Carpigiani K3-E Installation Manual

Combination shake/sundae dispenser K 3 – K3/E

Equipment Operating Manual

This manual is for the exclusive use of

licensees and employees of

McDonald’s Systems Inc

Manufactured by:

Carpigiani Group

Via Emilia, 45

Anzola dell'Emilia Bologna 40011

ITALY

Telephone:

Fax:

Edition:

5

Edited:

AM

Date:

10/2012

Checked:

SB/AO

Modification: 1.2.9

Approved;

RV

First Printing March 2006 Printed in Italy

Version 5: October 2012

Updates:

Carpigiani K 3 User’s guide

Table of Contents

CONVENTIONAL SYMBOLS ..................................................................................................... 5

REMOVING MACHINE FROM PACKAGING ................. ....................................................... 6

WEEE (WASTE ELECTRICAL AND ELECTRONIC EQUIPMENT) .................................. 7

TROUBLESHOOTING BACTERIA CONTAMINATION ...................................................... 7

1. INTRODUCTION ................................................................................................................... 9

1.1 GENERAL INFORMATION .................. .................................................. ....................... 9

1.1.1 MANUFACTURER'S IDENTIFICATION DATA .............................. ............................ 9

1.2 INFORMATION ABOUT THE MACHINE ........... ......................................................... 9

1.2.1 GENERAL DATA .......................................................................................................... 9

1.2.2 INTENDED USE ............ ............................................................................................... 9

1.2.3 NOISE ............................ ................................ ................................ ............................... 9

1.2.4 TECHNICAL FEATURES ... .. ..................................................................................... 10

1.2.5 MACHINE ASSEMBLY IDENTIFICATION ......... ................................ ... .................. 10

1.2.6 AUTOMATIC PASTEURISATION CYCLE ................................................................ 11

1.2.7 TEMPERATURE CONTROL ...................................................................................... 11

1.2.8 TANK LIDS HOLDER ................................................................... ... .......................... 11

1.2.9 MIXER (OPTIONAL) .................................................................................................. 12

2. INSTRUCTIONS FOR USE ................................................................................................ 13

2.1 CONTROLS ................................ .................. ...................... ..................... ..................... ..... 13

2.1.1 MILK SHAKE FUNCTIONS ..................... .................................................................. 14

2.1.2 SUNDAE FUNCTIONS .............................................................................................. 19

2.2 OPERATIONS ................................................................................................................ 24

2.2.1 DISPENSING MILK SHAKE ...................................................................................... 24

2.2.2 DISPENSING SUNDAE ............................................... .. ................................ ............. 24

2.3 PROGRAMMED CLEANING CYCLE ......................................................................... 24

2.4 POWER BLACK- OUT .................................................................................................. 25

3. DAILY CLOSING PROCEDURES .................................................................................... 26

3.1 SHAKE SIDE .................................................................................................................. 26

3.1.1 DISASSEMBLING AND CLEANING THE COMPONENTS: ....................................... 26

3.1.2 SANITIZING THE DOOR AREA: .................................................................................. 26

3.1.3 SYRUP LINE CLEANING / SANITIZING ........................................................ ... .......... 26

3.1.4 PREPARING THE MACHINE FOR THE OVERNIGHT HEAT TREATMENT CYCLE.

27

3.1.5 FRONT PANEL CLEANING ......................................................................................... 27

3.2 SUNDAE SIDE ............................................................................................................... 28

3.2.1. SANITIZING THE DOOR AREA SURFACE: .................................................................. 28

3.2.2 TOPPING PUMPS CLEANING: .................................................................................. 28

3.2.3 PREPARING THE MACHINE FOR THE OVERNIGHT PASTEURISATION CYCLE. 28

3.2.4 FRONT PANEL CLEANING ......................................................................................... 28

This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 2 of 63

Version 5: October 2012

Carpigiani K 3 User’s guide

4.

DAILY OPENING PROCEDURES............... ... ................................................................ .. 29

4.1 MILK SHAKE SIDE ....................................................................................................... 29

4.1.2 STARTING UP THE MACHINE: .. ... ................................ ... ................................ .. ..... 29

4.2 SUNDAE SIDE ............................................................................................................... 30

4.2.1 SANITIZING THE DOOR AREA: .................................................................................. 30

4.2.2 PREPARING HOT TOPPINGS: ................................................................................... 30

4.2.3 STARTING UP THE MACHINE: ................................................................................. 30

5. WEEKLY CLEANING ................................................. ....................................................... 31

5.1 WASHING AND SANITIZING OF THE TOPPING CONTAINERS ........................... 31

5.1.1 CLEANING OF THE TOPPING BINS: .................................................... ..................... 31

5.1.2 CLEANING OFTHE TOPPING HOPPER ..................................................... ............... 31

5.2 DISASSEMBLING, WASHING AND SANITIZING OF THE HOT TOPPING PUMPS

31

5.3 CHECK TOPPING PUMP TEMPERATURE AND VOLUME ...................................................... 33

6. EVERY 14 DAYS CLEANING ...... ................................ ... ................................ ... ............... 34

6.1 DISASSEMBLING AND CLEANING THE MILK SHAKE SIDE .................................... ............... 34

6.1.1 CLEANING THE SHAKE SYRUP SYSTEM .................................................................. 34

6.1.2 DRAINING AND CLEANING THE MILK SHAKE SIDE ........................... .. ............. 35

6.1.3 DISASSEMBLING OF THE SHAKE MIX PUMP ...................................................... 37

6.1.4 DISASSEMBLING OF THE SHAKE DISPENSING DOOR..... .................................. 38

6.1.5 DISASSEMBLING OF THE SHAKE CYLINDER’S BEATER ................................... 39

6.2 DISASSEMBLING AND CLEANING OF THE SUNDAE SIDE 40

6.2.1 DRAINING AND CLEANING OF THE SUNDAE SIDE ............................................ 40

6.2.2 DISASSEMBLING OF THE MIX PUMP................................................................. 42

6.2.3 DISASSEMBLING OF THE SUNDAE DISPENSING DOOR ................................... 43

6.2.4 DISASSEMBLING OF THE SUNDAE BEATER ........................................................ 43

6.3 WASHING AND SANITIZING OF COMPONENT PARTS ..................................... ...... ..... ..... ... .. 44

6.4 REASSEMBLY OF WASHED AND SANITIZED COMPONENT PARTS ................ 46

6.4.1 REASSEMBLY OF THE SHAKE CYLINDER BEATER ............................................. 46

6.4.2 REASSEMBLY OF THE SHAKE DISPENSING DOOR............................................. 47

6.4.3 REASSEMBLY OF THE SHAKE MIX PUMP ............................................................ 48

6.4.4 REASSEMBLY OF THE MIX HOPPER AGITATOR ............................................. 50

6.5 REASSEMBLY OF WASHED AND SANITIZED COMPONENT PARTS ..................... 50

6.5.1 REASSEMBLY OF THE SUNDAE BEATER .................................... ... ....................... 50

6.5.2 REASSEMBLY OF THE SUNDAE DISPENSING DOOR .......................................... 50

6.5.3 REASSEMBLING OF THE SUNDAE MIX PUMP ..................................................... 51

6.5.4 REASSEMBLING OF THE MIX TANK AGITATOR .................................................. 52

6.6 SANITIZING OF THE ENTIRE MACHINE ................................................................. 52

6.6.1 SANITIZE THE HOPPER ........................................................................................... 52

6.6.2 SANITIZE THE PUMP AND FREEZING CYLINDER .............................................. 52

6.6.3 DRAIN THE SANITIZER ............................................................................................ 52

6.7 SYRUP SANITIZING, PRIMING AND CALIBRATION (SHAKE SIDE) ...................... ..... 53

6.8 MIX PRIMING ............................. ................................................... ............................... 54

7. MONTHLY CLEANING ..................................................................................................... 55

7.1 CLEAN MESH FILTERS (ONLY FOR AIR COOLED VERSION) ............................................... 55

This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 3 of 63

Version 5: October 2012

Carpigiani K 3 User’s guide

8.

PREVENTATIVE MAINTENANCE ................................................................................. 56

8.1 CHECK OUT LIST ......................................................................................................... 56

8.2 PERIODICAL CHECK-UP AND MAINTENANCE ......................................................... 57

8.2.1 PERISTALTIC PUMP TUBE REPLACEMENT INSTRUCTION .................. .................................. 57

9. TROUBLESHOOTING ..................... ................................... ................................ ............... 59

9.1 ALARMS ........................................................................................................................ 59

FOLLOWING FIND THE ALARM LIST: ................ ............................................................... 59

This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 4 of 63

Version 5: October 2012

Carpigiani K 3 User’s guide

Conventional Symbols

ATTENTION ELECTRIC SHOCK DANGER

The staff involved is warned that the in observance of safety rules in carrying out the

operation described may cause an electric shock.

ATTENTION GENERAL DANGER

The staff involved is warned that the operation described may do harm if not carried ou t in

the observance of safety rules.

NOTE

It points out significant information for the staff involved.

WARNING

The staff involved is warned that the in observance of information may cause a loss of data

and damages to the machine.

PROTECTIONS

This symbol placed by description side means that the operator must use personal

protections against an implicit risk of accident.

SAFETY

When using industrial equipment and plants, one must be aware of the fact that drive

mechanisms (rotary motion), high voltage of the components, as well as parts subject to high

temperatures may cause serious damages to persons and things.

The person in charge for plant’s safety must be on the look-out that

- an uncorrect use or handling is av oid ed

- Safety devices must neither be removed nor tampered

- Only original spare parts are to be used especially as far as those components with safety fu nctions are

concerned (ex.: protection microswitches, thermostats).

To achieve the above, the following is necessary:

- At working place an instruction manual relevant to the machine should be available.

- Such documentation must be carefully read and regulations must consequently be followed.

- Only adequately skilled personnel will have to be assigned to electrical equipment.

WARNING

The machine must be installed only by a specialized and authorized technician; when

installing the machine, insert a differential magnetothermal protection switch on all poles of

the line, adequately sized to the absorption power shown on machine data plate and with

contact opening of 3 mm at least. This switch is used to cut off the power supply. Any

replacement of the power cable must be carried out only by a specialized and authorized

technician.

Never put your hand into the machine, during production and cleaning opera tions. Before carrying

out any maintenance operation, make sure that the machine is in “STOP” position and main switch

has been cut out.

It is forbidden to wash the machine by means of a stream of water under pressure.

Disconnect electrical power before removing any side or rear panel.

CARPIGIANI is not responsible for any accident that might happen during operation, cleaning

and/or servicing of its units, if this warning has not been fully complied with.

This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 5 of 63

Version 5: October 2012

Carpigiani K 3 User’s guide

Removing machine from packaging

1. Check the Shock-watch label which indicates whether the goods have been mishandled; inspect

the cardboard shipping carton for signs of damage. (See fig.1)

2. Cut the metal straps (beware of snapping metal), lift the cardboard carton up and off of the pallet (see picture

2).

3. Remove bag and Styrofoam prote ction. Inspect the m achine ag ain for sig ns of shipping da mage or

rough handling. If damage is visible, notify the r estaurant manager and/or the shipping company

(see fig. 3).

Fig. 1 Fig. 2

Fig. 3

CAUTION

removal from the pallet must be carried out by two qualified persons in material handling and in the

observation of safety rules.

4. The machine is attached to the pallet by 4 bolts. The bolt heads are on the bottom side of the pallet and

they tighten into threaded holes on the bottom of the machine. The two wooden shims, pl aced sideways

under the machine, make it possible to keep the wheels ¼" of the surface of the pallet (see fig. 4).

5. Now loosen the packing bolts from the bottom side of the pallet, on one side only, and let them drop to

the floor. It is not necessary to remove the side panels of the machine to do this (see fig. 4).

6. Slightly, incline the machine on one side and remove the wooden block. Please be careful. The wood blocks

keep the machine castors off the pallet by ¼" their removal will cause the machine to drop that distance (see

fig. 5).

7. Repeat the same procedure on the other side.

8. After the removal of the wooden blocks, the machine will directly rest with its wheels on the pallet.

9. In order to unload the machin e from the pallet, use the w ooden ramps, su pplied with the machine. Plac e the

wooden ramps in position against the rear side of the machine and push the machine from FRONT SIDE

moving it to the rear. Two persons, one in front and one in the rear, must handle and control the unit (see fig. 6).

Fig. 4 Fig. 5 Fig. 6

This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 6 of 63

Version 5: October 2012

Carpigiani K 3 User’s guide

WEEE (Waste Electrical and Electronic Equipment)

In accordance with European Directives 2006/66CE on batteries and accumulators and waste batteries

and accumulators and with 2002/96/EC on WEEE (Waste Electrical and Electronic

Equipment), the presence of the above symbol on the product or on its packaging

indicates that this item must not be disposed of together with the other normal unsorte d

municipal waste. Instead, it is the user’s responsibility to dispose of this product by

returning it to a collection point designated for the recycling of electrical and electronic

equipment waste. Separate collection of this waste helps to optimise the recovery and

recycling of any reclaimable materials and also reduces the impact on human health

and the environment.

For more information concerning the correct disposal of this product, please contact

your local authority or the retailer where this product was purchased.

Troubleshooting Bacteria Contamination

Product samples should be taken periodically by a qualified expert in order to asses the

bacteria count in the product. The bacteria count in the samples should be below the

figures given below:

Standard Plate Count (SPC)……………...50,000

Coliform …………………………………………10

Should the bacteria counts exceed the figures listed above then there is a source of bacterial

contamination. The source of contamination must be identified and corrected. High bacteria counts are

indicate that a product is not safe for consumption. You must inform the machine operator on how to

prevent bacterial contamination of the product.

Note: Soft serve yogurt

product. However, COLIFORM bacteria contamination is NOT ACCEPTABLE in any food product. The

information given below will help prevent coliform bacteria contamination problems.

The following is a list of possible bacteria contamination sources together with methods of

prevention.

will generally have high bacteria counts – this is normal and helps define the

SOURCE OF

CONTAMINATION

1 - Operator contact.

2 - Mix residue/deposits (milkstone

build-up).

This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 7 of 63

Version 5: October 2012

PREVENTION

1a - Wash hands and forearms thoro ughly.

1b - Wear rubber gloves if cuts or skin conditions exist.

1c - Wash hands periodically throughout the day.

2a - Provide the proper brushes.

2b - Thoroughly brush clean all parts and components to

prevent the formation of milkstone, a porous substance

which will house bacteria and contaminate fresh mix.

Carpigiani K 3 User’s guide

SOURCE OF

CONTAMINATION

3 - Worn or damaged parts.

4 - Incorrect cleaning and sanitation

procedures.

PREVENTION

3a - Lubricate all rubber parts contacting the mix with a food

grade lubricant.

3b - Inspect o-rings for damage. Only replace with factory

approved parts.

3c - Regularly check drip troughs for excessive leakage.

4a - Sink must be perfectly clean and contain enough solution

to cover the biggest component. Brush clean and sanitize

the freezer on a regular basis .

4b - Use the correct brushes, lubricants, and single service

towels.

4c - Store and use chemicals as directed by the instructions on

their labels.

4d - Use a few good employees to follow the cleaning

procedure correctly and consistently. Allow the employee

uninterrupted time to complete the cleaning procedure.

4e - Allow the sanitizing solution to stand in the hopper and

freezing cylinder for five minutes .

4f - Wash and sanitize the lubricant tube after each use.

Always replace the cap on the tube.

4g - Machine components and brushes should be air-dried

overnight. Never store them in the storage cooler.

4h - Always follow daily cleaning procedures. Regularly wipe

down the outside of the machine and dispensing spouts

with a sanitized towel.

5 - Improperly stored mix

5a - Use mix stock with oldest date first. Observe expiration

dates.

5b - Place the mix directly in the cooler. Do not stack mix

outside or under direct sunlight before placing it in the

cooler.

5c - Always leave one inch between the mix and other products

in the cooler to allow air to circulate.

5d - Mix must not remain at room temperature for long periods

of time.

5e - Hopper storage must maintain a temperature of 40°F

(4,4°C). Storage temperatures above 45°F will allow

bacteria to multiply to dangerous levels in less than one

hour.

5f - Once the mix is placed in the hopper, the ho pper covers

must be used to maintain the correct temperature and

minimize mix contamination.

This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 8 of 63

Version 5: October 2012

Carpigiani K 3 User’s guide

1. Introduction

1.1 GENERAL INFORMATION

1.1.1 MANUFACTURER'S IDENTIFICATION DATA

The machine has a data plate carrying manufacturer data, machine type and serial number, assigned

when it is manufactured.

LEGEND:

A= Serial number

B= Machine type

C= Voltage

D= Fuss/Breaker size

E= Gas type and weight

F= Frequency

1.2 INFORMATION ABOUT THE MACHINE

1.2.1 GENERAL DATA

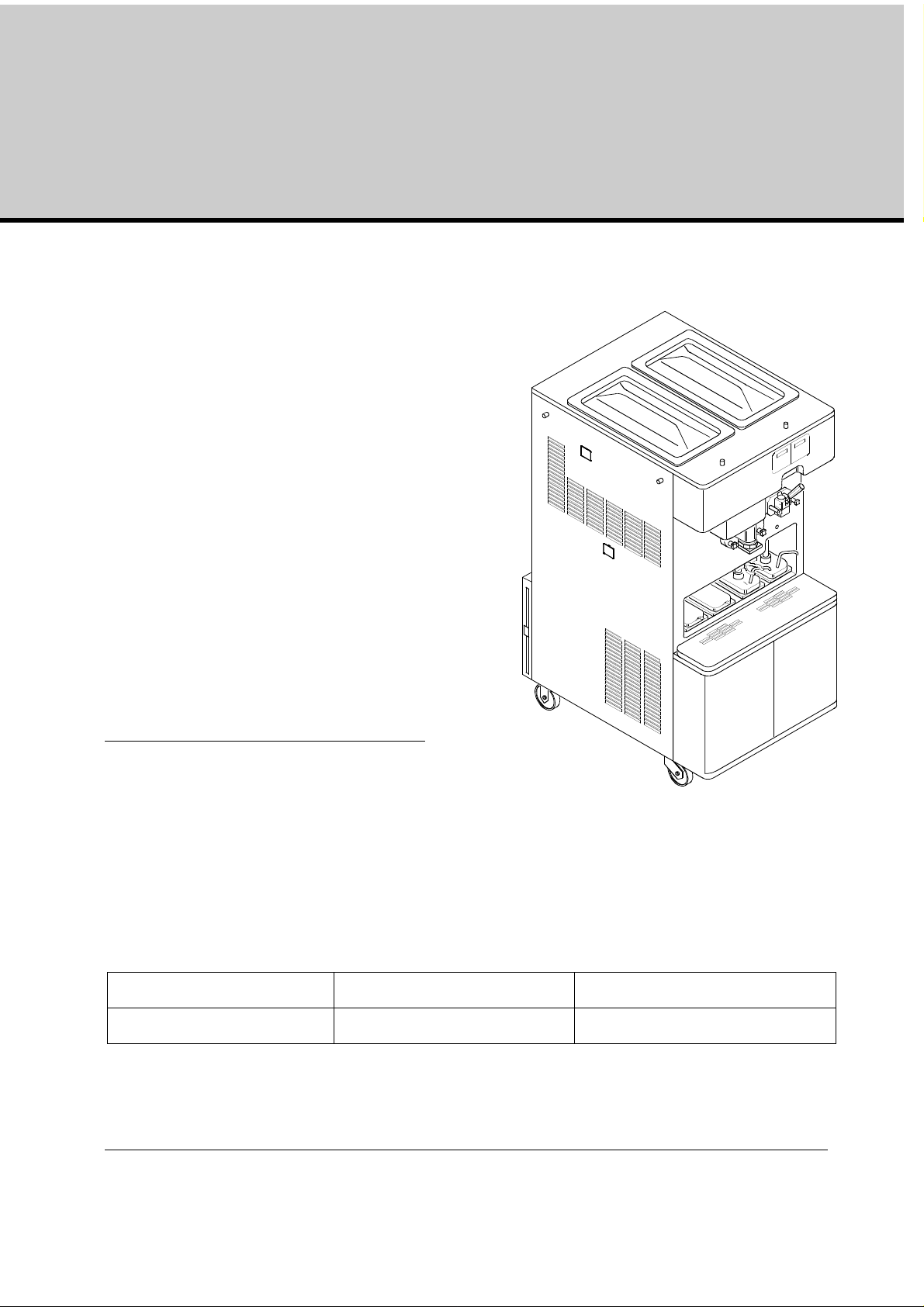

Electronic, self-heat-treatment, floor machine, for the production and immediate distribution of

milkshake/ice cream having the following main features:

Refrigerated upper tanks;

Cylinder feeding pumps (to control product overrun);

Automatic system to dispense the milkshake with a 4 flavours syrup selection;

Two containers for hot toppings, with pasteurisation temperature control;

Two containers for room temperature toppings;

Automatic pasteurisation system to heat-treatment the product inside the mix tank and inside the

cylinder during pause periods (for instance, during nig ht time);

Electronic consistency control system hard-o-matic.

1.2.2 INTENDED USE

The K 3 machine must only be used for the production of ice cream and milkshake, within the fu nctional

limits listed below:

Voltage: ±10%

Min. ambient temperature: 50°F (10°C)

Max. ambient temperature: 109°F (43°C)

Max relative ambient humidity: 85%

This machine has been designed for its use in closed places not subject to explosion-proof standards;

consequently, it shall be used in places complying with normal atmosphere..

1.2.3 NOISE

The continuous level of acoustic radiation pressure, which has been weighed and called A on working

place, turns to be lower than 70 dB(A), both by air-cooled and water-cooled units.

B

A

F

C

D

E

This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 9 of 63

Version 5: October 2012

Carpigiani K 3 User’s guide

1.2.4 TECHNICAL FEATURES

n

i

2

4

i

n

n

i

2

n

i

8

2

60 in

58 in

4

0

i

n

4

1

i

n

Hou rly Prod u ction * Hopper capacity Flavors Electrical supply

Model

K 3

K3/E

SUNDAE SHAKE

3,5 oz. / 100 gr

lb /kg

82 / 38 380 88 / 40 160

portions

lb / kg

1.2.5

MACHINE ASSEMBLY IDENTIFICATION

LEGEND:

1 Syrup tanks cabinet

2 Hopper cover

3 Hot toppings

4 Room temperature toppings

5 Dispensing head shake side

6 Dispensing head soft side

7 Air condenser

13,5 oz. / 400 ml

portions

SUNDAE

Gallons

Liters

5,25 gal

20 l

TTS

SUNDAE SHAKE Volt - V Phase Cycle - Hz kW Amps

Galons

Liters

5,25 gal

20 l

1 5

208 - 230 3 60 5,5 30

380 - 415 3 50 5,5 20

7

Installed

power

Full

load

2

Net

weight

lb / kg

871 / 395

1

6

5

3

4

1

This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 10 of 63

Version 5: October 2012

Carpigiani K 3 User’s guide

1.2.6 AUTOMATIC PASTEURISATION CYCLE

The machine has been pre-set in the factory to start automatically the pasteurisation cycle every night at 2

am. (the automatic pasteurisation time can be re-set at a different time by a trained technician.

1.2.7 TEMPERATURE CONTROL

When the machine is set to STOP, the tank temperature is controlled: if it is higher or equal to 59°F (15°C),

the execution of the pasteurisation program is forced. So, by pressing the PROD. button, the

pasteurisation program will automatically start.

NOTE:

After the machine’s brush cleaning, it is necessary to press the PROD. button within 60 minutes after the

front lid closing. During this 60 minutes the test at 59°F (15°C) is masked and Production is accepted. After

60 minutes, the machine does not accept the PROD. button any more and it sets to pasteurisation

function.

1.2.8 TANK LIDS HOLDER

When you need to refill the mix tank, lift the lid and turn it upside down. Insert the handle of the lid in the

slot of the holder placed on the other lid. You need not to remove the holder.

LID HOLDER

This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 11 of 63

Version 5: October 2012

Carpigiani K 3 User’s guide

1.2.9 MIXER (OPTIONAL)

Operating procedure

1. Hold a cup under soft-serve dispensing nozzle.

2. Pull draw lever completely forward and fill up

the cup.

3. Place a dome lid on top of the cup.

Tip: Set the cup on a level surface.

6. Push the cup onto the blender mixing spoon,

hold the cup with one hand and push the

switch on with the other hand. Using one hand,

blend the cup for 7 seconds. While blending,

move the cup from side to side and up and

down.

4. Hold the cup under the requested inclusion

dispenser. Slide the mix-in dispenser’s handle,

to dispense the product

5. Snap mixing spoon onto blender connector (be

careful not to touch spoon)

7. Once blender stop rorating, hold the cup in

one hand and release the mixing spoon from

the blender with the other hand.

8. Serve the cup.

This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 12 of 63

Version 5: October 2012

Carpigiani K 3 User’s guide

2. INSTRUCTIONS FOR USE

2.1 CONTROLS

The K 3 is equipped with two front push-button panels, one for the controls related to the SHAKE side and

one for the controls related to the SUNDAE side.

MILK SHAKE

DISPENSING BUTTONS

WHITE BASE DISPENSING BUTTON (for SMOOTHY)

- OPEN PISTON TO EMPTY THE MACHINE (CLEANING)

LCD back lights flashing for

warni ng :

“read info on display”

Warning light for LOW

mix level (reserve)

MAIN FUNCTIONS:

- Stop

- Production

Pasteurisation Led

lights on from start Past. till Past. End

“+” increase button for manager menu

Agitation Button/Lock button

Storage Led

lights on from Past. End

“-” decrease button for manager menu

Alarm and warning restore

IMPORTANT

Push-buttons are activated keeping the finger (not the nail) pressed on it for at least 1/2 second

(safety feature).

WARNING

TO REDUCE WEARING OF THE BEATER BLADE (POS. 430) USE AGITATION FUNCTION JUST FOR

THE TIME STRICTLY NECESSARY.

This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 13 of 63

Version 5: October 2012

Carpigiani K 3 User’s guide

2.1.1 MILK SHAKE FUNCTIONS

STOP BUTTON

By pressing this button during operation, the machine stops (LED on).

DISPLAY Comments

16:29:27 Tue

When the machine is in STOP, the display shows Time

and Date.

PRODUCTION BUTTON

Preparatio n (startup) :

machine is freezing the product. For that time, dispensing is not allowed.

Production (LED is always on):

desired consistency by the Hard-o-Tronic system. If the machine has been in the production

mode and then placed in Stop, the 15 minutes start up procedure will be automatically bypassed

if the time in Stop does not exceed 60 minutes; otherwise the start up procedure will be repeated.

By pressing this button when in STOP, the display indicates:

KEY

DISPLAY comments

Do Not Serve !

1

TEV +19°C W-14

Hopper +14°C

2

3

Cylinder +13°C

In this box the display shows in the first line (above):

Set=065 Hot=035

Lev=00000

Cones today

4

12345

Total Cones

5

0923456780

TEV+010 TGV-022

6

TEC+013 TE1-012

Pushing PROD again, we return to first display (1).

On pushing this button, its LED will blink for 15 minutes while the

The product is ready to be dispensed and it is kept at the

When the Milk Shake is not ready, the display shows: “DO

NOT SERVE“

In this box the display shows the Hopper’s temperature in

the first line (above) and the Cylinder’s temperature in the

second one.

Set=065: the shake consistency to be reached

Hot=035: the shake consistency actually detected in the

cylinder

Liv=00000 for technician

In this box the display shows the daily quantity of cones

(starting from 0:00 until 23:59).

In this box the display shows the total quantity of cones

In this box the display shows various probes of the SHAKE

part ( no °C nor °F are displayed).

This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 14 of 63

Version 5: October 2012

Carpigiani K 3 User’s guide

Machines equipped with “LONWORKS” device, Service Pin:

Activation of the service pin, proceed as follows:

1. Place one side of the machine in STOP

2. Press PROD

At the end of the procedure put the side in standard function (Production or Storage)

AGITATION BUTTON (CLEANING)

button for 10 seconds (a beep signal is activated)

By pressing this button from STOP, the led turns on and the display indicates:

KEY DISPLAY Comments

HOT=058 TEC+014

Beater + Pump ON

1

2

3

4

Pressing Production again we return to first display.

HOT=058 TEC+014

Pump ON

HOT=058 TEC+014

Beater ON

HOT=058 TEC+014

Beater + Heating

Pressing this button one time, the beater motor and the

mix pump motor will turn ON. HOT (consistency) and TEC

(cylinder’s temperature) are displayed in the first line.

Pressing this button for the second time we arrest the

beater motor but the mix pump remains on.

Pressing this button for the third time we activate the

beater motor and the mix pump motor stops.

Pressing this button for the fourth time we activate both the

beater motor and the mix pump motor and the heating as

well to help the product to melt.

LOCK BUTTON

To clean the keyboard panel with a clean towel it is recommended to block the keys of the

keyboard as follows:

Keep the

the keyboard is locked. At this point you can clean the keyb oard safely. To restart it, just

keep the same key pressed for 3 seconds and the led will turn off.

button pressed for 3 seconds, the respective led will flash indicating that

This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 15 of 63

Version 5: October 2012

Carpigiani K 3 User’s guide

PASTEURISATION FUNCTION / INCREASE FUNCTION

The pasteurisation function can be activated only if the mix in the hopper is a bove

the Medium Level (“ADD MIX” message on display must be off).

AUTOMATIC PASTEURISATION CYCLE:

(pasteurisation LED on) and the mix is above the medium level, the heat-treatment cycle

starts automatically at a certain time (as programmed in the Mana ger Menu normally at

2:00 AM).

During the display indicates “HEAT-TREATMENT CYCLE” the mix in the hopper and in the

cylinder is heated up to 65°C, k ept at 65°C for 30 minutes and finally cooled down to 2°C.

At the end of the cycle, the display shows “PASTO END” followed by date and hour of

termination. The machine passes automatically to STORAGE function.

To serve shake, press STOP, then the PROD button, but only if the machine hasn’t passed

automatically in PRODUCTION yet.

Note: Once the pasteurisation cycle has started, it can not be interrupted. The

complete pasteurisation cycle will take less than 4 hours to be completed.

During the pasteurisation and Pause cycles, the mix in the machine is very hot. Do

not attempt to recover the mix nor to disassemble the machine.

WARNING

Do not dispense sundae nor dismount the machine during the pasteurisation

because the product is very hot and under pressure.

while the machine is in production

STORAGE / DECREASE FUNCTION / RESET ALARM MESSAGES

The Storage Led lights ON as soon as the Pasteurisation cycle ends. The machine

preserves the mix at +2°C (35°F) in the hoppe r and in the cylinder.

- this button is also used to decrease the value in the Manager menu

- this button is also used to RESET the ALARM MESSAGES on the display.

MIX LEVEL SIGNAL

In each hopper we have 2 level sensors: MEDIUM level and LOW level.

- When the MIX LEVEL LED flashes, it means that the mix level in the hopper is lower

than the medium mix level sensor.

- When the MIX LEVEL LED is on, it means that the mix level in the hopper is lower

than the minimum mix level sensor.

The display indicates ADD MIX or MIX OUT.

Maximum filling

level indicator

Mix level

sensor

This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 16 of 63

Version 5: October 2012

Carpigiani K 3 User’s guide

When the LCD back light is blinking, that means an alarm has tripped.

When it becomes still, the alarm which has previously tripped, has automatically reset and

the indication on the display must be reset by pressing RESET button

.

EVENTS

In order to read the events, the machine must be in STOP, so keep the pressed until ****READ

EVENTS**** is displayed.

02:00:00 06 APR

The first event will appear on the display. Push or in order to scroll UP or DOWN the events

list.

START PASTEUR

PUSH TO EXIT THE EVENTS READING AND GO TO STOP.

MILK SHAKE DISPENSING BUTTONS

Every “coloured cup” button corresponds to a milk shake flavour.

In PRODUCTION, the product is disp e nsed ac co rd ing to the flavou r selected.

If, while dispensing milk shake, you push any “coloured cup” button, the milk shake will

immediately stop without reaching its automatic level; this function may be used to

dispense small portions. (tasting function).

When in STOP, by pushing th e button

pushing again it closes.

When in STOP, the “coloured cup” button are used for calibration of syrup quantity.

the piston opens and remains opened; by

SYRUP QUANTITY CHECK AND SYRUP SYSTEM CLEANING

While the machine is in STOP:

- Push one time only the “coloured cup” button.

- Syrup will be dispensed for 5/7 seconds.

- Check the quantity of the syrup using the calibration cup.

- If the quantity of syrup is not satisfactory then modify the calibration as explained in

the manager menu.

- By pushing a second time while the syrup pump is ON, the pump will run at MAX

speed in order to flush and clean the syrup tubes.

This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 17 of 63

Version 5: October 2012

Carpigiani K 3 User’s guide

MANAGER MENU

1) To access the Manager Menu press simultaneously both and keys, then release them

immediately.

On the display you will read the first step of the Manager Menu:

The first row indicates the step number, and the second row indicates the description and value.

Time

Step U01 10

2) Push

3) Push STOP to move to the next step.

4) To exit the Manager Menu push

The following table illustrates all steps of the Manager Menu:

U01 -> 06 Time and date settings

U07 Language selection.

U08 Start Production time.

U09 Start Pasteurisation time.

or in order to increase or decrease the value.

button.

STEP N°

(first row)

U01 Hours 00 23

U02 Minutes 00 59

U03 Day of Week SUN SAT

U04 Day of Month 01 31

U05 Month Jan Dec

U06 Year 2000 2099

U07 Language ITA DEU

U08 Start Prod. Hour 00

U09 Start Past .Hour 00 23+no

U10 Beeper Lev. Enabled No Yes+Man

U11 Syrup 1 pump speed 010 240

U12 Syrup 2 pump speed 010 240

U13 Syrup 3 pump speed 010 240

U14 Syrup 4 pump speed 010 240

Display

(second row)

Min Max

23+no+auto

U10 Disables/ enables the sound alarm when mix level is low..

U11 -> 14 Syrup pumps speed to calibrate the syrup quantity (1 oz fluid ounce in 5 or 7 sec)

THE MACHINE IS READY FOR START-UP ONLY AFTER IT HAS BEEN PERFECTLY

FOR HYGIENIC AND SAFETY REASONS, HANDS SHOULD

NEVER BE PLACED INSIDE THE MIX HOPPER WHILE THE MACHINE IS WORKING.

CLEANED AND SANITIZED.

Default

ENG

08

02

Yes

150

120

100

090

This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 18 of 63

Version 5: October 2012

Carpigiani K 3 User’s guide

2.1.2 SUNDAE FUNCTIONS

STOP BUTTON

By pressing this push-button during operation, the machine stops (LED on).

DISPLAY Comments

10:33:21 Fri

When the machine is in STOP, the display shows Time and Date.

PRODUCTION BUTTON

Press PROD button to start the production mode (LED on). The motor and compressor are

automatically controlled by HARD-O-TRONIC system.

By pressing this button from STOP, the display indicates:

KEY DISPLAY comments

Do Not Serve!

1

TEV +19°C W -14

Sundae Ready!

TEV +19°C W -14

Do Not Serve!

Beater HT Sensor

Hopper +14°C

2

3

Cylinder +13°C

In this box the display shows in the first line (above):

Set=100 Hot=085

Cones today

4

12345

Total Cones

5

0923456780

TEV+010 TGV-022

6

TEC+013 TE1-012

Topping +057

7

Set Topping +055

Pushing PROD again, we return to the initial display.

When the sundae is not ready , the display shows: “DO

NOT SERVE“

When the sundae has re ached the desired consistency the

display shows “SUNDAE READY”.

In case of ALARM, this will be displayed in the second row

In this box the display shows the Hopper’s temperature in

the first line (above) and the Cylinder’s temperature in the

second one.

Set=100: set HOT SOFT

HOT=085: the consistency actually detected in the soft

cylinder.

In this box the display shows the daily quantity of cones

(starting from 0:00 until 23:59).

In this box the display shows the total quantity of cones.

In this box the display shows various probes of the SHAKE

part ( no °C nor °F are displayed).

In this box the display shows the Topping probe ( no °C

nor °F are displayed), with the respective temperature sets.

This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 19 of 63

Version 5: October 2012

Loading...

Loading...