Carnes T310 Installation Manual

REGAL-BELOIT

Variable Speed AC Motor Drives

Installation and Operation Manual

Manual Number: SB183, 12/04

TABLE OF CONTENTS

1.0 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

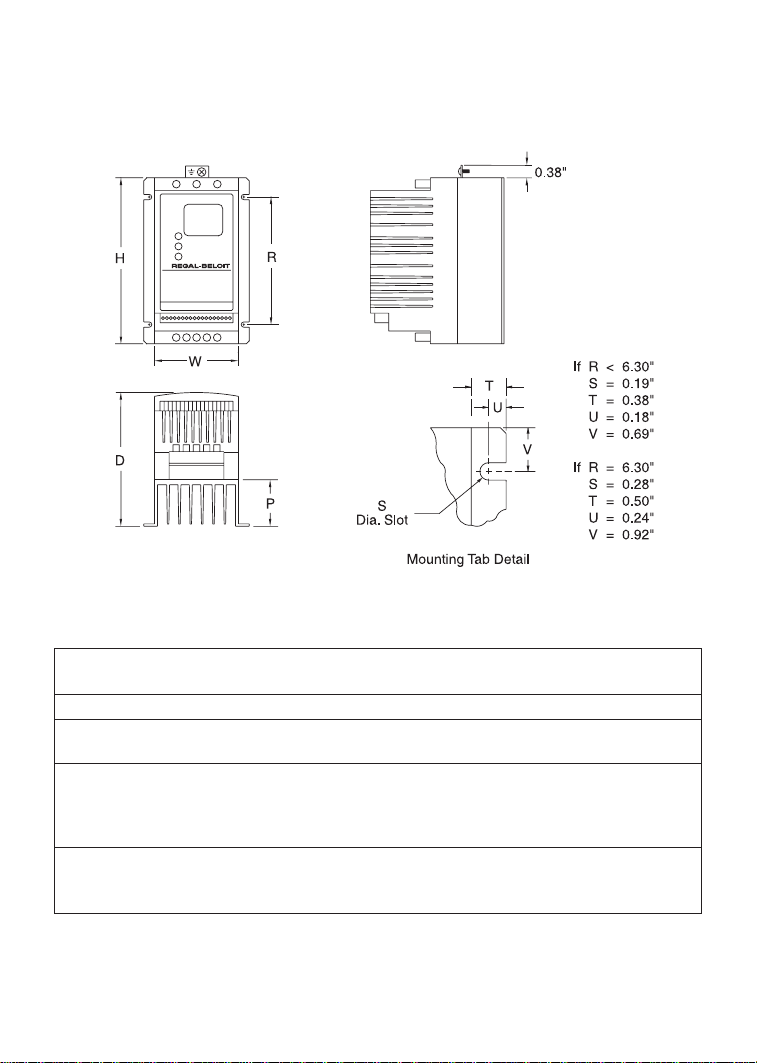

2.0 SpinMaster™ Plus DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . .2

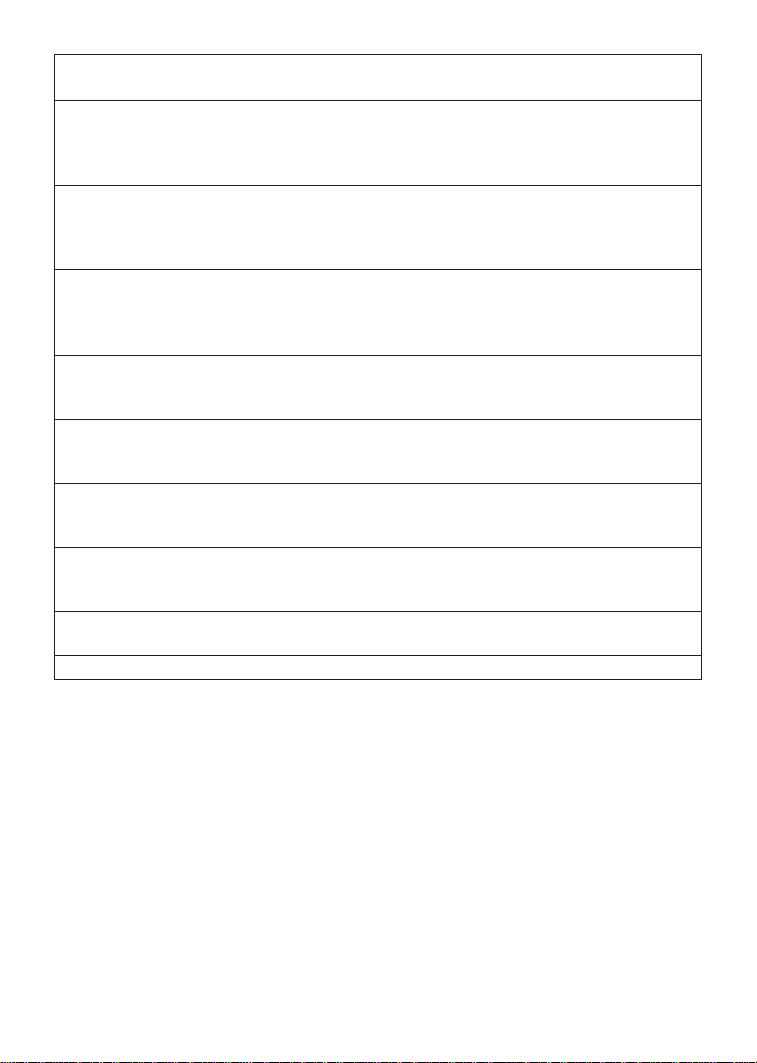

4.0 SpinMaster™ Plus SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . .4

5.0 SpinMaster™ Plus RATINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

6.0 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

7.0 INPUT AC POWER REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . .8

8.0 POWER WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

9.0 SpinMaster™ Plus POWER WIRING DIAGRAM . . . . . . . . . . . . .13

10.0 CONTROL WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

11.0 SpinMaster™ Plus CONTROL WIRING DIAGRAMS . . . . . . . . . .17

12.0 INITIAL POWER UP AND MOTOR ROTATION . . . . . . . . . . . . . .22

13.0 PROGRAMMING THE SpinMaster™ Plus DRIVE . . . . . . . . . . . .24

14.0 PARAMETER MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

15.0 DESCRIPTION OF PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . .31

16.0 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

17.0 SpinMaster™ Plus DISPLAY MESSAGES . . . . . . . . . . . . . . . . . .49

APPENDIX B – PI SETPOINT CONTROL OPTION . . . . . . . . . . .51

IMPORTANT NOTICE

The following , and information is supplied to you for

your protection and to provide you with many years of tr ouble free and safe operation of your

Marathon Electric product.

• Hazard of electrical shock! Capacitors retain charge after power is removed. Disconnect

incoming power and wait until the voltage between terminals B+ and B- is 0 VDC before

servicing the drive.

• Hazard of electrical shock! Wait three minutes after disconnecting incoming power

before servicing drive. Capacitors retain charge after power is removed.

• Automatic starting of equipment may cause damage to equipment and / or injury to

personnel! Automatic start should only be used on equipment that is inaccessible to personnel.

• DRIVES MUST NOT BE INSTALLED WHERE SUBJECTED TO ADVERSE ENVIRONMENTAL

CONDITIONS SUCH AS: COMBUSTIBLE, OILY, OR HAZARDOUS VAPORS OR DUST;

EXCESSIVE MOISTURE OR DIRT; VIBRATION; EXCESSIVE AMBIENT TEMPERATURES. CONSULT REGAL-BELOIT CORPORATION FOR MORE INFORMATION ON THE SUITABILITY OF

A DRIVE TO A PARTICULAR ENVIRONMENT.

• Severe damage to the drive can result if it is operated after a long period of storage or

inactivity without reforming the DC bus capacitors!

• Do not connect incoming AC power to output terminals T1, T2, or T3. Severe damage

to the drive will result.

• When operating in JOG mode, the STOP terminal (TB-1) and the STOP key (on the

optional remote keypad) WILL NOT

stop the drive. To stop the drive, remove the JOG

command.

• When operating in JOG mode, the STOP terminal (TB-1), the AUXILIARY STOP function

(see setting 08), and the STOP key on the optional remote keypad WILL NOT stop the

drive. To stop the drive, remove the JOG command.

• JOG REVERSE will operate the drive in reverse rotation even if ROTATION DIRECTION

(Parameter 17) is set to FORWARD ONLY.

• DO NOT connect incoming AC power to output terminals T1, T2, and T3! Severe damage to the drive will result. Do not continuously cycle input power to the drive more

than once every two minutes. Damage to the drive will result.

• Do not remove the EPM while power is applied to the drive. Damage to the EPM and/or

drive may result.

• Controlling the drive from the serial link without the watchdog timer could cause damage to equipment and/or injury to personnel!

• Consult qualified personnel with questions. All electrical repairs must be performed by

trained and qualified personnel only.

Resale of Goods:

In the event of the resale of any of the goods, in whatever form, Resellers/Buyers will include the following

language in a conspicuous place and in a conspicuous manner in a written agreement covering such sale:

The manufacturer makes no warranty or representations, express or implied, by operation of law or

otherwise, as the merchantability or fitness for a particular purpose of the goods sold hereunder.

Buyer acknowledges that it alone has determined that the goods purchased hereunder will suitably

meet the requirements of their intended use. In no event will the manufacturer be liable for consequential, incidental or other damages. Even if the repair or replacement remedy shall be deemed to

have failed of its essential purpose under Section 2-719 of the Uniform Commercial Code, the manufacturer shall have no liability to Buyer for consequential damages.

Resellers/Buyers agree to also include this entire document including the warnings and cautions above in

a conspicuous place and in a conspicuous manner in writing to instruct users on the safe usage of the

product.

SUB-MICRO DRIVE

INPUT POWER

TERMINALS

GROUND LUG

ELECTRONIC

PROGRAMMING

MODULE (EPM)

PROGRAMMING

BUTTONS

OUTPUT (MOTOR)

TERMINALS

3-DIGIT LED

DISPLAY

CONTROL

TERMINAL

STRIP

1.0 GENERAL

1.1 PRODUCTS COVERED IN THIS MANUAL

This manual covers the REGAL-BELOIT CORPORATION SpinMaster™ Plus Variable Frequency

Drive.

1.2 PRODUCT CHANGES

REGAL-BELOIT CORPORATION reserves the right to discontinue or make modifications to the

design of its products without prior notice, and holds no obligation to make modifications to

products sold previously. REGAL-BELOIT CORPORATION also holds no liability for losses of any

kind which may result from this action.

1.3 WARRANTY

REGAL-BELOIT CORPORATION warrants the SpinMaster™ Plus AC motor control to be free of

defects in material and workmanship for a period of twenty-four (24) months from date of

manufacture. If a SpinMaster™ Plus motor control, under normal use, becomes defective

within the stated warranty time period, contact REGAL-BELOIT’s Service Department for

instructions on obtaining a warranty replacement unit. REGAL-BELOIT CORPORATION reserves

the right to make the final determination as to the validity of a warranty claim, and sole

obligation is to repair or replace only components which have been rendered defective due

to faulty material or workmanship. No warranty claim will be accepted for components which

have been damaged due to mishandling, improper installation, unauthorized repair and/or

alteration of the product, operation in excess of design specifications or other misuse, or

improper maintenance. REGAL-BELOIT CORPORATION makes no warranty that its pr oducts ar e

compatible with any other equipment, or to any specific application, to which they may be

applied and shall not be held liable for any other consequential damage or injury arising from

the use of its products.

This warranty is in lieu of all other warranties, expressed or implied. No other

person, firm or corporation is authorized to assume, for REGAL-BELOIT

CORPORATION, any other liability in connection with the demonstration or

sale of its products.

1.4 RECEIVING

Inspect all cartons for damage which may have occurred during shipping. Carefully unpack

equipment and inspect thoroughly for damage or shortage. Report any damage to carrier

and/or shortages to supplier. All major components and connections should be examined for

damage and tightness, with special attention given to PC boards, plugs, knobs and switches.

1.5 CUSTOMER MODIFICATION

REGAL-BELOIT CORPORATION, its sales representatives and distributors, welcome the

opportunity to assist our customers in applying our products. Many customizing options are

available to aid in this function. REGAL-BELOIT CORPORATION cannot assume responsibility for

any modifications not authorized by its engineering department.

1

2

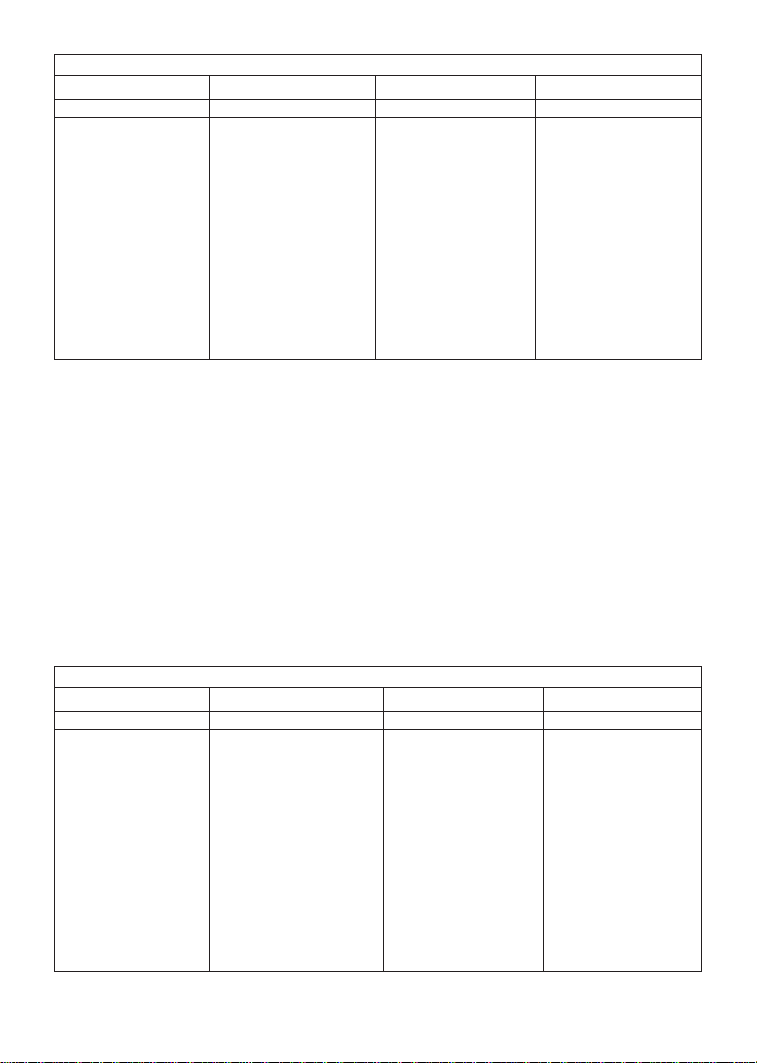

INPUT

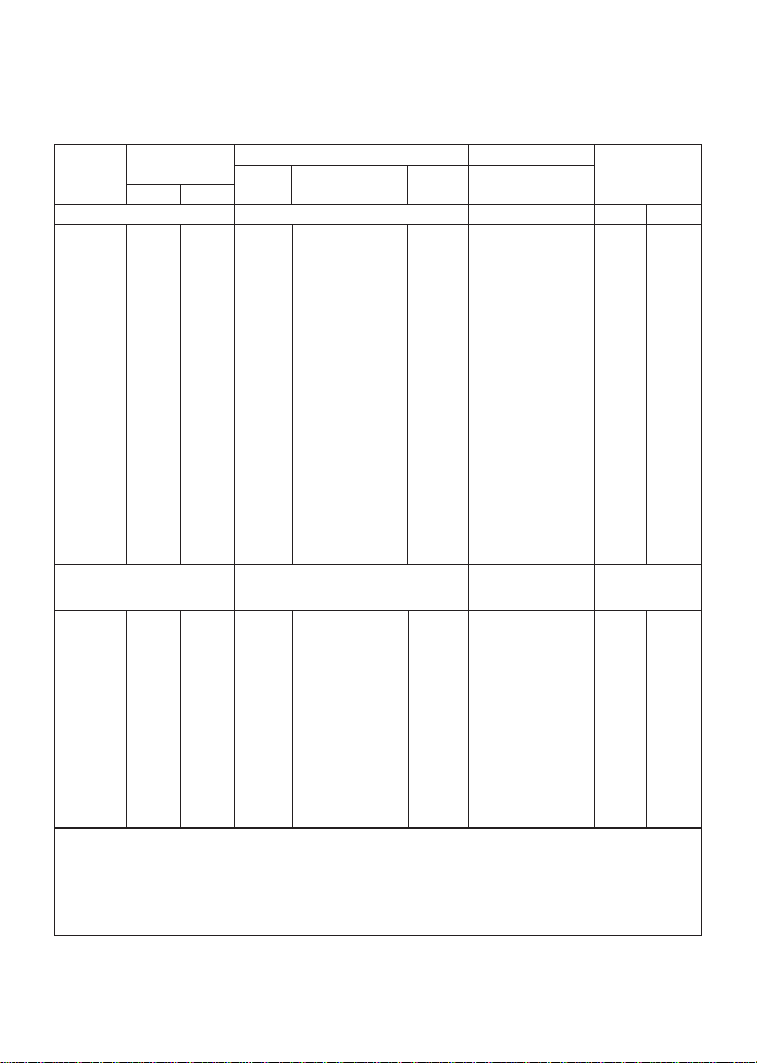

HP kW VOLTAGE MODEL H W D P R

0.25 0.20 208 / 240 T310 5.75 2.88 3.94 0.80 4.37

0.5 0.37 208 /240 T312 5.75 2.88 3.94 0.80 4.37

400 / 480 T332 5.75 2.88 3.94 0.80 4.37

1 0.75 208 / 240 T314 5.75 2.88 4.74 1.60 4.37

208 / 240 T324 5.75 2.88 4.74 1.60 4.37

400 / 480 T334 5.75 2.88 4.74 1.60 4.37

480 / 590 T354 5.75 2.88 4.74 1.60 4.37

1.5 1.1 208 / 240 T315 5.75 3.76 5.24 1.90 4.37

208 / 240 T325 5.75 2.88 5.74 2.60 4.37

400 / 480 T335 5.75 2.88 5.74 2.60 4.37

2.0 SpinMaster™ Plus DIMENSIONS

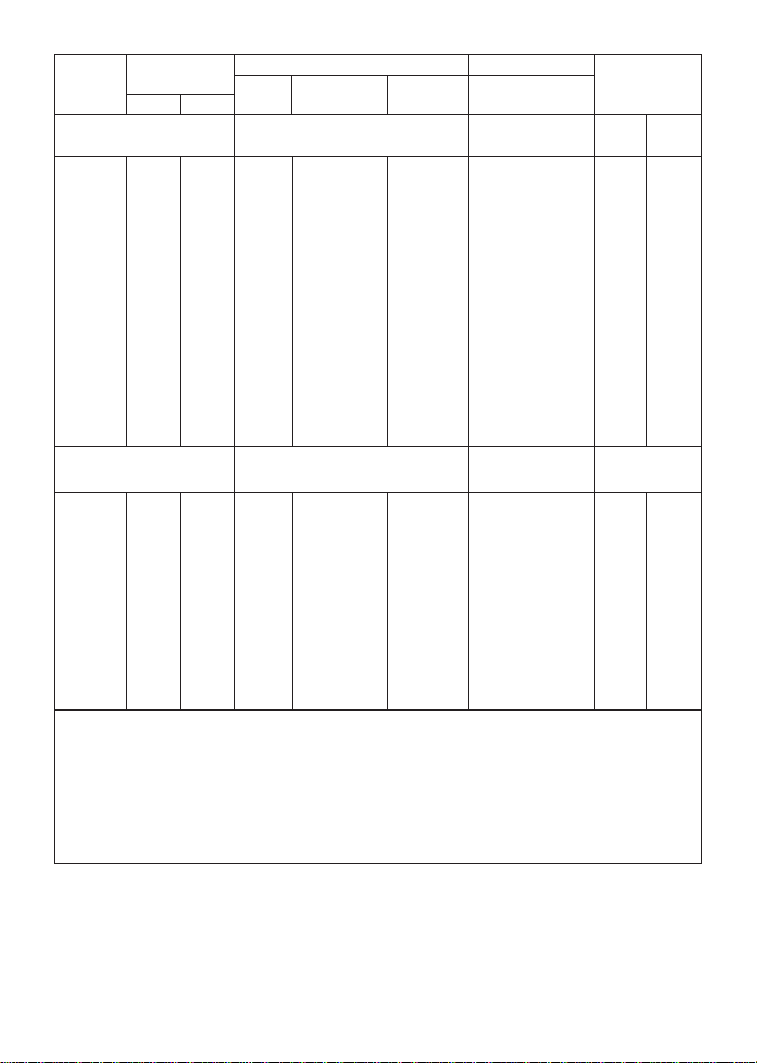

INPUT

HP kW VOLTAGE MODEL H W D P R

2 1.5 208 / 240 T316 5.75 3.76 6.74 3.40 4.37

208 / 240 T326 5.75 2.88 5.74 2.60 3.06

400 / 480 T336 5.75 2.88 5.74 2.60 4.37

480 / 590 T356 5.75 2.88 5.74 2.60 4.37

3 2.2 208 / 240 T317 5.75 3.76 6.74 3.40 3.25

208 / 240 T327 5.75 2.88 5.74 2.60 3.06

400 / 480 T337 5.75 2.88 5.74 2.60 3.06

480 / 590 T357 5.75 3.76 6.74 3.40 4.37

5 3.7 208 / 240 T318 7.75 5.02 7.18 3.40 4.81

208 / 240 T328 5.75 3.76 6.74 3.40 3.25

400 / 480 T338 5.75 3.76 6.74 3.40 3.25

480 / 590 T358 5.75 3.76 6.74 3.40 3.25

7.5 5.5 208 / 240 T329 7.75 5.02 7.18 3.40 4.81

400 / 480 T339 7.75 5.02 7.18 3.40 4.81

480 / 590 T359 7.75 5.02 7.18 3.40 4.81

10 7.5 208 / 240 T330 7.75 5.02 7.18 3.40 4.81

400 / 480 T340 7.75 5.02 7.18 3.40 4.81

480 / 590 T360 7.75 5.02 7.18 3.40 4.81

15 11 208 / 240 T331 9.75 6.68 8.00 3.60 6.30

400 / 480 T341 9.75 6.68 8.00 3.60 6.30

480 / 590 T361 9.75 6.68 8.00 3.60 6.30

20 15 208 / 240 T333 9.75 6.68 8.00 3.60 6.30

400 / 480 T342 9.75 6.68 8.00 3.60 6.30

480 / 590 T362 9.75 6.68 8.00 3.60 6.30

25 18.5 400 / 480 T343 9.75 6.68 8.00 3.60 6.30

480 / 590 T363 9.75 6.68 8.00 3.60 6.30

30 2.2 400/480 T344 9.75 6.68 8.00 3.60 6.30

3

4

4.0 SpinMaster™ Plus SPECIFICATIONS

Storage Temperature -20° to 70° C

Ambient Operating Temperature 0° to 50° C (up to 6 kHz carrier, derate above 6 kHz)

Ambient Humidity <95% (non-condensing)

Maximum Altitude 3300 ft (1000m) above sea level (without derating)

Input Line Voltages 208/240 Vac, 400/480 Vac, 480/590 Vac

Input Voltage Tolerance +10%, -15%

Input Frequency Tolerance 48 to 62 Hz

Output Wave Form Sine Coded PWM

Output Frequency 0 - 240 Hz (consult Factory for higher output

frequencies)

Carrier Frequency 4 kHz to 10 kHz

Service Factor 1.00 (up to 6 kHz carrier, derate above 6 kHz)

Efficiency Up to 98%

Power Factor (displacement) 0.96 or better

Overload Current Capacity 150% for 60 seconds, 180% for 30 seconds

Speed Reference Follower 0 - 10 VDC, 4 - 20 mA

Control Voltage 15 VDC

Power Supply for Auxiliary Relays 50 mA at 12 VDC

Analog Outputs 0 - 10 VDC or 2 - 10 VDC: Proportional to frequency

or load

Digital Outputs Open-collector outputs: 50 mA at 30 VDC

MODEL FOR MOTORS INPUT (50-60 Hz) OUTPUT HEAT LOSS

NUMBER RATED INPUT CURRENT POWER CURRENT (WATTS)

HP kW PHASE (AMPS) (kVA) (AMPS) (NOTE 6)

T310 SERIES (NOTE 3) 208/240 Vac 0 - 200/230 Vac STD THRU

T310 0.25 0.20 1 3.6/3.2 0.76 1.6/1.4 19 N/A

T310 0.25 0.20 3 1.9/1.7 0.71 1.6/1.4 19 N/A

T312 0.5 0.37 1 5.4/4.7 1.2 2.5/2.2 26 N/A

T312 0.5 0.37 3 3.1/2.7 1.1 2.5/2.2 26 N/A

T314 1 0.75 1 10.6/9.2 2.2 4.8/4.2 49 N/A

T314 1 .075 3 5.8/5.1 2.1 4.8/4.2 49 N/A

T315 1.5 1.1 1 13.9/12.0 2.9 6.9/6.0 82 N/A

T315 1.5 1.1 3 8.0/6.9 2.9 6.9/6.0 82 N/A

T316 2 1.5 1 14.8/12.9 3.1 7.8/6.8 86 N/A

T316 2 1.5 3 9.1/7.9 3.2 7.8/6.8 86 N/A

T317 3 2.2 1 19.7/17.1 4.1 11.0/9.6 130 N/A

T317 3 2.2 3 12.4/10.8 4.4 11.0/9.6 130 N/A

T318 5 3.7 1 29/26 6.1 17.5/15.2 212 N/A

T318 5 3.7 3 19.6/17.1 7.1 17.5/15.2 212 N/A

T320 - T330 SERIES

208/240 Vac 0 - 200/230 Vac

(NOTE 3)

T324 1 0.75 3 5.8/5.1 2.1 4.8/4.2 41 N/A

T325 1.5 1.1 3 8.0/6.9 2.9 6.9/6.0 69 N/A

T326 2 1.5 3 9.1/7.9 3.3 7.8/6.8 78 N/A

T327 3 2.2 3 12.4/10.8 4.5 11.0/9.6 117 N/A

T328 5 3.7 3 19.6/17.1 7.1 17.5/15.2 187 N/A

T329 7.5 5.5 3 28/25 10.3 25/22 286 N/A

T330 10 7.5 3 34/32 13.1 30/28 379 N/A

T331 15 11 3 54/48 20.0 48/42 476 N/A

T333 20 15 3 65/61 25.4 58/54 648 N/A

NOTE 3: The higher current ratings are for 208 Vac input and the lower current ratings

are for 240 Vac input.

NOTE 6: STD = standar d unit. V alues ar e worst-case (not typical) for 6 kHz carrier fr equency

at full speed and full load.

5

5.0 SpinMaster™ Plus RATINGS

MODEL FOR MOTORS INPUT (50-60 Hz) OUTPUT HEAT LOSS

NUMBER RATED INPUT CURRENT POWER CURRENT (WATTS)

HP kW PHASE (AMPS) (kVA) (AMPS) (NOTE 6)

T330 - T340 SERIES

400/480 Vac 0 - 400/460 Vac STD THRU

(NOTE 4)

T332 0.5 0.37 3 1.6/1.4 1.1 1.3/1.1 26 N/A

T334 1 0.75 3 2.9/2.5 2.1 2.4/2.1 40 N/A

T335 1.5 1.1 3 4.0/3.6 3.0 3.4/3.0 56 N/A

T336 2 1.5 3 4.6/4.0 3.3 3.9/3.4 67 N/A

T337 3 2.2 3 6.2/5.4 4.5 5.5/4.8 100 N/A

T338 5 3.7 3 9.8/8.6 7.1 8.7/7.6 168 N/A

T339 7.5 5.5 3 14.2/12.4 10.3 12.6/11.0 254 N/A

T340 10 7.5 3 18.1/15.8 13.1 16.1/14.0 310 N/A

T341 15 11 3 27/24 20.0 24/21 390 N/A

T342 20 15 3 35/31 25.8 31/27 530 N/A

T343 25 18.5 3 44/38 31.6 39/34 648 N/A

T344 30 2.2 3 53/45 37.4 46/40 770 N/A

T350 - T360 SERIES

480/590 Vac 0 - 460/575 Vac

(NOTE 5)

T354 1 0.75 3 2.2/2.0 1.9/2.0 1.9/1.7 40 N/A

T356 2 1.5 3 4.0/3.5 3.3/3.6 3.4/3.0 67 N/A

T357 3 2.2 3 4.7/4.7 3.9/4.8 4.2/4.2 100 N/A

T358 5 3.7 3 7.4/7.4 6.1/7.5 6.6/6.6 168 N/A

T359 7.5 5.5 3 11.2/11.2 9.3/11.4 9.9/9.9 254 N/A

T360 10 7.5 3 13.7/13.7 11.4/14.0 12.2/12.2 310 N/A

T361 15 11 3 22/22 18.3/22.5 19.0/19.0 390 N/A

T362 20 15 3 27/27 22.4/27.6 24/24 530 N/A

T363 25 18.5 3 31/31 25.8/31.7 27/27 648 N/A

NOTE 4: The higher current ratings are for 400 Vac input and the lower current ratings

are for 480 Vac input.

NOTE 5: The higher current ratings for for 480 Vac input and the lower current ratings are

for 590 Vac input.

NOTE 6: STD = standar d unit. V alues ar e worst-case (not typical) for 6 kHz carrier fr equency

at full speed and full load.

6

6.0 INSTALLATION

NOTE: SpinMaster™ Plus drives are intended for inclusion within other equipment, by

professional electrical installers. They are not intended for stand-alone operation.

DRIVES MUST NOT BE INSTALLED WHERE SUBJECTED TO ADVERSE

ENVIRONMENTAL CONDITIONS SUCH AS: COMBUSTIBLE, OILY, OR HAZARDOUS VAPORS OR

DUST; EXCESSIVE MOISTURE OR DIRT; VIBRATION; EXCESSIVE AMBIENT TEMPERATURES.

CONSULT REGAL-BELOIT CORPORATION FOR MORE INFORMATION ON THE SUITABILITY OF A

DRIVE TO A PARTICULAR ENVIRONMENT.

SpinMaster™ Plus models are suitable for UL pollution degree 2 environment only, and MUST

be installed in an electrical enclosure which will provide complete mechanical protection and

will maintain the internal temperature within the drive’s ambient operating temperature rating.

All drives models MUST be mounted in a vertical position for proper heatsink cooling.

Maintain a minimum spacing around the drive of at least 1 inch (25mm) on each side and 2

inches (50mm) on the top and bottom for units rated up to 5 HP (3.7kW). For units rated 7.5

- 30 HP (5.5 - 22 kW), maintain at least 2 inches (50mm) on each side and 4 inches (100mm)

on the top and bottom. Allow more spacing if the drive is mounted next to other

heat-producing equipment. Do not mount drives above other drives or heat producing

equipment. Fans or blowers should be used to insure proper cooling in tight quarters.

In order to properly size an enclosur e, the heat generated by the drive(s) must be known. Refer

to the HEAT LOSS columns in Section 5.0 - SpinMaster™ Plus RATINGS. The STD column is for

standard units. An enclosure manufacturer can then determine the required enclosure size

based on the total heat generated inside the enclosure (from the drive(s) and other heat

sources), the maximum allowable temperature inside the enclosure, the maximum ambient

temperature outside the outside the enclosure, and the enclosure properties.

The SpinMaster™ Plus is UL approved for solid state motor overload protection. Therefore, a

separate thermal overload relay is not required for single motor applications.

6.1 INSTALLATION AFTER A LONG PERIOD OF STORAGE

Severe damage to the drive can result if it is operated after a long period of

storage or inactivity without reforming the DC bus capacitors!

If input power has not been applied to the drive for a period of time exceeding three years

(due to storage etc), the electrolytic DC bus capacitors within the drive can change internally,

resulting in excessive leakage current. This can result in premature failure of the capacitors if

the drive is operated after such a long period of inactivity or storage.

In order to reform the capacitors and prepare the drive for operation after a long period of

inactivity, apply input power to the drive for 8 hours prior to actually operating the motor.

7

8

6.2 EXPLOSION PROOF APPLICATIONS

Explosion proof motors that are not rated for inverter use lose their certification when used for

variable speed. Due to the many areas of liability that may be encountered when dealing with

these applications, the following statement of policy applies:

“REGAL-BELOIT CORPORATION inverter products ar e sold with no warranty of

fitness for a particular purpose or warranty of suitability for use with explosion proof motors. REGAL-BELOIT CORPORATION accepts no responsibility

for any direct, incidental or consequential loss, cost, or damage that may arise

through the use of its AC inverter products in these applications. The

purchaser expressly agr ees to assume all risk of any loss, cost, or damage that

may arise from such application.”

7.0 INPUT AC POWER REQUIREMENTS

Hazard of electrical shock! Capacitors retain charge after power is removed.

Disconnect incoming power and wait until the voltage between terminals B+ and B- is 0 VDC

before servicing the drive.

The input voltage must match the nameplate voltage rating of the drive. Voltage fluctuation

must not vary by greater than 10% overvoltage or 15% undervoltage.

NOTE: Drives with dual input voltage ratings must be programmed for the proper supply

voltage (refer to Parameter 01 - LINE VOLTAGE SELECTION in Section 15.0 - DESCRIPTION OF

PARAMETERS).

The drive is suitable for use on a circuit capable of delivering not more than 5,000 RMS

symmetrical amperes at 5 HP (3.7kW), and below, and 18,000 RMS symmetrical amperes at

7.5 HP (5.5kW) and above, at the drive’s rated voltage.

If the kVA rating of the AC supply transformer is greater than 10 times the input kVA rating of

the drive(s), an isolation transformer or 2-3% input line reactor must be added to the line side

of the drive(s).

Three phase voltage imbalance must be less than 2.0% phase to phase. Excessive phase to

phase imbalance can cause severe damage to the drive’s power components.

Motor voltage should match line voltage in normal applications. The drive’s maximum output

voltage will equal the input voltage. Use extreme caution when using a motor with a voltage

rating which is different from the input line voltage.

9

7.1 INPUT VOLTAGE RATINGS

T310 through T318 drives are rated for 208/240 Vac, single or three phase, 50-60 Hz input.

The drive will function with input voltages of 208 to 240 Vac (+10%, -15%), at 48 to 62 Hz.

T324 through T331, and T333 drives are rated for 208/240 V ac, thr ee phase, 50-60 Hz input.

The drive will function with input voltage of 208 to 240 Vac (+10%, -15%), at 48 to 62 Hz.

T332, T334 through T344 drives are rated for 400/480 V ac, three phase, 50-60 Hz input. The

drive will function with input voltages of 400 to 480 Vac (+10%, -15%), at 48 to 62 Hz.

T354 through T363 drives are rated for 480/590 Vac, three phase, 50-60 Hz input, and will

function with input voltages of 480 to 590 Vac (+10%, -15%), at 48 to 62 Hz.

NOTE: Parameter 01 - LINE VOLTAGE SELECTION must be programmed according to the

applied input voltage. See Section 15.0 - DESCRIPTION OF PARAMETERS.

7.2 INPUT FUSING AND DISCONNECT REQUIREMENTS

A circuit breaker or a disconnect switch with fuses must be provided in accordance with the

National Electric Code (NEC) and all local codes. Refer to the following tables for proper

fuse/circuit breaker ratings and wire sizes.

The SpinMaster™ Plus drive is capable of withstanding up to 150% current overload for 60

seconds. Select a fuse or magnetic trip circuit breaker rated at 1.5 times the input current

rating of the drive (the minimum size should be 10 amps, regardless of input current rating).

Refer to Section 5.0 - SpinMaster™ Plus RATINGS.

Minimum voltage rating of the protection device should be 250 Vac for 208/240 Vac rated

drives, and 600 Vac for 400/480 Vac and 480/590 Vac drives.

NOTE 1: Applicable national and local electrical codes take precedence over

recommendations in the tables on the following page.

NOTE 2: Use UL Class CC or Class T fast-acting, current limiting type fuses. Select fuses with

low 12 T values, rated at 200,000 AIC. Recommended fuses are Bussman KTK-R, JJN and JJS.

Similar fuses with equivalent ratings by other manufacturers may also be acceptable.

NOTE 3: When using a Pulse Current or Universal Current sensitive Earth Leakage Circuit

Breaker (ELCB). The detection level must be rated 30mA or greater. Observe the following

when using ELCB’s:

1. Only install the ELCB between the supply mains and drive controller.

2. The ELCB can be activated by:

• Capacitive leakage currents between the cable screens during operation

(especially with long screened motor cables)

• Connecting several drives to the mains at the same time.

• Additional RFI filters

10

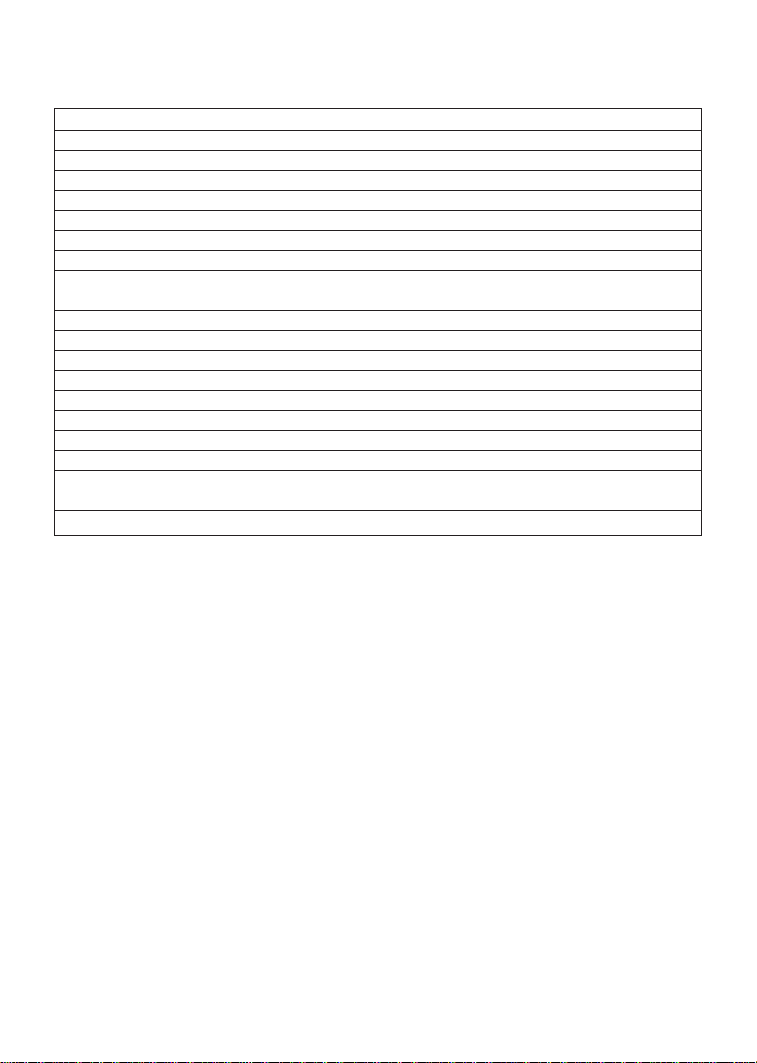

INPUT FUSE & CIRCUIT BREAKER RATINGS

208/240 Vac, 1 phase 208/240 Vac, 3 phase 400/480 Vac, 3 phase 480/590 Vac, 3 phase

MODEL RATING MODEL RATING MODEL RATING MODEL RATING

T310 10A T310 10A

T312 10A T312 10A T332 10A

T314 15A T314 & T324 10A T334 10A T354 10A

T315 20A T315 & T325 12 / 10A T335 10A

T316 25 / 20A T316 & T326 15 / 12A T336 10A T356 10A

T317 30 / 25A T317 & T327 20 / 15A T337 10A T357 10A

T318 45 / 40A T318 & T328 30 / 25A T338 15A T358 12A

T329 45 / 40A T339 20A T359 20A

T330 50 / 50A T340 30 / 25A T360 20A

T331 80 / 75A T341 40 / 35A T361 30A

T333 100 / 90A T342 50 / 45A T362 40A

T343 70 / 60A T363 45A

T344 80 / 70A

WIRE SIZE REQUIREMENTS

208/240 Vac, 1 phase 208/240 Vac, 3 phase 400/480 Vac, 3 phase 480/590 Vac, 3 phase

MODEL AWG mm2 MODEL AWG mm2 MODEL AWG mm2 MODEL AWG mm2

T310 14 1.5 T310 14 1.5

T312 14 1.5 T312 14 1.5 T332 14 1.5

T314 14 1.5 T314 & T324 14 1.5 T334 14 1.5 T354 14 1.5

T315 12 2.5 T315 & T325 14 1.5 T335 14 1.5

T316 12 2.5 T316 & T326 14 1.5 T336 14 1.5 T356 14 1.5

T317 10 4.0 T317 & T327 12 2.5 T337 14 1.5 T357 14 1.5

T318 8 6.0 T318 & T328 10 4.0 T338 14 1.5 T358 14 1.5

T329 8 6.0 T339 12 2.5 T359 14 1.5

T330 8 10 T340 10 4.0 T360 12 2.5

T331 6 16 T341 8 6.0 T361 10 4.0

T333 4 25 T342 8 10 T362 10 4.0

T343 6 16 T363 8 10

T344 6 16

7.3 INSTALLATION ACCORDING TO EMC REQUIREMENTS

The SpinMaster™ Plus Series can be installed to meet the

European standards for Electromagnetic Compatibility (EMC)

requirements. These requirements govern the permissible

electromagnetic emissions and immunity, both radiated and

conducted, of a drive system.

The EMC requirements apply to the final installation in its

entirety, not to the individual components used. Because ever y

installation is different, the recommended installation should

follow these guidelines as a minimum. Additional equipment

(such as ferrite core absorbers on power conductors) or

alternative wiring practices may be required to meet

conformance in some installations.

Filter: The input to the drive (or group of drives) must include a

filter to reduce the electrical noise reflected back to the AC Line.

Installation: Shielded cable must be used for all control and power cables and exposed wiring

must be kept as short as possible. The figure to the right shows the control cable (B) and motor

cable (C) with the shield grounded with clamps (A) to a grounded, electrically conductive

mounting panel (D). The motor cable must be of a low capacitance specification:

core/core < 75 pF/m, core/shield < 150 pF/m

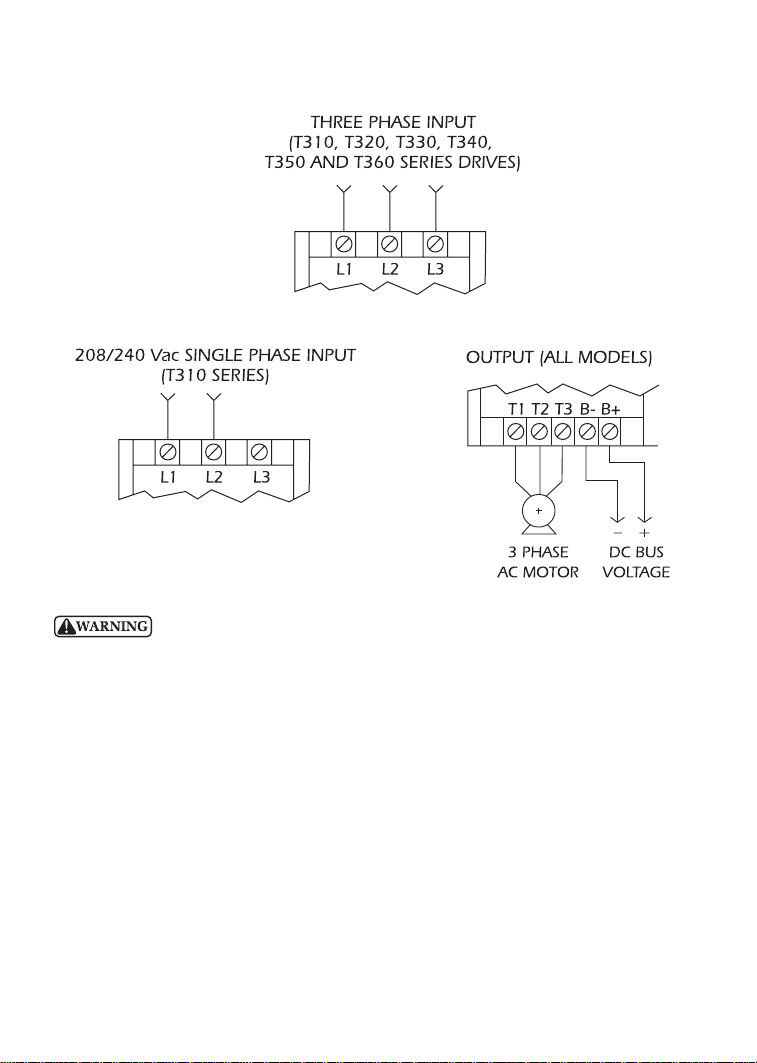

8.0 POWER WIRING

Hazard of electrical shock! Capacitors retain charge after power is removed.

Disconnect incoming power and wait until the voltage between terminals B+ and B- is 0 VDC

before servicing the drive.

Note drive input and output current ratings and check applicable electrical codes for required

wire type and size, grounding requirements, over-current protection, and incoming power

disconnect, before wiring the drive. Size conservatively to minimize voltage drop.

Strip off 0.24 inches (6mm) for the .25 - 5 HP, .35 inches (9mm) for the 7.5 - 10 HP and .5

inches (13mm) for the 15 HP and larger of insulation for input power, output power, and

DC Bus wiring. The input power, output power, and DC Bus terminals must be tightened

to a torque of 4.5 lb-in (0.5 Nm) for the .25 - 5 HP, 10 lb-in (1.2 Nm) for the 7.5 - 10 HP and

18 lb-in (2.0 Nm) for the 15 HP and larger.

Input fusing and a power disconnect switch or contactor MUST be wired in series with

terminals L1, L2, and L3 for three phase input models. For 208/240 Vac single phase input

models, use terminals L1 and L2. This disconnect must be used to power down the drive when

servicing, or when the drive is not to be operated for a long period of time, but should not be

used to start and stop the motor.

11

Repetitive cycling of a disconnect or input contactor (more than once every

two minutes) may cause damage to the drive.

8.1 INPUT AND OUTPUT WIRING

If the drive is rated for single and three phase input (T310 models), wire to terminals L1 and

L2 for single phase input, or wire to terminals L1, L2, and L3 for three phase input.

If the drive is rated for three phase input, wire the input to terminals L1, L2, and L3.

All three power output wires, from terminals T1, T2, and T3 to the motor, must be kept

tightly bundled and run in a separate conduit away from all other power and control wiring.

It is not recommended to install contactors or disconnect switches between the drive and

motor. Operating such devices while the drive is running can potentially cause damage to the

drive’s power components. If such a device is required, it should only be operated when the

drive is in a STOP state. If there is potential for the device to be opened while the drive is

running, the drive must be programmed for COAST to stop (see Parameter 4 - STOP METHOD),

and an auxiliary contact on the device must be interlocked with the drive’s run circuit. This will

give the drive a stop command at the same time the device opens, and will not allow the drive

to start again until the device is closed.

12

13

Do not connect incoming AC power to output terminals T1, T2, or T3. Severe

damage to the drive will result.

NOTES:

1. WIRE AND GROUND IN ACCORDANCE WITH NEC OR CEC, AND ALL APPLICABLE LOCAL

CODES.

2. Motor wires MUST be run in a separate steel conduit away from control wiring and

incoming AC power wiring.

3. Do not install contactors between the drive and the motor without consulting REGALBELOIT CORPORATION for more information. Failur e to do so may r esult in drive damage.

4. Use only UL and CSA listed and approved wire.

5. Minimum wire voltage ratings: 300 V for 120, 208 and 240 Vac systems, and 600 V for

400, 480, and 590 Vac systems.

6. Wire gauge must be based on a minimum of 125% of the rated input/output current of

the drive, and a minimum 75° C insulation rating. Use copper wire only.

9.0 SpinMaster™ Plus POWER WIRING DIAGRAM

14

10.0 CONTROL WIRING

10.1 CONTROL WIRING VS. POWER WIRING

External control wiring MUST be run in a separate conduit away from all other input and

output power wiring. If control wiring is not kept separate from power wiring, electrical noise

may be generated on the control wiring that will cause erratic drive behavior. Use twisted

wires or shielded cable grounded at the drive chassis ONLY. Recommended control wire is

Belden 8760 (2-wire) or 8770 (3-wire), or equivalent.

Strip off 0.20 to 0.25 inches (5 to 6mm) of insulation for control wiring and torque the

terminals to 2 lb-in (0.2 Nm). Be careful not to overtorque the control terminals, as this will

cause damage to the terminal strip. This is not covered under warranty and can only be

repaired by replacing the control board.

10.2 TB-2: CIRCUIT COMMON

The TB-2 terminals are used as circuit common for the start/stop, forward/reverse, input select,

local/remote, analog input, and analog output functions. There are three TB-2 terminals

available on the terminal strip, and they are all internally connected to each other on the main

control board. If necessary TB-2 may be connected to chassis ground.

NOTE: TB-2 must be connected to chassis ground when using serial communications.

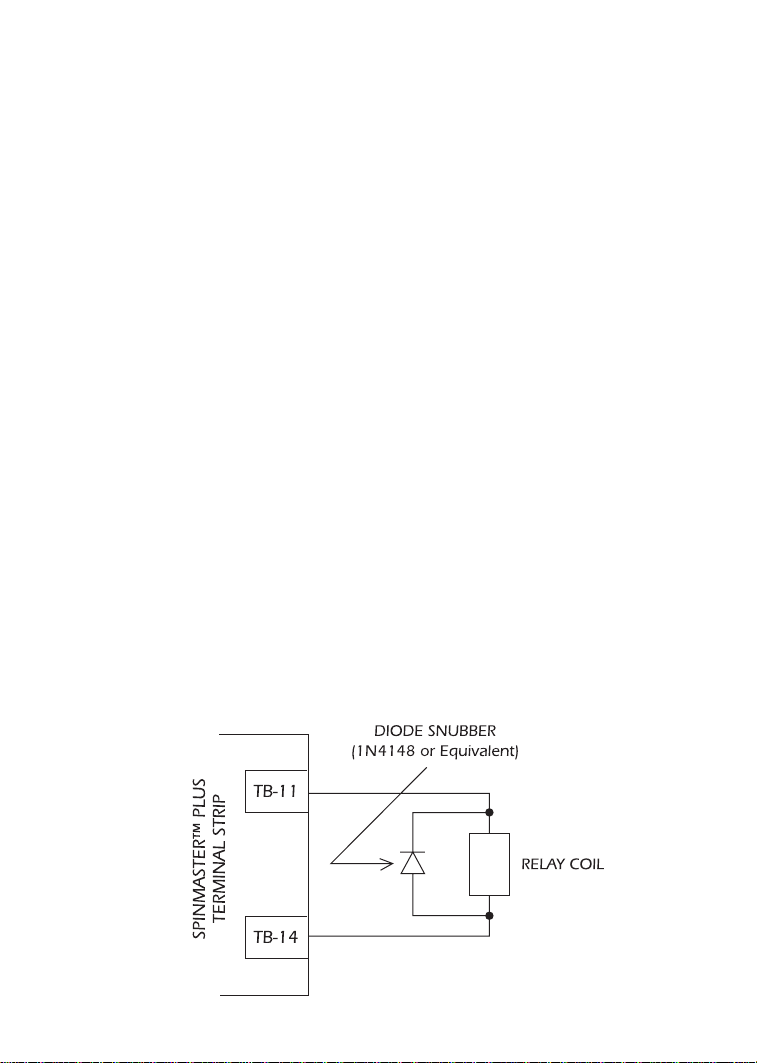

10.3 SURGE SUPPRESSION ON RELAYS

Current and voltage surges and spikes in the coils of contactors, relays, solenoids, etc, near or

connected to the drive, can cause erratic drive operation. Therefore, a snubber circuit should

be used on coils associated with the drive. For AC coils, snubbers should consist of a resistor

and a capacitor in series across the coil. For DC coils, a free-wheeling or flyback diode should

be placed across the coil. Snubbers are typically available fr om the manufacturer of the device.

10.4 START/STOP CONTROL

There are various control schemes that allow for 2-wire and 3-wire Start/Stop circuits. Refer to

the wiring diagrams in Section 11.0 - SpinMaster™ Plus CONTROL WIRING DIAGRAMS.

10.5 SPEED REFERENCE SIGNALS

The drive allows for three analog speed reference inputs:

SPEED POT Connect the wiper of a speed pot to terminal TB-5, and connect the high and

low end leads to terminals TB-6 and TB-2, respectively. The speed pot can be

2.5kΩ up to 10kΩ.

0-10 VDC Wire the positive to terminal TB-5 and the negative to terminal TB-2. TB-5 input

impedance is 120 kilohms.

4-20 mA Wire the positive to terminal TB-25 and the negative to terminal TB-2. TB-25

input impedance is 100 ohms.

15

10.6 SPEED REFERENCE SELECTION

If an analog speed reference input is used to control the drive speed, terminal TB-13A, 13B,

or 13C (Parameter 10, 11, or 12) may be programmed as the input select for the desired

analog input signal. When that TB-13 terminal is then closed to TB-2, the drive will follow the

selected analog speed reference input.

If an analog speed reference input is not selected on the terminal strip using TB-13A, 13B, or

13C, speed control will default to STANDARD mode, which is governed by the setting of

Parameter 05 - STANDARD SPEED SOURCE. The STANDARD SPEED SOURCE can be the L and

M buttons on the front of the drive, PRESET SPEED #1(Parameter 31), a 0-10 VDC signal, or a

4-20 mA signal.

0-10 VDC and 4-20 mA INPUT SIGNALS

TB-13A, TB-13B, and TB-13C can all be programmed to select a 0-10 VDC or 4-20 mA analog

speed reference input.

PRESET SPEEDS

TB-13A can be programmed to select PRESET SPEED #1, TB-13B to select PRESET SPEED #2,

and TB-13C to select PRESET SPEED #3. There are a total of seven preset speeds, which are

activated by different combinations of contact closures between TB-13A, 13B, 13C and TB-2.

Refer to Parameters 31-37 in Section 15.0 - DESCRIPTION OF PARAMETERS.

JOG

TB-13B can be programmed to select either JOG FORWARD or JOG REVERSE. The Jog speed

is set by PRESET SPEED #2. Close TB-13B to TB-2 to JOG, and open the contact to STOP.

When operating in JOG mode, the STOP terminal (TB-1) and the STOP key (on

the optional remote keypad) WILL NOT stop the drive. To stop the drive, remove the JOG

command.

JOG REVERSE will operate the drive in reverse rotation even if ROTATION

DIRECTION (Parameter 17) is set to FORWARD ONLY.

NOTE: If the drive is commanded to JOG while running, the drive will enter JOG mode and

run at PRESET SPEED #2. When the JOG command is removed, the drive will STOP.

MOTOR OPERATED POT (MOP) / FLOATING POINT CONTROL

TB-13B and TB-13C are used for this function, which controls the drive speed using contacts

wired to the terminal strip. Program TB-13B for DECREASE FREQ (05), and pr ogram TB-13C for

INCREASE FREQ (05). Closing TB-13B to TB-2 will cause the speed setpoint to decrease until

the contact is opened. Closing TB-13C to TB-2 will cause the speed setpoint to increase

until the contact is opened. The INCREASE FREQ function will only operate while the drive is

running.

16

NOTE: If TB-13A, TB-13B, and TB-13C ar e all pr ogrammed to select speed r efer ences, and two

or three of the terminals are closed to TB-2, the higher terminal has priority and will override

the others. For example, if TB-13A is programmed to select 0-10 VDC, and TB-13C is

programmed to select PRESET SPEED #3, closing both terminals to TB-2 will cause the drive to

respond to PRESET SPEED #3, because TB-13C overrides TB-13A.

The exception to this is the MOP function, which requires the use of TB-13B and TB-13C. This

leaves TB-13A to be used for some other function. If TB-13A is programmed for a speed

reference, and TB-13A is closed to TB-2, TB-13A will override the MOP function.

10.7 ANALOG OUTPUT SIGNALS

Terminal TB-30 can provide a 0-10 VDC or a 2-10 VDC signal proportional to output frequency

or load, and TB-31 can provide the same signals proportional to load only. The 2-10 VDC

signal can be converted to a 4-20 mA signal using a resistor in series with the signal such

that the total load resistance is 500 Ohms. Refer to Parameters 08 and 09 in Section 15.0 DESCRIPTION OF PARAMETERS.

NOTE: These analog output signals cannot be used with “loop-powered” devices that derive

power from a 4-20 mA signal.

10-8 DRIVE STATUS DIGITAL OUTPUTS

There are two open-collector outputs at terminals TB-14 and TB-15. The open-collector circuits

are current-sinking types rated at 30 VDC and 50 mA maximum.

The open-collector outputs can be programmed to indicate any of the following: RUN, FAULT,

INVERSE FAULT, FAULT LOCKOUT, AT SPEED, ABOVE PRESET SPEED #3, CURRENT LIMIT, AUTO

SPEED MODE, and REVERSE. Refer to Parameters 06 and 13 in Section 15.0 - DESCRIPTION

OF PARAMETERS.

The diagram below illustrates how the 12 VDC power supply at TB-11 can be used with the

open-collector output to drive an external relay:

Loading...

Loading...