Cornelius ABS Operator’s Manual

OPERATOR’S MANUAL

AUTOMATED BEVERAGE SYSTEM

This equipment chapter is to be inserted in

the Beverage Systems section of the

Equipment Manual.

MANUFACTURED

EXCLUSIVELY FOR

McDONALD’S

®

BY

IMI CORNELIUS

PHONE (800) 238-3600

www.cornelius.com

FOR SERVICE CALL

COKE SMILE

1-800-241-COKE

TABLE OF CONTENTS

WARRANTY ............................................................................................................................Page 2

INTRODUCTION .....................................................................................................................Page 4

SAFETY...................................................................................................................................Page 4

PARTS IDENTIFICATION/FUNCTION ....................................................................................Page 5

OPERATION MODES..............................................................................................................Page 11

AUTOMATIC OPERATION..................................................................................................Page 12

SEMIAUTOMATIC OPERATION .........................................................................................Page 17

MANUAL OPERATION........................................................................................................Page 19

MAJOR SUBSYSTEMS...........................................................................................................Page 23

DAILY START-UP ....................................................................................................................Page 39

CLOSING/SANITATION PROCEDURES ................................................................................Page 41

DAILY CLEANING PROCEDURES.........................................................................................Page 44

MONTHLY ...............................................................................................................................Page 45

QUARTERLY CLEANING/SANITATION PROCEDURES .......................................................Page 46

TROUBLESHOOTING.............................................................................................................Page50

WIRING & PNEUMATIC DIAGRAMS ......................................................................................Page 55

Part No. 569000181OPR

April 21, 2004

Revision: D

Revised: July 29, 2005

This manual is for the exclusive use of licensees and employees of McDonald’s Systems, Inc.

© 2004-2005 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

Printed In

The United States of America

Automated Beverage System

McDonald’s Automatic Beverage System

WARRANTY, DISCLAIMER OF WARRANTY AND LIMITATION OF REMEDY

Products covered by this Warranty include only Automatic beverage Dispenser (“ABS”) manufactures or sold by Cornelius after the date hereof (herein “Products”). THE TERM “PRODUCTS” DOES NOT INCLUDE, AND THIS WARRANTY IN NO EVENT EXTENDS TO,

ITEMS NOT MANUFACTURED OR SOLD BY CORNELIUS, SUCH AS ANY POS SYSTEMS (INCLUDING CABLE CONNECTING THE POS TO THE ABS) AND ANY

RECIRCULATING SYSTEM SUPPLYING CO2 WATER, WATER OR SYRUP TO THE

ABS.

WARRANTY

IMI Cornelius Inc., (Cornelius”) warrants to the original McDonald’s purchaser with respect

to each product purchased that:

1. For the lesser of (i) two (2) years from the date of installation or (ii) twenty seven (27) months from the date

of shipment by Cornelius, all parts comprising such Product (except Excluded Parts as defined below and

the refrigeration system of the precooler) are free from defects in materials;

2. For the lesser of five (5) years from the date of installation or sixty-three (63) months from the date of shipment by Cornelius (and subject to the service limitation set forth below), the parts (except Excluded Parts)

comprising the refrigeration system of the precooler of such Product, being only the compressor, evaporator,

condenser, and interconnecting tubing (but not access valves or any other part) are free from defects in materials; and

3. For the lesser of one (1) year from the date of installation or (ii) fifteen (15) months from the date of shipment by Cornelius that such Product conforms with those industry, government, or professional organizations standards to the extent expressly set forth in written product information disclosures in Cornelius

product literature and documentation;

Provided that the foregoing shall not apply to any warranty claim not made as promptly as possible and in any

event within thirty (30) days after the discovery thereof to the Cornelius Service Department at 101 Broadway

Street West, Osseo, MN, (800) 238-3600.

For the purposes of the foregoing warranties, “Excluded Parts” include all water filter cartridges, coin mechanisms, light bulbs, fuses, glass diaphragms, seals, o-rings, silicone or rubber parts, parts in contact with water or

the product dispensed and which become inoperative due to scale or chemical change, as well as normal maintenance items.

All service warranty claims above $400 require Cornelius authorization prior to repair/replacement. If service

occurs outside the standard Cornelius business hours, claim will be denied if part(s) are not returned and/or

returned are not found to be defective upon further inspection. See next paragraph.

It is not a defect, and thus these warranties do not apply to, repair, replacement or other service required by or

loss or damage resulting from (i) other that normal and proper use and service conditions with respect to such

Product, (ii) use of the product other that exclusively with soft drinks, soft drink syrup, or iced tea identified in

wring by Cornelius, (iii) improper voltage, (iv) inadequate wiring, (v) abuse, (vi) accident, (vii) alteration, (viii)

risk of transportation, (ix) misuse, (x) neglect, (xi) unauthorized repair, (xii) fire, flood or other acts of God, (xiii)

improper cleaning, or failure to follow installation, operating, or maintenance instructions, nor does these Warranties cover normally prescribed maintenance, cleaning, and adjustments.

IMI CORNELIUS

www.cornelius.com

2

© 2004-2005 The Coca-Cola Company, Cornelius

and McDonald’s Corporation. All Rights Reserved.

Automated Beverage System

Disclaimer of Warranty

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WARRANTIES OF MERCHANTABLITY AND FITNESS FOR A PARTICULAR PURPOSE, ALL

OF WHICH OTHER WARRANTIES ARE HEREBY DISCLAIMED AND EXCLUDED.

Remedy, Limitation of Remedy and Disclaimer of Liability

The remedy for any breach of this Warranty is limited to the repair or replacement or the defect part or the Product in which it is included, at the option of Cornelius. to the extent that, in the judgement of Cornelius, repair or

replacement should be performed through on-site service, such service is included in the Warranty for the lesser

of two (2) years from the date of installation or (ii) twenty seven (27) months from the date of shipment by Cornelius, and even then only to the extent of scheduled straight time labor to repair or replace the defective part and

travel time to destination ($40 per claim maximum). Such service is to be performed by a service agency authorized by Cornelius. Time and rate schedules for labor compensation will be published periodically by Cornelius.

Additional expenses including, but not limited to truck charges, overtime charges, material costs, are not the

responsibility of and will not be paid by Cornelius. Neither any part alleged to be defective and covered by this

warranty or the product in which it is included shall be returned to Cornelius without authorization from the Cornelius Service Department. The instructions for return will be given with any such authorization. All returned

parts and/or Products must be shipped prepaid to Cornelius. Return shipping costs of repaired or replacement

parts or Products will be prepaid by Cornelius, except that as to original purchasers in Alaska or Hawaii, Cornelius will pay shipping cost only to Seattle or San Francisco, respectively. Cornelius will not accept collect shipments. Replaced products or parts become property of Cornelius. Any product or parts returned to Cornelius

under the terms of this Warranty must be accompanied by a Returned Goods Authorization Number.

THE SOLE AND EXCLUSIVE REMEDIES FOR BREACH OF ANY OBLIGATION OF CORNELIUS

AND THE SOLE REMEDIES FOR CORNELIUS’ LIABILITY OF ANY KIND (INCLUDING LIABILITY FOR NEGLIGENCE) WITH RESPECT TO THE PRODUCTS AND RELATED SERVICES

SHALL BE THE REMEDY SET FORTH HEREIN, OR IF NO SUCH REMEDY APPLIES, THEN TO

USE REASONABLE EFFORTS TO PROMPTLY CURE SUCH BREACH.

IN NO EVENT SHALL CORNELIUS’ LIABILITY OF ANY KIND INCLUDE ANY SPECIAL, INDIRECT, PUNITIVE, INCIDENTAL OR CONSEQUENTIAL LOSS OR DAMAGE, EVEN IF CORNELIUS SHALL HAVE BEEN ADVISED OF THE POSSIBILITY OF SUCH POTENTIAL LOSS OR

DAMAGE.

CORNELIUS CUMULATIVE LIABILITY FOR DAMAGES UNDER OR IN RELATION TO A PRODUCT AND RELATED SERVICES FOR ANY CAUSE WHATSOEVER, AND REGARDLESS OF THE

FORM OF ACTION; WHETHER IN CONTRACT ON IN TORT INCLUDING NEGLIGENCE, SHALL

BE LIMITED TO THE COST OF SUCH PRODUCT.

No alteration or modification of the terms and conditions of this Warranty shall be valid unless expressly agreed

to in writing by Cornelius. Any different, additional, or conflicting terms or condition set forth in any order confirmation of other writing are expressly objected to by Cornelius and the terms of this Warranty shall exclusively

govern warranties and remedies with respect to the Products.

IMI CORNELIUS

www.cornelius.com

3

© 2004-2005 The Coca-Cola Company, Cornelius

and McDonald’s Corporation. All Rights Reserved.

Automated Beverage System

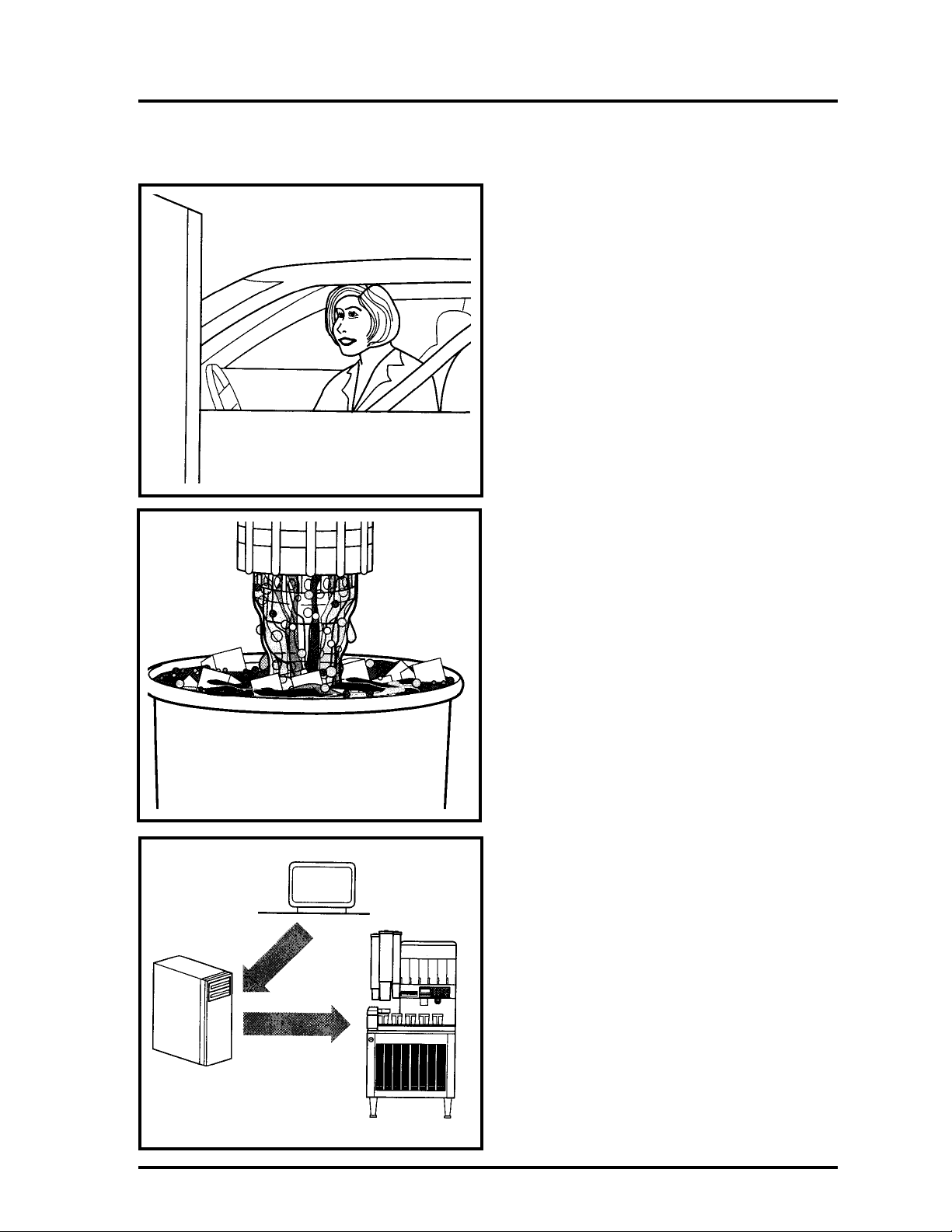

INTRODUCTION

The Automated Beverage System (A.B.S.) is

an automated cold beverage dispenser for

drive-thru applications. When a cold beverage

is ordered from the P.O.S. register, the A.B.S.

will automatically drop the cup, fill it with ice,

and dispense the correct amount and type of

any syrup-based cold beverage. The finished

drink is then moved by the conveyor to the

pick-up station and the drink description is

displayed on the panel.

The Automated Beverage System has three

modes of operation:

• Automatic Mode

In automatic mode, the customer places an

order at the drive-thru and the A.B.S.

automatically produces the order. If extra or

no ice drinks are ordered, they are entered

from the P.O.S. as a “grill order” and the

A.B.S.automatically produces the drink as

ordered.

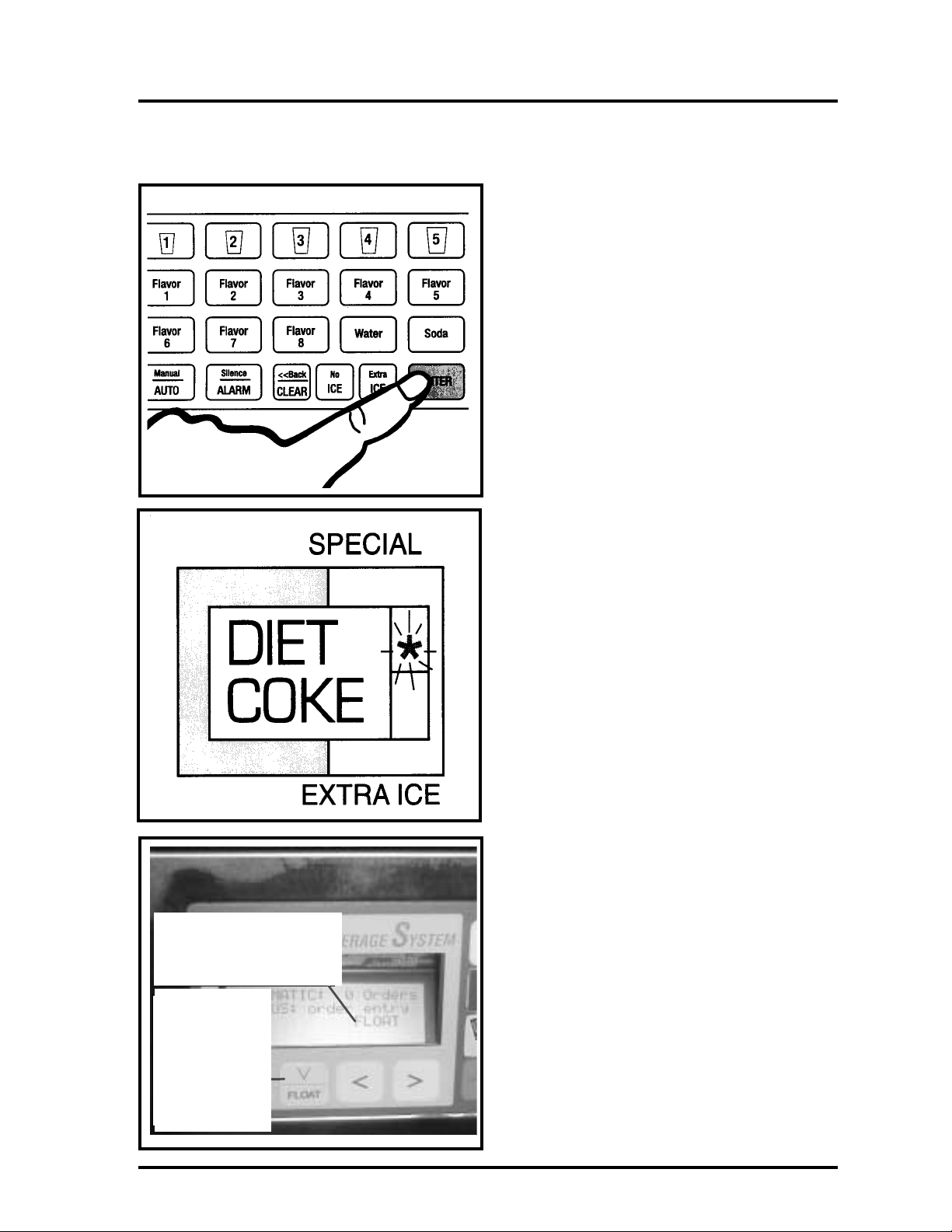

• Semiautomatic Mode

While in automatic mode, the operator

presses the desired cup size button, the desired

flavor button and ENTER, then the drink is

dispensed. If extra ice or no ice is required,

the EXTRA ICE or NO ICE button is pressed

after the flavor button has been pressed before

ENTER, then the drink is dispensed.

• Manual Mode

A drink can also be dispensed in manual

mode. Remove the conveyor. Enter the manual mode by pressing the Manual/Auto button.

(Don’t pull cups from A.B.S. Turret damage

may occur to cup tubes.) Locate a sleeve of

cups and remove a cup. Hold the cup under

the ice chute, press EXTRA ICE and ice is

dispensed. Hold the cup under the nozzle,

press and hold the desired flavor button, and

the drink is dispensed. Reinstall the conveyor

and return the A.B.S. unit to normal operation.

SAFETY

To avoid possible fatal electrical shock or serious injury to the Operator, it is highly recommended that a G.F.I. (ground fault circuit

interrupter) be installed in the electrical power

circuits to the unit.

Always disconnect power before cleaning or

servicing the unit. Do not use metal scrapers,

sharp objects or abrasives on the ice storage

hopper, top cover and the agitator disk, as

damage may result.

Always disconnect CO2 or air pressure to the

unit before cleaning or servicing the grabber

arm or ice chute. A disconnect switch for the

ice gate is located on the control box behind

the cup lid holder panel.

Insure that the unit is in manual mode before

removing or replacing the conveyor assembly

to avoid pinching fingers in the drain area.

The dispenser is very top heavy. To prevent

serious injury, exercise caution when moving

or setting the dispenser in place.

© 2004 The Coca-Cola Company, Cornelius

and McDonald’s Corporation. All Rights Reserved.

4

Automated Beverage System

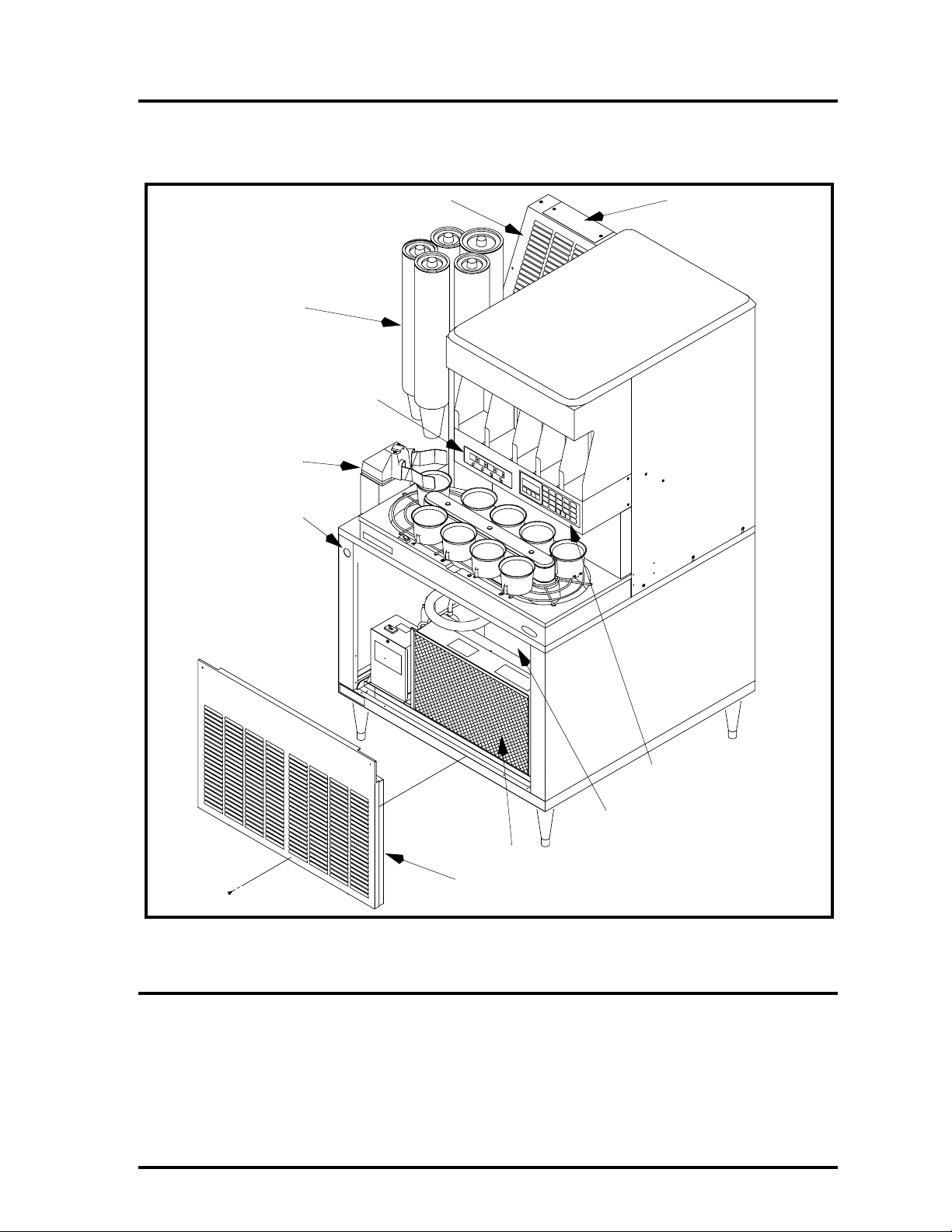

Illustrated Parts List

A.B.S. Unit Access

TURRET

FLAVOR DISPLAY

CUP GRABBER

ON/OFF SWITCH

1

2

CONTROL PANEL

OPTIONAL PRECHILLER

3

4

Automated Beverage System —

Assembled Unit Diagram

Ref CCUSA MFG.

Number Number Number Description

1 .................... ................ 560000260.....Ventilation Grill

PRINTED ON RECYCLED PAPER

2 .................... ................ 560000245.....Access Hole Cover

10% Post-Consumer Content

3 .................... ................ 560000291.....Air Filter

40% Pre-Consumer Content

4 .................... ................ 560000289.....Front Panel (Built before Serial No. 56A0019AB102)

...................... ................ 560002774.....Front Panel (Serial No. 56A0019AB102 and after)

© 2004-2005 The Coca-Cola Company, Cornelius

and McDonald’s Corporation. All Rights Reserved.

5

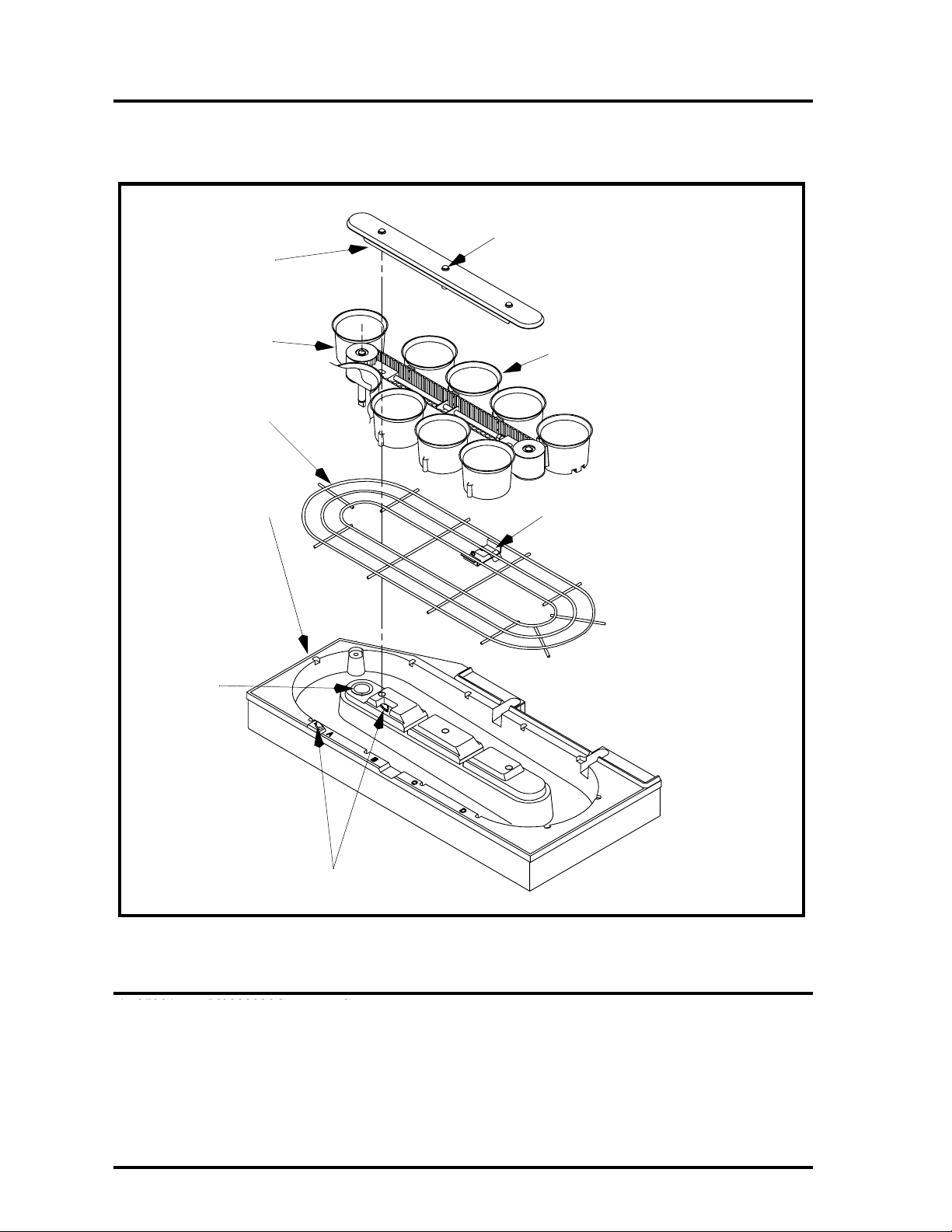

Automated Beverage System

Illustrated Parts List

Conveyor Assembly

1

THUMB SCREWS

2

3

4

5

CUP HOLDER

CUP POSTIONING BRACKET

POSITION “A” SENSOR

Automated Beverage System —

Ref CCUSA MFG.

Number Number Number Description

1 27921 ...... 560000320Conveyor Cover

1 ................ 27921........... 560000320 ...... Conveyor Cover

2 .............. 27922...................560000325 ..............Conveyor Assembly

2 ................ 27922........... 569000295 ...... Conveyor Assembly

3 .............. .............................560000315 ..............Cup Rest

3 ................ .....................560000315 ...... Cup Rest

4 .............. .............................560000306 ..............Drip Tray Assembly

4 ................ .....................560000306 ...... Drip Tray Assembly

5 ................ 20669........... 560002714 ...... Water Deflector

Conveyor/Cup Rest Assembly Diagram

6

© 2004-2005 The Coca-Cola Company, Cornelius

and McDonald’s Corporation. All Rights Reserved.

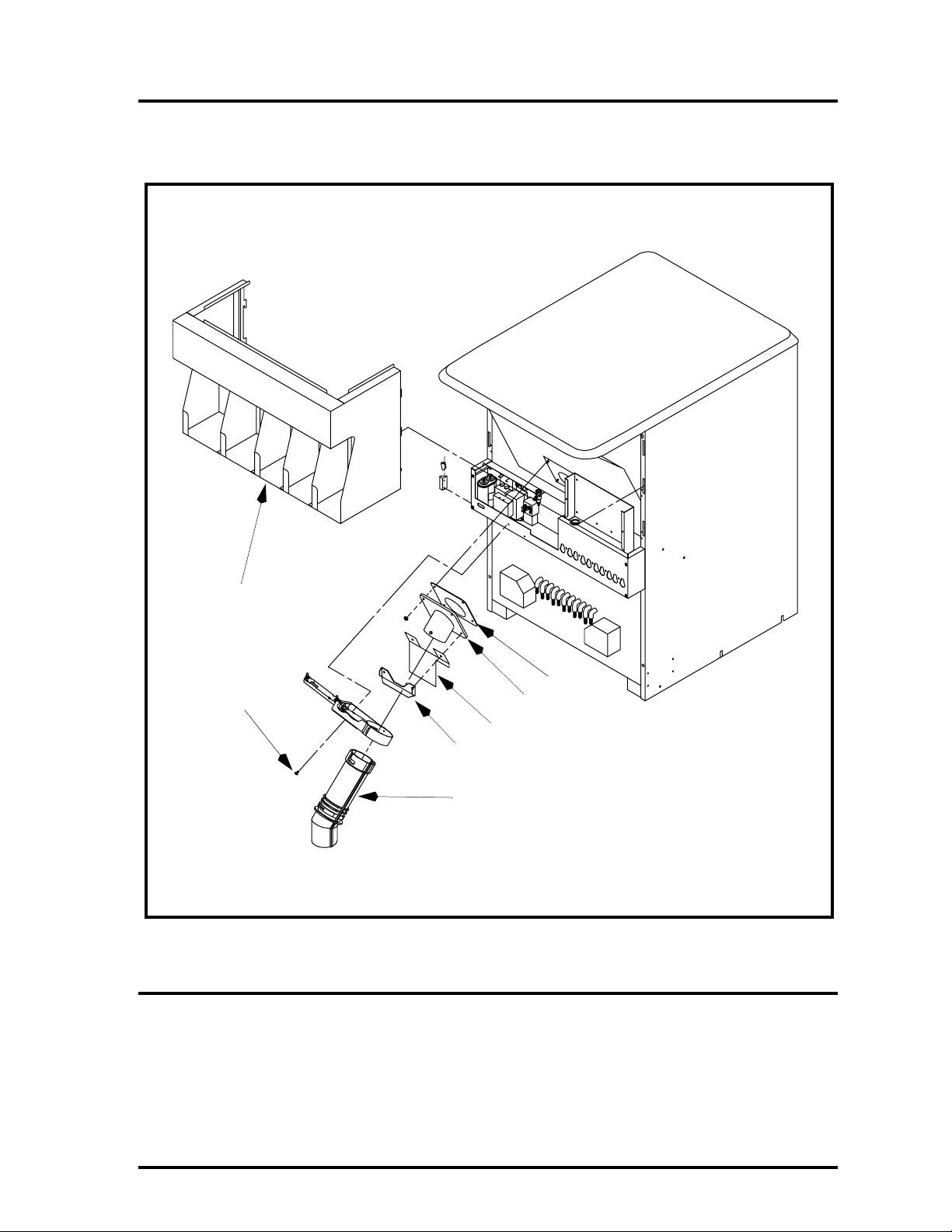

Automated Beverage System

Illustrated Parts List

Ice Chute Assembly

7

1

5

4

3

Automated Beverage System —

Ref CCUSA MFG.

Number Number Number Description

1 ................ ...................560000392..... Ice Chute Gasket

2 ................ ...................560000344..... Ice Chute Mounting Plate

3 ................ 27926......... 560000346..... Ice Chute

4 ................ ...................560002728..... Ice Chute Stiffener

5 ................ ...................560000398..... Machine Screw, Phillips Truss Head, No. 8 x .5”

6 ................ ...................560001548..... Ice Chute Shield

7 ................ ...................620014801..... Lid Holder Assembly

8 ................ 28076.........560001589..... Ice Chute Cleaning Brush (Not Shown)

Ice Chute Assembly Components Diagram

2

6

© 2004-2005 The Coca-Cola Company, Cornelius

and McDonald’s Corporation. All Rights Reserved.

7

Automated Beverage System

Illustrated Parts List

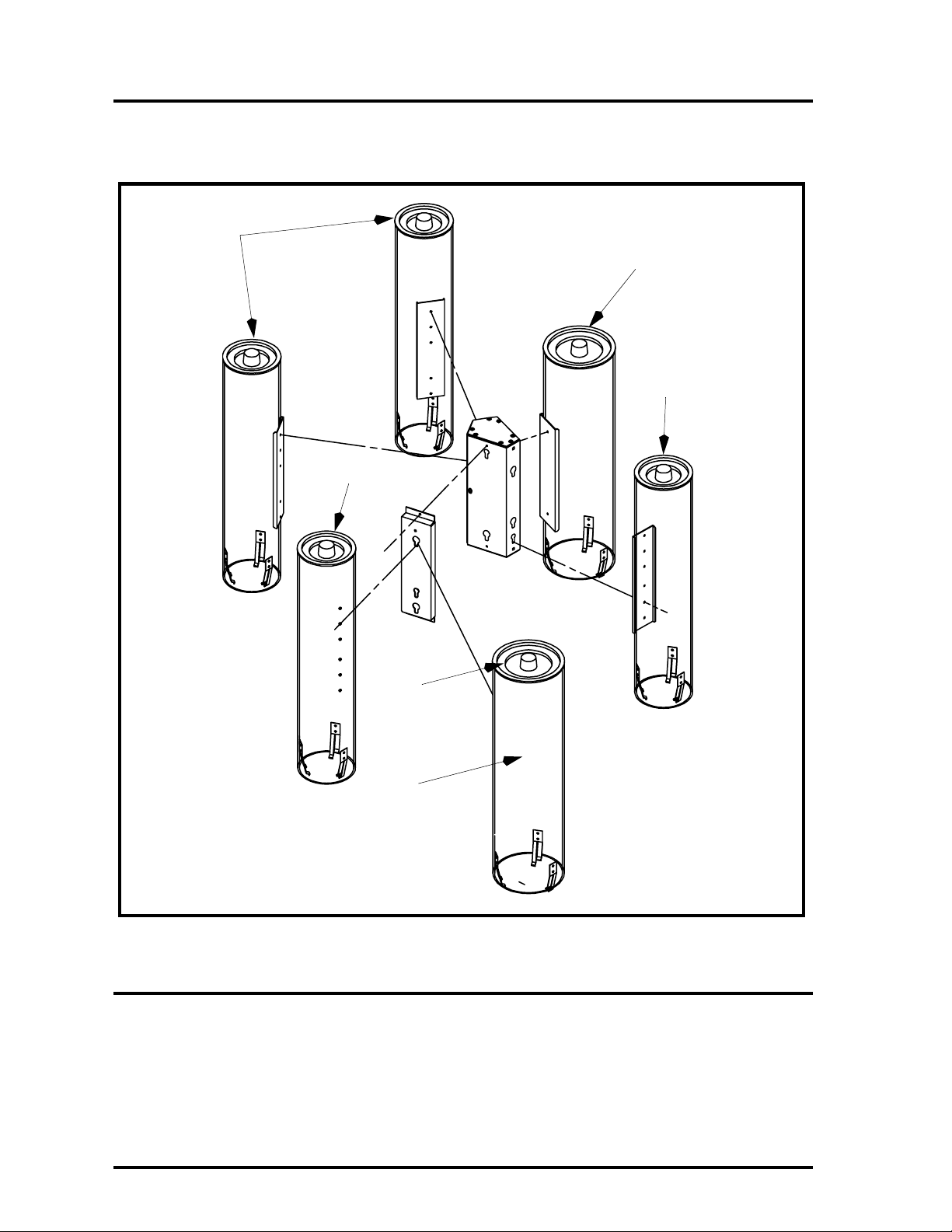

Cup Tube Assembly

2

2

1

2

1

3

Automated Beverage System —

Ref CCUSA MFG.

Number Number Number Description

1 ..............27916 ..........560000207 .......5” Cup Tube Cover (32 - 42 oz.)

2 ..............27915 ..........560000206 .......4” Cup Tube Cover (12 - 21 oz.)

3 ..............28377 ..........569000199 .......42 Oz. Cup Tube Kit

N/R .........28373 ..........569000172 .......12 Oz. Cup Tube Assembly Kit (Australian “Small” size)

N/R .........28374 ..........569000173 .......16 Oz. Cup Tube Assembly Kit (Australian “Medium” size, station 3)

N/R .........28375 ..........569000174 .......21 Oz. Cup Tube Assembly Kit (Australian “Large” size, station 1)

N/R ......... ....................569000175 .......32 Oz. Cup Tube Assembly Kit

N/R ......... ....................569000159 .......21 Oz. Cup Tube Assembly Kit (Australian “Large” size, station 2)

N/R ......... ....................569030035 .......Medium Cup Tube Assembly Kit Station 5, (Australian ABS only)

8

Cup Tube Components Diagram

© 2004-2005 The Coca-Cola Company, Cornelius

and McDonald’s Corporation. All Rights Reserved.

Automated Beverage System

Illustrated Parts List

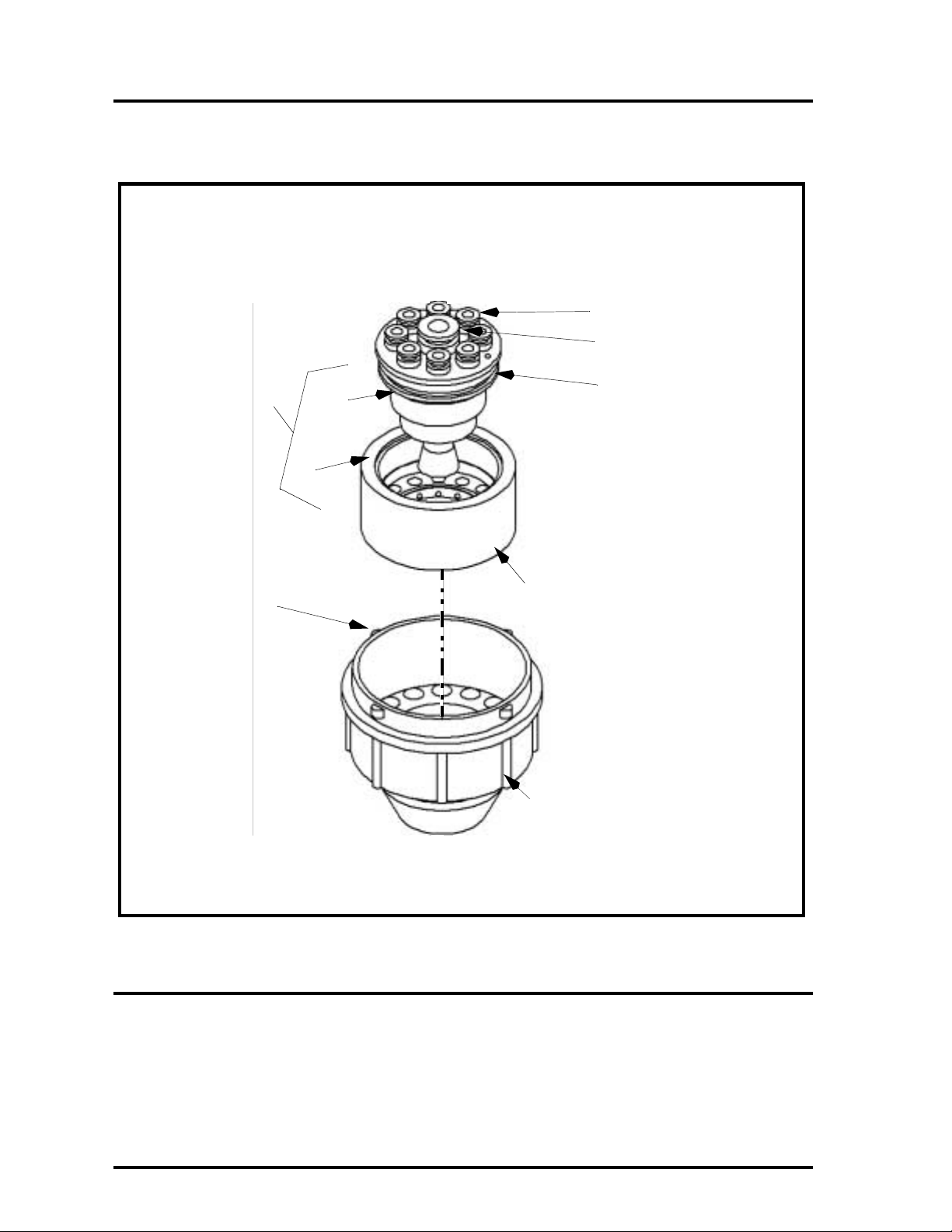

Agitator Assembly

2

4

3

1

Automated Beverage System —

Ref CCUSA MFG.

Number Number Number Description

1 ............... ............................15346 ...................... Agitator Assembly

1 .............. 15346................................Agitator Assembly

2 ............... ............................52887 ...................... Lid

2 .............. 52887................................Lid

3 ............... ............................53227 ...................... Disk

3 .............. 53227................................Disk

4 ............... ............................15087 ...................... Agitator Retainer

4 .............. 15087................................Agitator Retainer

© 2004-2005 The Coca-Cola Company, Cornelius

and McDonald’s Corporation. All Rights Reserved.

Ice Bin Components Diagram

9

Automated Beverage System

Illustrated Parts List

Nozzle Assembly

3

4

2

1

1

2A

2B

DIFFUSER BODY

DIFFUSER RING

5

Automated Beverage System —

Ref CCUSA MFG.

Number Number Number Description

.................. 161509 ................Complete Assembly

1................27940 560001545 .......... Nozzle

2................27939 560001544 .......... Diffuser

3................ 110677000 ..........O-Ring

6................ 325216000 ..........Nozzle Brush (Not Shown)

Nozzle Assembly Components Diagram

10

© 2004-2005 The Coca-Cola Company, Cornelius

and McDonald’s Corporation. All Rights Reserved.

Operational Modes

The A.B.S. has three modes of operation:

• Automatic (Normal Operation)

• Semi-Automatic (while in Auto)

•Manual

Automated Beverage System

Fully Automatic Operation

*Drink Position Display

Cup Extraction Position

Ice Fill Position

Beverage Fill Position

Conveyor Positions

*Drink Position Display - Showing Drink Locations in Conveyor

AN * IS DISPLAYED WHEN A

SPECIAL

DRINK IS DISPENSED FROM THE

A.B.S. PANEL INSTEAD OF THE

POS SYSTEM.

*

COKE

EXTRA ICE

A

B

C

D

SPECIALSPECIAL

EXTRA ICE

AB

EXTRA ICE

SPECIAL

COKE

EXTRA ICE

C

SPECIAL

EXTRA ICE

#

SPECIAL

EXTRA ICE

D

A # IS DISPLAYED

FOR ANY DRINK DISPENSED

WITH EXTRA ICE.

Location Diagram

© 2004-2005 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

11

Automated Beverage System

Automatic Operation

Order Entered On P.O.S.

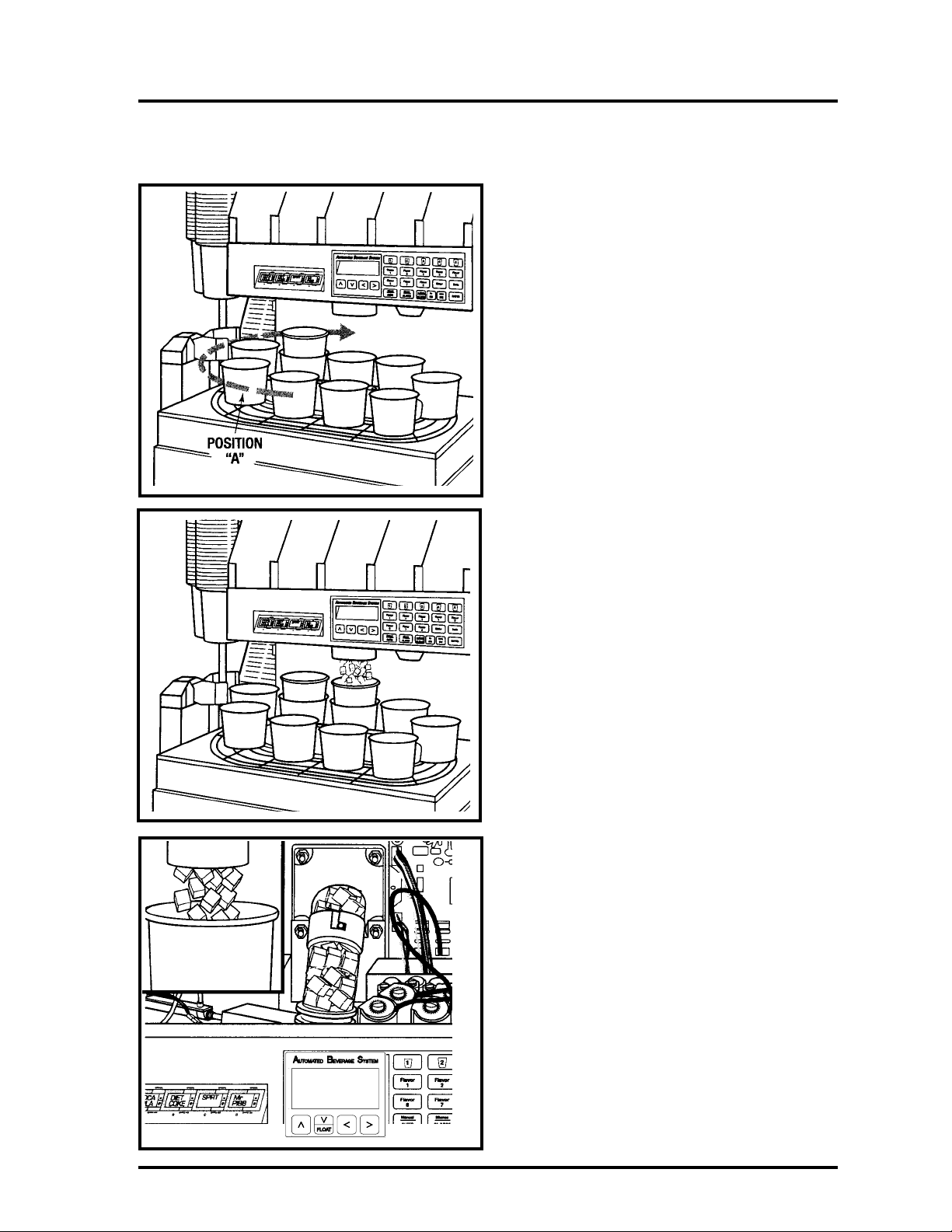

With the unit in automatic mode, the customer

places an order at the Drive-Thru.

Special Ice Drinks

Extra and no ice drinks are entered from the

P.O.S. as a “grill order.” The A.B.S. will automatically produce the drink to the special

order.

P.O.S. Signal To Manager’s Computer

The order is transmitted from the P.O.S. to the

store computer and from there to the A.B.S.

unit.

12

© 2004-2005 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

Automated Beverage System

Cup Turret Rotates

The cup turret rotates to move the proper size

cut to the extract position.

Automatic Operation

Cup Grabber Rises & Closes

The cup grabber is lifted by a pneumatic cylinder up to the cup. The travel is sensed by the

full travel sensor. If full height is reached, a

pneumatic cylinder closes the grabber arms

against the cup. A sensor detects if cups are

available.

Grabber Lowers & Opens

The cup grabber lowers, pulling the cup from

the cup tube and then the arms open dropping

the cup into the conveyor.

If the grabber should slide off a cup, it would

be detected by the cup sensor.

© 2004-2005 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

13

Automated Beverage System

Automatic Operation

Conveyor Operates

Sensors check for a cup in position “A.” If the

sensor is clear, the conveyor rotates clockwise

to move the cup to the ice chute.

This is based on only one drink being ordered.

If a second drink had been ordered, the conveyor would have moved only one position

and the second cup would have been extracted

and dropped into the conveyor. The two cups

would then be moved clockwise until the first

cup reaches the ice fill port.

Ice Portion Is Dispensed

The ice gate is opened by a pneumatic cylinder for the time needed to dispense the

selected ice portion. Correct operation is

insured by the ice gate full travel sensor.

14

The agitator continues to operate for the set

refill time to refill the ice chute.

© 2004-2005 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

Automated Beverage System

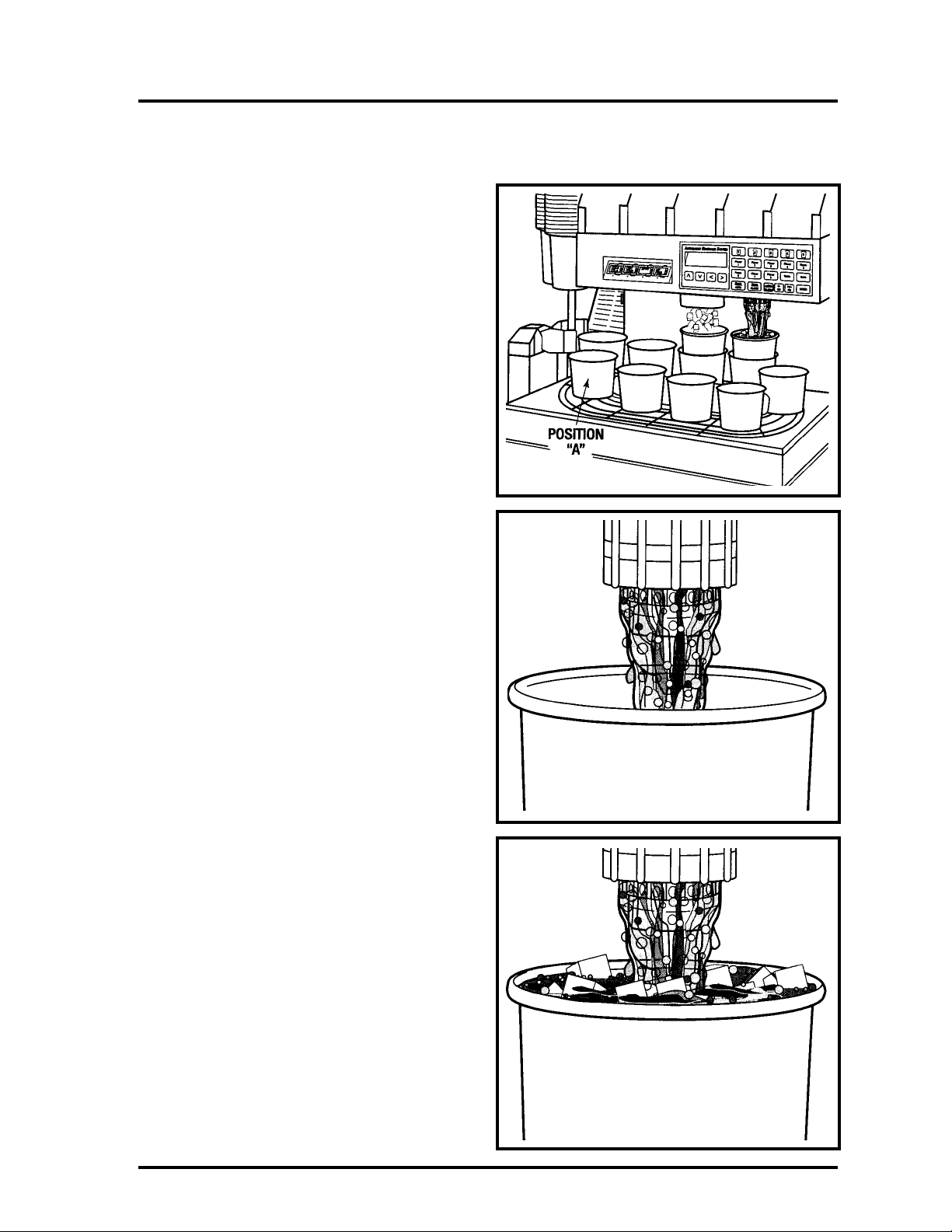

Cup To Dispensing Nozzle

Sensors check for a cup in position A. If the

sensor is clear, the conveyor moves the cup to

the beverage fill point. The valve opens to dispense the desired syrup and water in the

desired portions into the cup.

Automatic Operation

Beverage Dispensed

The computer sends the drink portion of the

order to the A.B.S. where the information is

interpreted and the drink is dispensed.

If the drink requires a top-off, the initial portion will be dispensed. After a delay, the balance of the drink will be dispensed.

© 2004-2005 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

15

Automated Beverage System

Automatic Operation

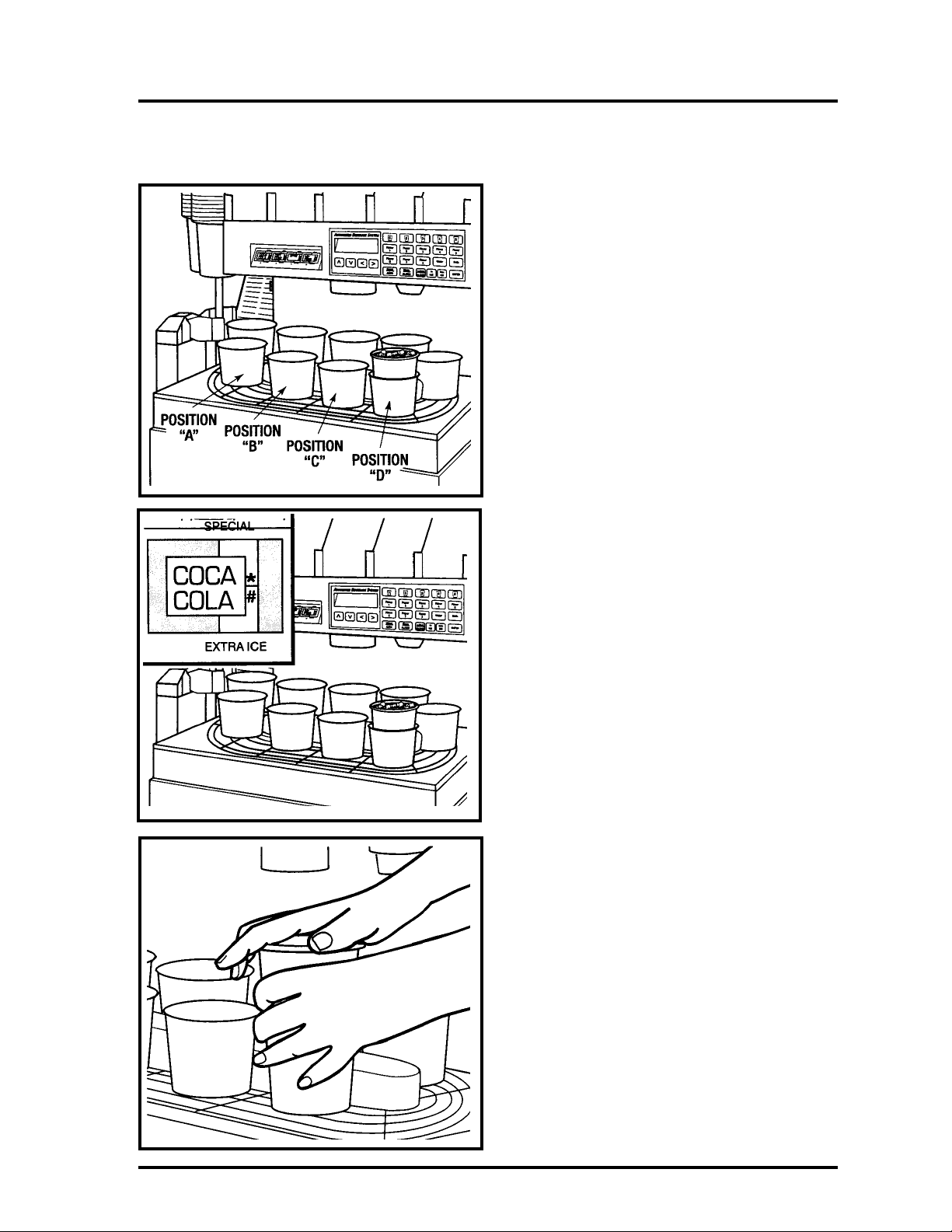

Cup Is Moved To Cup Serve Point

Sensors check for a cup in position “A.” If the

sensor is clear, the conveyor moves the cup to

cup serve position “D.”

The display will indicate the flavor of the beverage at cup serve position “D.”

Crew Member Serves Drink

A crew member caps the drink while still on

the conveyor and serves it with the remainder

of the order.

16

© 2004-2005 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

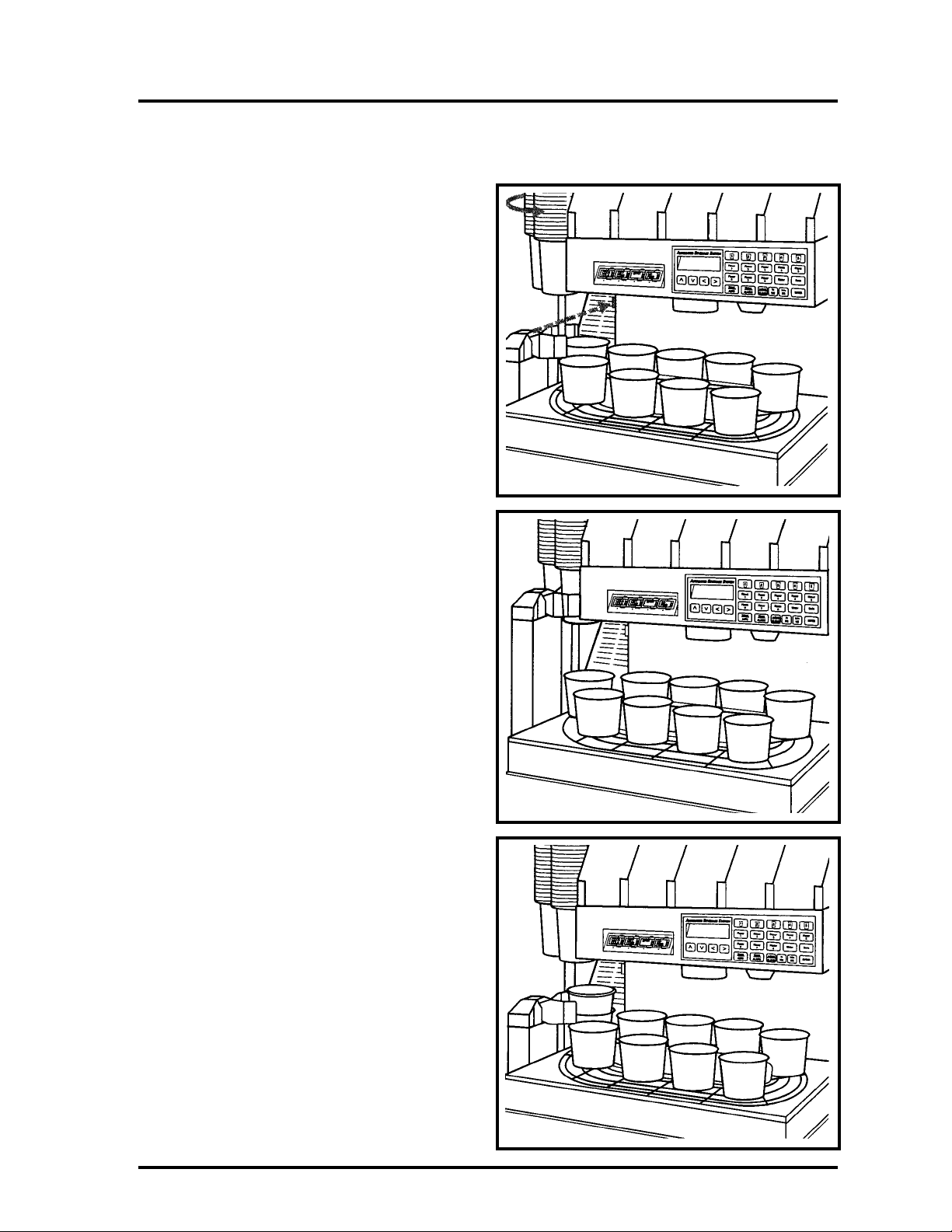

Automated Beverage System

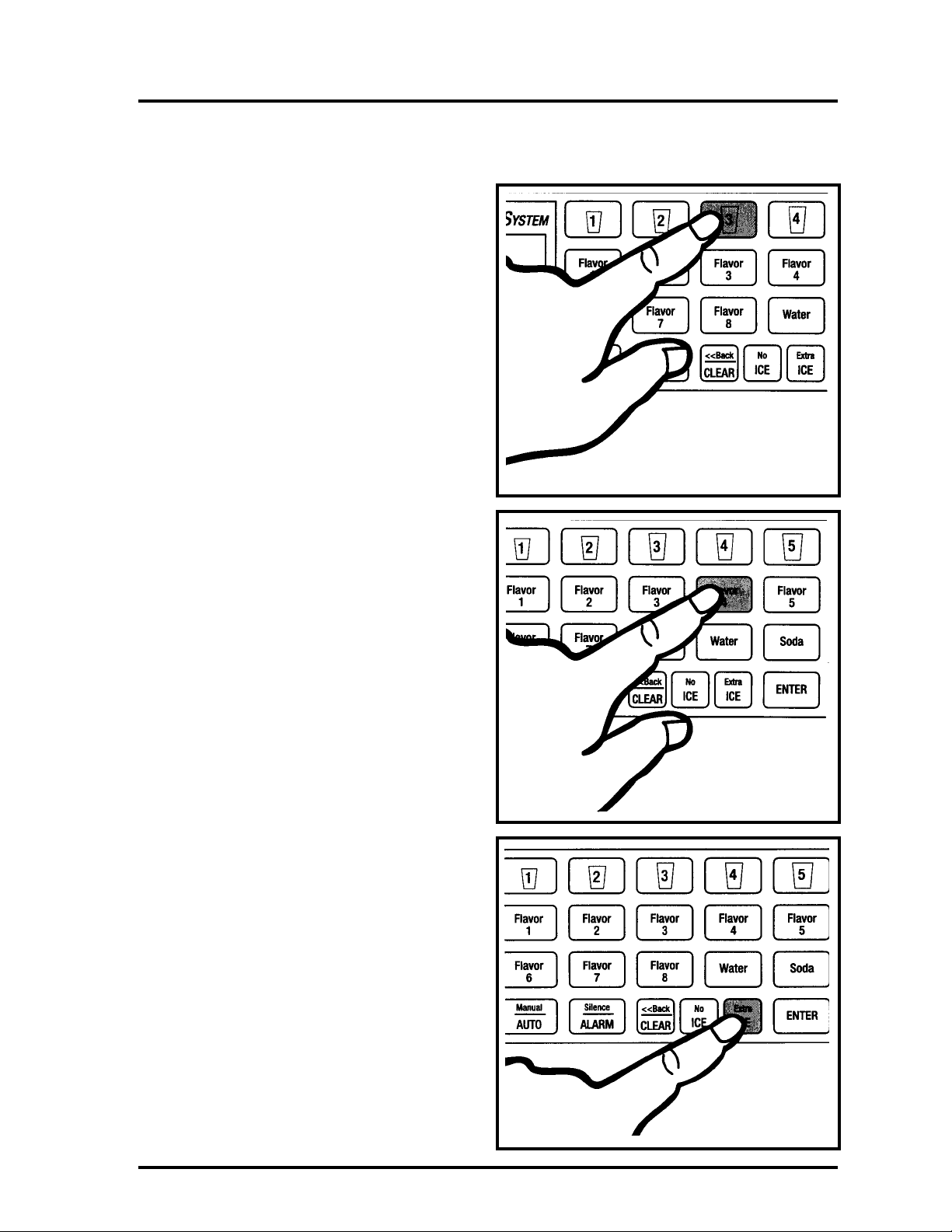

Semiautomatic Operation (Unit in Automatic)

Press Cup Size

While in automatic mode, to dispense a drink

in the semi-automatically, press the desired

cup size button.

Press Flavor

Press the desired flavor button.

Press Special Ice Requirement If

Requested

If extra ice is desired, press the EXTRA ICE

button. If no ice is required, press the NO ICE

button.

If normal ice is desired, no button is pressed.

© 2004-2005 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

17

Automated Beverage System

Semiautomatic Operation (Unit in Automatic)

When Correct, Press Enter

Sequence of pressing the cup size, flavor, and

special ice buttons is not important. At any

time, pressing any button will change the

selection of the drink to be dispensed. When

the correct order is displayed, press ENTER

and the drink will be dispensed.

The word “FLOAT” will

appear when the float option

The word “FLOAT” will appear

when the float option is applied

is applied to the drink order.

to the drink order.

This button oper-

This button op

ates as the

erates as the

DOWN arrow key

DOWN arrow

in the manual

key in the manual

mode, and as the

mode, and as the

“FLOAT” key

“FLOAT” key

while the unit is

in automatic.

while the unit is

in automatic.

Any drink entered in this manner will display

an illuminated asterisk in the SPECIAL section of the Drink Position Display identifying

the semiautomatic drink selected at the A.B.S.

panel.

ABS Float Dispensing

ABS Float Dispensing allows for the ABS to

dispense drinks, without ice, that are only a

pre-set portion full. Ice cream can then be

added after the dispense, to make it into a

“FLOAT” drink.

Ordering a Float Drink

1. Place the unit in AUTOMATIC MODE

2. Select the CUP SIZE

3. Select the FLAVOR

4. Press the DOWN ARROW/FLOAT KEY

5. Press ENTER

18

© 2004-2005 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

Loading...

Loading...