LB 302 • LB 502 • LB1002

LB 302 G • LB 502 G• LB 1002 G

OPERATION

MANUAL

CARPIGIANI CORPORATION OF AMERICA

3760 Industrial Drive • Winston-Salem, North Carolina 27105

336-661-9893 • 336-661-9895 (Fax)

TABLE OF CONTENTS

FORWARD........................................................................................................................................................... 3

PART 1 - INSTALLA TION......................................................................................................................................4

UNCRATING .................................................................................................................................................... 4

POSITIONING THE MACHINE ........................................................................................................................... 4

MACHINE EQUIPPED WITH AIR COOLED CONDENSER................................................................................... 5

MACHINE EQUIPPED WITH WATER-COOLED CONDENSER .............................................................................5

WATER VALVE ADJUSTMENT ..........................................................................................................................5

ELECTRICAL REQUIREMENTS ........................................................................................................................ 6

POWER SUPPLY ............................................................................................................................................ 6

WIRING ........................................................................................................................................................... 6

ELECTRICAL CONNECTIONS ........................................................................................................................... 6

BEATER ROTATION ......................................................................................................................................... 6

COMPLETING THE INSTALLATION.................................................................................................................... 7

MACHINE SAFETY SYSTEM - THERMAL RELAY .............................................................................................. 7

PROTECTION FOR THE OPERATOR ................................................................................................................ 7

PART 2 - EXPLANATION OF CONTROLS.............................................................................................................. 8

ICE CREAM DISPENSING HANDLE ................................................................................................................10

PART 3 - INITIAL CLEANING PROCEDURE ......................................................................................................... 1 1

PRELIMINARY CLEAN-OUT ............................................................................................................................ 11

BEATER DISASSEMBLY (MODELS LB 302 - LB 502 - LB 1002)....................................................................... 1 1

BEATER DISASSEMBLY (MODELS LB 302 G - LB 502 G - LB 1002 G) .............................................................12

FRONT DOOR DISASSEMBLY .......................................................................................................................12

ICE CREAM GATE DISASSEMBLY .................................................................................................................13

FILL CHUTE COVER DISASSEMBLY ..............................................................................................................13

CLEANING OPERATIONS ...............................................................................................................................13

PART 4 - ASSEMBLING THE FREEZER ...............................................................................................................14

FRONT DOOR RE-ASSEMBLY .......................................................................................................................14

BEATER RE-ASSEMBLY (MODELS LB 302 - LB 502 - LB 1002) ......................................................................14

BEATER RE-ASSEMBLY (MODELS LB 302 G - LB 502 G - LB 1002 G) .............................................................15

PART 5 - SANITIZING THE FREEZER ..................................................................................................................16

PART 6 - STARTING THE FREEZER ....................................................................................................................17

ICE CREAM PRODUCTION (PROCESSING) ....................................................................................................17

ICE CREAM CONSISTENCY ...........................................................................................................................17

CHANGING ICE CREAM CONSISTENCY .........................................................................................................17

DISPENSING ICE CREAM ..............................................................................................................................18

ICE CREAM DISPENSING HANDLE ................................................................................................................18

AFTERCOOLING............................................................................................................................................19

PART 7 - CLEANING PROCEDURE .....................................................................................................................20

PART 8 - TECHNICAL INFORMATION .................................................................................................................23

PART 9 - MANTEINANCE....................................................................................................................................24

PART 10 - TROUBLESHOOT GUIDE ...................................................................................................................25

© Copyright 1998, CARPIGIANI Corporation of America. All Rights Reserved.

CARPIGIANI Operation Manual - LB 302, LB 502, LB 1002, LB 302 G, LB 502 G, LB 1002 G

FORWARD

Thank you for selecting CARPIGIANI as your choice in equipment. CARPIGIANI machines are able to

meet today’s fast growing demands. Your CARPIGIANI freezer has been manufactured at one of the most

modern manufacturing plants and utilizes the most advanced equipment and technology available in the industry.

We at CARPIGIANI, take great pride and care in the manufacture of each and every freezer, using only the

finest components available, to provide you with years of trouble-free operation.

Over twenty-five years of experience in the manufacturing of dispensing equipment has guided us in the

preparation of this Operation Manual. PLEASE READ IT CAREFULLY. Keep it handy for future reference and

follow the instructions from the very first time your machine is put into service.

On the following pages you will find important information and procedures that describe the proper installation, sanitizing, operation, and maintenance of your CARPIGIANI machine. We feel certain that your full

compliance with these instructions will assure you of excellent performance, trouble-free operation, and profitable business for years to come.

USING THIS MANUAL

As you go through this manual, you will occasionally see special notes accompanied by this symbol:

Pay special attention to these notes - they contain special hints and precautions that are necessary for

the proper operation of your CARPIGIANI machine.

All technical data, pictures and drawings contained in this manual are not binding on the manufacturer, nor can the manufacturer be held liable

for any modification of the machine in part or whole. © Copyright 1998, CARPIGIANI Corporation of America. All rights reserved.

Page 3

Rev. 12/2002

CARPIGIANI Operation Manual - LB 302, LB 502, LB 1002, LB 302 G, LB 502 G, LB 1002 G

IMPORTANT!

Failure to follow operational and maintenance procedures may result in damage to the unit and/or

void your warranty. CARPIGIANI Corporation will

not be held responsible for any machine that is

not properly operated or maintained.

In the event this unit should malfunction, please contact

your CARPIGIANI distributor or an authorized service

agency.

PART 1

INSTALLATION

Before starting this procedure, carefully inspect the shipping case to ensure the unit has not been dropped, tampered with, or abused in such a way as to indicate the

unit may have been damaged in transit.

If you notice any damage to the outside of the ship-

ping case that may indicate possible hidden dam-

age, make a notation of the damage on the bill of

lading before signing. Contact the carrier immediately

and request an inspection of damage. If this procedure is

not adhered to you may forfeit your right to file a damage

claim and be responsible for subsequent repair costs.

• Remove the case by lifting it straight up and away from

the machine.

• The machine is also secured to the skid with strapping.

Use caution when cutting the strapping as it may spring

out injuring you or damaging the machine.

• Free the machine from the skid.

• Remove the single screw at the bottom of each side

panel.

• Remove the panels by sliding downward slightly, then

pull outward at the bottom and allow the panel to slide

down.

• You may remove the protective plastic coating that has

been laminated to the panels by peeling it off.

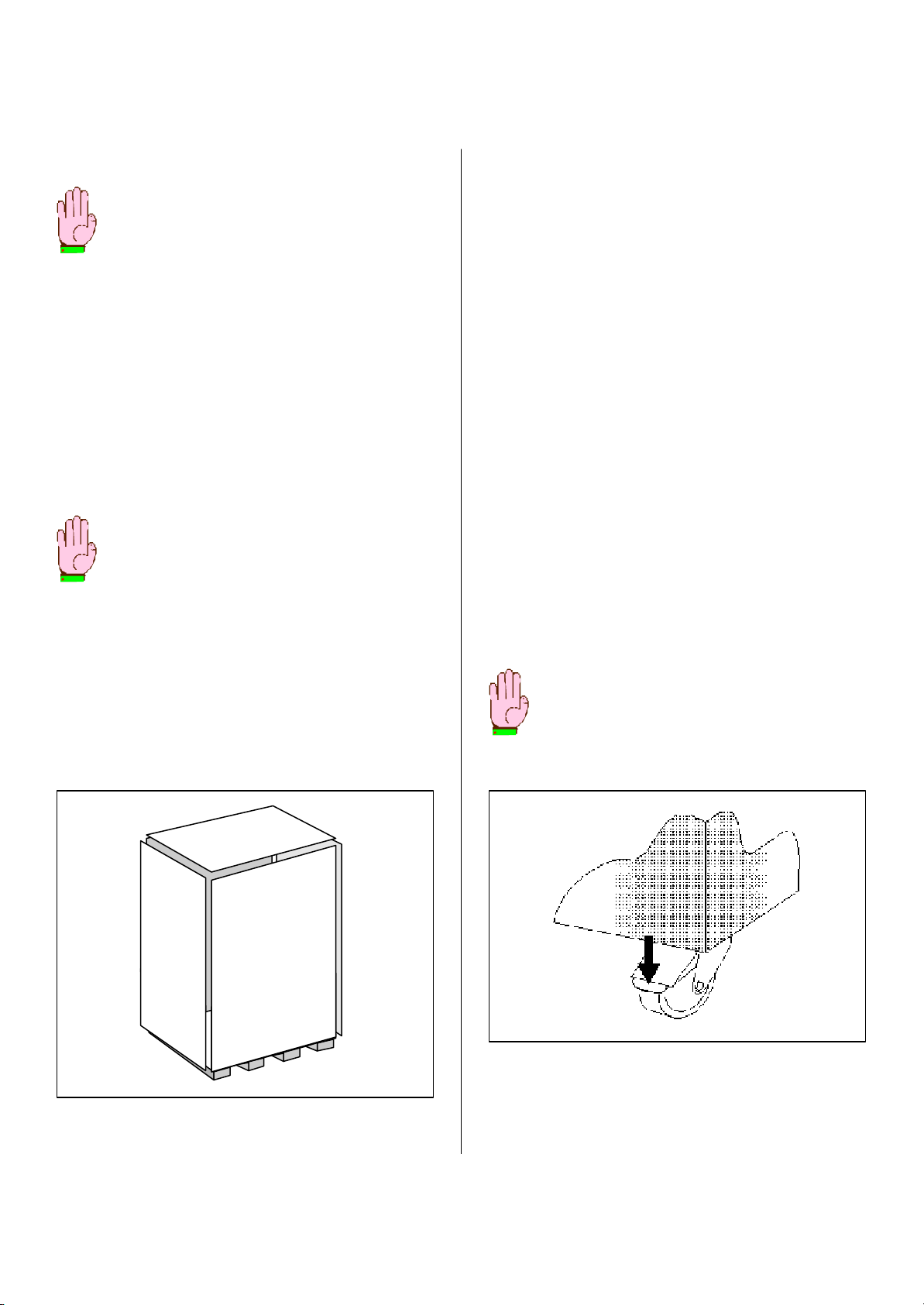

POSITIONING THE MACHINE

• The freezer is equipped with 2 pivoting front wheels to

allow easy location. Move the machine to the desired

location.

• The machine must stand level. Check the level condition by placing a level on the top of the freezer at each

corner.

• Lock the front wheels to prevent the freezer from moving.

UNCRA TING

• The case is secured to the skid with strapping.

Use caution when cutting the strapping as it may spring

out injuring you or damaging the machine.

Uncrating

Accurate leveling is necessary to allow for correct

drainage of the freezer barrel and to ensure correct overrun.

Positioning the machine with pivoting front wheels

Rev. 12/2002

Page 4

CARPIGIANI Operation Manual - LB 302, LB 502, LB 1002, LB 302 G, LB 502 G, LB 1002 G

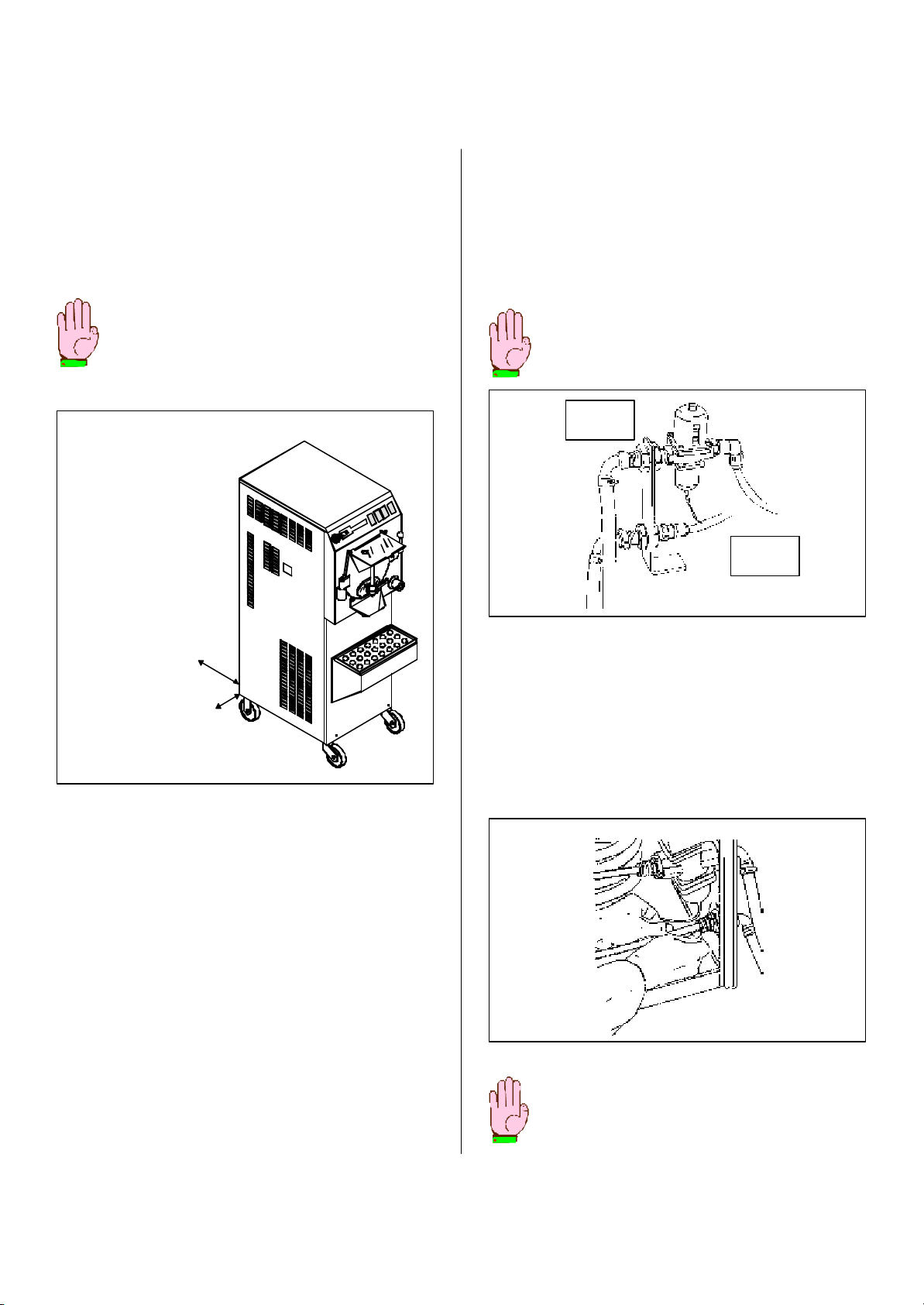

MACHINE EQUIPPED WITH AIR COOLED

CONDENSER

• Machines with air-cooled condenser must be installed

at least 2 feet (24 inches) away from any wall or object

to allow the free circulation of air around the condenser

(ref. Fig. 1).

Insufficient air circulation effects the operation and

output capacity of the machine. If these clearances

are not maintained, the production capacity will

be reduced, cycling will increase, and the machine

may stop completely.

Water cooled condenser:

A ≥≥ 4 in

B ≥≥ 6 in

Air cooled condenser:

A ≥≥ 24 in

B ≥≥ 6 in

MACHINE EQUIPPED WITH WA TER-COOLED

CONDENSER

• If the unit is water-cooled, it should be located close to

the water supply and within six feet of a drain.

• Connect the fitting marked “WATER IN” to the cold water supply. Connect the fitting marked “WATER OUT” to

a drain (ref. Fig.2).

All plumbing must meet local or state codes.

WATER

INLET

WATER

OUTLET

Figure 2

A

B

Figure 1

• It is necessary to clean the condenser each month to

eliminate dust, paper, etc., which may obstruct it.

Failure to do so may result in potential damage to the

machine and improper functioning.

• The machine should be within six feet of the power supply (a plug and receptacle or unfused disconnected).

• Position the machine to allow easy access for cleaning, servicing and maintenance.

• Position the machine away from direct sunlight.

For every 2EF over 68EF, the machine’s performance

will decrease by approximately 1%.

• Once the machine is set in position, it should be leveled as accurately as possible.

WATER VALVE ADJUSTMENT

The water valve is preset at the factory.

Proceed as follows if an adjustment is required:

• To maintain a head pressure of 235-255 psi while the

compressor is running, attach a refrigeration high pressure

gauge to the compressor’s high side discharge port.

• Open the water valve clockwise to increase the pressure or

counter clockwise to decrease the pressure (ref. Fig. 3).

Figure 3

Never expose water-cooled machines to temperatures at or below 32°F. without first draining the

water from the condenser. Serious damage to the

machine can occur if it is not properly drained.

Page 5

Rev. 12/2002

CARPIGIANI Operation Manual - LB 302, LB 502, LB 1002, LB 302 G, LB 502 G, LB 1002 G

ELECTRICAL REQUIREMENTS

• The wiring used to operate this freezer must be in

accordance with the National Electrical Code and/or local electrical codes, rules and regulations.

• The machine must be properly grounded . We recommend that a licensed electrician install the power

supply.

POWER SUPPLY

The power supply must be adequate enough to meet

requirements at all times. Voltage fluctuations with the

machine in operation should not exceed plus or minus

5% of the normal or rated voltage.

WIRING

• Adequate wiring must be provided with respect to wire

size or gauge. Unless otherwise required by the local

Electrical Codes, the same gauge wire at the machine

junction box should be used for the direct power line. A

separate circuit breaker with adequate fuse protection

should be employed.

• An unfused disconnected switch or a properly sized

plug and receptacle within 6 feet of the freezer, is recommended.

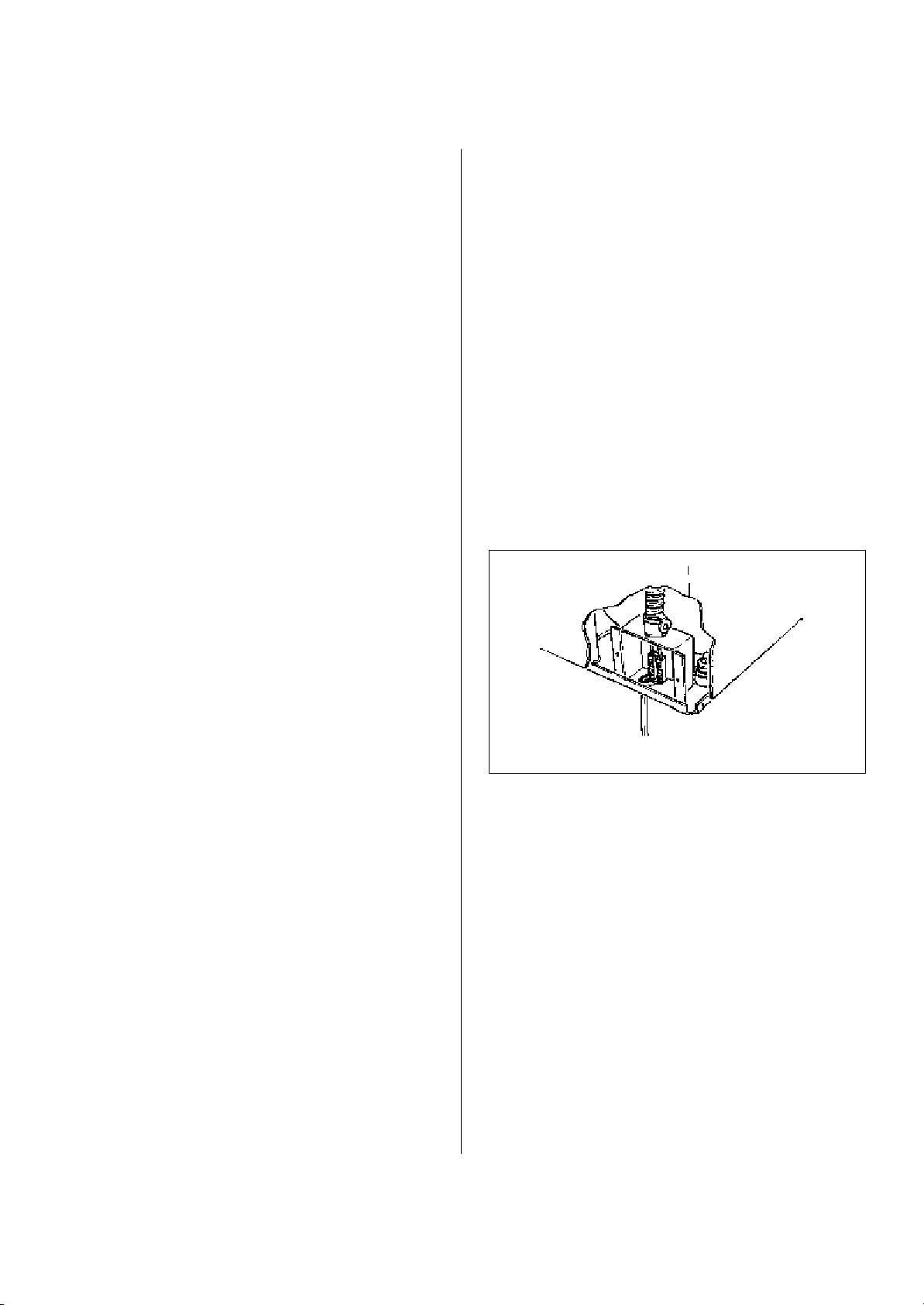

ELECTRICAL CONNECTIONS

• After you remove the panel on the left side of the machine, the wiring connection box can be found on the

bottom of the frame and is labeled “Connect Power Line

Here” (ref. Fig. 4).

• Feed the power line through the access hole located at

the bottom deck directly below the wiring connection

box.

• Connect the power line to the machine’s power lines

and wiring connection box.

• After connecting, the power line should be fastened to

the wiring connection box with appropriate electrical

hardware.

• In all installations, the machine must be properly

grounded. Because all high voltage components (the

controls are 24 volts) are connected with flexible conduit or cord, adequate ground continuity is assured by

running and fastening a ground line to the machine junction box ground lug (ref. Fig. 4).

CARPIGIANI freezers are equipped with protection for the

beater motor. Should the line voltage drop, or in the unlikely event a short circuit occurs, the overload protector

will automatically disconnect the starter and the machine

will stop immediately so that no permanent damage can

be caused to the motor.

The compressor is also internally protected. If the Klixon

protector trips due to an overload, the protector must first

cool down for several minutes before the compressor can

be restarted.

Figure 4

BEA TER ROTATION

After the electrical connections have been completed

check the rotation of the beater which should be counterclockwise when facing the front of the machine.

Rev. 12/2002

Page 6

CARPIGIANI Operation Manual - LB 302, LB 502, LB 1002, LB 302 G, LB 502 G, LB 1002 G

COMPLETING THE INSTALLA TION

The following pages contain important information and

procedures that describe the proper sanitizing, operation,

and maintenance of your CARPIGIANI machine. We feel

certain that your full compliance with these instructions

will ensure the excellent performance and trouble-free

operation of the machine and a profitable business for

years to come.

Failure to closely follow set-up and maintenance

procedures can void your warranty. CARPIGIANI

Corporation will not be responsible for any machine

not properly maintained.

In the event this unit should malfunction, please contact

your CARPIGIANI Distributor or an authorized service

agency.

EXTREME CARE MUST BE TAKEN WHEN RE-

MOVING SIDE, REAR, OR CONTROL BOX PANELS. ALWAYS TURN THE MACHINE TO THE

OFF POSITION. ALSO TURN OFF THE DISCONNECT SWITCH ON THE ELECTRICAL SUPPLY LINE

BEFORE EXPOSING ANY ELECTRICAL CONNECTIONS

AND/OR MOVING PARTS, SUCH AS BELTS, PULLEYS,

FAN BLADES AND BEATER.

PROTECTION FOR THE OPERATOR

A microswitch has been placed on the door of the barrel

with the beater assembly. The switch will immediately

stop the machine when the door is opened. When the

machine stops, the monitor will display "PT." The display will blink if the machine was running when it was

stopped. The display will be steady (not blinking) if the

machine was already stopped when the door was

opened. After closing the door, the machine remains

stopped and the display resets.

Make sure the machine is stopped before opening the front door.

MACHINE SAFETY SYSTEM - THERMAL RELAY

The Thermal Relay monitors amperage draw of the beater

motor. When maximum values are reached, the machine

will stop and the monitor will blink "RT" which is the code

that indicates the THERMAL CUT-OUT has been tripped.

Upon automatic resetting of the thermal relay, the display

will stop blinking. Before restarting operation, it is

important to investigate the reason the Thermal Cut-out

tripped. To restart the machine, press the desired button.

PRESSURE SWITCH

The Pressure Switch protects the cooling system

compressor. This switch will stop the compressor in the

event of water flow interruption (water-cooled system) or

air flow obstruction (air-cooled system); resetting is automatic.

If the compressor runs too long, or the machine continually stops and restarts it may indicate cooling is insufficient. Call your authorized service technician.

Page 7

Rev. 12/2002

CARPIGIANI Operation Manual - LB 302, LB 502, LB 1002, LB 302 G, LB 502G, LB 1002 G

PART 2

EXPLANATION OF CONTROLS

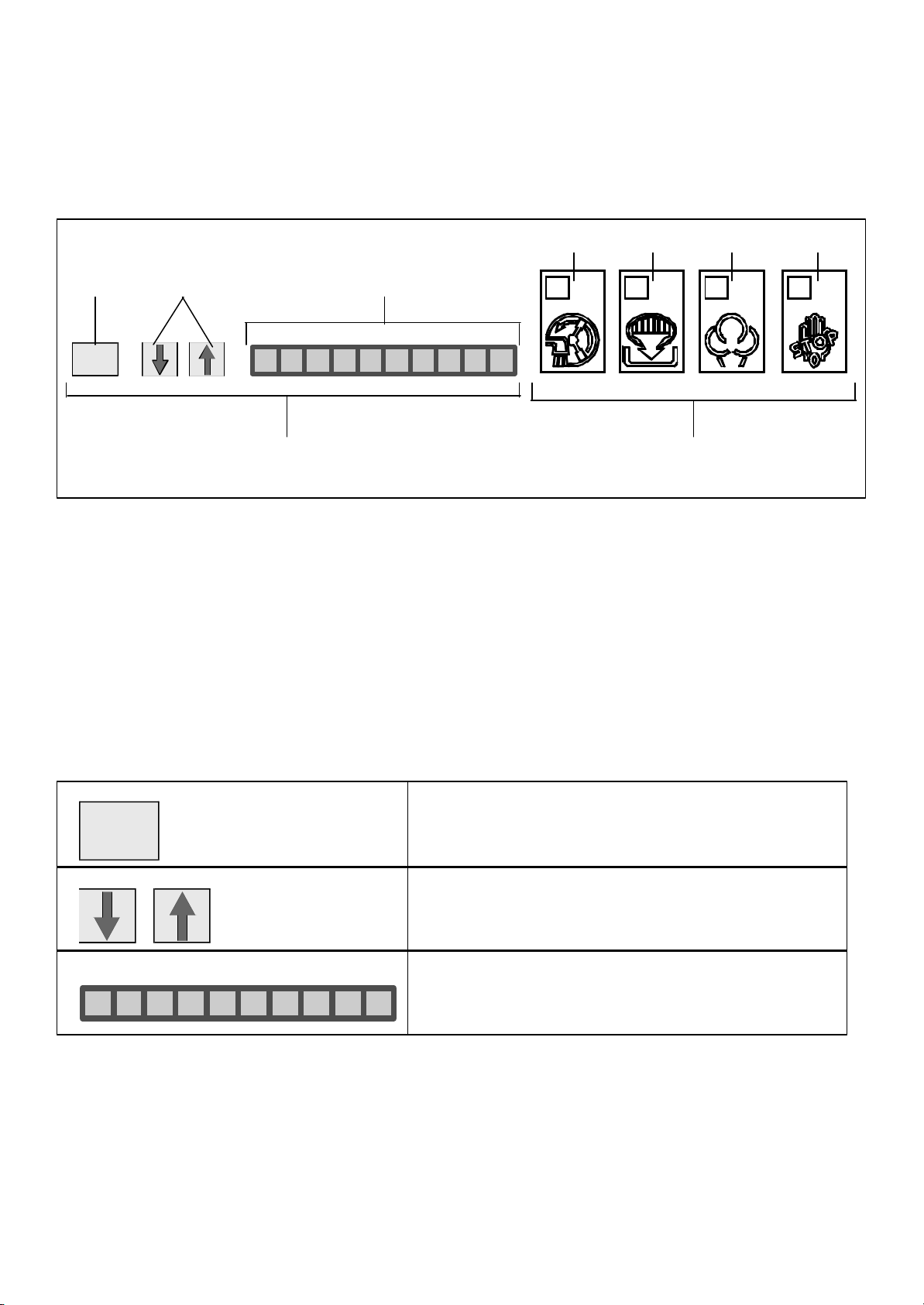

4 5 6 7

1 2

00

A B

MONITORING CONSISTENCY

The ice cream consistency monitor (Hard-O-Tronic) consists of 3 parts:

3

Control Panel

00

Rev. 3/98

Ref.1 DISPLAY displaying set calibration values

Ref.2 PUSH-BUTTONS for variation of calibration values

Ref.3 LED BAR for checking all processing phases in a real time.

Page 8

CARPIGIANI Operation Manual - LB 302, LB 502, LB 1002, LB 302 G, LB 502G, LB 1002 G

PUSHBUTTON PANEL

The machine has a diaphragm pushbutton panel on the front side. Each button has a symbol representing the corresponding function:

Ref. 4 Push-button CLEANOUT

When pressed, it just controls beater rotation, while the freezing system is cut

out.

Three minutes after inserting this function, the machine automatically sets to

"STOP" in order to avoid an excessive wear of beater and barrel.

Ref. 5 Push-button DISPENSE

When pressed, it controls beater rotation at high speed for an easy dispense of

the product .

Attention!

Three minutes after selecting and inserting this function, the machine

automatically sets to STOP in order to avoid an excessive wear of beater and

barrel.

Ref. 6 Push-button ICE CREAM PRODUCTION

When pressed, it automatically controls beater and compressor running.

Ice cream consistency is controlled by CARPIGIANI exclusive electronic

system called HARD-O-TRONIC, through which the best ice cream

processing value can be reached.

Ref.7 Push-button STOP

When pressing it, machine stops.

Attention!

If the machine is left in STOP more than 30 minutes and no other push-button

is pushed, the electronic card automatically switches off in order to reduce

energy consumption.

Press STOP in order to turn on the machine.

Page 9

Rev. 3/98

CARPIGIANI Operation Manual - LB 302, LB 502, LB 1002, LB 302 G, LB 502 G, LB 1002 G

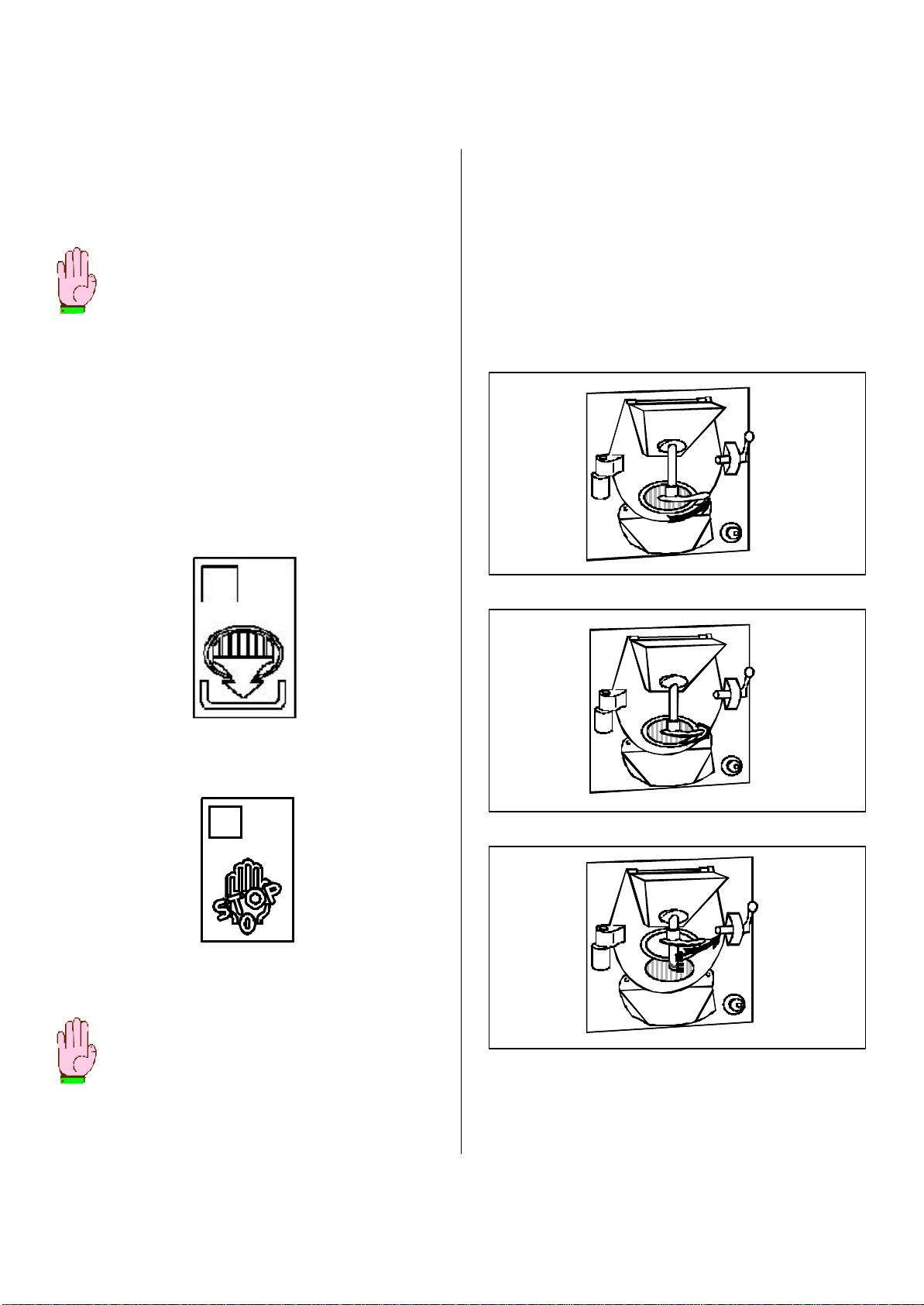

ICE CREAM DISPENSING HANDLE

LOCKING

• To lock the ice cream door, turn the handle to the right

until it stops (ref Fig. 5).

OPENING

• Turn the handle 90E to the left (ref Fig. 6).

• Lift the handle and the ice cream door then lock the ice

cream door in the top position by turning the handle

right until it stops (ref Fig. 7).

Figure 7

CLOSING

• Reverse the procedures described above.

Rev. 12/2002

Figure 5

Figure 6

Page 10

Page 10

CARPIGIANI Operation Manual - LB 302, LB 502, LB 1002, LB 302 G, LB 502 G, LB 1002 G

PART 3

INITIAL CLEANING PROCEDURE

This is a new machine and it must be completely disassembled, washed and sanitized before starting. Proceed

as follows:

PRELIMINARY CLEAN-OUT

• With the machine off and the beater front door closed,

use the hose and shutoff valve on the front of the machine to put water into the barrel.

• With machine on, press the "Clean Out" button and

allow the beater to run for the proper length of time.

• The machine will run for about 3 minutes and then will

automatically stop. The timer helps prevent unnecessary wear on the sliding shoes and barrel.

• Drain all water from barrel and open the door.

BEA TER DISASSEMBLY

(MODELS LB 302 - LB 502 - LB 1002)

• Remove the beater.

Beater mounted on models: LB 302 - LB 502

Beater mounted on models: LB 1002

Figure 9

Perform this operation with extreme care.

The beater may be damaged if it falls to the ground

or is impacted against another object.

• Remove the rear plug seal then remove the beater lip

seal from its seat on the beater shaft (ref Fig. 10).

Beater seal

Plug

seal

Beater mounted on models: LB 302 - LB 502

Plug seal

Stuffing

box

Figure 8

Page 11

Beater mounted on models: LB 1002

Figure 10

Rev. 12/2002

CARPIGIANI Operation Manual - LB 302, LB 502, LB 1002, LB 302 G, LB 502 G, LB 1002 G

BEATER DISASSEMBLY (MODELS LB 302 G - LB 502 G LB 1002 G)

• Remove beater with care, paying attention not to damage the sliding shoes.

Perform this operation with extreme care.

The beater may be damaged if it falls to the ground

or is impacted against another object.

• Disassemble sliding shoes, completely (ref. Fig. 12).

• Remove the beater lip seal from its seat on the beater

shaft (ref. Fig. 12).

• The sliding shoes mounted on the beater are "self-ad-

justing". An accurate cleaning ensures the system will

perform in full working order.

FRONT DOOR DISASSEMBLY

• Lift the door locking lever and shift it to the right (ref. Fig. 13).

• Open the door by rotating it on its hinge (ref. Fig. 13).

Beater

seal

Figure 13

• Lift the door and remove it (ref. Fig. 14).

• To perform cleaning operations, remove all movable parts

and seal with barrel.

Figure 11

Sliding

shoes

Beater mounted on models: LB 302 G - LB 502 G - LB 1002 G

Figure 12

Rev. 12/2002

Figure 14

Page 12

CARPIGIANI Operation Manual - LB 302, LB 502, LB 1002, LB 302 G, LB 502 G, LB 1002 G

ICE CREAM GATE DISASSEMBLY

• Lift the ice cream gate and remove OR (Ref. 1 - Fig. 15)

from sliding rod of ice cream gate and withdraw it which

will also release the lever.

• To perform cleaning, also remove the ice cream gate

OR (Ref. 2 - Fig. 15).

FILL CHUTE COVER DISASSEMBLY

• Remove the horizontal hinge pin (Ref. 3 - Fig. 15) then

remove the cover.

• The cover is provided with a small bulkhead (Ref.4 - Fig.15),

which prevents ice cream from going up into the fill chute

which must disassembled to be cleaned.

3

4

CLEANING OPERATIONS

• Wash all parts in lukewarm water (80-90 F) using a mild

non-foaming detergent. Scrub each of the parts with the

cleaning brushes provided in the Start-Up Kit.

Do not use hot water on plastic parts as damage

to the parts can result.

4) Air Dry

3) Sanitize

2) Rinse

1) Wash

Figure 16

Using your three-tank sink, wash, rinse and sanitize all of

the disassembled machine parts. Mix the sanitizing

solution to a 200ppm concetration with warm water. Allow

the parts to soak in the sanitizing solution for 3-5 minutes

2

before removing. Allow the parts to air-dry on the clean,

sanitized counter at the end of the sink.

Do not towel of sponge dry these parts.

1

Figure 15

Page 13

Rev. 12/2002

CARPIGIANI Operation Manual - LB 302, LB 502, LB 1002, LB 302 G, LB 502 G, LB 1002 G

PART 4

ASSEMBLING THE FREEZER

Once the parts have been washed, rinsed and sanitized,

the freezer is ready to be re-assembled. Prior to beginning the re-assembly procedure, sanitize your hands by

submerging them in the sanitizing solution.

FRONT DOOR RE-ASSEMBL Y

• Lubricate all rubber parts with the lubricant included in

the Start-Up Kit.

• Reassemble the components in reverse order to the

disassembly procedure previously stated. That is:

FILL CHUTE COVER

ICE CREAM DOOR

• Insert the assembled front door on the hinge (ref. Fig. 17).

Beater seal

Plug

seal

Beater mounted on models: LB 302 - LB 502

Beater seal

Plug

seal

Figure 17

BEA TER RE-ASSEMBL Y

(MODELS - LB 302 - LB 502 - LB 1002)

• Insert the rear plug seal (ref. Fig. 18).

• Lubricate the beater seal with a series of 3 pea size drop

on each side of the rubber beater seal, with the lubricant

included in the Start-Up Kit, then mount it (ref. Fig. 18).

• Position the beater into the freezing barrel; hold it with

both hands.

• Push the beater toward the bottom of the barrel.

In order to prevent damage to the beater and/or

freezing barrel, do not strike the beater against

the barrel rim.

Beater mounted on models: LB 1002

Figure 18

• Push beater deeply and, at the same time, turn it in

order to lock the end of beater shaft into its seat.

Figure 19

Rev. 12/2002

Page 14

CARPIGIANI Operation Manual - LB 302, LB 502, LB 1002, LB 302 G, LB 502 G, LB 1002 G

BEA TER RE-ASSEMBLY (LB 302 G - LB 502 G LB1002 G)

• Completely assemble the sliding shoes (ref. Fig. 20).

• Lubricate the beater lip seal with the lubricant included

in the Start-Up Kit and mount it (ref Fig. 20).

• Position the beater into the freezing barrel. To do that,

hold it with both hands and press the sliding shoes so

that it is easier to insert.

• Push the beater toward the bottom of the barrel.

In order not to damage the sliding shoes and/or

the freezing barrel, do not strike the beater against

the barrel rim.

Beater

seal

Beater mounted on models: LB 302 G - LB 502 G - LB 1002 G

Sliding

shoes

Figure 20

• Push the beater deeply and, at the same time, turn it in

order to lock the end of beater shaft into its seat.

Figure 21

Page 15

Rev. 12/2002

CARPIGIANI Operation Manual - LB 302, LB 502, LB 1002, LB 302 G, LB 502 G, LB 1002 G

PART 5

SANITIZING THE FREEZER

Before filling the machine with your liquid product, it must

be sanitized. The cleaning and sanitizing frequency cycles

must comply with all health codes in your area. Contact

your Board of Health for additional information.

Proper sanitizing of the machine is important. Sanitizing

retards the growth of bacteria and ensures excellent test

results when your machine is inspected by your local

health department and/or agriculture department.

To begin, you will need:

• A clean bucket.

• Sanitizer (sample packets were included in your StartUp Kit).

• A spatula (also included in the Start-Up Kit).

• A brush with plastic bristles.

SANITIZING PROCEDURES

• Mix the sanitizer (Stera Sheen green label or equivalent)

into the clean pail with at least two gallons of warm

water. Mix the sanitizer and water to make a 200-PPM

concentration of sanitizer solution. Using the spatula,

stir the solution until the sanitizer is completely

dissolved.

Do not exceed the formula recommended by the

sanitizer manufacturer – higher concentrations will

not increase the effectiveness. Do not use straight

chlorine bleach since it does not clean properly

and will damage plastic components. Do not leave

the sanitizing solution in the freezer longer than

on hour as it can corrode some parts.

• Pour the mix into the mixing tanks.

• With the machine off and the beater assembly door

closed, pour a non-corrosive sanitizing solution into the

freezing barrel.

• Push the “Cleanout” button.

• Run the machine for the correct time recommended for

this procedure – about 20-30 seconds.

Sanitizing Kit

Running the machine in the “Cleanout” mode for

excessive periods of time with the barrel empty or

with water and cleansing solutions will wear out

the beater shoes very quickly. Run the machine

ONLY for the time necessary to complete these

operations. To avoid unnecessary wear of the sliding shoes and barrel, the machine will automatically

stop after three minutes of uninterrupted running.

• Drain all sanitizer solution.

Do not touch the sterilized parts with hands, napkins, or anything else.

The machine is now sanitized and ready to be filled

with mix. Do not wipe aout any residual sanitizing

solution from the tank as this will contaminate the

machine with bacteria.

Rev. 12/2002

Page 16

CARPIGIANI Operation Manual - LB 302, LB 502, LB 1002, LB 302 G, LB 502 G, LB 1002 G

PART 6

STARTING THE FREEZER

ICE CREAM PRODUCTION (PROCESSING)

• Wash, sterilize, and thoroughly rinse the machine before use.

• Pour the desired quantity of mix into the barrel through

the front lid fill chute. Follow the minimum and maximum quantities shown in the table.

• Before filling the machine with mix, ensure the front door

and ice cream gate are properly closed.

• Push the “Production” button. The machine will start

the processing cycle by beating and cooling the mix.

• The LED lights on the Hard-O-Tronic display will light in

Production Button

sequence, indicating the status of processing. When

the LED panel blinks and you hear an audible alarm,

the processing cycle and the ice cream is ready to be

dispensed. The beater will continue to run, but the compressor has stopped.

ICE CREAM CONSISTENCY

BA

00

Hard-O-Tronic

CARPIGIANI sets the optimal ice cream consistency value

according to the mix being used. Hard-O-Tronic constantly

maintains ice cream in optimal condition. However, the

operator can also set “personalized” custom processing

cycles with the LB series.

High butter fat ice cream may require a higher consistency, while ice cream with low fat content (such as

shebert) requires a lower consistency setting.

CHANGING ICE CREAM CONSISTENCY

• To vary ice cream consistency, press the button (ref. B)

on the display panel while the machine is processing

ice cream.

• To achieve a harder ice cream, increase the setting value

displayed on the monitor (ref. A) by pushing the up arrow.

• To achieve a softer ice cream, decrease the setting value

displayed on the monitor by pressing the down arrow.

EXAMPLE:

To vary the consistency value from 10 to 7:

LED's

If ice cream is not dispensed soon after processing is

completed, beating of the ice cream will continue

while the Hard-O-Tronic system continuously monitors the consistency. If the consistency decreases,

the Hard-O-Tronic system will restart the compressor and processing to restore the ice cream to its

optimal thickness and consistency.

Page 17

• Press the button for ice cream processing.

Ice Cream Processing

• Repeatedly press the down arrow button until the value

7 is displayed. The new consistency value is immediately stored.

Rev. 12/2002

CARPIGIANI Operation Manual - LB 302, LB 502, LB 1002, LB 302 G, LB 502 G, LB 1002 G

• At the end of the processing cycle, the ice cream consistency value will be 7 instead of 10.

A typical value is 10. The new value will remain stored

until it is changed again.

Hourly output may vary depending upon: room and

cooling water temperature, type and quality of mix

used, and the consistency value that is set in the

machine.

DISPENSING ICE CREAM

When the production cycle is over (indicated by blinking

LEDs and an audible alarm), ice cream may be dispensed

from the barrel as follows:

• Place a container on the shelf under the ice cream door.

• Turn the ice cream gate handle.

• Lift the handle together with the ice cream gate.

• Push the “Distribution” button.

ICE CREAM DISPENSING HANDLE

LOCKING

• Lock the ice cream gate turning the handle to the right

until it stops.

OPENING

• Turn the handle 90° to the left (ref. Fig. 22).

• Lift the handle and the ice cream gate (ref. Fig. 23).

• Lock the ice cream gate on top by turning the handle to

the right until it stops (ref. Fig 24).

Figure 22

Distribution

Stop

• Press “Stop” when all product is removed.

To avoid unnecessary wear of the beater shoes

and barrel, the machine returns to the stop mode

after 3 minutes is non-use.

Figure 23

Figure 24

CLOSING

• Repeat the procedures (above) in reverse order.

Rev. 12/2002

Page 18

CARPIGIANI Operation Manual - LB 302, LB 502, LB 1002, LB 302 G, LB 502 G, LB 1002 G

AFTERCOOLING

This function (which is an exclusive feature of all LB models) is very useful in models with larger output capacity (2

containers per cycle or more).

If ice cream in each container needs further preparation,

such as garnish and variegation before storage, ice cream

that remains inside the machine at high speed dispense

may lose its original thickness.

At any moment during extraction, and when the operator

chooses, you may press the Production button to cool

the ice cream again.

The result is a steady consistency of ice cream, from the

beginning to the end of extraction.

After-cooling begins each time the Production button is pressed and runs for a duration of 20 seconds.

Distribution - Production

Page 19

Rev. 12/2002

CARPIGIANI Operation Manual - LB 302, LB 502, LB 1002, LB 302 G, LB 502 G, LB 1002 G

PART 7

CLEANING PROCEDURE

Cleaning and sanitizing schedules for your freezer are

determined by your local Health Department and / or

Department of Agriculture and must be followed

accordingly. Check with your local organization prior to

determining your cleaning schedule.

After determining your schedule, remove any ice cream

remaining in the barrel. Proceed as follows:

PRELIMINARY CLEAN-OUT

• With the machine off and the beater front door closed,

use the hose and shutoff valve on the front of the machine to put water in the barrel.

• Turn the machine on then press the Cleanout button

and let the beater run for the specified time. The machine will run for about three minutes then automatically stop. This helps prevent unnecessary wear on the

sliding shoes and barrel.

• Drain all water from the barrel then open the door to

remove the beater.

BEA TER DISASSEMBLY

(MODELS LB 302 - LB 502 - LB 1002)

• Remove the beater.

Perform this operation with extreme care.

The beater may be damaged if it falls to the ground

or is impacted against another object.

Beater mounted on models: LB 302 - LB 502

Beater mounted on models: LB 1002

Figure 26

Beater seal

Plug

seal

• Remove the rear plug seal then remove the beater lip

seal from its seat on the beater shaft (ref Fig. 27).

Figure 25

Rev. 12/2002

Beater mounted on models:LB 302 - LB 502

Plug seal

Stuffing

box

Beater mounted on models: LB 1002

Figure 27

Page 20

CARPIGIANI Operation Manual - LB 302, LB 502, LB 1002, LB 302 G, LB 502 G, LB 1002 G

BEATER DISASSEMBL Y (MODELS LB 302G - LB 502G - LB

1002G)

• Remove beater with care, paying attention not to dam-

age the sliding shoes.

Perform this operation with extreme care.

The beater may be damaged if it falls to the ground

or is impacted against another object.

• Disassemble sliding shoes, completely (ref. Fig. 29).

• Remove the beater lip seal from its seat on the beater

shaft (ref. Fig. 29).

• The sliding shoes mounted on the beater are "self-adjusting". An accurate cleaning ensures the system will

perform in full working order.

FRONT DOOR DISASSEMBLY

• Lift the door locking lever and shift it to the right (ref. Fig. 30).

• Open the door by rotating it on its hinge (ref. Fig. 30).

Beater

seal

Figure 30

• Lift the door and remove it (ref. Fig. 31).

• To perform cleaning operations, remove all movable parts

and seal with barrel.

Figure 28

Sliding

shoes

Beater mounted on models: LB 302 G - LB 502 G - LB 1002 G

Figure 29

Page 21

Figure 31

Rev. 12/2002

CARPIGIANI Operation Manual - LB 302, LB 502, LB 1002, LB 302 G, LB 502 G, LB 1002 G

ICE CREAM GATE DISASSEMBLY

• Lift the ice cream gate and remove OR (Ref. 1 - Fig. 32)

from sliding rod of ice cream gate and withdraw it which

will also release the lever.

• To perform cleaning, also remove the ice cream gate

OR (Ref. 2 - Fig. 32).

FILL CHUTE COVER DISASSEMBLY

• Remove the horizontal hinge pin (Ref. 3 - Fig. 32) then

remove the cover.

• The cover is provided with a small bulkhead (Ref.4 - Fig.32),

which prevents ice cream from going up into the fill chute

which must disassembled to be cleaned.

3

4

CLEANING OPERATIONS

• Wash all parts in lukewarm water (80-90 F) using a mild

non-foaming detergent. Scrub each of the parts with the

cleaning brushes provided in the Start-Up Kit.

Do not use hot water on plastic parts as damage

to the parts can result.

4) Air Dry

3) Sanitize

2) Rinse

1) Wash

Using your three-tank sink, wash, rinse and sanitize all of

the disassembled machine parts. Mix the sanitizing

solution to a 200ppm concetration with warm water. Allow

the parts to soak in the sanitizing solution for 3-5 minutes

before removing. Allow the parts to air-dry on the clean,

sanitized counter at the end of the sink.

Do not towel of sponge dry these parts.

2

FRONT DOOR RE-ASSEMBLY

(see Part IV - Page 14)

1

BEA TER RE-ASSEMBLY (LB302 - LB502-LB1002)

(see Part IV - Page 14)

Figure 32

BEA TER RE-ASSEMBLY (LB302G - LB502G LB1002G)

(see Part IV - Page 15)

SANITIZING THE FREEZER

(see Part V - Page 16)

Rev. 12/2002

Page 22

CARPIGIANI Operation Manual - LB 302, LB 502, LB 1002, LB 302 G, LB 502 G, LB 1002 G

PART 8

TECHNICAL INFORMATION

Model

LB 302

LB 502

LB 1002

LB 302 G

LB 502 G

LB 1002 G

* Output based on 4 batches per Hour at 40% overrun ** Output based on 4 batches per hour at 60% overrun

Weight

lbs

484

650

990

528

700

1052

D

input

3,7 kW

6,5 kW

9,5 kW

3,7 kW

6,5 kW

9,5 kW

Hourly

production

11 Gal. **

19 Gal. **

40 Gal. **

16 Gal. *

17 Gal. *

35 Gal. *

Qt. of mix per batchPower

min. max.

3 Qts.

7 Qts.

12 Qts.

3 Qts.

7 Qts.

12 Qts.

8 Qts.

14 Qts.

20 Qts.

8 Qts.

12 Qts.

20 Qts.

H

W

Measuring Dimensions

TECHNICAL INFORMATION

MODEL H D W

LB 302 55" 35" 20"

LB 502 55" 40" 24"

LB 1002 55" 47" 26"

MODEL H D W

LB 302 G 55" 35" 20"

LB 502 G 55" 40" 24"

LB 1002 G 55" 47" 26"

Page 23

Rev. 12/2002

CARPIGIANI Operation Manual - LB 302, LB 502, LB 1002, LB 302 G, LB 502 G, LB 1002 G

PART 9

MANTEINANCE

Any servicing operation requiring the

opening of machine panels must be carried

out with machine set to stop and disconnected from main switch!

Cleaning and lubricating moving parts is

forbidden!

Repairs of electrical and freezing plants

must be carried out by skilled engineers!

Operations necessary to proper machine running are such

that most of servicing is completed during production

cycle.

Servicing operations, such as cleaning of parts in contact

with the product, replacing of beater seal, disassembling

of beater assembly are to be carried out at the end of a

working day, so as to speed up serving operations required.

Here below you can find a list of routine servicing operations:

• Cleanout and replacement of beater seal

Cleaning should be carried out at the end of a working

day. Replacement of beater seal is necessary only after

checking the stuffing box, or in the event that product

drips inside the drip tray.

• Cleanout of beater assembly

At the end of a working day

• Cleanout of sliding shoes

At the end of a working day

• Cleanout of panels

To be carried out daily with neutral soap , seeing to it

that cleansing solution never reaches beater assembly at its inside.

• Cleanout and sterilization

At the end of each working day, according to procedures

described in section Part VII.

Your CARPIGIANI machine has been designed, engineered and manufactured to achieve high performance

and long durability.

The life expectancy of a machine, any machine, does

not depend only on the quality of its components and

design, but also on the beneficial effects of basic

maintenance procedures.

It is important to you, therefore, to become familiar with a

few of these basic procedures:

• Remove O-rings only with the O-ring extractor supplied

with the machine.

• Clean the machine according to the instructions.

• Lubricate all O-rings and seals, as instructed.

• The wearing or the improper cleaning of the beater shaft

seals, will result in leakage from the rear. Check the

drip chute pans frequently and replace seals, when so

necessary.

• Replace any O-ring that has a nick in it.

If not replaced, it will leak and interfere with the proper

performance of the machine.

• When all the spare parts supplied with the machine are

used, re-order immediately. Do not wait until the part is

required again.

• NEVER use the AUTO position for washing, sanitizing

and initially filling the freezing cylinder.

During the washing and sanitizing period, run the

machine only for the time strictly necessary for

this operation.Prolonged use of the beater in the

Cleaning position may cause severe damage to

the machine.

• Always wash metal, plastic or rubber parts in lukewarm

water. NEVER, NEVER USE HOT WATER!

If your Model is an air cooled machine, its efficiency depends on the air cooled condenser.

The fins of the condenser must be cleaned

every two or three months to assure efficiency.

Never use abrasive sponges to clean machine and

its parts, as it might scratch their surfaces.

Rev. 12/2002

Page 24

CARPIGIANI Operation Manual - LB 302, LB 502, LB 1002, LB 302 G, LB 502 G, LB 1002 G

PART 10

TROUBLESHOOT GUIDE

IRREGULARITY CAUSE PROCEDURE

Machine does not start Main switch is off Switch it on

Machine unplugged Check and plug in

Machine is not set at PRODUCTION Check push button for

PRODUCTIONis lit

Front lid is not closed well Check front lid closure

Compressor starts and Watercooled machine: Open water tap

then stops after a few water does not circulate

seconds without ice cream

being thick Check that hose is neither

squashed nor doubled up

Aircooled machine: Check that rear of machine air

does not circulate is at least 50 cm

from wall.

Clean obstruction from the condenser

After 15 minutes processing No gas Check leakage and weld

mix has not frozen and the

machine returns to Stop

Pressure switch has broken Check connection

down and replace, if need be

Machine runs but no No sugar in the mix Allow to thaw, then modify

ice cream comes from or replace the mix

ice cream door

Machine works but Too much sugar in Modify or replace

ice cream is too soft the mix the mix

Mix in drip drawer Beater seal missing Install if missing

or ruined Replace if ruined

Ice cream comes out Gasket missing or not Check and fix or replace

from behind front lid properly installed

Bacteria tests show Too high bacteria Improve preparation

too high bacteria charge charge in the mix procedure by sterilizing all

containers, spoons, etc.,

and have mix analyzed

before pouring it into the machine

Machine not clean Empty and thoroughly

enough wash the machine.

Carry out sterilization.

Page 25

Rev. 12/2002

Loading...

Loading...