Carrier 19 User Manual

Carrier

A Packaged Hermetic

Centrifugal

Liquid Chillers

19

Series

100-2000 tons

(352-7034 kW)

■ ■ I

On stream, on budget with energy-saving

solutions to comfort air conditioning

and process cooling challenges!

© Carrier Corporation 1979

Form 1 9-2P

The 19 Series: Built to save energy, save you money and get the job done right

Dr. Willis Carrier invented centrifugal refrigeration in 1922

and today, more than half a century and 25,000 machines

later. Carrier hermetic centrifugal liquid chillers still lead

the way in comfort air conditioning and process cooling.

What’s more, the modern day 19 Series centrifugals are

specifically designed to afford significant dollar savings on

utility bills, in every way possible.

The Carrier 19 Series centrifugal design philosophy has

always been to offer a variable line which meets each unique

specification while at the same time maintaining low first

costs and low operating costs. Incorporated in this

philosophy are such features as the 19 Series inline

impeller design, hermetically sealed compressor-motors,

gear drives and refrigerant options. The success of this

concept can be seen in the 25,000 plus machines which

have been applied to date.

Carrier’s hermetic centrifugals have always used various

refrigerants at different tonnage ranges in order to keep

the heat exchanger size and cost down. Now, over and

above the low first cost concept, Carrier offers refrigerant

options to meet your specific job requirements in the most

efficient way possible.

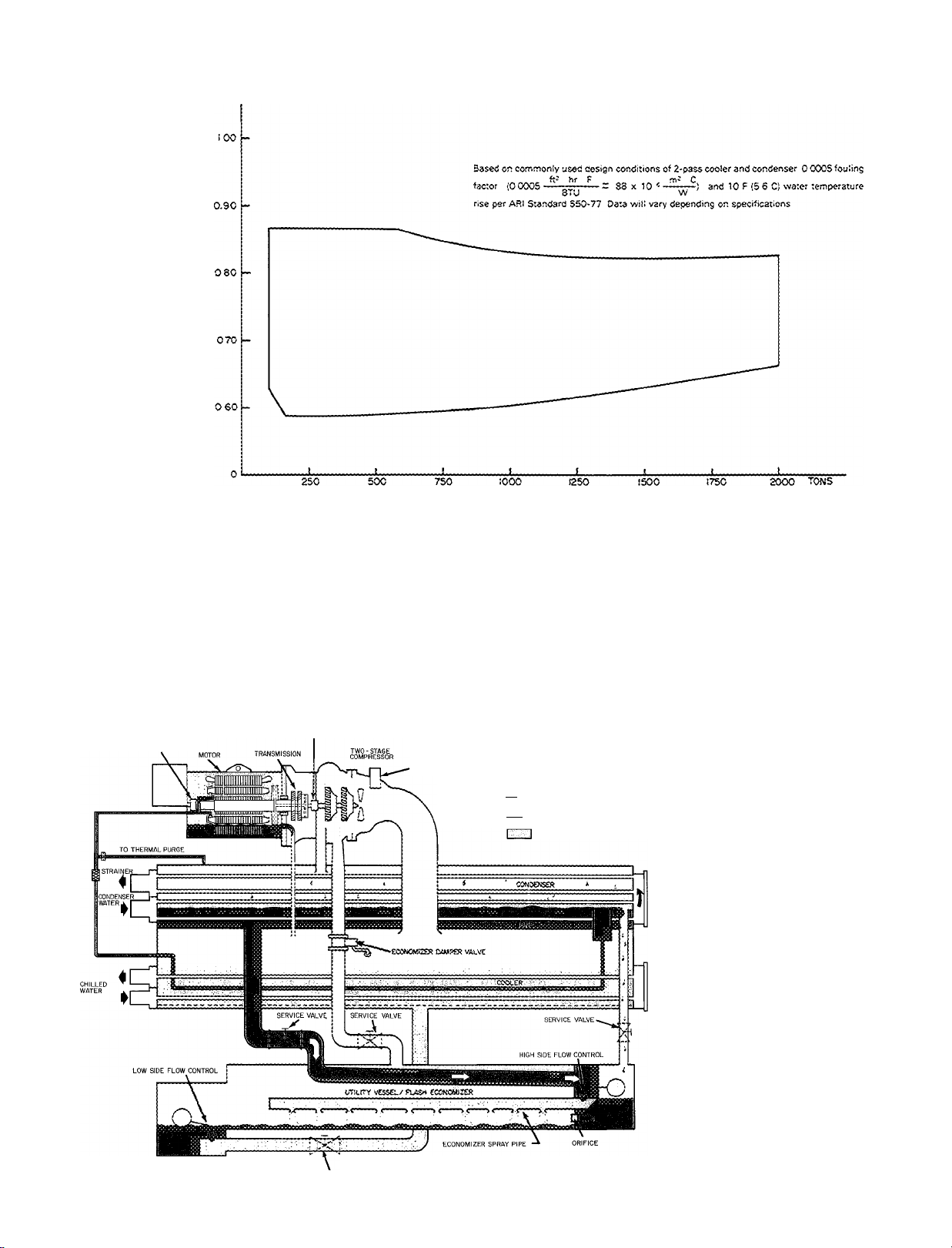

Tbe full hermetic line consists of four models, each with

a cycle, refrigerant and tonnage range specifically matched

to your application demands. From 100 tons (352 kW) to

2,000 tons (7034 kW), the Carrier hermetic centrifugals are

capable of performance at levels of .85 KW/Ton (3.0 KW/

kW) to .65 KW/Ton (2.3 KW/kW) and lower, depending on

design conditions. With features such as mix-match capa

bility, high performance heat exchangers, refrigerant

options, multi-pass water boxes as well as tbe 19 Series her

metic compressor designs, a Carrier centrifugal can be opti

mized to meet any job requirement. The “Low Energy Con

sumption Curve” illustrates performance levels possible

within the tonnage capabilities of the 19 Series hermetic line.

You get the most efficient, most reliable, energy-conscious

and completely packaged machine for your particular appli

cation. The hi-lift capabilities (up to 100 F) make the 19

line ideally suited for brine chilling, ice rink applications

and process cooling. In areas with cooling tower restric

tions, you can even specify a hi-lift Carrier centrifugal for

use with closed circuit water condensing systems. The

versatile Carrier centrifugals are also designed for low-lift

requirements of today’s energy-conscious market.

Not only can Carrier Sales Engineers optimize your

refrigeration requirements but they can optimize your total

system as well. Thru various specialized computer pro

grams, for example, a Carrier Sales Engineer can vary your

leaving chilled water temperature a degree or increase your

chilled water temperature differential from 10 to 14 F and

show how the total system is affected with respect to

operating costs. In this complex market of low energy con

sumption as well as low first cost, Carrier can offer you

productive ways to reduce your costs.

Energy-saving, precision

design: extends compressor

motor life, saves on

operating costs, increases

electrical efficiency

• Hermetic design

• Gear-drive compressors

• In-line impeller design

• Refrigerant-cooled motors

• Solid state capacity control

• Thermal purge

• 55 F (13 C) condenser water

• Flash and thermal economizer

• Multi-pass water boxes

• Compressor-motor-heat exchanger mix-match

Engineering excellence

provides lower first costs

and years of trouble-free

service

• Single-unit construction

• Factory-wired oil pump starter

• Permanent shipping bases

• Prepiped motor lubrication package

• Storage tank

• Factory start-up

• Integral chilled water sensor

• Elapsed-time indicator

Carrier’s computer approach to matching the machine

and capacity to a specific application gives you access to

literally thousands of condenser, compressor, cooler,

refrigerant and pass combinations. Initial costs arc lower

because you select only what you need — a smaller

package. Operating costs are reduced because the mix

matching of components allows lower energy consumption

selections. In addition, a Carrier Sales Engineer has the

ability to optimize selections, by varying conditions, thru

the use of the Performance Programs. Should your job

requirements demand performance other than what is

shown in this catalog, contact your Carrier Sales Engineer

(refer to page 50 for the office nearest you). Thru com

puterized selection he will be able to design your “custom

built” hermetic centrifugal.

D

Computer selection saves

time, cuts costs

Full line centrifugal service

centers assure optimal care

of your unit

Convenience options offered

for added energy efficiency,

‘tailor-made’ systems

s

g

U.

(T

UI

a

KWAW KW/TON

f 2SÎ U

( 36;

■: 24;

22;

20) '

s 18'

( 16) [—

"Carrier Offers Low Energy-Consumptiors Selections"

Î^OCO) )20C0)

riOOO) (400C)

CAPACITY

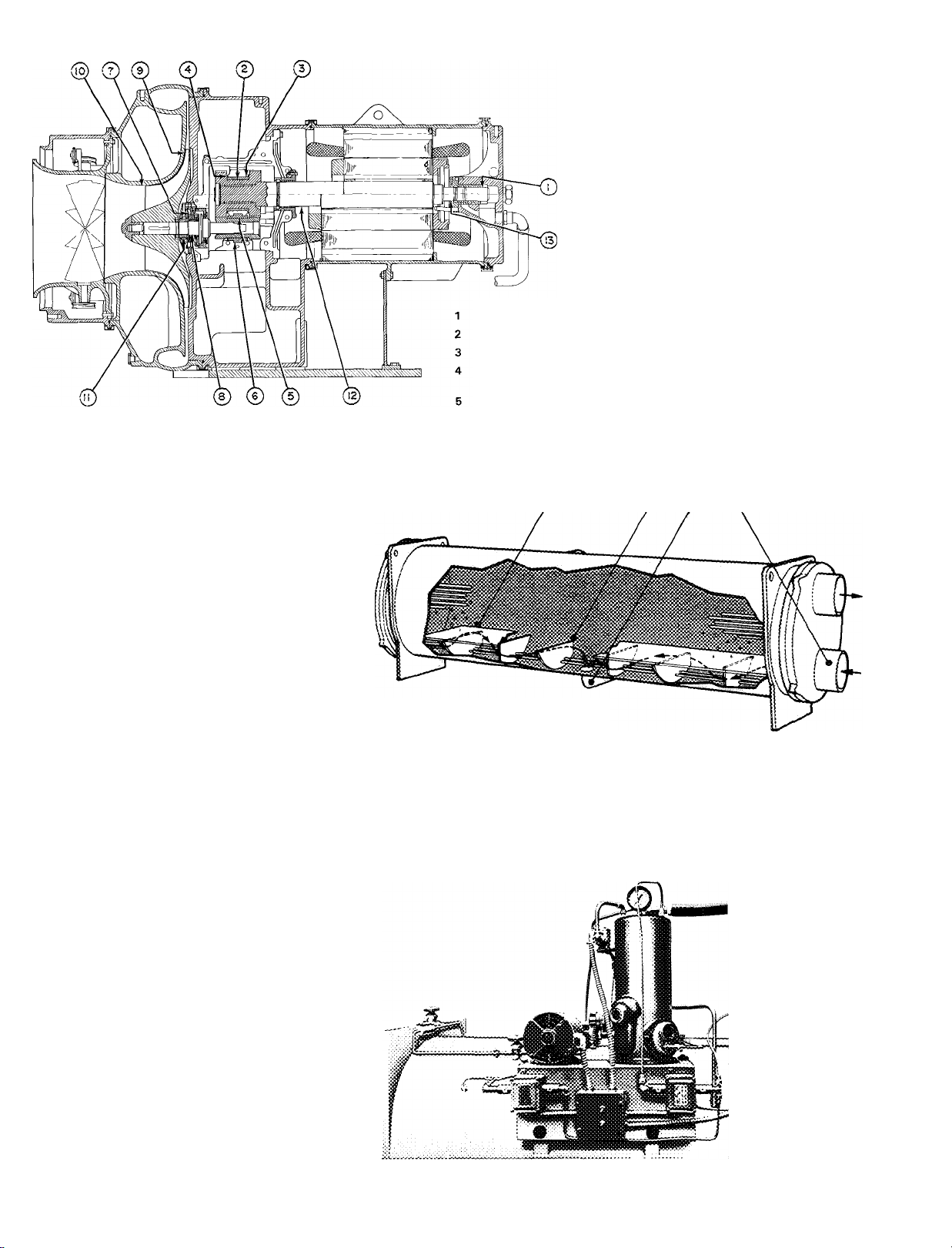

19 Series Centrifugals —

The ideal refrigeration cycle

BEARING AND SEAL

BEARING AND SEAL

VANE MOTOR

i I REFRIGERANT VAPOR

tliiSfel REFRIGERANT LIQUID

SERVICE VALVE

{5COC)

REFRIGERANT LIQUID/VAPOR

•SOCO)

^7000) kW

Carrier centrifugals use refrigerant

(R-11, 114, 12 or 500) in a standard

compression, single- or two-stage

refrigeration cycle. System water in

the cooler is chilled as its heat is

transferred to refrigerant at low tem

perature and pressure. As heat is re

moved from the water, the refrig

erant vaporizes and is drawn into the

compressor at a rate controlled by

the degree of the guide vane opening.

As the compressor raises the vapor

pressure, the saturation temperature

of the refrigerant rises above that of

the condenser water. Refrigerant

vapor is discharged directly into the

condenser, where relatively cool

condenser water removes heat from

the vapor, causing it to condense

again to liquid. The heated water

leaves the system, returning to a

cooling tower or other heat rejection

device. The liquefied refrigerant then

leaves the condenser, draining into

a chamber where a variable metering

device regulates refrigerant flow and

maintains a liquid seal to prevept

vapor from passing into the cooler.

As the refrigerant liquid goes thru

this metering device, part of it vapor

izes because of reduced pressure,

cooling the remaining liquid to the

temperature at which the cycle

began.

Energy-saving, precision design: extends compressor motor life, saves on operating costs, increases electrical efficiency

Hermetic design

Hermetic compressor design keeps

motor free of airborne dirf and mois

ture. It also isolates motor to keep heat

and sound from equipment room.

Eliminates shaft seal with its potential

refrigerant leakage.

■ Gear driven compressors

Gear driven compressors allow more

flexibility in selection than direct drive

because gear ratios can be fitted to

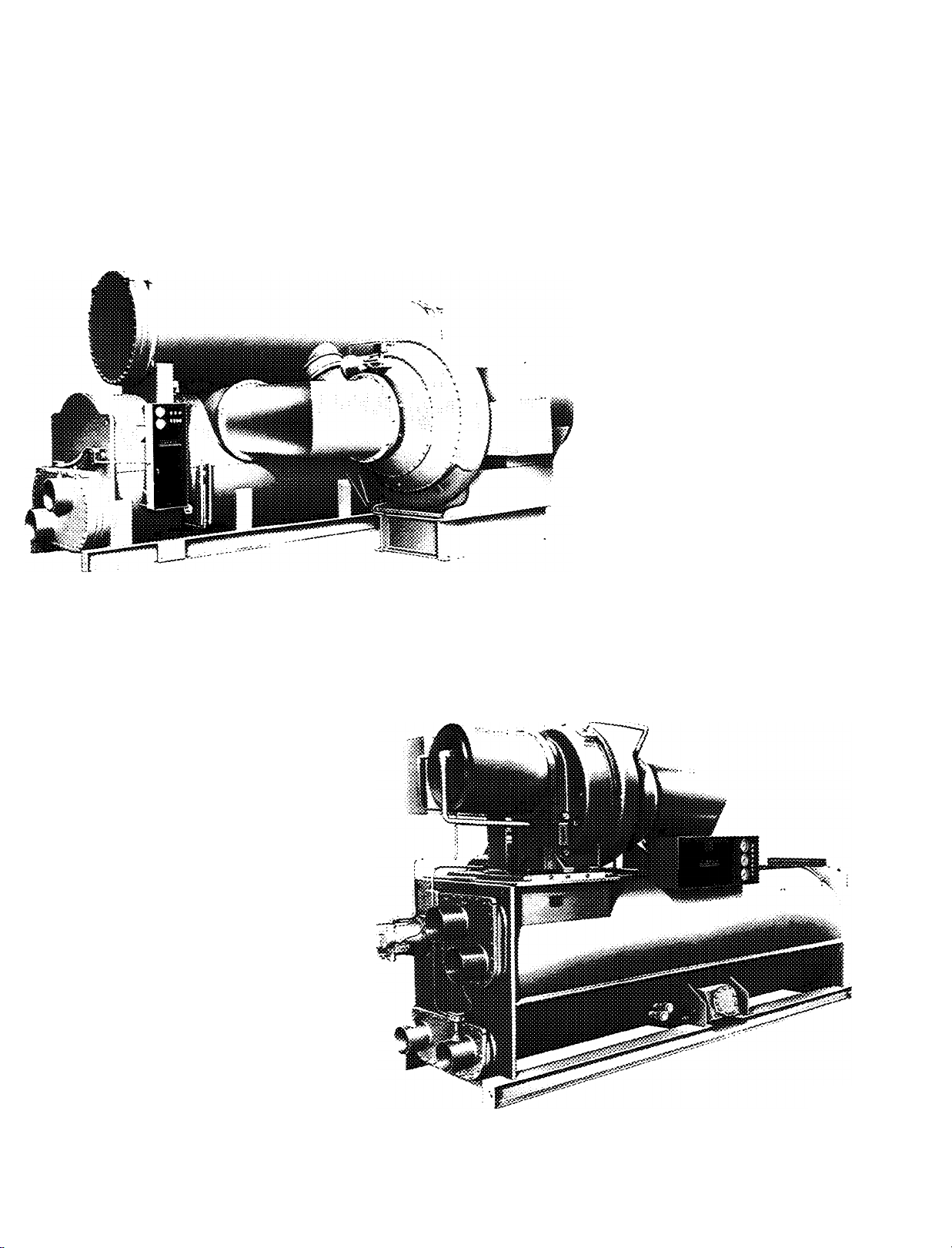

19CB

particular application. Gear driven

compressors also allow optimum im

peller speed, higher head applications

and increased operating efficiency.

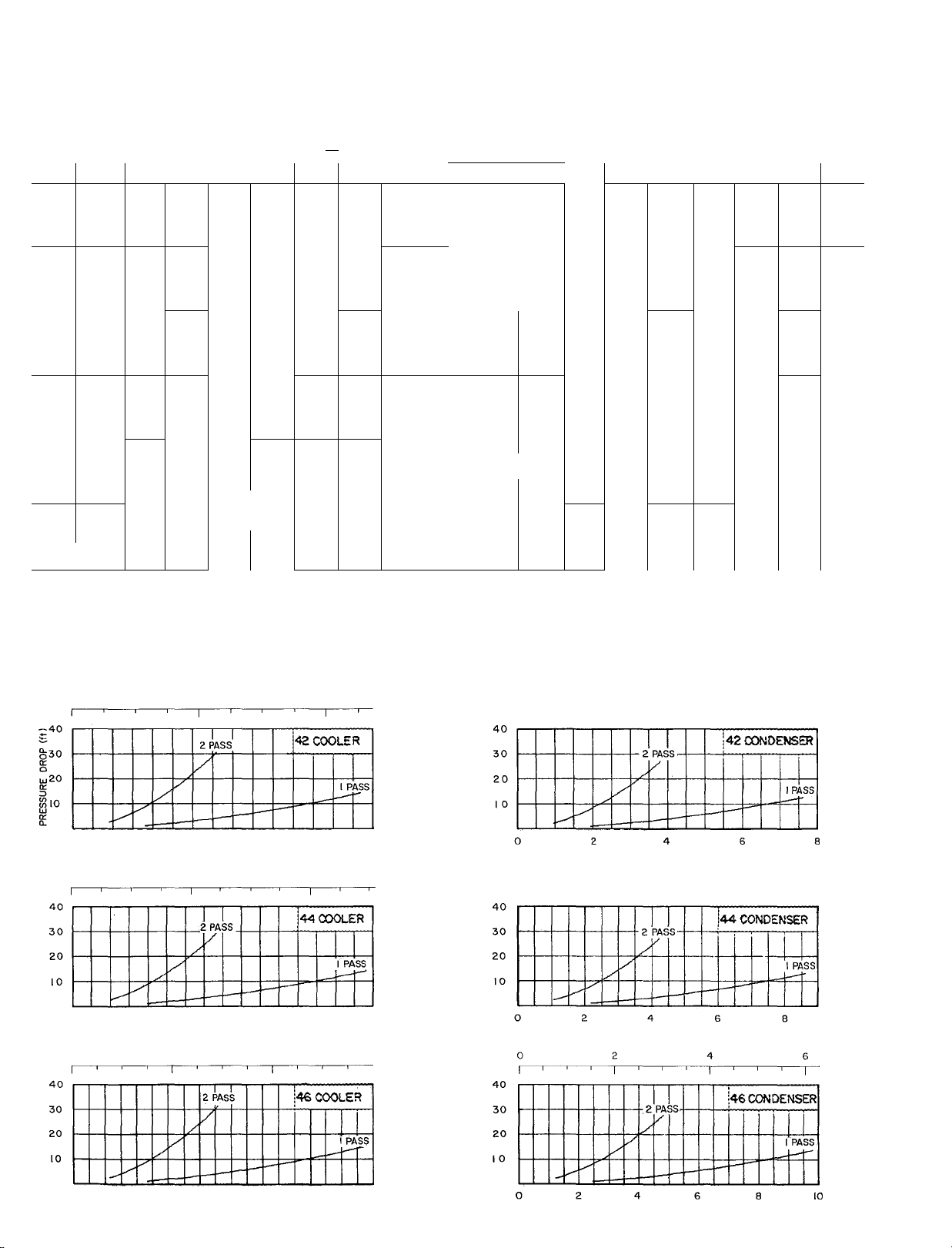

Multi-pass water boxes

The complete 19 Series line offers 1,2,3

and 4 pass water boxes on both the

coolers and condensers. The result is

better heat transfer when needed —

reducing operafing costs. In addition,

all pass arrangements are available at

no extra cost.

Refrigerant-cooled motor

All 19 Series compressors have

refrigerant-cooled motors that operate

at low, even temperatures throughout

the motor windings to insure long motor

life at high electrical efficiency.

19DH

Solid state capacity control

The capacity control module offers

solid state compactness and reliability,

with smooth and precise capacity mod

ulation from 100% to 10% of full load,

without hot gas bypass. It is more

efficient in maintaining leaving water

temperatures than any other type of

control. The convenient, centrally

located control center provides fully

automatic machine operation, com

plete with a full complement of safety

interlocks. Check operating status at a

glance, easily monitor all system oper

ating points. The highly sensitive,

factory-installed thermistor probe, solid

state amplifier, and guide vane actuator

are precisely matched and fully re

sponsive to changes in leaving chilled

water temperature. They help to main

tain your selected design temperature

throughout all operating load condi

tions. The result is efficient, trouble-free

operation with longer life expectancy.

All control connections can be made

quickly to a single terminal strip; and

once the solid state control has been

19EB

19FA

calibrated, control settings may be

changed without additional field

calibration.

55 F (13 C) condenser water

The Carrier metered refrigerant design

allows the 19 Series chillers to operate

efficiently with condenser water tem

perature as low as 55 F (13 C) without

condenser water bypass or mixing

tanks. The 55 F (13 C) condenser water

means reduced head pressures which in

turn means lower horsepower require

ments The end result is lower energy

costs and lower annual operating costs.

In addition, the absence of a condenser

water bypass and mixing tanks add up

to lower first costs and lower installation

costs.

m

LZZZ

Compressor-motor-

heat exchanger mix-match

Each model within the 19 Series line

has the capability of mix-matching

various heat exchanger sizes with an

array of compressor-motor combina

tions. As illustrated, mix-matching

allows you to mount a small capacity

compressor on a large heat exchanger.

This design concept optimizes specified

conditions, improving full and part load

performance.

19DH

In-line impeller design

In-line impeller design, with diaphragm

between stages, allows for more flexi

bility in compressor component selec

tion, which results in first cost savings

on other machine components. Also

provides higher head capabilities, pre

vents uneven loading and allows for

routine, easy maintenance.

— Motor End Bearing

— Gear Journal Bearing

— Driving Gear Bearing To Housing

— Thrust Clearance on Gear

Bearing (each side)

— Pinion Gear Journal Bearing

— Pinion Gear Bearing To Housing

— Thrust Bearing

LEGEND

8

9

10

11

12

13

— High-Speed Journal Bearing

— Front of Impeller to Volute Wall

— Impeller Eye to ID of Inlet Ring

— Labyrinth Behind Impeller to

Spacer Ring

— Labyrinth Behind Transmission

and Motor Shell

— End-Bell Bearing Labyrinth

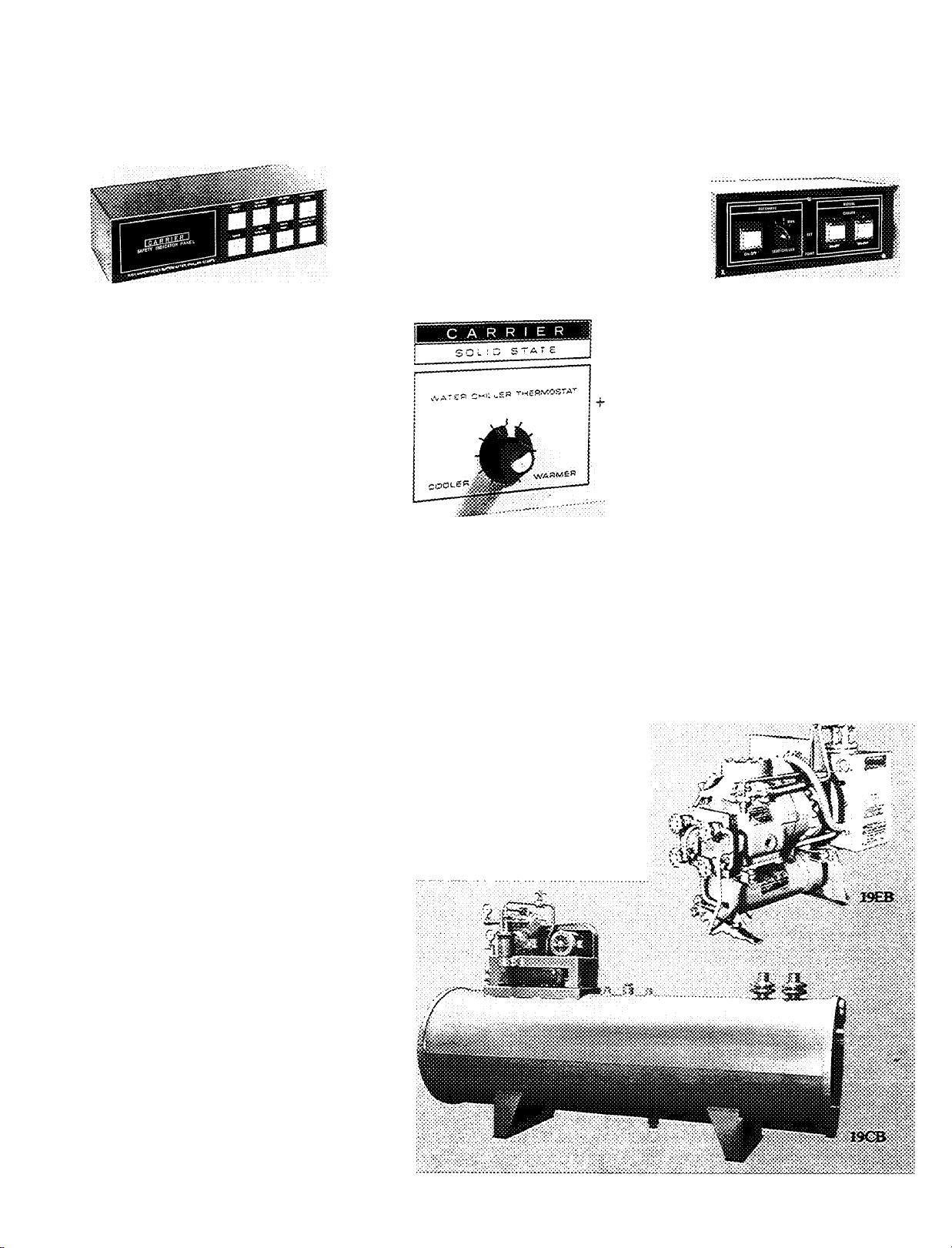

Flash and thermal economizer

Two-stage models thru 1,600 ton

(5627 kW) capacity feature a thermal

economizer. The thermal economizer

shown brings warm condensed refriger

ant into contact with the inlet (coldest)

water tubes where water as low as 55 F

(13 C) may be flowing. This low tem

perature water subcools the refrigerant

so when it moves on in the cycle it

has greater cooling potential, thus im

proving cycle efficiency and reducing

power/ton requirements. In addition, all

two-stage models employ a flash econo

mizer, not shown, to further improve

cycle efficiency. The liquefied refrig

erant leaves the condenser thru a

metering device and flows into the flash

economizer where the normal flashing

of part of the refrigerant into vapor is

used to cool the remaining refrigerant.

The flash vapor is diverted directly to

Thermal purge

The thermal purge effectively removes

air, water, and noncondensables from

the refrigerant system, promoting

greater operating efficiency and lower

maintenance costs. It needs no water

connections or air-cooled condenser.

It performs normal system purging

during periods of operation on R-11 and

R-114 machines. In addition, on R-11

machines it doubles as a pump for leak

testing or machine evacuation after

servicing. It also provides recovery of

refrigerant under normal purging

conditions.

19FA THERMAL ECONOMIZER

the compressor’s second stage so that it

does not have to be pumped thru the full

compression cycle. The flash econo

mizer generates savings and signifi

cantly lowers operating costs.

14 *5

14 — Thermal Economizer Partition Plate

15 — Refrigerant Flow Baffle

16 — Refrigerant Liquid Drain Line

17 — Condenser Water Inlet

J6 17

LEGEND

19DH

Engineering excellence provides lower first costs and years of trouble-free service

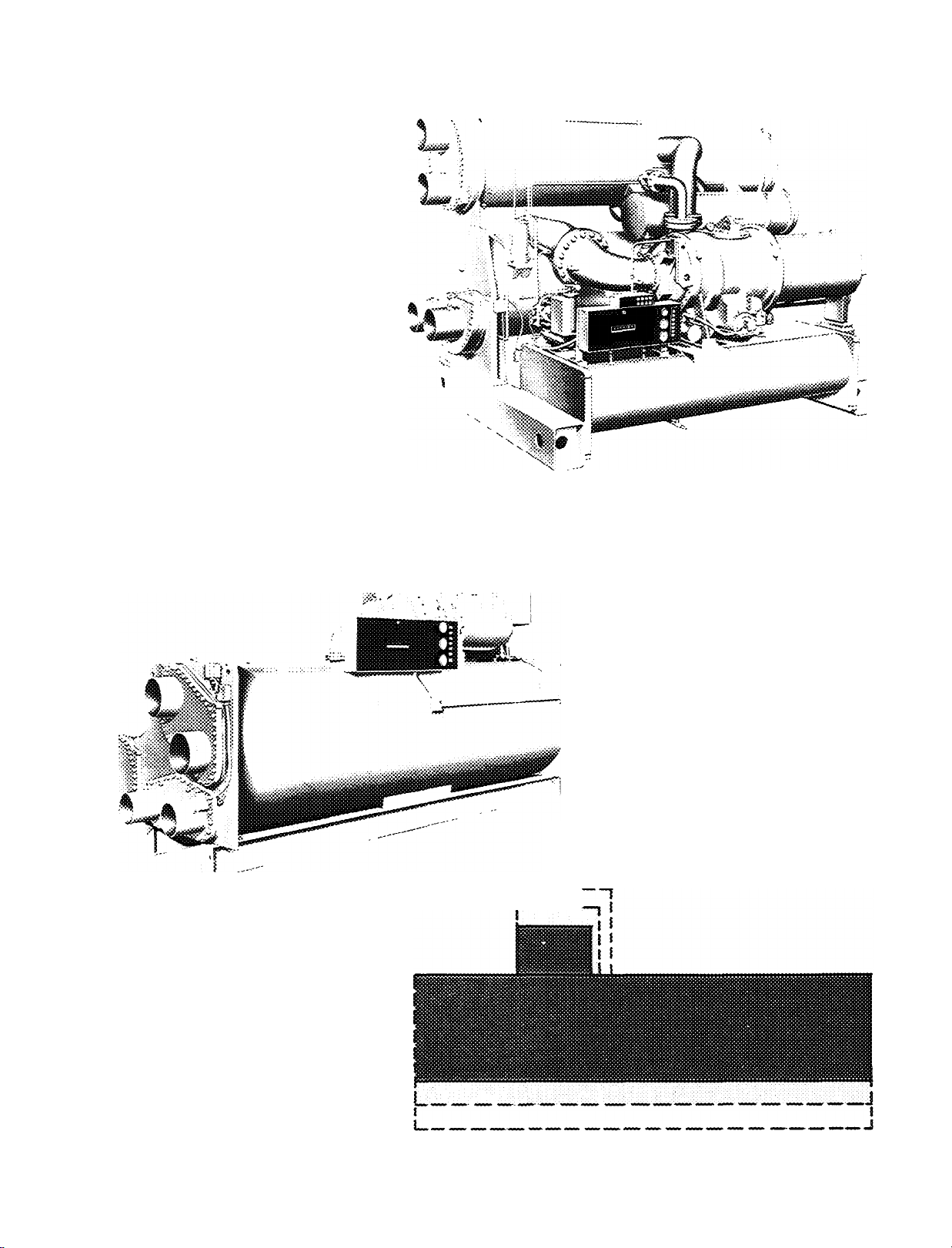

Single unit construction

Carrier centrifugals are the most com

pletely packaged units of their kind.

Chiller is shipped as a single unit com

plete with integral storage tanks where

required. Ready for quick connection

to water and electrical sources at the

job site. (Compressor is field installed

on the 1,600-2,000 ton (5627-7034 kW)

models; the heat exchanger and

economizer are factory assembled.) In

addition. Carrier centrifugals arrive at

the job site with controls mounted and

pre-wired including the chilled water

thermistor. All control connections can

be made to a single terminal strip. Single

unit construction assures minimum in

stallation time, minimum installation

costs.

Factory-wired oil pump starter

Models available for U.L. listing feature

a factory-wired oil pump starter The

starter is factory wired to the machine

with overloads and contactors sized by

Carrier for U.L. compliance. The entire

assembly is factory mounted to save in

stallation time and field labor costs.

Permanent shipping bases

Rigging can be done faster and the need

for costly concrete bases and supports

is eliminated with 19 Series permanent

shipping bases.

Prepiped motor lubrication package

The oil pump, motor, filter, cooler,

pressure controls, and electrical ter

minals are all prepiped and wired to

save on-site labor costs and installation

headaches.

Storage tank

The storage tank is an integral part of

the machine design on all R-12 and

R-500 units. No additional pipings,

fittings or valves are needed. No in

creased floor space is required which

saves you first cost dollars. Servicing or

testing may be easily accomplished

without time-consuming transfer to

separate containers which saves you

service dollars. Models using R-114

offer the storage tank as an option at

minimal cost. They are constructed to

ASME code requirements and include

all necessary connections for refrig

erant transfer system.

Factory start-up

Carrier start-up service for your ma

chine is included in the purchase price.

This assures you of trouble-free, work

ing installation right from the start. It

includes refrigerant transfer, leak test

ing and precision calibrating of the solid

state control settings and safety control

settings.

Integral chilled-water sensor

A chilled-water thermistor probe is fur

nished, installed in the leaving chilled

water nozzle as part of the machine’s

standard control system. A signal from

the sensitive solid-state device to the

central control module automatically

initiates immediate adjustments to com

pressor capacity. This eliminates the

need for accessory pneumatic equip

ment, separate sensing devices, saves

you initial equipment cost, and makes

installation easier, more economical. As

part of the machine’s standard control

system, it does not have to be specified

in another portion of the job, and thus

further reduces first and installation

costs.

Elapsed-time indicator

Every Carrier centrifugal features an

elapsed-time indicator to provide an

immediate and constant record of

machine operating hours. No over- or

underestimating when scheduling

maintenance. Mounted outside of the

control box for easy visibility.

Full line centrifugal service centers assure optimal care of your unit.

When you specify Carrier, you get a complete service

organization unequaled in the industry. Carrier Service

j Operations is a national organization in over 150 key loca

tions throughout the United States and Canada. This is

the one service organization that has grown up with the

air conditioning industry. Today, more and more owners

rely on Carrier Service Operations for an in-depth, practical

approach to energy conservation. This extraordinary full

time commitment to quality maintenance and service

proves Carrier’s interest in continued customer satis

faction. Your centrifugal, in fact your entire HVAC system,

will be in the care of people who are fully versed on the

design, manufacture, installation, start-up and maintenance

of your equipment.

Computer selection means “custom built” machinery — saves design time and lowers cost.

Supplementing the selections in this publication, Carrier

has, for your convenience, developed computer selection

and performance programs for 19 Series hermetic units

that incorporate 800,000 combinations of condenser,

compressor, and cooler components. Computerization of

this data allows you to take full advantage of Carrier’s

tremendous job-matching flexibility.

Only Carrier features the truly optimized selection and

performance programs which are far superior to the limited

combination, manual/ computer compromise selection

systems. With Carrier you have the ultimate flexibility —

you can specify an entering OR a leaving condenser water

temperature; a temperature differential or a water flow rate.

This unique service takes a minimal amount of time and

it’s completely free when you select Carrier.

Remember these advantages you’ll get from using

Carrier’s computer selection service when choosing your

19 Series hermetic centrifugal:

• Fast, accurate equipment selection.

• Comprehensive data, comparing best first cost and best

operating cost selection.

• Accurate matching of components at full and part load.

• Reliable forecasting of owning and operating costs.

• A clear picture of how the chiller functions with the

other components of your system.

• The capability to vary conditions, optimize selections

and define part load conditions with the performance

programs.

• Comparative flow rates applied to various condenser

water temperatures to assist you in selecting the cooling

tower.

• Savings all year long.

Convenience options offered for added energy-efficient, ‘tailor-made’ systems

Pneumatic capacity control

Complete pneumatic control systems

are available, if desired, for the centri

fugals in the 100 to 2000 ton (3527034 kW) sizes.

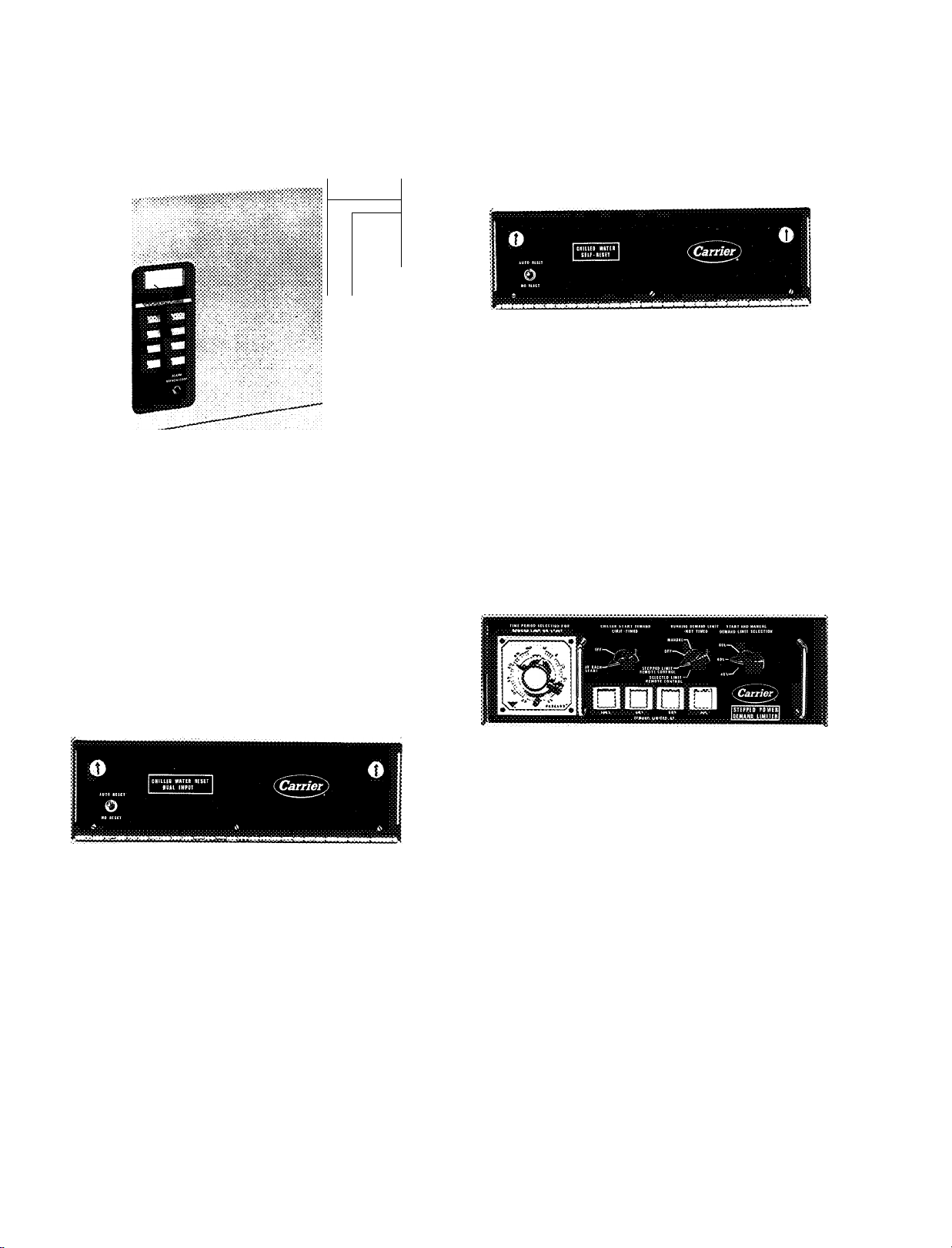

Safety indicator panel

This accessory provides the operator

with an instant trouble-shooting capa

bility. Seven panel lights monitor high

motor or bearing temperature, low

refrigerant temperature, high con

denser pressure, starter (overloads and

protective devices), low water flow

(chilled or condenser), low oil pressure,

low chilled water temperature. When

safety is tripped, the light goes on. Panel

does not affect the integrity of the

central control system, is easily con

nected to the machine without disturb

ing factory wiring. In addition, a remote

sound or light alarm can be easily field

installed to alert you, should a safety

light be tripped on the indicator panel.

Only a simple two-wire hook-up is

required.

Selective insulation

The 19 Series machines are adequately

insulated at the factory to meet most

application demands. However, addi

tional insulation packages are available

for specific machine applications.

Isolation assembly

A combination of soleplates, jacking

screws, leveling pads and neoprene

pads are available in isolation packages.

Specify this option for installations

requiring special mounting. Isolation

pads are shipped at no charge.

Remote control set point

Select or alter machine chilled water

temperature from a remote location by

specifying this optional solid state

control.

Pumpout unit

Factory mounted, complete with

starter, controls and all necessary inter

connecting refrigerant piping. Permits

easy transfer of refrigerant between

machine and storage tank. Speeds

servicing and minimizes downtime. On

multiple machine applications, a single

pumpout unit saves first costs. Not

required for R-ll units.

Lead-lag control

Desirable when two or more machines

are installed in series or parallel. Cen

tralized control features the following

capabilities;

• parallel operation

• series operation with split or common

point control

• two or more chiller operations

• uneven sized chillers working

together

• independent control of chillers both

manually and automatically

• automatic lead-lag operation

• reassignment of lead-lag hierarchy

• automatic standby

Panel lights indicate system operating

mode.

Hot gas bypass

When a machine is expected to run at

light load and elevated condensing tem

peratures or at minimum load for ex

tended periods of time, a hot gas bypass

is recommended. The hot gas bypass is

factory mounted and wired, manual or

automatic. It virtually eliminates com

pressor surging at extreme part-load

conditions and smooths out the ma

chine’s full operating cycle, whatever

the load fluctuation.

Additional energy-saving options

Chilled water self-reset control

This device permits the leaving chilled water tempera

ture to rise as the load on the machine decreases.

The higher the leaving chilled water temperatures, the

less work the compressor is forced to do.

The power monitor control

An electronic, energy-saving device which continuously

monitors building electric demand and sheds preselected

loads in stages during peak power usage periods. The

power monitor control reduces power consumption and

minimizes power demand charges.

Chilled water reset-dual input

A device that causes the leaving chilled water tempera

ture control set point to change in proportion to a change

in a remote temperature such as return chilled water or

outdoor air temperature.

Adjustable stepped-rcset control

A device that permits leaving chilled water tempera

ture to rise in predetermined adjustable steps. Operator

is in control of demand limit so amount of reset is not

dependent on machine load but on the amount of change

of resistance in the probe circuit.

Stepped power demand limiter

This option makes it possible to limit power demand in

four ways:

1. At start-up each chiller can be held to a preselected

maximum current draw for any time period of up to

one hour.

2. During normal operation, chiller load can be auto

matically reduced in up to 3 stages in response to

increased total building power consumption.

Chiller demand can semi-automatically be lowered in

3.

a single stage in response to increased total building

power consumption.

4.

Chiller demand can also be lowered manually.

Stepped power demand limiter minimizes the likeli

hood of getting demand charges. Also has timer which

increases flexibility of operator. Operator can change

demand limit without being at controls and can also

adjust demand limit manually.

#

10

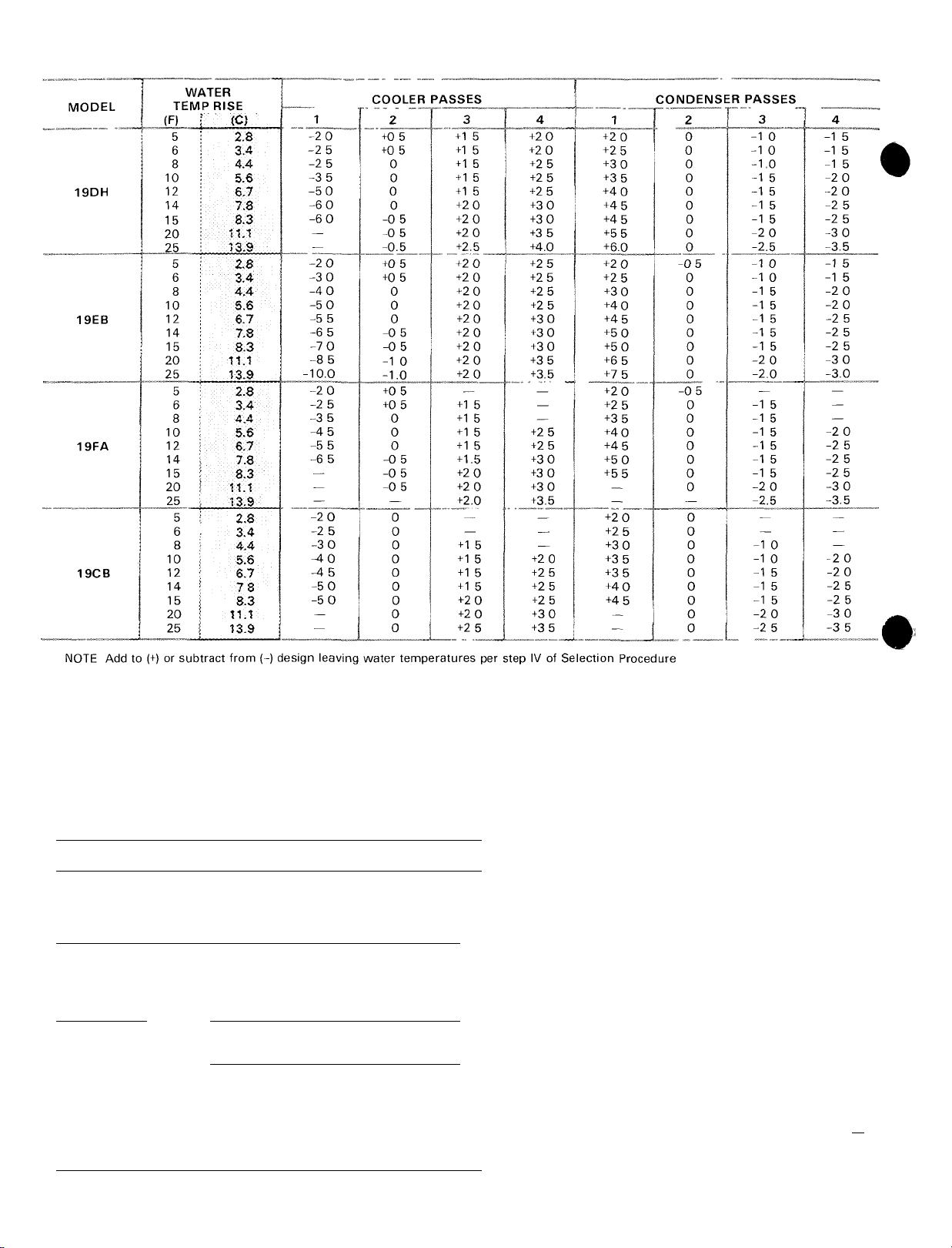

PASS-RISE TEMPERATURE ADJUSTMENT (F/C*)

*To convert the temperature adjustment factor to °C, divide by 1 8

Metric

tech

Area

cm2 100

cm3

m3 1 0

m2

Length

mm 1.0

mm 0 03937

mm 0 003281

m 1 0

m

Mass

kg

kg

Power

kcal/h 1 163

kcal/h 3 968 Btu/h 0 2931

HP metric

HP metric

Mcal/h 1 163

Mcal/h

X =

0 1550

10 76

3 281 ft

2 205

0 9863

0 3307

English

unit X =

ip2

«2

in

ft

lb

HP(550

Ton refr 3 517

645 2

0 09290

25 4

304 8

0 3048

1 0

0 4536

0 7355

0 7457

CONVERSION TABLE

SI unit

mm2

mm2

m2

m2

mm

mm

mm

m

m

kg

kg

w

w

kW

kW

kW

kW

Metric

tech

Pressure

mm w g 4°C

mm w g, 4°C

mm Hg 0°C

mm Hg 0°C

kg/cm^

kg/cm^

Temperature”

Interval

°C

y

Velocity

m/s

m/s

__

m/s _

Volume/Time

m®/h

m^/h

m^/h

L/h

__

L/h

Metric

tech

Temperature

“C

°C

0 03937

0 03937

^14 22

1 8

3.281

196.9

0 5886

4 403

4 403x10-3

Conversion

factor =

(»Cx18)+32 °F

English

unit

inHjO 39 2 F

in Hg 32“ F

psi

°F

ft/s

ft/min

fH/min

U S gal/min

U S gal/min

nEhglish

Un»

0 009806

0 2491

0 1333

3.386

98.07

6 895

1 0

0^5556

1 0

0 3048

0.00508

0 2778

0 4719

0 06309

2 778x10-“'

0 06309 _

Conversion

factor =

“C+273 15

(°F-32)-r1.8

SI unit

kPa

kPa

kPa

kPa

kPa

kPa

K

°C

m/s

m/s

m/s

Us

L7s

tVs

Us

Us

____

SI unit

K

°c

_

#

12

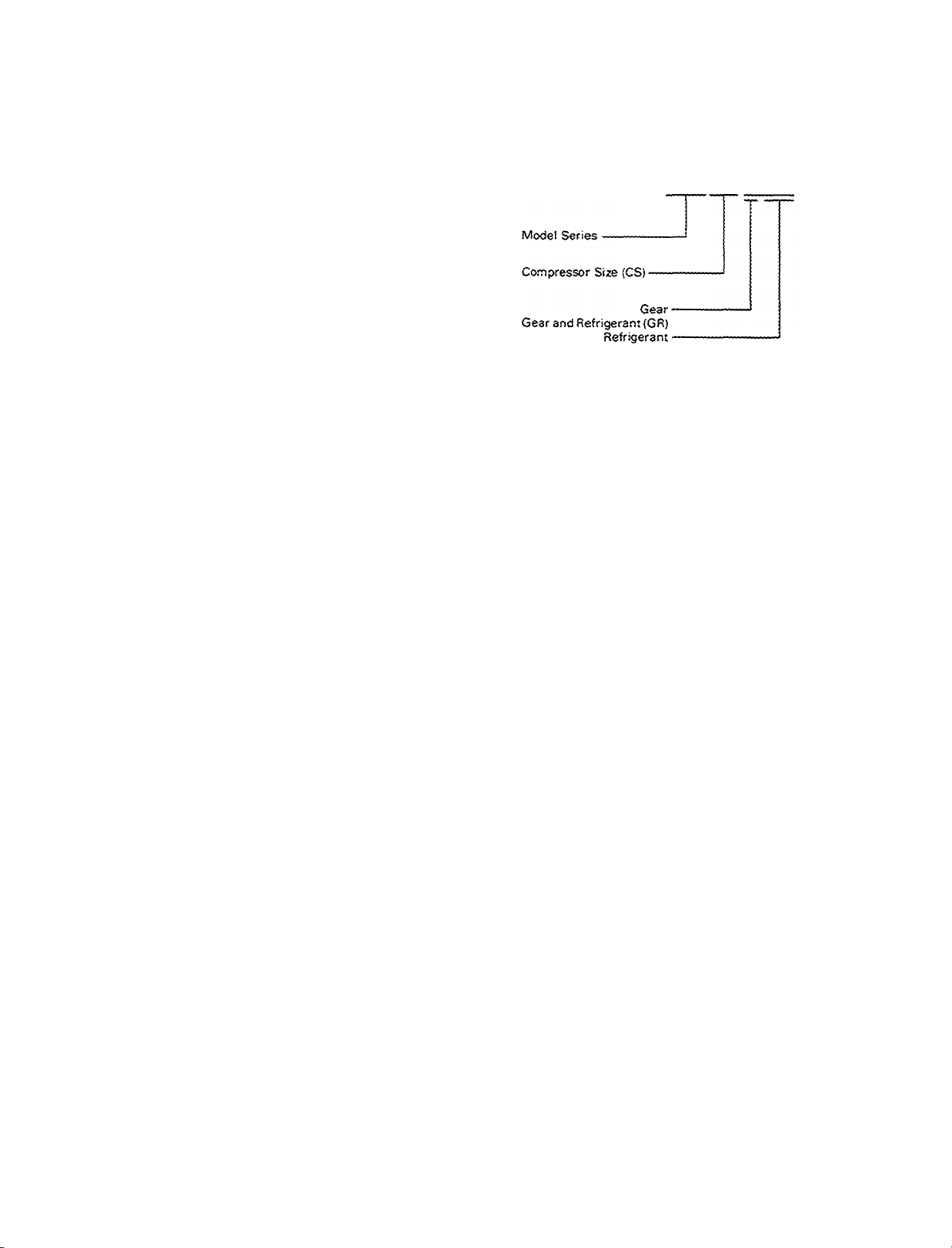

Using the 19DH,EB,CB model numbers

When ordering 19DH, 19EB or 19CB chillers, use the

ordering code described below. Chiller nozzle arrange

ment and compressor voltage must be listed separately.

Using the 19FA model number

When ordering 19FA chillers, use the ordering system

described below.

(19C8) Condenser-------------------------------------------------Heat Exchanger (HE) (UN){19CB) Cooler------------------

19EB8165DK

Model (19DH, 13EB, 19CS)-

Heat Exchanger or Unisheil (UN) •

Compressor (CS)

Motor---------------------------------------

List chiller model in first 4 code number positions

Obtain Unishell or heat exchanger size from step V of the Selec

tion Procedure and enter in positions 5 & 6

Obtain compressor size from step V of the Selection Procedure

and enter in positions 7 & 8

Obtain motor size from step VII of the Selection Procedure and

enter in positions 9 & 10

-----------------------

13FA563-B-500-2425-L-EC

Cooler -

Heat Exchangers (HE)

Condenser-

Base Size (S, small or L, large)

Motor Size (MS)-------------------------------------------------------------

1 List chiller model in first 4 code number positions

2 Obtain compressor size from step V of the Selection Procedure

and enter in positions 5, 6 and 7

3 Also from step V of the Selection Procedure, obtain gear size

and refrigerant used Enter gear size in position 8, next enter

refrigerant in 9-11 (May only need to use 9 & 10 )

4 Obtain heat exchanger size from step V of the Selection Pro

cedure and enter the cooler size in positions 12 & 13 and the

condenser size in positions 14 & 1 5

5 Base size is indicated in position 16

6 Obtain motor size from step VII of the Selection Procedure and

enter in positions 17 & 18

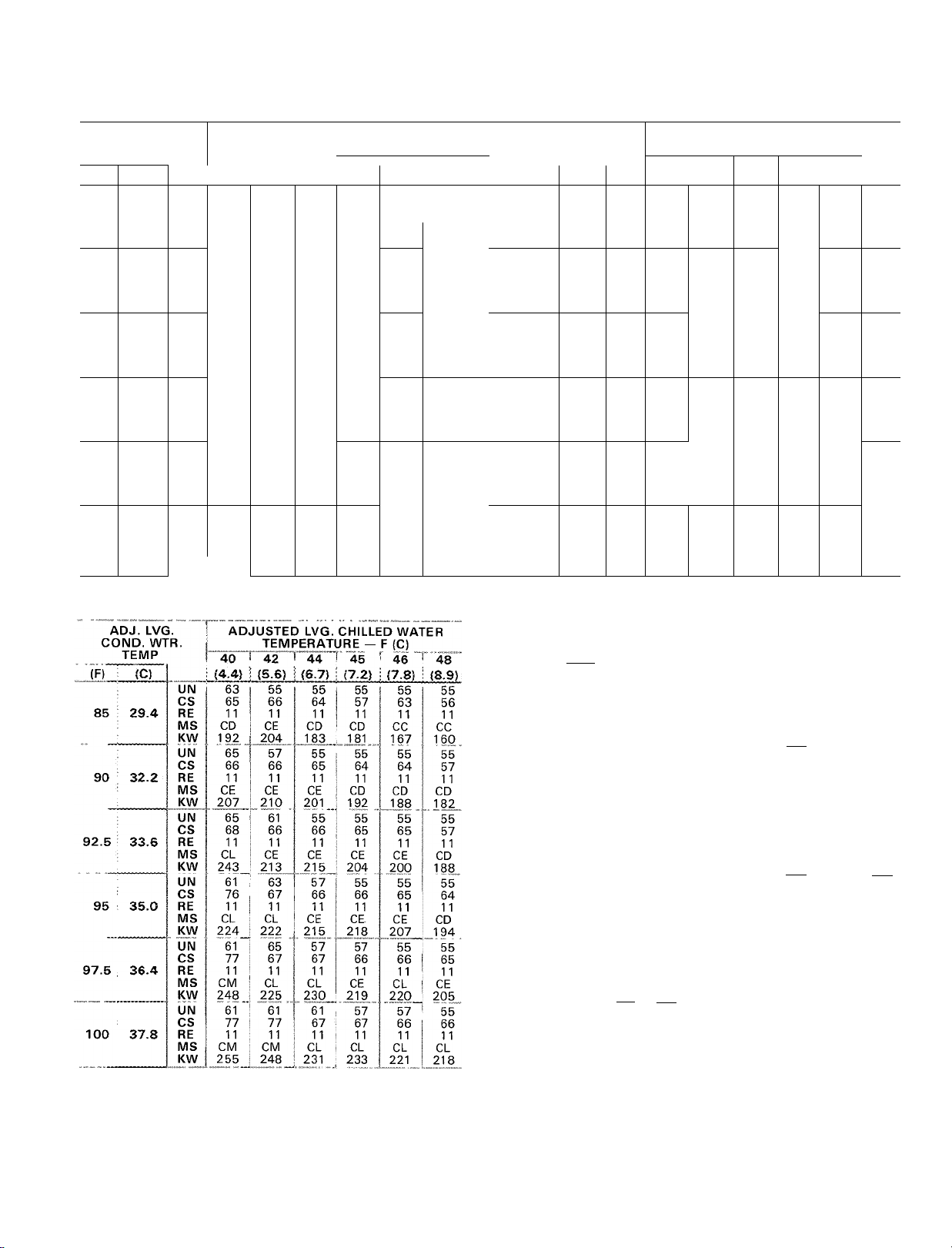

Part-load energy requirements

At part load, chiller energy requirements are aifected by

many variables, such as degree of load, chilled water flow,

condenser water flow, entering condenser water tempera

ture, leaving chilled water temperature, and the percentage

of compressor loading at design conditions.

Because of these many variables, a typical part-load

curve (% Standard Rating Tons versus % Standard

Rating Kw Input) may have appreciable inaccuracies

when applied to a specific chiller and set of conditions.

Carrier, therefore, does not recommend the use of

such curves in making operating cost studies.

Instead, thru computer analysis. Carrier will provide

you with accurate and detailed information on the energy

requirements for your selected chiller at the expected

jobsite conditions.

Energy savings can be significant if the chiller can be

operated with a relatively low entering condenser water

temperature. And, since conditions of design load and

design wet-bulb temperature can occur rather infrequently,

the opportunity for such savings exists during most of the

operating season. Each chiller is capable of operating

efficiently with entering condenser water temperatures

down to 55 F (13 C). This capability assures you of both

energy conservation and excellent part-load performance,

because “custom-made chillers” give the best part-load

performance.

13

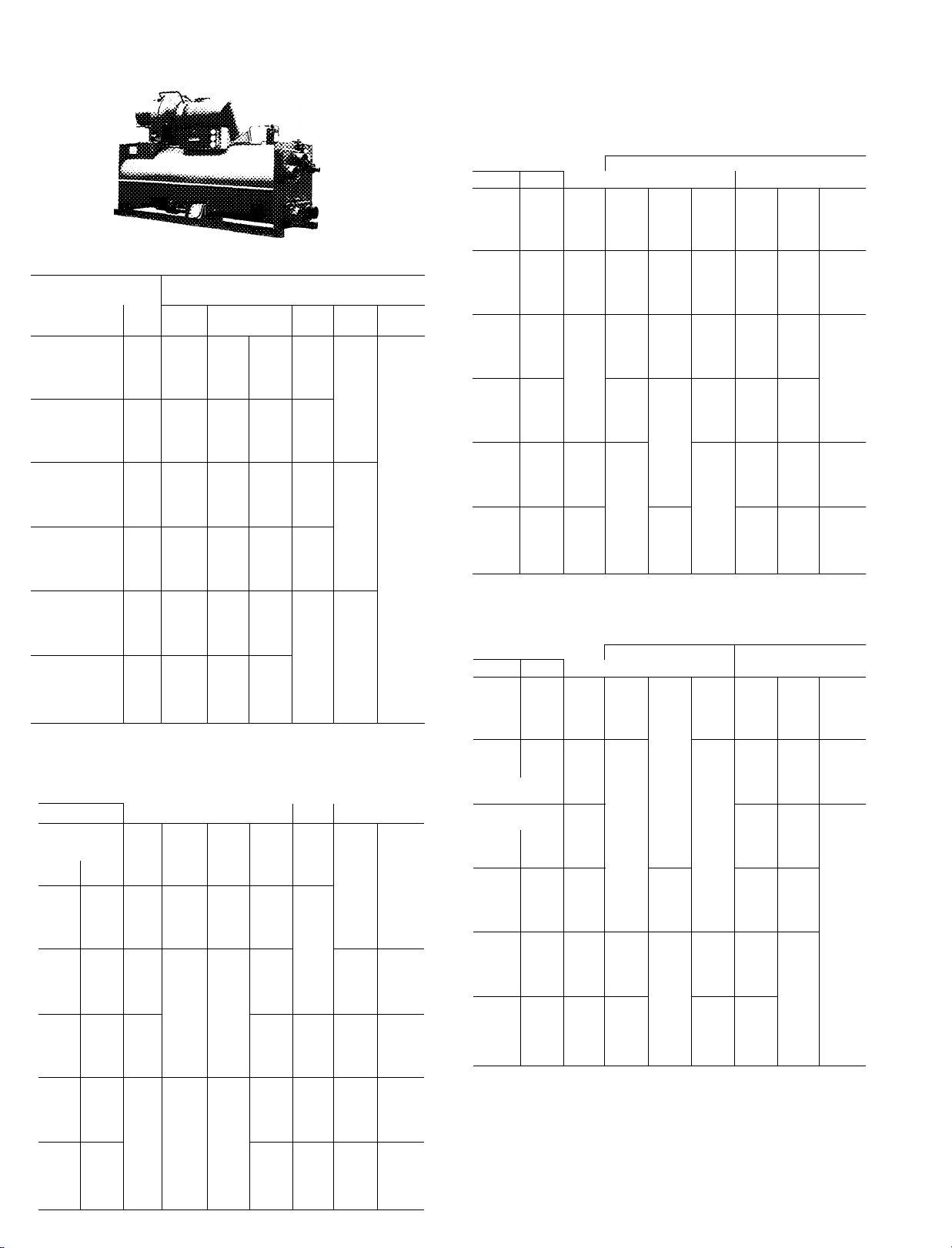

19DH Selection data

19DH*

100-450 TONS

(352-1583 kW)

100 Ton Selections (352 kW)

ADJ. LVG.

COND. WTR.

TEMP.

(F) ! (C)

1

;

85 ! 29.4

90 ; 32.2

92.5 ; 33.6

95 ; 35.0

•

97.5 ! 36.4

:

100 ! 37,8

UN 42 42 42 42

CS 13 13

RE

MS AA

KW 78 76

UN 42 42

CS

RE

MS

KW 86

UN

CS 15

RE 11

MS AA

KW 92 86 83 80

UN

CS

RE

MS AB

KW 97 92

UN 42 42

CS

RE

MS AC AB

KW 107 97

UN 42 42

CS

RE

MS

KW

125 Ton Selections (440 kW)

ADJ. LVG.

CONO. WTR.

TEMP.

(C) (4.4)

(F)

85

29.4

90

32.2

92.5

97.5 36.4 RE

95

100

33.6

35.0

37.8

UN 42

CS 27 20 13 19 12 12

RE 11 11 11 11 11 1 1

MS

KW

UN 42 42 42 42 42 42

CS

RE 11 11

MS AC AC

KW 114 107

UN 42

CS 29 22

RE 11 11

MS AD AC

KW 117 114 106 102 102

UN

CS 30 23

RE 11 11

MS AD AD AC AC

KW 125 121

UN

CS

MS AE AD

KW 136 125

UN

CS 31 24 23 23

RE 11 11

MS AE AE AD AD AD AC

KW 139

ADJUSTED LVG CHILLED WATER

TEMPERATURE — F (C)

42 ! 44 i

40

(4.4)

(5.6) ! (6.7)

11 11

AA AA AA

14 14 13 13

11 11 11 11 11

AA AA AA AA

AC

111

40

AB AB AB AA AA AA

101

r 42

83

42 42 42 42 42

14 14

11 11 11 11

AA AA

42 42 42 42 42

16 15 15 14 14

11 11 11 11 11

AA AA AA AA

17 16 15 15 15

11

11

17 17

11 11 11 11 11

AC

107

ADJUSTED LVG. CHILLED WATER

TEMPERATURE — F (C)

(6.7)

(5.6)

42

97 96

29 21 20 13

42 1

44

42

24 30 22 22

11

11

44 44

135

45

(7.2)

13 12

11 11

74

42

78 77 76

89

42 42

11 11 11

AA AA

92

42 42

16

AB AB AB

97 96

44 T 45

(7.2)

42

11

AB AB

100

42

21

1 1

AC AB

42

21

11 11

110

42 42

11 11

AD

117

42

11

125 122 116 111

46

(7.8)

* *

68

42

42

13

AA

13 13

AA AA

79

84

85

42

AA

91 89

42

16 16

95

46 48

(7.8)

42 42

88 87

13

11 11 11

AB AB

100 98 95

42 42 42

20

13

11 11 11

AB

42 42

21 14 13

11

AC

108 108 101

AC AC AC

115 114 107

42

15

11

42 42 42

22

11 11 11

48

(8.9)

*

*

*

*

*

(8.9)

42

84

13

13

AB

98

42

11

AB

42

14

11

14

150 Ton Selections (528 kW)

ADJ. LVG.

COND. WTR.

TEMP.

85

90

95

100

(C)

29.4

32.2

33.6

35.0

37.8

UN 46

CS 35 27 27 27 26 19

RE 11

MS

KW

UN 46

CS 37

RE 11 11 11 11 11

MS AE AD

KW 141

UN 50 46 46 46 46 ^ 46

CS 37 36

RE 11 11 11 11 11 11

MS AE AE

KW 142 134 127 121 119

UN

CS 37 37 35 28 28 20

RE 11 11 11 11 11 11

MS AE AE AE AE AD AD

KW 141 144

UN 50 53 46 46 46 46

CS 47 36 36 29

MS CB AE AE AE AE AD

KW 156

UN 50 50 51 50 46

CS 47 47 36 29 29

RE 11 11 11 11 11

MS CC CB AE AE AE

KW

(F)

92.5

97.5 36.4 RE 11 11 11 11

ADJUSTED LVG. CHILLED WATER

TEMPERATURE — F (C)

40 42 44

(4.4)

(5.6)

46 46

11 11

AD

AD AC AC AC AB

124

116 112 113 105 102

46 46

35

127 119

53 46 46

136 139

156

160

175 Ton Selections (615 kW)

ADJ. LVG.

COND. WTR.

(F)

85 29.4

90 32.2

92.5 33.6

95

97.5

100

LEGEND

CS — Compressor

GR — Gear-Refrigerant

HE — Heat Exchanger

KW — Power Input

MS — Motor Size

RE — Refrigerant

UN — Unishell

14

TEMP.

(C)

35.0

36.4

37.8

UN

CS 43 43 34

RE

MS

KW

UN

CS 51 44 35 35 35 34

RE 11

MS

KW 147 144 141 142

UN

CS 52 44

RE

MS CC CB

KW

UN

CS

RE

MS CC CC CB CB AE AE

KW

UN

CS 54

RE 11 11

MS CD

KW

UN

CS

RE

MS CD CD

KW

ADJUSTED LVG CHILLED WATER

TEMPERATURE — F (C)

40 1 42

(4.4)

(5.6)

50 50 51 50 50 50

11 11 11 11 11 11

AE

AE AE AE AE AD

133

138

50 50

11 11 11 11 11

CB

CB AE

50 50

11 11

156

150

50 50 50

53 52 44

11 11 11

166 156

50 50 50 50 50

46 45 45 44 34

CC CC

183 169 157 155

50 50

54

47 46 45

11 11 11 11

189 186

(6.7)

(6.7) (7.2)

45

(7.2)

44 44

11

46

27 27 20

AD

AD AD

117 115

27 27

28

AD

AD AD AD

46

130 128 127 119

136

138

139

44

45

34

130

130

143

148

168

51 50

53

AE

50

44

11

AE AE AE

CB

143

11

146 144

11

11

CB

50

CC CC

160

53 51

35

11

50

44

50

r 48

46

(7,8) (8.9)

11 11

46 46

46

28

11 11

130 122

138

46 48

(8.9)

(7.8)

34 26

128 116

AE AE

141 131

35 34

11

142

53 51

35 34

11 11

11 11

CB AE

148 140

50 I 50

45 45

11 11

CC CB

157 153

44

19

11

AC

105

20

115

46

27

46

28

11

AE

129

11

136

138

#

50

50

53

200 Ton Selections (703 kW)

ADJ. LVG

COND. WTR.

TEMP.

(C> (4.4)

(F)

85

29.4

90

32.2

92.5 33.6

95

35.0

97.5 36.4

100

37.8

UN 51

CS

RE 11 11

MS

KW

UN

CS

RE

MS CC

KW 166

UN

CS 59

RE

MS CD

KW 176

UN

CS 60 52

RE

MS CD

KW

UN

CS 61

RE

MS

KW

UN

CS

RE 11 11

MS

KW

A

DJUSTED LVG.

TEMPERAT

" 42 “I 44

¡5.6) ; (6.7)

51 51

57

50

CB

CB AE

156 151

53 51 51 51

58 51

11 11

CC

164 155

53 51

58 51 50

11 11

CC CC

170 164 156

53

53 51"’ 51

11

11 11 11

CD CC

188 175 171

53 53

59 51 51

11 11 11

CE CD

207 181 171

53 53

61

60

CE CD

215 193

CHILLED WATER

JRE — F (C)

49 49 42

11

140 136

50

11

CB CB

51 51

11 11

51 51

53 53

CC

53 53

52

11

CD

181 177 171

45

(7.2)

51

11 11

AE

50

11

152

CC

CC

167 164

11

CC CC CC

168 169

52

11 11

CD CC

46

(7.8)

(8.9)

51

AE

136

51

43 42

11

CB AE

152

141

51 51

43

11 11

CC CB

156 151

51

51

11

CC CC

156

51 51

51 44

11 11

166

53 51

51 51

CC

169

275 Ton Selections (%7 kW)

ADJ. LVG.

COND. WTR.

48

51

42 CS

11

AE MS CE

51 UN

11 90

43

51

43

11 95

1 1 100

TEMP.

(F) (C)

85

29.4

32.2

92.5

33.6

35.0

97.5 36.4

37.8

40

(4.4)

UN 61

RE 11

KW

203 197

61 61 65

CS 81

RE

11

CL

MS

KW

219

UN 61

CS 82

RE 11

MS CL CL

KW

233 222

UN 61

CS

RE

11 11

MS CM CL

KW

248 236 221

UN 61

CS

RE 11

MS CN

KW 276

UN

61 61

CS 84

RE

11 11 11

MS CN CN

KW 281

ADJUSTED LVG. CHILLED WA1

TEMPERATURE — F (C)

42

44

(5.6)

(6.7)45(7.2)

61

73

CD CD

CE

210

63 61

73 64 64

11 11

73

11

61

74

11

CD

195

196 178 171

65

11

CE

CL

210

223 202

65

66

11 11

CL CL

11

61

66 64

11 11 11

63 61 61

66 65 64

224 224

83

^ 61 61

75 74

CL CE

11 11

65 61 61

65 67 64

219 241

77 76

11 11

CM CL

251 236

77 76

276 250

6Ì 61

CM CM

61

75 75

11 11 11

CL CL

232 234

61 61

11

246

76

■ ER

48

46

(7.8)

(8.9)

61 61

63

11 11

CD CD

61 61

CE CD

184

11 11

CE

CE

217 201

11 11

CL

CE

208

63 61

66

CL

222

65 61

66 66

11 11

CL

CL

236 236

56

63

65

250 Ton Selections (879 kW)

300 Ton Selections (1055 kW)

ADJ. LVG.

CONO WTR

TEMP.

(F) (C)

85 29.4

90 32.2

92 5 33.6

95 35.0

97 5 36.4

100 37.8

UN

CS

RE

MS

KW.

un'

CS

RE

MS

KW

UN

CS

RE

MS

KW

UIM^

CS

RE

MS

K^

UN

CS

RE

MS

KW

UN

CS

RE

MS

KW

ADJUSTED LVG. CHILLED WATER

40

(4.4Ì

61

80

11

CL

223

61

82

11

CM

252

61

83

11

CN

267

61

90

11

CN

274

éf

84

11

CP

306

63

84

11

CP

307

TEMPERATURE — F JC)

44 "T

42

¡5.6)

61

73

11

CL

219

61

81

11

CL

236

’ 61 ’

81

11

CM

243

61

82

11

CM

259^

61

83

11

CN

274

61

84

11

CP

303

211

(6.7) :

61

73

11

CE

61

73

11

CL

225

6l’

74

11

CL

240

éi"

75

11

CM

255

61

82

11

CM

258

61

83

11

CN

273

45

¡7.2)

61

72

11

CD

197

61

73

11

CL

2M

"'61

73

11

CL

228

61 ’

74

11

CM

242

61

75

11

CM

259

61

76

11

CN

274

46

(7.8)

61

72

11

CD

.1?3

61

73

11

CE

.217„

6Ì"

73

11

CL

224

6l"

74

11

CL

238

61

74

11

CM

246

61

75

11

CM

262

48

63

63

11

CD

189

65

64

11

CE

212

65

64

11

CE

218

73

11

CL

223

61

74

11

CL

238

61

75

11

CM

252

*For additional tonnage and performance selections contact your nearest Carrier Sales Office (see page 50)

15

19DH Selection data (cont)

350 Ton Selections (1231 kW) 400 Ton Selections (1407 kW)

ADJ. LVG.

CONO. WTR.

TEMP.

(fT

92.5

97 5 36.4

100

(C) (4.4)

85

29.4

90

32.2

33.6

95

35.0

37.8

UIM

CS 95

RE 11

MS

KW 271

UN 63

CS

RE

MS CP

KW

UN 65

CS 97

RE

MS CP

KW 311

UN 65

CS

RE 11

MS CQ

KW 344

UN 65

CS 98

RE 11

MS CQ

KW 352

UN

CS 98

RE

MS

KW

LEGEND

CS — Compressor

GR - Gear-Refrigerant

HE — Heat Exchanger

ADJUSTED LVG. CHILLED WATER

_ JTEMPERATURE — F (C)

42 44

40

(5.6) (6.7)

63

63

87

CN CM CM CL CL

11 11

255 247

gg

95

97

11

11

CN CM

279 263 259

309

CQ

358

63

96

11 11

11

CP CN

297

63

97 89

98

11 11

CP

317

65 63

97 90

11 11

CP CP

319 316

65

72

91

11 11 11 11 11 11

CQ CP

352 318 321 305

KW — Power Input

MS — Motor Size

RE — Refrigerant

UN — Unishell

45 46

(7.2) (7.8)

63 63 63

80 86

229 225

63 63 63

87

11 11 11 11 90

CM

63 63

88 87 80 80

CN

278 265

63 63 63 63

CP CN CN CM

296 282 276 261

CP

300

65 63 63 63

90 90

CP

79 72 CS

11

11

80

80

CM CM

254

63

11

11

CM

264

88 81 80

11

11

63

63

82

89

11

11

CN CN

294

89

CP CN

ADJ. LVG.

COND. WTR.

48

(8.9)

63 UN

11 85 23.4 RE

CL

220

63

73 CS

249 KW 335 339 309 294

63

11

CM

252

11

63

81

11

276 KW

82 CS 97 97 97 89

295 KW

TEMP.

95

(C>

32.2

35.0

36.4 RE

37.8

(F)

92.5 33.6

97.5

100

MS

KW

UN

RE 11 11

MS

UN

CS

RE

MS

KW

UN

CS 97 97 96 95 87

RE

MS CQ CQ

KW 348 350 333 318 297

UN 77

CS

MS

UN

RE

MS CQ CQ CQ

ADJUSTED LVG. CHILLED WATER

TEMPERATURE — F (C)

40 142 44 45

(4.4)

(5.6) (6.7)

76 71

95 95 94 87 86

11

CP CP CN CN CM CM

298

CQ CQ CP CN CN CN

CQ CQ CQ CP CP CN

338 344

11

301

77 72

97 97

78 73 71

97

97 96 95

1 1

11 11 11 11 11

76

*

11 11 11 11

97

*

11 11 11 11 11

CQ

353

*

*

(7.2)

71

71

11

11

279 275 256

326 313 299 286

CQ

71

71

94

95

11

11

71

71

71

CQ

71

73

97 96

97

CQ

356

352

76 73 72

11 11 11 11

357

358

46 48

(7.8)

(8.9)

71

11 11

71

87 80

11 11

281

288

71

94

71

CP

71

CQ

338 317

356

71

79

247

71

71

87

71

11

CP

71

88

CP

71

CQ

334

UNISHELL COOLER

FLOW RATE L/s

.2

2 4

FLOW RATE. GPM (lOO's)

100;

50

- 100

- 50

iOO

UNISHELL CONDENSER

- 100

50

.2

- 100

-* 0

100

50

16

50

-* 0

Loading...

Loading...