Carpigiani KW 77 Owner’s Manual

P.O. Box 4069 • Winston-Salem, NC 27115 • 336-661-9893 • 336-661-9895 (Fax)

KW-77

Counter Model

Whipped Topping Dispenser

OPERATION MANUAL

Foreword

Thank you for selecting Coldelite to meet your operation and growing demands.

Your Coldelite freezer has been manufactured utilizing the most advanced technology and

modern equipment available in the industry. We at Coldelite, take great pride and care in

the manufacturing of each and every freezer, using only the finest components available, to

provide you with many years of trouble free operation.

Many years of experience in the manufacturing of soft serve dispensing equipment

have guided us in the preparation of this Operation Manual. PLEASE READ IT

CAREFULLY and keep it in an available place for future reference and most of all, follow

the instructions carefully.

On the following pages, you will find important information and procedures, which

describe the proper installation, sanitizing, operation, and maintenance of your Coldelite

freezer. We feel certain that your compliance with these instructions will assure excellent

performance, trouble-free operation and profitable business for years to come.

All technical data, pictures and drawings contained in this operation manual are not binding on the manufacturer, nor can the

manufacturer be held liable for any modification to the freezer in part or completely.

2

Part Number:

Index Page #

Foreword

Part I Installation

A) Uncrating 4

B) Positioning the Machine 4

C) Electrical Requirements 5

Part II Explanation of Controls

A) Electronic Control Panel 5-6

B) Mix Injection Pump 7

C) Texturizer and Dispensing Head 7

Part III Initial Cleaning Procedure 8

Part IV Assembling the Dispenser

A) Assembling the Mix Injection Pump 9

B) Assembling the Texturizer and Dispensing Head 10

C) Assembling the Front Drip Cup 11

Part V Sanitizing the Dispenser 11

Part VI Starting the Dispenser 12

Part VII Operating the Dispenser 12

Part VIII Periodic Cleaning Procedures 13

Part IX Technical Information

A) Refrigeration 13

B) Pump Drive Motor 13

Part X Maintenance

A) Troubleshooting Guide 14-15

3

!! IMPORTANT !!

B) Positioning the Machine

Failure to closely follow operational and

maintenance procedures may result in damage to

the unit and / or void your warranty. Coldelite

Corporation will not be responsible for any

machine not properly operated or maintained.

Part I – Installation

Before starting this procedure, ensure that the

shipping carton does not show any evidence of

damage due to dropping or mishandling. This

may indicate that the dispenser was damaged

during transit or delivery.

!! IMPORTANT !!

Should the outside of the shipping carton give

any indication of possible damage, state this on

the bill of lading prior to signing. Contact the

freight carrier and request an inspection of

damage. If this procedure is not adhered to, you

will forfeit your rights to file a damage claim

and be responsible for subsequent repair costs.

After removing the machine from the shipping

pallet, it is now ready to be located in its final

location. Prior to choosing a location keep in

mind that the dispenser should be accessible for

periodic maintenance and have adequate space

for necessary airflow. Please allow 6 inches of

clearance on both sides of the dispenser.

The dispenser must also be level to ensure proper

drainage from the mix tank. To level, place a

level on all corners and shim as needed.

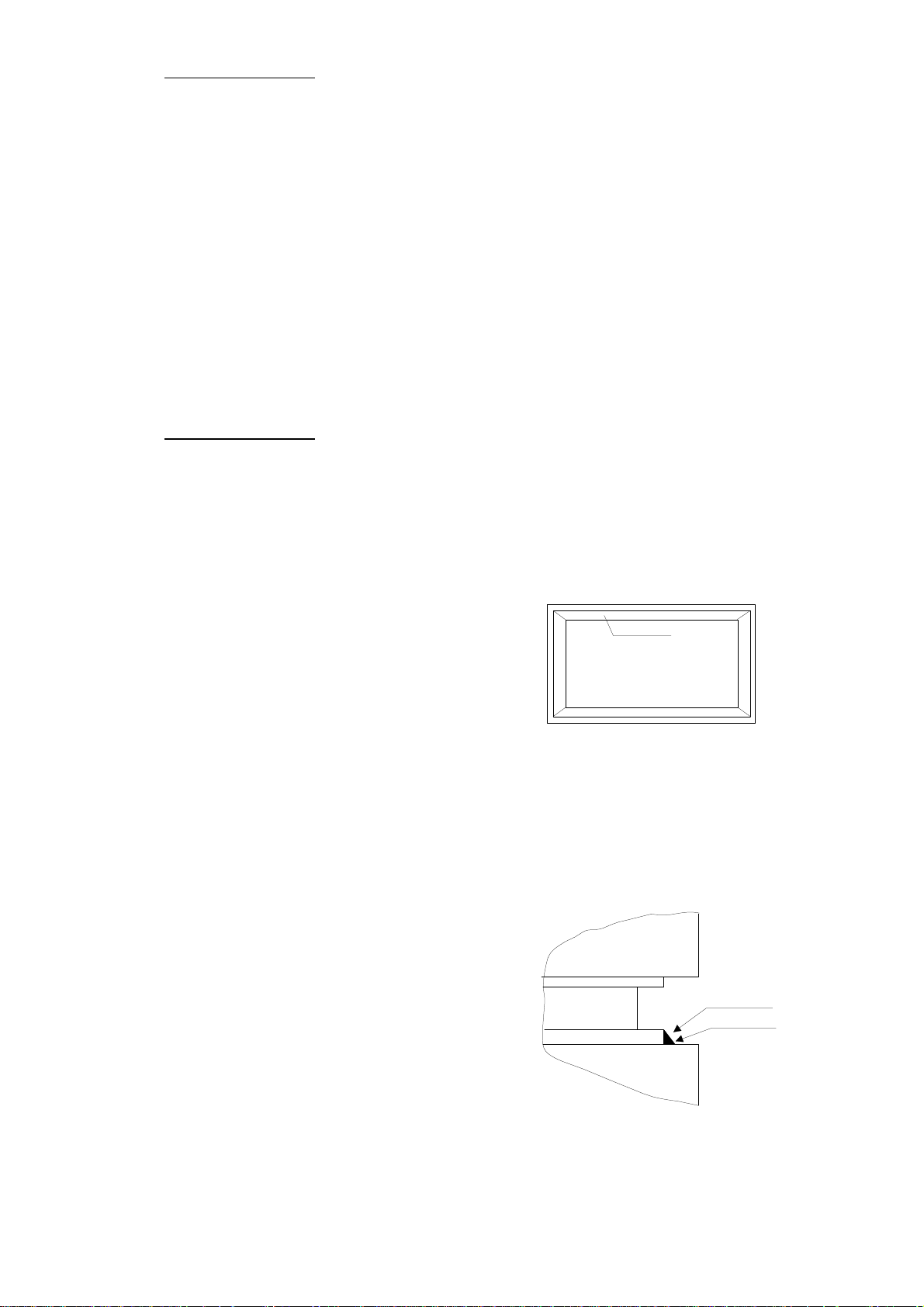

To seal the dispenser to the counter, proceed as

follows:

Determine the exact location you would like to

install the dispenser. Clean the counter top

thoroughly of any dust, dirt or oil.

Apply a thin bead (1/4”) of General Electric

RTV-102 (or equivalent) silicone sealant to the

lower mounting rim of the dispenser. (Refer to

Figure 1)

Mounting Rim

A) Uncrating the Dispenser

1) The outer shipping carton is secured to the

shipping pallet with strapping. When cutting this

strapping, do so with caution as it may spring out

quickly. After cutting the strapping, lift the

shipping carton straight up and off of the freezer.

2) Remove the protective foam boards and plastic

wrapping from the outside of the freezer.

3) Unwind the power supply cord and inspect for

any damage that may have occurred during

transportation. If the cord is damaged or cut in

any way, contact an Authorized Service Agent

before connecting to a power source.

Machine Bottom

Figure 1

Carefully lift the machine and place on the

counter in the exact predetermined location.

Remove any excess sealant from the base and

counter to create a flawless seam between the

counter top and machine base (Refer to Figure 2)

Machine

Silicone Sealant

Machine Base

Counter

Counter Surface

Figure 2

4

Allow the sealant to dry thoroughly before

operating the dispenser. Please refer to the sealant

manufacturer specs on the sealant tube.

Part II – Explanation of the Controls

A) Front Touch Pad / CPU Unit

THE MACHINE IS INTENDED FOR

INDOOR USE

C) Electrical Requirements

!!! WARNING !!!

This machine must be properly grounded.

Failure to provide adequate grounding can

result in severe electrical shock and / or fatal

bodily injury.

This machine is provided with a power cord

connected to the unit. You should have already

inspected the cord for any damages that may have

occurred during shipping. If there is no damage to

the cord, you may plug it into the electrical

receptacle.

For this dispenser, you will need to provide a

dedicated electrical circuit with a rating of

115vac / 60hz / 1phase – 15amperes. This

receptacle should be no farther than 6 feet from

the dispenser and at no times should an extension

cord be used. This electrical circuit must comply

with your local and / or state regulations.

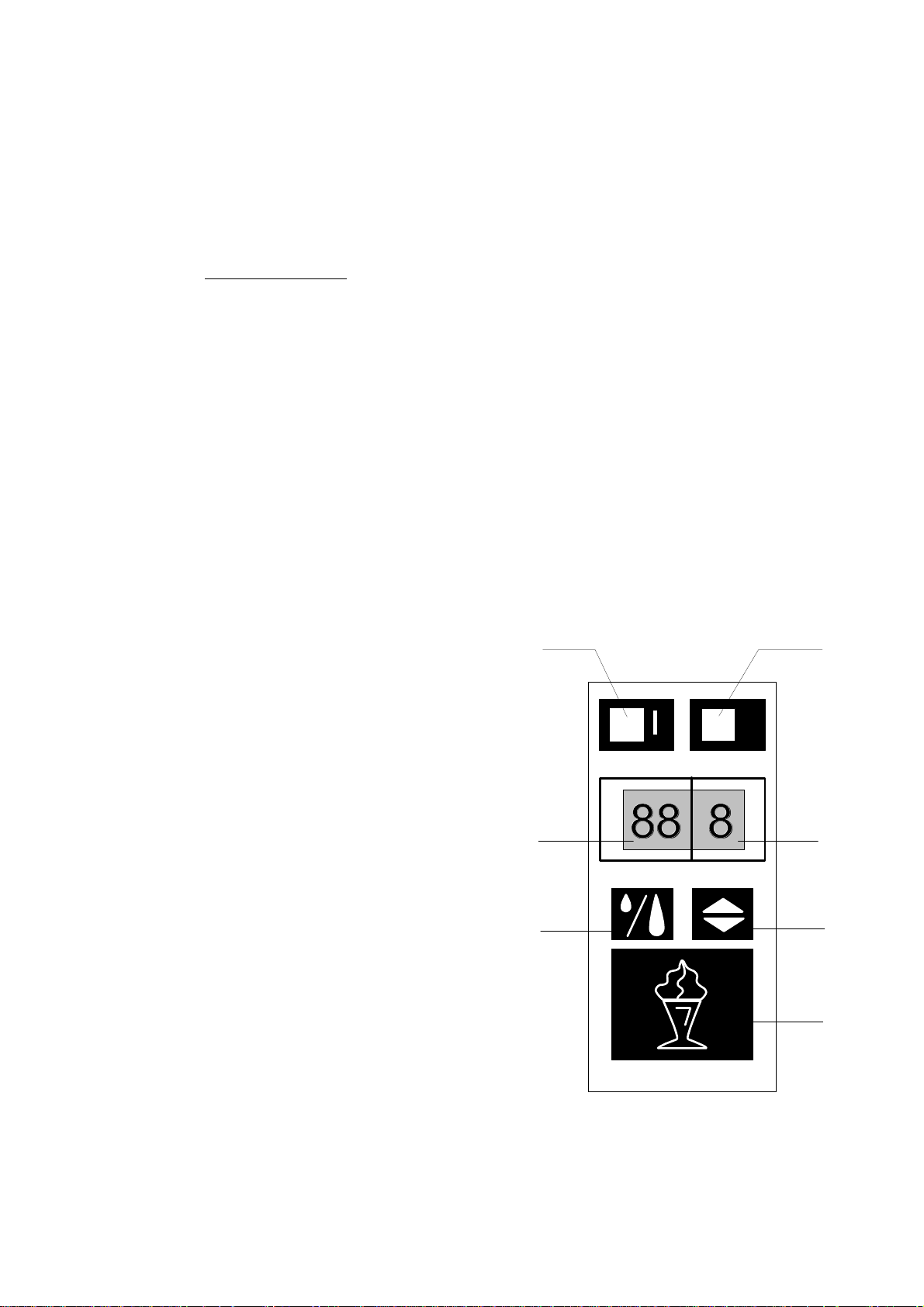

The model KW-77 machine is equipped with a

central CPU unit. This unit contains the front

touch pad, which monitors and controls the

functions of the machine. The front touch pad is

also the switching mechanism which operates the

following:

*Refrigeration of the product

*Activates the pump for dispensing

*Set the mix tank storage temperature

*Set the portion size or continuous dispense

mode

*Calibrate the temperature sensing probe

*Displays mix tank temperature

Also contained in the CPU unit is a delay timer

for the compressor. This delay will not allow the

compressor to immediately start, but delay the

start for three minutes. This delay will allow the

internal refrigerant pressures to equalize, which

will minimize high starting loads on the

compressor.

571.2571.1

ON

OFF

0

570.1

+

°F

571.4

t

570.2

sec.

571.5

571.3

Front Switch Pad

5

Loading...

Loading...