Cornelius CCM0322, CCM0322AH1 Installation Manual

CCM and CCU Series Installation, Start-up and Maintenance Manual Manual Number 631806051

Nordic Ice Maker

Model CCM and CCU Series

Installation, Start-up and Maintenance Manual

IMI CORNELIUS INC.

www.cornelius.com

Publication Number: 631806051

Revision Date: April 16, 2010

Revision: F

Visit the IMI Cornelius web site at www.cornelius.com

for all your Literature needs.

*

Forward

Page i

How To Use This Manual

Cornelius provides this manual as an aid to the service technician in installation and maintenance of the

CCM and CCU Series cube ice machines. Do not attempt to perform installation, start-up or maintenance unless

you have read and fully understand this manual.

If at any time you encounter conditions that are not addressed in this manual, please contact the Cornelius

Technical Service Department at:

E-Mail: tech.service@Cornelius.com

Website :

www.cornelius.com

Telephone Number

800-238-3600 All Departments

Any Service communication must include:

• Model Number

• Serial number

• A detailed explanation of the problem

Keep this manual for future reference.

The Cornelius CCM and CCU Series Service Parts Manuals are available separately.

Cornelius icemakers and dispensers are not approved for outdoor installation.

WARNING: Always disconnect electrical power and shut off water supply whenever maintenance or

repairs are performed on the ice machine and related equipment.

CAUTION: Always wear protective eyewear whenever maintenance or repairs are performed on the ice

machine and related equipment.

Table of Contents

Page ii

Foreward Page i

Table of Contents Page ii

Freight Claim Procedure Page iii

Model Number and Serial Number Format Page 1

Installation Guidelines Page 2

Remote Condenser Guidelines Page 4

Electrical and Plumbing Requirements Page 6

How the Machine Works Page 13

Start-Up Procedure Page 14

General Maintenance Page 16

Cleaning Procedure Page 17

Cabinet Care Page 18

Winterizing Procedure Page 19

Maintenance Record Page 20

Freight Claim Procedure

Page iii

Freight Claims Important!

Inspect Promptly

This merchandise has been carefully inspected and packed in accordance with the carrier’s packing specifications.

Responsibility for safe delivery has been assumed by the carrier. If loss or damage occurs, you as the consignee must

file a claim with the carrier and hold the container for carrier’s inspection.

Visible Loss or Damage

Any external evidence of loss or damage must be fully described and noted on your freight bill or express receipt and

signed by the carrier’s agent. The claim should be filed on a form available from the carrier.

Concealed Loss or Damage

If loss or damage does not appear until merchandise has been unpacked, make a written request for inspection by the

carrier within 15 days of the delivery date. Then file a claim on a form from the carrier.

File Claim Without Delay

Do Not Return Damaged Merchandise to Cornelius

Model and Serial Number Format

Page 1

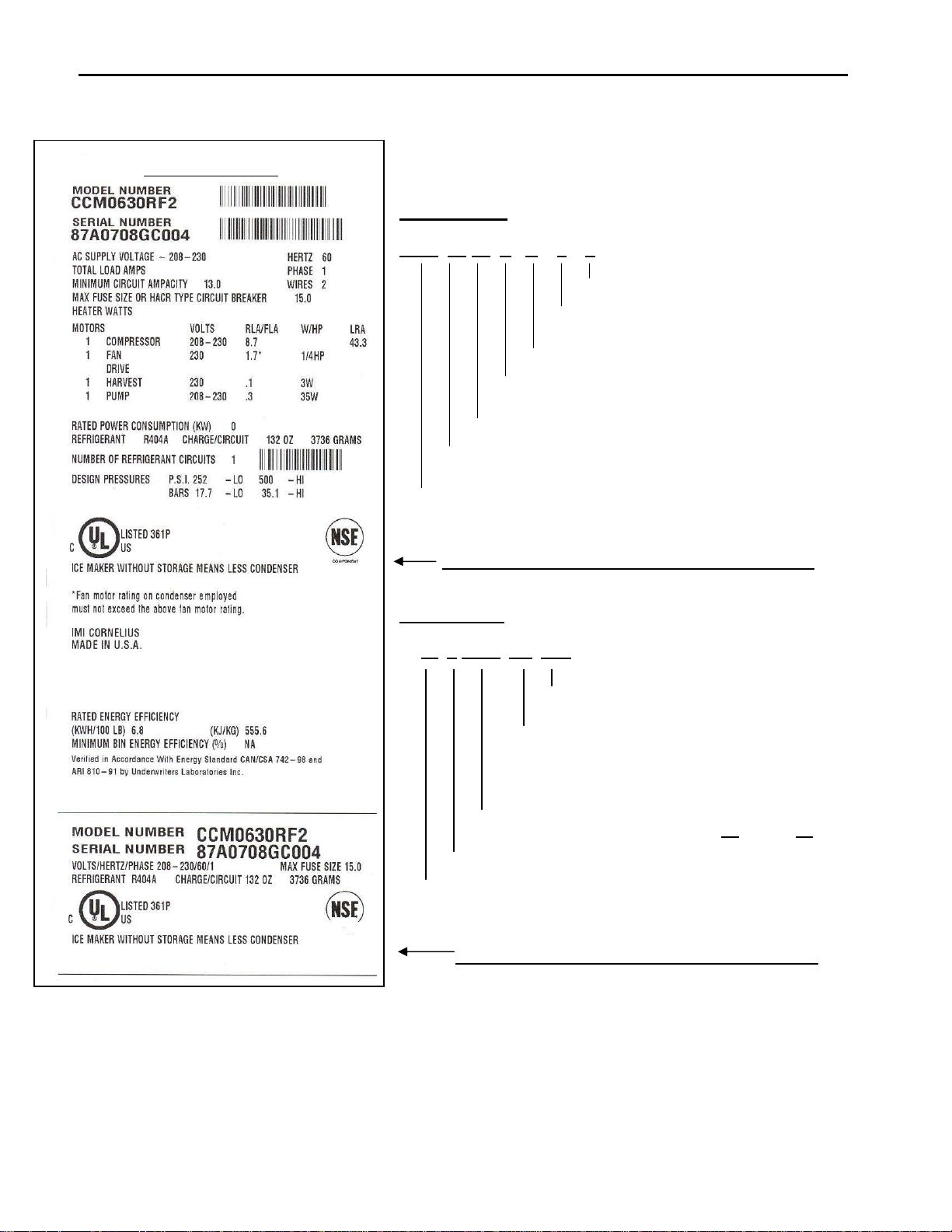

Model and Serial Number Format

The serial number format and machine specifics are detailed on the

data plate.

Model Number

CCM 06 30 A H 1 2

Engineering Rev Level

Voltage:1=115V, 2=230V, 3=230V 3ph 5=50Hz.

Cube Size: H=Half Cube, F=Full Cube

Condenser Type: A=Air, W=Water, R=Remote

Cabinet Width (in inches)

Approximate Production X 100 in 24 hours 70°F Air / 50°F Water

Series: Cornelius Cuber Modular (U=Undercounter)

Large data plate will be placed on the back of the unit.

Serial Number

87

A 0708 GC 004

Sequencial Serial Number

Product Line

GC=Cuber

GB=Remote Condenser

GA= Dispenser

Date Code, Year Month format. (2007

August 08)

Revision Level (Internal)

Manufacturing Facility

Small data plate will be placed by the service valves

.

Sam

p

le Data Plate

Note: The date code will change monthly and yearly to reflect the date of manufacture.

Installation Guidelines

Page 2

Installation Guidelines

For proper operation of the Cornelius ice machine, the following installation guidelines mu st be followed. Failure to do

so may result in loss of production capacity, premature part failures, and may void all warranties.

Reference the installation parameters prior to installing the machine:

Ambient Operating Temperatures

Minimum Operating Temperature: 50°F (10°C)

Maximum Operating Temperature 100°F (38°C), 110°F (43°C) on 50 Hz. Models.

Note: Cornelius icemakers and dispensers are not approved for outdoor installation.

Incoming Water Supply (See Electrical and Plumbing Diagrams for line sizing)

Minimum incoming water temperature: 40°F (4.5°C)

Maximum incoming water temperature: 100°F (38°C)

Minimum incoming water pressure: 20 psi (1.4 bar)

Maximum incoming water pressure: 60 psi (4.1 bar)

Note: If water pressure exceeds 60 psi (4.1 bar), a water pressure regulator must be installed.

Drains

All drain lines must be installed per local codes. Flexible tubing is not recommended. Route bin drain, purge drain and

water condenser drain individually to a floor drain. The use of condensate pumps for draining water is not

recommended by Cornelius. Cornelius assumes no responsibility for improperly installed equipment.

Note: The purge drain fitting is plastic; DO NOT apply heat to the purge drain area; DO NOT over tighten.

Water Filtration

A water filter system should be installed with the ice machine.

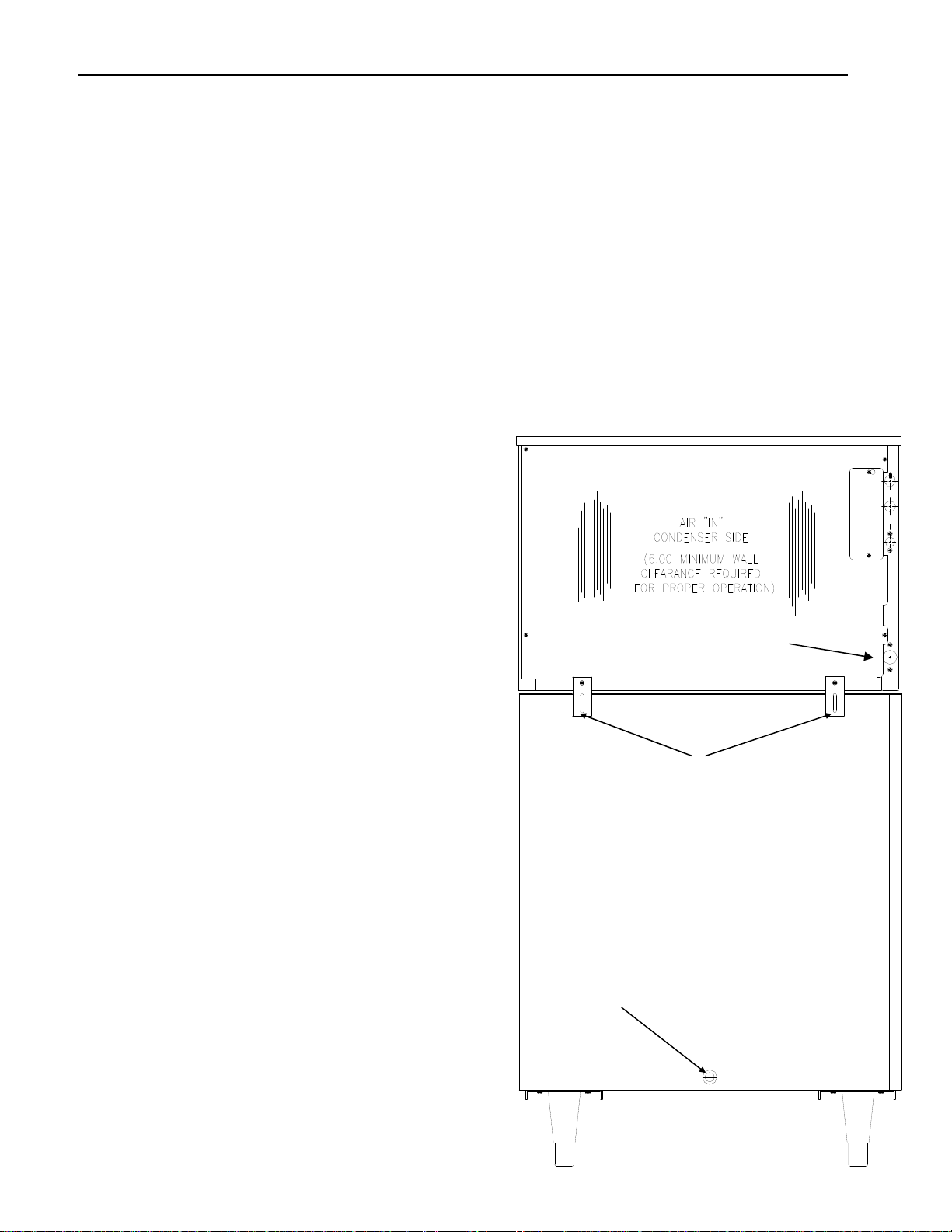

Clearance Requirements

Self-contained air cooled ice machines must have a minimum of 6 inches (15cm) of clearance at the rear, top, and

sides of the ice machine for proper air circulation.

Stacking

If the ice machines are to be stacked, refer to the instructions in the stacking kit. Cornelius does not endorse stacking

air-cooled ice machines.

Dispenser Application

A thermostatic bin control kit should be installed if the CCM Series ice machine is placed on a dispenser. A bin top

may or may not be required. (Exception is the CHD22 and CHD30 Series Dispenser)

Electrical Specifications

Refer to the serial plate at the rear of the ice machine to make sure proper voltage and circuit breaker size have been

supplied. Make sure the machine is on a dedicated circuit. European installations require that the electrical supply

fixed wiring must be provided with a disconnect means having a separation of at least 3mm in all poles. The ice

machines are provided

without an electrical cord set and are designed and agency approved to be permanently

connected.

The 115 volt Undercounter series ice makers are supplied with an electrical cord, all other ice makers will

need to be installed and wired per local electrical codes.

CAUTION: Electrical connection must be made or a cord installed by a

qualified electrician or there is danger of an

electrical fire.

Adjustments

Level the machine within 1/8 inch in all directions.

Check the bin control for proper adjustment.

Check the water in the water trough for proper level.

Check the ice bridge for proper thickness.

Check the water regulating valve adjustment if water cooled.

Installation Guidelines

Secure the machine on top of the bin or dispenser.

Attach the ice machine to the bin with the mounting straps provided with the bin or dispenser. Insure that the back of

the ice machine is flush with the back of the bin. Proper functioning of the bin door requires the bin door, when it is

opened, to be in a stable position.

If the ice machine is too far forward on the bin, the opened door may not be stable, resulting in an unexpected closing

of the bin door. If the ice machine is to be mounted on a bin or dispenser other than a Cornelius, refer to the

manufacturers instructions for machine mounting. Cornelius will not be responsible for damage or injury that results

from unexpected closing of the bin door as a result of the ice machine being too far forward on the bin.

If the ice machine is to be stacked on top of another ice machine, a stacking kit will need to be installed. Refer to the

installation instructions included with the stacking kit.

Important!

A water filtration system should be installed with all ice machines. Check the filter manufacturer's instructions for

proper installation.

All water supply lines must be installed per local codes.

Use 1/4 inch O.D. minimum on air cooled machines. On

water cooled machines 3/8 inch O.D. minimum tubing

must be run to the condenser. The water supply for the

float can “T” off from the condenser line using 1/4 inch

O.D. minimum tubing. Make 2 coils of extra tubing so that

the machine can be pulled away from the wall if service is

needed.

Page 3

All drain lines must be installed per local codes. The

purge drain should be a minimum of 5/8 inch O.D. tubing.

The condenser drain on water cooled units should be 3/8

inch O.D. minimum. The drain line fittings on Cornelius

bins are 3/4 FPT. The bin drain should be a minimum of

3/4 inch O.D. Cold water drains should be insulated to

prevent condensation from forming.

IMPORTANT!

Attach the ice machine to the bin or

dispenser with the provided

mounting hardware. Insure the back

of the ice machine is flush with the

back of the bin.

Warning!

Do not apply heat directly to the

back of bin as damage may occur

to plastic parts.

Warning! Do not over-tighten as

damage may occur to plastic

parts

Warning!

Do not apply heat directly to the back of bin as damage

may occur to plastic parts.

Do not over-tighten the purge drain fitting as damage

may occur to plastic parts.

Connect power supply to the terminal block in the control

box or at the rear junction box if equipped.

Ensure the machine is level within 1/8 inch in all

directions.

Remove any shipping or packaging material.

If the machine has a remote condenser, reference the

Remote Condenser Installation Guidelines.

Once the machine has been installed, follow the

start-up procedures.

Loading...

Loading...