ColorPASS-Z40e/Z20e

PS-NX40W/20W

REVISION 0

AUG.2000

COPYRIGHT© 2000 CANON INC. 2000 2000 2000 ColorPASS-Z40e/Z20e REV.0 A UG. 2000 PRINTED IN JAPAN (IMPRIME AU JAPON)

FY8-13GW-000

Application

This manual has been issued by Canon Inc. for qualified persons to learn technical

theory, installation, maintenance, and repair of products. This manual covers all

localities where the products are sold. For this reason, there may be information in this

manual that does not apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to

improvements or changes in products. When changes occur in applicable products or in

the contents of this manual, Canon will release technical information as the need arises.

In the event of major changes in the contents of this manual over a long or short period,

Canon will issue a new edition of this manual.

The following paragraph does not apply to any countries where such provisions are

inconsistent with local law.

Trademarks

The product names and company names used in this manual are the registered

trademarks of the individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this

manual may not be copied, reproduced or translated into another language, in whole or

in part, without the written consent of Canon Inc.

COPYRIGHT © 2000 CANON INC.

Printed in Japan

Imprimé au Japon

Caution

Use of this manual should be strictly supervised to avoid disclosure of confidential information.

COPYRIGHT© 2000 CANON INC. 2000 2000 2000 ColorPASS-Z40e/Z20e REV.0 A UG. 2000 PRINTED IN JAPAN (IMPRIME AU JAPON)

INTRODUCTION

1 Symbols Used

This documentation uses the following symbols to indicate special information:

Symbol Description

Indicates an item of a non-specific nature, possibly classified as Note, Caution,

or Warning.

Indicates an item requiring care to avoid electric shocks.

Indicates an item requiring care to avoid combustion (fire).

Memo

REF.

Indicates an item prohibiting disassembly to avoid electric shocks or problems.

Indicates an item requiring disconnection of the power plug from the electric

outlet.

Indicates an item intended to provide notes assisting the understanding of the

topic in question.

Indicates an item of reference assisting the understanding of the topic in question.

Provides a description of a service mode.

Provides a description of the nature of an error indication.

Refers to the Copier Basics Series for a better understanding of the contents.

COPYRIGHT© 2000 CANON INC. 2000 2000 2000 ColorPASS-Z40e/Z20e REV.0 A UG. 2000

i

INTRODUCTION

2 Outline of the Sevice Manual

This Service Manual provides basic facts and figures needed in the field when servicing

the ColorPASS/PS-NX, and consists of the following chapters:

Chapter 1

Chapter 2

Chapter 3

Chapter 4

Chapter 5

Chapter 6

Appendix contains a table of specifications and a list of tools.

In addition to this manual, the ColorPASS/PS-NX comes with the Getting Started, Job

Management Guide, Printing Guide, Configuration Guide, Color Guide for use by the user.

All service persons are encouraged to read these documents at least once to find out how the

ColorPASS/PS-NX may be set up by making various optional settings.

The ColorPASS/PS-NX is a maintenance-/inspection-free product.

Introduction

outline of operation.

introduces the ColorPASS/PS-NX’s features and provides an

Preparing for Installation

tion work.

nstallation

outline of its control panel.

Disassembly/Assembly

ColorPASS/PS-NX.

Troubleshooting

with a list of error messages.

Parts Catalog

shows how to install the ColorPASS/PS-NX, and provides an

shows how to disassemble and assemble the

provides tables of typical problems and actions to take

contains diagrams of parts and parts names.

discusses things to do before stating the installa-

The description in this Service Manual are subject to change without notice for product

improvement or other reasons, and major changes will be communicated in the form of Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this Service Manual and all relevant Service Information bulletins and be able to identify and isolate

faults in the machine.

The following are the trademarks or registered trademarks of the respective entities:

EFI and Fiery is a registered trademark of Electronics for Imaging, Inc.

PostScript is a registered trademark of Adobe Systems Incorporated.

EPS (Encapsulated PostScript) is a registered trademark of Altsys Corporation.

Apple, AppleTalk, EtherTalk, TrueType, and Macintosh are registered trademarks of

Apple Computer, Inc.

Windows is a registered trademark of Microsoft Corporation.

ii

COPYRIGHT© 2000 CANON INC. 2000 2000 2000 ColorPASS-Z40e/Z20e REV.0 A UG. 2000

INTRODUCTION

NetWare, Novell, and Internetwork Packet Exchange (IPX) are registered trademarks of

Novell, Inc.

Pentium, Celeron are registered trademarks of Intel Corporation.

UNIX is a registered trademark of System Laboratories.

All brand names and product names used in this Service Manual are trademarks, regis-

tered trademarks, or trade names of their respective holders.

COPYRIGHT© 2000 CANON INC. 2000 2000 2000 ColorPASS-Z40e/Z20e REV.0 A UG. 2000

iii

INTRODUCTION

Terminology and conv entions

The term “ColorPASS” is used throughout this manual to refer to the ColorPASS-Z40e/

Z20e and PS-NX40W/20W.

The term “ColorPASS” is used in this manual to refer to the ColorPASS-Z40 Color

Server.

The term “Network administrator” refers to the person responsible for maintaining the

network at the customer site.

The term “Control Panel” refers to the area on the top of the ColorPASS including the

green/red activity light, the display window (LCD-liquid crystal display), and the buttons on

the sides of the display window.

The term “System software” refers to the software installed on the ColorPASS hard disk

drive.

References to other ColorPASS manuals, such as the Configuration Guide, are displayed

in italics.

Precautions

Always observe the following general precautions when installing and servicing the

ColorPASS:

1. Never alter an existing network without permission.

The ColorPASS will probably be connected to an existing Local Area Network (LAN)

based on Ethernet or Token Ring hardware. The network is the link between the

customer’s computer, existing laser printers, and other prepress equipment. Never disturb the LAN by breaking or making a network connection, altering termination, installing or removing networking hardware or software, or shutting down networked devices

without the knowledge and express permission of the system or network administrator

or the shop supervisor.

2. Never enter an IP address in ColorPASS Network Setup.

Only the network administrator should enter an IP address on a network device.

Assigning the ColorPASS an incorrect IP address may cause unpredictable errors on any

or all devices connected to the network.

3. Always disconnect power before openig the ColorPASS.

4. Handle the ColorPASS Control Panel display window with care.

The ColorPASS display window is made of glass. If the glass breaks and the liquid crystal inside leaks out, avoid contact with it. If you do come in contact with the liquid crystal, wash it off with soap and water immediately.

5. Avoid pressing the surface of the display window.

Applying pressure to the display window will cause it to change color.

6. Use a soft cloth moistened with isopropyl or ethyl alcohol to clean the surface of the

ColorPASS display window.

Other solvents, such as water, may damage the polarizer on the display window.

7. Use care when handling parts of the ColorPASS as some edges on the unit may be

sharp.

For example, be careful when:

• Plugging in cables at the back of the unit

• Using the power switch to power on/off the unit

iv

COPYRIGHT© 2000 CANON INC. 2000 2000 2000 ColorPASS-Z40e/Z20e REV.0 A UG. 2000

INTRODUCTION

8. Follow standard ESD (electrostatic discharge) precautions while working on the internal

components of the ColorPASS.

Static is always a concern when servicing electronic devices. It is highly unlikely that

the area around the copier and the ColorPASS is static-free. Carpeting, leather-soled

shoes, synthetic clothing fibers, silks, and plastics may generate a static charge of more

than 10,000 volts. Static discharge is capable of destroying the circuits etched in silicon

microchips, or dramatically shortening their life span. By observing standard precautions, you may avoid extra service calls and save the cost of a new board.

When possible, work on a ground-connected antistatic mat. Wear an antistatic grounding

strap, grounded at the same place as the antistatic mat. If that is not possible:

• Attach a grounding strap to your wrist. Attach the other end to a good ground.

• When you unpack the ColorPASS from the carton for the first time, touch a metal

area of the copier to discharge the static on your body.

• Before you remove the ColorPASS side panel and before you handle internal compo-

nents, touch a metal part of the ColorPASS.

• Leave new electronic components inside their antistatic bags until you are ready to

install them. When you remove components from an antistatic bag, place them on a

grounded antistatic surface, component-side up.

• When you remove an electronic component, place it into an antistatic bag immedi-

ately. Do not walk across a carpet or vinyl floor while carrying an unprotected board.

9. Handle printed circuit boards by their edges only, but avoid touching the contacts on the

edge of the board.

10. Never set a cup of coffee-or any liquid-on or near the ColorPASS or the copier.

COPYRIGHT© 2000 CANON INC. 2000 2000 2000 ColorPASS-Z40e/Z20e REV.0 A UG. 2000

v

CONTENTS

Contents

CHAPTER 1 INTRODUCTION

1 Features............................................... 1-1

2 Outline of Operation ........................... 1-2

2.1 Outline ....................................... 1-2

2.2 Operation ................................... 1-2

2.3 Print Options .............................. 1-3

3 User Software .....................................1-4

CHAPTER 2 PREPARING FOR INSTALLATION

1 Outline ................................................2-1

2 Checking the Customer Site ...............2-3

2.1 Copier Model ............................. 2-3

2.2 Power .........................................2-5

2.3 Network ..................................... 2-5

2.4 System Contact Person .............. 2-5

2.5 Setting Customer

Expectations............................... 2-5

3 Unpacking the ColorPASS ................. 2-7

3.1 To Unpack the ColorPASS.........2-7

3.2 ColorPASS Panels......................2-9

4 Installing the ColorPASS on

the copier .......................................... 2-10

CHAPTER 3 INSTALLATION

1 Installation ..........................................3-1

1.1 Preliminary Checkout ................3-1

1.1.1 To Connect Power and Start

the ColorPASS ..................... 3-1

1.2 Connecting to the Copier ........... 3- 3

1.2.1 To Connect the ColorPASS

To the Copier .......................3-3

1.3 Verifying the Connection ........... 3 -4

1.3.1 Printing the ColorPASS

Test Page.............................. 3-4

1.3.2 Checking Scanning

and Printing ......................... 3-5

1.4 Installing Additional Options..... 3- 6

1.5 Connecting to the Network ........ 3-6

1.5.1 To Connect a Twisted Pair

Cable to the ColorPASS ...... 3-7

2 Control Panel ...................................... 3-8

2.1 Using the Control Panel............. 3- 8

2.1.1 Activity Light ...................... 3-9

2.1.2 Buttons.................................3-9

2.2 Control Panel Screens

and Icons .................................. 3-10

2.3 Functions Menu .......................3-12

3 Shutting Down and Restarting

the ColorPASS .................................. 3-14

3.1 To Shut Down

the ColorPASS ......................... 3-14

3.2 To Restart the ColorPASS........ 3-14

vi

COPYRIGHT© 2000 CANON INC. 2000 2000 2000 ColorPASS-Z40e/Z20e REV.0 AUG. 2000

CHAPTER 4 DISASSEMBLY/ASSEMBLY

CONTENTS

1 Points to Note .....................................4-1

1.1 General Cautions........................4-1

1.2 Shut Down the ColorPASS ........ 4-1

1.3 Handling the Parts......................4-1

2 Before Disassembling the Unit........... 4- 2

2.1 Overview.................................... 4-2

2.2 System Software Service ...........4-2

2.3 Accessing ColorPASS Internal

Components ............................... 4-4

2.3.1 Shutting Down and

Restarting the ColorPASS .... 4-4

3 Externals.............................................. 4-5

3.1 To open the ColorPASS ............. 4-5

4 Checking ColorPASS Internal

Connections ........................................4-7

4.1 To Check Board and Cable

Connections ............................... 4-7

4.2 T o Check Motherboard

DIMM Connections ................... 4-9

4.3 Restoring ColorPASS

Functionality After Service ....... 4-10

4.3.1 To Reassemble the

ColorP ASS.........................4-10

5 Electrical Parts .................................. 4-12

5.1 Outline ..................................... 4-12

5.2 SCSI Board .............................. 4-12

5.2.1 To Remove the SCSI

Board ................................. 4-12

5.2.2 To Replace the SCSI

Board ................................. 4-13

5.3 Video Board ............................. 4-14

5.3.1 To Remove the Video

Board ................................. 4-14

5.3.2 To Replace the Video

Board ................................. 4-15

5.4 UIB Board................................ 4-16

5.4.1 To Remove the UIB

Board ................................. 4-16

5.4.2 To Replace the UIB

Board ................................. 4-16

5.5 Ethernet board.......................... 4-17

5.5.1 To Remove the Ethernet

Board ................................. 4-17

5.5.2 To Replace the Ethernet

Board ................................. 4-17

5.6 Motherboard ............................ 4-18

5.6.1 Removing the ColorPASS

motherboard.......................4-18

5.6.2 Replacing the mother

board .................................. 4-20

5.7 Replacing Parts on the Mother

board ........................................4-22

5.7.1 DIMMs ..............................4-22

5.7.2 Motherboard CPU ............. 4-24

5.7.3 BIOS Chip .........................4-25

5.7.4 Motherboard battery .......... 4-25

5.7.5 Motherboard jumpers ........4-27

5.8 Fans .......................................... 4-28

5.8.1 Back panel fans.................. 4-28

5.8.2 CPU Fan ............................4-30

5.9 Power Supply........................... 4-31

5.9.1 Checking Voltages ............. 4-31

5.9.2 Removing and replacing

the power supply ................ 4-32

5.10 Hard Disk Drive ....................... 4-34

5.10.1 To Remo v e the Hdd ........... 4-35

5.10.2 To Replace the Hdd ............ 4-36

6 ColorPASS System

Software Service ............................... 4-37

6.1 Retrieving Backup System

Software ................................... 4-38

6.1.1 To Restore Backu p

System Software ................ 4-38

6.2 Installing system software

from a CD ................................ 4-40

6.2.1 To Install ColorPASS

System Software ................ 4-40

COPYRIGHT© 2000 CANON INC. 2000 2000 2000 ColorPASS-Z40e/Z20e REV.0 AUG. 2000

vii

CONTENTS

CHAPTER 5 TROUBLESHOOTING

1 Preliminary On-site Checkout ............5-1

1.1 The Troubleshooting Process.....5-1

1.2 Where Problems Occur .............. 5-2

1.3 Before You go to the

Customer Site............................. 5-4

1.4 Preliminary on-site Checkout ....5-5

1.4.1 Checking Interface Cables... 5 -5

1.4.2 Checking Internal

Components ......................... 5-6

2 Checking the ColorPASS as a

Stand-alone Unit ................................. 5-8

2.1 To Isolate the ColorPASS .......... 5-8

2.2 Errors and Beep Codes during

Startup Diagnostics .................... 5-8

2.3 General ColorPASS system

3 Checking the Entire ColorPASS

System .............................................. 5-13

3.1 Checking the Copier

3.1.1 Printing the ColorPASS

3.1.2 Checking Scanning and

3.2 Checking Network

3.3 Printing to the ColorPASS ....... 5-15

CHAPTER 6 PARTS CATALOG

error conditions ........................ 5-11

Interface ...................................5-13

T est Page ............................ 5-13

Printing ..............................5-14

Connections ............................. 5-15

APPENDIX

1 Specifications..................................... A-1

2 Special Tools ...................................... A-2

viii

COPYRIGHT© 2000 CANON INC. 2000 2000 2000 ColorPASS-Z40e/Z20e REV.0 AUG. 2000

CHAPTER 1

INTRODUCTION

COPYRIGHT© 2000 CANON INC. 2000 2000 2000 ColorPASS-Z40e/Z20e REV.0 A UG. 2000

CHAPTER 1 INTRODUCTION

1 Features

The ColorPASS Color Server adds computer connectivity and highly efficient Adobe

PostScript 3 color printing capability to color copiers. It is optimized for high-speed network communications, processing, rasterization, and printing of continuous tone color and

monochrome pages.

The ColorPASS, as an integral part of a color printing system, enables users to:

• Send images over AppleTalk, TCP/IP, and Novell networks to print on ColorPASS supported devices.

• Spool print jobs and select a printing priority for each job. Users can control spooled

print jobs sent to the ColorPASS with remote user software running on networked PC

and Mac OS computers.

• Print files in color, grayscale, and black and white.

• Use the copier as a high-resolution color scanner with Fiery Scan software.

• Use 136 resident PostScript fonts (126 Adobe Type 1 PostScript, and 10 TrueType),

plus two Adobe Multiple Master fonts used for font substitution when printing PDF

files. Fiery Downloader or any third-party LaserWriter downloader, such as the Adobe

Font Downloader, can be used to download additional fonts.

• Use built-in ColorWise™ color management and NetWise™ network features.

ColorPASS

Networked computers

Copier

or workstations

F01-100-01 ColorPASS printing system

COPYRIGHT© 2000 CANON INC. 2000 2000 2000 ColorPASS-Z40e/Z20e REV.0 A UG. 2000

1-1

CHAPTER 1 INTRODUCTION

2 Outline of Operation

2.1 Outline

The ColorPASS enables the customer to use a color copier as a printer and scanner. Users

can print to the ColorPASS from networked PCs running Microsoft Windows, from networked Mac OS computers, and from networked UNIX workstations running TCP/IP.

2.2 Operation

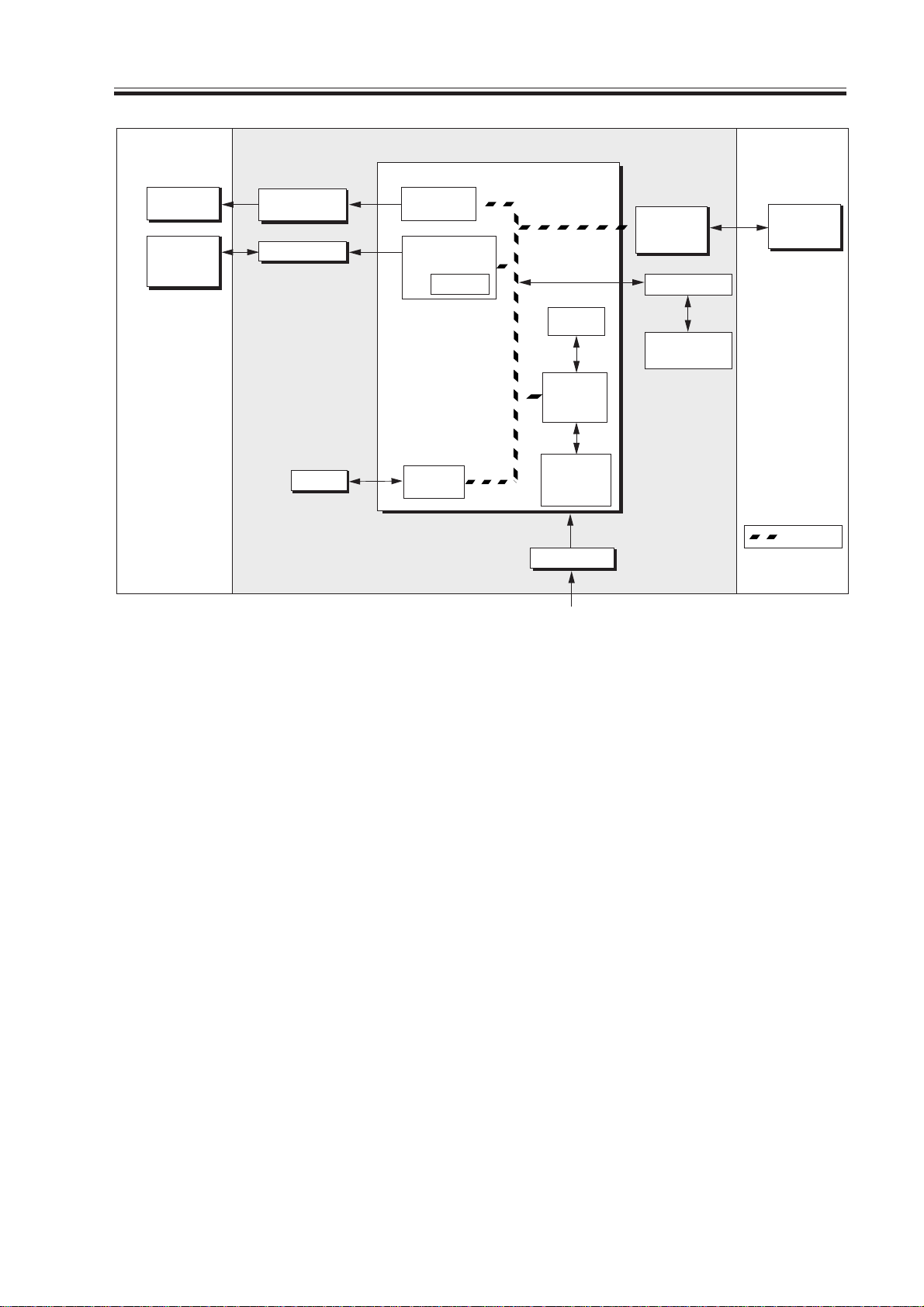

The ColorPASS custom-designed boards and system software are responsible for efficient

image processing and printing controls. The main functions of ColorPASS components and

software are described below.

The ColorPASS uses specialized circuit boards, the motherboard and the video board, to

process image data for printing and scanning images.

The motherboard includes a 433MHz CPU chip which controls the image data transfer to

and from the video board and runs the interpreter. The interpreter rasterizes the page description file and then compresses the image pattern into memory using compression technology.

The interpreter outputs compressed raster data through the image frame buffer memory to

the ColorPASS video board. The video board decompresses the image data and sends it to

the copier through the copier interface cable. The raster data supplied to the laser in the

copier charges the drum and renders the final image on paper at full copier engine speed.

High-speed DIMMs (dual in-line memory modules) on the motherboard hold the image

data during printing. The ColorPASS is configured with 128MB of memory.

When Fiery Scan™ uses the copier as a scanner, the ColorPASS acquires RGB (red,

green, and blue) image data from the copier, stores it in memory, and transmits it to the

computer that requested the scan.

1-2

COPYRIGHT© 2000 CANON INC. 2000 2000 2000 ColorPASS-Z40e/Z20e REV.0 A UG. 2000

CHAPTER 1 INTRODUCTION

Networked

computers

Network

interface

Ethernet

board

SCSI board

HDD

External Devices

SCSI

CD-ROM

drive

ColorPASS

Motherboard

I/O Control

BIOS

CPU

PCI/

Memory

Controller

IDE

interface

Memory

and

interpreter

Power supply

AC power

+3.3/+5/±12V DC

Video

board

UIB board

Operation

panel board

Copier

Copier

PCI Bus

F01-202-01 ColorPASS functional diagram

2.3 Print Options

The ColorPASS’s efficient capabilities allow users to use a variety of applications to cre-

ate and print pages of text and/or images.

Printing over a network allows ColorPASS users to print documents directly from applications in which they were created. In addition, the ColorPASS offers an efficient way to

print files that have been saved in PostScript, EPS (Encapsulated PostScript), or PDF (Portable Document Format). These files can be downloaded directly to the ColorPASS using

Fiery Downloader ™, one of the remote utilities for use with the ColorPASS.

COPYRIGHT© 2000 CANON INC. 2000 2000 2000 ColorPASS-Z40e/Z20e REV.0 A UG. 2000

1-3

CHAPTER 1 INTRODUCTION

3 User Software

The full set of ColorPASS user software is provided on the User Software CD.

Adobe PS Printer Driver

PostScript Printer

Description files (PPDs)

PostScript Screen Fonts

(Mac OS only)

Fiery Downloader

Fiery Spooler

(Mac OS only)

ColorWise Pro Tools

Fiery Scan

Fiery Link

Command WorkStation

software

Color management files

Color reference files

Fiery WebTools

Enables users to print to the ColorPASS from Windows 95/98, Windows

NT 4.0, and Mac OS computers; also supports special ColorPASS and

PostScript 3 features.Windows 2000 users should use the Microsoft

PostScript Printer Driver provided with Windows 2000.

For use with the PostScript printer driver that allows the ColorPASS to

appear in popular applications’ Print and Page Setup dialog boxes. The

ColorPASS PPDs provide information about the ColorPASS and the

user’s particular copier model to the application and printer driver being

used.

PostScript screen and printer screen fonts for the 136 PostScript printer

fonts installed on the ColorPASS (126 Adobe Type 1 and 10 TrueType).

See the Printing Guide for a complete list of PostScript fonts installed on

the ColorPASS.

Enables users to print PostScript files, Encapsulated PostScript (EPS)

files, and Portable Document Format (PDF) files directly to the

ColorPASS without opening the application in which they were created.

Fiery Downloader also enables users to manage the printer fonts installed

on the ColorPASS.

Enables users to view the order and priority of print jobs, customize

printer settings for jobs, delete jobs, and move jobs between queues. It

can also be used to view job accounting information.

ICC-open color management and calibration tools; enables users to edit

and download ICC profiles.

Plug-in modules for Photoshop that enable users to scan images from the

copier directly into applications.

Enables users to monitor the status of the connected ColorPASS and the

print jobs sent to it.

Enables the operator to control the ColorPASS functions from Windows

95/98, Windows NT 4.0 workstations, Windows 2000.

To use the Command WorkStation, see the Job Management Guide.

ColorSync and ICM color management files that enable users to maintain

consistent color from the original artwork to the colors displayed on the

monitor to the printed output.

Reference pages that users can print to view the range of colors available

on the ColorPASS. For the most predictable color results, refer to these

pages when defining colors in applications. For more information on

color management, see the Color Guide.

The ColorPASS can support Internet or intranet access with Fiery

WebTools. WebTools include Status, WebSpooler, WebLink, Installer, and

WebSetup. For more information about WebTools, see the user documentation.

1-4

COPYRIGHT© 2000 CANON INC. 2000 2000 2000 ColorPASS-Z40e/Z20e REV.0 A UG. 2000

CHAPTER 2

PREPARING FOR INSTALLATION

COPYRIGHT© 2000 CANON INC. 2000 2000 2000 ColorPASS-Z40e/Z20e REV.0 A UG. 2000

CHAPTER 2 PREPARING FOR INSTALLATION

1 Outline

This chapter includes the following information:

• Summary of the installation sequence

• Checking the customer site

• Unpacking the ColorPASS

• ColorPASS top and back panels overview

Familiarize yourself with Chapters 2 and 3 of this guide before you attempt an installation. The installation sequence described in this chapter is designed to make your job as

easy as possible. Installation problems are easier to avoid and diagnose if you proceed from

the component to the system level and verify functionality at each stage.

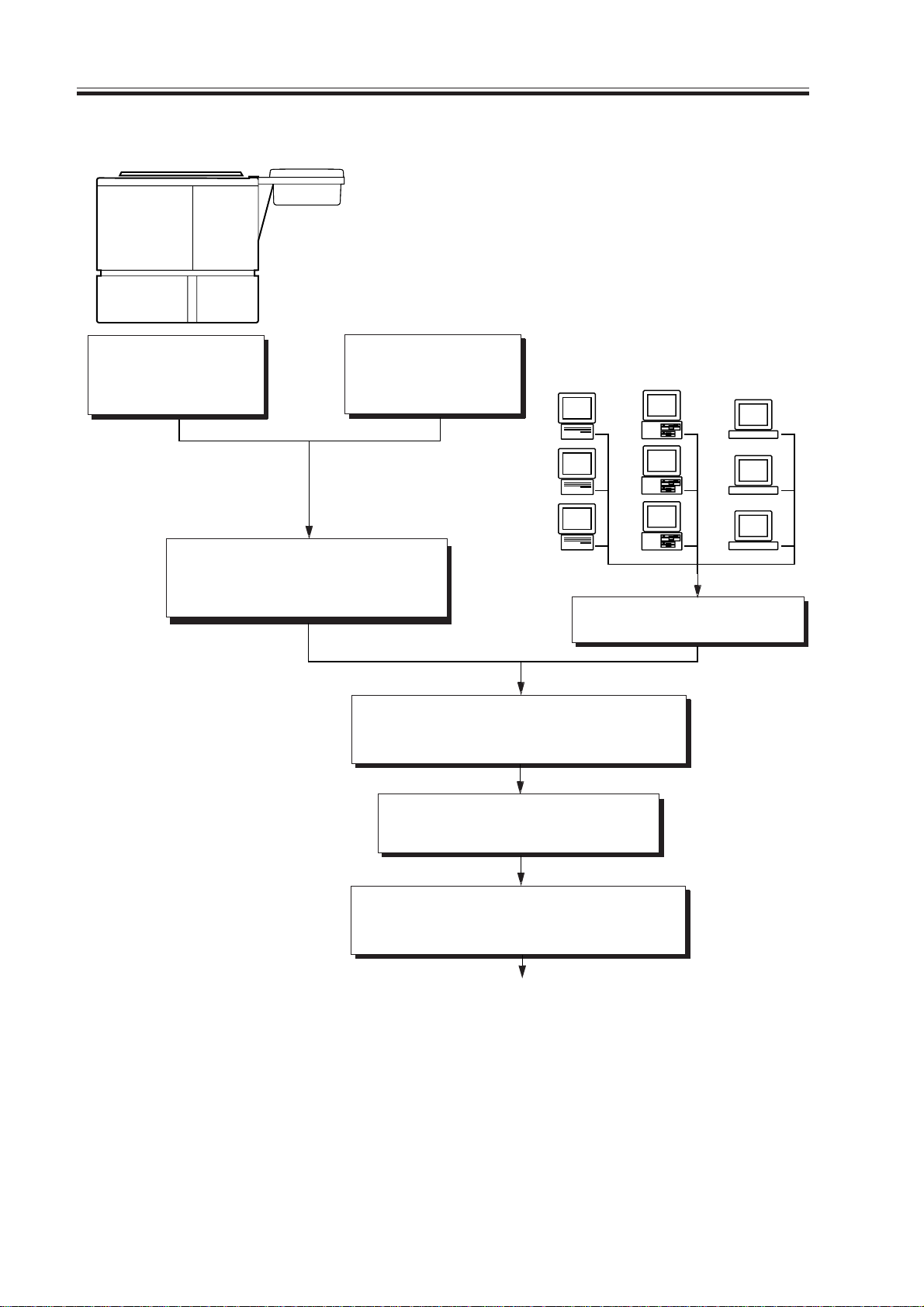

F02-100-01 on page 2-2 outlines the recommended installation procedure for connecting

the ColorPASS to the copier.

Because the ColorPASS is a node on the customer’s computer network, make sure that

you coordinate your scheduled installation with the network administrator at the customer

site. Refer the network administrator to the Configuration Guide for network setup information.

COPYRIGHT© 2000 CANON INC. 2000 2000 2000 ColorPASS-Z40e/Z20e REV.0 A UG. 2000

2-1

CHAPTER 2 PREPARING FOR INSTALLATION

Copier

ColorPASS

Check installation

requirements and verify

site conditions; page 2-3

Connect copier interface cable; page 3-3

Print a ColorPASS Test Page; page 3-4

Perform Test Scan/print; page 3-5

Unpack the ColorPASS,

page 2-6

Initial startup; page 3-1

Network administrator connects the ColorPASS

to the network and verifies the connection;

see page 3-8 and the Configuration Guide

Mac OS

computers

Verify network operation without

computers

the ColorPASS connected.

PC

UNIX

workstations

2-2

Network administrator configures Setup

options; see the Configuration Guide

Network administrator installs ColorPASS

user software on networked computers that

print to the ColorPASS; see Getting Started

Full ColorPASS functionality

F02-100-01 Recommended installation steps and references

COPYRIGHT© 2000 CANON INC. 2000 2000 2000 ColorPASS-Z40e/Z20e REV.0 A UG. 2000

CHAPTER 2 PREPARING FOR INSTALLATION

2 Checking the Customer Site

Before you install the ColorPASS, check site conditions and inform the customer of any

installation requirements.

2.1 Copier Model

■ What copier model is installed?

■ Is there space near the copier for the ColorPASS?

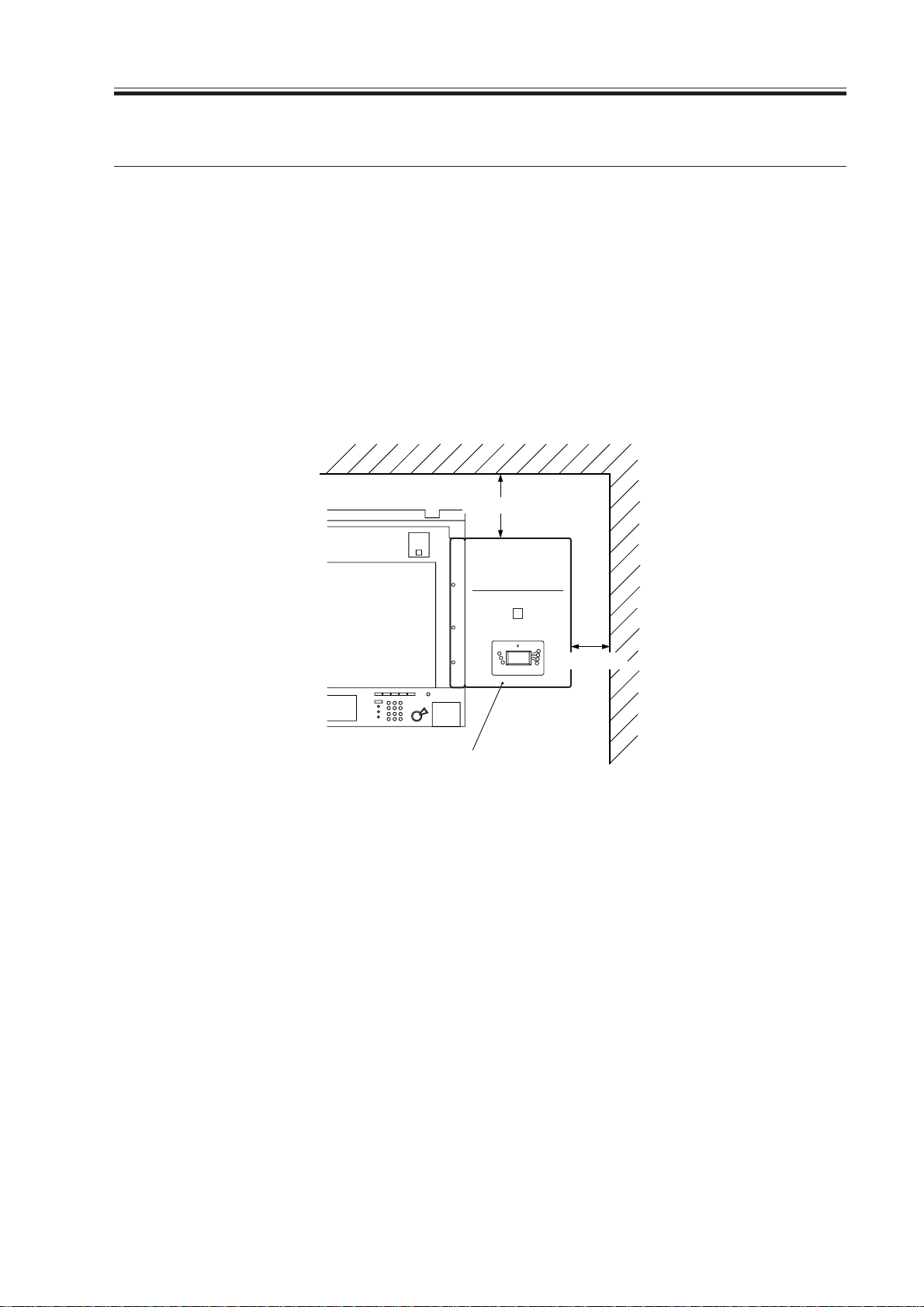

Allow at least 20cm of space at the back panel of the ColorPASS and at least 10cm of

space at the side panel of the ColorPASS (see the following illustration.) You may need

to move the copier out from the wall for easier access to the connectors.

20cm min

10cm min

ColorPASS

F02-201-01

■ Does the copier require service or adjustments?

Copy the copier color test page before you install the ColorPASS.

If the copied image indicates that the copier needs adjustment, inform the customer.

After getting approval, complete the copier service needed.

a. CLC1100 series

■ Has the correct board (IP-ED BOARD-B1 or INTERFACE BOARD-D1) been installed

in the copier?

Contact your authorized representative for more information.

■ Is the service mode COPIER>OPTION>INT-FACE>REMOTE set to 2?

COPYRIGHT© 2000 CANON INC. 2000 2000 2000 ColorPASS-Z40e/Z20e REV.0 A UG. 2000

2-3

CHAPTER 2 PREPARING FOR INSTALLATION

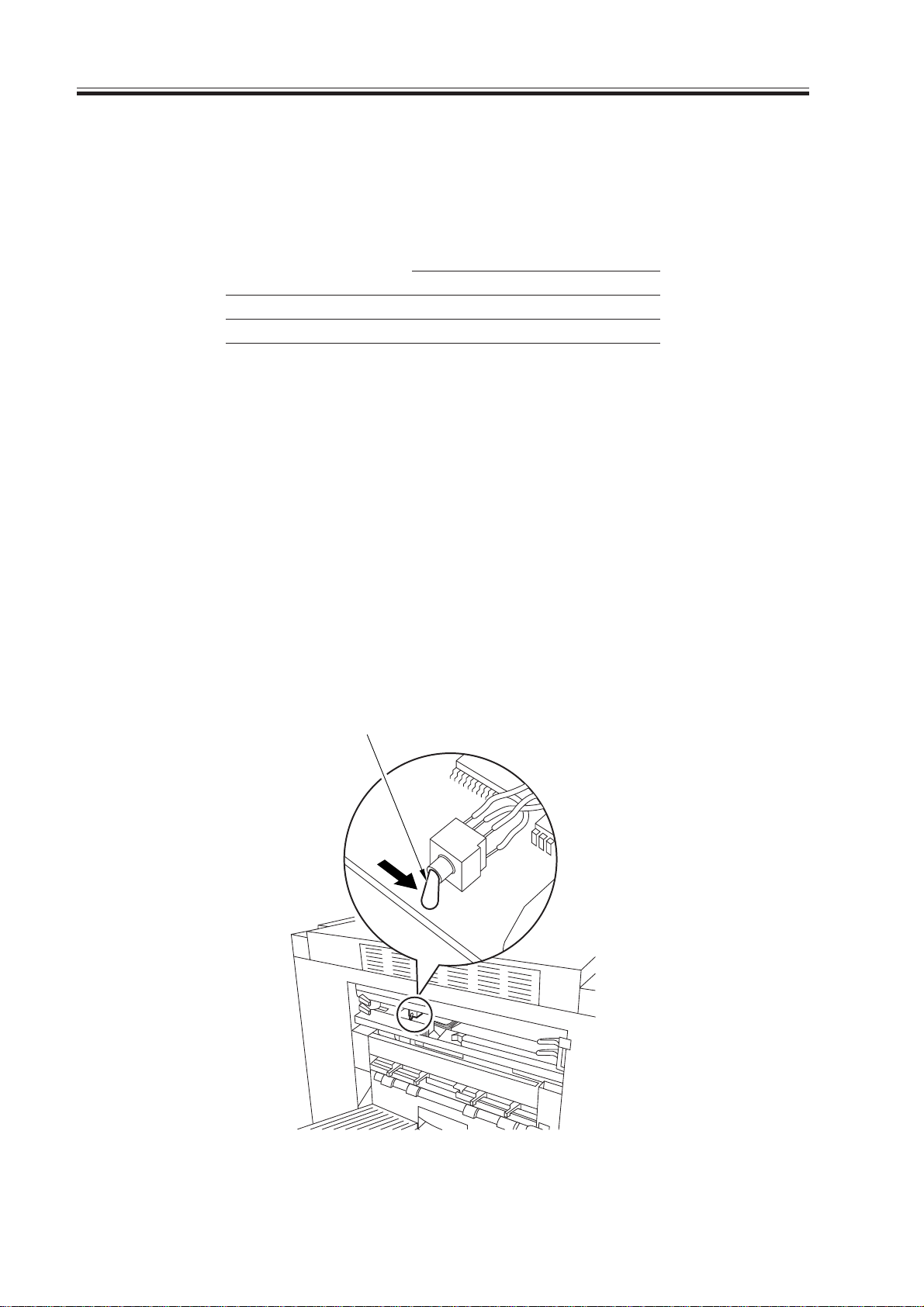

b. CLC700/800/900

1) If a toggle switch is found on the image processor ED PCB of the CLC700/800/900 Series, set the switch to the left. If no toggle switch is found, you may skip the setting.

2) Set the following in user mode I/F switching.

Copier User mode setting

I/F switching

CLC700/800 Before step 2 A

CLC700/800/900 After step 3 C

T02-201-01

3) Select settings for service mode. (For details, see the copier’ Service Manual.)

a. ADJUST PASCAL-MD

Specify whether the gradation should be smoothed for output form the ColorPASS:

0: Do not change

1: Do not use

2: Smooth gradation. (However, copying speed will be lower by 0.5 sec.)

b. OPTION REMOTE

Set it to suit the preference of the user.

c. OPTION IPU-TYPE

Set it to ‘00’.

d. OPTION FIL-TYPE

Set it to ‘01’.

Toggle switch

F02-201-02

2-4

COPYRIGHT© 2000 CANON INC. 2000 2000 2000 ColorPASS-Z40e/Z20e REV.0 A UG. 2000

CHAPTER 2 PREPARING FOR INSTALLATION

2.2 Power

■ Is there a dedicated grounded electrical outlet near the copier for the ColorPASS?

Locate the grounded electrical outlet that will supply power to the ColorPASS. You

should not run the ColorPASS and the copier on the same circuit. Use a surge suppressor for the ColorPASS.

• Do not use a 3-prong adapter in a 2-hole ungrounded outlet.

• Do not use an extension cord.

• Do not plug the ColorPASS into a circuit with heating or refrigeration equipment (including water coolers).

• Do not plug the ColorPASS into a switchable wall outlet. This can result in the

ColorPASS being turned off accidentally.

2.3 Network

■ What is the network cable and connection type?

■ Is the network connection ready and tested for ColorPASS installation?

To verify that the network is functioning before you attach the ColorPASS:

• Ask the network administrator to print a document on a shared printer over the network.

• Ask the network administrator to verify the computer and network requirements as

specified in Getting Started.

2.4 System Contact Person

■ Will the person responsible for the computers and the network be available at the time

set for installation? Get a name as a contact.

2.5 Setting Customer Expectations

If the site is ready, installation takes about one hour. The customer should be informed of

the following:

• Some nodes on the network may be unavailable for up to one hour.

• The copier may be unavailable for up to one hour.

• The network administrator needs to be available during the installation for network

connectivity.

Equipment downtime and impact on the network can be minimized if the network administrator installs a network connector for the ColorPASS and confirms network

functionality with the connector in place before the date scheduled for the ColorPASS

installation.

• The network administrator should have a networked computer available during the

installation. The appropriate software should already be installed. Documentation for

the networked computer and the network operating software should be available.

• The network administrator should install the user software shipped with the

ColorPASS (user documentation is also included) onto networked PC and Mac OS

computers that will print to the ColorPASS.

COPYRIGHT© 2000 CANON INC. 2000 2000 2000 ColorPASS-Z40e/Z20e REV.0 A UG. 2000

2-5

CHAPTER 2 PREPARING FOR INSTALLATION

This guide covers ColorPASS hardware installation and service. It provides

general information on connecting the ColorPASS to the customer’s net-

Memo

work. Network setup and configuration information goes beyond the scope

of this guide. For network setup and configuration information, the network

administrator should use the Configuration Guide.

2-6

COPYRIGHT© 2000 CANON INC. 2000 2000 2000 ColorPASS-Z40e/Z20e REV.0 A UG. 2000

CHAPTER 2 PREPARING FOR INSTALLATION

3 Unpacking the ColorPASS

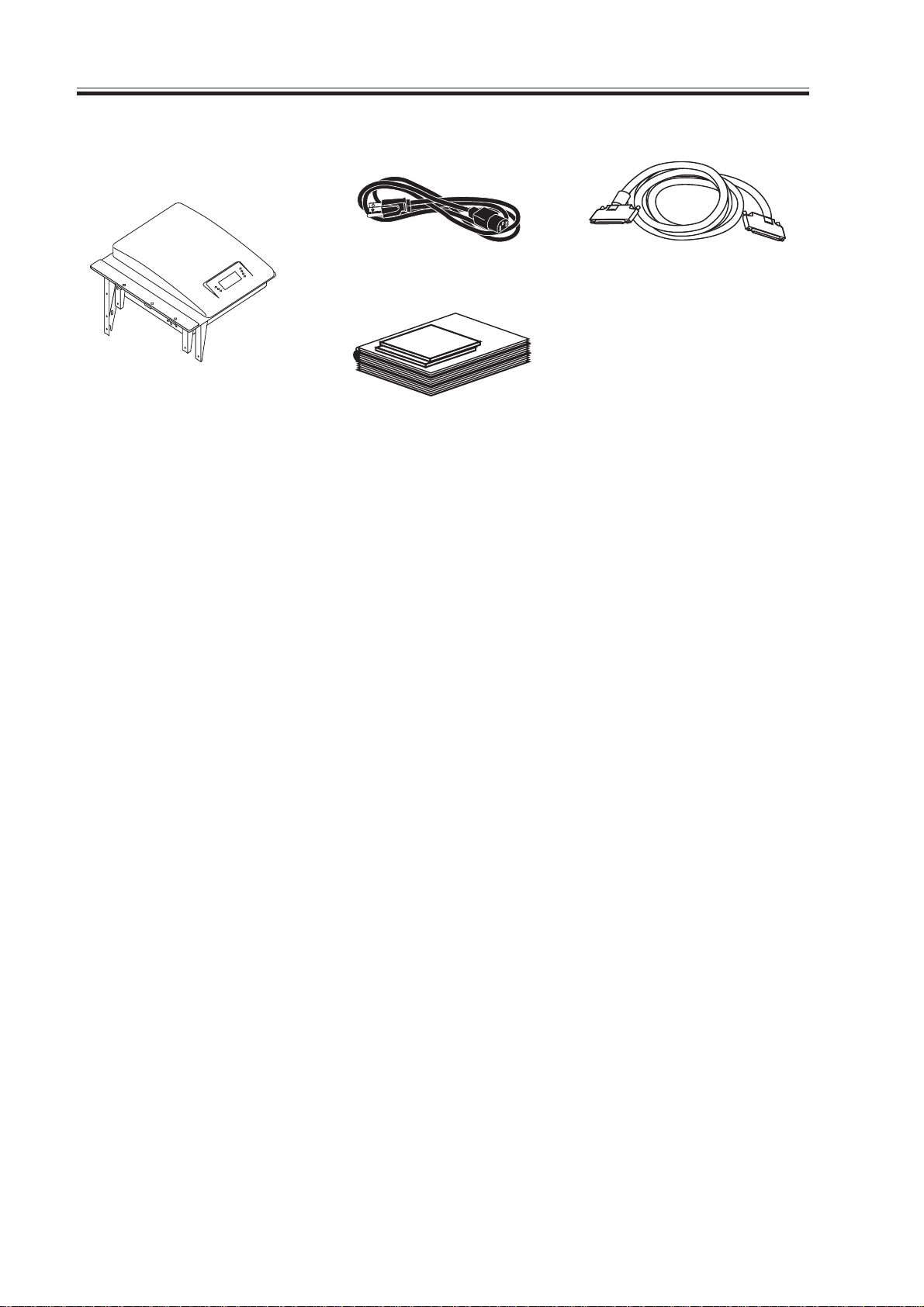

The ColorPASS is assembled and shipped from the factory in a box that includes all nec-

essary cables and documentation, as shown in F02-301-01 on page 2-7.

3.1 To Unpack the ColorPASS

1. Open the ColorPASS Color Server box and remove the packing material.

Save the original boxes and packing materials. If you need to transport the ColorPASS

at a later date, the original box and packing material will ensure safe shipment.

2. Remove the contents from the top container. Inspect the contents for visible damage.

The top container should include the following items:

• Bags containing a copier interface cable and an AC power cable.

• Media package (includes a package of user documentation and software).

3. Give the media package to the customer or the network administrator.

Let the customer or network administrator know that in order to take full advantage of

the ColorPASS, the user software must be installed on computers that will print to the

ColorPASS.

4. Set aside the remaining components from the top container.

5. Remove the top container and any packing materials.

Set aside the packing material and note the orientation of the ColorPASS inside the shipping container in case you need to repack it later.

6. Carefully lift the ColorPASS out of the box.

COPYRIGHT© 2000 CANON INC. 2000 2000 2000 ColorPASS-Z40e/Z20e REV.0 A UG. 2000

2-7

CHAPTER 2 PREPARING FOR INSTALLATION

ColorPASS power cable Copier interface cable

ColorPASS

Media Package

F02-301-01 Contents of ColorPASS shipping box

2-8

COPYRIGHT© 2000 CANON INC. 2000 2000 2000 ColorPASS-Z40e/Z20e REV.0 A UG. 2000

CHAPTER 2 PREPARING FOR INSTALLATION

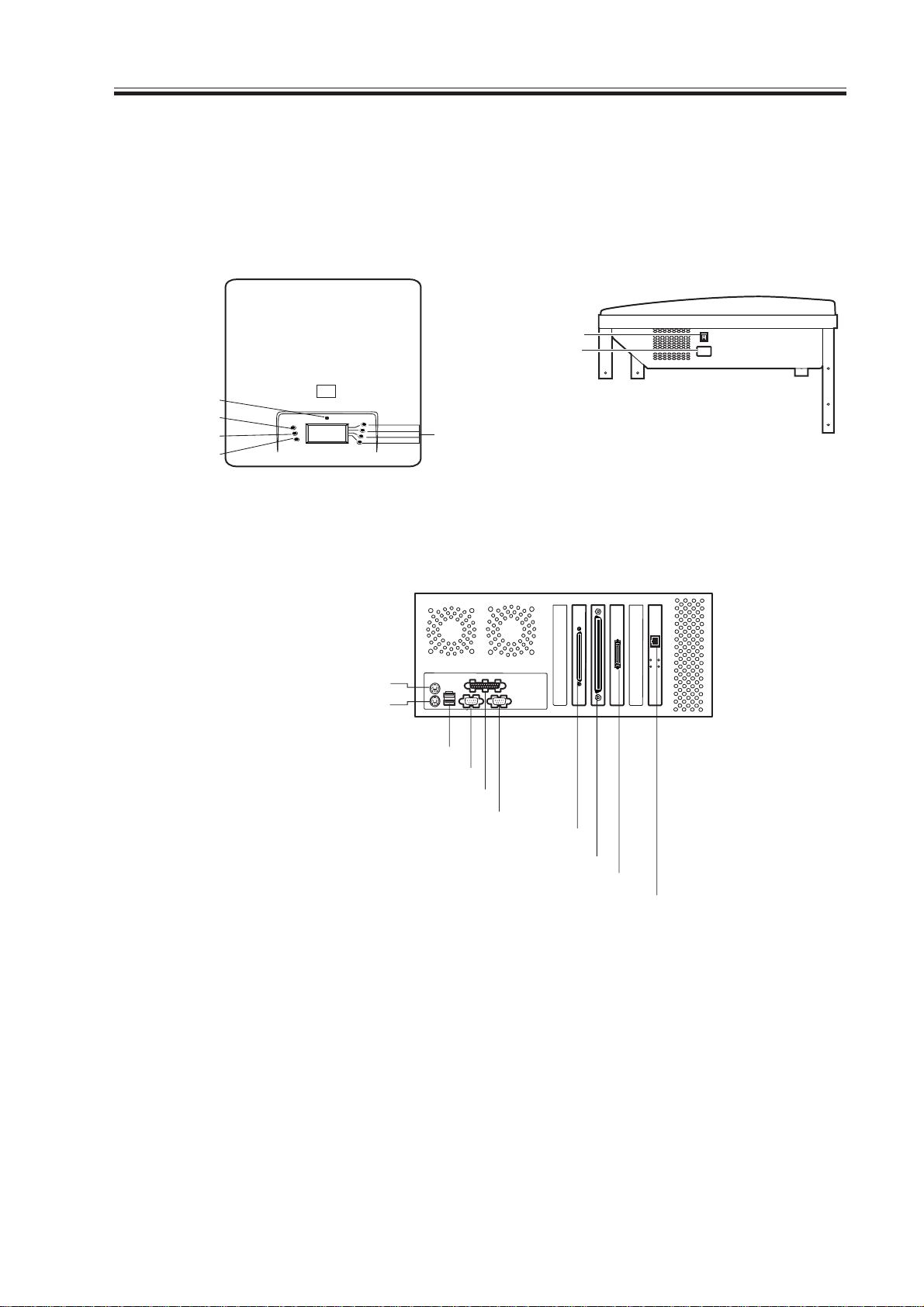

3.2 ColorPASS Panels

Once you have unpacked the ColorPASS, you can familiarize yourself with the top and

back of the ColorPASS before you install it.

Top panel

Side panel

Power switch

Power connector

Activity light

Up button

Menu button

Down button

Line selection

buttons

Mouse connector(not used)

Keyboard connector(not used)

USB connectors(not used)

Serial connector(not used)

Parallel connector(not used)

Serial connector(not used)

F02-302-01 Front and back panels

Back panel

SCSI connector(CD-ROM)

Copier interface connector

Parallel connector(not used)

Ethernet RJ-45 connector

COPYRIGHT© 2000 CANON INC. 2000 2000 2000 ColorPASS-Z40e/Z20e REV.0 A UG. 2000

2-9

CHAPTER 2 PREPARING FOR INSTALLATION

4 Installing the ColorPASS on the copier

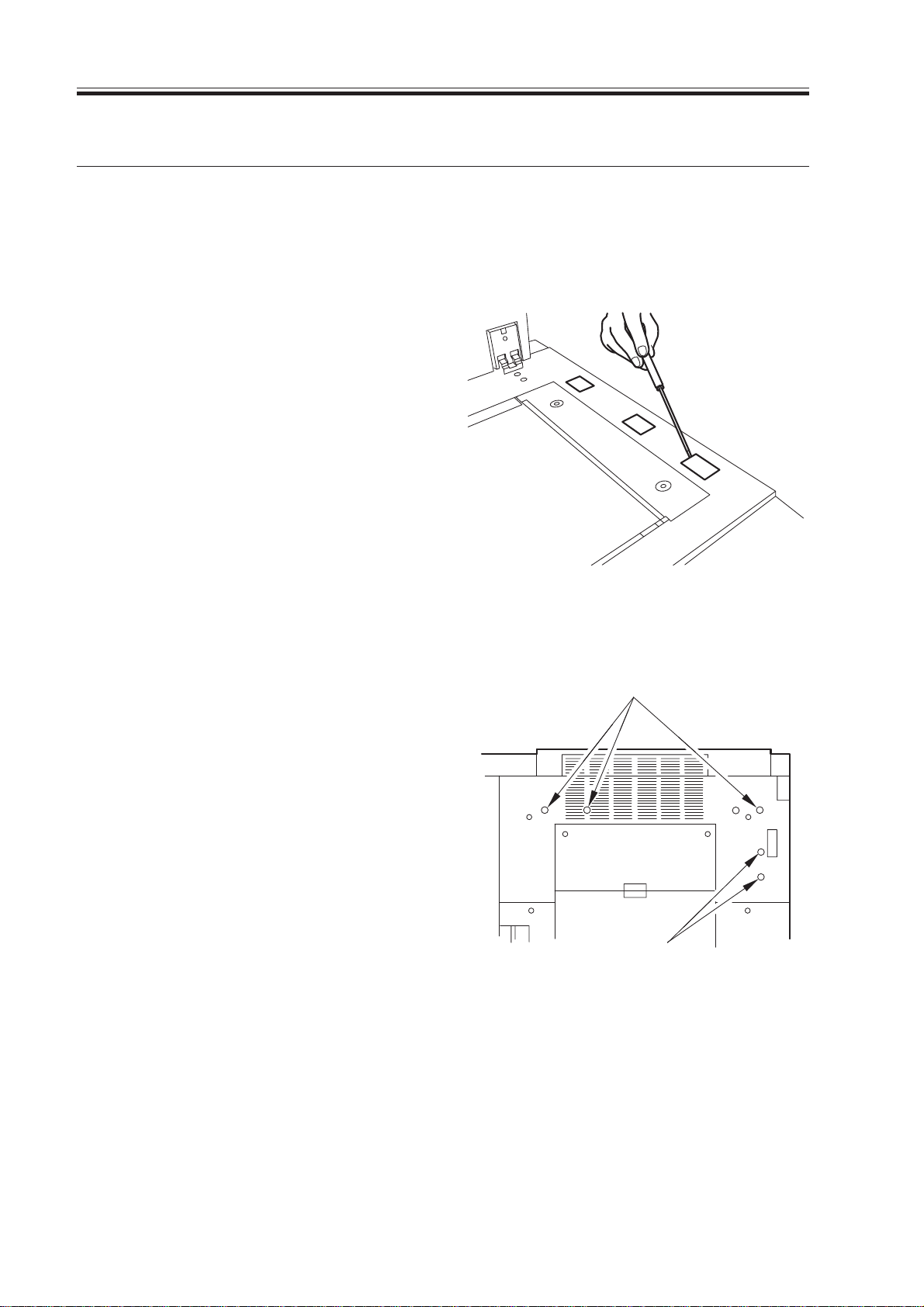

1) Remove the three face plates from the

edge of the main copier unit as shown

in F02-400-01 (CLC1100 series).

The CLC900 series copier remove only

two face plates.

2) Detach the five stickers shown in F02400-02.

F02-400-01

Removing face plates from copier

F02-400-02 Sticker locations

2-10

COPYRIGHT© 2000 CANON INC. 2000 2000 2000 ColorPASS-Z40e/Z20e REV.0 A UG. 2000

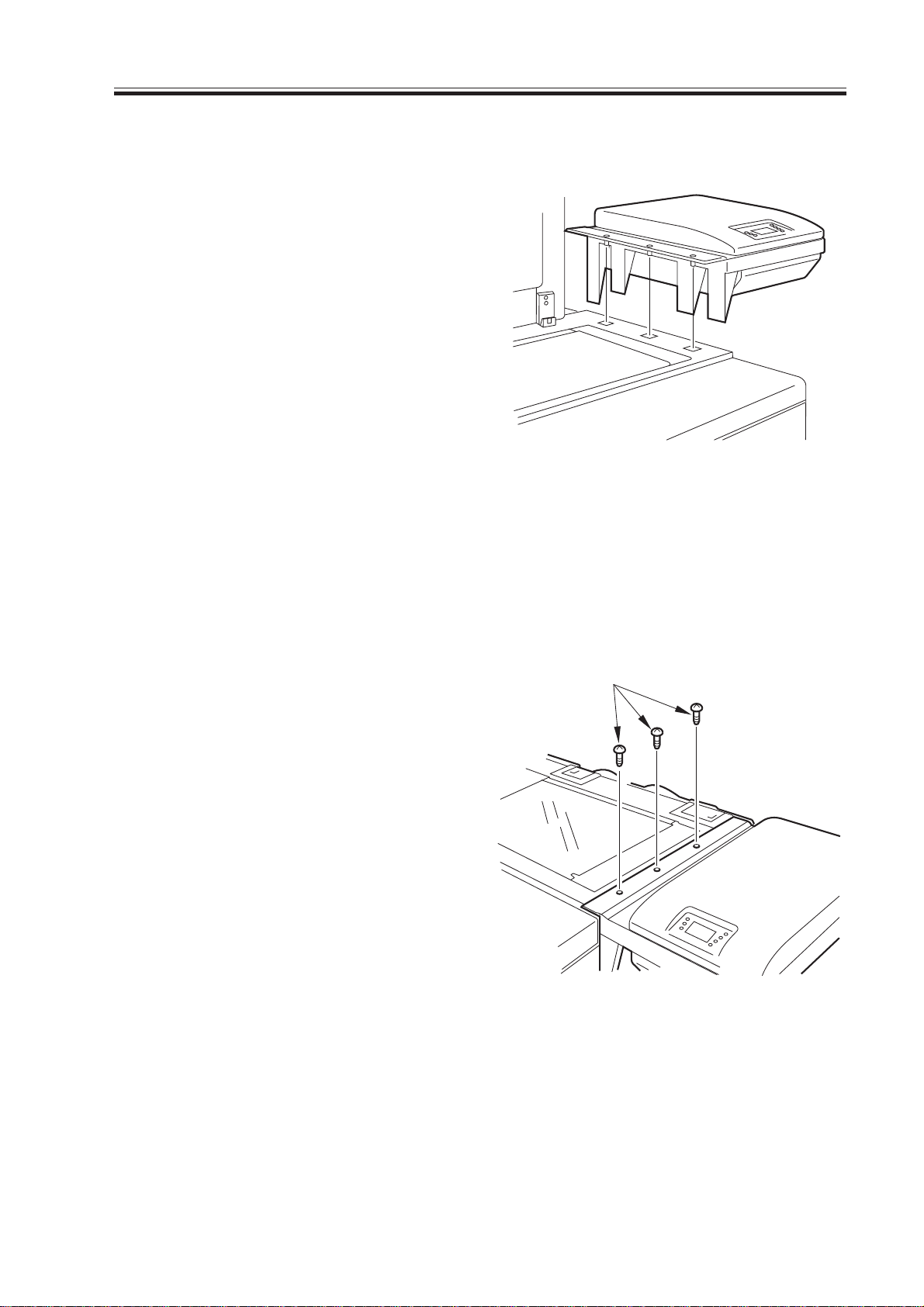

3) Insert the ColorPASS bosses into the

holes on the copier top edge as shown

in F02-400-03.

4) Mount the ColorPASS to the copier

with three screws (M4×6) (CLC1100

series).

Attach the face plates (round) to the

ColorPASS after fixing the unit in

place.

The CLC900 series copier requires only

two screws for ColorPASS installation.

CHAPTER 2 PREPARING FOR INSTALLATION

F02-400-03 Inserting ColorPASS bosses

F02-400-04

Installing ColorPASS mounting screws

COPYRIGHT© 2000 CANON INC. 2000 2000 2000 ColorPASS-Z40e/Z20e REV.0 A UG. 2000

2-11

CHAPTER 2 PREPARING FOR INSTALLATION

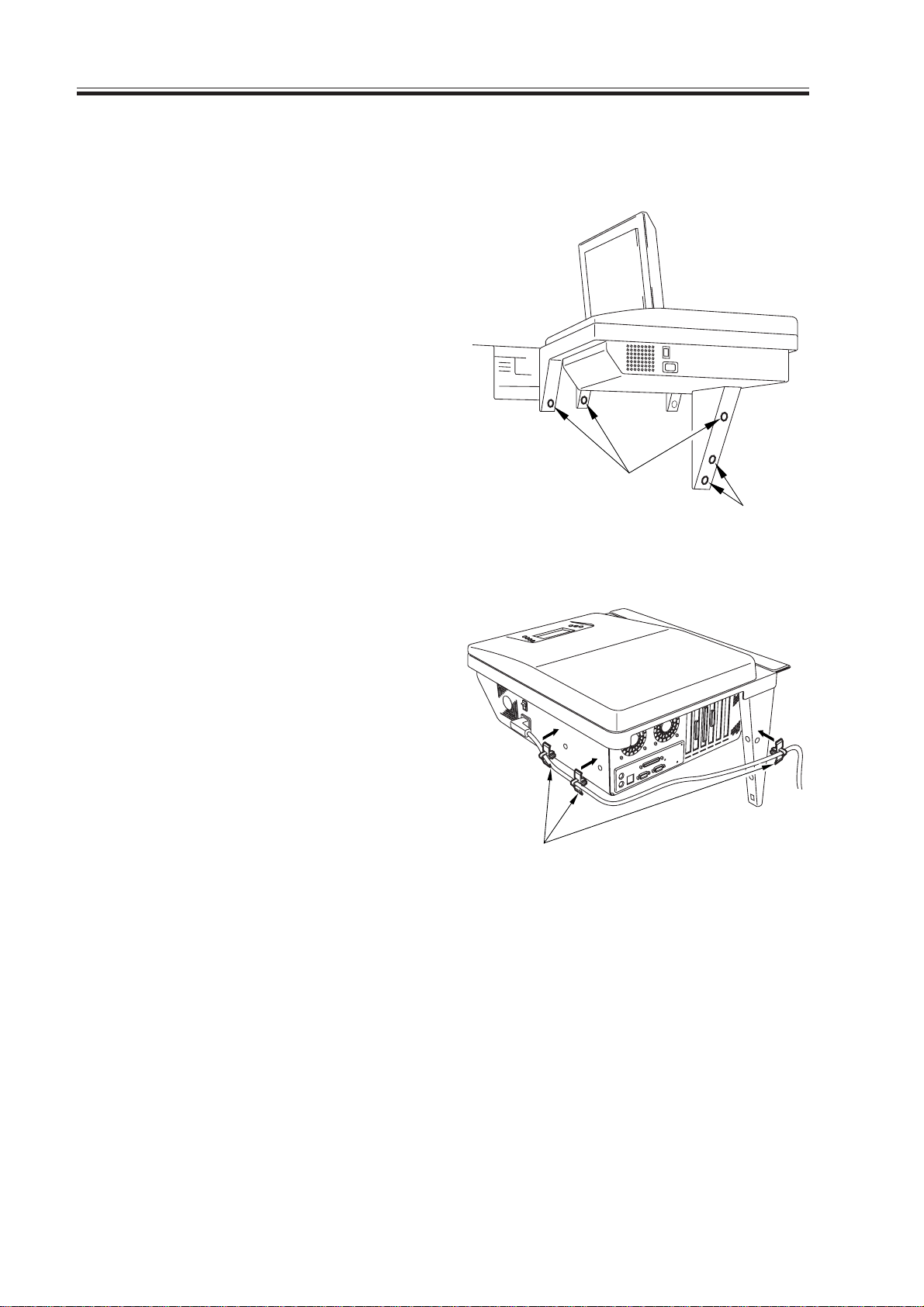

5) Insert five screws into the holes on the

supports of the ColorPASS as shown in

the following illustration. Tighten the

screws.

Upper side three places TP screws

(M4×10).

Lower side two places RS tightening

screws (M4×33).

F02-400-05

Inserting screws into ColorPASS supports

6) Fix the power cable in place to the

ColorPASS using three cable clamps.

F02-400-06 Fix the power cable

2-12

COPYRIGHT© 2000 CANON INC. 2000 2000 2000 ColorPASS-Z40e/Z20e REV.0 A UG. 2000

Loading...

Loading...