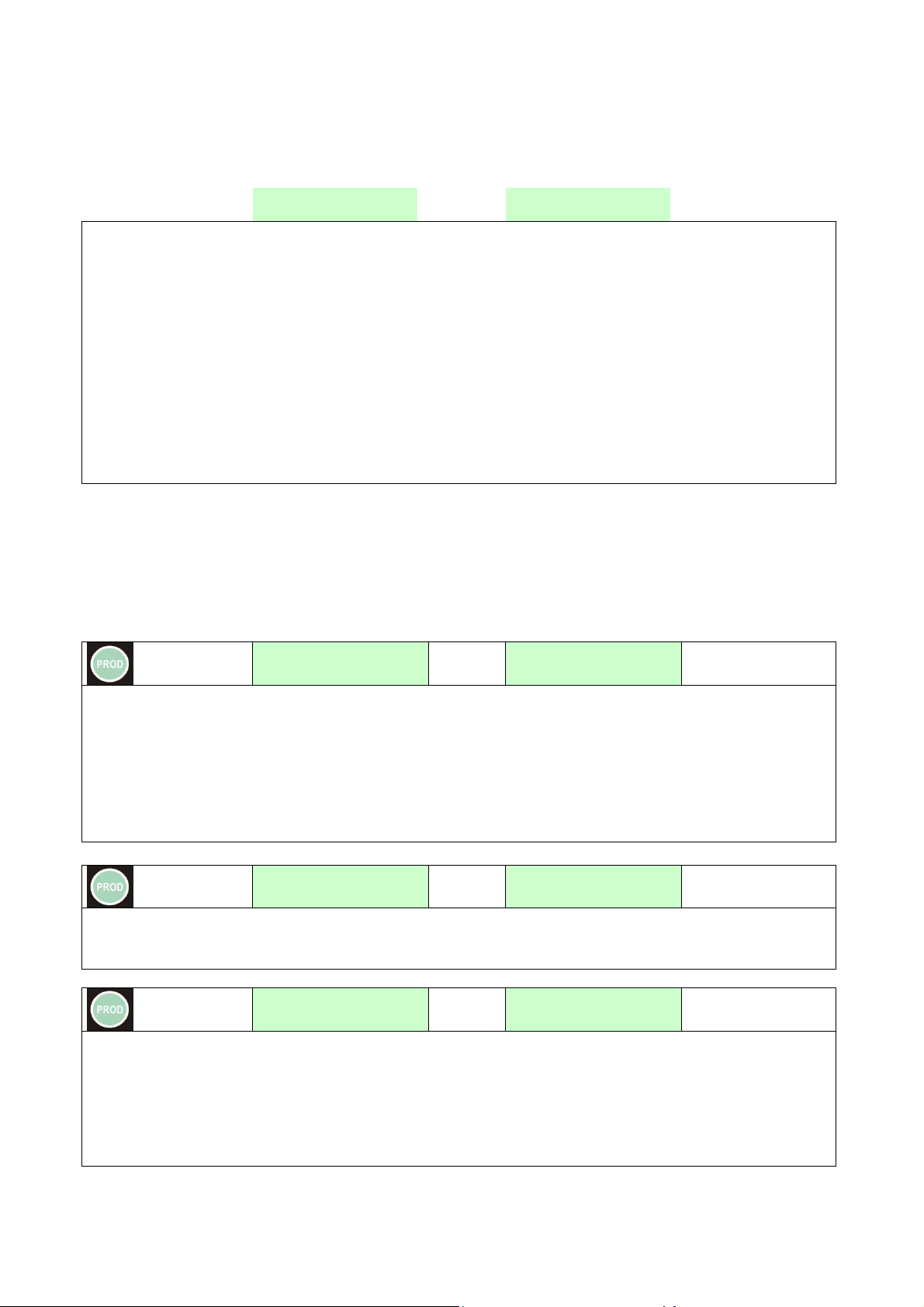

Page 1

File

+ vers. SW

mek_5.doc

SW:

k3soft23.mot

k3shake23.mot

mek3_6.doc

SW:

k3soft23.mot

k3shake23.mot

Ita-Eng-Fra-Deu

mek3_7.doc

k3soft23.mot

k3shake23.mot

Ita-Eng-Fra-Deu

mek3_7.doc

SW:

k3soft23.mot

k3shake23.mot

Ita-Eng-Fra-Deu

mek3_8.doc

SW:

k3soft32.mot

k3shake32.mot

Ita-Eng-Fra-Deu

mek3_10.doc

SW:

k3soft32.mot

k3shake32.mot

Ita-Eng-Fra-Deu

mek3_11.doc

SW:

k3soft32.mot

k3shake32.mot

Ita-Eng-Fra-Deu

mek3_12.doc

SW:

k3soft37.mot

k3shake37.mot

mek3_13.doc

SW:

k3soft37.mot

k3shake37.mot

mek3_14.doc

SW:

k3soft42.mot

k3shake42.mot

mek3_15.doc

SW:

k3soft48.mot

k3shake45.mot

mek3_16.doc

SW:

k3soft49.mot

k3shake49.mot

Date Changes

06/07/2007

Ita-Eng-Fra-Deu

27/09/2007

Ita-Eng-Fra-Deu

18/10/2007

Ita-Eng-Fra-Deu

24/10/2007

Ita-Eng-Fra-Deu

12/02/2008

Ita-Eng-Fra-Deu

12/05/2008

Ita-Eng-Fra-Deu

05/06/2008

Ita-Eng-Fra-Deu

23/04/2009

Ita-Eng-Fra-Deu

28/09/2009

Ita-Eng-Fra-Deu

22/01/2010

Ita-Eng-Fra-Deu

16/03/2012

Ita-Eng-Fra-

Deu-Rus

17/05/2012

Ita-Eng-Fra-

Deu-Rus

- Tables HOT Settings as of for European markets updated

- “Black” decal K3 also inserted

- Updating of versions sw 22

- Daily cones not zeroed in blackout

- Blackout stored in Events

- Setup sensors: new procedure

- Note: with cards 116 the inductive sensor led does not fully switch off.

- solenoid valves position updated. Pages 5 and 66

- keypad names upgraded

03/01/08 : wienerschnitzel becomes GM

Pages:

- 42: Step U11 inserted (not used)

18,80,81 : Pasteurization IMS and autosetup

Pages:

- 11,72 : corrections to temperature checks

Pages:

- 36, 97 : Timeout Prd and Alarm ICE adjusted. Only stored in the Events and

immediately restored.

- Cleaning updated, Alarm Belt, T85, MP in pasto break 10”ON/10’OFF, 5

interventions of timeout prd, Programming Table updated M, T46 and

description, revisions in black-out and alarms inserted.

- 83, 122: Automatic calibration

- 13, 77: TEV and W displayed on the first production page and Lev (ms)

- 32, 95: Pasto inhibited in Wash today

- 51: TET offset

- 46,111: tab prog.

- 107, 108: user prog.

- 116: delay level

- 44, 45, 47, 109, 110, 113: Russian and modifications to the programming

table + corrections

- 49, 114: note about trimmer hot

- 64, 131: correction to reprogramming

- 58-63 and 125-130: corrections

- 139: index

- 47, 113: sw version

- 45: U12

- 49: corrections

KK 33

““EELLEECCTTRROONNIICCSS HHAANNDDBBOOOOKK”

”

Page 2

This handbook gives information and procedures to assist technicians in setting up and

repairing the machine. This is the reason why this handbook is reserved for

TECHNICIANS, only.

When turning power on to the machine, it carries out an operating self-test of the

display and all leds light up.

The monitor displays a software version and the machine sets back at the function it

was in when power was switched off (see BLACKOUT).

ABBREVIATIONS

For the sake of convenience some abbreviations have been included in this manual,

namely:

EVRC

EVFC

EVRV

EVFV

EVRT

MA

MC

MP

Solenoid valve Cylinder Heating

1=shake 2=soft

Solenoid valve Cylinder Cooling

1=shake 2=soft

Solenoid valve Tank Heating

1=shake 2=soft

Solenoid valve Tank Cooling

1=shake 2=soft

Solenoid valve Topping Heating

(soft side, only)

Beater Motor

1=shake 2=soft

Compressor Motor

1=shake 2=soft

Pump Motor

1=shake 2=soft

TEV

TEC

TGV

TE

TET

MMV

MIR-SF

MV

Tank Thermostat

1=shake 2=soft

Cylinder Thermostat

1=shake 2=soft

Tank Ice Thermostat

1=shake 2=soft

Evaporator Thermostat

1=shake 2=soft

Topping Thermostat

(soft side, only)

Tank Mixer Motor

(one)

Micro Spigot – Photoelectric Sensor

Fan Motor

1=shake 2=soft

2

Page 3

SOFT SIDE

SOFTWARE VERSION

When turning on to the machine, the display indicates the software version.

FOR EXAMPLE

If the machine fails to work, your Technician will always have to specify this number

(software version), as well as the machine serial number you will find on the data

plate, so as to take the best advantage of Carpigiani Technical Service.

K3 Soft

ver.k3soft23

meaning sw version = 23

3

Page 4

AVAILABLE CONTROLS

KA configuration

General Market configuration

Note 1

When pressing a key and relevant function is accepted, the machine keyboard block

will emit a sound signal (beep).

Note 2

This handbook refers to machine standard configuration. As far as General Market

version is concerned, we beg you to make reference to relevant keyboard.

4

Page 5

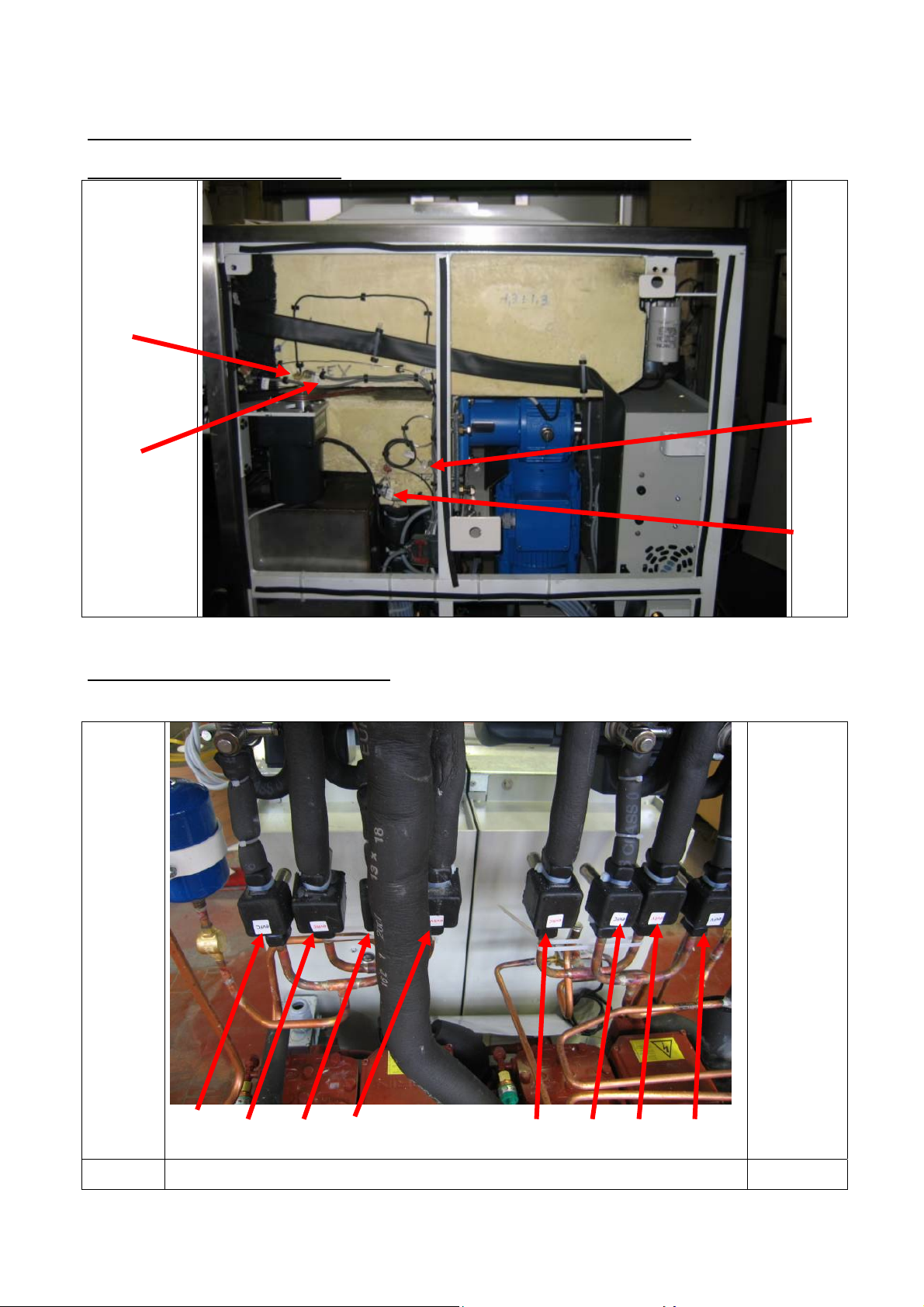

POSITION FOR SENSORS and SUNDAE SOLENOID VALVES

TEV2 – TEC2 – TGV2 – TE2

FRONT

TGV2

TEV2

TEC2

TE2

SOLENOID VALVES - front sight

SHAKE

EVFC1 EVRC1 EVFV1 EVRV1 EVRC2 EVFC2 EVRV2 EVFV2

SOFT

5

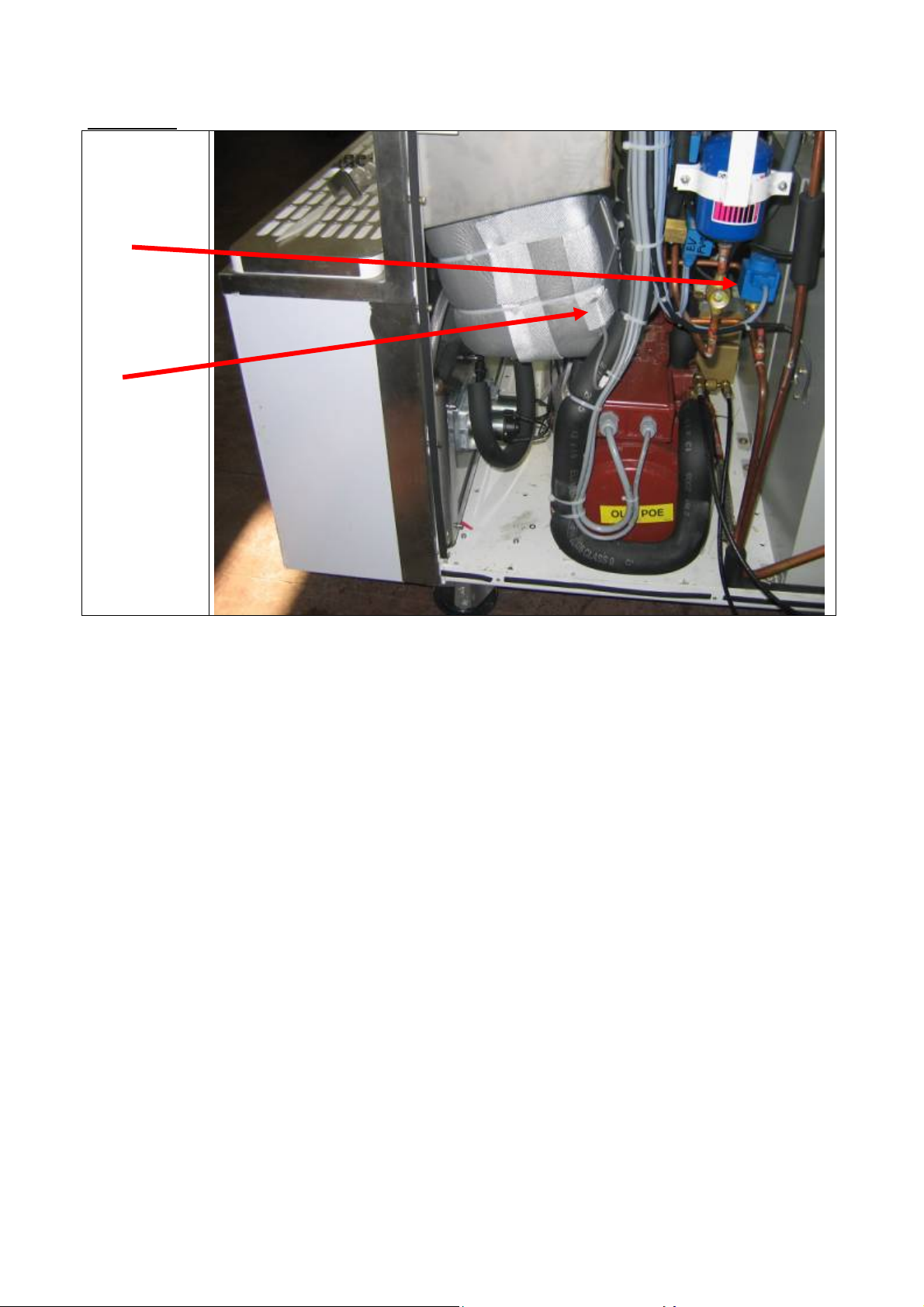

Page 6

TOPPING

FRONT

EVRT

TET

6

Page 7

DAYLIGHT TIME

From MARCH 30th to OCTOBER 30

The machine clock will automatically be moved ahead 1 hour for the daylight savings

time change over

02:00 a.m. on 30

. This means that when passing from 01:59 a.m. on 30

th

March, the clock will automatically be moved ahead 1 hour. 1

minute after 01:59 a.m. the display will show 03:00 a.m. (summer time).

Passing from 01:59 a.m. on October 30

be set back to normal for the end of daylight savings time. One minute after the clock

reaches 01:59 a.m. on October 30th it will move back by 1 hour and the time

displayed will be 01:00 a.m.

Clock time will then remain this way until next March 30

th

included, daylight time is active.

th

to 02:00 a.m. on October 30th, the time will

th

th

March to

Daylight time is only active when the step Ora Legale (Daylightsav Time) is set to

Yes.

7

Page 8

FUNCTIONS

STOP

In this function the machine is OFF and relative led is ON (stop button lights up).

From the Stop position any other function may be selected. In order to change a

function, IT IS ALWAYS NECESSARY to press the stop button for 2 seconds first.

The display shows the following:

- ENGLISH - - ITALIAN -

10:33:21 Fri

10:33:21 Ven

In order to set the machine at Stop from Production, Pasteurization and Storage, push

the stop key and hold it down for 2 seconds. The machine will not recognize the stop

command if the button is not held for at least 2 seconds, this helps avoid accidentally

hitting the button and stopping the machine.

If the machine is left at Stop with mix above the level sensor, the writing “Why in

STOP??” will be displayed flashing and with an intermittent beep after 30’’; it warns

the user to set the machine at Production, Pasteurization or Storage.

MA – MP HOUR COUNTER RESET

If you continue to press

for 20 seconds, after the display changes to “read

events”, MP counter will be reset. The display now shows “Reset hrs Count”.

In order to reset MA counter, it is not only necessary to press Stop

for 20

seconds, but also to have the MIR (photoelectric sensor) in a busy condition (Photocell

concealed); the display shows “Reset hrs Count”.

8

Page 9

TOTAL AND PARTIAL CONE COUNTER RESET

If you press Stop

within 1 second of turning the machine’s power on and hold it

down for at least 5 seconds, total and partial (daily) cones will be reset.

Display as follows:

- ENGLISH - - ITALIAN -

Reset Cone Count

Azzeramento Coni

Cone count is measured in groups of 5.

9

Page 10

EVENTS

The machine is provided with a large memory that helps us store most of the events

(historian).

To read the events stored in memory, you must have the machine in STOP

Press Stop

and keep it pressed for 3 seconds. the monitor will display the

following sequence:

- ENGLISH- - ITALIAN -

**READ EVENTS***

Log Number 00014

Year 2006

09:00:08 15 Feb

Stop

*LETTURA EVENTI*

Numero Ev.00014

Anno 2006

09:00:08 15 Feb

Stop

total events

The last screen shows the stored event, in this example it shows the STOP button was

pressed at 8 seconds after 9 a.m. on Feb. 15

th

.

Events can then be scrolled with Increment

(next event) and Decrement keys

(the event before).

In order to leave the “Read events” mode, either press the Stop button for 2 seconds

or do not touch any key for 30 seconds.

Stored events are Pasteurization steps, alarms, function changes, blackouts.

An Autosetup procedure does not cancel events from memory

10

Page 11

TEMPERATURE CONTROLS

When the machine is in STOP with the mix in the tank at a low level (low level

uncovered), the TEV temperature control is actuated.

If the TEV is greater than 15°C, the display visualises “Pasteurise !”.

Therefore, pressing the Production key, the machine passes automatically to the

Pasteurisation mode.

This control is not active during the successive 60 seconds after gaining access to the

STOP function or during the successive 60 seconds after the spigot head has been

closed.

If in all these cases, TEV<15°C, then all functions without any time limits are

permitted.

From Stop, a time will be computed if the mix level is covering the level sensor.

If down time exceeds 24 hours, the display will be as follows:

10:33:21 Fri

Wash Today !!!

10:33:21 Ven

Lavare oggi !!!

and Wash procedure must be executed: machine wash is forced and Production

inhibited.

Reset conditions are the same as those for Wash (IMS- Safety Magnetic Switch

opening and reclosing).

11

Page 12

SOFT ICE PRODUCTION

The access to Production is only enabled if the mix is above the minimum

level sensor.

The product is cooled down in the cylinder till Hot programmed in step HOT 1 (see

programming table) has been reached.

After the desired consistency has been reached (Hot), the beater goes on running for

3 more seconds (or a time programmed in step Ritardo Agitat.1 - Delay Beater 1)

and it will then switch off

If necessary, tank storage will take place, now, provided that

TEV2 (tank Thermostat 2) Temp. Conserv. - Storage Temp.

After reaching Hot, if no cone is dispensed, the beater will start every 10 minutes

(Timer Ciclico - Cyclic Timer) and will run for 10 seconds, in order to control ice

cream consistency: should this be below HOT 1 – Different Hot 1 (Hot 1

Different.), the compressor and relevant solenoid valve EVFC2 (Solenoid Valve

Cylinder Cooling) will also start so as to bring ice cream back to the programmed

consistency.

If HOT has already been reached and your machine is in stand-by mode of Production,

when you dispense a cone, the beater motor will restart and run for 15 seconds to

control the consistency.

During ice cream distribution, when mix in the tank is below the minimum level

sensor, the display will show the message

Aggiungere Mix - Add Mix , and only allow

you to distribute the number of cones set in step Ultimi Coni - Last Cones.

MP runs for 6’’ (programmable in step T41) every 10’ (fix).

12

Page 13

Once in Production mode, display shows the following:

- ENGLISH- - ITALIAN -

Sundae Ready !

TEV +19°C W -14

The first line on top refers to ice cream ready for distribution (

yet at right consistency (

The display

set in step Blocco Hot 1 - Hot Block 1 and you must thus wait.

For further details, see paragraph DO NOT SERVE.

The second line refers to the number of days to next wash. The example above shows that there are still 14 days to

wash day.

The second line concerns the TEV temperature, followed by the days (W=Wash) until the next wash.

Non Estrarre ! - Do not Serve ! means that ice cream has not yet reached HOT

Non Estrarre ! - Do not Serve !).

Gelato Pronto !

TEV +19°C W -14

Gelato Pronto ! - Sundae Ready !) or not

By pressing Production, you move to the different “windows” or screens described

below:

Key

In this window, the first line (on top) displays the hopper temperature:

= ON, when the hopper is cooled +014°C=sundae hopper temperature (TEV2)

The second line displays the cylinder temperature:

= ON, when the cylinder is cooled +013°C=sundae cylinder temperature (TEC2)

In this window, the first line (top) displays:

Set=100: Set HOT SOFT HOT=085: soft cylinder current consistency reading

In this window the display shows Cones of the day (starting from 0:00 to 23.59) :

12345 = number of cones relevant to SUNDAE side.

Daily cones are reset:

- on midnight switching

- by pressing Stop on switching on (see paragraph STOP)

- ENGLISH - - ITALIAN - Notes

Hopper +014°C

Cylinder +013°C

Set=100 Hot=085

Vasca +014°C

Cilindro +013°C

Set=100 Hot=085

TEV2

TEC2

Cones Today

12345

Coni Odierni

12345

13

Page 14

Total Cones

0923456780

Coni Totali

0923456780

In this window, the display shows total Cones:

0923456780= number of cones relevant to Sundae side.

To reset them, switch machine off and then on. Soon after switching power on (within 1 minute), press

Stop

and hold the key down for 5 seconds.

TEV+010 TGV-022

TEC+013 TE1-012

TEV+010 TGV-022

TEC+013 TE1-012

TEV2 TGV2

TEC2 TE2

In this window the display shows all sensors relevant to SUNDAE side (no display of °C nor °F):

TEV = Sundae side Hopper Thermostat

TEC = Sundae side Cylinder Thermostat

TGV = Sundae side Hopper Ice Thermostat

TE1 = Sundae side Cylinder Evaporator Thermostat

Topping +057

Set Topping +055

Topping +057

Set Topping +055

TET

In this window the display shows the Topping sensor (no display of °C nor °F) with relevant temperature set:

Topping = Topping Thermostat

Set Topping = Topping Temperature Set

By pressing Production again, machine returns to its starting display.

14

Page 15

DO NOT SERVE

When selecting Production, the display will be Non Estrarre ! - Do Not Serve !

meaning that the ice cream needs to reach an ideal consistency and therefore do not

serve till the message switches off:

- ENGLISH - - ITALIAN -

Do Not Serve !

TEV +19°C W -14

Non Servire !

TEV +19°C W -14

The first time when is accessed the Production the machine has to reach the Set HOT

to extinguish the writing, the following times it will be had the standard operation

through Hot Block

Once Hot Block has been reached, the routine operation starts.

Message on the display will be as follows:

Sundae Ready !

TEV +19°C W -14

Gelato Pronto !

TEV +19°C W -14

In particular:

If the consistency decreases below the value programmed in step Blocco Hot 1 - Hot

Block 1,

Non Servire ! - Do Not Serve ! will light up on the display. This means that

ice cream is not ready for distribution.

Writing will become

Gelato Pronto ! - Sundae Ready ! ONLY after that Blocco Hot 1 is

reached.

If a cone is dispensed (MIR-Photoelectric sensor activated) while

Not Serve !

is lit up on the display, all outputs will switch off (MA, MC, EVFC OFF; MP,

Non Servire ! - Do

will also turn OFF if it was ON).

If the hopper needs to cool for storage, MC + EVFV will be left ON.

As soon as the photocell is deactivated (no longer covered), Production restarts, so

restarting MA and MC + EVFC.

If the consistency value goes below Hot Block – 5 points hysteresis, the message

Non Servire ! - Do Not Serve ! will again light up on the display.

15

Page 16

MIX OUT

When mix is low (below the medium level sensor), the first line on display will show

the blinking message

the keyboard will light up

Aggiungere Mix ! - Add Mix ! and hopper medium level led on

.

When the mix is below the medium level sensor, an intermittent acoustic warning

(beep) will also be activated.

- ENGLISH - - ITALIAN - Notes

Add Mix !

TEV +19°C W -14

Aggiungere Mix !

TEV +19°C W -14

low med. level

When mix is out (below the low level sensor) the first line on display will show a fixed

message

light up

The second line displays the number of cones you can still distribute (

Last Cones

Note:

With messages Aggiungere Mix ! - Add Mix ! and Mix Esaurita ! - Mix Out ! on

display, the access to next Production screens is not allowed.

Mix Esaurita ! - Mix Out ! and hopper low level led on the keyboard will

.

Ultimi Coni -

) before the machine automatically sets at Storage mode.

- ENGLISH - - ITALIAN - Notes

Mix Out

Last Cones 5

Mix Esaurita !

Ultimi Coni 5

Low level out

Nr of remaining cones

16

Page 17

ICE IN THE CYLINDER

In Production, if the temperature TE2 reaches a value less than or equal to the one set

in step Ghiaccio Cilin. - Ice Cylinder, alarm

Ghiaccio Cilind. - Ice Cylinder will

activate and will be stored among the events, ONLY.

This alarm is not displayed.

Under the said condition, all outputs to the cylinder will be deactivated and the

machine will set to hopper cooling, if need be.

When Production timeout ends, consistency will be tested again in order to check

whether TE2 has risen in the meantime higher than Ghiaccio Cilin. - Ice Cylinder.

TIMEOUT PRD

In Production, if consistency does not reach its set point within the time programmed

in step Timeout Prd., the cycle will be forced to end as if HOT had been reached and

the alarm will be stored among the events (not on display).

If Hot Block is not reached within 15 minutes after production starts, the machine will

set to Stop and alarm Timeout Prd. will be displayed.

17

Page 18

PASTEURIZATION

No Pasteurization process will ever start if the mix inside the tank is below

medium level sensor.

Pasteurization process is automatically executed every day at 2:00am

(provided that time has been programmed in step Ora Avvio Pasto - Start Pasto

Time).

The machine is normally in Production and at the appointed Pasteurization time, it will

automatically enter into the Pasteurization program and carry out the cycle.

Warning: if the front lid is open at the automatic Pasteurization time (Pasto

Start Time), your machine will allow Production only after closing it.

If, step Ora Avvio Pasto - Start Pasto Time is set to “no” in the program,

automatic Pasteurization is disabled and it can only be executed manually (General

Market).

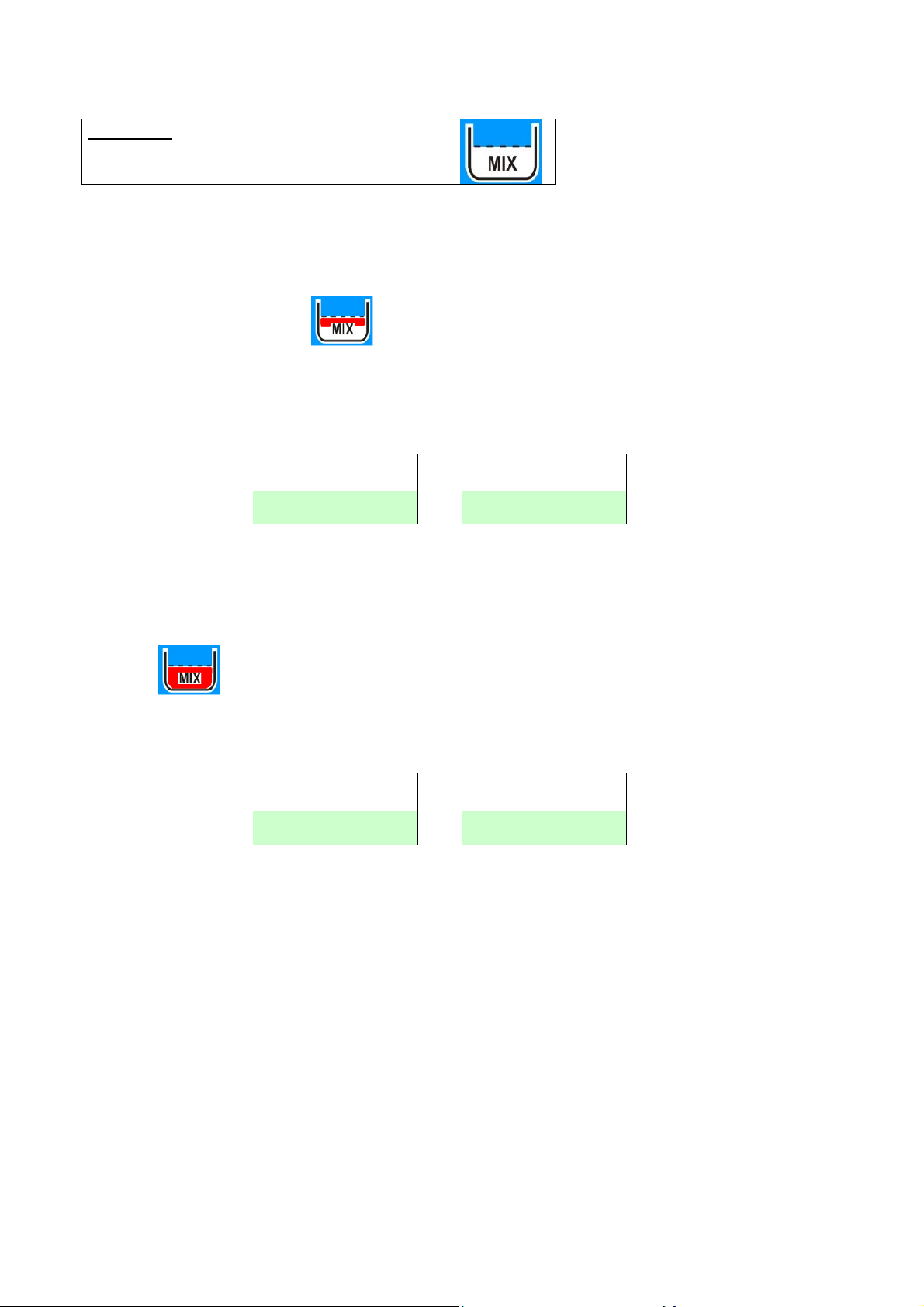

In order to activate Manual Pasteurization, press the Pasteurization key

and

hold it down for 5 seconds.

Warning: 5 seconds after the access to Pasteurization, the cycle must be completed.

If the Pasteurization is not

successfully completed, your machine will NOT enter

Production, till the execution of a full Pasteurization cycle.

To force the access to Pasteurization even though the machine is in reserve (medium

level low mix), it is necessary for you to press the Storage key

and hold it down

30 seconds.

By this, you will “skip” hopper level control block and you can now press the

Pasteurization button for 5 seconds to enter in Manual Pasteurization.

18

Page 19

The product in both the hopper and the cylinder is heated up to 149°F (65°C), kept at

this temperature for 30 minutes (fixed time), and then cooled down to reach the

storage temperature.

At the end of the cycle, the monitor displays “Fine Pasto- Pasto End -”, followed

by date and time, meaning that the pasteurization process has been correctly

executed

.

The beater in the cylinders turns cyclically during Heating, pause, Cooling (149°F

(65°C) down to 68°F (20°C) in the cylinder) and since the moment when the cylinder

reaches the storage temperature; whereas, during cooling, from 68°F (20°C) down to

cylinder storage temperatures, beating is continuous.

The beater inside the cylinder normally runs 15 seconds and stops 30 seconds

Even in the event that the tank reaches the storage temperature earlier than the

cylinder and TE>68°F (20°C), the beater is ON (continuous).

19

Page 20

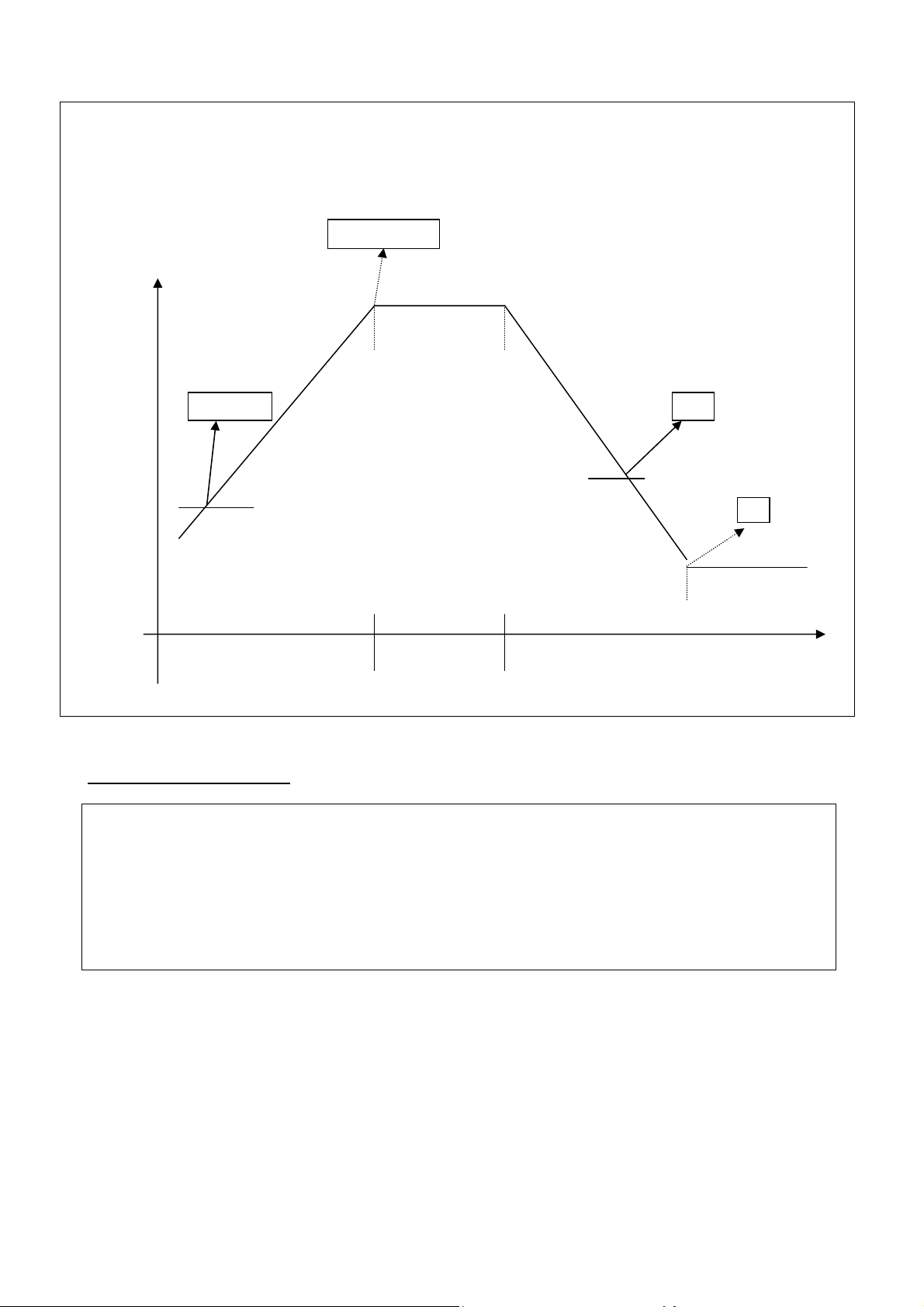

Pasteurization Sundae side

55°65°85°

°C

TEC= 10°C 20°

MA+MC+EVRC 15” ON

MC+EVRV 70” ON

MA+MC+EVRC 15” ON

MC+EVRV 70” ON

MA+MC+EVFC 15” ON

MC+EVFV 90” ON

30’

Pasteurization Graph

Cycle Description

On heating cycle start between cylinder and hopper:

MA+MC+EVRC 15”ON and MC+EVRV 70”ON.

In Cooling, operation till TEC=20°C as follows:

MA+MC+EVFC 15”ON and MC+EVFV 90”ON.

When TEC reaches 20°C MA is always ON, also in hopper cooling:

MA+MC+EVFC 15”ON and MC+EVFV 90”ON.

MA+MC+EVFC 15” ON

MC+EVFV 90” ON

2°

Time

20

Page 21

HEATING

Heating is executed with “positive hysteresis”, meaning that if a temperature of 149°F

(65°C) has been set, heating will be deactivated at 156.2°F (69°C) and will then

restart at 149°F (65°C).

If you want to skip heating and 30 minute pause, press the Storage key

for 3

seconds (at least 5 seconds after the Pasteurization is initiated); by doing this

you will set the machine at the Cooling cycle without a previous pause of 30 minutes.

Once entering Pasteurization, the display is as follows:

In this window, first line (on top) displays:

-Riscaldamento- - Heating – i.e., heating step of Pasteurization process.

On the second line:

Non Servire ! - Do Not Serve ! meaning that ice cream must not be dispensed.

- ENGLISH - - ITALIAN - Notes

- Heating Do Not Serve !

-Riscaldamento Non Servire !

Pressing Pasteurization

leads to the screens described here below:

Key

- ENGLISH - - ITALIAN - Notes

Hopper +023°C

In this window, the first line (on top) displays the Hopper temperature (TEV2) whilst the second line displays the

Cylinder temperature (TEC2).

: The arrow indicates what side is heated.

Cylinder -013°C

Vasca +023°C

Cilindro -013°C

TEV2

TEC2

Key

In this window all sensor temperatures are displayed.

- ENGLISH - - ITALIAN - Notes

TEV+066 TGV+070

TEC+067 TE1+068

TEV+066 TGV+070

TEC+067 TE1+068

TEV2 TGV2

TEC2 TE2

During Heating process, the compressor heats cylinder and hopper in turns.

Default times in heating step are normally 15 seconds for cylinders and 70 seconds for

hopper.

21

Page 22

ACTIVATED UNITS

On start, MP is activated for a fixed time of 30 seconds, where as MMV runs for the

duration of the entire cycle.

In Cylinder Heating, the following units are activated: MA, MC, EVRC for 15 seconds

(see the table below). The following units are activated: MC, EVRV, for 70 seconds

(see the table below).

By EVRC, MP and MA it is always meant SUNDAE side.

If the hopper reaches the Pasteurization temperature earlier than the cylinder, beating

in the cylinder will begin to run continuously.

Following checks are also executed:

If TEV < TEC by : >= 4°C ON EVRV 86” / ON EVRC 15”

If TEV < TEC by : >=3°C and <4°C ON EVRV 78” / ON EVRC 15”

If TEV < TEC by : >=2°C and <3°C ON EVRV 74” / ON EVRC 15”

If TEV < TEC by : >=1°C and <2°C ON EVRV 72” / ON EVRC 15”

DELTA TGV-TEV

(Alarm Belt)

Conditions for belt alarm are monitored under the following parameters:

- TEV and TGV sensors cannot already be in an alarm state of their own

- machine must be in Heating or Pasteurization Pause

In Heating of Pasteurization program, if TGV temperature turns > than the TEV

temperature by the value programmed in step Delta TGV-TEV,

Alarm Belt

will be displayed and machine will set to Stop.

Allarme Cinghia -

Check driving belt or whether the rotor is in its seat.

22

Page 23

PAUSE

If you want to skip the 30 minute pause after the temperature of 149°F (65°C) has

been reached, press the Storage key

2 seconds; by doing this you will set the

machine to the Cooling cycle without the 30 minute pause.

- ENGLISH - - ITALIAN - notes

-Heating Pause Do Not Serve !

In this window the first line (on top) displays:

-Pausa Pasto Non Servire !

-Pausa Pasto- -Heating Pause- i.e., Pasteurization pause (or break).

On second line:

Non Servire ! - Do Not Serve ! meaning that it must not be served in this step.

Pressing Pasteurization leads to the screens described below:

Key

In this window the first line (on top) displays the Hopper temperature (TEV2) whilst the second line displays the

Cylinder temperature (TEC2).

: The arrow indicates what side is heated.

- ENGLISH- - ITALIAN - Notes

Hopper +065°C

Cylinder +066°C

Vasca +065°C

Cilindro +066°C

TEV2

TEC2

Key

In this window, Pause decreasing Time is displayed.

- ENGLISH - - ITALIAN - Notes

Pause Time 30:00 Tempo Pausa30:00

Key

In this window all sensor temperatures are displayed.

- INGLESE - - ITALIANO - Note

TEV+066 TGV+070

TEC+067 TE1+068

TEV+066 TGV+070

TEC+067 TE1+068

TEV2 TGV2

TEC2 TE2

23

Page 24

ACTIVATED UNITS

MMV runs for the duration of the entire cycle.

If the Pasteurization temperature is reached either by the cylinder or by the hopper,

MMV will run continuously, whilst MA runs for 15 seconds and stops for 2 minutes,

until pause time has finished.

If the cylinder needs be heated during the pasteurization pause, MA (will run

continuously) MC and EVRC will start.

If the hopper, alone, needs be heated during the pasteurization pause, MC and EVRV

will be activated.

If both the cylinder and hopper need to be heated at the same time during the

pasteurization pause, heating will begin to cycle: 15sec. MA, MC and EVRC and 70 sec.

MC and EVRV (still applicable times given in previous table relevant to ON-OFF times

in relation to TEC and TEV temperatures).

MP will be activated in pause for 10” every 10’.

24

Page 25

COOLING

The product is cooled down to the cylinder and hopper Storage temperatures

(Temp.Conservaz. – Storage Temp.).

- ENGLISH - - ITALIAN - Notes

- Cooling -

Do Not Serve !

In this window the first line (on top) displays

-RaffreddamentoNon Servire !

-Cooling- - Cooling - : i.e., Pasteurization cooling step.

On the second line:

Non Servire ! Do Not Serve ! : that it must not be served in this step.

Pressing Pasteurization

Key

In this window the first line (on top) displays

Cylinder temperature (TEC2).

: The arrow indicates what side is cooled.

- ENGLISH - - ITALIAN - Notes

Hopper +065°C

Cylinder +066°C

leads to the screens described here below:

Vasca +065°C

Cilindro +066°C

the Hopper temperature (TEV2) whilst the second line displays the

TEV2

TEC2

Key

In this window all sensor temperatures are displayed.

- ENGLISH - - ITALIAN - Notes

TEV+066 TGV+070

TEC+067 TE1+068

TEV+066 TGV+070

TEC+067 TE1+068

TEV2 TGV2

TEC2 TE2

ACTIVATED UNITS

MMV runs for the duration of the entire cycle, till TEV reaches the Storage

temperature.

In Cylinder Cooling, following units are activated: MA, MC, EVFC, MV 15 sec. (see

table).

In Hopper Cooling, following units are activated: MC, EVFV, MV 90 sec. (see table).

On cycle end, the machine sets at Storage and

- Fine Pasto –

25

Page 26

(- Pasto End -)

with time and relevant day of the week are displayed.

In this window the first line (on top) displays

- Fine Pasto – (- Pasto End -): i.e., Pasteurization (Storage) holding step.

On the second line:

- time and day of the week

- ENGLISH- - ITALIAN - notes

- Pasto End 10:17:50 Mon

- Fine Pasto 10:17:50 Mon

:

ACTIVATED UNITS

When the Storage setpoint has been reached and the hopper needs to be cooled, MMV

is activated for the duration of hopper cooling (in parallel with EVFV).

In Cylinder Cooling the following units are activated: MA, MC, EVFC, MV.

In Hopper Cooling the following units are activated: MC, EVFV, MV.

Anti-icing

When the temperature TGV reaches a value smaller/same as –0.4°F (-18°C) (step

Antigh.Vasca – Hopper Defrost) EVRV energizes (and EVFV goes on being

energized). The display indicates an upward arrow. When TGV increases by the value

programmed in the step Ist.Antig.Vasca – Hop.Defrost Hys, EVRV switches off.

26

Page 27

STORAGE

The Storage program has the function to bring the product which is both inside the

hopper and inside the cylinder to the temperature of 39.2°F (4°C) (this value can be

programmed in step Temp.Conservaz. – Storage Temp.).

As far as the hopper is concerned, storage is controlled by TEV2 whereas, as to the

cylinder, it is controlled by sensor TEC2.

Every time you set the machine at the function Storage, values of sensors TEC2

(temperature in the cylinder) and TEV2 (temperature in the hopper) are read.

If both the cylinder and hopper need be cooled at the same time, the hopper has

priority over the cylinder.

Storage in that case takes place on a cyclic basis.

When storing the hopper EVFV + MC are activated for 90 seconds.

When storing the cylinder MA + MC + EVFC are activated for 15 seconds.

When entering the Storage mode, you will have the following display:

In this window the first line (on top) displays the Hopper temperature (TEV2) whilst the second line displays the

Cylinder temperature (TEC2).

: The arrow indicates what side is cooled

- ENGLISH - - ITALIAN - Notes

Hopper +015°C

Cylinder +012°C

Vasca +015°C

Cilindro +012°C

TEV2

TEC2

Pressing Storage leads to the screens described here below:

Tasto

In this window all sensor temperatures are displayed.

- ENGLISH - - ITALIAN - Notes

TEV+066 TGV+070

TEC+067 TE1+068

TEV+066 TGV+070

TEC+067 TE1+068

TEV2 TGV2

TEC2 TE2

27

Page 28

ACTIVATED UNITS

MMV runs during the entire cycle, till TEV reaches the Storage temperature.

Active units in Cylinder Cooling: MA, MC, EVFC, MV for 15 seconds.

Active units in Hopper Cooling: MC, EVFV, MV for 90 seconds.

MP runs for 6’’ (programmable in step T41) every 10’ (fix).

28

Page 29

TOPPING

This function is automatically activated in Production if:

- the topping tank has a sufficient quantity of water to cover topping level sensor,

- in Programming mode, step Set Topping is not = 0

-Hot has not been reached (when EVFC is off)

If the above conditions are met, MC and EVRT will start and heat topping water up to

the temperature set in the Programming (usually 131°F (55°C)) and hold it at that

temperature through thermostatic control.

If you exit from Production, warm gas will deactivate.

29

Page 30

CLEANING

In this function MA and MP will be activated for 30”, after that, the machine will

automatically return to Stop, so as to avoid a severe wear of the cylinders.

When entering Cleaning, the display will be as follows:

In this window, the first line (on top) displays HOT1 and TEC2

The second line shows how to enable/disable the outlets:

- will be activated (Beater and Pump) for 30”.

- ENGLISH- - ITALIAN - Notes

HOT=058 TEC+014

Beater + Pump ON

HOT=058 TEC+014

HOT2 TEC2

Agita + Pompa ON

Pressing Cleaning leads to the screens described here below:

HOT=058 TEC+014

Pump ON

In this window, the first line (on top) displays HOT2 and TEC2.

MA will be deactivated and only does MP run for 30”.

HOT=058 TEC+014

Pompa ON

By pressing Cleaning again MA is activated again:

HOT=058 TEC+014

Beater ON

In this window, the first line (on top) displays HOT2 and TEC2.

MP will be deactivated and only does MA run for 3 minutes.

HOT=058 TEC+014

Agitatore ON

By pressing Cleaning again :

HOT2 TEC2

HOT1 TEC2

HOT=058 TEC+014

In this window, the first line (on top) displays HOT2 e TEC2.

MA and MC+EVRC will be activated till the Set TEC Cleaning (T85).

Beater + Heating

HOT=058 TEC+014

Agitat + Riscald

By pressing Cleaning again initial display will be shown.

HOT2 TEC2

30

Page 31

MA AND MP HOUR COUNTER

By pressing the Pasteurization key from Cleaning, you will get the access to MA and

MP hour counter display.

MP hours 00000

MA hours 00002

Ore MP 00000

Ore MA 00002

To exit from Hour Counter display and return to Cleaning, press Pasteurization

To reset the Hour Counters, see paragraph STOP.

.

31

Page 32

WEEKLY CLEANING WASH DAYS

In Production, the first screen displays the number of days to next wash:

Second line refers to the number of days to next wash. The example shows that wash is in 14 days.

The day the machine must be washed, the function Ice cream Production is inhibited

and the machine will not accept the function. Display will be as follows:

- ENGLISH - - ITALIAN -

Do Not Serve !

TEV +19°C W -14

Non Servire !

TEV +19°C W -14

08:10:05 Wed

Wash today!

08:10:05 Mer

Lavare oggi !

In this condition, automatic Pasteurization is inhibited.

In order to set the number of days back to the programmed value (Giorni Lavaggio

– Wash Days) it is thus necessary to wash your machine or to remove the front lid

and mount it back (or yet, disconnect and re-connect IMS).

Note

Wash day starts decrementing 23.53 to 23.56.

32

Page 33

CLEANING THE DISPLAY

Keyboard block

By pressing the Cleaning key

disabled and Cleaning led will blink.

This will enable you to clean the capacitive keyboard without causing any casual

function changes.

The machine will remain in the same function.

In order to enable the keys back, press the Cleaning key

for 3 seconds from any function, all keys are

again for 3 seconds.

33

Page 34

ALARMS

The machine issues possible alarm messages on the display and makes the writing

blink.

In case of alarm which has reset, the writing will be on display in a fixed way (it will

not blink).

To reset the writing, press Storage/Reset key

.

The machine can be used in ice cream production even if an alarm is active; if it is a

critical alarm, the machine will not allow you to select ice cream production program;

should this be the case, press STOP and do not use the machine till it is repaired.

Here below is the alarm list:

ALARM

Aggiungere Mix

Add Mix

The display indicates Aggiungere Mix Add Mix when the

mix is below the MEDIUM level sensor. An intermittent beep

will be activated (only if step Abilita Beep Liv in

DESCRIPTION

Programming User is set to YES and the machine is not in

Stop).

Mix Esaurita

Mix Out

The display indicates Mix Esaurita-Mix Out when the mix

is below the LOW level sensor. When the mix is below the

low level sensor and in Production you distribute a number

of cones same as/or higher than the value set in step Ultimi

Coni- Last Cones, not only will Mix Esaurita- Mix Out be

displayed, but also your machine will move to Storage

mode.

Term.Sicur.Cil

Safety Therm.Cyl

(TESC2)

Term.Sicur.Vasca

Safety Therm.Hop

(TESV2)

Cylinder Safety Thermostat SUNDAE tripped.

Machine sets at Stop.

Hopper Safety Thermostat SUNDAE tripped.

Machine sets at Stop.

Termico Agitator Overload beater (bimetallic) motor SUNDAE tripped.

34

Page 35

Overload Beater

(PTMA2)

Machine sets at Stop.

Pressostato

Pressure Switch

(PR2)

Termico Compres.

Overload Compres

(PTMC2)

All. Sonda Vasca

Al. Hopper Probe

(TEV2)

Pressure Switch SUNDAE tripped.

Machine sets at Stop:

- after the 3

rd

tripping occurring within 1 hour

- if pressure switch contact is opened 2 minutes running.

If the machine was in Pasteurization mode, Pasteurization

program shall be re-executed.

Check cooling water flow (in water cooled units).

Overload Compressor Motor SUNDAE.

Machine sets to Stop.

Hopper sensor SUNDAE faulty.

This is a critical alarm: consequently, the machine sets to

Stop, either from Production or from Storage and

Pasteurization modes.

All. Sonda Cilin

Al. Cylind.Probe

(TEC2)

All.Sonda Gh.Vas

Al. IceHop.Probe

(TGV2)

Portello Aperto

Spigot Opened

(IMS2)

Cylinder sensor SUNDAE faulty.

This is a critical alarm: consequently, the machine sets to

Stop, from the Storage and Pasteurization modes, it does

not however, se to Stop from production because

consistency is controlled.

Tank evaporator sensor SUNDAE faulty.

This alarm does not cause a machine (which is in the

running function) to stop.

In Pasteurizing Heating mode the alarm is eliminated.

Safety Magnet Switch SUNDAE.

If opened 10 sec., it resets Wash message (Wash).

IMS opening also resets Pasteurization flag, so that if the

machine was in Pasteur. mode, you can directly enter

Production by opening and closing the front lid.

35

Page 36

All. Sonda Evap.

Alarm Cylinder evaporator sensor SUNDAE.

Al. Evapor.Probe

(TE2)

Ritorno tensione

Power On

Ghiaccio Cilin.

Ice Cylinder

(ICE2)

This alarm does not cause a machine (which is in the

running function) to stop.

In Pasteurization Heating mode the alarm is eliminated.

Power return after a blackout.

Check blackout table in Pasteurization and Production.

Event stored in all functions except STOP.

Anti-icing cylinder SUNDAE read by sensor TE2.

In Production, when TE2 temp. gets lower than the value set

in step Ghiaccio cilin. Ice Cylinder, machine sets to

reached-HOT state and stores the alarm Ghiaccio Cilin. Ice

Cylinder in the events.

This alarm can be caused by an insufficient mix feeding to

the cylinder.

Check pump efficiency.

If the alarm occurs in Stop, it is necessary to check/replace

the sensor TE2 because temperature is not being “read”

properly by the CPU.

36

Page 37

Timeout Prd.

In Production, starting time of the beater motor is checked.

Timeout Prd.

Allarme cinghia

Belt Alarm

(DELTA TGV-TEV)

If the beater motor is ON for 6 minutes (Timeout Prd.) and

Hot has not been reached, the machine sets to a “reachedHOT state” with alarm “Timeout Prd.” in the events.

The Timer will be reset on MIR and on MA starting.

After 5 interventions the alarm remains on the display and

the machine sets at Storage mode.

Check mix charge in cylinder, pump in the hopper and

freezing unit.

In Heating Pasteurization, if the temperature TGV2 becomes

> than TEV2 value programmed in step DELTA TGV-TEV,

“Allarme cinghia- Belt alarm“ is displayed and the

machine sets to Heating mode.

Check the driving belt or if the rotor is in its seat.

The alarm automatically resets.

W -n gg

W -n days

(Wash)

Warning: this alarm is not active if TEV or TGV probe is

inhibited.

In Production, “TEV +19°C W –n” Wash in n days is

displayed: this means that n days remain until machine

wash. Alarm Wash might also be caused by leaving machine

in stop for 24 hours mix above the level sensor

See WEEKLY CLEANING.

37

Page 38

T

Non Servire !

In Production, every time consistency value goes below the

Do Not Serve !

No Acqua Topping

No Topping Water

(AL16)

All.Sonda Topping

Al.Topping Probe

AL17 (TET)

one programmed in step Blocco Hot, cone red led lights up

to indicate wait until ice cream is ready and “Non Servire

!” Do not Serve shows on the display. If, in such a case,

you try to distribute cones, all units stop (MA and MC) till

the photocell is no longer busy. As soon as it is set free,

both MA and MC re-start in order to bring ice cream to its

proper consistency.

When the Topping led is on, the level sensor in the topping

tank must be covered with water, otherwise, heating will

automatically switch off and “No Acqua Topping” No

Water Topping will be shown on the display.

Alarm Topping (TET) sensor.

TET is the sensor indicating the temperature of topping tank.

In case of trouble, All.Sonda Topping. Al. Topping Probe

Invertire Fasi

Invert Phases!

Pastorizzare !

Pasto needed !

will be displayed.

It is necessary to exchange 2 phases on the threephase line

in order to get the correct beater rotation direction. The

alarm resets by switching power off and on again (after

exchanging the phases).

When machine has been set to Stop with mix above low

level sensor for over 60 minutes, TEV temperature is

checked and if it is 59°F (15°C) or higher, Pasteurization is

needed. So pressing the Production key, will cause the

machine to automatically set to Pasteurization, unless you

open its front lid and close it again. In this case, test on

EV

≥ 59°F (15°C) will be cancelled for a time of 60 minutes

and Production will be accepted.

If in all these cases, TEV<59°F (15°C), all functions will be

accepted with no time limits.

38

Page 39

Why in STOP ?? If the machine is left in the Stop position with mix covering

the level sensor, the message “Why in STOP?” will be

displayed 30 seconds later and an intermittent beep will be

emitted. All this to warn the user to set the machine to

Production, Pasteurization or Storage.

Above mentioned message will be deleted by entering

Production, having low mix level, or pressing Reset (Stor.)

key.

To have the message back on the display, it is necessary to

first enter Production, Storage or Pasteurization.

Temp Vasca calda

Hopper Temp Warm

Temp Cilindro calda

Barrel Temp Warm

Temp Vasca Boll

A 4-hour timer is enabled in Production and Storage modes.

If the TEV stays above 5°C for more than 4 hours

consecutively or if, when power returns after a blackout,

TEV>5°C, the message “Hopper Temp Warm” is displayed.

This can be cancelled by pressing the Storage key.

Signal only.

A 4-hour timer is enabled in Production and Storage modes.

If the TEC stays above 5°C for more than 4 hours

consecutively or if, when power returns after a blackout,

TEV>5°C, the message “Barrel Temp Warm” is displayed.

This can be cancelled by pressing the Storage key.

Signal only.

A 1-hour timer is enabled in Production and Storage modes.

Hopper Temp High

If the TEV stays above 5°C for more than 1 hour

consecutively or if, when power returns after a blackout,

TEV>15°C, the message “Hopper Temp High” is displayed.

This can be cancelled by pressing the Storage key.

Signal only.

39

Page 40

Temp Cilindr Bollen

A 1-hour timer is enabled in Production and Storage modes.

Barrel Temp High

If the TEC stays above 5°C for more than 1 hour

consecutively or if, when power returns after a blackout,

TEC>15°C, the message “Barrel Temp Hight” is displayed.

This can be cancelled by pressing the Storage key.

Signal only

40

Page 41

BLACKOUT

In the event of blackout, if the machine was in Cleaning, on power return, it sets to

STOP.

While if it was in Heating mode in Pasteurization or in Pause mode during

Pasteurization program, on power return, the machine is again in the function where it

was before power failure (Power On on display).

If the machine was in:

Soft ice production, Storage or Cooling in Pasteurization, on power return, the

machine checks the temperature TEV and how long the power failure lasted; if a

blackout lasts more

than what indicated in the table below, the machine will repeat

the pasteurization completely and alarm “Ritorno Tensione” or “Power On” will be

stored in the “events list“.

Otherwise, if blackout time is shorter

than the one indicated in the table below, the

machine will return to the function where it was before blackout.

Temperature TEV

68°C 50°C

49°C 15°C

14°C 10°C

9°C 4°C

Timer

30 minutes

10 minutes

20 minutes

2 hours

41

Page 42

AUTOSETUP

If necessary, autosetup is only to be done after Carpigiani service’ authorization.

CAUTION: After an autosetup, sensor offset values are zeroed. Before executing it, it

is consequently advisable to always carry out a Download for Programming Table.

The procedure sets all programmable values according to the one indicated in the

column of relevant model.

To do that, switch machine off and then on again.

WAIT for 1 second after switching on and then press

Hold

pressed till the following will be on display:

K3 Soft

ver.K3Soft23

Autosetup Done

.

followed by a beep.

Release the key

, now.

The machine is now programmed according to the values indicated in the

corresponding column (see programming table).

42

Page 43

EVENT LIST

The machine is provided with a large memory that helps us store most of the

events (function you select, alarms,...).

To read the events stored in the memory you must have the machine in STOP,

then press

and keep pushing it 5 seconds.

On the display you’ll get the last event occurred with relevant date and time.

Es.:

First line is relevant to date/time and the second one to the event.

- ENGLISH- - ITALIAN -

12:10:36 22 May

Start Pasteur.

12:10:36 22 May

Avvio Pasto

Events are scrolled with Increment

(next event) and Decrement keys

(previous event).

If you don’t push any button for 30 sec. or you push STOP, the machine will go to

STOP.

The events list helps us understand when and how many times a certain alarm has

occurred.

Moreover, we can have a report that tells us about the pasteurization cycle and check:

Pasteurization Start

Pause Start (End Heating)

Pause End (Start Cooling)

Pasteurization End

Blackout events

NB: The highest number of storable events is 1000.

A further event will cancel the last one (the thousandth).

While reading the events you can also delete them, holding Cleaning key down for 3’’.

43

Page 44

PROGRAMMING USER SUNDAE

1) For access to the Programming User (Manager Menu) press the

Stop and Storage keys at the same time and soon release them.

The first step of programming User is now displayed.

The first line is relevant to the description and the second one to the step number (U=User) and to the value.

- ENGLISH - - ITALIAN -

Hours

Step U01 10

Ora

Step U01 10

2) Press Increment or Decrement keys to change the value.

Press Stop

to enter the next step.

See programming table.

3) To exit from programming, do not press any key for 30 seconds or

press Production or Cleaning.

Machine returns to Stop, now.

Step

U01

U02

U03

U04

U05

U06

U07

U08

U09

U10

U11

U12

Display ITA Display ENG Min Max Default

Ora Hours

Minuti Minutes

Giorno Settimana Day of Week

Giorno del Mese Day of Month

Mese Month

Anno Year

Linguaggio Language

Ora Avvio Prod. Start Prod. Time

Ora Avvio Pasto Start Pasto Time

Abilita Beep Liv Lev. Beep Enable

Ora Avvio CIP Start CIP Time

Tempo Mixer Mixer Timer

00 23

00 59

Sun Sat

01 31

Jan Dec

2000 2099

Eng Eng Eng

00 23+no 08

00 23+no 02

No Yes Yes

No No No

-01 60 05

/

44

Page 45

Step

U01 Hour/time

Hour setting

U02 Minutes

Minutes setting

U03 Day of the Week

Week day setting.

U04 Day of the Month

Month day setting.

U05 Month

Month setting.

U06 Year

Year setting

U07 Language

Language setting ITA – ENG – FRA – DEU - RUS

Note

U08 Distr. Start time

Setting of Automatic Distribution Starting time.

When setting at no, no automatic Distribution will ever start.

When setting at auto, automatic Distribution will start as soon as

Pasteurization is completed.

U09 Past. Start time

Setting of automatic Pasteurization start time. When set at no, no automatic

Pasteurization will ever start.

U10 Beep Liv Enable

When setting at YES, an intermittent beep will be emitted as soon as the mix

is below the medium low level sensor, alarm not active when in Stop, being

OFF, or if the alarm is disabled.

U11 Start CIP Time

Not used.

U12 Mixer Timer

= -1: the output is utilised to activate the fan of the electrical enclosure and

therefore the mixer is deactivated.

= 0: Mixer management (active whilst the key is pressed)

> 0: Mixer management with delay. On releasing the mixer activation key,

the mixer remains ON for the time set in seconds at this step.

45

Page 46

PROGRAMMING TECHNICIAN SUNDAE

A technician may change some machine parameters.

In order to enter the Technician Programming mode, it is necessary to press Stop and

Storage at the same time, and hold them down for 10 seconds.

The monitor now displays:

Release the keys.

The first step of Programming Technician is now displayed:

14:10:22 Mon

******PROG******

- ENGLISH - - ITALIAN -

HOT 1

Step T01 +100

HOT 1

Step T01 +100

The first line is relevant to the description and the second one to the step number

(T=Technician) and to the value

In order to leave the Programming mode, do not press any push-button 30 seconds or

press Production or Cleaning.

When a programming table value is changed, the event “Table Updated M” is

registered to point out the manual updating of the table.

46

Page 47

PROGRAMMING TABLE SUNDAE

Eprom flash version: k3soft49 SOFT part

Step

T01 HOT 1 HOT 1 N 000 120 100

T03 Isteresi Hot 1 Hot 1 Different. N 000 020 014

T05 Gas Caldo 1 Hot Gas 1 sec/10 002 020 003

T07 Ritardo Agit. 1 Delay Beater 1 sec 001 020 003

T09 Blocco Hot 1 Hot Block 1 N 000 120 020

T11 Timer Ciclico Cyclic Timer min 001 015 010

T12 Trimmer Hot 1 Trimmer HOT 1 N 010 255 121

T14 Ritardo Monofase Single Phase Del msec 000 500 000

T15 Ghiaccio Cilind. Ice Cylinder °C -033 010 -023

T16 Timeout Prd Timeout Prd min 001 059 010

T17 Ultimi Coni Last Cones N 001 099 005

T19 Set Topping Set Topping °C 000 070 055

T23 Temp. Conservaz. Storage Temp °C 001 006 003

T25 Antighiac. Vasca Hopper Defrost °C -030 000 -018

T26 Ist.Antig.Vasca Hop. Defrost Hys °C 002 010 006

T27 Ritar. Mixer Vas Delay Hop. Mixer min 001 099 001

T28 Pasto Vasca Pasto Hopper °C 065 085 065

T29 Pasto Cilindro Pasto Cylinder °C 065 085 065

T30 Delta TGV-TEV Delta TGV-TEV °C 010 099 035

T33 Regolazione TEV Offset TEV °C TEV-9 TEV+9 to be set

T34 Regolazione TEC Offset TEC °C TEC-9 TEC+9 to be set

T35 Regolazione TGV Offset TGV °C TGV-9 TGV+9 to be set

T36 Regolazione TE1 Offset TE1 °C TE1-9 TE1+9 to be set

T39 Giorni Lavaggio Wash Days N 001 042 014

T40 Fahrenheit Fahrenheit Y/N No Yes No

T41 Tempo MP Ciclico MP Cyclic Time sec 000 010 006

T42 Setup TET Setup TET °C TET-20 TET+20 to be set

T43 Ora Legale Daylightsavtime Y/N No Yes Yes

T46 Tempo MP Time MP sec 000 090 15

T62 Setup TEV Setup TEV N 450 650 557

T63 Setup TEC Setup TEC N 450 650 553

T64 Setup TVM Setup TVM N 300 500 408

T65 Setup TCM Setup TCM N 300 500 406

T66 Allarme RTA1 Alarm RTA1 Y/N No Yes Yes

T68 Allarme RTC1 Alarm RTC1 Y/N No Yes Yes

T70 Allarme TESC1 Alarm TESC1 Y/N No Yes Yes

T72 Allarme TESV1 Alarm TESV1 Y/N No Yes Yes

T73 Setup PZV Setup PZV N -20 90 005

T74 Setup PZC Setup PZC N -20 90 005

T75 Allarme PR1 Alarm PR1 Y/N No Yes Yes

T77 Al. Timeout Prd Al Timeout Prd Y/N No Yes Yes

T78 Post Freddo Vas Post Hopper Stor Y/N No Yes Yes

T84 LON LON Y/N No Yes No

T85 Set TEC Pulizia Set TEC Cleaning °C 000 050 020

T86 Reset Ore Motori Reset Hours N 000 004 000

Display ITA Display ENG U.M. Min Max K3

400/50/3

Test value

47

Page 48

48

Page 49

NOTES TO PROGRAMMING TABLE SUNDAE

Step

T01 HOT 1

When increasing this number, one gets harder ice cream and also an increase

in value of beater motor absorption

T03 Hot 1 Different. (Hysteresis)

A minor value makes HOT more sensitive by ice cream dispensing. With

machine in Production and MIR being energized, after the compressor cuts

out by HOT, the compressor is cut in again when consistency displayed is

lower than HOT minus value set in this step

T05 Hot Gas 1

Warm gas solenoid valve excitation time (EVRC2).

Every time EVFC2 de-energizes, EVRC2 will be energized for a time that can

NOTE

be program in this step.

Time is programmable according to tenths of the second.

T07 Delay Beater 1

It is the amount of time the beater will continue running after the compressor

stops for HOT.

T09 Hot Block 1

Hot SUNDAE value under which everything stops (MA and MC OFF) if you try

to dispense a cone.

As soon as MIR reopens, Production starts again and MA and MC are ON

again.

Keyboard displays:” Do not serve!”.

If consistency raises over Block Hot , “Ice cream Ready!” will be displayed.

If consistency lowers below Block Hot – 5 points hysteresis, you return to the

block condition with message “Do not serve!”.

49

Page 50

T11 Cyclic Timer

Cyclic timer in Ice cream Production.

Every 10 minutes (programmed in this step) the beater goes ON for ice

cream consistency control

T12 Trimmer Hot 1

It’s a number automatically

If the number is increased, ice cream consistency at the end of a production

cycle will decrease.

Caution: to change this number, it is necessary to make certain that beater

motor current DOES NOT exceed 100% of rating value

N.B. The value shown in the Programming table is indicative. This parameter

is calibrated differently for each machine and normally shown on an adhesive

label in the electrical enclosure.

T14 Single Phase Del

Lag Singlephase programming is necessary for a HOT value of “000” on

display when the product is completely liquid in SINGLEPHASED machines.

.

set after Auto-set-up procedure.

Lag Singlephase is already set in machines supplied by Carpigiani; when the

electronic card of a machine must be replaced, it is necessary to program the

Lag Singlephase again at relevant value.

By threephased machines, value shall be 000.

T15 Ice Cylinder.

When the temperature read through TE2 reaches a value which is less than or

equal to the one programmed in this step, the machine sets at the “reached

HOT” and cuts out the cylinder cooling compressor.

This can only occur if the machine is in Production.

Alarm Ice Cylinder is stored in event list.

T16 Timeout Prd

In Production, a time that can be programmed in this step is activated. If

HOT setpoint is not reached within the programmed time, the machine will

react as if HOT has been reached anyway and alarm “Timeout Prd.” Will be

stored in the event list.

50

Page 51

T17 Last Cones

It’s the number of cones the machine can dispense in Production after led of

low level sensor switches on.

The machine will then automatically set at Storage.

T19 Set Topping

Sets the temperature at which the hot topping well will be kept by

thermostat.

If step is set at 0, topping option and its alarms will be disabled

T23 Storage Temp.

Cylinder/hopper temperature storage.

It is controlled in Storage, Production and Pasteurization.

T25 Hopper Defrost

When the temperature TGV reaches a value which is less than or equal to the

one programmed, the warm gas solenoid valve energizes (EVRV) to defrost

the hopper (EVFV still ON).

T26 Hop. Defrost Hys

Hysteresis defrost hopper.

In hopper cooling, When the temperature TGV reaches a value which is less

than or equal to the one programmed in step Defrost Hopper, warm gas

solenoid valve energizes for tank defrosting, till the temperature TGV raises

by the value set in this step.

See step Defrost Hopper.

T27 Delay Hop. Mixer

Time in minutes during which the hopper mixer motor continues running after

cooling the hopper.

This step is used to achieve a better thermal exchange and to prevent icing

around the hopper walls

T28 Paso Hopper

Hopper pasteurization temperature.

.

51

Page 52

T29 Pasto Cylinder

Cylinder pasteurization temperature.

T30 Delta TGV-TEV

In Heating of Pasteurization program, if TGV2 temperature turns > than TEV2

by value programmed in step Delta TGV-TEV “Alarm Belt” will be displayed

and machine will set to Stop.

Check driving belt or whether the rotor is in its seat

T33 Offset TEV

Setting hopper temperature TEV2.

In this step you can set the real temperature of the mix in the hopper.

It is necessary to set the sensor after setting your machine at Storage mode,

at a temperature of 39.2°F (4°C).

Thanks to this electronic CPU, your machine shall not

temperature for the sensor setting.

With an accurate thermometer check the temperature in the hopper; if the

reading is not 39.2°F (4°C) (value indicated on display), press the increment

or decrement keys till the temperature agrees with the one read through the

thermometer.

NB: When replacing a sensor it is important to cover the sensor with a

conductive paste before inserting it into its bulb-holder.

T34 Offset TEC

Cylinder temperature TEC2 setting.

See Setting TEV2.

have a room

T35 Offset TGV

Hopper evaporator temperature TGV2 (for hopper defrosting).

This temperature must be adjusted with the sensor of a precise thermometer

into the bulb-holder which you find in hopper evaporator.

See Setting TEV2.

52

Page 53

T36 Offset TE1

Cylinder evaporator temperature (Sundae side) TE2

See Setting TEV2.

T39 Wash days

It indicates the number of days until the machine must be washed.

Machine needs be cleaned or it will jam up (production not accepted).

T40 Fahrenheit

Display of temperature in °C (No) or in °F (Yes).

Relevant temperatures displayed will be marked by °C or °F.

T41 MP Cyclic Time

In Production and Storage MP is activated for a time programmed in this step

every 10’ (fix).

T42 Setup TET

.

TET topping cylinder temperature calibration.

See TEV2 Adjustment.

T43 Daylightsavtime

Enabling (Yes) or disabling (No) Daylight Time. See relevant paragraph.

T46 Time MP

Activation time of MP in Production.

T62 Setup TEV

See the paragraph “SENSORS SETTING in case of CPU REPLACEMENT”

T63 Setup TEC

See the paragraph “SENSORS SETTING in case of CPU REPLACEMENT”

T64 Setup TVM

See the paragraph “SENSORS SETTING in case of CPU REPLACEMENT”

53

Page 54

T65 Setup TCM

See the paragraph “SENSORS SETTING in case of CPU REPLACEMENT”

T66 Alarm RTA1

Enabling (YES) or disabling (NO) alarm for beater motor overload relay:

“Termico Agitator”.

T68 Alarm RTC2

Enabling (YES) or disabling (NO) alarm for compressor motor overload relay:

“Termico Compres.”.

T70 Alarm TESC1

Enabling (YES) or disabling (NO) Cylinder Safety thermostat alarm.

T72 Alarm TESV1

Enabling (YES) or disabling (NO) Tank Safety thermostat alarm.

T73 Setup PZV

See the paragraph “SENSORS SETTING in case of CPU REPLACEMENT”

T74 Setup PZC

See the paragraph “SENSORS SETTING in case of CPU REPLACEMENT”

T75 Alarm PR1

Enabling (YES) or disabling (NO) the high-pressure switch alarm: “Pressure

switch ”.

T77 Al. Timeout Prd

Enabling (YES) or disabling alarm “Timeout Prd”.

T78 Post Hopper Stor

Enabling (YES) or disabling (NO) Hopper post-cooling.

If set at Yes, when in Production, EVFV switches off after reaching the storage

temperature; and a Hot cycle is carried out in the cylinder.

54

Page 55

T84 LON

Enables Echelon alarm operation.

Only active on machines with LON devices.

T85 Set TEC Cleaning

When the Heated Cleaning function is selected, the EVRC is enabled with MA

until it reaches the setting entered for this step.

If the temperature has already been reached when the function is selected,

the machine will set itself in Stop mode.

T86 Reset Hour

1 = MP hour reset.

2 = MA hour reset.

3 = MA+MP hour reset.

4 = total cone counter reset.

Once set, this enables the reset at the closure of the programming function,

resetting itself then to 000 (no reset) automatically.

If an alarm is enabled, the machine will be protected by that alarm.

When an alarm is disabled, the machine will not

be protected by the alarm and you

will be working on your own risk.

Disabling an alarm can be useful when a component is broken, for example, if safety

thermostat is broken and its contacts are opened, the machine will never heat up.

To bypass that temporarily, disable alarm TESV : the machine will not care about the

safety thermostat.

Caution: after replacing a safety thermostat, do not forget to enable

the alarm so as

to protect your machine.

55

Page 56

HOT SETTING

In order to set the machine, fill the cylinder with mix and select the Production

function. With ammetric pliers check beater motor input.

Once the compressor has been activated, provide a short circuit between earth

(yellow/green) and pin8 of the 18-pin terminal board 3 (see card layout).

Pin8 of MRS3

An increasing number will be on display . Intermittent beep sound.

When current read through the ammetric pliers (Amp Meter) is same as the beater

motor rated value, eliminate the short circuit in order to complete HOT setting

procedure and store the “TRIMMER HOT” setting value in programming step

Trimmer Hot1.

WARNING: NEVER EXCEED MOTOR INPUT RATING VALUE.

USA K3

208-230/60/3

Soft side

Beater motor current LOADLESS 2,93 A

Display

30 120

Step

Trimmer Hot 1

402 W

Beater motor current in PRODUCTION

HOT

4,42 A

1430 W

100 120

56

Page 57

GM K 3

400/50/3

Sundae side

Beater motor (no load value)

2.05 A

331 W

Current Beater motor in PRODUCTION

HOT

2.82 A

1390 W

Display

22

100

Step

Trimmer Hot 1

106

128

57

Page 58

CARD LAYOUT

The machine electronics consists of a two-deck CPU (573700115).

On the base you find the CPU, whilst on upper deck connected through “needle beds”

there are all terminal boards.

The compatible alternative always with code 573700115 is on a single layer.

ELECTRONIC CARD

Code 573.700.115

2 layers

As an alternative

ELECTRONIC CARD

Code 573.700.115

1 layer

58

Page 59

TRANSFORMER

The electric transformer is a

multivoltage one

59

Page 60

Connectors

573.700.115 2

layers

MRS1

(230V output)

MRS2

(24V output)

MRS6

(feed)

MRS5

(not used)

MRS4

(PTC sensor)

MRS3

(inputs)

LCD keypad

Not used

LED keypad

Serial port

60

Page 61

Connectors

573.700.115 1

layer

MRS1

(230V output)

MRS2

(24V output)

MRS6

(feed)

MRS5

(not used)

MRS4

(PTC sensor)

MRS3

(inputs)

Not used

LCD keypad

LED keypad

Serial port

61

Page 62

J1, J2

(European

ammeter scale)

Both jumpers are

positioned towards

the outside of the

card

For T/A red

Jumper 573.700.115 2 layers

J3, J4

(American

ammeter scale)

Both jumpers are

positioned towards

the inside of the

card

For T/A black

62

Page 63

J10, J8

(European

ammeter scale)

Both jumpers are

positioned towards

the inside of the card

For T/A red

Jumper 573.700.115 1 layer

J9, J7

(American

ammeter scale)

Both jumpers are

positioned towards

the outside of the

card

For T/A black

63

Page 64

SOFTWARE UPGRADE

For a CPU software upgrade, it is necessary to use the special serial cable supplied by

Carpigiani, connect it to the CPU through the Serial access (see electronic card layout)

and to serial port RS232 of any Personal Computer (PC).

The software Upgrade can be done by transferring the new software from the

computer to the CPU using M16C Flasher.

Once you have connected your PC (RS 232) to the CPU (Serial access ) with the

special cable code 577.400.032, connect the machine to the mains.

After installing theM16C Flasher it is necessary:

- to start the program and press the push-button Settings

- shape settings as follows

Configuration shall be executed for the first time, only.

- Close Settings window

- Press the arrow next to Settings push-button and select Prog new file…

- Select Program K3Soft*.mot

After a software upgrade offsets relevant to sensors and Trimmer Hot shall be

programmed again

64

Page 65

TABLE °C-OHM

The table here below shows the relation between the temperature read by a PTC

sensor and relevant resistance in OHM, as read by a tester.

It is useful to check right sensor readings.

TEMPERATURE °C OHM

-50 503,5

-45 528,9

-40 555,2

-35 582,5

-30 610,6

-25 639,6

-20 669,6

-15 700,5

-10 732,2

-5 764,9

0 798,5

5 832,9

10 868,3

15 904,6

20 941,8

25 980

30 1019

35 1058,9

40 1099,7

45 1141,5

50 1184,1

55 1227,6

60 1272,1

65 1317,5

70 1363,7

75 1410,9

80 1459

85 1508

90 1557,9

95 1608,7

100 1660,4

105 1713

110 1766,5

115 1820,9

65

Page 66

SENSORS SETTING in case of CPU REPLACEMENT

This procedure enables you to reset the calibration of sensors TEV and TEC from old

CPU to the new one in case of CPU replacement.

(First of all it is necessary to check whether feeding the old CPU, its display is still

legible).

Only in this case can you go ahead with the following procedure of sensor setting.

1) Set the machine at Stop

2) Press simultaneously Production and Storage and hold them 10’’ down.

3) The display shows “Setup Sensors”, release the keys now. You will see the figures

relevant to the sensors TEV and TEC for about 13’’. For example:

TEV+562 TEC+542

TVM+408 TCM+406

And then you will see the following figures for about 7’’

PZV+005 PZC+005

4) Take note of these figures to program them on the new CPU

5) Replace the CPU and do the autosetup.

6) Enter the programming and set the 6 figures read before in steps T62(Setup TEV),

T63(Setup TEC), T64(Setup TVM), T65(Setup TCM), T73(Setup PZV), T74(Setup PZC).

7) Leave the programming mode.

8) Press Production and Storage simultaneously for 10’’ to enter “Setup Sensors”

again.

9) Release the keys and press them again until you see

Setup Sensors

Release the keys and then it you will see

Setup Sensors OK!

for a few seconds. The procedure is finished.

SHAKE SIDE

66

Page 67

SOFTWARE VERSION

As soon as power is turned on to the machine, the monitor displays

the software

version.

For example:

K3 Shake

ver.K3shake23

means version sw = 23

In case of machine malfunction, your Technician will have always to specify this

number (software version), as well as the machine serial number you can find on the

data plate, so as to take best advantage of Carpigiani Technical Service.

67

Page 68

AVAILABLE CONTROLS

KA configuration

General Market configuration

Note 1

When pressing a key and the functions is accepted, the machine keyboard block will

emit a sound signal (beep).

Note 2

This handbook refers to machine standard configuration. As far as General Market

version, we beg you to make reference to relevant keyboard

68

Page 69

POSITION FOR SENSORS and SHAKE SOLENOID VALVES

TEV1 – TEC1 – TGV1 – TE1

BACK

TEV1

TEC1

TGV1

TE1

SOLENOID VALVES – front sight

SHAKE

EVFC1 EVRC1 EVFV1 EVRV1 EVRC2 EVFC2 EVRV2 EVFV2

SOFT

69

Page 70

DAYLIGHT TIME

From MARCH 30th to OCTOBER 30

The machine clock will automatically be set forward by 1 hour. This means that when

passing from 01:52 a.m. on March 30

th

included, daylight time is active.

th

to 01.53 a.m. on March 30th, the clock will

automatically move ahead of 1 hour

. The display on the changeover at 01:53 a.m. will

show 02:53 (summer time).

Shifting from 01:52 a.m. to 01:53 a.m. on October 30

th

, the time will automatically be

set back by 1 hour for the end of daylight savings time. When the clock reaches

01:53, it will move back by 1 hour and time displayed will be 00:53 (from this point it

will count normally). The clock time will remain tin this setting until the next March

th

30

when the next changeover occurs.

Checking occurs during 3 minutes between 01:53 a.m. and 01:56 a.m.

Daylight time is only active when the step Ora Legale (Daylightsav Time) is set to

Yes.

70

Page 71

FUNCTIONS

STOP

In this function the machine is OFF and relative led is ON (stop button lights up).

From the Stop position any other function may be selected. In order to change a

function, IT IS ALWAYS NECESSARY to press the stop button for 2 seconds first.

The display shows the following:

- ENGLISH- - ITALIAN -

10:33:21 Fri

10:33:21 Ven

In order to set the machine at Stop from Production, Pasteurization and Storage, push

the stop key and hold it down for 2 seconds. The machine will not recognize the stop

command if the button is not held at least 2 seconds, this helps avoid accidentally

hitting the button and stopping the machine.

If the machine is left at Stop with mix above the level sensor, the writing “Why in

STOP??” will be displayed flashing and with an intermittent beep after 30’’; it warns

the user to set the machine at Production, Pasteurization or Storage.

DEPRESSURIZING THE CYLINDER

In Stop,

by pressing , the piston will open to its maximum setting in order to

allow cleaning and depressurizing of the cylinder. The display shows “Piston Open”.

By pressing

again, the piston will return to its closed position.

71

Page 72

DRYING AND CLEANING THE SYRUP LINES

In Stop:

colored keys are used to portion the syrup quantity.

- Press a colored key once and the display will show a message similar to the one in

the following example:

- INGLESE - - ITALIANO -

16:29:27 Tue

Syrup 1 145

16:29:27 Tue

Sciroppo 1 145

- Relevant peristaltic pump (in this case pump 1) will start and run for 5 seconds (step

Syrup Calib Time ) at the speed displayed beside the pump number (in the example

speed is 145).

- Check the quantity of syrup with the small calibration measuring cylinder

(“calibration cup”). After 5 seconds (or amount of time programmed) the Increasing

and Decreasing keys will blink (8”) in order to allow you to change pump

speed in case the syrup quantity is too low or too high.

- Press Stop when you want to stop the distribution earlier than the calibration time.

- By pressing the same colored key a second time while the Pump is activated, the

pump will operate at its maximum speed for 3 minutes in order to clean the syrup

pipe.

On the display:

- ENGLISH - - ITALIAN -

16:29:27 Tue

Syrup 1 cleaning

16:29:27 Tue

Sciroppo1 puliz.

In this case, too, press Stop if you want to stop syrup pipe cleaning.

To store speed values, pass to Production, Cleaning, Storage or

Pasteurization modes, before disconnecting the machine from main.

72

Page 73

MA – MP HOUR COUNTER RESET

If you continue to press

for 20 seconds, after the display changes to “read

events”, MP counter will be reset. The display now shows “Reset hrs Count”.

In order to reset MA counter, it is not only necessary to press Stop

for 20

seconds, but also to have the rotor cap open IMSB (for this case, first press the stop

button and then while holding it down open the rotor cap). The display shows “Reset

hrs Count”.

TOTAL AND PARTIAL CONE COUNTER RESET

If you press Stop

within 1 second of turning the machine’s power on and hold it

down for at least 5 seconds, total and partial (daily) cones will be reset.

Display as follows:

- ENGLISH - - ITALIAN -

Reset Cone Count

Azzeramento Coni

Cone count is measured in group of 5.

73

Page 74

EVENTS

The machine is provided with a large memory that helps us store most of the events

(history).

To read the events stored in memory, you must have the machine in STOP

Press Stop

and keep it pressed some 3 seconds. The monitor will display the