Page 1

Type 8x92, 8x93

Positioner / Process controller

- Software Tool for Communication

Software Tool for Communication for Positioner / Process controller

Kommunikationssoftware für Positioner / Prozessregler

Logiciel de communication pour positionneur / régulateur de process

Supplement to Operating Instructions

Ergänzung zur Bedienungsanleitung

Complément aux manuel d‘utilisation

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

© 2013 Bürkert Werke GmbH

Operating Instructions 1301/01_EU-ML_00810024 / Original DE

Page 3

Software Tool - 8x92 / 8x93

Communication software (Software Tool)

for positioner / process controller

Table of ConTenTs

1. SUPPLEMENTARY OPERATING INSTRUCTIONS ..............................................................................................................6

1.1. Symbols ......................................................................................................................................................................................6

2. GENERAL INFORMATION ................................................................................................................................................................7

2.1. Contact address .....................................................................................................................................................................7

2.2. Information on the internet ...............................................................................................................................................7

3. PRODUCT DESCRIPTION ...............................................................................................................................................................8

3.1. Required components .........................................................................................................................................................8

3.1.1. Windows 2000, XP, Vista ....................................................................................................................... 8

3.1.2. Windows XP, Vista, 7 ............................................................................................................................... 8

3.2. Definitions of terms for PACTware / FDT / DTM ..................................................................................................8

4. CONTROL AND DISPLAY ELEMENTS ......................................................................................................................................9

4.1. Overview of screen display ..............................................................................................................................................9

4.2. PACTware control and display elements ...............................................................................................................10

4.2.1. Toolbar .......................................................................................................................................................10

4.2.2. Status bar ..................................................................................................................................................11

4.3. Control and display elements of Bürkert DTMs .................................................................................................12

4.3.1. Toolbar .......................................................................................................................................................12

4.3.2. Status bar ..................................................................................................................................................12

4.3.3. Navigation area and work area .............................................................................................................13

4.3.4. Buttons for data transfer ........................................................................................................................14

4.3.5. Icons ...........................................................................................................................................................14

5. INSTALLATION ...................................................................................................................................................................................15

5.1. System requirements .......................................................................................................................................................15

5.2. Installing PACTware and DTMs ...................................................................................................................................16

5.2.1. PACTware version 3.6 and .NET Framework 1.1 including SP1 .................................................16

5.2.2. PACTware version 4.1 and .NET Framework 2.0 ............................................................................17

5.2.3. Bürkert device DTM ................................................................................................................................18

English

3

Page 4

Software Tool - 8x92 / 8x93

6. OPERATION AND FUNCTION ....................................................................................................................................................19

6.1. Starting PACTware .............................................................................................................................................................19

6.2. Creating a project ...............................................................................................................................................................19

6.2.1. General description ................................................................................................................................19

6.2.2. Creating a project for Bürkert positioners .........................................................................................21

6.3. Basic settings .......................................................................................................................................................................24

6.3.1. Activation of device DTMs .....................................................................................................................24

6.3.2. Device identification................................................................................................................................26

6.3.3. Running the automatic adjustment for TUNE FUNCTIONS ................................................... 27

6.4. Transferring parameters ..................................................................................................................................................29

6.4.1. Reading parameters from the device ..................................................................................................29

6.4.2. Write parameters to the device ............................................................................................................30

6.5. Parameterization .................................................................................................................................................................30

6.5.1. Parameterizing functions .......................................................................................................................31

6.6. Error messages ...................................................................................................................................................................32

6.6.1. Error messages while the X.TUNE function is running ................................................................ 32

6.6.2. Error messages while the PQ.LIN function is running ...................................................................32

6.6.3. Error messages while the P.TUNE function is running ..................................................................33

7. BASIC FUNCTIONS .........................................................................................................................................................................34

7.1. Overview of basic functions ..........................................................................................................................................34

7.2. Basic functions - parameter .........................................................................................................................................34

7.3. Basic functions - setting parameter .........................................................................................................................35

7.3.1. ACTUATOR -

Inputting the operating mode of the pneumatic actuator ...............................................................35

7.3.2. INPUT -

Enter the standard signal .......................................................................................................................35

7.3.3. BUS.COMM -

Adjust the selection / parameters of the field bus interface ..........................................................36

7.3.4. RESET -

Reset to factory settings ........................................................................................................................36

7.3.5. TUNE FUNCTIONS -

Automatic adjustment of the positioner / process controller to the relevant

operating conditions ...............................................................................................................................36

4

English

Page 5

Software Tool - 8x92 / 8x93

8. AUXILIARY FUNCTIONS ...............................................................................................................................................................37

8.1. Overview of auxiliary functions ...................................................................................................................................37

8.2. Adding auxiliary functions (ADD.FUNCTION) ......................................................................................................38

8.3. Removing auxiliary functions (ADD.FUNCTION) ................................................................................................38

8.4. Auxiliary functions - parameter....................................................................................................................................... 39

8.5. Auxiliary functions - setting parameter ...................................................................................................................39

9. DEINSTALLATION OF PACTWARE/ DTMS..........................................................................................................................40

9.1. Deinstallation process ......................................................................................................................................................40

English

5

Page 6

Software Tool - 8x92 / 8x93

Supplementary operating instructions

1. SUPPLEMENTARY OPERATING

INSTRUCTIONS

The supplementary operating instructions describe the communication software for positioner / process controller

TopControl and SideControl.

Safety Information!

Safety instructions and information for using the device may be found in the corresponding operating

instructions.

• The operating instructions must be read and understood.

1.1. Symbols

DANGER!

Warns of an immediate danger!

• Failure to observe the warning will result in a fatal or serious injury.

WARNING!

Warns of a potentially dangerous situation!

• Failure to observe the warning may result in serious injuries or death.

CAUTION!

Warns of a possible danger!

• Failure to observe this warning may result in a moderate or minor injury.

NOTE!

Warns of damage to property!

• Failure to observe the warning may result in damage to the device or the equipment.

Indicates important additional information, tips and recommendations.

Refers to information in these operating instructions or in other documentation.

→ Designates a procedure which you must carry out.

6

English

Page 7

Software Tool - 8x92 / 8x93

General information

2. GENERAL INFORMATION

2.1. Contact address

Germany

Bürkert Fluid Control Systems

Sales Center

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Contact addresses can be found on the final pages of the printed operating instructions.

And also on the Internet at:

www.burkert.com

2.2. Information on the internet

The operating instructions and data sheets for device types can be found on the Internet at:

www.burkert.com

English

7

Page 8

3. PRODUCT DESCRIPTION

3.1. Required components

3.1.1. Windows 2000, XP, Vista

• Microsoft .NET Framework 1.1

• Microsoft .NET Framework 1.1 Service Pack 1

• PACTware Version 3.6

including HART protocol driver from Codewrights GmbH

• Bürkert device DTM

"8692 Positioner TopControl"

"8693 Process controller TopControl"

"8792 Positioner SideControl"

“8793 Process controller SideControl”

Software Tool - 8x92 / 8x93

Product description

• Firmware Version C.01 or higher for types 8692 and 8693 or B.01 or higher for types 8792 and 8793

• Adapter USB-RS232, ID number 227093 (HART communication on the 4/20 mA interface is not possible).

3.1.2. Windows XP, Vista, 7

• Microsoft .NET Framework 2.0

• PACTware Version 4.1

including HART protocol driver from Codewrights GmbH

• Bürkert device DTM

“8692 Positioner TopControl”

“8693 Process controller TopControl”

“8792 Positioner SideControl”

“8793 Process controller SideControl”

• Firmware Version C.01 or higher for types 8692 and 8693 or B.01 or higher for types 8792 and 8793

• Adapter USB-RS232, ID number 227093 (HART communication on the 4/20 mA interface is not possible).

3.2. Definitions of terms for PACTware / FDT / DTM

PACTware (Process Automation Configuration Tool):

Manufacturer- and field bus-independent software for start-up, operation, and maintenance of all types of field

devices. This general product series includes the DTMs (Device Type Managers) of the corresponding field device

manufacturers. They are integrated according to interface specification FDT 1.20.

Therefore a DTM belonging to the relevant device type is always required to operate a field device.

FDT (Field Device Tool):

Standardized interface description; defines data exchange between the various DTMs and the frame application,

for example PACTware.

DTM (Device Type Manager):

The DTM is the actual control module of actuators, sensors, and field components. It includes all specific data and

functions of a specific device type and returns all elements and dialogs needed for operation.

8

A DTM is only capable of running within a frame program such as PACTware.

English

Page 9

Software Tool - 8x92 / 8x93

Control and display elements

4. CONTROL AND DISPLAY ELEMENTS

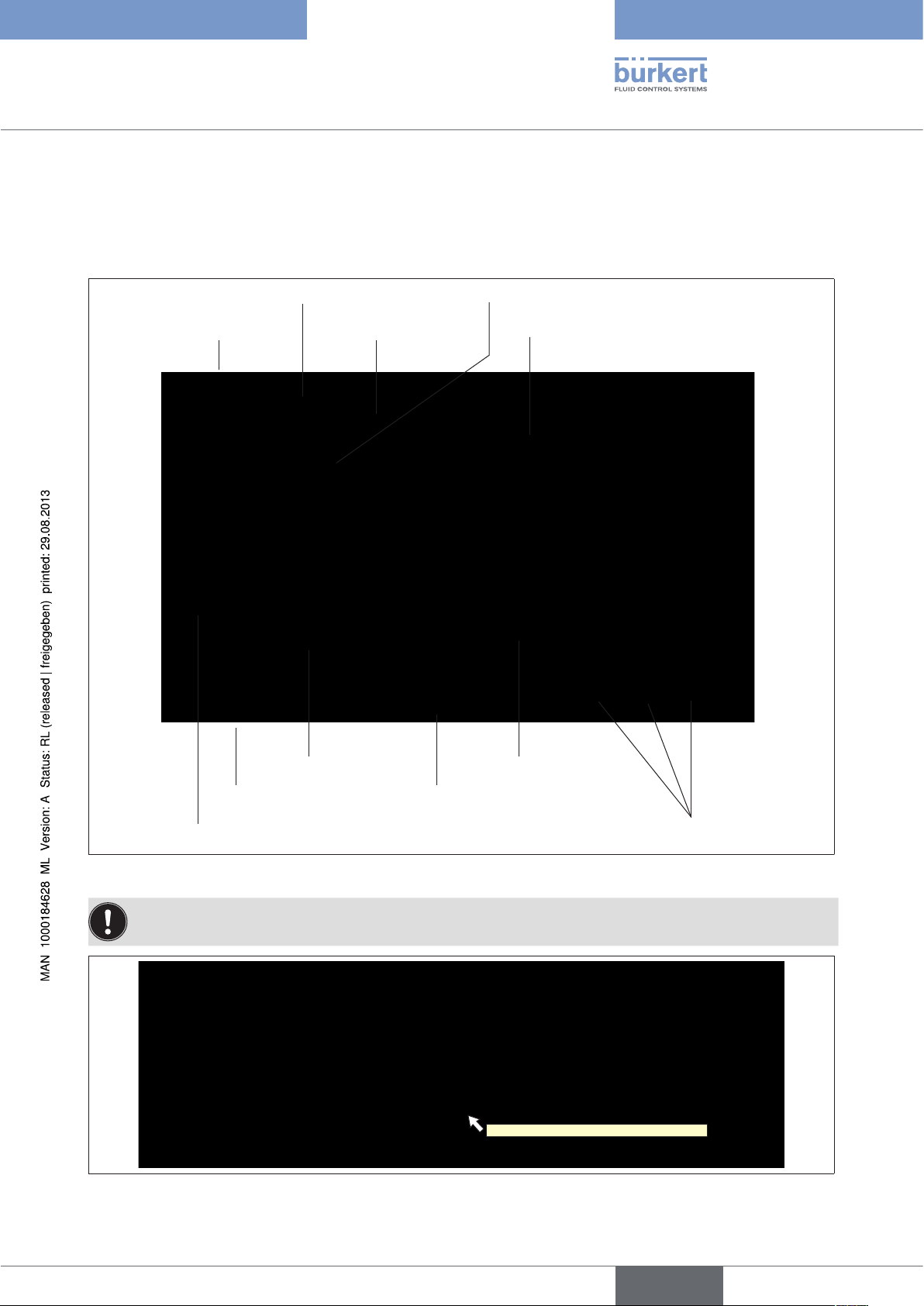

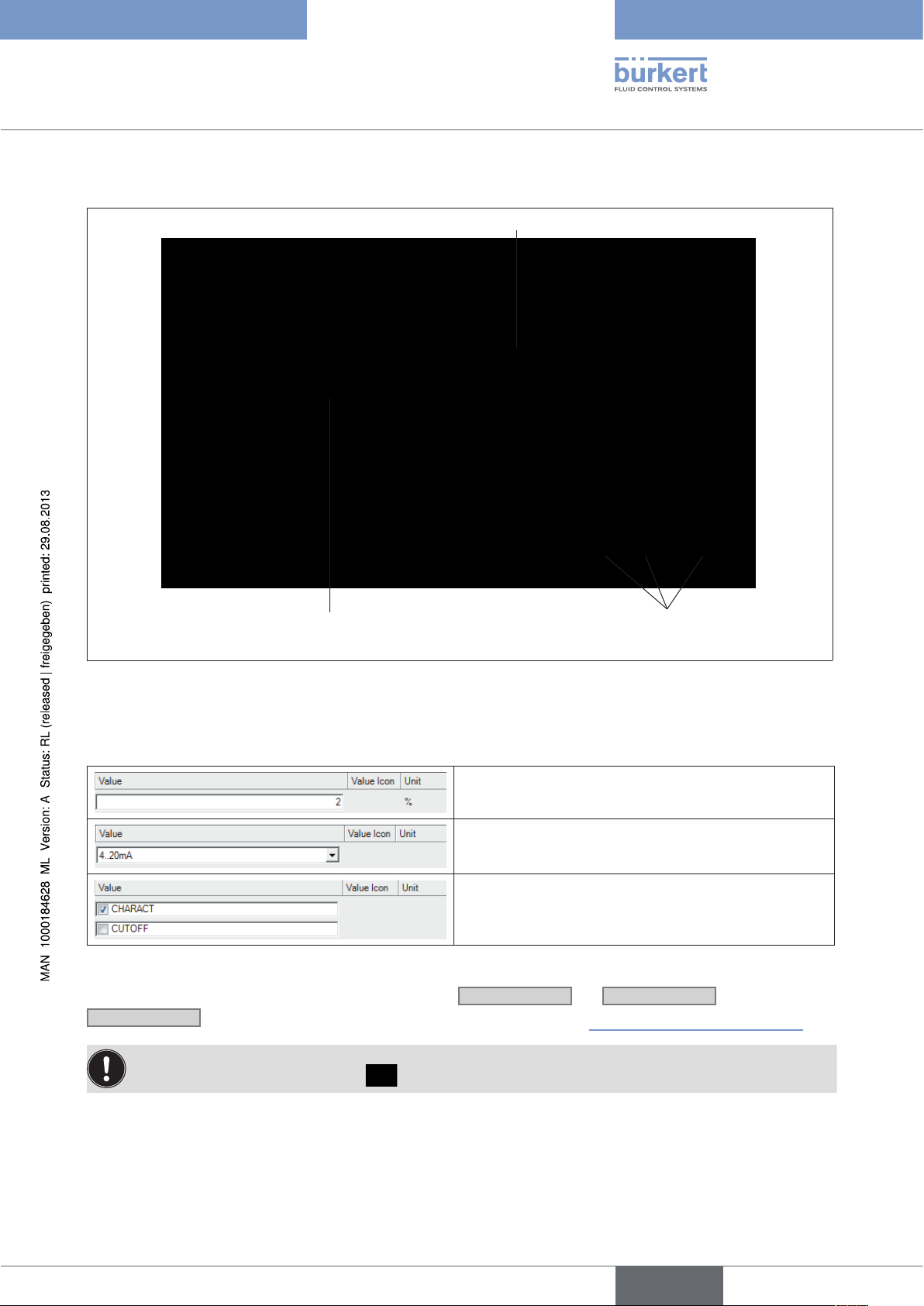

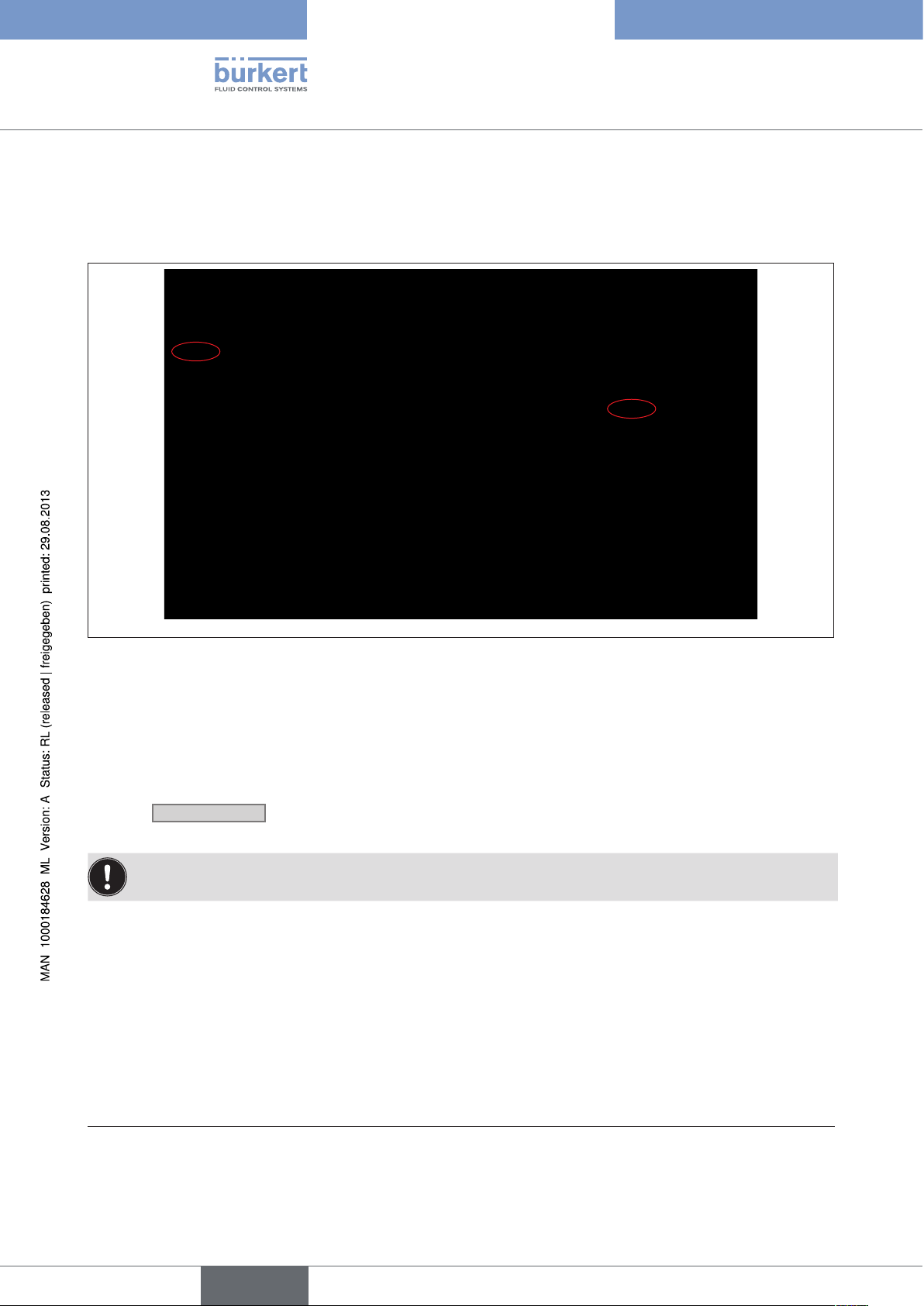

4.1. Overview of screen display

PACTware toolbar

PACTware window

DTM window

DTM toolbar

Identification area

Navigation area

PACTware status bar

Project window

Figure 1: Overview of screen display

Many icons and parameter have Tooltips (brief explanation) which clarify the function.

Figure 2: Tooltip

DTM status bar

Work area

Operating mode of actuator (single- or double-acting)

Buttons

9

English

Page 10

Software Tool - 8x92 / 8x93

Control and display elements

4.2. PACTware control and display elements

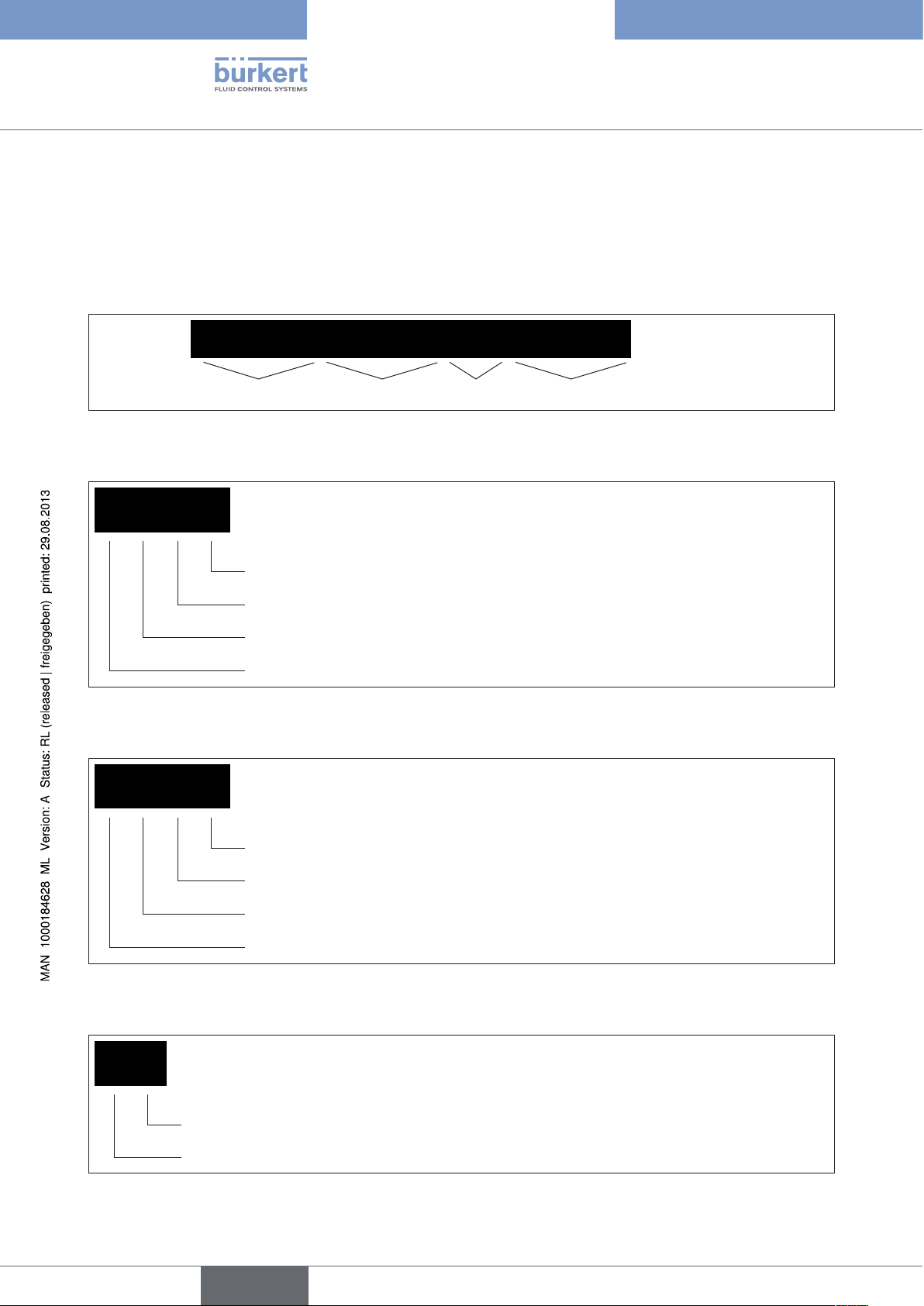

4.2.1. Toolbar

The toolbar is a combination of frequently required commands from the menu bar and project view. It is divided

into 4 sections.

Section 1 2 3 4

Figure 3: PACTware toolbar

Section 1: Icons for project administration

Print the current project

Save the current project

Open an existing project

Create a new project

Figure 4: PACTware toolbar - Section 1

Section 2: Icons for working with DTMs

Write current data to file

Write all data to the device

Read all data from the device

Edit current data

Figure 5: PACTware toolbar - Section 2

Section 3: Icons for activating specific PACTware windows

10

Device catalog

Project view

Figure 6: PACTware toolbar - Section 3

English

Page 11

Software Tool - 8x92 / 8x93

Control and display elements

Section 4: Icons for working with DTMs

Break the connection

Create a connection between the selected DTM and the field device

Delete the selected DTM from the project

Insert an additional DTM into the project at the selected position

Figure 7: PACTware toolbar - Section 4

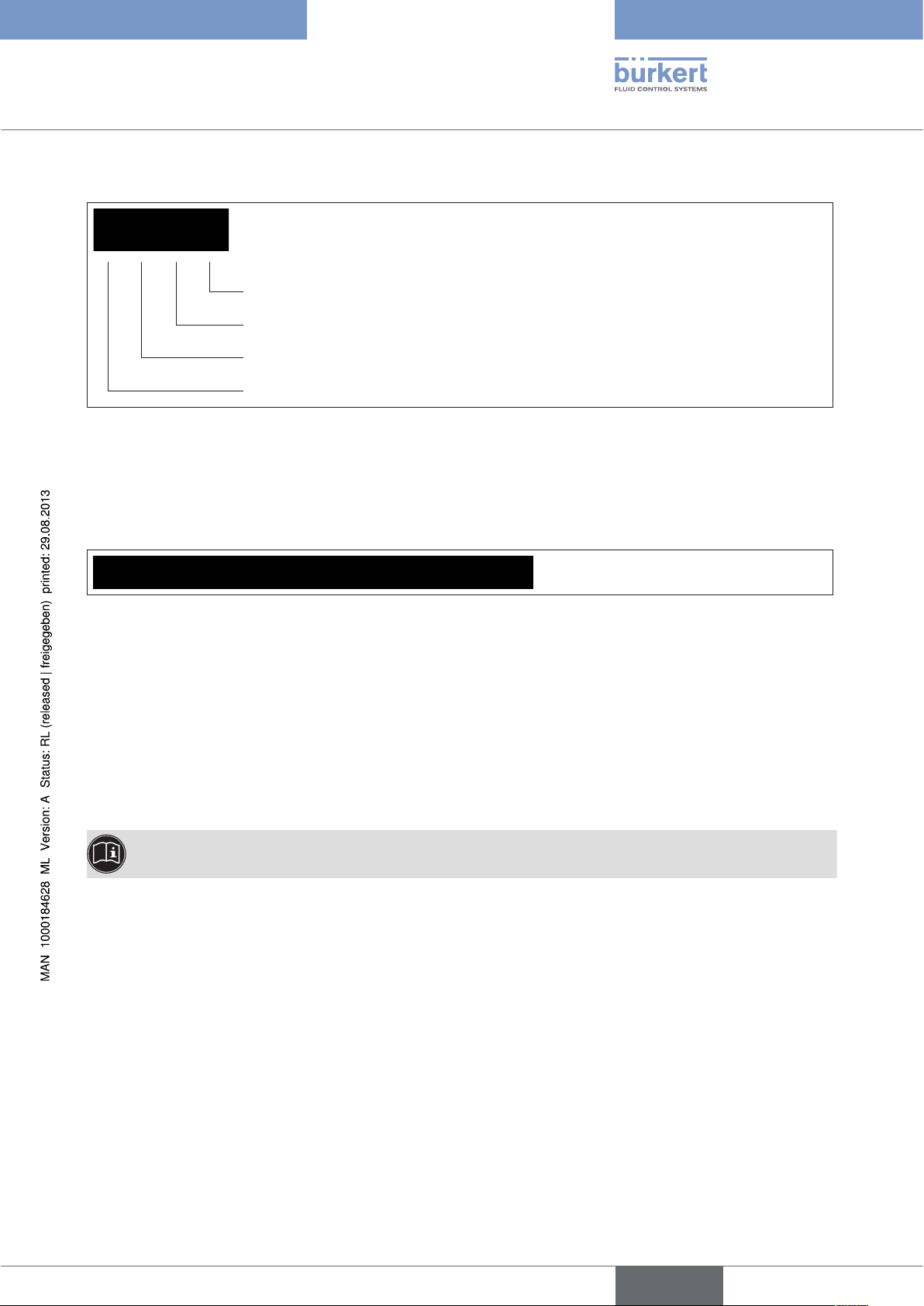

4.2.2. Status bar

The status bar contains information about the current state of the project being processed.

Figure 8: Status bar

Meaning of the displays (from left to right):

• Connection status: Broken / connected

• Project has been changed (indicated by an asterisk)

• There are error messages. The icon flashes if the messages have not been displayed on the error monitor yet. A

Tooltip indicates the number of error messages present.

• Name of the project

• Active user role

More extensive explanations describing operation and how to create a project are available in the PACTware online help.

English

11

Page 12

Software Tool - 8x92 / 8x93

Control and display elements

4.3. Control and display elements of Bürkert DTMs

4.3.1. Toolbar

Figure 9: DTM toolbar

The section on the left contains icons for the screen display:

Show and hide identification range

Show and hide navigation range

The second section is a combination of icons for device communication:

Read parameters from device

You can select here between: Read all parameters from the device

Read directory only

Read directory and subdirectories only

Write parameters to device

You can select here between: Write all parameters to device

Write directory only

Write directory and subdirectories only

Cyclic update of parameters in display (every 2 seconds)

Table 1: DTM icons

The two sections on the right contain the help function and the print function .

4.3.2. Status bar

The status bar contains information about the current state of the project being processed.

Figure 10: Status bar

Meaning of the displays (from left to right):

• Connection status: Broken / connected

• Communication status

• Data source: Database / device

• Instance data record

• Device status

• Direct mode

• Device diagnostics

• User status

12

• Progress bar

English

Page 13

Software Tool - 8x92 / 8x93

Control and display elements

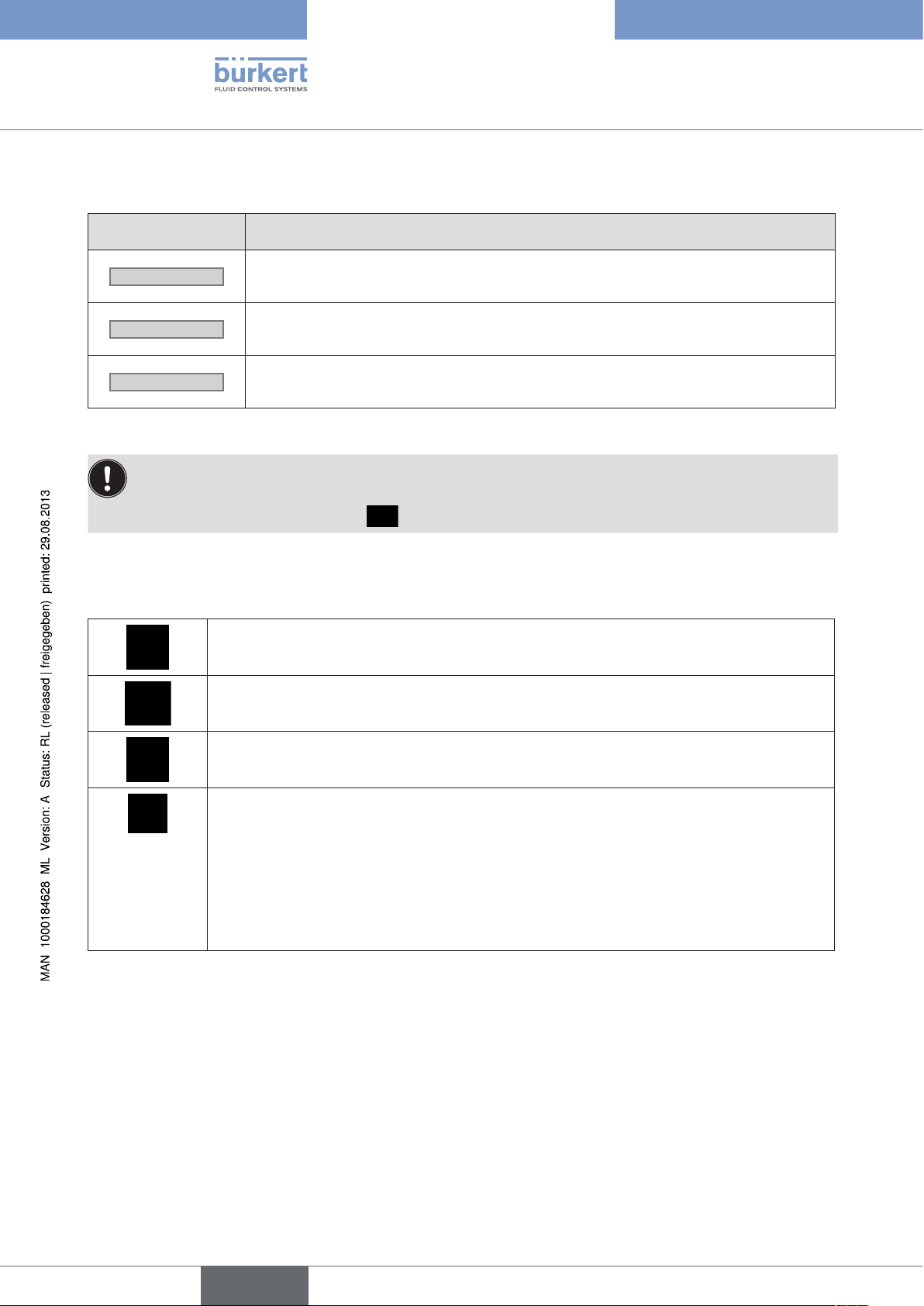

4.3.3. Navigation area and work area

Value entry in the work area

Selection of function

in the navigation area

Figure 11: Bürkert DTM screen display

Buttons for

data transfer

Functions are displayed in the navigation area.

When you click on the required function, it is highlighted in color and the corresponding (entry) screen appears:

Entry field for texts or values

Input via dropdown list

Select via checkbox

Table 2: Input screens

Parameters can be transferred to the database with the

Cancel

closes the DTM window without saving (see also Section “4.3.4. Buttons for data transfer”).

Apply

or

OK

buttons.

You can save the project with the "File / Save" menu item.

To transfer to the device, select the

icon.

English

13

Page 14

4.3.4. Buttons for data transfer

Button Description

Software Tool - 8x92 / 8x93

Control and display elements

OK

Cancel

Apply

Table 3: Buttons for data transfer

The DTM window closes

Modified values are transferred to the database.

The DTM window closes

Modified values are not transferred to the database.

The DTM window remains open

Modified values are transferred to the database.

If you exit the program without saving the project, the data in the database is not saved.

You can save the project with the "File / Save" menu item.

To transfer to the device, select the

icon.

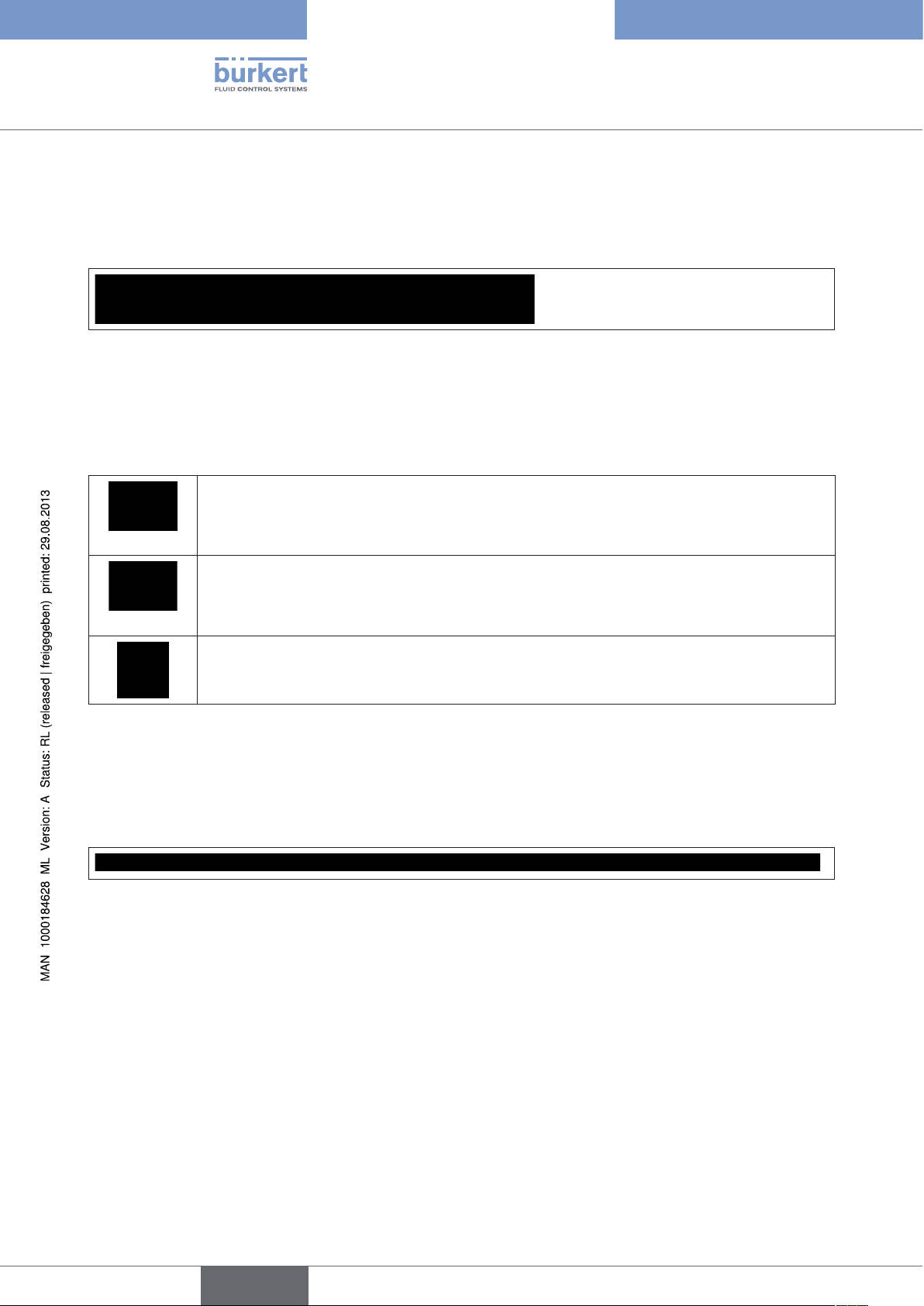

4.3.5. Icons

Modified value not saved or not written to device

Saved to database

14

Device data

• Invalid input value

• Configuration error with communication

One or more parameters with different value ranges in the device and DTM

• Validation error with communication error

Wrong device connected (wrong manufacturer, type or device version)

Device not in communication mode (for example device in input mode)

Communication error

Table 4: Icons

English

Page 15

Software Tool - 8x92 / 8x93

Installation

5. INSTALLATION

5.1. System requirements

Hardware:

Processor: Intel Pentium/ AMD, at least 500 MHz

Working memory: At least 128 MB RAM

Hard disk: At least 250 MB free storage space

Graphics resolution: At least 1024 x 768

1 USB port to connect the Adapter USB-RS232, ID number 227093

Software:

Operating system Windows 2000/XP/Vista:

PACTware 3.6 + Microsoft .NET Framework 1.1 + .NET Framework 1.1 SP1

Operating system Windows XP/Vista/7:

PACTware 4.1 + Microsoft .NET Framework 2.0

Administrator rights are required for installation.

Windows must be rebooted after the installation. Then you must log into Windows under the same name,

because the installation is completed during the reboot.

English

15

Page 16

Software Tool - 8x92 / 8x93

Installation

5.2. Installing PACTware and DTMs

Select the appropriate PACTware version depending on the operating system in use, see chapter “5.1. System

requirements”.

All installation programs are available on the Bürkert homepage and on CD.

Before the installation, exit all programs that are open.

5.2.1. PACTware version 3.6 and .NET Framework 1.1 including

SP1

Installation of PACTware requires the presence of software platform:

Microsoft .NET Framework 1.1 with Service Pack 1 (SP1)

Procedure to follow if "Microsoft .NET Framework 1.1 with Service Pack 1 (SP1)" is not present yet on the target

computer:

→ Download and / or open the Zip file (1000103878), which includes the Microsoft.NET 1.1 framework.

→ Start "Dotnetfx.exe".

→ Download and / or open the Zip file (1000103880), which includes the Microsoft.NET 1.1 SP1 framework.

→ Start "NDP1.1sp1*.exe".

Procedure PACTware Setup:

→ Download and / or open the Zip file (1000103690), which includes the PACTware setup and unzip in a tem-

porary directory.

→ Start “Setup.exe”.

Setup file "PACTware36setup.zip" contains

• the basic setup for PACTware 3.6 with online help in various languages

16

• the HART communication DTM for PACTware 3.6

• the Generic HART DTM (not required)

After you have selected the installation language, the installation is performed.

At this point the HART communications DTM can also be installed. It is required because communication with

Bürkert devices runs via the HART protocol and the physical layer has an RS232 interface rather than a HART

interface.

English

Page 17

Software Tool - 8x92 / 8x93

Installation

Optional components such as the manual are not installed here.

If PACTware 2.4, PACTware 3.0 or PACTware 3.5 are already installed, all passwords can be transferred for

PACTware 3.6 at the end of the installation.

During the installation, a program group is entered in the Windows start menu for the current user and a link to

PACTware 3.6 appears on the desktop.

5.2.2. PACTware version 4.1 and .NET Framework 2.0

Download and / or open the Zip file “PACTware 4.1 SP1 Buerkert.zip“ and unzip in a temporary directory. This zip

file contains all the necessary installation components.

Installation of PACTware requires the presence of software platform:

Microsoft .NET Framework 2.0

Procedure to follow if “Microsoft .NET Framework 2.0“ is not present yet on the target computer:

→ Start setup

with a 64-bit operating system in directory dotNet\dotNET_20\x64

or with other operating systems in directory \dotNet\dotNET_20\x86.

Procedure PACTware Setup:

→ Start \PACTware\PACTware.msi.

Setup file contains:

• the basic setup for PACTware 4.1 with online help in various languages

• the HART communication DTM for PACTware 4.1

• the Generic HART DTM (not required)

After you have selected the installation language, the installation is performed.

At this point the HART communications DTM can also be installed. It is required because communication with

Bürkert devices runs via the HART protocol and the physical layer has an RS232 interface rather than a HART

interface.

Optional components such as the manual are not installed here.

If PACTware 2.4, PACTware 3.0, PACTware 3.5 or PACTware 3.6 are already installed, all passwords can be

transferred for PACTware 4.1 at the end of the installation.

During the installation, a program group is entered in the Windows start menu for the current user and a link to

PACTware 4.1 appears on the desktop.

English

17

Page 18

5.2.3. Bürkert device DTM

Procedure:

→ Start "Setup.exe" in the directory

AdditionalSetups\BuerkertDTMs\SETUP_Positioner_Typen_869X_879X_V1.0.0.

or alternative

→ Start “Setup.exe” in the master directory:

After you have selected the language,

Software Tool - 8x92 / 8x93

Installation

you can choose which components should be installed:

select PACTware 4.1 SP1 and Buerkert DTM Positioner 3-wire.

18

After you have selected the installation language, the installation is performed.

English

Page 19

Software Tool - 8x92 / 8x93

Operation and function

6. OPERATION AND FUNCTION

6.1. Starting PACTware

→ Start PACTware from the Windows start menu.

6.2. Creating a project

6.2.1. General description

AS a precondition for operating field devices, the device network must be represented in a PACTware project.

PACTware provides an area for this purpose where all installed DTMs are shown: The Device Catalog. Normally

the DTMs have the same name as the devices to facilitate control.

PACTware also provides a second area where the device network is represented: The Project Window. The

actual device network is represented in this project window by inserting DTMs from the device catalog. The

"HOST-PC" entry serves as the starting point for inserting a DTM. The required DTMs can be transferred from the

device catalog into the project window by double clicking or using drag and drop.

If you do not want the project window or device catalog to be visible, they can be activated in the menu

bar under "View".

If the Bürkert device DTMs are not visible in the device catalog, the device catalog must first be updated.

To update the device catalog:

→ Switch to the "Device catalog" window with "View / Device catalog" (F3)

→ Click

→ Confirm the question "Create new PACTware device catalog?" with

Update device catalog

Yes

→ After the device catalog is opened again, the Bürkert device DTMs are present; see “Figure 12: Device

catalog with HART Comm DTM and Bürkert device DTMs”

English

19

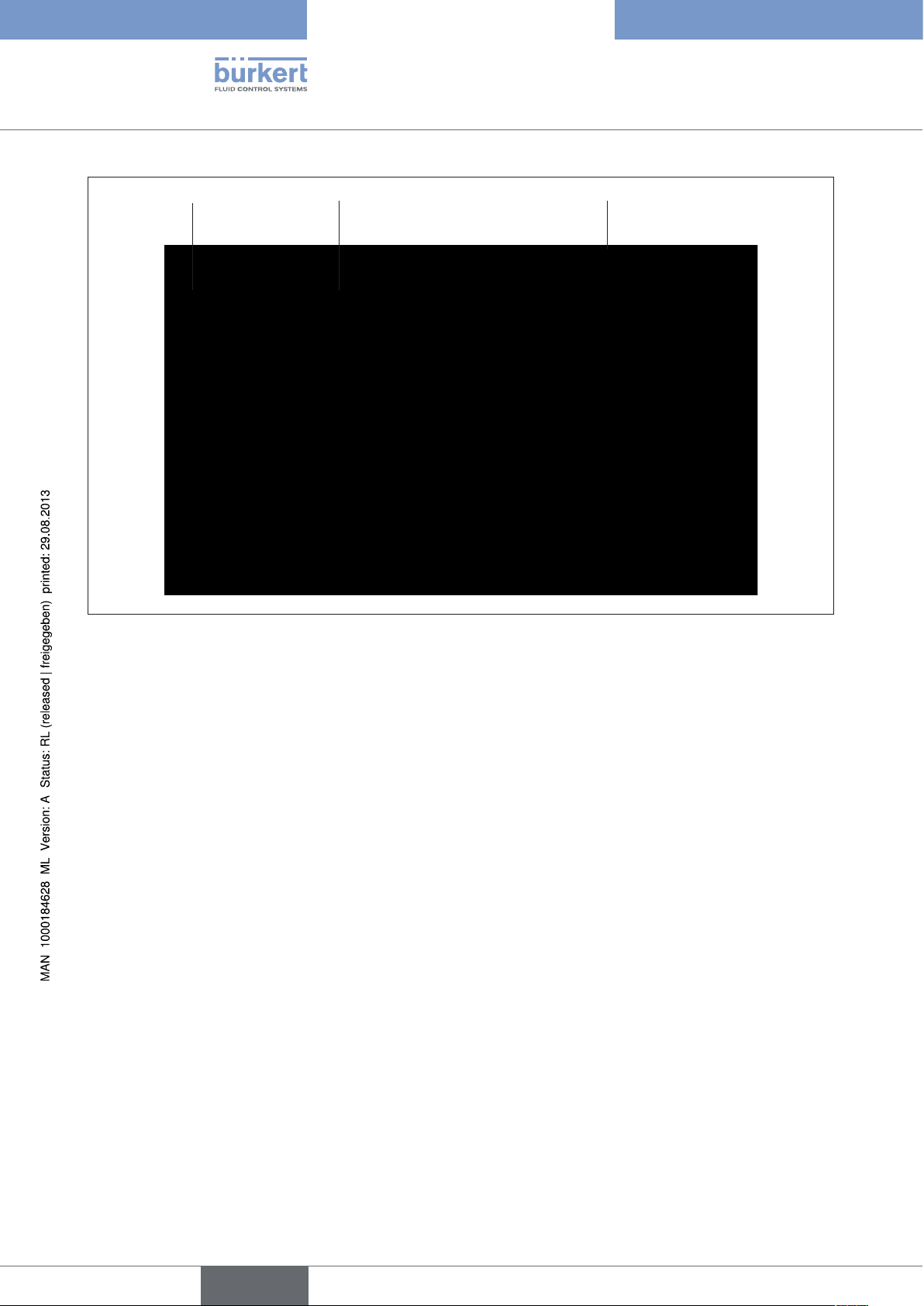

Page 20

Project window PACTware windowDevice catalog

Software Tool - 8x92 / 8x93

Operation and function

Figure 12: Device catalog with HART Comm DTM and Bürkert device DTMs

20

English

Page 21

Software Tool - 8x92 / 8x93

Operation and function

6.2.2. Creating a project for Bürkert positioners

To be able to communicate with positioners and process controllers of types 8692, 8693, 8792 and 8793, first

select HART communication DTM and then a Bürkert device DTM:

1. To select a HART communication DTM and set parameter:

→ Select "HART Communication, Fa. Codewrights GmbH" from the device catalog and double click or drag and

drop to integrate it into the project.

Figure 13: To integrate a HART communication DTM:

→ Settings for the following parameters (mark communication DTM, then select the "Device / Parameter" menu

item with the menu bar or double click on the integrated communication DTM (COM1...n)):

Buerkert Werke GmbH

Figure 14: HART communication DTM - set parameters

21

English

Page 22

Communication interface: Extended HART modem

Software Tool - 8x92 / 8x93

Operation and function

Serial interface: Port: COM1…n, depending on the connection

1)

Baudrate: 9600

Parity: None

The remaining parameters can retain their default settings.

22

Figure 15: Settings of the HART communications DTM

→ Click

OK

to transfer the set parameters to the database.

You can save the project with the "File / Save" menu item.

1) Depending on the device setting, factory setting: 9600 Bd

English

Page 23

Software Tool - 8x92 / 8x93

Operation and function

2. To select a Bürkert DTM:

Select "8692 Positioner TopControl" or "8693 Process controller TopControl" or "8792 Positioner SideControl"

or “8793 Process controller SideControl”from the device catalog and double click or drag and drop to integrate it

into the project.

Figure 16: Integrating a device

The project is now created and can be saved under "File / Save".

You can determine under PACTware "Tools / Options," in the "Project" area whether the last project

should be opened when the program starts (see “Figure 17: PACTware options”).

Figure 17: PACTware options

23

English

Page 24

Software Tool - 8x92 / 8x93

Operation and function

6.3. Basic settings

The basic settings of the positioner / process controller are implemented at the factory.

Once the device DTMs are activated, the basic settings can be adapted user-specifically:

• Define the device identification

• Run the automatic adjustment X.TUNE

• Transfer parameters (see chapter “6.4. Transferring parameters”)

• Parameterization of functions (see chapter “6.5. Parameterization”).

6.3.1. Activation of device DTMs

The DTM window is used for device identification, defining the basic settings, and parameterization of the device.

The window can be activated as follows:

• Double click on the required DTM in the project window or

• Right click and select "Parameters" or

• With the PACTware "Device / Parameters" menu item.

DTM window

Identification area

24

Figure 18: DTM window

English

Navigation area

Work area

Page 25

Software Tool - 8x92 / 8x93

Operation and function

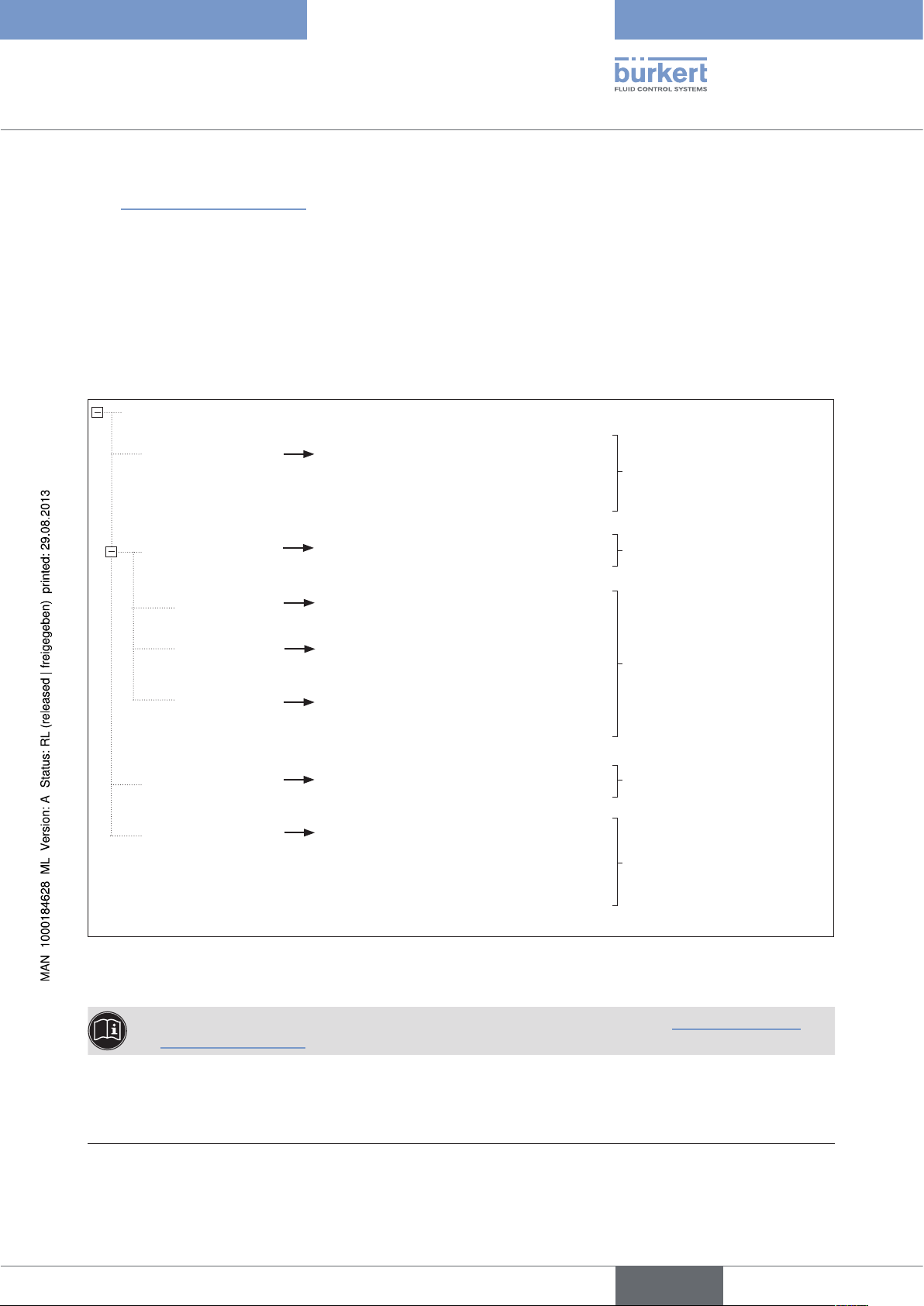

The navigation area contains the parameters and functions of the selected device in the folder structure

(see “Figure 19: Navigation area”):

Identification: Enter user-specific device designations

Device menu: Parameterization of functions

Adding auxiliary functions

RESET: Reset to factory settings

TUNE FUNCTIONS: Automatic adjustment of the positioner / process controller to the relevant operating

conditions

Parameter

Identification

Device menu

ACTUATOR

2)

INPUT

BUS.COMM

RESET

TUNE FUNCTIONS

Description

Device indicator (TAG)

Date

Device menu configure

Operating mode actuator

Set-point value input

Bus type - only readable

RESET

Start X.TUNE

Start PQ.LIN

Start P.TUNE

3)

3)

Enter user-specific device

designations

Adding auxiliary

functions

Device menu items for

parameterization of

functions

Reset to factory settings

Automatic adjustment of the

positioner / process controller to the relevant operating conditions

Figure 19: Navigation area

You can find a description and parameterization of individual functions in Sections “7. Basic functions”

and “8. Auxiliary functions”.

2) only for TopControl: Type 8692 and Type 8693

3) only for process controller Type 8693 and 8793

English

25

Page 26

Software Tool - 8x92 / 8x93

Operation and function

6.3.2. Device identification

User-specific device data can be entered in the navigation area under the "Identification" item.

Figure 20: Identification

Description: User-specific device description

4)

Tag: User-specific device indicator (TAG)

Date: User-specific date

→ Click

Apply

to transfer the modified parameters to the database.

You can save the project with the "File / Save" menu item.

4)

26

4) As per HART specification

English

Page 27

Software Tool - 8x92 / 8x93

Operation and function

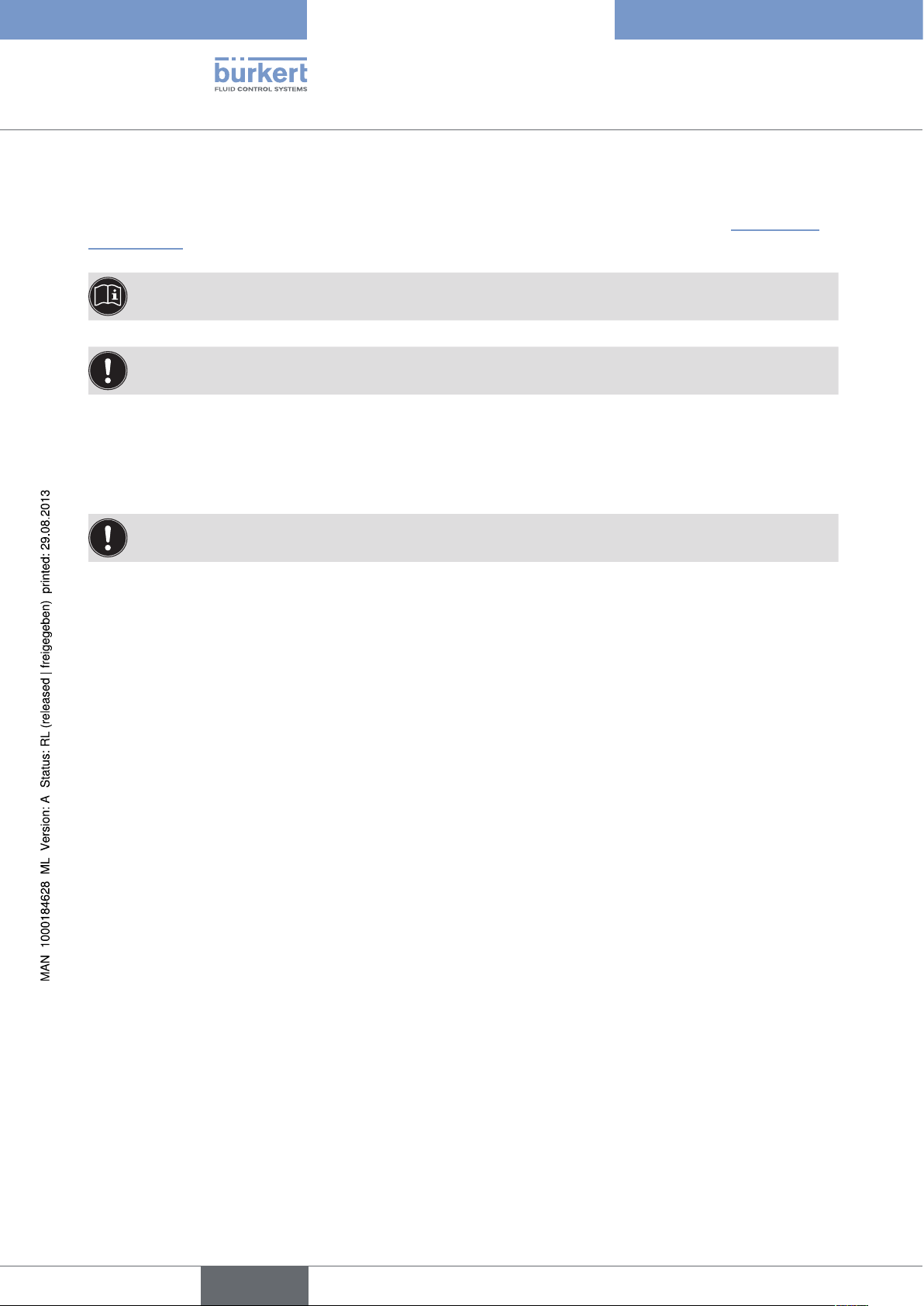

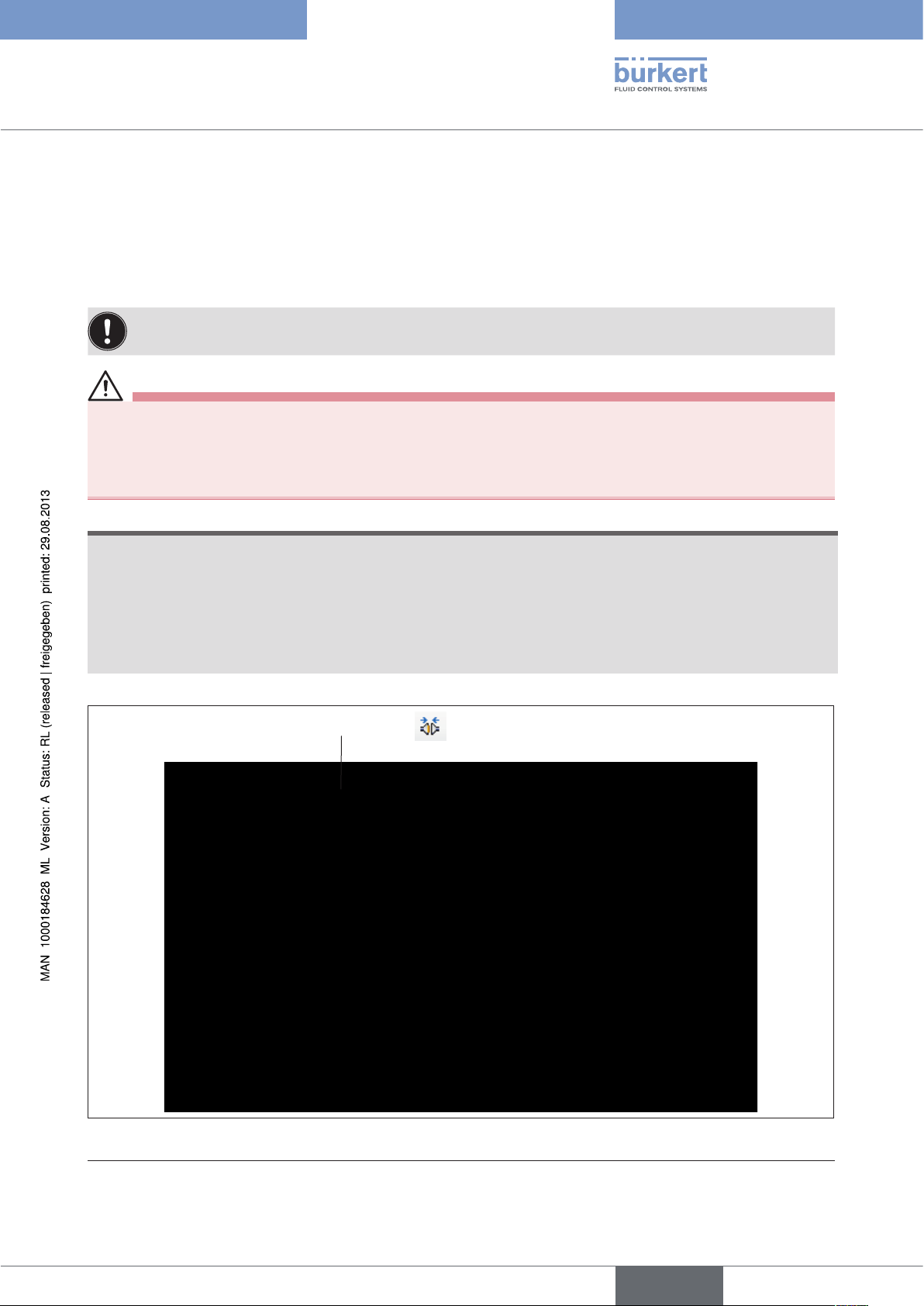

6.3.3. Running the automatic adjustment for TUNE FUNCTIONS

X.TUNE Automatic adjustment of the positioner

5)

PQ-LIN

P.TUNE

While the TUNE FUNCTIONS is running, the valve automatically moves from its current position!

• Never run TUNE FUNCTIONS while a process is running!

• Take appropriate measures to prevent the system / positioner / process controller from being unintentionally

actuated!

Automatic linearization of the process characteristic

5)

Self-optimization of the process controller

The TUNE FUNCTIONS must be run for a function check of the positioner / process controller to adjust

to specific local features.

WARNING!

NOTE!

Avoid maladjustment of the controller due to an incorrect compressed air supply or applied operating

medium pressure!

• Run TUNE FUNCTIONS whenever the compressed air supply (= pneumatic auxiliary energy) is available

during subsequent operation.

• Run the TUNE FUNCTIONS function preferably without operating medium pressure to exclude interference

caused by flow forces.

Set up connection

Figure 21: Starting TUNE FUNCTIONS

5) only with process controller Type 8693 and 8793

27

English

Page 28

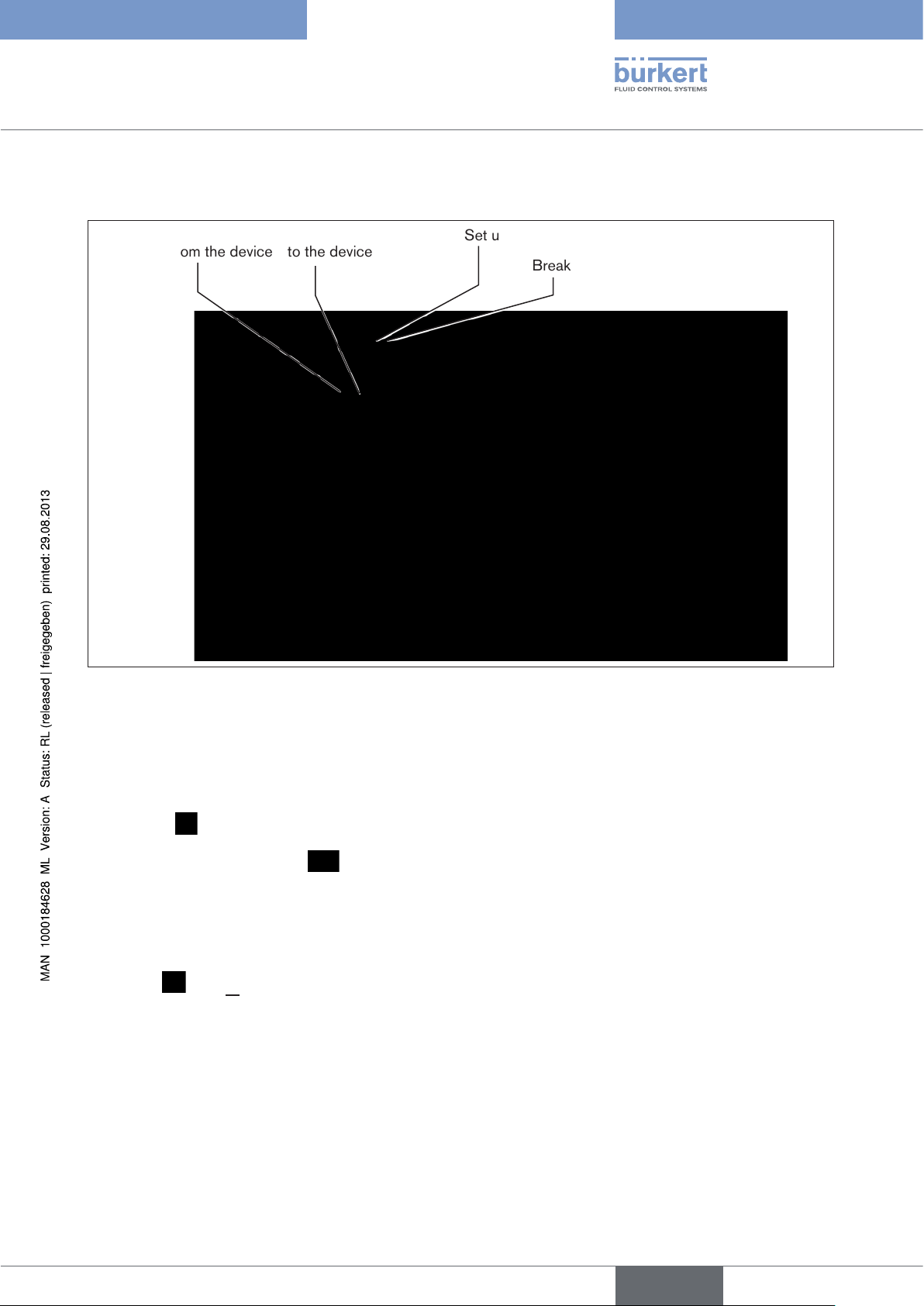

Procedure example: function X.TUNE:

→ Set up connection

→ Set up TUNE FUNCTIONS in the navigation area

Software Tool - 8x92 / 8x93

Operation and function

→ Start X.TUNE. To do this, click

Start X.TUNE

6).

The progress of X.TUNE is shown in the communication software:

XTUNE start POS 100 ... XTUNE end

Automatic adjustment can be interrupted with the

When the automatic adjustment completes, the message "XTUNE end" appears

► ► ►

Break X.TUNE

button.

7)

.

The changes are automatically transferred to the positioner's / process controller’s memory (EEPROM) after the

X.TUNE function is successful.

After X.TUNE is complete, read the device parameter for processing from the positioner / process controller (see chapter “6.4.1. Reading parameters from the device”).

28

Figure 22: X.TUNE (example Type 8693)

6) X.TUNE can also be started on the positioner / process controller (see the relevant device operating

instructions).

7) If an error occurs, an error message appears (see Chapter “6.6. Error messages”).

English

Page 29

Software Tool - 8x92 / 8x93

Operation and function

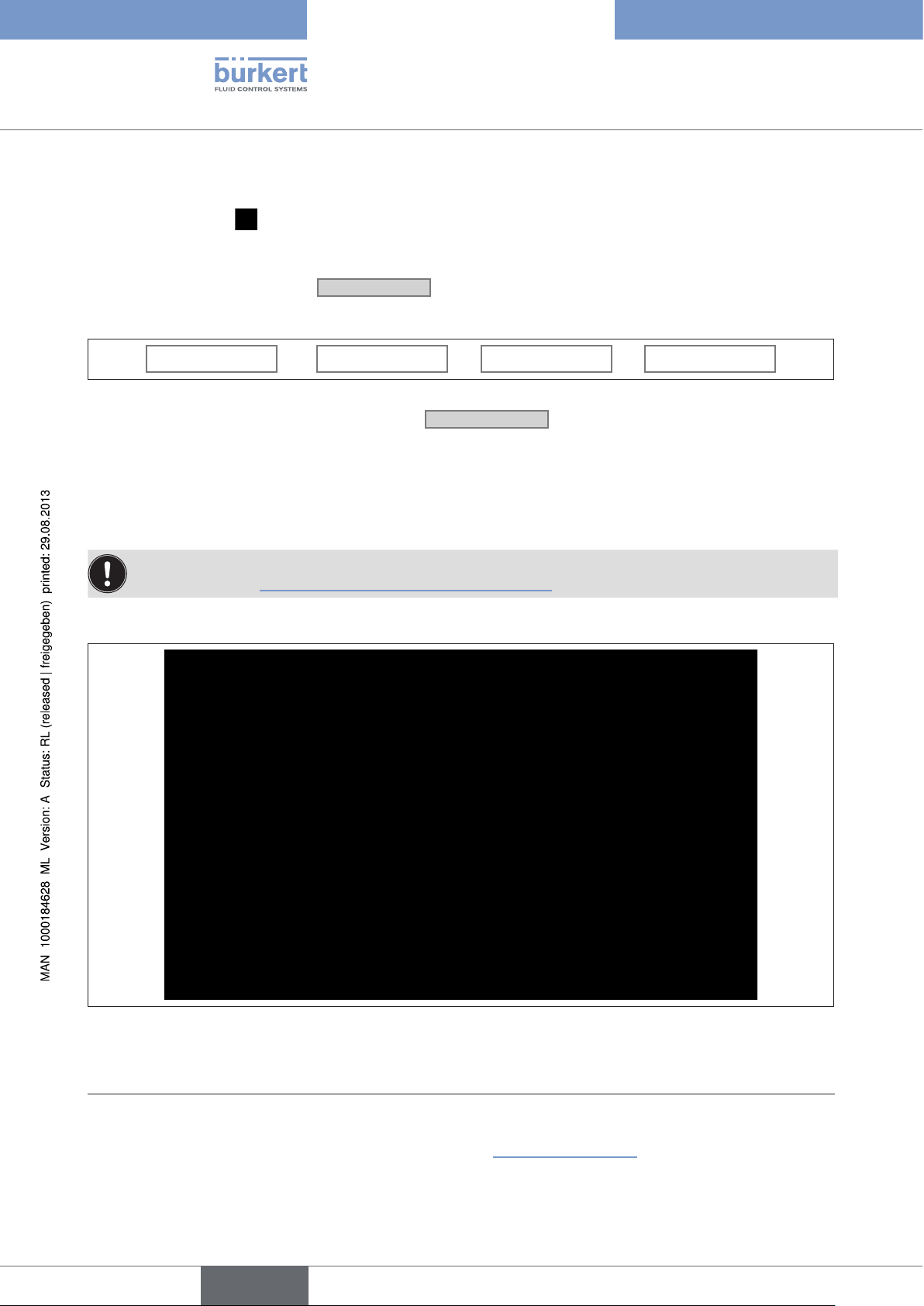

6.4. Transferring parameters

DTM: Read parameters from the device

Figure 23: Transferring parameters

DTM: Write parameters

to the device

Set up connection

Break connection

6.4.1. Reading parameters from the device

Procedure:

→ Connect

→ Read parameters from device

with option to select: Read all parameters from device

Read directory only

Read directory and subdirectories only

If the parameters are transferred using the PACTware "Device / Load from device" menu item or using the

PACTware

icon, all parameters are read from the device.

29

English

Page 30

Software Tool - 8x92 / 8x93

Operation and function

6.4.2. Write parameters to the device

NOTE!

If changes are made and transferred with the "Write all parameters to device" function, it is possible that

parameters in the device will be unintentionally overwritten!

• Read the current device data before you make the changes or

• transfer only the modified parameters by using the selection options "Write directory only" or "Write directory

and subdirectories only".

Procedure:

→ Connect

→ Write parameters to device

with option to select: Write all parameters to device

Write directory only

Write directory and subdirectories only

If the parameters are transferred using the PACTware "Device / Store to device" menu item or using the

PACTware

icon, all (!) parameters will be written to the device.

More extensive explanations describing operation and how to create a project are available in the PACTware

online help. For start-up and parameterization, refer also to the operating instructions for the relevant device.

6.5. Parameterization

A distinction is made in parameterization between offline and online mode.

Offline mode

In Offline mode the project can be created and parameters can be changed and saved without devices connected. Then the data can be saved later to connected devices in Online mode

Online mode

In Online mode the device to be parameterized must be connected and ready for operation. Selecting the corresponding DTM by right clicking and selecting the "Connect" command or with PACTware menu "Device /

Connect" causes Online mode to be prepared. Then parameters can be read directly from the device or trans-

8)

ferred to the device

.

8)

.

30

8) Note regarding read / write device data:

The device DTM is a universally valid DTM containing all parameters for all device variants. A check therefore

determines before the data transfer from DTM which device variant is connected and deactivates the

parameters/ menu items of variants not present in the DTM.

English

Page 31

Software Tool - 8x92 / 8x93

Operation and function

6.5.1. Parameterizing functions

Value entry in the work area

Selection of function

in the navigation area

Figure 24: Parameterizing functions

Procedure:

Buttons

→ Select the function in the navigation area (highlighted in color)

→ Select or enter the values in the work area

→ Modified values can be transferred to the database with the

you exit the function with the

You can save the project with the "File / Save" menu item.

All setting that are made must still be transferred to the device (see chapter “6.4. Transferring parameters”).

Cancel

button, the changes are not transferred.

Apply

or

OK

button. If

English

31

Page 32

Software Tool - 8x92 / 8x93

Operation and function

6.6. Error messages

6.6.1. Error messages while the X.TUNE function is running

Display Cause of fault Remedial action

ERR 1:

No pilot air

ERR 2:

Pilot air failed during

X.TUNE

ERR 3:

Control system

deaeration side leaking

ERR 4:

Control system aeration

side leaking

Table 5: Error messages for X.TUNE

No pilot air connected Connect pilot air

Pilot air failure while the X.TUNE function was

running

Actuator or control system deaeration side

leaking

Control system aeration side leaking Not possible, device defective

Check pilot air supply

Not possible, device defective

6.6.2. Error messages while the PQ.LIN function is running

Display Cause of fault Remedial action

ERR 1:

No pilot air or no

change to process

variable

No compressed air connected

No change to process variable

Connect compressed air

Check process and, if required,

switch on pump or open the shutoff valve.

32

ERR 2:

Current node (valve

stroke) was not reached

Table 6: Error messages for PQ.LIN

Current node of the valve stroke was not

reached, as

• Pilot air failed during P.Q’LIN

• X.TUNE was not run.

English

Check pilot air

Run X.TUNE

Check process sensor

Page 33

Software Tool - 8x92 / 8x93

Operation and function

6.6.3. Error messages while the P.TUNE function is running

Display Cause of fault Remedial action

ERR 1:

No pilot air or no

change to process

No pilot air connected

No change to process variable

variable

Table 7: Error messages for P.TUNE

Connect pilot air

Check process and, if required,

switch on pump or open the shutoff valve.

Check process sensor

English

33

Page 34

Software Tool - 8x92 / 8x93

Basic functions

7. BASIC FUNCTIONS

7.1. Overview of basic functions

The following basic functions are created as device menu items in the navigation area in the factory:

ACTUATOR

INPUT

BUS.COMM

RESET

TUNE FUNCTIONS

9)

Inputting the operating mode of the pneumatic actuator

Entry of the standard signal for the set-point value

Adjust the selection / parameters of the field bus interface

Reset to factory settings

Automatic adjustment of the positioner / process controller to the relevant operating

conditions

Table 8: Basic functions

7.2. Basic functions - parameter

Parameterization and transfer of parameters are described in sections “6.5. Parameterization” and “6.4.

Transferring parameters”.

NOTE!

If changes are made and transferred with the "Write all parameters to device" function, it is possible that

parameters in the device will be unintentionally overwritten!

34

• Read the current device data before you make the changes or

• transfer only the modified parameters by using the selection options "Write directory only" or "Write directory

and subdirectories only".

Modified values can be transferred to the database with the

button. If you exit the function with the

Cancel

button, the changes are not transferred.

Apply

or

OK

You can save the project with the "File / Save" menu item.

9) Only for Types 8692 / 8693

English

Page 35

Software Tool - 8x92 / 8x93

Basic functions

7.3. Basic functions - setting parameter

7.3.1. ACTUATOR -

Inputting the operating mode of the pneumatic actuator

Only for Types 8692 / 8693.

The operating mode of the pneumatic valve actuator used in combination with the positioner / process controller

can be input in this menu option.

The operating mode of the actuator has been preset at the factory.

CFA and CFB: single-acting

CFI: double-acting

The control function (CF) of the actuator can be found on the type label.

ACTUATOR

Figure 25: ACTUATOR function

Operating mode actuator

7.3.2. INPUT -

Enter the standard signal

Under this menu option, enter the standard signal used for the set-point value.

→

Factory setting: 4 – 20 mA

INPUT

setpoint input

single-acting

single-acting

double-acting

4 ... 20 mA

4 ... 20 mA

0 ... 20 mA

0 ... 10 V

0 ... 5 V

Figure 26: INPUT function

35

English

Page 36

7.3.3. BUS.COMM -

Adjust the selection / parameters of the field bus interface

Select the field bus interface for the positioner / process controller.

→

Factory setting: without bus

BUS.COMM

Figure 27: BUS.COMM function

When you select a field bus, the corresponding bus parameters can be adjusted.

Bus type - only readable

without bus

without bus

Profibus DP-V1

DeviceNet

Software Tool - 8x92 / 8x93

Basic functions

7.3.4. RESET -

Reset to factory settings

This function can be used to reset the positioner to the factory settings.

RESET

Figure 28: DIR.CMD function

Procedure:

RESET

→ Connect

→ Click

The parameters of the serial interface are set to the following default values:

9600 Bd, parity NONE and 1 stop bit.

Execute

.

→ If there is a deviation from the settings in the communication DTM, the parameters of the serial

interface are readjusted (either on the device side or PC side with the HART communication DTM, see

chapter “6.2.2. Creating a project for Bürkert positioners”).

Execute

36

7.3.5. TUNE FUNCTIONS -

Automatic adjustment of the positioner / process controller

to the relevant operating conditions

A description of the TUNE FUNCTIONS may be found in Section “6.3.3. Running the automatic

adjustment for TUNE FUNCTIONS”.

English

Page 37

Software Tool - 8x92 / 8x93

Auxiliary functions

8. AUXILIARY FUNCTIONS

8.1. Overview of auxiliary functions

The following auxiliary functions can be added to the device menu:

CHARACT

Selection of the transfer characteristic between input signal and stroke (correction

characteristic)

CUTOFF

DIR.CMD

DIR.ACTUATOR

SPLITRANGE

Sealing function for position controller

Effective sense of direction between input signal and nominal position

Assignment of the aeration state of the actuator chamber to the actual position

Signal split range; input signal as % for which the valve runs through the entire stroke

range.

X.LIMIT

X.TIME

X.CONTROL

P.CONTROL

10)

SECURITY

SAFE POSITION

SIGNAL ERROR

BINARY INPUT

OUTPUT

CAL.USER

SET FACTORY

Limit the mechanical stroke range

Limit the control speed

Parameterize the positioner

Parameterize the process controller

Code protection for settings

Definition of the safety position

Configuration of signal level fault detection

Activation of the binary input

Configuration of the output (option)

Calibration (only a device menu item can be activated)

Reset to factory settings (only a device menu item can be activated, run RESET: see

chapter “7.1. Overview of basic functions”)

SERIAL IO

EXTRAS

POS.SENSOR

SERVICE

SIMULATION

DIAGNOSE

Table 9: Auxiliary functions

Configuration of serial interface

Configuration of display

11)

Setting interface for remote sensor

For internal use only

Simulation (only a device menu item can be activated)

Diagnostic menu (option)

10) Only available for process controller Type 8693 and 8793

11) Only available for process controller Type 8793 - only possible for Type 8793 Remote

English

37

Page 38

Software Tool - 8x92 / 8x93

Auxiliary functions

8.2. Adding auxiliary functions (ADD.FUNCTION)

Procedure:

→ When you select the "Device Menu" function in the navigation area (highlighted in color), the auxiliary func-

tions appear in the work area.

→ Activate the auxiliary functions you need in the checkboxes. They will be added to the folder structure in the

navigation area immediately

Parameterization is performed in the relevant function.

38

Figure 29: Configuring auxiliary functions

8.3. Removing auxiliary functions (ADD.FUNCTION)

Procedure:

→ When you select the "Device Menu" function in the navigation area (highlighted in color), the auxiliary func-

tions appear in the work area.

→ Deactivate the auxiliary functions you do not need in the checkboxes. They will be removed from the folder

structure in the navigation area immediately.

English

Page 39

Software Tool - 8x92 / 8x93

Auxiliary functions

8.4. Auxiliary functions - parameter

Parameterization and transfer of parameters are described in Sections “6.5. Parameterization” and “6.4.

Transferring parameters”.

NOTE!

If changes are made and transferred with the "Write all parameters to device" function, it is possible that

parameters in the device will be unintentionally overwritten!

• Read the current device data before you make the changes or

• transfer only the modified parameters by using the selection options "Write directory only" or "Write directory

and subdirectories only".

Modified values can be transferred to the database with the

button. If you exit the function with the

You can save the project with the "File / Save" menu item.

Cancel

button, the changes are not transferred.

Apply

or

8.5. Auxiliary functions - setting parameter

The additional functions are described in detail in the relevant operating instructions of the positioner /

process controller.

OK

English

39

Page 40

Software Tool - 8x92 / 8x93

Deinstallation of PACTware/ DTMs

9. DEINSTALLATION OF PACTWARE/ DTMS

9.1. Deinstallation process

Procedure:

→ Select the "Software" item in the system control (via "Start / Settings / System Control").

→ Select "HART Communication DTM" or "Buerkert Positioner DTM" from the "PACTware" list and click "Change /

remove".

→ Run the deinstallation as suggested by the wizard and complete the process by rebooting Windows.

40

English

Page 41

Software Tool - 8x92 / 8x93

Kommunikationssoftware (Software Tool) für Positioner / Prozessregler

Inhalt

1. ERGÄNZENDE BEDIENUNGSANLEITUNG .........................................................................................................................44

1.1. Darstellungsmittel ..............................................................................................................................................................44

2. ALLGEMEINE HINWEISE ..............................................................................................................................................................45

2.1. Kontaktadressen .................................................................................................................................................................45

2.2. Informationen im Internet ...............................................................................................................................................45

3. PRODUKTBESCHREIBUNG ........................................................................................................................................................46

3.1. Erforderliche Komponenten ..........................................................................................................................................46

3.1.1. Windows 2000, XP, Vista .....................................................................................................................46

3.1.2. Windows XP, Vista, 7 .............................................................................................................................46

3.2. Begriffsdefinitionen PACTware / FDT / DTM .......................................................................................................46

4. BEDIEN- UND ANZEIGEELEMENTE .......................................................................................................................................47

4.1. Übersicht Bildschirmanzeige .......................................................................................................................................47

4.2. Bedien- und Anzeigeelemente PACTware ............................................................................................................48

4.2.1. Symbolleiste .............................................................................................................................................48

4.2.2. Statusleiste ...............................................................................................................................................49

4.3. Bedien- und Anzeigeelemente der Bürkert DTMs ............................................................................................50

4.3.1. Symbolleiste .............................................................................................................................................50

4.3.2. Statusleiste ...............................................................................................................................................50

4.3.3. Navigationsbereich und Arbeitsbereich ............................................................................................. 51

4.3.4. Schaltflächen zur Datenübernahme .................................................................................................... 52

4.3.5. Symbole .....................................................................................................................................................52

5. INSTALLATION ...................................................................................................................................................................................53

5.1. Systemanforderungen ......................................................................................................................................................53

5.2. PACTware und DTMs installieren ...............................................................................................................................54

5.2.1. PACTware Version 3.6 und .NET Framework 1.1 einschließlich SP1 ........................................54

5.2.2. PACTware Version 4.1 und .NET Framework 2.0 ............................................................................55

5.2.3. Bürkert Geräte DTM ...............................................................................................................................56

deutsch

41

Page 42

Software Tool - 8x92 / 8x93

6. BEDIENUNG UND FUNKTION ...................................................................................................................................................57

6.1. PACTware starten ...............................................................................................................................................................57

6.2. Projekt erstellen ..................................................................................................................................................................57

6.2.1. Allgemeine Beschreibung .....................................................................................................................57

6.2.2. Projekt für Bürkert Positioner erstellen ...............................................................................................59

6.3. Grundeinstellungen ...........................................................................................................................................................62

6.3.1. Aktivieren der Geräte DTM....................................................................................................................62

6.3.2. Geräteidentifikation .................................................................................................................................64

6.3.3. Ausführen der automatischen Anpassungen - TUNE FUNKTIONEN ..................................65

6.4. Parameter übertragen ......................................................................................................................................................67

6.4.1. Parameter aus dem Gerät lesen .......................................................................................................... 67

6.4.2. Parameter in das Gerät schreiben ......................................................................................................68

6.5. Parameter einstellen .........................................................................................................................................................68

6.5.1. Parameter einstellen bei Funktionen ...................................................................................................69

6.6. Fehlermeldungen ................................................................................................................................................................70

6.6.1. Fehlermeldungen bei der Durchführung der Funktion X.TUNE ..................................................70

6.6.2. Fehlermeldungen bei der Durchführung der Funktion PQ.LIN ...................................................70

6.6.3. Fehlermeldungen bei der Durchführung der Funktion P.TUNE ..................................................71

7. GRUNDFUNKTIONEN ........................................................................................................................................................................ 72

7.1. Übersicht Grundfunktionen ...........................................................................................................................................72

7.2. Grundfunktionen - Parameter ......................................................................................................................................72

7.3. Grundfunktionen - Parameter einstellen ................................................................................................................73

7.3.1. ACTUATOR -

Eingabe der Funktionsweise des pneumatischen Antriebs ...........................................................73

7.3.2. INPUT -

Eingabe des Normsignals .....................................................................................................................73

7.3.3. BUS .COMM -

Auswahl / Parameter einstellen der Feldbusschnittstelle ..............................................................74

42

7.3.4. RESET -

Rücksetzen auf die Werkseinstellungen ............................................................................................74

7.3.5. TUNE FUNKTIONEN -

Automatische Anpassung des Positioners / Prozessreglers an die jeweiligen Betriebsbedin-

gungen .......................................................................................................................................................74

deutsch

Page 43

Software Tool - 8x92 / 8x93

8. ZUSATZFUNKTIONEN ...................................................................................................................................................................75

8.1. Übersicht Zusatzfunktionen ..........................................................................................................................................75

8.2. Zusatzfunktionen hinzufügen (ADD.FUNCTION) ...............................................................................................76

8.3. Zusatzfunktionen entfernen (ADD.FUNCTION) ..................................................................................................76

8.4. Zusatzfunktionen - Parameter ........................................................................................................................................ 77

8.5. Zusatzfunktionen - Parameter einstellen...............................................................................................................77

9. DEINSTALLATION VON PACTWARE / DTMS.....................................................................................................................78

9.1. Deinstallationsablauf ........................................................................................................................................................78

deutsch

43

Page 44

Software Tool - 8x92 / 8x93

Ergänzende Bedienungsanleitung

1. ERGÄNZENDE BEDIENUNGSANLEITUNG

Die ergänzende Bedienungsanleitung beschreibt die Kommunikationssoftware für Positioner / Prozessregler TopControl und SideControl.

Informationen zur Sicherheit!

Sicherheitshinweise und Informationen für den Einsatz des Geräts finden Sie in der dazugehörigen

Bedienungsanleitung.

• Die Bedienungsanleitung muss gelesen und verstanden werden.

1.1. Darstellungsmittel

GEFAHR!

Warnt vor einer unmittelbaren Gefahr!

• Bei Nichtbeachtung sind Tod oder schwere Verletzungen die Folge.

WARNUNG!

Warnt vor einer möglicherweise gefährlichen Situation!

• Bei Nichtbeachtung drohen schwere Verletzungen oder Tod.

VORSICHT!

Warnt vor einer möglichen Gefährdung!

• Nichtbeachtung kann mittelschwere oder leichte Verletzungen zur Folge haben.

HINWEIS!

Warnt vor Sachschäden!

• Bei Nichtbeachtung kann das Gerät oder die Anlage beschädigt werden.

bezeichnet wichtige Zusatzinformationen, Tipps und Empfehlungen.

44

verweist auf Informationen in dieser Bedienungsanleitung oder in anderen Dokumentationen.

→ markiert einen Arbeitsschritt, den Sie ausführen müssen.

deutsch

Page 45

Software Tool - 8x92 / 8x93

Allgemeine Hinweise

2. ALLGEMEINE HINWEISE

2.1. Kontaktadressen

Deutschland

Bürkert Fluid Control Systems

Sales Center

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Die Kontaktadressen finden Sie im Internet unter:

www.burkert.com

2.2. Informationen im Internet

Bedienungsanleitungen und Datenblätter zu den Gerätetypen finden Sie im Internet unter:

www.buerkert.de

deutsch

45

Page 46

3. PRODUKTBESCHREIBUNG

3.1. Erforderliche Komponenten

3.1.1. Windows 2000, XP, Vista

• Microsoft .NET Framework 1.1

• Microsoft .NET Framework 1.1 Service Pack 1

• PACTware Version 3.6

einschließlich HART-Protokoll-Treiber, Fa. Codewrights GmbH

• Bürkert Geräte DTM

„8692 Positioner TopControl“

„8693 Prozessregler TopControl“

„8792 Positioner SideControl“

„8793 Prozessregler SideControl“

Software Tool - 8x92 / 8x93

Produktbeschreibung

• Firmware Version ab C.01 bei Gerätetypen 8692 und 8693 bzw. ab B.01 bei Gerätetypen 8792 und 8793

• Adapter USB-RS232, Ident-Nr. 227093 (HART Kommunikation über die 4/20 mA - Schnittstelle ist nicht möglich).

3.1.2. Windows XP, Vista, 7

• Microsoft .NET Framework 2.0

• PACTware Version 4.1

einschließlich HART-Protokoll-Treiber, Fa. Codewrights GmbH

• Bürkert Geräte DTM

„8692 Positioner TopControl“

„8693 Prozessregler TopControl“

„8792 Positioner SideControl“

„8793 Prozessregler SideControl“

• Firmware Version ab C.01 bei Gerätetypen 8692 und 8693 bzw. ab B.01 bei Gerätetypen 8792 und 8793

• Adapter USB-RS232, Ident-Nr. 227093 (HART Kommunikation über die 4/20 mA - Schnittstelle ist nicht möglich).

3.2. Begriffsdefinitionen PACTware / FDT / DTM

PACTware (Process Automation Configuration Tool):

Hersteller- und feldbusunabhängige Software zur Inbetriebnahme, Bedienung und Wartung von Feldgeräten aller

Art. In dieses Rahmenprogramm werden die DTM (Device Type Manager) der entsprechenden Feldgerätehersteller eingebunden. Die Einbindung erfolgt nach der Schnittstellenspezifikation FDT 1.20.

Zur Bedienung eines Feldgeräts ist also immer ein DTM erforderlich, der zu diesem Gerätetyp passt.

46

FDT (Field Device Tool):

Standardisierte Schnittstellenbeschreibung, definiert den Datenaustausch zwischen den verschiedenen DTMs

und der Rahmenapplikation, z. B. PACTware.

DTM (Device Type Manager):

Der DTM ist das eigentliche Bedienmodul der Aktoren, Sensoren und Feldkomponenten. Er beinhaltet alle spezifischen Daten und Funktionen eines bestimmten Gerätetyps und liefert alle Elemente und Dialoge zur Bedienung.

Ein DTM ist nur lauffähig in einem Rahmenprogramm wie z. B. PACTware.

deutsch

Page 47

Software Tool - 8x92 / 8x93

Bedien- und Anzeigeelemente

4. BEDIEN- UND ANZEIGEELEMENTE

4.1. Übersicht Bildschirmanzeige

PACTware Fenster

PACTware Symbolleiste

DTM Fenster

DTM Symbolleiste

Identifikationsbereich

Navigationsbereich

PACTware Statusleiste

Projektfenster

Bild 1: Übersicht Bildschirmanzeige

Viele Symbole und Parameter haben Tooltips (Kurzinfo), die die Funktion erläutern.

Bild 2: Tooltip

DTM Statusleiste

Arbeitsbereich

Schaltflächen

47

deutsch

Page 48

Software Tool - 8x92 / 8x93

Bedien- und Anzeigeelemente

4.2. Bedien- und Anzeigeelemente PACTware

4.2.1. Symbolleiste

Häufig benötigte Befehle aus der Menüleiste und der Projektansicht sind in einer Symbolleiste zusammengefasst.

Die Symbolleiste ist in 4 Abschnitte aufgeteilt.

Abschnitt 1 2 3 4

Bild 3: PACTware Symbolleiste

Abschnitt 1: Symbole für Projektverwaltung

Drucken des aktuellen Projekts

Speichern des aktuellen Projekts

Öffnen eines bestehenden Projekts

Anlegen eines neuen Projekts

Bild 4: PACTware Symbolleiste - Abschnitt 1

Abschnitt 2: Symbole für Arbeit mit DTMs

aktuelle Daten in Datei schreiben

alle Daten in das Gerät schreiben

alle Daten aus dem Gerät lesen

aktuelle Daten bearbeiten

Bild 5: PACTware Symbolleiste - Abschnitt 2

Abschnitt 3: Symbole für Aktivierung bestimmter PACTware Fenster

48

Gerätekatalog

Projektansicht

Bild 6: PACTware Symbolleiste - Abschnitt 3

deutsch

Page 49

Software Tool - 8x92 / 8x93

Bedien- und Anzeigeelemente

Abschnitt 4: Symbole für Arbeit mit DTMs

die Verbindung trennen

Verbindung zwischen dem selektierten DTM und dem Feldgerät herstellen

den selektierten DTM aus dem Projekt löschen

einen weiteren DTM an der selektierten Position ins Projekt einfügen

Bild 7: PACTware Symbolleiste - Abschnitt 4

4.2.2. Statusleiste

Die Statusleiste enthält Informationen über den aktuellen Zustand des bearbeiteten Projekts.

Bild 8: Statusleiste

Die Anzeigen bedeuten (von links nach rechts):

• Verbindungsstatus : getrennt / verbunden

• Projekt wurde geändert (durch Stern gekennzeichnet)

• Fehlermeldungen liegen vor. Das Symbol blinkt, wenn die Meldungen noch nicht im Fehlermonitor angezeigt

wurden. Ein Tooltip zeigt die Anzahl der anstehenden Fehlermeldungen an.

• Name des Projekts

• aktive Benutzerrolle

Weiterführende Erklärungen zur Bedienung und Projekterstellung entnehmen Sie bitte der Online-Hilfe

von PACTware.

deutsch

49

Page 50

Software Tool - 8x92 / 8x93

Bedien- und Anzeigeelemente

4.3. Bedien- und Anzeigeelemente der Bürkert DTMs

4.3.1. Symbolleiste

Bild 9: DTM Symbolleiste

Der linke Abschnitt enthält Symbole zur Bildschirmanzeige:

Identifikationsbereich ein- und ausblenden

Navigationsbereich ein- und ausblenden

Im zweiten Abschnitt sind die Symbole für die Gerätekommunikation zusammengefasst:

Parameter aus dem Gerät lesen

hier kann unterschieden werden zwischen: Alle Parameter aus dem Gerät lesen

Nur Verzeichnis lesen

Nur Verzeichnis und Unterverzeichnisse lesen

Parameter ins Gerät schreiben

hier kann unterschieden werden zwischen: Alle Parameter ins Gerät schreiben

Nur Verzeichnis schreiben

Nur Verzeichnis und Unterverzeichnisse schreiben

Zyklische Aktualisierung angezeigter Parameter (2 s)

Tabelle 1: DTM Symbole

In den beiden rechten Abschnitten befinden sich die Hilfefunktion und die Druckfunktion.

4.3.2. Statusleiste

Die Statusleiste enthält Informationen über den aktuellen Zustand des bearbeiteten Projekts.

Bild 10: Statusleiste

Die Anzeigen bedeuten (von links nach rechts):

• Verbindungsstatus: getrennt / verbunden

• Kommunikationszustand

• Datenquelle: Datenbank / Gerät

• Instanzdatensatz

• Gerätezustand

• Direktmodus

• Gerätediagnose

• Benutzerstatus

50

• Progress (Fortschrittsanzeige)

deutsch

Page 51

Software Tool - 8x92 / 8x93

Bedien- und Anzeigeelemente

4.3.3. Navigationsbereich und Arbeitsbereich

Werteeingabe im Arbeitsbereich

Auswahl der Funktion im

Navigationsbereich

Bild 11: Bildschirmanzeige Bürkert DTM

Schaltflächen zur

Datenübenahme

Die Auswahl der Funktionen erfolgt im Navigationsbereich.

Durch Anklicken wird die gewünschte Funktion farbig hinterlegt und im Arbeitsbereich erscheint die entsprechende (Eingabe-) Maske:

Eingabefeld für Texte oder Werte

Eingabe über Auswahlliste

Auswahl über Kontrollkästchen

Tabelle 2: Eingabemasken

Die Parameter werden über die Schaltflächen

nommen. Mit

Abbrechen

wird das DTM Fenster ohne speichern geschlossen (siehe auch Kapitel „4.3.4.

Übernehmen

oder

OK

in die Datenbank über-

Schaltflächen zur Datenübernahme“).

Das Speichern des Projektes erfolgt im Menü „Datei / Speichern“.

Die Übertragung in das Gerät erfolgt mit dem Symbol

deutsch

51

Page 52

4.3.4. Schaltflächen zur Datenübernahme

Schaltfläche Beschreibung

Software Tool - 8x92 / 8x93

Bedien- und Anzeigeelemente

OK

Abbrechen

Übernehmen

Tabelle 3: Schaltflächen zur Datenübernahme

Das DTM Fenster wird geschlossen

geänderte Werte werden in die Datenbank übernommen.

Das DTM Fenster wird geschlossen

geänderte Werte werden nicht in die Datenbank übernommen.

Das DTM Fenster bleibt geöffnet

geänderte Werte werden in die Datenbank übernommen.

Wird das Programm ohne speichern des Projekts verlassen, sind die Daten der Datenbank nicht gesichert.

Das Speichern des Projektes erfolgt im Menü „Datei / Speichern“.

Die Übertragung in das Gerät erfolgt mit dem Symbol

4.3.5. Symbole

Geändeter Wert, nicht gespeichert, bzw. nicht ins Gerät geschrieben

in Datenbank gespeichert

Tabelle 4: Symbole

Gerätedaten

• ungültiger Eingabewert

• Konfigurationsfehler bei Kommunikation:

Ein oder mehrere Parameter mit unterschiedlichen Wertebereichen im Gerät und DTM

• Validierungsfehler bei Kommunikation:

falsches Gerät angeschlossen (falscher Hersteller, falscher Typ, falsche Geräte-

version)

Gerät nicht im Kommunikationsmodus (z.B. Gerät im Eingabemodus)

Kommunikationsfehler

52

deutsch

Page 53

Software Tool - 8x92 / 8x93

Installation

5. INSTALLATION

5.1. Systemanforderungen

Hardware:

Prozessor: Intel Pentium/ AMD, mindestens 500 MHz,

Arbeitsspeicher: Mindestens 128 MB RAM,

Festplatte: Mindestens 250 MB freier Speicherplatz,

Grafikauflösung: Mindestens 1024 x 768,

1 USB Port zum Anschluss des Adapters USB-RS232, Identnummer 227093

Software:

Betriebssystem Windows 2000/XP/Vista:

PACTware 3.6 + Microsoft .NET Framework 1.1 + .NET Framework 1.1 SP1

Betriebssystem Windows XP/Vista/7:

PACTware 4.1 + Microsoft .NET Framework 2.0

Zur Installation werden Administratorrechte benötigt.

Nach der Installation ist ein Windows-Neustart mit anschließender Windows-Anmeldung unter demselben Namen

erforderlich, da während des Neustarts die Installation fertig gestellt wird.

deutsch

53

Page 54

Software Tool - 8x92 / 8x93

Installation

5.2. PACTware und DTMs installieren

Abhängig vom vorhandenen Betriebssystem ist die entsprechende PACTware Version auszuwählen, siehe Kapitel

„5.1. Systemanforderungen“.

Sämtliche Installationsprogramme sind auf der Bürkert Homepage und auf CD verfügbar.

Vor der Installation alle laufenden Programme beenden.

5.2.1. PACTware Version 3.6 und .NET Framework 1.1

einschließlich SP1

Voraussetzung für die Installation von PACTware ist das Vorhandensein der Software-Plattform:

Microsoft .NET Framework 1.1 mit Service Pack 1 (SP1)

Vorgehensweise, falls „Microsoft .NET Framework 1.1 mit Service Pack 1 (SP1)“ auf dem Zielrechner noch nicht

vorhanden ist:

→ Download und/oder Öffnen der Zip-Datei (1000103878), welche das Microsoft.NET 1.1 framework enthält.

→ „Dotnetfx.exe“ starten.

→ Download und/oder Öffnen der Zip-Datei (1000103880), welche das Microsoft.NET 1.1 SP1 framework

enthält.

→ „NDP1.1sp1*.exe“ starten.

Vorgehensweise PACTware Setup:

→ Download und/oder Öffnen der Zip-Datei (1000103690), welche das PACTware Setup enthält und in ein

temporäres Verzeichnis entpacken.

→ „Setup.exe“ starten.

Das Setup Zip-File enthält:

• das Basis-Setup für PACTware 3.6 mit Online-Hilfe in verschiedenen Sprachen

54

• den HART Kommunikations DTM für PACTware 3.6

• den Generic HART DTM (wird nicht benötigt)

Nach Wahl der Installationssprache werden Sie durch die Installation geführt.

An dieser Stelle kann auch der HART Kommunikations DTM installiert werden. Dieser ist nötig, da die Kommunikation mit den Bürkert Geräten über das HART Protokoll abläuft, wobei auf der physikalischen Schicht keine

HART-, sondern eine RS232-Schnittstelle vorhanden ist.

deutsch

Page 55

Software Tool - 8x92 / 8x93

Installation

Optionale Komponenten wie beispielsweise das Handbuch werden hier nicht installiert.

Falls PACTware 2.4, PACTware 3.0 oder PACTware 3.5 schon installiert sind, können am Ende der Installation

alle Passwörter für PACTware 3.6 übernommen werden.

Durch die Installation wird eine Programmgruppe für den aktuellen Benutzer im Windows Start-Menü eingetragen

und ein Link zu PACTware 3.6 wird auf dem Desktop angezeigt.

5.2.2. PACTware Version 4.1 und .NET Framework 2.0

Download und/oder Öffnen der Zip-Datei „PACTware 4.1 SP1 Buerkert.zip“ und in ein temporäres Verzeichnis

entpacken. Diese Zip-Datei enthält alle nötigen Installations-Komponenten.

Voraussetzung für die Installation von PACTware ist das Vorhandensein der Software-Plattform:

Microsoft .NET Framework 2.0

Vorgehensweise, falls „Microsoft .NET Framework 2.0“ auf dem Zielrechner noch nicht vorhanden ist:

→ Starten des Setup

bei 64 Bit Betriebssystemen im Verzeichnis \dotNet\dotNET_20\x64

bzw. bei anderen Betriebssystemen im Verzeichnis \dotNet\dotNET_20\x86.

Vorgehensweise PACTware Setup:

→ \PACTware\PACTware.msi starten.

Das Setup enthält:

• das Basis-Setup für PACTware 4.1 mit Online-Hilfe in verschiedenen Sprachen

• den HART Kommunikations DTM für PACTware 4.1

• den Generic HART DTM (wird nicht benötigt)

Nach Wahl der Installationssprache werden Sie durch die Installation geführt.

An dieser Stelle kann auch der HART Kommunikations DTM installiert werden. Dieser ist nötig, da die Kommunikation mit den Bürkert Geräten über das HART Protokoll abläuft, wobei auf der physikalischen Schicht keine

HART-, sondern eine RS232-Schnittstelle vorhanden ist.

Optionale Komponenten wie beispielsweise das Handbuch werden hier nicht installiert.

Falls PACTware 2.4, PACTware 3.0, PACTware 3.5 oder PACTware 3.6 schon installiert sind, können am Ende

der Installation alle Passwörter für PACTware 4.1 übernommen werden.

Durch die Installation wird eine Programmgruppe für den aktuellen Benutzer im Windows Start-Menü eingetragen

und ein Link zu PACTware 4.1 wird auf dem Desktop angezeigt.

deutsch

55

Page 56

Software Tool - 8x92 / 8x93

Installation

5.2.3. Bürkert Geräte DTM

Vorgehensweise:

→ „Setup.exe“

im Verzeichnis AdditionalSetups\BuerkertDTMs\SETUP_Positioner_Typen_869X_879X_V1.0.0 starten.

oder alternativ:

→ „Setup.exe“