Craftsman 917353771, 917353770, 917353731, 917353730 Owner’s Manual

.Assembly

®Operation

. Msintenance

. RepairParts

I:RRFTSIVinNo

33 CHAIN SAW

OR

CHAIN SAW

MODEL NO,S.

917.353730

917.353731

IMPORTANT:

I

AND INSTRUCTIONS

_ CAREFULLY

|

I

MODEL NOS.

917.353770

917.353771

Sears, Roebuck and Co_, Chicago, Illo 60684, U,S.A_

MODEL ;

NUMBER_

SERIAL

NUMBEL

THE MODEL AND SERIAL NUMBERS

WILL BE FOUND ON THE MODEL

PLATE LOCATED BELOW "ON-OFF"

SWITCH

YOU SHOULD RECORD BOTH MODEL

AND SERIAL NUMBERS AND KEEP

IN A SAFE PLACE FOR FUTURE REF-'

ERENCE.

CONGRATULATIONS...

on your purchase of a Craftsman 3°7

Chain Saw. tt has been designed, engin-

eered and manufactured to give you de-

pendability and pe_'formanceoShould you

experience any problem you cannot

easily remedy, please contact your near-

eat Sears, Roebuck and Coo store_ They

have competent, welt-trained technicians

and the proper tools and parts to service

or repair this unit.

Please read and retain this manual Fol-

[pwlng the ]_ules for _pfe Ot2eratzon ,

"'Assqmbly", "Operation", and-Mainten-

ance" instructions will help you achieve a

long, safe, service life for your Chain Saw°

ENJOY USING YOUR

NEW CRAFTSMAN 3.7

CHAIN SAW TO MAKE...

4;

LOG DISCS...

for paths, pat os steps. Simplest of all

Chmn Saw prolects.. Cut 4 thtck slices

from a log at least 10!' in diame_ter. Treat

with wood preservative and place on a

fi_m bed"of crushed rock.. :

FIRE WOOD...

Your National Forest Ra_qgermay permit

removal of dead or downed timber for a

_odest fee -- a clear) forest is lesssuscep-

t!ble tO fires and disease_Quick burning

evergreens will split easily to kindle slow-

er burning hardwoods_ Measure "_i0urfire-

place before you start -- logs don_t bend.

FENCES...

make good neighbors, especially the rus-

tic split rails so suggestiveof the "good

old days". Use cedar or redwood, or any

good splitting wood. Split rails with an ax

and wedges, notch and fit so your fence

is self supporting.,

TABLES AND BENCHES...

from half logs, slices or planks drilled and

pegged. Legs of smaller diameter logs

are whittled, fitted and wedged into drill-

ed tops.

With other tools, good Chain S_w techni-

que, and your imagination you'll soon be

inventing many other Chain Saw projects.

BY THE 1NAY...

Don't forget to visit your' nearby Sears

store for Chain Saw accessories, Chain

Guards and Saw Maintenance Items that

can make your projects more enjoyable°

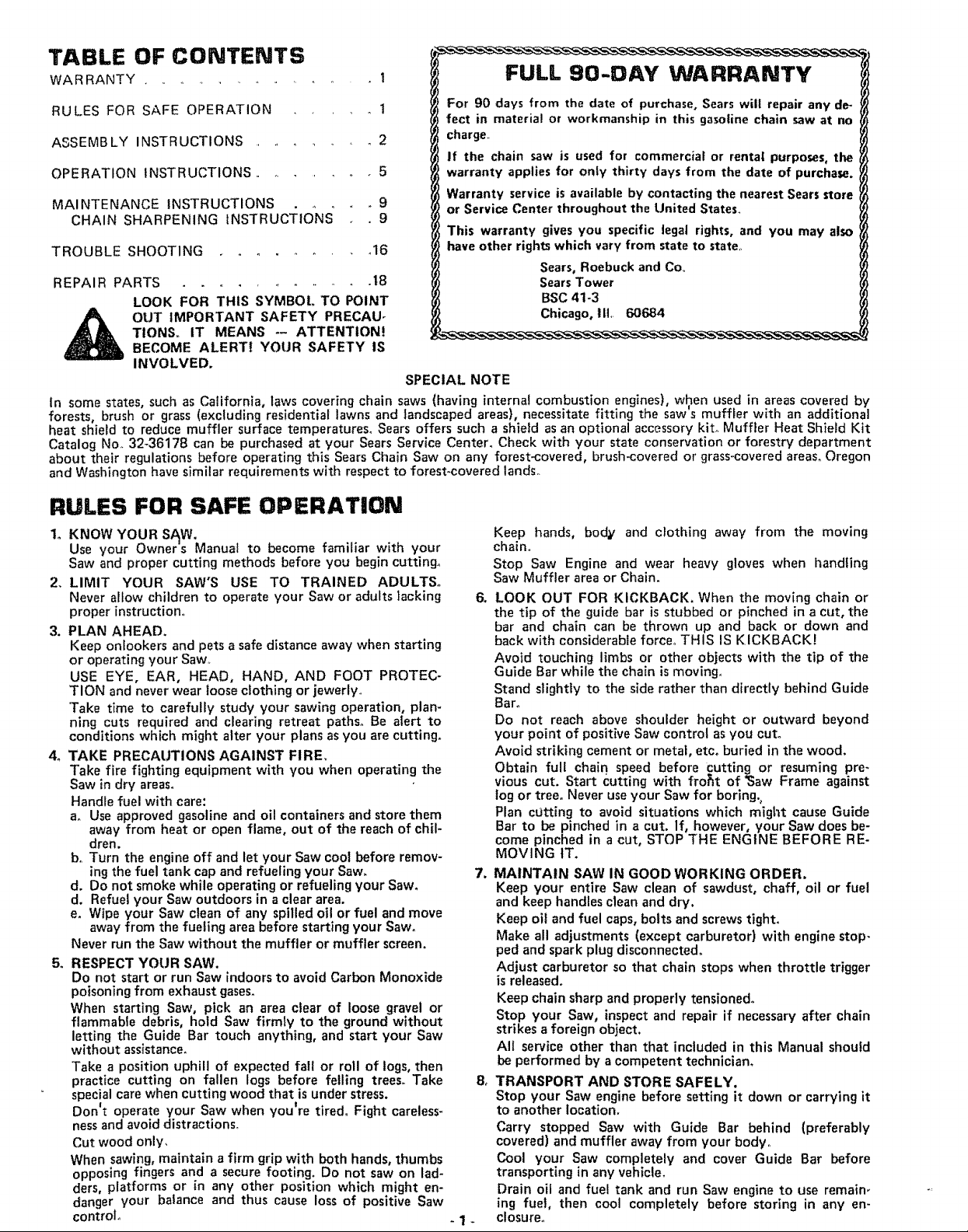

TABLE OF CONTENTS

WARRANTY ................. 1

RULES FOR SAFE OPERATION ...... 1

ASSEMBLY INSTRUCTIONS ........... 2

OPERATION INSTRUCTIONS ........... 5

MAINTENANCE INSTRUCTIONS ...... 9

CHAIN SHARPENING INSTRUCTIONS ., 9

TROUBLE SHOOTING ............ 16

REPAIR PARTS ............. 18

LOOK FOR THIS SYMBOl. TO POINT

OUT IMPORTANT SAFETY PRECAU-

TIONS. IT MEANS -- ATTENTION!

BECOME ALERT! YOUR SAFETY IS

INVOLVED,

FULL 90-DAY WARRANTY

For 90 days from the date of purchase, Sears will repair any de-

fect in material or workmanship in this gasoline chain saw at no

charge

If the chain saw is used for commercial or rental purpo_s, the

warranty applies for only thirty days from the date of purchar_.

Warranty service is available by contacting the nearest Sears store

or Service Center throughout the United States_

This warranty gives you specific legal rights, and you may also

have other rights which vary from state to state.

Sears, Roebuck and Co,1

Sears Tower

BSC 41-3

Chicago, !il 60684

SPECIAL NOTE

In some states, such as California, laws covering chain saws (having internal combustion engines}, when used in areas covered by

forests, brush or grass (excluding residential lawns and landscaped areas}, necessitate fitting the saw's muffler with an additional

heat shield to reduce muffler surface temperatures, Sears offers such a shield as an optional accessory kit° Muffler Heat Shield Kit

Catalog No. 32-36178 can be purchased at your Sears Service Center. Check with your state conservation or forestry department

about their regulations before operating this Sears Chain Saw on any forest-covered, brush-covered or grass-covered areas, Oregon

and Washington have similar requirements with respect to forest-covered lands°

RULES FOR SAFE OPERATION

1o KNOW YOUR ShtW,

Use your Owner s Manual to become familiar with your

Saw and proper cutting methods before you begin cutting,

2, LIMIT YOUR SAW'S USE TO TRAINED ADULTS.

Never allow children to operate your Saw or adults lacking

proper instruction,,

3, PLAN AHEAD.

Keep onlookers and pets a safe distance away when starting

or operating your Saw,,

USE EYE, EAR, HEAD, HAND, AND FOOT PROTEC-

TION and never wear loose clothing or jewerly.,

Take time to carefully study your sawing operation, plan-

ning cuts required and clearing retreat paths° Be alert to

conditions which might alter your plans asyou are cutting,

4o TAKE PRECAUTIONS AGAINST FIRE,

Take fire fighting equipment with you when operating the

Saw in dry areas_

Handle fuel with care:

a. Use approved gasoline and oil containers and store them

away from heat or open flame, out of the reach of chil-

dren,

bo Turn the engine off and let your Saw cool before remov-

ing the fuel tank cap and refueling your Saw,

d. Do not smoke while operating or refueling your Saw.

d. Refuel your Saw outdoors in a clear area.

e, Wipe your Saw clean of any spilled oil or fuel and move

away from the fueling area before starting your Saw,

Never run the Saw without the muffler or muffler screen.

5. RESPECT YOUR SAW.

Do not start or run Saw indoors to avoid Carbon Monoxide

poisoning from exhaust gases.

When starting Saw, pick an area clear of loose gravel or

flammable debris, hold Saw firmly to the ground without

letting the Guide Bar touch anything, and start your Saw

without assistance,

Take a position uphill of expected fall or roll of logs, then

practice cutting on fallen logs before felling trees° Take

special care when cutting wood that is under stress.

Don_t operate your Saw when you're tired° Fight careless-

ness and avoid distractions,

Cut wood only,

When sawing, maintain a firm grip with both hands, thumbs

opposing fingers and a secure footing. Do not saw on lad-

ders, platforms or in any other position which might en-

danger your balance and thus cause loss of positive Saw

control.

-1-

6_

Keep hands, body and clothing away from the moving

chain°

Stop Saw Engine and wear heavy gloves when handling

Saw Muffler area or Chain.

LOOK OUT FOR KICKBACK, When the moving chain or

the tip of the guide bar is stubbed or pinched in a cut, the

bar and chain can be thrown up and back or down and

back with considerable force° THIS IS KICKBACK!

Avoid touching limbs or other objects with the tip of the

Guide Bar while the chain is moving.

Stand slightly to the side rather than directly behind Guide

Bar°

Do not reach above shoulder height or outward beyond

your point of positive Saw control as you cut.

Avoid striking cement or metal, etc. buried in the wood.

Obtain full chain speed before cutting or resuming pre*

vious cut. Start cutting with fro_t of _3aw Frame against

log or tree. Never use your Saw for boring.0

Plan c_tting to avoid situations which might cause Guide

Bar to be pinched in a cut. If, however, your Saw does be-

come pinched in a cut, STOP THE ENGINE BEFORE RE-

MOVING IT.

7. MAINTAIN SAW IN GOOD WORKING ORDER,

Keep your entire Saw clean of sawdust, chaff, oil or fuel

and keep handles clean and dry.

Keep oil and fuel caps, bolts and screwstight.

Make all adjustments (except carburetor) with engine stop-

ped and spark plug disconnected.

Adjust carburetor so that chain stops when throttle trigger

is released.

Keep chain sharp and properly tensioned.

Stop your Saw, inspect and repair if necessaryafter chain

strikes a foreign object.

All service other than that included in this Manual should

be performed by a competent technician.

8, TRANSPORT AND STORE SAFELY.

Stop your Saw engine before setting it down or carrying it

to another location.

Carry stopped Saw with Guide Bar behind (preferably

covered) and muffler away from your body°

Cool your Saw completely and cover Guide Bar before

transporting in any vehicle,

Drain oil and fuel tank and run Saw engine to use remain _

ing fuel, then cool completely before storing in any en-

closure,

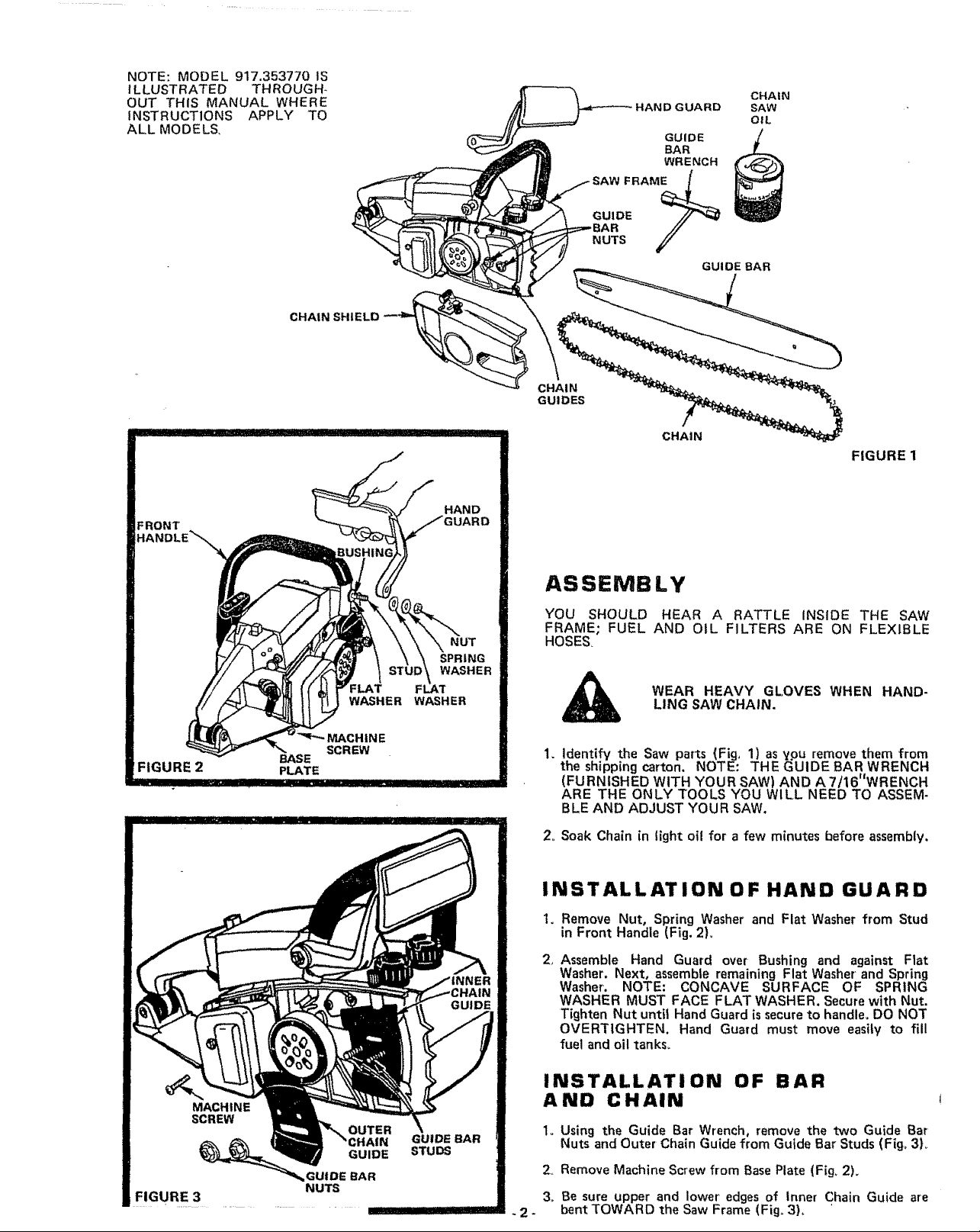

NOTE: MODEL 917.353770 tS

ILLUSTRATED THROUGH-

OUT THIS MANUAL WHERE

INSTRUCTIONS APPLY TO

ALL MODELS,

HAND GUARD

CHAIN

SAW

OIL

GUIDE

BAR

WRENCH

FRAM_

GUIDE /F'_

BAR //

NUTS

GUIDE BAR

CHAIN

GUIDES

FIGURE 2

FLAT

WASHER

"_" MACHtN E

SCREW

BASE

PLATE

HAND

NUT

SPRING

WASHER

WASHER

CHAIN

FIGURE 1

ASSEMBLY

YOU SHOULD HEAR A

FRAME; FUEL AND OiL

HOSES_

RATTLE INSIDE THE SAW

FILTERS ARE ON FLEXIBLE

WEAR HEAVY GLOVES WHEN HAND-

LING SAW CHAIN,

.

Identif_¢ the Saw parts (Fig, 1) as ypu remove them from

the shipping carton, NOTE: THE GUIDE BAR WRENCH

(FURNISHED WITH YOUR SAW) AND A 7/16"WRENCH

ARE THE ONLY TOOLS YOU WILL NEED TO ASSEM-

BLE AND ADJUST YOUR SAW.

2o Soak Chain in light oil for a few minutes before assembly,

-2-

INSTALLATION OF HAND GUARD

1. Remove Nut, Spring Washer and Flat Washer from Stud

in Front Handle (Fig. 2L

2_

Assemble Hand Guard over Bushing and against Flat

Washer, Next, assemble remaining Flat Washer and Spring

Washer. NOTE: CONCAVE SURFACE OF SPRING

WASHER MUST FACE FLAT WASHER. Secure with Nut.

Tighten Nut until Hand Guard is secure to handle, DO NOT

OVERTIGHTEN. Hand Guard must move easily to fill

fuel and oil tanks_

INSTALLATION OF BAR

A ND C H AIN

1o Using the Guide Bar Wrench, remove the two Guide Bar

Nuts and Outer Chain Guide from Guide Bar Studs (Fig_ 3L

2. Remove Machine Screw from Base Plate (Fig. 2).

3. Be sure upper and lower" edges of inner Chain Guide are

bent TOWARD the Saw Frame (Fig. 3). '

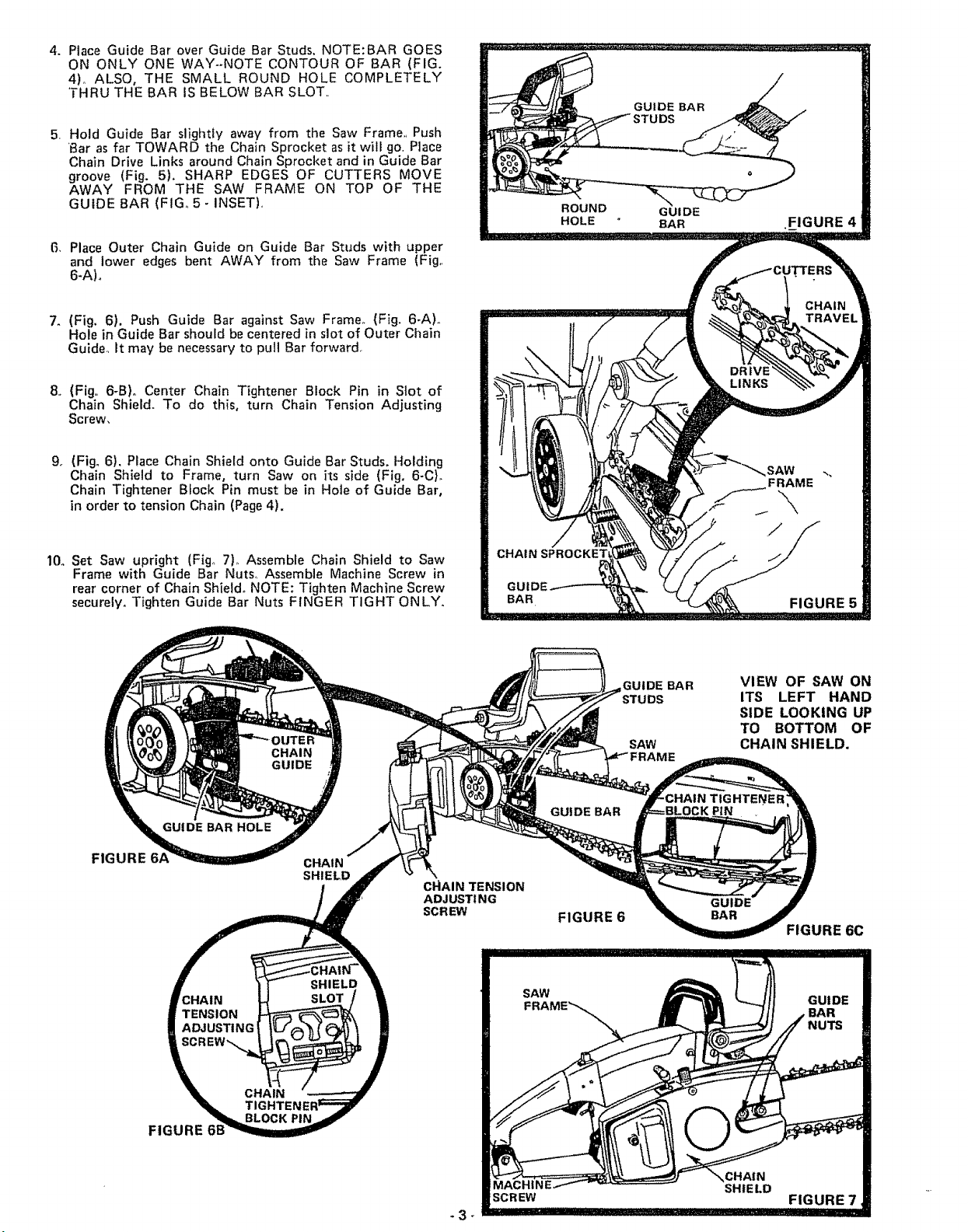

4. Place Guide Bar over Guide Bar Studs, NOTE:BAR GOES

ON ONLY ONE WAY--NOTE CONTOUR OF BAR (FIG.

4)° ALSO, THE SMALL ROUND HOLE COMPLETELY

THRU THE BAR IS BELOW BAR SLOT.

5, Hold Guide Bar slightly away from the Saw Frame., Push

_Baras far TOWARD the Chain Sprocket as it will go. Place

Chain Drive Links around Chain Sprocket and in Guide Bar

groove (Fig. 5), SHARP EDGES OF CUTTERS MOVE

AWAY FROM THE SAW FRAME ON TOP OF THE

GUIDE BAR (FIGo 5- INSET),

B, Place Outer Chain Guide on Guide Bar Studs with upper

and lower edges bent AWAY from the Saw Frame (Fig,,

6-A) o

7. (Fig. 6). Push Guide Bar against Saw Frame. (Fig. 6-A)o

Hole in Guide Bar should be centered in slot of Outer Chain

Guide It may be necessary to pull Bar forward.

8o (Fig., 6-B)o Center Chain Tightener Block Pin in Slot of

Chain Shield. To do this, turn Chain Tension Adjusting

Screw,

go (Fig° 6), Place Chain Shield onto Guide Bar Studs, Holding

Chain Shield to Frame, turn Saw on its side (Fig. 6-C)_

Chain Tightener Block Pin must be in Hole of Guide Bar,

in order to tension Chain (Page 4).

10. Set Saw upright (Fig° 7), Assemble Chain Shield to Saw

Frame with Guide Bar Nuts_ Assemble Machine Screw in

rear corner of Chain Shiel& NOTE: Tighten Machine Screw

securely, Tighten Guide Bar Nuts FINGER TIGHT ONLY.

GUIDE BAR

ROUND GUIDE

HOLE BAR

CHAIN SPROCKETI

GUIDE

BAR

.FIGURE 4

CHAIN

TRAVEl

DRIVE'

LINKS

FIGURE 5

FIGURE

CHAIN

GUIDE

GUIDE BAR HOLE

CHAIN

SHIELD

CHAIN TENSION

ADJ USTI N G

SCREW

GUIDE BAR

SAW

GUIDE BAR

FIGURE 6

VIEW OF SAW ON

ITS LEFT HAND

SIDE LOOKING UP

TO BOTTOM OF

CHAIN SHIELD.

'tGHTENEB

PIN

GUIDE

BAR

FIGURE 6C

CHAIN

TENSION

ADJUSTING

CHAIN

TIGHTE

BLOCK PIN

SHIEL[

SLOT

-3-

LOOSEr

FIGURE 8

CHAIN TENSION

EW

GUIDE

TENSION CHAIN

2_

3_

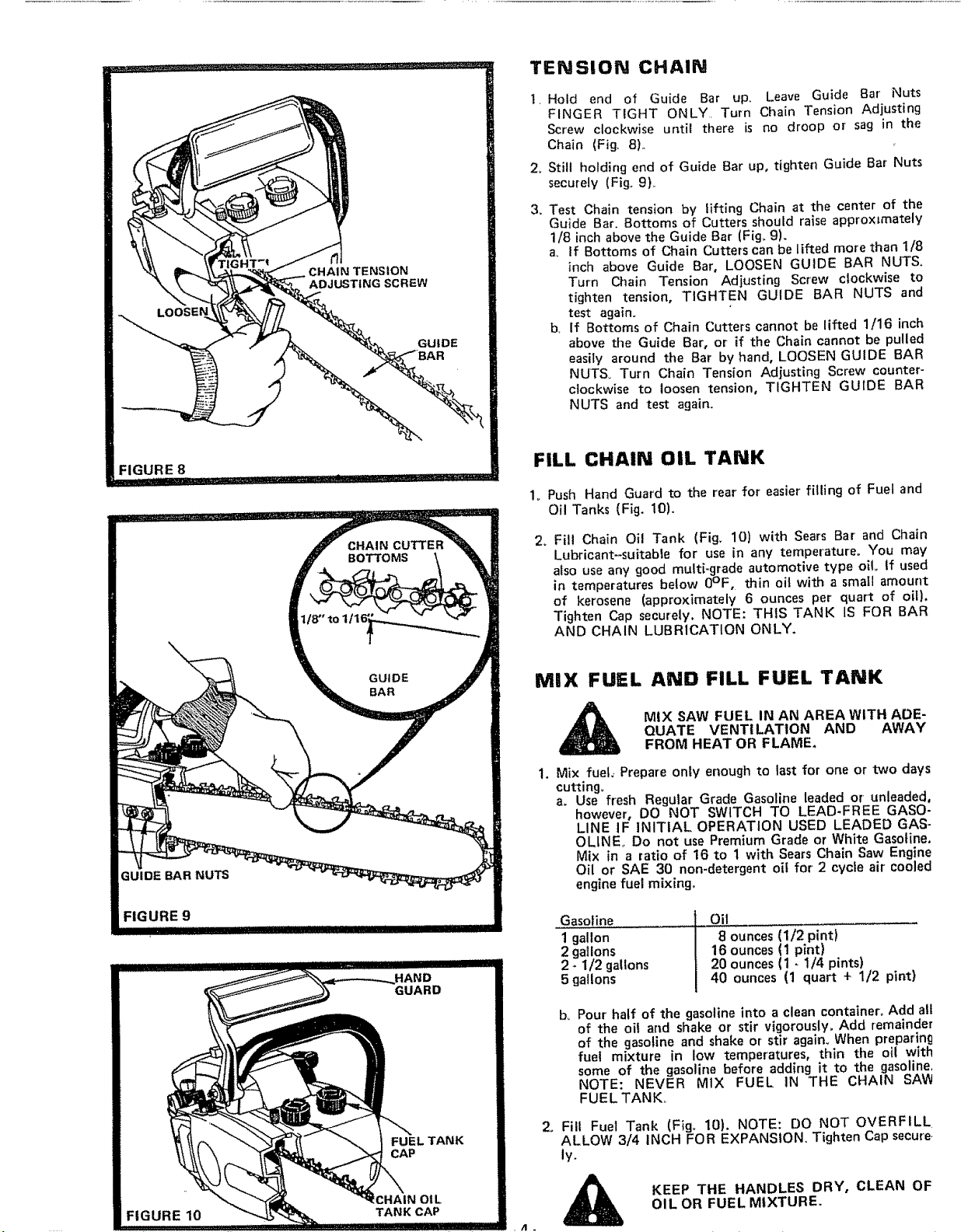

Hold end of Guide Bar upo Leave Guide Bar Nuts

FINGER TIGHT ONLY. Turn Chain Tension Adjusting

Screw clockwise until there is no droop or sag in the

Chain (Fig. 8),,

Still holding end of Guide Bar up, tighter} Guide Bar Nuts

securely (Fig,, 9).

Test Chain tension by lifting Chain at the center of the

Guide Bar. Bottoms of Cutters should raise approx=mately

1/8 inch above the Guide Bar (Fig, 9).

a. If Bottoms of Chain Cutters can be lifted more than 1/8

inch above Guide Bar, LOOSEN GUIDE BAR NUTS.

Turn Chain Tension Adjusting Screw clockwise to

tighten tension, TIGHTEN GUIDE BAR NUTS and

test again.

b, if Bottoms of Chain Cutters cannot be lifted 1/16 inch

above the Guide Bar, or if the Chain cannot be pulled

easily around the Bar by hand, LOOSEN GUIDE BAR

NUTS_ Turn Chain Tension Adjusting Screw counter-

clockwise to loosen tension, TIGHTEN GUIDE BAR

NUTS and test again,

FILL CHAIN OIL TANK

1. Push Hand Guard to the rear for easier filling of Fuel and

Oil Tanks (Fig. 10).

2_ Fill Chain Oil Tank (Fig, 10) with Sears Bar' and Chain

Lubricant--suitable for use in any temperature_ You may

also use any good multi-grade automotive type oil. if used

in temperatures below 0°F, thin oil with a small amount

of kerosene (approximately 6 ounces per quark of oil).

Tighten Cap securely. NOTE: THIS TANK IS FOR BAR

AND CHAIN LUBRICATION ONLY.

MIX FUEL AND FILL FUEL TANK

MIX SAW FUEL IN AN AREA WITH ADE-

QUATE VENTILATION AND AWAY

FROM HEAT OR FLAME,

t. Mix fuel.. Prepare only enough to last for one or two days

cutting_

a. Use fresh Regular Grade Gasoline leaded or unleaded,

however, DO NOT SWITCH TO LEAD-FREE GASO-

LINE IF INITIAL OPERATION USED LEADED GAS-

OLINEo Do not use Premium Grade or White Gasoline,

Mix in a ratio of 16 to 1 with Sears Chain Saw Engine

Oil or SAE 30 non-detergent oif for 2 cycle air cooled

engine fuel mixing,,

Gasoline

1 gallon

2gallons

2 - 1/2 gallons

5 gallons

Oil

8 ounces (1/'2 pint)

16 ounces (1 pint)

20 ounces (1 - 1/4 pints)

40 ounces (1 quart + 1/2 pint)

b,, Pour half of the gasoline into a clean container_ Add all

of the oil and shake or stir vigorously, Add remainder

of the gasoline and shake or stir again_ When preparing

rue| mixture in low temperatures, thin the oil with

some of the gasoline before adding it to the gasoline.

NOTE: NEVER MIX FUEL IN THE CHAIN SAW

FUELTANK_

2o Fill Fuel Tank (Fig_ 10). NOTE: DO NOT OVERFILL.

ALLOW 3/4 INCH FOR EXPANSION. Tighten Cap secure

ly.

KEEP THE HANDLES DRY, CLEAN OF

CAP OIL OR FUEL M|XTURE.

OPERATION

STARTING

MOVE CHAIN SAW AT LEAST 10 FEET

AWAY FROM FUELING POINT.,

Make sure your Saw is fueled and Chain Oil Tank filled

properly (Page4).

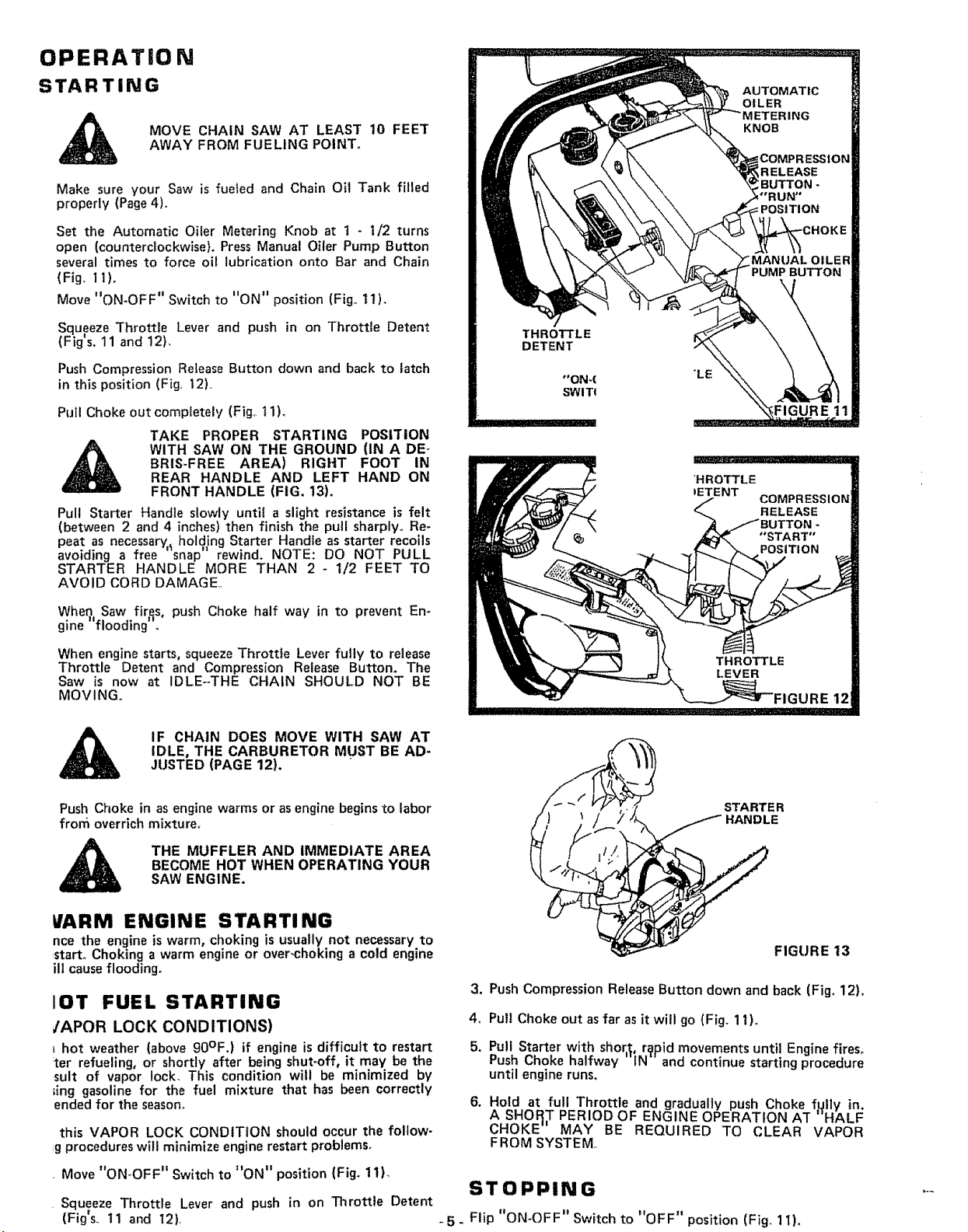

Set the Automatic Oiler Metering Knob at 1 - 1/2 turns

open (counterclockwise). Press Manual Oiler Pump Button

several times to force oil lubrication onto Bar and Chain

(Fig. 11),

Move "ON-OFF" Switch to "ON" position (Fig° tt),

Squeeze Throttle Lever and push in on Throttle Detent

(Fig's. 11 and 12),

Push Compression Release Button down and back to latch

in this position (Fig, 12),,

Pull Choke out completely (Fig_, 11),

TAKE PROPER STARTING POSITION

WITH SAW ON THE GROUND (IN A DE_

BRIS-FREE AREA) RIGHT FOOT IN

REAR HANDLE AND LEFT HAND ON

FRONT HANDLE (FIG. 13).

Pull Starter Handle slowly until a slight resistance is felt

(between 2 and 4 inches) then finish the pull sharply, Re-

peat as necessary_ holding Starter Handle as starter recoils

avoiding a free snap rewind. NOTE: DO NOT PULL

STARTER HANDLE MORE THAN 2 - 1/2 FEET TO

AVOID CORD DAMAGE,,

When Saw fires, push Choke half way in to prevent En-

. llf .* II

g ne OOolng

When engine starts, squeeze Throttle Lever fully to release

Throttle Detent and Compression Release Button. The

Saw is now at IDLE-THE CHAIN SHOULD NOT BE

MOVING°

FIGURE 11

IF CHAIN DOES MOVE WITH SAW AT

IDLE, THE CARBURETOR MUST BE AD-

JUSTED (PAGE 12).

Push Choke in as engine warms or asengine begins to labor

from overrich mixture,

THE MUFFLER AND IMMEDIATE AREA

BECOME HOT WHEN OPERATING YOUR

SAW ENGINE.

_/ARM ENGINE STARTING

nce the engine is warm, choking is usually not necessary to

start. Choking a warm engine or over-choking a cold engine

ill cause flooding.

lOT FUEL STARTING

IAPOR LOCK CONDITIONS)

hot weather (above 90°F.) if engine is difficult to restart

ter refueling, or shortly after being shut-off, it may be the

suit of vapor lock. This condition will be minimized by

;ing gasoline for the fuel mixture that has been correctly

ended for the season°

this VAPOR LOCK CONDITION should occur the follow-

g procedures will minimize engine restart problems,

. Move "ON-OFF" Switch to "ON" position (Fig, 11)_

Squeeze Throttle Lever and push in on Throttle Detent

, If

(Figs., 11 and 12),

)//_/ STARTER

E

FIGURE 13

3. Push Compression Release Button down and back (Fig, 12).

4, Pull Choke out as far as it will go (Fig. 11).

5. Pull Starter with shor_, r_pid movements until Engine fires,

Push Choke halfway IN and continue starting procedure

until engine runs.

6. Hold at full Throttle and gradually push Choke f_lly in.

A SHO_,T PERIOD OF ENGINE OPERATION AT HALF

CHOKE MAY BE REQUIRED TO CLEAR VAPOR

FROM SYSTEM°

STOPPING

-5 - Flip _ON-OFF" Switch to _'OFF" position (Fig, t t),

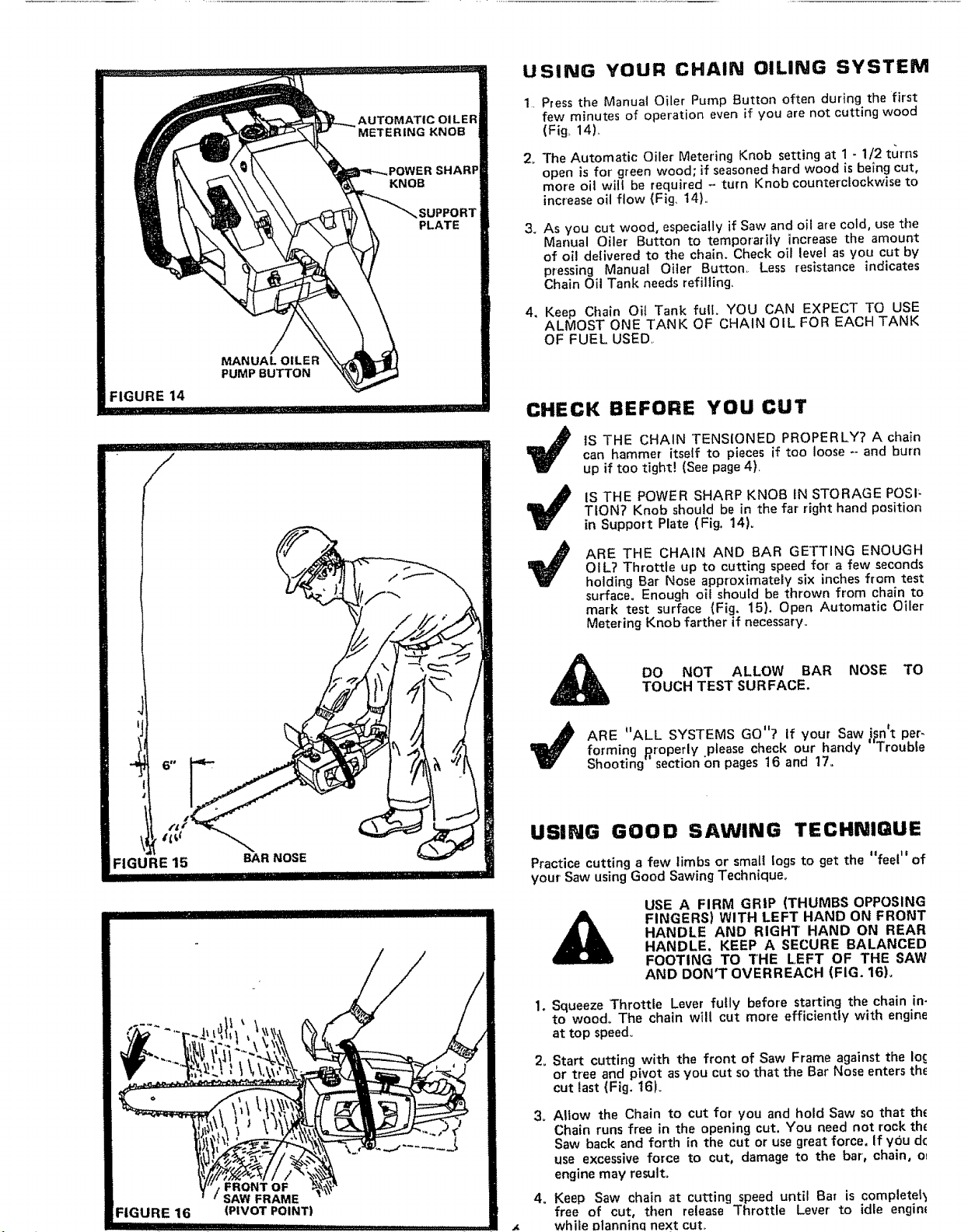

USING YOUR CHAIN OILING SYSTEM

1, Press the Manual Oiler Pump Button often during the first

few minutes of operation even if you are not cutting wood

(Fig, 14).

2+ The Automatic Oiler Metering Knob setting at 1 -1/2 turns

open is for green wood; if seasoned hard wood is being cut,

more oil will be required -* turn Knob counterclockwise to

increase oil flow (Fig, 14)+

3+ As you cut wood, especially if Saw and oil are cold, use the

Manual Oiler' Button to temporarily increase the amount

of oil delivered to the chain. Check oil level as you cut by

pressing Manual Oiler Button, Less resistance indicates

Chain Oil Tank needs refilling.

4, Keep Chain Oil Tank fulI+ YOU CAN EXPECT TO USE

ALMOST ONE TANK OF CHAIN OIL FOR EACH TANK

OF FUEL USED,

CHECK BEFORE

¢

¢

YOU CUT

lS THE CHAIN TENSIONED PROPERLY? A chain

can hammer itself to pieces if too loose -- and burn

up if too tight! (See page 4),

IS THE POWER SHARP KNOB iN STORAGE POSI_

TION? Knob should be in the far right hand position

in Support Plate (Fig. 14)+

ARE THE CHAIN AND BAR GETTING ENOUGH

OIL? Throttle up to cutting speed for a few seconds

holding Bar Nose approximately six inches from test

surface+ Enough oil should be thrown from chain to

mark test surface (Fig. 15}. Open Automatic Oiter

Metering Knob farther if necessary.

DO NOT ALLOW BAR NOSE TO

TOUCH TEST SURFACE.

q_ ARE "ALL SYSTEMS GO"? if your Saw i_n't per-forming Rroperly .please check our handy Trouble

Shooting- section on pages 16 and 17+

USING GOOD SAWING TECHNIQUE

Practice cutting a few limbs or small fogs to get the "feel '_of

your' Saw using Good Sawing Technique,

USE A FIRM GRIP (THUMBS OPPOSING

FINGERS) WITH LEFT HAND ON FRONT

HANDLE AND RIGHT HAND ON REAR

HANDLE. KEEP A SECURE BALANCED

FOOTING TO THE LEFT OF THE SAW

AND DON'T OVERREACH (FIG. 16),

1. Squeeze Throttle Lever fully before starting the chain in-

to wood+ The chain will cut more efficiently with engine

at top speed+

2+ Start cutting with the front of Saw Frame against the Ioc,

or tree and pivot asyou cut so that the Bar Nose enters th_

cut last (Fig. t6)+

3, Allow the Chain to cut for you and hold Saw so that the

Chain runs free in the opening cut. You need not rock th_

Saw back and forth in the cut or use great force, If y0u dc

use excessive force to cut, damage to the bar+,chain, o_

engine may result+

4. Keep Saw chain at cutting speed until Bar is completel_

free of cut, ttmn release Throttle Lever to idle engim

USING GOOD TREE FELLING TECHNIQUE

A SAFE WORKING PROCEDURE IS

YOUR FIRST LINE OF DEFENSE TO-

WARD PREVENTING ACCIDENTS

1. SIZE UP THE TREE.

a. Determine natural felling direction ....

-- toward the direction of natural lean.

-- toward the side with more or heavier branches.,

-- (if heavily leaved) with the direction of the wind.t

b., Avoid felling a tree ....

-- if it shows signs of rot which may make felling unpre-

dictable.

-- if it's natural felling direction must be changed to

avoid obstacles.,

-- if hanging dead limbs (_widov_ makers =_)cannot be

removed before felling.,

-- if wind is strong or gusty.

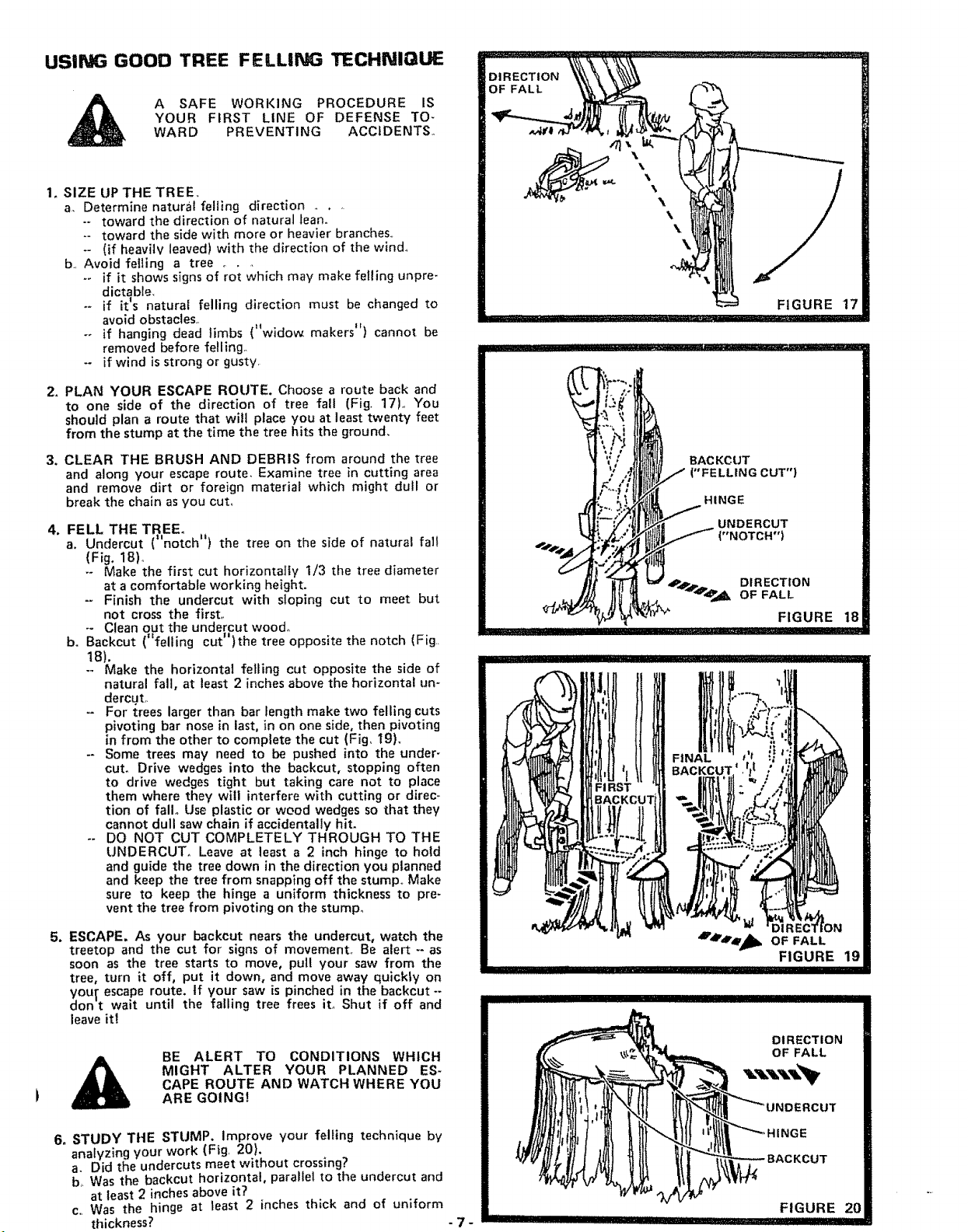

2. PLAN YOUR ESCAPE ROUTE, Choose a route back and

to one side of the direction of tree fall (Fig, 17),, You

should plan a route that will place you at least twenty feet

from the stump at the time the tree hits the ground,

3. CLEAR THE BRUSH AND DEBRIS from around the tree

and along your escape route, Examine tree in cutting area

and remove dirt or foreign material which might dull or

break the chain as you cut_

4. FELL THE T_EE. ,

a. Undercut ( notch ) the tree on the side of natural fall

(Fig. 18),

-- Make the first cut horizontally I/3 the tree diameter

at a comfortable working height.

-- Finish the undercut with sloping cut to meet but

not cross the first,,

-- Clean out the undercut wood.

fl , Ii

b. Backcut ( felling cut )the tree opposite the notch (Fig..

18).

- Make the horizontal felling cut opposite the side of

natural fall. at least 2 inches above the horizontal un-

dercut,,

-- For trees larger than bar length make two felling cuts

pivoting bar nose in last, in on one side. then pivoting

in from the other to complete the cut (Fig. 19).

-- Some trees may need to be pushed into the under-

cut. Drive wedges into the backcut, stopping often

to drive wedges tight but taking care not to place

them where they will interfere with cutting or direc-

tion of fallo Use plastic or wood wedges so that they

cannot dull saw chain if accidentally hit.

-- DO NOT CUT COMPLETELY THROUGH TO THE

UNDERCUT. Leave at least a 2 inch hinge to hold

and guide the tree down in the direction you planned

and keep the tree from snapping off the stump., Make

sure to keep the hinge a uniform thickness to pre-

vent the tree from pivoting on the stump°

5. ESCAPE. As your backcut nears the undercut, watch the

treetop and the cut for signs of movement., Be alert -- as

soon as the tree starts to move, pul! your saw from the

tree, turn it off, put it down, and move away quickly on

you[ escape route. If your saw is pinched in the backcut--

don t wait until the falling tree frees it., Shut if off and

leave itl

BE ALERT TO CONDITIONS WHICH

MIGHT ALTER YOUR PLANNED ES-

CAPE ROUTE AND WATCH WHERE YOU

ARE GOINGI

6. STUDY THE STUMP. Improve your felling technique by

analyzing your work (Fig. 20).

a. Did the undercuts meet without crossing?

b;. Was the backcut horizontal, parallel to the undercut and

at least 2 inches above it?

c,, Was the hinge at least 2 inches thick and of uniform

thickness? -7-

BACKCUT

("FELLING CUT"}

HINGE

UNDERCUT

("NOTCH")

IIIIIIIIIIIIIIIII

Ot RECTION

OF FALL

FIGURE 20

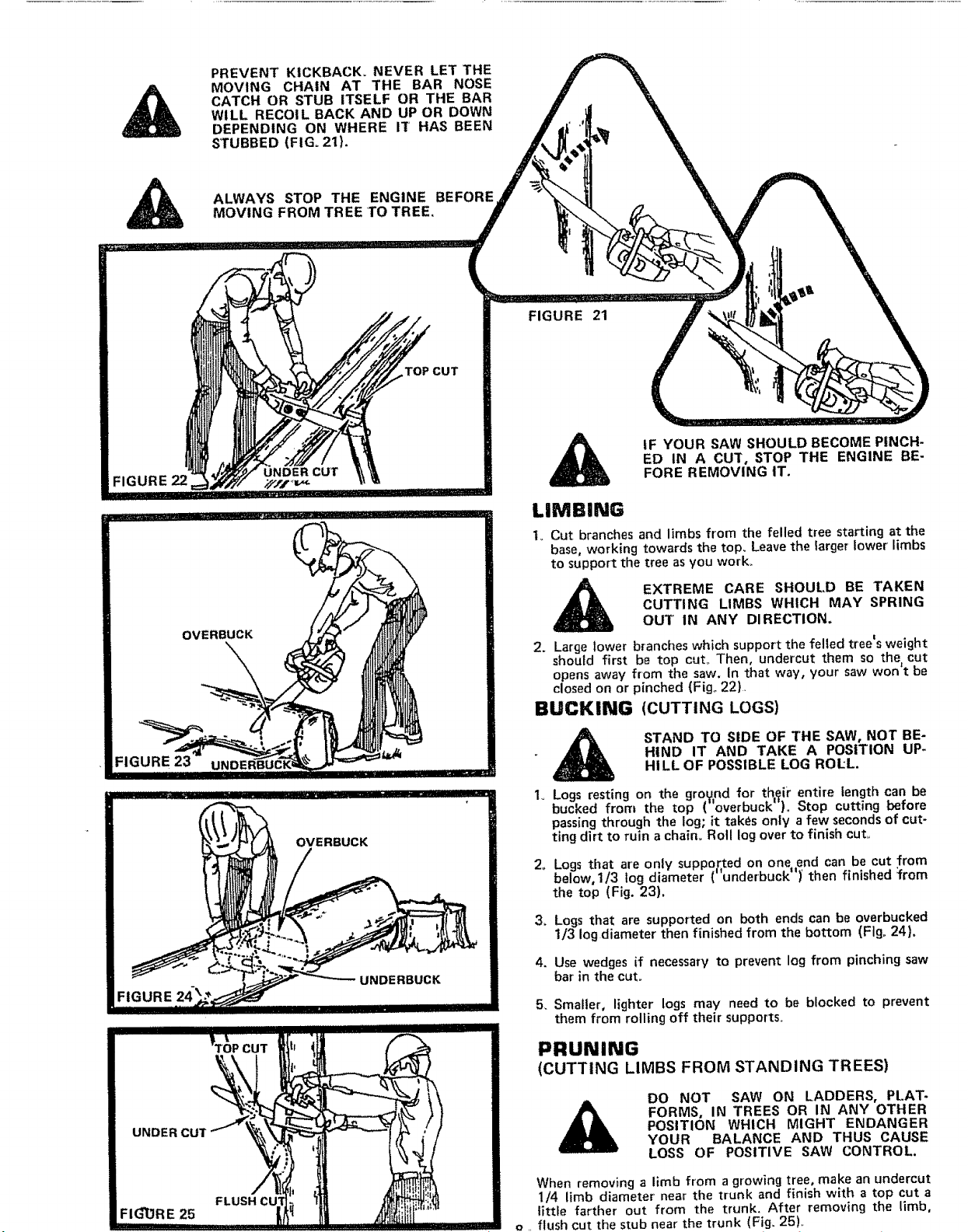

PREVENT KICKBACK. NEVER LET THE

MOVING CHAIN AT THE BAR NOSE

CATCH OR STUB ITSELF OR THE BAR

WILL RECOIL BACK AND UP OR DOWN

DEPENDING ON WHERE IT HAS BEEN

STUBBED (FIG. 21).

ALWAYS STOP THE ENGINE BEFORE

MOVING FROM TREE TO TREE.

FIGURE 22

,TOPCUT

FIGURE 21

IF YOUR SAW SHOULD BECOME PINCH-

ED IN A CUT, STOP THE ENGINE BE-

FORE REMOVING IT.

LIMBING

I,, Cut branches and limbs from the felled tree starting at the

base, working towards the top, Leave the larger lower limbs

to support the tree as you work°

EXTREME CARE SHOUL.D BE TAKEN

CUTTING LIMBS WHICH MAY SPRING

OUT IN ANY DIRECTION,

2. Large lower branches which support the felled tree's weight

should first be top cut° Then, undercut them so the cut

opens away from the saw, n that way, your saw won't be

closed on or pinched (Fig,. 22}.

BUCKING (CUTTING LOGS)

2_

.

4.

STAND TO SIDE OF THE SAW, NOT BE-

HIND IT AND TAKE A POSITION UP-

HILL OF POSSIBLE LOG ROLL.

Logs resting on the ground for their entire length can be

I II |#

bucked from the top ( overbuck ),, Stop cutting before

passing through the log; it takes only a few secondsof cut-

ting dirt to ruin a chain. Roll log over to finish cut,,

Logs that are only suppo,r,ted on one.end can be cut from

below, 1/3 log diameter ('under'buck")' then finished '_rom

the top (Fig. 23),

Logs that are supported on both ends can be overbucked

1/3 log diameter then finished from the bottom (FIgo24).

Use wedges if necessary to prevent log from pinching saw

bar in the cut.

5. Smaller, lighter logs may need to be blocked to prevent

them from rolling off their supports.

PRUNING

(CUTTING LIMBS FROM STANDING TREES)

DO NOT SAW ON LADDERS, PLAT-

FORMS, IN TREES OR IN ANY OTHER

POSITION WHICH MIGHT ENDANGER

YOUR BALANCE AND THUS CAUSE

LOSS OF POSITIVE SAW CONTROL.

When removing a limb from a growing tree, make an undercut

1/4 limb diameter near the trunk and finish with a top cut a

little farther out from the trunk. After removing the limb,

fhJ_h _l_t fh_ _t=lh noor th_ tr_lnk {_';rt _}_

Loading...

Loading...