Page 1

USER’S MANUAL

Model : CBM-202PC Series

Control LSI for Citizen Thermal Printer Mechanism

Rev. 1.0, November 1st, 1996

Rev. 1.1, February 2nd, 1997

Japan CBM Corporation

Information Systems Div.

Page 2

CBM-202PC User’s Manual

NOTICE

1. Description in this manual are subject to changes without prior notification.

2. Upon finding of any inappropriateness, error, or omission concerning contents of this manual,

please contact us at any time.

3. Notwithstanding the above Item 2, we will not be responsible for the influences of employment of this

manual.

2

CITIZEN

Page 3

CBM-202PC User’s Manual

CONTENTS

1.OUTLINE................................................................................................................................................................5

1.1 MODEL CLASSIFICATIONS.....................................................................................................................5

2. GENERAL SPECIFICATIONS.............................................................................................................................5

2.1 OUTER APPEARANCE..............................................................................................................................5

2.2 STRUCTURE...............................................................................................................................................5

2.3 DATA TRANSFER SYSTEM.....................................................................................................................5

2.4 PRINT FUNCTION......................................................................................................................................6

2.5 OPERATING VOLTAGE AND CURRENT CONSUMPTION.................................................................6

2.6 OPERATING FREQUENCY.......................................................................................................................6

3. HARDWARE SPECIFICATIONS.........................................................................................................................7

3.1 ABSOLUTE MAXIMUM RATINGS..........................................................................................................7

3.2 ELECTRICAL CHARACTERISTICS.........................................................................................................7

3.3 TERMINAL PIN CONFIGURATION.........................................................................................................8

3.4 RESET CIRCUIT.......................................................................................................................................13

3.5 OSCILLATION CIRCUIT.........................................................................................................................14

3.6 HEAD-UP DETECTION CIRCUIT...........................................................................................................15

3.7 HEAD DETECTION CIRCUIT.................................................................................................................16

3.8 PAPER END DETECTION CIRCUIT.......................................................................................................17

3.9 MOTOR CONTROL CIRCUIT.................................................................................................................18

3.10 AUTO CUTTER CONTROL CIRCUIT ..................................................................................................19

3.11 PARALLEL INTERFACE CIRCUIT.......................................................................................................20

3.12 SERIAL INTERFACE CIRCUIT.............................................................................................................22

3.13 SWITCH CIRCUIT..................................................................................................................................24

3.14 ERROR OUTPUT CIRCUIT....................................................................................................................25

3.15 FUNCTION SELECTION CIRCUIT.......................................................................................................26

3.16 EXTERNAL RAM INTERFACE ............................................................................................................29

4. OPERATING TIMING........................................................................................................................................32

5. PACKAGE SPECIFICATIONS...........................................................................................................................33

6. SPECIAL REMARKS FOR MOUNTING...........................................................................................................34

6.1 CAUTIONS................................................................................................................................................34

6.2 REFLOW MOUNTING.............................................................................................................................34

6.3 RECOMMENDED CONDITIONS FOR VARIOUS MOUNTING METHODS.....................................34

6.4 CLEANING METHOD..............................................................................................................................36

6.5 STORAGE METHOD................................................................................................................................36

7. COMMAND LIST................................................................................................................................................37

8. CHARACTER CODE TABLE.............................................................................................................................39

8.1 INTERNATIONAL....................................................................................................................................39

3

CITIZEN

Page 4

CBM-202PC User’s Manual

8.2 INTERNATIONAL CHARACTER CODE TABLE..................................................................................40

4

CITIZEN

Page 5

CBM-202PC User’s Manual

1.OUTLINE

This LSI, through use of the Japan CBM Corp. gate array, serves to control CITIZEN line thermal

printer, being featured by the following:

(1) High print quality due to a detector which detects temperature to adjust print density automatically.

(2) Both parallel and serial interfaces are available.

(3) Print density can be freely selected with the function selection terminal.

(4) Bar-code printing is available.

(5) Prints such as double width, double high and bit image printing are available by various commands.

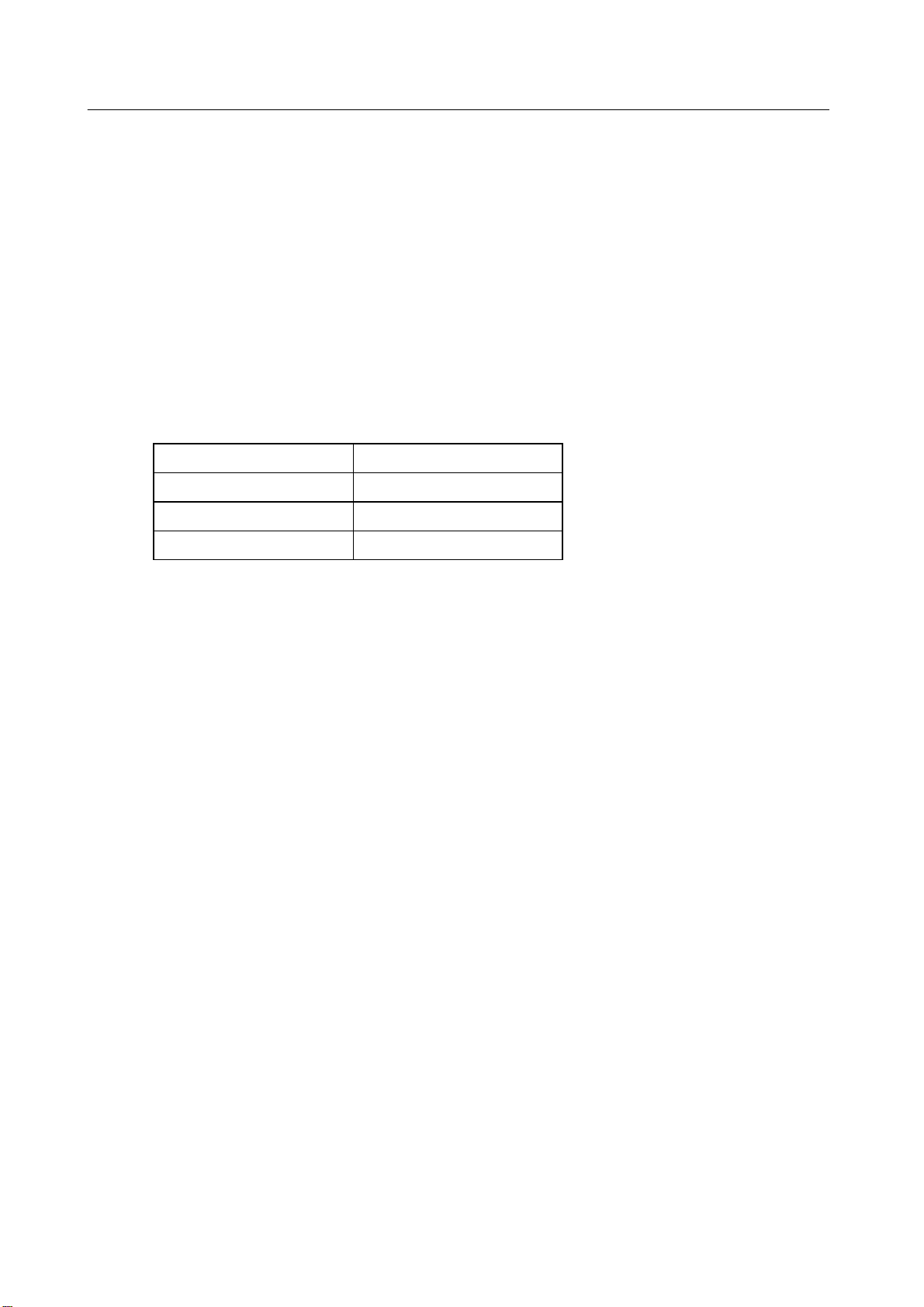

1.1 MODEL CLASSIFICATIONS

LSI (Chip) Model name Applied Printer Mechanism

CBM-202PC-01 LT-380

CBM-202PC-02 LT-381

CBM-202PC-03 LT-282/283

2. GENERAL SPECIFICATIONS

2.1 OUTER APPEARANCE

100-pin flat package

2.2 STRUCTURE

C-MOS LSI

2.3 DATA TRANSFER SYSTEM

Parallel transfer or serial transfer (Selectable by User)

(1) 8-bit parallel transfer

(Conforms to Centronics.)

(2) Asynchronous type serial transfer (Selectable by User)

1200, 2400, 4800, 9600, 19200 bps

Parity : odd, even, none

7 bits, 8 bits

5

CITIZEN

Page 6

2.4 PRINT FUNCTION

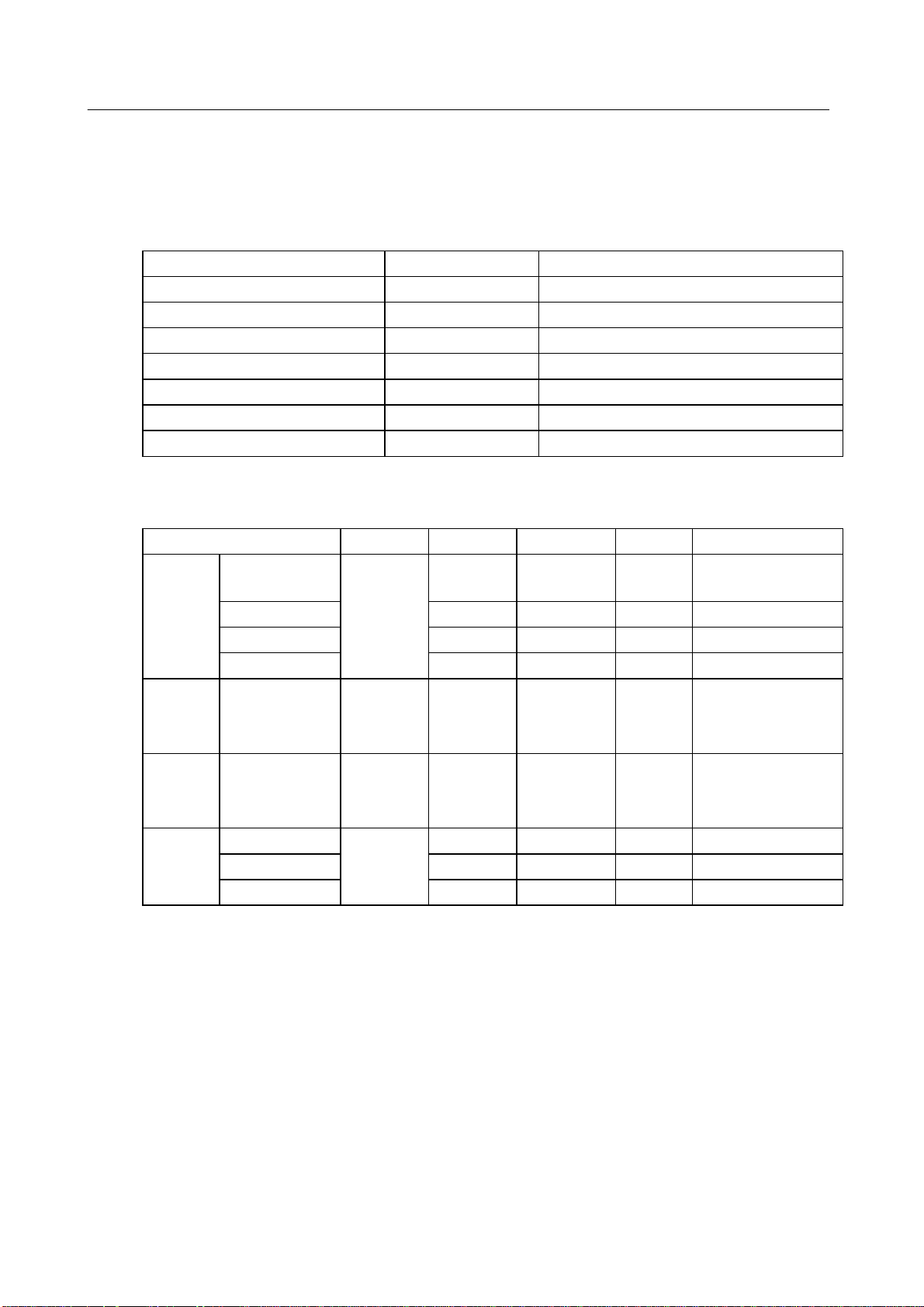

(1) No. of Print Columns and Print Speed

Machine Type

LT-282 37 448 50

LT-283 34 416 50

No of

Digits

Total No of

Dots

Character Size (mm) Print Speed (m/s)

1.25×3.00 (Font A)

0.88×2.13 (Font B)

LT-380 48 576 50

LT-381 48 576

2.5 OPERATING VOLTAGE AND CURRENT CONSUMPTION

Voltage : DC 5V± 5%

Current consumption : Max. 80mA

2.6 OPERATING FREQUENCY

16MHz

CBM-202PC User’s Manual

50

6

CITIZEN

Page 7

3. HARDWARE SPECIFICATIONS

3.1 ABSOLUTE MAXIMUM RATINGS

ITEM SYMBOL RATINGS

Supply voltage VCC

Input voltage Vi

Reference supply voltage V

Analog supply voltage AVCC

Analog input voltage VAN

Operating temperature Topr

Storage temperature Tstg

3.2 ELECTRICAL CHARACTERISTICS

ITEM SYMBOL

Input

"HIGH"

level

Input

"LOW"

level

Output

"HIGH"

level

Output

"LOW"

level

RES, STBY, NMI

MDO, MD1, MD2

EXTAL

THEM 2.0

Others

Total input

terminal

Total output

terminal

RESO

LEDER, LEDPE

Others

VIH

V

IL

V

OH

VOL

CBM-202PC User’s Manual

-0.3 to+7V

-03 to Vcc+0.3V

REF

-0.3 to AVcc+0.3V

-0.3 to+7V

-0.3 to AVcc+0.3V

-20 to+75℃

-55 to+125℃

MIN MAX UNIT CONDITION

Vcc−0.7 Vcc+0.3

Vcc×0.7 Vcc+0.3

AVcc+0.3

2.0

−0.3

3.5

−

−

Vcc+0.3

0.5

−

0.4 V

1.0 V

V

V

V

V

V

V

0.4 V

IOH=−1 mA

IOL=2.6 mA

IOL=10 mA

IOL=1.6 mA

7

CITIZEN

Page 8

CBM-202PC User’s Manual

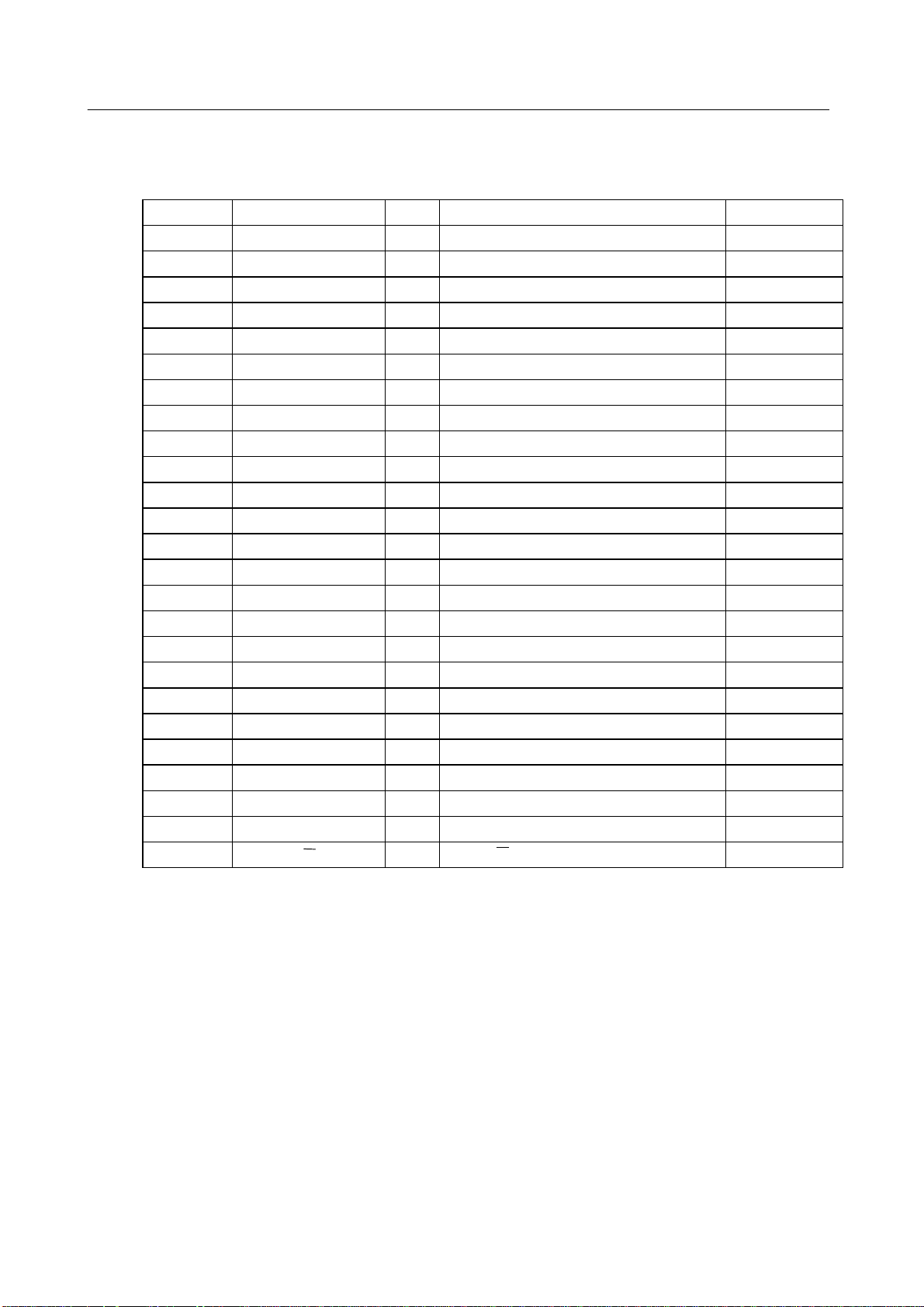

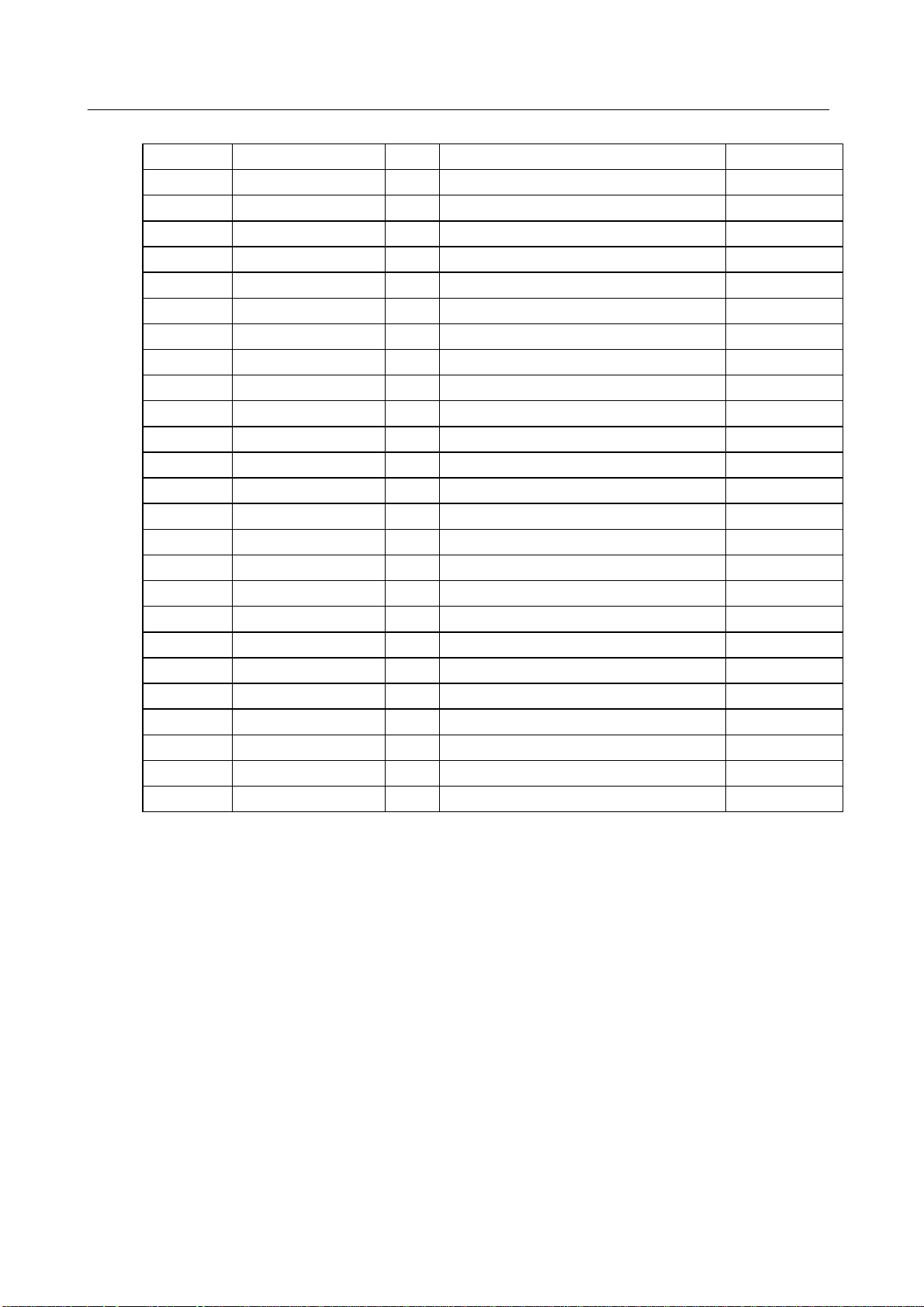

3.3 TERMINAL PIN CONFIGURATION

PIN NO. SIGNAL NAME I/O FUNCTION LOGIC

1 VCC

2 LFSW I LF switch input LOW

3 LEDER O Error LED output LOW

4 LEDPE O Paper end LED output LOW

5 NC

6 NC

7 NC

8 DRQ I DMA request LOW

9 NC

10 RESO O Watchdog output LOW

11 VSS

12 DTR O Serial DTR (RS-232C) HIGH

13 TXD O Serial TXD (RS-232C) HIGH

14 DI I Print head output data HIGH

15 RXD I Serial RXD (RS-232C) HIGH

16 CP I Print head clock HIGH

17 NC

18 CTSW I Cutter switch input LOW

19 NC

20 NC

21 NU

22 VSS

23 MOTORA O Motor A

24 MOTORB O Motor B

25 MOTORA O Motor A

I = Input, O = Output, I/O = Input/Output

−

−

−

−

−

−

−

−

−

−

−

VCC

NC

NC

NC

NC

GND

NC

NC

NC

RESERVED

GND

−

−

−

−

−

−

−

−

−

−

−

−

−

−

8

CITIZEN

Page 9

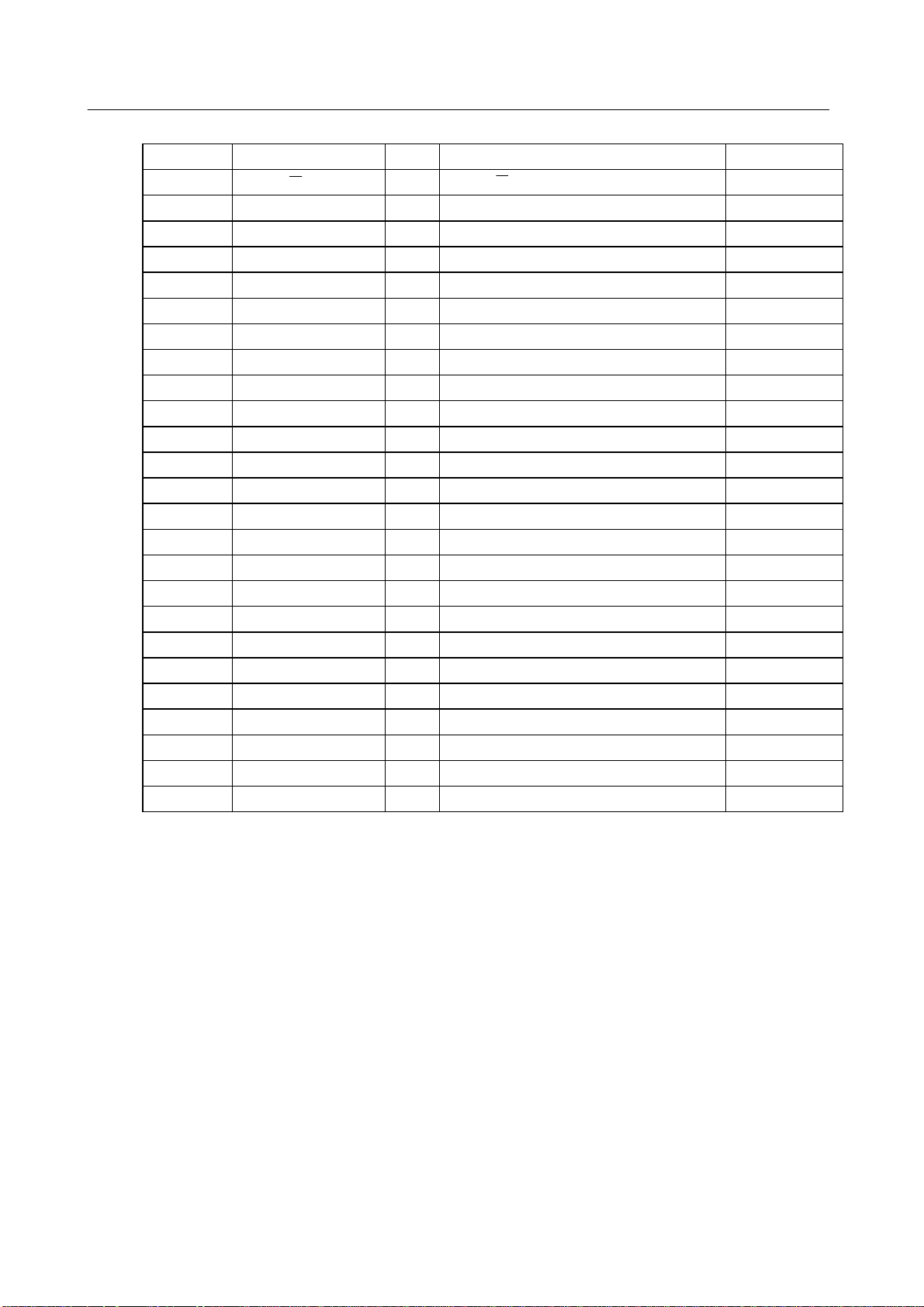

CBM-202PC User’s Manual

PIN NO. SIGNAL NAME I/O FUNCTION LOGIC

26 Motor B O Motor B

−

27 D0 I/O D0 HIGH

28 D1 I/O D1 HIGH

29 D2 I/O D2 HIGH

30 D3 I/O D3 HIGH

31 D4 I/O D4 HIGH

32 D5 I/O D5 HIGH

33 D6 I/O D6 HIGH

34 D7 I/O D7 HIGH

35 VCC

−

VCC

−

36 A0 O A0 HIGH

37 A1 O A1 HIGH

38 A2 O A2 HIGH

39 A3 O A3 HIGH

40 A4 O A4 HIGH

41 A5 O A5 HIGH

42 A6 O A6 HIGH

43 A7 O A7 HIGH

44 VSS

−

GND

−

45 A8 O A8 HIGH

46 A9 O A9 HIGH

47 A10 O A10 HIGH

48 A11 O A11 HIGH

49 A12 O A12 HIGH

50 A13 O A13 HIGH

9

CITIZEN

Page 10

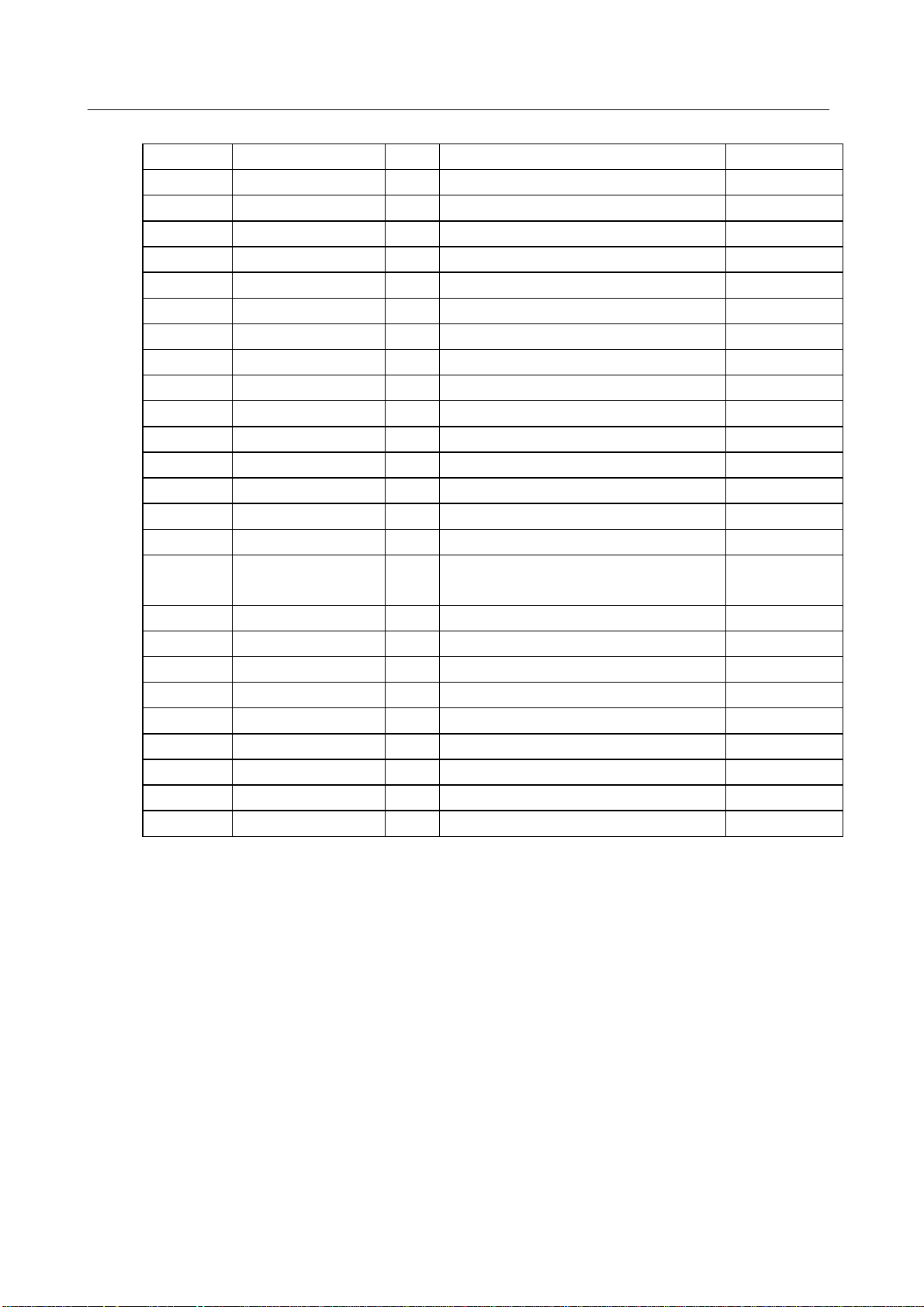

CBM-202PC User’s Manual

PIN NO. SIGNAL NAME I/O FUNCTION LOGIC

51 A14 O A14 HIGH

52 A15 O NC

53 A16 O NC

54 A17 O NC

55 A18 O NC

56 A19 O NC

57 VSS

58 P60 O NC

59 P61 O NC

60 P62 O NC

61

62 STBY I

63 RES I Reset input LOW

64 NMI I

65 VSS

66 EXTAL

67 XTAL

68 VCC

69 P63 O NC

70 RD O RD LOW

71 HRW O HRW LOW

72 P66 O NC

73 MD0 I

74 MD1 I

75 MD2 I

φ

−

GND

O Clock output HIGH

(Pull up in VCC with 10KΩ.)

(Pull up in VCC with 10K Ω.)

−

GND

−

EXTAL (16 MHz)

−

XTAL (16 MHz)

−

VCC

( Pull up in VCC with 10KΩ.)

(Pull down in GND with 10KΩ.)

(Pull up in VCC with 10K Ω.)

−

−

−

−

−

−

−

−

−

LOW

LOW

−

−

−

−

−

−

HIGH

LOW

HIGH

10

CITIZEN

Page 11

CBM-202PC User’s Manual

PIN NO. SIGNAL NAME I/O FUNCTION LOGIC

76 AVCC

77 VREF

78 THERM I Head temperature detection terminal

79 NC I

80 NC I

81 NC I

82 NC I

83 NC I

84 NC I

85 NC I

86 AVSS

87 STB I Parallel data interrupt LOW

88 HEADUP I Headup detection terminal LOW

89 CS2 O Gate array chip selection LOW

90 CS1 O RAM chip selection LOW

91 CS0 O (Kanji ROM chip selection.

92 VSS

93 NC O NC

94 STRB1 O Head Strobe 1 LOW

95 STRB2 O Head Strobe 2 LOW

96 STRB3 O Head Strobe 3 LOW

97 INH O Motor control LOW

98 LATCH O Head latch signal LOW

99 PAPER I Paper end input HIGH

100 DSR I Serial DSR (RS-232C) HIGH

−

VCC

−

VCC

(Pull down in GND with 10K Ω.) −

(Pull down in GND with 10K Ω.) −

(Pull down in GND with 10K Ω.) −

(Pull down in GND with 10K Ω.) −

(Pull down in GND with 10K Ω.) −

(Pull down in GND with 10K Ω.) −

(Pull down in GND with 10K Ω.) −

−

GND

Only for Japanese use.)

−

GND

−

−

−

−

LOW

−

−

11

CITIZEN

Page 12

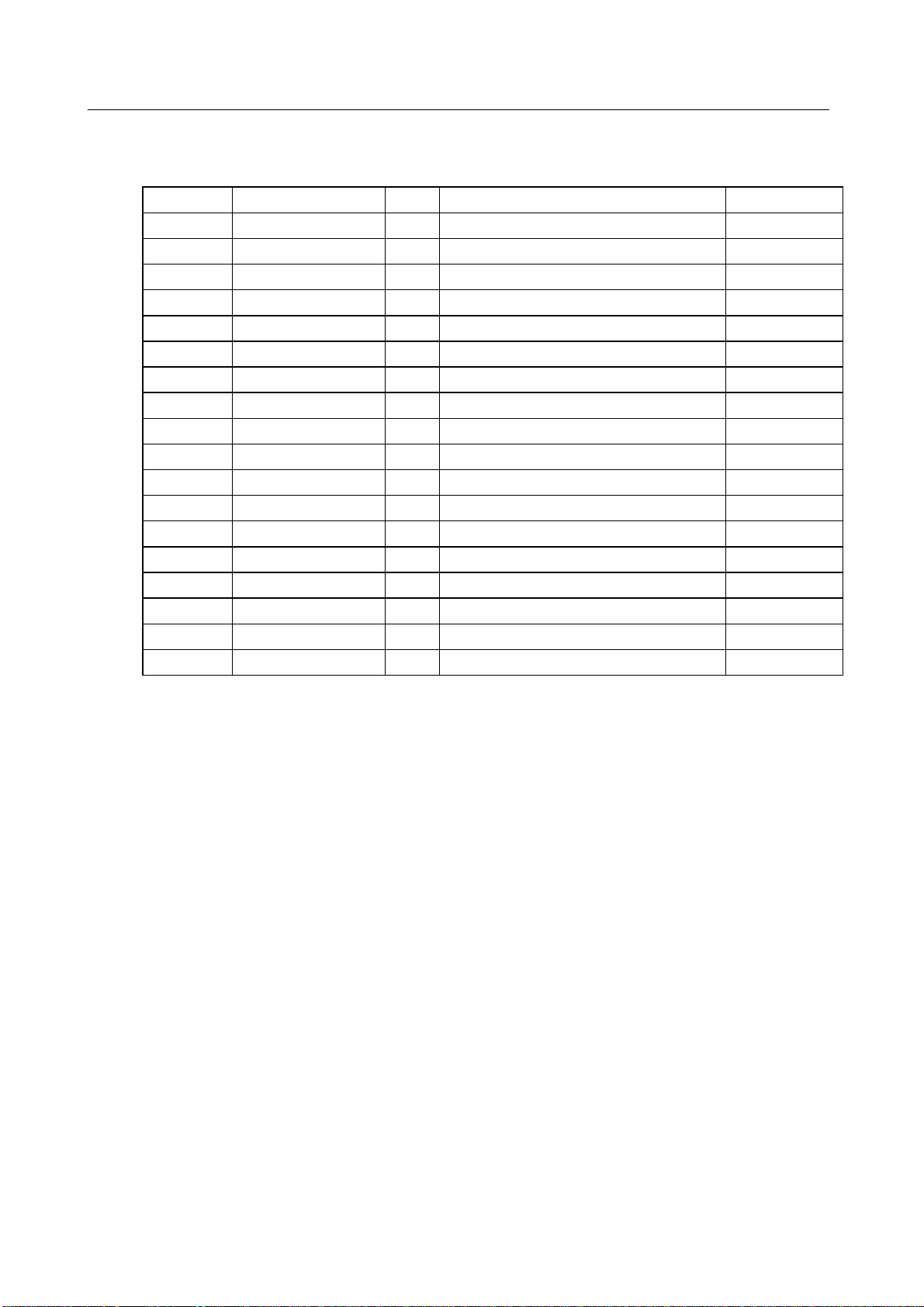

Pin Arrangement and Functions of Gate Array(CBM-202LA)

PIN NO. SIGNAL NAME I/O FUNCTION LOGIC

44 D7 I Parallel input data D7 HIGH

45 D6 I Parallel input data D6 HIGH

46 D5 I Parallel input data D5 HIGH

47 D4 I Parallel input data D4 HIGH

48 D3 I Parallel input data D3 HIGH

49 D2 I Parallel input data D2 HIGH

50 D1 I Parallel input data D1 HIGH

51 D0 I Parallel input data D0 HIGH

52 STROBE I Parallel STROBE LOW

55 BUSY O Parallel BUSY HIGH

58 PAO7 O NC

59 ACK O Parallel ACK

61 PE O Parallel paper end HIGH

62 FAULT O Parallel FAULT LOW

63 CUTTERX O Cutter X

64 CUTTERY O Cutter Y

65 PAO1 O NC

67 PAO0 O NC

CBM-202PC User’s Manual

−

−

−

−

−

−

12

CITIZEN

Page 13

3.4 RESET CIRCUIT

With RES terminal set to "Low", reset state is created.

In order to assure resetting, it is necessary to hold "Low" for min. 20ms on supply of power and

for min. 625ns while in operation.

When external reset is not used, those parts inside the broken lines are not required.

CBM-202PC User’s Manual

13

CITIZEN

Page 14

3.5 OSCILLATION CIRCUIT

A clock oscillator, being installed, generates a system clock and an internal clock. Two clock supplying

methods are available including one to connect a ceramic oscillator and the other to input an external clock.

When using a ceramic oscillator, you are recommended to use CSTCS16.00MX0C3 (with a condenser)

manufactured by Murata Mfg. Co.. For input of an external clock, two methods are available,

one of which is to open XTAL terminal and the other of which is to input an antiphase clock in

XTAL terminal.

CBM-202PC User’s Manual

14

CITIZEN

Page 15

3.6 HEAD-UP DETECTION CIRCUIT

Up/down state of the head is detected so that no power is supplied in head-up state, with the head-up sensor

installed in the printer. With head UP, it becomes "OPEN". With head DOWN, it becomes "CLOSE".

In head UP state, CPU's HEADUP (Pin 88) gets "HIGH", where printing is immediately stopped with error

output if it is while in print operation. Printing is resumed when it becomes head DOWN.

CBM-202PC User’s Manual

15

CITIZEN

Page 16

3.7 HEAD DETECTION CIRCUIT

VP is controlled so as to prevent the head from electrolytic etching.

When turning ON the VP, set 11VC (Pin 4) of the gate array (CBM-202LA)to "HIGH".

When turning it OFF, set the HVC to "LOW".

It is also provided with a temperature detection circuit which serves to prevent print quality from being

deteriorated or destroyed by temperature. This function, through use of a thermistor installed in the printer,

detects temperature based on which energy applied to the head is determined. Further, when head

temperature has exceeded 60℃, printing is stopped so that the head is protected from being destroyed.

For protection of CPU runaway, make connection so that the gate array is reset by output of the CPU

watchdog timer. The CPU itself has been set to which resetting can work. Further, to prevent the head

strobe from being turned ON at that time, place a pull-up resistance in STRB1 to STRB3 each by one.

CBM-202PC User’s Manual

16

CITIZEN

Page 17

3.8 PAPER END DETECTION CIRCUIT

Existence of printing paper is detected by the paper sensor which is installed in the paper

not to supply power when paper runs our.

Without printing paper, CPU PAPER (Pin 99) gets "HIGH". When this takes place while in printing

operation, the operation stops at the end of the line, sending an error output. Printing is automatically

resumed when paper is supplied.

CBM-202PC User’s Manual

17

CITIZEN

Page 18

3.9 MOTOR CONTROL CIRCUIT

Except while in paper feed, the motor is held unexcited by CPU INH (Pin 97) so that heating of the motor is

prevented. While INH is held in "HIGH", the motor is maintained unexcited.

On supply of power, 4 dot lines of line feed is performed to meet the motor phase.

Avoid continuous printing over 15 min.

CBM-202PC User’s Manual

18

CITIZEN

Page 19

3.10 AUTO CUTTER CONTROL CIRCUIT

This CPU, by using the gate array (CBM-202LA), has auto cutter control function.

When an auto cutter is not used, set DS1-1 to OFF. When DS1-1 is ON, alarm state is created where

normal operation is interrupted.

CBM-202PC User’s Manual

19

CITIZEN

Page 20

3.11 PARALLEL INTERFACE CIRCUIT

This circuit performs 8-bit parallel interface by mainly using the gate array ports. When the parallel

interface is not used, pull up STB (Pin 52) of the gate array (CBM-202LA) through use of 10KΩ

resistance. Also, either connect CPU's STB (Pin 87) to INTR (Pin 56) of the gate array or pull it up with

10K Ω resistance.

CBM-202PC User’s Manual

20

CITIZEN

Page 21

CBM-202PC User’s Manual

Gate Array Signal Names and Functions

SIGNAL NAME PIN NO. I/O FUNCTION

STROBE 52 Input The signal to read data (negative logic)

D0 51

D1 50

D2 49

D3 48

D4 47

D5 46

D6 45

D7 44

ACK 59 Output

BUSY

PE 61 Output

FAULT 62 Output

GND

Timing Chart

55

Input

Output

Input data (positive logic)

Signal to indicate that data have been read.

(negative logic)

Signal to indicate that data receiving is possible.

(positive logic) Send data while it is in

"LOW".

Signal which is output when printing paper

runs out . (positive logic)

Signal to indicate a printer error (negative

logic)

21

CITIZEN

Page 22

3.12 SERIAL INTERFACE CIRCUIT

Serial interface applies asynchronous serial system.

When not using serial interface, pull up, CPU's RXD (Pin 15) and DSR (Pin 100) with

10K Ω resistance.

CBM-202PC User’s Manual

22

CITIZEN

Page 23

Transmits data while this signal is held in "LOW".

Signal Names and Functions

SIGNAL NAME PIN NO. I/O FUNCTION

TXD

RXD

DSR

DTR

13

15

100

12

CBM-202PC User’s Manual

Output

Input

Input

Output

Transmits status.

When data receiving is not available while in

XON/XOFF, XOFF (13H) is transmitted.

When receiving is made possible, XON (11H) is

transmitted.

Receiving data signal.

On occurrence of a framing error or parity error, the

data are printed in "?".

With this signal held in "LOW" when data are

transmitted from CPU while DTR/DSR has been

selected, transmitting takes place. With this signal

held in "HIGH", transmitting is does not take place

until it gets "LOW".

If writing takes place while in "HIGH", overrun error

is created, where data are ignored.

23

CITIZEN

Page 24

3.13 SWITCH CIRCUIT

This circuit is provided with switch input function for printer paper feeding.

Also, a function for self printing is equipped through use of this switch. (Either supply power as pushing

this switch or apply resetting in power supplied state as pushing this switch. Self printing starts

automatically and, on completion of printing, normal standby state is recovered.)

CBM-202PC User’s Manual

24

CITIZEN

Page 25

3.14 ERROR OUTPUT CIRCUIT

Two kinds of error output are held for output of various errors. (Max. 10mA current can be taken for

display with mainly LED, etc.. When this level is exceeded, however, CPU may be destroyed. Pay

attention, therefore, to select an appropriate current control resistance, LED, etc..)

CPU's LEDPE (Pin 4) is exclusively for output of paper error. When printing paper has got scarce,

"LOW" is output automatically. When paper is supplied, it becomes "HIGH".

CPU's LEDER (Pin 3) output various other errors in the following patterns:

ERROR DISPLAY PATTERN RECOVERY

CBM-202PC User’s Manual

Head UP

Head DOWN

Memory check

Not available

Head overheat

Head temperature lowered

Macro execution standby

LF switch

Cutter motor lock

Paper jamming cancelled

25

CITIZEN

Page 26

3.15 FUNCTION SELECTION CIRCUIT

The gate array input ports have terminals for function selection. To connect a DIP switch, etc., do it as it

is. When fixing with a jumper, etc., connect to GND only for those to be set to "LOW".

GATE ARRAY

PIN NO. SIGNAL NAME

33 PAI0 Auto cutter Equipped None

32 PAI1 CR Selection LF Ignored

31 PAI2 Print density

30 PAI3 DTR/XON-XOFF XON-XOFF DTR/DSR

29 PAI4

28 PAI5

27 PAI6

26 PAI7

PAI 3 is valid only when serial interface is used.

GATE ARRAY

PIN NO. SIGNAL NAME

43 PBI0

42 PBI1

39 PBI2

38 PBI3 Auto loading Valid Invalid

37 PBI4 Input buffer 4K bytes 72 bytes

36 PBI5 Print density

35 PBI6 Bit length 8 bits 7 bits

34 PBI7 Type of printer mechanism LT-282 LT-283

PBI6 is valid only when serial interface is used.

CBM-202PC User’s Manual

FUNCTION “LOW” “HIGH”

See Table③

Interface

FUNCTION “LOW” “HIGH”

Selection of international

character

See Table①

See Table②

See Table③

26

CITIZEN

Page 27

CBM-202PC User’s Manual

①Interface

INPUT SYSTEM

Parallel

Serial

PARITY BAUD RATE PAI7 PAI6 PAI5 PAI4

− −

None

19200 HIGH LOW HIGH LOW

Odd

1200 HIGH HIGH HIGH LOW

2400 HIGH HIGH LOW HIGH

4800 HIGH HIGH LOW LOW

9600 HIGH LOW HIGH HIGH

1200 HIGH LOW LOW HIGH

2400 HIGH LOW LOW LOW

4800 LOW HIGH HIGH HIGH

HIGH HIGH HIGH HIGH

9600 LOW HIGH HIGH LOW

19200 LOW HIGH LOW HIGH

Even

1200 LOW HIGH LOW LOW

2400 LOW LOW HIGH HIGH

4800 LOW LOW HIGH LOW

9600 LOW LOW LOW HIGH

19200 LOW LOW LOW LOW

27

CITIZEN

Page 28

CBM-202PC User’s Manual

②International Characters

International Characters PBI2 PBI1 PBI0

Japan (JIS) HIGH HIGH HIGH

Japan (Shift JIS) HIGH HIGH LOW

Sweden HIGH LOW HIGH

Denmark I HIGH LOW LOW

U.K. LOW HIGH HIGH

Germany LOW HIGH LOW

France LOW LOW HIGH

U.S.A. LOW LOW LOW

③Print Density

Print Density PAI 2 PAI 1

Light HIGH HIGH

Standard HIGH LOW

Dark LOW HIGH

Darker LOW LOW

28

CITIZEN

Page 29

3.16 EXTERNAL RAM INTERFACE

An external SRAM of 32 K bytes is always necessary for printing. When no external RAM is

connected, normal operation cannot be obtained.

CBM-202PC User’s Manual

29

CITIZEN

Page 30

Bus Timing

CBM-202PC User’s Manual

VCC=5.0V±10%, AVCC=5.0V±10%, VF=4.5V〜AVCC,

VSS=AVSS=0V, φ2〜16MHz, TA=−20〜+75℃

ITEM SYMBOL MIN MAX

Clock cycle time tcyc 62.5 500

Clock pulse width "LOW" level time tCL 20

Clock pulse width "HIGH" level time tCH 20

Clock rise time tCR

Clock breaking time tCF

Address delay time tAD

−

−

−

Address hold time tAH 10

Address strobe delay time t

Write strobe delay time t

ASD

WSD

Strobe delay time tSD

Write data strobe pulse width 1 t

Write data strobe pulse width 2 t

Address setup time 1 t

Address setup time 2 t

Read data setup time t

Read data hold time t

Write data delay time t

Write data setup time 1 t

Write data setup time 2 t

Write data hold time t

Read data access time 1 t

Read data access time 2 t

WSW1

WSW2

AS1

AS2

RDS

RDH

WDD

WDS1

WDS2

WDH

ACC1

ACC2

35

65

10

40

20

0

35

5

20

−

−

−

−

−

−

−

−

10

10

30

−

30

30

30

−

−

−

−

−

−

60

−

−

−

55

115

Unit: ns

30

CITIZEN

Page 31

CBM-202PC User’s Manual

31

CITIZEN

Page 32

4. OPERATING TIMING

Operating timing after resetting is canceled for this CPU is shown below:

CBM-202PC User’s Manual

32

CITIZEN

Page 33

5. PACKAGE SPECIFICATIONS

CBM-202PC User’s Manual

33

CITIZEN

Page 34

6. SPECIAL REMARKS FOR MOUNTING

6.1 CAUTIONS

As relative humidity gets low, static electricity tends to be charged. Although surface mount type

packages need to be stored in dry environments not to be affected by humidity, there is no worry for

charging as the packages in storage are not subject to friction. However, during handling and mounting to

substrates where friction and electric discharge are likely to take place, the relative humidity is

recommended to be 45 to 75% for prevention of electric charge.

6.2 REFLOW MOUNTING

The pattern on a PCB board has been formed to facilitate soldering with the package lead pins,

where a fixed amount of soldering paste is applied by screen process printing and the package is mounted.

The package is temporarily fixed by surface tension of soldering paste.

Then, with solder being reflowed, the package lead and the pattern on the base board are fitted by surface

tension of the reflowed solder.

Although the design value of the lead joint part pattern on a PCB board varies by soldering paste material,

reflow conditions, etc., the standard level is 1.1 to 1.3 times of the width of a lead pin subject to soldering.

CBM-202PC User’s Manual

6.3 RECOMMENDED CONDITIONS FOR VARIOUS MOUNTING METHODS

Mounting methods most commonly applied to surface mounting devices are the infrared rays reflow

method, the vapor phase reflow method, and the flow soldering method.

In all of these mounting methods, as the entire part of a package is heated, strong thermal stress is applied

to the package. For reliability assurance sake, therefore, not only temperature of the solder joint part but

also temperature of the package surface need to be controlled. As the recommended mounting conditions,

use package surface temperature for the reflow method and solder temperature as well as dipping time

for the flow soldering method.

The basic understanding of the recommended conditions is explained in Fig. 6.1:

Fig. 6.1

Peak temperature

and time

Thermal gradient 1

Package

surface

temperature

Thermal

gradient 2

Preparatory

heating

Time

34

CITIZEN

Page 35

CBM-202PC User’s Manual

1) Thermal Gradient 1

On a sudden temperature increase, unevenness in temperature is produced among package parts of

a surface mounting device, where difference in thermal expansion coefficients of materials can

cause a warp in the package, resulting in damaged chips. Attention, therefore, should be paid to the

upper limit for the increase speed. The lower limit is based on operation efficiency of the reflow

device.

2) Preparatory Heating

The parts and base boards are prepared at a temperature below the solder melting temperature so that

solder jointing is stabilized and thermal shock is lessened. In general, the temperature is set to a level

close to the rated temperature of the surface mounting device.

3) Thermal Gradient 2

The upper limit of increase temperature, as in 1), is determined based on necessity to maintain the

peak temperature and time within the specific range.

4) Peak Temperature and Time

The greatest care must be taken to minimize damage of a package. As a peak temperature directly

influences to reduce package strength and steam pressure inside a package, temperature should be held

low. Also, as steam pressure rises as time passes, set time as short as possible. Conditions shown

here indicate, not in mean values but in the maximum values, the points at which both the above

allowable region and the solder available region are satisfied. On setting conditions, therefore, be

careful not to exceed the upper limit values.

The recommended conditions for the various mounting methods are shown in Figs. 6.2 and 6.3:

Fig. 6.2 Recommended Conditions for Infrared Rays Reflow and Air Reflow

Package

Surface

Temperature

235℃ max

1 to 4℃ / sec.

140 to 160

℃

10 sec. max.

max

max. 60 sec.

1 to 5℃ / sec.

Time

Fig. 6.3 Recommended Conditions for Vapor Phase Reflow

Package

Surface

Temperature

215℃ max

140 to 160

℃

max. 60 sec.

30 sec. max.

max

1 to 5℃ / sec.

Time

35

CITIZEN

Page 36

CBM-202PC User’s Manual

6.4 CLEANING METHOD

As flux residue from soldering adversely affects reliability of parts and base PCB, it should be normally

removed by cleaning.

Ultrasonic cleaning, for example, is performed in the following conditions, for which cares should be taken

to an applied frequency, electricity (especially, peak power), time and device resonance to prevent the

device from breakage:

Frequency ..... 28 to 29KHz (Device should not resonate.)

Ultrasonic output ..... 15W/1 (1 time)

Time ..... 30 seconds and less

Others ..... Neither a device nor a PCB board directly touches an oscillation

source.

6.5 STORAGE METHOD

Epoxy resin used in plastic packages, when stored in a humid place, cannot escape

from moisture absorption. Absorbed moisture content, as it gets high, can suddenly

vaporize on soldering implementation, causing peeling of resin/lead frame joint or even

causing a crack on a package. It is, therefore, important to store it in dry environment

(under normal temperature and humidity within 5 to 35 ℃and 45 to 75%RH) in dampproof

package. After opening the package, please keep it in the specified environments to avoid

development of moisture absorption and perform reflow implementation in the shortest

possible time. When restoring it in the dampproof package, place new silica gel.

To remove water content having been absorbed during transport, storage, and handling,

drying (at 125 ℃) for 16 to 24 hours is recommended to be performed.

Store external terminals as they are not yet subject to machining.

This is to prevent soldering failure from taking place on implementation caused by

produced rust, etc..

36

CITIZEN

Page 37

CONTROL

1 HT Horizontal tab command

09H

2 CR Print comm

and 0DH

3 LF Printing and paper feed

0DH

4 ESC SP

1BH 20H n

5 ! Collective specifying printing mode

1BH21H n

6 % Specifying/canceling download character set

1BH25Hn

8 * Specifying the bit image mode

1BH2Amn1n2[d]k

9 - Specifying/canceling underline

1BH2DH n

10 2

Specifying 1/6

-

inch line feed rate

1BH32H

12 @ Initializi

ng the Printer

1BH40H

13 D

Setting horizontal tab position

1BH44H[n]k00H

14 E

Specifying/canceling highlighting

1BH45Hn

15 G

Specifying/canceling double printing

1BH47Hn

16 J

Printing and feeding paper n/203 inch

1BH4An

17 R

Selecting the internationa

l characters

1BH52Hn

19 c4 NOP

1BH63H34Hn

20 c5

Enabling/disabling the panel switches

1BH63H35Hn

21 d

Printing and feeding the paper by n lines

1BH64Hn

22 p

NOP

1BH70Hmn1n2

23 t

Selecting the character code table

1BH74Hn

24 v Transmitting the printer status (Serial type)

1BH75Hn

25 u

NOP

1BH76H

26 {

Specifying/canceling the inverted characters

1BH7BHn

27 V

turned

1BH56Hn

28 $

Specifying the absolute positions

1BH24Hn1n2

29 ¥ Specifying the relative positions

1BH5Cn1n2

30

GS k

Printing the bar code

1DH6BHn[“d”]k00H

7. COMMAND LIST

CODE

CBM-202PC User’s Manual

FUNCTION CODE

Setting the right space amount of the character

7

11

18

& Defining download characters 1BH26H5nm

[ap1p2...p5xa]m-n+1

3 Setting line feed rate of minimum pitch 1BH33Hn

c3 NOP

1BH63H33Hn

Specifying/canceling the 90 ° - right-

37

CITIZEN

Page 38

CBM-202PC User’s Manual

31 w

1DH77n

32

h

Selecting the height of the bar code

1DH68Hn

33 H

Selecting of print posi

tion of HRI code

1DH48Hn

34 f Selecting the font of HRI code

1DH66Hn

35 * Defining the download bit image

1DH2An1n2[d]n1xn2x

36 / Printing the download bit image

1DH2FHm

37 :

Starting/ending macro definition

1DH3AH

38 ^

Executing the macro

1DH5En1n2n

3 39 ESC =

Data input control

1BH3DHn

40 a

Aligning the characters

1BH61Hn

41 i

Activating auto cutter (Full cut)

1BH69H

42 m

Activating auto cutter (Partial cut)

1BH6DH

Selecting the horizontal size (scale factor) of bar code

38

CITIZEN

Page 39

8. CHARACTER CODE TABLE

8.1 INTERNATIONAL

CBM-202PC User’s Manual

39

CITIZEN

Page 40

8.2 INTERNATIONAL CHARACTER CODE TABLE

CBM-202PC User’s Manual

40

CITIZEN

Loading...

Loading...