Page 1

Advance

Product

Data

Packaged

Air-Cooled

Flotronic™

Liquid Chiller

Nominal 60-Ton Capacity

Features

• Unit nominal capacity serves virtually any large com

mercial or institutional air conditioning need or industrial

process cooling requirement.

• High-tech solid-state electronic control circuitry tested

to U.S. Government Space Agency standards.

• Microprocessor control maintains total control over

chiller functions, permitting intelligent control of the

refrigerant cycle.

• Diagnostic module with digital display included to

permit rapid troubleshooting just by pressing a button.

• Electronic expansion valves (EXV) operate down to

ISpsig (103 kPa) pressure differential. (Ordinary ther

mostatic expansion valve typically requires lOOpsig

[690 kPa] differential.) This reduces compressor motor

power requirements and improves the unit EER.

• Flotronic™ chiller provides up to 28% efficiency im

provement over standard 30GB chillers on an annual

basis.

• Additional operating cost savings with precise multiplestep compressor capacity control.

• Multiple compressors and dual refrigerant circuits help

to protect against the possibility of loss of total capacity.

• Semi-hermetic 06E compressors are serviceable in

the field.

30GB060

Designed for outdoor installation to minimize required

mechanical room space.

Air-cooled condenser design saves condenser water

and eliminates cooling tower.

Domestic units will operate to 115 F (46 C).

Protection against freeze-up — low water temperature

cutoff and electric heaters protect cooler.

Available as standard with aluminum fins and copper

tubes for normal applications, or with all-copper coils.

Field-installed accessories

• Demand limit control module (required for remote

ON/OFF control)

• Leaving chilled water temperature reset accessory board

• Sensor kit assembly for outdoor or space temperature

reset of chilled water temperature

• Ground current refrigeration circuit protection

• Discharge and suction pressure gage panel

• Oil pressure switch package includes oil pressure

switches (2) for unit

• Capacity control: accessory electric suction cutoff

unloader

• Motormaster® head pressure control (requires unit

modification for low-ambient operation)

Factory-Installed option (FlOP)

Thermal expansion valves — For those situations where

energy savings of the EXV are secondary and equipment

first costs are most important. With this option, the

electronic expansion valve and controls related to the

EXV function, head pressure control and its related

part-load energy savings, are deleted from unit and are

replaced by thermal expansion valves and liquid line

solenoid valves. Minimum operating ambient for FlOP

TXV-equipped units with standard head pressure control

is 32 F. Contact your Carrier representative for details

on operation at temperatures below 32 F. The FlOP model

continues to have microprocessor features and diagnostic

capability. Standard accessories are useable.

2-87

Form 30GB-1APD

Page 2

Table of contents

Page

Features .............................................................................1

Field-Installed Accessories ...............................................1

Factory-Installed Option (FIOP)......................................1

Model Number Nomenclature ..........................................2

Physical Data....................................................................2

Application Data ............................................................2-6

Selection Procedure

Performance Data

..........................................................

...........................................................

7-9

Model number nomenclature

30GB 060 - 6

30GB-AIR-COOLED

OUTDOOR LIQUID CHILLER

UNIT SIZE (approximates chiller capacity in tons)

Page

Dimensions .................................................................... 10

Mounting Weights ......................................................... 10

Electrical Data ............................................................... 11

Controls ....................................................................... 11,12

Control Sequence

..........................................................

13

Typical Installation ........................................................ 14

6

Guide Specifications

....................................................

— 1 575-3-60

— 5 208/230-3-60

— 6 460-3-60

15,16

Physical data

MODEL 30GB 060

APPROX OPER WT - lb 4900

REFRIG CHG — lb

Circuit 1 65

Circuit 2 85

COMPRESSORS, Type...Rpm Reciprocating,

(No.) Circuit 1* (1) 6275

(No.) Circuit 2 (1) A299

Capacity Control Steps 4

Circuit 1 (%) 43

Circuit 2 (%) 57

Minimum Step Capacity (%)

CONDENSER FANS — Type Propeller, Direct Drive

Fan Speed — Rpm 1080

No. Biades...Diameter-in.

Circuit 1/Circuit 2 4...26/3 ..30

No. Fans...Total kW

Totai Airfiow — Cfm

CONDENSER COiLS — Type

Tubes (Copper), OD-in. '/2

Fins/in. Circuit 1/Circuit 2 14 2/15.0

No. Rows Circuit 1/Circuit 2 %

Face Area (sq ft) Circuit 1 57 5

Max. Working Pressure

Refrig psig

COOLER — No. ...Type

Modei 10HA400— 824

No. Refrigerant Circuits 2

Net Water Volume — Gal.

(includes nozzles)

Max. Working Press. — psig Refrigerant Side-235,

WATER CONNECTIONS MPT

Inlet and Outlet — in. 3

Drain — in. FPT

*6 prefix indicates one electric unioader.

"A” prefix indicates no unloader.

tCopper fins aiso avaiiabie

Circuit 2

Semi-Hermetic 1750

29

6. 1 92

46500

Plate Fins (Aluminumf)

57.5

450

One...Direct Expansion,

Shell & Tube

17 7

Water Side-150

%

Application data

Leveling unit

Unit must be level when installed to ensure proper oil

return to the compressors.

While most outdoor locations are suitable for 30GB

units, the roof is a common site that presents a problem

if roof has been pitched to aid in water removal. To

assure proper oil return, be sure that unit is level,

particularly in its major lengthwise dimension, as com

pressor oil return piping runs in that direction.

It should be determined prior to installation if any

special treatment is required to assure a level installation.

Cooler temperature

1. Maximum leaving chilled water temperature (LCWT)

for Model 30GB is 70 F (21 C). Unit can start and pull

down with up to 95 F (35 C) entering water tempera

ture due to MOP (maximum operating pressure)

feature of the expansion valve. For sustained opera

tion, it is recommended that entering water temperature

not exceed 85 F (29.4 C).

2. Minimum LCWT for standard Model 30GB is 40 F

(4.5 C). It is permissible to use a standard micro

processor-controlled Flotronic chiller with leaving

water temperatures in the range of 34 F (1°C) to 39.9 F

(4.4 C) only if a protective brine solution (20% antifreeze

solution, or greater) is used and microprocessor dip

switch is properly set. (See Controls and Trouble

shooting book for further information.) Special order

medium temperature brine units must be ordered for

operation with leaving water temperatures in the range

of 34 F (1°C) to 15 F (-9C). For ratings below 40 F

4.5 C) LCWT, contact your local Carrier representative.

Page 3

Application data (cont)

MINIMUM COOLER WATER FLOW RATES

AND MINIMUM LOOP VOLUME

UNIT 30GB

060 67

NOTES.

1. Minimum flow based on 1 5 fps veiocity in cooier without special

cooler baffling

2. Minimum Loop Volumes:

Gallons = V X ARl Cap (tons)

APPLICATION

Normal Air Conditioning

Process Type Cooling

Low Ambient Unit Operation

MINIMUM

FLOW (1)

Gpm ft of water

PRESSURE

DROP

3.8

MINIMUM

VOLUME (2)

Gallons

180

Leaving water temperature reset

Accessory board* may be installed in 30GB chillers to

provide reset of LCWT in constant water flow systems.

Reset reduces compressor power usage at part load when

design LCWT is not necessary. Humidity control should

be considered since higher coil temperatures resulting

from reset will reduce latent heat capacity. Three reset

options are offered;

From return water temperature* — Increases LCWT

temperature set point as return (or entering) water tem

perature decreases (indicating load decrease). Option

may be used in any application where return water provides

accurate load indication. Limitation of return water reset is:

LCWT may only be reset to value of design return water

temperature. Return reset is the simplest of 3 reset acces

sories available, as return water sensor is already installed.

From outdoor temperature* — Increases LCWT as

outdoor ambient temperature decreases (indicating load

decrease). This reset should be applied only where outdoor

ambient is an accurate indication of load. An accessory

thermistor is required.

From space temperature* — Increases LCWT as space

temperature decreases (indicating load decrease). This

reset should be applied only where space temperature is

an accurate indication of load.

For details on applying a reset option, refer to 30GB

Controls and Troubleshooting Instructions.

*Obtain ordering part numbers from current price pages.

c. Special cooler baffling is required to allow minimum

flow rate to be reduced 12%.

CHILLER COOLER

RECIRCULATION

SUPPLY

RETURN

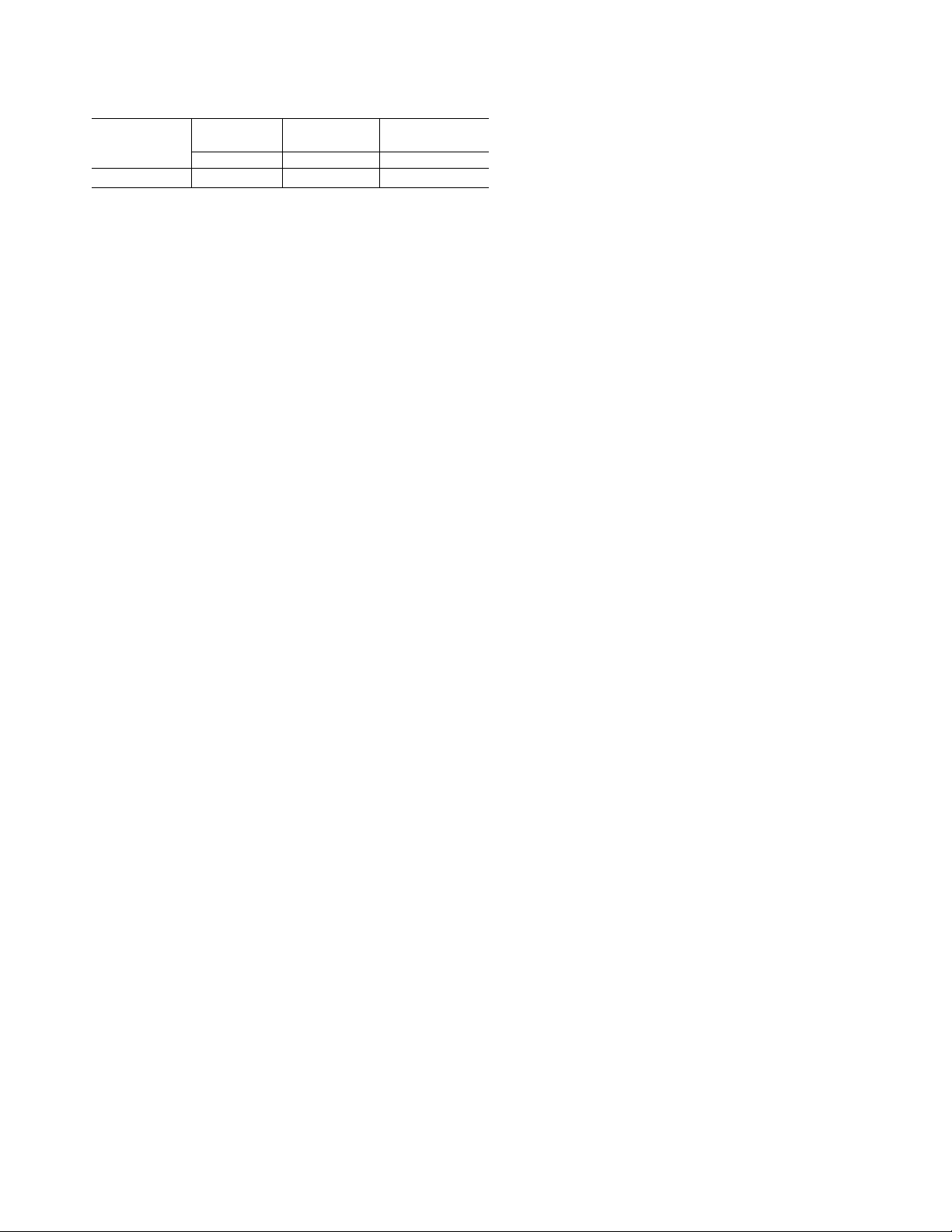

Maximum cooler flow (> 5 gpm/ton or < 5 F range

[>0.09 L/s . kW or <2.7 C range]) results in practical

maximum pressure drop through cooler.

a. Return water may bypass the cooler to keep pressure

drop through cooler within acceptable limits. This

permits a higher AT with lower water flow through

cooler and mixing after the cooler.

b. Special cooler baffling is available by special order,

to permit a cooler flow rate increase of 10%.

CHILLER COOLER

BYPASS

SUPPLY

RETURN

Cooler flow range

Ratings and performance data in this publication are

for a cooling range of 10°F or 6°C. Flotronic^" chillers with

microprocessor control may be operated at a different

temperature range provided flow limits are not exceeded.

For minimum flow rates, see Table. High flow rate is limited

by pressure drop that can be tolerated. If another range is

used, apply LCWT correction as given in selection example.

Minimum cooler flow (maximum cooler temperature

range) for standard units is shown in Table. When gpm

(L/s) required is lower (or range higher), follow recom

mendations below:

a. Multiple smaller chillers may be applied in series, each

providing a portion of the design temperature range.

b. Cooler water may be recirculated to raise flow rate.

However, mixed temperature entering cooler must

be maintained a minimum of at least 5°F (2.8°C) above

the leaving chilled water temperature.

Variable cooler flow rates may be applied to a standard

30GB chiller. Unit will, however, attempt to maintain a

constant leaving chilled water temperature. In such cases,

minimum flow must be in excess of minimum flow given in

Table and flow rate must change in steps of less than 10%

per minute. Apply 6 gallons per ton (6.5 liters per kW) water

loop volume minimum if flow rate changes more rapidly.

Water loop volume — In circulation must equal or

exceed 3 gallons (11.4 liters) per nominal ton of cooling

(3.25 liters per kW) for temperature stability and accuracy

in normal air conditioning applications. (For example, a

30GB060 would require 180 gallons in circulation in system

loop — see Table.) For process jobs where accuracy is

vital or for operation at ambient below 32 F (0°C) with low

unit loading conditions, there should be from 6 to 10 gallons

Page 4

Application data (cont)

per ton (6.5 to 10.8 liters per kW). To achieve this volume,

it is often necessary to install a tank in the loop. Tank

should be baffled to insure that there is no stratification

and that water (or brine) entering tank is adequately mixed

with liquid in the tank.

GOOD

GOOD

Cooler fouling factor used to calculate tabulated ratings

was 0.0005 ft2. hr. °F/Btu (0.000088 m^. K/W). As fouling

factor is increased, both unit capacity and compressor

power decrease. Standard ratings should be corrected

using following multipliers:

FOULING FACTOR

ENGLISH

((F . hr. °F/Btu)

0.0005 0.000088 1.00

0.001 0.000176 0.97

0.002 0.000352 0.91

SI

(m*. K/W)

CAPACITY

MULTIPLIER

COMPRESSOR

POWER

MULTIPLIER

1 00

0.98

0.91

Cooler protection in form of ethylene glycol (or other

suitable brine) is recommended when operating in areas

which experience temperatures below 32 F (0°C) to

protect cooler should there be a loss of cooler heater

power. Even though unit cooler is protected with insula

tion and an electric heater that protects the cooler down

to 10 F (-12 C), it does not protect water piping external

to unit. Use only antifreeze solutions approved for heat

exchanger duty. Use of automotive antifreezes is not

recommended because of the fouling that can occur once

their relatively short-lived inhibitor breaks down.

Draining cooler and outdoor piping is recommended if

system is not to be used during freezing weather condi

tions. See section below for low-ambient operation.

Condenser

Altitude correction factors must be applied to standard

ratings at altitudes above 2000 ft (610m) using following

multipliers:

ALTITUDE

ENGLISH

(ft)

0

2000

4000 1220

6000

8000 2440

10000

SI

(m)

0 1 00

610 0 99

1830 0,97

3050 0.95

CAPACITY

MULTIPLIER

0 98

0.96

COMPRESSOR

POWER

MULTIPLIER

1.00

1.01

1.02

1.03

1.04

1.05

Condenser airflow restrictions will affect the unit

capacity, condenser head pressure and compressor

power input. Correction factors to be applied for external

static restrictions up to 0.2 in. wg (50 Pa) are shown below.

EXTERNAL

STATIC

RESISTANCE

ENGLISH

(in. wg)

0.0 0.0

0.1 25

0.2 50 0 968 1.03

SI

(Pa)

CAPACITY

MULTIPLIER

1 00 1.00

0 986

COMPRESSOR

POWER

MULTIPLIER

1 01

High-ambient temperature — Standard 30GB chillers

can operate to 115 F (46 C) ambient temperature.

Low-ambient operation

Flotronic^“ 30GB chillers with electronic expansion valves

(EXV) will start and operate at ambients down to 0°F

(-18 C) with following field provisions:

Wind baffles must be added for operation below 32 F (0°C).

A WARNING

Operation at low ambient is not recommended if

minimum load on chiller is below minimum step of

unloading.

Protection against freeze-up — It is recommended

that field-installed chilled water piping be protected at

lower ambient temperatures by wrapping with field-supplied

heating cable and covering with 2-in. (50-mm) thick closed

cell insulation.

Antifreeze solution must be added to water loop to

protect loop down to 15 F (8 C) below minimum operating

ambient temperature.

For operation of EXV-equipped chillers below 0°F

(-18 C) and for operation of TXV-equipped (factoryinstalled option) chillers below 32 F (0°C), down to -20 F

(-29 C), the Carrier Motormaster® condenser head pres

sure control and its associated components must be

added. Consult your local Carrier representative for

complete details.

Provide sufficient volume in the chilled water loop — At

least 6 gallons per ton of refrigerant (6.5 liters per kilowatt)

is recommended minimum, provided there is a moderate

system load.

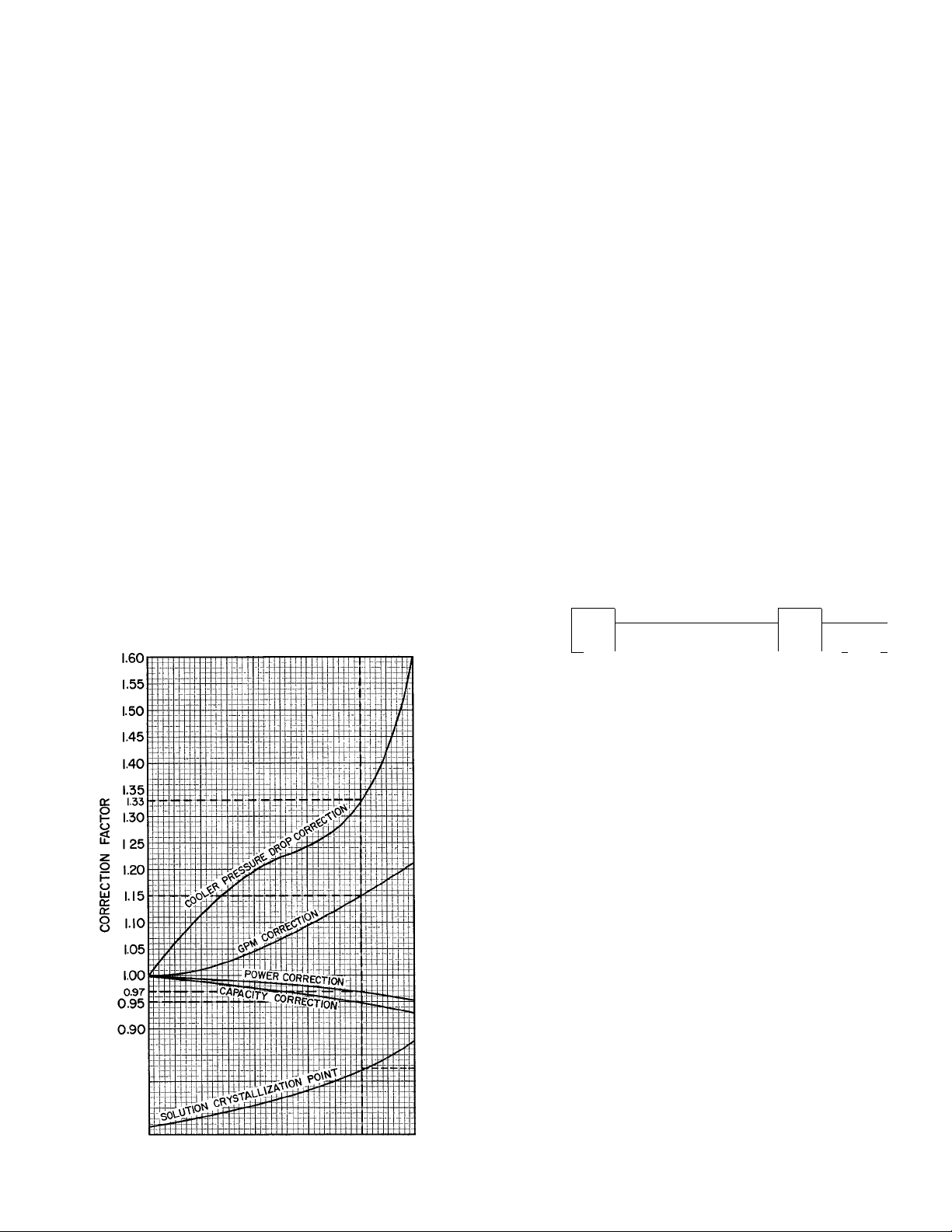

Capacity Correction (Antifreeze)

Ethylene glycol (or other suitable brine) should be used in

installations where subfreezing temperatures are ex

pected. Unit performance data must be corrected for

the addition of ethylene glycol as shown in following

example. Correction factors may be derived from follow

ing curves.

Example: Where a 5 F outdoor temperature is anticipated,

determine concentration of ethylene glycol to protect

system to -10 F ambient temperature at zero flow.

Enter the solution crystallization point curve at -10 F,

read 40% concentration of ethylene glycol is required to

prevent crystals from forming in solution.

Consider the 30GB060 unit from the Selection Pro

cedure (Water) example (refer to correction curves at

40% solution).

Page 5

Application data (cont)

Correct unit capacity — On glycol performance

capacity correction curve, read 0.95.

Corrected capacity = 0.95 x determined capacity

- 0.95 X 61.3

= 58.2 tons

Correct chilled water flow — On the gpm correction

factor curve, read 1.15.

Chilled water flow (at corrected capacity)

24 X corrected capacity

temperature rise

24 X 58.2 tons

14 F

99.8 U.S. gpm

= U.S. gpm

Chilled water flow (40% solution) = 1.15x99.8

= 114.7 U.S. gpm

Correct cooler pressure drop — On cooler pressure

drop correction curve, read 1.33.

On cooler pressure drop curve, for 114.7 gpm, read

PD = 10 ft water gage. The pressure drop for 40% solution =

1.33 X 10.0 = 13.3 ft water.

Correct compressor power input (kW) — On power

correction curve, read 0.97 correction factor at 40%

EG concentration.

Power input from Selection Procedure example

= 71.1 kW.

Corrected power input = 0.97 x 71.1 = 68.9 kW.

Oversizing chillers

Oversizing chillers by more than 15% at design conditions

must be avoided as the system operating efficiency would

be affected adversely (resulting in greater/excessive

electrical demand). When future expansion of equipment

is anticipated, it is strongly recommended that a single

chiller be installed to meet present load requirements

and a second chiller added to meet the additional load

demand.

It is also recommended that the installation of 2 smaller

chillers be considered where operation at minimum load

is critical. The operation of a smaller chiller loaded to a

greater percent of minimum is preferred to operating a

single chiller at or near its minimum recommended value.

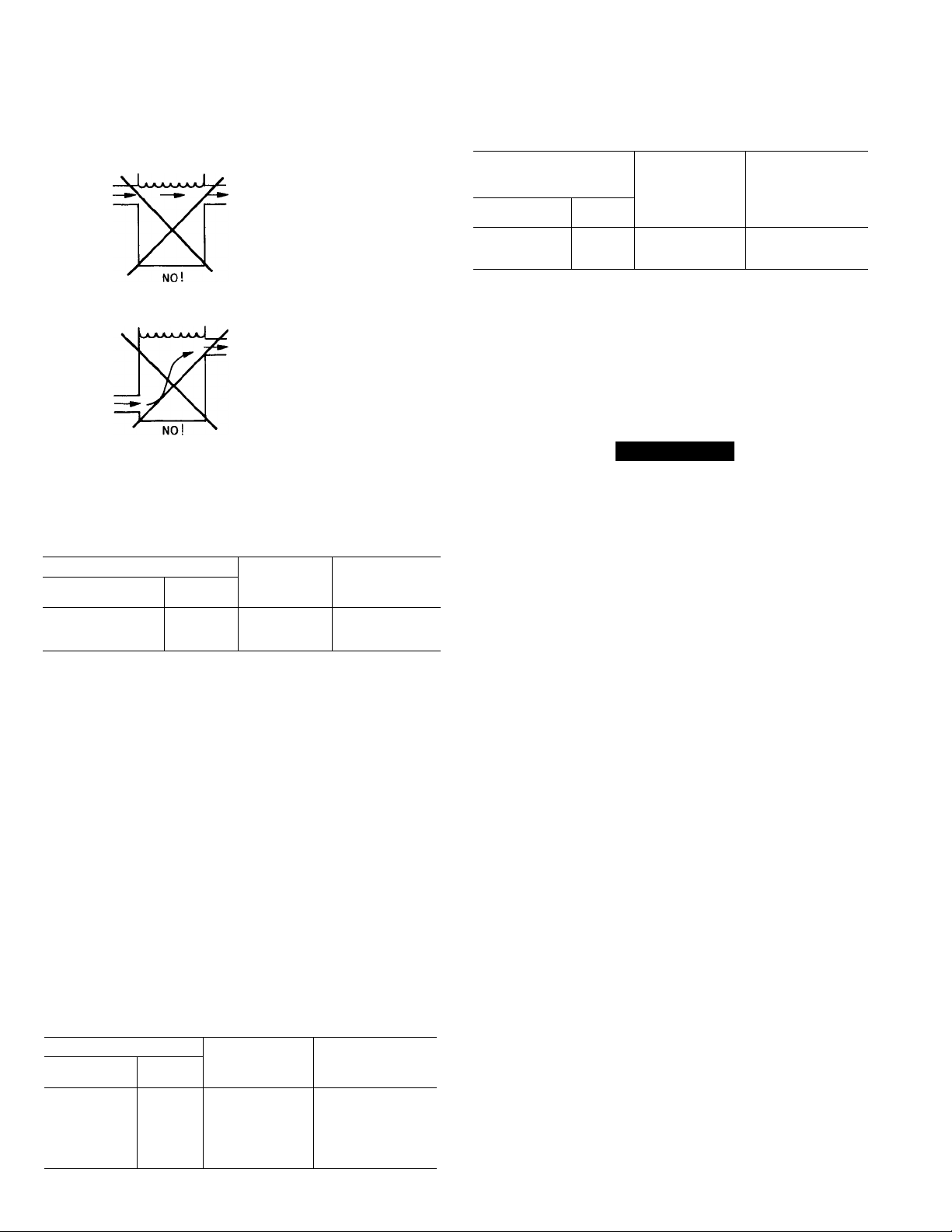

Multiple chillers

Where chiller capacities greater than 200 tons (703 kW)

are required, or where stand-by capability is desired,

chillers may be installed in parallel. Units should be of

equal size to ensure balanced water flows. Where a large

temperature drop (>25F [13.9 C]) is desired, chillers

may be installed in series. Water temperature sensors

need not be moved for multiple chiller operation. A 10-ft

(3-m) separation is required between units for airflow,

and a 6-ft (1.8-m) distance is required from units to

obstructions. See figure. See Physical Data for service

clearances.

ETHYLENE GLYCOL PERFORMANCE

CORRECTION FACTORS AND SOLUTION

CRYSTALLIZATION POINTS

(F)

-40

-20

-10

0

+20

40

10 20 30 40

% CONCENTRATION (BY WEIGHT)

ETHYLENE GLYCOL

50

(C)

r-40

c -30

-20

-10

0

(3m) (I.Sm)

10 FT 6 FT

* MINIMUM

////// //

MULTIPLE UNIT SEPARATION

MINIMUM

Electrical/utility interests

Energy management — See 30GB Controls and Trouble

shooting manual and accessory installation instructions

for details.

Demand limiting (also called load shedding) — When

utilities demand for electricity exceeds a certain level,

loads are shed to keep electricity demand below a pre

scribed maximum level. Typically, this happens on hot

days when air conditioning is most needed.

Load shedding must be done intelligently. Demand

may be limited on Model 30GB by resetting water tem

perature, or by using a demand limit accessory that

unloads the chiller to a given predetermined percent of

the load. Both features require signal from an intelligent

central control. Do not cycle demand limiter for less than

10 minutes on and 5 minutes off.

Duty cycling cycles electrical loads at regular intervals

regardless of need. This reduces electrical operating

costs of a building by “fooling” demand indicating

devices. Duty cycling of compressors or fans is not

recommended since motor winding and bearing life

suffer from constant cycling.

Page 6

Application data (cont)

Time clock shutdown (or other controlled shutdown

not associated with leaving chilled water temperature)

requires use of accessory demand limit control module.

Second step of the demand limit control (0-50% of

capacity) is set for 0 (zero) capacity. This allows unit to

go through a normal pumpout cycle at shutdown.

Part-wind start

Not generally required on 30GB chillers due to use of

multiple compressors allowing smaller electrical load

increments, but is available if required. Maximum

instantaneous current flow (see ICF in Electrical Data)

should be used in determining need.

Vibration isolation

Compressors are spring isolated,

isolation is not generally required.

External vibration

Hot gas bypass usage (units with TXV only)

Hot gas bi^pass usage, while frequently specified, is not

normally recommended because it results in equipment

being applied below its normal application range. Before

applying hot gas bypass, it is recommended that use of 2

machines be considered, including one that can be run at

the system minimum load without addition of hot gas

bypass. In those instances where there is no alternative,

it is recommended that the appropriate hot gas bypass

package can be used with the factory option TXV unit.

Medium temperature brine application — Application

of 30GB outdoor chillers for brine duty within the 39.9 F

to 34 F (4.4 C to 1°C) range is possible with proper field

change of control configuration. Application in the

range 34 F to 15 F (1°C to -9.4 C) requires 30GB unit

with factory modification.

Selection procedure

I Determine unit size and operating conditions

required to provide specified capacity at given

conditions:

Capacity required............................................. 60 tons

Leaving chilled water temperature ....................... 45 F

Chilled water temperature rise

Condenser entering air temperature (CEAT) .. 95 F

Loop volume

Ratings are based on 10 F rise and are suitable for rise

from 5 F to 15 F without adjustment. In this case,

however, greater accuracy is desired.

II Correct LCWT for 14 F cooler water tempera

ture rise.

Enter correction curve at 14 F and read a correction

of 0.3 F. Corrected LCWT is, therefore, 45 + 0.3 = 45.3 F.

III Determine capacity, unit size and power input.

Enter rating table at given CEAT and LCWT —

respectively 95 F and 45 F.

Read down capacity column until the capacity nearest

to but higher than specified required capacity is

reached. In this case, 60.9 tons is delivered by a

30GB060. Interpolate between 45 F and 46 F to find

.............................................

.............................

230 gallons

14 F

determined capacity and power input at corrected

LCWT (45.3 F). Values are:

Capacity

Power input

IV Calculate corrected cooler water flow.

Water _ 24 x corr capacity in tons

flow temperature rise F

V Calculate the cooler pressure drop.

Enter cooler pressure drop curve at the corrected

flow rate (105.1 U.S. gpm) and read, for the 30GB060,

a pressure drop of 9 ft of water.

VI Check loop volume and cooler water flow rate.

Minimum loop volume, from application data, is

180 gallons for 30GB060. Therefore, given volume of

230 gallons is satisfactory. Minimum water flow rate,

from application data, is 67 gpm for 30GB060. Flow rate

of 105.1 gpm is well above minimum required.

.........................................................

.....................................................

U.S. gpm

24 X 61.3

14

105.1 U.S. gpm

61.3 tons

71.1 kW

Page 7

Performance data

STANDARD RATINGS* — REFRIGERANT 22

COMPRESSOR

POWER INPUT

(kW)

(tons)

59 7

CAPACITY

(Btuh)

716,400 68.4

UNIT

30GB

060

*Per ARl Standard 590-81, Section 7 2

NOTE: 95 F condenser entering air temperature; 54 F entering/

44 F leaving cooler water; 0 0005 № • hr • °F/Btu cooler fouling

allowance.

30GB060 PART-LOAD EFFICIENCY (EXV UNITS ONLY)

BUILDING COOLING LOAD PROFILE

FAN POWER

(kW)

7.81

COOLER WATER

PRESSURE DROP

(ft water)

13.7

MINIMUM CAPACITY STEP (%)

MODEL 30GB

060 29 29

‘Includes factory-furnished unloader where applicable.

fWith field-installed accessory unloader

NOTE: See Table of Capacity Control Steps.

STANDARD UNIT‘ WITH ACCESSORY

ENERGY EFFICIENCY

RATIO

(EER)

94

EER

Capacity (Btuh)

Input Power (W)

STANDARD UNIT

UNLOADERt

(17.8) (12 1) (-6.5) (-1) (4.5) (10) (15.5) (21) (265)02.9) (37.9) (C)

OUTDOOR TEMPERATURE

1

1 I ZERO LOAD AT 0°F (-17.8 C) OPT

OUTSIDE

% SYSTEM

FULL LOAD

100

90

80

70 66 5

60 57.0

50 47.5 8.5

40 38.0 3 1

30 28 5

AMBIENT

TEMP

F

95.0

85 5 29.8 10.6

76 0 24.3 11.8

C F

35.0

19.0 13.0

13.9

-2.0

UNIT

EER

9.4

14.2

16.9

21.6 40 62.0 16 7

26.2

I 2 I ZERO LOAD AT 20 F (-6.5 C) OPT

OUTSIDE

% SYSTEM

FULL LOAD

100

90

80 80.0 26 5

70 72.5 22.3

60

50 57.5 14.0

40 50.0 10.0

30 42.5 5.9

ODT — Outdoor Temperature

NOTES:

1 Above efficiency ratings obtained at 54/44 F (12.2/6.7 C) cooler

water; full load at 95 F (35 0).

2 The longer the time operating at low temperatures, the greater the

difference in operating costs favoring a Flotronic™ unit over a

standard TXV unit

AMBIENT

TEMP

F

95 0 35.0 9.4 100

87 5 30.9 10.0

65.0 18 2

C

UNIT

EER

10.5

11.1

11 6

12.6

14.7

16.9

3 I ZERO LOAD AT 40 F (4.4 C) OPT

OUTSIDE

% SYSTEM

FULL LOAD

100

90

80

70

60 73 0

50

30 56.5

AMBIENT

TEMP

C

95 0

89 5

84 0 28.9

78 5

67.5 19 7

35.0

31.9

25.8

22 8

136

UNIT

EER

94

103

11 1

12.0

12 8

142

17.3

20.4

I 4 I ZERO LOAD AT 55 F (12.5 C) OPT

OUTSIDE

% SYSTEM

FULL LOAD

90

80

70

60

50

40

30

Contact your local Carrier representative for a computer analysis

of operating costs.

EER = Energy Efficiency Ratio

Capacity (Btuh)

Input Power (W)

AMBIENT

TEMP

F

95.0 35.0 9.4

91 0

87.0 30.6

83 0 28.3

79.0 26.1 10.9

75 0 23.9 11 2

71 0

67.0 19.3

C

32 8 9.8

21 7

UNIT

EER

10.2

10.6

12.7

14.4

Page 8

Performance data (cont)

TOTAL COOLER PRESSURE DROP (Water Side)

300-

270

240-

210

180-

ISO

120-

90-

75-

•5 60-1

a.

K

45-

o

UJ

5

(f>

UJ

30-

a.

27

24

21

18-

15-

12-

9-

80 90100

COOLER WATER FLOW (6PM)

-T—

3

7 10 15 20

COOLER WATER FLOW (L/S)

CAPACITY CONTROL STEPS

LOADING SEQUENCE A (Note 1)

UNIT 30GB060

Standard

(One Unloader)

Accessory Unloader

Added to

Compressor No. 2

‘Compressor unloaded.

NOTES:

1. The microprocessor has a random number generator that selects

loading sequence A or B, which in turn determines the com

pressor circuit that is energized first. This evens out operating

hours on each circuit over an extended period of time

CONTROL

STEPS

1 29 1

2

3 72 2

4

1

2

3

4

%

DISPLACEMENT

(Approximate)

43

100.0 2

38

66

85

100

No.

of

Compr

1

1

2

2

2

Operating

No.

of

Cyl

4

6

10

12 1 2

4

8

10

12

Compressor No.

Circuit 1 Circuit 2

1*

1

1*

1*

1*

1*

1

If unit operation is anticipated with system load below minimum

unloaded capacity of chiiler:

a. Consider using 2 smaller units in place of larger unit.

b. Increase water loop volume to ensure adequate run time (see

Application Data).

600 TOO 1000

30

LOADING SEQUENCE B (Note 1)

No.

of

Compr

—

—

2

2*

2

2

—

—

—

1

2

2

2

No.

of

Cyl

—

— — —

—

—

4

8

10

12

800

—I

-----

1—I

40 50 60

Operating

Compressor No.

Circuit 1

__ __

— —

—

1*

1

1

Circuit 2

—

2*

2*

2*

2

Page 9

Performance data (cont)

COOLING CAPACITIES - 30GB060

CONDENSER ENTERING AIR TEMPERATURE (F)

LCWT

SDT kW

113.2 63.7

114.3 65.1 145.7

121.8 74 6 187.0

125.1 78.5

40

42

44

45

46

48

50

55

60

Cap.

58.5

60 9

63 4 115.3 66.5 151.7

64.6 115.9 67.2 154.7

65.9 116.5 67.9 157.8

68.4 1176

71.1 118.8 70.8 170.4

77.9

85.2

LCWT

Cap.

40

42

44

45

46

48

50

55

60

Cap.

Flow Rate

kW

LCWT

PD

SDT

NOTES:

Ratings appiy to units with electronic or thermai expansion vaives.

1

Aii ratings are based on.

2

a. A cooler chilled water temperature rise of 10° F. When greater

b. A fouling factor of 0.0005 in the cooler,

c Refrigerant 22.

3 When a corrected LCWT is used, cooler pressure drop must also

be corrected for new LCWT :

a Enter rating tabie for corrected LCWT By interpolation,

b Calculate corrected flow rate through the cooler.

c. Enter cooier pressure drop curve at corrected fiow rate and

4. When chiiled water temperature rise is iess than 5°F, high fiow

rate will normally be accompanied by an excessive pressure drop.

In such cases, contact your Carrier representative for speciai

selection of a cooler with wider baffle spacing.

51.6 131.1

53.8

56.1

57.2 133.7

58.4

60.8 135.3

63 2

69 5

76.2

accuracy is desired, correct design LCWT, before entering

rating tabies, by reference to the LCWT correction curve.

determine corrected capacity (tons) and power input (kW) to

compressor at its rated voltage,

24 X capacity in tons

“ X X .—“US Qpm

temperature rise F

read pressure drop

SDT kW

132.1

133 2

134 2 75.1 139.9 124

136.4

139.3

142.4 87.8 183.1 20.7 —

Cooling Capacity Tons of Refrigeration

U S Gpm

Compressor Power input

Leaving Chilied Water Temperature (F)

Pressure Drop (Ft of Water)

Compressor Saturated Discharge Temperature (F)

85

Cooler

PD

Cap.

66.5

75.8

122.0 71.4

126 2

129.4 81.0

69.4

Flow

Rate

139 9 124 56 7 1177

164 0

204 6 25.6 82 9

13.4 59.1 118.7

144 61.5 119.8

15 0 62 7 120 3

15 6 64.0 120 9

16.8

18.0 69 1 123.2

21.5

CONDENSER ENTERING AIR TEMPERATURE (F)

105

Cooler

Flow

Rate

70.0 123 3

71.7 128 7

73 4 134 2

74.3 137.0

76 9 145.7 13.4

78.7

83.2

151 6 144 59 2

166 8 17.3

10.5 50 2

11 4 52.4

11 9 53 5

Cap. SDT

PD

9.7 48.1

140.0

141.0

142.0

54 6

56 9 144.1

142.5

143.1 78.2

145.2

— — —

LEGEND

SDT

— —

90

Cooler

kW

65.4

66.9 141.4

68.4 147.2

69.1 150.2

69 9 153 2 14.7 62.1

72 9 165.7 17 1

76 9 182.0

Flow

Rate

135.6 11 7 55 0 122.1

159 4 15.9

199 3

Cap.

PD

12.6 57.3 123 2 68.6 137.1

13.6 59.7 124.2 70.1

14.2 60.9 124 8

64 6 126.5 73.3 154 8 15.0

20 5 73.8 130.6 79.1 177 0 19.4

24.3 80.7 133 8

67.1 127 6

115

Cooler

kW

72 6 114.9 8.5

74 4 120.1 92

76.3 125 4

77.3 128 1 10.5

80.1 136.3

82.1 142.0 12.7

Flow

Rate

PD

10 0

130 8 10.9

11 8

—

— —

—

95

Cooler

SDT

125.3 71 7 148.7 13.9

kW

Flow

Rate

131 5

67.0

142 9 129

70.9 145 8

161.0

74.9

83 4

193.9 23.1

PD

11.0

11.9

13 4

16 2

5 lO i5 20

COOLER CHILLED WATER TEMPERATURE RISE (F)

Above 10F, ADD correction to design LCWT, below 10 F, SUBTRACT

Page 10

Dimensions

DIMENSIONS

DIM.

A

B

C

D

E

F

G

H

J

ft-in.

(mm)

UNIT

30GB060

13-7%

(4162)

11-3

(3429)

12-5%

(3797)

10-0%

(3061 )

5-8%2

(1730)

5-3%

(1619)

4-6%

(1387)

7-6

(2286)

5-0

(1524)

TOP VIEW

'AMER. STD.

ST PIPE THO.

4"-(070 UNIT)

COOLER END VIEW

Space for service and airflow.

Mounting weights (approximate) lb

WEIGHT DISTRIBUTION

SUPPORT UNIT

POINTS

1

2 1528

3 922

4 872

30GB060

1578

SIDE VIEW

10

Page 11

Electrical data ~ 60 Hz

UNIT

460

575

Volts

Supplied*

Min Max

187 254

414

518 632

MCA

508 155

342

128

MORA

(Fuse)

500 846 119

225 415 53 73

125

30GB

Nameplate

060

NOTE: As shipped, all units are XL (across the line) start.

•Units are suitable for use on electrical systems where voltage

supplied to the unit terminals is not below or above the listed

minimum and maximum limits.

f30GB060 has 2 compressors.

jaOGBOeO has one FOB for all fans.

GENERAL ELECTRICAL NOTES:

1 Unit listings are:

UL — Underwriters Laboratories: 30GB060

2. Electrical data based on unit conforming to ARl Standard 590,

Section 8.1. Maximum Loading Conditions (115 F ambient at

-10% voltage)

3. All units have single-location power connection to simplify fieldpower wiring Main power must be supplied from a field-supplied

fused disconnect. Unit must be properly grounded.

4. Control circuit power must be supplied from a separate source

through a field-supplied fused disconnect. (See Note 9.)

5. Crankcase and cooler heaters are wired into the control circuit

so they are always operable as long as the control circuit power

supply disconnect is on, even if any safety device is open or the

unit CN/CFF switch is off.

208-230

ICF

335

RLA (ea)

45 59

COMPRESSORSt

Compressor No.

2

1

158.5 506 690

6. Heaters are wired ahead of the control circuit fuse; thus, they are

7. Cn all voltages, 30GB060 has one terminal block, with 3 con

8. Maximum incoming wire size for each terminal block is 500 MCM.

9. Amperage required for control circuit is as follows:

10. Power draw of control circuits includes both crankcase heaters

LRA (ea)

1

253 345

176 276

protected by the overcurrent protective device in the control

circuit power supply.

ductors from the fused disconnect.

UNIT

30GB

060

and cooler heaters Each compressor has a crankcase heater

that draws 200 watts of power

Cooler heaters: 060 - 360 watts — band heaters (360 watts total).

Total MTA

CB h O.

2 1

166 222 6 (1)

73 90 6 (1)

63 82 6(1)

POWER

SUPPLY

208/230-3-60

460-3-60

575-3-60

2

Total

Fans

(Ph)

FAN MOTORS*

FLA (ea)

Fan No.

3,4,5,6

1,2

4.6 7 7

2.3 3.3

1.8 2.6

CONTROL

CIRCUIT

Power

115-1-60

115-1-60

115-1-60

MTA

(FCB)

Amps

15

15

15

35

18

14

Controls

Microprocessor — Microprocessor controls overall

unit operation. Its central executive routine controls a

number of processes simultaneously. These include

internal timers, reading inputs, A to D conversions, fan

control, display control, diagnostic control, output relay

control, demand limit, capacity control, head pressure

control and temperature reset. Some processes are

updated almost continuously, others every 2 to 3 seconds,

and some every 30 seconds.

The microprocessor routine is started by switching

control circuit ON-OFF circuit breaker switch to ON.

(This switch is also used to reset microprocessor should

any safety trip and also functions as circuit breaker for

electronic processor and relay boards.)

When the switch is closed, a 2-minute initialization

routine is begun. During this time, inputs are checked,

EXV and internal constants are initialized and a 20

appears on display. If display button is pushed during this

period, control goes into a 42-step Quick Test routine,

normally used for a readiness check during start-up, or

for service.

Microprocessor controls capacity of chiller by cycling

compressors and unloaders on and off at a rate to satisfy

actual dynamic load conditions. Control will maintain

leaving water temperature set with dial on display board

through intelligent cycling of compressors. Accuracy will

depend on loop volume, loop flow rate, load, outside air

temperature, number of stages, and particular stage

being cycled off. No adjustment for cooling range or

cooler flow rate is required, because the control auto

matically compensates for cooling range by measuring

both return water temperature and leaving water

temperature. This is referred to as leaving water tem

perature control with return water temperature

compensation.

The basic logic for determining when to add or remove

a stage is a time band integration of deviation from set

point plus rate of change of leaving water temperature.

When leaving water temperature is close to set point and

slowly moving closer, logic prevents addition of another

stage. If leaving water temperature is less than 35 F

(1.7 C) for water, or 6°F (21°C) below the set point for

brine units, the unit is shut off until the water tempera

ture goes 6°F (3.3°C) above the set point, to protect

against freezing.

If l°F/minute (0.6°C/minute) pulldown control has

been selected (factory setting), no additional steps of

capacity will be added as long as difference between

leaving water temperature and set point is greater than

4°F (2.2°C) and rate of change in leaving water tempera

ture is less than l°F/minute (0.6°C/minute).

If it has been less than 90 seconds since the last capacity

change, compressors will continue to run unless a safety

trips. This prevents rapid cycling and also helps return oil

during short on periods.

Where available (requires accessory unloaders on some

units), 2 sequences are used to obtain circuit lead-lag

operation, which evens out compressor operating hours.

First, as unit turns on, microprocessor functioning as a

random number generator, determines which circuit will

start first. Also, when decreasing from maximum stage,

control will again randomly select which circuit to run

longest.

The control also performs other special functions

when turning on or off. When a circuit is to be turned off,

EXV is closed first and compressor is run for an additional

10 seconds to pump out refrigerant that was in the cooler.

Again, at start-up, if compressor hasn’t run in the last

15 minutes, EXV is held closed for 10 seconds while

11

Page 12

Controls (cont)

compressor runs to pump out any refrigerant that has

migrated to the cooler. The oil pressure switch is bypassed

for one minute during start-up and for 45 seconds during

normal operation.

Thermistors — Eight thermistors are used for tempera

ture sensing inputs to microprocessor. (A ninth [TIO]

may be used as a remote temperature sensor for optional

LCWT reset.)

T1 Cooler leaving chilled water temperature

T2 Cooler entering water (return temperature)

T3 Saturated condensing temperature — Circuit #1

T4 Saturated condensing temperature — Circuit #2

T5 Cooler saturation temperature — Circuit #1

T6 Cooler saturation temperature — Circuit #2

T7 Return gas temperature entering compressor

cylinder — Circuit #1

T8 Return gas temperature entering compressor

cylinder — Circuit #2

TIO Remote temperature sensor (accessory)

The microprocessor uses these temperatures to control

capacity, fan cycling and electronic expansion valve

(EXV) operation.

Electronic expansion valve (EXV) — To control flow

of refrigerant for different operating conditions, EXV

piston moves up and down over slot orifices through which

refrigerant flows to modulate size of opening. Piston is

moved by a stepper motor through 760 discrete steps. The

piston is repositioned by microprocessor every 3 seconds.

The EXV is used to control superheat in compressor.

Two thermistors in each circuit (T5 and T7/T6 and T8) are

used to determine superheat. One thermistor (T5/T6) is

located in cooler and other (T7/T8) in compressor after

motor in the gas passage entering the cylinders. The EXV

is controlled to maintain superheat entering pistons at

approximately 15 F (8.3 C) to20F (11.1 C), which results

in slightly superheated refrigerant leaving cooler.

Both on shutdown and start-up, unless compressor has

run in last 15 minutes, compressor runs for 10 seconds,

while EXV is closed and removes refrigerant from cooler.

These pumpout cycles minimize amount of excess

refrigerant that can go to compressor on start-up and cause

oil dilution which would result in eventual bearing wear.

The microprocessor software is programmed so that

EXV functions as an MOP. (maximum operating pressure)

valve, limiting the suction temperatures to 55 F (12.8 C).

This makes it possible to start unit at high water tempera

tures, up to 95 F (35 C), without overloading compressor.

Another feature that is factory set (which may be eliminated

in the field by repositioning a dip switch on the micro

processor) limits rate of pulldown to 1°F (0.6°C) per minute

thereby reducing the kW demand on start-up.

Accessory controls — Demand can be further limited

by keeping a selected number of compressors from

turning on by utilizing demand limit control accessory.

This interfaces with microprocessor to control unit so

that chiller’s kW demand does not exceed its setting.

It is activated from an external switch.

Microprocessor is programmed to accept various

accessory temperature reset options, based on return

water temperature, outdoor temperature, or space

temperature, that reset the LCWT. An accessory

thermistor (TIO, above) is required if outdoor tempera

ture or space temperature reset is elected.

Compressor protection and control system (CPCS)

(30GB060) — Compressor protection boards are used

to control and protect compressors. One board is used

for each compressor to control compressor contactor(s)

and crankcase heater(s) in response to a command from

microprocessor. The board also provides compressor

ground current protection, shutting off compressor if a

2 to 3 ampere ground current is sensed by a toroid around

the compressor power leads. A high-pressure protector

and a discharge gas temperature protector are connected

in series with CPCS board, so that if they open, compressor

stops. Microprocessor senses this through feedback

switch input.

The CPCS control system is available as an accessory

on 30GB060. The 30GB060 unit is factory equipped with

a control relay that operates same as CPCS except that

ground current refrigerant circuit protection is not

provided.

Complete electronic control system contains several

additional components.

Relay board — Relay board, connected to microprocessor

by a ribbon cable, drives all of 24-v, 115-v, or 230-v loads.

Relays control compressors, fans, and unloaders, if used.

Display board — Display board, also connected to

microprocessor by a ribbon cable, is used to communicate

with operator. In addition to leaving water set point

potentiometer, board contains 2-digit LED display. The

LED display is normally off after initialization period,

to extend its life. Pressing display button will result in

LED displaying the appropriate overload or status code.

If this is done, display will show from one to 3 codes

alternating every 2 seconds, as follows:

CODE

1. 0-12

STATUS

Capacity stage

Number of stages in operation

2. 20-24

20

21

22

24

3. 51-87

Operating Mode

Initialization

Temperature Reset

Demand Limit

Pulldown Control

Overload Codes

Alarm light/circuit energized.

NOTE: These codes take priority.

51-58

59,60

61

63,64

65

70

71-80

81-87

Compressor fault

Loss of charge (circuit 1, circuit 2)

Low water flow

Low oil pressure (circuit 1, circuit 2)

Low water temperature

Illegal configuration

Thermistor failure

Reset/Set Point/Limit Failure

These codes are summarized on a chart in each unit’s

control box, and are described in detail in the Controls

and Troubleshooting book.

12

Page 13

Control sequence

Off cycle — During unit off cycle, crankcase and, if

ambient temperature is below 36 F (2 C), cooler and

control box heaters are energized. Electronic expansion

valves are closed.

Start-up — After control circuit ON/OFF circuit breaker

switched ON, prestart process takes place for 2 minutes,

when microprocessor checks itself and waits for tem

perature to stabilize. First circuit to start may be no. 1 or 2,

(automatic lead/lag feature). The controlled pull down

feature limits compressor loading on start-up to reduce

demand on start-up and unnecessary compressor usage.

The microprocessor limits supply water temperature

decrease (start-up only) to 1°F (0.6 C) per minute.

Capacity control — On first call for cooling, micro

processor starts initial compressor and fan stage on lead

circuit. The electronic expansion valve remains closed

for 10 seconds, permitting a pumpout on start-up. After

pumpout, the valves open and, if necessary, additional

outdoor fans are energized. Crankcase heaters are de

energized when a compressor is started. As additional

cooling is required, lag circuit starts. If further cooling is

needed, compressors are added, alternating between

lead and lag circuits. Speed at which capacity is added or

decreased is controlled by temperature deviation from

set point and rate of temperature change of chilled water.

As less cooling is required, circuits shut down (or

unload) in an order that evens out each circuit’s com

pressor run time. When no further cooling is called for

On each compressor circuit), expansion valve closes and

compressor and fans continue to run while pumping

down cooler.

Low-temperature override feature prevents LCWT

from overshooting the set point and possibly causing a

nuisance trip-out by the freeze protection.

High-temperature override feature allows chiller to

add capacity quickly during rapid load variations.

Demand limit — If applied, unit step controls limit

total power draw of unit to selected point by controlling

number of operational compressors during periods of

peak electrical demand or time clock shutdown. Consult

Accessory Demand Limit Control Module Installation

Instructions for further details.

Reset accessory — If applied, microprocessor compares

either return water, space or outdoor temperature with

the accessory board settings, and adjusts leaving chilled

water temperature appropriately.

Electronic expansion valve and outdoor fan control —

Expansion valve opens and closes on signal from micro

processor to maintain an approximate 20 F (11C)

refrigerant superheat entering the compressor cylinders.

(The compressor motor increases the refrigerant super

heat from the approximate 5 F [3 C] leaving the cooler to

that entering the cylinders.) Outdoor fans (operated by

microprocessor) run to as low an ambient as possible to

maintain a minimum expansion valve pressure differential.

Abnormal conditions (alarm light) — All control safeties

in chiller operate through compressor protection board

or control relay and microprocessor. High-pressure switch

and discharge gas thermostat directly shuts down

compressor(s) through compressor protection board or

control relay. For other safeties, microprocessor (1) makes

appropriate decision to shut down a compressor due to

a safety trip or bad sensor reading (2) energizes alarm light

and (3) displays appropriate failure code on the display.

Chiller holds in safety mode until reset. It then reverts to

normal control when unit is reset.

Safeties include: Oil-pressure switch cuts out if pressure

differential is below minimum. Switch is bypassed on

start-up for 45 seconds. Loss-of-charge switch cuts out if

system pressure drops below minimum. High-pressure

switch cuts out compressors if compressor discharge

pressure increases to 395 psig (2724 kPa). Discharge gas

thermostat opens when discharge gas temperature

exceeds maximum 295 F (146 C). Ground current safety

opens on sensing a current-to-ground in compressor

windings in excess of 2.5 amps. Loss of flow protection

provided by temperature differences between entering

and leaving water temperature sensors. Flow switch is

not required. Freeze-up protection provided by leaving

water temperature sensor if cooler temperature drops

to 35 F (1.8 C). Sensor failures are detected by the

microprocessor.

Diagnostics — Microprocessor may be put through

Quick Test (see Controls and Troubleshooting book)

without additional equipment or tools. Quick Test

confirms microprocessor is functional, informs observer

through LED display the condition of each sensor and

switch in chiller, and allows observer to check for proper

operation of fans and compressor(s).

13

Page 14

Typical installation

NOTES:

1. Wiring and piping shown are generai points-of-connection

guides oniy and are not intended for or to include all details for a

specific installation.

AIRFLOW THROUGH

AIR-HANDLING UNIT

CONTROL WIRING

CHILLED WATER PIPING

ST - STARTER

FD - FUSED DISCONNECT

2. All wiring must comply with applicable local and national codes

3 All piping must follow standard piping techniques. Refer to

Carrier System Design Manual for details.

#

14

Page 15

Guide specifications

1. GENERAL

1.1 Furnish and install complete, factory-assembled

air-cooled reciprocating liquid chiller units of the

type, size and capacity shown on the equipment

schedules. Unit shall be for outdoor use and rated

in accordance with ARI Standard 590 latest edition.

1.2 Equipment schedules and specifications are based

on Carrier Model 30GB060.

1.3 Reciprocating liquid chillers specified in this section

are of the air-cooled single-piece unit packaged type.

1.4 Units shall be of the packaged air-cooled type as

shown on the drawings and consist of a reciprocating

compressor or multiples thereof, direct-expansion

liquid cooler, air-cooled condenser and factory

wiring and piping contained within the unit en

closure. Unit shall contain a complete operating

charge of refrigerant R-22.

1.5 Unit shall contain factory-installed diagnostic

system, capable of indicating status of all safeties

and energizing remote alarm.

1.6 Unit construction shall comply with ANSI B9.1

safety code, NEC (National Electrical Code) and

ASME Code.

1.7 Unit shall be capable of starting with up to 95 F

(35C) entering water temperature to the cooler.

1.8 Unit shall control leaving water temperature

±

_____

^F (

____

^C) from design point.

1.9 Unit shall be listed with UL.

2. UNIT CASING

2.1 Unit shall be enclosed in a galvanized steel casing,

zinc phosphatized, and coated with a baked enamel

finish, capable of withstanding Federal Test Method

Standard No. 141 (Method 6061) 500-hour salt

spray test.

3. COMPRESSOR

3.1 Each compressor shall be of the reciprocating

serviceable hermetic type only, and shall be

equipped with an automatically reversible oil pump,

operating oil charge, suction and discharge shutoff

valves, and shall be factory mounted on spring

vibration isolators.

3.2 Compressor motor shall be cooled by suction gas

passing around motor winding and shall be thermally

protected. Manual restart shall be required after

stoppage due to thermal and pressure overload.

3.3 Each compressor shall be equipped with an insert

type crankcase heater factory sized to control oil

dilution during shutdown.

3.4 Compressor speed shall not exceed 1750 rpm

(29.2 rps).

4. COOLER

4.1 Cooler shall be shell-and-tube type, with removable

heads. Seamless copper tubes shall be rolled into

tube sheets.

4.2 Cooler shall be tested and stamped in accordance

with ASME code for refrigerant side working

pressure of 235psig (1620 kPa) and a minimum

water side working pressure of 150 psig (1034 kPa).

4.3 Shell shall be insulated with a minimum of 3/4-in.

(19-mm) closed cell polyvinyl chloride (PVC) foam

insulation of maximum K factor 0.28. Heaters along

the shell, under the insulation, shall protect cooler

against freeze-up down to 10 F (-12 C).

4.4 Cooler shall have 2 independent direct-expansion

refrigerant circuits for all models.

5. CONDENSER

5.1 Air-cooled condenser coils shall have aluminum

(copper) fins mechanically bonded to seamless

copper tubes, cleaned, dehydrated, sealed, leak

tested at 150 psig (1034 kPa) and pressure tested

at 450 psig (3103 kPa).

5.2 Condenser fans shall be propeller type with PVCcoated steel wire safety guards, balanced statically

and dynamically and discharge vertically.

5.3 Condenser fan motors shall have inherent over

current protection.

6. REFRIGERANT COMPONENTS

6.1 Refrigerant circuit components shall include hot-gas

muffler, high side pressure relief device, liquid-line

shutoff valve, replaceable-core filter drier, moisture

indicating sight glass, and stepper motor actuated

electronic expansion valve (or thermal expansion

valve).

6.2 Expansion valves shall have maximum operating

pressure characteristics to limit inlet suction

pressure.

6.3 If unloaders are to be used, they shall be electrically

actuated suction cutoff cylinder unloaders.

6.4 For 30GB060 units, gages are available as

accessories.

7. CHILLER CONTROLS

7.1 Unit controls, including microprocessor, shall be

factory mounted and wired in a weatherproof

enclosure with hinged access doors for easy access.

Unit shall have automatic lead-lag available with

accessory unloader package. All units shall have

pumpdown at beginning and end of every circuit

cooling cycle, loss-of-charge protection, inherent

low water flow protection, low chilled water tem

perature safety, low- and high-suction superheat

protection for each circuit. Low oil pressure

protection for each circuit, individual solid-state

compressor protection board and ground current

protection for each compressor are accessories

for 30GB060. Unit shall have low control voltage

to unit, field power and control circuit terminal

blocks, compressor and fan motor circuit breakers,

control circuit breaker, ON/OFF switch, replace

able relay board, leaving chilled water set point

board, and a diagnostic digital display module, a

microprocessor board, a temperature reset board

(accessory).

7.2 Unit shall control capacity based upon leaving

water temperature and will be compensated by

return water temperature.

7.3 Capaciti! control — Chillers shall have no less

than 4 steps of control.

15

Page 16

Guide specifications (cont)

7.4 Electronic ground current sensing device shall be

available as accessory for each compressor to

monitor the compressor 3-phase power supply. It

shall be activated when no more than 2.5 amps is

measured to ground and shall deactivate the

compressor to prevent formation of compressor

contaminants.

8. ELECTRICAL REQUIREMENTS

8.1 Unit primary electrical power supply shall be

connected at a single location on unit.

8.2 Unit shall be capable of operation on.

3-phase, 60 cycle supply. Control voltage shall be

provided by a separate single-phase power supply

_______

V. The unit (LRA) ICF shall not exceed

_____

amps.

8.3 Each compressor motor shall be operated and

protected against electrical overload by means of

definite-purpose contactors and calibrated, ambient-

compensated, magnetic-trip circuit breakers. The

circuit breakers shall open all 3 phases in the event

of overload in any one phase, single phasing or

phase reversal and shall be manually reset.

8.4 Electrical requirements for unit for sizing of wiring

and overcurrent protection devices shall be selected

to allow unit operation at ARI Standard 590, Section

8.1. Maximum Loading Conditions (115 F ambient

temperature at 10% under voltage).

9. WARRANTY

9.1 The manufacturer shall provide a one-year parts

warranty on the compressors (with optional 4-year

extension) and a one-year parts warranty on other

unit components.

. volt,

Specifiers note — Application of 30GB outdoor chillers

for brine duty within the 39.9 F to 34 F (4.4 C to 1°C)

range is possible with proper field change of control

configuration. Application in the range 34 F to 15 F (1°C to

-9.4 C) requires 30GB unit with factory modification.

Carrier Corporation • Syracuse, New York 13221

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs

Book|2 Form 30GB-1APD Printed in U S.A PC 111 Catalog No 523-002

Tab Isc

without notice and without incurring obligations.

2-87

UNITED

TECHNOLOGIES

CARRIER

Loading...

Loading...