CAT 735 User Manual

735 |

® |

|

|

Articulated Truck |

|

|

|

Engine

Engine Model |

Cat® C15 ACERT™ |

|

Gross Power – SAE J1995 |

324 kW |

435 hp |

Net Power – SAE J1349 |

313 kW |

419 hp |

Weights |

|

|

Rated Payload |

32.7 tonnes |

36 tons |

Body Capacities |

|

|

Heaped SAE 2:1 |

19.7 m3 |

25.8 yd3 |

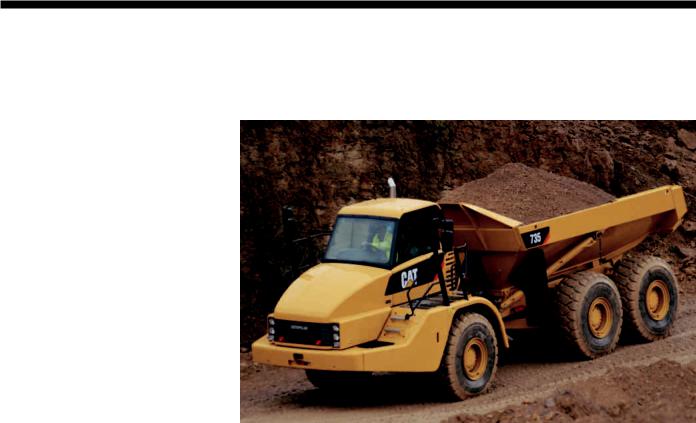

735 Articulated Truck

The 735 Caterpillar® Articulated Truck is a world-leading earthmoving solution.

Cat® C15 Engine with ACERT Technology

The core concept behind ACERT technology is advanced combustion. ACERT engine technology carefully controls the combustion process to reduce pollutant levels while maintaining performance and efficiency. pg. 4

Serviceability

Long service intervals and easy maintenance provide better machine availability, resulting in lower owning and operating costs. pg. 10

Performance and Productivity –

Power Train

The Cat C15 ACERT engine, matched with the seven-speed forward and

two speed reverse electronic controlled transmission, provides a wide operating range for smooth shifting. pg. 5

Complete Customer Support

Your Cat dealer offers a wide range of services that can be set up under a customer support agreement when you

purchase your equipment. The dealer will help you choose a plan that can cover everything from machine configuration to eventual replacement. pg. 11

Performance and Productivity –

Suspension and Traction Control

Three-point front suspension provides a smooth ride, allowing the operator to travel at speed over rough terrain. Cross-axle differential locking system provides full driveline locking for maximum performance in adverse conditions. pg. 6

The 735 offers proven reliability and durability, high performance, low fuel consumption, operator comfort and low operating costs.

2

Operator Comfort |

Ease of Operation |

Large center-mounted cab, oscillating |

Ergonomically designed wrap-around |

front axle, air suspension seat, full-size |

dash, tilt and telescopic steering wheel, |

trainer seat and large storage space |

easy-to-reach controls and outstanding |

provide exceptional operator comfort. |

all-around viewing promote fast, |

pg. 7 |

confident machine operation. pg. 8 |

Durability and Reliability

The 735 has built-in durability and reliability. Cat purpose-built articulated truck drivetrain components, front frame and hitch ensure maximum performance in the toughest applications. pg. 9

New Feature

3

Cat C15 Engine with ACERT Technology

A combination of proven systems and innovative new technologies, ACERT engines optimize performance while meeting EPA Tier 3 and EU Stage 3a engine exhaust emission regulations.

ACERT Technology. The Cat C15 ACERT engine introduces a series of evolutionary, incremental improvements that provide breakthrough engine technology built on systems and components developed by Caterpillar® with proven reliability. The technology capitalizes on Cat expertise in four core engine systems: fuel, air, electronics and after treatment. ACERT technology is a unique and revolutionary systems solution that enables Cat engines to meet today’s clean air regulations, thus establishing the building blocks for attaining tomorrow’s more stringent standards.

C15 Block. The one-piece, gray iron block features generous ribbing for stiffness and heavy bearing bulkheads for rigidity and strength as the crankshaft turns. Straight O-ring connection points reduce the loss of engine oil and fluids.

Cylinder Head and Piston Technology.

The C15 has a cross-flow cylinder head with refined port geometry, which improves breathing and provides better combustion. The Monotherm/steel pistons have a forged steel design, which offers high strength, light weight and tighter tolerances. The result is better oil control, minimal blow-by and long liner life.

Advanced Diesel Engine Management (ADEM) A4 Engine Controller.

The ADEM A4 electronic control module manages fuel delivery to get the best performance per liter or gallon of fuel used. The engine management system provides flexible fuel mapping, allowing the engine to respond quickly to varying application needs. It tracks engine and machine conditions while keeping the engine operating at peak efficiency.

Fuel Delivery. Multiple injection fuel delivery involves a high degree of precision. Precisely shaping the combustion cycle lowers combustion chamber temperatures, generating fewer emissions and optimizing fuel

combustion. This translates into more work output for your fuel cost.

Noise Reduction Technologies.

Noise reduction has been achieved through design changes to the isolated top cover, oil pan, multiple injection strategy, insulated timing case cover, sculpted crankcase and gear train refinements.

4

Performance and Productivity – Power Train

Integrated power train with more power, greater performance and lower fuel consumption – the power to do more work.

Mechanically Actuated Electronic Unit Injection (MEUI). A highly evolved fuel system with a proven record of reliability in the field. It combines the technical advancement of an electronic control system with the simplicity

of direct mechanically controlled unit fuel injection. It excels in its ability to control injection pressure over the entire engine operating speed range. These features allow the C15 to have

complete control over injection timing, duration and pressure.

Air-to-Air Aftercooling (ATAAC).

ATAAC keeps air intake temperatures down and, in concert with the tight tolerance combustion chamber components, maximizes fuel efficiency and minimizes emissions. Significant improvements in airflow are generated by a turbocharger, unique cross-flow head and a single overhead camshaft.

Wastegate Turbocharging. Single wastegate turbocharger provides higher boost over a wide range, outstanding low-end performance with improved peak torque and engine response.

Electronic Transmission. The Caterpillar seven-speed electronically controlled transmission is designed specifically for the articulated truck and its applications. It features anti-hunt shift strategy for speed continuity. It also incorporates Individual Clutch Modulation (ICM)

to ensure constant shift times even when the oil is cold.

Two Reverse Gears. The transmission arrangement provides a second reverse gear for improved performance when operating in longer rear hauling applications. First gear reverse is now of a lower ratio for increased rimpull on wet or steep grades.

Controlled Throttle Shifting (CTS).

Significantly reduces power train stress and clutch wear by controlling engine speed, torque converter lock-up and transmission clutch engagements.

Engine Overspeed Inhibitor. Electronic Transmission Control (ETC) protects against engine overspeeding by shifting the transmission up one gear at specified rpm settings. If the transmission is in its highest gear, torque converter lockup disengages.

Directional Shift Management.

Regulates engine speed during directional shifts to prevent damage caused by high-speed directional changes.

Caterpillar Engine Compression Brake.

Provides extra braking effort on downhill grades. It is an excellent match for the Cat C15 ACERT engine, turning it into a power absorbing air compressor. It has very fast response time and produces no additional heat, so it can be used continuously.

Usable Rimpull. Power train components work together to offer more usable rimpull at higher speeds on effective grades. In first gear, the torque converter overcomes grade resistance by sending more torque to the wheels and preventing engine lugging. On downhill grades, the engine compression brake works like

a brake by slowing the machine.

Hydraulic Fan. The remote-mounted hydraulic fan is temperature sensitive providing variable speeds when needed, which minimizes power requirements. The result is more power to the ground and faster cycle times.

5

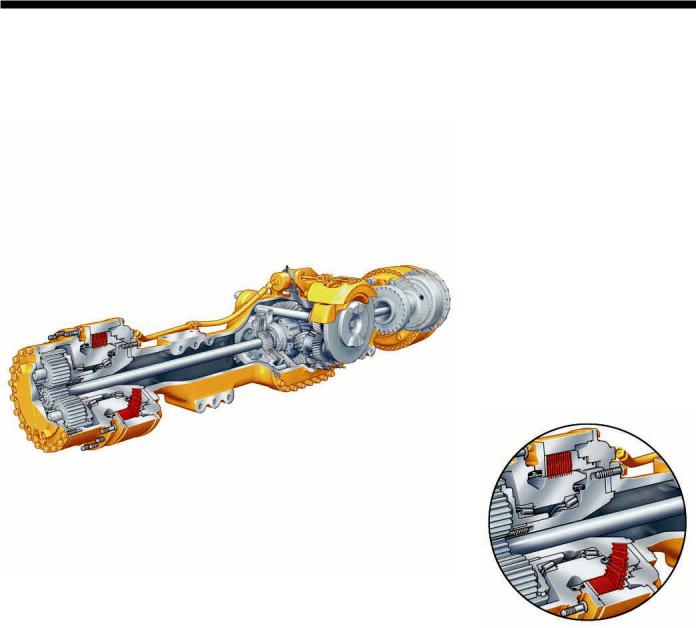

Performance and Productivity – Suspension and Traction Control

Suspension systems and traction control – delivering power to the ground in all conditions.

Front Suspension. The three-point front suspension oscillates ±6° to provide a smooth ride, allowing the operator to travel at speed over rough terrain and softening impact loads on structures and components.

A-Frame Construction. The front suspension uses an oscillating A-frame with a lateral tie rod to control axle sideways movement. The independent low-pressure, oil-nitrogen suspension cylinders provide an excellent ride

in rough conditions. Low pressure ensures consistent damping and increased seal life.

Front Suspension Cylinders. Large bore, low pressure cylinders are purpose designed for tough applications and offer a soft, smooth ride.

Mounting Points. Suspension mounting points are integrated into the axle housing, increasing reliability.

Rear Suspension. Features a walking beam geometry with Caterpillar designed rear suspension mounts which provide a reliable and stable ride for excellent load retention.

Traction Control. The traction control system is comprised of a wet clutched inter-axle differential and wet clutched cross-axle differentials. All differentials can be engaged and disengaged on-the- go for maximum versatility. When used together, the differentials provide

100 percent driveline locking.

Inter-Axle Differential Lock. Locks all three axles in unison and modifies torque distribution for excellent traction in poor underfoot conditions and on grades. It is operated by a switch located at the footrest.

Cross-Axle Differential Locks.

Provides full driveline locking – all three axles and all six wheels –

for maximum performance in the most adverse conditions. Acts in unison with the inter-axle differential lock when the footswitch is actuated and the dash-mounted switch is selected.

Fast Hoist Cycle Times. Fast body raise and lower times mean less time spent in the dump area.

Service brake detail

Enclosed, Oil-Cooled Brakes.

Multi-plate oil-immersed brakes are fitted to both front and center axles. These brakes provide outstanding stopping capability, while maintaining maximum durability and low wear characteristics.

Exhaust Heat System. The body comes exhaust heat ready.

Load-Carrying Capacity. The 735 has a large target area to provide consistently high load-carrying capacity. Its diverging flow design gives clean load ejection, which maximizes production and avoids the waste of material carry-back.

6

Loading...

Loading...