Portable Manual

iR2020/2016 Series

Sep 14 2005

Application

This manual has been issued by Canon Inc. for qualified persons to learn technical theory, installation, maintenance, and repair

of products. This manual covers all localities where the products are sold. For this reason, there may be information in this

manual that does not apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to improvements or changes in products. When

changes occur in applicable products or in the contents of this manual, Canon will release technical information as the need

arises. In the event of major changes in the contents of this manual over a long or short period, Canon will issue a new edition

of this manual.

The following paragraph does not apply to any countries where such provisions are inconsistent with local law.

Trademarks

The product names and company names used in this manual are the registered trademarks of the individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may not be copied, reproduced or

translated into another language, in whole or in part, without the written consent of Canon Inc.

COPYRIGHT © 2001 CANON INC.

Printed in Japan

Caution

Use of this manual should be strictly supervised to avoid disclosure of confidential information.

Symbols Used

This documentation uses the following symbols to indicate special information:

Symbol Description

Indicates an item of a non-specific nature, possibly classified as Note, Caution, or Warning.

Indicates an item requiring care to avoid electric shocks.

Indicates an item requiring care to avoid combustion (fire).

Indicates an item prohibiting disassembly to avoid electric shocks or problems.

Indicates an item requiring disconnection of the power plug from the electric outlet.

Indicates an item intended to provide notes assisting the understanding of the topic in question.

Memo

Introduction

REF.

Indicates an item of reference assisting the understanding of the topic in question.

Provides a description of a service mode.

Provides a description of the nature of an error indication.

Introduction

The following rules apply throughout this Service Manual:

1. Each chapter contains sections explaining the purpose of specific functions and the relationship between electrical and mechanical systems with reference to the timing of operation.

In the diagrams, represents the path of mechanical drive; where a signal name accompanies the symbol , the arrow indicates the

direction of the electric signal.

The expression "turn on the power" means flipping on the power switch, closing the front door, and closing the delivery unit door, which results in

supplying the machine with power.

2. In the digital circuits, '1'is used to indicate that the voltage level of a given signal is "High", while '0' is used to indicate "Low".(The voltage value, however, differs from circuit to circuit.) In addition, the asterisk (*) as in "DRMD*" indicates that the DRMD signal goes on when '0'.

In practically all cases, the internal mechanisms of a microprocessor cannot be checked in the field. Therefore, the operations of the microprocessors

used in the machines are not discussed: they are explained in terms of from sensors to the input of the DC controller PCB and from the output of the

DC controller PCB to the loads.

The descriptions in this Service Manual are subject to change without notice for product improvement or other purposes, and major changes will be communicated in the form of Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this Service Manual and all relevant Service Information bulletins and be

able to identify and isolate faults in the machine."

Contents

Contents

Chapter 1 Maintenance and Inspection

1.1 Periodically Replaced Parts ...............................................................................................................................1

1.1.1Overview .........................................................................................................................................................1

1.1.2Reader Unit.....................................................................................................................................................1

1.1.3Printer Unit ......................................................................................................................................................1

1.2 Durables and Consumables...............................................................................................................................1

1.2.1Overview .........................................................................................................................................................1

1.2.2Reader Unit.....................................................................................................................................................1

1.2.3Printer Unit ......................................................................................................................................................1

1.3 Scheduled Servicing Basic Procedure .............................................................................................................2

1.3.1Scheduled Servicing......................................................................................................................................2

Chapter 2 Standards and Adjustments

2.1 Scanning System .................................................................................................................................................3

2.1.1Procedure after Replacing the CIS .............................................................................................................3

2.2 Image Formation System ...................................................................................................................................3

2.2.1Procedure after Replacing the Developing Assembly .............................................................................3

2.3 Electrical Components ........................................................................................................................................3

2.3.1Procedure after Replacing the Image Processor PCB ...........................................................................3

Chapter 3 Error Code

3.1 Error Code Details ...............................................................................................................................................5

3.1.1Error Code Details .........................................................................................................................................5

3.2 Jam Code..............................................................................................................................................................6

3.2.1Jam Codes (Related to Printer Unit)...........................................................................................................6

3.2.2Jam Codes (Related to Finisher) ................................................................................................................7

3.2.3Jam Codes (Related to ADF).......................................................................................................................7

3.2.4Jam Codes (Related to Duplex Unit) ..........................................................................................................7

3.2.5Jam Codes (Related to Inner 2-way Tray).................................................................................................7

Chapter 4 User Mode Items

4.1 User Mode Items..................................................................................................................................................9

4.1.1Common Settings ..........................................................................................................................................9

4.1.2Copy Settings .................................................................................................................................................9

4.1.3FAX Settings.................................................................................................................................................10

4.1.4Address Book Set. .......................................................................................................................................10

4.1.5Printer Settings.............................................................................................................................................10

4.1.6Timer Settings ..............................................................................................................................................11

4.1.7Report Settings ............................................................................................................................................11

4.1.8Adjust./Cleaning ...........................................................................................................................................11

Contents

4.1.9System Settings ..........................................................................................................................................11

Chapter 5 Outline of Components

5.1 Clutch/Solenoid .................................................................................................................................................15

5.1.1List of Clutches/Solenoids ........................................................................................................................15

5.2 Motor ................................................................................................................................................................... 15

5.2.1List of Motors ...............................................................................................................................................15

5.3 Fan ......................................................................................................................................................................16

5.3.1List of Fans................................................................................................................................................... 16

5.4 Sensor................................................................................................................................................................. 17

5.4.1List of Sensors............................................................................................................................................. 17

5.5 Switch..................................................................................................................................................................19

5.5.1List of Switches............................................................................................................................................ 19

5.6 Lamps, Heaters, and Others ...........................................................................................................................19

5.6.1List of Lamps, Heaters, and Others ......................................................................................................... 19

Chapter 6 System Construction

6.1 System Construction ........................................................................................................................................ 21

6.1.1Pickup/ Delivery /Original Handling Accessories System Configuration (iR2020/iR2020J)............ 21

6.1.2Pickup/ Delivery /Original Handling Accessories System Configuration (iR2016/iR2016J)............ 22

6.1.3Reader Heater/ Cassette Heater System Configuration....................................................................... 23

6.1.4Printing/Transmitting Accessories System Configuration (iR2020J/iR2016J) .................................. 23

6.1.5Printing/Transmitting Accessories System Configuration (iR2020/iR2016) ...................................... 24

6.1.6Functions of the Printing/Transmission Functions (iR2020/iR2016)................................................... 24

6.2 Product Specifications...................................................................................................................................... 25

6.2.1Product Specifications................................................................................................................................25

6.3 Function List....................................................................................................................................................... 26

6.3.1Printing Speed (iR2020/iR2020J).............................................................................................................26

6.3.2Printing Speed (iR2016/iR2016J).............................................................................................................27

6.3.3Types of Paper ............................................................................................................................................ 28

Chapter 7 Upgrading

7.1 Upgrading........................................................................................................................................................... 31

7.1.1Overview of Upgrade.................................................................................................................................. 31

7.1.2Overview of Service Support Tool............................................................................................................ 31

Chapter 1 Maintenance and Inspection

1.1 Periodically Replaced Parts

Chapter 1

1.1.1 Overview

iR2016J / iR2016 / iR2020 / / iR2016i / iR2020i

The machine has parts that must be replaced on a periodical basis to ensure a specific level of functional performance. (The loss of the function of any of these parts

will significantly affect the machine performance, regardless of the presence/absence of external changes or damage.)

If possible, schedule the replacement so that it coincides with a scheduled service visit.

0011-0421

The timing of replacement may vary depending on the site environment or user habit.

1.1.2 Reader Unit

iR2016J / iR2016 / iR2020 / / iR2016i / iR2020i

0011-0422

The reader unit does not have parts that require periodical replacement.

1.1.3 Printer Unit

iR2016J / iR2016 / iR2020 / / iR2016i / iR2020i

0011-0423

The printer unit does not have parts that require periodical replacement.

1.2 Durables and Consumables

1.2.1 Overview

iR2016J / iR2016 / iR2020 / / iR2016i / iR2020i

The machine has parts that may require replacement once or more during the period of product warranty because of wear or damage. Replace them as needed by

referring to their indicated estimated lives.

- Checking the Timing of Replacement

Use the following service mode item to check the timing of replacement:

#COUNTER > DRBL-1

- FX-UNIT: Fixing Unit

- TR-ROLL: Transfer roller

- DV-UNIT-C: Developing unit

- M-PU-RL: Manual feed pickup roller

- M-SP-PD: Manual feed separation pad

1.2.2 Reader Unit

iR2016J / iR2016 / iR2020 / / iR2016i / iR2020i

The reader unit does not have parts that are classified as durables.

1.2.3 Printer Unit

iR2016J / iR2016 / iR2020 / / iR2016i / iR2020i

0011-0424

0011-0425

0011-0426

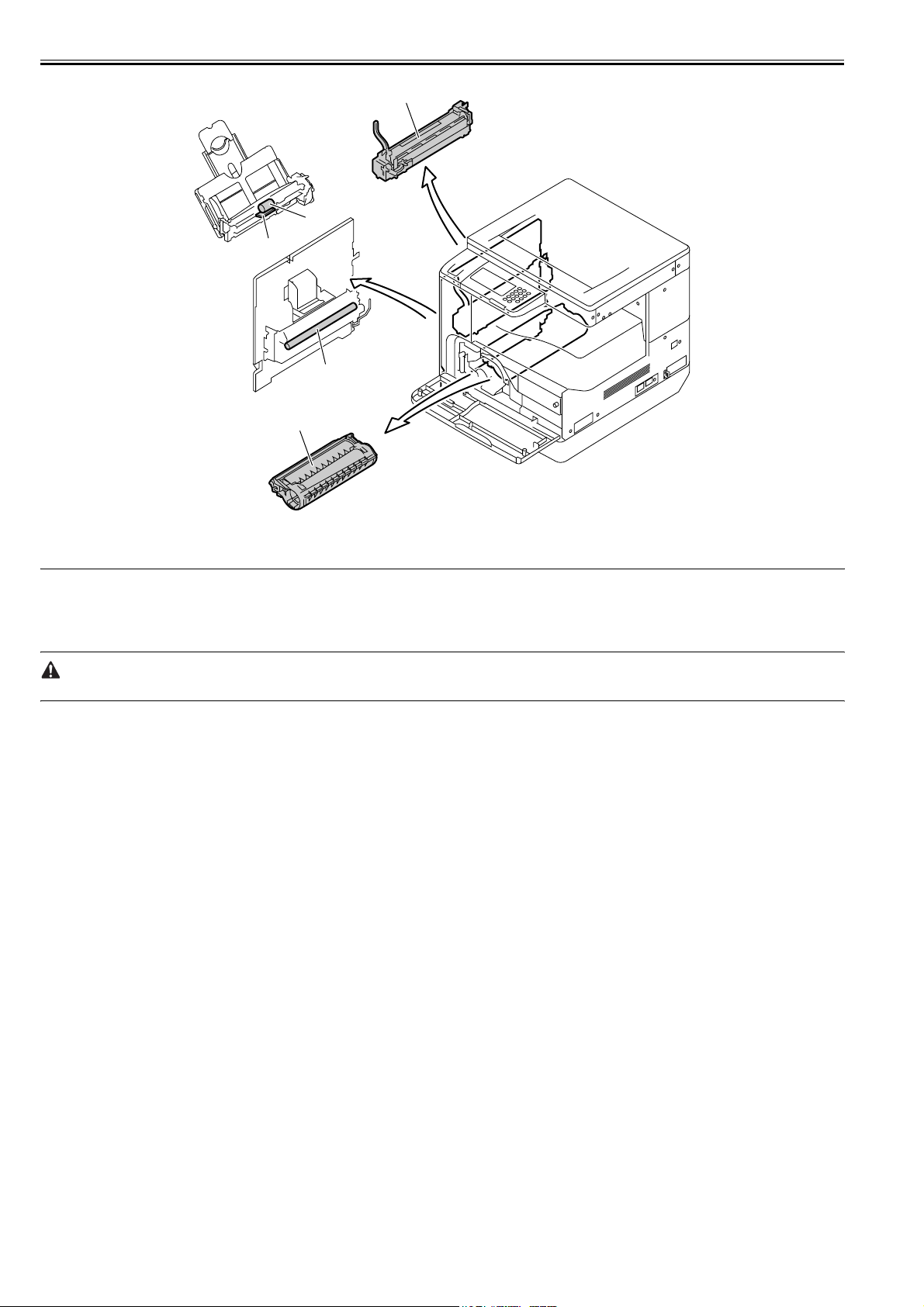

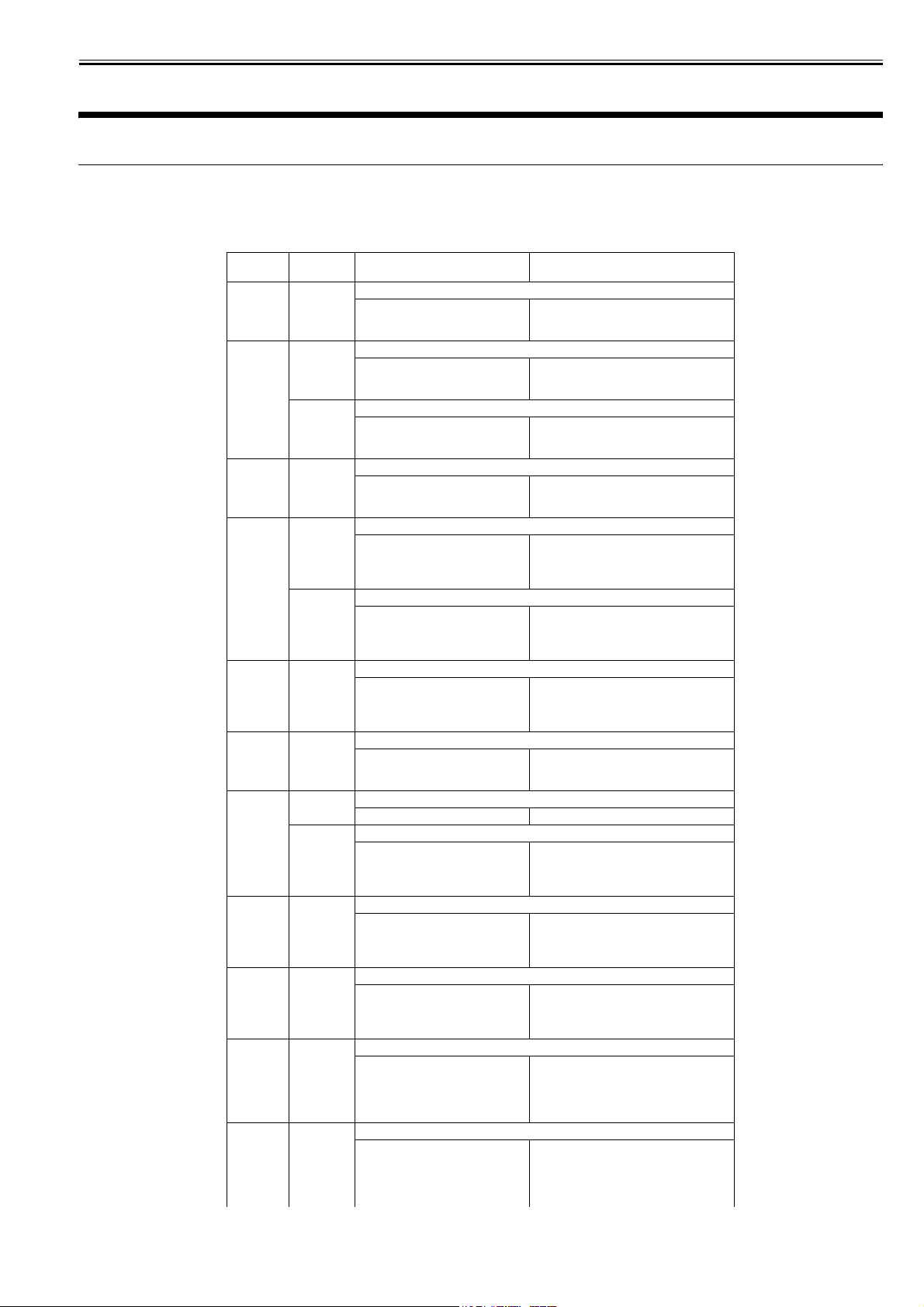

T-1-1

Ref. Parts name Parts No. Q'ty Life Remarks

[1] Manual feed pickup roller FL2-3202-000 1 150K

[2] Manual feed separation pad FL2-3201-000 1 150K

[3] Devrloping unit FM2-3286-000 1 150K

[4] Transfer roller FC6-4313-000 1 150K

[5] Fixing unit (120V) FM2-3345-000 1 150K

Fixing unit (230V) FM2-3352-000 1 150K

The value is the mean value collected from the results of evaluation. The parts number may change because of changes in design.

As of Aug. 2005

1

Chapter 1

[5]

[1]

[2]

[4]

[3]

F-1-1

1.3 Scheduled Servicing Basic Procedure

1.3.1 Scheduled Servicing

iR2016J / iR2016 / iR2020 / / iR2016i / iR2020i

The reader and printer unit does not have items that require scheduled servicing.

Be sure to clean the copyboard glass and the ADF reading glass during every service visit.

0011-2842

2

Chapter 2

Chapter 2 Standards and

Adjustments

2.1 Scanning System

2.1.1 Procedure after Replacing the CIS

iR2016J / iR2016 / iR2020 / / iR2016i / iR2020i

After replacing the contact image sensor (CIS), go through the following

steps to perform inter-channel output correction:

1) Enter the service mode.

Sequentially press the User Mode key " ", 2 key, 8 key, and User Mode

key " " on the operation panel.

2) Using the arrow keys on the operation panel, display "TEST MODE".

3) Press the OK key.

4) Press the 2 key. "SCAN TEST" appears.

5) Press the 1 key.

After completion of the above steps, contact sensor output correction will be

performed and parameters will be set automatically.

2.2 Image Formation System

2.2.1 Procedure after Replacing the Developing Assembly

iR2016J / iR2016 / iR2020 / / iR2016i / iR2020i

<Going through the Developer Idling Mode>

0011-2391

0011-2545

- Read position adjustment (Stream reading: Only when the ADF is installed)

1) Enter the service mode.

Press the User Mode key " ", 2 key, 8 key, User Mode key " " on the

operation panel of the host machine.

2) Using the arrow keys on the operation panel, display "TEST MODE".

3) Press the OK key.

4) Press the 2 key. "SCAN TEST" appears.

5) Press the 3 key. "SHEET POS ADJ" appears.

The optical system starts scanning. Several seconds later, automatic adjustment of the reading position finishes and "OK" appears.

If automatic adjustment fails, "NG" appears. Perform the following procedure:

Clean the white roller of the DADF and the document glass of the host machine, and then retry auto adjustment.

After replacing the developing assembly, go through the following steps

in the developing assembly idle rotation mode before installing the toner cartridge.

1) Plug the power cord into the outlet.

2) Open the front cover.

3) With the front cover open, turn on the main power switch.

4) When a message appears on the operation panel display, press the

following keys to enter the service mode:

Additional Functions key > 2 key > 8 key > Additional Functions key

5) Select "#PRINT" using the + or - key, and then press the OK key.

6) Select "#PRINT SW" using the + or - key, and hen press the OK key.

Confirm that the following message is displayed:

Message: #PRINT SW 001 00000000

7) Press the following keys and confirm the message:

# key > 1 key > 1 key

Message: #PRINT SW 011 00000000

8) Position the cursor to Bit-1 (second from right) using the + or - key, and

press the 1 key, and then confirm the following message:

Message: #PRINT SW 011 00000010

9) Press the OK key. Confirm that "SW 011" changes to "SW 012".

Message: #PRINT SW 012 00000000

10) Press the Reset key to exit the service mode.

11) Close the front cover. The machine will run in the developer idling mode

for about 1 minute.

12) When the machine stops, the idling mode ends.

Install, the toner cartridge following the above-mentioned procedure.

2.3 Electrical Components

2.3.1 Procedure after Replacing the Image Processor

PCB

iR2016J / iR2016 / iR2020 / / iR2016i / iR2020i

After replacing the image processor PCB with a new one, input the all value

printed on the service label affixed to the rear cover.

Make the following adjustments:

- Correction of output between CIS channels

1) Enter the service mode.

Sequentially press the User Mode key " ", 2 key, 8 key, and User Mode

key " " on the operation panel.

2) Using the arrow keys on the operation panel, display "TEST MODE".

3) Press the OK key.

4) Press the 2 key. "SCAN TEST" appears.

5) Press the 1 key.

After completion of the above steps, contact sensor output correction will be

performed and parameters will be set automatically.

0011-2555

3

Chapter 3 Error Code

3.1 Error Code Details

Chapter 3

3.1.1 Error Code Details

iR2016J / iR2016 / iR2020 / / iR2016i / iR2020i

Display

Code

E000 0000 Startup error

E001 0000 Abnormally high temperature (detected by main thermistor)

E002 0000 Low temperature during temperature control.

E003 0000 Abnormally low temperature (detected by main thermistor)

E007 0000 Fixing film sensor failure

E010 0000 Main motor failure

E019 0000 Waste toner full detection

E052 0000 Erroneous connection to duplex unit

E100 0000 BD detection PCB failure

E197 0000 Printer engine communication error

E716 0000 Erroneous communication with optional cassette

Detail Code Main Cause/Symptom Countermeasure

0001 Abnormally high temperature (detected by sub thermistor)

0001 Abnormally low temperature (detected by sub thermistor)

0001 Waster toner full detection sensor is faulty.

T-3-1

The temperature detected by the main

or sub thermistor does not rise to the

specified value during startup control.

The main thermistor detected an

abnormally high temperature (240 deg

C) during temperature control.

The sub thermistor detected an

abnormally high temperature (295 deg

C) during temperature control.

The target temperature is not reached

during temperature control.

After the temperature detected by the

main thermistor has reached the

specified value, it does not reach the

specified value during initial rotation.

After the temperature detected by the

sub thermistor has reached the

specified value, it does not reach the

specified value during initial rotation.

The fixing film sensor is faulty. - Check the connector of the fixing film

The main motor is faulty. - Check the connector of the main motor.

The waste toner full state was detected. Replace the drum unit.

The waste toner full state was detected

continuously for five or more seconds

while the main motor was turning.

Disconnection of the duplex unit was

detected after power-on, detection of

normal connection to the duplex unit,

and start of communication.

The BD detection PCB is faulty. - Check the connector of the BD detection

Erroneous communication between the

DC controller PCB and image

processor PCB was detected.

Disconnection of the optional cassette

was detected after power-on, detection

of normal connection to the optional

cassette, and start of communication.

- Check the fixing film connector.

- Replace the fixing film unit.

- Replace the DC controller PCB.

- Check the connector of the fixing film unit.

- Replace the fixing film unit.

- Replace the DC controller PCB.

- Check the connector of the fixing film unit.

- Replace the fixing film unit.

- Replace the DC controller PCB.

- Check the connector of the fixing film unit.

- Replace the fixing film unit.

- Replace the DC controller PCB.

- Check the connector of the fixing film unit.

- Replace the fixing film unit.

- Replace the DC controller PCB.

- Check the connector of the fixing film unit.

- Replace the fixing film unit.

- Replace the DC controller PCB.

sensor.

- Replace the fixing film sensor.

- Replace the DC controller PCB.

- Replace the main motor.

- Replace the DC controller PCB.

- Check the connector of the waster toner full

sensor.

- Replace the waste toner full sensor.

- Replace the DC controller PCB.

- Check the connectors of the duplex unit and

DC controller PCB.

- Replace the duplex controller PCB.

- Replace the DC controller PCB.

PCB.

- Replace the laser scanner unit.

- Replace the DC controller PCB.

- Check the connectors of the DC controller

PCB and image processor PCB.

- Replace the DC controller PCB for normal

connection.

- Replace the image processor PCB.

- Check the connectors of the optio nal cassette

PCB and DC controller PCB.

- Replace the optional cassette PCB for

normal connection.

- Replace the DC controller PCB.

0011-2580

5

Loading...

Loading...