Page 1

OOPPEERRAATTIIOONN AANNDD IINNSSTTRRUUCCTTIIOONN MMAANNUUAALL

GGRRAANNIITTAA MMAACCHHIINNEE

MMooddeellss::

RReeff..:: SSLL99000044991122332

GGHHZZ —— 222288 SSFF FFRREEEEZZIINNGG PPOOIINNTT

RReeff..:: SSLL99000044991122333

GGHHZZ —— 334422 FFFF FFRREEEEZZIINNGG PPOOIINNTT

111155 VV.. —— 6600 HHzz..

2

3

GHZ-228 SF FREEZING POINT

GHZ-342 FF FREEZING POINT

Page 2

Copyright© Freezing Point , 2004

Page 3

Granita Machine Operation and Instruction Manual

INDEX

Index _____________________________________________________________ 3

Unpacking _________________________________________________________ 4

Important __________________________________________________________ 4

Positioning the machine _____________________________________________ 4

Important __________________________________________________________ 4

Familiarizing yourself with the Controls_________________________________ 5

Cleaning and Sanitizing instructions ___________________________________ 6

1 Unlock handle l oc k i n g s y s t e m _______________________________ 6

2 Cleaning the bowl_______________________________________________ 6

3 Cleaning the bowl gasket_________________________________________ 7

4 Cleaning the spiral ______________________________________________ 7

5 Cleaning the drip trays___________________________________________ 8

6 Cleaning the spigot _____________________________________________ 8

7 Reassembly____________________________________________________ 9

8 Cleaning the condenser __________________________________________ 9

How to operate ____________________________________________________ 10

Liquid density adjustment ___________________________________________ 11

Tank with padlock__________________________________________________ 11

Defrost timer-programming procedures________________________________ 12

List of components parts - Model GHZ-228 SF FREEZING POINT____________13

Exploded View – Model GHZ-228 SF FREEZING POINT ____________________14

List of components parts - Model GHZ-342 FF FREEZING POINT ____________15

Exploded View – Model GHZ-342 FF FREEZING POINT ____________________16

Wiring Diagram – Model GHZ-228 SF FREEZING POINT __________________ 17

Wiring Diagram – Model GHZ-342 FF FREEZING POINT___________________ 18

Watertightness and Transmission Elements ____________________________ 19

Cover GHZ________________________________________________________ 19

Spiral Shovel ______________________________________________________ 20

Tank and Shovel guide______________________________________________ 20

Full Tap PULL _____________________________________________________ 21

Trouble shooting guide _______________________________________ 22 and 23

All technical data, pictures and drawings contained in this operation manual are not binding on the manufacturer, nor can

the manufacturer be held liable for any modification to the dispenser in par or completely.

3

Page 4

Granita Machine Operation and Instruction Manual

UNPACKING

IMPORTANT

Prior to starting this procedure, ensure that the shipping carton does not show any evidence of

damage due to dropping or mishandling. This may indicate that the dispenser was damaged during

transit and/or delivery. If any damage is visible on the shipping carton, indicate this on the shipping

receipt.

You can now proceed in the unpacking process by first carefully cutting the plastic strapping which

secures the carton top and bottom. After cutting these straps, lift the carton top straight up and off

of the dispenser.

After lifting the box off the machine, carefully remove the styrofoam from the sides of the machine.

Next remove the four plastic legs, technical and instruction manual, and any other items found in

the mix tanks.

POSITIONING THE MACHINE

Prior to choosing a location please keep in mind that your dispenser should be readily accessible

for periodic maintenance and have adequate space for necessary air flow. After selecting a

location, you are now ready to place your dispenser.

Place the machine at the desired location. Make sure that there is enough space for ventilation on

both sides (about 8” on each side for 2 and 3 bowl units). Carefully lay the machine on its back and

screw the legs to the bottom. Gently tip machine onto its feet.

To ensure the highest quality in the shipping of your unit, we have left the plastic on both the unit

and the drip trays for protection against scratching in transit. Please remove before operating

your machine.

Install the drip pans and cover grates onto the front of the unit.

IMPORTANT

Before connecting power to the machine, check the label on the back of the machine to verify the

voltage and amperage draw of the unit and then do the same for the electrical outlet. Carefully

inspect the power supply cord on your dispenser for any possible damage which may have

occurred during transportation. If ANY damage is visible, DO NOT plug the machine into the power

supply, contact your authorized service agent to replace the power cord.

4

Page 5

Granita Machine Operation and Instruction Manual

FAMILIARIZING YOURSELF WITH THE CONTROLS

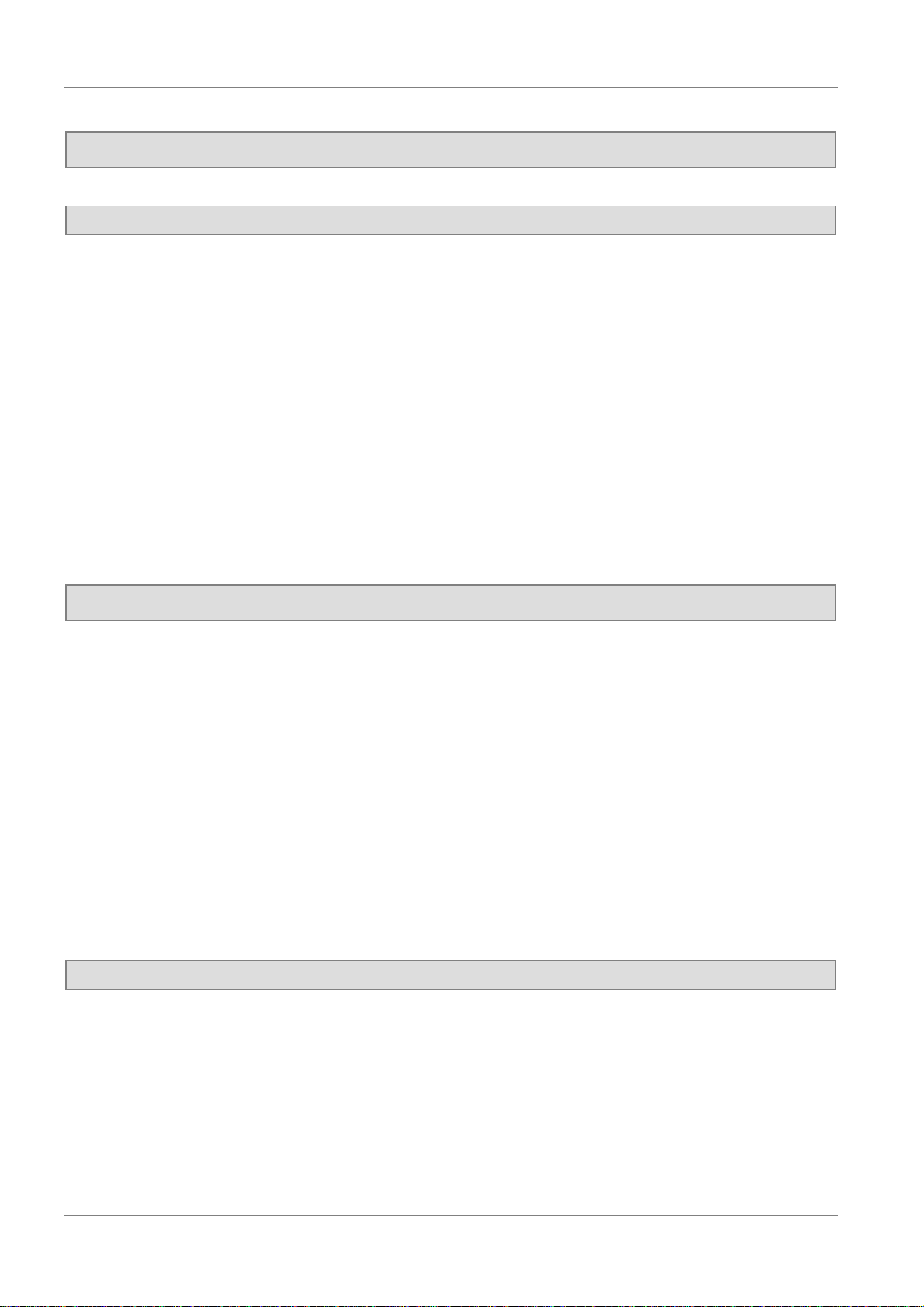

On the right side of the machine are the following switches and controls. (Figure 1)

Main Power

“0” Position: Off position. Power is turned off to all functions.

“I” Position: On position. Machine has power.

Display light

“0” Position: Lights are off.

“I” Position: Lights are on. Display lights have power

Agitator Switch

“0” Position: Agitator is off.

“I” Position: Agitator is on.

Cooler Switch

“0” Position: Off position.

“I” Position: Cool drink mode.

“II” Position: Frozen mode.

/

Left bowl Right bowl

Compressor green light

If the compressor green light is on,

the compressor should be working

Automatic defrost / standby timer

This timer will automatically switch your

dispenser from the frozen drink to the chilled

drink mode. This timer can be programmed to

switch the machine at any time of the day or

night. The standard settings are:

Switch to chilled from frozen – 11:00 PM

Switch to frozen from chilled – 9:00 AM

For all seven days of the week.

Find detailed programming instructions on page

12.

Figure 1

. (Figure 2)

Figure 2

5

Page 6

Granita Machine Operation and Instruction Manual

CLEANING & SANITIZING PROCEDURES

Cleaning is a very important operation to guarantee flavour and the conservation of the product

stored in the bowl.

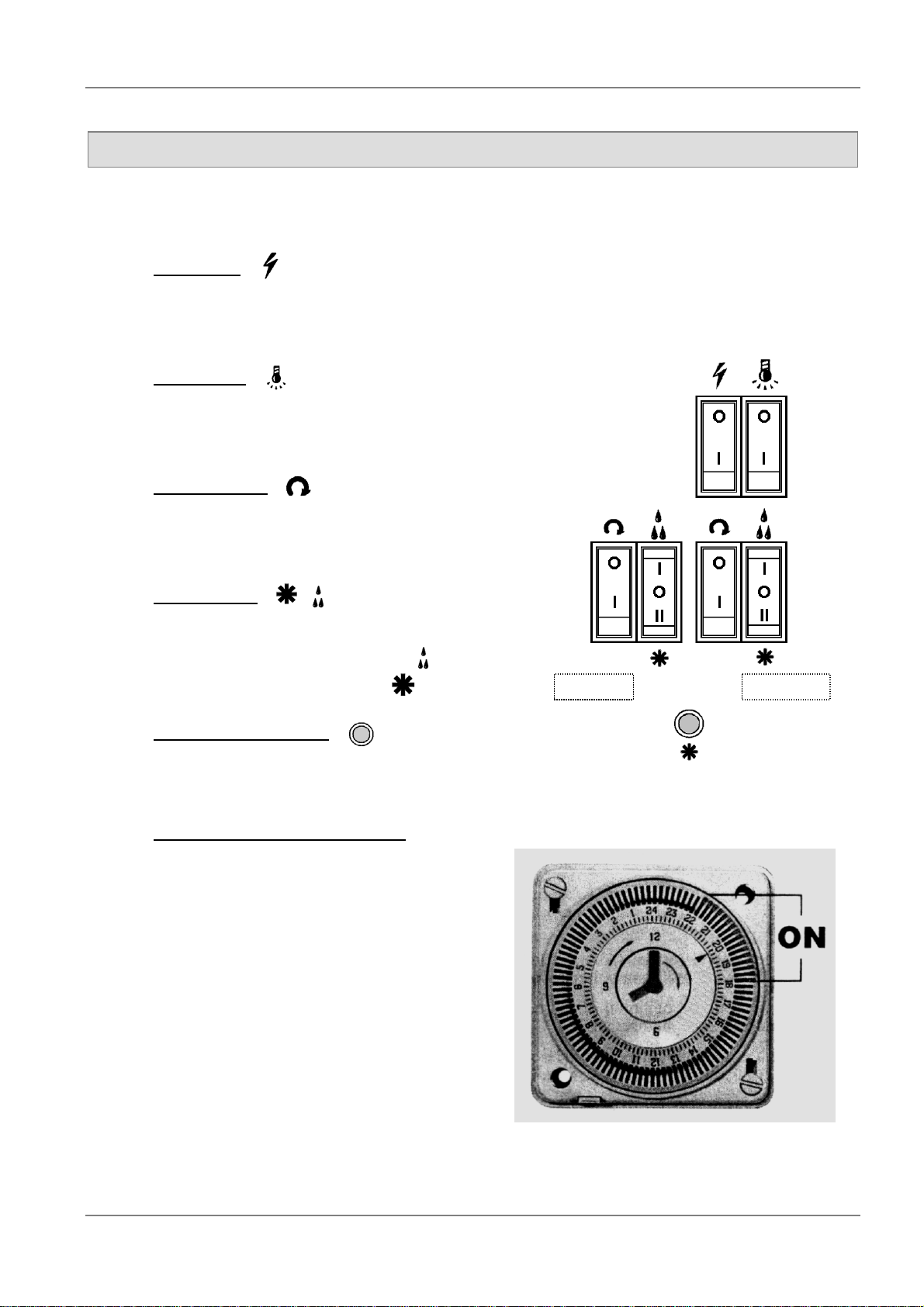

1 UNLOCK HANDLE LOKING SYSTEM

The machines come from factory with a

handle locking system (fig 3) (locker (3)

not included).

To unlock, remove the locker and pull out

the rod (1) (arrow A).

2 CLEANING THE BOWL

1.1. Turn off all switches and disconnect from

the main power.

Figure 3

1.2. Empty the liquid contents and remove the

lid.

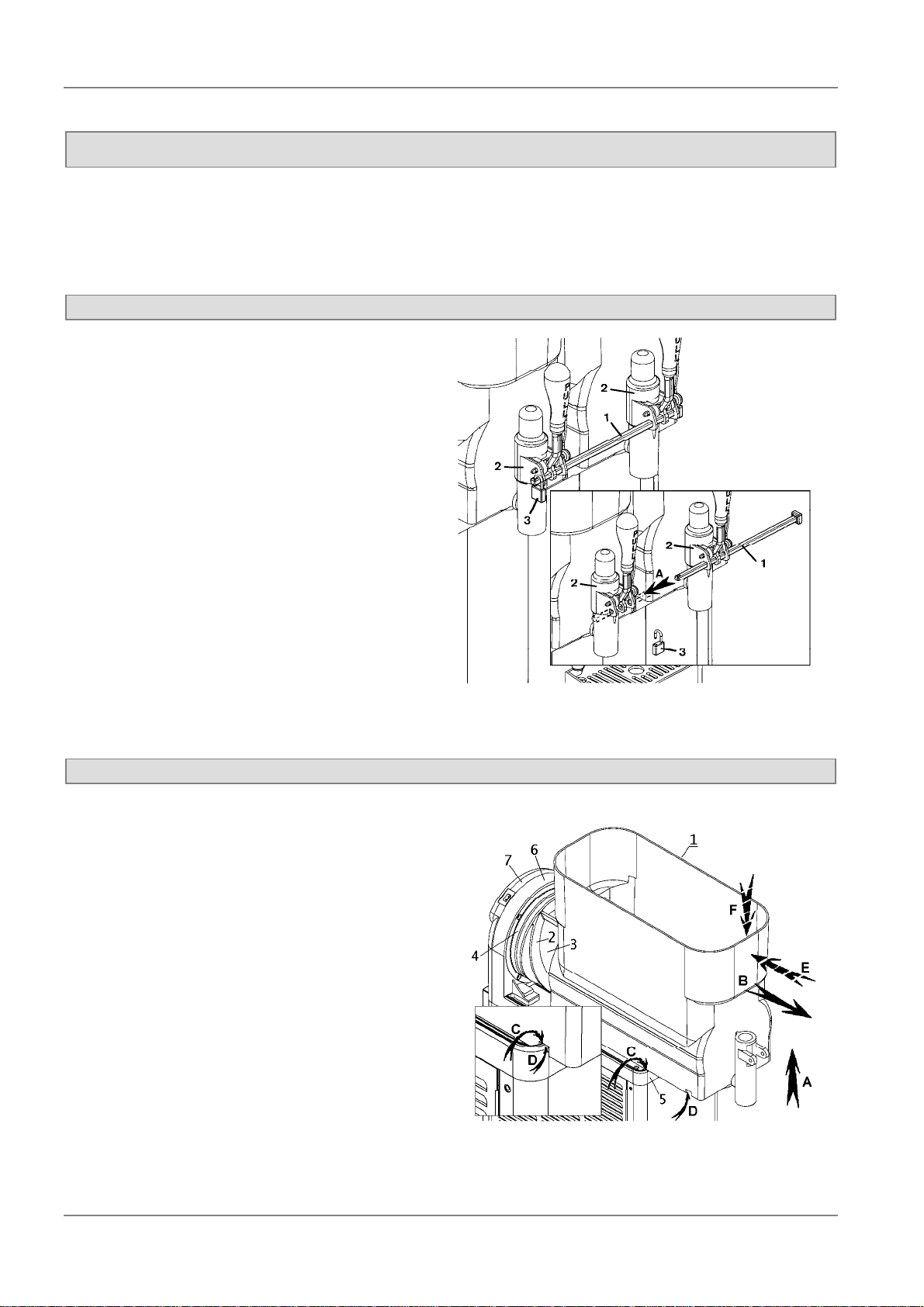

1.3. To remove the bowl, (Figure 4) push

bowl upward (arrow A) taking the bowl

out of the gauge notch (arrows C and D)

and then pull the bowl forward off of the

bowl gasket.

6

Figure 4

Page 7

Granita Machine Operation and Instruction Manual

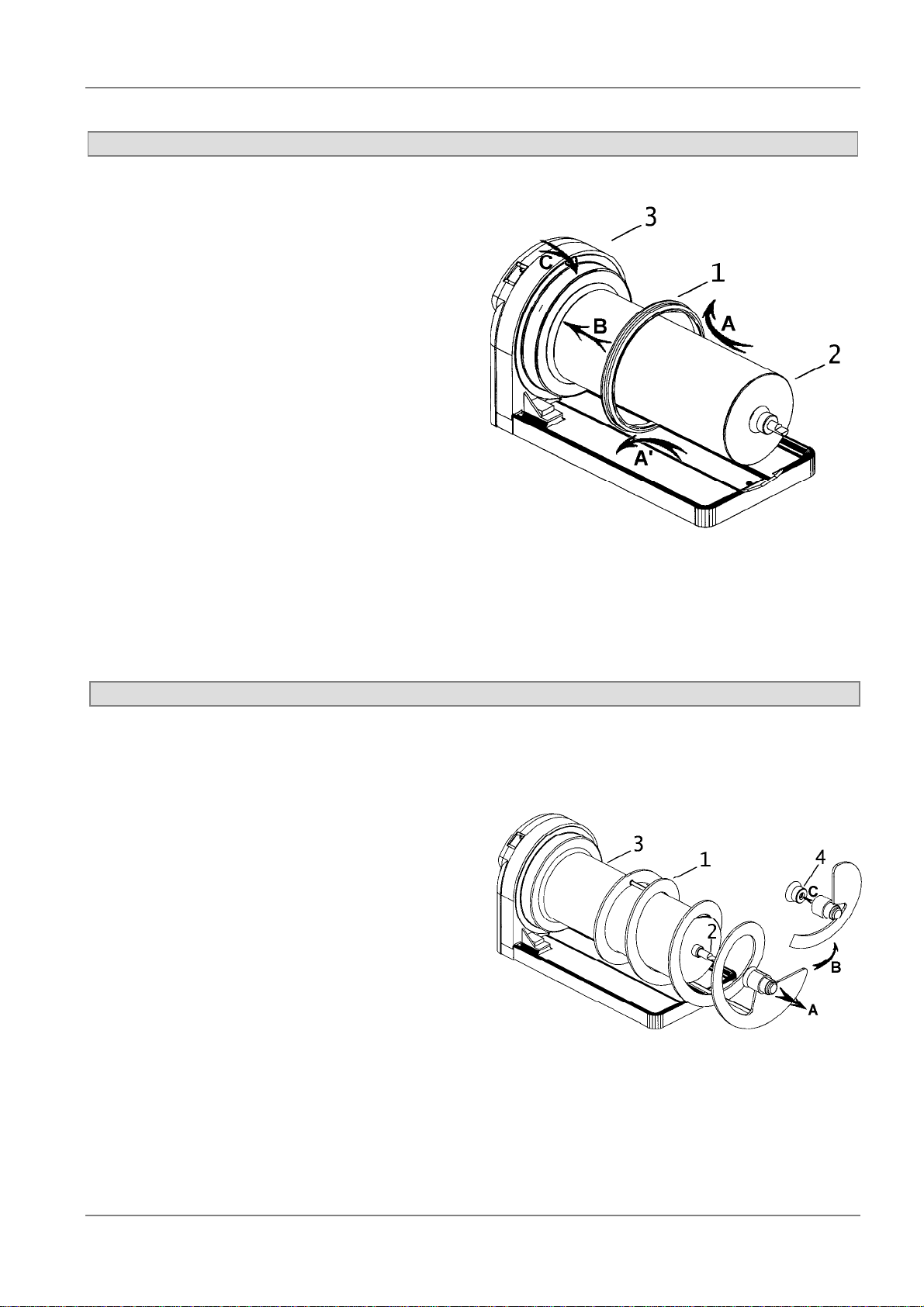

3 CLEANING THE BOWL GASKET

2.1. Once the bowl has been removed,

pull the spiral (Figure 5) forward

(arrow A) and take the head out of

the shaft end (#2).

2.2. On the spiral there is a silicone gasket

(#4) to make the axis leak-proof. Pull

it forward (C) and clean (#4) with

warm water.

4 CLEANING THE SPIRAL

Figure 5

After following the procedures for removing the

spiral, remove the bowl gasket (Figure 6, #1)

from the holder by pulling forward and the

evaporator (#3) will be released for cleaning.

Once all of the elements have been

disassembled proceed to clean with nonabrasive neutral pH detergent. Use a cloth or a

sponge to avoid scratching the bowl and other

elements.

Figure 6

7

Page 8

Granita Machine Operation and Instruction Manual

5 CLEANING THE DRIP TRAY(S)

The front drip tray(s) (Figure 7)

should be emptied daily or more

frequently if necessary. To remove

the drip pan, push the pan slightly

upward (arrow A), then bring it

forward (arrow B) and remove the

grid (arrow C). Put the grid (#2)

back on the tray and place the

spigots (arrows F) in the holes

(arrows D, E and G) on the front

panel (#3).

6 CLEANING THE SPIGOT (Fig.8)

For machines with a handle locking system,

remove the spigot padlock and then take the

locking spigot rod away (#8 – arrow I), remove the

fastener (#7 – arrow J), disconnect the dispensing

handle (#1 – arrow K). By pushing upward (arrow

L), take the spring (#3) out from its holder (#2 –

arrow M), then push the piston downward (#6 –

arrow N), remove the o-ring (#5 – arrow P) and the

special gasket (#4 – arrow Q).

Figure 7

Proceed to clean everything with water and neutral

soap, rinse and reassemble after lubricate without

damaging the gaskets as follows: put in place the

special gasket (#4 – arrow A), put the o-ring (#5)

back in its piston slot (#6 – arrow C), insert the

spring (#3 – arrow D), put the cap in place (#2 –

arrow E), put the handle in place (#1 – arrow F),

insert the fastener (#7 – arrow G), and if you want

to lock the spigot, insert the locking spigot rod (#8

– arrow H) and lock.

8

Figure 8

Page 9

Granita Machine Operation and Instruction Manual

7 REASSEMBLY

Once the machine has been thoroughly cleaned, please follow the directions for reassembling the

machine using previous illustrations.

1. Slide trip trays into place (Figure 7).

2. Reassemble the spigot by reversing the steps

that you performed in (Figure 8). Lubricate with

food grade lubricant parts #4 and #5 (O-ring

and Special gasket) (Figure 9).

3. Assemble the bowl gasket wet (Figure 6).

Assemble the gasket by pulling as arrows A

and A´ indicate and place it in its setting (arrow

C) following the direction of arrow B.

4. Assemble the spiral (Figure 5). Lubricate with

food grade lubricant the silicone gasket (#4)

and insert it in the head of the spiral (C). Insert

the spiral (#1) around the evaporator (#3) and

fit the head in the shaft by turning slightly until it

is placed in its setting.

5. To replace the bowl push backward until the

gauge notch fits in its place inserting the head

of the spiral in the stainless tube end.

Please note

8 CLEANING THE CONDENSER

At least once a month, depending on the working

conditions (presence of dust, grease, etc.) we

recommend to clean the condenser.

First of all, you need to disassemble the left side

panel (2, 3 and 4 bowl model), or the back panel (1

bowl model), by unscrewing them.

Brush off dust and dirt with a soft-bristled brush. Be

careful not do damage the ribs (see Fig. 10).

Please note: a clean condenser is essential to the

operation and longevity of the unit and they should

contact there Local service company for advise on

a preventive maintenance program for this and all

refrigeration equipment.

: The bowl gasket must be wet. This allows the bowl assembly easier.

Figure 9

Figure 10

9

Page 10

Granita Machine Operation and Instruction Manual

HOW TO OPERATE

1. Once the bowl has been cleaned, fill the tank with the desired liquid product (3 gallons). Do not

overfill the tank. NOTE THAT WHEN READY, SLUSH OCCUPIES MORE VOLUME THAN

THE LIQUID (approximately 3.5 gallons of slush). Be sure to consider product ratio (not

exceeding 3 gallons total mix for slush) before mixing or pouring product into tank. IN

ORDER TO KEEP YOUR MACHINE IN GOOD WORKING CONDITION KEEP YOUR

MACHINE FULL.

2. If using natural products as a base (coffee,

lemon juice, orange juice, etc.), it is required

that 5 to 7 oz. of sugar per gallon be added.

Follow the dilution instructions on the bottle. In

general the brix ratio of the product solution

shouldn’t be less than 12.

3. To operate, press main power switch and

agitator switch to ON position (Figure 11).

NOTE: The agitator switch must be to ON

position before setting to liquid or slush

mode.

LEFT RIGHT

3.1 For slush, press the cooler switch to

bottom position ( II / ).

3.2 For liquid, press the cooler switch to up

position ( I / ) . If the machine is being

used as a liquid cooler, it is provided with

an inside thermostat for controlling the

liquid temperature.

Note that your machine is equipped

with a time delay relay that provides for

a four minute delay from the time of the

initial start. This is to prevent the

compressor from short cycling. Once

the compressor is ON, the green light

will be on.

Note: The cooler switch is a three position

switch and in order to have the compressor

off, all the cooler switches need to be in the

middle position.

4. To illuminate the transparency on top of the unit

and the product in the bowl press the display

light switch to down position ( I / ).

CAUTION: IF THE MACHINE IS STOPPED AT

NIGHT WITH ICE IN THE TANK, REMOVE ALL

ICE SLABS BEFORE STARTING.

LEFT

MIDDLE RIGHT

Figure 11

2 bowls

3 bowls

10

Page 11

Granita Machine Operation and Instruction Manual

LIQUID DENSITY ADJUSTEMENT

To adjust the density/consistency of the slush there is an

adjustment knob (Figure 12, #2) at the rear, right corner

of the dispenser (#1).

Turn the knob right (clockwise) or left (counter clockwise)

(arrow C and B) The consistency indicator (#4) will go up

or down (arrow D and E)

To firm up the product, turn the set knob counter

clockwise, which will move the indicator down to a higher

number position

To soften / warm up the product, turn the set knob

clockwise, which will move the indicator up to a lower

number position

NOTE: when using a new product, or on initial start up, it

is recommended that you set the consistency indicator to

the lowest/warmest setting and increase as desired.

Please note that the machines are pre-set at the factory

at a medium setting (number 2.5)

TANK WITH PADLOCK

Fitting the lid over the tank (Figure 13):

Figure 12

1º Slide the rim into the slot situated at the back of the tank.

Lift slightly the front of the lid.

2º Lower the lid and fit onto the tank.

3º Insert the padlock into holes of the front rims of the tank

and the lid. Close it.

Note:

A. The lid can be turned back to front (reversible). Proceed

as above.

B. In order to take off the lid, the padlock must be opened

and released; then follow the instructions in reverse

order

Figure 13

11

Page 12

Granita Machine Operation and Instruction Manual

DEFROST TIMER PROGRAMMING PROCEDURES

COARSE

ADJUSTEMENT

FINE

ADJUSTEMENT

Turn switching dial in the

direction of the arrow until the

current time is almost

opposite the marking arrow F

(here 19.45).

Continue turning the minute

hand in the direction of the

arrow until the current time is

opposite the marking arrow F

(here: 20.00).

12

Page 13

Granita Machine Operation and Instruction Manual

LIST OF COMPONENTS PARTS – Model GHZ-228 SF FREEZING POINT

r

N

Reference Description

1 SL300951200 Full evaporation device

2 SL300970240 Left side panel GB-20/30 UL01

3 SL300970272 Upper tray GB-220 - black

4 SL300310051 Stainless steel screw NFE 27128 M4x10

5 SL300970275 Front panel GB-220 V/2001

6 SL38WZC0005 Output fuse 5 Amp.

7 SL300970233 Condenser SEN122 GHZ 2/3 RP BAF1

8 SL300901135 Full fuse holder

9 SL300310148 Zinc screw DIN 933 M6x10

10 SL300950427 Zinc screw DIN 84 M4x25

11 SL300000233 Ventilator winding Ø 254 x 28º

12 SL37TKU1N16 Motoventilator 16 W. 115/60

13 SL300951202 Electronic regulator 115/60

14 SL300950230 Drainpipe

15 SL300950571 Transformer 50 VA 120V-12V

16 SL300970297 Command side panel GB-220 PRG01

17 SL300951088 Black 20 Amp. switch

18 SL300951253 Green pilot light U.L.

19 SL300951089 Change-over switch

20 SL300970122 Screen for leaking GHZ – chrome

21 SL300970121 Tray for leaking GHZ - chrome

22 SL300970331 Cable with jack cover GB-10

23 SL300310157 Zinc screw DIN 84 M4x20

24 SL300310052 Stainless steel screw NFE 27128 M6x10

25 SL300950583 Zinc screw DIN 7981 B- 3’5x 9’5

26 SL300350467 Full mechanical thermostat

27 SL300970274 Tap screw GB-10 - black

28 SL300951748 Thermostat support GHZ-228 RP UL

29 SL300310271 Zinc nut DIN 934 M6

30 SL300310354 Zinc washer DIN 9021 M6

31 SL300310160 Zinc screw DIN 933 M6x15

32 SL300310322 Zinc screw DIN 7971 B-3’5x21’5

33 SL300950075 Supplement

34 SL37ZG12155 Compressor T2155GK 115/60

35 SL310000411 Full chassis GHZ-228 STN/UL 02

36 SL300951357 Rubber foot H-40 V/99

37 SL300310134 Zinc screw DIN 933 M8x20

38 SL300950265 Zinc scr ew D IN 84 M 5x6

39 SL300950640 Compressor condenser T2155GK 115/60

40 SL300951627 Upper tray tap - black

41 SL300950735 Connection rule PA-44

42 SL300950737 Connection rule complement PA-52

43 SL300950568 Special nut N901034 M4

44 SL300951457 Evaporation device support cover GHZ - chrome

45 SL310000320 Evap. device support GHZ PZ-1 - black

46 SL300310042 Stainless steel screw DIN 963 M4x12

47 SL300950587 Full miniruptor V/99

48 SL300950810 Zinc screw DIN 7971 B-2’5x25

r

N

Reference Description

49 SL310000321 Evap. device support GHZ PZ-2 - black

50 SL300950760 Zinc screw DIN 7971 B-2’9 x 13

51 SL310000103 Short regulation rod GHZ-14 V/99 - black

52 SL3GS12036A Holding in place of regulation system

53 SL3GS12037B Regulation system spring guide

54 SL300950116 Regulation spring GHZ-14

55 SL300950833 Nut supplement foot

56 SL300310203 Stainless steel nut DIN 934 M4

57 SL300950445 Zinc screw DIN 7971 B-2’9 x 9’5

58 SL300970155 Electrovalve clamp V/99

59 SL300951264 Electrovalve bobbin 115/60

60 SL300970159 Double electrovalve body V/99

61 SL3GS24711D Full double electrovalve 115/60

62 SL300970239 Back panel GB-220 V/2001

63 SL300970242 Right side panel GB-20/30 V2001

64 SL300310141 Zinc scre w DIN 84 M3 x25

65 SL300951101 Double electrovalve support deck

66 SL300950428 Device distancing back panel

67 SL300950624 Adjustable supplement foot V/US

68 SL300950641 Compressor relay T2155GK 115/60

69 SL300950642 Compressor klixon T2155GK 115/60

70 SL300500118 Pass cable PA-107

71 SL300310101 Zinc screw DIN 933 M8x35

72 SL300310255 Zinc washer DIN 125 M10

73 SL300310205 Zinc nut DIN 934 M8

74 SL300950746 Zinc screw DIN 933 M6x50

75 SL300951921 Zinc screw DIN 7981 B-3’9x13

76 SL300310320 Zinc screw DIN 7971 B-2’2x7

77 SL300310353 Zinc washer DIN 125 M6

78 SL300950798 Tran sformer cover

79 SL300950759 Zinc screw DIN 933 M6x12

80 SL300970276 Command side panel cover - black

81 SL38GZDG060 Transformer washer

82 SL300970294 Bolt cove r - black

83 SL300310250 Brass nut DIN 934 M6

84 SL300950649 Brass washer DIN 125 M6

85 SL300950648 Brass screw DIN 933 M6x25

86 SL300950210 Zinc screw DIN 933 M4x45

87 SL300901578 Zinc washer DIN 125 M4

88 SL300951368 Supplement foot tap V/US

89 SL300950840 Full adjustable foot V/US

90 SL300951412 Lock ing

91 SL310000400 Locking special screw

92 SL300970277 Daily hourly timer

93 SL300951365 Relay 115V/60Hz

94 SL300900005 Zinc nut DIN 934 m3

95 SL300951694 Obturator

13

Page 14

Granita Machine Operation and Instruction Manual

EXPLODED VIEW – Model GHZ-228 SF FREEZING POINT

14

Page 15

Granita Machine Operation and Instruction Manual

LIST OF COMPONENTS PARTS – Model GHZ-342 FF FREEZING POINT

Nr Reference Description

1 SL300950585 Full evaporation device

2 SL300970240 Left side panel GB-20/30 UL 01

3 SL300970273 Upper tray GB-330 – black

4 SL300310051 Stainless steel screw NFE 27128 M4x10

5 SL300970245 Front panel GB-330 V/2001

6 SL38WZC0005 Output fuse 5 Amp.

7 SL300970233 Condenser SENC0122 GHZ 2/3 RP BAF1

8 SL300901135 Fuse holder 5x20

9 SL300906167 Zinc nut DIN 934 M5

10 SL300310355 Zinc washer DIN 125 M5

11 SL300000233 Ventilator winding Ø 254 x 28º

12 SL37TKU1N16 Motoventilator 16 W. 115/60

13 SL300951202 Electronic regulator 115/60

14 SL300950230 Drainpipe

15 SL300950572 Transformer 60VA 120V/12V

16 SL300970298 Command side panel GB-330 PRG01

17 SL300951088 Black 20 Amp. switch

18 SL300951253 Green pilot light

19 SL300951089 Black change-over switch

20 SL300970122 Screen for leaking GHZ – chrome

21 SL300970121 Tray for leaking GHZ - chrome

22 SL300970331 Cable with jack cover GB-10

23 SL300310157 Zinc screw DIN 84 M4x20

24 SL300310052 Stainless steel screw NFE 27128 M6x10

25 SL300950583 Zinc screw DIN 7981 B-3’5x9’5

26 SL300310179 Zinc screw DIN 84 M5x15

27 SL300350467 Full mechanical thermostat

28 SL300950448 Thermostat support GHZ-342 V/95

29 SL300310271 Zinc nut DIN 934 M6

30 SL300310354 Zinc washer DIN 9021 M6

31 SL300310160 Zinc screw DIN 933 M6x16

32 SL300310322 Zinc screw DIN 7971 B-3’5x21’5

33 SL300950075 Supplement

34 SL300951256 Compressor T2178GK 115/60

35 SL310000426 Full chassis GHZ-342 STN/UL 02

36 SL300951357 Rubber foot GHZ-14 V/99

37 SL300310134 Zinc screw DIN 933 M8x20

38 SL300950210 Zinc screw DIN 933 M4x45

39 SL300951257 Compressor condenser T2178GK 115/60

40 SL300951627 Upper tray tap - black

41 SL300950735 Connection rule PA-44

42 SL300950737 Connection rule complement PA-52

43 SL300950568 Special nut N901034 M4

44 SL300951457 Evaporation device support cover GHZ - chrome

45 SL310000320 Evap. device support GHZ PZ-1 - black

46 SL300310042 Stainless steel screw DIN 963 M4x12

47 SL300950587 Full miniruptor V/99

48 SL300950810 Zinc screw DIN 7971 B-2’5x25

49 SL310000321 Evap. device support GHZ PZ-2 - black

50 SL300950760 Zinc screw DIN 7971 B-2’9x13

51 SL310000103 Short regulation rod GHZ-14 - black

Nr Reference Description

52 SL3GS12036A Holding in place of regulation system

53 SL3GS12037B Regulation system spring guide

54 SL300950116 Regulation spring GHZ-14 - hard

55 SL300950833 Nut supplement foot

56 SL300310203 Stainless steel nut DIN 934 M4

57 SL300950265 Zinc scre w DIN 84 M5 x6

58 SL300970155 Electrovalve clamp V/99

59 SL300951264 Electrovalve bobbin 115/60

60 SL300970157 Triple electrovalve body V/99

61 SL3GS36711D Full triple electrovalve 115/60 V/99

62 SL300970246 Back panel GB-330 V/2001

63 SL300970242 Right side panel GB-20/30 V2001

64 SL300310141 Zinc scre w DIN 84 M3 x25

65 SL300951101 Double electrovalve support deck

66 SL300950428 Device distancing back panel

67 SL300950624 Adjustable supplement foot V/US

68 SL300951258 Compressor relay T2178GK 115/60

69 SL300951259 Condenser running T2178GK 115/60

70 SL300500118 Pass cable PA-107

71 SL300310101 Zinc screw DIN 933 M8x35

72 SL300310255 Zinc washer DIN 125 M10

73 SL300310205 Zinc nut DIN 934 M8

74 SL300950746 Zinc screw DIN 933 M6x50

75 SL300950427 Zinc scre w DIN 84 M4 x25

76 SL300950759 Zinc screw DIN 933 M6x12

77 SL300310353 Zinc washer DIN 125 M6

78 SL300310320 Zinc screw DIN 7971 B-2’2x7

79 SL300951368 Antiskid supplement foot tap

80 SL300901578 Zinc washer DIN 125 M4

SL38GZDG06

81

82 SL300950798 Tran sformer cover

83 SL300310250 Brass nut DIN 934 M6

84 SL300950649 Brass washer DIN 125 M6

85 SL300950648 Brass screw DIN 933 M6x25

86 SL37TBH1411 Motoventilator 120x120x38 20/50

87 SL300950445 Zinc screw DIN 7971 B-2’9 x 9’5

88 SL300950840 Full adjustable foot V/US

89 SL300970294 Bolt cove r - black

90 SL300970276 Command side panel cover - Black

91 SL300951575 Operation box compressor T2180GK

92 SL300950035 Condenser SENC0014 GHZ-114/456

93 SL300970274 Tap screw GB-10 - black

94 SL300970277 Daily hourly timer

95 SL300951365 Relay 115/60

96 SL300900005 Zinc nut DIN 934 M3

97 SL300310148 Zinc screw DIN 933 M6x10

98 SL300951412 Loking

99 SL310000400 Locking special screw

100 SL300951694 Pass cable 31583

101 SL300951921 Zinc screw DIN 7981 B-3'9x13

102 SL300970091 Spacer front panel GB

Transformer washer

15

Page 16

Granita Machine Operation and Instruction Manual

EXPLODED VIEW – Model GHZ-342 FF FREEZING POINT

16

Page 17

Granita Machine Operation and Instruction Manual

WIRING DIAGRAM – Model GHZ-228 SF FREEZING POINT

Number

Description

Number

Description

1 General switch

2 Electronic regulator

3 Compressor pilot light

4 Compressor

5 Motor ventilator

6 Bowls light switch

7 Transformer

8 Full fuse holder

9 Bowls light

10 Left shovels switch

11 Engine for left shovels

12 Left liquid/iced drink switch

13 Left mechanical thermostat

14 Left micro regulation

15 Left electrovalve

16 Switch relays

17 Right shovels switch

18 Engine for right shovels

19 Right liquid/iced drink switch

20 Right mechanical thermostat

21 Right micro regulation

22 Right electrovalve

23 Hourly timer

24 Compressor klixon

25 Compressor relay

26 Connector lights

27 Socket display lamp

17

Page 18

Granita Machine Operation and Instruction Manual

WIRING DIAGRAM – Model GHZ-342 FF FREEZING POINT

Number

Description

Number

Description

1 General switch

2 Electronic regulator

3 Compressor pilot light

4 Compressor

5 Motor ventilator 1

6 Bowls light switch

7 Transformer

8 Full fuse holder

9 Bowls light

10 Left shovels switch

11 Engine for left shovels

12 Left liquid/iced drink switch

13 Left mechanical thermostat

14 Left micro regulation

15 Left electrovalve

16 Switch relay

17 Central shovels switch

18 Engine for central shovels

19 Central liquid/iced drink switch

20 Central mechanical thermostat

21 Central micro regulation

22 Central electrovalve

23 Right shovels switch

24 Engine for right shovels

25 Right liquid/iced drink switch

26 Right mechanical thermostat

27 Right micro regulation

28 Right electrovalve

29 Hourly timer

30 Compressor klixon

31 Compressor relay

32 Connector lights

33 Socket display lamp

34 Motor ventilator 2

18

Page 19

Granita Machine Operation and Instruction Manual

WATERTIGHTNESS AND TRANSMISSION ELEMENTS

Number Reference Description

1 SL300951752 Evaporator cap GHZ-14 2001

2 SL300951857 Watertight shaft joint GHZ-14 2002

3 SL310000104 Tank joint - black

4 SL3GS12030A Beater Drive Shaft

5 SL300950254 Shocked DIN 471 E-12

6 SL300950321 Transmission shaft racor GHZ-14 V/95

7 SL3MS4M015C Gear motor

Only parts with numbers will be stock items;

others will be special ordered.

COVER GHZ

Number

Reference Description

1 SL310001057 Reversible top cover GHZ chrome

2 SL300951706 Transparency GHZ beach

3 SL3GS24317A Lamp holder B-15-S

4 SL300950100 Lamp 21W. 12V.

5 SL300950679 Neutral cable EURO

6 SL300950583 Zinc screw DIN 7981 B- 3’5x 9’5

7 SL300970252 Full cable cover

8 SL300310633 Wing passes DIN 94 2x5

9 SL300950646 Connection rule Ø4

10 SL300951583 Cover under base GHZ v/padlock

11 SL300951595 Transparency support cover GHZ

12 SL310001056 Full tank rev. cover GHZ - chrome

19

Page 20

Granita Machine Operation and Instruction Manual

SPIRAL SHOVEL

Number Reference Description

1 SL3GS12009D Full spiral shovel

TANK AND SHOVEL GUIDE

Number Reference Description

1 SL300951582 Tank GHZ v/padlock

2 SL300951369 Padlock (optional)

20

Page 21

Granita Machine Operation and Instruction Manual

FULL TAP PULL

Number Reference Description

1 SL300951671 Dispensing handle GHZ PULL - black

2 SL300951672 Tap spring cap GHZ PULL - black

3 SL300951647 Tap spring GHZ PULL - hard

4 SL310000105 Piston special gasket - black

5 SL310000106 Tap gasket - black

6 SL310000089 Tap piston GHZ PULL - black

7 SL300951670 Tap fastener GHZ PULL - black

SL300970279 Locking tap rod GB-220 - black

8

2

21

Page 22

Granita Machine Operation and Instruction Manual

TROUBLE SHOOTING GUIDE

Trouble Possible Causes Remedy

Machine overheats • Machine vents are blocked • Check that nothing is obstructing the

vents

The tap drips • O-rings may be improperly

placed

Machine is not cooling the

product*

The unit does not work • No power

• Voltage may be labelled

improperly

• Does the machine have

power?

• The condenser is dirty

• No refrigerant

• Switch Power cord loose or

damaged

• Defective

• Wiring disconnected

• Make sure that the o-rings are in place

and have no cuts.

• Check that the piston is correctly closed

and nothing is obstruction its outlet.

• Verify that the spring works correctly.

• Verify that the voltage supply matches

the label on the back of the machine.

• Check to see if the machine is plugged

in.

• Clean the condenser carefully with a

brush trying not to damage the ribs.

See figure 7.

• Contact authorized service agency.

• Connect unit to power supply.

• Locate problem and correct. Replace

power cord if necessary.

• Replace switch.

• Check wiring for loose connection or

broken wire.

One of the augers does not

work

No pilot light when unit is on • Defective wiring connection

Compressor does not start • Defective overload

• Motor connection loose

• Defective switch

• Auger is stuck

• Bad gear reducer motor

• Defective density switch

• Burned out bulb

• Defective thermostat

• Defective relay

• Defective compressor

22

• Check wiring to motor.

• Replace switch.

• Check auger, replace if necessary.

• Replace.

• Check wiring.

• Check switch.

• Replace bulb.

• Replace thermostat.

• Replace.

• Replace.

• Replace.

Page 23

Granita Machine Operation and Instruction Manual

TROUBLE SHOOTING GUIDE (cont’d)

Trouble Possible Causes Remedy

Unit cools but does not

freeze

One bowl does not cool* • Defective solenoid valve

One bowl cools but does not

freeze*

Noisy auger • No lubricant

• Switch is not on

• The condenser is dirty

• Not enough air around the unit

• Less than 12% sugar content

• Density switch at lower level

off

• Defective thermostat

• Defective density switch

• Defective front panel switch

• Density switch at lower level

defective

• Front panel switch set for

liquid

• Defective gear reducer motor

• Check that switch is on right position.

• Clean the condenser carefully with a

brush (do not to damage the ribs).

• Remove other objects that may be

blocking airflow around unit.

• Remix with 12% sugar content.

• Turn on density switch.

• Replace.

• Replace.

• Replace.

• Replace.

• Replace.

• Check that switch is in right position.

• Lubricant auger.

• Replace.

Drippy nozzle or valve • O-Rings worn or defective • Replace O-Rings.

Leaky Bowl • Gasket improperly installed or

defective

Cover light does not work • Burned out bulb

• Defective cable

• Defective plug

• Defective fuse

• Defective transformer

• Defective light switch

• Reinstall gasket, replace if necessary.

• Replace bulb.

• Replace cable.

• Replace plug.

• Replace fuse.

• Replace transformer.

• Replace switch

23

Loading...

Loading...