Page 1

Instructions for use

Contents Page

I

1- GENERAL ..................................................................................................................................................................................3

1.1 - GENERAL SAFETY RECOMMENDATIONS

1.1.1 - STANDARD SAFETY DEVICES ...................................................................................................................3

1.2 - FIELD OF APPLICATION

1.3 - OVERALL DIMENSIONS (Standard Protection)

1.4 - SPECIFICATION .......................................................................................................................................................4

2 - HANDLING AND HOISTING ....................................................................................................................................................4

3 - COMMISSIONING ....................................................................................................................................................................5

3.1 - ANCHORING

3.2 - ELECTRICAL CONNECTION

3.3 - ADAPTER MOUNTING

3.4 - GUARD MOUNTING AND ADJUSTMENT

3.5 - SPACER WD

4 - CONTROLS AND COMPONENTS

4.1 - BRAKE PEDAL

4.2 - DISTANCE AND DIAMETER GAUGE

4.3 - WIDTH GAUGE (Option)............................................................................................................................................6

4.4 - AUTOMATIC WHEEL POSITIONING..........................................................................................................................6

4.5 - KEYBOARD................................................................................................................................................................6

5 - INDICATIONS AND USE OF THE WHEEL BALANCER

5.1 - INITIAL SCREEN .....................................................................................................................................................7

5.1.1 - SCREEN-SAVE SCREEN .............................................................................................................................7

5.2 - MENU ACCESS DIAGRAM

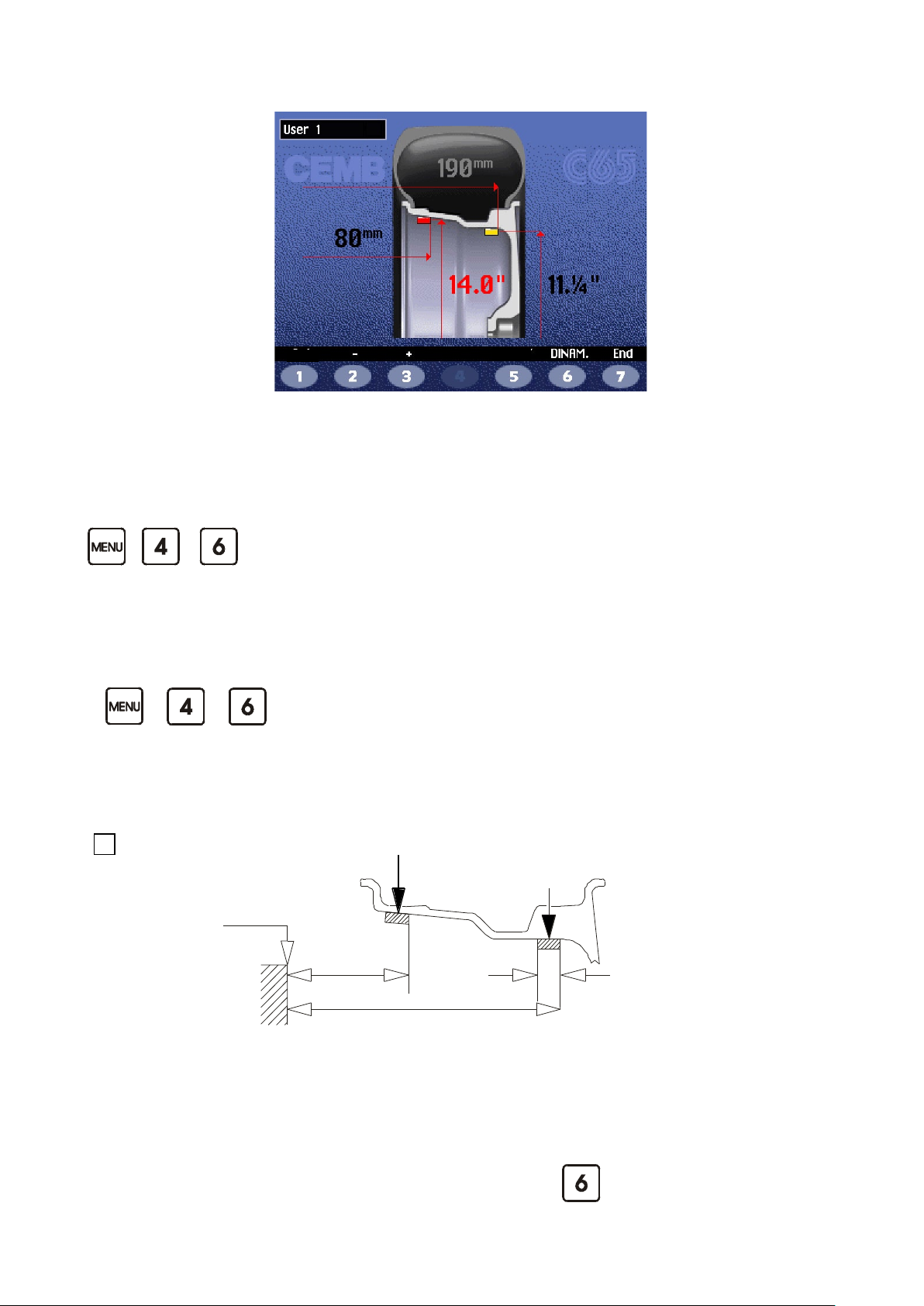

5.3 - PRESETTING OF WHEEL DIMENSIONS

5.3.1 - AUTOMATIC PRESETTING ..........................................................................................................................9

5.3.2 - TO CALL MEMORIZED MEASUREMENTS ................................................................................................10

5.3.3 - MANUAL PRESETTING ..............................................................................................................................11

5.4 - USER CONTROL

5.4.1 - USER MEMORIZATION ..............................................................................................................................13

5.4.2 - TO CALL USER ...........................................................................................................................................13

5.5 - RESULT OF MEASUREMENT

5.5.1 - INDICATION OF EXACT CORRECTION WEIGHT POSITION ..................................................................15

5.5.2 - “SPLIT” CONTROL ......................................................................................................................................16

5.5.3 - UNBALANCE OPTIMIZATION ....................................................................................................................17

5.5.4 - ALU AND STATIC MODES ..........................................................................................................................17

5.5.5 - TO CANCEL STATIC UNBALANCE ............................................................................................................18

5.6 - ECCENTRICITY MEASUREMENT (OPTIONAL) ................................................................................................... 19

6 - SETUP ..................................................................................................................................................................................20

6.1 - LANGUAGE ............................................................................................................................................................. 20

6.2 - UNIT OF UNBALANCE MEASUREMENT

6.3 - UNBALANCE DISPLAY THRESHOLD ....................................................................................................................20

6.4 - UNBALANCE DISPLAY PITCH

6.5 - SPIN WITH GUARD CLOSED ................................................................................................................................20

6.6 - SCREEN-SAVER TIME

6.7 - VISUAL ECCENTRICITY CHECK

6.8 - ACUSTIC SIGNAL.....................................................................................................................................................20

.............................................................................................................................................................5

...............................................................................................................................................................5

..........................................................................................................................................................6

..........................................................................................................................................3

................................................................................................................................... 5

.............................................................................................................................................5

........................................................................................................................................... 6

.......................................................................................................................................8

.................................................................................................................................................... 13

................................................................................................................................14

...............................................................................................................................20

...........................................................................................................................................20

...........................................................................................................................20

............................................................................................................3

.......................................................................................................3

..................................................................................................................5

........................................................................................................................6

.........................................................................................................7

................................................................................................................ 9

..............................................................................................................20

CAUTION

7 - SPECIAL CALIBRATIONS AND FUNCTIONS ......................................................................................................................21

7.1 - ENABLING OF WIDTH MEASUREMENT (Option)

7.2 - PRESETTING THE CUSTOMER AND USER NAME

7.3 - ENABLING OF ECCENTRICITY MEASUREMENT

7.4 - CALIBRATIONS

7.4.1 - GAUGE CALIBRATION.................................................................................................................................21

7.4.2 - WHEEL BALANCER CALIBRATION .............................................................................................................21

7.4.3 - AMBIENT TEMPERATURE ...........................................................................................................................21

7.4.4 - SELF-DIAGNOSTIC WHEEL BALANCING MACHINE ................................................................................22

7.4.4.1 - TO CHECK THE ENCODER .....................................................................................................................22

7.5 - CONTROL OF SERIAL OUTPUT RS232C (OPTION) ..............................................................................................22

8 - ERRORS .................................................................................................................................................................................23

9 - ROUTINE MAINTENANCE .....................................................................................................................................................24

9.1 - SCHEDULED MAINTENANCE .................................................................................................................................24

9.2 - TO REPLACE THE FUSES

10 - RECOMMENDED SPARE PARTS LIST

........................................................................................................................................................21

..................................................................................................................................... 24

..............................................................................................................................25

..................................................................................................21

...............................................................................................21

.................................................................................................21

I 0426 - 1

GB

Page 2

I 0426 - 2

I 0426 - 3

GB

GB

Page 3

1- General

1.1 - General safety recommendations

- The balancing machine should only be used by duly authorized and trained personnel.

- The balancing machine should not be used for purposes other than those described in the instruction

manual.

- Under no way should the balancing machine be modied except for those modications made explicitly by

the manufacturer.

- Never remove the safety devices. Any work on the machine should only be carried out by duly authorized

specialist personnel.

- Do not use strong jets of compressed air for cleaning.

- Use alcohol to clean plastic panels or shelves (AVOID LIQUIDS CONTAINING SOLVENTS).

- Before starting the wheel balancing cycle, make sure that the wheel is securely locked on the adapter.

- The machine operator should not wear clothes with apping edges. Make sure that unauthorized personnel

do not approach the balancing machine during the work cycle.

- Avoid placing counterweights or other objects in the base which could impair the correct operation of the

balancing machine.

1.1.1 - Standard safety devices

- STOP push button for stopping the wheel under emergency conditions.

- The safety guard of high impact plastic is with shape and size designed to prevent risk of counterweights

from ying out in any direction except towards the oor.

- A microswitch prevents starting the machine if the guard is not lowered and stops the wheel whenever the

guard is raised.

1.2 - Field of application

The machine is designed for balancing car or motorcycle wheels weighing less than 75 kg. It can be operated within

a temperature range of 0° to + 45°C.

It can measure the geometric radial run-out of the wheels (optional).

1.3 - Overall dimensions (standard protection)

1

I 0426 - 3

GB

Page 4

I 0426 - 5

GB

GB

1.4 - Specication

Single phase power supply ....................................... 115 - 230 V 50-60 Hz

Protection class ........................................................ IP 54

Max. power consumption .......................................... 1,1 Kw

Monitor ..................................................................... SVGA 15”

Balancing speed approx............................................ 180 min

Cycle time for average wheel (14 Kg) ..................... 6 seconds

Balancing accuracy ................................................... 0,5 grammi

Position resolution ..................................................... ± 1.4 °

Average noise level

Distance rim - machine.............................................. 0 - 250 mm (400 mm can be preset)

Larghezza cerchione impostabile ............................. 1.5” ÷ 20” or 40 ÷ 510 mm

Diameter setting range .............................................. 10” ÷ 26” or 265 ÷ 665 mm

Total wheel diameter within guard

Total wheel width within guard

................................................... < 70 dB(A)

............................. 870 mm (standard) - 1067 (42”)

................................... 430 mm (standard) - 500 (42”)

-1

2 - Handling and hoisting

2 3

I 0426 - 4

NB: DO NOT HOIST THE MACHINE USING DIFFERENT GRIPS.

Page 5

A

B

3 - Commissioning

3.1 - Anchoring

The machine can be operated on any at non-resilient oor.

Make sure that the machine rests solely on the three support points provided (g.3).

It is advisable to secure the system to the ground using the specic feet (see Figure 3) in the event of continual use

with wheels weighing over 35 Kg.

3.2 - Electrical connection

The machine is supplied with a single phase mains cable plus earth (ground).

The supply voltage (and mains frequency) is given on the machine nameplate. It may NOT be changed.

Connection to the mains should always be made by expert personnel.

The machine should not be started up without proper earth (ground) connection.

Connection to the mains should be through a slow acting safety switch rated at 4A (230V) or 10A (115V) .

3.3 - Adapter mounting

The balancing machine is supplied complete with cone adapter for fastening wheels with central bore.

Other optional adapters can be mounted:

a) Back-off screw B and remove threaded end-piece A.

b) Fit the new adapter.

4

3.4 - Guard mounting and adjustment

a) Fasten the components to the base as illustrated in specic exploded view.

b) The position of the wheel guard when closed can be adjusted with relative screw accessible at the back. Correct

position is the one which keeps the tube exactly horizontal with wheel guard closed.

c) Check that the microswitch is held down when the guard is closed.

d) Adjust the angular position of microswitch control.

3.5 - Spacer WD

5

When balancing very wide wheels (9”), there is not

enough space to turn the distance gauge. To withdraw

the wheel from the machine side, t spacer WD on the

adapter body and secure it with the standard issue

nuts. When centring the wheel with the cone on the

inside, t the DC spacer to obtain spring thrust.

I 0426 - 5

GB

Page 6

I 0426 - 7

GB

4 - Controls and components

4.1 - Brake pedal

This pedal allows the operator to hold the wheel when tting the counterweights. It must not be actuated during the

measuring cycle.

6

4.2 - Automatic distance and diameter gauge

This gauge allows measurement of the distance of the wheel from the machine and the wheel diameter at the point of

application of the counterweight.

It also allows correct positioning of the counterweights on the inside by using the specic function (see INDICATION

OF EXACT CORRECTION WEIGHT POSITION) which allows reading, on the monitor, the position used for the measure-

ment within the rim (For calibration, see GAUGE CALIBRATION).

The gauge can only be used with the counterweight pincers mounted.

4.3 - Automatic width gauge (optional)

Width gauging is through a SONAR device which measures the distance of the wheel without mechanical contact,

merely by closing the guard and each time a valid measurement has been made with gauge DISTANCE AND DIAME-

TER GAUGE.

4.4 - Automatic wheel positioning

At the end of the spin, the wheel is positioned according to the unbalance on the outside or else according to the

static unbalance (when selected).

Accuracy is +/-20 degrees.

4.5 - Keyboard

FUNCTION KEYS: they immediately select corresponding function

7

Selection of special functions

Conrm

Starts measuring cycle

Stops measuring cycle

N.B. - Press the buttons with the ngers only: never use the counterweight pincers or other pointed objects.

- When the beep signal is enabled (see section ACUSTIC SIGNAL), pressing of any push button is

accompanied by a “beep”.

I 0426 - 6

GB

Page 7

GB

5 - Indications and use of the wheel balancer

The monitor shows several information and suggests various alternative ways of use to the operator.

This is through various “screens”.

5.1 - Initial screen

Static

Buttons enabled

: main functions screen (see MENU ACCESS DIAGRAM)

2

Dimensions gauge: when extracted, the Dimensions screen is selected (see PRESETTING OF WHEEL DIMENSIONS).

If the machine remains on the initial screen for a certain amount of time without being used, the system is automatically switched to a screen-save. Striking of any key, movement of the wheel of distance + diameter gauge will cause

automatic switching from the screen-save menu to the initial screen.

5.1.1 - Screen-save screen

N.B.: Name of the wheel balancer’s owner. Can be preset via the monitor (see section PRESETTING THE CUSTOMER

AND USER NAME).

: type of correction (see ALU AND STATIC MODES)

: balancing spin (see RESULT OF MEASUREMENT)

I 0426 - 7

Page 8

I 0426 - 9

GB

5.2 - Menu access diagram

N.B. - The symbol

indicates the presence of a further menu.

- To return to the previous menu, press button

- To return to the initial screen, press button

Set-up machine parameters

Language

Unbalance measuring unit

Unbalance threshold

Visualization step

Start by wheel guard lowering

Screensave time

More

Abort

English

H

Set-up machine parameters

Visual eccentricity check

Acustic signal

User control

B

user control

A

C

D

selections

Load user

Save user

Optimization

Dimensions

Set-up

Special functions

Abort

5

PASSWORD : + + +

ONLY FOR SPECIALIST PERSONAL

3

Special functions

Width measure

Eccentricity measureament

Owner address

Users name

Calibrations

7

Previous

Calibrations

Distance

Diameter

Width

Abort

Abort

E

F

I 0426 - 8

GB

Abort

Page 9

b

Pos B

Pos A

b

5.3 - Presetting of wheel dimensions

5.3.1 - Automatic Presetting

INDICATOR: Width

Sonar function

enabled

INDICATOR

L.T. function enabled

(see Buttons Enabled)

Manual

The screen appears upon removing the distance + diameter gauge.

The indication “dimension acquired” is given by the symbol of the correction weight which changes from blue to red.

- Standard wheels: Using the appropriate handgrip, move the end of the gauge against the rim in one of the

positions A/B shown in gure 8:

- Hold the gauge still in position for at least 2 seconds.

N.B. - Always use the round part of the gauge striker surface.

8

If the beep signal is enabled (see ACUSTIC

SIGNAL), successful acquisition of the dimensions

is accompanied by a “beep”.

6

- Press

- In manual mode, preset width “b”

(see MANUAL PRESETTING).

- Normally the “nominal” width is stamped on

the rim; or else measure dimension “b” with the

calliper gauge (standard accessory).

AUTOMATIC WIDTH MEASUREMENT (OPTIONAL)

Gradually lower the guard after carrying out measurement of distance + diameter in automatic mode.

If the width measured is incorrect (out of range), the following message appears:

“Sonar measure is out of range:”

“F1 = repeat”

“F2 = manual set-up”

I 0426 - 9

GB

Page 10

I 0426 - 11

FE

FI

GB

GB

Press F1 to re-lower the guard and repeat the width measurement. Press F2 to go to the dimensions

panel for manual insertion of the width measurement.

The calibration performed as such is necessary for modes AL1,2,3,4,CTS,Static, Dynamic.

Manually presetting is possible by using the push buttons as described in TO CALL MEMORIZED MEASUREMENTS.

9

- Wheel ALU-S (correction from the inside for two balancing planes with direct calibration):

After the measurement carried out for the inside FI as described in g. 9, pull out the gauge further to memorize the

data for the outside FE: keep this position for at least 2 seconds.

The counterweight symbols change colour.

When the acoustic signal is enabled (see ACOUSTIC SIGNAL), the acquisition is accompanied by a “beep”.

The following buttons are enabled:

Select the dimensions presetting in manual mode screen.

6

Return to initial screen.

7

Balancing spin

5

AUTOMATIC WIDTH MEASUREMENT OPTION enabled:

The button LT (LIGHT TRUCK) serves for improved dimensional calibration of

large size wheels such as off-the-road vehicles, trucks, or wheels which project

by a large amount from the rim. Press button LT after the distance measurement

and immediately upon lowering the wheel guard for width measurement. The

optional feature is automatically disabled upon measuring another wheel.

5.3.2 - To call memorized measurements

2

4

3

Press the button with relative user’s name:

- when

MEMORIZATION) while disregarding other measurements made in the meantime.

- when

is pressed, the stored measurements will be called (USER

2

is pressed, the currently preset dimensions are saved.

I 0426 - 10

Page 11

b

a

d

5.3.3 - Manual presetting

Select Unit

If necessary, the dimensions can be inserted or edited in manual mode as follows:

4

- press

by pulling out the distance + diameter gauge).

- press

- press

- press

- press

Denition of dimensions:

d = DIAMETER: Preset the nominal diameter stamped on the rim.

b = WIDTH: Preset the nominal width indicated on the rim.

a = DISTANCE: Preset the distance of the inside of the wheel from the machine, after measuring

it with relative gauge as described in g. 8.

10

+

to select the dimension to be preset .

2

/

5

to change unit of measurement.

6

to preset the dimensions for the ALU-S correction mode

or else press

3

to preset the required value.

6

from the Dimensions in automatic mode screen (which can be reached

I 0426 - 11

GB

Page 12

I 0426 - 13

dI

dE

aI

aE

14 mm

GB

GB

- ALU S wheel

Select Unit

Likewise in the ALUS correction mode, the dimensions can be entered or changed manually by using the buttons

indicated on the screen and by following the diagram indicated by the graph.

To access the Manual ALUS dimensions presetting screen, press:

1) CUTTING SETTING TYPE OF CORRECTION = ALUS

+ or from the dimensions screen in automatic mode (can be reached by pulling out the distance

+ diameter gauge)

2) CURRENT SETTING TYPE OF CORRECTION ≠ ALUS

+ +

For a clearer understanding of the indications given by the graph, consult the following diagram:

11

+ +

distance reading

- To return to the standard wheel dimensions presetting screen, press button .

I 0426 - 12

Page 13

5.4 - USER control

Save user

Abort

The wheel balancer can be used simultaneously by 4 different users who, through a simple sequence, can memorize

their work condition and call it when needed. The users’ names can be memorized (CALIBRATIONS).

5.4.1 - USER memorization

- Preset the dimensions correctly according to the procedures already described in sections AUTOMATIC

PRESETTING and TO CALL MEMORIZED MEASUREMENTS.

- Press

- Press

; the “MENU” window appears on the monitor.

2

; a window appears with the list of available USERS. The current user is displayed in red.

- Press the number corresponding to the required USER. The system returns to the initial screen automatically.

5.4.2 - To call USER

- Perform a measuring spin with any dimensions.

- Press button

- Press

; the “MENU” window appears on the screen.

: a window appears with the list of available USERS. The current user is displayed in red.

- Press the number corresponding to the required USER. The system automatically returns to the initial screen with

recalculation of the unbalance values on the basis of the effective dimensions of the USER called.

- Alternatively, proceed as described in section TO CALL MEMORIZED MEASUREMENTS.

N.B. - The dimensions memorized as USER are lost when the machine is switched off.

- The USER control is also valid for the ALUS dimensions.

- The current USER is always displayed in the Measurements and Dimensions screens.

I 0426 - 13

GB

Page 14

I 0426 - 15

GB

5.5 - Result of measurement

After performing a balancing spin, the unbalance values are displayed as well as arrows useful for positioning the

point of application of the correction weight. After positioning the wheel, apply the weight in the 12 o’clock position.

If the unbalance is less than the chosen threshold value, the “OK” appears instead of the unbalance value to indicate,

on that particular side, the wheel is in tolerance; the residual unbalance can be displayed by pressing button

with an accuracy of 0.5 g (0.1 oz).

The following buttons are enabled:

Display of residual unbalance

2

4

6

7

Selection of correction mode (DYNAMIC, STATIC, ALU1, ALU2, ALU3, ALU4, CTS). When the mode

is changed, the unbalance values are recalculated automatically on the basis of the previous spin (ALU

AND STATIC MODES).

Eccentricity measurement graph (optional). The symbol appearing above the button changes to

red if the eccentricity is excessive.

Split control for splitting of unbalance over presettable components (“SPLIT” CONTROL). Button only

enabled in STATIC or ALUS correction.

Indication of the longitudinal position of the unbalance (INDICATION OF EXACT CORRECTION

WEIGHT POSITION) is enabled

For selection of special functions

Balancing spin.

N.B.. If the machine remains on this screen without being used for more than the time preset in the Setup

parameters (6), the screen automatically returns to the screen-save.

I 0426 - 14

GB

Page 15

FI

FE

5.5.1 - Indication of exact correction weight position

It is recommended to always use this function when correcting the unbalance through adhesive weights: ALUS,

STATIC.

In all cases this function allows cancelling approximations in the mounting of counterweights with consequent

reduction of the residual unbalance.

- Press button

- Pull out the rim distance + diameter gauge in position A, gure 8. Approach of the weight to the correction

position is indicated by a moving coloured arrow [ ].

- When a xed arrow [ ] is reached, rotate the wheel to correction position (FI or FE) and apply the counterweight

by turning the tip of the gauge towards the outside, into the position in which the pincers touches the wheel.

Compensation is made for the fact that the weight application position is no longer at 12 o’clock (g. 11).

When the acoustic signal is enabled (see ACOUSTIC SIGNAL), the reaching of a xed arrow [ ] is accompanied by

a “beep”.

12

7

from the Measurements screen.

I 0426 - 15

GB

Page 16

I 0426 - 17

GB

5.5.2 - “SPLIT” control

The SPLIT function is only possible in the case of static unbalance or ALUS on the outside. It serves for concealing

any stick-on unbalance correction weights behind the rim spokes.

TO PRESET THE NUMBER OF RIM SPOKES

- From the STATIC or ALUS measurement screen, press

6

;

- A window appears on the display indicating the currently preset number of spokes.

- Set the required number of spokes in the range 3 to 12 by pressing

- press

- Bring a spoke to the 12 o’clock position.

- press

The ALUS unbalance on the inside does not vary while as regards the STATIC unbalance and that ALUS on the

outside:

- Gradually turn the wheel until an unbalance value appears.

- Apply an adhesive weight of the value indicated on the screen for the outside or STATIC, behind

the spoke in the 12 o’clock position.

- Again turn the wheel until a new unbalance value appears.

- Apply an adhesive weight of the value indicated on the screen for the outside or STATIC, behind

the spoke in the 12 o’clock position.

- Perform a spin to check for correct wheel balancing.

N.B. When SPLIT is enabled, the icon appears to the left of the screen.

to conrm the presetting.

; the Measurement Screen reappears with the unbalance values already split.

and

2

I 0426 - 16

GB

Page 17

5.5.3 - Unbalance optimization

UNBALANCE OPTIMIZATION

Make sure that the previous spin was made with the wheel now tted on the wheel

balancer.

Trace the rim adaptor position with a reference mark to allow re-assembling on the

adaptor in the same position.

Remove the wheel from the balancer.

Turn the tyre 180° on the rim.

Re-assemble the wheel on the balancer by positioning the rim reference mark with

the adaptor’s.

Close the wheel guard and push (START)

Abort

The symbol is displayed automatically for static unbalance exceeding 30 grams (1.1 oz). The program

allows reducing the total unbalance of the wheel by compensating, when possible, the unbalance of the tyre with that

of the rim. It requires two spins with rotation of the tyre on the rim in the second spin.

Press

+

3

after a rst spin and follow the instructions appearing on the monitor.

5.5.4 - ALU and static modes

CORRECTION TYPE

STATIC

DYNAMIC

From the Measurement screen, press button

2

: a window with the possible modes appears.

Select the type required through the numeric keys. The return to the Measurement screen with the recalculated

values is automatic. A symbol always appears at the top of the screen indicating the enabled weight application

position.

I 0426 - 17

GB

Page 18

I 0426 - 19

GB

STANDARD Balancing of steel or light alloy rims with application of

clip-on weights on the rim edges

STATIC The STATIC mode is necessary for motorcycle wheels or

when it is not possible to place the counterweights on both

sides of the rim.

ALU 1 Balancing of light alloy rims with application of adhesive

weights on the rim shoulders.

ALU 2 Balancing of alloy rims with hidden application of the

adhesive weight on the outside. The position of the

outside weight is on the adapter surface.

12/13 mm

Resting surface

ALU 3 Combined application: clip-on weight inside and hidden

adhesive weight on the outside (Mercedes). Outside weight

position is the same as ALU 2.

ALU 4 Combined application: clip-on weight the outside and hidden

adhesive weight inside

CTS Special balancing with snap-in adhesive weights between

the edge of the tyre and rim, for both sides.

5.5.5 - Automatic minimization of static unbalance

Initial unbalance

phase shift

Possible approximations

residual static

With

conventional

wheel balancer

residual static

residual static

Choice with minimum

static residual

residual static

This program is designed to improve the quality of balancing without any mental effort or loss of time by the operator. In fact by using the normal commercially available

weights, with pitch of 5 in every 5 g, and by applying the

two counterweights which a conventional wheel balancer

rounds to the nearest value, there could be a residual

static unbalance of up to 4 g. The damage of such approximation is emphasized by the fact that static unbalance

is cause of most of distur-bances on the vehicle. This new

function, resident in the machine, automatically indicates

the optimum entity of the weights to be applied by approximating them in an “intelligent” way according to their

position in order to minimize residual static unbalance.

I 0426 - 18

GB

Page 19

5.6 - Eccentricity measurement (optional)

The much enlarged gures show the outer tyre surface and axis of wheel rotation.

Fig. A shows measurement of the total Peak-to-Peak eccentricity dened as maximum radial deviation of the tyre

surface.

Fig. B shows measurement of the eccentricity of the 1st harmonic, i.e. the eccentricity of that circle which “recopies”

the tyre shape, by averaging the local deviations of the tyre from the round shape.

Obviously the P.P. measurement is normally greater than that of the 1st harmonic. Tyre manufacturers normally

supply two different tolerances for the two eccentricities.

At the end of the balancing spin it is possible to automatically measure the eccentricity of the tyre through the

SONAR sensor installed on the guard. The sensor should be positioned by hand in front of the tyre tread.

V.p/p.:

GRAPH 1 - (yellow)

V. 1h.:

GRAPH 2 - (red)

V.actual:

GRAPH 1 : represents the actual Peak-to-Peak eccentricity.

GRAPH 2 : represents the eccentricity of the 1st harmonic. For a wheel in optimum conditions, such graph

should approach a straight line.

When the wheel is moved, the cursor on the screen indicates the actual value, with the phase referred to the

eccentricity measurement sensor.

I 0426 - 19

GB

Page 20

I 0426 - 21

GB

6 - Setup (see Diagram showing access to the menus)

The Setup screen provides the user with many possibilities required for presetting the machine according to his own

requirements. Such settings remain unaltered even when the machine is switched off.

The following buttons are enabled:

: return to previous window

: return to Measurement screen

from to : for selection of the parameter.

7

6.1 - Language

This function allows selecting the language to be used for displaying descriptive and diagnostic messages regarding

machine operation.

6.2 - Unit of unbalance measurement

It is possible to select whether to display the unbalance values expressed in grams or ounces .

6.3 - Unbalance display threshold

This consists of the unbalance threshold below which the wording “-OK-” appears on the screen at the end of the

spin instead of the unbalance; the presettable values vary according to the unit of measurement selected.

6.4 - Unbalance display pitch

This represents the display pitch of the unbalance and varies according to the unit of measurement selected. The

selection “5 g” (1/4 oz) enables display of the correction values on both sides such as to bring the static unbalance to

0 (theoretical). It is recommended to preset this function as standard use of the machine as it improves the balancing

quality. The computer makes a complex calculation which allows cancelling the residual static unbalance by varying

the value and position of the counterweights xed in steps of 5 grams (1/4 oz).

6.5 - Spin with guard closed

When “ON” is selected the automatic start of the spin is enabled when the guard is closed.

6.6 - Screen-saver time

When the machine remains unused for longer than the time preset with this function, the processor automatically

returns to the Initial screen. Preset the time in seconds.

6.7 - Visual eccentricity check

At the end of wheel acceleration, as soon as the motor is disengaged, the guard can be opened for visual control of

any wheel eccentricity as the rotation speed gradually drops.

Do not strike the wheel during the entire deceleration stage; to brake the wheel, close the guard. However, avoid

using the brake as far as possible because this may compromise unbalance measurements. The unbalance values

measured are only displayed when the wheel has come to a standstill.

This function is active for only one machine run.

6.8 - Acoustic signal

When “ON” is selected. the sending of an acoustic signal (beep)) is enabled in the following cases:

- when any push button is pressed;

- when dimensions are acquired in automatic mode;

- when the correct angular position for weight application is reached in the Measurement screen;

- when the correct angular position for weight application is reached in the Position Repeater screen.

I 0426 - 20

GB

Page 21

DISTANZA

0 (Zero calibro)

- CAUTION -

7 - Special calibrations and functions (see Access diagram)

In order to gain access to the “Reserved Calibrations and functions” it is necessary to enter a password.

Any incorrect operation within the functions described below could impair the operation of the wheel balancing

machine. Unauthorized use will cause cancellation of the warranty on the machine.

7.1 - Enabling of width measurement (optional)

This function enables/disables automatic width measurement with SONAR or contact device: select “OFF” under

normal conditions and “SONAR” if the machine has provision for automatic width measurement.

7.2 - Presetting the customer and user name

The machine can be customized by presetting:

a) The name appearing on the Initial screen (screen-save).

b) The name of 4 different machine users ( USER NAME).

An “ideal” keyboard appears on the monitor with the set of characters available for composition of the wordings.

The Customer’s name consists of three lines, each max. 30 characters.

The USER NAME consists of a wording max. 15 characters.

7.3 - Enabling of eccentricity measurement (option)

Enables/disables measurement of the tyre eccentricity during an unbalance measurement spin.

7.4 - Calibrations

When

7.4.1- Gauge calibration

Select the gauge to be calibrated and follow the instructions appearing on the monitor.

N.B.:

- In the width SONAR calibration it is necessary to enter one dimension which can be measured as follows:

A - GAUGE “ZERO” DISTANCE

SONAR “ZERO” DISTANCE

7.4.2 - Wheel balancer calibration

For calibration of the machine, proceed as follows:

- Use a medium-sized wheel with steel rim. Example: 6” x 14” (± 1”)

- Preset the wheel dimensions with GREAT CARE.

- Follow the instructions appearing on the monitor.

6

is pressed from the Special Functions menu, access is gained to the Calibration menu.

gauge

DISTANCE

7.4.3 - Ambient temperature

Ambient temperature is important for correct use of the sonars. Set the average temperature of the area where the

wheel balancer is installed.

I 0426 - 21

GB

Page 22

I 0426 - 23

GB

7.4.4 - Self-diagnostic wheel balancing machine

An automatic self-diagnostics cycle is provided for easier trouble shooting. At the end of the self-diagnostics cycle,

several parameters are displayed which are useful for the Technical Service Department in order to identify machine

faults.

Returns to previous menu.

7.4.4.1 - To check the encoder

When the spindle is rotated:

- the angular position “POS” should vary from 0 to 128;

- the wording “UP” should appear when rotated clockwise and “DOWN” when rotated in the opposite direction.

Check for correct

Encoder check

Width

Check for correct operation of the distance

gauge; the number

increases when the

gauge is pulled out.

operation of the diameter gauge; the number

increases when

the gauge is rotated

outwards

Check of the eccentricity sonar (option):

the number decreases when a surface

is approached to the

sonar.

Check of the width sonar (option):

the number decreases when a surface is approached to the sonar.

In the event of failure or faulty operation of the wheel balancing machine, notify the Technical Service of all the parameters displayed.

7.5 - Control of serial output RS232C (option)

This option enables/disables the sending of the measured unbalance and phase values to serial output RS232C.

Transmission speed = 9600 baud

Data format = 7 bit Start

7 bit Data

1 bit Even parity

1 bit Stop

At the end of each unbalancing measuring spin, the balancing machine enables the RTS signal, then places the “$”

character on standby to be able to transmit the data; all functions remain on hold until data transmission is enabled,

at the end of which the RTS signal is reset to the inactive state.

The items of data transmitted via serial line are in ASCII format and are separated between each other by the <cr>

character (0x0d).

Sending sequence is as follows:

- 0000 <cr>

- Value of correction weight, left side <cr>

- Correction phase, left side <cr>

- Value of correction weight, right side <cr>

- Correction phase, right side <cr>

The rst 5 zero bytes represents the start of transmission message. The correction values are expressed in grams, in

steps of .1 gram. The phase values are expressed in degrees, in the range 0% 359.

I 0426 - 22

GB

Page 23

8 - Errors

ERROR Nr.:

Open guard

ERRORS CAUSES CONTROLS

Err. 1 No rotation signal. 1. Verify belt tautness.

Err. 2 Speed too low during detection.

Err. 3 Unbalance too high. 1. Verify wheel dimension settings.

Err. 4 Rotation in opposite direction.

Err. 5 Guard open

Err. 7 / Err. 8 NOVRAM parameter read error 1. Repeat machine calibration

Err. 9 NOVRAM parameter write error. Replace the computer board.

Err. 11 Speed too high error.

Err. 12 Unbalance measuring cycle error. 1. Verify phase pick-up board function.

Err.13 /

Err.14 /

Err.15 /

Err.16 /

Err.17 /

Err.18

During unbalance measurement rotation,

wheel speed is less than 42 rpm.

After pressing [START], the wheel begins

to rotate in the opposite direction (anticlockwise).

The [START] pushbutton was pressed

without rst closing the guard.

During unbalance measurement rotation,

wheel speed is more than 270 rpm.

Unbalance measurement error. 1. Verify phase pick-up board function.

2. Verify the function of the phase pick-up board and, in particular,

the reset signal.

3. Replace the phase pick-up board.

4. Replace the computer board.

1. Make sure that a vehicle wheel is mounted on the wheel balancer.

2. Verify belt tautness.

3. Verify the function of the phase pick-up board and, in particular,

the reset signal.

4. Replace the computer board.

2. Check detection unit connections.

3. Perform machine calibration.

4. Mount a wheel with more or less known unbalance (less than 100

grammes) and verify the response of the machine.

5. Replace the computer board.

1. Verify the connection of the UP/DOWN – RESET signals on the

phase pick-up board.

1. Reset the error by pressing pushbutton [7]=End.

2. Close the guard.

3. Verify the function of the protection uSwitch.

4. Press the [START] pushbutton.

2. Shut down the machine.

3. Wait for a minimum time of ~ 1 Min.

4. Re-start the machine and verify correct operation.

5. Replace the computer board.

1. Check if there is any damage or dirt on the timing disc.

2. Verify the function of the phase pick-up board and, in particular,

the reset signal.

3. Replace the computer board.

2. Verify correct motor operation.

3. Verify belt tautness.

4. Replace the computer board.

2. Check detection unit connections.

3. Verify machine earth/ground connection.

4. Mount a wheel with more or less known unbalance (less than 100

grammes) and verify the response of the machine.

5. Replace the computer board.

I 0426 - 23

GB

Page 24

I 0426 - 25

GB

Err. 20 The wheel comes to a halt before comple-

Err.40/

Err.41/

Err.42/

Err.43

ting positioning correctly.

Eccentricity graph plotting procedure error. Perform a new eccentricity measurement.

1. Make sure that the wheel to be balanced is at least 10” in diameter.

2. Verify the correct setting of wheel dimensions on screen.

3. Verify belt tautness.

4. For wheels less than 12” in diameter wheels: disenable the

eccentricity measurement procedure

Err.45/

Err.46/

Err.47/

Err.48

Err.50/

Err.51/

Err.52/

Err.53

Err.54 Sonar readout error.

Err.55 Sonar readout error.

Eccentricity graph value display readout

error.

Eccentricity graph current value cursor

plotting procedure error.

Sonar value readout impossible.

Sonar values are insufcient for correct

measurement of eccentricity.

Perform a new eccentricity measurement.

Perform a new eccentricity measurement.

1. Position the eccentricity measurement sonar correctly before

performing the measurement.

2. Check eccentricity sonar connections.

3. Check the power supplies on the power card.

4. Replace the eccentricity measurement sonar.

5. Make sure that the wheel does not halt before completing at least

4/5 revolutions after the rst braking impulse.

6. Verify belt tautness.

7. Replace the computer board.

1. Position the eccentricity measurement sonar correctly before

performing the measurement.

2. Make sure that the wheel does not halt before completing at least

4/5 revolutions after the rst braking impulse.

3. Verify belt tautness.

4. Mount a wheel of medium dimensions (14”x5 ”) and perform an

eccentricity measurement . If in these conditions error 55 no longer

occurs, this means that the wheel inertia causing the problem is

such as to half the wheel before having acquired the minimum

number of values necessary for reliable eccentricity measurement.

9 - Routine maintenance

9.1 - Scheduled maintenance

Switch off the machine from the mains before carrying out any operation.

Grease lubricate the movable blade of the weight dispenser

9.2 - To replace the fuses

Remove the weight holder shelf to gain access to the power supply board where some fuses are located (see

Exploded Views). If fuses require replacement, use ones of the same current rating. If the fault persists, contact

Technical Service.

NONE OF THE OTHER MACHINE PARTS REQUIRE MAINTENANCE.

I 0426 - 24

GB

Page 25

10 - Recommended spare parts list (For further details, see exploded drawings)

CODE DESCRIPTION

020600503 Bearing 6005-2Z dia. 25/47/12

181198630 Spring 19863P

080077007 Rigid belt Poly V - TB2 - 770 - 7 Vee’s

67M38954H Position pick-up board with cable

182245870 Spring, brake lever 24587P

05PR39772 LEXAN panel

182185750 Spring, rim distance gauge

67M48208A Power board

681002000 Fuses DM 5x20 - 2A

511231002 Switch KL 1002 + Q555

86SC65498 Computer board

86SB36752 Cable, automatic rim distance gauge

86SB36751 Cable, automatic diameter gauge

801100172 15” colour monitor SVGA

86SB35179 Width sonar (standard protection)

86SB45568 Width sonar (42" protection)

86SB34144 Cable with microswitch for standard protection

86SB38585 Cable with microswitch for 42” protection

SPECIAL PARTS FOR 230V MACHINES

50FG55641 Single phase motor 230V/50-60 Hz -0.18Kw 4p. HB63D-4

86SZ52116 Complete power board

611000314 Braking transformer 30VA 230 - 0/50

568001458 Capacitor 14MF 450 V FASTON screw M8

611035188 Power transformer 40VA

SPECIAL PARTS FOR 115V MACHINES

50FG55643 Single phase motor 115V/50-60Hz- 0.18Kw 4p HB63D-4

86SZ52117 Complete power board

611000313 Braking transformer 30VA 115-0/25

568002557 Capacitor 25MF 450V FASTON screw M8

611035187 Power transformer 40VA

SPECIAL PARTS FOR EMS SONAR (option)

86SB43673 EMS Sonar

I 0426 - 25

GB

Loading...

Loading...