Page 1

Operation Manual

Encapsulator

B-390

115 9347 7 en

Page 2

Page 3

Table of contents

Table of contents

1 About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2 Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.1 User qualification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Proper use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Improper use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4 Safety warnings and safety signals used in this manual . . . . . . . . . . . . . . . . . 7

2.5 Product safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.5.1 General hazards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.5.2 Safety measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.5.3 Built-in safety elements and measures . . . . . . . . . . . . . . . . . . . . . . . . 10

2.6 General safety rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.7 Disclaimer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.1 Scope of application and delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.1.1 Standard instrument. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.1.2 Standard accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1.3 Optional accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1.4 Recommended spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2 Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.3 Materials used. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4 Description of function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.1 Functional principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2 Connections at the Encapsulator B-390. . . . . . . . . . . . . . . . . . . . . . . . 18

5 Putting into operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.1 Installation site. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2 Installing the Encapsulator B-390 . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.3 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.4 Assembling of the bead producing unit . . . . . . . . . . . . . . . . . . . . . . . . 22

5.5 Single (inner) nozzles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.6 Electrode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.7 Pressure bottle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.7.1 Installation of the pressure bottle . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.8 Option: Concentric nozzle system . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.8.1 Mounting of CN nozzles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.9 Final installation check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Read this manual carefully before installing and running your system and note the safety precautions

in chapter 2 in particular. Store the manual in the immediate vicinity of the instrument, so that it can be

consulted at any time.

No technical modifications may be made to the instrument without the prior written agreement of

BUCHI. Unauthorized modifications may affect the system safety, the EU conformity or result in accidents.

This manual is copyright. Information from it may not be reproduced, distributed, or used for competitive purposes, nor made available to third parties. The manufacture of any component with the aid of

this manual without prior written agreement is also prohibited.

The English manual is the original language version and serves as basis for all translations

into other languages.

3 B-390 Operation Manual, Version C

Page 4

Table of contents

6 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.1 Starting up the instrument. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.2 Screens and menu functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.3 Menu structure of the control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.4 Manual air pressure control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.5 Practicing with the Encapsulator, using water . . . . . . . . . . . . . . . . . . . . . 35

6.6 Practicing with the Encapsulator, using alginate solution. . . . . . . . . . . . . . . . 38

6.6.1 Preparation of 1.5 % Na-alginate solution . . . . . . . . . . . . . . . . . . . . . . . 38

6.6.2 Working with alginate solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.7 Theoretical background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.7.1 Bead productivity and cell density . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7 Maintenance and repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.1 Customer service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.2 Housing condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.3 Sealing conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.4 Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7.4.1 Cleaning the nozzle after each immobilization run . . . . . . . . . . . . . . . . . . . 47

7.4.2 Cleaning a clogged nozzle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.4.3 Cleaning the bead producing unit . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

8 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

8.1 Malfunctions and their remedy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

9 Shutdown, storage, transport and disposal . . . . . . . . . . . . . . . . . . . . . . . . 50

9.1 Storage and transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

9.2 Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

10 Declarations and requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

10.1 FCC requirements (for USA and Canada) . . . . . . . . . . . . . . . . . . . . . . . 52

10.2 Health and Safety Clearance form . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

10.3 Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4 B-390 Operation Manual, Version C

Page 5

1 About this manual

This manual describes the Encapsulator B-390. It provides all information required for its safe operation and to maintain it in good working order. It is addressed to laboratory personnel in particular.

If the instrument is used in a manner not specified in this manual, the protection provided by the

instrument may be impaired.

Abbreviations

EPDM Ethylene Propylene Dimonomer

FEP Fluorelastomer

PTFE Polytetrafluoroethylene

1 About this manual

5 B-390 Operation Manual, Version C

Page 6

2 Safety

This chapter points out the safety concept of the instrument and contains general rules of behavior

and warnings from direct and indirect hazards concerning the use of the product.

For the user's safety all safety instructions and the safety messages in the individual chapters shall

strictly be observed and followed. Therefore, the manual must always be available to all persons

performing the tasks described herein.

2.1 User qualification

The instrument may only be used by laboratory personnel and other persons, who on account of

training and professional experience know the dangers, which can develop when operating the instrument.

Untrained personnel or persons, who are currently being trained, require careful supervision by a qualified person. The present Operation Manual serves as a basis for training.

2 Safety

2.2 Proper use

The Encapsulator B-390 has been designed and built as laboratory instrument.

The Encapsulator B-390 is a semi-automated instrument used for the polymer encapsulation of

chemical substances, bio-molecules, drugs, flavor & fragrances, pigments, extracts, cells and microorganisms under open conditions. Aseptic working conditions are possible, because all parts in

contact with the encapsulation mixture are autoclavable.

The bead formation is based on the fact that a controlled, laminar liquid jet is broken into equally sized

beads, if vibrated at an optimal frequency.

The Encapsulator B-390 provides just such controlled conditions to generate beads between 0.15 to

2 mm. The instrument is ideally suited to encapsulate particles < 50 µm.

If the instrument is used with potentially toxic or hazardous substances, it has to be installed inside a

closed fume hood or glove box. In such case, the complete processing and system handling has to

be performed within the ventilated box to avoid toxication and other hazardous situations to the user

and the environment.

2.3 Improper use

Applications not mentioned in section 2.2 are considered to be improper. Applications which do not

comply with the technical data (see section 3 of this manual) are also considered to be improper.

The operator bears the sole risk for any damages or hazards caused by improper use!

The following uses are expressly forbidden:

• Installation or use of the instrument in rooms, which require ex-protected instruments.

6 B-390 Operation Manual, Version C

Page 7

2.4 Safety warnings and safety signals used in this manual

DANGER, WARNING, CAUTION and NOTICE are standardized signal words for identifying risk levels,

related to personal injury and property damage. All signal words, which are related to personal injury

are accompanied by the general safety sign.

For your safety it is important to read and fully understand the below table with the different signal

words and their definitions!

Sign Signal word Definition Risk level

DANGER

Indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

2 Safety

★★★★

WARNING

CAUTION

NOTICE

no

Supplementary safety information symbols may be placed in a rectangular panel on the left to the

signal word and the supplementary text (see below example).

Space for

supplementary

safety

information

symbols.

Table of supplementary safety information symbols

The below reference list incorporates all safety information symbols used in this manual and their

meaning.

Indicates a hazardous situation which, if not avoided, could result

in death or serious injury.

Indicates a hazardous situation which, if not avoided, may result

in minor or moderate injury.

Indicates possible property damage, but no

practices related to personal injury.

!

SIGNAL WORD

Supplementary text, describing the kind and level of hazard/risk seriousness.

• List of measures to avoid the herein described, hazard or hazardous situation.

• ...

• ...

(property damage only)

★★★☆

★★☆☆

★☆☆☆

Symbol Meaning

General warning

Electrical hazard

7 B-390 Operation Manual, Version C

Page 8

Explosive gases, explosive environment

Harmful to live-forms

Device damage

Pressurized gas/air

2 Safety

Hot Surface

Wear laboratory coat

Wear protective goggles

Wear protective gloves

Additional user information

Paragraphs starting with NOTE transport helpful information for working with the device/software or its

supplementaries. NOTEs are not related to any kind of hazard or damage (see example below).

NOTE

Useful tips for the easy operation of the instrument/software.

8 B-390 Operation Manual, Version C

Page 9

2.5 Product safety

Safety warnings in this manual (as described in section 2.4) serve to make the user alert and to avoid

hazardous situations emanating from residual dangers by giving appropriate counter measures.

However, risks to users, property and the environment can arise when the instrument is damaged,

used carelessly or improperly.

2.5.1 General hazards

The following safety messages show hazards of general kind which may occur when handling the

instrument. The user shall observe all listed counter measures in order to achieve and maintain the

lowest possible level of hazard.

Additional warning messages can be found whenever actions and situations described in this manual

are related to situational hazards.

!

Warning

Death or serious injuries by use in explosive environments.

• Do not operate the instrument in explosive environments.

• Do not operate the instrument with explosive gas mixtures.

• Before operation, check all gas connections for correct installation.

• Directly withdraw released gases and gaseous substances by sufficient ventilation.

2 Safety

!

Warning

Pressure increase in the inlet-system due to clogged nozzles.

Bursting of the inlet system.

Death or serious poisoning by contact or incorporation of harmful substances at use.

• Clean nozzle immediately after use, see section 7.4.

!

Warning

Death or serious injuries by contact with high voltage.

• Only open the housing of the product when machine is switched off and unplugged.

Risk of instrument short-circuits and damage by liquids.

• Do not spill liquids over the instrument or parts of it.

• Wipe off any liquids instantly.

• Ensure a safe positioning of the sample vessel.

• Do not move the instrument when it is loaded with liquid.

• Keep external vibrations away from the instrument.

Notice

9 B-390 Operation Manual, Version C

Page 10

2 Safety

Risk of instrument damage by wrong mains supply.

• External mains supply must meet the voltage given on the type plate.

• Check for sufficient grounding.

Risk of damaging labratory glasses or utensils by moving syringe pump unit.

• Do not place any laboratory glasses or other utensils on the Encapsulator.

2.5.2 Safety measures

Always wear personal protective equipment such as protective eye goggles, protective clothing, and

gloves when working with the instrument.

2.5.3 Built-in safety elements and measures

Notice

Notice

High voltage and electrostatic charges

• Safety current limitation.

• Internal grounding to arrest electrostatic charges.

Air/Gas

• Over pressure safety valve (opens at 1.5 bar)

10 B-390 Operation Manual, Version C

Page 11

2.6 General safety rules

Responsibility of the operator

The head of laboratory is responsible for training his personnel.

The operator shall inform the manufacturer without delay of any safety-related incidents which might

occur during operation of the instrument. Legal regulations, such as local, state and federal laws

applying to the instrument must be strictly followed.

Duty of maintenance and care

The operator is responsible for the proper condition of instrument at use and that maintenance,

service and repair jobs are performed with care and on schedule by authorized personnel only.

Spare parts to be used

Use only genuine consumables and genuine spare parts for maintenance to assure good system

performance and reliability. Any modifications to the spare parts used are only allowed with the prior

written permission of the manufacturer.

Modifications

Modifications to the instrument are only permitted after prior consultation with and with the written

approval of the manufacturer. Modifications and upgrades shall only be carried out by an authorized

BUCHI technical engineer. The manufacturer will decline any claim resulting from unauthorized modifications.

2 Safety

2.7 Disclaimer

Use and marketing of any material produced with the Encapsulator are in the sole responsibility of the

operator.

11 B-390 Operation Manual, Version C

Page 12

3 Technical data

This chapter introduces the reader to the instrument and its specifications. It contains the scope of

delivery, technical data, requirements and performance data.

3.1 Scope of application and delivery

The scope of delivery can only be checked according to the individual delivery note and the listed

order numbers.

NOTE

For additional information about the listed products, see www.buchi.com or contact your local dealer.

3.1.1 Standard instrument

3 Technical data

Table 3-1: Standard instrument

Product Order no.

Encapsulator B-390

50 – 60 Hz, 100 – 240 V

Complete Encapsulator B-390 system for microencapsulation

under open working conditions with integrated nozzle heating

and with liquid pumping by air pressure.

11058210

12 B-390 Operation Manual, Version C

Page 13

3.1.2 Standard accessories

3 Technical data

Table 3-2: Standard accessories

Set of 8 single nozzles 11057918

Set of 8 single nozzles with high precision

opening of 0.08, 0.12, 0.15, 0.20, 0.30,

0.45, 0.75 and 1.00 mm, made of stainless steel 316L including nozzle rack

Pressure bottle 500 mL 11058190

Pressure bottle 1000 mL 11058191

Glass bottles with fittings, tubes and air

filter, working pressure up to 1.5 bar,

autoclavable

3.1.3 Optional accessories

Grounding set 11058189

Operation Manual English 11593477

Table 3-3: Optional accessories

Product Order no.

Concentric nozzle set 11058051

Set of 7 external nozzles with high precision opening of 0.2, 0.3, 0.4, 0.5, 0.6, 0.7

and 0.9 mm made of stainless steel, incl.

1000 mL pressure bottle

13 B-390 Operation Manual, Version C

Page 14

3.1.4 Recommended spare parts

3 Technical data

Table 3-4: Recommended spare parts

Product Order no.

O-ring set for single nozzle 11057954

O-ring set for concentric nozzle 11057955

Pre-filters for nozzle,

diameter 7 mm (10 pcs.)

Drain filters for reaction vessel,

diameter 35 mm (10 pcs.)

11057957

11057958

14 B-390 Operation Manual, Version C

Page 15

3.2 Technical data

Table 3-5: Technical data Encapsulator B-390

Power consumption max. 150 W

Connection voltage 100–240 VAC

Mains supply voltage fluctuations up to ±10% of the nominal voltage

Frequency 50/60 Hz

Fuse 3.15 A

Dimensions (W × H × D) 32×29×34 cm

Weight 7 kg

Nozzle diameter of single (= core) nozzles 0.08, 0.12, 0.15, 0.20, 0.30, 0.45, 0.75 and 1.00 mm

Nozzle diameter of shell nozzles 0.20, 0.30, 0.40, 0.50, 0.60, 0.70 and 0.90 mm

Droplet size range 0.15 to 2.00 mm

Vibration frequency 40 to 6,000 Hz

Electrode tension 250 to 2,500 V

Heating 30 to 70 °C

Pump rate by air pressure 0.5 to 200 mL/min

Maximal allowed air pressure in the system 1.5 bar

Reactor gross volume 4.5 liter

Reactor working volume 2 liter

Parts in contact with medium autoclavable

Sterile working conditions limited

Overvoltage category II

Pollution degree 2

Environmental conditions:

3 Technical data

Temperature 5–40 °C for indoor use only

Altitude up to 2000 m

Max. relative humidity (curve parameter) Maximum relative humidity 80 % up to 31 °C, then

decreasing linearly to 50 % relative humidity at 40 °C

Table 3-6: Material and Approvals

Material in contact with sample stainless steel, silicone, glass, FEP, PTFE

Approvals CE, CSA

3.3 Materials used

Table 3-7: Materials used

Component Material description

Bead producing unit Stainless steel, PTFE, glass fibers

Nozzles Stainless steel, sealings: EPDM

Pressure bottle Stainless steel, 3.3 boroscillate glass, FEP, PTFE

15 B-390 Operation Manual, Version C

sealings: silicone, EPDM

sealings: silicone, EPDM

Page 16

4 Description of function

This chapter explains the basic working principle of the Encapsulator B-390. It also shows how the

instrument is structured and provides a general functional description of its assembly.

4.1 Functional principle

The instrument provides the following key functions:

Reproducible bead size from one production to the next

– Adjustable parameters (nozzle size, liquid flow rate and vibration frequency) determine bead

size.

Reproducible bead formation

– In the range of 0.15 mm to 2.0 mm.

4 Description of function

High bead size uniformity

– Due to the integrated Electrostatic Dispersion Unit (EDU); approximately 5 % relative standard

deviation of bead size using pure alginate.

Immediate process control

– Visual monitoring in the light of a stroboscope lamp.

High cell viability

– Bead formation technique is at low shear stress and under physiological conditions, thus

resulting in high cell survival.

Batch size

– T

he batch size is of 5 mL to 1’000 mL and the dead volume is approximately 2 mL.

Set of 8 single nozzles

– The 8 nozzle sizes of 0.08, 0.12, 0.15, 0.20, 0.30, 0.45, 0.75 and 1.0 mm cover the bead size

range of approximately 0.15 mm to 2.0 mm.

Delivery of the polymere mixture

– By air pressure with flow rates from 70 mL/h (0.08 mm nozzle) to 2’500 mL/h (1.0 mm nozzle).

High bead production

– Up to 6000 beads are produced per second depending on encapsulation conditions and

polymer mixture.

16 B-390 Operation Manual, Version C

Page 17

4 Description of function

Figure 4-1: Schematic representation of the Encapsulator B-390

a Pressure bottle

Bead producing unit

Vibration unit

Single nozzle

Electrode

Dispersion control

Vibration control

LED/stroboscope

Polymerization bath

Magnetic stirrer

(P) Air pressure

17 B-390 Operation Manual, Version C

Page 18

4 Description of function

The main parts of the Encapsulator B-390 are the control unit, the bead producing unit, and the pressure bottle. All parts of the instrument which are in direct contact with the immobilization mixture can

be sterilized by autoclaving.

The product to be encapsulated (active ingredients, enzymes, chemicals and cells) is mixed with an

encapsulating polymer (typically alginate) and the mixture put into the pressure bottle a see figure

4-1. The polymer-product mixture is forced into the bead producing unit by air pressure (P). The

liquid then passes through a precisely drilled nozzle and separates into equal size droplets on

exiting the nozzle. These droplets pass through an electrical field between the nozzle and the electrode resulting in a surface charge. Electrostatic repulsion forces disperse the beads as they drop

to the polymerization bath. The polymerization bath must be electrically grounded.

Bead size

The bead size is controlled by several parameters including the vibration frequency, nozzle size, flow

rate, and physical properties of the encapsulation mixture. In general, the bead size is twice the nozzle

diameter. But, by varying the jet velocity and the vibration frequency, the range can be adjusted by

about 1 - 15 %.

Optimal parameters for bead formation are indicated by visualization of real-time bead formation in the

light of a stroboscope lamp . When optimal parameters are reached, a standing chain of droplets is

clearly visible. Once established, the optimal parameters can be preset for subsequent bead production runs with the same encapsulating mixture.

Depending on several variables, up to 6000 beads are generated per second and collected in the

polymerization bath , which is continuously mixed by a magnetic stir bar. In addition, the reaction

solution must be electrically grounded to eliminate the electrostatic charges coming from the charged

bead surface. At the conclusion of the production run, the hardening solution is drained off, washing

solutions, or other reaction solutions, are added to further process the beads if needed.

4.2 Connections at the Encapsulator B-390

Front connections (See figure 5-2)

• Main switch

• Air out

• Electrode

• Ground

Rear connections (See figure 5-1)

• Electric supply

• Air inlet

• Vibration

• Optional plug(s)

18 B-390 Operation Manual, Version C

Page 19

5 Putting into operation

This chapter describes how the instrument has to be installed. It also gives instructions for the initial

startup.

NOTE

Inspect the instrument for damages during unpacking. If necessary, prepare a status report immediately to inform the postal company, railway company or transportation company. Keep the original

packaging for future transportation.

5.1 Installation site

Put the instrument on a stable, horizontal surface. Consider the maximum product dimensions and

weight. The instrument must be set up in such a way that the main switch and the mains plug are

easily accessible at all times.

Obtain the environmental conditions as described in section 3.2 “Technical data”.

5 Putting into operation

!

Warning

Death or serious injuries by use in explosive environments.

• Do not operate the instrument in explosive environments.

!

Warning

Death or serious poisoning by contact or incorporation of harmful substances.

• Wear safety goggles.

• Wear safety gloves.

• Wear a laboratory coat.

• Clean the instrument and all accessories thoroughly to remove possibly dangerous

substances.

• Do not clean dusty parts with compressed air.

• Store the instrument and its accessories at a dry place.

19 B-390 Operation Manual, Version C

Page 20

5.2 Installing the Encapsulator B-390

Place the instrument on the lab bench with convenient access to an AC electrical outlet and to

compressed air. Place the instrument in a way that disconnection of the electric supply plug is

possible at all times.

Connect the external air/gas supply (=air inlet) and the vibration unit as shown in figure 5-1.

1

2

5 Putting into operation

a Air inlet (blue tube 2.6×4.0 mm)

Electric supply socket with inte-

4

3

grated fuse

Socket for vibration unit

Optional socket

Figure 5-1: Rear view of the control unit

All controlling systems for bead production are incorporated in the control unit. Vibration frequency,

light intensity, electrostatic dispersion and heating, are controlled on the touch screen. Air pressure

is regulated with the pressure regulating valve. The pressure is electronically indicated on the touch

screen. The pumping rate of the polymer mixture is controlled with the liquid flow regulating valve.

The integrated stroboscope lamp allows real time jet breakup control. The main switch is on the front

panel. The bead producing unit is attached to the carrier plate with two screws (M3×25).

a Vibration unit

Touch screen

Pressure regulating valve

1

8

7

6

11

12

10

9

2

3

Mains switch

Plug for grounding wire

Air outlet

Liquid flow regulating valve

Liquid flow regulating valve

Heating block

Carrier plate

k Electrode

Stroboscope lamp

5

Figure 5-2: Front view of the control unit

4

20 B-390 Operation Manual, Version C

Page 21

Installation of the air line

A 3 m air tube (2.6×4.0 mm) is included with each Encapsulator to connect it to external compressed

air or nitrogen.

1. Stick the air tube into the air inlet plug.

2. Attach the other side of the air tube to the external gas supply.

3. Deliver gas to the Encapsulator at 1.5 to 2 bar (23 to 30 psi) when running the instrument.

NOTE

The integrated pneumatic system (valve and fittings) will tolerate up to 7 bar (100 psi) at the inlet. An

over pressure safety valve, which opens at 1.5 bar, is incorporated after the pressure regulating valve, so

that the maximum air pressure at the air outlet is 1.5 bar. However the working range is from 0 to 1 bar.

5.3 Electrical connections

5 Putting into operation

Verify that the electrical requirement of the unit, stated on the type plate of the control unit, corresponds to voltage of your local electrical network. Connect the power plug of the Encapsulator to the

mains supply.

Caution

!

Risk of instrument damage by wrong mains supply.

• External mains supply must meet the voltage given on the type plate.

• Check for sufficient grounding.

• Additional electrical safety measures such as residual current breakers may be necessary to

meet local laws and regulations! External connections and extension lines must be provided

with an earthed conductor lead (3-pole couplings, cord or plug equipment). All used power

cords shall be equipped with molded plugs only to avoid risks due to unobservant defective

wiring.

21 B-390 Operation Manual, Version C

Page 22

5.4 Assembling of the bead producing unit

5 6

41

3

98

2

7

The bead producing unit is the central part of the Encapsulator B-390. It is fully autoclavable.

Figure 5-3 shows the different parts of the bead producing unit. The assembled bead producing unit

is attached with the screw on the carrier plate of the control unit. The vibration unit is placed on the

magnet holder without the need of further attachment.

5 Putting into operation

a Magnet Holder *

O-Ring (14×1.78)

Pulsation chamber

Pre-filter with 50 µm mesh

O-Ring (3.68×1.78)

Luer Lock

Screw M3×8

Screw M3×25

Screw M3×6

*with attached fixation ring and

screws M3×5.

You can remove the fixation

ring for cleaning.

Do not remove either the

magnet or the glass fiber

reinforced PTFE membranes!

Figure 5-3: Parts of the bead producing unit

5.5 Single (inner) nozzles

A high quality nozzle is crucial for homogenous bead production. The holes of the Encapsulator

nozzles are precisely drilled using the newest technology. Every Encapsulator B-390 is delivered with

a set of 8 nozzles; nozzle aperture sizes are 80, 120, 150, 200, 300, 450, 750 µm and 1.0 mm. They

are made completely of stainless steel.

Figure 5-4: Set of 8 nozzles on the nozzle rack

The nozzle rack contains 8 nozzles (80, 120, 150, 200, 300, 450, 750 µm, and 1.0 mm). The size of

the O-ring is 4.47×1.78.

22 B-390 Operation Manual, Version C

Page 23

5.6 Electrode

The electrode is part of the electrostatic dispersion unit. It is attached from below to the heating block.

The distance between the electrode and the nozzle tip can be changed as needed. This distance is

approximately 3 to 8 mm. It should be set so that the droplets are formed near the upper side of the

electrode.

When the beads pass through the electrode they pick up the electrostatic charge. This electrostatic

charge is transferred to the polymerization bath and accumulates if the vessel is not grounded. The

electrostatic field created by the accumulated charges can be so strong that small beads are repelled

over the bath and will no longer enter it. Therefore, the grounding hook attached to the grounding wire

is put into the polymerization bath so that the electrostatic charges will flow to ground, see figure 5-8.

2

5 Putting into operation

a Electrode hole

Screws of the clip to change

the length of the clip

1

Figure 5-5: Electrode with two clips

Figure 5-6: Grounding set

23 B-390 Operation Manual, Version C

Page 24

5 Putting into operation

Figure 5-7: Position of the electrode below the carrier plate

Figure 5-8: Grounding the polymerization bath

24 B-390 Operation Manual, Version C

Page 25

5.7 Pressure bottle

The pressure bottle is an autoclavable container used to push the encapsulation mixture by air pressure into the bead producing unit. Figure 5-9 shows the different parts of the pressure bottle. The

glass recipient has a guaranteed pressure resistance of 1.5 bar.

The liquid flow rate is controlled at two levels:

1. With the air pressure by the pressure regulation system, and

2. with the liquid flow regulating valve situated on top of the control unit. The reproducibility of the

liquid flow rate from one run to the other is usually ±5 %.

5 Putting into operation

1 3 42

5

89

Figure 5-9: Pressure bottle with HEPA filter for sterile pumping of the immobilization mixture with air pressure

a Pressure stable flask of 500 mL or 1,000 mL

HEPA air filter

PTFE tube (4×6)

Silicone tube for liquid (4×7)

Silicone tube for air (5×8)

Luer lock male, 4.8 mm ID

Nipple for quick coupling

Two port cap

Cap with PTFE fitting for 6 mm tubes

67

The air passes through a silicone tube with an inner diameter of 5 mm (5×8 mm). The Hepa-filter

prevents contamination of the sterile immobilization mixture and should be replaced according to the

manufacturer’s instructions or if signs of reduced air passage are noticeable.

The liquid passes from the inside of the bottle through a PTFE tube (3×6 mm) to the silicone tube

outside of the bottle. This silicone tube is attached to the bead producing unit with the luer lock male .

25 B-390 Operation Manual, Version C

Page 26

5.7.1 Installation of the pressure bottle

5 Putting into operation

1. Assemble and – if needed - autoclave the

pressure bottle.

2. Fill the bottle with the immobilization mixture.

3. Attach the silicone tube of the pressure bottle

to the luer lock inlet of the bead producing

unit.

4. Pass the silicone tube in the liquid regulating

flow valve. Squeeze it so that no liquid can

pass.

5. Insert the nipple g of the air tube into the

quick coupling of the air outlet at the control

unit.

Figure 5-10: Installed pressure bottle

26 B-390 Operation Manual, Version C

Page 27

5.8 Option: Concentric nozzle system

The concentric nozzle system (CN system) is an optional kit to the single nozzle unit. It is for the

production of capsules in a one-step procedure. The system consists of CN bead producing unit, a

set of 7 shell nozzles (0.20, 0.30, 0.40, 0.50, 0.60, 0.70 and 0.90 mm) and one pressure bottle of

1000 mL. The shell liquid is pumped by air pressure using the pressure bottle.

The main parts of the concentric nozzle unit are (refer to figure 5-12):

• the nozzle pair with shell a and core nozzle.

• CN bead producing unit with CN pulsation body and magnet

holder .

5 Putting into operation

Figure 5-11: Capsule formation

Figure 5-12: Schematic description of the concentric nozzle system

a Shell nozzle

Core nozzle

CN pulsation body

Magnet holder

Luer connection, for

core liquid

Luer connection, for

shell liquid

Vibration unit

Carrier plate

27 B-390 Operation Manual, Version C

Page 28

5 Putting into operation

Figure 5-13: CN bead producing unit with set of 7 shell nozzles. The following nozzle apertures are standard:

0.20, 0.30, 0.4, 0.50, 0.60, 0.70 and 0.90 mm.

1 4

2

Figure 5-14: Single parts of the CN bead producing unit

3

7

8

5 6

9

10

a Screw M3×6

Luer lock female

Pre-filter grid 50 µm mesh, D= 7 mm

O-Ring 14.0×1.78

Screw M3×8

Screw M3×25

O-Ring 3.68×1.78

CN pulsation body

O-Ring 12.42×1.78

CN membrane holder

28 B-390 Operation Manual, Version C

Page 29

5.8.1 Mounting of CN nozzles

2

Figure 5-15: Mounting of the inner nozzle

5 Putting into operation

Put the O-ring 12.42×1.78 in the grove of the CN

1

bead producing unit. Put the inner nozzle (with

attached O-ring) into the hole of the CN bead

producing unit. There is no thread. The inner

nozzle is centered and fixed by the shell nozzle.

a Exit of the shell liquid

O-ring 12.42×1.78

Put carefully the shell nozzle over the inner

nozzle. Attach the shell nozzle with two screws

(M3×6). The shell nozzle centers and fixes the

inner nozzle.

Figure 5-16: Mounting of the shell nozzle

Figure 5-17: Installation of the concentric nozzle system

29 B-390 Operation Manual, Version C

Page 30

5 Putting into operation

Attach the complete CN bead producing unit to the carrier plate with two screws (M3×25). Attach the

silicone tube of the core liquid to the core inlet port and the silicone tube of the shell liquid to the shell

inlet port.

Pass the silicone tubes in the liquid regulating flow valves. Squeeze them so that no liquid can pass.

Figure 5-18: Connection of the pressure bottles to the air outlet. A T-piece feeds both pressure bottles.

5.9 Final installation check

This check has to be carried out after every installation and prior to the first encapsulation process. All

connected supply media (e.g. mains voltage and gas pressure) must match the technical data of the

installed system or system set-up.

• Inspect all glass components for damage.

• Check all other electrical connections for proper connection, such as optional or external components, e.g. magnetic stirrer, vibration unit, etc.

30 B-390 Operation Manual, Version C

Page 31

6 Operation

10

This chapter gives examples of typical instrument applications and instructions on how to operate the

instrument properly and safely. See also section 2.5 “Product safety” for general warnings.

6.1 Starting up the instrument

• Make sure the Encapsulator B-390 is properly connected to the mains supply.

• Carry out a final installation check (see section 5.9) before every bead production.

• Switch on the Encapsulator B-390. The system runs an internal check.

6.2 Screens and menu functions

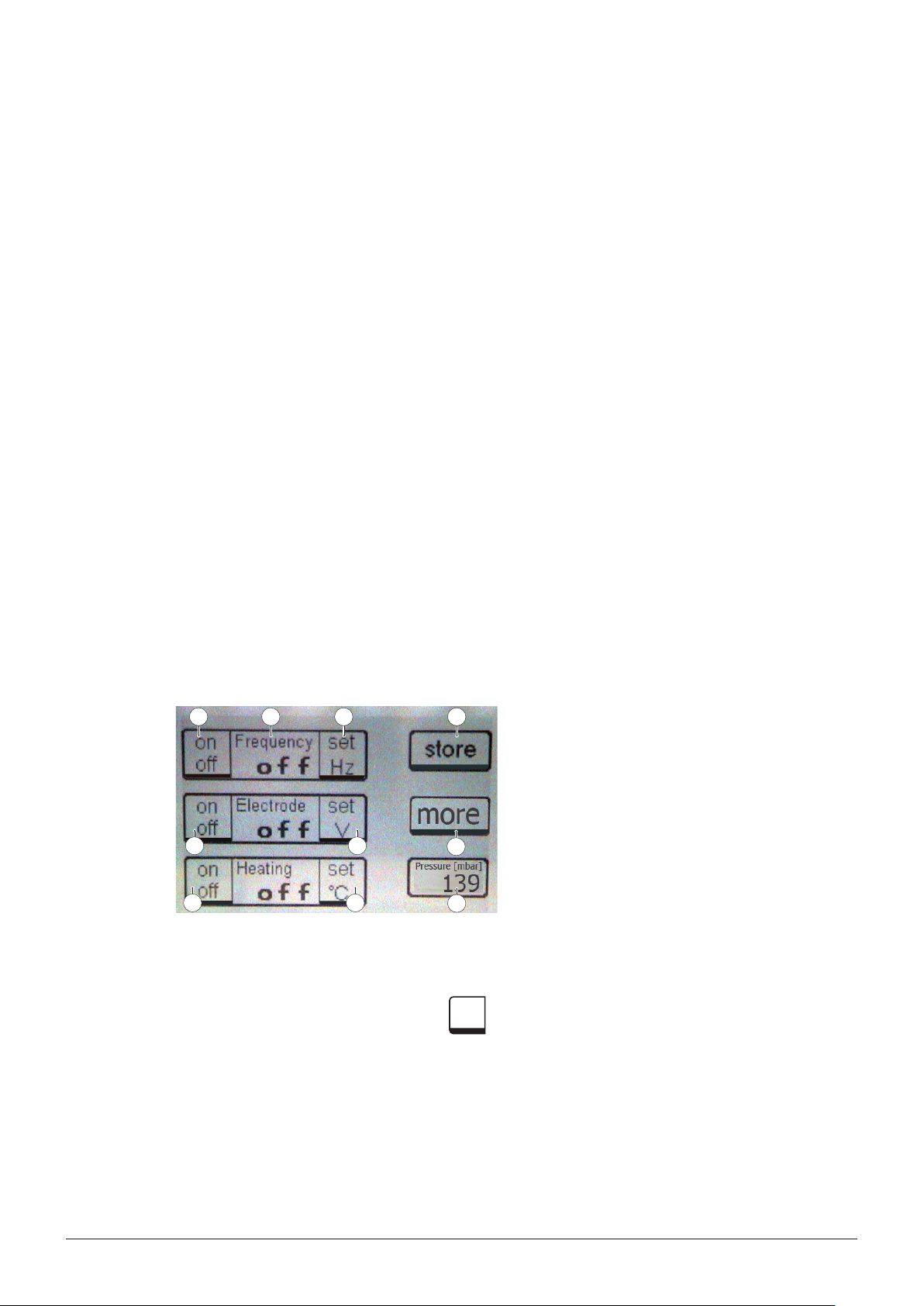

All controlling systems for bead production are incorporated in the control unit. Vibration, frequency,

heating, light intensity of stroboscope lamp, and electrostatic dispersion (electrode) are controlled on

the touch screen. Air pressure is regulated with the pressure regulating valve. The pressure is indicated

on the touch screen.

The integrated stroboscope lamp allows real time jet breakup control.

When the Encapsulator is switched on the touch screen runs an initialization program for few seconds.

Then the screen shows the start menu with four sub-parts (see figure 6-1 to 6-5) for frequency, electrode, heating and more options concerning frequency. Further are on the screen the indication of the

pressure and the button “store” for saving the set values.

6 Operation

21

5 6

8 9

Screen 6-1: Start menu of the Encapsulator touch screen

3 4

7

NOTE

Icons with a thick bar at the bottom e.g.

on

off

a on/off switch for frequency control.

Indication of control parameter and status of control

(value or off).

Button for passing to screen 6-2 for setting frequency

parameters.

Button for storing set values: press twice within one

second. A sound indicates that the values are stored.

on/off switch for electrode control.

Button for passing to screen 6-3 for setting electrode

parameters.

Button for passing to screen 6-5 for setting more

frequency parameters.

on/off switch for heating control.

Button for passing to screen 6-4 for setting heating

parameters.

Indication of pressure.

activate/stop a process or lead to another screen.

31 B-390 Operation Manual, Version C

Page 32

Screen 6-2: Frequency regulation

Screen 6-3: Electrostatic dispersion unit

6 Operation

The frequency regulation generates the appropriate electric oscillation in the vibration unit. Pressing on the (+) and

(–) buttons will change the frequency. Pressing the “on/off”

button activates or deactivates frequency. Pressing “Esc”

will return you to the start menu and the set value will be

kept.

The electrostatic dispersion unit is used to charge the

surface of the beads. The repulsion forces induced by the

equally charged surfaces prevent the beads from hitting

each other in flight, and from hitting each other as they enter

the hardening solution. The applied voltage often lies in the

range of 500 to 2000 V, depending primarily on the bead

size and the liquid flow velocity. In this way, the Encapsulator

B-390 can routinely generate bead batches with homogeneity greater than 95 %.

Pressing on the (+) and (–) buttons changes the electrostatic

dispersion parameter. The system needs few moments to

reach the set value. Pressing “Esc” will return you to the

start menu and the set value will be kept.

Pressing on the (+) and (–) buttons will change the heating

parameter. The system will need several minutes to reach

the set value. Pressing the “on/off” button activates or

deactivates heating. Pressing “Esc” will return you to the

start menu and the set value will be kept.

Screen 6-4: Heating regulation

Note

The indicated temperature is the temperature near the heater. The temperature of the bead

producing unit and of the nozzle are some degrees lower.

When starting the heating; an internal program starts to compensate for this temperature difference

as much as possible. Therefore the real heating might be delayed for up to 2 minutes.

!

Caution

Hot surface while heating is switched on.

• Do not touch the heating block or the carrier plate while heating is switched on. The surface of

both elements becomes hot during heating!

• Allow both elements to cool down before touching them if heating has been switched on

before.

32 B-390 Operation Manual, Version C

Page 33

Screen 6-5: More options concerning amplitude of vibration

and light Intensity of the stroboscope lamp.

6.3 Menu structure of the control unit

The figure below shows a schematic overview of all menus of the Encapsulator B-390, each with the

available functionality.

6 Operation

The light intensity of the stroboscope lamp and amplitude

( = intensity) of the vibration can be set from 1 to 9. Above

a frequency of 1500 Hz the amplitude can be set from 1

to 12. By increasing the amplitude the vibration becomes

stronger. Values above 3 are mainly for solutions with

viscosity > 100 mPa s. Pressing on the (+) and (-) buttons

will immediately change the parameters.

Pressing the “Esc”-button will cause a return to the start

menu and the set value will be kept.

Frequency[Hz]

FrequencyOn/Off

Set Frequency

Electrode [V]

ElectrodeOn/Off

Set Electrode

Figure 6-1: Menu structure of the control unit

Main menu

FrequencyOn/Off

ElectrodeOn/Off

HeatingOn/Off

Store function

Set Freq. | Set Elect. | Set Heat.

More

|

Heating [°C]

Heating On/Off

Set Temperature

more Frequency

Set Light Intensity

Set Amplitude

33 B-390 Operation Manual, Version C

Page 34

6.4 Manual air pressure control

In the control unit the pressure is manually controlled by the pressure regulating valve, integrated in

the front panel of the control unit (see figure 6-2). Set the air pressure at a value which is 0.2 to 0.3 bar

higher then the maximal air pressure needed during the encapsulation procedure; but not higher then

1 bar. Turning the knob of the pressure regulating valve clockwise increases the pressure, counterclockwise decreases the pressure. The knob of the pressure regulating valve has two positions. If it

is pushed in, it is locked, if it is pulled out, it is unlocked. Turning the knob counter-clockwise reduces

the pressure via the self-venting system in the valve. The pressure is indicated on the touchscreen (see

screen 6-1).

Note

• The pressure of air or nitrogen entering the control unit on the rear panel of the Encapsulator

should be below 7 bar (100 psi). The prefered range is between 1.5 and 2 bar (20 to 30 psi).

• Be aware that the pressure regulation system reacts relatively slowly, because the displacement

of air in or out through the constriction valve is delayed.

6 Operation

• Do not leave the gas supply line on when the Encapsulator is not being used. The self-venting

system in the valve would drain the gas tank.

• The maximum pressure at the air outlet is 1.5 bar (20 psi). This value is controlled by an incorporated overpressure safety valve, which opens at 1.5 bar. However the working range is from 0 to

1 bar.

Figure 6-2: Air pressure regulating system for manual

air pressure control - turning the pressure regulating

valve clockwise increases the pressure.

34 B-390 Operation Manual, Version C

Page 35

6.5 Practicing with the Encapsulator, using water

Before working with encapsulation polymers, use water for practicing with the Encapsulator to

become familiar with the effects of the controls.

1. Assemble the bead producing unit, screw the 0.30 mm single nozzle to the bead producing unit

and attach all on the carrier plate with the screw (M3×25). Fix the electrode. Place the vibration

unit on the bead producing unit.

2. Fill the pressure bottle with 200 to 300 mL distilled water and screw on the assembled cap. Pass

the silicon tube (4×7 mm) between the blades of the flow regulating valve and attach the male luer

lock fitting of the silicon tube to the female luer lock fitting of the bead producing unit. Squeeze the

valve by turning the knob clock wise so that the silicon tube is closed.

3. Open the external pressurized air supply. The air inlet pressure is optimally at 1.5 to 2 bar (20 to 30

psi). However the system tolerates air inlet pressures of up to 7 bar (100 psi).

4. Set the air outlet pressure to 0.2 bar with the pressure regulating valve. Check the readout periodi-

cally to verify that the air pressure still corresponds to the set value. Activate the vibration control

system and set the frequency at 800 Hz.

6 Operation

5. Open the flow regulating valve by turning the knob counter-clock wise until the water flows

through the silicone tubing and the bead producing unit to the nozzle where it forms a continuous

liquid jet. Adjust the liquid flow and/or the frequency to obtain a good bead chain in the light of the

stroboscope lamp. The desired setting is when the beads within the bead chain are clearly separated for several centimeters, starting 3 to 5 mm below the nozzle. Record the position of the flow

regulating valve for this desired setting.

6. Increase the vibration frequency until the bead chain becomes unstable. Then increase the liquid

flow rate by slowly increasing the air pressure until a uniform bead chain is restored. Repeat this in

the opposite direction by decreasing the flow rate and compensating by decreasing the vibration

frequency. This may be done until you become familiar with the relationship between these two

settings. Record the values in table 6-1.

NOTE

• The liquid flow rate and the vibration frequency influence each other within a given working range.

The working range itself is mainly determined by the nozzle diameter and the viscosity of the polymer

mixture.

• An air pressure setting between 0.05 to 0.15 bar is sufficient to pump distilled water. Greater

working pressures indicate problems such as a clogged nozzle.

General Rules:

• Higher frequencies generate smaller bead sizes.

• Lower liquid flow rates generate smaller bead sizes.

35 B-390 Operation Manual, Version C

Page 36

Table 6-1: Determination of the working field (with pressure bottle)

Nozzle size:

6 Operation

Air pressure Clear bead chain without

electrostatic tension

Lowest

frequency

Highest

frequency

Clear bead chain with

electrostatic tension

Electrostatic

Voltage

Lowest

frequency

Highest

frequency

Nozzle size:

Air pressure Clear bead chain without

electrostatic tension

Lowest

frequency

Highest

frequency

Clear bead chain with

electrostatic tension

Electrostatic

Voltage

Lowest

frequency

Highest

frequency

36 B-390 Operation Manual, Version C

Page 37

6 Operation

7. Set the liquid flow rate and the vibration frequency to a value where a clear bead chain is obtained.

Activate the electrostatic dispersion unit at 300 V and increase the tension stepwise by 100 V until

the one-dimensional liquid jet is transformed into a funnel-like multi-line stream. The higher the

electrostatic charge the earlier the bead chain is separated. This prevents the beads from hitting

each other in flight, and from hitting each other as they enter the hardening solution. Therefore the

Encapsulator can routinely generate bead batches with homogeneity greater than 95 %. If nothing

happens, check that the electrode is connected to the control unit.

8. Change the vibration frequency and the flow rate and observe their influence on the electrostatic

tension needed to generate a jet separation. The use of electrostatic tension enlarges the working

range.

It can happen that after some time, the beads no longer enter, or actually jump out of the beaker.

This is due to the fact that electrostatic charges have accumulated in the electrically isolated

beaker. To avoid this phenomenon, place the supplied stainless steel clip of the grounding wire

over the edge of the beaker so it extends into the receiving liquid and connect the green-yellow

wire to the grounding plug on the front panel of the control unit. (See figure 6-3).

Figure 6-3: Grounding the open polymerization bath

General Rule:

The larger the beads, the higher the electrostatic voltage needed to seperate the jet.

9. Change the amplitude of the vibration. You will observe only slight changes of the bead chain.

Very often values between 1 and 3 are optimal for low viscous solutions. If using immobilization

mixtures with rather high viscosity (> 150 mPa s), values higher than 3 might be more appropriate.

10. Repeat this procedure with another nozzle size.

General Rule:

• Smaller nozzles generate smaller bead sizes.

• The final bead diameter will be approximately 2 times the nozzle size.

37 B-390 Operation Manual, Version C

Page 38

6.6 Practicing with the Encapsulator, using alginate solution

After getting comfortable with the bead formation controls, perform test runs with non-sterile alginate solutions. Sodium alginate is the most commonly used polymer, but there are others in use

with varying properties. We recommend the low viscosity grade alginate. The alginate concentration

strongly influences the viscosity and this in turn influences the pressure drop in the nozzle. Therefore, the maximum concentration of the alginate solution is a function of the nozzle diameter (see the

following table).

Table 6-2: Recommended alignate concentration (based on dry weight) for different nozzle diameters

Nozzle diameter Concentration of low viscosity grade alginate

Working range Recommended concentration

80 to 120 µm 0.75 to 1.4 % 1.1 to 1.2 %

120 to 200 µm 1.0 to 1.6 % 1.3 to 1.4 %

200 to 300 µm 1.2 to 1.8 % 1.5 to 1.6 %

300 to 500 µm 1.5 to 2.5 % 1.8 to 2.0 %

6 Operation

NOTE

Under normal storage conditions the alginate powder contains 10 - 12 % water. Therefore we refer to

the alginate concentration on a dry weight base.

6.6.1 Preparation of 1.5 % Na-alginate solution

1. Take a 400 mL beaker and weigh in 3.3 g Na-alginate powder of low viscosity grade.

2. Add 200 mL of deionized water and mix vigorously with a laboratory mixer for 1 to 2 minutes.

3. Alginate has the tendency to get lumpy. Remove the alginate lumps from the beaker and the mixer

blades with a spatula and mix again for 1 to 2 minutes. If lumps remain in the liquid, repeat mixing.

4. Then let the mixture stand so that the trapped air bubbles will escape from the liquid.

5. If needed, de-gas the mixture under reduced pressure.

6. Dissolution of alginate with a magnetic stirrer takes much more time and should be done over-

night.

NOTE

Alginate solutions will support the growth of microorganisms and are stable for about 2 weeks in a

refrigerator. An indication of microbial contamination is reduction of the mixture’s viscosity. Alginate

solutions can be stored for much longer time, even at room temperature, if sterilized or if preservatives are added, like 0.05 % NaN3.

38 B-390 Operation Manual, Version C

Page 39

6.6.2 Working with alginate solution

1. Attach a 200 µm or 300 µm nozzle to the assembled bead producing unit. Attach all to the carrier

plate. Check that the electrode is attached. Put the vibration unit on the bead producing unit. Put

a magnetic stirrer below the nozzle and a large beaker on the stirrer. Fill the beaker with 100 mM

CaCl2 so that at least 2 cm (approx. ¾”) is filled with the polymerization liquid. Put a magnetic stir

bar in the beaker and adjust the stirrer, so that a slight vortex is visible. Also, place the grounded

clip over the edge of the beaker and into the liquid. At this time, either cover the beaker with a

plate (petri dish) or move it and the stirrer out of the way and position an empty beaker (and the

grounding clip) under the nozzle in its place.

2. Fill the pressure bottle with the above described 1.5 % alginate solution and screw on the

assembled cap. Pass the silicon tube (4×7 mm) between the blades of the liquid flow regulating

valve and attach the male luer lock fitting of the silicon tube to the female luer lock fitting of the

bead producing unit. Squeeze the valve by turning the knob clock wise so that the silicon tube is

closed.

3. Open the external pressurized air supply. The air inlet pressure is optimally at 1.5 to 2 bar (20 to 30

psi). However the system tolerates air inlet pressures of up to 7 bar (100 psi).

6 Operation

4. Set the air pressure to 0.4 bar at the pressure regulation system. Check the readout periodically to

verify that the air pressure still corresponds to the set value. Activate the vibration control system

and set the vibration frequency at 1100 Hz for the 200 µm nozzle and at 800 Hz for the 300 µm

nozzle.

5. Open the liquid flow regulating valve by turning the knob counter-clock wise until the liquid flows

through the silicone tubing and the bead producing unit to the nozzle where it forms a continuous

liquid jet. Adjust the liquid flow and/or the frequency to obtain a good bead chain in the light of the

stroboscope lamp. The desired setting is when the beads within the bead chain are clearly separated for several centimeters, starting 3 to 5 mm below the nozzle. Record the position of the flow

regulating valve for this desired setting.

6. Increase the vibration frequency until the bead chain becomes unstable. Then increase the liquid

flow rate by slowly increasing the air pressure or by slowly opening the flow regulating valve until

a uniform bead chain is restored. Repeat this in the opposite direction by decreasing the flow rate

and compensating by decreasing the vibration frequency. This may be done until you become

familiar with the relationship between these two settings.

NOTE

An air pressure setting from 0.1 to 0.8 bar is generally sufficient to pump the polymer mixture.

Working pressures greater than 1.0 bar should be avoided and are indicative of problems such as:

• Clogged nozzle,

• Overly viscous polymer mixture,

• Under sized nozzle for the polymer mixture in use.

7. Activate the electrostatic dispersion unit at 500 V. Increase the voltage by steps of 100 V to get a

circular dispersal of the bead stream 3 to 10 cm (1” to 4”) after the electrode. An optimal distance

is about 5 cm (approx. 2”) below the electrode.

39 B-390 Operation Manual, Version C

Page 40

6 Operation

NOTE

The stronger the circular dispersal of the bead stream the better is the bead homogeneity. This does

not only depend on the electrostatic tension, but the liquid flow rate and the vibration frequency are

also factors. Ideally, the bead should separate from the liquid jet within the electrostatic field between

the nozzle and the end of the electrode.

8. As soon as a symmetrical and stable dispersal is obtained, remove the plate from the beaker

filled with polymerization solution or replace the beaker of water with the beaker of polymerization

solution and the stir plate (and the grounding forceps), and collect the beads for about 1 minute.

Record the process parameters in table 6-3 while the beads are accumulating. Cover or switch

the beaker and stop the bead production by turning off the electrostatic voltage and vibration

control.

NOTE

Clean the nozzle thoroughly immediately after each run with distilled water to avoid nozzle clogging or

partial occlusion due to dried out polymer mixture.

9. Check the beads under a microscope with a micrometer scale eyepiece, and record your obser-

vations of diameter, uniformity and shape in table 6-3.

10. Repeat this process for each change in process parameters.

Table 6-3: Encapsulator trial test work sheet (pressure bottle)

Nozzle size [µm]

Alginate concentr. [%]

Position of the flow regulating valve

Vibration frequency [Hz]

Amplitude

Approximate bead size [µm]

Homogeineity [%]

Comments

NOTE

When producing small beads with a diameter <500 µm, it may occur that their shape is not spherical

but somewhat oval. This is mainly due to the surface tension of the polymerization solution. A very

critical point for the bead is it‘s entrance into the polymerization solution. If the surface tension is

high, then the bead is partially held back at the surface and polymerization starts before the bead can

regain a round shape. This problem can be eliminated by adding a small quantity of surfactant like

Tween 20 to the polymerization mixture.

11. Compare the influence of the electrostatic tension by collecting beads at the same vibration

frequency and pumping rate with and without the electrostatic tension function turned on.

40 B-390 Operation Manual, Version C

Page 41

6.7 Theoretical background

Equ. 1:

When a laminar jet is mechanically disturbed at the frequency ƒ,

beads of uniform size are formed1. The optimal wavelength λ

breakup, according to Weber2 is given by:

Equ. 2:

where: D = nozzle diameter

η = dynamic viscosity [Pa s]

ρ = density [kg/m3]

(ca. 1000 kg/m3 for alginate solutions)

σ = surface tension [N/m]

(ca. 55×10-3 N/m for alginate solutions)

opt

6 Operation

for

λ

is the optimal wavelength to get the best bead formation for the given nozzle diameter and the

opt

viscosity of the encapsulation mixture. It is possible to change λ

by 30 % and still achieve a good

opt

bead formation.

The diameter of a bead = d [m] can be calculated with the flow rate = V’ [m3/s] and the frequency of

the pulsation ƒaccording to:

Equ. 3:

The jet velocity = v [m/s] and the nozzle diameter = D [m] are correlated to the flow rate (V’) according

to:

Equ. 4:

Figure 6-4 shows the dependence of the flow rate to the jet velocity and the nozzle diameter as calculated by Equation 4. Because the liquid must flow laminarly the working range of the jet velocity will

normally lay between 1.5 and 2.5 m/s, depending on the liquid viscosity and the nozzle diameter.

1

Lord Rayleigh 1878. Proc. London Math. Soc. 10:4.

2

Weber C. 1936. Zeitschrift für angewandte Mathematik und Mechanik. 11:136.

41 B-390 Operation Manual, Version C

Page 42

6 Operation

Figure 6-4: Influence of the liquid jet velocity and the nozzle diameter on flow rate, as calculated by Equation 4.

Figure 6-5 shows the correlation between the vibration frequency and the bead diameter for five

different flow rates as calculated by equation 4. Lower flow rates, which corresponds to lower

pumping rates, produce smaller beads. Higher vibration frequencies produce smaller beads also.

Figure 6-5: Influence of the vibration frequency and the flow rate on the bead diameter as calculated by Equation 4.

42 B-390 Operation Manual, Version C

Page 43

6 Operation

Table 6-4: Optimal working conditions for the Encapsulator determined with alginate solution

Nozzle diameter [µm] Flow rate * [mL/min] Frequency interval ** Amplitude Air pressure [bar]

1.0 mm 30 to 40 40 to 220 Hz 2 to 6 0.3 to 0.6

750 µm 19 to 25 40 to 300 Hz 2 to 5 0.3 to 0.5

450 µm 9 to 14 150 to 450 Hz 2 to 5 0.3 to 0.5

300 µm 5.5 to 7 400 to 800 Hz 1 to 3 0.3 to 0.5

200 µm 3.5 to 4.5 600 to 1200 Hz 1 to 3 0.4 to 0.6

150 µm 2.3 to 2.8 800 to 1800 Hz 1 to 3 0.4 to 0.6

120 µm 1.5 to 1.8 1000 to 2500 Hz 1 to 4 0.5 to 0.7

80 µm 1.1 to 1.3 1300 to 3000 Hz 1 to 4 0.5 to 0.7

* Tested with 2 % low viscosity grade alginate solution for 750 µm and 1.0 mm nozzle, with 1.5 %

alginate solution for the 150 to 500 µm nozzle and with 1.2 % alginate solution for the 80 and 120 µm

nozzles.

**Upper values with application of high voltage.

NOTE

For solutions with a viscosity different from the tested one, it can be said that:

• the higher the viscosity the higher the minimal jet velocity

• the higher the viscosity the higher the working flow rate

• the higher the viscosity the lower the optimal frequency

• the higher the viscosity the larger the beads

6.7.1 Bead productivity and cell density

Figures 6-6 and 6-7 indicate the amount of beads formed from 1 mL of liquid. About 30,000 beads

with a diameter of 0.4 mm will be formed, but only 2,000 with a diameter of 1 mm.

Figures 6-8 and 6-9 indicate the number of cells which are encapsulated in one bead for a given

cell density and bead diameter. These figures may help you select the appropriate cell density in the

immobilization mixture. For example, if the immobilization mixture contains 1×106 cells per mL, then

about 33 cells are, on average, in each 0.4 mm bead, but, about 520 cells will be in each 1 mm bead.

43 B-390 Operation Manual, Version C

Page 44

6 Operation

Figure 6-6: Amount of beads with a diameter of 0.3 to 0.6 mm formed from 1 mL of immobilization mixture.

Figure 6-7: Amount of beads with a diameter of 0.6 to 1.1 mm formed from 1 mL of immobilization mixture.

44 B-390 Operation Manual, Version C

Page 45

6 Operation

Figure 6-8: Amount of cells per bead made from different cell concentrations for bead diameters of 0.3 to 0.6 mm.

Figure 6-9: Amount of cells per bead made from different cell concentrations for bead diameters of 0.6 to 1.1 mm.

45 B-390 Operation Manual, Version C

Page 46

7 Maintenance and repairs

This chapter gives instructions on maintenance work to be performed in order to keep the instrument

in good and safe working condition. All maintenance and repair work requiring the opening or removal

of the instrument housing must be carried out by trained personnel and only with the tools provided

for this purpose.

Note

Use only genuine consumables and spare parts for any maintenance and repair work in order to

assure warranty and continued system performance. Any modifications of the Encapsulator B-390 or

parts of it need prior written permission of the manufacturer.

7.1 Customer service

Only authorized service personnel are allowed to perform repair work on the instrument. Authorization requires a comprehensive technical training and knowledge of possible dangers which might arise

when working at the instrument. Such training and knowledge can only be provided by BUCHI.

7 Maintenance and repairs

Addresses of official BUCHI customer service offices are given on the BUCHI website under:

www.buchi.com. If malfunctions occur on your instrument or you have technical questions or application problems, contact one of these offices.

The customer service offers the following:

• Spare part delivery

• Repairs

• Technical advice

7.2 Housing condition

Check the housing for visible defects (switches, plugs, cracks) and clean it regularly with a damp cloth.

The Encapsulator control unit should be handled as with any other piece of electrical equipment. The

front panel is covered by a polyamide sheet, so that it may be cleaned with a mild detergent solution

or alcohol.

7.3 Sealing conditions

It is recommended to check the integrity of the sealings on a regular base. Gaskets, O-rings and silicone tubing should be replaced periodically (approximately once per year). Check all parts before use

and replace if needed.

46 B-390 Operation Manual, Version C

Page 47

7.4 Cleaning

7 Maintenance and repairs

!

Warning

Pressure increase in the inlet-system due to clogged nozzles.

Bursting of the inlet system.

Death or serious poisoning by contact or incorporation of harmful substances at use.

• Clean nozzle immediately after use, see following section.

Wear laboratory coat

Wear protective goggles

Wear protective gloves

7.4.1 Cleaning the nozzle after each immobilization run

It is critical to clean the nozzle immediately after use so that the encapsulation medium (alginate, etc.)

will not dry and clog the system.

1. Leave the nozzle in place on the bead producing unit.

2. Attach a 20 mL or 60 mL syringe to the bead producing unit and inject 20 to 60 mL of distilled

water or of the solvent used for the encapsulation polymer.

3. If needed unscrew the nozzle from the bead producing unit, rinse with deionized water (see

figure 7-1) or an appropriate solvent and dry the nozzle with a flush of air.

47 B-390 Operation Manual, Version C

Page 48

7 Maintenance and repairs

Figure 7-1: Cleaning procedure of the nozzle

– Take a syringe containing air on top and water on the bottom.

– Push the air through the nozzle (left figure).

– Push the water through the nozzle immediately afterwards (right figure).

– Examine the nozzle tip under a stereoscopic microscope to make sure the passage is

clear and clean.

NOTE

If lipophilic immobilization solutions were used, then use appropriate solvents for cleaning. Do not use

acid solution for alginate, as this would create a precipitate.

7.4.2 Cleaning a clogged nozzle

Unscrew the nozzle. Pass air or water through the nozzle as shown in figure 7-1.

If the nozzle tip is not clear, soak the nozzle in water, the appropriate solvent, in 1N NaOH or 1N

sulfuric acid (never use HCl) according to the encapsulation mixture for 1 hour at room temperature,

with periodic agitation. Sonication of full stainless steel nozzles is also a helpful procedure. Wear

appropriate protection equipment. Rinse with distilled water, with air and let dry.

Examine the nozzle tip under a stereoscopic microscope to make sure the passage is clear and clean.

NOTE

If lipophilic immobilization solutions were used, then use appropriate solvents for cleaning. Do not use

acid solution for alginate, as this would create a precipitate.

7.4.3 Cleaning the bead producing unit

Disassemble the bead producing unit. However the magnet holder should not be disassembled!

Wash all parts, with a mild detergent solution, 0.01N NaOH or 0.01N sulfuric acid (never use HCl) as

appropriate.

Rinse thoroughly with hot water, then with distilled water and let dry.

48 B-390 Operation Manual, Version C

Page 49

8 Troubleshooting

8.1 Malfunctions and their remedy

The table below lists possible operating errors and their cause. As remedy set the parameter stepwise

in the opposite direction or fix the missing part.

Table 8-1: Possible cause

Problem Possible cause

Unstable liquid stream The liquid flow rate is too low.

Unstable bead chain The frequency is too high or too low.

8 Troubleshooting

The nozzle is not adequately cleaned (frequent cause).

The frequency is too high.

The amplitude is too high.

The liquid flow rate is too high or too low.

The Nozzle is not adequately cleaned.

The amplitude is too low or too high.

Non-homogenous bead-size-distribution The liquid flow rate is too high.

The frequency is too high.

The electrostatic tension is too low.

The immobilization mixture is a non-Newtonian liquid, making it

difficult to extrude or to prill.

The bead chain does not separate The electrode is not connected to the control unit.

The electrical tension is too low.

The electrode is not on.

Beads are not visible in the strobo light The vibration unit is not activated.

The vibration unit is not put on the bead producing unit.

The vibration frequency is too low or too high.

The viscosity of the immobilization mixture is too high.

49 B-390 Operation Manual, Version C

Page 50

9 Shutdown, storage, transport and disposal

9 Shutdown, storage, transport and disposal

This chapter instructs how to shut down and to pack the instrument for storage or transport. Specifications for storage and shipping conditions can also be found listed here.

9.1 Storage and transport

Switch off the instrument and remove the power cord. Wait until all hot parts (e.g. heating block and

carrier plate) have cooled down.

To disassemble the Encapsulator B-390 follow the installation instructions in section 5 in reverse

order. Remove all liquids and dusty residues before packaging the instrument.

!

Warning

Death or serious poisoning by contact or incorporation of harmful substances.

• Wear safety goggles

• Wear safety gloves

• Wear a laboratory coat

• Clean the instrument and all accessories thoroughly to remove possibly dangerous substances

• Do not clean dusty parts with compressed air

• Store the instrument and its accessories at a dry place in its original packaging

50 B-390 Operation Manual, Version C

Page 51

9.2 Disposal

For instrument disposal in an environmentally friendly manner, a list of materials is given in chapter 3.3.

This helps to ensure that the components can be separated and recycled correctly.

You have to follow valid regional and local laws concerning disposal. For help, please contact your

local authorities!

NOTE

When returning the instrument to the manufacturer for repair work, please copy and complete the

health and safety clearance form in section 10.2 and enclose it with the instrument.

9 Shutdown, storage, transport and disposal

51 B-390 Operation Manual, Version C

Page 52

10 Declarations and requirements

10.1 FCC requirements (for USA and Canada)

English:

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to both Part 15 of the FCC Rules and the radio interference regulations of the Canadian

Department of Communications. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses and can radiate radio frequency energy and, if not installed and used

in accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

Français:

Cet appareil a été testé et s’est avéré conforme aux limites prévues pour les appareils numériques

de classe A et à la partie 15 des réglementations FCC ainsi qu’à la réglementation des interférences

radio du Canadian Department of Communications. Ces limites sont destinées à fournir une protection adéquate contre les interférences néfastes lorsque l’appareil est utilisé dans un environnement

commercial.

Cet appareil génère, utilise et peut irradier une énergie à fréquence radioélectrique, il est en outre

susceptible d’engendrer des interférences avec les communications radio, s’il n’est pas installé et

utilisé conformément aux instructions du mode d’emploi. L’utilisation de cet appareil dans les zones

résidentielles peut causer des interférences néfastes, auquel cas l’exploitant sera amené à prendre les

dispositions utiles pour palier aux interférences à ses propres frais.

10 Declarations and requirements

52 B-390 Operation Manual, Version C

Page 53

10.2 Health and Safety Clearance form

Health and Safety Clearance

Declaration concerning safety, potential hazards and safe disposal of waste.

For the safety and health of our staff, laws and regulations regarding the handling of

dangerous goods, occupational health and safety regulations, safety at work laws and

regulations regarding safe disposal of waste, e.g. chemical waste, chemical residue or

solvent, require that this form must be duly completed and signed when equipment or

defective parts were delivered to our premises.

Instruments or parts will not be accepted if this declaration is not present.

Equipment

Model: Part/Instrument no.:

1.A Declaration for non dangerous goods

We assure that the returned equipment

has not been used in the laboratory and is new

was not in contact with toxic, corrosive, biologically active, explosive, radioactive or

other dangerous matters.

is free of contamination. The solvents or residues of pumped media have been

drained.

1.B Declaration for dangerous goods

List of dangerous substances in contact with the equipment:

Chemical, substance Danger classification

We assure for the returned equipment that

all substances, toxic, corrosive, biologically active, explosive, radioactive or

dangerous in any way which have pumped or been in contact with the equipment

are listed above.

the equipment has been cleaned, decontaminated, sterilized inside and outside and

all inlet and outlet ports of the equipment have been sealed.

2. Final Declaration

We hereby declare that

- we know all about the substances which have been in contact with the equipment

and all questions have been answered correctly

- we have taken all measures to prevent any potential risks with the delivered

equipment.

10 Declarations and requirements

Company name or stamp:

Place, date:

Name (print), job title (print):

Signature:

53 B-390 Operation Manual, Version C

Page 54

10.3 Declaration of conformity

10 Declarations and requirements

54 B-390 Operation Manual, Version C

Page 55

Page 56