CAT Titan 250 User Manual

TITAN 250

Turbomachinery Package Specification

Oil & Gas an d P o w e r G e n e r a t i o n Ap p l i c a t i o n s

Generator Set

TURBOMACHINERY PACKAGE

SPECIFICATION

TM

Titan

Solar Turbines Incorporated

P.O. Box 85376

San Diego, CA 92186-5376

250 Generator Set

Caterpillar is a trademark of Caterpillar Inc. Solar, Titan, SoLoNOx, and Turbotronic are trademarks of Solar Turbines

Incorporated. All other trademarks, service marks, or registered trademarks appearing in this specification are the

intellectual property of their respective companies. Specifications are subject to change without notice.

Direct customers of Solar Turbines Incorporated that receive this Turbomachinery Package Specification directly from

Solar Turbines Incorporated may make limited copies of parts of this specification for use in the creation of their own

specification documents. However, such customers shall not distribute any part of this Turbomachinery Package

Specification outside their own organizations for any other purpose. Any other use without the permission of Solar

Turbines Incorporated is strictly prohibited.

© 2008 Solar Turbines Incorporated. All rights reserved. TPS250GS/908 - Preliminary

Turbomachinery Package Specification Titan 250 Generator Set

Table of Contents

1 INTRODUCTION........................................................................................................................5

1.1 General Description ..........................................................................................................5

1.2 Overview ...........................................................................................................................5

2 TITAN 250 GAS TURBINE GENERATOR SET .......................................................................6

2.1 General Description ..........................................................................................................6

2.2 Package Description.........................................................................................................6

2.3 Major Components and Systems......................................................................................6

3 TITAN 250 GAS TURBINE......................................................................................................10

3.1 General Description ........................................................................................................10

4 REDUCTION-DRIVE GEARBOX ............................................................................................13

4.1 General Description ........................................................................................................13

5 GENERATOR AND ASSOCIATED EQUIPMENT..................................................................14

5.1 General Description ........................................................................................................14

5.2 Functional Description ....................................................................................................14

6 START SYSTEM .....................................................................................................................17

6.1 General Description ........................................................................................................17

6.2 Functional Description ....................................................................................................17

6.3 Backup Slow Rotation System........................................................................................18

7 FUEL SYSTEM........................................................................................................................21

7.1 General Description ........................................................................................................21

8 LUBRICATION SYSTEM.........................................................................................................24

8.1 General Description ........................................................................................................24

9 TURBOTRONIC 4 CONTROL SYSTEM.................................................................................29

9.1 Overview .........................................................................................................................29

9.2 System Architecture........................................................................................................29

9.3 Component Descriptions.................................................................................................31

9.4 System Monitoring and Control Functions......................................................................32

9.5 TT4000 Display and Monitoring System.........................................................................34

10 GENERATOR CONTROL AND MONITORING......................................................................40

10.1 General Description ........................................................................................................40

10.2 Generator Control ...........................................................................................................41

11 ENCLOSURE...........................................................................................................................45

11.1 General Description ........................................................................................................45

11.2 Standard Features ..........................................................................................................46

11.3 Optional Features ...........................................................................................................46

12 AIR INLET SYSTEM................................................................................................................52

12.1 General Description ........................................................................................................52

13 EXHAUST SYSTEM................................................................................................................55

13.1 General Description ........................................................................................................55

13.2 Turbine Exhaust Heat Recovery System........................................................................55

14 ACCESSORY EQUIPMENT....................................................................................................57

14.1 DC Power Supply and Battery Charger System.............................................................57

14.2 Turbine Cleaning System................................................................................................57

14.3 Package Lifting Kit ..........................................................................................................59

14.4 Engine Removal Equipment ...........................................................................................59

© 2008 Solar Turbines Incorporated. All rights reserved. TPS250GS/908 - Preliminary

2

Turbomachinery Package Specification Titan 250 Generator Set

15 MARINIZATION.......................................................................................................................61

15.1 General Description ........................................................................................................61

16 QUALITY ASSURANCE AND TESTING................................................................................63

16.1 Quality Assurance...........................................................................................................63

16.2 Testing ............................................................................................................................63

17 PRESERVATION, INSTALLATION, AND DOCUMENTATION.............................................66

17.1 General Description ........................................................................................................66

17.2 Preservation....................................................................................................................66

17.3 Site Requirements ..........................................................................................................66

17.4 Mechanical Installation Requirements............................................................................66

17.5 Documentation................................................................................................................67

18 CERTIFICATION .....................................................................................................................70

18.1 General Description ........................................................................................................70

18.2 National Electrical Code..................................................................................................70

18.3 Canadian Electrical Code ...............................................................................................70

18.4 Conformité Européenne Mark.........................................................................................71

18.5 International Electrotechnical Commission Safety Assessment.....................................72

18.6 Offshore Marine Applications..........................................................................................72

18.7 Summary.........................................................................................................................73

19 SUPPORT SERVICES.............................................................................................................74

19.1 Construction Services .....................................................................................................74

19.2 Customer Services..........................................................................................................74

19.3 Contract Power and Leasing Services............................................................................75

19.4 Solar’s Worldwide Locations...........................................................................................75

CONVERSION CHART..................................................................................................................76

LIST OF ABBREVIATIONS...........................................................................................................77

LIST OF SOLAR’S ENGINEERING SPECIFICATIONS...............................................................80

LIST OF SOLAR’S PRODUCT INFORMATION LETTERS..........................................................80

© 2008 Solar Turbines Incorporated. All rights reserved. TPS250GS/908 - Preliminary

3

Turbomachinery Package Specification Titan 250 Generator Set

Table of Figures

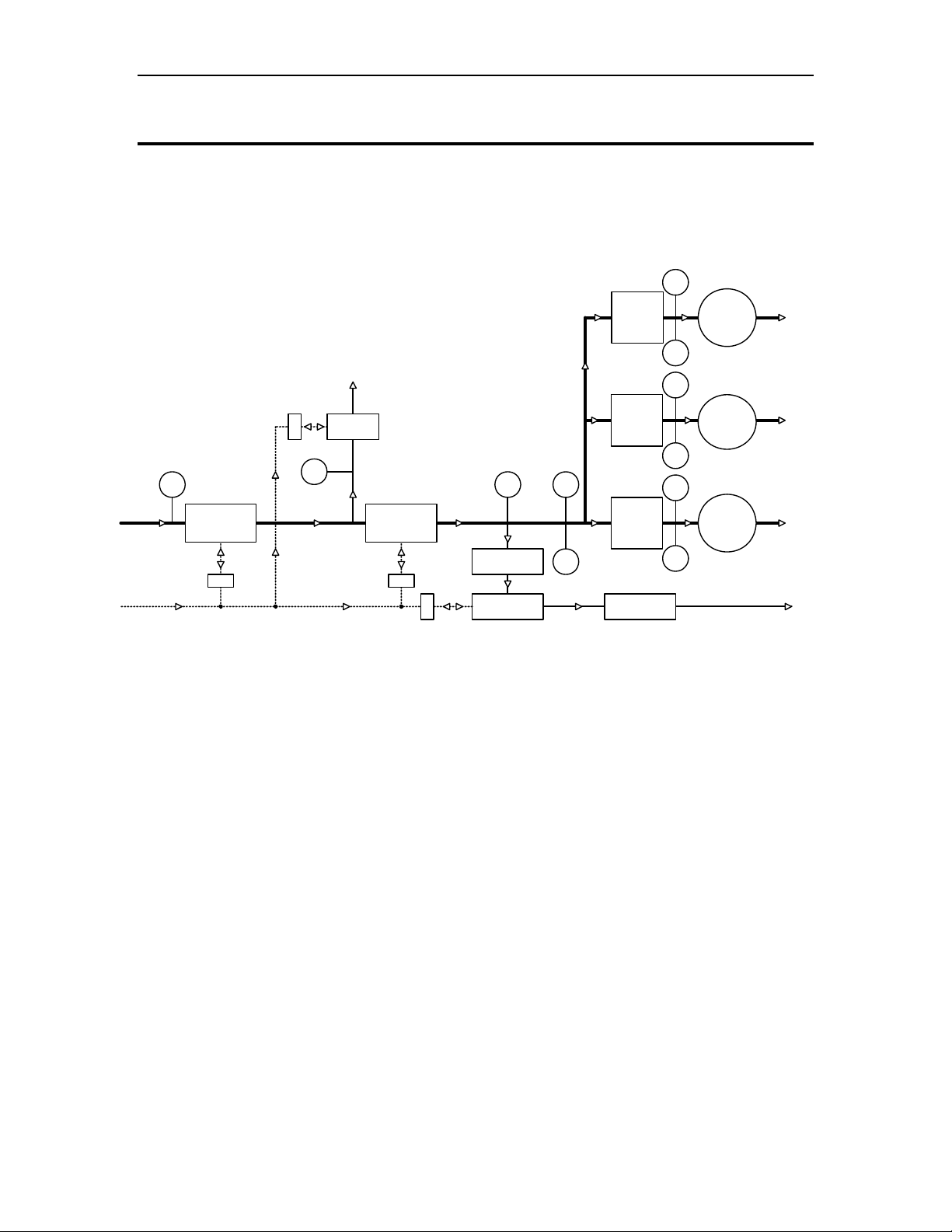

Figure 1. Typical Titan 250 Gas Turbine Generator Set.............................................................6

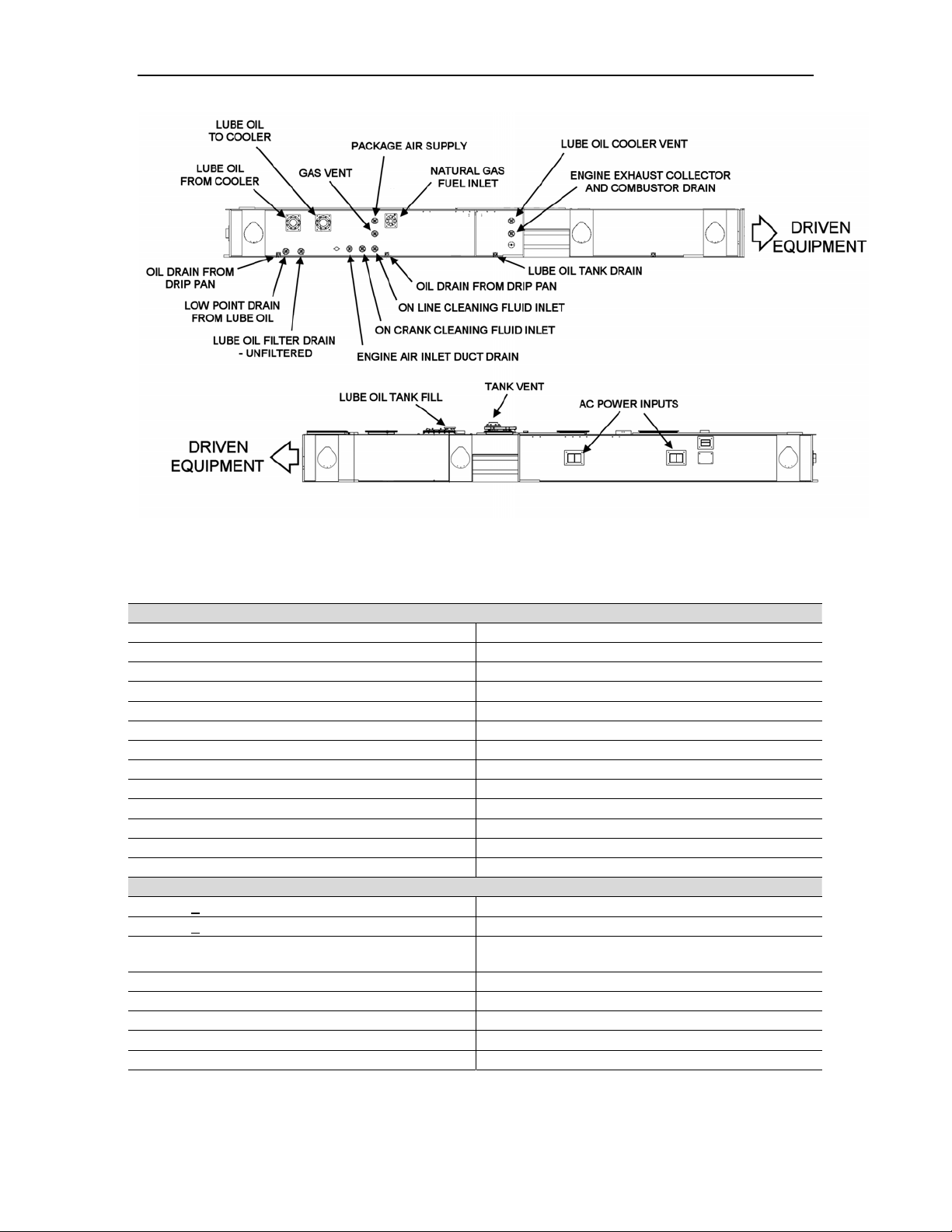

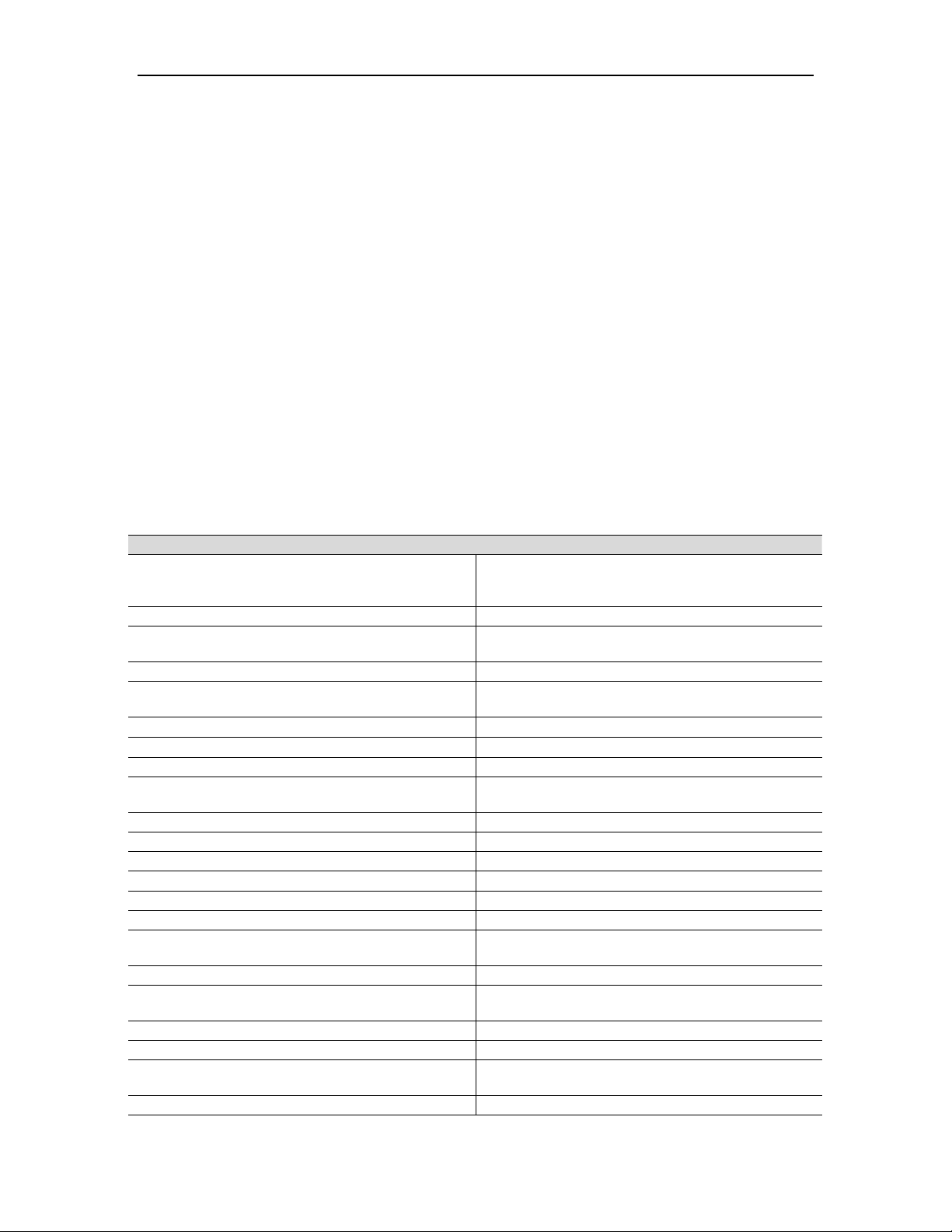

Figure 2. Typical Titan 250 Generator Set Service Connections (Driver Skid) ..........................8

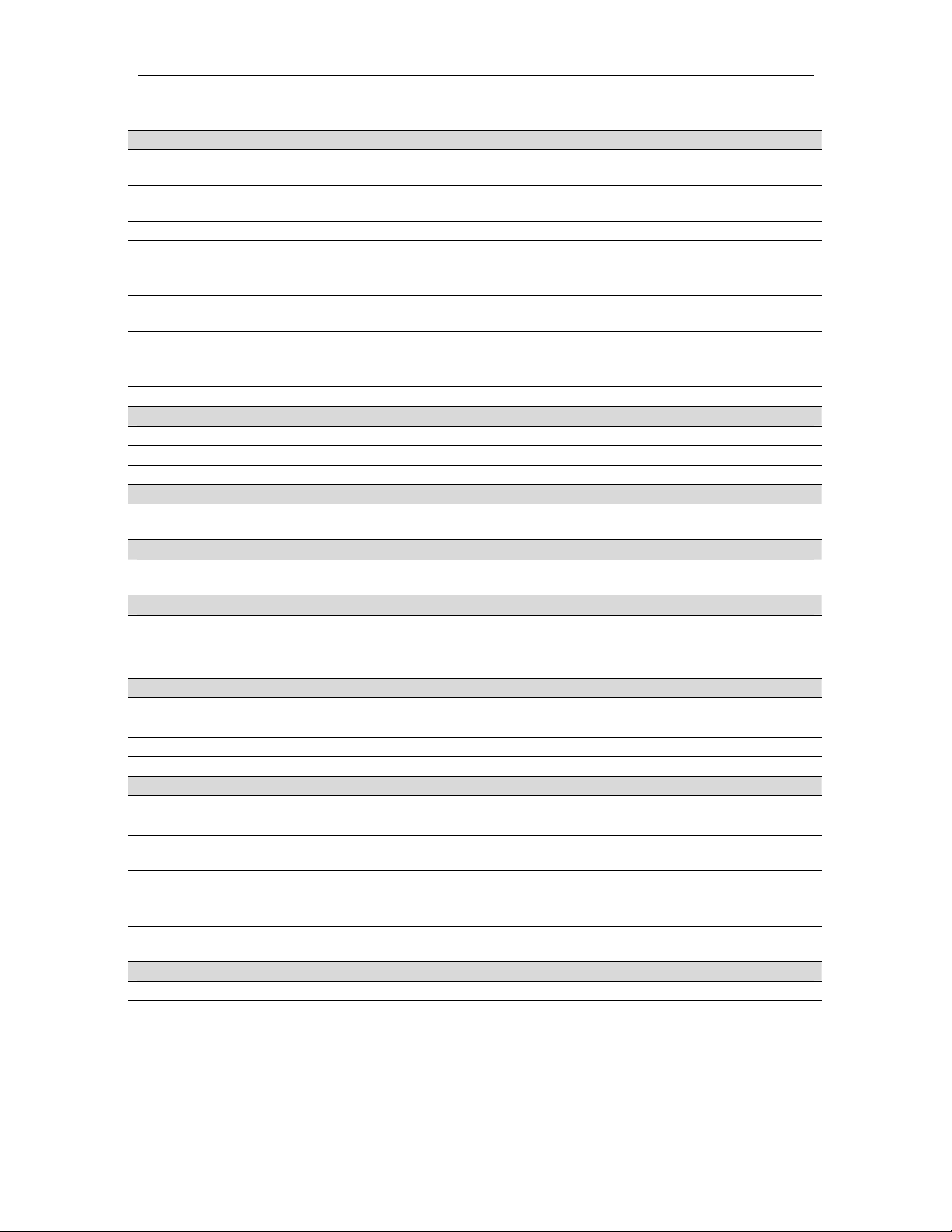

Figure 3. Titan 250 Two-Shaft Gas Turbine Cutaway ..............................................................10

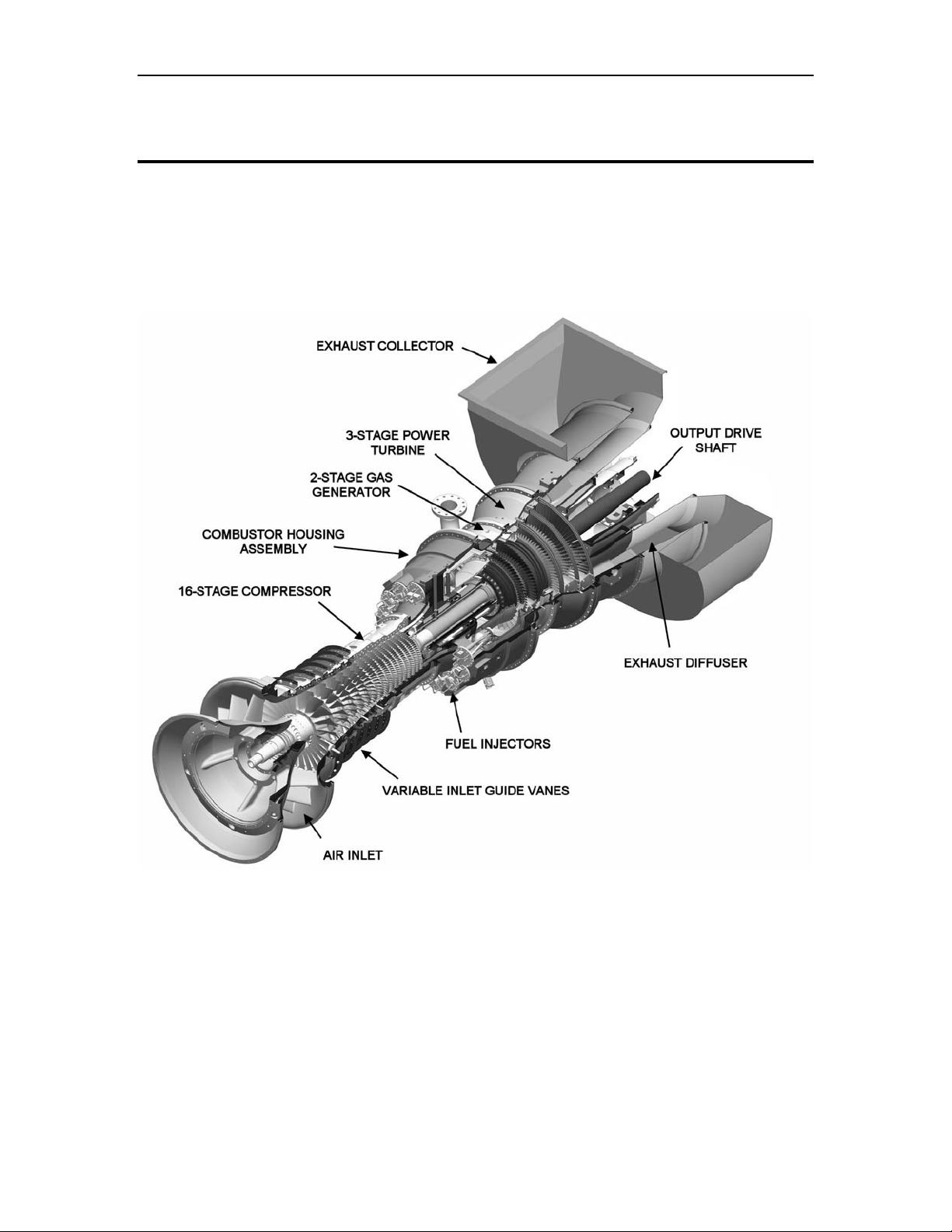

Figure 4. Typical Combustion Process .....................................................................................11

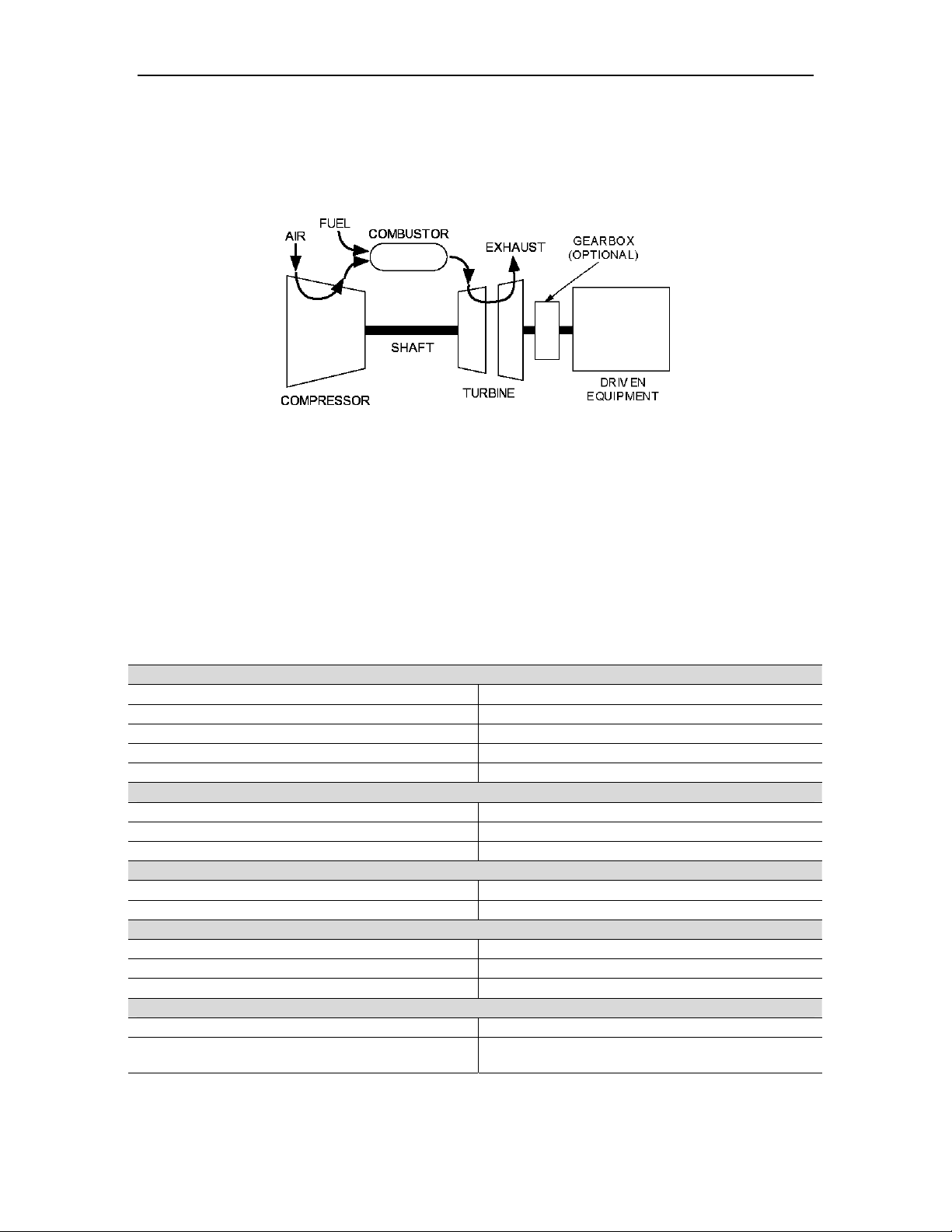

Figure 5. Typical Reduction Gearbox for the Titan 250 Generator Set....................................13

Figure 6. Typical Open Drip-Proof Generator with Permanent Magnet Exciter System ..........14

Figure 7. Direct-Drive AC Starter Motor and VFD Cabinet.......................................................17

Figure 8. Typical Direct-Drive AC Start System........................................................................18

Figure 9. Turning Gear Assembly.............................................................................................18

Figure 10. Typical Fuel System Schematic ................................................................................21

Figure 11. Typical Lube Oil System............................................................................................26

Figure 12. Typical Onskid Control System..................................................................................30

Figure 13. Typical Offskid Control System..................................................................................30

Figure 14. Turbotronic 4 System Architecture ............................................................................31

Figure 15. Typical TT4000 Operation Summary Display Screen ...............................................35

Figure 16. Typical TT4000 Strip Chart Display...........................................................................35

Figure 17. Typical TT4000S Engine Summary Screen ..............................................................36

Figure 18. Typical TT4000S Generator Summary Screen .........................................................36

Figure 19. Typical Generator, Exciter, and Generator Control Module Arrangement ................41

Figure 20. Typical Generator Metering Panel.............................................................................44

Figure 21. Typical Complete Package Enclosure.......................................................................45

Figure 22. Typical Fire and Gas System.....................................................................................48

Figure 23. Typical CO2 Fire Suppression Cylinders and Cabinets .............................................49

Figure 24. Typical Water Mist Fire Suppression Cylinders and Cabinet ....................................49

Figure 25. Typical Titan 250 Turbine Air Inlet and Exhaust Systems.........................................52

Figure 26. Typical Battery Charger.............................................................................................57

Figure 27. Turbine Cleaning System ..........................................................................................58

Figure 28. Turbine Cleaning Cart................................................................................................58

Figure 29. Separation of Engine Sections ..................................................................................59

Figure 30. Rails and Fixtures for Axial Separation of Engine Sections ......................................59

© 2008 Solar Turbines Incorporated. All rights reserved. TPS250GS/908 - Preliminary

4

Turbomachinery Package Specification Titan 250 Generator Set

1 Introduction

1.1 General Description

Solar Turbines Incorporated is a worldwide leader in the design, manufacture, and

installation of industrial gas turbines. Solar's 40 years of experience integrating high

technology with fluid compression, liquid pumping, power generation, and cogeneration

applications has resulted in more than 12,500 gas turbine installations in 92 countries

around the world. Solar gas turbine packages have logged more than 1.3 billion operating

hours around the world in a wide range of applications. Solar gas turbine packages are

complete operational systems that require a minimum of site preparation prior to

installation.

The Titan 250 generator sets represent years of intensive engineering and manufacturing

design. Solar gas turbines are manufactured to rigid industrial standards and are

thoroughly tested in modern facilities. Solar's operations are certified by Det Norske

Veritas (DNV) to conform to International Standardization Organization (ISO) 9001:2000

Standard for Quality Management Systems.

1.2 Overview

This document describes product features and provides product specification information

for the Titan 250 generator sets. Included are basic package configurations, ancillary

descriptions, installation requirements, and a list of customer support services available

at the time of publication. Please note that changes in equipment, service descriptions,

and specifications may occur without prior notice.

© 2008 Solar Turbines Incorporated. All rights reserved. TPS250GS/908 - Preliminary

5

Turbomachinery Package Specification Titan 250 Generator Set

2 Titan 250 Gas Turbine Generator Set

2.1 General Description

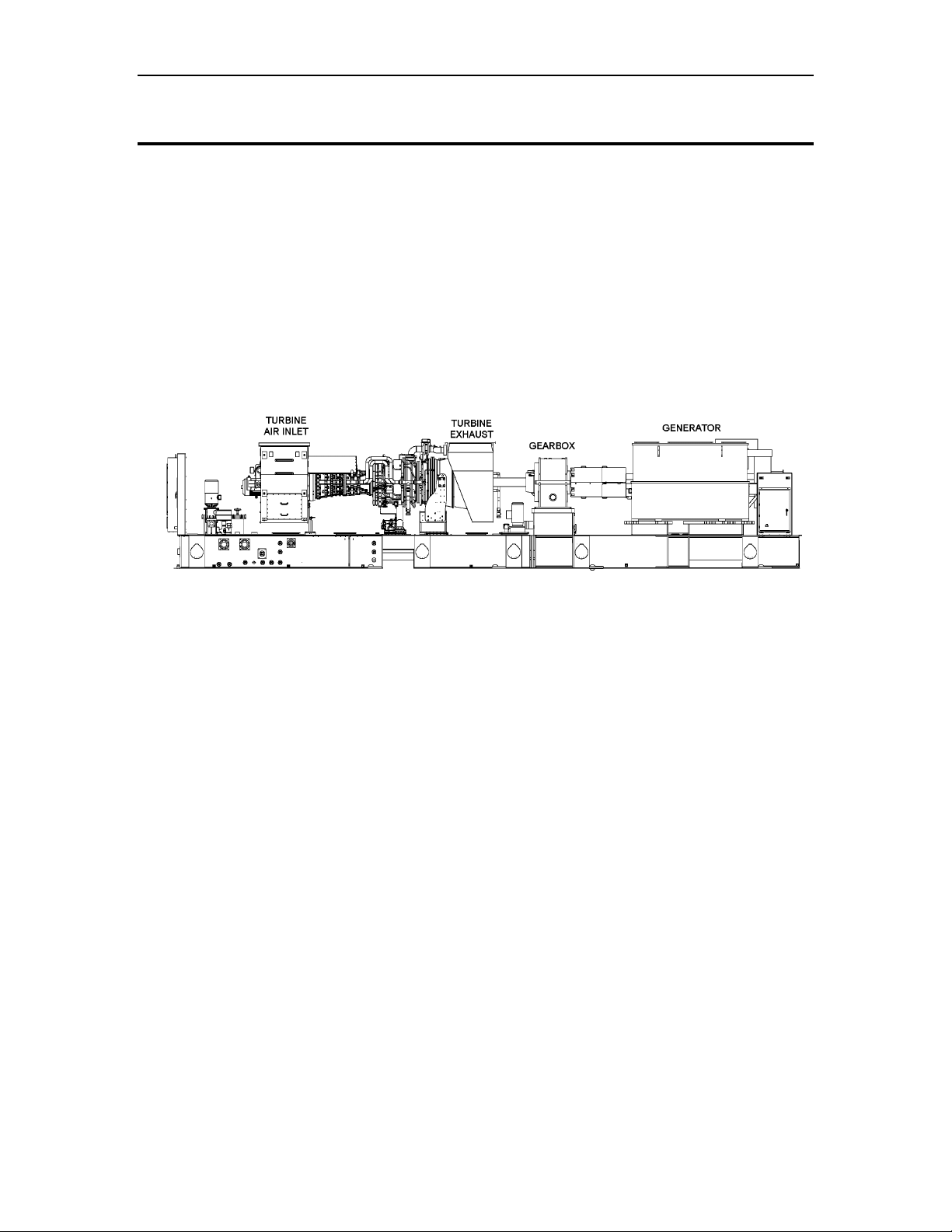

The Titan 250 gas turbine generator set (Figure 1) is a completely integrated and fully

operational package equipped with all accessories and auxiliary systems required for

operation. In addition to the standard package features, a wide array of optional

equipment is available to meet the customer’s installation and operation requirements.

Designed specifically for industrial service, Solar’s gas turbine generator sets are

compact, lightweight, and require minimal floor space for installation. Proven packaging

designs greatly reduce installation costs, time, materials, and labor.

The package features a radial exhaust resulting in a short overall package length that

conserves valuable mounting space.

Figure 1. Typical Titan 250 Gas Turbine Generator Set

2.2 Package Description

The gas turbine generator set consists of an axial-flow gas turbine engine, generator, and

reduction-drive gearbox. These components are installed in-line on a two-piece heavysteel base frame referred to as the skid. The skid is a structural steel assembly with

beam sections and cross members welded together. The two sections of the skid can be

separated to facilitate handling and shipment but when bolted together they form a rigid

structure suitable for three-point mounting. Drip pans are included to collect any potential

liquid leakage. Package connection points for fuel, lube oil, air, and water are located on

the outer edge of the skid.

Electrical connections are made in onskid junction boxes. Machined mounting surfaces

on the skid facilitate component alignment. The gearbox is bolted directly to the engine

and coupled by means of a splined interconnecting drive shaft that eliminates the need

for field alignment. The gearbox and generator are connected by means of a flexible

dry-disk, shear-type coupling enclosed in a coupling guard. Jacking points are provided

to facilitate alignment of the generator to the gearbox.

2.3 Major Components and Systems

Major components and systems of the gas turbine generator set typically include:

• Gas turbine

• Reduction-drive gearbox

• Generator

• Start system

© 2008 Solar Turbines Incorporated. All rights reserved. TPS250GS/908 - Preliminary

6

Turbomachinery Package Specification Titan 250 Generator Set

• Fuel system

• Lubricating oil system

• Turbotronic™ 4 Control System

• Onskid electrical wiring

• Skid with drip pans

• Piping and manifolds

• Ancillary air inlet system

• Ancillary exhaust system

• Package enclosure (if specified) with:

− Ventilation system

− Fire detection and suppression system

− Combustible gas detection system

2.3.1 Package Electrical System

The onskid package electrical system can be furnished to meet the following certification

requirements:

• National Electrical Code (NEC)

• Canadian Electrical Code (CEC)

• Conformité Européenne (CE) Mark

• European Committee for Electrotechnical Standardization (CENELEC)

When supplied, the offskid control console, variable frequency drives, batteries, and

battery charger are not approved for hazardous duty areas and must be installed in a

nonhazardous area.

Three-Phase Motor Voltage

All three-phase motors and three-phase electrical components have the same voltage

rating. Motor starters and contactors are not provided.

2.3.2 Service Connections

The Titan 250 generator set is supplied with self-contained systems for starting, fuel, lube

oil, and control. All service connections (Figure 2) are conveniently located on the outer

edges of the skid.

© 2008 Solar Turbines Incorporated. All rights reserved. TPS250GS/908 - Preliminary

7

Turbomachinery Package Specification Titan 250 Generator Set

Figure 2. Typical Titan 250 Generator Set Service Connections (Driver Skid)

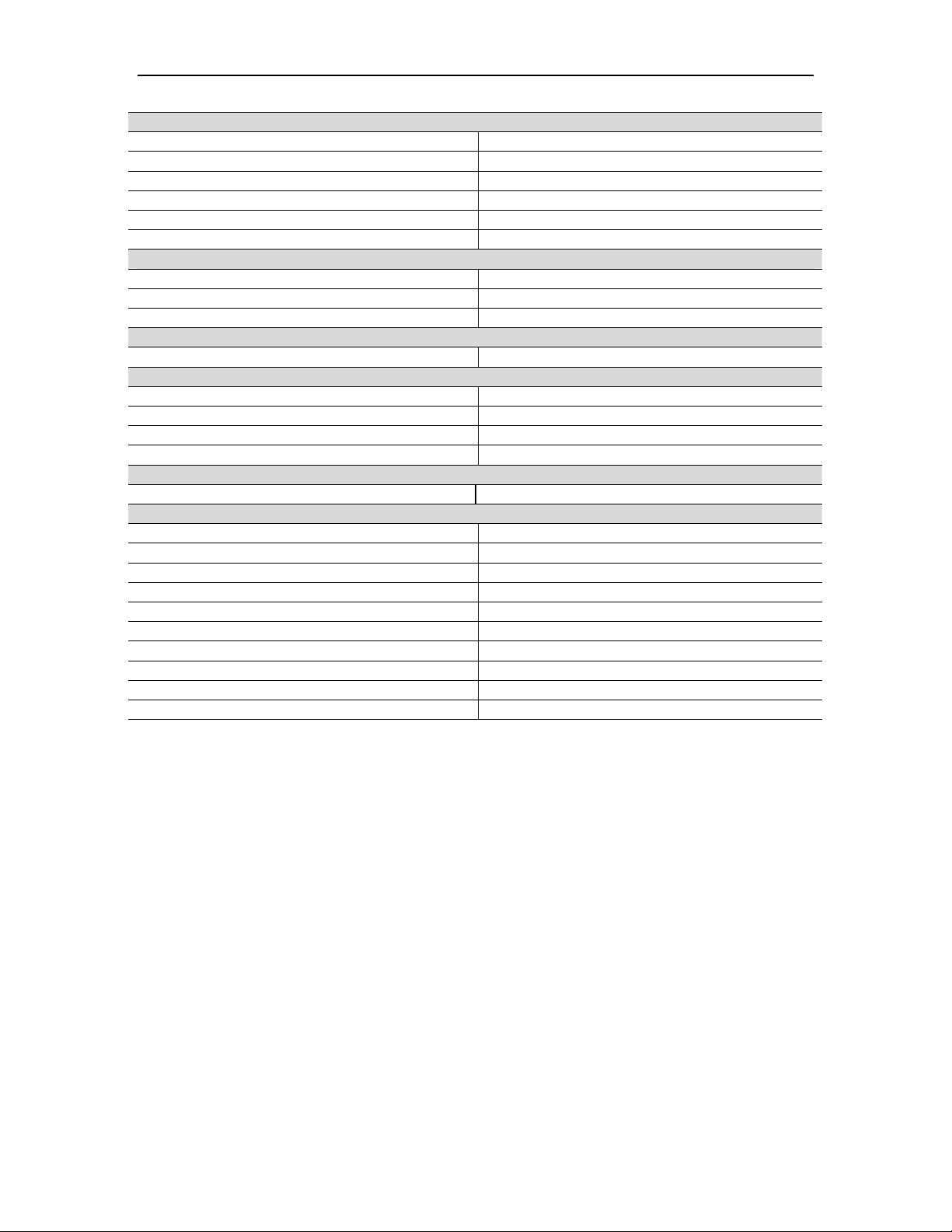

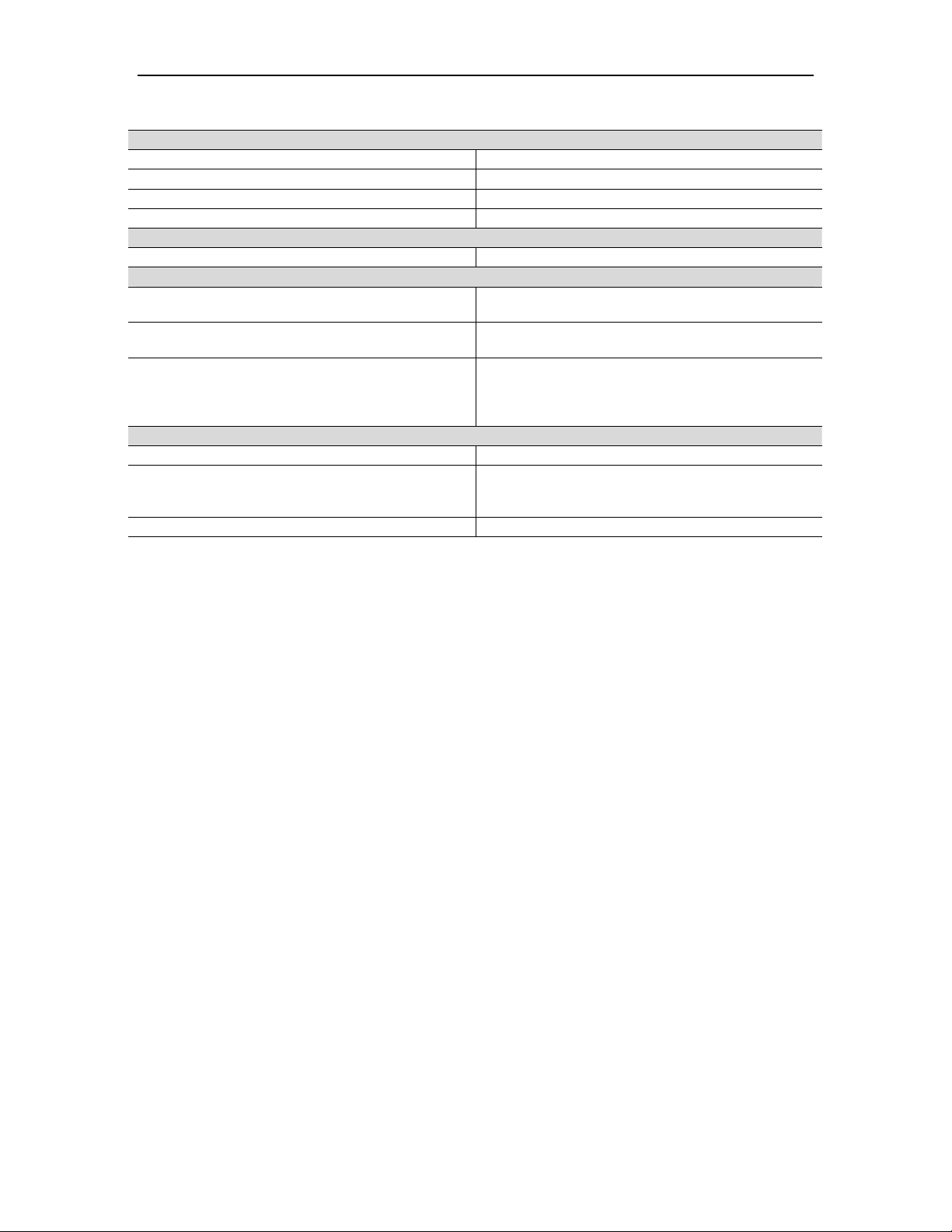

Table 1. Package Specifications

Dimensions

Approximate Package Measurements

Height, Unenclosed 3.89 m (12 ft 9 in.)

Height, Enclosed 4.12 m (13 ft. 6 in.)

Width (to skid edges) 3.37 m (11 ft 1 in.)

Width (including lifting bollards) 3.60 m (11 ft 10 in.)

Length, Engine Skid 10.29 m (33 ft 9 in.)

Length, Generator Skid

Approximate Package Weights

AC Start Motor Assembly 450 kg (990 lb)

Gas Turbine Assembly 19 050 kg (42,000 lb)

Total Driver (unenclosed package, without oil) 49 900 kg (110,000 lb)

Total Driver (enclosed package, without oil) 57 600 kg (127,000 lb)

Generator (unenclosed)

Piping and Tubing Thickness

Piping > 76.2 mm (3 in.) Nominal Pipe Size (NPS) Schedule 40 (Unless Otherwise Specified)

Piping < 50.8 mm (2 in.) NPS Schedule 80 (Unless Otherwise Specified)

Tubing 3.175 mm (0.125 in.) Nominal Tubing Size

(NTS)

Tubing 6.35 mm (0.25 in.) NTS 1.245 mm (0.049 in.) Minimum Wall Thickness

Tubing 12.7 mm (0.50 in.) NTS 1.651 mm (0.065 in.) Minimum Wall Thickness

Tubing 19.05 mm (0.75 in.) NTS 1.651 mm (0.065 in.) Minimum Wall Thickness

Tubing 25.40 mm (1.00 in.) NTS 2.108 mm (0.083 in.) Minimum Wall Thickness

Tubing 31.75 mm (1.25 in.) NTS 2.768 mm (0.109 in.) Minimum Wall Thickness

0.889 mm (0.035 in.) Minimum Wall Thickness

© 2008 Solar Turbines Incorporated. All rights reserved. TPS250GS/908 - Preliminary

8

Turbomachinery Package Specification Titan 250 Generator Set

Construction Materials

Piping, Manifolds, and Tubing < 10.2 cm (4 in.)

Note (a)

Piping, Manifolds, and Tubing > 10.2 cm (4 in.)

Note (a)

Piping Interface Connections 316L Stainless Steel (Unless Otherwise Specified)

Flange Assembly Hardware 316L Stainless Steel

Pipe Support Brackets

Pipe Flexible Couplings

Tubing Dual Ferrule Compression Fittings 316L Stainless Steel

Sliding Lube Oil Drain Couplings and Plates

Lube Oil Vent Flame Arrestor Aluminum

Electrical System Certifications

NEC Class 1, Group D, Division 1 or 2

CENELEC Zone 1 or 2, Group II

CE, ATEX Zone 2, Group II

Three-Phase Package Motors

Optional Motor Voltage Ratings

Single-Phase Battery Charger

Optional Battery Charger Voltage Ratings

Single-Phase Lighting and Space Heater Voltage

Optional Package Lighting and Space Heater

Voltage Ratings

316L Stainless Steel (Unless Otherwise Specified)

Carbon Steel (Unless Otherwise Specified)

Carbon Steel (Standard)

316L Stainless Steel (Optional)

Carbon Steel (Standard)

316L Stainless Steel (Optional)

Carbon Steel (Standard)

316L Stainless Steel (Optional)

380, 400, or 415 VAC, 50 Hz

460 VAC 60 Hz

220, 230, 240, 380, 400, 415, 440, 460, or 480

VAC, 50 Hz or 60 Hz

120, 220, 230, or 240 VAC, 50 Hz or 60 Hz

Ingress Protection (IP) Ratings

Onskid Junction Boxes IP56 to IP66

Control Console IP50

Battery Charger, NEC IP22

Battery Charger, CE IP31

Solar’s Applicable Engineering Specifications

ES 9-56 Fusion Welding

ES 9-58 Standard Paint Program – Turbomachinery

ES 1593

ES 1762

ES 2201 Auxiliary Air

ES 2231

Solar’s Applicable Product Information Letters

PIL 127 Product Certification

Notes:

(a) All package piping is fabricated from 316L stainless steel with the exception of lube oil vent

lines and any piping welded directly to a carbon steel lube oil tank or tank cover.

Guidelines for NEC Compliance of Solar’s Product Lines: Class I, Group D, Division 1

and Division 2

Standards and Practices for Electrical Systems for Gas Turbine Packages Installed In

Hazardous Areas (CENELEC/IEC Standards – European ATEX Directive 94/9/EC)

Standards and Practices for The Design and Installation of Cable Channels and TC

Rated Cables Installed In Class 1, Division 2 Hazardous Areas

© 2008 Solar Turbines Incorporated. All rights reserved. TPS250GS/908 - Preliminary

9

Turbomachinery Package Specification Titan 250 Generator Set

3 Titan 250 Gas Turbine

3.1 General Description

The two-shaft Titan 250 gas turbine (Figure 3) is a completely integrated and selfcontained prime mover. The Titan 250 gas turbine combines high performance operation

with rugged industrial construction. This design philosophy allows for high efficiency, low

maintenance, and a long service life. The Titan 250 gas turbine is designed for a high

degree of compliance with American Petroleum Institute (API) requirements.

Figure 3. Titan 250 Two-Shaft Gas Turbine Cutaway

3.1.1 Principles of Operation

During the typical combustion process (Figure 4), air is drawn into the gas turbine air inlet

and is compressed by the multi-stage, axial-flow engine compressor. The compressed air

is directed into the annular combustion chamber at a steady flow. Fuel is injected and

mixed with the compressed air and ignited during the start cycle. Continuous combustion

will be maintained as long as there is an adequate flow of pressurized air and fuel. Hotpressurized gas from the combustor expands through and drives the turbine, dropping in

pressure and temperature as it exits the turbine. This combustion cycle converts the

energy in the fuel into kinetic rotating power at the turbine output shaft.

© 2008 Solar Turbines Incorporated. All rights reserved. TPS250GS/908 - Preliminary

10

Turbomachinery Package Specification Titan 250 Generator Set

For combustion, the gas turbine requires approximately one-fourth of the total air it

compresses. The excess air is mixed with the combustion products to reduce the gas

temperature at the turbine first stage-inlet. The cooling air also keeps metal temperatures

in the combustor and turbine assembly relatively low to ensure a long service life.

Figure 4. Typical Combustion Process

3.1.2 SoLoNOx Combustion System

The Titan 250 incorporates Solar’s proprietary SoLoNOx dry emissions system that

reduces pollution by limiting the formation of nitrous oxides (NOx), carbon monoxide

(CO), and unburned hydrocarbons (UHC). This system uses lean premix combustion to

lower the maximum flame temperature and reduce pollution formation. Solar’s

engineering staff will work with the customer to meet local permitting emission

requirements.

Table 1. Titan 250 Gas Turbine Specifications

Compressor

Type Axial Flow

Number of Stages 16

Compression Ratio 24:1

Flow (Nominal) 67.3 kg/sec (148 lb/sec)

Speed, Maximum 10,500 rpm

Combustion Chamber

Type Annular

Ignition Torch

Number of Fuel Injectors 14 (SoLoNOx, Low Emissions)

Gas Generator

Type Axial

Number of Stages 3

Power Turbine

Type Axial

Number of Stages 2

Speed 7000 rpm

Bearings

Radial 5 Tilt Pad with Proximity Probes

Thrust

2 Tilt Pad with Resistance Temperature Device

Probes

© 2008 Solar Turbines Incorporated. All rights reserved. TPS250GS/908 - Preliminary

11

Turbomachinery Package Specification Titan 250 Generator Set

Construction Materials

Compressor Case

- Forward Section Nodular Iron

- Aft Section WC6 Alloy Steel

Combustor Case 410 Stainless Steel

Exhaust Diffuser Nodular Iron

Accessory Gear Housing Ductile Iron

Protective Coatings

Compressor Rotor and Stator Blades Inorganic Aluminum

Nozzles, First and Second Stage Precious Metal Diffusion Aluminide

Blades, First and Second Stage Precious Metal Diffusion Aluminide

Approximate Weight

Gas Turbine Assembly 19 050 kg (42,000 lb)

Performance

Output Power Note (a)

22 370 kW (30,000 hp)

Heat Rate 9000 kJ/ kW-hr (6360 Btu/ kW-hr)

Exhaust Flow 245 660 kg/hr (541,590 lb/hr)

Exhaust Temperature 465°C (865°F)

Temperature Monitoring

Turbine T5 (12) Thermocouples

Vibration Monitoring

Turbine Bearing #1 Displacement Probes, X and Y axis

Turbine Bearing #2 Displacement Probes, X and Y axis

Turbine Bearing #3 Displacement Probes, X and Y axis

Turbine Bearing #4 Displacement Probes, X and Y axis

Turbine Bearing #5 Displacement Probes, X and Y axis

Gas Producer Rotor Shaft Displacement Probe, Axial Position

Power Turbine Rotor Shaft Displacement Probe, Axial Position

Gas Producer Rotor Shaft Keyphasor

Power Turbine Rotor Shaft Keyphasor

Accessory Gearbox Velocity Pickup

Notes:

(b) Performance is calculated under the following conditions:

Nominal Rating - ISO at 15°C (59°F), Sea Level

No Inlet/Exhaust Losses

Relative Humidity at 60%

LHV = 31.5 to 43.3 MJ/nm

3

(800 to 1,100 Btu/scf)

© 2008 Solar Turbines Incorporated. All rights reserved. TPS250GS/908 - Preliminary

12

Turbomachinery Package Specification Titan 250 Generator Set

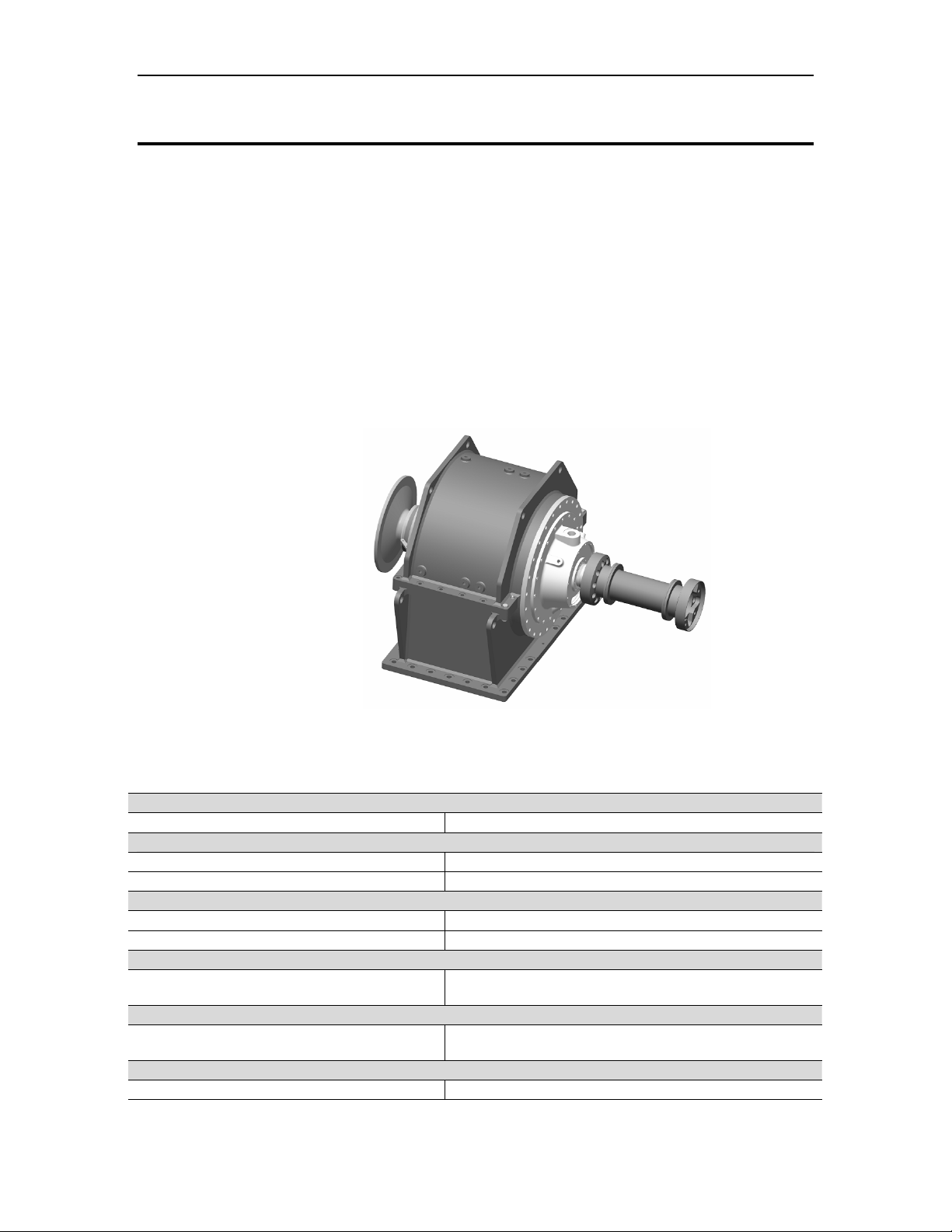

4 Reduction-Drive Gearbox

4.1 General Description

The reduction-drive gearbox (Figure 5) is an industrial, epicyclic, star-gear design

selected specifically for generator set applications. The gearbox uses few moving parts,

which provides high reliability and ease of assembly and disassembly. The reduction

gearbox is designed for continuous-duty operation and reduces the output speed of the

turbine to the required operating speed of the generator. The gearbox is coupled to the

gas turbine through a balanced high-speed shaft, splined at both ends. The output shaft

is coupled to the generator through a flexible disk-type dry coupling enclosed in a

coupling guard. The design of the gearbox facilitates straight-through shafting, avoiding

offset problems and permitting engine, gear, and generator alignment from a common

base. Gear lubrication is provided by the package lube oil system.

The gearbox is designed to provide 99% reliability between major inspections and

overhauls.

Figure 5. Typical Reduction Gearbox for the Titan 250 Generator Set

Table 2. Reduction-Drive Gearbox Specifications

Approximate Weight

Gearbox 7300 kg (16,100 lb)

Output Speed

50 Hz Service 1500 rpm

60 Hz Service 1800 rpm

Inspection and Overhaul Intervals

Major Inspection Interval 30,000 hours

Overhaul Interval 100,000 hours

Compliance

American Petroleum Institute (API)

Ratings

American Gear Manufacturers Association

(AGMA)

Vibration Monitoring

Gearbox Acceleration Probe

© 2008 Solar Turbines Incorporated. All rights reserved. TPS250GS/908 - Preliminary

613 Compliant With Exceptions, Refer to Solar’s

Standard List of Exceptions

In Excess of 1.10 for Generator Applications

13

Turbomachinery Package Specification Titan 250 Generator Set

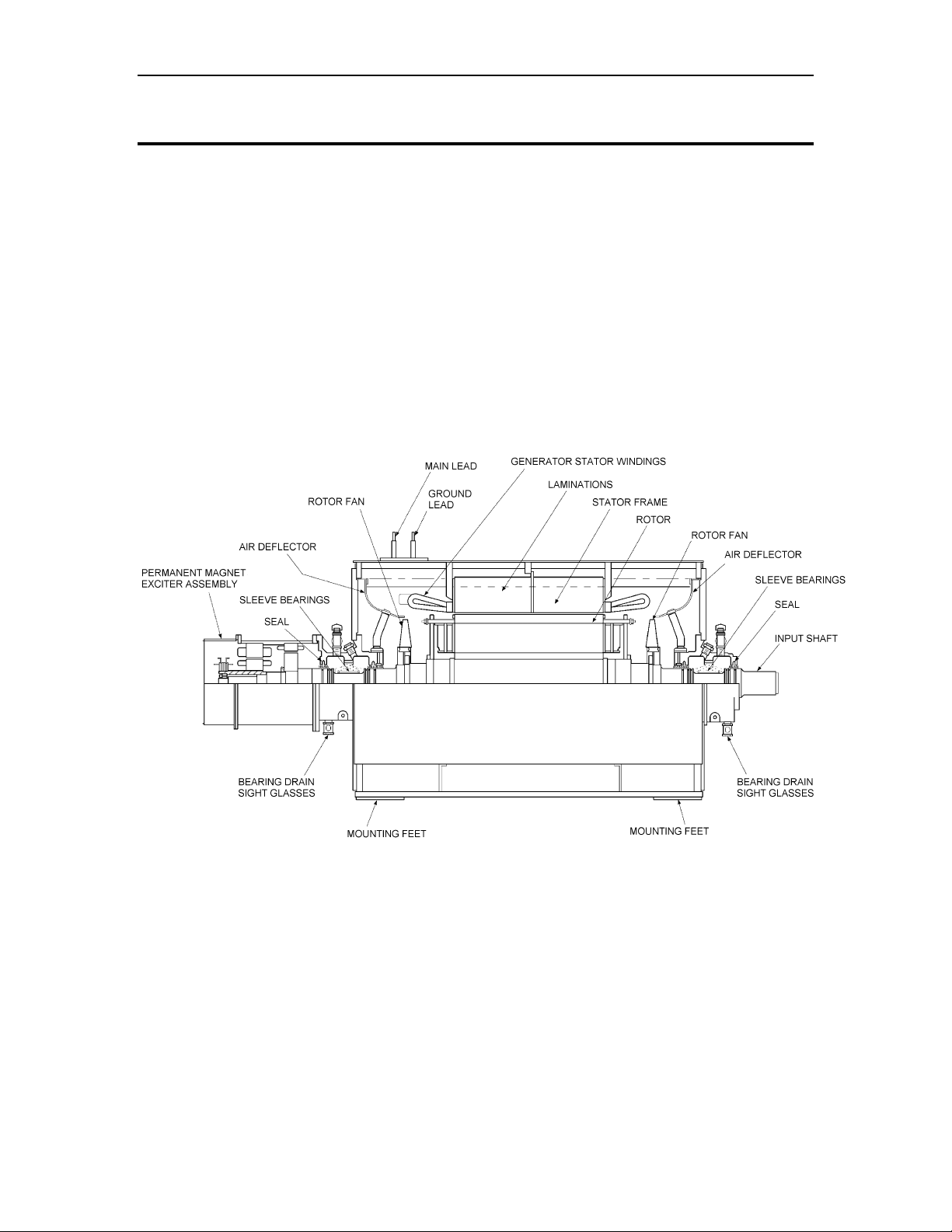

5 Generator and Associated Equipment

5.1 General Description

For maximum flexibility, the gas turbine package can be provided with several different

generator types and voltage outputs to accommodate a broad range of application

requirements. The generator, exciter, and control system are integrated to provide

optimal performance.

The standard generator type supplied is open drip-proof (ODP) (Figure 6). However the

following other enclosure types are available to meet a variety of environmental

conditions and cooling requirements:

• Closed air circuit air cooled (CACA)

• Closed air circuit water-to-air cooled (CACW)

• Totally enclosed air-to-air cooled (TEAAC)

• Totally enclosed water-to-air cooled (TEWAC)

Figure 6. Typical Open Drip-Proof Generator with Permanent Magnet Exciter System

5.2 Functional Description

During generator operation, three-phase AC power generated by the exciter armature is

converted to DC power by a rectifier. The DC output from the rectifier is applied as field

excitation current to the generator rotor windings to create magnetic flux. The generator

voltage output is controlled by the generator field current and the generator field current

is controlled by a brushless exciter. The amount of DC current applied to the exciter field

determines the exciter output voltage. A potential transformer senses the bus potential

and provides a signal to the combined generator control module (CGCM) for excitation

control.

© 2008 Solar Turbines Incorporated. All rights reserved. TPS250GS/908 - Preliminary

14

Turbomachinery Package Specification Titan 250 Generator Set

Any variations in bus potential will also be sensed and corrected by this circuit. After

voltage builds, the generator accelerates to 100% speed and excitation and voltage

control is assumed by the CGCM. A crosscurrent-compensating transformer provides the

signal to the CGCM for reactive loadsharing between multiple paralleled units.

It should be noted that the generator rotor windings rotate and the generator armature is

stationary. The exciter field coils are also stationary and the exciter armature rotates with

the main generator rotor shaft. As a result, a single rotating assembly consisting of the

exciter armature, exciter rectifier, and the generator rotor windings is formed. This single

rotating assembly greatly simplifies all electrical connections within the generator.

5.2.1 Standard Features

Generators include the following standard features:

• Sleeve bearings with pressure fed sumps

• Terminal box

• Form wound stator windings

• Amortisseur windings

• Rotor balance to 125% rated speed

• Anti-condensation space heaters

• Permanent magnet generator (PMG)

• Rotating armature-type VAC exciter

• Full-wave rectifier assembly

Special order generators are available to meet unique customer requirements including

non-U.S. specifications.

5.2.2 Rotor

The salient, four-pole, forged rotor is dynamically balanced to minimize vibration. Motor

fans move cooling air through the generator and around the rotor. The rotors have

layer-wound field windings cemented with a high-strength resin and are baked to cure the

resin. The rotor is in electrical and mechanical balance at all speeds up to 125% of rated

speed.

5.2.3 Stator

The stator is built with high-grade silicon steel laminations that are precision-punched and

individually insulated. Windings are typically form-wound and treated with thermosetting

synthetic varnish or vacuum pressure impregnated (VPI) epoxy for maximum moisture

resistance, high dielectric strength, and high bonding qualities. The windings are braced

to withstand shock loads such as motor starting and short circuits. Space heaters can be

supplied to minimize condensation during shutdowns.

5.2.4 Shaft

The shaft diameter provides the necessary stiffness to avoid torsional vibration. The

turbine-driven generator set is given a complete torsional analysis.

5.2.5 Frame

The frame is heavy-duty steel and is fabricated with deep welds and internal reinforcing

for extra rigidity and strength. The frame also includes lifting lugs.

5.2.6 Exciter

Excitation current for the generator field coils is provided by a brushless rotating exciter

with a PMG pilot exciter. The exciter is mounted directly on the generator rotor shaft. The

exciter consists of two basic parts, a small three-phase, AC generator with rotating

© 2008 Solar Turbines Incorporated. All rights reserved. TPS250GS/908 - Preliminary

15

Turbomachinery Package Specification Titan 250 Generator Set

armature and a three-phase, full-wave, diode-type bridge rectifier that rotates with the

armature. The pilot exciter is a PMG that rotates with the main generator rotor shaft. It

feeds the exciter field windings with excitation current and is controlled by the CGCM.

5.2.7 Bearing Lubrication System

The generator is supplied with a force-fed bearing lubrication system consisting of onskid

piping and a filter strainer. Oil is supplied from the package lube oil system.

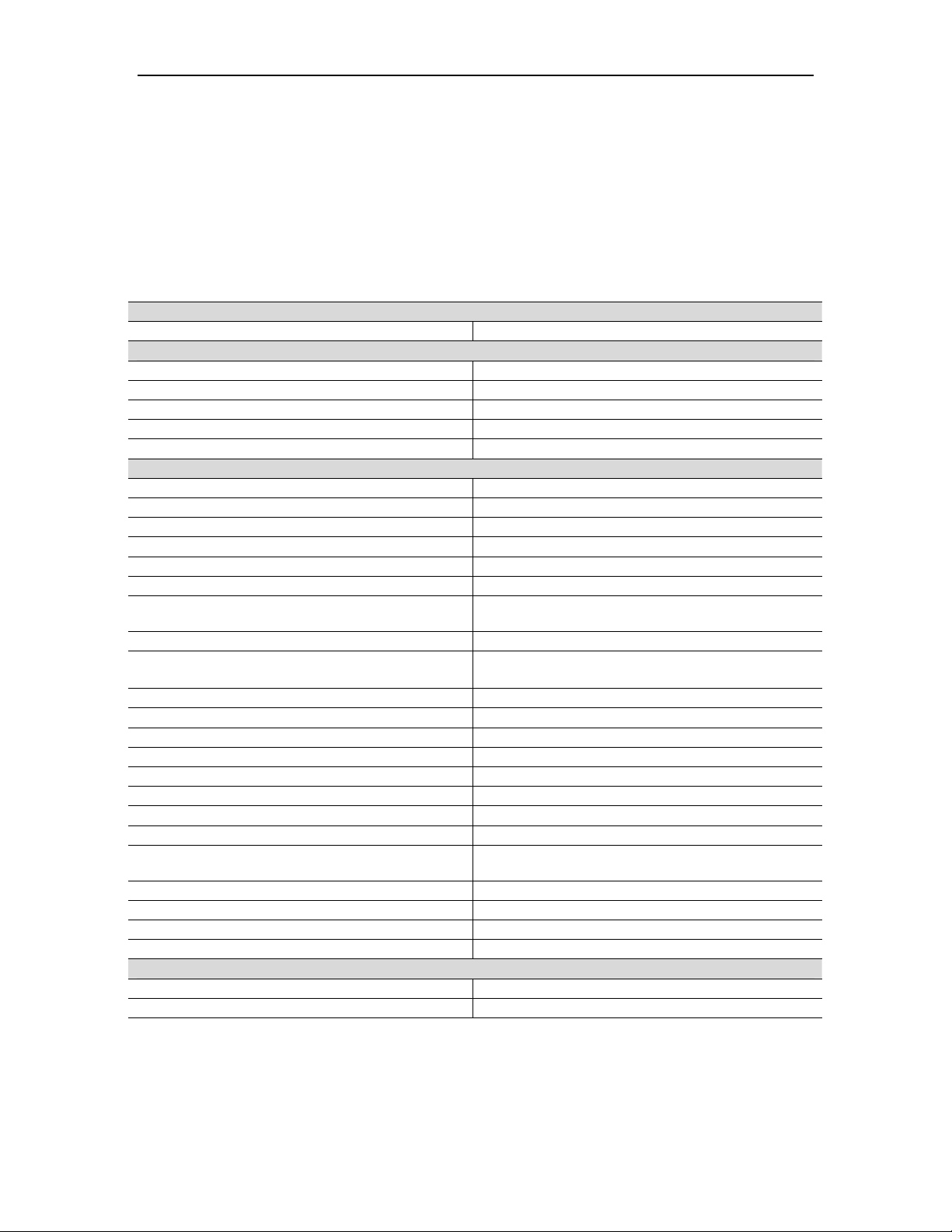

Table 3. Generator and Associated Equipment Specifications

Approximate Weight

Generator (Typical Open Drip Proof) 45 000 kg (99,200 lb)

Construction Types

Open Drip Proof (OPD), Air Cooled Standard

Closed Air Circuit Water-to-Air Cooled (CACW) Optional

Closed Air Circuit, Air Cooled (CACA) Optional

Totally Enclosed Air-to-Air Cooled (TEAAC) Optional

Totally Enclosed Water Air Cooled (TEWAC) Optional

Generator

Optional Voltage Ratings See Note (a)

Frequency Ratings 50 or 60 Hz

Number of Poles 4

Number of Leads 6

Connection Wye

Stator Windings Form Wound

Insulation

Temperature Rise See Note (b)

Overload Capacity

Overload Compliance NEMA

Short Circuit Capability 300% For 10 seconds

Rotor Balance To 125% of Rated Speed

Maximum Wave Form Deviation 10%

Maximum Harmonic Content 3%

Telephone Influence Factor (TIF)

Balanced 100

Residual 75

Efficiency

Space Heater

Voltage 120, 220, 230, or 240 VAC

Frequency 50 or 60 Hz

Phase 1 Phase

Vibration Monitoring

Generator Bearing Driven End Displacement Probes, X and Y axis

Generator Bearing Exciter End Displacement Probes, X and Y axis

Notes:

(a) Other voltages can be provided to meet specific customer requirements.

(b) A 80°C (144°F) temperature rise is based on the generator nameplate rating at 40°C (104°F)

and a power factor of 0.8 for continuous duty service.

11,000, 12,470, or 13,800 VAC,

National Electrical Manufacturers Association

(NEMA) Class F

NEMA Class B,

-150% Rated Current for One Minute

-110% Rated Current for Two Hours

The combined generator, exciter, and regulator

efficiency at full load is nominally 97%.

© 2008 Solar Turbines Incorporated. All rights reserved. TPS250GS/908 - Preliminary

16

Turbomachinery Package Specification Titan 250 Generator Set

6 Start System

6.1 General Description

The start system includes a direct-drive AC starter motor driven by a solid-state variable

frequency drive (VFD). The start system provides torque to initiate engine rotation and to

assist the engine in reaching a self-sustaining speed. The starter motor is mounted

directly on the gas turbine accessory drive gearbox. The VFD regulates voltage and

frequency to the starter motor for engine rotation as commanded by the Turbotronic 4

control system.

6.2 Functional Description

To begin gas turbine rotation, the VFD initially provides low-frequency AC power to the

starter motor. The VFD gradually increases the speed of the starter motor until the gas

turbine reaches purging speed. When purging is completed, the control system activates

the fuel system. The speed of the starter motor is gradually increased until the gas

turbine reaches starter dropout speed. The VFD then deenergizes the starter motor and

the motor clutch assembly is disengaged.

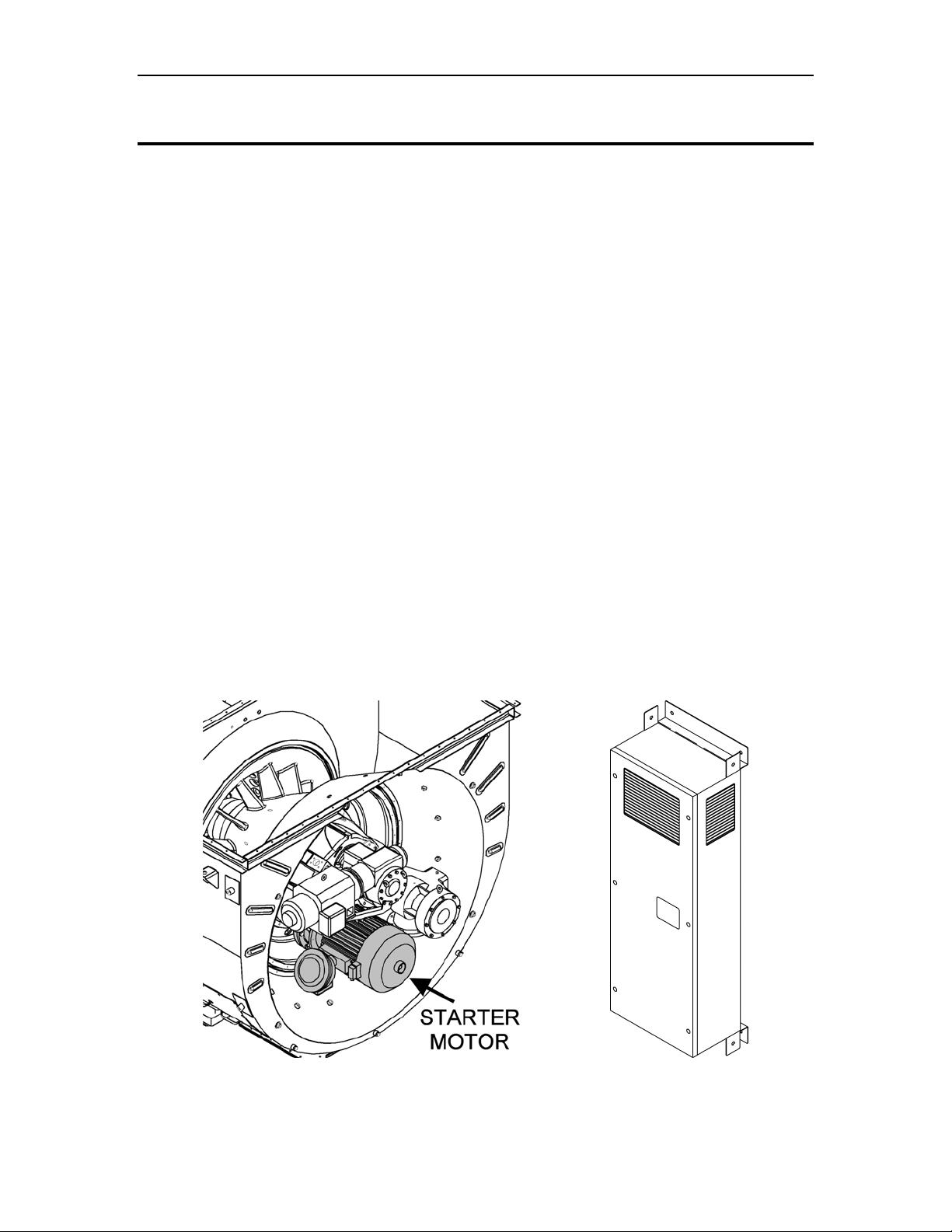

6.2.1 Starter Motor

The starter motor (Figure 7) provides high breakaway starting torque and acceleration

from standstill to starter dropout speed. The motor is standard frame size and is

constructed to be explosion proof and flameproof. The motor includes an integral

over-temperature protection thermostat connected to the Turbotronic 4 control system for

hazardous area motor certification and protection. Separate cable entry points are

provided for power connections, thermal protection wiring, and the space heater wiring.

Starting power is transferred to the gas turbine via the reduction-drive gearbox and overrunning clutch and shaft assembly. After a shutdown, the starter motor rotates the turbine

at low speed to prevent deformation of the rotor during cool down.

Figure 7. Direct-Drive AC Starter Motor and VFD Cabinet

© 2008 Solar Turbines Incorporated. All rights reserved. TPS250GS/908 - Preliminary

17

Turbomachinery Package Specification Titan 250 Generator Set

6.2.2 Variable Frequency Drive

The VFD (Figure 7) is a motor speed controller that provides pulse-width modulated

power with variable frequency and voltage to the starter motor. Controlled by the

Turbotronic 4 control system, the VFD regulates voltage and frequency to the starter

motor to control engine speed from standstill to starter dropout speed. The system is

capable of performing up to six start attempts per hour, as well as extended purge cycles

for heat recovery unit applications and engine wash cycles. The VFD cabinet is designed

for installation in a non-hazardous location. Electrical disconnects and overcurrent

protection devices are not provided.

6.2.3 Power Wiring

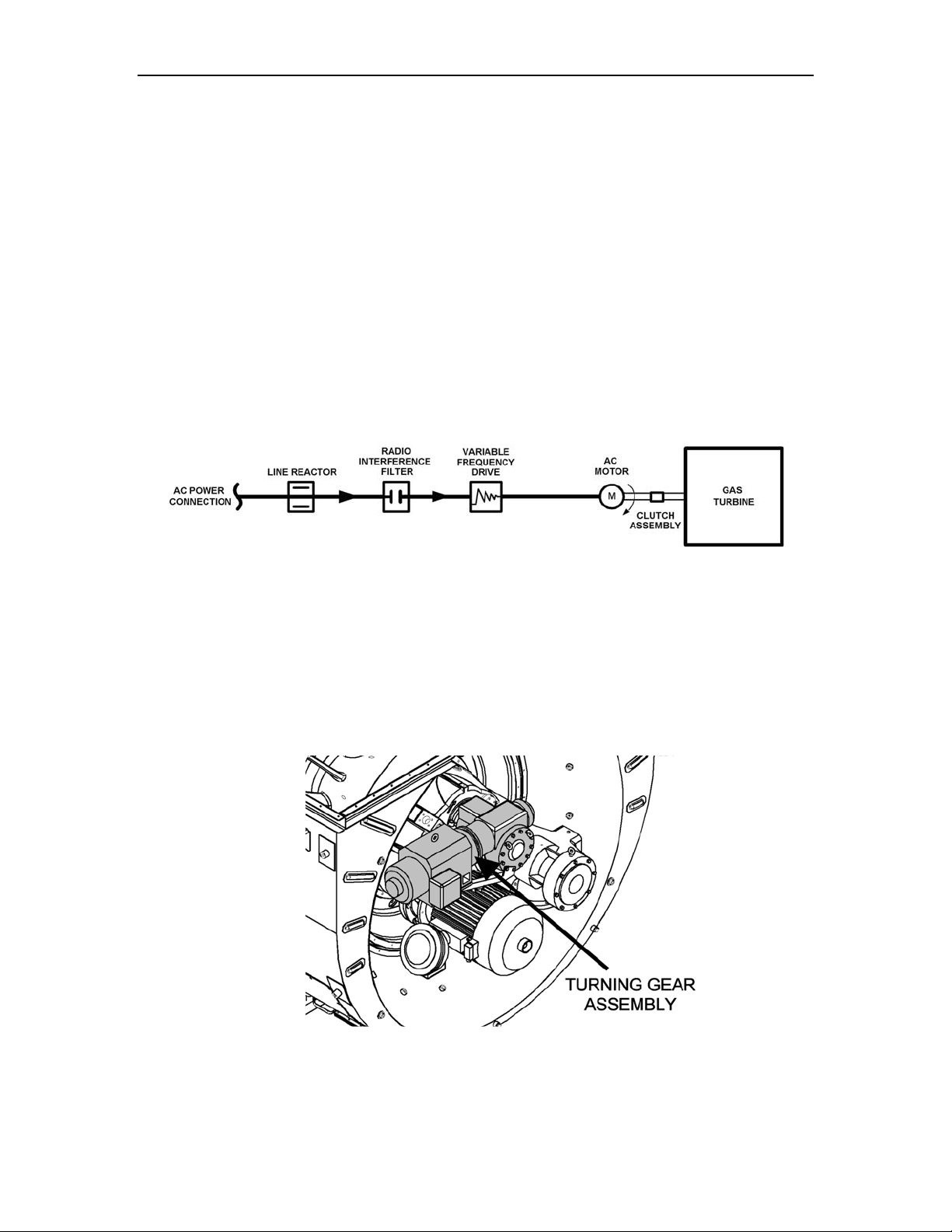

The start system (Figure 8) requires customer-furnished, three-phase AC input.

Additional three-phase AC power wiring is required to connect the VFD to the starter

motors. A start contactor is not required for VFD operation. A customer-furnished fused

disconnect at the VFD input is recommended. Optional motor space heater wiring is

available.

Figure 8. Typical Direct-Drive AC Start System

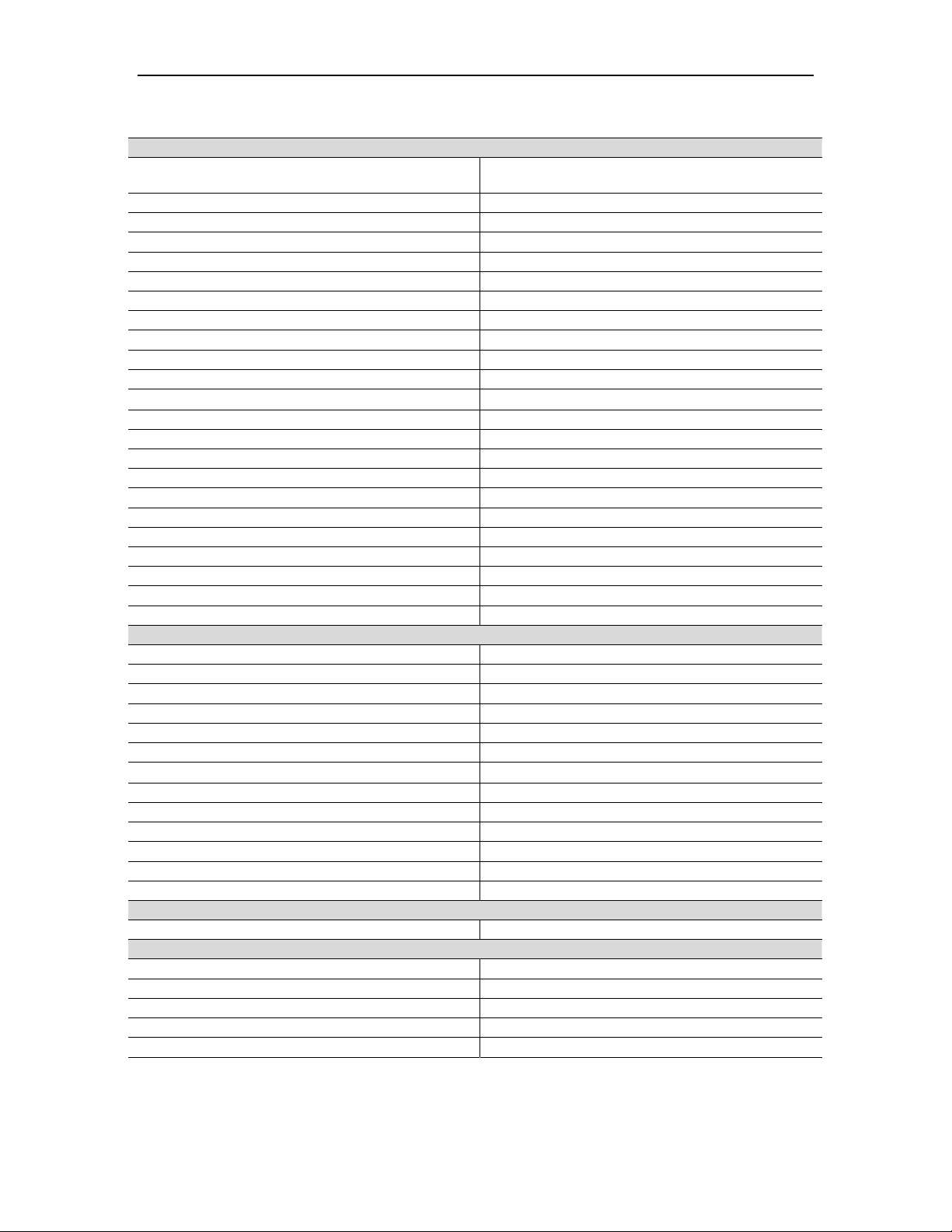

6.3 Backup Slow Rotation System

The Titan 250 package is equipped with a DC powered turning gear system (Figure 9) to

ensure low speed rotation of the turbine as backup for the DAC starter motor in the event

of loss of AC power to the package. The system engages the decelerating turbine at low

speed and maintains rotation for a specified time.

Figure 9. Turning Gear Assembly

© 2008 Solar Turbines Incorporated. All rights reserved. TPS250GS/908 - Preliminary

18

Turbomachinery Package Specification Titan 250 Generator Set

Table 4. Start System Specifications

Variable Frequency Drive

Optional Voltage Input Ranges See Note (a)

Minimum Input Current

- 380 to 460 VAC Input 525 amps

- 500 to 600 VAC Input 342 amps

Voltage Output Range 0 to 460 VAC, (0 to 240 Hz)

Maximum Line Distribution Capacity 1000 kVa

Maximum Fault Current Capacity See Note (b)

Maximum Breakaway Amperage 383 amps

Maximum Breakaway Torque 918 N-m (677 ft-lb)

Power Factor 0.96

Efficiency 98%

Minimum/Maximum Operating Temperature

Heat Rejection

- 380 to 460 VAC Input 7350 watts

- 500 to 600 VAC Input 9485 watts

Input Fuse Rating 600 amp

Approximate Measurements

- Height 220 cm (87 in.)

- Width 69 cm (24 in.)

- Depth 60 cm (28 in.)

Approximate Weight 28 831 kg (850 lb)

- Length 73 cm (29 in.)

- Diameter 46 cm (18 in.)

Starter Motor

Motor Type Squirrel-cage Induction

Motor Voltage Rating 380 AC, (0 to 133 Hz)

Power 93 kW (125 hp)

Operating Speed 0 to 7000 rpm

Maximum Breakaway Amperage 659 amps

Maximum Breakaway Torque 488 N-m (360 ft-lb)

Minimum/Maximum Operating Temperature

Space Heater Voltage 115 VAC, 60 Hz

Approximate Measurements

- Length 66 cm (26 in.)

- Diameter 45.7 cm (18 in.)

Approximate Weight

- AC Starter Motor Assembly 450 kg (990 lb)

Power Wiring

VFD to Starter Motors Power Cable Length

Turning Gear Motor

Motor Type Squirrel-cage Induction

Motor Voltage Rating 240 VDC

Power 3.73 kW (5 hp)

Operating Speed 2500 rpm

Turbine Rotation Speed 300 rpm

380 to 460 VAC, (48 to 62 Hz)

500 to 600 VAC, (48 to 62 Hz)

30 000 amps

-10 to 40°C (14 to 104°F)

-40 to 60°C (-40 to 140°F)

38 m (123 ft), See Note (c)

© 2008 Solar Turbines Incorporated. All rights reserved. TPS250GS/908 - Preliminary

19

Turbomachinery Package Specification Titan 250 Generator Set

Applicable Engineering Specifications

Solar’s Engineering Specification ES 1593

Solar’s Engineering Specification ES 1762

Applicable Product Information Letters

Solar’s Product Information Letter PIL 149 Direct-drive AC Start Systems

Notes:

(a) If the customer-furnished input voltage is greater than 600 VAC ±5%, a step-down

transformer is recommended.

(b) Feeder circuits exceeding this limit require the use of an isolation transformer, line reactor, or

other means of adding similar impedance to limit fault current.

(c) Longer cable runs may require an onskid marshalling box and/or output line reactor.

Guidelines for NEC Compliance of Solar Product

Lines: Class I, Group D, Division 1 and Division 2

Standards and Practices for Electrical Systems For

Gas Turbine Packages Installed in Hazardous Areas

(CENELEC Standards)

© 2008 Solar Turbines Incorporated. All rights reserved. TPS250GS/908 - Preliminary

20

Turbomachinery Package Specification Titan 250 Generator Set

7 Fuel System

7.1 General Description

The fuel system (Figure 10), in conjunction with the control system, includes all

necessary components to control ignition and fuel flow during all modes of operation.

TP

LEGEND

TP = PRESSURE TRANSMITTER

RT = RTD (TEMPERATURE)

VS = VALVE SOLENOID

PILOT

FUEL

CONTROL

VALVE

TP

PILOT FUEL

MANIFOLD

TO FUEL

INJECTORS

GAS VENT

VENT

VALVE

TP

SECONDARY

SHUT OFF

VALVE

V

S

FUEL

AIR

TP

V

S

PRIMARY

SHUT OFF

VALVE

VS VS

Figure 10. Typical Fuel System Schematic

7.1.1 SoLoNOx Combustion System

The SoLoNOx combustion system uses special fuel injectors with main and pilot fuel

ports. The fuel injected through these ports is controlled during starting and steady-state

operation to maintain stable combustion and minimize the formation of nitrous oxides

(NOx), carbon monoxide (CO), and unburned hydrocarbon (UHC) emissions. To further

regulate emission levels, combustion airflow is regulated using a bleed valve mounted on

the combustor case. The SoLoNOx combustion system also includes an additional inlet

gas filter/coalescer for mounting offskid.

TORCH

REGULATOR

TORCH SHUT

OFF VALVE

TP

MAIN

FUEL

CONTROL

VALVE #1

TPRT

MAIN

FUEL

CONTROL

VALVE #2

TP

TORCH

REGULATOR

TP

TP

TP

MAIN FUEL

MANIFOLD

#1

MAIN FUEL

MANIFOLD

#2

TO FUEL

INJECTORS

TO FUEL

INJECTORS

TO TORCH

7.1.2 Fuel System

The SoLoNOx fuel system includes:

• Supply pressure transmitter

• Pilot air operated primary gas fuel shutoff valve

• Pilot air operated secondary gas fuel shutoff valve

• Pilot air operated gas vent valve

• Electrically operated fuel control valves (2)

• Torch with shutoff valve and pressure regulators

• Main fuel manifold

• Fuel injectors

© 2008 Solar Turbines Incorporated. All rights reserved. TPS250GS/908 - Preliminary

21

Turbomachinery Package Specification Titan 250 Generator Set

• Fuel pilot control valve

• Fuel pilot manifold

• Inlet gas filter/coalescer loose shipped for field installation

Component Operation

The gas fuel pressure supplied to the turbine skid must meet minimum and maximum

pressure and flow requirements. If the gas fuel pressure is too high or too low, the control

system will prevent turbine operation. Pneumatically actuated primary and secondary gas

fuel shutoff valves are controlled using pilot air pressure. For each valve, pilot air

pressure is admitted to and exhausted from a pneumatic actuator through a solenoid

valve. Fail-safe operation ensures both valves will close in case pilot air pressure is lost.

The gas fuel control valves and the SoLoNOx fuel pilot control valve, are powered by

integrated DC motor-driven actuators. Integrated actuator electronics provide precise

closed-loop valve control based on position command inputs versus position feedback

outputs. The three valves are fast acting and provide fuel metering for light-off,

acceleration, full load, and load transient conditions. Fail-safe operation ensures both

valves will close in case the command signal or control power is lost. During the start

sequence prior to ignition, the control system will verify gas pressure and perform a gas

valve check to verify proper operation of all gas fuel valves.

Table 5. Fuel System Specifications

Gas Fuel System

Acceptable Gas Fuels See Note (a)

Fuel Quality Refer to Solar’s Engineering Specification ES 9-98

Compliance

Minimum/Maximum Gas Fuel Supply Pressure

Minimum Flow Rate 3513 to 5480 kg/hr (7746 to 12086 lbm/hr), See

Minimum/Maximum Fuel Supply Temperature

Primary Gas Fuel Shutoff Valve Pneumatically Actuated Spring-Closed Ball Valve

Secondary Gas Fuel Shutoff Valve Pneumatically Actuated Vane Type Valve

Gas Fuel Control Valve and SoLoNOx Fuel Pilot

Control Valve

Actuator Voltage 120 VDC

Valve Discrete Signals 0 to 24 VDC

Valve Analog Signals 4 to 20 mA

Maximum Operating Pressure 4137 kPag (600 psig)

Maximum Operating Temperature 93°C (200°F)

Response Time Less Than 100 msec From 10-to-90% Stroke

Valve Body

Gas Fuel Filter (Conventional Units Only) 10 Micron

Offskid Coalescing Filter Module (SoLoNOx Units

Only)

Maximum Operating Pressure 3447 kPag (500 psig)

Maximum Flow 122 m3/min (4300 ft3/min)

Minimum/Maximum Operating

Temperatures

Filtration Efficiency β0.3 > 200 per ISO 4572

Natural Gas

Propane

Butane

National Association of Corrosion Engineers

(NACE) Compliant

2240 to 3447 kPag (325 to 500 psig), See Note (b)

Note (b)

-40 to 93°C (-40 to 200°F), See Note (c)

Actuator Valve

Aluminum (Standard)

Stainless Steel (Optional)

-29 to 100°C (-20 to 212°F)

© 2008 Solar Turbines Incorporated. All rights reserved. TPS250GS/908 - Preliminary

22

Turbomachinery Package Specification Titan 250 Generator Set

Customer-Furnished Pilot Air System

Fluid Clean-Dry Air

Air Quality

Minimum/Maximum Regulated Pressure Range 689 to 1379 kPag (100 to 200 psig)

Pilot Air Filter 10 micron

Construction Materials

Piping, Manifolds, and Tubing 316L Stainless Steel

Applicable Engineering Specifications

Solar’s Engineering Specification ES 9-98

Solar’s Engineering Specification ES 1593

Solar’s Engineering Specification ES 1762

Applicable Product Information Letters

Solar’s Product Information Letter PIL 148 LPG and NGL Fuels

Solar’s Product Information Letter PIL 162

Solar’s Product Information Letter PIL 176 Siloxanes in Gas Fuel

Notes:

(a) The gas fuel system is designed to operate with fuels that comply with Solar’s Engineering

Specification ES 9-98. Most commercially available natural gas fuels comply with ES 9-98.

The gas fuel system can be modified to operate with fuels that do not comply with ES 9-98.

Solar gas turbines can operate on low Btu fuels. Please contact Solar Turbines for

assistance in evaluating fuel characteristics and gas turbine requirements.

(b) Fuel pressure and flow requirements can be affected by several factors such as; fuel

temperature, fuel lower heating value, air inlet temperature, fuel composition, fuel specific

gravity, engine injector type, inlet duct loss, relative humidity, site elevation, and piping length

and diameter. Based on site conditions, minimum fuel pressure and flow requirements may

be less than stated values. Please contact Solar Turbines for site-specific fuel pressure and

flow requirements.

(c) Fuel must have a differential temperature (ΔT) of at least 27°C (50°F) above fuel dew point

temperature.

(d) The particle size in the air stream should not exceed 10μ. Since it is impractical to remove

100% of all particles larger than 10μ, this is defined as ß10 > 100, or 99% efficient. Oil or

hydrocarbon content should not exceed 1 ppm. The dew point at line pressure shall be at

least 6°C (10°F) below the minimum temperature to which any part of the air system is

exposed or between -29°C and 93°C (-20°F and 200°F). Air should be free of all corrosive

contaminants, hazardous gases, flammables, and toxics.

See Note (d)

Fuel, Air, and Water (or Steam) for Solar Gas

Turbine Engines

Guidelines for NEC Compliance of Solar Product

Lines: Class I, Group D, Division 1 and Division 2

Standards and Practices for Electrical Systems for

Gas Turbine Packages Installed In Hazardous

Areas (CENELEC/IEC Standards – European

ATEX Directive 94/9/EC)

Recommendations for the Sourcing, Handling,

Storage and Treatment of Fuels for Solar Gas

Turbines

© 2008 Solar Turbines Incorporated. All rights reserved. TPS250GS/908 - Preliminary

23

Turbomachinery Package Specification Titan 250 Generator Set

8 Lubrication System

8.1 General Description

The lubrication system, (Figure 11) circulates oil under pressure to the gas turbine and

driven equipment. Lube oil is supplied from the lube oil tank located in the driver frame.

Oil temperature is maintained at optimal levels by a thermostatic control valve, oil tank

heater, and optional oil cooler.

The lubrication system incorporates the following components:

• Oil tank

• Oil tank heater

• Lube oil (customer furnished)

• Gas turbine driven main lube oil pump

• AC Motor-driven pre/post lube oil pump

• DC Motor-driven backup lube oil pump

• Duplex lube oil filter system with replaceable elements

• Oil level, pressure, and temperature indications

• Pressure and temperature regulators

• Strainers

• Oil tank vent separator

• Oil tank vent flame trap

Optional features include:

• Offskid oil cooler

• Stainless steel oil tank and tank covers

• Stainless steel filter system

8.1.1 Lube Oil

Lube oil is customer furnished. Petroleum base or synthetic oil with a viscosity grade of

C32 or C46 may be used. Synthesized hydrocarbon oils are recommended due to lower

pour point, higher viscosity index, better heat transfer, and lower oxidation rate. Lube oil

must conform to Solar’s Engineering Specification ES 9-224.

8.1.2 Gas Turbine-Driven Main Lube Oil Pump

The main lube oil pump is mounted on an integral accessory drive gearbox. This

positive-displacement pump provides lube oil pressure for normal operation.

8.1.3 AC Motor-Driven Pre/Post Lube Oil Pump

The pre/post lube oil pump provides lube oil pressure during package starting and for

post-lube cooling of the gas turbine and driven equipment bearings. The pre/post lube oil

pump provides lube oil pressure during a gas turbine roll down in the event the main lube

oil pump has failed.

8.1.4 DC Motor-Driven Backup Lube Oil Pump

The backup lube oil pump provides lube oil pressure for post lube cooling of the gas

turbine and driven equipment bearings in the event the pre/post lube oil pump fails. The

backup lube oil pump provides lube oil pressure during a gas turbine roll down in the

event the main lube oil pump and pre/post lube oil pump have both failed. The backup

lube oil pump also provides lube oil pressure during an emergency condition such as a

© 2008 Solar Turbines Incorporated. All rights reserved. TPS250GS/908 - Preliminary

24

Loading...

Loading...