Chrysler Sebring 2007 User Manual

2007 Chrysler Sebring

2007 ENGINE 2.7L DOHC - Service Information - Sebring

2007 ENGINE

2.7L DOHC - Service Information - Sebring

DESCRIPTION

ENGINE

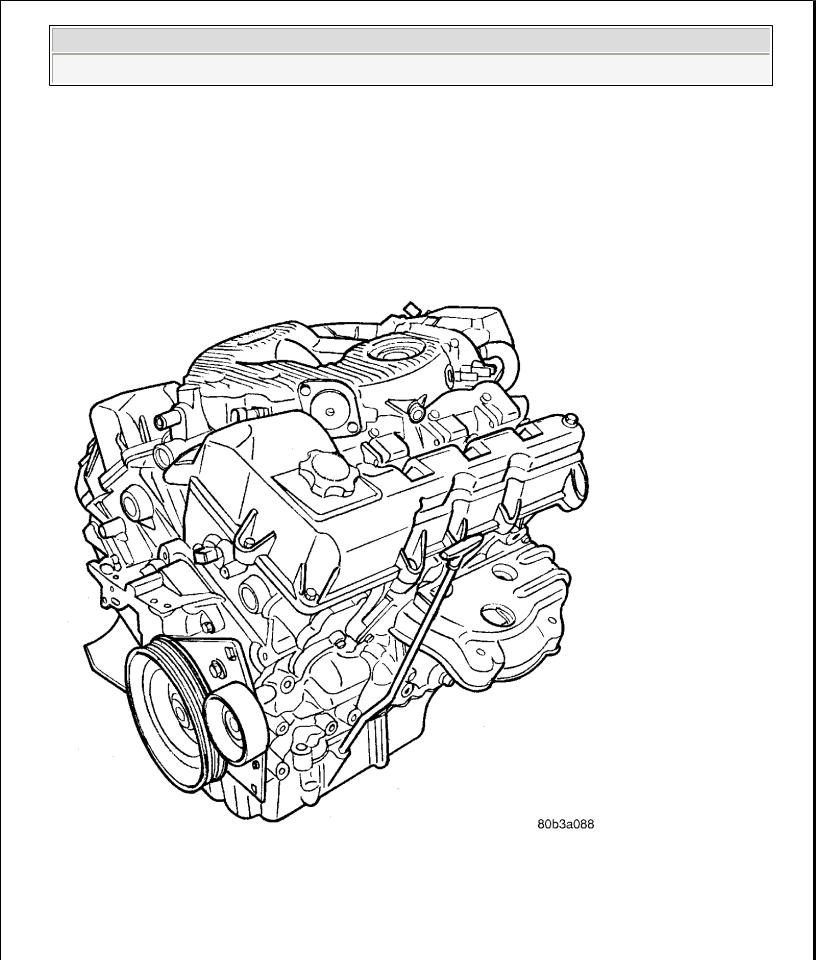

Fig. 1: View Of 2.7 Liter Engine

Courtesy of CHRYSLER LLC

The 2.7 Liter (167 Cubic Inches) 60 degree V6 engine is a double overhead

2007 Chrysler Sebring

2007 ENGINE 2.7L DOHC - Service Information - Sebring

camshaft design with hydraulic lifters and four valves per cylinder. The engine does not have provisions for a free wheeling valve train.

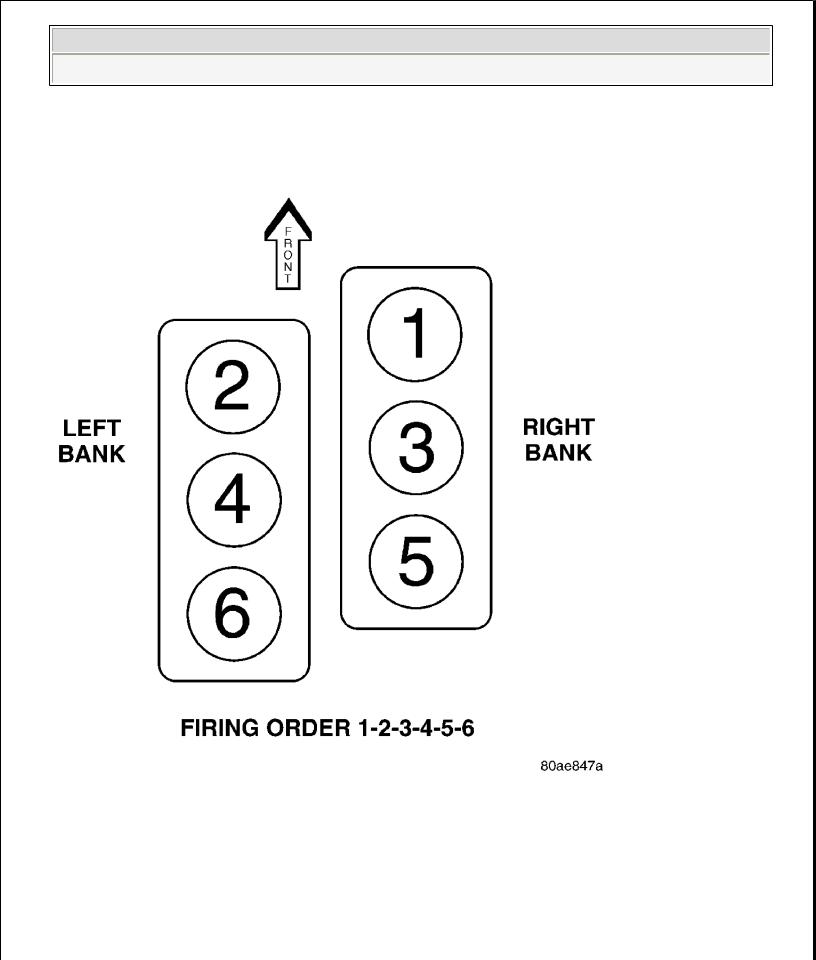

Fig. 2: Cylinder Numbering & Firing Order

Courtesy of CHRYSLER LLC

The cylinders are numbered from front to rear, with the right bank odd numbered and the left bank even numbered. The firing order is 1-2-3-4-5-6.

2007 Chrysler Sebring

2007 ENGINE 2.7L DOHC - Service Information - Sebring

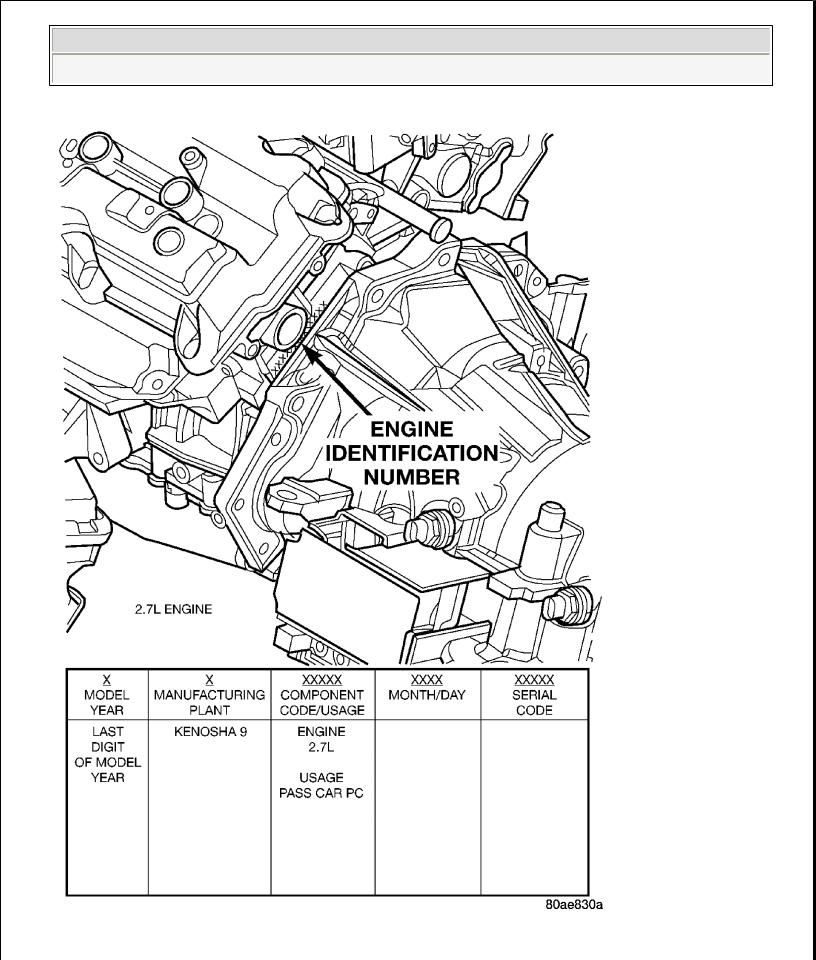

Fig. 3: Engine Identification

2007 Chrysler Sebring

2007 ENGINE 2.7L DOHC - Service Information - Sebring

Courtesy of CHRYSLER LLC

The engine identification number is located on the rear of the cylinder block just below the left cylinder head.

DIAGNOSIS AND TESTING

ENGINE DIAGNOSIS - MECHANICAL

CONDITION |

POSSIBLE CAUSES |

|

CORRECTION |

|

VALVETRAIN NOISE |

1. High or low oil level |

1. |

Check and correct |

|

|

in crankcase. |

engine oil level. |

||

|

2. |

Thin or diluted oil. |

2. |

Change oil to correct |

|

|

|

viscosity. |

|

|

3. |

Thick oil |

3. |

(a.) Change oil and |

|

|

|

filter. |

|

|

|

|

(b.) Run engine to |

|

|

|

|

operating temperature. |

|

|

|

|

(c.) Change oil and filter |

|

|

|

|

again. |

|

|

4. |

Low oil pressure. |

4. |

Check and correct |

|

|

|

engine oil level. |

|

|

5. |

Dirt in tappets/lash |

5. |

Replace rocker |

|

adjusters. |

arm/hydraulic lash |

||

|

|

|

adjuster assembly. |

|

|

6. |

Worn rocker arms. |

6. |

Inspect oil supply to |

|

|

|

rocker arms. |

|

|

7. |

Worn tappets/lash |

7. |

Install new rocker |

|

adjusters. |

arm/hydraulic lash |

||

|

|

|

adjuster assembly. |

|

|

8. |

Worn valve guides. |

8. |

Ream guides and install |

|

|

|

new valves with oversize |

|

|

|

|

stems. |

|

|

9. |

Excessive runout of |

9. |

Grind valve seats and |

|

valve seats on valve |

valves. |

||

|

faces. |

|

|

|

2007 Chrysler Sebring

2007 ENGINE 2.7L DOHC - Service Information - Sebring

|

10. Missing adjuster |

10. Replace rocker |

|

||

|

pivot. |

arm/hydraulic lash |

|

||

|

|

|

adjuster assembly. |

|

|

|

|

|

|

|

|

CONNECTING ROD |

1. Insufficient oil |

1. |

Check engine oil level. |

|

|

NOISE |

supply. |

|

|

|

|

|

2. |

Low oil pressure. |

2. |

Check engine oil level. |

|

|

|

|

Inspect oil pump relief |

|

|

|

|

|

valve and spring. |

|

|

|

3. |

Thin or diluted oil. |

3. |

Change oil to correct |

|

|

|

|

viscosity. |

|

|

|

4. |

Thick oil |

3. |

(a.) Change oil and |

|

|

|

|

filter. |

|

|

|

(b.) Run engine to |

|

|

|

|

|

operating temperature. |

|

|

|

|

|

(c.) Change oil and |

|

|

|

|

|

filter again. |

|

|

|

|

|

5. |

Excessive bearing |

5. |

Measure bearings for |

|

|

clearance. |

correct clearance. Repair |

|

||

|

|

|

as necessary. |

|

|

|

6. |

Connecting rod |

6. |

Replace crankshaft or |

|

|

journal out-of-round. |

grind surface. |

|

||

|

7. |

Misaligned |

7. |

Replace bent |

|

|

connecting rods. |

connecting rods. |

|

||

|

|

|

|

|

|

MAIN BEARING NOISE |

1. Insufficient oil |

1. |

Check engine oil level. |

|

|

|

supply. |

|

|

|

|

|

2. |

Low oil pressure. |

2. |

Check engine oil level. |

|

|

|

|

Inspect oil pump relief |

|

|

|

|

|

valve and spring. |

|

|

|

3. |

Thin or diluted oil. |

3. |

Change oil to correct |

|

|

|

|

viscosity. |

|

|

|

4. |

Thick oil |

3. |

(a.) Change oil and |

|

|

|

|

filter. |

|

|

|

(b.) Run engine to |

|

|

|

|

|

operating temperature. |

|

|

|

|

|

|

|

|

|

|

2007 Chrysler Sebring

2007 ENGINE 2.7L DOHC - Service Information - Sebring

|

(c.) Change oil and |

|

|

|

|

|

filter again. |

|

|

|

|

|

4. |

Excessive bearing |

4. |

Measure bearings for |

|

|

clearance. |

correct clearance. Repair |

|

||

|

|

|

as necessary. |

|

|

|

5. |

Excessive end play. |

5. |

Check thrust bearing |

|

|

|

|

for wear on flanges. |

|

|

|

6. |

Crankshaft journal |

6. |

Replace crankshaft or |

|

|

out-of-round or worn. |

grind journals. |

|

||

|

7. |

Loose flywheel or |

7. |

Tighten to correct |

|

|

torque converter. |

torque. |

|

||

|

|

|

|

|

|

OIL PRESSURE DROP |

1. Low oil level. |

1. |

Check engine oil level. |

|

|

|

2. |

Faulty oil pressure |

2. |

Install new sending |

|

|

sending unit. |

unit. |

|

||

|

3. |

Low oil pressure. |

3. |

Check sending unit and |

|

|

|

|

main bearing oil |

|

|

|

|

|

clearance. |

|

|

|

4. |

Clogged oil filter. |

4. |

Install new oil filter. |

|

|

5. |

Worn parts in oil |

5. |

Replace worn parts or |

|

|

pump. |

pump. |

|

||

|

6. |

Thin or diluted oil. |

6. |

Change oil to correct |

|

|

|

|

viscosity. |

|

|

|

7. |

Oil pump relief valve |

7. |

Remove valve and |

|

|

stuck. |

inspect, clean or replace. |

|

||

|

8. |

Oil pump suction |

8. |

Remove oil pan and |

|

|

tube loose. |

install new tube or clean, |

|

||

|

|

|

if necessary. |

|

|

|

9. |

Oil pump cover |

9. |

Install new oil pump. |

|

|

warped or cracked. |

|

|

|

|

|

10. Excessive bearing |

10. Measure bearings for |

|

||

|

clearance. |

correct clearance. |

|

||

|

|

|

|

|

|

OIL LEAKS |

1. Misaligned or |

1. |

Replace gasket(s). |

|

|

|

deteriorated gaskets. |

|

|

|

|

|

2. |

Loose fastener, |

2. |

Tighten, repair or |

|

|

|

|

|

|

|

2007 Chrysler Sebring

2007 ENGINE 2.7L DOHC - Service Information - Sebring

|

|

broken or porous metal |

|

replace the part. |

||

|

|

part. |

|

|

|

|

|

3. |

Misaligned or |

3. |

Replace as necessary. |

||

|

|

deteriorated cup or |

|

|

|

|

|

|

threaded plug. |

|

|

|

|

OIL CONSUMPTION OR |

|

1. PCV system |

|

1. Check system and |

||

|

|

|||||

SPARK PLUGS FOULED |

|

malfunction. |

|

repair as necessary. Refer |

||

|

|

|

|

|

to Appropriate Diagnostic |

|

|

|

|

|

|

Information. |

|

|

|

2. |

Worn, scuffed or |

|

2. |

Hone cylinder bores. |

|

|

broken rings. |

|

Install new rings. |

||

|

|

3. |

Carbon in oil ring |

|

3. |

Clean pistons and |

|

|

slots. |

|

install new rings. |

||

|

|

4. |

Rings fitted too |

|

4. |

Remove rings and |

|

|

tightly in grooves. |

|

check grooves. If groove |

||

|

|

|

|

|

is not proper width, |

|

|

|

|

|

|

replace piston. |

|

|

|

5. |

Worn valve guide(s). |

|

5. |

Replace cylinder head |

|

|

|

|

|

(s). |

|

|

|

6. |

Valve stem seal(s) |

6. |

Replace seal(s). |

|

|

|

worn or damaged. |

|

|

|

|

|

|

|

|

|

|

|

ENGINE OIL LEAK INSPECTION

Begin with a thorough visual inspection of the engine, particularly at the area of the suspected leak. If an oil leak source is not readily identifiable, the following steps should be followed:

1.Do not clean or degrease the engine at this time because some solvents may cause rubber to swell, temporarily stopping the leak.

2.Add an oil soluble dye (use as recommended by manufacturer). Start the engine and let idle for approximately 15 minutes. Check the oil dipstick to make sure the dye is thoroughly mixed as indicated with a bright yellow color under a black light.

3.Using a black light, inspect the entire engine for fluorescent dye, particularly at

2007 Chrysler Sebring

2007 ENGINE 2.7L DOHC - Service Information - Sebring

the suspected area of oil leak. If the oil leak is found and identified, repair as necessary.

4.If dye is not observed, drive the vehicle at various speeds for approximately 24 km (15 miles) and repeat inspection.

5.If the oil leak source is not positively identified at this time , proceed with the AIR LEAK DETECTION TEST METHOD as follows:

Disconnect the fresh air hose (make-up air) at the cylinder head cover and plug or cap the nipple on the cover.

Remove the PCV valve hose from the cylinder head cover. Cap or plug the PCV valve nipple on the cover.

Attach an air hose with pressure gauge and regulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to more than 20.6 kPa (3 PSI) of test pressure.

Gradually apply air pressure from 1 psi to 2.5 psi maximum while applying soapy water at the suspected source. Adjust the regulator to the suitable test pressure that provides the best bubbles which will pinpoint the leak source. If the oil leak is detected and identified, repair per service information procedures.

If the leakage occurs at the crankshaft rear oil seal area, refer to

INSPECTION FOR REAR SEAL AREA LEAKS.

6.If no leaks are detected, turn off the air supply. Remove the air hose, all plugs and caps. Install the PCV valve and fresh air hose (make-up air). Proceed to next step.

7.Clean the oil off the suspect oil leak area using a suitable solvent. Drive the vehicle at various speeds approximately 24 km (15 miles). Inspect the engine for signs of an oil leak by using a black light.

NOTE: If oil leakage is observed at the dipstick tube to block location; remove the tube, clean and reseal using Mopar® Stud & Bearing Mount (press fit tube applications only) and for O-ring style tubes, remove tube and replace the O-ring seal.

2007 Chrysler Sebring

2007 ENGINE 2.7L DOHC - Service Information - Sebring

INSPECTION FOR REAR SEAL AREA LEAKS

Since it is sometimes difficult to determine the source of an oil leak in the rear seal area of the engine, a more involved inspection is necessary. The following steps should be followed to help pinpoint the source of the leak.

If the leakage occurs at the crankshaft rear oil seal area:

1.Disconnect the battery.

2.Raise the vehicle.

3.Remove torque converter or clutch housing cover and inspect rear of block for evidence of oil. Use a black light to check for the oil leak. If a leak is present in this area, remove transmission for further inspection.

Circular spray pattern generally indicates seal leakage or crankshaft damage.

Where leakage tends to run straight down, possible causes are a porous block, oil gallery cup plug, bedplate to cylinder block mating surfaces and seal bore. See proper repair procedures for these items.

4.If no leaks are detected, pressurize the crankcase as described in step 5 under ENGINE OIL LEAK INSPECTION.

CAUTION: Do not exceed 20.6 kPa (3 psi).

5.If the leak is not detected, very slowly turn the crankshaft and watch for leakage. If a leak is detected between the crankshaft and seal while slowly turning the crankshaft, it is possible the crankshaft seal surface is damaged. The seal area on the crankshaft could have minor nicks or scratches that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft polishing is necessary to remove minor nicks and scratches. The crankshaft seal flange is especially machined to complement the function of the rear oil seal.

2007 Chrysler Sebring

2007 ENGINE 2.7L DOHC - Service Information - Sebring

6.For bubbles that remain steady with shaft rotation, no further inspection can be done until disassembled.

7.After the oil leak root cause and appropriate corrective action have been identified, replace component(s) as necessary.

ENGINE DIAGNOSIS - PERFORMANCE

CONDITION |

POSSIBLE CAUSE |

|

CORRECTION |

|

ENGINE WILL NOT |

1. Weak battery. |

1. |

Test battery. Charge or |

|

START |

|

|

replace as necessary. Refer |

|

|

|

|

to DESCRIPTION . |

|

|

2. |

Corroded or loose |

2. |

Clean and tighten |

|

battery connections. |

battery connections. Apply |

||

|

|

|

a coat of light mineral |

|

|

|

|

grease to terminals. |

|

|

3. |

Faulty starter. |

3. |

Test starting system. |

|

|

|

Refer to DIAGNOSIS |

|

|

|

|

AND TESTING . |

|

|

4. |

Faulty coil(s) or |

4. |

Test and replace as |

|

control unit. |

needed. (Refer to |

||

|

|

|

Appropriate Diagnostic |

|

|

|

|

Information) |

|

|

5. |

Incorrect spark plug |

5. |

Check and adjust gap as |

|

gap. |

needed. |

||

|

6. |

Contamination in |

6. |

Clean system and |

|

fuel system. |

replace fuel filter. |

||

|

7. |

Faulty fuel pump. |

7. |

Test fuel pump and |

|

|

|

replace as needed. (Refer |

|

|

|

|

to Appropriate Diagnostic |

|

|

|

|

Information) |

|

8. Incorrect engine timing. 8. Check for a skipped timing chain.

ENGINE STALLS OR 1. Idle speed too low. IDLES ROUGH

1. Test minimum air flow. (Refer to Appropriate Diagnostic Information)

2007 Chrysler Sebring

2007 ENGINE 2.7L DOHC - Service Information - Sebring

|

2. |

Incorrect fuel |

2. |

(Refer to Appropriate |

|

|

mixture. |

Diagnostic Information) |

|

||

|

3. |

Intake manifold |

3. |

Inspect intake manifold |

|

|

leakage. |

gasket, manifold and |

|

||

|

|

|

vacuum hoses. |

|

|

|

4. |

Faulty coil(s). |

4. |

Test and replace as |

|

|

|

|

necessary. (Refer to |

|

|

|

|

|

Appropriate Diagnostic |

|

|

|

|

|

Information) |

|

|

|

|

|

|

|

|

ENGINE LOSS OF |

1. Dirty or incorrectly |

1. |

Set gap as needed or |

|

|

POWER |

gapped plugs. |

replace plug(s). |

|

||

|

2. |

Contamination in |

2. |

Clean system and |

|

|

fuel system. |

replace fuel filter. |

|

||

|

3. |

Faulty fuel pump. |

3. |

Test and replace as |

|

|

|

|

necessary. (Refer to |

|

|

|

|

|

Appropriate Diagnostic |

|

|

|

|

|

Information) |

|

|

|

4. |

Incorrect valve |

4. |

Correct valve timing as |

|

|

timing. |

needed. |

|

||

|

5. |

Leaking cylinder |

5. |

Replace cylinder head |

|

|

head gasket. |

gasket. |

|

||

|

6. |

Low compression. |

6. |

Test compression of |

|

|

|

|

each cylinder. |

|

|

|

7. |

Burned, warped or |

7. |

Replace valves. |

|

|

pitted valves. |

|

|

|

|

|

8. |

Plugged or |

8. |

Check exhaust system |

|

|

restricted exhaust |

restriction. Replace parts, |

|

||

|

system. |

as necessary. |

|

||

|

9. |

Faulty coil(s). |

9. |

Test and replace as |

|

|

|

|

necessary. (Refer to |

|

|

|

|

|

Appropriate Diagnostic |

|

|

|

|

|

Information) |

|

|

|

|

|

|

|

|

ENGINE MISSES ON |

1. Dirty or incorrectly |

1. |

Set gap as needed or |

|

|

ACCELERATION |

gapped spark plugs. |

replace plug(s). |

|

||

|

|

|

|

|

|

2007 Chrysler Sebring

2007 ENGINE 2.7L DOHC - Service Information - Sebring

|

2. |

Contamination in |

2. |

Clean fuel system and |

|

|

|

Fuel System. |

replace fuel filter. |

||

|

3. |

Burned, warped or |

3. |

Replace valves. |

|

|

|

pitted valves. |

|

|

|

|

4. |

Faulty coil(s). |

4. |

Test and replace as |

|

|

|

|

|

necessary. (Refer to |

|

|

|

|

|

Appropriate Diagnostic |

|

|

|

|

|

Information) |

|

ENGINE MISSES AT |

|

1. Dirty or incorrect |

|

Set gap as needed or |

|

|

1. |

||||

HIGH SPEED |

|

spark plug gap. |

replace plug(s). |

||

|

|

2. |

Faulty coil(s). |

2. |

Test and replace as |

|

|

|

|

necessary. (Refer to |

|

|

|

|

|

Appropriate Diagnostic |

|

|

|

|

|

Information) |

|

|

|

3. |

Dirty fuel injector |

Test and replace as |

|

|

|

(s). |

necessary. (Refer to |

||

|

|

|

|

Appropriate Diagnostic |

|

|

|

|

|

Information) |

|

|

|

4. |

Contamination in |

4. |

Clean system and |

|

|

fuel system. |

replace fuel filter. |

||

|

|

|

|

|

|

ENGINE DIAGNOSIS - INTRODUCTION

Engine diagnosis is helpful in determining the causes of malfunctions not detected and remedied by routine maintenance.

These malfunctions may be classified as either mechanical (e.g, a strange noise) or performance (e.g, engine idles rough and stalls).

Refer to. See DIAGNOSIS AND TESTING.

Additional tests and diagnostic procedures may be necessary for specific engine malfunctions that cannot be isolated with the Service Diagnosis charts. Information concerning additional tests and diagnosis is provided within the following:

Cylinder Compression Pressure Test

2007 Chrysler Sebring

2007 ENGINE 2.7L DOHC - Service Information - Sebring

Cylinder Combustion Pressure Leakage Test

Cylinder Head Gasket Failure Diagnosis

Intake Manifold Leakage Diagnosis

Lash Adjuster (Tappet) Noise Diagnosis

Engine Oil Leak Inspection

CYLINDER COMBUSTION PRESSURE LEAKAGE TEST

The combustion pressure leakage test provides an accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

Exhaust and intake valve leaks (improper seating).

Leaks between adjacent cylinders or into water jacket.

Any causes for combustion/compression pressure loss.

WARNING: DO NOT REMOVE THE PRESSURE CAP WITH THE SYSTEM HOT AND UNDER PRESSURE BECAUSE SERIOUS BURNS FROM COOLANT CAN OCCUR.

Check the coolant level and fill as required. DO NOT install the pressure cap.

Start and operate the engine until it attains normal operating temperature, then turn the engine OFF.

Clean spark plug recesses with compressed air.

Remove the spark plugs.

Remove the oil filler cap.

Remove the air cleaner.

Calibrate the tester according to the manufacturer's instructions. The shop air source for testing should maintain 483 kPa (70 psi) minimum, 1,379 kPa (200 psi)

2007 Chrysler Sebring

2007 ENGINE 2.7L DOHC - Service Information - Sebring

maximum, with 552 kPa (80 psi) recommended.

Perform the test procedures on each cylinder according to the tester manufacturer's instructions. While testing, listen for pressurized air escaping through the throttle body, tailpipe and oil filler cap opening. Check for bubbles in the coolant.

All gauge pressure indications should be equal, with no more than 25% leakage per cylinder.

FOR EXAMPLE: At 552 kPa (80 psi) input pressure, a minimum of 414 kPa (60 psi) should be maintained in the cylinder.

CYLINDER COMPRESSION PRESSURE TEST

The results of a cylinder compression pressure test can be utilized to diagnose several engine malfunctions.

Ensure the battery is completely charged and the engine starter motor is in good operating condition. Otherwise the indicated compression pressures may not be valid for diagnosis purposes.

1.Check engine oil level and add oil if necessary.

2.Drive the vehicle until engine reaches normal operating temperature. Select a route free from traffic and other forms of congestion, observe all traffic laws and accelerate through the gears several times briskly.

3.Remove all spark plugs from engine. As spark plugs are being removed, check electrodes for abnormal firing indicators fouled, hot, oily, etc. Record cylinder number of spark plug for future reference.

4.Remove the Auto Shutdown (ASD) relay from the PDC.

5.Be sure throttle blade is fully open during the compression check.

6.Insert compression gauge adapter Special Tool 8116 or the equivalent, into the #1 spark plug hole in cylinder head. Connect the 0-500 psi (Blue) pressure transducer (Special Tool CH7059) with cable adapters to the DRBIII®. For Special Tool identification, see SPECIAL TOOLS.

7.Crank engine until maximum pressure is reached on gauge. Record this pressure as #1 cylinder pressure.

2007 Chrysler Sebring

2007 ENGINE 2.7L DOHC - Service Information - Sebring

8.Repeat the previous step for all remaining cylinders.

9.Compression should not be less than 689 kPa (100 psi) and not vary more than 25 percent from cylinder to cylinder.

10.If one or more cylinders have abnormally low compression pressures, repeat the compression test.

11.If the same cylinder or cylinders repeat an abnormally low reading on the second compression test, it could indicate the existence of a problem in the cylinder in question. The recommended compression pressures are to be used only as a guide to diagnosing engine problems. An engine should not be disassembled to determine the cause of low compression unless some malfunction is present.

STANDARD PROCEDURE

FORM-IN-PLACE GASKETS AND SEALERS

There are numerous places where form-in-place gaskets are used on the engine. Care must be taken when applying form-in-place gaskets to assure obtaining the desired results. Do not use form-in-place gasket material unless specified. Bead size, continuity and location are of great importance. Too thin a bead can result in leakage while too much can result in spill-over which can break off and obstruct fluid feed lines. A continuous bead of the proper width is essential to obtain a leakfree gasket.

There are numerous types of form-in-place gasket materials that are used in the engine area. Mopar® Engine RTV GEN II, Mopar® ATF-R TV and Mopar® Gasket Maker gasket materials, each have different properties and can not be used in place of the other.

MOPAR® ENGINE RTV GEN II is used to seal components exposed to engine oil. This material is a specially designed black silicone rubber RTV that retains adhesion and sealing properties when exposed to engine oil. Moisture in the air causes the material to cure. This material is available in three ounce tubes and has a shelf life of one year. After one year this material will not properly cure. Always inspect the package for the expiration date before use.

2007 Chrysler Sebring

2007 ENGINE 2.7L DOHC - Service Information - Sebring

MOPAR® ATF RTV is a specifically designed black silicone rubber RTV that retains adhesion and sealing properties to seal components exposed to automatic transmission fluid, engine coolants and moisture. This material is available in three ounce tubes and has a shelf life of one year. After one year this material will not properly cure. Always inspect the package for the expiration date before use.

MOPAR® GASKET MAKER is an anaerobic type gasket material. The material cures in the absence of air when squeezed between two metallic surfaces. It will not cure if left in the uncovered tube. The anaerobic material is for use between two machined surfaces. Do not use on flexible metal flanges.

MOPAR® BED PLATE SEALANT is a unique (green-in-color) anaerobic type gasket material that is specially made to seal the area between the bed plate and cylinder block without disturbing the bearing clearance or alignment of these components. The material cures slowly in the absence of air when torqued between two metallic surfaces and will rapidly cure when heat is applied.

MOPAR® GASKET SEALANT is a slow drying, permanently soft sealer. This material is recommended for sealing threaded fittings and gaskets against leakage of oil and coolant. Can be used on threaded and machined parts under all temperatures. This material also will prevent corrosion. Mopar® G asket Sealant is available in a 13 oz. aerosol can or 4oz./16 oz. can w/applicator.

SEALER APPLICATION

Mopar® Gasket Maker material should be applied spar ingly 1 mm (0.040 in.) diameter or less of sealant to one gasket surface. Be certain the material surrounds each mounting hole. Excess material can easily be wiped off. Components should be torqued in place within 15 minutes. The use of a locating dowel is recommended during assembly to prevent smearing material off the location.

Mopar® Engine RTV GEN II or ATF RTV gasket material should be applied in a continuous bead approximately 3 mm (0.120 in.) in diameter. All mounting holes must be circled. For corner sealing, a 3.17 or 6.35 mm (1/8 or 1/4 in.) drop is placed in the center of the gasket contact area. Uncured sealant may be removed with a shop towel. Components should be torqued in place while the sealant is still wet to the touch (within 10 minutes). The usage of a locating dowel is recommended

2007 Chrysler Sebring

2007 ENGINE 2.7L DOHC - Service Information - Sebring

during assembly to prevent smearing material off the location.

Mopar® Gasket Sealant in an aerosol can should be a pplied using a thin, even coat sprayed completely over both surfaces to be joined and both sides of a gasket. Then proceed with assembly. Material in a can w/applicator can be brushed on evenly over the sealing surfaces.

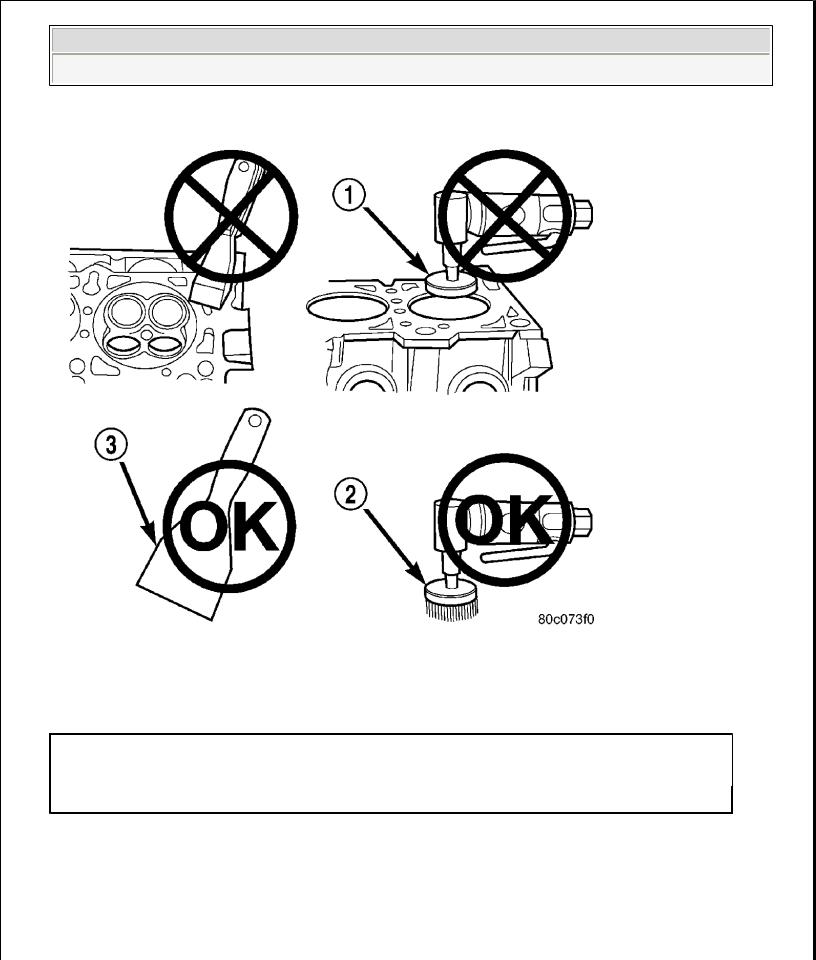

ENGINE GASKET SURFACE PREPARATION

To ensure engine gasket sealing, proper surface preparation must be performed, especially with the use of aluminum engine components and multi-layer steel cylinder head gaskets.

Never use the following to clean gasket surfaces:

Metal scraper

Abrasive pad or paper to clean cylinder block and head

High speed power tool with an abrasive pad or a wire brush

NOTE: Multi-Layer Steel (MLS) head gaskets require a scratch free sealing surface.

Only use the following for cleaning gasket surfaces:

Solvent or a commercially available gasket remover

Plastic or wood scraper

Drill motor with 3M Roloc™ Bristle Disc (white or y ellow)

CAUTION: Excessive pressure or high RPM (beyond the recommended speed), can damage the sealing surfaces. The mild (white, 120 grit) bristle disc is recommended. If necessary, the medium (yellow, 80 grit) bristle disc may be used on cast iron surfaces with care.

2007 Chrysler Sebring

2007 ENGINE 2.7L DOHC - Service Information - Sebring

Fig. 4: View Of Proper Tool Usage For Surface Preparation Courtesy of CHRYSLER LLC

1 - ABRASIVE PAD

2 - 3M ROLOC™ BRISTLE DISC

3 - PLASTIC/WOOD SCRAPER

HYDROSTATIC LOCKED ENGINE

When an engine is suspected to be hydrostatically locked, regardless of what caused the problem, the following steps should be used.

2007 Chrysler Sebring

2007 ENGINE 2.7L DOHC - Service Information - Sebring

CAUTION: DO NOT use starter motor to rotate the engine, severe damage may occur.

1.Inspect air cleaner, induction system and intake manifold to insure system is dry and clear of foreign material.

2.Remove negative battery cable.

3.Place a shop towel around the spark plugs when removing them from the engine. This will catch any fluid that may possibly be in the cylinder under pressure.

4.With all spark plugs removed, rotate engine crankshaft using a breaker bar and socket.

5.Identify the fluid in the cylinder(s) (i.e, coolant, fuel, oil or other).

6.Make sure all fluid has been removed from the cylinders. Inspect engine for damage (i.e, connecting rods, pistons, valves, etc.)

7.Repair engine or components as necessary to prevent this problem from reoccurring.

CAUTION: Squirt approximately one teaspoon of oil into the cylinders, rotate engine to lubricate the cylinder walls to prevent damage on restart.

8.Install new spark plugs.

9.Drain engine oil and remove oil filter.

10.Install a new oil filter.

11.Fill engine with specified amount of approved oil.

12.Connect negative battery cable.

13.Start engine and check for any leaks.

ENGINE CORE AND OIL GALLERY PLUGS

2007 Chrysler Sebring

2007 ENGINE 2.7L DOHC - Service Information - Sebring

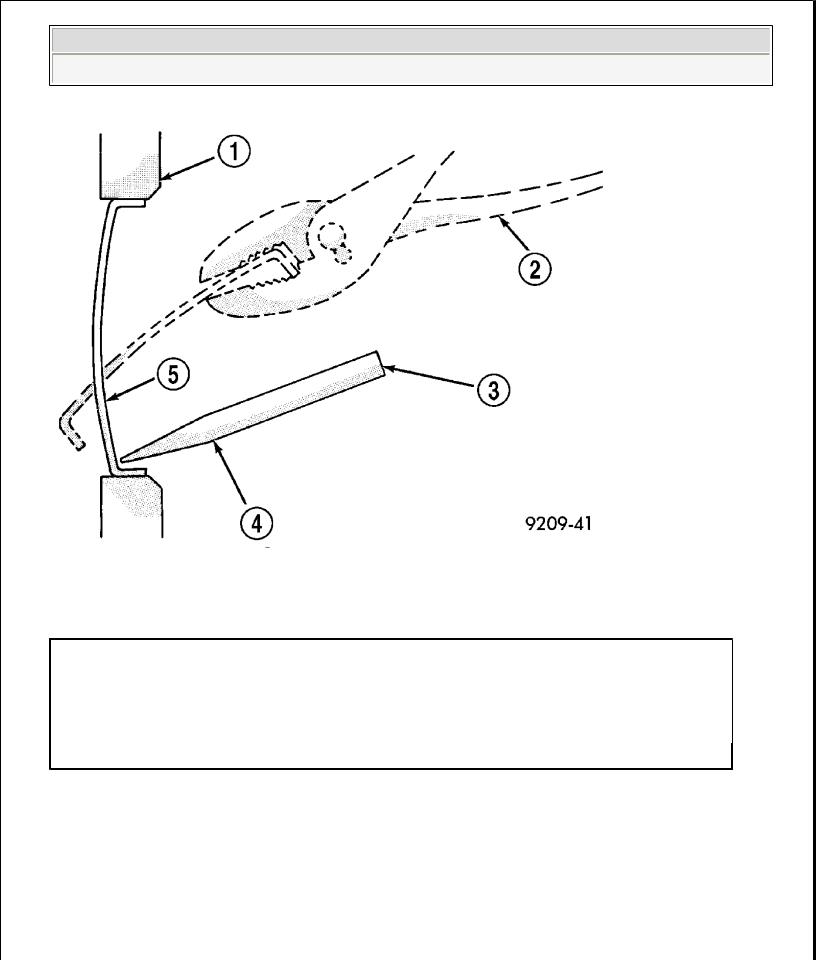

Fig. 5: Removing Engine Core Plug

Courtesy of CHRYSLER LLC

1 - CYLINDER BLOCK

2 - REMOVE PLUG WITH PLIERS

3 - STRIKE HERE WITH HAMMER

4 - DRIFT PUNCH

5 - CUP PLUG

Using a blunt tool such as a drift and a hammer, strike the bottom edge of the cup plug. With the cup plug rotated, grasp firmly with pliers or other suitable tool and remove plug.

CAUTION: Do not drive cup plug into the casting as restricted cooling can result and cause serious engine problems.

2007 Chrysler Sebring

2007 ENGINE 2.7L DOHC - Service Information - Sebring

Thoroughly clean inside of cup plug hole in cylinder block or head. Be sure to remove old sealer. Lightly coat inside of cup plug hole with Mopar® Stud and Bearing Mount. Make certain the new plug is cleaned of all oil or grease. Using proper drive plug, drive plug into hole so that the sharp edge of the plug is at least 0.5 mm (0.020 in.) inside the lead-in chamfer.

It is not necessary to wait for curing of the sealant. The cooling system can be refilled and the vehicle placed in service immediately.

REPAIR OF DAMAGED OR WORN THREADS

Damaged or worn threads (excluding spark plug and camshaft bearing cap attaching threads) can be repaired. Essentially, this repair consists of drilling out worn or damaged threads, tapping the hole with a special Heli-Coil Tap, (or equivalent) and installing an insert into the tapped hole. This brings the hole back to its original thread size.

CAUTION: Be sure that the tapped holes maintain the original center line.

Heli-Coil tools and inserts are readily available from automotive parts jobbers.

REMOVAL

ENGINE ASSEMBLY

2007 Chrysler Sebring

2007 ENGINE 2.7L DOHC - Service Information - Sebring

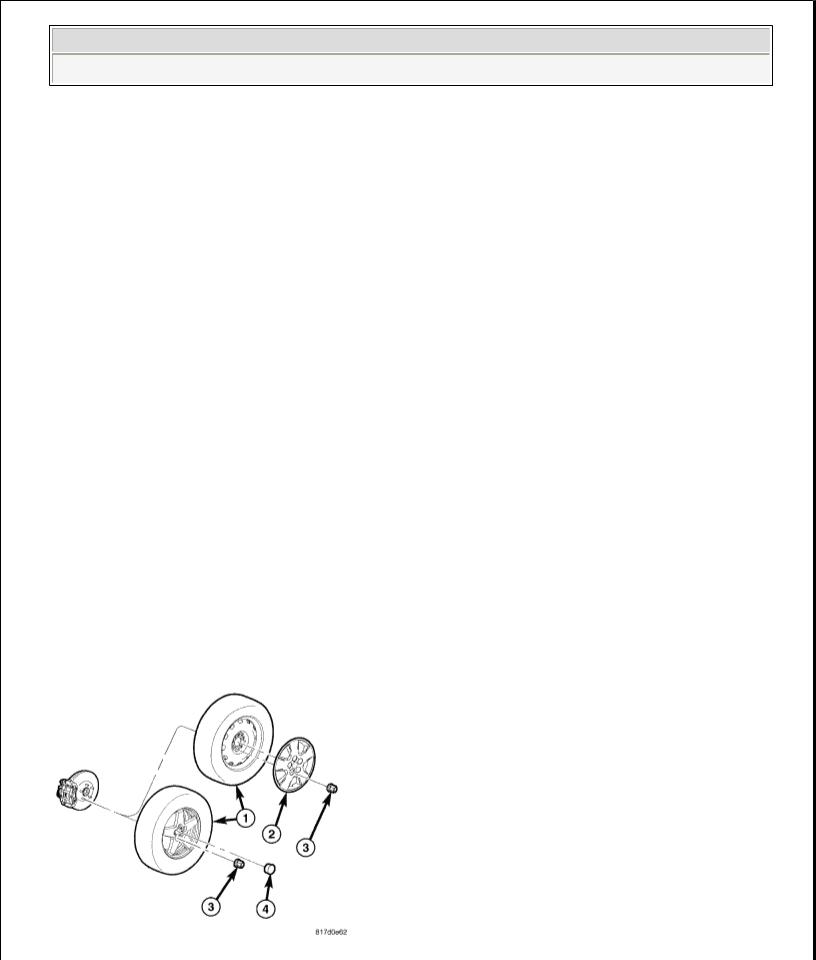

Fig. 6: Identifying Tire & Wheel Mounting

Courtesy of CHRYSLER LLC

1.Release fuel pressure. Refer to STANDARD PROCEDURE .

2.Disconnect negative battery cable.

3.Drain cooling system.

4.Remove both front wheels (1).

Fig. 7: Identifying Inlet Hose & Electrical Connection

Courtesy of CHRYSLER LLC

5.Discharge A/C system using a suitable refrigerant recovery machine.

6.Remove throttle body air inlet hose (1) and air cleaner housing assembly. See

REMOVAL.

2007 Chrysler Sebring

2007 ENGINE 2.7L DOHC - Service Information - Sebring

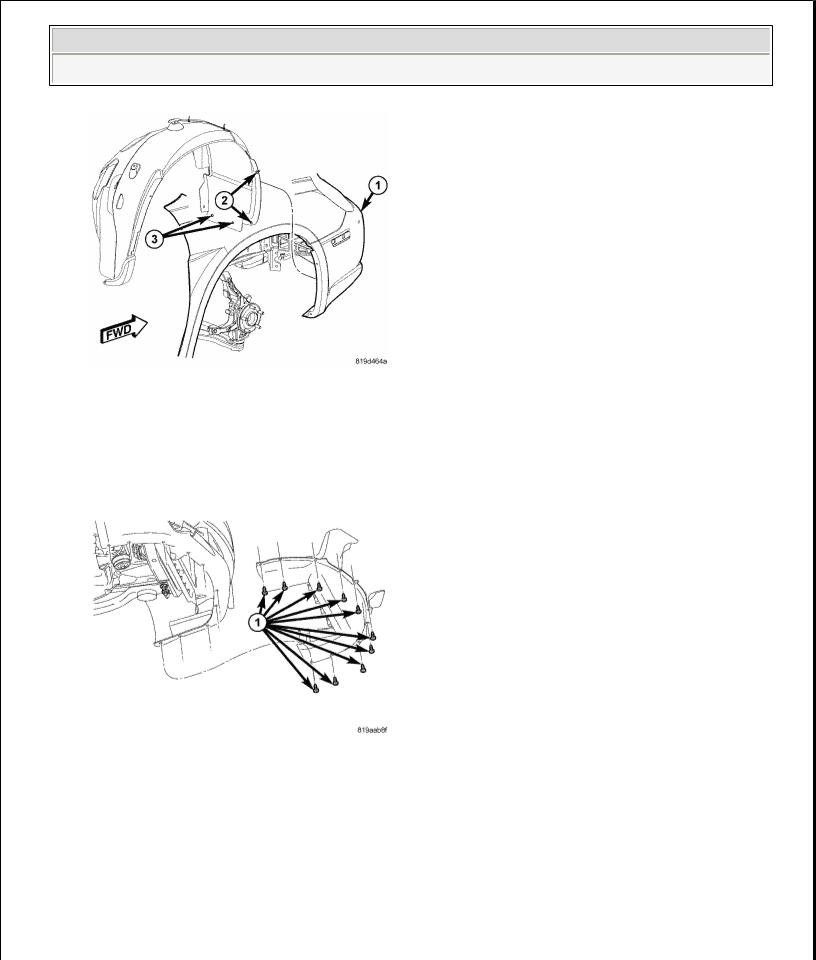

Fig. 8: Identifying Front Splash Shields

Courtesy of CHRYSLER LLC

7. Remove left and right splash shields (2). Refer to REMOVAL .

Fig. 9: Identifying Front Lower Fascia Closeout

Courtesy of CHRYSLER LLC

8. Remove front fascia closeout (1). Refer to REMOVAL .

2007 Chrysler Sebring

2007 ENGINE 2.7L DOHC - Service Information - Sebring

Fig. 10: Identifying Upper Radiator Hose

Courtesy of CHRYSLER LLC

1 - ELECTRICAL CONNECTOR

2 - UPPER RADIATOR HOSE

9. Disconnect upper (2) and lower radiator hoses at radiator.

Fig. 11: Identifying A/C Line

Courtesy of CHRYSLER LLC

1 - A/C LINE

2 - SUPPORT BRACKET

2007 Chrysler Sebring

2007 ENGINE 2.7L DOHC - Service Information - Sebring

10. Automatic Transmission Equipped Vehicles:

Remove the transaxle oil cooler lines. Plug lines and fittings to prevent debris from entering transaxle or cooler circuit.

Disconnect transmission electrical harness connectors. Disconnect transmission shift cable.

11. Disconnect A/C lines (1) at condenser.

Fig. 12: Identifying A/C Line

Courtesy of CHRYSLER LLC

1 - A/C LINE

2 - SUPPORT BRACKET

12. Manual Transmission Equipped Vehicles:

Disconnect transmission shift cables and remove from retaining bracket. Disconnect back up lamp switch connector.

13. Disconnect A/C lines (1) at condenser.

2007 Chrysler Sebring

2007 ENGINE 2.7L DOHC - Service Information - Sebring

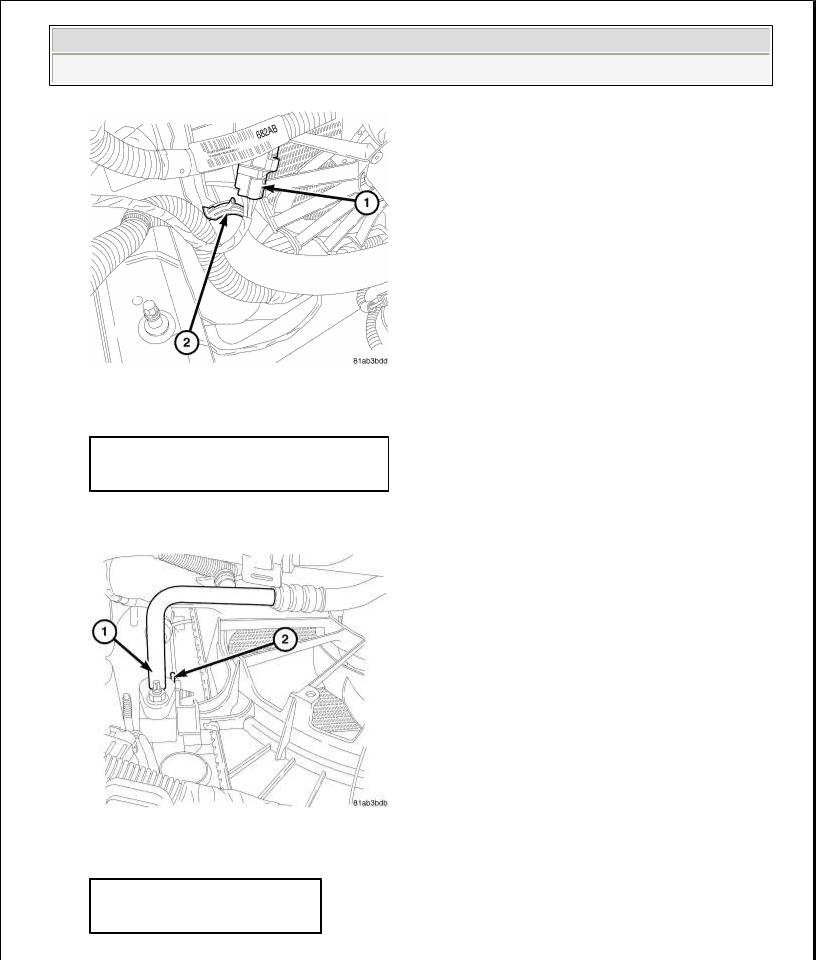

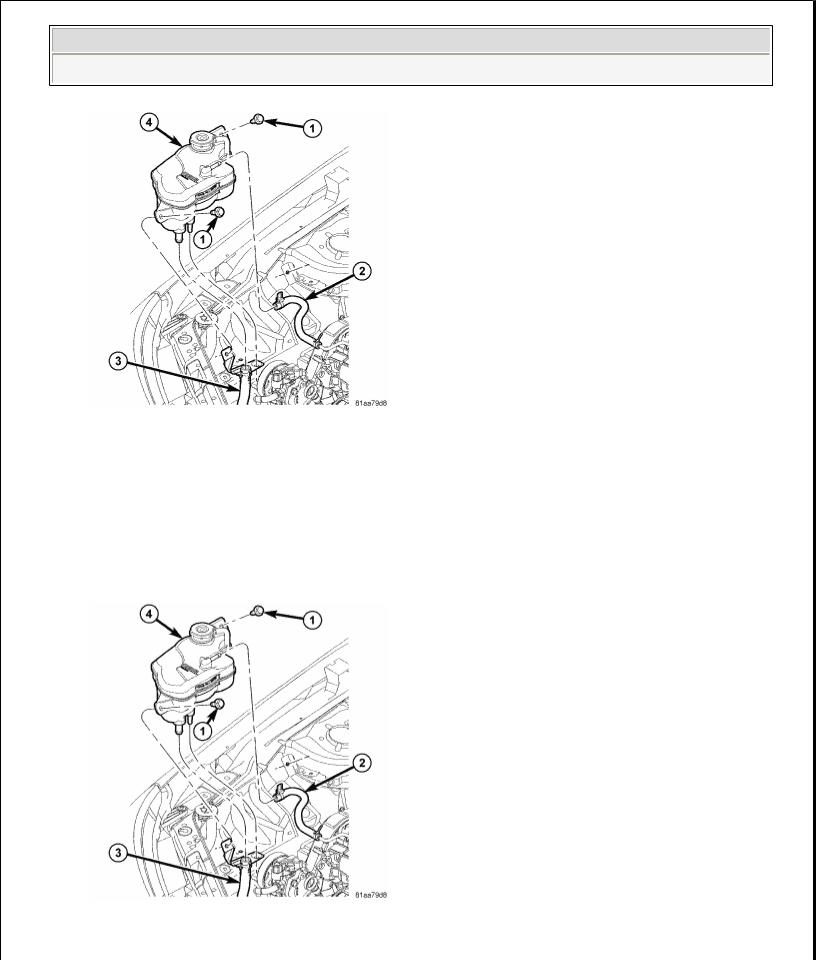

Fig. 13: View Of Coolant Recovery Container - Pressure System Courtesy of CHRYSLER LLC

14.Disconnect the hose from the engine to the coolant recovery container (2).

15.Remove cooling module (fan, radiator, A/C condenser).

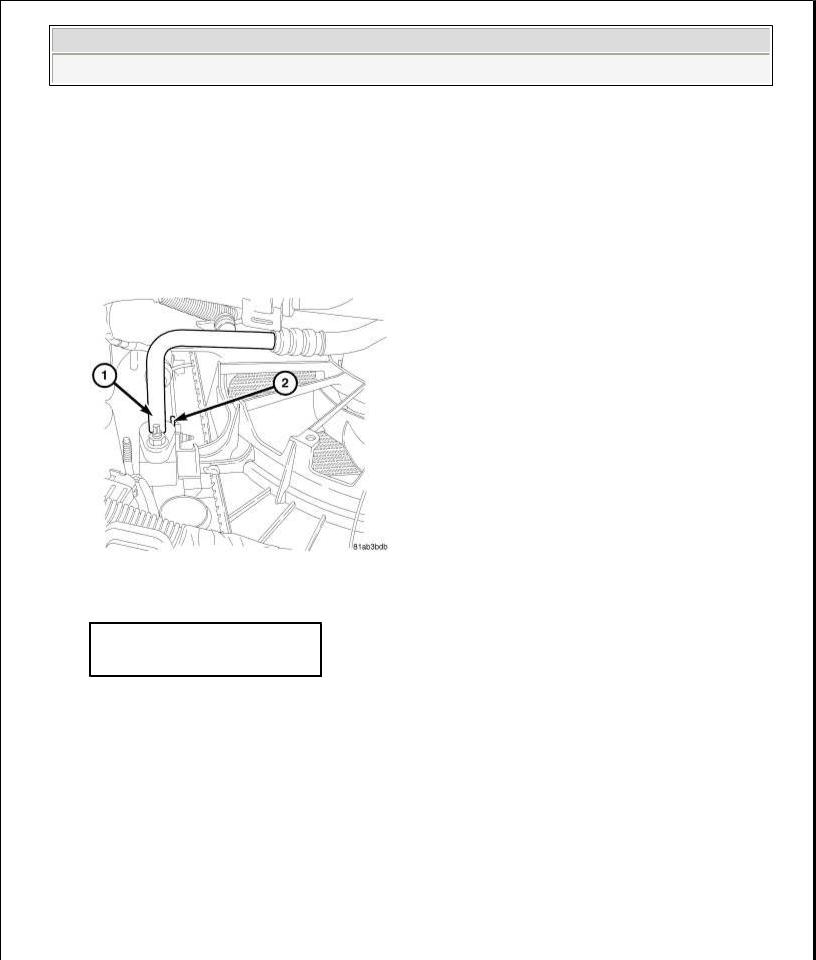

16.Remove fasteners attaching ABS brake module to lower radiator crossmember. Support module with a suitable retaining strap.

Fig. 14: View Of Coolant Recovery Container - Pressure System Courtesy of CHRYSLER LLC

2007 Chrysler Sebring

2007 ENGINE 2.7L DOHC - Service Information - Sebring

17.Disconnect engine electrical harness from PCM and bulkhead connectors.

18.Disconnect brake line from retaining clips that attach to lower radiator crossmember.

19.Disconnect hose from the radiator to the coolant recovery container (3).

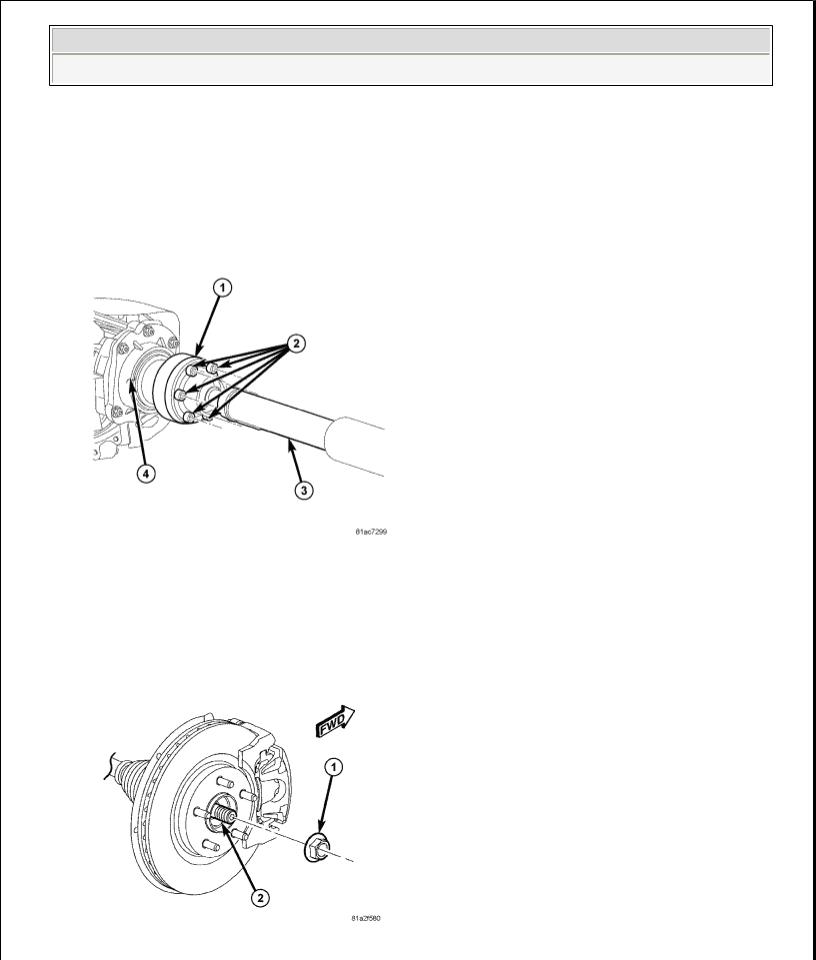

Fig. 15: Identifying Propeller Shaft To PTU & Fasteners Courtesy of CHRYSLER LLC

20.Remove the propeller shaft to ptu fasteners (2). (If equipped). Refer to

REMOVAL .

Fig. 16: Identifying Axle Shaft Hub Nut

2007 Chrysler Sebring

2007 ENGINE 2.7L DOHC - Service Information - Sebring

Courtesy of CHRYSLER LLC

21. Remove both axle shafts (2). Refer to REMOVAL .

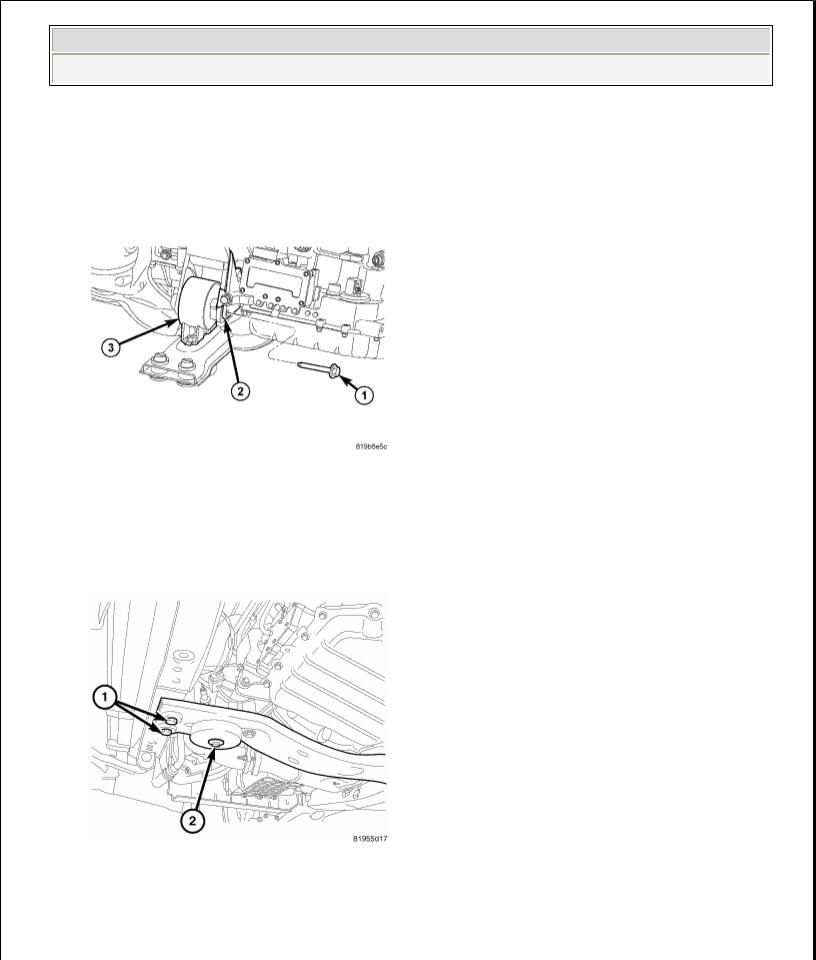

Fig. 17: Identifying Engine Mount Horizontal Thru Bolt

Courtesy of CHRYSLER LLC

22.Remove front engine mount thru bolt (1). Remove front engine mount (3) from lower radiator crossmember.

Fig. 18: Identifying Engine Mount/Cross Member

Courtesy of CHRYSLER LLC

23. Remove lower radiator crossmember (2).

2007 Chrysler Sebring

2007 ENGINE 2.7L DOHC - Service Information - Sebring

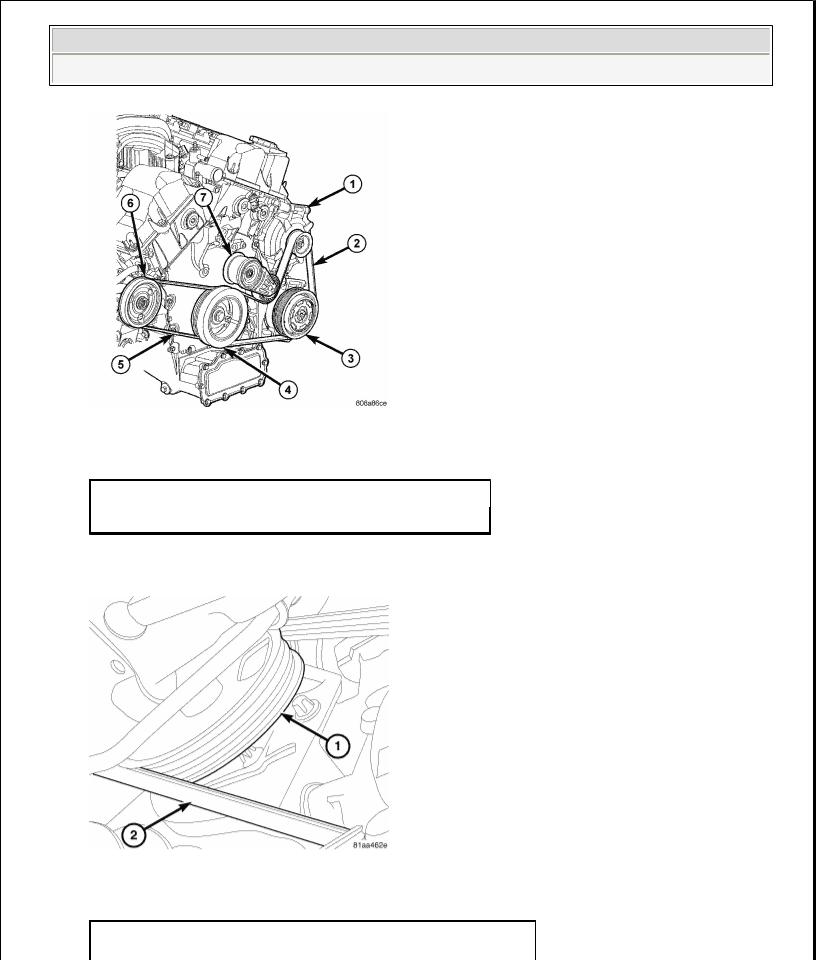

Fig. 19: Accessory Drive Belt System - 2.7L

Courtesy of CHRYSLER LLC

1 - GENERATOR

2 - IDLER/TENSIONER

24. Remove accessory drive belts (2). Refer to REMOVAL .

Fig. 20: Removing/Installing Stretch To Fit Power Steering Belt Courtesy of CHRYSLER LLC

1 - POWER STEERING PULLEY

2007 Chrysler Sebring

2007 ENGINE 2.7L DOHC - Service Information - Sebring

2 - STRETCH TO FIT POWER STEERING BELT

2 - STRETCH TO FIT POWER STEERING BELT

25. Remove power steering belt (2). Refer to REMOVAL .

Fig. 21: Identifying Rear Power Steering Pump Mounting Bracket Bolts Courtesy of CHRYSLER LLC

26.Remove power steering pump and bracket (1) as an assembly. Do not disconnect power steering lines from pump. Reposition pump and support with suitable retaining strap. Refer to REMOVAL .

27.Disconnect heater return hose from pipe connection at right front frame rail area.

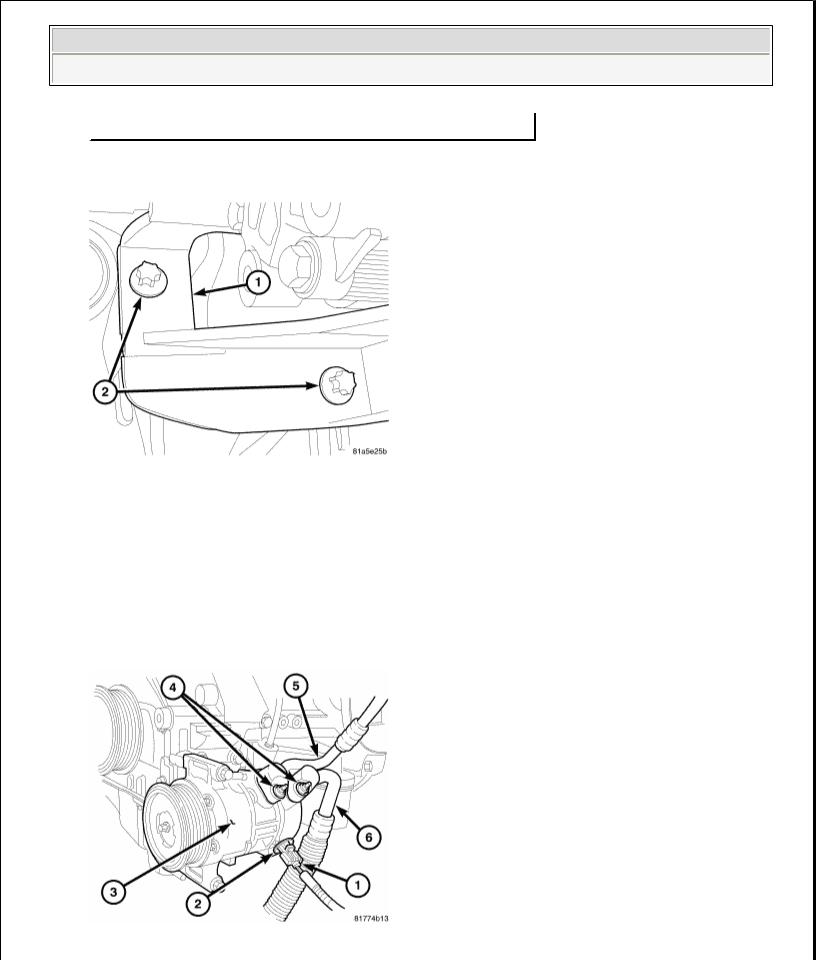

Fig. 22: A/C Compressor-Refrigerant Lines

Loading...

Loading...