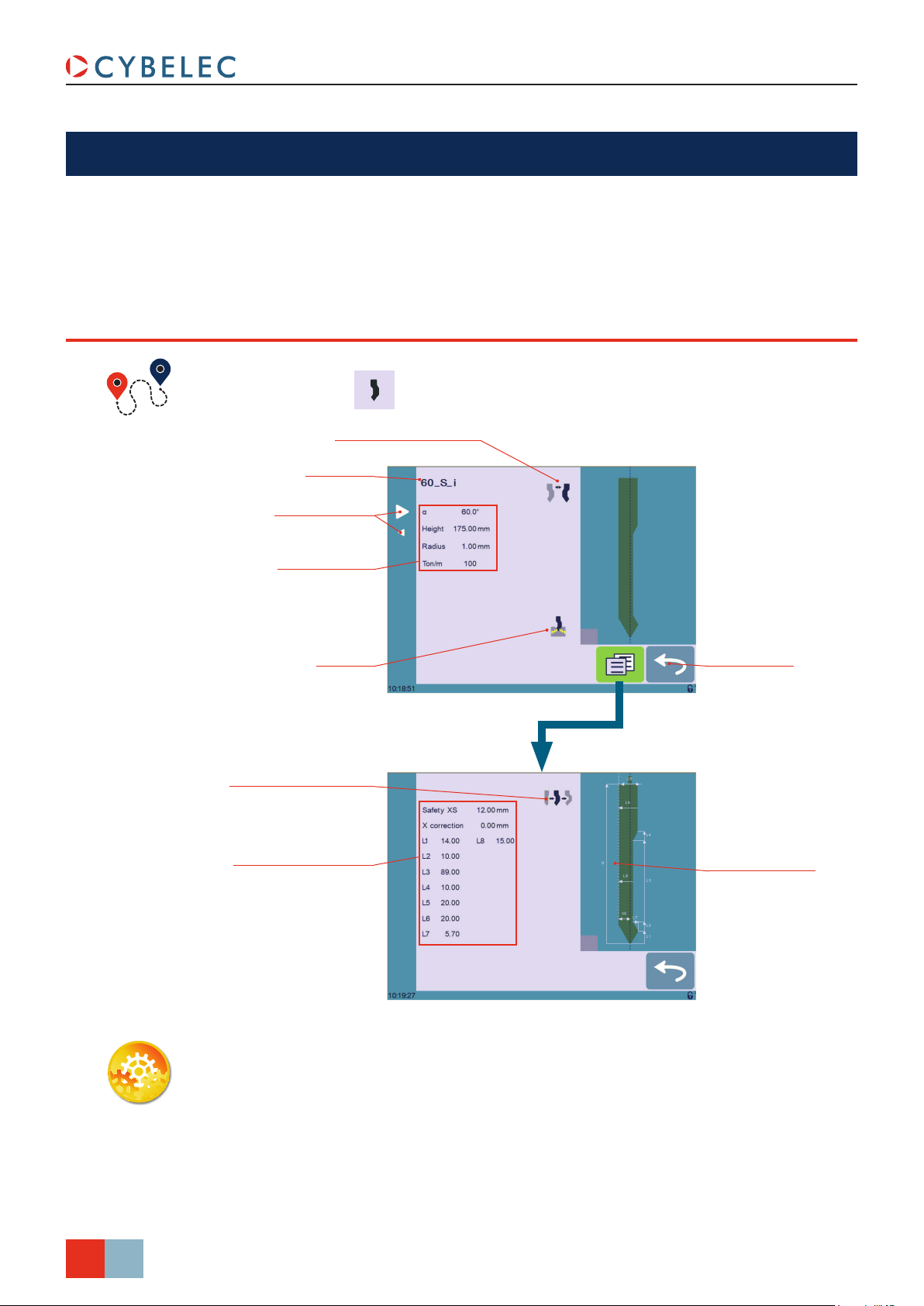

How to create or modify a punch?

If no punch is yet created, the punch will have no name (??? is displayed). If a punch

already exists, then the last punch used will be selected, here 60_N (modifications will

not alter the existing punch as they will be saved under another name).

1. Touch the punch icon

2. Enter the basic characteristics (α (punch angle), Height, Radius and Ton/m) for the

new punch to be created.

3. Touch the

4. Select the

5. Touch the

6. Select the punch type (straight, normal or gooseneck) with this icon

7. Enter the more specific dimensions L1 to Lx by referring to the graphic

representation on the right of the screen. Touching this image will display the default

representation of the tool, making it easier to identify the various dimensions.

button to invert the punch if necessary.

or icon to define the tool as resistant for bottoming.

button to display the More page.

to access the punch details.

.

The dimensions L1 to Lx are the same as the ones used in PC 1200, DNC 880S,

ModEva’s. If you use the same tools, print them from PC1200 to easily program

them in the CybTouch. Of course consider giving the same tools the same

name.

8. Enter the following values:

• Safety XS: Security distance between the tool and the back gauge for X axis.

• X correction: If the punch is not perfectly aligned.

9. Return to previous page

.

To be allowed to save a tool, a level 2 password is required.

10. Touch the punch name (here 60_S_i).

11. Touch Save punch to overwrite the existing tool or Save punch as if you want to

save your tool under another name.

12. Enter the name of the new punch using the alphanumerical keypad.

We recommend that you follow the naming conventions explained in Naming

Tools (see page 22).

13. Touching the button brings you back to the program page, with the punch you

just saved being selected and ready to be used.

Sept.

2014

V3.1

19/38

Page 28

dieS

CybTouch 12 PS User Manual

Bend Numerical Page →

Die mounting direction

Die name

Browsing through

existing dies

Basic die data

Bottoming

Die more specic data

Return to Bend

Numerical Page

Touch the die to display

its default shape, allowing

an easier identication of

the various dimensions

Setting inStructionS:

Selecting a die is the same as selecting a punch; simply browse through the existing dies

in your library using the arrows buttons, and then return to Bend Numerical Page.

20/38

Sept.

2014

V3.1

Page 29

CybTouch 12 PS User Manual

How to create or modify a die?

If no die is yet created, the die will have no name (??? is displayed). If a die already exists,

then the last one used will be selected, here 30_12 (modifications will not alter the

existing die as they will be saved under another name).

Ve

1. Touch the die icon to access the

Ve

die details.

R

2. Enter the basic characteristics (Ve,

R

α (die angle), Height, Radius and

Ton/m) for the new die to be created.

3. Touch the

button to invert the

die if necessary.

4. Select the

5. Touch the

or icon to define the tool as resistant for bottoming.

button to display the More page.

6. Enter the more specific dimensions L1 to Lx by referring to the graphic

representation on the right of the screen. Touching this image will display the default

representation of the tool, making it easier to identify the various dimensions.

The dimensions L1 to Lx are the same as the ones used in PC 1200, DNC 880S,

ModEva’s. If you use the same tools, print them from PC1200 to easily program

them in the CybTouch. Of course consider giving the same tools the same

name.

7. Enter the following values:

• Safety XS: Security distance between the tool and the back gauge for X axis.

• Safety RS: Security distance between the tool and the back gauge for R axis.

• Retr. zone: Retraction zone.

8. Return to previous page

.

To be allowed to save a tool, a level 2 password is required.

9. Touch the die name (here 30_12).

10. Touch Save die to overwrite the existing tool or Save die as if you want to save your

tool under another name.

11. Enter the name of the new die using the alphanumerical keypad.

We recommend that you follow the naming conventions explained in Naming

Tools (see page 22).

12. Touching the button brings you back to the program page, with the die you just

saved being selected and ready to be used.

Sept.

2014

V3.1

21/38

Page 30

naMinG ToolS

CybTouch 12 PS User Manual

It is recommended that you use naming conventions for your tools.

Below you will find a simple convention allowing you to precisely identify a punch or die

through its name.

Of course, depending on your needs you may need to create more rules for punch and die

naming.

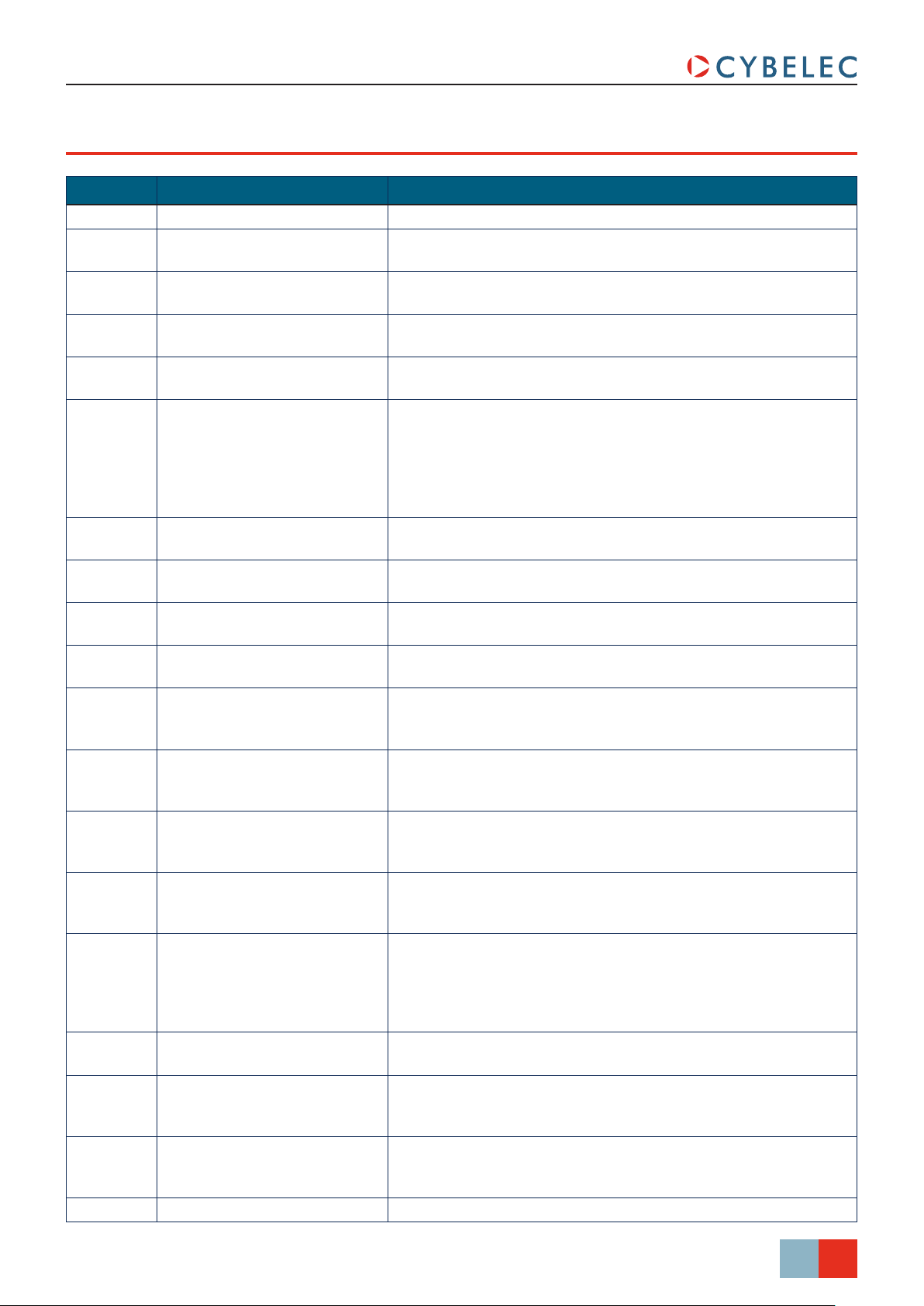

Punches

Dies

The name of the punch should be built in the following manner: first its angle, followed by

its type, and then whether it is inverted or not.

punch anGle (°) punch Type inverTed or noT

30

60

90

Following these rules, here are some examples of punch names: 90_N_i, 60_G, 30_S,

and so on, and so forth.

The name of the die should be built in pretty much the same manner: first its width (Ve

dimension), followed by its angle, and then whether it is inverted or not.

_

N = Normal

S = Straight

G = Gooseneck

_ i = If inverted

ve (mm) die anGle (°) inverTed or noT

12

16

20

_

30

_ i = If inverted

86

22/38

Sept.

2014

V3.1

Following these rules, here are some examples of die names: 12_86_i, 16_86, 20_30,

and so on, and so forth.

Page 31

CybTouch 12 PS User Manual

CreatinG a Part ProGraM

There are three ways to create a program part: with the TouchProfile Mode, with the

Numerical Mode (see page 26), and with the L-Alpha Mode (see page 27).

In this chapter the machine is considered operational: machine parameters,

tools (see Tools Management, page 18), materials (see Materials, page 7),

etc. are already configured and programmed.

Touchprofile Mode

Bend Numerical Page →

Program number

Zoom button

To Automatic Bend

Sequencing (optional)

To L-Alpha Mode

In this mode, the operator can very intuitively draw a profile directly on the screen.

Setting inStructionS:

1. Touch the program number and select

New program in the list.

2. First select the material, its thickness

and the tools to be used for the part by

touching their respective icons.

3. Draw the profile by touching the

screen where you want to add a

segment.

Program number

Tools selection

Material and thickness

Touching this icon allows erasing

the last segment added.

4. Touch on the middle of a segment to

modify its value.

Sept.

2014

V3.1

23/38

Page 32

5. Touch on an angle to modify its value.

Touching the

icon will open a

yellow pop-up, in which it possible to:

CybTouch 12 PS User Manual

• Activate (and deactivate) a special

tool by touching its icon, and select

it from a list by pressing ???.

• Change the value of the radius (see

also Step bending, page 16) and

define how many steps the NC will

make to execute it.

6. Should it prove difficult to select

a particular segment or angle, it

is possible to zoom on an area by

touching this button and then on

the desired zone.

One can also choose to enter the

length and angle values in the L-Alpha

Mode page by pressing this

button.

7. Once all the segments and angles

are adjusted, press this button

to access the Automatic Bend

Sequencing (optional) (see page 24).

Special tools

Special tools

Maximum distance to

Maximum distance to

ideal curve

ideal curve

Number of steps to

Number of steps to

execute the step bending

execute the step bending

Large radius value

Large radius value

Activate/deactivate zoom

Activate/deactivate zoom

Toggle zoom in/zoom out

Toggle zoom in/zoom out

auToMaTic bend SequencinG (opTional)

Bend Numerical Page → →

Bend Numerical Page → →

Once the shape of the part has been defined, the bending sequence for the part can be

automatically determined by the CybTouch.

Delete last bend

Delete all bends

Setting inStructionS:

1. Simply touch the bend sequence calculation button . Once the sequence is

calculated, the Bend 2D screen is displayed.

Launch automatic bend

sequence calculation

Automatic bend sequence

calculation criteria

24/38

Sept.

2014

V3.1

2. If the option is not installed, simply touch the bend in the order that you want them

performed. A small number is displayed on the bend, indicating its position in the

sequence.

Page 33

CybTouch 12 PS User Manual

Pressing the back button will erase the last bend in the sequence. If you wish

to delete all bends, simply touch the

3. Immediately after determining the last bend to be selected, the Bend 2D screen here

Touch the drawing to

below is displayed.

Browsing through

the bends

toggle between

Bend Order page

and this one

button.

Next gauging point

Switch between stop or

support gauging

More Page

4. In the Bend 2D page, the operator must determine the back gauge and part position

for each bend, and if necessary the special parameters on the More Page (see

page 14).

5. Press

6. Start the hydraulic pump motor (by pressing this button

and select Bend num page to return to the Bend Numerical Page.

if available. It turns red

when the motor is running the button becomes red).

7. Press the

button to position the machine according to the data that were just

entered.

8. When the machine is ready to bend, a

button is displayed.

9. Press the foot switch to execute the bend.

Sept.

2014

V3.1

25/38

Page 34

nuMerical Mode

CybTouch 12 PS User Manual

It is also possible to simply create a part program directly on the Bend Numerical Page.

Current step (sequence) number

Program number

Add step or next step

Angle of the bend

Length of the ange

To TouchProle Mode

Material used and thickness

Tools selection

More Page

Setting inStructionS:

1. Touch the program number and select New program in the list.

2. First select the tools to be used for the part by touching their respective icons (see

Tools Management, page 18).

3. Touch the material’s name (here Steel). The More Page (see page 14) is displayed.

4. In the More Page, select the Material used, enter the Material thickness, the Bending

length, and other sequence parameters (Opening (TDC), Slow speed return, etc.).

5. Touch the

6. Touch the numerical value next to the angle icon

button to return to the Bend Numerical page.

, and enter the value for the

first bend you wish to create (here 90°).

7. Touch the numerical value next to the segment length icon

, and enter the value

for the first segment you wish to create (here 30.00 mm).

8. Add the next bend to the program by touching

.

9. Proceed in the same manner to create the other segments of the part.

10. Touch

11. Start the hydraulic pump motor (by pressing this button

to return to the first bend.

if available. It turns red

when the motor is running the button becomes red).

12. Press the

button to position the machine according to the data that were just

entered.

13. When the machine is ready to bend, a

button is displayed.

14. Press the foot switch to execute the bend.

26/38

Sept.

2014

V3.1

Page 35

CybTouch 12 PS User Manual

l-alpha Mode

Bend Numerical Page →

Bend Numerical Page →

Program number

Segment length

Angle value

More parameters for step

To Automatic Bend

Sequencing (optional)

To TouchProle Mode

This page is only available if user preference Show page L-alpha num (see

page 6) is set to yes.

In this mode, the operator can define each step (length or angle) of a profile on a table.

Setting inStructionS:

1. Touch the program number, select

New program in the list and press

this button

to access the L-alpha

mode.

2. First select the material, its thickness

and the tools to be used for the part by

touching their respective icons.

3. Touch the first value in the table (here

200.00). The window to the right is

displayed.

4. Enter the value for the first segment’s

length and touch the

button to add

another step.

Program number

Tools selection

Material and thickness

Step number

Step value

Browsing through

the steps

Click on OK when prompted to create

new step.

5. Proceed in the same manner for all

steps and angles of the profile.

6. If a bend needs special parameters

(large radius, special tool), press in

the more field of the corresponding

sequence.

A special punch or /and die means

there must be an additional working

station.

Sept.

2014

V3.1

27/38

Page 36

7. A yellow pop-up is displayed, in which

it possible to:

• Activate (and deactivate) a special

tool by touching its icon, and select

it from a list by pressing ???.

• Change the value of the radius.

CybTouch 12 PS User Manual

Special tools

Special tools

Max. distance to

Max. distance to

ideal curve

ideal curve

Number of steps to

Number of steps to

execute the step bending

execute the step bending

bend correcTion

• Define how many steps the NC will

make to execute the step bending.

8. A small More icon shows that

something special is programmed on

the bend.

9. To remove the icon (and special

parameters), return to the yellow popup, touch all the activated functions to

make them turn gray, and select OK.

10. Once all the segments and angles

are adjusted, press this button

to access the Automatic Bend

Sequencing (optional) (see page 24).

Large radius value

Large radius value

More icon – means

More icon – means

special functions on bend

special functions on bend

Touching a step number allows deleting it

Touching a step number allows deleting it

or inserting a new one right after it

or inserting a new one right after it

Angle Correction (Y axis)

All program corrections are made in the Bend Numerical Page (see page 14).

Corrections can be made to:

• The angle (Y1 + Y2, see Angle Correction (Y axis) and/or crowning if available, see

Crowning, page 29),

• The back gauge position (X and R, if available), see Back gauge (X & R axes)

Correction, page 29.

After physically measuring the angle, if corrections are to be made, they must be done on

this page, and not directly in the program step.

Bend Numerical Page →

Angle correction

Y1 axis correction

Pinch Point correction

Crowning correction

Y2 axis correction

X axis correction

R axis correction

28/38

Sept.

2014

V3.1

Page 37

CybTouch 12 PS User Manual

Setting inStructionS:

1. Touch the angle correction icon,

Pressing this button will reset all

angle corrections.

2. Depending on the position of the sheet metal in the press, it may be necessary to

and enter the physically measured

value of the angle. The numerical

control will automatically calculate the

Y1 and Y2 axes corrections.

fine-tune the beam’s corrections. It is possible by simply touching this

icons, and entering the desired values.

Reset corrections button

Reset corrections button

or this

Crowning

Back gauge (X & R axes) Correction

3. Corrections to the crowning value can be made by touching this icon

4. The numerical control automatically calculates the Pinch Point height. If it needs

correction, it can be done by touching this icon

.

.

The grayed value next to the Pinch Point correction icon is the value calculated

by the numerical control, and thus the value onto which the correction will be

applied.

5. Touching this icon allows applying a correction to the back gauge X axis

position.

6. Touching this icon

position.

allows applying a correction to the back gauge R axis

The grayed values next to the back gauge correction icons are the value

calculated by the numerical control, and thus the values onto which the

corrections will be applied.

The back gauge positions corrections can also directly be made on the Bend

Numerical Page (see page 14).

Back gauge (X axis)

position correction value

Back gauge (Y axis)

height correction value

Sept.

29/38

2014

V3.1

Page 38

SavinG and loadinG a ProGraM

SavinG a proGraM

After creating a program, an operator can save the program in order to use it again:

1. In the Bend Numerical Page, touch the Program number (e.g. P0).

2. Touch Save program.

CybTouch 12 PS User Manual

loadinG a proGraM

To call (load) a program:

3. Enter the number you wish to give to the program (e.g. 1 for P1), followed by

4. The program is now called P1 and is saved in the CybTouch.

1. In the Bend Numerical Page, touch the Program number (ex: P1).

2. Touch Call program.

3. Select the program to be loaded from the list (e.g. 002 for P2).

4. The selected program (P2) is then loaded into the work memory and is ready to be

used.

.

deleTinG a proGraM

To delete a program:

Sept.

30/38

2014

V3.1

1. In the Bend Numerical Page, touch the Program number (ex: P1).

2. Touch Delete program.

3. Select from the list the program to be deleted.

4. Touch

to confirm.

Page 39

CybTouch 12 PS User Manual

eaSybend PaGe

The EasyBend page is used for individual bends, for example when an external worker

needs to interrupt production just to make a single bend (usually with the same tools).

(Menu Button) → EasyBend

The program currently being used for production is only temporarily interrupted

(no need to save it) when switching to the EasyBend page, and then resumed

again when returning to the program page (Menu Button → Current program).

MakinG a bend on The eaSybend paGe

See Basic Page Description, page 14 for more information on the different

controls on the EasyBend page.

Setting inStructionS:

1. Touch the material’s name (here Steel). The More Page (see page 14) is displayed.

Select the Material (see page 15) used, enter the Material thickness and the

Bending length.

2. Touch one of the tool’s icon (

configure tools, please refer to section Tools Management, page 18.

3. Enter the angle

4. Enter the flange’s length

5. Enter the back gauge height value

or ) to select a punch or die. To learn how to

for the first bend you wish to create (here 90°).

(here 100.00 mm).

(here 34.00 mm)

6. Press this button

eventually required extra data for the bend.

7. Start the hydraulic pump motor (by pressing this button

when the motor is running the button becomes red).

8. Press the

entered.

9. When the machine is ready to bend, a

10. Press the foot switch to execute the bend.

button to position the machine according to the data that were just

to go to the More Page (see page 14) and enter the

button is displayed.

if available. It turns red

Sept.

31/38

2014

V3.1

Page 40

error and warninG MeSSaGeS

Following is a list of warning and error

messages which may be displayed on the

interactive message line of the CybTouch.

There are two types of messages:

• Warning Messages, which are displayed on a green background. They are information or instructions that will disappear automatically.

• Error Messages (machine or NC

errors), which are displayed on a red

background. They inform the user of an

error occurring on the machine or NC,

and sometimes require intervention by

the end user or a technician.

When reporting error messages, please ALWAYS indicate the error number at

the end of the line. This number also refers to the first column in the section

below.

Interactive

message line

CybTouch 12 PS User Manual

Message number

WarninG MeSSaGeS

MSG nr. MeSSaGe deScripTion

W01 Not implemented This message is displayed when a function is in development but

not yet fully implemented.

W02 Ignore This message appears when the desired action makes no sense,

like for example clearing the indexation when the indexation was

not made.

W03 Code accepted This message is displayed when the correct password has been

entered.

W04 Please press 2 seconds This message reminds the operator to keep the start pump

button

W05 The pump is on This message appears after the pump starting cycle has been

correctly executed.

W06 The pump is off This message indicates that the pump has been stopped.

W07 Select at least one bend This message is displayed when the operator tries to go to the

Bend 2D screen from the Bend Order screen before defining

the first bend of the sequence (see Automatic Bend Sequencing

(optional), page 24).

W08 Touch OK to continue Indicates that a validation is required to continue.

W09 Step n° This message appears in the More Page (see page 14), it

indicates the step sequence number when browsing through the

program’s steps.

W10 Cycle in progress While this message is displayed, the machine cycle is in progress

and the screen is locked, except for the Stop button.

W11 Machine is indexed Indicates the indexation cycle was successful.

W12 Identification OK In the Axis Wizard, indicates the identification cycle was

successful.

pressed for 2 seconds.

32/38

Sept.

2014

V3.1

Page 41

CybTouch 12 PS User Manual

MSG nr. MeSSaGe deScripTion

W13 Touch the zoom center

W14 Touch to create a new

segment

W15 Touch one length or angle to

start the profile

W16 Eco mode This message appears when the Eco mode starts, after the timer

W17 Enter the measured angle This message is displayed when the operator must enter the

W18 Empty field Operator did not enter a value.

W19 24V I/O power on 24V to the inputs/outputs is now available.

W20 Please select a field This message is displayed when trying to set the time (see Set

W21 Set seconds

W22 Set minutes

W23 Set hour

W24 Set day

W25 Set month

W26 Set year

W27 Touch the small graphic to

toggle screen

W29 End of list This message is displayed when reaching the end of the list in

W30 Serial number from 100’000

thru 231’071

W31 New option code When installing a new option in the Service Page (see

W32 Data entry in progress Operation impossible: data entry in progress. Wait until the data

W33 Indexation in progress Operation impossible: indexation in progress. Wait until the

W34 RFlink disconnected When the RFLink connection to a laptop has been shut down

W35 Access not allowed Operator needs another level password.

W36 Beam not at TDC, move beam

up

W37 Moving direction has been

inverted

W38 Counting direction has been

inverted

When the zoom function

is activated, indicates that the HMI

will zoom around the next touch on the screen.

When creating a new part in the TouchProfile Mode (see

page 23), this message reminds the operator to touch the

screen to create a part’s segment.

When creating a new part in the L-Alpha Mode (see page 27),

reminds the operator to touch the table to begin creating a part.

defined in the machine parameters is over.

physically measured angle value in the Bend Correction page.

Clock, page 8) and no field (minute, seconds, etc.) has been

selected.

In the Set Clock (see page 8) page, when the corresponding

field is selected, indicates that it can be set using the up and

down arrows.

This message appears once at the beginning of the bend manual

sequencing, telling the operator that he can toggle from the Bend

Order page to the Bend 2D page simply by touching the graphic

at the bottom of the screen (see Automatic Bend Sequencing

(optional), page 24).

one of the different menus

.

This message appears only when entering the serial number. It

indicates the range of the number to be entered. Attention, this

operation is normally done at the factory, with a serial number is

related to the options installed on the machine. Do not change it!

page 10).

is entered to try again.

indexation is finished to try again.

from the latter.

Wizard message: Rotary direction of the motor has been

changed.

Wizard message: Counting direction of the axis has been

changed.

Sept.

2014

V3.1

33/38

Page 42

CybTouch 12 PS User Manual

MSG nr. MeSSaGe deScripTion

W39 Moving and counting

directions have inverted

W40 OK Indicates a cycle or operation has properly ended.

W41 No movement executed

W42 Enter next measured angle When using double or triple angle measurement, tells the

W43 OK, correction done Appears when an angle correction has been entered and applied.

W45 Enter unlock interface

password

W46 Enter password level 1 or

greater

W47 Enter password level 3 This message is displayed when a password of level 3 or higher

W48 Enter new password

W49 Confirm new password

W50 Enter password for backup This message is displayed when trying to create a backup.

W51 Enter password for restore This message is displayed when trying to restore a backup.

W52 Enter password for init This message appears on the page displayed after the system

W53 Enter password for delete all

backups

Wizard message: Both the rotary direction of the motor and the

counting have been changed.

Axis Wizard message: Operator pressed

but no movement

was made.

operator to enter the next measured value.

This message is displayed when parameter P02.04 Level 0 Lock

HMI is set to yes and the screen is touched.

This message is displayed when a password of level 1 or higher

is needed to execute a specific operation.

is needed to execute a specific operation.

These messages are displayed when changing passwords.

crashed (soft or hardware problem), when the operator tries to

format the machine.

This message is displayed when trying to delete all backups.

34/38

Sept.

2014

V3.1

Page 43

CybTouch 12 PS User Manual

error MeSSaGeS

MSG nr. MeSSaGe deScripTion

E02 Pump motor off The pump motor needs to be on for the sequence to start.

E03 Buffer Full The part-program memory is full, you cannot add another

sequence.

E04 Code refused The level code to access the selected page is not correct. Try

again or ask for it if you do not have it.

E05 File not compatible The loaded part-program is incompatible with the NC. This part

should be deleted.

E06 Machine parameter file

problem

E07 Machine parameters not

compatible, please format data

E08 Lismisc File not compatible Information message, which will disappear when restarting the

E09 Save program problem This file is corrupt and cannot be saved. Try to restart the NC. If

E10 File not found [ ] A file is missing and the code indicates which one. Call Cybelec

E11 Write to file problem This file is corrupt and cannot be saved. Try to restart the NC. If

E12 X under minimum limit Operator entered a value under the limit, or a memorized value in

E13 X over maximum limit Operator entered a value over the limit, or a memorized value in

E14 Fw SetVar Error [ ] May occur when a feature is configured, but the dedicated input/

E15 Bottoming not allowed This message is displayed when a bottoming sequence is

E16 Fw Axes Error [ ] ... Axis manager error. The number gives more information. Most

E17 Programming error Machine parameters incorrectly configured, the error page is

E18 No Backgauge defined All the back gauges programmed in Machine Parameters have

E19 Quantity = 0 When pressing start, the programmed amount of parts to

E20 Cycle repeat = 0 Cannot start cycle because repeat cycle function is set to “0”.

This file is corrupt and cannot be saved. Try to restart the NC. If

the problem persists, format the memory.

This message appears when a software update has been made

over a much older version and the parameters are no longer

compatible. It can also appear if the uploaded parameters (with

RFlink) are much older or newer than the current software

version and they are not be compatible. A new start up of the

machine must be made. Contact your dealer.

NC.

the problem persists, format the memory.

with this code to know which file is missing.

the problem persists, format the memory.

the program is under the limit. The wrong value flashes and must

be corrected.

the program is over the limit. The wrong value flashes and must

be corrected.

output is not configured. Usually this is solved by loading the

default input/output configuration (see the machine parameters).

programmed and bottoming is not allowed with either one of the

tools.

common errors are described in messages E55 to E68.

If other error numbers are listed, please send conditions of

problem, traces and parameters to the Cybelec Technical support

for assistance.

displayed.

none selected for mode. Select at least one mode other than

none.

be made is ‘0’. See Number of parts, page 17 for more

information.

Sept.

2014

V3.1

35/38

Page 44

CybTouch 12 PS User Manual

MSG nr. MeSSaGe deScripTion

E21 No material defined (define

one or more in MP)

E24 Identification Error [ ] During the Axis Wizard, there was an error identifying one of the

E25 No FAST task running [ ] Switch OFF the machine for 1 min and restart it again.

E26 NULL pointer to axis struct. This message indicates a software bug. Write it all down and

E27 MUTEX Error [ ] This message indicates a software bug. Write it all down and

E28 I/O no 24V or overload (output

in safety off)

E29 Radio link error, code [ ] The RFlink chip has detected an error. Check the environment

E30 Touchscreen error, code [ ] Please contact your machine dealer with this specific code and

E31 “Crowning” analog input not

configured

E32 “Crowning” analog output not

configured

E33 Syntax error in XML file This file is corrupt and cannot be used. Try to restart the NC. If

E34 Memory allocation problem

(xml)

E35 Endless loop on process task Process error. Please restart the NC and inform your dealer.

E37 WARNING: Overloop intern This error should normally never happen on the machine. It

E38 Unknown key There is a list of known screen zones, and the pressed zone is

E39 “Start” input refused The start command is not accepted in this page/situation.

E40 R under minimum limit The programed position value for axis R is below the value of the

E41 Thickness smaller than min The thickness entered for the material is below the minimum

E42 Thickness greater than max The thickness entered for the material is above the maximum

E43 Configuration error Input/output incorrectly configured in machine parameters, the

E44 “External stop” input is active External stop may be caused by safety devices, emergency

No materials programmed in the Material pages (in User

preferences). A material must be selected to perform

calculations.

axes. The error number (typically E55, E56 or E57) gives more

information. See also message E16.

contact Cybelec.

contact Cybelec.

The 24V power supply for the inputs/outputs is no longer present

or an output is overloaded. Reset any safety device on the

machine, check protection grids and rear guards are closed, etc.

If the problem persists, switch machine OFF for 3 min and restart

it again. If the problem still persists, check the machine manual

and/or ask a service technician to check your machine.

for disturbances (cell phone, wi-fi) and that the material works

properly. If the problem persists, write the error number down

and send it Cybelec.

details.

While configuring (setting up) the NC, the Crowning dedicated

input was not configured but is requested to run properly.

While configuring (setting up) the NC, the Crowning dedicated

outputs were not configured but are requested to run properly.

the file is a part-program, try to delete it.

There was a problem while trying to read a file in the memory.

The file is probably corrupted. The number gives more

information, write it down.

means there are too many elements in a coded list.

not in it. This error can normally not happen in the field.

minimum limit switch position.

value defined in the User Preferences (see Materials, page 7).

value defined in the User Preferences (see Materials, page 7).

error input/output page is displayed. Check for unauthorized

doubled output or inputs.

This message can also be displayed if the chosen configuration

requires more icons on the first page than there room available.

buttons, rear protection guards, etc. See machine instructions.

36/38

Sept.

2014

V3.1

Page 45

CybTouch 12 PS User Manual

MSG nr. MeSSaGe deScripTion

E45 Error: backgauge “rest” mode

and retract

E46 “Pressure” analog output not

configured

E47 R over maximum limit The programed position value for axis R is above the value of the

E48 Stop doesn’t exist This error means the operator is trying to make a bend without a

E50 Value out of limit This message is displayed when the value the operator is trying

E51 Error[ ][ ][ ][ ]... Internal management error. Write the error’s codes down and

E52 Punch does not exist This message is displayed when trying to create a new part

E53 Die does not exist This message is displayed when trying to create a new part

E55 Identification Error 1 (No

motion detected)

E56 Identification Error 2 (Not

enough oscillations)

E57 Identification Error 3

(Amplitude of the oscillation)

E58 Fw Axes Error 32 [Trajectory

tracking error]

E59 Fw Axes Error 311 [MaxSpeed

too high !]

E60 Fw Axes Error 312 [MaxSpeed

too small !]

E61 Fw Axes Error 313

[Acceleration too small or

MaxSpeed too high !]

E62 Fw Axes Error 314

[Acceleration too high or

MaxSpeed too small !]

E66 Fw Axes Error 33 [Maximum

voltage time exceeded (10V)]

E67 Fw Axes Error 39 [Speed

tracking error]

E68 Fw Axes Error 316 [MinPosition

or MaxPosition outside limit ! ]

It is not allowed to program a Back gauge retraction (see

page 15) with a support type of back gauge finger.

While configuring (setting up) the NC, dedicated input or output

are not configured but are requested to run properly.

maximum limit switch position.

back gauge or with a back gauge whose mode is none. Select a

valid back gauge.

to be program is bigger than the maximum authorized value.

the software’s number (see Information, page 11) and call

Cybelec.

before having selected a punch in the list (see Punches, page

18).

before having selected a die in the list (see Dies, page 20).

No motion detected. Should not happen if you started the Wizard

from the beginning. If the error remains, check limit switches,

drive, wiring, etc.

Not enough oscillations Increase the identification time. See

machine parameters manual.

Oscillation amplitude. Increase the identification voltage. See

machine parameters manual.

This is a regulator error. The axis could not follow its trajectory.

This may be due to high friction, resistance or an obstacle on the

axis movement. This may also be a drive problem.

Call a technician.

Max speed or encoder resolution too high.

Max speed or encoder resolution too low.

2

Acceleration too low (mm/s

) or max speed too high. This needs

to be corrected. Please note that acceleration is not a ramp

distance.

2

Acceleration too high (mm/s

) or max speed too low. This needs

to be corrected.

This is a regulator error. The axis could not follow its trajectory.

This may be due to higher friction, resistance or an obstacle on

the axis movement. It may also be a drive problem.

Call a technician.

This is a regulator error. The axis could not follow its trajectory.

It may be due to higher friction, resistance or an obstacle on the

axis movement. It may also be a drive problem.

Call a technician.

Axis position counter is out of max or min limit.

Verify physical axis position and set the axis counter accordingly.

Sept.

2014

V3.1

37/38

Page 46

CybTouch 12 PS User Manual

MSG nr. MeSSaGe deScripTion

E69 The machine is not indexed !

No limit

E70 Progr. angle is smaller than the

die angle

E71 Progr. angle is smaller than the

punch angle

E72 Depth safety The calculated angle causes the punch, material, and die to

E73 Collision backgauge-tool This message appears to warn that, with the parameters cannot

E74 Beam error No [ ][ ][ ]

E75 Beam: static gains not found

E76 Error in the parameter beam

(you must correct it before

continuing)

E77 Error in the sequence

parameter (you must correct it

before continuing)

E78 RS232: parity error

E79 RS232: overrun

E80 RS232: framing

E81 RS232: noise

E82 PCSS event No xx

E83 PCSS error time out

E84 PCSS error checksum

E85 PCSS error buffer rec to small

E86 File access error There was an error when trying to access a file while

E87 Unknown error An unknown error occurred while trying to program an option.

E88 RS232: port already open

E89 Solution not found This message indicates that the bending sequence automatic

Before the machine is indexed, the NC doesn’t know where the

axes are. In manual page, movements are authorized but the

electronic stroke limits are not activated. Operator is responsible

for stopping axis movement before mechanical limit is reached.

The programmed angle is smaller than the die angle. Change die.

The programmed angle is smaller than the punch angle. Change

punch.