Page 1

Soft ice cream dispenser “K 503”

Equipment Operating Manual

Telephone:

Fax:

Issue: 8 Date: 2015/08 Changes: 2.1.1

Issued by: AM Checked by: AM Approved by: RL

Manufactured by:

Carpigiani

First Printing: Apr. ‘08

Version 8: 2015/08

Replaces:

Printed in Italy

Page 2

Carpigiani K-503 Equipment Manual

Table of Contents

CONVENTIONAL SYMBOLS ................................................................................................. 4

REMOVING MACHINE FROM PACKAGING ................. ................................... ... ............. 6

WEEE (WASTE ELECTRICAL AND ELECTRONIC EQUIPMENT) .............................. 7

TROUBLESHOOTING BACTERIA CONTAMINATION .................................................. 7

1. INTRODUCTION ............................................................................................................... 9

1.1 GENERAL INFORMATION .................................. .. ................................................... 9

1.1.1 MANUFACTURER IDENTIFICATION DATA ........................................................... 9

1.2 INFORMATION ABOUT THE MACHINE ............................................................. 10

1.2.1 GENERAL INFORMATION ...................................................................................... 10

1.2.2 INTENDED USE ........................................................................................................ 10

1.2.3 NOISE .............................. ............................. ................................ ............................. 10

1.2.4 TECHNICAL FEATURES .......................................................................................... 11

1.2.5 MACHINE ASSEMBLY IDENTIFICATION ......................... ..... ... ..... ...... ..... ... ..... ..... 11

1.2.6 PASTEURIZATION AUTOMATIC CYCLE (ONLY FOR PASTEURIZING

VERSIONS) ........................................................................................................................ ........ 12

1.2.7 TEMPERATURE CHECK (ONLY FOR PASTEURIZING VERSIONS) .................... 12

2. INSTRUCTIONS FOR USE ............................................................................................ 13

2.1 CONTROLS................................................................................................................ 13

2.1.1 FUNCTIONS .............................................................................................................. 14

2.2 EVENTS ............................ ................................ ................................ ......................... 18

2.3 GEAR REPLACEMENT ............................................................................................ 18

2.4 MANAGER MENU .................................................................................................... 19

2.5 OPERATION .............................................................................................................. 20

2.5.1 ICE CREAM DISPENSING ....................................................................................... 20

2.5.2 DISPENSING SPEED ................................................ ...... ..... ... ..... ..... ...... .. ...... ..... ... .. 20

2.6 PROGRAMMED CLEANING CYCLE ................................................................... . 20

2.7 POWER ON .................................. ... ..... ..... ... ..... ...... .. ...... ..... ... ..... ..... ... ..... ...... .. ...... ... 21

3. DAILY CLOSING PROCEDURES ....................................... ................................... ...... 22

PREPARE THE MACHINE FOR THE OVERNIGHT HEAT-TREATMENT CYCLE .................... 22

TOPPING PUMPS CLEANING ...................... .................................................................. ........ 22

DISASSEMBLE AND CLEAN THE COMPONENTS ................................................................ 23

CLEAN THE SPIGOT DOOR AREA. ........................................................................................ 23

4. DAILY OPENING PROCEDURES............. .................................................................. . 24

SANITIZE THE DOOR AREA ................................................................................................... 24

PREPARE THE HOT TOPPING ....................................................... ... ................................... .. 24

START THE MACHINE ............................................................................................................. 25

6. WEEKLY CLEANING .................................................. ...................................................... 27

6.1 WASHING AND SANITIZING OF THE TOPPING CONTAINERS ..................... 27

Page 2 of 44

s\\\\crp01s0023\cb_ut_r&d_pt\archivio_manuali\libretti istruzione\carpigiani &\k 503 &\ed_2015 _08\nativi\mi_k 503_ed 08_it_en.docx

Version 8: 2015/08

Page 3

Carpigiani K-503 Equipment Manual

6.1.1 CLEANING THE TOPPING CONTAINERS: ................................................................... 27

6.1.2 CLEANING THE TOPPING HOPPER ........................................................................... 27

6.2 DISASSEMBLY, WASHING AND SANITIZING OF TH E HOT TOPPING PUMPS

27

6.3 CHECK TOPPING PUMP TEMPERATURE AND VOLUME ............................... 29

7. CLEANING EVERY 14 DAYS ....................................................................................... 30

7.1 DISASSEMBLING AND CLEANING .................... ... ................................... ........... 30

7.1.1 DRAINING AND CLEANING THE ICE CREAM ..................................................... 30

7.1.2 DISASSEMBLING THE MIX PUMP ............................................... .. ........................ 32

7.1.3 DISASSEMBLING THE SPIGOT DOOR ................................................................. 33

7.1.4 BEATER REMOVAL .................................................................................................. 33

7.2 DISASSEMBLING AND CLEANING THE OTHER COMPONENTS: ................. 34

7.3 WASHING AND SANITIZING COMPONENTS ........................... ... ...................... 34

7.4 REASSEMBLY OF WASHED AND SANITIZED COMPONENTS ...................... 35

7.4.1 REASSEMBLY OF THE BEATER ............................................................................. 35

7.4.2 REASSEMBLY OF THE SPIGOT DOOR .................................................................. 36

7.4.3 REASSEMBLY OF THE MIX PUMP......................................................................... 37

7.4.4 REASSEMBLY BEATER HOPPER ............................................................................ 37

7.5 SANITIZATION OF THE WHOLE MACHINE ....................................................... 38

7.5.1 SANITIZE THE HOPPER ................................................................................................ 38

7.5.2 SANITIZE THE PUMP AND CYLINDER ................................................................. 38

7.5.3 DRAIN THE SANITIZER ................................................................................................. 38

7.5.4 PREPARING THE TOPPING AREA ............................................................................... 38

8. PREVENTIVE MAINTENANCE .................................. ... .............................................. 40

8.2 PERIODICAL CHECK-UP AND MAINTENANCE ................................................ 41

8.3 WATER COOLING .......... ... ................................... .................................. ................. 41

8.4 AIR COOLING ........................................................................................................ .. . 41

9. TROUBLESHOOTING ..................... ................................... .................................. ......... 42

9.1 ALARMS .................................................................................................................... 42

s\\\\crp01s0023\cb_ut_r&d_pt\archivio_manuali\libretti istruzione\carpigiani &\k 503 &\ed_2015 _08\nativi\mi_k 503_ed 08_it_en.docx

Version 8: 2015/08

Page 3 of 44

Page 4

Carpigiani K-503

Equipment Manual

Conventional Symbols

WARNING: ELECTRIC SHOCK HAZARD

The staff involved is warned that the in observance of safety rules in carrying out the

operation described may cause an electric shock.

WARNING: GENERAL HAZARD

The staff involved is warned that the operation described may do harm if not carried out in

the observance of safety rules.

NOTE

It points out significant information for the staff involved.

WARNING

The staff involved is warned that the in observance of information may cause a loss of data

and damages to the machine.

PROTECTIONS

This symbol placed by description side means that the operator must use personal

protections against an implicit risk of accident.

MACHINE OPERATOR

He/she is an unskilled person, who has no specific expertise and can only carry out easy

chores, such as the machine operation by means of controls available on the push-button

panel, and filling and drawing of products used during operations.

MAINTENANCE ENGINEER

He/she is a skilled engineer for the operation of the machine under normal conditions;

he/she is able to carry out interventions o n mechanical parts and all adjustments, as well

as maintenance and repairs. He/she is qualified for interventions on electrical and

refrigeration components.

SAFETY

When using industrial equipment and plants, one must be aware of the fact that drive

mechanisms (rotary motion), high voltage components, as well as parts subject to high

temperatures may cause serious damages to persons and things.

Who is in charge of plant safety must be on the look-out that:

- an incorrect use or handling is avoided;

- safety devices must neither be removed nor tampered;

- only original spare parts are to be used especially as far as those compo nents with safety functions are

concerned (e.g.:protection micro switches, thermostats).

To achieve the above, the following is necessary:

- an instruction manual relevant to the machine should be available at the working place;

- such documentation must be carefully read and regulations must consequently be followed;

- only adequately skilled personnel will have to be assigned to electrical equipment.

s\\\\crp01s0023\cb_ut_r&d_pt\archivio_manuali\libretti istruzione\carpigiani &\k 503 &\ed_2015 _08\nativi\mi_k 503_ed 08_it_

Version 8: 2015/08

Page 4 of 44

en.docx

Page 5

Carpigiani K-503 Equipment Manual

WARNING

The machine must be exclusively installed by authorized technicians. When installing the

machine, insert a differential magnetothermal protection switch on all poles of the line,

adequately sized to the absorption power shown on machine identification plate and with a

contact opening of 3 mm at least. This switch is used to cut off the power supply. Any

replacement of the power cable must be carried out only by a specialized and authorized

technician.

Never put your hand into the machine, both during production and cleaning operations. Before carrying

out any maintenance operation, make sure that the machine is in “STOP” position and that the main switch

has been cut out.

It is forbidden to wash the machine by means of a stream of water under pressure.

Disconnect electrical power before removing any side or rear panel.

CARPIGIANI is not responsible for any accident that might happen during operation, cleaning

and/or servicing of its units, if this warning has not been fully complied with.

s\\\\crp01s0023\cb_ut_r&d_pt\archivio_manuali\libretti istruzione\carpigiani &\k 503 &\ed_2015 _08\nativi\mi_k 503_ed 08_it_en.docx

Version 8: 2015/08

Page 5 of 44

Page 6

Carpigiani K-503 Equipment Manual

REMOVING MACHINE FROM PACKAGING

1. Check the Shock-watch label which indicates whether the goods have been mishandled; inspect the

cardboard shipping carton for signs of damage.(

2. Cut the metal straps (be ware of snapping metal), lift t he cardboard carton up and off of the pallet (see

fig. 2).

3. Remove bag and Styrofoam protection. Inspect the machine again for signs of shipping damage or rough

handling. If damage is visible, notify the restaurant manager and/or the shipping company (see fig. 3).

Fig. 2

Fig. 1

Fig. 3

Removal from the pallet must be carried out by two qualified persons in material handling and in

compliance with the safety rules.

4. The machine i s attached to th e pallet by 4 bolts. Th e bolt heads ar e on the bottom si de of the pallet and th ey

tighten into threaded holes on the bottom of the machine. The two wooden shims, placed sideways under the

machine,

5. Now loosen the packing bolts from the bottom side of the pallet, on one side only, and let them drop to the floor.

It is not necessary to remove the side panels of the machine to do this (see fig. 4).

6. Slightly, incline the machine on one side and remove the wooden block. Please be careful. The wood blocks

keep the machine wheels off the pallet by ¼"

drop that distance (see fig. 5).

7. Repeat the same procedure on the other side.

8. After the removal of the wooden blocks, the machine will directly rest w ith its wheels on the pallet.

9. In order to unload the machine from the pallet, use the wooden ramps

enable to keep the wheels ¼" of the surface of the pallet (see fig. 4).

Place the wooden ramps against the rear side of the machine and push the machine

from the FRONT SIDE moving it to the rear. Two persons, one in front and one in the

rear, must handle and control the machine (see fig. 6).

see fig. 1).

WARNING

, therefore their removal will cause the machine to

supplied with the machine.

s\\\\crp01s0023\cb_ut_r&d_pt\archivio_manuali\libretti istruzione\carpigiani &\k 503 &\ed_2015 _08\nativi\mi_k 503_ed 08_it_en.docx

Version 8: 2015/08

Page 6 of 44

Page 7

Carpigiani K-503

Equipment Manual

Fig. 4 Fig. 5 Fig. 6

WEEE (Waste Electrical and Electronic Equipment)

In conformity with the European Directives 2006/66/EC, on batteries and accumulator s and waste batteries

and accumulators, and 2002/96/EC, also known as WEEE, the presence of the symbol

on the side of the product or packaging means that the pro duct must not be disposed

of with normal urban waste. Instead, it is the user’s responsibility to dispose of this

product by returning it to a collection point designated for the recycling of electrical and

electronic equipment waste. Separate collection of this waste helps to optimize the

recovery and recycling of any reclaimable materials and also reduces the impact on

human health and the environment.

For more information concerning the correct disposal of this product, please contact

your local authority or the retailer where this product was purchased.

Troubleshooting Bacteria Contamination

Product samples should be taken periodically by a qualified expert in order to assess the

bacteria count in the product. The bacteria count in the samples should be below the

figures given below:

Standard Plate Count (SPC)……………..50,000

Coliform …………………………………………10

Should the bacteria counts exceed the figures listed above then there is a source of bacterial

contamination. The source of contamination must be identified and corrected. High bacteria counts

indicate that a product is not safe for consumption. You must inform the machine

operator on how to prevent bacterial contamination of the product.

Note: The soft yogurt

will have high bacteria counts. This is normal and helps define the product. However,

coliform bacteria contamination is NOT ACCEPTABLE in any food product. The

information given below will help prevent coliform bacteria contamination problems.

The following

methods of prevention.

list contains possible bacteria contamination sources along with

s\\\\crp01s0023\cb_ut_r&d_pt\archivio_manuali\libretti istruzione\carpigiani &\k 503 &\ed_2015 _08\nativi\mi_k 503_ed 08_it_

Version 8: 2015/08

Page 7 of 44

en.docx

Page 8

Carpigiani K-503 Equipment Manual

SOURCE OF

CONTAMINATION

1 - Contact with the operator.

2 - Mix residue/deposits (milkstone

build-up).

3 - Worn or damaged parts.

4 - Incorrect cleaning and sanitation

procedures.

PREVENTION

1a - Wash hands and forearms thoroughly.

1b - Wear rubber gloves if cuts or skin conditions exist.

1c - Wash hands periodically thro ughout the day.

2a -

Use the brushes supplied with the machine.

2b - Thoroughly brush clean all parts and components to

prevent the formation of

bacteria and contaminate fresh mix.

3a - Lubricate all rubber parts

a food grade lubricant.

3b - Inspect o-rings for damage. Only replace with factory

approved parts.

3c - Regularly check drip troughs for exces si ve leak ag e.

4a -

The container where cleaning is carried out must

be perfectly clean and contain enough solution to

cover the biggest component. Brush clean and

sanitize the freezer on a regular basis.

4b - Use the correct brushes, lubricants, and single service

towels.

4c - Store and use chemicals according to the instructions

on their labels.

4d - Use a few good employees to follow the cleaning

procedure correctly and consistently. Allow the employee

uninterrupted time to complete the cleaning procedure.

4e -

Leave the sanitizing solution in the hopper and in

the cylinder for a few minutes.

4f - Wash and sanitize the lubricant tube after each use.

Always replace the cap on the tube.

4g - Machine components and brushes should be air-dried

overnight.

Do not put them back in the machine if

they are still wet.

4h - Always follow daily cleaning procedures. Regularly wipe

down the outside of the machine and dispensing spouts

with a sanitized towel.

milk lumps, which will house

in contact with the mix with

s\\\\crp01s0023\cb_ut_r&d_pt\archivio_manuali\libretti istruzione\carpigiani &\k 503 &\ed_2015 _08\nativi\mi_k 503_ed 08_it_en.docx

Version 8: 2015/08

Page 8 of 44

Page 9

Carpigiani K-503

Equipment Manual

SOURCE OF

CONTAMINATION

5 - Improperly stored mix.

PREVENTION

5a - Use mix stock with oldest date first. Observe expiration

dates.

5b - Place the mix directly in the cooler. Do not stack mix

outside or under direct sunlight before placing it in the

cooler.

5c - Always leave one inch between the mix and ot her products

in the cooler to allow air to circulate.

5d - Mix must not remain at room temperature for long periods

of time.

5e - Hopper storage must maintain a temperature of 40°F

(4,4°C). Storage temperatures above 45°F will allow

bacteria to multiply to dangerous levels in less than one

hour.

5f - Once the mix is placed in the hopper, the hopper covers

must be used to maintain the correct temperature and

minimize mix contamination.

1. INTRODUCTION

1.1 GENERAL INFORMATI ON

1.1.1 MANUFACTURER IDENTIFICATION DATA

The machine has a plate indicating manufacturer data, machine type and serial number.

LEGEND:

=

Serial number

A

=

Machine type

B

=

Voltage

C

=

Main switch ampere rating

D

=

Gas type and weight

E

Machine code

=

F

=

Condensation type

G

=

Frequency

H

Power input

=

I

Matr.

Gas

A

B

ANZOLA EMILIA - BOLOGNA - ITALY

DE

C

V

A

kg

Cod

air

F

G

.

Hz

HI

kW

MPa

s\\\\crp01s0023\cb_ut_r&d_pt\archivio_manuali\libretti istruzione\carpigiani &\k 503 &\ed_2015 _08\nativi\mi_k 503_ed 08_it_

Version 8: 2015/08

Page 9 of 44

en.docx

Page 10

Carpigiani K-503 Equipment Manual

1.2 INFORMATION ABOUT THE MACHINE

1.2.1 GENERAL INFORMATION

Electronic, heat-treatment, floor standing machine, for the production and immediate distribution of ice

cream having the following main features:

refrigerated upper hoppers;

pasteurization system to treat the mix inside the hopper and inside the cylinder during pause periods (only for

pasteurizing version);

electronic consistency control system hard-o-tronic;

two containers for hot toppings, with heating temperature control;

two containers for room temperature toppings.

1.2.2 INTENDED USE

The K-503 machine must only be used for the production of ice cream, within the functional limits listed

below:

Voltage: ±10%

Min. ambient temperature: 50°F (10°C)

Max. ambient temperature: 109°F (43°C)

Max. ambient relative humidity: 85%

This machine is designed to be used in closed places not subject to explosion-proof standards. As a matter

of fact, it shall be used in places complying with normal atmosphere.

1.2.3 NOISE

The continuous level of acoustic radiation pressure, which has been weighed and called A on working

place, turns out to be lower than 70 dB(A), both by air-cooled and water-cooled units.

s\\\\crp01s0023\cb_ut_r&d_pt\archivio_manuali\libretti istruzione\carpigiani &\k 503 &\ed_2015 _08\nativi\mi_k 503_ed 08_it_en.docx

Version 8: 2015/08

Page 10 of 44

Page 11

Carpigiani K-503

1.2.4 TECHNICAL FEATURES

MODEL

80 mm

Hourly

production *

80 gr.

portions

50 mm 50 mm

Hopper

capacity

liters

Flavours

Equipment Manual

1040 mm

with drip tray

Electrical supply

Volt Phase Cycle kW

In stalled

power

1470 mm

Net weight

Kg

1520 mm

1576 mm

K-503 2 x 430 2 x 18 2 + 1 400 3 50 6 398

1.2.5 MACHINE ASSEMBLY IDENTIFICATION

LEGEND:

1 Control panel

2 Cylinder front spigot door

3 Drip tub

4 Mix hopper cover

5 Topping area

s\\\\crp01s0023\cb_ut_r&d_pt\archivio_manuali\libretti istruzione\carpigiani &\k 503 &\ed_2015 _08\nativi\mi_k 503_ed 08_it_

Version 8: 2015/08

4

1

2

5

3

Page 11 of 44

en.docx

Page 12

Carpigiani K-503 Equipment Manual

1.2.6 PASTEURIZATION AUTOMATIC CYCLE (ONLY FOR PASTEURIZING VERSIONS)

The machine is pre-set to automatically start the heat-treatment cycle every night at 2 a.m.. The automatic

pasteurization can be set at different times (see chapter 2.3 of the Manager Menu, step U09).

1.2.7 TEMPERATURE CHECK (ONLY FOR PASTEURIZING VERSIONS)

1. When the machine is in STOP mode, the temperature in the hopper is checked: if it is equal to or

higher than 15°C (59°F) the pasteurization program is enabled.

s\\\\crp01s0023\cb_ut_r&d_pt\archivio_manuali\libretti istruzione\carpigiani &\k 503 &\ed_2015 _08\nativi\mi_k 503_ed 08_it_en.docx

Version 8: 2015/08

Page 12 of 44

Page 13

Carpigiani K-503

play

Equipment Manual

2. INSTRUCTIONS FOR USE

2.1 CONTROLS

The K-503 machine is equipped with a front push-button panels.

Warning light for LOW mix

DRY FILLING BUTTON

level

Flashing LCD display to

warn:

"read information on the

dis

"

MAIN FUNCTIONS:

- STOP

-

Production

Beating button/Lock button

Increase Button:

- lights on from the beginning to the end

of the heat-treatment cycle

- “+” increase button for manager menu

IMPORTANT

Push-buttons are activated keeping the finger (not the nail) pressed on it for at least 1/2 second.

WARNING

TO REDUCE BEATER BLADE WEAR (POS. 430) USE THE BEATER FUNCTION ONLY FOR THE

NECESSARY TIME.

Pasteurization LED (only for pasteurizing ve rsions)

- lights on from the beginning to the end of the

heat-treatme nt cycle

- “+” increase button for manager menu

Storage Led / Reset Button

- Lights on at the end of the

heat-treatment cycle

- “-” decrease button for

manager menu

- Push to reset alarm messages

s\\\\crp01s0023\cb_ut_r&d_pt\archivio_manuali\libretti istruzione\carpigiani &\k 503 &\ed_2015 _08\nativi\mi_k 503_ed 08_it_

Version 8: 2015/08

Page 13 of 44

en.docx

Page 14

Carpigiani K-503 Equipment Manual

2.1.1 FUNCTIONS

STOP BUTTON

By pressing this push-button during operation, the machine stops (LED on).

DISPLAY Notes

10:33:21 Fri When the machine is in STOP, the display sh ows Time and Date.

10:33:21 Fri

Overload Beater

In case is an ALARM ac tivated, the ba cklight of the LCD displ ay will flas h,

and the display indicates the kind of ALAR M.

START / PRODUCTION BUTTON

Press START button to start the production mode (LED on). The motor and compresso r

are automatically controlled by HARD-O-TRONIC system.

By pressing this button from STOP, the display indicates:

KEY

1

2

3

4

5

DISPLAY Notes

Do Not Serve !

Wash In 14 days

Sundae Ready !

Wash In 14 days

Do Not Serve !

Overload Beater

Hopper +14°C

Cylinder +13°C

Set=090 Hot=085

MIR = 0

Cones today

1543

Total Cones

123456789

When the soft ice cream is not ready, the display shows: "DO NOT

SERVE".

When the soft ice cream has reached the desired co nsistency the display

shows “READY“.

In case of ALARM, it will be displayed on the second row.

While in Production mode, it’s possible to go to the next page of the

display by pushing PROD key. Temperatures are indicated.

Pushing PROD again, we move to the next pa ge showing actual

consistency and the SET to be reached. The second row shows MIR = 0

when the handle is closed and MIR=1 when the handle is opened.

Pushing PROD again, we move to the next page s howing the cones

today counter.

Pushing PROD again, we move to the next page sh owing the total cones

counter.

6

7

TEV=+10 TGV=-22

TEC=+13 TE1=-12

TET=+60 Pushing PROD again, we move to the next page showing the actual

Pushing PROD again, we move to the next page s howing the

temperature in the hopper and in the cylinder.

Topping temperature.

Page 14 of 44

s\\\\crp01s0023\cb_ut_r&d_pt\archivio_manuali\libretti istruzione\carpigiani &\k 503 &\ed_2015 _08\nativi\mi_k 503_ed 08_it_en.docx

Version 8: 2015/08

Page 15

Carpigiani K-503 Equipment Manual

g

g

Pushing PROD again, we move to the next page that is the first page.

HOT TOPPING

In PROD. function the hot topping container is heated automatically to reach the

desired temperature. In case the water level in the bainmarie is too low the display

will indicate an alarm in order to refill with water.

BEATING BUTTON

By pressing this button from STOP, the led turns on. The beater and the mix pump motor

KEY

1

2

3

4

get ON until you press STOP or after 3 minutes. The display indicates:

DISPLAY Notes

HOT=58 TEC=+13

Beater + Pump ON

HOT=58 TEC=+13

Pump ON

HOT=58 TEC=+13

Beater ON

HOT=58 TEC=+13

Beater + Heating

Pushin

one time this button, the beater motor and the

mix pump motor will turn ON.

Pushing a second time this button, the beater motor will

STOP whereas the mix pump remains ON.

Pushin

a forth time this button, the beater pump will

STOP whereas the beater turns ON.

Pushing a forth time this button, the cylinder is heated

up to the Set value (default 30°C) in order to melt the ice

cream before cleaning.

version)

LOCK BUTTON

To clean the keyboard panel with a clean towel it is recommended to block the keys of the

keyboard as follows:

Push for 3 seconds button, the respective LED will flash indicating that the keyboard

is blocked. At this stage you can clean the keyboard without any risk. To reactivate the

keyboard push for 3 seconds button, the LED will get off.

The heat-treatment function can be activated only if the mix in both hoppers is

above the Medium Level (“ADD MIX” message on display must be off).

AUTOMATIC HEAT-TREATMENT CYCLE:

- LED on) and the mix is above the medium level in both sides, the heat-treatment cycle

starts automatically at a certain time (as programmed in the Man ager Menu normally at

2:00 AM).

While the display indicates “HEAT-TREATMENT CYCLE” the mix in the hopper and in the

cylinder is heated up to 68°C, kept at 68°C for 30 minutes and then coo led down to the

storage temperature.

When both sides reach the storage temperature, the display shows “PASTO END”

followed by date and hour of termination. The machine passes automatically to STORAGE

function.

To serve soft ice cream, press STOP then the PR OD button.

PASTEURIZATION FUNCTION / INCREASE FUNCTION (only for pasteurizing

while the machine is in production (both sides

s\\\\crp01s0023\cb_ut_r&d_pt\archivio_manuali\libretti istruzione\carpigiani &\k 503 &\ed_2015 _08\nativi\mi_k 503_ed 08_it_en.docx

Version 8: 2015/08

Page 15 of 44

Page 16

Carpigiani K-503 Equipment Manual

Note: once the heat-treatment cycle has started, it can’t be interrupted. The

complete heat-treatment cyc le wi ll tak e less than 4 hours to be com ple te d.

During the heating and Pause cycles, the mix in the machine is very hot. Do not

attempt to draw mix or disassemble the machine.

The heat-treatment cycle is performed on both sides simultaneously. It is not

possible to perform heat-treatment in one side only.

WARNING

Do not draw soft ice cream or disassemble the machine during the heat-treatment

because the product is very hot and under pressure.

This button is also used to start a heat-treatment cycle manually on both sides (left and

right).

This button is used to increase the value in the manager menu or water quantity setting.

STORAGE / DECREASE FUNCTION / RESET ALARM MESSAGES

The Storage Led lights ON as soon as the heat-treatment cycle ends. The machine

preserves the mix at the storage temperature in the hopper and in the cylinder.

- This button is used to decrease the value in the manager menu.

- This button is also used to RESET the ALARM MESSAGES on the display.

- This button is also used to start a STORAGE cycle manually on the desired side (left or

right).

DRY FILLING BUTTON

A Dry Filling cycle can only start from Production.

The cycle is enabled with mix below Medium or Low levels.

Production with mix below medium level and low level covered

1. The display will read:

Add Mix

An intermittent acoustic signal is activated.

Press the DF key .

The Increase and Decrease keys turn on and the display shows:

Liters 00.10

The quantity of water can be modified pressing the Increase and Decrease

keys in steps of 0.05 liters, within 5" after the DF key is pressed.

If no key is pressed for 10", quantity selection pha se will be quit a nd the displa y goes back

to the previous screen.

s\\\\crp01s0023\cb_ut_r&d_pt\archivio_manuali\libretti istruzione\carpigiani &\k 503 &\ed_2015 _08\nativi\mi_k 503_ed 08_it_en.docx

Version 8: 2015/08

Page 16 of 44

Page 17

Carpigiani K-503 Equipment Manual

2.

Confirm water quantity of water with the DF key

3.

Now water dispensing starts. The procedure can be interrupted at any time by pressing

STOP.

At the end of water dispensing, there is a first mixing phase.

4.

Fast beating in the hopper is enabled for a set time. The display will show the timer

decreasing on the second line:

Dry Filling

Please Wait 2:59

The procedure can be interrupted at any time by pressing STOP.

5.

At the end of the first mixing phase, there is a second mixing phase.

At the end of mixing, DF ends. The machine goes back to standard Production.

6.

Production with mix below low level

The display will read:

Carry out Dry

Filling

An intermittent acoustic signal is activated.

The Dry Filling phases are the same described before, but with the following differences:

Production is never enabled and at the e n d of the D F proc ed ure the machine will

•

automatically Stop

The quantity can be modified in steps of 0.10 liters.

•

•

During the second mixing phase (phase 5) Production is not enabled and the display

will show:

Dry Filling

Mix 7:59

When the timer times out, beating is disabled and the machine will Stop.

During this phase if the medium level is not covered an intermittent acoustic signal is

activated

.

MIX LEVEL SIGNAL

Every hopper features 2 level sensors: MEDIUM level and LOW level.

- When the MIX LEVEL LED flashes, it means that the mix level in the hopper is lower

than the medium mix level sensor.

s\\\\crp01s0023\cb_ut_r&d_pt\archivio_manuali\libretti istruzione\carpigiani &\k 503 &\ed_2015 _08\nativi\mi_k 503_ed 08_it_en.docx

Version 8: 2015/08

Page 17 of 44

Page 18

Carpigiani K-503

dicato

- When the MIX LEVEL LED is on, it means that the mix level in the hopper is lower than

the minimum mix level sensor.

The display indicates ADD MIX or MIX OUT

When the LCD back light is blinking, that means an alarm has tripped.

When the alarm has reset, the back light of the LCD display becomes solid on. Reset the

indication on the display by pressing RESET button .

2.2 EVENTS

Equipment Manual

Maximum

filling level

in

Mix level

sensor

r

In order to read the events, the machine should be in STOP then push until ****READ EVENTS****

is displayed.

02:00:00 06 APR

START PASTEUR.

The first event will appear on the display. Push or in order to scroll UP or DOWN the events

list.

Push to exit the events reading and go to STOP.

2.3 GEAR REPLACEMENT

The machine counts the number of portions served. When this counter reaches a SET value, then a

message will appear on the display (every time you pull down the handle) in order to remind you that you

should change the gears of the mix pump. The gears are considered as parts subject to wear so they must

be replaced regularly as suggested on the display.

s\\\\crp01s0023\cb_ut_r&d_pt\archivio_manuali\libretti istruzione\carpigiani &\k 503 &\ed_2015 _08\nativi\mi_k 503_ed 08_it_

Version 8: 2015/08

Page 18 of 44

en.docx

Page 19

Carpigiani K-503

Equipment Manual

2.4 MANAGER MENU

1) To access the manager menu push simultaneously both keys and then release

immediately.

On the display you will read the first step of the Manager Menu:

The first row indicates the step number, and the second row indicates the description and value.

2) Push or in order to increase or decrease the value.

3) Push STOP to move to the next step.

4) To exit the Manager Menu push BEATING key .

The following table illustrates all the steps of the manager menu:

Step

(first row)

U01 Hours 00 23

U02 Minutes 00 59

U03 Day of Week Sun Sat

U04 Day of Month 01 31

U05 Month Jan Dec

U06 Year 2000 2099

U07 Language Dut Por

U08 Start Prod. Time 00 23+no+ auto

U09 Pas-M/Sto-S Time 00 23+NO

U10 HOT 1 000 120

U11 Set Topping 000 070

Display ENG

step U01

Hour 10

(second row)

Min Max

Default

Chi

08

02

100

055

Note: The STEP U09 value must be set to the same value in both sides of the machine.

THE MACHINE IS READY FOR START-UP ONLY AFTER IT HAS BEEN PERFECTLY

FOR HYGIENIC AND SAFETY REASONS, HANDS SHOULD NEVER BE PLACED INSIDE THE

MIX HOPPER DURING THE MACHINE OPERATION.

CLEANED AND SANITIZED.

s\\\\crp01s0023\cb_ut_r&d_pt\archivio_manuali\libretti istruzione\carpigiani &\k 503 &\ed_2015 _08\nativi\mi_k 503_ed 08_it_

Version 8: 2015/08

Page 19 of 44

en.docx

Page 20

Carpigiani K-503 Equipment Manual

2.5 OPERATION

2.5.1 ICE CREAM DISPENSING

In order to dispense soft ice cream, place a cup or a cone under the spout and slowly pull down the dispensing

handle. As soon as the soft ice cream com es out, twist the cup or the cone to make a nice sha pe ice cream.

When the portion has reached the desired size, close the dispensing handle and quickly pull the cone or

the cup down in order to sharpen the tip.

2.5.2 DISPENSING SPEED

The flow of ice cream coming out from the s pigot door can

be controlled by regulating properly the bolt and nut (no. 056

and no. 214). The nut blocks the bolt in its positi ons.

- If you want to increase the dispensing speed

unscrew the nut to release the bolt, then screw the

bolt so that the handle opens more, then block the

bolt.

- If you want to decrease the dispensing speed

unscrew the nut to release the bolt, then unscr ew

the bolt so that the handle opens less, then block

the bolt.

2.6 PROGRAMMED CLEANING CYCLE

The machine is equipped with an automatic system that

calls for washing of the parts in contact with the product at

least every 14 days (or 3 days for no pasteurizing

versions).

In PROD. the second row of the display indicates the days remaining to the next cleaning.

Sundae Ready !

Wash in 14 days

s\\\\crp01s0023\cb_ut_r&d_pt\archivio_manuali\libretti istruzione\carpigiani &\k 503 &\ed_2015 _08\nativi\mi_k 503_ed 08_it_en.docx

Version 8: 2015/08

Page 20 of 44

Page 21

Carpigiani K-503 Equipment Manual

2.7 POWER ON

In the event of Power On, if the machine was:

- in Cleaning mode, when the power is supplied again, it sets to STOP.

- in Pasteurization Heating phase or Pause during Pasteurization (only for pasteurizing versions) or

Production, when power is supplied again, the machine will continue with the function it wa s performing

when the blackout occurred (the display will show the message Power On).

- In Pasteurization Cooling mode (only for pasteurizing machines), when the power is supplied again, the

machine checks the temperature in the hopper and the duration of the blackout; if the time is greater than

certain parameters, the machine will completely repeat pasteuriz ation, memorizing the mes sage "Power On"

in the "event log"; otherwise, it will set to the functio n in which it was before the blackout.

- In Production or Storage mode, the machine checks the temperature of the hoppers. If the temperature is

below the one set by the manufacturer, the machine sets to the function in which it was before the blackout;

or the machine checks the temperature in the hopper and th e time th e b lacko ut lasted. If it las ted as long as

indicated in the table below, the machine completely repeats pasteurization and "Power On" is memorized in

the event log.

-

TEV Temperature

68°C 50°C

49°C 15°C

14°C 10°C

9°C 4°C

WARNING

If a blackout exceeds four hours, to avoid health hazards in the dispensed product, it is

necessary to disassemble, to wash, to rinse and to sanitize the machine as indicated in Section 7 of this

manual.

Time

30 minutes

10 minutes

20 minutes

2 hours

s\\\\crp01s0023\cb_ut_r&d_pt\archivio_manuali\libretti istruzione\carpigiani &\k 503 &\ed_2015 _08\nativi\mi_k 503_ed 08_it_en.docx

Version 8: 2015/08

Page 21 of 44

Page 22

Carpigiani K-503 Equipment Manual

3. DAILY CLOSING PROCEDURES

Make sure your hands are clean and sanitized before performing the following procedures.

PREPARE THE MACHINE FOR THE OVERNIGHT HEAT-TREATMENT CYCLE (only for pasteurizing versions)

1. Open the hopper covers to verify the mix level.

2. Fill the hopper with s undae mix (or make a dry filling) to the Max level. T he “ADD MIX” message on the display

must be off.

3. Keep the machine in “PRODUCTION” Mode (green button light ON).

DO NOT FILL ABOVE “MAX LEVEL”.

WARNING

If the mix in one of the two hoppers is below the medium level ("ADD MIX" message on the display), the heat-

treatment cycle will not start in both sides.

TOPPING PUMPS CLEANING

4. Remove topping containers and pumps.

5. Open the drain shut-off valve to drain the water in the hot topping hopper.

Use the clean and sanitized towels to clean the topping area.

6.

DISASSEMBLE AND CLEAN THE COMPONENTS

s\\\\crp01s0023\cb_ut_r&d_pt\archivio_manuali\libretti istruzione\carpigiani &\k 503 &\ed_2015 _08\nativi\mi_k 503_ed 08_it_en.docx

Version 8: 2015/08

Page 22 of 44

Page 23

Carpigiani K-503 Equipment Manual

7. Remove hopper covers. Wash, rinse and sanitize them at the sink.

8. Using a clean, sanitized towel, carefully wipe the outside area and the rim of the

hoppers. Make sure that no debris falls into the hopper.

9. Place back the sanitized hopper covers on the machine.

10. Remove the drip tray and the two drip trays from the sides of the machine. Wash, rinse, sanitize and dry them at

the sink.

11. Clean the shelf under the drip tray with a clean sanitized towel and place back the drip tray and the drip drawers to

their positions.

CLEAN THE SPIGOT DOOR AREA.

12. Fill an empty pail with Sanitizer prepared in water 70-90°F (21-32°C) (follow the instructions of the

sanitizer manufacturer).

13. Return to the machine with a small amount of sanitizer solution in a pail.

14. Dip the door spout brush in the pail of sanitizer and brush clean the dispensing spouts.

15. Spray the sanitizing solution on the dispensing area and on the spigot door, under the piston lid and all

around the spigot door.

16. Clean the spigot door with a sanitized cloth as well as the front panel ar ea around the spigot door and

all the surrounding areas.

NOTE:

when cleaning the keyboard panel with a clean, sanitized towel it is recommended that you lock the keys of the

keyboard as follows.

Press the

clean the keyboard without any risk. To unlock the keyboard press the

key for five seconds. Its LED will flash indicating t hat the keyboard is locked. At this stage you can

key for another five seconds and the LED

will turn off.

Page 23 of 44

s\\\\crp01s0023\cb_ut_r&d_pt\archivio_manuali\libretti istruzione\carpigiani &\k 503 &\ed_2015 _08\nativi\mi_k 503_ed 08_it_en.docx

Version 8: 2015/08

Page 24

Carpigiani K-503 Equipment Manual

4. DAILY OPENING PROCEDURES

Only for pasteurizing version:

- Check that the heat-treatment cycle has been successfully completed and

both displays indicate the message "PASTO END", followed by the time

and day of completion.

- If the heat-treatment cycle was not successfully completed the machine

will be locked down. Check the reason by reading the alarm messages and

press to reset the message on the display. Press the STOP

button of the both sides and then the PROD button of the both sides to run

a manual heat-treatment cycle. If the heat-treatment cycle is successfully

completed, the lockdown resets automatically and the machine is ready to

start production. No product can be dispensed during the heat cycle

(approximately 4 hours).

Make sure your hands are clean and sanitized before performing the following procedures.

SANITIZE THE DOOR AREA

- Fill an empty pail with Sanitizer prepared in water 70-90°F (21-32°C) (1 package in 2-1/2 gallons (9-1/2 liters) of water =

100 PPM] and mix the powder).

- Return to the machine with a small amoun t of sanitizer solu tio n in a pail

- Soak the brushes in the sanitizing solu t io n an d ru b t he s p ig ot d oor dis pensing area, the spigot d oor it se lf , the lev er

area and all around the spigot door including the dispensing spouts.

- Spray the spigot area and spigot spouts with sanitizer.

- Wipe exterior of machine with clean sanitized towel.

PREPARE THE HOT TOPPING

- Make sure that the drain tap is closed then refill hot-topping bainmarie with clean water to reach the level

indicated. Fill in the hot topping hopper with water until the indicated level is reached. Inside the topping hopper

there is a level sensor, and when the water level is low, an alarm appears on the display until the proper level is

restored.

- Refill containers with toppings if needed.

-

Place back the topping covers and the pumps (press the dispensing pistons and remove the first product

dispensed). As soon as the machine is in PROD and the water level is sufficient the topping heaters will

automatically turn on.

Page 24 of 44

s\\\\crp01s0023\cb_ut_r&d_pt\archivio_manuali\libretti istruzione\carpigiani &\k 503 &\ed_2015 _08\nativi\mi_k 503_ed 08_it_en.docx

Version 8: 2015/08

Page 25

Carpigiani K-503 Equipment Manual

-

As soon as the machine is in PRO D and the water level is sufficient the topping heaters will automatically turn

on.

START THE MACHINE

The machine is in STORAGE function. Push STOP and PROD to start the machine. Within a few minutes the sundae

is ready to be served.

s\\\\crp01s0023\cb_ut_r&d_pt\archivio_manuali\libretti istruzione\carpigiani &\k 503 &\ed_2015 _08\nativi\mi_k 503_ed 08_it_en.docx

Version 8: 2015/08

Page 25 of 44

Page 26

Carpigiani K-503 Equipment Manual

5. CLEANING OF PARTS IN CONTACT WITH THE PRODUCT

IMPORTANT

Cleaning and sanitation must be carried out at the end of every working day as a habit and

with utmost care in order to guarantee the production quality in the observance of

necessary healthy rules.

If dirt is left enough time to dry out, this increases the risk of stains, marks and damage to surfaces.

Removing dirt is much easier if done immediately after use. Since there is also a risk that some elements

containing acid or saline substances can damage the surfaces, prolonged soaking is not recommended.

Never use solvents, alcohol, or detergents that can damage the machine parts or pollute

Never use powder or abrasive cleaning products, scourers or pointed tools when cleaning by hand. There

is a risk of leaving the surfaces opaque or of re moving or weakening the protective film on the surface,

scratching it.

Never use metal or synthetic scouring pads under any circumstances to prevent any abrasion or removal

of ferrous parts leading to problems of surface oxidation or weakening.

Do not use detergents containing chlorine or chlorine comp ounds; using these detergents, which include

bleach, ammonia, hydrochloric acid and scale removers can attack the steel compou nd used, causing it to

stain or oxidize permanently.

At the end of washing and before refitting any parts, always dry them with a clean, soft clo th th at is suitab le

for use with foods; since any type of moisture with a high mineral or chlorine content can attack metal

surfaces and leave opaque traces.

WARNING

production functional parts.

s\\\\crp01s0023\cb_ut_r&d_pt\archivio_manuali\libretti istruzione\carpigiani &\k 503 &\ed_2015 _08\nativi\mi_k 503_ed 08_it_en.docx

Version 8: 2015/08

Page 26 of 44

Page 27

Carpigiani K-503

Equipment Manual

6. WEEKLY CLEANING

On a weekly basis, certain machine parts must be disassembled, washed, sanitized and reassembled. The following is the list of operations to be performed weekly in addition to the regular

daily cleaning procedure.

Make sure your hands are clean and sanitized before performing the following procedures.

6.1 WASHING AND SANITIZING OF THE TOPPING CONTAINERS

6.1.1 CLEANING THE TOPPING CONTAINERS:

a) Remove the topping pumps and containers from the machine and take them to the sink.

b) Discard the toppings weekly to break the bacterial cycle.

c) Wash the containers thoroughly with detergent and hot water 122-140°F (50-60°C), eliminating any

product residue.

d) Place the containers into the Sanitizer solution prepared in water 70-90°F (21-32°C) for 1 minute

(follow the instructions of the sanitizer manufacturer).

e) Make sure that the containers are empty and leave them out to air-dry.

6.1.2 CLEANING THE TOPPING HOPPER

a) Place an empty container under the drain shut-off valve inside the syrup cabinet.

b) Open the shut-off valve and drain the water completely from the topping hopper (warning: water is

hot).

c) Close the shut-off valve.

6.2 DISASSEMBLY, WASHING AND SANITIZING OF THE HOT TOPPING PUMPS

Clean the hot-topping pumps:

place the lower end of the pump into a containe r of clean warm water and operate the p ump until the

water being discharged is clear.

DISASSEMBLY

STEP 1

Loosen the locking collar until the plunger assembly can be removed from the pump cylinder.

NOTE

The plunger spring is slightly compressed so use care when removing the knob.

STEP 2

Remove the discharge tube assembly by rotating it counterclockwise until the flats

on the discharge tube bushing clears the valve body locking grooves, then carefully

pull the discharge tube assembly from the valve body .

STEP 3

Separate the O-ring from the discharge tu be bushing by squeezing on the O-ring

and sliding it in the bushing groove until the O-ring can be rolled out from the

groove.

STEP 4

Remove the cylinder assembly from the valve body by applying down pressure on the

cylinder assembly while rotating it counterclockwise direction until the tabs of the

cylinder assembly clear the locking grooves on the valve body.

STEP 5

Remove the O-ring from the valve body.

STEP 6

Place all parts in a clean container.

s\\\\crp01s0023\cb_ut_r&d_pt\archivio_manuali\libretti istruzione\carpigiani &\k 503 &\ed_2015 _08\nativi\mi_k 503_ed 08_it_

Version 8: 2015/08

Page 27 of 44

en.docx

Page 28

Carpigiani K-503

Equipment Manual

WASHING

NOTE

O NOT

D

STEP 1

Wash all pump components in the detergent and hot water 122-140°F (50-60°C).

STEP 2

Rinse them with clear water. Use the supplied brushes to clean the discharge tube assembly and the valve

body. It is recommended that the small parts be washed in a pan or other container so they will not be lost.

STEP 3

Sanitize the pump components immersing them in a container with Sanitizer prepared in water 70-90°F

(21-32°C) and please wait for 1 minute (follow the instruction of the sanitizer manufacturer).

STEP 4

Allow the pump parts to air-dry after sanitizing.

use tools that can scratch polished surfaces. Do use clean and sanitized brushes.

REASSEMBLY

STEP 1

Lubricate and position the knob O-ring in its groove on the knob. Set the knob aside.

STEP 2

Assemble the washer, the spring, the head insert, and the head tube on the piston and stem assembly.

STEP 3

Slip the gaging collars (if they are used) onto the head tube, then place the locking collar on the head tube.

STEP 4

Hold onto the head tube and push the piston and stem assembly into the head

tube, compressing the spring. When the threaded end of the stem projects through

the head tube, thread the knob onto the piston and stem assembly.

STEP 5

Set the assembled plunger assembly aside.

STEP 6

Lubricate the O-ring with approved lubricant and install the O-ring in its groove on

the discharge tube assembly bushing. Temporarily set the discharge tube

assembly aside.

STEP 7

Lubricate the O-ring with food grade lubricant and install the O-ring in its groove

in the valve body.

STEP 8

Align the tabs on the cylinder flange with the notches in the valve body. Tilt the

cylinder assembly slightly and slide the widest section of the flange under the

center locking groove of the valve body. Rotate the cylinder assembly clockwise

while applying down pressure on the cylinder assembly until the flange tabs

fully engage the locking grooves of the valve body.

STEP 9

Position the discharge tube assembly on the valve body, aligning the flats on the

discharge tube assembly bushing with the locking tabs on the valve body. Push

down on the discharge tube assembly until it is seated. Rotate the discharge tube

assembly clockwise to lock it in pl ace.

STEP 10

Slide the lid onto the discharge tube assembly and the cylinder assembly and

secure the lid with the discharge tube nut.

STEP 11

Apply food grade lubricant to the discharge fitting O-ring and install the O-ring

on the discharge tube fitting. Install the fitting in the discharge tube by pushing

the fitting into the discharge tube and rotating it in a clockwise direction.

STEP 12

s\\\\crp01s0023\cb_ut_r&d_pt\archivio_manuali\libretti istruzione\carpigiani &\k 503 &\ed_2015 _08\nativi\mi_k 503_ed 08_it_

Version 8: 2015/08

Page 28 of 44

en.docx

Page 29

Carpigiani K-503 Equipment Manual

Apply a small amount of food grade lubricant to the seal flare, install the plunger

assembly in the pump body assembly, and tighten the locking collar.

6.3 CHECK TOPPING PUMP TEMPERATURE AND VOLUME

NOTE: this procedure should be performed on a morning after the pumps were disassembled and

cleaned.

STEP 1

Dispense one serving of topping into a soft ice cream cup. Discard this sample.

STEP 2

Dispense second serving into a soft ice cream cup.

STEP 3

Insert the digital thermometer into the topping. Let the digital thermometer stabilize for 20 seconds.

NOTE: topping temperature should be between 115

and 125F (46 and 52C) and must be this

temperature before the pump calibration can begin. Water bath temperature should be between

and 145F (57 and 63C).

135

STEP 4

If the temperature is too cold or too warm, call service to adjust.

STEP 5

Hold the small chamber of the calibrating cup under the dispensing nozzle.

STEP 6

Push the dispensing handle down for one full stroke. The topping should be directed to th e bottom of the

calibrating cup.Do not allow the topping to fall on the sides of the cup.

NOTE: The amount of dispensed topping should be one fluid ounce (29.6 ml).

STEP 7

If the amount of dispensed topping is not correct, consult the troubleshooting section of your equipment

manual.

STEP 8

Repeat for the other topping pump.

s\\\\crp01s0023\cb_ut_r&d_pt\archivio_manuali\libretti istruzione\carpigiani &\k 503 &\ed_2015 _08\nativi\mi_k 503_ed 08_it_en.docx

Version 8: 2015/08

Page 29 of 44

Page 30

Carpigiani K-503 Equipment Manual

7. CLEANING EVERY 14 DAYS

After at least every 14 days (or 3 days for no pasteurizing version) from the last brush cleaning, the

machine must be thoroughly washed and restarted. This system inhibits the production function at

the end of the 14th day. Every time product is dispensed the display indicates the number of days

to the next scheduled cleaning.

The following is the list of operations to be performed on the 14

daily and weekly cleaning procedure.

NOTE

MAKE SURE YOUR HANDS ARE CLEAN AND SANITIZED

7.1 DISASSEMBLING AND CLEANING

7.1.1 DRAINING AND CLEANING THE ICE CREAM

Remove the covers to wash rinse and sanitize.

Drain the machine.

STEP 1

Place an empty pail under the SOFT ICE CREAM spouts.

STEP 2

Push the “STOP” button.

STEP 3

Pull the dispensing handles and drain the ice cream.

STEP 4

th

day in addition to the regular

Press the key.

STEP 5

When the product coming out becomes liquid, push the “STOP” button and leave the spouts open.

STEP 6

Remove the pressure tubes

In the hoppers, disconnect the pressure pipes from the mix pumps, turn then counter clockwise and pull

them up to remove them from their seat and let the product flow completely out.

Remove the mix pumps:

Grasp the pumps and turn them in a clockwise direction of 45° then pull them out towards you. Make sure

that the pumps drive shafts and seals are taken out with the pumps.

Remove the mix beaters:

Remove the beaters by pulling them upwards.

STEP 7

Rinse the machine

Close the dispensing handles, pour 2.5 gallons (9.5 liters) of cool, clean water into the mix hoppers.

Use the white hopper brush to scrub the mix hopper, mix level sensor and the outside the beater shaft.

Use the small brush to clean the mix inlet hole and the drive hub of the mix pump.

Drain rinse water from hopper and cylinder

Place an empty pail under the spout. Open the dispensing handles and let the water drain out.

STEP 8

Rinse with warm water until the solution runs clear.

STEP 9

Press button and let the beater run for 10 seconds.

STEP 10

Turn the machine off by pushing the “STOP” button and let the water flow out.

STEP 11

Clean the machine

s\\\\crp01s0023\cb_ut_r&d_pt\archivio_manuali\libretti istruzione\carpigiani &\k 503 &\ed_2015 _08\nativi\mi_k 503_ed 08_it_en.docx

Version 8: 2015/08

Page 30 of 44

Page 31

Carpigiani K-503 Equipment Manual

Fill the hopper with 2-1/2 gallons (9-1/2 liters) of warm all purpose cleaning solution.

STEP 12

Clean the hopper walls, the level sensor and outside of the beater shaft using the supplied brushes.

STEP 13

Pull the dispensing handles and let the liquid flow out completely.

STEP 14

Rinse the machine

Rinse with clear water, pull the spigot handle and let the water flow out.

STEP 15

Sanitize the machine

Fill the hopper with Sanitizer prepared in water 70-90°F (21-32°C) (follow the instruction of th e sanitizer

manufacturer).

STEP 16

Press button and let the beater run for 10 seconds.

Use the white hopper brush to scrub the mix hopper, mix level sensor and the outside of the beater shaft.

Use the small brush to clean the mix inlet hole and the drive hub of the mix pump.

STEP 17

Push the “STOP” button. Let the Sanitizer solution stand for a minimum of 1 minute.

STEP 18

Pull the dispensing handle and let the water flow completely out.

s\\\\crp01s0023\cb_ut_r&d_pt\archivio_manuali\libretti istruzione\carpigiani &\k 503 &\ed_2015 _08\nativi\mi_k 503_ed 08_it_en.docx

Version 8: 2015/08

Page 31 of 44

Page 32

Carpigiani K-503

Equipment Manual

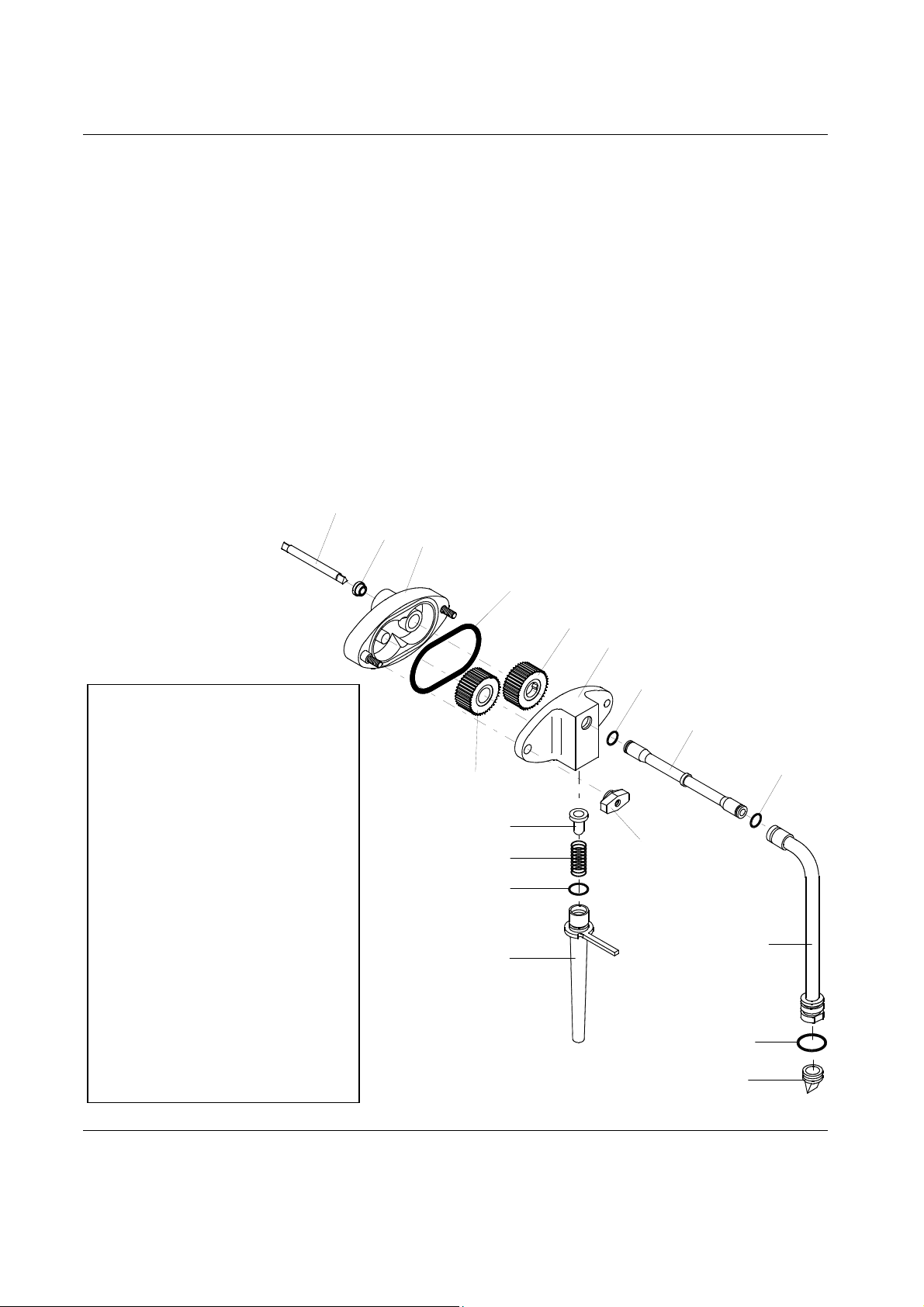

7.1.2 DISASSEMBLING THE MIX PUMP

STEP 1

Remove the drive shaft (no. 96) and the seal (no. 24 3).

STEP 2

Keeping the feeding tube (no. 271) upward turn it counterclockwise and pull it out.

STEP 3

Pull the spring (no. 206) and the back flow valve (no. 245) out. Using the o-ring extractor, remove the large

O-ring (no. 1126).

STEP 4

Unscrew the 2 knobs (no. 8) and separate the cover (no. 202) from the pump body (no. 39).

STEP 5

Using the o-ring extractor, remove the large O-ring (no. 1178). Tapping the pump body against the palm of

your hand, remove the pump gears (no. 38-no. 38A).

STEP 6

Disconnect the connection tube (no. 207) from the pressure pipe. Remove the O-rings (no. 1131, 1117 and

1126).

STEP 7

Remove the duck bill valve (no. 31) from the pressure pipe.

96

243

39

1178

38A

202

Pos.

8

31

32

38

38A

39

96

202

206

207

243

245

271

1117

1126

1131

1178

Description

Knobs

Valve

Compression pipe

38

Driven gear

Driving gear

Pump body

Pump drive shaft

Pump cover

Spring

Connection pipe

Seal

Valve

Feeding tube

O-ring

O-ring

O-ring

O-ring

245

206

1126

1412

271

1117

8B

207

1117

8

32

1131

s\\\\crp01s0023\cb_ut_r&d_pt\archivio_manuali\libretti istruzione\carpigiani &\k 503 &\ed_2015 _08\nativi\mi_k 503_ed 08_it_

Version 8: 2015/08

31

Page 32 of 44

en.docx

Page 33

Carpigiani K-503

Equipment Manual

7.1.3 DISASSEMBLING THE SPIGOT DOOR

WARNING

Before disassembling the dispensing head, make sure that the hopper and the cylinder are completely

drained.

Pos. Description

5

6

7A

8A

30A/B

43

056

214

302

303

1153

1285

STEP 1

With the machine in STOP mode, remove the

four retaining knobs (no. 8A) and pull the

spigot door towards you sliding it off the front

panel studs.

STEP 2

Remove the pivot O-ring (no. 1285).

STEP 3

Pull the dispensing handles (no. 5) so the pistons (no. 30 and 302) raise in its housing and pull the pivot

pin (no. 6) out releasing the dispensing handles (no. 5).

STEP 4

Using the dispensing handle, pull the pistons (no. 30 and 302) out completely.

STEP 5

Using the o-ring extractor, remove:

7.1.4 BEATER REMOVAL

STEP 1

Pull the beater (no. 21) out of the cylinder; please be

careful not to hit the cylinder with the shaft of the beater.

STEP 2

Slide the beater seal (no. 28) out of the beater shaft. Check

the beater seal and don’t forget it in the cylinder.

The beater seal is very important. It must be checked

regularly for wear and tear. It must always be on the

beater shaft and properl y lubr ic ated, du rin g ope ration ,

STEP 3

Pull out and remove the idler (no. 24) and the pusher

beater end (no. 25).

Dispensing handle

Handle pin

Spigot door

Knob

Piston

Piston handle

Nut

Dispensing handle adjustment

screw

Central piston

Central dispensing piston O-ring

O-ring

O-ring

a) the 2 piston O-rings (no. 1153 and 303);

b) spigot door O-ring (no. 1188).

WARNING

otherwise mix will leak in the drip tray.

s\\\\crp01s0023\cb_ut_r&d_pt\archivio_manuali\libretti istruzione\carpigiani &\k 503 &\ed_2015 _08\nativi\mi_k 503_ed 08_it_

Version 8: 2015/08

Page 33 of 44

en.docx

Page 34

Carpigiani K-503

Equipment Manual

7.2 DISASSEMBLING AND CLEANING THE OTHER COMPONENTS:

7.2.1 Remove the drip tray and the drip troughs to wash, rinse and sanitize.

7.2.2 Disassemble, clean and sanitize the topping pumps and containers (follow the procedure

described at section 5).

7.3 WASHING AND SANITIZING COMPONENTS

STEP 1

Fill a clean sink with the sanitizer solution.

STEP 2

Wash the disassembled parts with the detergent solution and scrub them thoroughly with the brushes

provided with the machine. As you proceed, rinse with hot water. Make sure all lubricant and mix film is

removed from parts.

STEP 3

Fill another sink with sanitizer prepared in water 70-90°F (21-32°C) (follow the instructions of the sanitizer

manufacturer).

STEP 4

Soak the components in the sanitizing solution. Leave them for at least 1 minute.

STEP 5

Place the components on the soft ice cream tray to air-dry.

STEP 6

Return to the machine with a small amount of Sanitizer.

STEP 7

Dip a brush into the sanitizer and thoroughly brush the freezing cylinder.

STEP 8

Dip a brush into the sanitizer and thoroughly brush clean the mix inlet hole and the pump drive hub

openings in the rear of the mix hopper.

STEP 9

Spray the back of cylinder with sanitizer.

Repeat steps 7 , 8 and 9 several times.

s\\\\crp01s0023\cb_ut_r&d_pt\archivio_manuali\libretti istruzione\carpigiani &\k 503 &\ed_2015 _08\nativi\mi_k 503_ed 08_it_

Version 8: 2015/08

Page 34 of 44

en.docx

Page 35

Carpigiani K-503

)

)

)

y

Equipment Manual

7.4 REASSEMBLY OF WASHED AND SANITIZED COMPONENTS

7.4.1 REASSEMBLY OF THE BEATER

STEP 1

Put the pusher beater end (no. 25) on the beater (no. 21) and align the idler shaft gr oove with the frame

front slot and insert the end of the idler shaft in the rear housing.

STEP 2

Lubricate the sides of the beater seal (no. 28) and slide it onto the beater shaft.

STEP 3

Insert the beater assembly into the cylinder. Push it while turning it clockwise until it engages in its rear

hub, otherwise the dispensing head cannot be fastened properly, mix can flo w out and serious damage

may occur.

1) Wash

2

Rinse

Sanitize

3

Air-Dr

4

Page 35 of 44

s\\\\crp01s0023\cb_ut_r&d_pt\archivio_manuali\libretti istruzione\carpigiani &\k 503 &\ed_2015 _08\nativi\mi_k 503_ed 08_it_

Version 8: 2015/08

en.docx

Page 36

Carpigiani K-503 Equipment Manual

7.4.2 REASSEMBLY OF THE SPIGOT DOOR

STEP 1

Lubricate and slide the 2 piston O-ring (no. 1153 and 303) into their seats.

STEP 2

Lubricate the piston (no. 30 and 302) and insert them, pointed end do wn, in the dispensing head (no. 7A)

making sure that the piston square notch lines up with the rectangular opening on the spigot front.

STEP 3

Position the dispensing handle (no. 5) on the spigot door (no. 7A) and insert the pivot pin (no. 6) in its

housing through the handle hole. Lubricate and slide the O-ring (no. 1289) into its seat on the pivot pin.

Lubricate and slide into its seat the large dispensing door O-ring (no. 1188).

STEP 4

Insert the dispensing spigot door onto the fron t panel studs and fasten it with the knobs (no. 8A), hand

tight.

s\\\\crp01s0023\cb_ut_r&d_pt\archivio_manuali\libretti istruzione\carpigiani &\k 503 &\ed_2015 _08\nativi\mi_k 503_ed 08_it_en.docx

Version 8: 2015/08

Page 36 of 44

Page 37

Carpigiani K-503

Equipment Manual

7.4.3 REASSEMBLY OF THE MIX PUMP

STEP 1

Lubricate and place back the two O-rings (no. 1117) on the connection tube (no. 207).

STEP 2

Lubricate and place back the O-ring (no. 1131) and the duck bill valve (no. 31) on the pressure pipe (no.

32).

STEP 3

Insert the connection tube assembly in the pressure pipe (no. 32).

STEP 4

Place the pressure pipe in a sanitizing solution or leave it in the hopper to be mounted after the sanitization

of the whole machine.

STEP 5

Lubricate the surface of the pump gears (no. 38-no. 38A) and insert the pump gears into the pump body

(no. 39).

STEP 6

Lubricate and place back the pump body O-ring (no. 1178).

STEP 7

Lubricate and place back the drive shaft seal (no. 243) into the pump body (no. 39).

STEP 8

Lubricate and place back the O-ring (no. 1412) on the feeding tube (no. 271).

STEP 9

Hold the pump cover (no. 202) upside down and insert the back flow valve (no. 245) and spring (no. 206)

in their pump cover housing.

STEP 10

Insert the feeding tube (no. 271) in the pump

cover: push and turn it clockwise.

STEP 11

Lubricate the drive shaft (no. 96). Place back

the drive shaft into the rear of mix hopper,

pushing it towards the back and rotating it

slightly until it engages in the drive hub. Hold

the pump body assembly, with the blocking pin

hook on the right, keep your thumbs over the

pump gears so that they remain in place, push

and turn the pump

Pos.

clockwise until the drive

shaft matches with the

driving gear. Now turn the

pump counter clockwise

until it locks onto the

blocking pin.

STEP 12

Assemble the pump

cover (no. 202) with the

feeding tube downwards

onto the pump body and

turn the two knobs (no.

8B) tightly.

7.4.4 REASSEMBLY

BEATER HOPPER

STEP 1

Place back the beater in its

seat in the hopper: make

8

31

32

38

38A

39

96

202

206

207

243

245

271

1117

1126

1131

1178

Description

Knob

Valve

Compression pipe

Driven gear

Driving gear

Pump body

Pump drive shaft

Pump cover

Spring

Connection pipe

Drive shaft seal

Valve

Feeding tube

O-ring

O-ring

O-ring

O-ring

sure to engage it onto its

shaft correctly.

96

243

39

1178

38A

202

1117

207

38

245

206

1412

8

271

8B

1117

32

1131

31

s\\\\crp01s0023\cb_ut_r&d_pt\archivio_manuali\libretti istruzione\carpigiani &\k 503 &\ed_2015 _08\nativi\mi_k 503_ed 08_it_

Version 8: 2015/08

Page 37 of 44

en.docx

Page 38

Carpigiani K-503

Equipment Manual

7.5 SANITIZATION OF THE WHOLE MACHINE

The machine must be sanitized before mix is poured in.

7.5.1 SANITIZE THE HOPPER

With the machine in STOP mode, fill the hopper to the maximum level with

70-90°F (21-32°C) (follow the instructions of the sanitizer manufacturer) and allow to drain into the

cylinder.

Using the brush, clean the mix level probes, the entire surface of the mix hopper, the surface of the mix

pump and the outside of the hopper beater.

7.5.2 SANITIZE THE PUMP AND CYLINDER

Press the button and let the beater run for about 5 seconds. Press the STOP button. The

cylinder and the pump are now filled with the sanitizing solution.

Return to the mac hine with a small amount of sanitiz er solution in a p ail.

Dip the door spout brush in the pail of sanitizer and brush clean the dispensing spout. Repeat the

operation 2 times.

Wipe the exterior of machine with clean sanitized towel. Repeat the operation 2 times.

Please wait for at least 5 minutes before proceeding with the next instructions.

7.5.3 DRAIN THE SANITIZER

Place an empty pail under the dispensing shut-off valve.

Allow all of the sanitizer to drain and pull dispensing handles down.

If the sanitizing solution does not flow out completely, keep the dispensing handles down and press the

Sanitizer prepared in water

button, keep the beater running for 5 seconds so that the last solution resid ues flow out then

push STOP.

WARNING

Do not keep the beater running for more than the time strictly needed to complete cleaning and

sanitization. Without the lubrication of mix butterfat the beater blades wear out quickly.

7.5.4 PREPARING THE TOPPING AREA

Make sure that the drain shut-off valve is closed then fill the hot topping hopper with clean water; don’t

exceed the max water level (if you should exceed the max water level in the topping hopper, use the

shut-off-valve to drain the water in excess).

Reassemble the sanitized topping pumps and containers.

Reassemble on the machine the sanitized drip tray and drip troughs.

7.6 MIX LOADING - HOW TO MAKE A DRY FILLING AFTER CLEANING AND SANITIZING THE

MACHINE

Make sure your hands are clean and sanitized.

s\\\\crp01s0023\cb_ut_r&d_pt\archivio_manuali\libretti istruzione\carpigiani &\k 503 &\ed_2015 _08\nativi\mi_k 503_ed 08_it_

Version 8: 2015/08

Page 38 of 44

en.docx

Page 39

Carpigiani K-503 Equipment Manual

Take the mix pressure pipe from the sanitizing solution and insert it in its position in the bottom of

the hopper. Connect it to the pump.

Rotate the water shut-off-valve in the direction of the hopper.

The machine is in STOP mode cleaned and sanitized; push Production (START button).

The display will show the message "Perform Dry-Filling".

Press the DF key .

The Increase and Decrease keys turn on and the display shows:

Liters 00.10

The quantity of water can be modified pressing the Increase and Decrease keys in

steps of 0.10 liters, within 5" after the DF key is pressed.

If no key is pressed for 10", quantity selection phase will be quit and the d isplay goes back to the

previous screen.

Confirm water quantity of water with the DF key

Now water dispensing starts. The procedure can be interrupted at any time by pressing STOP.

At the end of water dispensing, there is a first mixing phase.

Fast beating in the hopper is enabled for a set time. The display will show the timer decreasing on

the second line:

Dry Filling

Please Wait 2:59

The procedure can be interrupted at any time by pressing STOP.

At the end of the first mixing phase, there is a second mixing phase.

At the end of mixing, DF ends. Machine sets to STOP mode.

s\\\\crp01s0023\cb_ut_r&d_pt\archivio_manuali\libretti istruzione\carpigiani &\k 503 &\ed_2015 _08\nativi\mi_k 503_ed 08_it_en.docx

Version 8: 2015/08

Page 39 of 44

Page 40

Carpigiani K-503 Equipment Manual

7.7

MIX LOADING - HOW TO FILL THE MACHINE WITH LIQUID MIX AFTER CLEANING AND

SANITIZING THE MACHINE

Make sure your hands are clean and sanitized.

Pour the liquid mix in one hopper.

Only when the mix stops bubbling from the bottom of the hopper, reassemble the pressure pipe

in its position in the bottom of the hopper. Make sure your hands are clean and sanitized.

Press the button and let run the beater for only five seconds just to check that the pump

works well, then push STOP.

Turn the pressure pipe towards the pump and connect the tube to the pump.

Replace on the machine the sanitized hopper cover.

Fill the second hopper with mix following the steps described above.

Set to Production b oth sides o f the m achin e pushing START Button so the heat-treatment cycle

automatically starts.

At the end of the Pasteurization, press Stop and then press START Button to start the

Automatic freezing operation. When the HOT reaches the set value, the product is ready to be

dispensed.

8. PREVENTIVE MAINTENANCE

WARNING

Never put your hands into the machine, neither during the operation nor during cleaning.

Before servicing, make sure the machine has been set in “STOP” and the main switch

has been cut out.

WARNING

Any servicing operation requiring the opening of machine panels must be carried out

with machine set to stop and disconnected from main supply!

Cleaning and lubricating moving parts is forbidden!

“Repairs to units and parts of the electrical, mechanical, air supply and cooling systems

must be carried out by specialist technicians approved by the manufacturer and if

necessary, according to agreed routine and special maintenance schedules as provided

by the customer with reference to specific intervention methods and according to the

intended use of the machine”.

Operations necessary to proper machine running are such that most of servicing is completed during production

cycle.

Servicing operations, such as cleaning of parts in contact with the product, replacing of stuffing box, disassembling

of beater assembly are to be carried out ev ery 14th days clea ning.

8.1

CHECK UP LIST

s\\\\crp01s0023\cb_ut_r&d_pt\archivio_manuali\libretti istruzione\carpigiani &\k 503 &\ed_2015 _08\nativi\mi_k 503_ed 08_it_en.docx

Version 8: 2015/08

Page 40 of 44

Page 41

Carpigiani K-503 Equipment Manual

During cleaning operations, check carefully the integrity of parts subject to wear: if they appear worn out or