Page 1

User’s Manual

THERMAL PRINTER MECHANICAL

CONTROL LSI

MODEL

Rev.1.01 Added notes Dec.14th,1998

CBM-202PC-04

Page 2

CBM-202PC-04 User’s Manual

<CAUTIONS>

1. Prior to using the printer, read this manual thoroughly for correct operation. After reading the manual, keep it

carefully at hand for your future reference.

2. The information herein is subject to change without prior notice due to technical improvements. Upon actual

use of the printer, inquire for the up-to-date specifications.

3. It is strictly prohibited to copy part or all of the information contained in this m anual without our prior

permission.

4. If you have any question about the information herein or notice any clerical erroror omission, please contact us.

5. We will not be responsible for the effects from the results of operating the printer, regardless of Section 4.

6. We cannot guarantee that the information herein does not infringe upon the industrial property, etc. of a third

party, except when there is a written agreement to that effect.

2 CITIZEN

Page 3

CBM-202PC-04 User’s Manual

CONTENTS

1. OUTLINE............................................................................................................................................................ 5

1.1 Applicable Printer ........................................................................................................................................ 5

2. MAINTENANCE AND SERVICE.................................................................................................................... 6

3. BASIC SPECIFICATIONS................................................................................................................................ 7

3.1 Shapes and Dimensions.................................................................................................................................. 7

3.2 Structure........................................................................................................................................................ 7

3.3 Data Transfer Method .................................................................................................................................... 7

3.4 Printing Function ........................................................................................................................................... 7

3.5 Operating Voltage and Power Consumption.................................................................................................... 7

3.6 Operating Frequency...................................................................................................................................... 7

4. HARDWARE SPECIFICATIONS.................................................................................................................... 8

4.1 Absolute Maximum Ratings...................................................................................................... ..................... 8

4.2 Electrical Characteristics................................................................................................................................ 8

4.3 Pin Layout and Functions............................................................................................................................... 9

4.4 Gate ArrayPin Layout and Functions ............................................................................................................13

4.5 Reset Circuit.................................................................................................................................................14

4.6 Oscillation Circuit.........................................................................................................................................15

4.7 Head-up Detection Circuit.............................................................................................................................16

4.8 Head Control Circuit.....................................................................................................................................17

4.9 PaperEnd Detection Circuit..........................................................................................................................18

4.10 Motor Control Circuit ...................................................................................................................................19

4.11 Auto CutterControl Circuit...........................................................................................................................20

4.12 Parallel Interface Circuit ...............................................................................................................................21

4.13 Serial Interface Circuit..................................................................................................................................23

4.14 Switch Circuit...............................................................................................................................................24

4.15 Error OutputCircuit......................................................................................................................................25

4.16 Function Selection Circuit .............................................................................................................................27

4.17 External RAMInterface................................................................................................................................30

3 CITIZEN

Page 4

CBM-202PC-04 User’s Manual

5. PRINTER MECHANISM CONTROL SYSTEM ......................................................................................... 33

5.1 Head Drive...................................................................................................................................................33

5.1.1 Head Dividing Method.....................................................................................................................33

5.1.2 Thermal Head Application Energy....................................................................................................34

5.2 Motor Drive..................................................................................................................................................34

5.3 Auto Loading................................................................................................................................................35

6. SELF-PRINTING.............................................................................................................................................36

7. OPERATION TIMING.................................................................................................................................... 37

8. SPECIFICATIONS OF PACKAGE................................................................................................................ 38

9. PRECAUTIONS FOR MOUNTING .............................................................................................................. 39

9.1 Precautions...................................................................................................................................................39

9.2 Reflow Mounting..........................................................................................................................................39

9.3 Recommended Conditions for Different Mounting Methods..........................................................................39

9.4 Clearing Method...........................................................................................................................................41

9.5 StorageMethod.............................................................................................................................................41

10. PRINT CONTROL FUNCTIONS................................................................................................................... 42

10.1 Command List..............................................................................................................................................42

10.2 Command Details............................................................................................................. ............................44

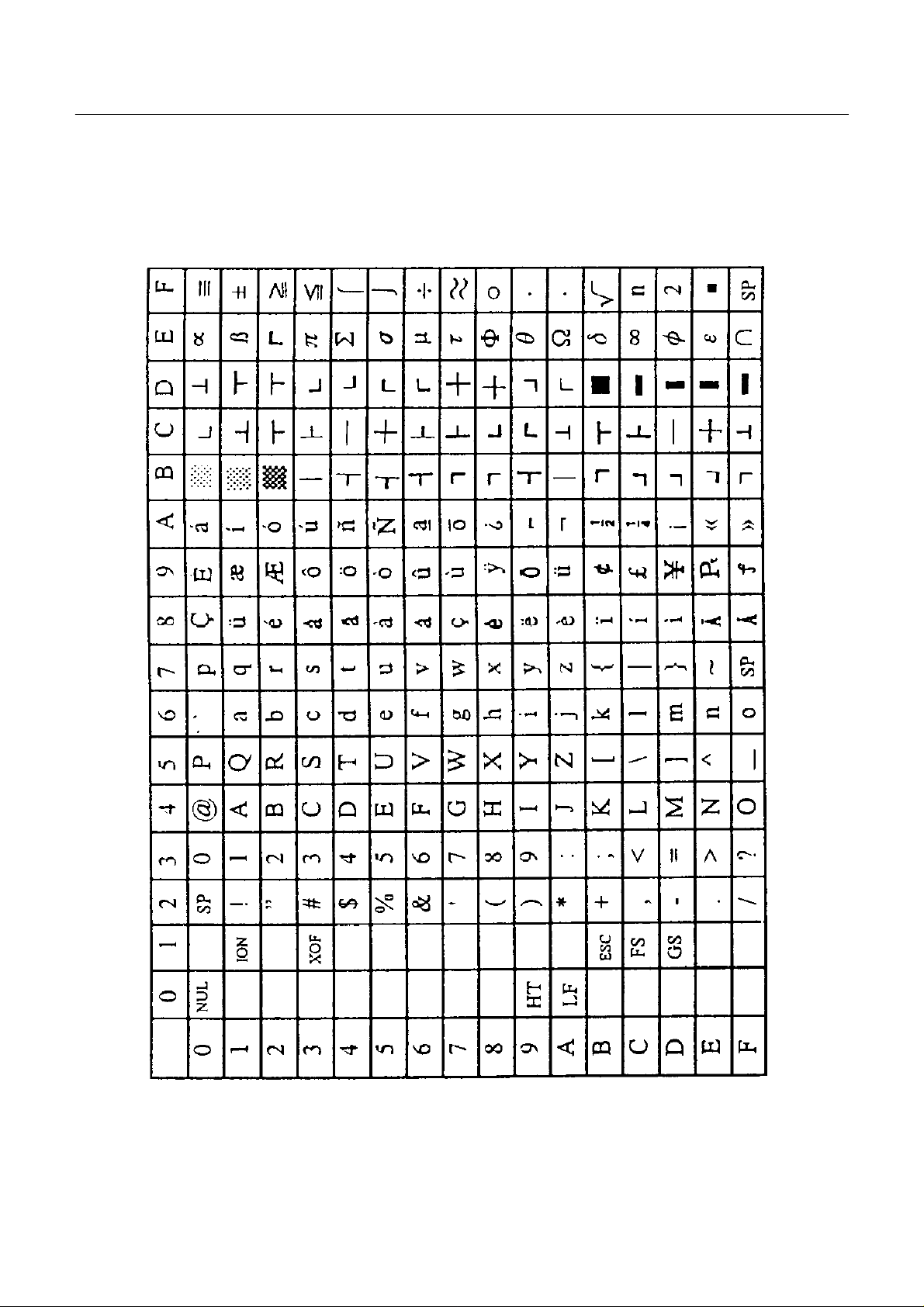

11. CHARACTER CODES TABLE...................................................................................................................... 86

11.1 International..................................................................................................................................................86

11.2 Domestic ......................................................................................................................................................87

11.3 International Character Codes Table..............................................................................................................88

4 CITIZEN

Page 5

CBM-202PC-04 User’s Manual

1. OUTLINE

This LSI is designed to control the line thermal printer LT-286 by using our Gate Array. It has the following

features.

(1) Capable of providing high-quality printing by detecting a temperature and automatically correcting

printingdensity.

(2) Capable of providing high-quality printing by detecting a voltage and automatically correcting printing

density .

(3) Capable of selecting the parallel or serial interface.

(4) Capable of selecting printing density via a function selectionterminal.

(5) Capable of printing a bar code.

(6) Capable of printing double-width/height characters, bit images, and so onby various commands.

1.1 Applicable Printer

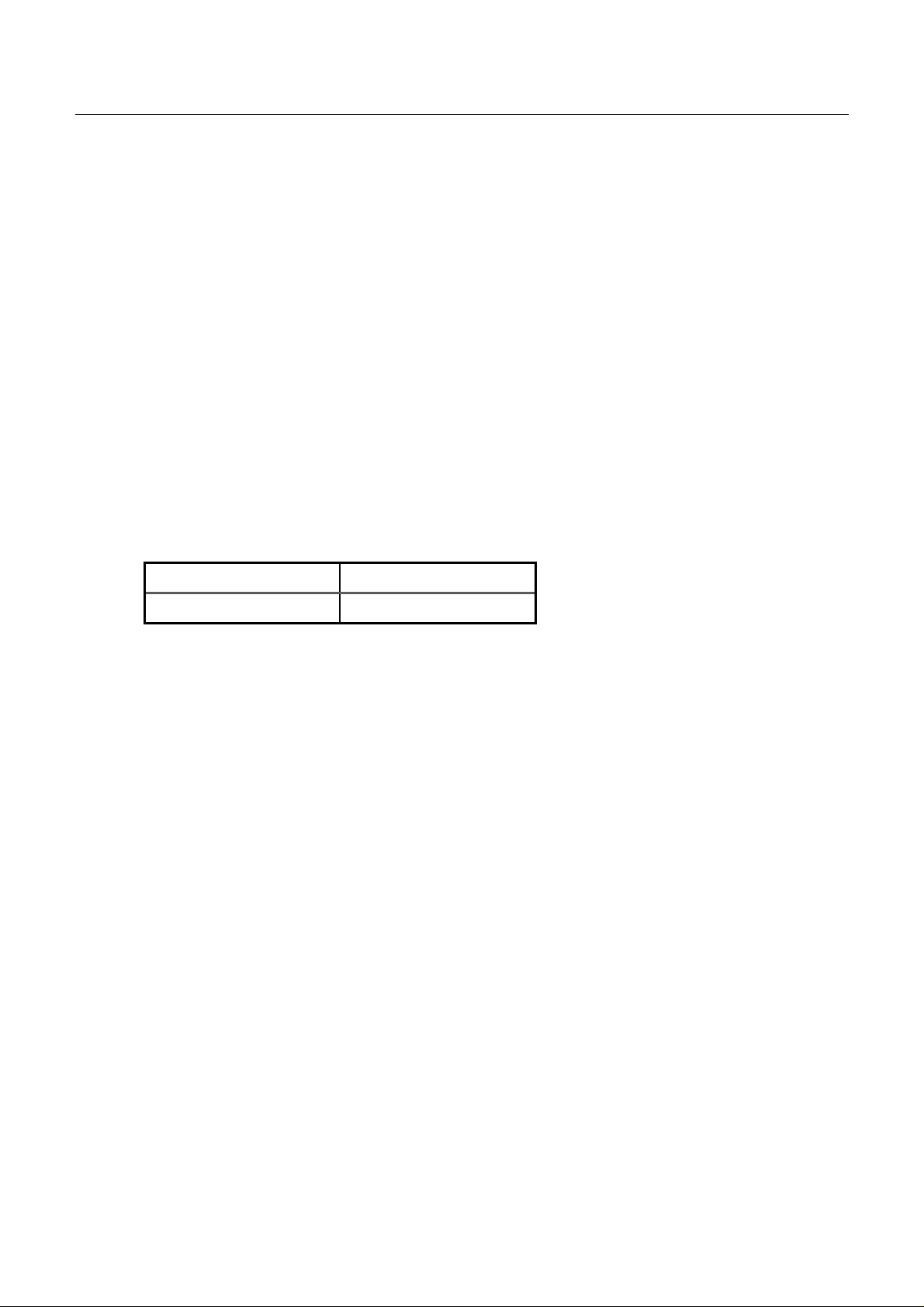

LSI Name Applicable Mechanism

CBM-202PC-04 LT-286

5 CITIZEN

Page 6

CBM-202PC-04 User’s Manual

2. MAINTENANCE AND SERVICE

For the informationonmaintenance and service, please contact our dealer or at the following address.

Northern America Other Areas

CBM America Corporation Japan CBM Corporation

Service Center Information Systems Division

365 VanNess Way CBM Bldg.,5-68-10 Nakano

Suit 510 Nakno-ku, Tokyo 164-0001

Torrance, CA 90501, U.S.A Japan

TEL +1-310-781-1460

FAX +1-310-781-9157 FAX +81-3-5345-7541

TEL +81-3-5345-7540

6 CITIZEN

Page 7

CBM-202PC-04 User’s Manual

3. BASIC SPECIFICATIONS

3.1 Shape and Dimensions (Refer to the “8. SPECIFICAT IONS OF PACKAGE”.)

100-pin flat package

3.2 Structure

C-MOS LSI

3.3 Data Transfer Method

Parallel transfer or serial transfer (Selectable)

(1) 8-bit parallel transfer (CENTRONICS based)

(2) Asynchronous serial transfer (Selectable)

1,200, 2,400, 4,800, 9,600, or 19,200 bps

Parity: Odd, Even, or None parity; 8 bits

3.4 Printing Function

(1) Printing columns and printing speed

Model Digits Total Dots Character Size (mm) PrintingSpeed(m/s)

LT-286

Note) The printing speed above applies when the thermal printer is driven in the following environment:

• Drive voltage(VH) = 7.2 V

• Thermal head temperature = 30°C or more

• Simultaneous power-on(print) dots = Within 64 dots

32 1.25×3.00(Font A)

42

384

0.88×3.00(Font B)

3.5 Operating Voltage and Power Consumption

• Voltage : 5V DC ±5%

• Current consumption : 80mA at maximum

3.6 Operating Frequency

50

• 16 MHz

7 CITIZEN

Page 8

4. HARDWARE SPECIFICATIONS

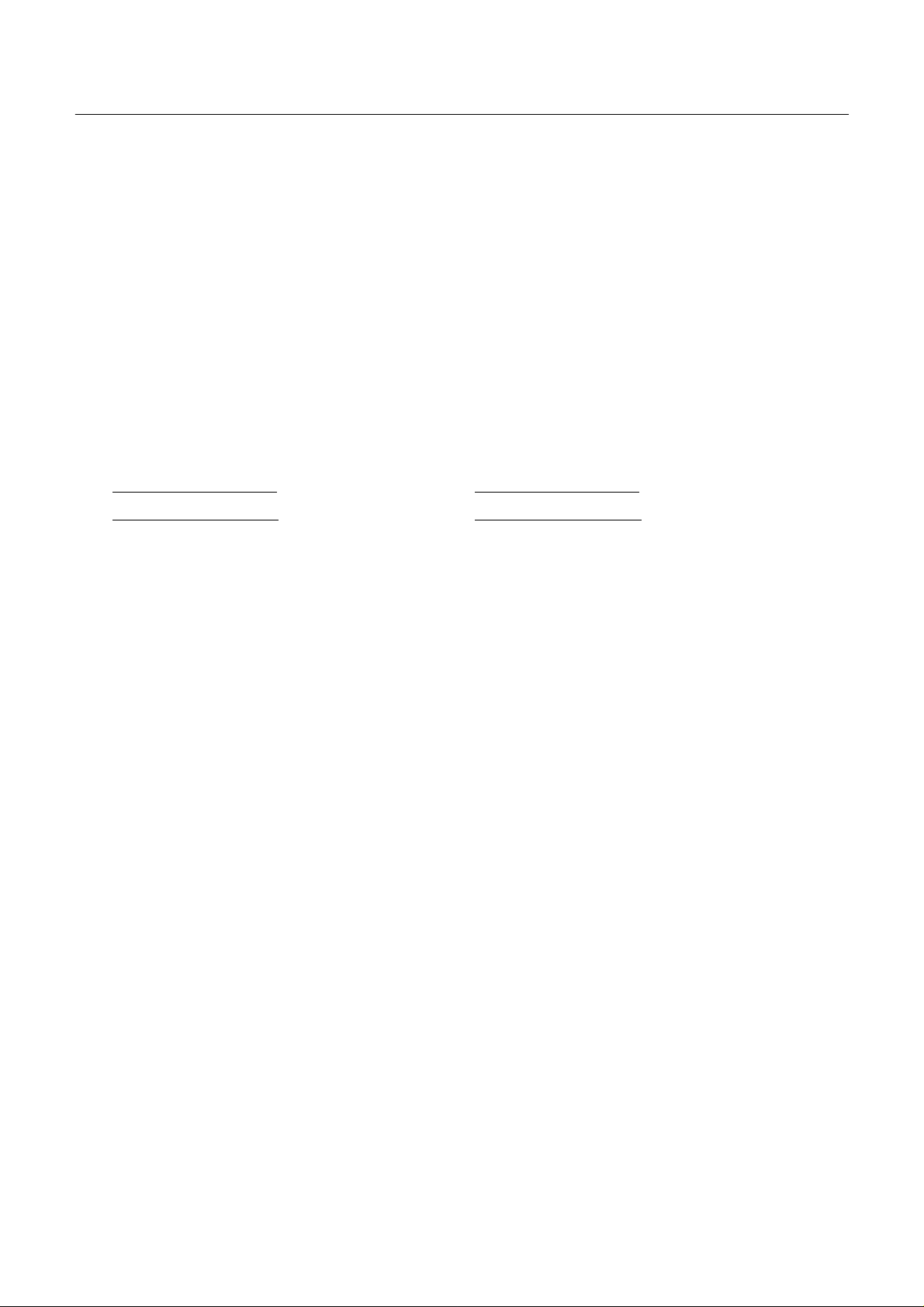

4.1 Absolute Maximum Ratings

Item Sym bo l Rating

Supply voltage Vcc –0.3 ~ +7.0V

Input voltage Vi –0.3 ~ Vcc+0.3V

CBM-202PC-04 User’s Manual

Reference supply voltage V

Analog supply voltage AVcc –0.3 ~ +7V

Analog input voltage V

Operatingtemperature Topr –20 ~ +75°C

Storage temperature Tstg –55 ~ +125°C

4.2 Electrical Characteristics

Item Symbol MIN MAX Unit Condition

RES,STBY,NM1

MD0,MD1,MD2

Input

"HIGH"

Level

Input

"LOW"

level

Output

"HIGH"

level

Output

"LOW"

level

EXTAL

THEM 2.0 AVcc+0.3 V

Others

All input term inals V

All output terminals V

RESO – 0.4 V IOH= 2.6

LEDER,LEDPE – 1.0 V IOL=10

Others

REF

AN

–0.3 ~ AVcc+0.3V

–0.3 ~ AVcc+0.3V

Vcc–0.7 Vcc+0.3 V

V

IH

Vcc×0.7

Vcc+0.3 V

2.0 Vcc+0.3 V

IL

0H

V

0L

–0.3 0.5 V

3.5 – V IOH=–1

0.4 V IOL= 1.6

mA

mA

mA

mA

8 CITIZEN

Page 9

CBM-202PC-04 User’s Manual

4.3 Terminal Layout and Functions

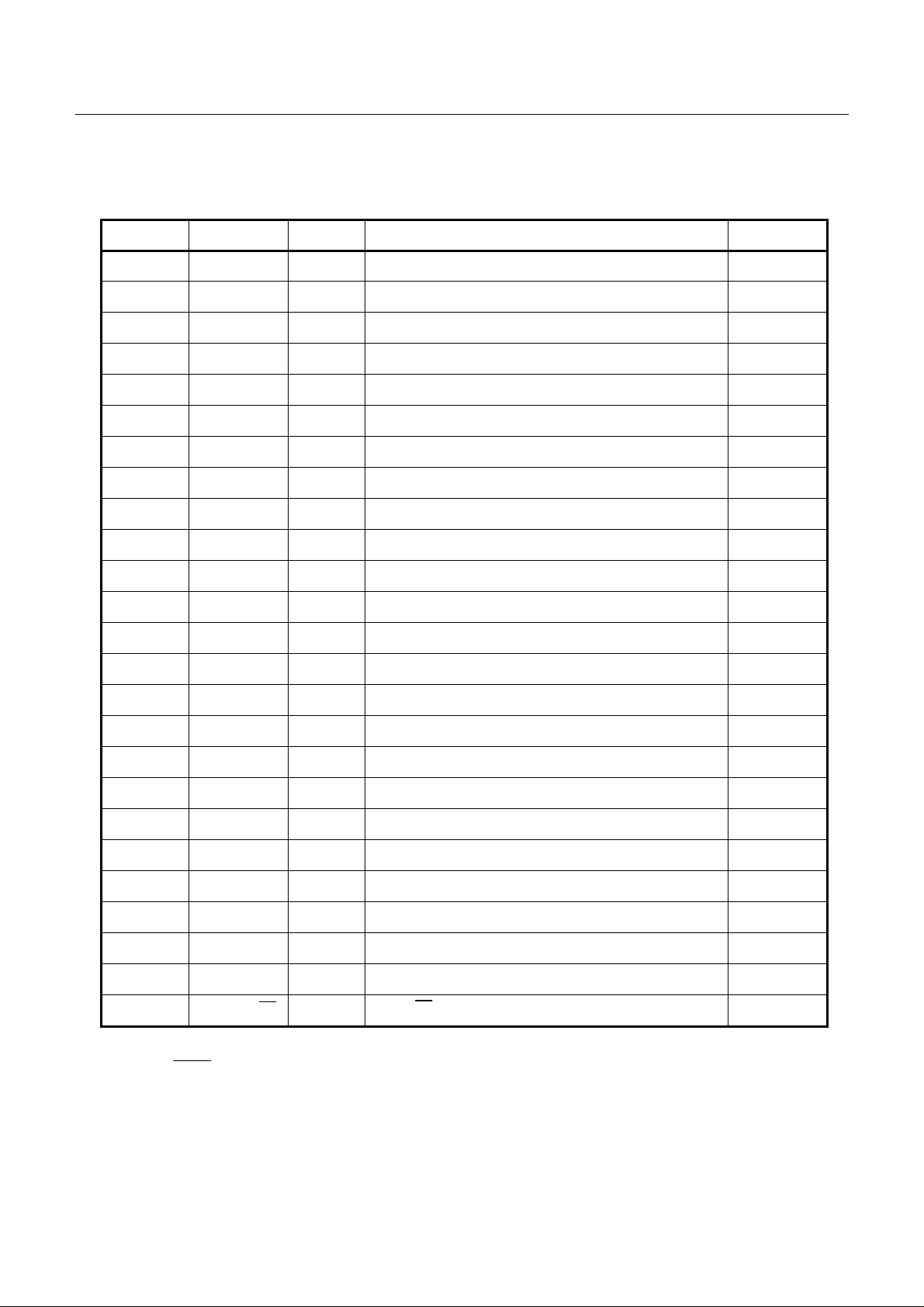

PinNo. Signal I/O Function Logic

1 VCC – VCC –

2 LFSW Input LF switch input LOW

3 LEDER Output Error LED output LOW

4 LEDPE Output Paper end LED output LOW

5NC–NC –

6 LATCH Output Head latch signal LOW

7 P APER Input Paper end input NC HIGH

8 DRQ Input DMA request LOW

9NC–NC –

10 RES0 Output Watchdog output LOW

11 VSS – GND –

12 DTR Output Serial DTR (RS-232C) HIGH

13 TXD Output Serial TXD (RS-232C) HIGH

14 DI Input Print head output data HIGH

15 RXD Input Serial RXD (RS-232C) HIGH

16 CP Input Print head clock HIGH

17 NC – NC –

18 CTSW Input Cutter switch input LOW

19 NC – NC –

20 NC – NC –

21 NU – RESERVED –

22 VSS – GND –

23 MOTORA Output Motor A –

24 MOTORB Output Motor B –

25 MOTORA Output Motor A –

Note) For notation of the signals whose logic is "LOW"(Negative), a representatio nof

XXX(Upper line) will be omittedfor the subsequent notations.

9 CITIZEN

Page 10

CBM-202PC-04 User’s Manual

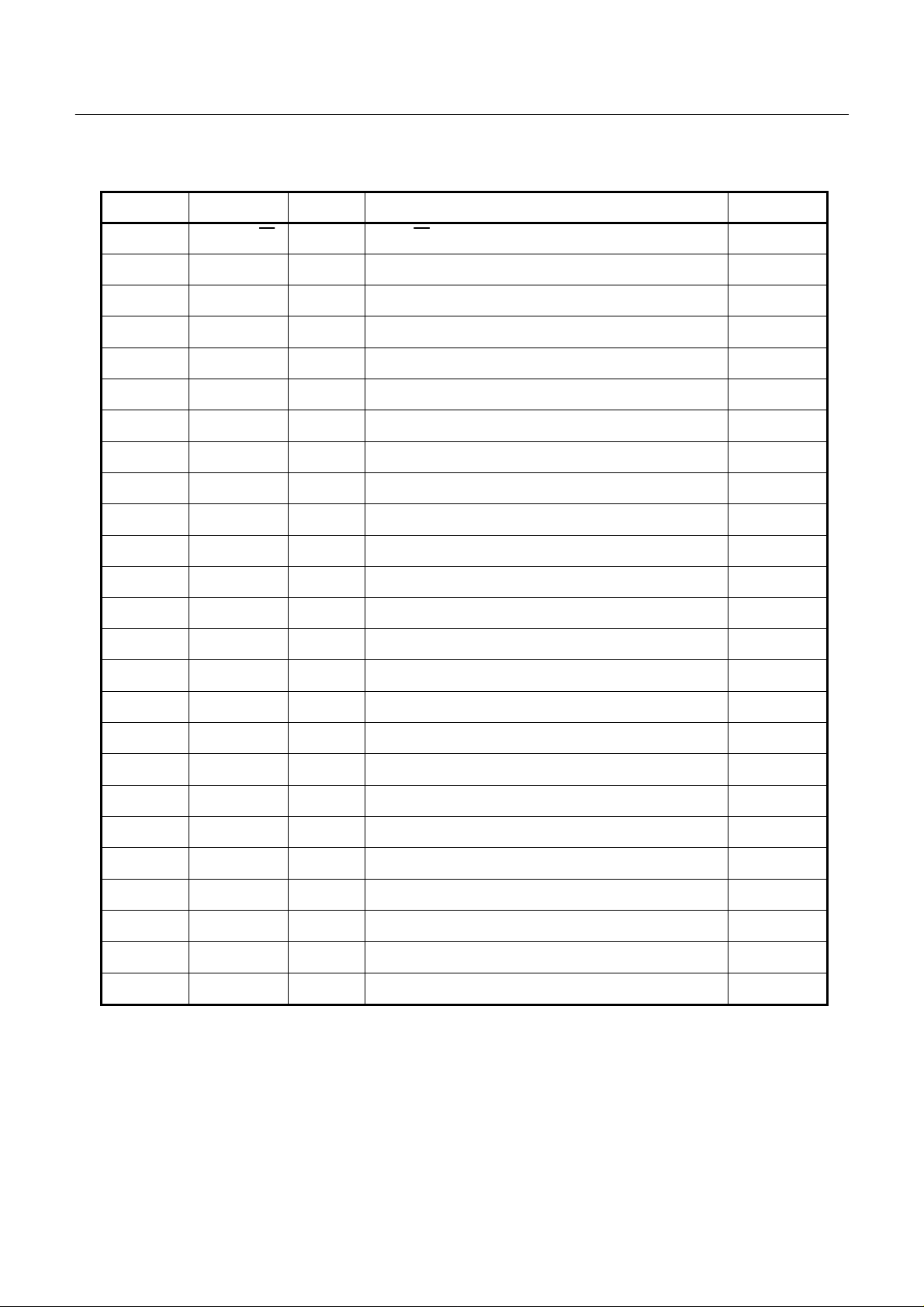

Pin No. Signal I/O Function Logic

26 MOTORB Output Motor B –

27 D0 I/O D0 HIGH

28 D1 I/O D1 HIGH

29 D2 I/O D2 HIGH

30 D3 I/O D3 HIGH

31 D4 I/O D4 HIGH

32 D5 I/O D5 HIGH

33 D6 I/O D6 HIGH

34 D7 I/O D7 HIGH

35 VCC – VCC –

36 A0 Output A0 HIGH

37 A1 Output A1 HIGH

38 A2 Output A2 HIGH

39 A3 Output A3 HIGH

40 A4 Output A4 HIGH

41 A5 Output A5 HIGH

42 A6 Output A6 HIGH

43 A7 Output A7 HIGH

44 VSS – GND –

45 A8 Output A8 HIGH

46 A9 Output A9 HIGH

47 A10 Output A10 HIGH

48 A11 Output A11 HIGH

49 A12 Output A12 HIGH

50 A13 Output A13 HIGH

10 CITIZEN

Page 11

CBM-202PC-04 User’s Manual

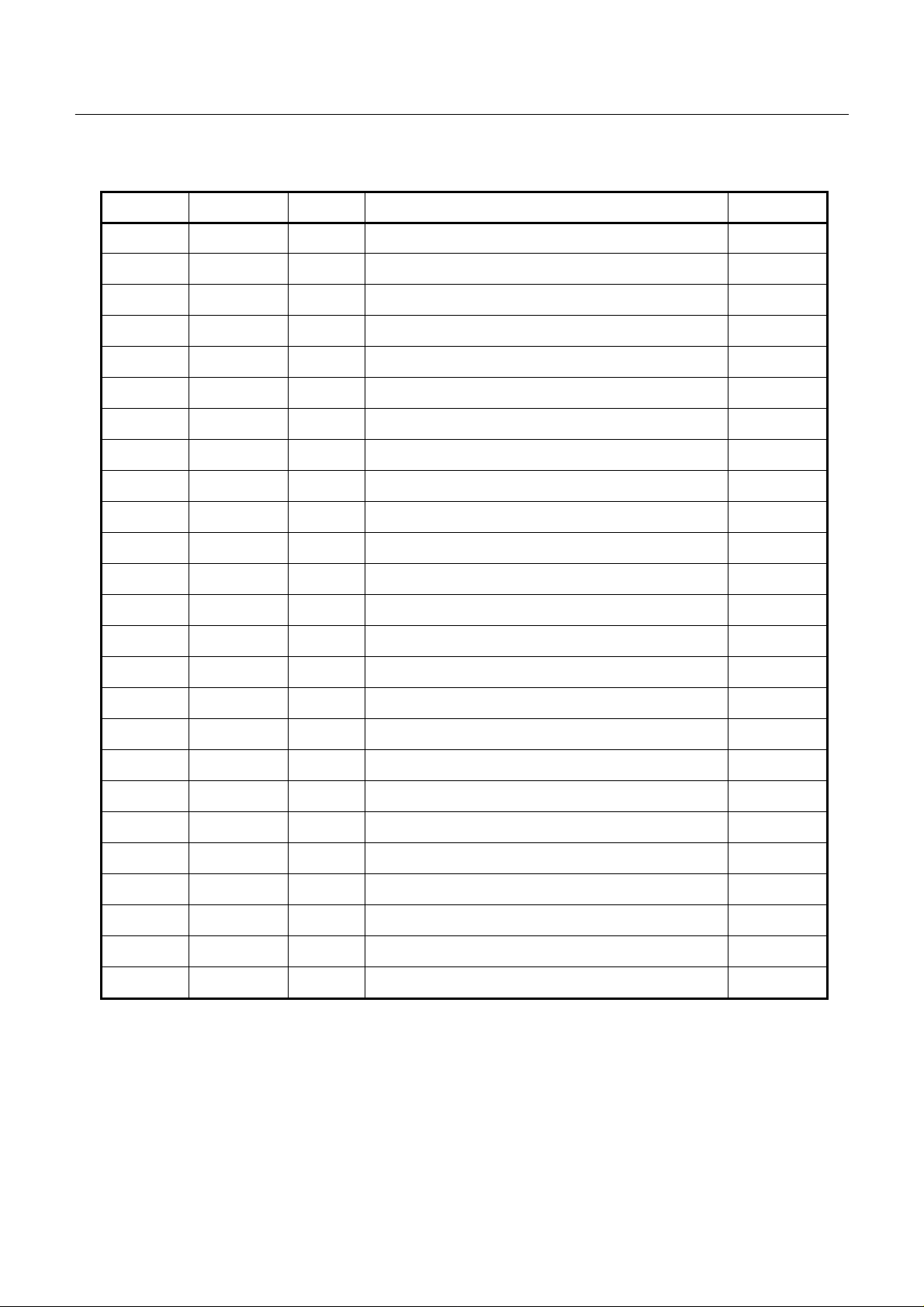

PinNo. Signal I/O Function Logic

51 A14 Output A14 HIGH

52 A15 Output NC

53 A16 Output NC

54 A17 Output NC

55 A18 Output NC

56 A19 Output NC

57 VSS

–

GND

58 P60 Output NC

59 P61 Output NC

60 P62 Output NC

61

φ

62 STBY Input

Output Clock output HIGH

(PulluptoVCCat10kΩ)

–

–

–

–

–

–

–

–

–

LOW

63 RES Input Reset input LOW

64 NMI Input

65 VSS

66 EXTAL

–

–

(PulluptoVCCat10kΩ)

GND

EXTAL (16MHz)

LOW

–

–

67 XTAL

68 VCC

–

–

XTAL (16MHz)

VCC

69 P63 Output NC

–

–

–

70 RD Output RD LOW

71 HRW Output HRW LOW

72 P66 Output NC

73 MD0 Input

74 MD1 Input

75 MD2 Input

(PulluptoVCCat10kΩ)

(Pull down to GND at 10kΩ)

(PulluptoVCCat10kΩ)

–

HIGH

LOW

HIGH

11 CITIZEN

Page 12

CBM-202PC-04 User’s Manual

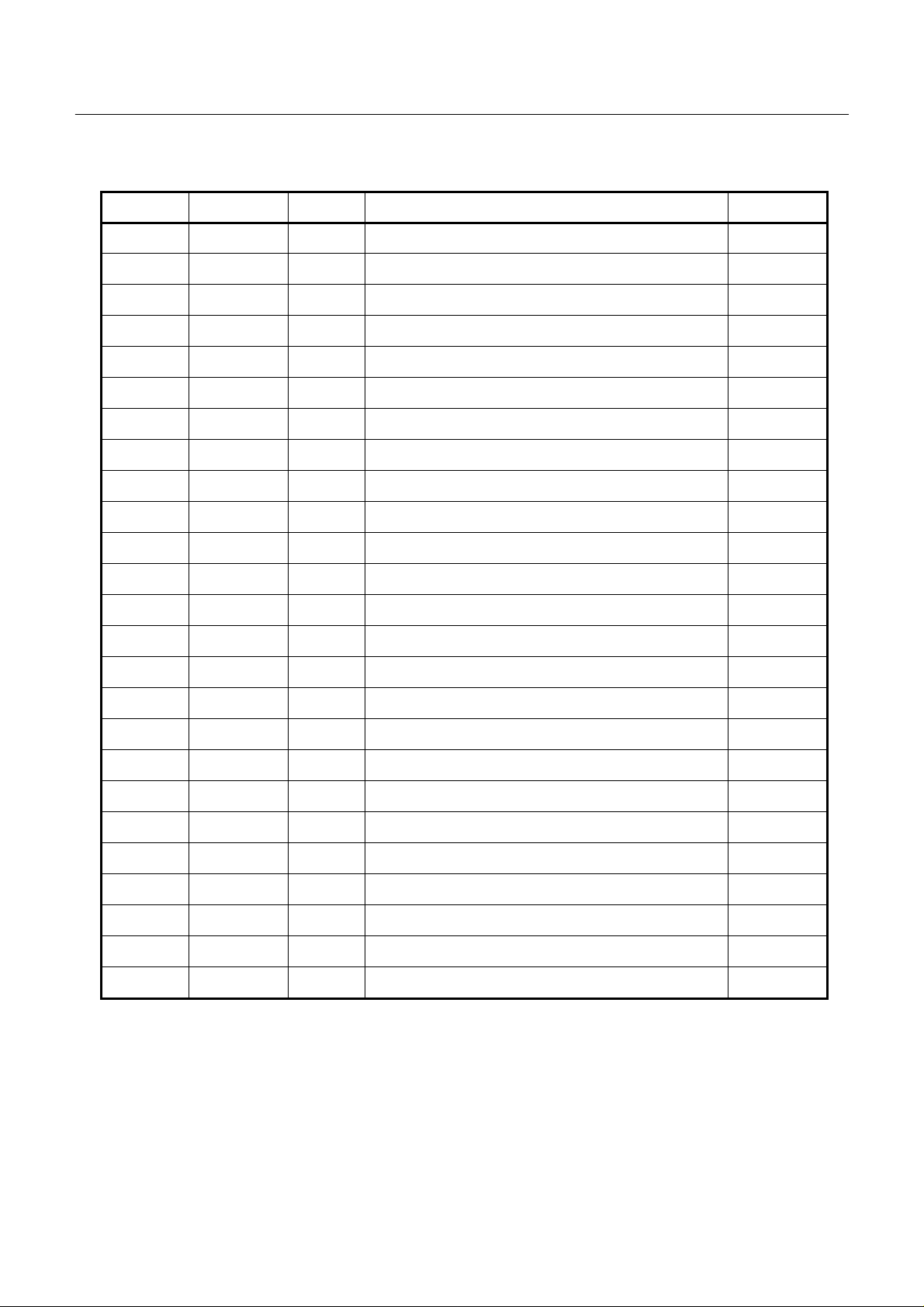

PinNo. Signal I/O Function Logic

76 AVCC

77 VREF

–

–

VCC

VCC

78 THERM Input Head temperature detection terminal

79 NC Input

(Pull down to GND at 10kΩ)

80 DETECV Input Voltage detection terminal

81 NC Input

82 NC Input

83 NC Input

84 NC Input

85 NC Input

86 AVSS

–

(Pull down to GND at 10kΩ)

(Pull down to GND at 10kΩ)

(Pull down to GND at 10kΩ)

(Pull down to GND at 10kΩ)

(Pull down to GND at 10kΩ)

GND

–

–

–

–

–

–

–

–

–

–

–

87 STB Input Parallel data interrupt LOW

88 HEADUP Input Head up detection terminal LOW

89 CS2 Output Gate Array chip select LOW

90 CS1 Output RAM chip select LOW

91 CS0 Output Kanji ROM chip select LOW

92 VSS

–

GND

93 NC Output NC

–

–

94 STRB1 Outp ut Head strobe 1 HIGH

95 STRB2 Outp ut Head strobe 2 HIGH

96 STRB3 Outp ut Head strobe 3 HIGH

97 STRB4 Outp ut Head strobe 4 HIGH

98 STRB5 Outp ut Head strobe 5 HIGH

99 STRB6 Outp ut Head strobe 6 HIGH

100 DSR Input Serial DSR (RS-232C) HIGH

12 CITIZEN

Page 13

CBM-202PC-04 User’s Manual

4.4 Gate Array (CBM202LA) Terminal Layout and Functions

PinNo. Signal I/O Function Logic

44 D7 Input Parallel input data D7 HIGH

45 D6 Input Parallel input data D6 HIGH

46 D5 Input Parallel input data D5 HIGH

47 D4 Input Parallel input data D4 HIGH

48 D3 Input Parallel input data D3 HIGH

49 D2 Input Parallel input data D2 HIGH

50 D1 Input Parallel input data D1 HIGH

51 D0 Input Parallel input data D0 HIGH

52 STROBE Input Parallel STROBE LOW

55 BUSY Output Parallel BUSY HIGH

58 PAO7 Output NC

59 ACK Output Parallel ACK

–

–

61 PE Output Parallel paper end HIGH

62 FAULT Output Parallel FAULT LOW

63 CUTTERA Output Cutter A

64 CUTT ERB Output Cutter B

65 CUTT ERC Output Cutter C

67 CUTTERD Output Cutter D

–

–

–

–

13 CITIZEN

Page 14

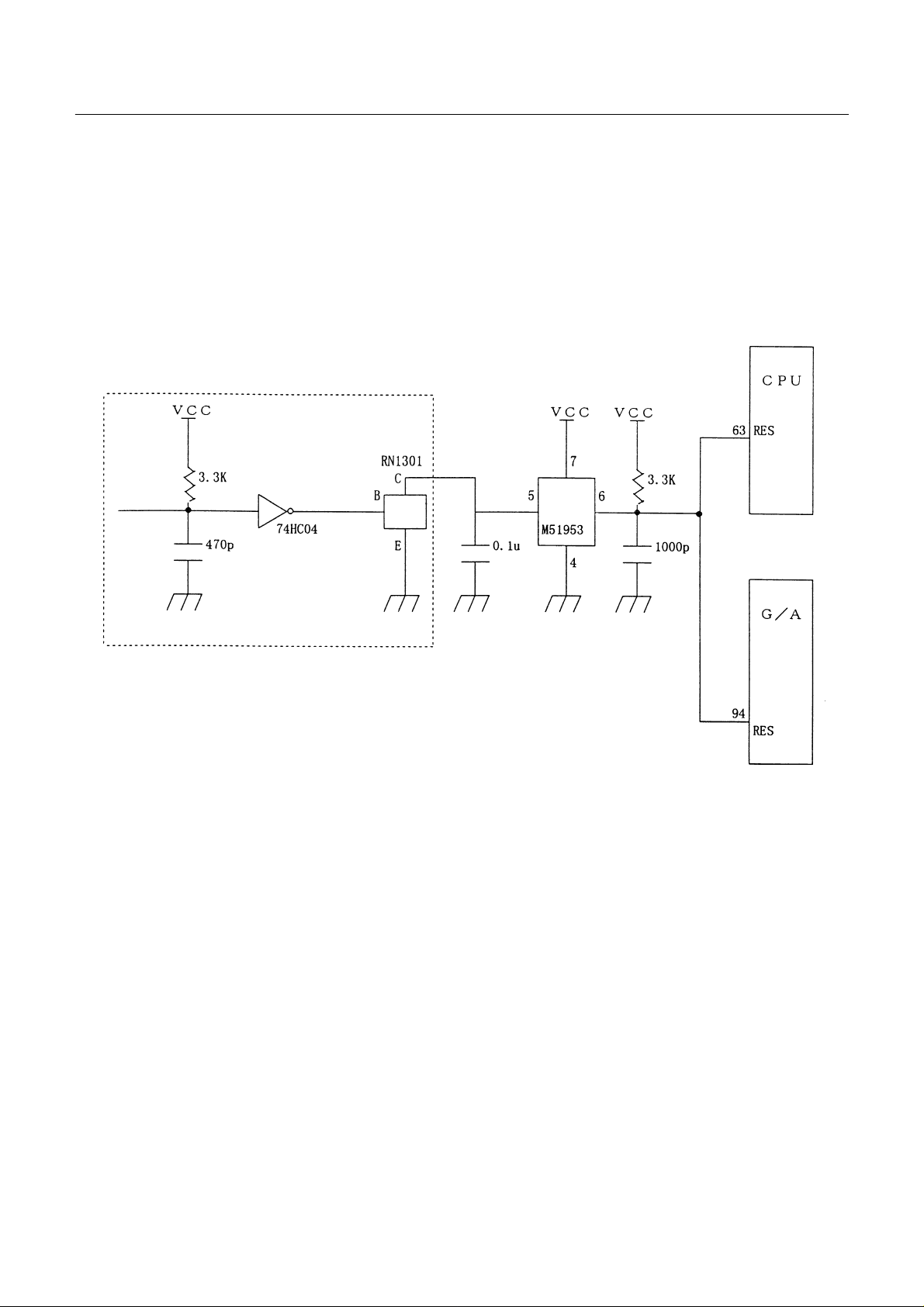

4.5 Reset Circuit

The reset state is effectuated by setting the RES terminal to "Low." To surely reset, it is necessary to set it

to "Low" at least for 20ms at power-on and for 625ns while operating.

If an external reset is notused, the parts enclosed by dotted lines are not required.

CBM-202PC-04 User’s Manual

14 CITIZEN

Page 15

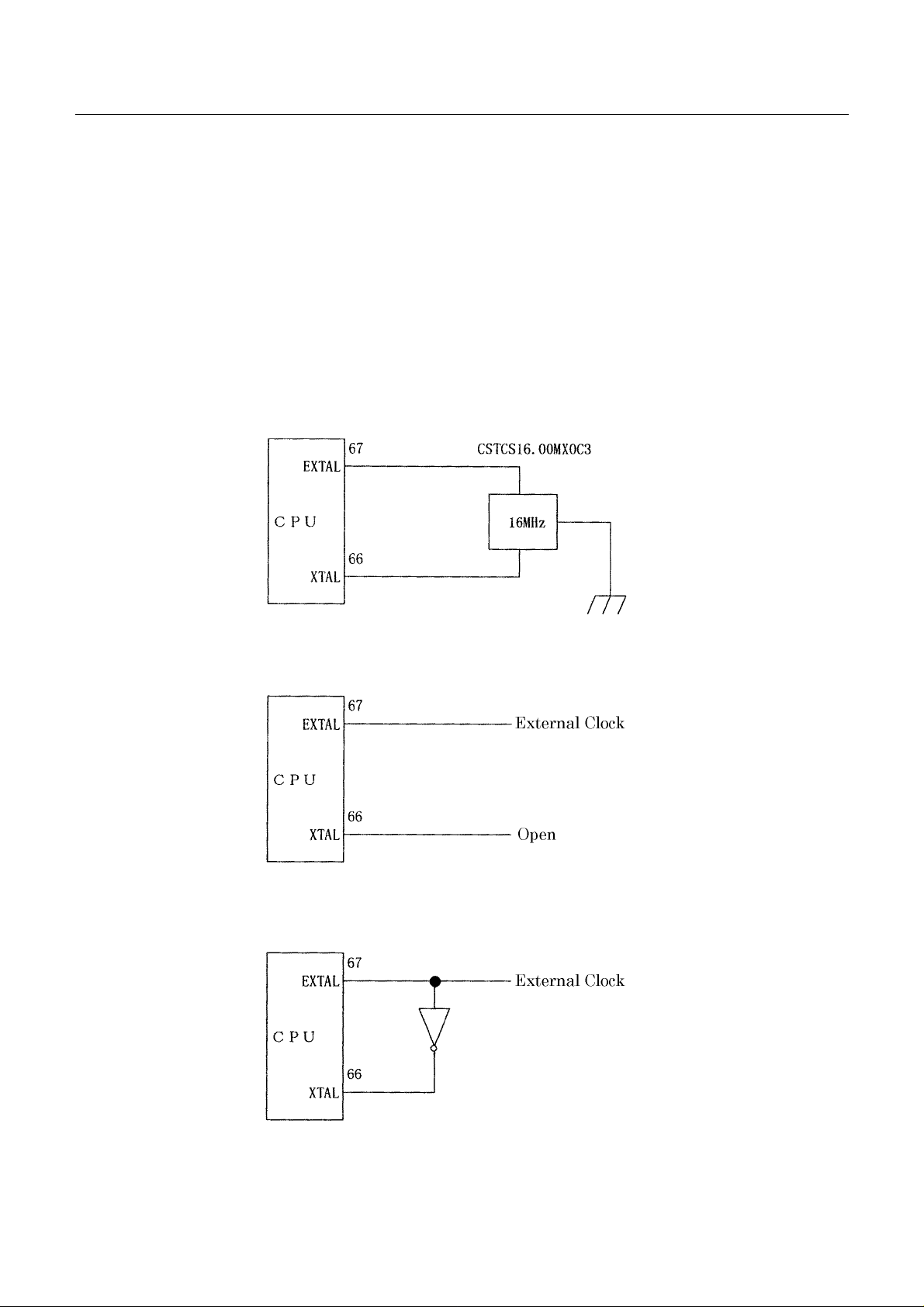

4.6 Oscillation Circuit

The oscillation circuit incorporates a clock oscillator which generates a system clock and an internal clock.

There are two methods to supply a clock; one is to connect a ceramic oscillator, and the other is to input an

external clock.

When using the ceramic oscillator, we recommend the CSTCS16.00MXOC3 (With capacitor) made by

MURATA. When inputting the external clock, you may either open the XTAL terminal or input an

antiphase clock to the XTAL terminal.

CBM-202PC-04 User’s Manual

15 CITIZEN

Page 16

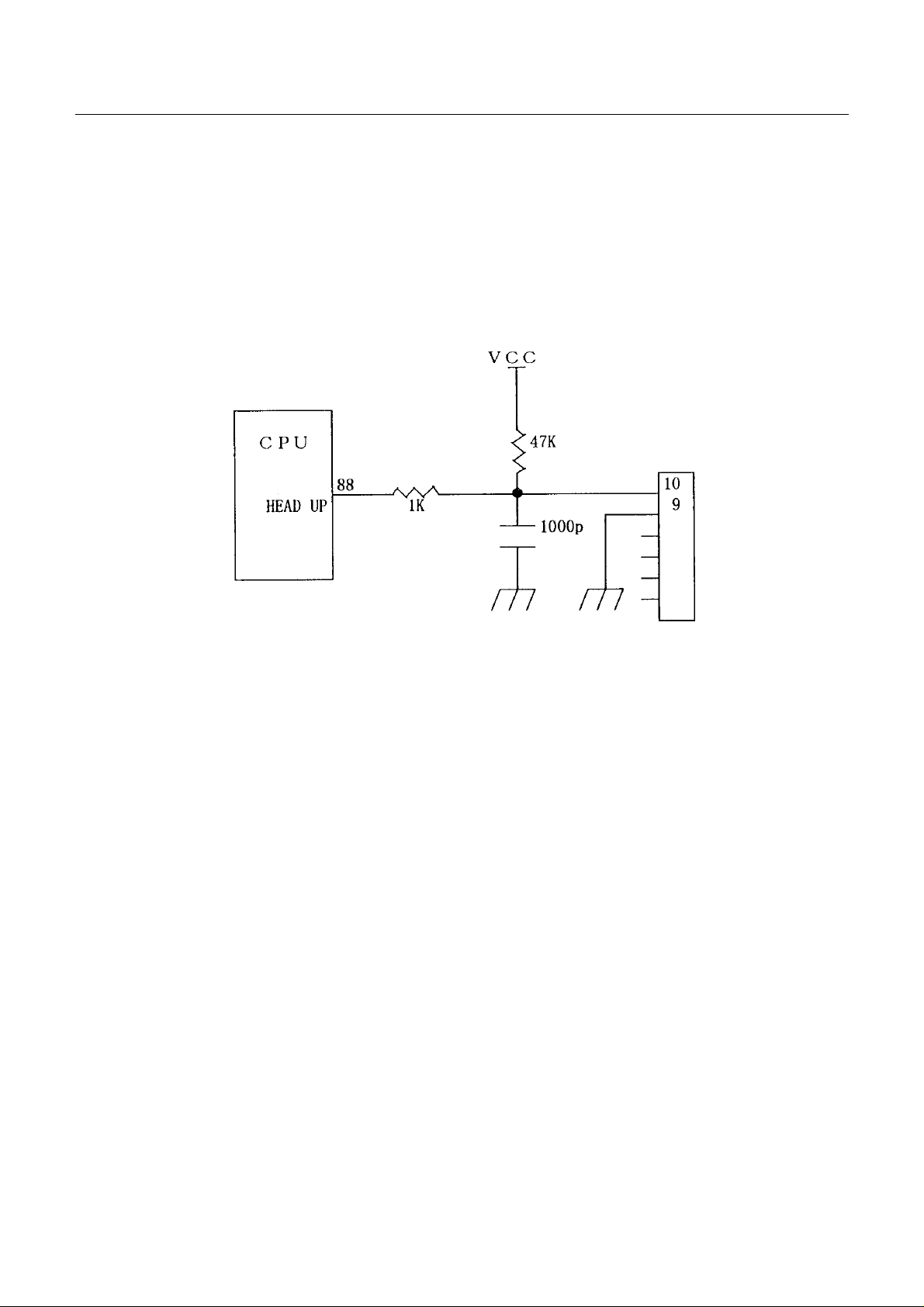

4.7 Head-up Detection Circuit

Print head up/down is detected by a head-up sensor built in the printer so that the printer will not be energized

on with the head up. The circuit is "opened" when the print head is up, and "closed" when down.

When the print head is up, HEADUP (Pin 88) of the CPU is turned to "High," and if the printer is printing, it

will immediately stop printing and output an error. It resumes printing when the print head is down.

CBM-202PC-04 User’s Manual

16 CITIZEN

Page 17

CBM-202PC-04 User’s Manual

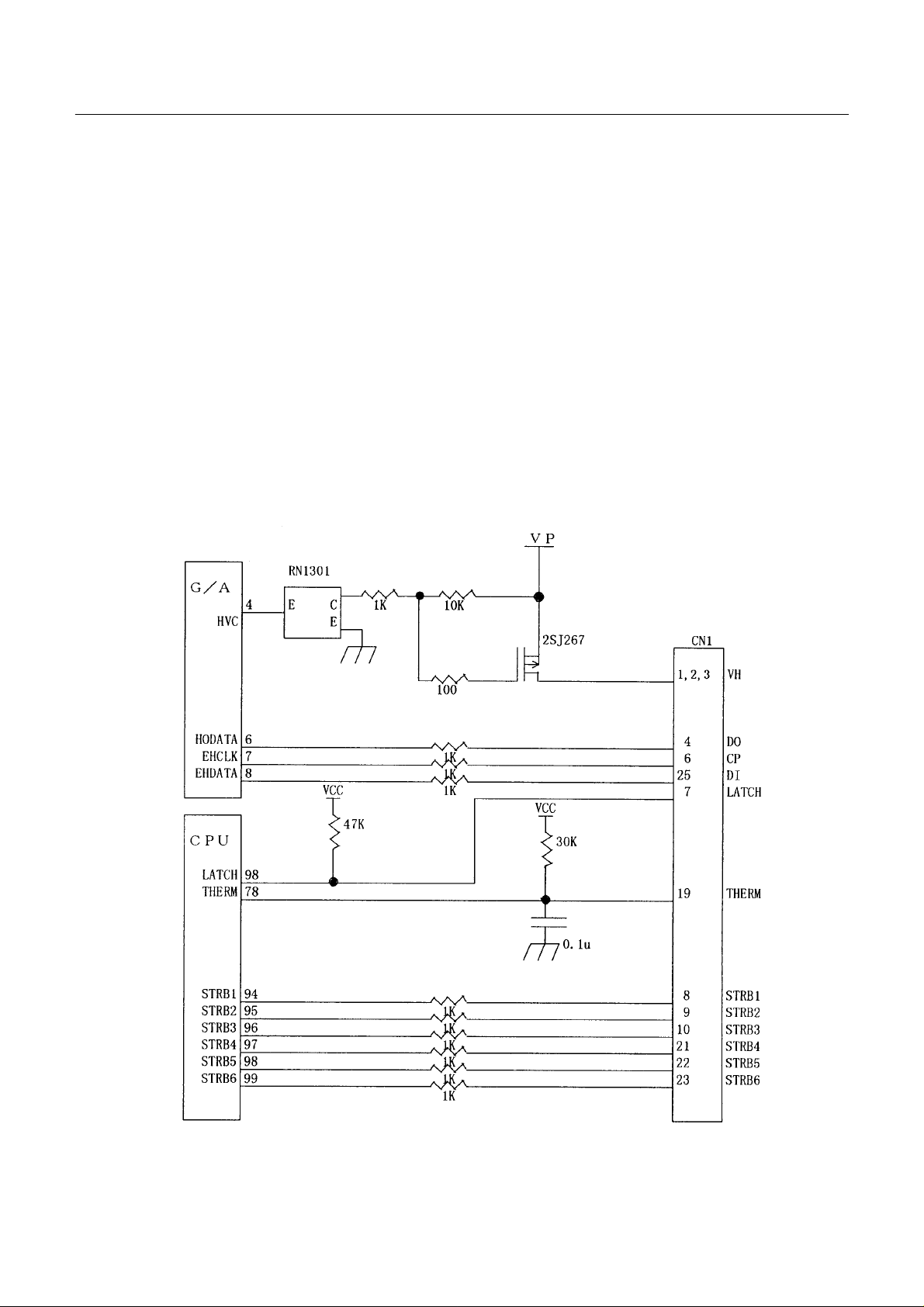

4.8 Head Control Circuit

VP is controlled in order to prevent electrolytic corrosion of the printing head. HVC(Pin-4) of the Gate

Array is turned to "HIGH" when turning on VP , and turned to "LOW" when turning it off.

A temperature detection circuit is provided in order to prevent deterioration of the printing quality or breakage

of the printing head due to a temperature. This function detects a temperature by means of a thermistor

included in the printer and determines according to that temperature how much energy should be applied to

the printing head. If a temperature of the printing head exceeds 60•, it will stop printing to prevent breakage

of the printinghead.

As a protection when the CPU crashes, connect in such a manner that the Gate Array will be reset by an

output from the watchdog timer of the CPU. The CPU itself has been set so that it will be reset. So that

the head strobe will not be turned to ON at that time, be sure to insert one pull-up resistor into STRB1 through

STRB3, respectively.

17 CITIZEN

Page 18

4.9 PaperEnd Detection Circuit

A paper sensor built in the printer detects whether there is the printing paper, so that the printer will not be

turned on when it has no paper.

When the printer has no paper,PAPER (Pin7) of the CPU is turned to "HIGH." If printing is

under way, it will stop after printing that line, and output an error. When the paper is set,

printingis automatically resumed.

CBM-202PC-04 User’s Manual

18 CITIZEN

Page 19

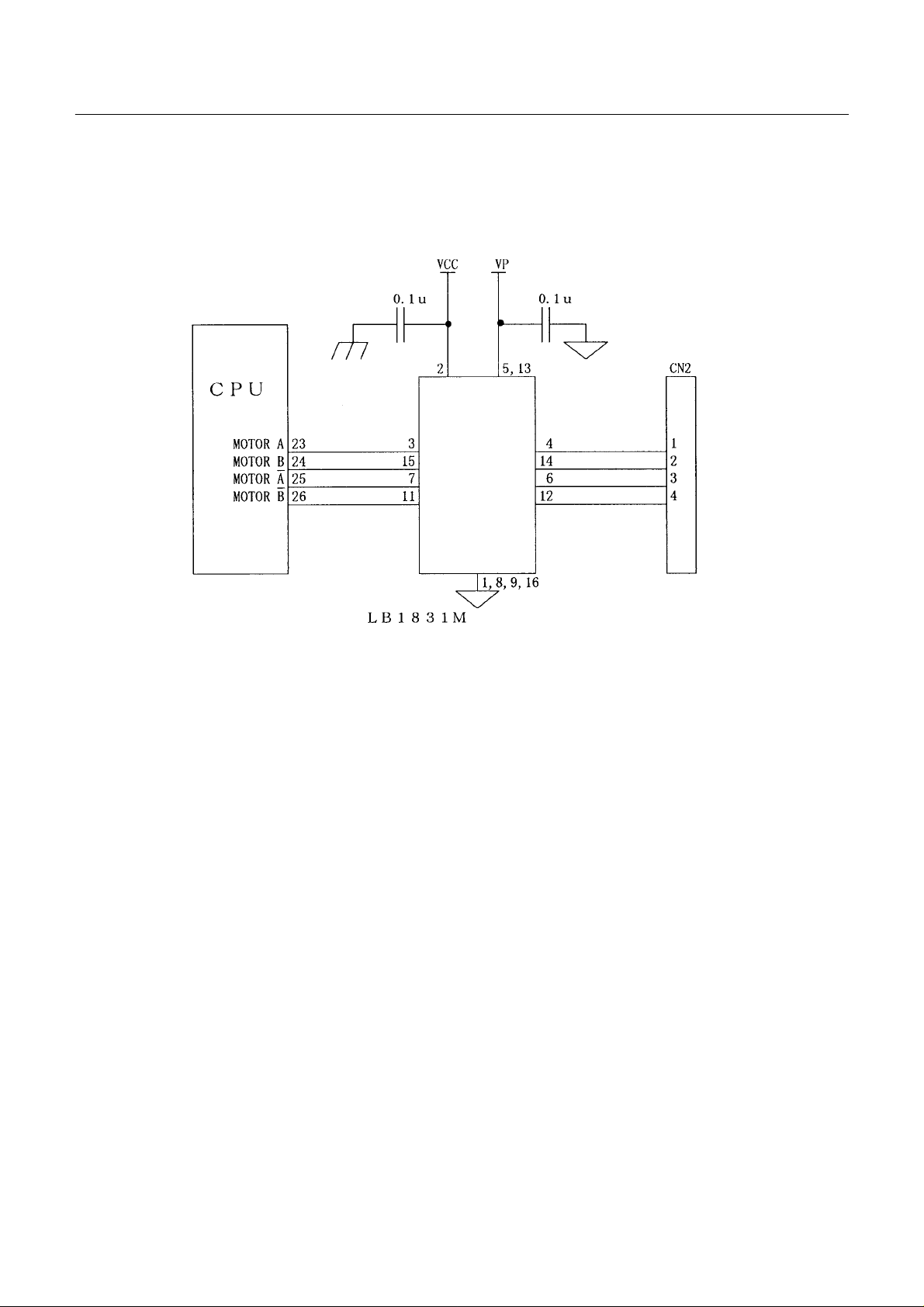

4.10 Motor Control Circuit

Avoidrunning the motor continuously for 15 minutes or more.

CBM-202PC-04 User’s Manual

19 CITIZEN

Page 20

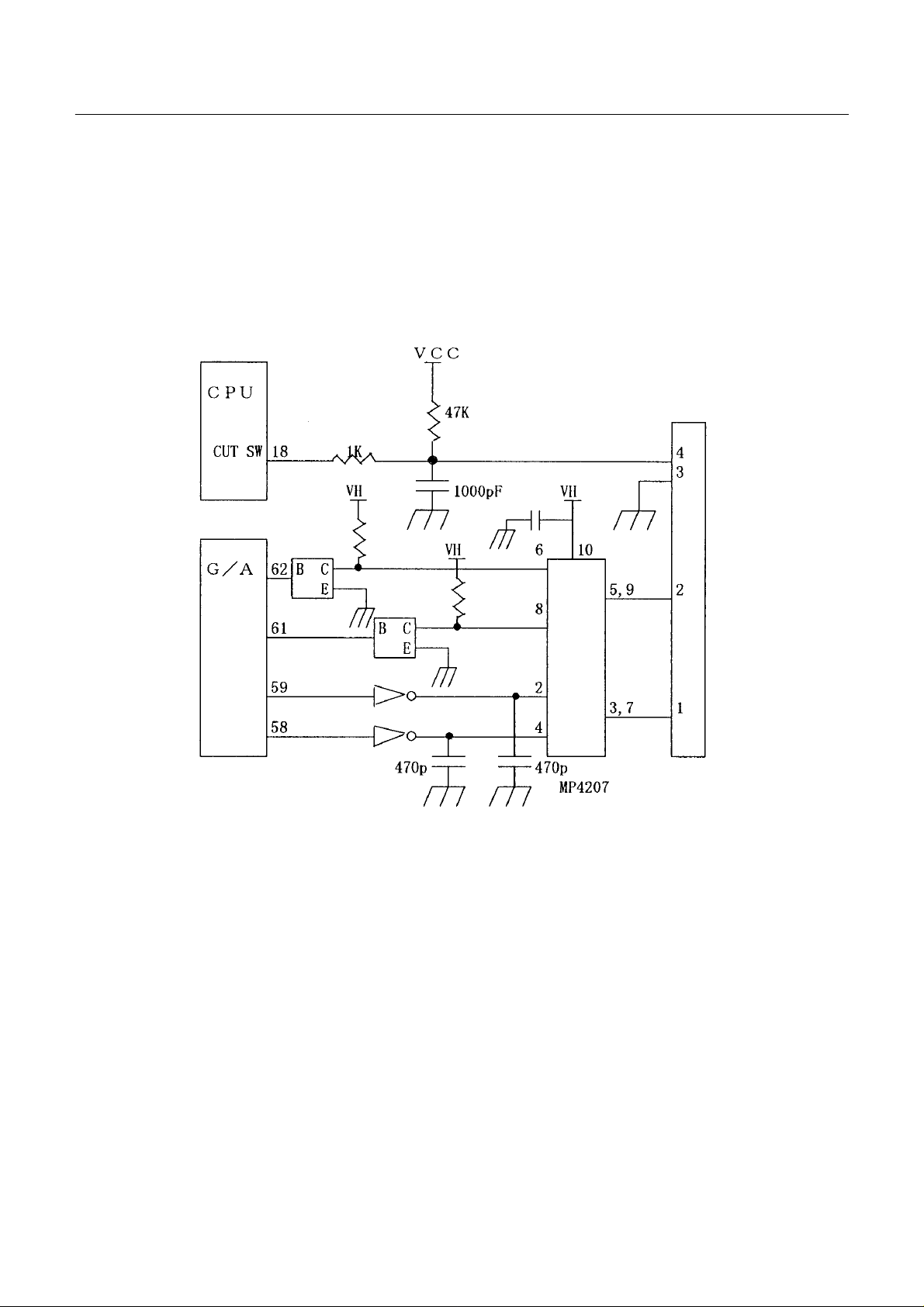

4.11 Auto Cutter Control Circuit

This CPU has a function to control the auto cutter, using the Pin 33 of the Gate Array.

When the auto cutter is not used, set the Pin 33 of the Gate Array to "HIGH." If se t to "LOW,"

the printer will not function properly, resulting in an alarm.

CBM-202PC-04 User’s Manual

20 CITIZEN

Page 21

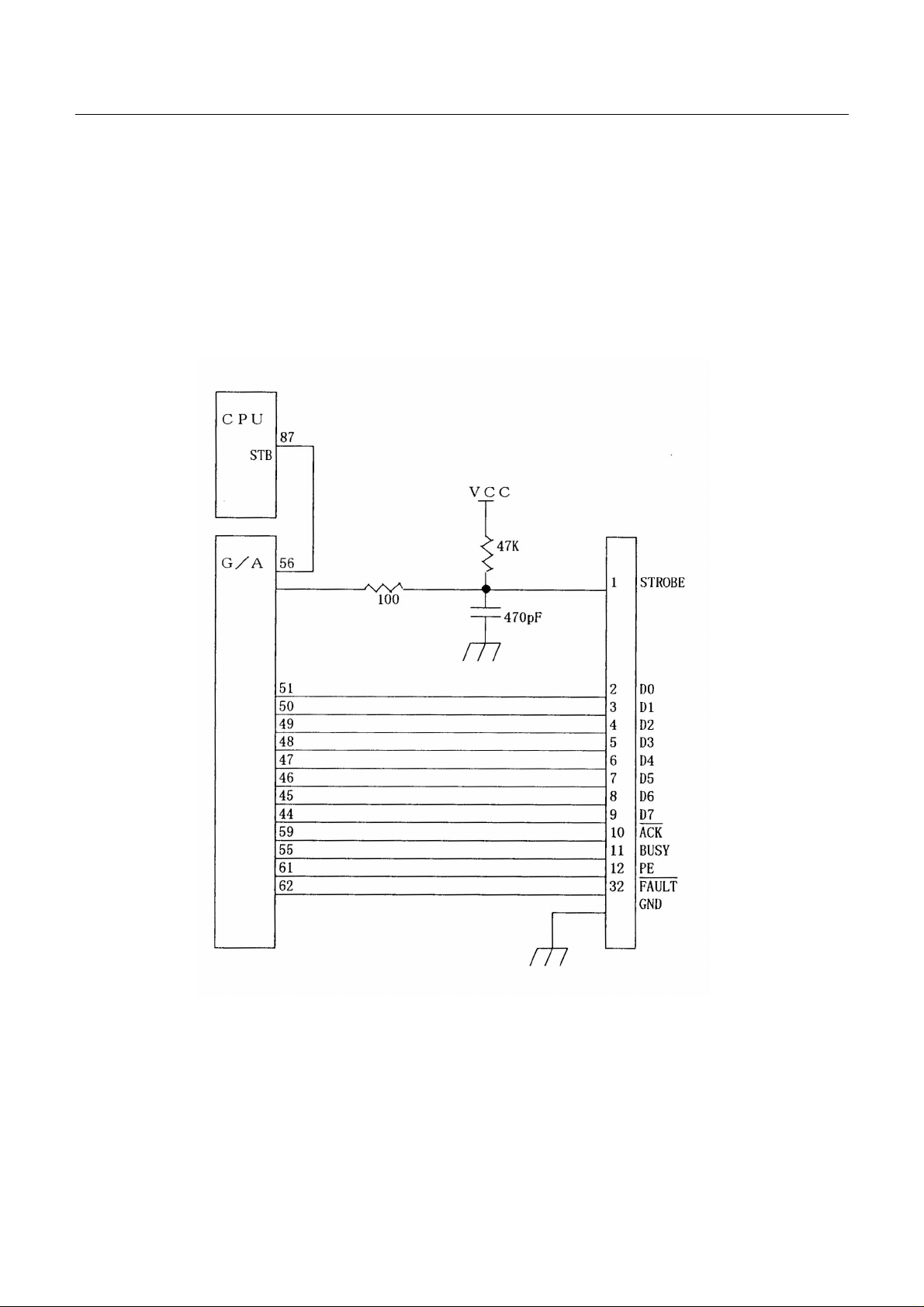

4.12 ParallelInterface Circuit

The Gate Array ports are mainly used to provide an 8-bit parallel interface.

When the parallel interface is not used, pull up STB(Pin 52) of the Gate Array with a 10kΩ resistor.

STB(Pin 87) of the CPU should be connected to INTR(Pin 56) of the Gate Array or pulled up with a 10kΩ

resistor.

1) Circuit

CBM-202PC-04 User’s Manual

21 CITIZEN

Page 22

2) Gate Array Signals and Their Functions

Signal Pin No. I/O Functio n

STROBE 52 Input A signal to read in the data.(Negative logic)

D0 51

D1 50

D2 49

CBM-202PC-04 User’s Manual

D3 48

D4 47

D5 46

D6 45

D7 44

ACK 59 Output

BUSY 55 Output

PE 61 Output A signal to be output when the paper runs out. (Positive logic)

FAULT 62 Output A signal to indicate a printer error. (Negative logic)

GND

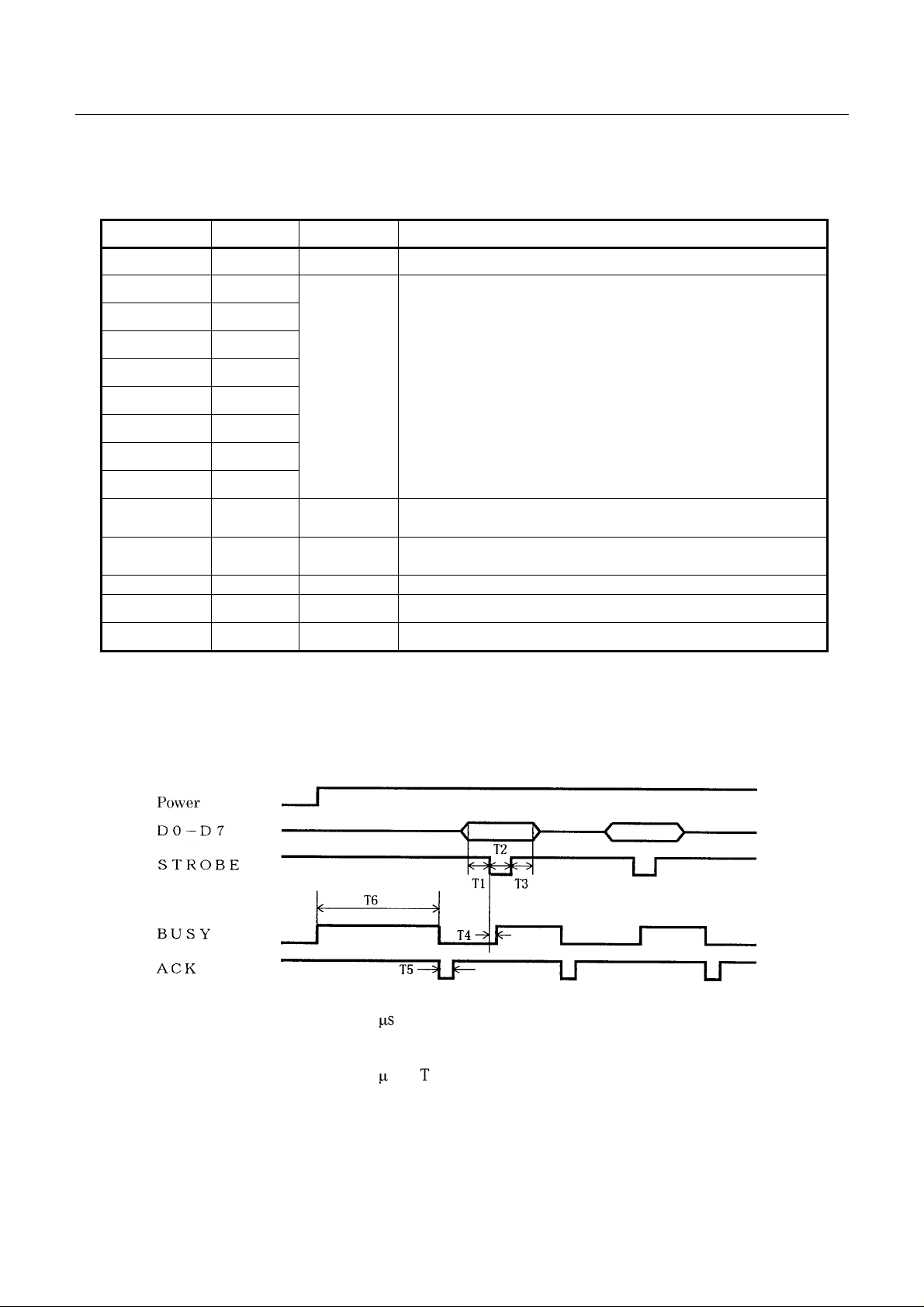

3) Timing chart

Input Input data (Positive logic)

A signal to indicate that the data has been read. (Negative

logic)

A signal to indicate that the data cannot be received. (Positive

logic) Send the data when at "LOW."

T1, T2, T3 : 0.5sMIN

T4 : 270 ns MAX

T5 : 2.3sTYP

T6 : 500 ms MIN

22 CITIZEN

Page 23

CBM-202PC-04 User’s Manual

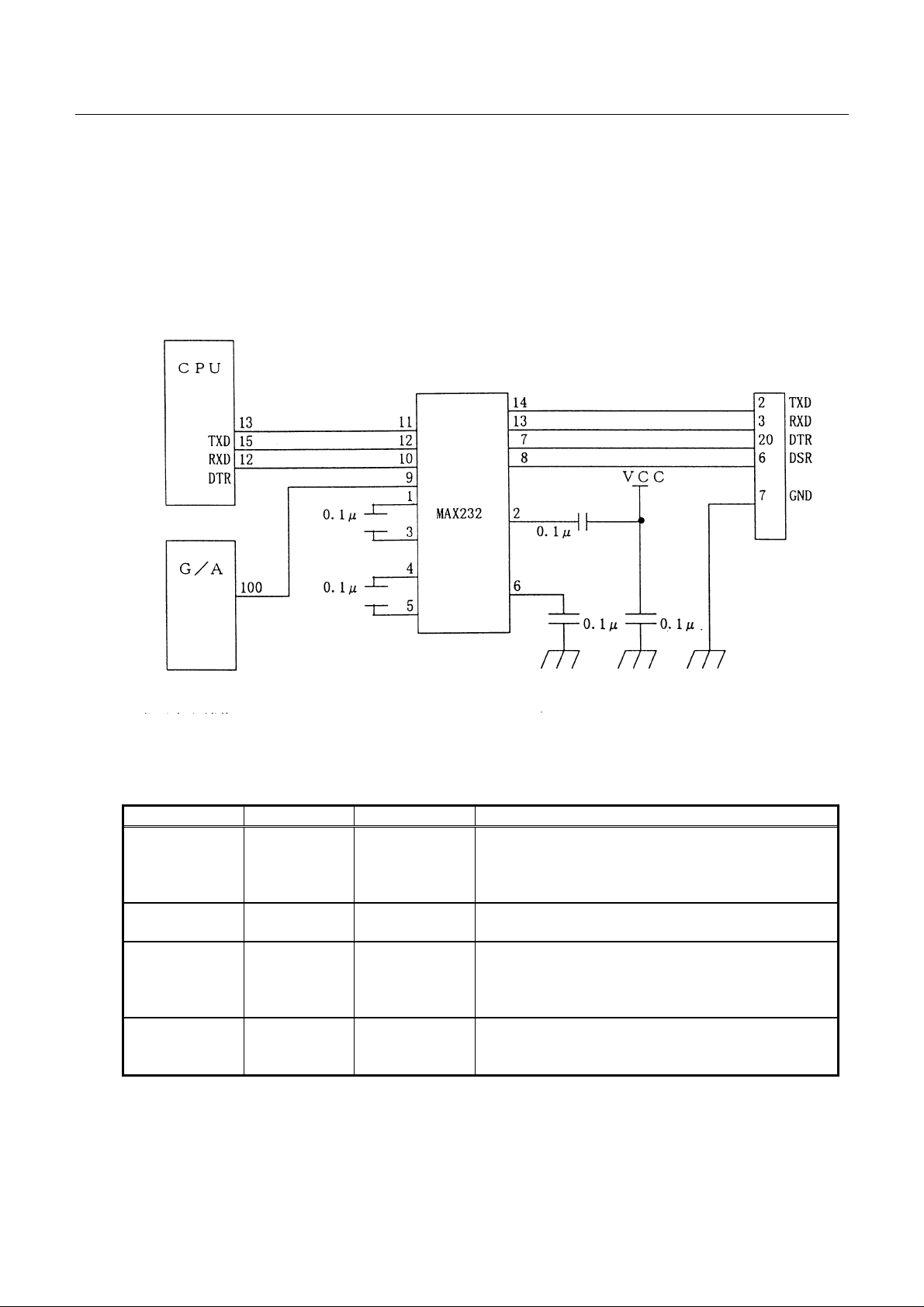

4.13 Serial Interface Circuit

A serial interface is an asynchronous serial system. When the serial interface is not used, pull up RXD (Pin

15) and DSR (Pin 100) ofthe CPU with a 47kΩ resistor.

1) Circuit

2) Signal names and their functions

Signal Name Pin No. Input/Output Function

Transmits the status.

TXD 13 Output

RXD 15 Input

DSR 100 Input

DTR 12 Output

If data reception is disabled when XON/XOFF is

selected, XOFF(13H) will be transmitted, and if data

reception is enabled, XON(11H) will be transmitted.

Received data signal. If a framing error or parity

error occurs, the relevant data will be printed "?".

With DTR/DSR selected, if this signal is "LOW," the

data will be transmitted from the CPU. If "HIGH,"

the data will be transmitted after the signal is turned

to "LOW."

Transmit the data when this signal is "LOW." If

written when it is "HIGH," an overrun error will

result, ignoring the data.

23 CITIZEN

Page 24

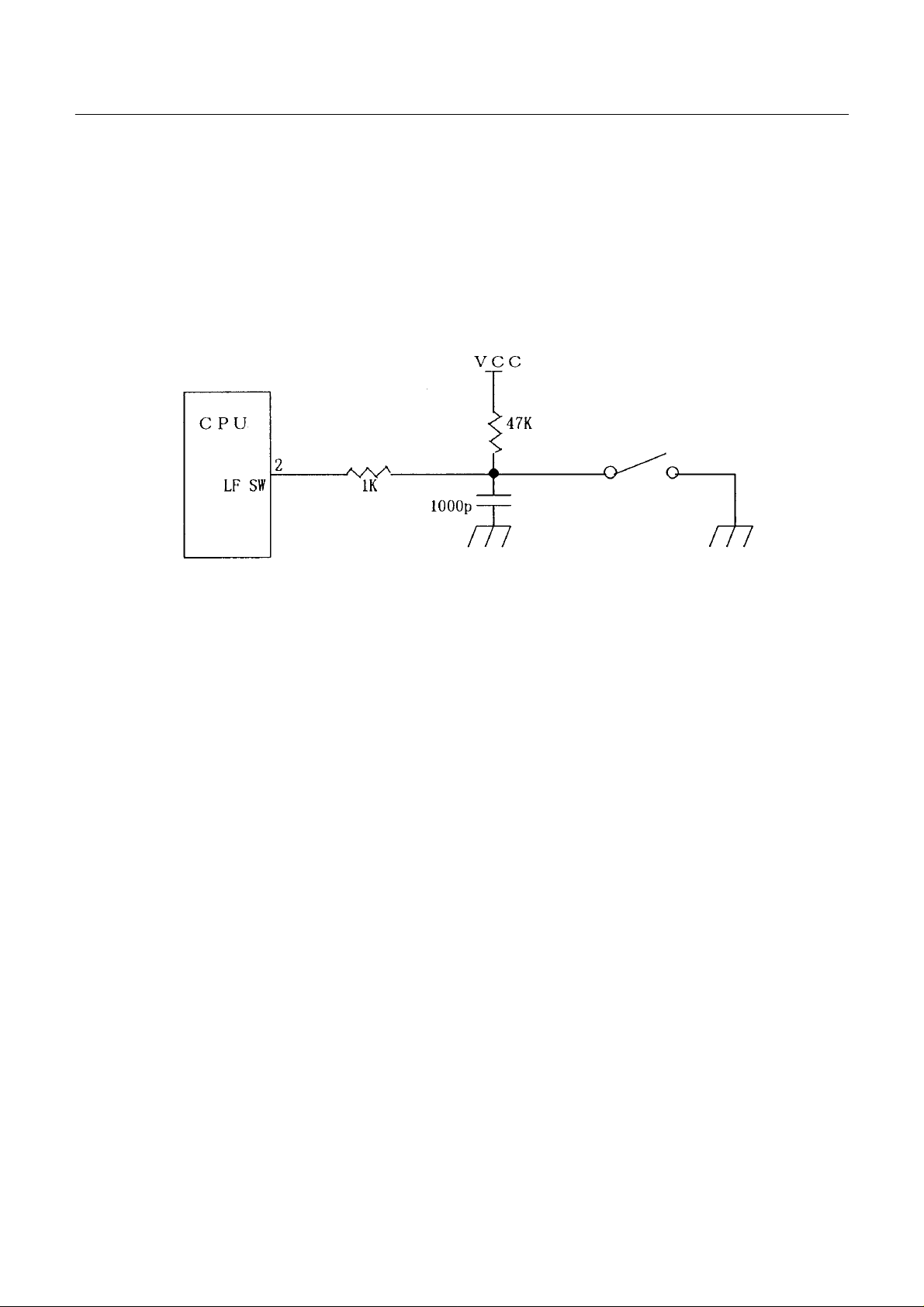

4.14 Switch Circuit

The printer has a switch input function for paper feed. Also provided is a function to perform self -printing,

using this switch. (Turn on the power while holding down this switch, or apply a reset with this switch held

down whenthe power has beenalready turned on. The printer automa ticallystarts self-printing and returns

to the normal waiting state after printing is completed.)

CBM-202PC-04 User’s Manual

24 CITIZEN

Page 25

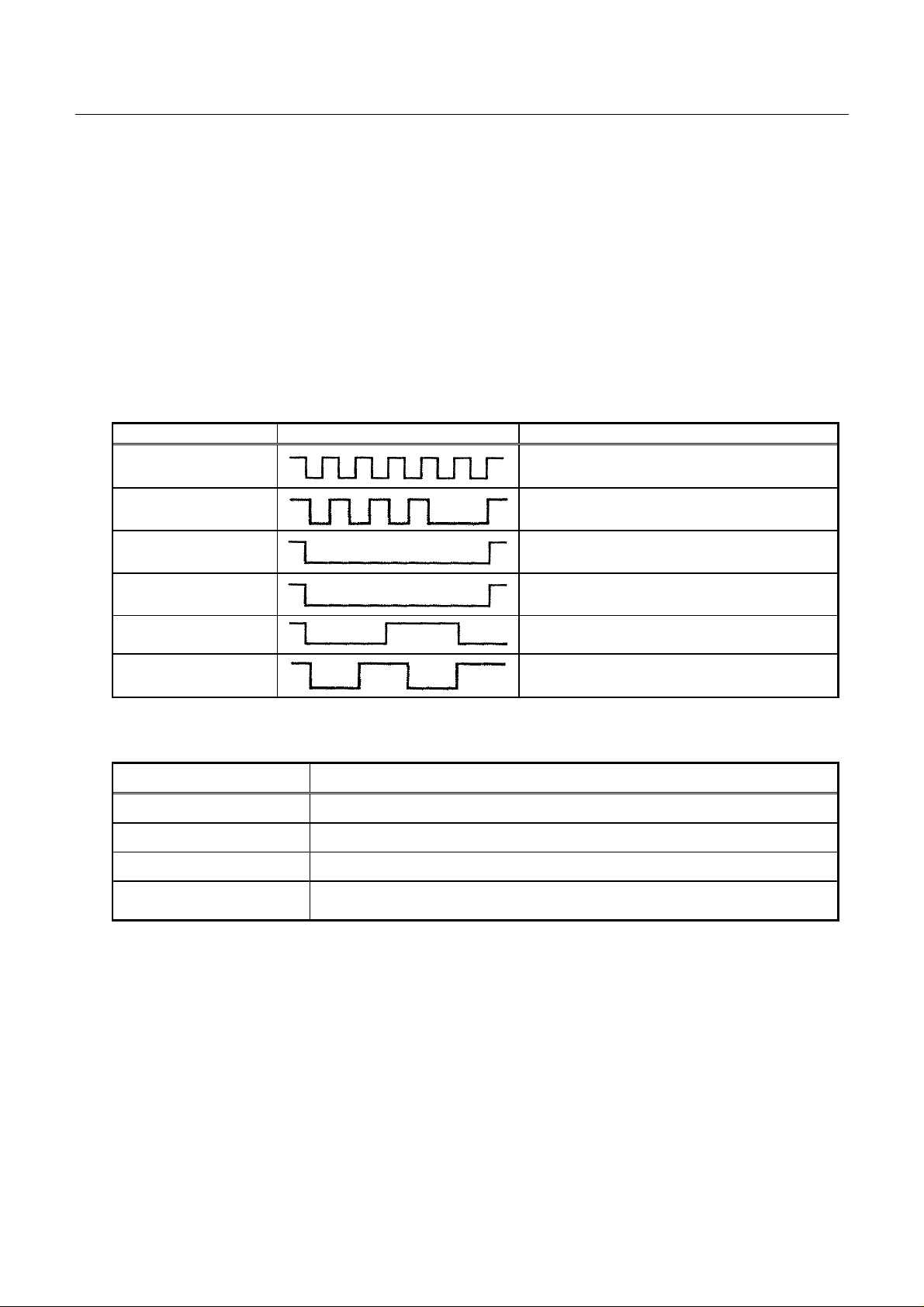

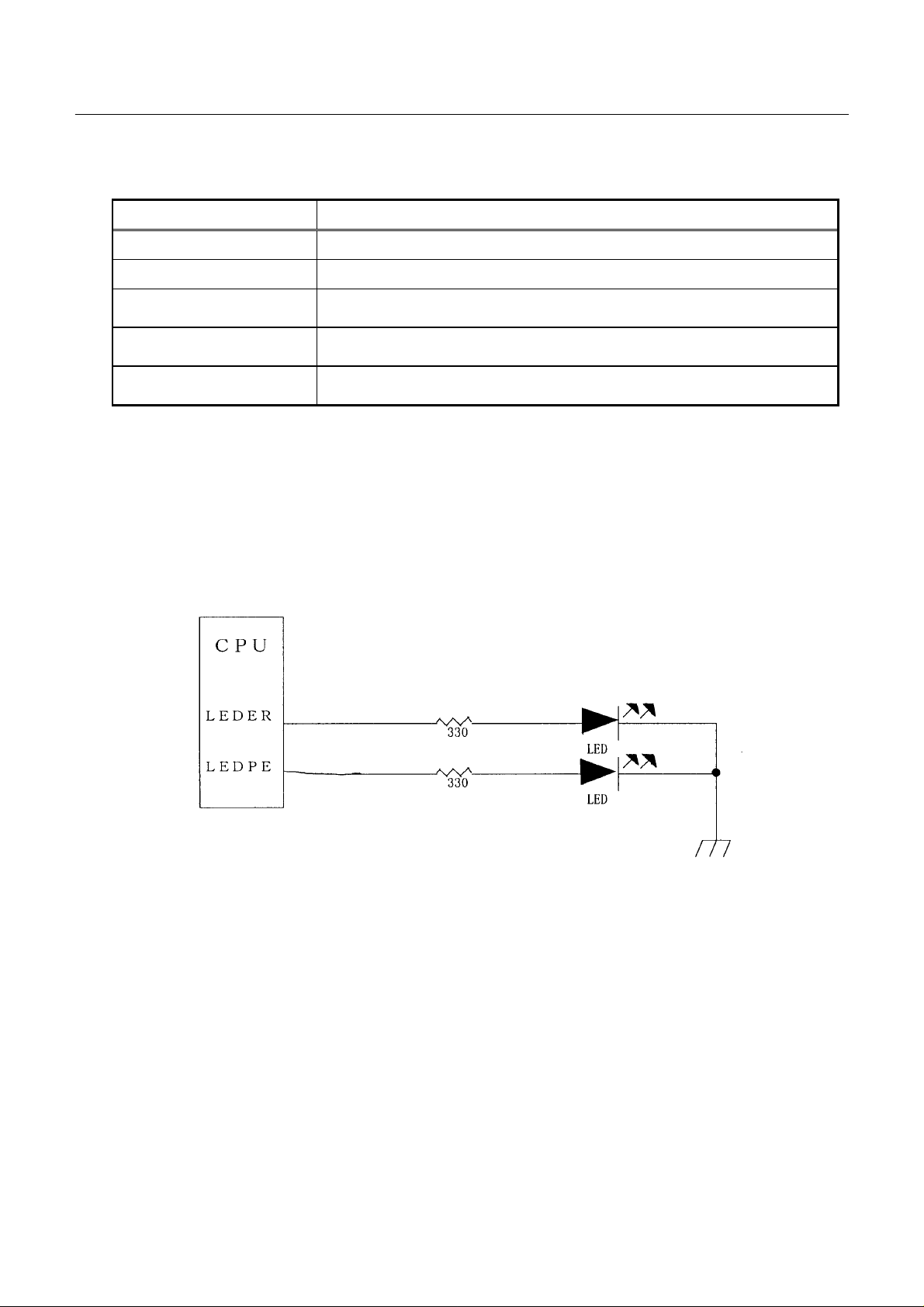

4.15 ErrorOutput Circuit

The printer has two kinds of error outputs. (Up to a current of 10mA is available in order to mainly indicate

with the LEDs. If this limit is exceeded, the CPU may be destroyed. Select the current control resistors,

LEDs, etc. carefully.)

LEDPE(Pin 4) of the CPU is a paper error exclusive output. "LOW" is output when the printing paper runs

out, and "HIGH" is output when new printing paper is set. LEDER(Pin 3) of the CPU outputs other errors

in the follow ing patterns.

1) Error output pattern

Error Display Pattern Description

Memory error

CBM-202PC-04 User’s Manual

Blinks at intervals of 200ms

Cutter lock

(Cutter error)

Head-up

VH voltageerror

Headtemperature

error

Macro execution wait

2) Error descriptions

Error Description

Head-up The head-up lever has been shifted up.

VH voltage error Whenthe VH voltage is beyondan allowable range (4.2 ~ 8.5V)

Headtemperatureerror When a headtemperatureis less than 0°C or 65°C or more

Cutter lock

(ASC-220-5V)

Note) The upper-limit voltage of 8.5V for the VH voltage error is a voltage assumed only immediately after

When t he cutter is locked due to an external factor (Paper jam, etc.) at cutter

drive time

Blinks at intervals of 150 ms(6 times) and 500

ms(1 time) as one cycle.

Illuminated until the error is reset.

Illuminated until the error is reset.

Blinks at intervals of 1 sec.

Blinks at intervals of 500ms

charging the battery when the battery power is used and cannot be normally used. A maximum

normal voltage is 7.2V.

25 CITIZEN

Page 26

CBM-202PC-04 User’s Manual

3) Resetting methods

Error ResettingMethod

No-paper Set the paper. See Note 1.

Head-up Shift down the head-up lever.

VH voltageerror

Headtemperatureerror

Cutter lock(ACS-220-5v)

Set the VH voltage to within the allowable range(4.2 ~ 8.5 V) and turn on the

power again, or set the LFSW(Pin-2) of the CPU to Active. See Note 2.

At the lower limit(Less than 0°C), printing is enabled at 0°C or more.

At the upper limit(65°C or more), printing is enabled at 60°C or less.

Eliminate the paper jam and set LFSW(Pin-2) of the CPU to Active or turn

on the power again.

Note)

1. If auto loading has not been selected with the function selection J4(Jumper), set the paper manually.

If it has been selected, the auto loadingfunction will be enabledto facilitate pap e rreplac e ment.

2. The upper-limit voltage of 8.5V for the VH voltage error is a voltage assumed only immediately after

charging the battery when the battery power is used and cannot be normally used. A maximum

normal voltage is 7.2V.

26 CITIZEN

Page 27

4.16 Function Selection Circuit

The input port of the Gate Array has function selecting terminals. When connecting the DIP switch, and so

on, connect them as they are. When fixing with a Jumper, and so on, only the terminals you want to set to

"LOW" should be connected to GND.

CBM-202PC-04 User’s Manual

Gate Array

Function “LOW” “HIGH”

Pin No. Signal

33 PAI0 Auto cutter Enabled Disabled

32 PAI1 CR change LF operation Ignored

31 PAI2 Printing density See Table (3)

30 PAI3 DTR/XON–XOFF XON–XOFF DTR/DSR

29 PAI4

28 PAI5

Interface See Table (1)

27 PAI6

26 PAI7

P AI3 is valid only when the serial interface is used.

Gate Array

Function “LOW” “HIGH”

Pin No. Signal

43 PBI0

42 PBI1

International

characters selection

See Table (2)

39 PBI2

38 PBI3 Auto loading Enabled Disabled

37 PBI4 Drive system Dynamic drive Fixed division

36 PBI5 Printingdensity See Table (3)

35 PBI6 Unused

34 PBI7 Unused

––

––

P AI6 is valid only when the serial interface is used.

27 CITIZEN

Page 28

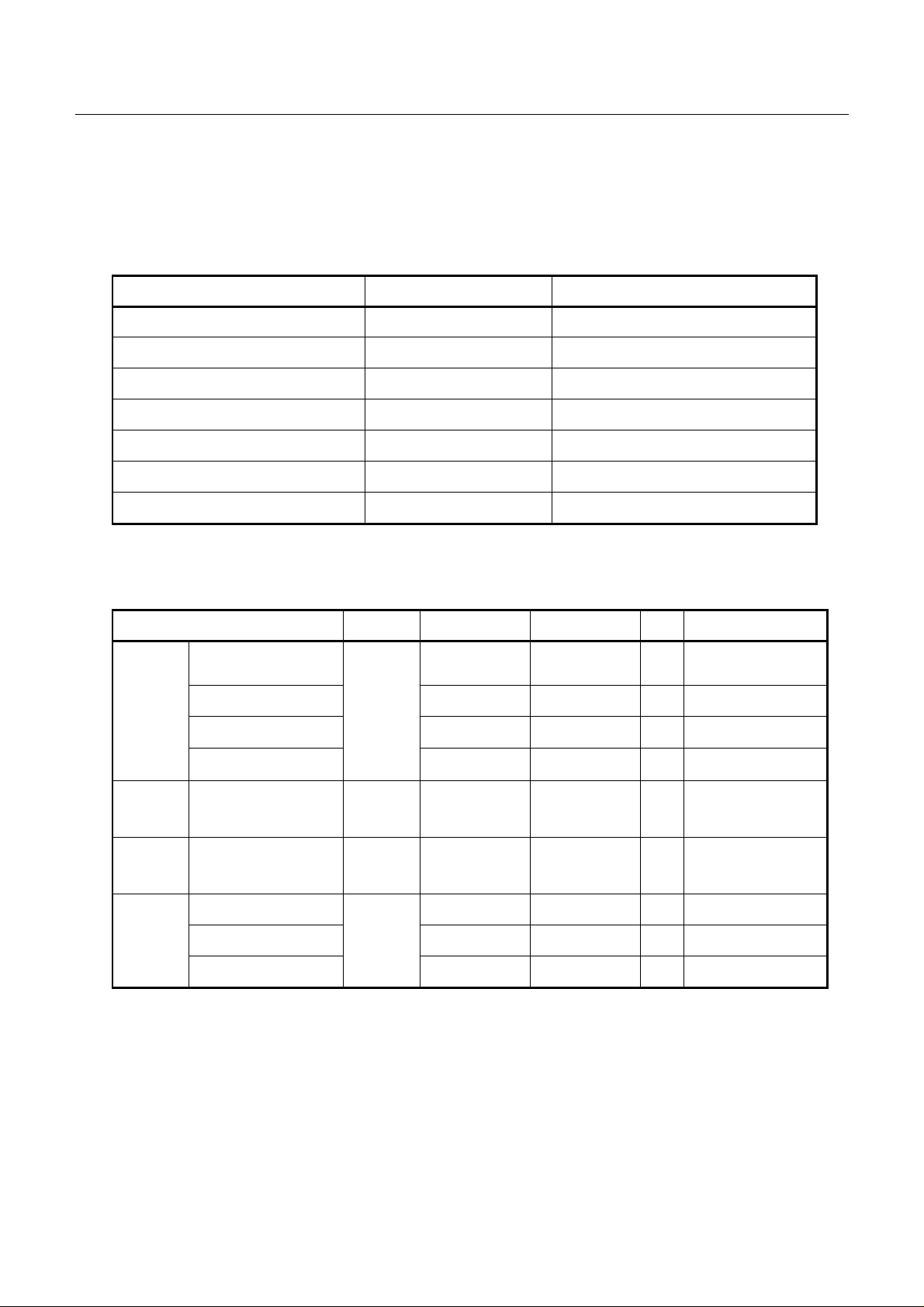

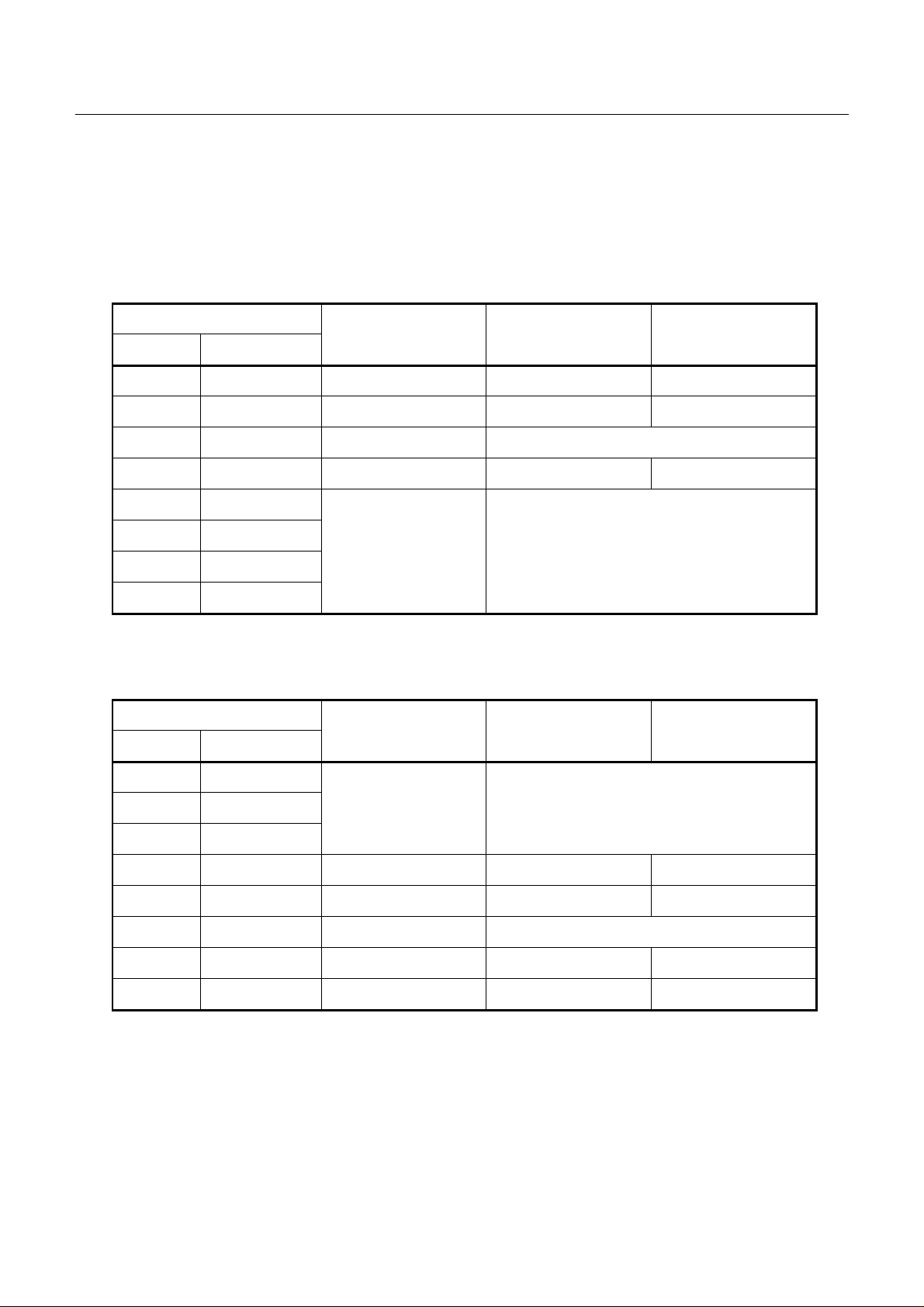

(1) Interface

CBM-202PC-04 User’s Manual

Input

System

Parallel

Serial

Parity Baud Rate PAI7 PAI6 PAI5 PAI4

––

HIGH HIGH HIGH HIGH

1200 HIGH HIGH HIGH LOW

2400 HIGH HIGH LOW HIGH

None

4800 HIGH HIGH LOW LOW

9600 HIGH LOW HIGH HIGH

19200 HIGH LOW HIGH LOW

1200 HIGH LOW LOW HIGH

2400 HIGH LOW LOW LOW

Odd

4800 LOW HIGH HIGH HIGH

9600 LOW HIGH HIGH LOW

19200 LOW HIGH LOW HIGH

1200 LOW HIGH LOW LOW

2400 LOW LOW HIGH HIGH

Even

4800 LOW LOW HIGH LOW

9600 LOW LOW LOW HIGH

19200 LOW LOW LOW LOW

28 CITIZEN

Page 29

(2) International characters

International Characters PBI2 PBI1 PBI0

Japan (JIS) HIGH HIGH HIGH

Japan (Shift JIS) HIGH HIGH LOW

Sweden HIGH LOW HIGH

Denmark I HIGH LOW LOW

U.K. LOW HIGH HIGH

Germany LOW HIGH LOW

France LOW LOW HIGH

U.S.A. LOW LOW LOW

(3) Printing density

CBM-202PC-04 User’s Manual

PrintingDensity PAI2 PBI5

Light HIGH HIGH

Standa rd HIGH LOW

Slightlydark LOW HIGH

Dark LOW LOW

29 CITIZEN

Page 30

4.17 External RAM Interface

A 32 KB external SRAM is always required for printing. The printer does not function properly unless the

external RAM is connected.

1) Circuit

CBM-202PC-04 User’s Manual

30 CITIZEN

Page 31

CBM-202PC-04 User’s Manual

Bus Timing

2)

VCC= 5.0V±10%, AVCC= 5.0V±10%, VREF= 4.5V ~ AVCC, VSS=AVSS= 0V, φ = 2 ~ 16MHz,

–

TA=

20~75°C

Item Symbol MIN MAX

Clockcycle time t cyc 62.5 500

Clock pulse width "LOW" level time

Clock pulse width "HIGH" level time

Clock rise time

Clock fall time

Address delay time

Address hold time

Address strobe delay time

Write strobe delay time

Strobe delay time

Write data strobe pulse width 1

Write data strobe pulse width 2

Address setup time 1

Address setup time 2

Read data setup time

Readdatahold time

t

CL

t

CH

t

CR

t

CF

t

AD

t

AH

t

ASD

t

WSD

t

SD

t

WSW1

t

WSW2

t

AS1

t

AS2

t

RDS

t

RDH

20

20

10

35

65

10

40

20

–

–

–

–

–

10

10

30

–

–

–

–

30

30

30

–

–

–

–

–

0

–

Write data delay time

Write data setup tim e1

Write data setup tim e2

Write data hold time

Readdata accesstime 1

Readdata accesstime 2

t

WDD

t

WDS1

t

WDS2

t

WDH

t

ACC1

t

ACC2

–

35

5

20

–

–

60

–

–

–

55

115

Unit : ns

31 CITIZEN

Page 32

CBM-202PC-04 User’s Manual

32 CITIZEN

Page 33

CBM-202PC-04 User’s Manual

5. PRINTER MECHANISM CONTROL SYSTEM

5.1 Head Drive

5.1.1 ThermalHead Control System

The LT-286 is driven by this LSI has a 1-line printing head divided into 6 blocks of 64 dots each. With this

LSI, you can choose either a Fixed Division Number System which drives the printing head by always

dividing it into 6 blocks of 64 dots each ora Variable Division Number System which simultaneously drives it

by consolidatingseveral blocks according to the number of activate head dots. This selection is made with a

function selection terminal or command. For selecting withthe function selecting terminal, see "4.16 Function

SelectionCircuit. " For selectingwith the command, see "10.2 Co mmand Details."

(1) Fixed Division Number System

The blocks of the printing head to be simultaneously driven have been determined in advance. Printing is

performed, dividing into 6 blocks of 64 dots each from the left corner of the printing surface of the printing

paper. Since the printing head is always driven in the same order, this method can assure high-quality

printing. In the Fixed Division Number System, the blocks of the printing head driven in the 1st and 2nd

steps of the motor have been determined as shown in Fig. 5.1.

Fig. 5.1

1st Block;

64 Dots

2nd Block;

64 Dots

1st Step of Motor

3rd Block;

64 Dots

4th Block;

64 Dots

5th Block;

64 Dots

2nd Step of Motor

6th Block;

64 Dots

(2) Variable Division Number System

This method counts the number of printing dots for each block of each printing head in the printing dot line

and drives the blocks collectively in such a manner not to exceed the maximum number of driving dots(64

dots). Fig. 5.2 shows an example when the number of printing dots in every block of 1 to 6 is 64 dots or

less.

Fig. 5.2

1st Block;

64 Dots

2nd Block;

64 Dots

3rd Block;

64 Dots

1st Step of Motor

4th Block;

64 Dots

5th Block;

64 Dots

6th Block;

64 Dots

2nd Step of Motor

Different from the Fixed Division Number System, this method drives all the printing heads in the 1st

step of the motor and simply feeds the paper in the 2nd step of the motor.

33 CITIZEN

Page 34

CBM-202PC-04 User’s Manual

5.1.2 Thermal Head Application Energy

This LSI automatically controls the energy applied to the thermal head according t o a temperature and Vp

voltage. Wi ththe function selection terminal, print density can be set to the following4 kinds of ranks listed

in Fig. 5.3.

Fig. 5.3

Gate Array Pin-31 GateArrayPin-36 Print Density Level

LOW LOW Light 0 80 %

LOW HIGH Standard 1 100 %

HIGH LOW S lightly dark 2 120 %

HIGH HIGH Dark 3 150 %

Print Density

5.2 Motor Drive

There are the following features:

1) Prevents heat generation of the motor and restrains current consumption through PWM control.

Rate

2) Controls acceleration at start time.

3) Capable of providing fine control according to a voltage(VH) applied to the motor to realize optimum

paper feed.

Table 5.1 lists the maximum drive speeds at major voltages.

Table 5.1

VH Voltage Max. Drive Speed At Auto Loading

5 V 300 pps 75 pps

6 V 490 pps 122 pps

7.2 V 800 pps 200 pps

Notes)

• The maximum drive speed may slightly differ depending on the actual processing time or voltage

detection accuracy.

• If the head drive time becomes longer tha n the 1-step time of the motor during printing, the motor

will be driven after the head. During printing, therefore, the drive speed will be slowed down due to

the head divided driving method.

• The drive speed at auto loading time is 1/4 of the m aximum drive speed at each VH voltage.

34 CITIZEN

Page 35

5.3 Auto Loading

Autoloadingis a functionto facilitate replacement of the printing paper.

It is enabled by setting the function selection terminal(Gate Array Pin 38) to "LOW."

Functioning:

1) Make the PE sensor detect PE once.

2) Insert the printing paper into the printing paper insertion slot until the PE sensor detects the paper

again. When this is done, the paper should be inserted at a right angle to the insertion slot; insert it

until it comes to the end.

3) When this is done, if the head-up lever is shifted down, auto loading will be performed. If the

head-uplever is shiftedup, shift it down. Then, autoloading will be performed.

4) See Table 5.1 for the drivespeed.

CBM-202PC-04 User’s Manual

35 CITIZEN

Page 36

CBM-202PC-04 User’s Manual

6. SELF-PRINTING

This LSI displays the setting of the function selection terminal and has a test print function to print Kanji when

printing the half-size characters or using the specified Kanji ROM(CBM-202KG-01).

Theprocedureisasfollows:

1) Turn on the power, setting LFSW(Pin 2) of the CPU to "LOW." Turn on both Vcc and VH almost

simultaneously, or turn on Vcc, followed by VH(Within 500ms after Vcc).

Fig. 6.1 shows a print sample(A print differs from actual dimensions).

Fig. 6.1

36 CITIZEN

Page 37

7. OPERATION TIMINGS

The followingshows operation timings after resetting this CPU.

CBM-202PC-04 User’s Manual

37 CITIZEN

Page 38

8. SPECIFICATIONS OF PACKAGE

CBM-202PC-04 User’s Manual

38 CITIZEN

Page 39

9. PRECAUTIONS FOR MOUNTING

9.1 Precautions

If a relative humidity drops, the LSI will be electrified with static electricity more easily. The surface

mounting package must be stored in a dry atmosphere to prevent humidity absorption, but while it is being

stored, it will not be electrified because it will not have friction, etc. When handling or mounting it onto the

PCB where friction or electric discharge may be expected, the relative humidity is desired to be 45~75%

from a viewpoint of prevention of electrification.

9.2 Reflow Mounting

Using the screen printing method, etc., apply a constant amount of solder paste to the pattern on the PCB,

whichwas formed intothe specifiedshaperequired for solderingthelead pinstoa package mounting section,

and mount the package onto it. It will be temporarily fixed by the surface tension of the solder paste.

Then, if the solder is melted(reflow) again, the leads of the package and the pattern of the PCB will be

matched by a self-alignment effect through the surface tension of the molten solder.

Although the lead joint pattern design values of the PCB depend on the solder paste material used, reflow

condition, etc., they should be preferably 1.1~1.3 times larger than a soldered lead pin width.

CBM-202PC-04 User’s Manual

9.3 Recommended Conditions for Different Mounting Methods

The most common mounting methods employed for the surface mounting devices are the infrared reflow

method, vapor phase reflow method, and flow solder method. As all of those mounting methods must heat

the entire package and apply a strong thermal stress, they require you tomanage not only a temperature at the

solder joints,but that on the package surface, froma viewpoint of maintenance of reliability. Therefore, the

recommended mounting conditions are given in terms of the package surface temperature for the reflow

method, and in terms of solder temperature and immersion time for the flow solder method.

The following describes the concepts of the recommended conditions, using Fig. 9.1.

Fig. 9.1

39 CITIZEN

Page 40

CBM-202PC-04 User’s Manual

1) Temperature gradient 1

If a temperature rises abruptly, each joint of the surface mounting device to the package will have

different t emperature. As a result, t he package may warp due to a difference in the thermal expansion

factor of the material, thus damaging the chip. Therefore, it is necessary to heed the upper limit of an

ascendingrate. The lower limit depends on the activity rate of the reflow unit.

2) Preheating

The temperature of the parts and PCB is adjusted under the melting temperature of the solder to stabilize

soldering and ease a thermal shock. Generally, set to near the rated temperature of the surface

mounting device.

3) Temperature gradient 2

The upper limit of the ascending temperature is the same as in 1). The lower limit is determined by

necessityto contain the peak temperature and time m e ntionedin 4) within the specifiedranges.

4) Peak tempe rature and time

In order to minimize damages on the package, the peak temperature and time must be most heeded.

Since the peak time has a direct effect on a drop of package strength and a steam pressure in the package,

it is desired to be kept as low as possible. The peak time is required to be minimized because the steam

pressure increases along with a lapse of time. The conditions mentioned here are provided at a

coincident point of the above-mentioned allowable range and a solderable range. As they are

represented by upper-limit values, not average values, care should be taken not to exceed the upper-limit

values when setting the conditions. Fig. 6.2 and Fig. 6.3 shows the recommended conditions for the

different m ounting methods.

Fig. 9.2 Infrared Reflow and Air Reflow Recommended Conditions

40 CITIZEN

Page 41

Fig. 9.3 Vapor Phase Reflow Recommended Conditions

CBM-202PC-04 User’s Manual

6.4 Cleaning Method

After soldering, eliminate/clean remaining flux off the PCB because it affects reliability of the parts and PCB

wiring, as a rule.

As an example, ultrasonic cleaning is employed under the following conditions. In order to prevent

destruction of the device, pay attention to an applied frequency, electric power(particularly peak power), time

and resonance of the device.

• Frequency ----- 28~29kHz (The device should not resonate)

• Ultrasonic output ----- 15W/each time

• Time ----- 30sec or less

• Others ----- The deviceandPCB should not directly touch a vibration source.

6.5 Storage Method

The epoxy resin used for the plastic package cannot resist absorbing moisture when it is stored in a

high-humidity place. If more moisture is absorbed, it will be abruptly vaporized at the time of soldering

and cause exfoliation of the resin/lead frame interface, resulting in the cracks of the package in the worst case.

As it is important to store in a dry atmosphere(preferably normal temperature and humidity; 5~35°C and

45~75 % RH as guides), the package is packed damp-proof. After unpacking it, store it under a prescribed

environment in order to minimize moisture absorption, and perform reflow mounting as quickly as possible.

When you re-store it in damp-proof packing, put moisture-free silica gel in it and seal again. When you

want to eliminate moisture absorbed during transportation, storage, or handling, it is recommended to dry(At

125°C) for 16~24 hours.

The external terminals should be stored unprocessed. This is to avoid a soldering failure due to occurrence

of rust at the time of mounting.

41 CITIZEN

Page 42

CBM-202PC-04 User’s Manual

10. PRINT CONTROL FUNCTIONS

10.1 Commands List

Control Code Function Code Page

1 HT Horizontal tab command 09H

2 LF Printing and paper feed 0DH

3 CR Print command 0DH

4 ESC SP Setting th e right space amount of the character 1BH 20H n

5 ESC ! Collective specifying printing mode 1BH21H n

6 ESC % Specifying/canceling download character set 1BH 25Hn

7 ESC & Defining download characters 1BH 26H 5 n m[a p1 p2 ... psxa]m-n+1

8 ESC * Specifying the bit image mode 1BH 2AH mn1n2[d]k

9 ESC – Specifying/canceling underline 1BH 2DH n

10 ESC 2 Specifying 1/6-inch line feed rate 1BH 32H

11 ESC 3 Setting line feed rate of minimum pitch 1BH 33H n

12 ESC = Data input control 1BH 3DH n

13 ESC @ Initializing the Printer 1BH 40H

14 ESC D Setting horizontal tab position 1BH 44H [n]k00H

15 ESC E Specifying/canceling highligh ting 1BH 45H n

16 ESC G Specifying/canceling double printing 1BH 47H n

17 ESC J Printing and feeding paper n/203 inch 1BH 4AH n

18 ESC R Selecting the international character set 1BH 52H n

19 ESC V

20 ESC a Aligningthe characters 1BH 61H n

21 ESC c3 NOP

22 ESC c4 NOP

23 ESC c5 Enabling/disabling the panel switches 1BH 63H 35H n

24 ESC d Printing and feeding the paper by n lines 1BH 64H n

25 ESC i Activating auto cutter (Full cut) 1BH 69H

26 ESC m Activating auto cutter (Partial cut) 1BH 6DH

27 ESC p NOP

28 ESC t Selecting the character code table 1BH 74H n

29 ESC u NOP

30 ESC v Transmitting the printer status (Serial type) 1BH 76H n

31 ESC { Specifying/canceling the inverted characters 1BH 7BH n

32 ESC $ Specifying the absolute positions 1BH 24H n1 n2

33 ESC ¥ Specifying the relative positions 1BH5C n1 n2

34 GS k Printing the bar code 1DH 6BH n [“d”]k00H

35 GS w

36 GS h Selecting the height of the bar code 1DH 68H n

37 GS H Selecting of print position ofHRI code 1DH 48H n

38 GS f Selecting the font of HRI code 1DH66H n

39 GS * Defining the download bit image 1DH2An1n2[d]n1xn2x8

40 GS / Printing the download bit image 1DH 2FH m

Specifying/Canceling90°-right- turned Characters

Selecting the horizontal size (scale factor) of bar

code 1DH 77H n

1BH 56H n

45

45

46

46

47

49

50

52

54

54

55

56

57

58

59

60

60

61

62

63

64

64

65

66

67

68

69

70

71

72

76

77

78

79

80

82

42 CITIZEN

Page 43

CBM-202PC-04 User’s Manual

41 GS : Starting/ending macro definition 1DH 3AH

42 GS ^ Executing the macro 1DH5E n1n2 n3

43 DC2 A Selecting the Print drive system 12H 41H n 85

83

84

Notes: 1. In the table n, n1, n2, n3, m, a, s, p, and d denote the parameters for each command.

2. In the table, [ ]kdenotes a repeat count of k-times.

3. In the table, ’ ’ denotes an ASCII character.

43 CITIZEN

Page 44

CBM-202PC-04 User’s Manual

10.2 Command Details

10.2.1 Description of Items

XXXX ALL

[Function] Com m and Function

[Code] A sequence of code constituting a command is represented in hexadecimal number for <

>H, binary number for < >B, and decimal number for < >, respectively; [ ]k

represents a repeat count of k-times.

[Range] Describes an argument value(Setting range) for the command.

[Outline] Describes a command outline.

[Caution] Describes a caution as required.

[Default] Describes an initial value for the commandwhen accompanied by an argu ment.

[See Also] Describes the associated commands for use.

[Sample Program] Describes a coding example in the Q-BASIC sample program.

This example is only for your reference and differs depending on the language used,

version, and so on. Fordetails, see themanual for the language used.

44 CITIZEN

Page 45

10.2.2 Details

HT

[Function] Horizontal Tab Command

[Code] <09>H

[Outline] Shifts the printing position to the next horizontal tab position.

• Ignored when the next horizontal tab position has not been set.

[Caution] • The horizontal tab position is set by ESC D.

• Initial setting of the horizontal tab position is each 8 characters in 9th, 17th, 25th,

column s.

[SeeAlso] ESC D

[Sample Program]

LPRINT "0123456789012345678901" ;

LPRINT CHR$ (&HA) ;

LPRINT CHR$ (&H9) + "AAA" ;

LPRINT CHR$ (&H9) + "BBB" ;

LPRINT CHR$ (&HA);

LPRINT CHR$ (&H1B) + "D" ;

LPRINT CHR$ (3) + CHR$ (7) + CHR$ (14) + CHR$ (0) ;

LPRINT CHR$ (&H9) + "AAA" ;

LPRINT CHR$ (&H9) + "BBB" ;

LPRINT CHR$ (&H9) + "CCC" + CHR$ (&HA) ;

[PrintResults]

CBM-202PC-04 User’s Manual

LF

[Function] Printing and Paper Feed

[Code] <0A>H

[Outline] Prints data inside the input buffer and feeds lines based on the line feed amount having

been set.

• The head of the line becomes the next print starting position.

[SeeAlso] ESC 2, ESC 3

[Sample Program] [Print Results]

LPRINT "AAA" + CHR$ (&HA) ;

LPRINT "BBB" + CHR$ (&HA) ;

LPRINT CHR$ (&HA) ;

LPRINT "CCC" + CHR$ (&HA) ;

45 CITIZEN

Page 46

CBM-202PC-04 User’s Manual

CR

[Function] Print Command

[Code] <0D>H

[Outline] 1) When the func tion selecting terminal(Gate Array Pin 32) is HIGH.

This command is ignored.

2) When the functionselectingterminal(Gate Array Pin 32) is LOW.

Withdata heldinside the internalprint buffer, printing and line feed are performed.

Without data inside the internal print buffer, however, no printing is perfor med.

[SeeAlso] LF

[Sample Program] [Print Results]

LPRINT "AAA" + CHR$ (&HD) ;

LPRINT "BBB" + CHR$ (&HD) ;

LPRINT CHR$ (&HD) ;

LPRINT "CCC" + CHR$ (&HD) ;

ESC SP n

[Function] Se tting the right space amount of the character

[Code] <1B>H<20>H<n>

[Range] { 0 ≤ n ≤ 20 } Data is described in Hex code.

[Outline] The rightward space amount is set in dot unit (1/20 3inch unit).

In the initial value, it is n=0.

[Caution] The rightward space amount in double wide mode is made double of the set volume.

[Default] n = 0

[Sample Program]

LPRINT CHR$ (&H1B) + " " + CHR$ (0) ;

LPRINT "AAAAA" + CHR$ (&HA) ;

LPRINT CHR$ (&H1B) + " " + CHR$ (1) ;

LPRINT "AAAAA" + CHR$ (&HA) ;

LPRINT CHR$ (&H1B) + " " + CHR$ (12) ;

LPRINT "AAAAA" + CHR$ (&HA) ;

[PrintResults]

46 CITIZEN

Page 47

ESC ! n

[Function ] Collective SpecifyingPrintingMode

[Code] <1B>H<21>H<n>

[Range] { 0 ≤ n ≤ FF } Data is described in Hex code.

[Outline] Printing modeis assigned. Each n bit indicates the following:

Bit Function 0 1

0 Character Font Font A Font B

1 Undefined

2 Undefined

3 High-lighting Canceled Specified

4 Double height Canceled Specified

5 Double width Canceled Specified

6 Undefined

7 Underline Canceled Specified

CBM-202PC-04 User’s Manual

Value

[Caution] • With double height and double width being specified simultaneously, double wide and

double high characters are consisted.

• An underline is attached to the full character width, which, however, is not attached to

the part having been skipped by the horizontal tab. Neither is it attached to 90°

-right-turned characters.

• The underline width is as having been specified by <ESC - >. (The default setting is 1

dot width. )

• Specification with this command is invalid to Kanji, except specification and

cancellation of highlighting

• In case that double height character and normal character exist in same one line, the

layout of underline is consistent one.

[Default] n = 0

[See Also] ESC E, ESC –

47 CITIZEN

Page 48

[Sample Program]

[PrintResults]

CBM-202PC-04 User’s Manual

LPRINT CHR$ (&H1B) + " ! " + CHR$ (&H00) + "H" ;

LPRINT CHR$ (&H1B) + " ! " + CHR$ (&H01) + "H";

LPRINT CHR$ (&H1B) + " ! " + CHR$ (&H08) + "H";

LPRINT CHR$ (&H1B) + " ! " + CHR$ (&H10) + "H";

LPRINT CHR$ (&H1B) + " ! " + CHR$ (&H20) + "H";

LPRINT CHR$ (&H1B) + " ! " + CHR$ (&H80) + "H";

LPRINT CHR$ (&H1B) + " ! " + CHR$ (&HB9) + "H";

LPRINT CHR$ (&HA) ;

48 CITIZEN

Page 49

CBM-202PC-04 User’s Manual

ESC % n

[Function] Specifying/Canceling Download Character Set

[Code] <1B>H<25>H<n>

[Range] { 0 ≤ n ≤ FF } Data is described in Hex code.

[Outline] Specifying/canceling download characters. Further, only the lowest bit (n0) is valid for n.

The lowest bit (n0) indicates the following.

n0 Function

0 Canceling download character set

1 Specifying download character set

[Caution] Download characters and download bitimages can not be defined simultaneously.

[Default] n = 0

[SeeAlso] ESC &

[Sample Program]

GOSUB SETCHR DATA 6

LPRINT CHR$ (&H1B) + "%" + CHR$ (0) ; DATA &HFF, &H80, &H00

LPRINT "@A" + CHR$ (&HA) ; DATA &H80, &H80, &H00

LPRINT CHR$ (&H1B) + "%" + CHR$ (1) ; DATA &H80, &H80, &H00

LPRINT "@A" + CHR$ (&HA) ; DATA &H80, &H80, &H00

END DATA &HFF, &HFF, &HFF

SETCHR : DATA &HFF, &HFF, &HFF

LPRINT CHR$ (&H1B) + "&" ; DATA 12

LPRINT CHR$ (3) + "@" + "A" ; DATA &HFF, &HFF, &HFF

FOR J=1 TO 2 DATA &H80, &H07, &HF9

READ REP DATA &H80, &HFF, &HF9

LPRINT CHR$ (REP) ; DATA &H87, &HFE, &H01

FOR I=1 TO REP•3 DATA &H9F, &H06, &H01

READD DATA &HF8, &H06, &H01

LPRINTCHR$ (D) ; DATA &HF8, &H06, &H01

NEXT I DATA &H9F, &H06, &H01

NEXT J DATA &H87, &HFE, &H01

RETURN DATA &H80, &HFF, &HF9

DATA &H80, &H07, &HF9

DATA &HFF, &HFF, &HFF

[PrintResults]

49 CITIZEN

Page 50

ESC & s n m[a[p]s × a]m–n+1

[Function] Defining Download Character

[Code] <1B>H<26>H<s><n><m>[<a><p1><p2>···<ps×a>]m-n+1

[Range] {s = 03}

{20 (Hex) ≤ n ≤ m ≤ 7E (Hex)}

{0 ≤ a ≤ 0C(Hex)} (Font A)

{0 ≤ a ≤ 0A(Hex)} (Font B)

[Outline] Defines the font of download characters of alphanumeric characters.

• "s" indicates the number of bytes in vertical direction.

• "n" indicates the start character code and m the end character code. To define only one

character, set n=m.

• Character codes definable includes 95 ASCII codes in total between <20>H ~ <7E>H.

• "a" indicates the number of dots in horizontal direction for definition.

• "p" is the data to be defined, which indicate a pattern equal to "a" dot in horizontal

directionfrom the left end. The rest of the pattern on the right side is filled with space.

The rest of data to be defined is s x a.

CBM-202PC-04 User’s Manual

• Download characters thus defined remain valid until redefinition, ESC @ execution,

GS * execution, or power OFF is practiced.

[Caution] Download characters and download bitimages can not be defined simultaneously.

Running this command clears the definition of the download bit image.

[Default] Same as the internal character set

50 CITIZEN

Page 51

[Example]

CBM-202PC-04 User’s Manual

Create each data bit by setting "1" for a printed dot and "0" for an unprinted dot.

[Sample Program] [Print Results]

SeeSample ProgramandPrint Results for ESC % onPage49.

51 CITIZEN

Page 52

CBM-202PC-04 User’s Manual

ESC*mn1n2[d]k

[Function] Specifying the Bit Image Mode

[Code] <1B>H<2A>H<m><n1><n2> [ <d> ] k

[Range] {m= 0, 1, 32, 33 bit imagemode (See the table below.)}

{0 ≤ n1 ≤ FF(Hex)}

{0 ≤ n2 ≤ 03(Hex)}

{0 ≤ d ≤ FF(Hex)}

{k = n1 + FF(Hex) × n2 (m = 0, 1)

{k=(n1+FF(Hex)× n2) × 3} (m = 32, 33)

[Outline] According to the number of dots specifiedin n1, n2,specify the bit image of mode n.

• The No. of dots printed is divided by 256, whose quotient is taken as n2 and residualas

n1.

• The total no. of dots printed in the bit image is equal to n1 + (256 x n2).

• When bit image data have been input in excess of dot position of one line(448 dots) ,

theexcessdata arediscarded.

• d is bit imag edata, th ebitssubject to printingare taken as "1" and those not as"0".

• The bit imagemodes specified by m are shown as follows:

m(Hex) Mode

0 8-dot single density 8 67 DPI 101 DPI 192

1 8-dot double density 8 67 DPI 203 DPI 384

32 24-dot single density 24 203 DPI 101 DPI 192

33 24-dot double density 24 203 DPI 203 DPI 384

[Caution] • When the values set in m (Bit image mode) are out of the above range, the data

followingafter n1 is processed as normal printingdata.

• After completion of bit image printing, printer returns to normal data processing

mode.

Vertical Direction Horizontal Direction

No. of Dots Dot Density Dot Density Max. No. of Dots

52 CITIZEN

Page 53

[Example]

[Sample Program]

[PrintResults]

CBM-202PC-04 User’s Manual

LPRINT CHR$ (&H1B) + "*" ;

LPRINT CHR$ (0) + CHR$ (20) + CHR$ (0) ; IMG1 :

GOSUB IMG1 LPRINT CHR$ (&HFF) ;

LPRINT CHR$ (&HA) ; FOR I=1 TO 18

LPRINT CHR$ (&H1B) + "*" ; LPRINT CHR$ (&H85) ;

LPRINT CHR$ (1) + CHR$ (20) + CHR$ (0) ; NEXT I

GOSUB IMG1 LPRINT CHR$ (&HFF) ;

LPRINT CHR$ (&HA) ; RETURN

LPRINT CHR$ (&H1B) + "*" ; I MG2 ;

LPRINT CHR$ (32) + CHR$ (20) + CHR$ (0) ; LPRINT CHR$ (&HFF) ;

GOSUB IMG2 LPRINT CHR$ (&HFF) ;

LPRINT CHR$ (&HA) ; LPRINT CHR$ (&HFF) ;

LPRINT CHR$ (&H1B) + "*" ; FOR I=1 TO 18

LPRINT CHR$ (33) + CHR$ (20) + CHR$ (0) ; LPRINT CHR$ (&H80) ;

GOSUB IMG2 LPRINT CHR$ (&H00) ;

LPRINT CHR& (&HA) ; LPRINT CHR$ (&H05) ;

END NEXT I

LPRINT CHR$ (&HFF) ;

LPRINT CHR$ (&HFF) ;

LPRINT CHR$ (&HFF) ;

RETURN

53 CITIZEN

Page 54

CBM-202PC-04 User’s Manual

ESC – n

[Function] Specifying/ Canceling Underline

[Code] <1B>H<2D>H<n>

[Range] {0 ≤ n ≤ 02} Data is describedinHex cod e.

[Outline] Specifying /cancelingan underline.

• Types of underlines by n value are shown below:

n (Hex) T ype

0 Canceling an underline.

1 Specifying an underline for 1-dot width.

2 Specifying an underline for 2-dots width.

[Caution] • An underline is attached to the full character width. It is, however, not attached to the

part having been skippedby horizontal tab command.

• An underline is not attachedto a 90° - right-turned characters.

• Specification/cancellation with this command is invalid to Kanji.

[See Also] ESC !, FS –

[Sample Program]

LPRINT CHR$ (&H1B) + "–" + CHR$ (0) ;

LPRINT "AAAAA" ;

LPRINT CHR$ (&H1B) + "–" + CHR$ (1) ;

LPRINT "AAAAA" + CHR$ (&HA) ;

[PrintResults]

ESC 2

[Function] Sp ecifying1/6 inch line feedrate

[Code] <1B>H<32>H

[Outline] The line feed rate per line is specifie d by 1/6 inch.

[Sample Program] [Print Results]

LPRINT "AAAAA" + CHR$ (&HA) ;

LPRINT CHR$ (&H1B) + "3" + CHR$ (0) ;

LPRINT "AAAAA" + CHR$ (&HA) ;

LPRINT CHR$ (&H1B) + "3" + CHR$ (50) ;

LPRINT "AAAAA" + CHR$ (&HA) ;

LPRINT CHR$ (&H1B) + "2" ;

LPRINT "AAAAA" + CHR$ (&HA) ;

LPRINT "AAAAA" ;

LPRINT CHR$ (&H1B) + "J" + CHR$ (100) ;

LPRINT "AAAAA" + CHR$ (&HA) ;

LPRINT "AAAAA" + CHR$ (&HA) ;

54 CITIZEN

Page 55

CBM-202PC-04 User’s Manual

ESC 3 n

[Function] Setting line feedrate of minimum pitch

[Code] <1B>H<33>H<n>

[Range] {0 ≤ n ≤ FF} Data is described in Hex code.

[Outline] The line feed rate per line is specifie dby n/360 inch.

Since an actual mechanical pitch is 1/203 inch, it is internally converted approximate to

the value specifiedwiththis command.

[Default] The initial value is n = 60 (1/6 inch) (18H), being 4.23 mm line feed rate.

[Sample Program] [Print Results]

SeeSample ProgramandPrint Results for ESC 2 onPage 54.

55 CITIZEN

Page 56

ESC = n

[Function] Data Input Control

[Code] <1B>H<3D>H<n>

[Range] {0 ≤ n ≤ FF} Data is described in Hex code.

[Outline] Selecting equipment in which data input from the host is effective.

• Each bit of n indicates as follows:

Value

Bit Equipment 0 1

0 Printer Invalid Valid

1 Not defined

2 Not defined

3 Not defined

4 Not defined

5 Not defined

6 Not defined

7 Not defined

• When the printer has not beenselected, this printer abandonsall the received data until

it is selectedby this command.

CBM-202PC-04 User’s Manual

[Caution] • Even when the printer has not been selected, it can b ecome BUSY state through

printer operation.

• When the printer is deselected, this printer discards all the data until it is selected with

this command.

[Default] • The initial value of n is "1".

[Sample Program]

LPRINT "AAAAA" ;

LPRINT CHR$ (&H1B) + "=" + CHR$ (0) ;

LPRINT "aaaaa" + CHR$ (&HA) ;

LPRINT CHR$ (&H1B) + "=" + CHR$ (1) ;

LPRINT "AAAAA" + CHR$ (&HA) ;

[PrintResults]

56 CITIZEN

Page 57

CBM-202PC-04 User’s Manual

ESC @

[Function] Initializing the Printer

[Code] <1B>H<40>H

[Range] Clears data stored in the print buffer and brings various settings to the initial state

(Default state).

[Caution] • Data inside the internal input buffer are not cleared.

• Dip switches setting are red once again.

[Sample Program] [Print Results]

LPRINT CHR$ (&H1B) + " ! " + CHR$ (&H30) ;

LPRINT CHR$ (&H1B) + "V" + CHR$ (1) ;

LPRINT "AAA" + CHR$ (&HA) ;

LPRINT CHR$ (&H1B) + "@" ;

LPRINT "AAA" + CHR$ (&HA) ;

57 CITIZEN

Page 58

ESC D [ n ] k NUL

[Function] Setting Horizontal Tab Position

[Code] <1B>H<44>H [ <n> ] k<00>H

[Range] {0 ≤ n ≤ FFH} Data is described in Hex code.

{0 ≤ k ≤ 20H} Data is described in Hex code.

[Outline] Specifyinga horizontal tab position.

• "n" indicates the no. of columns from the beginning to the horizontal tab position. At

this time, n= set position•1 is to b e specified. For example, to set the position at 9th

column, n=8 is to be specified.

• k denotes the number of horizontal tab positions you want to set.

• The tab position is set at position where it is "character width x n" from the line

beginning. The character width, at this time, includes the rightward space amount.

In double wide characters, itis made double of the ordinary case.

• Tab positions can be specified are maximum32. Specifying exceeding this is ignored.

• <n> k, which denotes a setting position, is input in the increasing order and ends at

<00> H.

• ESC D NUL clears all the set tab positions. Following clearing, horizontal tab

command is ignored.

CBM-202PC-04 User’s Manual

[Caution] When the data, <n> k, is equal t o or smaller than its preceding data, <n> k-1, it is

assumed that tab setting is finished. If this is the case, the next data onward will be

processed as normal data.

When the data, <n> k, exceeds a 1-line print area, set the horizontal tab position,

assuming "Set column position = Maximum print column + 1."

The horizontal tab position does not change even if the character width is altered after

setting the horizontal tab position.

th

[Default] • Initial value is specified for each eight characters(9

.17th.25thcolumn)ofANK

characters.

[SeeAlso] HT

[Sample Program] [Print Results]

SeeSample ProgramandPrint Results for HT onPage45.

58 CITIZEN

Page 59

ESC E n

[Function] Specifying/canceling highlighting

[Code] <1B>H<45>H<n>

[Range] {0 ≤ n ≤ FF} Data is described in Hex code.

[Outline] Specifying /c an c eling the highlightingcharacters.

• "n" is valid only for the lowest bit (n0).

• Control by the lowest bit (n0) is shown as follows:

n0 T ype

0 Canceling highlighting.

1 Specifying highlighting.

• This is effective to all characters.

CBM-202PC-04 User’s Manual

• Dot configuration of a highlighted character includes one extra dot added at its side.

[Caution] • The print result of Double printingand highlight character printing is completely same.

[SeeAlso] ESC !

[Example]

[Sample Program]

LPRINT CHR$ (&H1B) + "E" + CHR$ (0) ;

LPRINT "AAA BBB" + CHR$ (&HA) ;

LPRINT CHR$ (&H1B) + "E" + CHR$ (1) ;

LPRINT "AAA BBB" + CHR$ (&HA) ;

[PrintResults]

59 CITIZEN

Page 60

CBM-202PC-04 User’s Manual

ESC G n

[Function] Specifying/canceling Double Printing

[Code] <1B>H<47>H<n>

[Range] {0 ≤ n ≤ FF} Data is described in Hex code.

[Outline] Specifying/c anc eling the double printing.

• "n" is valid only for the lowest bit (n0).

• Control by n is shown as follows.

n0 Type

0 Canceling double printing.

1 Specifying double printing.

• This is effective to all characters.

[Caution] • The print result of Double printingand highlight character printing is completely same.

[SeeAlso] ESC E

[Sample Program]

LPRINT CHR$ (&H1B) + "G" + CHR$ (0) ;

LPRINT "AAA BBB" + CHR$ (&HA) ;

LPRINT CHR$ (&H1B) + "G" + CHR$ (1) ;

LPRINT "AAA BBB" + CHR$ (&HA) ;

[PrintResults]

ESC J n

[Function] Printing and feeding paper n/203 inch

[Code] <1B>H<4A>H<n>

[Range] {0 ≤ n ≤ FF} Data is described in Hex code.

[Outline] Prints data inside the print buffer and feeds paper by n/360 inch. Since an actual

mechanical pitch is 1/203 inch, it is internally converted approximate to the value

specifiedwiththis command.

• Specified volume does not remain.

• The beginningof the line is to be considered as the next printingstart position.

• Initial value is not defined.

[Sample Program] [Print Results]

SeeSample ProgramandPrint Results for ESC 2 onPage 54.

60 CITIZEN

Page 61

CBM-202PC-04 User’s Manual

ESC R n

[Function] Sele c ting the International Character Set

[Code] <1B>H<52>H<n>

[Range] {0 ≤ n ≤ 0A) Data is described in Hex code.

[Outline] Dependingon the value of n, following character sets are specified.

n(Hex) Character Set

0 U.S.A.

1France

2Germany

3 U.K.

4Denmark•

5Sweden

6 Italy

7Spain

8 Japan

9Norway

ADenmark•

[Default] • The initial value of n indicates the character set specified by the function selecting

terminal(Gate Array Pin 39,42,43).

[See Also] Character Code Table (International Character Set)

[Sample Program]

FOR I=0 TO 10

LPRINT CHR$ (&H1B) + "R" + CHR$ (I) ;

LPRINT " #$@[¥]^" ;

LPRINT CHR$ (&H60) + "{¥}

LPRINT "n=" + STR$ (I) ;

LPRINT CHR$ (&HA) ;

NEXT I

•

";

[PrintResults]

61 CITIZEN

Page 62

ESC V n

[Function] Specifying/Canceling 90°-right- turned Characters

[Code] <1B>H<56>H<n>

[Range] {0 ≤ n ≤ 1} Data is described in Hex code.

[Outline] Specifying/c anc eling characters 90°-right- turned character.

• "n" means the followings.

n (Hex) Conditio n

0

1

[Caution] • No underlines are attached to 90°-right- turned characters .

Canceling

Specifying

90°-right- turned Characters

90°-right- turned Characters

CBM-202PC-04 User’s Manual

[Default] • The initial value of n is "0".

[Sample Program] [Print Results]

LPRINT CHR$ (&H1B) + "V" + CHR$ (0) ;

LPRINT "AAAAA" ;

LPRINT CHR$ (&H1B) + "V" + CHR$ (1) ;

LPRINT "AAAAA" + CHR$ (&HA) ;

62 CITIZEN

Page 63

CBM-202PC-04 User’s Manual

ESC a n

[Function] Aligningthecharacters

[Code] <1B>H<61>H<n>

[Range] {0 ≤ n ≤ 2} Data is described in Hex code.

[Outline] All the printed data withinone line are aligned in the specified position.

• Depending on n value, positional alignment is carriedoutas in the table below:

n (Hex) Position

0 Left end alignment

1Centering

2 Right end alignment

[Caution] • This is valid only when n is inputted at the beginning of line.

• The initial value of n is "0".

[Sample Program]

LPRINT CHR$ (&H1B) + "a" + CHR$ (0) ;

LPRINT "AAAAA" + CHR$ (&HA) ;

LPRINT CHR$ (&H1B) + "a" + CHR$ (1) ;

LPRINT "AAAAA" + CHR$ (&HA) ;

LPRINT CHR$ (&H1B) + "a" + CHR$ (2) ;

LPRINT "AAAAA" + CHR$ (&HA) ;

[PrintResults]

63 CITIZEN

Page 64

CBM-202PC-04 User’s Manual

ESC c5 n

[Function] Enabling/Disabling the Panel Switches

[Code] <1B>H<63>H<35>H<n>

[Range] {0 ≤ n ≤ FF} Data is described in Hex code.

[Outline] Selecting the LF switch valid/invalid by LFSW(Pin 2).

• "n" is valid only in the lowest bit (n0).

• "n" bit means the followings.

n0 Conditio n

0 LF SW valid.

1 LF SW invalid.

[Caution] Whenthe panel switch is disabled withthis command, the LF switchis disabled.

Therefore, the paper cannot be fed by operating the LF switch.

[Default] • The initial value of n is "0".

[Sample Program]

LPRINTCHR$(&H1B)+"c5"+CHR$(0);············WhenenablingtheLFswitch

LPRINTCHR$(&H1B)+"c5"+CHR$(1);············Whendisabling the LF switch

ESC d n

[Function] Printing and Feeding the paper by n lines

[Code] <1B>H<64>H<n>

[Range] * {0 ≤ n ≤ FF} Data is described in Hex code.

[Outline] Prints data inside the buffer and feeds paper by n lines.

• Specified line does not remain.

• The beginningof the line is to be considered as the next printingstart position.

[Default] • The initial value is not defined.

[Sample Program]

LPRINT "AAAAA"

LPRINT CHR$ (&H1B) + "d" + CHR$ (2) ;

LPRINT "AAAAA" + CHR$ (&HA) ;

[PrintResults]

64 CITIZEN

Page 65

ESC i (When Using Auto Paper Cutter)

[Function] Full Cut

[Code] <1B>H<69>H

[Outline] Activating auto cutter unit (Full cut)

[Caution] • This is valid only when n is inputted at the beginning of line.

• Prior to cutting the paper, feed the paper from the printing position to beyond the

paper cutting position of the cutter. Otherwise, the character just after print will remain

on this side of the cutter.

[Sample Program]

LPRINT "AAAAA" ;

LPRINT CHR$ (&H1B) + "J" ;

LPRINT CHR$ (150) ;

LPRINT CHR$ (&H1B) + "i" ;

LPRINT "AAAAA" ;

LPRINT CHR$ (&H1B) + "J" ;

LPRINT CHR$ (150) ;

LPRINT CHR$ (&H1B) + "i" ;

[PrintResults]

CBM-202PC-04 User’s Manual

65 CITIZEN

Page 66

ESC m (When Using Auto Paper Cutter)

[Function] Partial Cut

[Code] <1B>H<6D>H

[Outline] Activating auto cutter unit (Partial cut)

[Caution] • This is valid only when n is inputted at the beginning of line.

• Prior to cutting the paper, feed the paper from the printing position to beyond the

paper cutting position of the cutter. Otherwise, the character just after print will remain

on this side of the cutter.

[Sample Program]

LPRINT "AAAAA" ;

LPRINT CHR$ (&H1B) + "J" ;

LPRINT CHR$ (150) ;

LPRINT CHR$ (&H1B) + "m" ;

LPRINT "AAAAA" ;

LPRINT CHR$ (&H1B) + "J" ;

LPRINT CHR$ (150) ;

LPRINT CHR$ (&H1B) + "m" ;

[PrintResults]

CBM-202PC-04 User’s Manual

66 CITIZEN

Page 67

CBM-202PC-04 User’s Manual

ESC t n

[Function] Selecting the Character Code Table

[Code] <1B>H<74>H<n>

[Range] {0 ≤ n ≤ 1} Data is described in Hex code.

[Outline] Selecting Page n on the character code table:

The character code table is selected depending on the value of n.

"n" means the followings.

n (Hex) Condition

0 Page0(IBMCharacter #2)

1 Page 1(Domestic Character)

[Default] The initial value of n is subject to the character set for the country specified by the

functionselecting terminal (Gate Array Pin 39,42,43).

• When Japan is selected: Domestic characters

• When non-Japan is selected: IBM characters #2

[See Also] Character Code Table

[Sample Program]

LPRINT CHR$ (&H1B) + "t" + CHR$ (0) ;

LPRINT"n=0 ";

FOR C=&HB1 TO &HB5

LPRINT CHR$ (C) ;

NEXT C

LPRINT CHR$ (&HA) ;

LPRINT CHR$ (&H1B) + "t" + CHR$ (1) ;

LPRINT"n=1 ";

FOR C=&HB1 TO &HB5

LPRINT CHR$ (C) ;

NEXT C

LPRINT CHR$ (&HA) ;

[PrintResults]

67 CITIZEN

Page 68

CBM-202PC-04 User’s Manual

ESC v (Serial Interface Only)

[Function] Transmitting the printer status(Serial type)

[Code] <1B>H<76>H

[Outline] Current printer status is transmitted..

[Caution] • Status sent out consists of 1 byte whosecontent is as inthe table below.

• In DTR/DSR control, after receptible state of the host (DSR sign al being in SPACE

state) is confirmed, only 1 byte is transmitted.

InXON/XOFF control, DSR signal state not being confirmed, only 1 byteis transmitted.

• In DTR/DSR control, when the host is in unreceptible state(DSR signal being in

MARK state), it waits until receptible state is created.

• In paper end (paper near end) status, this command may be unreceptible state due to

BUSY state.

Remarks. This command is valid only for serial interface model.

Value

Bit Function 0 1

0 Not defined

1 Not defined

2 Paper end With paper Without paper

3 Not defined

4 Not used Fixed to 0 –

5 Not defined

6 Not defined

7 Not defined

[Sample Program]

OPEN "COM1:N81NN" AS #1 ;

PRINT #1, CHR$ (&H1B) + "v" ;

A$ = INPUT$ (1, #1) ;

CLOSE #1

68 CITIZEN

Page 69

ESC { n

[Function] Specifying/Canceling the Inverted Characters

[Code] <1B>H<7B>H<n>

[Range] {0 ≤ n ≤ FF} Data is described in Hex code.

[Outline] Specifying/c anc eling inverted characters.

• "n" is valid only for the lowest bit (n0).

• Bit n (n0) means the followings.

n0 Condition

0 Canceling inverted characters.

1 Specifying inverted characters.

[Caution] • Inverted printingmeans printing the line at 180 °turned.

• This is valid only when this is specified at the beginning of a line.

[Default] • The initial value of n is "0".

[Sample Program]

LPRINT CHR$ (&H1B) + "{" + CHR$ (0) ;

LPRINT "AAAAA" + CHR$ (&HA) ;

LPRINT "BBBBB" + CHR$ (&HA) ;

LPRINT CHR$ (&H1B) + "{" + CHR$ (1) ;

LPRINT "AAAAA" + CHR$ (&HA) ;

LPRINT "BBBBB" + CHR$ (&HA) ;

[PrintResults]

CBM-202PC-04 User’s Manual

69 CITIZEN

Page 70

CBM-202PC-04 User’s Manual

ESC $ n1 n2

[Function] Specifyingthe Absolute Positions

[Code] <1B>H<24>H<n1><n2>

[Range] {0 ≤ n1 ≤ FF}

{0 ≤ n2 ≤ 1} Data is described in Hex code.

[Outline] The printing start position is specified in the number of dots (1/203 inch unit) from the

beginning of line.

• The number of dots is divided by 256, whose quotient is taken as n2 and the residual

as n1.

• Therefore, the printing start position is equal to n1 + n2 x 256 from the beginning of

line..

[Caution] • Specifying beyond the end of line is ignored.

[Default] • The initial value is not specified.

[SeeAlso] ESC ¥

[Sample Program]

LPRINT CHR$ (&H1B) + "$" ;

LPRINT CHR$ (0) + CHR$ (0) + "A" ;

LPRINT CHR$ (&H1B) + "$" ;

LPRINT CHR$ (50) + CHR$ (0) + "B" ;

LPRINT CHR$ (&H1B) + "$" ;

LPRINT CHR$ (0) + CHR$ (1) + "C" ;

LPRINT CHR$ (&HA) ;

LPRINT CHR$ (&H1B) + "$" ;

LPRINT CHR$ (100) + CHR$ (0) + "A";

LPRINT CHR$ (&H1B) + "¥" ;

LPRINT CHR$ (&HC2) + CHR$ (&HFF) + "B" ;

LPRINT CHR$ (&HA) ;

[PrintResults]

70 CITIZEN

Page 71

CBM-202PC-04 User’s Manual

ESC ¥ n1 n2

[Function] Specifying the Relative Positions

[Code] <1B>H<5C>H<n1>< n2>

[Range] {0 ≤ n1 ≤ FF}

{0 ≤ n2 ≤ FF} Data is described in Hex code.

[Outline] The printing start position is specified in the number of dots(1/203 inch unit) from the

current position.

• Rightward direction is taken as plus and leftward direction asminus.

• To specify N dot inminus (left) direction, use a complement of N for assignment.

• N dots = 65536 – N

• The number of dots is divided by 256, whose quotient is taken as n2 and the residual

as n1.

[Caution] • Specifying exceeding the topof line or the end of line is ignored.

[Default] • The initial value is not specified .

[SeeAlso] ESC $

[Sample Program] [Print Results]

SeeSample ProgramandPrint Results for ESC $ onPage 70.

71 CITIZEN

Page 72

CBM-202PC-04 User’s Manual

GSkn[d]kNUL

[Function] Printing the Bar Code

[Code] <1D>H<6B>H<n> [ < d> ] k <00>H

[Range] {0 ≤ n ≤ 7} Data are described in Hex code.

[Outline] Specifyinga type of bar code and printing bar codes.

• The beginningof line is considered as the next printing start position.

• Depending on the value of n, the following bar cod e can be selected.

d indicates a character code to be printed and k indicates the number of character to be

printed.

n (Hex) Bar Code System Maximum Columns

0 UPC-A --1 UPC-E --2 J AN13 (EAN) --3 JAN 8 (EAN) --4CODE39 13

5ITF 22

6 CODABAR (NW-7) 17

7 CODE 128 15

[Caution] • When data being heldinthe printbuffer, thiscommand is ignored.

• Regardless of the specified feed pitch, this command feeds the paper to be required to

print a bar code.

• If the character code d cannot be printed in the respective bar code system, the bar

code so far willbe printed, processing thesubsequent data as normaldata.