Canon Scoopic 16M Repair manual

CANON REPAIR GUIDE

CANON SCOOPIC 16- M

(REF. NO. 3-70202)

i

I -

CANON INC. JAPAN

CONTENTS

Page

Introduction

Disassembly

1. Lens Unit .

2. External Parts .

3. Base Plate .

l

!

1

4. Drive Unit .

Replacement and Adjustment

1. Film Chamber .

2. Film Transport .

3. Selector Switch .

4. Electrical Parts .

5. EE Unit .

6. Lens Unit .

1

2 '" 5

2

3

4

5

6 '" 21

6

9

12

16

17

20

I

7. Mis cellaneous .

1

21

I

!

I

I

I

1

j

I

I

.1

j

I

J

I

!

Introduction

The Canon Scoopic 16-M is a high quality 16mm cine camera designed for

professional and advanced amateur use. It is designed to meet the current market

demands for high quality, versatility and ease of operation in a compact package.

It provides all the features of the original Scoopic 16 such as built-in zoom

lens, automatic exposure control (EE), automatic film threading, 100 ft. film

load, and "human engineering" body and grip shape. New features of the Scoopic

16-M are provision for single frame photography, macro focusing lens, and

the adoption of the true transmis sion "T" number marking system for the aperture

rather than the theoretical "F" number marking.

The camera has also been designed for easy maintanence. Most adjustments

can be made from the outside without major stripdown.

1

!

I

1

I

I

!

I

1

I

j

I

I

I

I

1

!

1

I

j

1

j

I

I

1

I

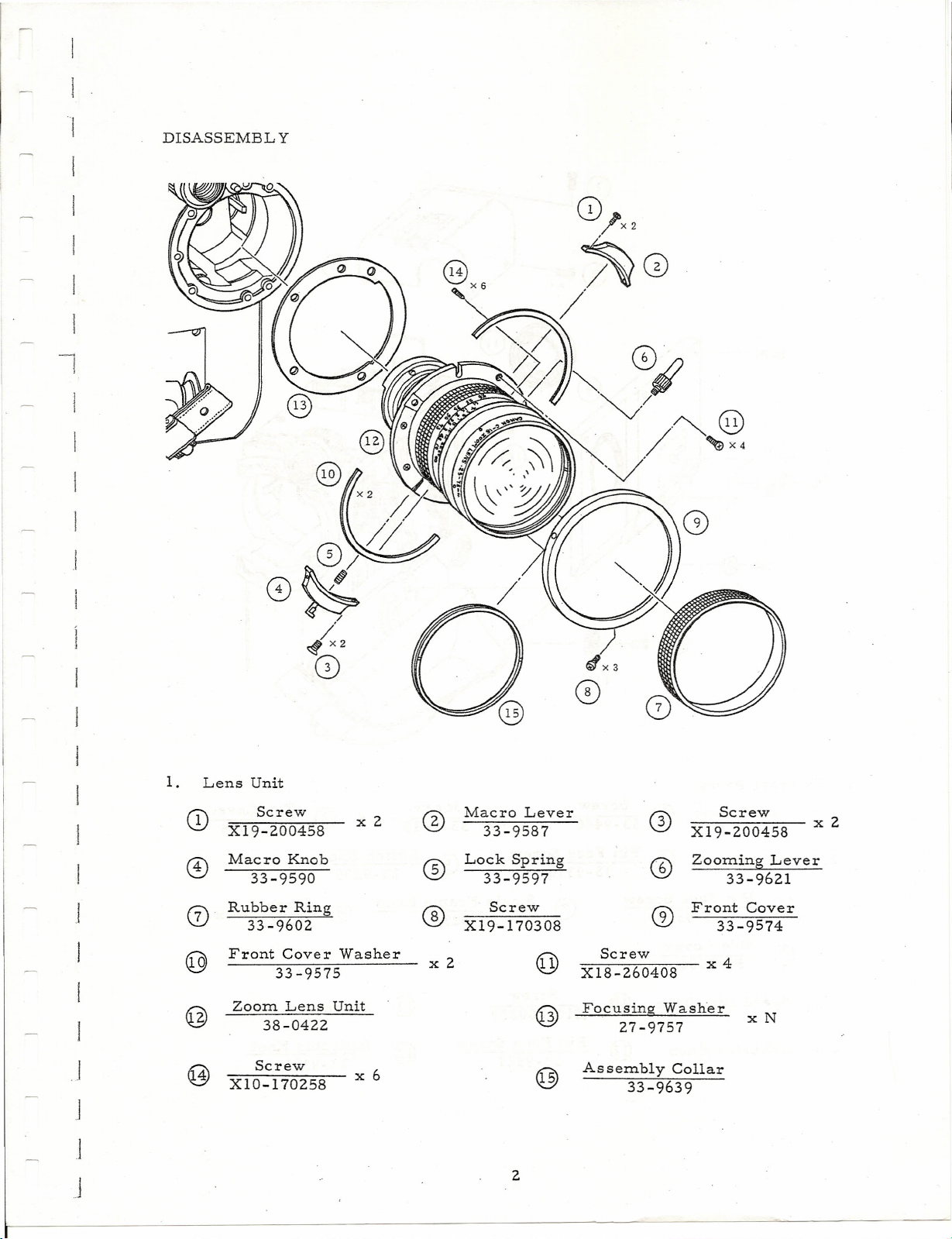

DISASSEMBL Y

I

I

I

I

//

all/

0~

1

I

I

I

l.

Lens Unit

!

CD

I

I

I

I

I

I

®

6)

@

@

Screw

X19-200458

Macro Knob

33-9590 33-9597

Rubber Ring

33-9602

Front Cover Washer

Zoom Lens Unit

38-0422

~ x z

33-9575

/

CD

x 2

Macro Lever

@

33-9587

Lock Spring

®

®

x 2

Screw

X19-l70308 33-9574

@

@

Screw

X18-260408

Focusing Washer

G)

@

@

27-9757

Screw

X19-200458

Zooming Lever

33-9621

Front Cover

x4

xN

x2

J

~

Screw

XlO-170258

x 6

@

Assembly Collar

33-9639

I

I

2

J

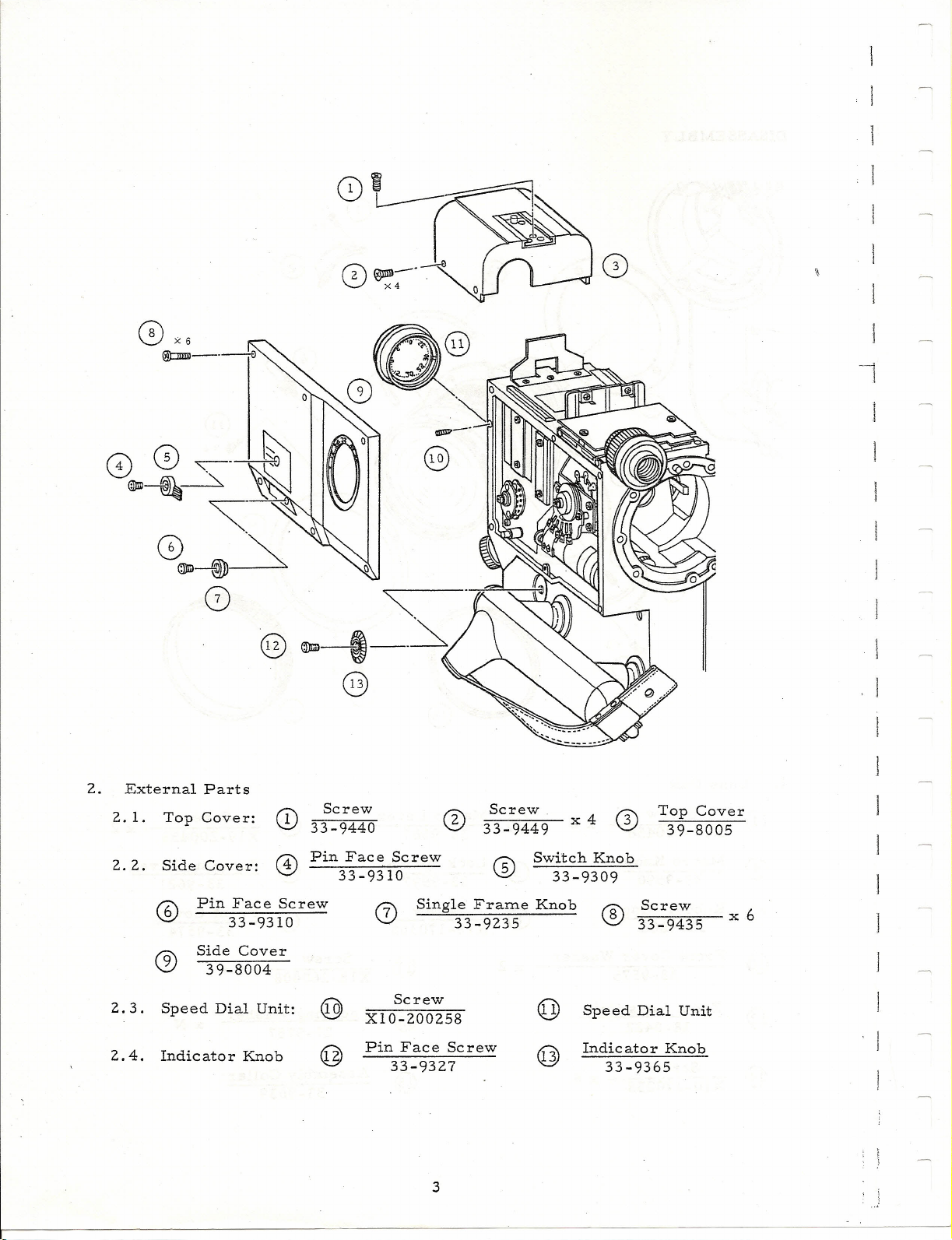

2.

External Parts

2.1.

Top Cover:

@llll-I--~

Screw

33-9440

@

"""'.

Screw

33-9449

CD

Top Cover

39-8005

x

4

2.2.

2.3. Speed Dial Unit:

2.4. Indicator Knob

Side Cover:

Pin Face Screw

33-9310

Side Cover

39-8004

Pin Face Screw

33-9310

Screw

XIO-200258

Pin Face Screw

33-9327

Switch Knob

®

5 33-9309

Single Frame Knob

33-9235

3

Screw

®

8

33-9435

Speed Dial Unit

Indicator Knob

33-9365

x6

1-

l

I

I

1

1

1

I

I

I

I

1

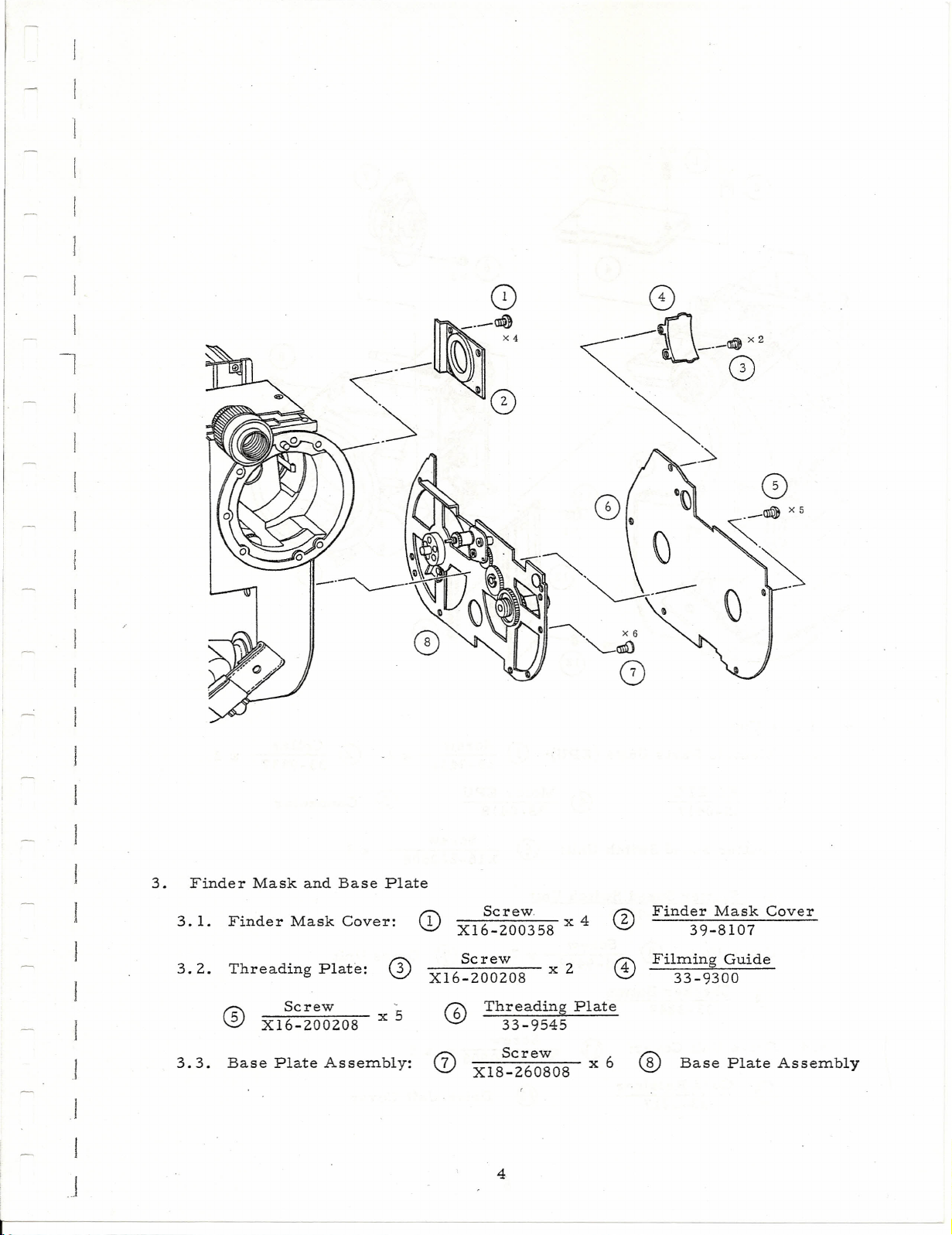

3.

Finder Mask and Base Plate

3.1.

3.2.

3.3.

Finder Mask Cover:

Threading Plate:

f?\

o

Base Plate Assern.bly:

Screw

X16-200208

Screw.

X16-200358 x 4

Screw

---,------ x

X16-200208

,

x

5

@

Threading Plate

33-9545

Screw

-~-:-:-::-::--- X

XlS-260S08

2

Finder Mask Cover

39-8107

Filrn.ing Guide

33-9300

6

®

Base Plate Assern.bly

I

4

J

(,\ x

xz0

0(5 ,

I~

Ls.! ~

2

fi

!~

f:\

0

8,

l

I

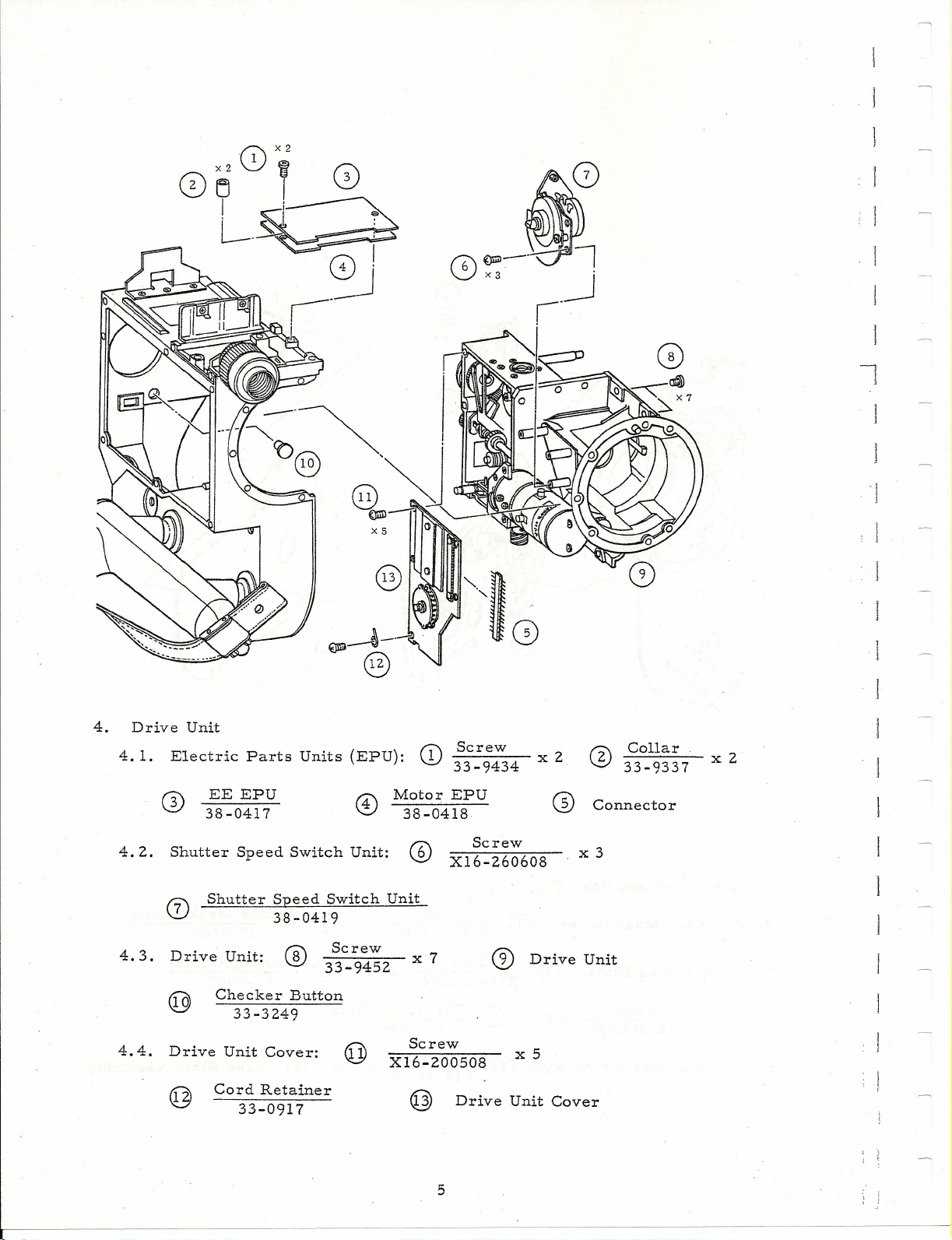

4. Drive Unit

4.1.

4.2.

4.3.

4.4.

Electric Parts Units (EPU):

Shutter Speed Switch Unit:

(j)

7 38-0419

Drive Unit:

Drive Unit Cover:

EE EPU

38-0417

Shutter Speed Switch Unit

®

Checker Button

33-3249

Cord Retainer

33-0917

f.4\

':::.J

Screw

33-9452

Motor EPU

X16-200508

G)

33-9434

38-0418

x16-z60608

x

7

Screw

Drive Unit Cover

Screw

Screw

(2)

x

®

fz\

'-.!::J

Connector

x 3

x2

Drive Unit

5

Collar

33-9337

x

2

5

I

I

I

I

I

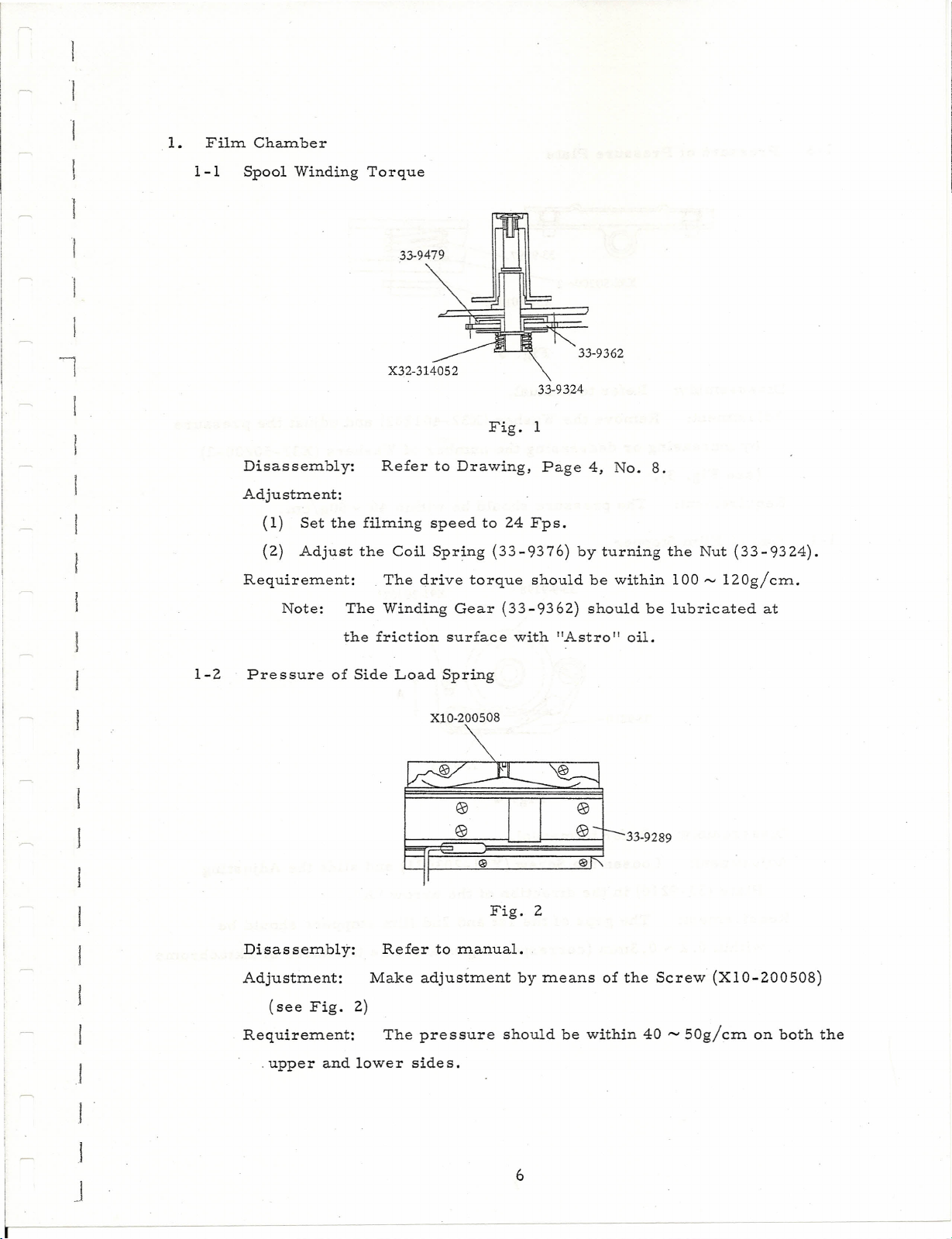

1.

Fil:m Cha:mber

1-1

Spool Winding Torque

,33-9479

I

I

33-9362

X32-314052

33-9324

Fig. 1

Disasse:mbly: Refer to Drawing, Page 4, No.8.

Adjust:ment:

(1) Set the fil:ming spe ed to 24 Fp s.

(2) Adjust the Coil Spring (33-9376) by turning the Nut (33-9324).

Require:ment: The drive torque should be within 100", 120g/c:m.

Note: The Winding Gear (33-9362) should be lubricated at

1

J

1-2

1

Pressure of Side Load Spring

the friction surface with "Astro" oil.

XI0-200508

!

I

J

1

I

I

1

I

Disasse:mbly: Refer to :manual.

Adjust:ment: Make adju strn ent by :means of the Screw (XIO-200508)

(see Fig. 2)

Require:ment: The pressure should be within 40 ~ 50g/c:m on both the

.upper and lower sides.

Fig. 2

33-9289

J

I

I

6

J

Loading...

Loading...