CAME ZL180 SERIES Installation Manual

ZL180 SERIES

INSTALLATION MANUAL

ZL180

CONTROL PANEL

FOR 24V OPERATORS

Englis

h

E

Pag.

2

2 - Manual code:

319U17

319U17 ver.

12

12 04/20109 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

ENGLISH

The ZL180 control panel is designed to control the F7024N, A3024N and A5024N swing gate operators.

The use of this product for purposes other than as described above and installation executed in a manner other than

as instructed in this technical manual are prohibited.

FUSES

protection: fuse type:

Motor/s 6.4 A-F

Electronic board (power supply line) 1.6 A-F

Accessories 2 A-F

Control devices 630 mA-F

TECHNICAL FEATURES

Power supply 230 V - 50/60 Hz

max. rated power 300 W

Power draw when idling 85 mA

Max power of 24 V accessories 34 W

Insulation rating II

Material ABS

Protection rating IP54

operating temperature -20 / +55°C

This product is engineered and manufactured by CAME cancelli

automatici s.p.a. and complies with current safety regulations.

Guaranteed 24 months if not tampered with.

The control panel works on 230 V AC of power, through the

term

inals L-N, 50/60 Hz frequency.

Both command and control devices and accessories are 24 V

po

wered. Warning! Accessories must not exceed 34 W overall.

The control unit is fi tted with an amperometric device which

constantly regulates the motor’s drive coeffi cient.

When the gate runs into an obstacle, the amperometric sensor

immediately detects an overcharge in the drive and redirects the

gate’s direction of movement, and:

- opens it if it is closing

(1)

;

- closes it if it is opening.

(1)

Warning!: in this case, after 3 consecutive obstacle detections, the gate

will stop open excluding the automatic closing function; for movement to

start again press the command button or use the remote control.

All connections are protected by quick fuses, see table.

The card provides and controls the following functions:

- automatic closing after an open-command;

- pre-fl ashing by the motion indicator;

- obstacle detection when gate is still in any position;

- continual monitoring of photocell operation.

The following command modes are possible:

- open/close;

- open/close and maintained action;

- partially open;

- complete stop;

- open/stop/close.

After detecting an obstacle and depending on the type of

connection used, the photocells may cause:

- reopening of the gate when it is closing;

- partial stop.

Apposite trimmers regulate:

- the automatic closing run time;

- the second gate leaf’s motion time difference;

- the amperometric device’s detection sensitivity, in separately

in terms of normal opening and closing and braking.

Further implemented options:

- controlling of just one gearmotor;

- peripheral speed reduction (for gate leaves of over 3 m);

- option to change opening endpoint fromt Stop to

Deceleration. With the function of slowing down is mandatory

setback mechanical;

- connecting up an electric lock (alternatively to the 2nd radio

channel or the “Open Gate” indicator light) and possibly adding

the “Ram Blow” function.

Make sure you respect the distances and cable diameters as shown in “cable types and minimal thicknesses” table.

The overall power of the motors must not exceed 300 W.

4 Description

2.1 - INTENDED USE

1 Legend of symbols

This symbol indicates sections to be read with particular care.

This symbol indicates sections concerning safety

This symbol indicates notes to communicate to users.

2 Intended use and application

3 Reference Standards

“IMPORTANT INSTALLATION, SAFETY INSTRUCTIONS”

“CAUTION: IMPROPER INSTALLATION MAY CAUSE SERIOUS DAMAGE, FOLLOW ALL INSTALLATION INSTRUCTIONS CAREFULLY”

“THIS MANUAL IS ONLY FOR PROFESSIONAL INSTALLERS OR QUALIFIED PERSONS”

2.2 - APPLICATION

For its quality processes management Came Cancelli Automatici is ISO 9001:2000 certified, and for its environmental management it

is

ISO 14001 certified. Came designs and manufactures entirely in Italy.

This product complies with the following standards: see chapter 13 - Conformity declaration - pag. 21.

A B C D E F G H I I

1

3

7 69

10

13

14

5

15

4

2

1211

8

A =

B =

C =

D =

E =

F =

G =

H =

I =

Pag.

3

3 -

Manual code

:

319U17

319U17

ver.

1.2

1.2

04/2010

9 © CAME cancelli automatici s.p.a. -

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

ENGLISH

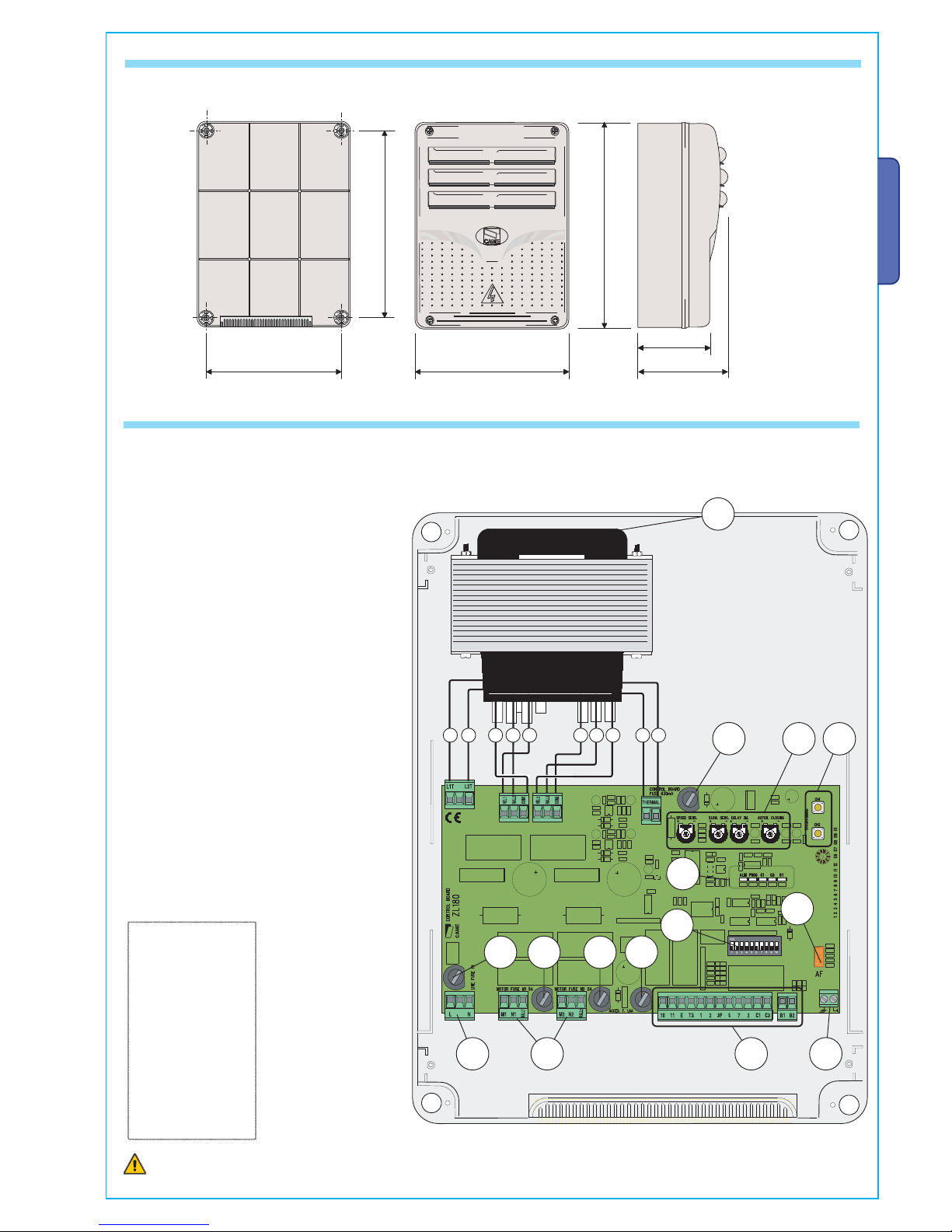

4.1 - DIMENSIONS, SPANS AND ANCHORING HOLES

4.2 - MAIN COMPONENTS

Warning! Before acting on the machinery, cut off the main power

supply and dis

connect any emergency batteries.

1 - Transformer

2

- Control unit fuse

3 - Trimmers (see page 9)

4 - Buttons for memorising the radio code

5 - Plug for the remote control frequency card

6 - Terminal board for connecting the antenna

7 - Terminal blocks for connecting accessories,

control and safety

8 - Terminal board for connecting the gearmotors

9 - Terminal board for 230 V AC power grid

10 - Line fuse

11 - M1 motor fuse

12 - M2 motor fuse

13 - Accessories fuse

14 - Fucntions selector

15 - Control and signalling LED unit

Black

White

Grey

Orange

Red

Blue

Brown

Yellow

Violet

LINKS

THE TRANSFORMER

295

215

!!

Pag.

4

4 - Manual code:

319U17

319U17 ver.

12

12 04/20109 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

ENGLISH

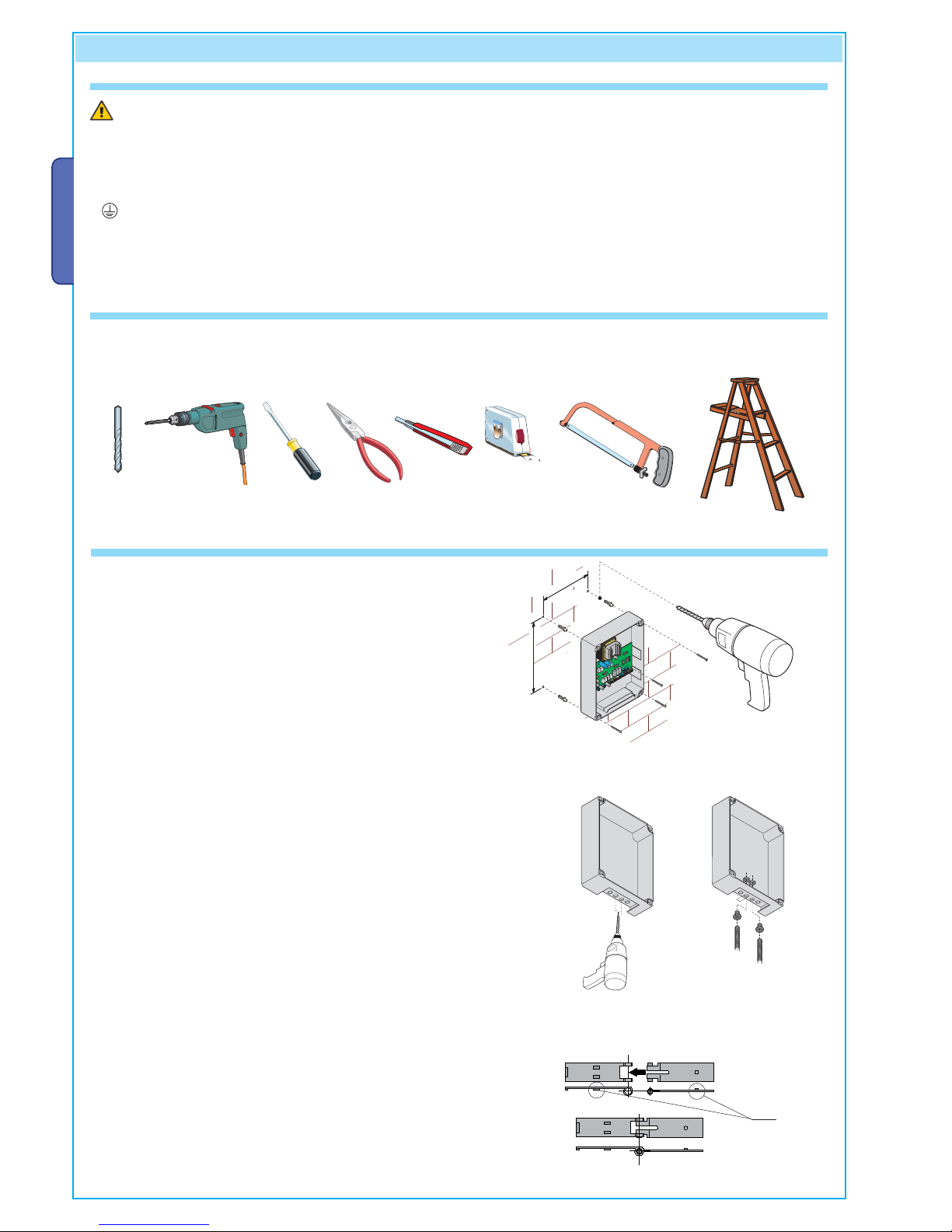

Before installing do the following:

• Check that the panel’s anchoring point is protected from possible blows, and that the anchoring surface is solid. Also check that the

anchoring is done using the appropriate bolts, screws etc.

• Make sure you have a suitable omnipolar cut-off device with contacts more than 3 mm apart, and independent (sectioned off) power

supply.

•

Make sure that any connections inside the case (that provide continuance to the protective circuit) are fitted with extra insulation

as compared to the other conductive parts inside;

• Make sure you have suitable tubing and conduits for the electrical cables to pass through and be protected against mechanical

damage.

Make sure you have all the tools and materials you will need for the installation at hand to work in total safety and compliance with the

current standards and regulations. The following figure illustrates the minimum equipment needed by the installer.

Here are some examples.

Fix the base of the panel in a protected area; we suggest

using round top Phillips recessed head screws of max. 6mm in

diameter.

5.3 - FIXING AND MOUNTING THE BOX

Perforate the pre-punched holes and insert the cable glands with

the corrugated tubing for the electrical cables to travel through

N.B.: the pre-punched holes have the following diameters:

23m 29 and 37 mm.

Assemble the pressure hinges.

5 Installation

5.1 - PRELIMINARY CHECKS

5.2 - TOOLS AND MATERIALS

15 mm~

Pag.

5

5 -

Manual code

:

319U17

319U17

ver.

1.2

1.2

04/2010

9 © CAME cancelli automatici s.p.a. -

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

ENGLISH

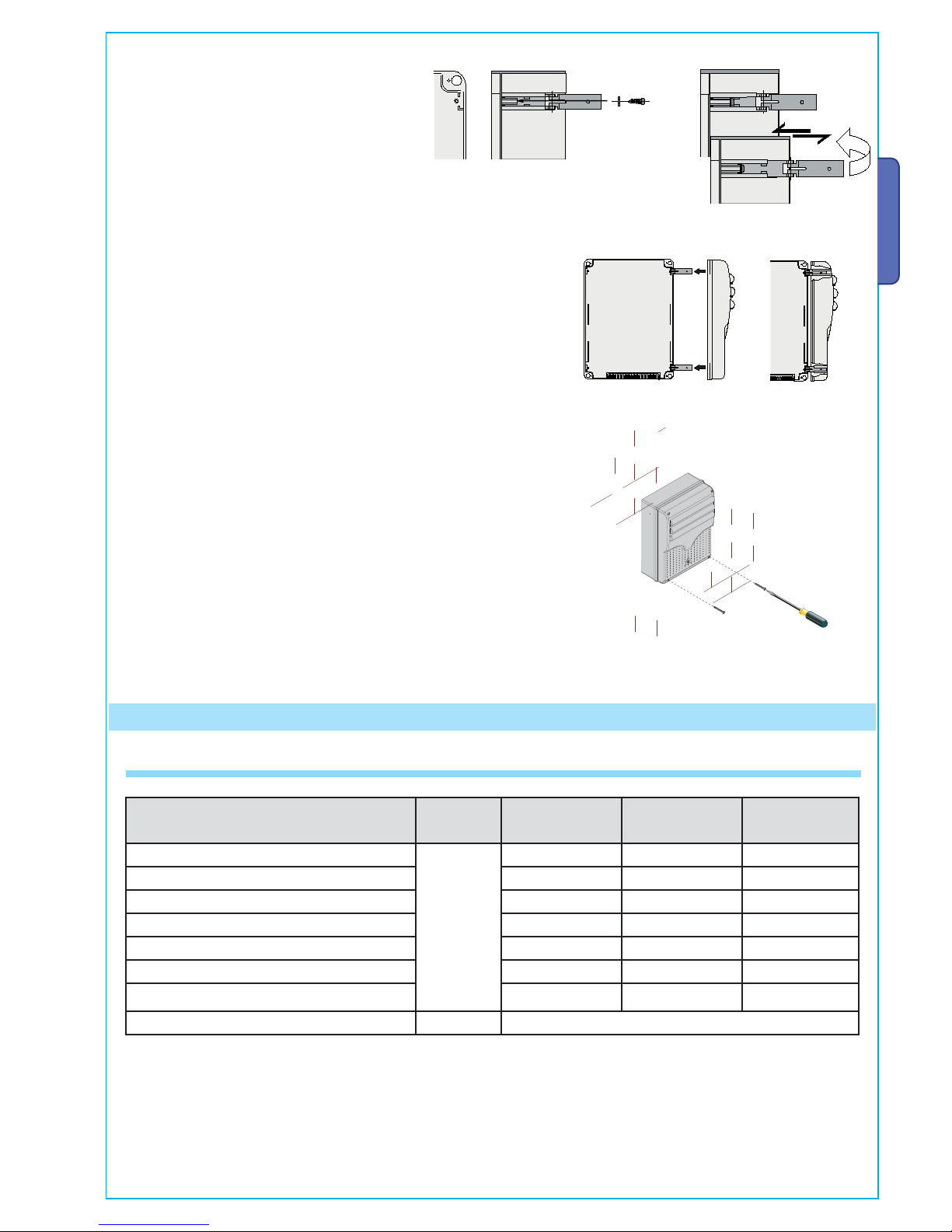

They must slide in order to turn

After the adjustments and settings, fix the cover using the provided

screws.

Insert the pressure hinges into the box (on the

left or right as you wish) and set them using the

provided screws and washers.

Snap the cover into place onto the hinges. Close it and fix it using the

provided screws.

6.1 - CABLE LIST AND MINIMUM THICKNESSES

N.B.: If the cable length differs from that specified in the table

, then you must determine the proper cable diameter based on the actual

power draw from the connected devices and according to the CEI EN 60204-1 standards.

For connections that require several, sequential loads, the sizes given on the table must be re-evaluated based on actual power draw

and distances.

When connecting products that are not specified in this manual, please follow the documentation provided with said products.

Connections

Type

of cable

Length of cable

1 < 10 m

Length of cable

10 < 20 m

Length of cable

20 < 30 m

Control panel power supply 230 V

FROR CEI

20-22

CEI EN

50267-2-1

3G x 1,5 mm

2

3G x 2,5 mm

2

3G x 4 mm

2

Motor power supply 24 V 3 x 1 mm

2

3 x 1,5 mm

2

3 x 2,5 mm

2

flashing lamp 2 x 0,5 mm

2

2 x 1 mm

2

2 x 1,5 mm

2

Transmitter photocells 2 x 0,5 mm

2

2 x 0.5 mm

2

2 x 0,5 mm

2

Receiver photocells 4 x 0,5 mm

2

4 x 0,5 mm

2

4 x 0,5 mm

2

Power supply to accessories 2 x 0,5 mm

2

2 x 0,5 mm

2

2 x 1 mm

2

Control and safety devices 2 x 0,5 mm

2

2 x 0,5 mm

2

2 x 0,5 mm

2

Antenna connection RG58 max. 10 m

6 Electrical connections

+

-

Pag.

6

6 - Manual code:

319U17

319U17 ver.

12

12 04/20109 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

ENGLISH

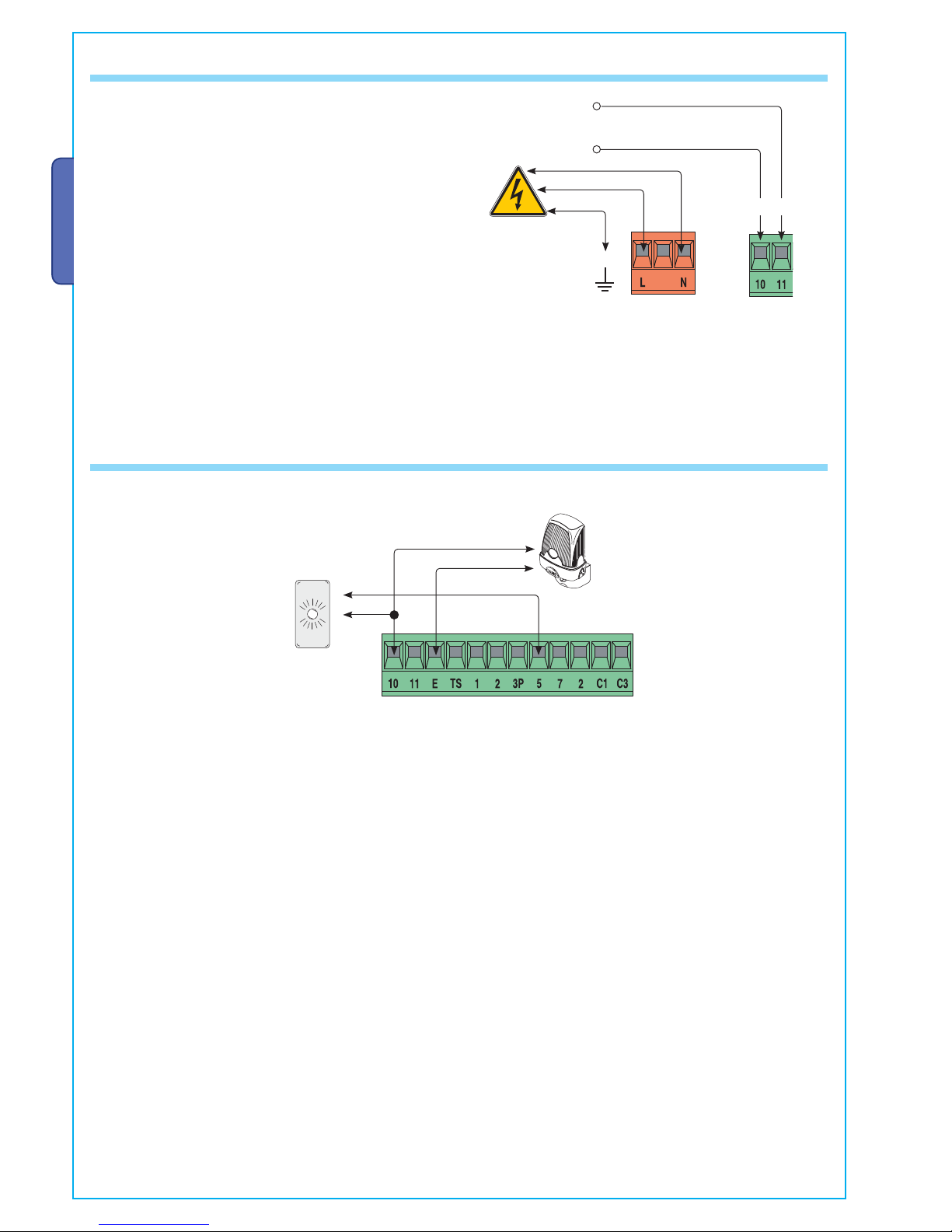

Terminals for powering the following accessories:

- 24 V AC (normally alternated power)

- 24 V AC (continuous power) when the emergency batteries

are in operation.

Overall power allowed: 34 W

Power supply

230 V AC 50/60 Hz

6.4 - POWER SUPPLY TO AND ACCESSORIES

6.3- SIGNALLING AND LIGHTING DEVICES

Open gate indicator-light

(socket rating: 24 V - 3 W max.).

- Turns on when the gate is ajar or

open. It turns off when the gate is

closed.

(Also see Chapt. 6.5)

Signal Flasher

(socket rating: 24 V - 25 W max.)

- Flashes during opening and

closing phases

Pag.

7

7 -

Manual code

:

319U17

319U17

ver.

1.2

1.2

04/2010

9 © CAME cancelli automatici s.p.a. -

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

ENGLISH

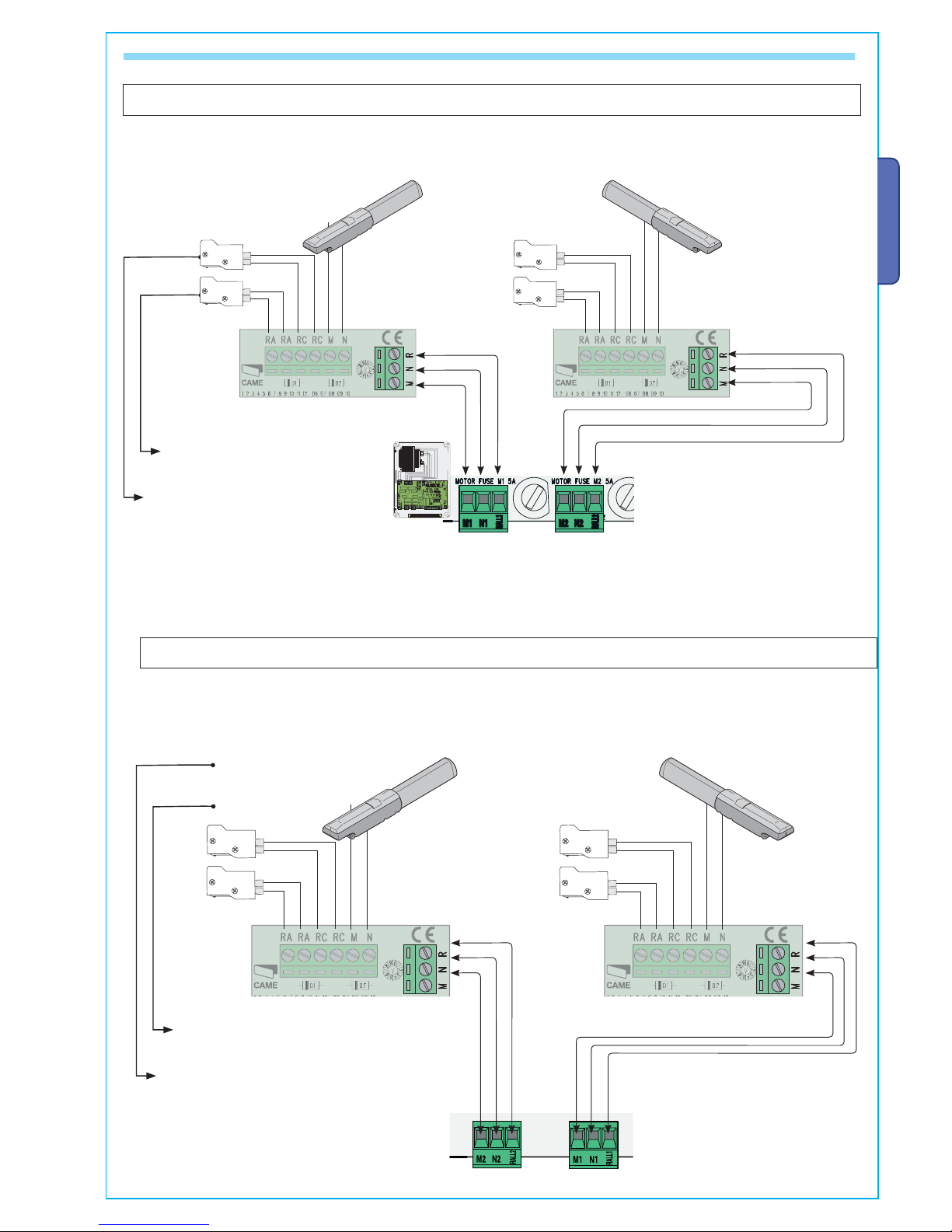

24V DC gearmotor

featuring delayed action on closing (M2),

Left-hand installed (inside view)

- Standard installation -

24V DC gearmotor

featuring delayed action on opening (M1),

Left-hand installed (inside view)

- Standard installation -

A302 4N-A5024N gearmotors

RA-RA = Opening-speed blocker

microswitch

RC-RC = Closing-speed reduction

microswitch

6.4 - CONNECTING TO THE GEARMOTORS

RA-RA = Microswitch

Opening programmable.

RC-RC = Closing-speed reduction

microswitch

A302 4N-A5024N gearmotors

24V DC gearmotor

featuring delayed action on closing (M2),

Left-hand installed (inside view)

- Standard installation -

24V DC gearmotor

featuring delayed action on opening (M1),

Left-hand installed (inside view)

- Standard installation -

LO

CK

UNLOCK

CAM

E

LOCK

UNLOCK

CAM

E

LO

CK

UNLOCK

CAM

E

LOCK

UNLOCK

CAM

E

Pag.

8

8 - Manual code:

319U17

319U17 ver.

12

12 04/20109 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

ENGLISH

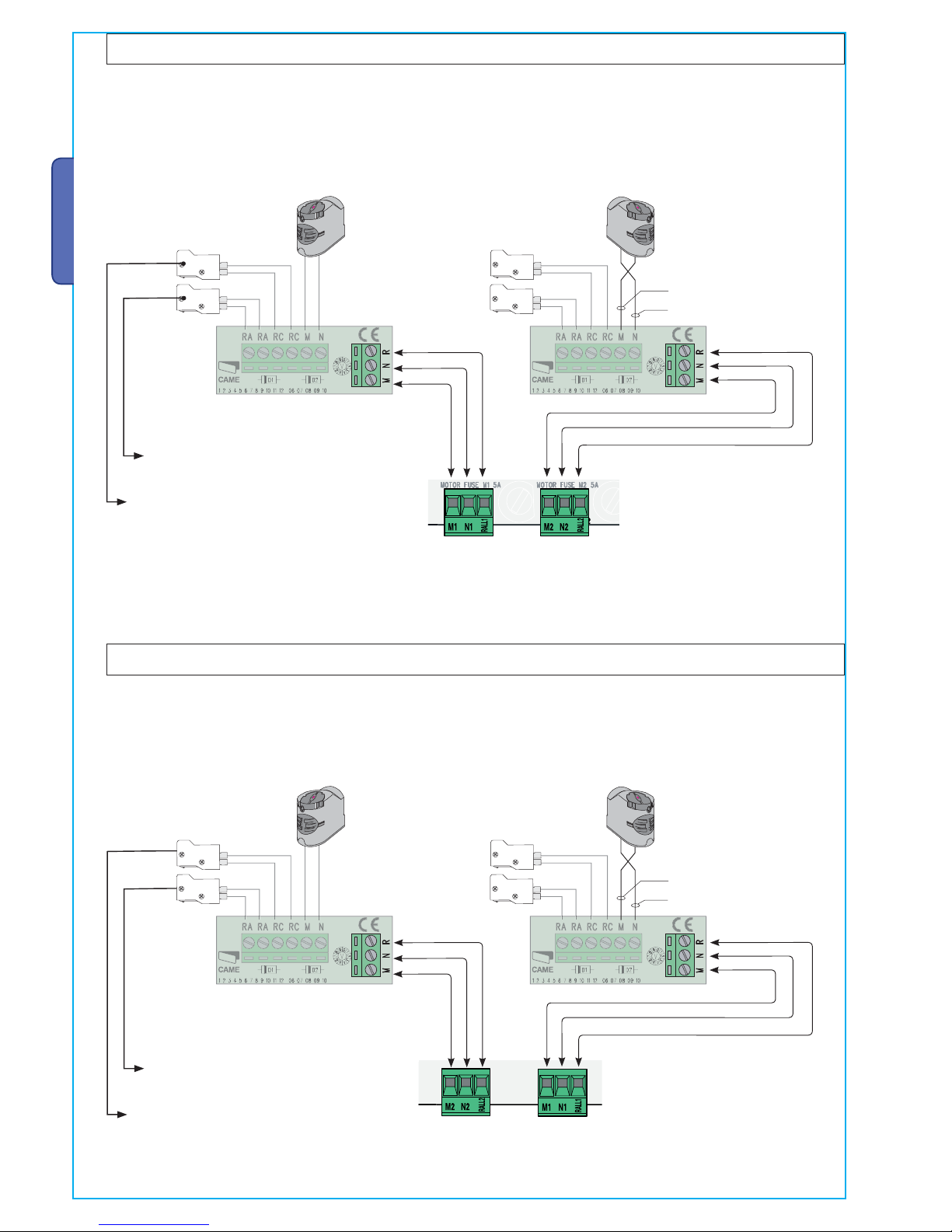

RC-RC = Closing-speed reduction

microswitch

M = red

N = b

lack

F7024N gearmotors

RA-RA = Microswitch

Opening programmable.

RA-RA = Opening-speed blocker

microswitch

RC-RC = Closing-speed reduction

microswitch

M = red

N = b

lack

F7024N gearmotors

24V DC gearmotor

featuring delayed action on closing

(M2),

Left-hand installed (inside view)

- Standard installation -

24V DC gearmotor

featuring delayed action on opening

(M1),

Left-hand installed (inside view)

- Standard installation -

24V DC gearmotor

featuring delayed action on closing

(M2),

Left-hand installed (inside view)

- Standard installation -

24V DC gearmotor

featuring delayed action on opening

(M1),

Left-hand installed (inside view)

- Standard installation -

Loading...

Loading...