Page 1

Instructions for use

Table of contents Page

1 - GENERAL 3

1.1 - GENERAL SAFETY REGULATIONS 3

1.1.1 - STANDARD SAFETY DEVICES 3

1.2 - FIELD OF APPLICATION 3

1.3 - OVERALL DIMENSIONS 3

1.4 - TECHNICAL DATA 3

2 - HANDLING AND LIFTING 4

3 - STARTUP 4

3.1 - ANCHORING 4

3.2 - ELECTRICAL CONNECTION 4

3.3 - FLANGE MOUNTING 4

3.4 - WHEEL GUARD ASSEMBLY AND ADJUSTMENT (OPTIONAL) 4

3.5 - WD SPACER 5

4 - CONTROLS AND COMPONENTS 5

4.1 - AUTOMATIC DISTANCE AND DIAMETER GAUGE 5

4.2 - KEYBOARD AND DISPLAY 5

4.2.1 FUNCTION MENU MANAGEMENT 6

5 - INSTRUCTIONS FOR USE OF THE WHEEL BALANCER 7

5.1 - USING THE GAUGE INSTALLED ON THE MACHINE 7

5.1.1 - DATA SETTING 7

5.2 - AUTOMATIC PRESETTING 7

5.2.1 - STEEL OR ALUMINUM WHEEL RIMS. SPRUNG COUNTERWEIGHTS 7

5.2.1.1 - STATIC & COMBINED MODES 8

5.2.2 - RIMS WITH INTERNAL COUNTERWEIGHT 8

5.3 - MEASUREMENT RESULT 9

5.3.1 - MEASUREMENT PRECISION 9

5.4 - RECALCULATION OF THE UNBALANCE VALUES 9

5.5 - EXACT POSITIONING OF THE ADHESIVE WEIGHT BY MEANS OF THE GAUGE WITH CLIPS 9

5.6 - SPLIT FUNCTION 10

5.7 - UNBALANCE OPTIMIZATION 11

5.8 - AUTOMATIC MINIMISATION OF STATIC UNBALANCE 12

6 - SET-UP 12

6.1 - AUTODIAGNOSTICS 12

6.2 - AUTOCALIBRATION 12

6.3 - MANUAL DIMENSION PRESETTING 13

6.3.1 - STEEL WHEEL RIMS 13

6.3.2 - ALU S RIMS 13

6.3.2.1 - ALU-S VARIANT WITH INSIDE CLAMP WEIGHT 14

6.4 - DISPLAY SAVER 15

6.5 - AUTOMATIC GAUGES CALIBRATION 15

6.5.1 - RIM DISTANCE GAUGE 15

6.5.2 - DIAMETER GAUGE 16

7 - ERRORS 17

7.1 - INCONSISTENT UNBALANCE READINGS 18

8 - ROUTINE MAINTENANCE 18

8.1 - REPLACING THE PROTECTION FUSES 18

9 - LIST OF RECOMMENDED SPARE PARTS 19

I

I 0410 - 1

GB

Page 2

I 0410 - 2

I 0410 - 3

GB

GB

Page 3

640

1070

1244

1395

1167

1 - General

1.1 - General safety regulations

-The wheel balancer may only be used by duly authorized and trained personnel.

- The wheel balancer must not be used for purposes other than those described in the instruction manual.

- The wheel balancer must not be modied in any way except for those modications made

explicitly by the manufacturer.

- Do not remove the safety devices. Any work on the machine must be carried out by specialised personnel

only.

- Avoid using strong jets of compressed air for cleaning.

- Use alcohol to clean plastic panels or shelves (AVOID LIQUIDS CONTAINING SOLVENTS).

- Before starting the wheel balancing cycle, make sure that the wheel is securely locked on the ange.

- The machine operator must not wear clothes with apping parts. Do not allow unauthorized personnel to

approach the wheel balancer when the cycle is running.

- Avoid placing objects in the base which could impair the correct operation of the wheel balancing machine.

1.1.1 - Standard safety devices

- Stop push button for stopping the wheel under emergency conditions.

- The wheel guard is not compulsory since the rotation speed is less than 100 min

1.2 - Field of application

The machine is designed for balancing wheels of cars, light commercial vehicles or motorcycles weighing less than 75 kg.

It can be operated in a temperature range of 0° to + 45° C.

-1.

1.3 - Overall dimensions

1

1.4 - Technical data

Single-phase power supply 230 V - 50/60 Hz

Protection class IP 54

Max. power absorbed 1,5 KW

Breakaway Current 13 A

Balancing speed < 100 min

Max. resolution of measurement 1 gram

Position resolution ± 1.4 °

Average noise < 70dB (A)

Rim-machine distance 0 - 270 mm

Rim width setting range 1.5” - 20” or 40 - 510 mm

Diameter setting range 10” - 26” or 265 - 665 mm

-1

I 0410 - 3

GB

Page 4

A

B

I 0410 - 5

GB

2 - Handling and lifting

2 2a

3 - Startup

NOTE: DO NOT LIFT THE WHEEL

BALANCER USING OTHER GRIPS

3.1 - Anchoring

The machine can operate on any at non resilient oor.

Make sure that the machine rests solely on the three support points provided (Fig.2a).

3.2 - Electrical connection

The machine is supplied with a single-phase mains cable plus earth (ground).

(any extension cables must have a cross-section of no less than 2.5 mm2).

The power supply voltage (and mains frequency) is indicated on the machine identication plate and cannot be

changed. Connection to the mains must always be made by expert personnel.

The machine must not be set up without proper earthing.

Connection to the mains should be through a slow acting safety switch rated at 16 A (230V). See enclosed diagram.

3.3 - Flange mounting

3

The wheel balancer is supplied complete with cone anges

for xing wheels with a central hole. To mount other optional ange

adaptors :

a) Remove the threaded end-piece A after unscrewing the screw B.

b) Mount the new ange (see attached sheets).

NOTE: CAREFULLY CLEAN THE COUPLING SURFACES BEFORE

PERFORMING ANY OPERATION.

3.4 - Wheel guard assembly and adjustment (optional)

a) Fix the components to the base as described in the attachment “WHEEL GUARD ASSEMBLY SEQUENCE” at

the end of the manual.

Note: Do not lean on the guard during the wheel balancing cycle.

I 0410 - 4

GB

Page 5

Spring

DC

WD

Cone

3.5 - WD spacer

3a

To move the wheel away from the machine side (e.g. for

very wide wheels), t the WD spacer on the ange body

and secure it with the standard issue nuts. When centring

the wheel with cone from the inside, mount the DC spacer

to obtain spring thrust. These devices are optionals (see

ange details enclosed).

4 - Controls and components

4.1 - Automatic distance and diameter gauge

Allows automatic measurement of the distance from the machine and the wheel diameter at the counterweight

application point. The same gauge can be used to position the counterweights correctly inside the wheel, using the

specic function that suggests the position memorised during measurement inside the rim.

4.2 - Keyboard and display

4

6

1

7

8

9

3

15

5E5I

1-2 Digital readouts, AMOUNT OF

UNBALANCE, inside/outside

3-4 Digital readouts, POSITION OF

UNBALANCE, inside/outside

5I INSIDE correction position selection button

5E EXTERNAL SIDE and STATIC correction

position selection button

10 Push button, unbalance reading < 5 g

(.25 oz)

11 Push button, SPLIT (unbalance spread)

12 Position repeater push button

13 Push button, cycle start

14 Push button, emergency/home

15 Dot matrix function display

6 Push button, FUNCTIONS MENU

7 Push button, MENU selection conrmation

8 Maximize/MENU button

9 Minimize/MENU button

Note: - Press buttons only with your ngers. Do not use the counterweight grippers or other pointed

objects.

2

4

13 14

RED

GREEN

YELLOW

10

11

12

I 0410 - 5

GB

Page 6

I 0215 - 7

0I

MENU

STOP

I 0410 - 7

GB

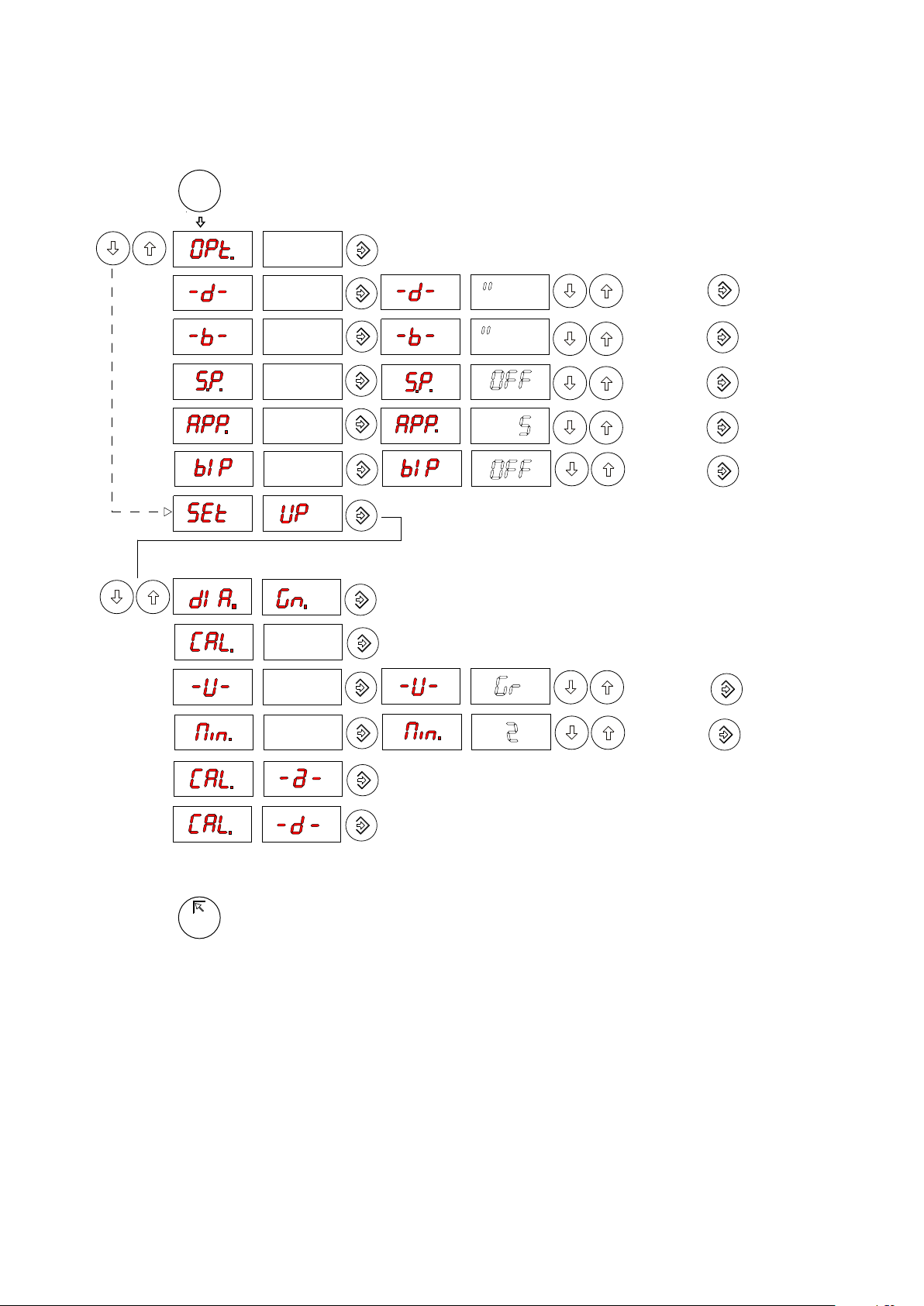

4.2.1 - Function menu management

See chapter on unbalance optimisation

UP

UP

DOWN

DOWN

See chapter on AUTODIAGNOSTICS

See chapter on AUTOCALIBRATION

diameter

mm/inch

mm/inch

width

start from

guard closing

approx.1-5 g or

0.1-0.25 oz

on/off beep

signal

g/oz unit of

measure

unbalance

Screen-saver

duration

(in minutes)

CONFIRM

CONFIRM

CONFIRM

CONFIRM

CONFIRM

CONFIRM

CONFIRM

Calibration of automatic RIM DISTANCE gauge

Calibration of automatic DIAMETER gauge

RETURN TO MEASUREMENT FRAME

I 0410 - 6

GB

Page 7

b

5 - Instructions for use of the wheel balancer

5.1 - Using the gauge installed on the machine

5.1.1 - Data setting

For clamp weights, use the gauge in the top position A.

For adhesive weights, use the gauge as preferred in top position A or

bottom position B.

Note: Always use the round part of the striker plate resting on

the rim.

Indication of gauge in movement

5a

5

POS. A

POS. B

5.2 - Automatic presetting

The machine automatically detects the correct balancing program for steel and aluminium rims (ALU-S).

ALU

The counterweight position proposed may be changed using the two

5.2.1 - Steel or aluminum wheel rims. Sprung counterweights

5b

buttons.

5c

Pull out the gauge as far as the inner edge of the rim. Hold it in this

position until a “beep” is heard.

Indication of dimensions acquired

Return the gauge to rest position. The machine has automatically

detected DISTANCE + DIAMETER and goes to MANUAL WIDTH

SETTING.

- The nominal width is normally stamped

on the rim; if not, proceed to measure

dimension “b” with the calibre gauge

(supplied as standard).

5d

I 0410 - 7

GB

Page 8

I 0410 - 9

GB

5.2.1.1 - Static & combined modes

After calibration as per STEEL OR ALUMINUM WHEEL RIMS. SPRUNG COUNTERWEIGHTS, it is possible to modify the

position of the correction weights using the

5.2.2 - Rims with internal counterweight

6

ALU

buttons.

STATIC: Select by pressing

Balancing of light alloy rims with application of adhesive weights

on the shoulders of the rims.

Combined balancing: adhesive weight on the outside and clip-on

weight on the inside.

Combined balancing: adhesive weight on the inside and clip-on

weight on the outside.

Slide out the gauge on the LH side, at the point where a weight is

to be tted. Wait for the “beep”. Slide it out further towards the RH

side and wait for a second “beep”. The wheel balancer

automatically identies ALU S mode.

ALU

(5E)

Counterweight position automatically suggested.

ALU

(5I) can be used to set the alternative position indicated.

I 0410 - 8

GB

Page 9

5.3 - Measurement result

After performing a balancing spin, the amounts of unbalance are shown on the digital readouts.

The illuminated LEDs 3 and 4 indicate the correct angular position of the wheel to mount the counterweights (12

o’clock).

7a

Fig. 7A - Inside correction

7b

Fig. 7B - Outside correction

If the unbalance is less than the threshold value selected,

the values below the threshold can be read.

5.3.1 - Measurement precision

The machine uses special devices (WP) to ensure the best possible measurement speed and controlled measurement

precision less than 1 gr. Operation is automatic and the measurement is highlighted as soon as sufcient precision is

reached. In the event of excessive vibration of the oor or exceptional shock, the wheel balancer might execute the

maximum number of permissible measurements. In this case, the following symbol is displayed:

Correct the result all the same and check with a test launch.

is displayed instead of the unbalance value; with

<T

5.4 - Recalculation of the unbalance

Automatic on varying set-up with the buttons

ALU

.

5.5 - Exact positioning of the adhesive weight by means of the gauge with clips

- press

- Fit the correction weight in the specic gauge seat with the adhesive

part facing upwards

- bring the wheel into correct angular position for the plane to be

corrected

- withdraw the gauge until the correction plane indication arrows turn

green

INSIDE CORRECTION POSITION

OUTSIDE CORRECTION POSITION

- rotate the gauge until the correction weight adheres to the rim

- the fact that the weight application position is no longer vertical (Fig. 8)

is automatically compensated

- to cancel this function, press button again

8

N.B. : It is not possible to put automatically the correction

weight in the Fig.5/B position; always rotate the rim in

Fig.5/A upwards.

I 0410 - 9

GB

Page 10

15

30

15

30

15

30

MENU

START

START

STOP

I 0410 - 11

GB

5.6 - Split function (hidden weight)

The SPLIT function is used to position the adhesive weights behind the wheel spokes so that they are not visible. Input

the wheel dimensions and do a spin.

- Place the wheel in the outside unbalance correction position.

- Set one of the top spokes to 12 o’clock.

- Press

Indication of rst positioning detected

- Follow the UP/DOWN indication of the arrows and set the second top

spoke to 12 o’clock position.

- Press

- Place the rst Split unbalance in correction position 1

- Correction position 1 (indicator 1)

1

- Correction position 2 (indicator 2)

2

N.B.: If errors 24/25/26 are displayed, see the table on page 17 and

repeat the split function with greater care.

To return to normal unbalance display, press any button.

To carry out a new spin, press the button

START

.

I 0410 - 10

GB

Page 11

MENU

START

START

STOP

5.7 - Unbalance optimisation

- This function serves to reduce the amount of weight to be added in order to balance the wheel

- It is suitable for static unbalance greater than 30 g.

- It improves the residual eccentricity of the tyre.

No previous

unbalance

measurement

Unbalance already measured

unbalance measurement

- With a piece of chalk make a reference mark on the ange and the rim

- With the aid of a tyre remover, turn the tyre on the rim by 180°

- Ret the wheel in such a way that the reference marks on the rim and

the ange coincide.

- RH display: percentage reduction value

- LH display: actual static unbalance value which can be reduced by

rotation

RIM IN POSITION INDICATION

- Mark the tyre (12 o’clock position)

TYRE IN POSITION INDICATION

- Mark the rim (12 o’clock position)

Turn the tyre on the rim until the marks correspond to obtain the

optimization shown on the display.

CANCEL OPTIMISATION IN ANY PHASE

I 0410 - 11

GB

Page 12

START

START

START

STOP

I 0410 - 13

GB

5.8 - Automatic minimization of static unbalance

This program is designed to improve the quality of

balancing without any mental effort or loss of time by

the operator. In fact by using the normal commercially

available weights, with pitch of 5 in every 5 g, and by

applying the two counterweights which a conventional

wheel balancer rounds to the nearest value, there could

be a residual static unbalance of up to 4 g. The damage

of such approximation is emphasized by the fact that

static unbalance is cause of most of disturbances on

the vehicle. This new function, resident in the machine,

automatically indicates the optimum entity of the

weights to be applied by approximating them in an

“intelligent” way according to their position in order to

minimize residual static unbalance.

residual static

With conventional

wheel balancer

Initial unbalance

phase shift

Possible approximations

residual static residual static

residual static

Choice with minimum

static residual

6 - Set up

6.1 - Autodiagnostics

performs tests useful for maintenance staff

6.2 - Autocalibration

For autocalibration proceed as follows:

- Fit a metal wheel of average dimensions on the shaft. Example 6” x 14” (± 1”)

- Set the exact dimensions of the wheel mounted.

CAUTION !! Setting incorrect dimensions will result in the machine not being properly calibrated and hence all the

subsequent measurements will be incorrect until a new autocalibration is performed with the correct

dimensions!! N.B.: Use steel wheel rims detection from “MANUAL DIMENSION PRESETTING”.

- Perform a spin under normal conditions.

- Add a 100 g. sample weight (3.5 oz) on the outside in any angular

position.

- Shift a 100 g sample weight from the outside to the inside keeping

the same angular position.

- Turn the wheel until the 100 g weight is in the 12 o’clock position.

END OF AUTOCALIBRATION

I 0410 - 12

GB

CANCEL AUTOCALIBRATION IN ANY PHASE

Page 13

d

b

a

6.3 - Manual dimension presetting (Use only in particular cases or for test)

6.3.1 - Steel wheel rims (use for setting dimensions in AUTOCALIBRATION)

9

- Setting:

Press or

Set with the rated width that, in general, is shown on

the rim, or measure width “b” with the calliper gauge supplied.

6.3.2 - Alu-s rims

- Press the button for more than 2 seconds

- Preset using the nominal diameter “d” indicated on the

tyre

- Press the button for more than 2 seconds

- Preset using distance “a” for the inside of the wheel

from the machine.

N.B.: This setting is also valid for the correction modes

indicated at “STATIC & COMBINED MODES”

10

0 gauge

I 0410 - 13

GB

Page 14

I 0410 - 15

GB

- Setting:

6.3.2.1 - Alu-s variant with inside clamp weight

To go to these functions:

- press one of the two buttons for more than 2 seconds

- Hold the button down for more than 2 seconds

- Hold the button down for more than 2 seconds

- Hold the button down for more than 2 seconds

N.B.: when dE is not set, dE = dI - 1” is automatic

- Setting:

11

0 gauge

To go to these functions:

- press one of the two buttons for more than 2 seconds

- press one of the two buttons for more than 2 seconds

- press one of the two buttons for more than 2 seconds

I 0410 - 14

GB

- press one of the two buttons for more than 2 seconds

N.B.: when dE is not set, dE = dI - 2” is automatic

Page 15

6.4 - Display saver

It is possible to enable a screen saver function which temporarily replaces the data displayed with moving symbols.

This function acts when the balancing system is not used for the time period de ned in the relative set-up:

Modify time expressed in minutes.

CONFIRM

If the value is set to 0, the display saver is automatically

disenabled. The display saver is not active in the balancing

machine set-up menu.To return to normal balancing machine

function, simply press any button or move the wheel.

6.5 - Automatic gauges calibration

6.5.1 - Rim distance gauge

- Shift the distance gauge to position 0, keeping it quite still,

press

- Move the gauge to position 15, press

CORRECT CALIBRATION

- Return the gauge to rest position.

- The wheel balancer is ready for operation.

N.B.: In the event of errors or faulty operation, the writing "P.O.”

appears on the display : shift the gauge to position 0 and repeat

the calibration operation exactly as described above. If the

error persists, contact the Technical Service Department. In the

event of incorrect input in the rim distance gauge calibration

function, press

STOP

to cancel it.

I 0410 - 15

GB

Page 16

40 mm

40 mm

I 0410 - 16

I 0410 - 17

GB

GB

6.5.2 - Diameter gaugeE40 mm

Place the round part of the gauge terminal on the ange as shown in

the gure and press

.

- The number 353 ± 1° appears on the left display .

- Turn the gauge downward position the round part of the gauge

terminal at 40 mm (radial distance) from the ange as indicated

in the gure.

- The number 256 ± 3° should appear on the left display.

- If not, press the button

holding the gauge still at 40 mm: the

number 256 appears on the left display.

- Return the gauge to rest position.

In the event of incorrectly accessing the diameter gauge calibration

function, press

S�T�O�P�

to cancel it.

Page 17

7 - Errors

During machine operation there may be various causes of malfunctioning which, if detected by the microprocessor,

are indicated on the display:

ERRORS CAUSES CONTROLS

Black The wheel balancer does not come on. 1. Check proper connection to the mains.

Err. 1 No rotation signal. 1. Check belt tautness.

Err. 2 Too low speed during measurement.

Err. 3 Too high unbalance. 1. Check the wheel dimension setting.

Err. 4 Rotation in opposite direction.

Err. 5 Guard open

Err. 7 /

Err. 8 /

Err. 9

Err. 11 Too high speed error.

Err.14/

Err.15/

Err.16/

Err.17/

Err. 18/

Err. 19

Err. 20 Wheel at standstill. The wheel is at a

Err.21 Motor on for more than 15 seconds. 1. Check functioning of the phase generator.

Err.22 Maximum number of spins possible for

During the unbalance measurement

revolutions, the wheel speed has fallen to

below 42 rpm.

After pressing [START], the wheel

starts turning in the opposite direction

(anticlockwise).

The [START] pushbutton was pressed

without rst closing the guard.

NOVRAM parameter read error 1. Repeat machine calibration

The average spinning speed is greater than

240 rpm.

Unbalance measurement error. 1. Check functioning of the phase generator.

standstill for more than one second after

START.

the unbalance measurement has been

exceeded.

2. Check and if necessary replace the fuses on the power board.

3. Replace the computer board.

2. Check functioning of the phase generator and, in particular, the

reset signal.

3. Replace the phase generator.

4. Replace the computer board.

1. Check that a vehicle wheel has been mounted on the wheel

balancer.

2. Check belt tautness.

3. Check functioning of the phase generator and, in particular, the

reset signal.

4. Replace the computer board.

2. Check the sensor connections.

3. Run the machine calibration function.

4. Mount a wheel with a more or less known unbalance (less than 100

grams) and check the machine response.

5. Replace the computer board.

1. Verify the connection of the UP/DOWN - RESET signals on the

phase generator.

1. Reset the error.

2. Close the guard.

3. Verify the function of the protection Switch.

4. Press the [START] button.

2. Shut down the machine.

3. Wait for at least ~ 1 min.

4. Restart the machine and check proper functioning.

5. Replace the computer board.

1. Check if there is any damage or dirt on the timing disc.

2. Check functioning of the phase generator and, in particular, the

reset signal.

3. Replace the computer board.

2. Check the sensor connections.

3. Check the machine earthing connection.

4. Mount a wheel with a more or less known unbalance (less than 100

grams) and check the machine response.

5. Replace the computer board.

1. Check functioning of the phase generator.

2. Check the connections on the power board.

3. Replace the computer board.

2. Check the connections on the power board.

3. Replace the computer board.

1. Check that a vehicle wheel has been mounted on the wheel

balancer.

2. Check belt tautness.

3. Check functioning of the phase generator and, in particular, the

reset signal.

4. Replace the computer board.

I 0410 - 17

GB

Page 18

I 0410 - 19

GB

Err. 24 Distance between the spokes smaller

Err. 25 Distance between the spokes greater

Err. 26 Distance between the rst selected spoke

Err.32/

Err.33/

Err.34/

Err.35/

Err.36/

Err.37

than 18 degrees.

than 120 degree

and unbalance greater than 120°.

Errors related to test functions of the wheel

balancer.

1. The minimum distance between the spokes where to split the

unbalance must be greater than 18 degrees

2. Repeat the SPLIT function increasing the distance between the

spokes.

1. The minimum distance between the spokes where to split the

unbalance must be smaller than 120 degrees

2. Repeat the SPLIT function increasing the distance between the

spokes.

1. To perform the SPLIT function correctly, the unbalance must be

inside two spokes no more than 120° apart.

2. Repeat the SPLIT function selecting a spoke nearer the unbalance.

1. Cancel the error and continue using the wheel balancer as normal.

7.1 - Inconsistent unbalance readings

It may occur that after balancing a wheel, when removing it from the wheel balancer and then remounting it, the

wheel is not balanced.

This is not the result of an incorrect indication by the machine, but only of incorrect mounting of the wheel on the

ange, i.e. in the two mountings the wheel has assumed a different position with respect to shaft axis of the wheel

balancer. If the wheel has been mounted on the ange with screws, it may be that the screws have not been tightened correctly in gradual criss-cross manner one after the other, or (as often occurs) holes have been drilled in the

wheel with too wide tolerances.

Small errors, up to 10 grams (0.4 oz), are to be considered normal in wheels locked with a cone: the error is normally

greater for wheels locked with screws or studs.

If, after balancing, the wheel is still unbalanced when retted on the vehicle, this could be due to the unbalance of

the brake drum or very often is due to the screw holes in the rim and the drum drilled with too wide tolerances. In this

case a readjustment would be advisable using the wheel balancer with the wheel mounted.

8 - Routine maintenance

Before carrying out any operation on the machine, cut the power supply to the machine.

8.1 - Replacing the protection fuses

A protection fuse is tted on the power board, accessible by dismantling the weight shelf (see Exploded Drawings). If fuses

require replacement, use ones with an identical current rating.

If the fault persists, contact Technical Service.

NONE OF THE OTHER MACHINE PARTS REQUIRE MAINTENANCE.

I 0410 - 18

GB

Page 19

9 - List of recommended spare parts (references on exploded drawings)

CODE DESCRIPTION

181198630 Spring 19863P

67M64690A Phase generator board

05PR59195 LEXAN Panel

182185750 Distance gauge spring

681002000 Fuse DM5x20 - 2A

511242101 Bipolar stub switch

86SC59755 Computer board

86SB59758 Cable, automatic rim distance gauge

86SB59757 Cable, automatic diameter gauge

86SB59759 Cable with micro protection

568007058 Capacitor 70MF 450V Faston screw M8

50FG58735 Stator 230V/50 - 60 Hz

SPECIAL PARTS FOR 230V MACHINES

67M56989C Power board

SPECIAL PARTS FOR 115V MACHINES

67M65573B Power board

613010009 Auto-transformer

I 0410 - 19

GB

Loading...

Loading...