Page 1

Type XXXX

MFC Family

- Digital Communication

Fieldbus devices and serial communication (RS 232 / RS 485)

Feldbusgeräte und serielle Kommunikation (RS 232 / RS 485)

Appareils bus terrain et communication sérielle (RS 232 / RS 485)

Supplement to Operating Instructions

Ergänzung zur Bedienungsanleitung

Complément aux instructions de service

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten!

Sous réserve de modifications techniques.

© 2009 - 2011 Bürkert Werke GmbH

Operating Instructions 1107/08_EU-ML_00804553 / Original DE

Page 3

MFC Family

Description of Communication with MFC Family Devices

Contents

1. SUPPLEMENTARY OPERATING INSTRUCTIONS ..............................................................................................................5

1.1. Symbols ......................................................................................................................................................................................5

2. GENERAL INFORMATION ................................................................................................................................................................6

2.1. Contact Addresses ................................................................................................................................................................6

2.2. Information on the Internet ...............................................................................................................................................6

2.3. English terms ...........................................................................................................................................................................6

3. SERIAL COMMUNICATION .............................................................................................................................................................7

3.1. General Information..............................................................................................................................................................7

3.2. Commands .............................................................................................................................................................................12

3.3. Error messages ...................................................................................................................................................................26

4. PROFIBUS DP START-UP ...........................................................................................................................................................30

4.1. Address setting for BUS devices ...............................................................................................................................30

4.2. Technical Data ......................................................................................................................................................................31

4.3. DP alarm mode ....................................................................................................................................................................31

4.4. PROFIBUS PDI/PDOs ......................................................................................................................................................31

4.5. Explanation of variables used in cyclic data traffic ..........................................................................................32

4.6. Acyclic data ............................................................................................................................................................................33

5. DEVICENET START-UP ..................................................................................................................................................................34

5.1. Terms .........................................................................................................................................................................................34

5.2. Configuration of Process Data ....................................................................................................................................35

5.3. Acyclic data ............................................................................................................................................................................35

english

3

Page 4

MFC Family

6. CANOPEN START-UP .....................................................................................................................................................................36

6.1. CANopen general ................................................................................................................................................................36

6.2. CANopen emergency ........................................................................................................................................................39

6.3. CANopen – Service Data Transfer .............................................................................................................................43

6.4. CANopen – Process Data Transfer ...........................................................................................................................44

6.5. CANopen – Communication Object .........................................................................................................................50

6.6. Acyclic data ............................................................................................................................................................................50

7. ACYCLIC DATA TRANSFER WITH PROFIBUS, DEVICENET AND CANOPEN ...................................................51

7.1. CANopen-Manufactory Object .....................................................................................................................................51

7.2. CANopen-Identity Object ................................................................................................................................................51

7.3. DeviceNet S-Identity Object ..........................................................................................................................................52

7.4. S-Analog Sensor Object .................................................................................................................................................53

7.5. S-Analog Actuator Object ..............................................................................................................................................54

7.6. S-Single Stage Controller Object ..............................................................................................................................56

7.7. Bürkert General Description Object .........................................................................................................................57

7.8. Bürkert MFC Family Object ...........................................................................................................................................57

8. STARTING UP THE MODBUS ....................................................................................................................................................66

8.1. General Information...........................................................................................................................................................66

8.2. Modbus in general ..............................................................................................................................................................66

8.3. Modbus register and communication objects ....................................................................................................70

9. ANNEX ....................................................................................................................................................................................................79

9.1. Description of bit fields ...................................................................................................................................................79

9.2. Table of units .........................................................................................................................................................................83

4

english

Page 5

MFC Family

Supplementary Operating Instructions

1. SUPPLEMENTARY OPERATING

INSTRUCTIONS

The Supplementary Operating Instructions describe communication with MFC family devices.

Safety Information!

Safety instructions and information for using the device may be found in the corresponding operating instructions.

• The operating instructions must be read and understood.

1.1. Symbols

DANGER!

Warns of an immediate danger!

• Failure to observe the warning may result in a fatal or serious injury.

WARNING!

Warns of a potentially dangerous situation!

• Failure to observe the warning may result in serious injuries or death.

CAUTION!

Warns of a possible danger!

• Failure to observe this warning may result in a moderate or minor injury.

NOTE!

Warns of damage to property!

• Failure to observe the warning may result in damage to the device or the equipment.

Indicates important additional information, tips, and recommendations which are important for your safety

and the flawless functioning of the device.

Refers to information in these operating instructions or in other documentation.

→ Designates a procedure that must be carried out.

english

5

Page 6

2. GENERAL INFORMATION

2.1. Contact Addresses

Germany

Contact address:

Bürkert Fluid Control System

Sales Center

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Phone: 07940 - 10 91 111

Fax: 07940 - 10 91 448

E-mail: info@de.buerkert.com

MFC Family

General Information

International

Contact addresses can be found on the final pages of the printed operating instructions.

And also on the Internet at:

www.burkert.com

2.2. Information on the Internet

The operating instructions and data sheets for device types can be found on the Internet at:

www.burkert.com

Complete documentation is also available on CD and can be ordered under ID number 804625.

2.3. English terms

English technical terms and proper nouns appear just as they were in the original German version (i.e. in English).

The English variables and function names, etc. that were used in the German version are also unchanged in the

English version.

6

english

Page 7

MFC Family

Serial Communication

3. SERIAL COMMUNICATION

3.1. General Information

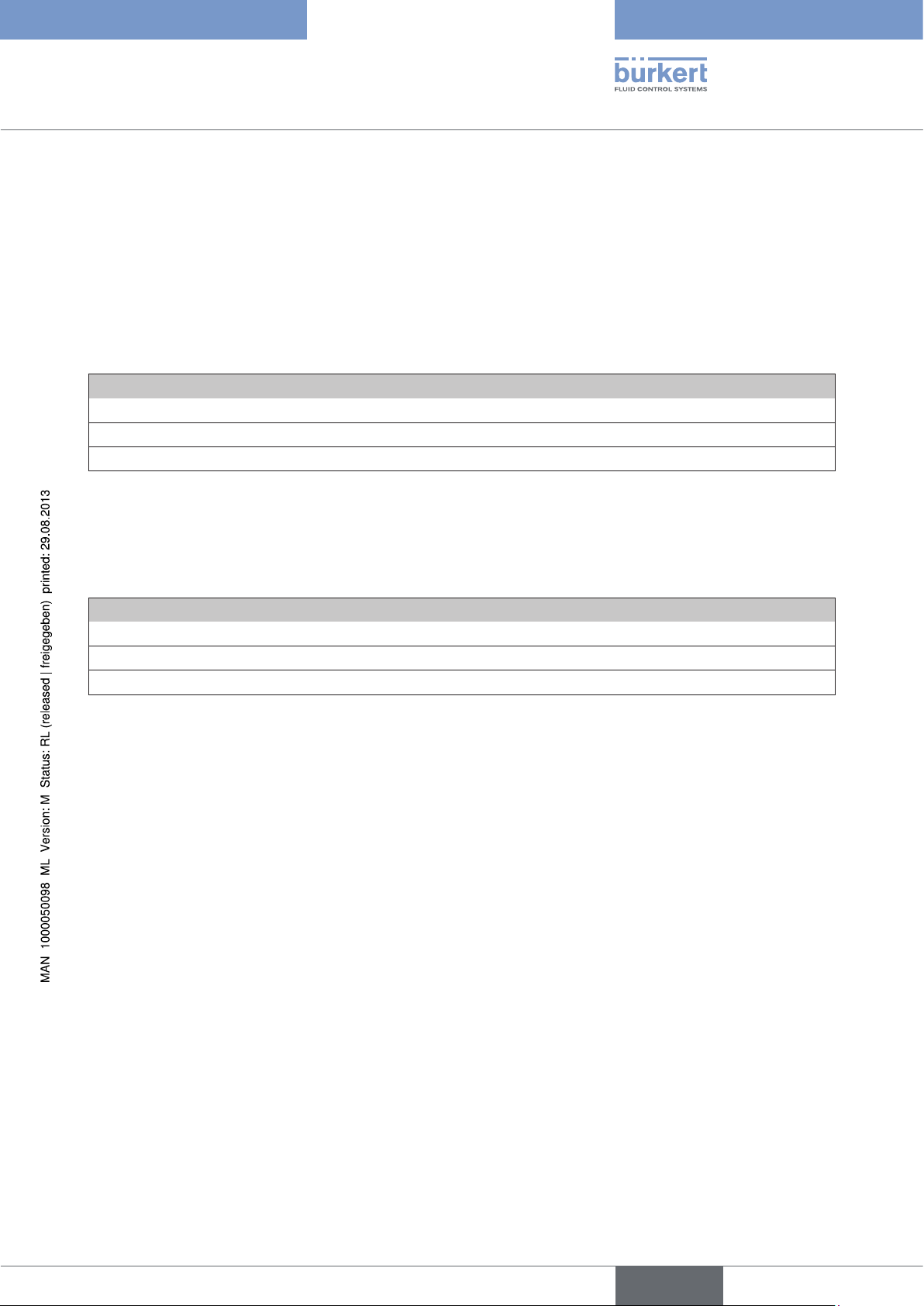

3.1.1. RS232 - Driver included in the device

(e.g. for types 8626/8006, 8716/8706, 8712/8702)

MFC / MFM PC (SUB-D 9-pin plug)

RS232 TxD (pin 6 SUB-HD socket) Pin 2

RS232 RxD (pin 14 SUB-HD socket) Pin 3

RS232 GND (pin 15 SUB-HD socket) Pin 5

3.1.2. RS232 - Driver not included in the device

(e.g. for type 8711/8701)

MFC / MFM

TxD From device (pin 15 SUB-D plug)

RxD From device (pin 14 SUB-D plug)

GND From device (pin 11 SUB-D plug)

3.1.3. Transfer protocol

Transfer channels

The following lines are used for the serial interface:

Wire-conducted communication

GND Ground

RxD Reception line (as seen by MFC)

TxD Transmission line (as seen by MFC)

Data format

The layout of the serial interface protocol is as follows:

Transfer rate Standard 9600 Bd (differs from HART)

Data bits 8

Parity None (differs from HART)

Stop bits 1

Hardware handshake No

7

english

Page 8

MFC Family

Serial Communication

Telegram

General Information

The layout of the transmission telegram is based on the HART protocol. HART is a master slave protocol, i.e. each

transmission is started by a master device (PC or manual operating unit). The slave device (field device, MFC / MFM)

responds only to a master telegram if the device was addressed by the telegram.

Exception: Burst message

Additional information about the HART protocol may be found under:

http://www.hartcomm.org/

http://www.romilly.co.uk/

A distinction is drawn between short frame and long frame telegrams. They consist of the following characters:

Short frame

Preamble 2 – 20 bytes 0xFF

Delimiter 1 byte

Master → Slave 0x02

Slave → Master 0x06

Burst message 0x01

Address 1 byte

(Master address + Burst info + Polling address)

Command 1 byte

Byte count 1 byte

Status

2 bytes, for slave Master

(for meaning see “3.3. Error messages” )

Data 0 – 255 bytes

Checksum 1 byte

Long frame

Preamble 2 – 20 bytes 0xFF

Delimiter 1 byte

Master → Slave 0x82

Slave → Master 0x86

Burst message 0x81

Address 5 bytes

Command 5 bytes

Byte count 1 byte

Status

2 bytes, for slave Master

(for meaning see “3.3. Error messages”)

Data 0 – 255 bytes

Checksum 1 byte

8

english

Page 9

MFC Family

Serial Communication

Preamble

The preamble consists of 2 to 20 0xFF characters (differs from HART). It is used to synchronize the data transfer.

Delimiter

Telegrams are distinguished from each other mainly by the delimiter:

Message type Short frame Long frame

Master → Slave 0x02 0x82

Slave → Master 0x06 0x86

Burst message from slave 0x01 0x81

Master: PC or manual operating unit

Slave: Field device, MFC/MFM

Address

The address field contains both the master address and the slave address of the message. One byte is used for this

purpose in a short frame, while 5 bytes are used in a long frame. Each device must respond to a long frame address

of 0 (= broadcast address), i.e. bit 0/1=X, bits 0 – 37=0.

The highest-order bit in both formats indicates which master is involved in communication.

(1: Primary master, continuously connected hosts;

0: Secondary master, manual operating units)

Short frame address (1 byte)

Bit 7 0 Secondary master

1 Primary master

Bit 6 0 Not in burst mode

1 In burst mode (not supported)

Bits 0 – 5 Polling address (0 – 32), bit 5 = MSB, bit 0 = LSB

m b x x x x x x

x Polling address

b Burst info

m Master address

english

9

Page 10

MFC Family

Serial Communication

Long frame address (5 bytes)

Bit 39 0: Secondary master

1: Primary master

Bit 38 0: Not in burst mode

1: In burst mode (not supported)

Bits 32 – 37 Manufacturer's ID code (0x78 = Buerkert),

Bit 37 = MSB, bit 32 = LSB

Bits 24 – 31 Device type code (0xEE = Mass flow controller/meter),

Bit 31 = MSB, bit 24 = LSB

Bits 0 – 23 Device ID number,

Bit 23 = MSB, bit 0 = LSB

(matches the device serial number)

Each field unit must respond to address 0 (bits 0 – 23 = 0).

Bit 37 Bit 23 Bit 0

| | |

mb x x x x x x x y y y y y y y y z z z z z z z z z z z z z z z z z z z z z z z z

z Device ID number

y Device type code

x Manufacturer's

ID code

b Burst info

m Master address

Command

Commands are divided into the following categories in conformity with HART:

Universal commands Commands 0 – 30

Standard commands Commands 32 – 126

Device-specific

Commands 128 – 253

command

(reserved: 31, 127, 254, 255)

Byte count

The byte count indicates how many more bytes come before the checksum, i.e. the number of status bytes +

number of data bytes. This results in a maximum total number of 255 status and data bytes.

Response code

Transferred only from the slave to the master in a response telegram. Consists of 2 bytes. The status bytes are

used to detect communication errors or for the operating status of the slave device.

Data

Data bytes, depending on the command. A maximum of 255 data bytes can be transferred.

• Float – IEEE 754 single precision (4 bytes) float

10

english

Page 11

MFC Family

Serial Communication

Checksum

The checksum is an XOR (exclusive OR, anticoincidence) combination of all bytes from the starting byte (delimiter)

up to and including the last data byte.

An XOR combination is the logical combination function of two logical values ("0" and "1"). It yields a result of "1"

if one but not both of the two values is "1".

english

11

Page 12

3.2. Commands

MFC Family

Serial Communication

Command number

Command name

0x00

ReadUniqueldentifier

Request

Command 0x00

Byte count 0

Data -

Response

Command 0x00

Byte count 14 (18)

Status 2 bytes, device status

Data 12 (16) bytes

0 "254" (expansion)

1 manufacturer identification code

2 manufacturer‘s device type code

3 number of preambles required

4 universal command revision

5 device-specific command revision

6 software revision

7 hardware revision

8 device function flags

9 – 11 device ID number

(12 common-practice command revision)

(13 common tables revision)

(14 data link revision)

(15 device family code)

1)

1)

2)

2)

2)

12

Description

HART-Universal Command 0.

1)

First byte transferred: MSB

2)

Reserved for later versions

english

Page 13

MFC Family

Serial Communication

Command number

Command name

0x01

ReadPrimaryVariable

Request

Command 0x01

Byte count 0

Data -

Response

Command 0x01

Byte count 7

Status 2 bytes, device status

Data 5 bytes

0 PV units code

1 – 4 primary variable (float)

Description

HART-Universal Command 1.

PV Unit 0 x 39

%

1)

PV Actual flow X (±)

(see also “3.3.3. Codings and units”)

Example:

All data as hexadecimal numbers (prefix 0x) short frame

Primary master

Short address 0

Data sent

Data received

• Read Primary Variable

0xFF 0xFF 0x02 0x80 0x01 0x00 0x83

0xFF 0xFF 0x06 0x80 0x01 0x07 0x00 0x00 0x39 0x41 0xC8 0x00 0x00

0x30 0x39 for PV Unit = %

0x41C80000 = 25.0 IEEE 754 floating point

1)

First byte transferred: MSB

13

english

Page 14

MFC Family

Serial Communication

Command number

Command name

0x03

ReadCurrentAndFourDynamicVariables

Request

Command 0x03

Byte count 0

Data -

Response

Command 0x03

Byte count 26

Status 2 bytes, device status

Data 24 bytes

0 – 3 current (mA) (float)

4 PV units code

5 – 8 primary variable (float)

9 SV units code

10 – 13 secondary variable (float)

14 TV units code

15 – 18 third variable (float)

19 FV units code

20 – 23 fourth variable (float)

1)

1)

1)

1)

1)

14

Description

HART-Universal Command 3.

New variable assignment as of firmware version A.00.28.09:

current Actual flow scaled to 4 – 20 mA

PV Unit %

PV Actual flow X (±)

SV Unit %

SV Set-point value flow W

TV Unit %

TV Positioning set-point value y 2 (valve duty cycle)

FV Unit sec

FV Device sampling time,

since power-on or SyncTA command

1)

First byte transferred: MSB

english

Page 15

MFC Family

Serial Communication

Command number

Command name

0x06

WritePollingAddress

Request

Command 0x06

Byte count 1

Data 1 byte

0 polling address

Response

Command 0x06

Byte count 3

Status 2 bytes, device status

Data 1 byte

0 polling address

Description

HART-Universal Command 6:

Command for changing the HART polling address.

english

15

Page 16

MFC Family

Serial Communication

Command number

Command name

0x27

EepromControl

Request

Command 0x27

Byte count 1

Data 1 byte

0 = Write to EEPROM

1 = Copy content of EEPROM to RAM

Response

Command 0x27

Byte count 3

Status 2 bytes, device status

Data 1 byte

0 = Write to EEPROM

1 = Copy content of EEPROM to RAM

Description

HART-Universal Command 39.

Command to write/read parameters (for example the polling address) to/from EEPROM.

16

english

Page 17

MFC Family

Serial Communication

Command number

Command name

0x80

ReadVersion

Request

Command 0x80

Byte count 0

Data -

Response

Command 0x80

Byte count 36

2) 3) 4) 5)

Status 2 bytes, device status

Data 34 bytes

0 – 1 Device type (unsigned int), e.g. 8626

2 Device number, z. B. 1

3 – 6 Device ID number (unsigned long)

7 – 10 Device serial number (unsigned long)

11 – 14 Software ID number (unsigned long)

15 Software version x (x.y.z.cc): A – Z

16 Software version y (x.y.z.cc): 0 – 99

17 Software version z (x.y.z.cc): 0 – 99

18 Software version cc (x.y.z.cc): 0 – 99

19 EEPROM layout version x (x.y): A – Z

20 EEPROM layout version y (x.y): 0 – 99

21 Table_x version (x.y): A – Z

22 Table_y version (x.y): 0 – 99

23 – 26 Bios ID number (unsigned long)

27 Bios version x (x.y.z.cc): A – Z

28 Bios version y (x.y.z.cc): 0 – 99

29 Bios version z (x.y.z.cc): 0 – 99

30 Bios version cc (x.y.z.cc): 0 – 99

31 MFi software version x (x.y): A – Z

32 MFi software version y (x.y): 0 – 99

33 MFi software version x (x.y): A – Z

1)

1)

1)

2)

2)

3)

3)

4)

4)

4)

4)

4)

5)

5)

5)

Description

Command to read device information and the software version.

1)

First byte transferred: LSB

2)

Version-dependent – available with firmware version A.00.29.02 or later

3)

Version-dependent – available with firmware version A.00.63.00 or later

4)

Version-dependent – available with firmware version A.00.64.00 or later

5)

Version-dependent – available with firmware version A.00.83.03 or later

17

english

Page 18

MFC Family

Serial Communication

Command number

Command name

0x92

ExtSetpoint

Request

Command 0x92

Byte count 5

Data 1 byte

0 Internal set-point value settings

1 External set-point value settings

4 bytes

0 – 3 Set-point value [%] (float)

Response

Command 0x92

Byte count 7

Status 2 bytes, device status

Data 1 byte

0 Internal set-point value settings

1 External set-point value settings

4 bytes

0 – 3 Set-point value [%] (float)

1)

1)

18

Description

Available as of firmware version A.00.28.09.

Determines the set-point value settings and describes the external set-point value as a percentage:

Internal = analog - the set-point value settings is assigned by the analog set-point value signal that is

created

External = digital via serial interface

Do not use this command if you are using a bus device (PROFIBUS, DeviceNet, etc.). The digital set-point

value settings via the serial interface has a higher priority.

1)

First byte transferred: MSB

Example:

All data as hexadecimal numbers (prefix 0x) short frame

Primary master

Short address 0

Data sent

Data received

• Set-point value settings digital 0.0% (

0x00000000 IEEE 754)

0xFF 0xFF 0x02 0x80 0x92 0x05 0x01 0x00 0x00 0x00 0x00 0x14

0xFF 0xFF 0x06 0x80 0x92 0x07 0x00 0x00 0x01 0x00 0x00 0x00 0x00 0x12

• Set-point value settings digital 50.0% (

0x42480000 IEEE 754)

0xFF 0xFF 0x02 0x80 0x92 0x05 0x01 0x42 0x48 0x00 0x00 0x1E

0xFF 0xFF 0x06 0x80 0x92 0x07 0x00 0x00 0x01 0x42 0x48 0x00 0x00 0x18

english

Page 19

MFC Family

Serial Communication

• Set-point value settings digital 100.0% ( 0x42C80000 IEEE 754)

0xFF 0xFF 0x02 0x80 0x92 0x05 0x01 0x42 0xC8 0x00 0x00 0x9E

0xFF 0xFF 0x06 0x80 0x92 0x07 0x00 0x00 0x01 0x42 0xC8 0x00 0x00 0x98

• Switch set-point value settings to analog set-point value settings:

0xFF 0xFF 0x02 0x80 0x92 0x05 0x00 0x00 0x00 0x00 0x00 0x15

FF FF 06 80 92 07 00 00 00 .............

english

19

Page 20

MFC Family

Serial Communication

Command number

Command name

0x93

GetAddDeviceInfo

Request

Command 0x93

Byte count 0

Data -

Response

Command 0x93

Byte count 10

Status 2 bytes, device status

Data 8 bytes

0 – 1 Bit field ERRORS

2 – 3 Bit field OTHERS

4 – 5 Bit field LIMITS

6 – 7 Reserved (bit field)

Description

Available as of firmware version A.00.28.09.

1)

1)

1)

1)

Command for reading additional device information such as error bits, operating states (AutoTune, Safepos, etc.),

states of threshold values and binary inputs/outputs.

1)

First byte transferred: LSB

20

english

Page 21

MFC Family

Serial Communication

Command number

Command name

0x94

GetBusAddress

Request

Command 0x94

Byte count 0

Data -

Response

Command 0x94

Byte count 4

Status 2 bytes, device status

Data 2 bytes

0 – 1 Bus address (unsigned int)

1)

Description

Available as of firmware version A.00.28.09.

Command for reading the bus address (PROFIBUS, DeviceNet, etc.). If the connected device is not a bus

device, the error "Access denied" is returned in the response.

1)

First byte transferred: LSB

english

21

Page 22

MFC Family

Serial CommunicationSerial Communication

Command number

Command name

0x95

SetBusAddress

Request

Command 0x95

Byte count 2

Data 2 bytes

0 – 1 Bus address (unsigned int)

1)

Response

Command 0x95

Byte count 4

Status 2 bytes, device status

Data 2 bytes

0 – 1 Bus address (unsigned int)

1)

Description

Available as of firmware version A.00.28.09.

Command for setting the bus address (PROFIBUS, DeviceNet, etc.). If the connected device is not a bus

device, the error "Access denied" is returned in the response.

1)

First byte transferred: LSB

22

english

Page 23

MFC Family

Serial Communication

Command number

Command name

0x96

GetTotalizer

Request

Command 0x96

Byte count 1

Data 1 byte

0 Index of calibration gases

Response

Command 0x96

Byte count 8

Status 2 bytes, device status

Data 1 byte

Index of calibration gases

0 Gas 1

1 Gas 2

5 bytes

1

Unit

2 – 5

Totalizer value (Float)

Description

Available as of firmware version A.00.28.09.

Reads the totalizer value for the gas with the selected index in the unit that was transferred (167 = Nl; in

reference to 1013 mbar, 273 K).

english

23

Page 24

MFC Family

Serial Communication

Command number

Command name

0x97

ClearTotalizer

Request

Command 0x97

Byte count 1

Data 1 byte

0 index of calibration gases

Feedback

Command 0x97

Byte count 3

Status 2 bytes, device status

Data 1 byte

Index of calibration gases

0 Gas 1

1 Gas 2

Description

Available as of firmware version A.00.28.09.

Deletes the totalizer value of the corresponding gas.

24

english

Page 25

MFC Family

Serial Communication

Command number

Command name

Device types

0x98

ExtSetpointWithoutAnswer

0xEE

Request

Command 0x92

Byte count 5

Data 1 byte

0 Set-point value settings, internal

1 Set-point value settings, external

4 bytes

1 – 4 Set-point value [%] (float)

Response

Command Byte count Status -

Data -

Description

1)

Available as of firmware version A.00.51.06.

Determines the set-point value settings and describes the external set-point value as a percentage:

Internal = analog - the set-point value settings is assigned by the analog

set-point value signal that is created

External = digital via serial interface

Do not use this command if you are using a bus device (PROFIBUS, DeviceNet, etc.). The digital set-point

value settings via the serial interface has a higher priority.

No response is sent for this command.

1)

First byte transferred: MSB

english

25

Page 26

MFC Family

Serial Communication

3.3. Error messages

2 bytes, device status

Error messages are saved in the device status. If the device status is 0, no error occurred.

3.3.1. First status byte

Communication error

Error code

Error name

Description UART error, receive buffer, overflow was detected.

Error code

Error name

Description An incorrect checksum was received.

Error code

Error name

Description UART error, framing error was detected.

Error code

Error name

Description UART error, overrun error was detected.

Error code

Error name

Description UART error, parity error was detected.

0x82

overflow

0x88

checksum

0x90

framing

0xA0

overrun

0xC0

parity

26

english

Page 27

MFC Family

Serial Communication

Command error

Error code

Error name

0x02

invalid_selection

Description An invalid data range was selected.

Error code

Error name

Description

Error code

Error name

Description

Error code

Error name

0x03

parameter_too_large

Transfer parameter too large. It may be a table or array index from the data range, i.e. an

incorrect value range.

0x04

parameter_too_small

Transfer parameter too small. It may be a table or array index from the data range, i.e. too low

for the value range.

0x05

too_few_data_bytes

Description Not enough data bytes were received.

Error code

Error name

0x07

write_protected

Description Device is write-protected.

Error code

Error name

Description

Error code

Error name

Description

0x10

access_restricted

The command that was sent cannot be executed (currently). Access was denied. The cause

could be, for example, that the necessary access rights are lacking or the command is not

permitted in the current operating mode.

0x40

no_command

Invalid/incorrect command, i.e. the command that was received is not supported by the

device.

english

27

Page 28

Device status

MFC Family

Serial Communication

Error code

Error name

0x20

device_busy

Description Device is busy.

Internal device-specific error messages

Error code

Error name

Description

Error code

Error name

Description

0x01

timeout

The time limit was exceeded, i.e. too much time passed between a valid received delimiter

and a complete command.

0x41

wrong_command

Incorrect command structure, i.e. the command is valid and exists, but the number of bytes

transferred does not match. Only 1 byte was transferred for a 2-byte variable.

28

english

Page 29

MFC Family

Serial Communication

3.3.2. Second status byte

Second status byte

Bit 7 Field device malfunction

Bit 6 reserved for future purposes

Bit 5 reserved for future purposes

Bit 4 reserved for future purposes

Bit 3 reserved for future purposes

Bit 2 reserved for future purposes

Bit 1 reserved for future purposes

Bit 0 reserved for future purposes

UART errors take precedence in error detection.

Multiple UART errors cannot be detected simultaneously.

3.3.3. Codings and units

Manufacturer coding (HART standard)

Hex Dec Description

0x78 120 Buerkert

0xFA 250 not used

0x FB 251 none

0xFC 252 unknown

0xFD 253 special

Units (HART standard)

Hex Dec Unit Description

0x33 51 sec Seconds

0x39 57 % Percent

0xA7 167 Nl Normalized liters (reference condition p = 1015 mbar

0xFA 250 - not used

0xFB 251 - none

0xFC 252 - unknown

0xFD 253 - special

abs

, T = 273,15 K

english

29

Page 30

MFC Family

PROFIBUS DP Start-up

4. PROFIBUS DP START-UP

4.1. Address setting for BUS devices

4.1.1. Devices without rotary switch for address setting

The BUS address of devices can be set either with the Bürkert configuration tool MassFlowCommunicator in the

"Views" → "PROFIBUS/DeviceNet/CANopen" view or directly with the BUS master.

After an address is changed, it must be initialized on the slave and also on the master. Depending on the BUS, it

may be necessary to send an appropriate telegram.

To ensure the setting was made without problems, a device reset should be performed (turn the electrical

power off and back on).

4.1.2. Devices with rotary switch for address setting

When the device is turned on, the address set as the slave address on the rotary switches is applied. Valid

addresses are:

• PROFIBUS 0 … 126

• DeviceNet 0 … 63

• CANopen 1 … 127

If the address has been set outside the permissible range, the address setting has the validity as described in

section “4.1.1”.

LBS Ones place, x 1

0 – 9 The number

multiplied by 1

MBS Tens place, x 10

0 – 9 The number

multiplied by 10

A → 100

B → 110

C → 120

D → 130

E → 140

F → 150

→ 0 – 9

→ 0 – 90

30

Thus the address consists of LSB + MSB.

MSB LBS Address

0 1 1

6 3 63

A 0 100

C 7 127

If you want to make an address setting with the BUS master and there are rotary switches available, set

the address to a value outside the valid range.

english

Page 31

MFC Family

PROFIBUS DP Start-up

4.2. Technical Data

GSD file BUV10627.GSD

Symbols BUV10627.BMP address 0 – 126

Standard: 126

4.3. DP alarm mode

DP alarm mode is not supported.

Siemens-specific:

Use value "DPV0" in the hardware configurator. There is no change in the communication protocol.

The value changes only the "alarm mode support".

Additional information is available in the Simatic S7 help.

4.4. PROFIBUS PDI/PDOs

You can make all settings required for bus communication in this input window. The important items are the

BUS address of the device (BUS AdrProfibus) and the process data to be send (input SPS or PDIs) and to be

received (output SPS or PDOs). They can be activated and deactivated with the option fields.

→ Apply the changed settings in the menu bar under "Functions" / "Write Data to Device".

No more than 10 process data items may be selected. This includes both process input data items and

process output data items.

english

31

Page 32

MFC Family

PROFIBUS DP Start-up

4.5. Explanation of variables used in cyclic data traffic

Process data Explanation Identifier

Actual value Actual value

(1 word = 2 bytes)

Value range 0 – 1000

Set-point Set-point value

(1 word = 2 bytes)

Value range 0 – 1000

Active gas

(used gas type)

Nominal flow Gas 1 Nominal flow in Nl/min of

Nominal flow Gas 2 Nominal flow in Nl/min of

Status limits

Status errors

Status others

Status LEDs

Status binary outputs

Default values via bus

whose calibration curve is used for control:

gas 1 or gas 2

(1 word = 2 bytes)

Value range 0 – 1

calibration for gas 1

float = 4 bytes

calibration for gas 2

float = 4 bytes

Read only

Bit field for states of device-internal threshold value:

(1 word = 2 bytes)

see “9.1. Description of bit fields”

min. value 0, max. value 65535

Read only

Bit field for device errors that are present.

(1 word = 2 bytes)

see “9.1. Description of bit fields”

min. value 0, max. value 65535

Read only

Bit field for current states in the controller.

(1 word = 2 bytes)

see “9.1. Description of bit fields”

min. value 0, max. value 65535

Read only

Bit field for communication states.

(1 word = 2 bytes)

see “9.1. Description of bit fields”

min. value 0, max. value 65535

Reserved bit field

(1 word = 2 bytes)

see “9.1. Description of bit fields”

Bit field for states of LEDs and binary outputs as they can

be assigned by the bus. To do this, the corresponding

functions must be configured in the device with the

PC program.

(1 word = 2 bytes)

see “9.1. Description of bit fields”

41,40,00 (HEX); PDI

41,40,01 (HEX); PDI

81,40,01 (HEX); PDO

41,40,02 (HEX); PDI

41,83,03 (HEX); PDI

41,83,04 (HEX); PDI

41,40,05 (HEX); PDI

41,40,06 (HEX); PDI

41,40,07 (HEX); PDI

41,40,08 (HEX); PDI

41,40,09 (HEX) PDI

41,40,0B (HEX); PDI

81,40,0B (HEX); PDO

32

english

Page 33

MFC Family

PROFIBUS DP Start-up

Process data Explanation Identifier

Totalizer value Gas 1 Totalizer value of calibration for

gas 1 in Nl.

Float = 4 bytes

Totalizer value Gas 2 Totalizer value of calibration for

gas 2 in Nl.

Float = 4 bytes

Actual value as float

Set-point as float

Control output y2 (2 bytes)

AddMeasureValue Additional value as float (4 bytes)

Xp Additional pressure value (2 bytes)

(4 bytes)

Default: 0 –1 00 %

Parameterization of the unit.

(see also “7.4. S-Analog Sensor Object”)

(4 bytes)

Default: 0 – 100 %

Parameterization of the unit.

(see also “7.6. S-Single Stage Controller Object”)

Only for MFC control output y2 of the controller, in units

per thousand

Value range 0 … 1000

Value as a percentage

This value is only supported by a few MFCs. If the value is

not supported, 0% is returned.

Value in units per thousand

Value range 0 … 1000

41,83,03 (HEX); PDI

41,83,0D (HEX); PDI

41,83,0E (HEX) PDI

81,83,0E (HEX) PDO

81,83,0E (HEX) PDO

41,40,10 (HEX); PDI

41,83,11 (HEX); PDI

41,40,12 (HEX); PDI

This value is only supported by a few MFCs. If the value is

not supported, 0% is returned.

4.6. Acyclic data

See “7. Acyclic Data Transfer with PROFIBUS, DeviceNet and CANopen”

33

english

Page 34

MFC Family

DeviceNet Start-up

5. DEVICENET START-UP

5.1. Terms

DeviceNet

DeviceNet is a field bus system based on the CAN protocol (Controller Area Network). It enables actuators and

sensors (slaves) to be networked with higher-level controllers (master).

The DeviceNet profile "Mass Flow Controller Device" is supported with strict compliance to DeviceNet

specifications.

With DeviceNet it is necessary to differentiate between cyclical or event-driven high-priority process messages

(I/O messages) and acyclical low-priority management messages (explicit messages).

Protocol sequence

The protocol process conforms to the DeviceNet specification Release 2.0.

Technical Data

EDS file

Icons

Baudrate

Address

Process data

BUER8626.EDS

BUER8626.ICO

125, 250, 500 kBit/s

Factory setting 125 kBit/s

0 – 63

Factory setting 63

5 static input assemblies

4 static output assemblies

34

english

Page 35

MFC Family

DeviceNet Start-up

5.2. Configuration of Process Data

5 static input and 2 static output assemblies can be selected to transmit process data via an I/O connection.

These assemblies contain selected attributes combined into one object so that process data can be transmitted

collectively via an I/O connection.

The process data is selected by setting the device parameters Active Input Assembly and Active Output

Assembly or - if supported by the DeviceNet-Master/Scanner - by setting Produced Connection Path and

Consumed Connection Path when an I/O connection is initialized according to the DeviceNet specification.

Assembly Object general

Attribute address

Name Description of the input data attributes

ASS_NumberOfObjects 4, x, 1

ASS_Memberlist 4, x, 2

ASS_Data 4, x, 3

(class, instance

attribute, data type)

Assembly Object

Attribute address

Direction data Description of data attributes

Input / output Not active 4, 0, 3

Input Status byte + Flow(INT) 4, 2, 3

Input Statusbyte + Flow(INT) + Setpoint(INT)

+ ActuatorOverrideByte + ValveDutyCycle(INT)

Output Setpoint(INT) 4, 7, 3

Output ActuatorOverrideByte + Setpoint(INT) 4, 8, 3

Input Flow + status errors 4, 21, 3

Input Flow + status errors + status limits 4, 22, 3

Input Flow + status errors + status limits + status others 4, 23, 3

(class, instance

attribute, data type)

4, 6, 3

5.3. Acyclic data

See “7. Acyclic Data Transfer with PROFIBUS, DeviceNet and CANopen”

english

35

Page 36

MFC Family

CANopen Start-up

6. CANOPEN START-UP

6.1. CANopen general

6.1.1. Terms used

CANopen

CANopen is a field bus system based on the CAN protocol (Controller Area Network).

CANopen is a standard of CAN in Automation (CiA).

The CANopen communication model provides two methods of communication mechanisms:

• Unconfirmed transmission of data blocks of up to 8 bytes to transfer process data (PDO "Process Data Object")

without additional overhead compared to SDO.

• Confirmed transmission of data between two nodes with direct access to entries of the object dictionary

(SDO "Service Data Object") of the addressed node.

Protocol sequence

The protocol sequence complies with CANopen communication profile CiA draft standard 301 V 4.02.

6.1.2. Technical Data

EDS file

Baudrate

Address

Process data

Buerkert_COP8626.EDS

20, 50, 100, 125, 250, 500, 800, 1000 kBit/s

Factory setting 125 kBit/s

1 – 127

Factory setting 127

4 TxPDOs

1 RxPDO

36

english

Page 37

MFC Family

CANopen Start-up

6.1.3. Assignment of process data objects

See “6.4. CANopen – Process Data Transfer”

Predefined ID connection set

CANopen defines a standard identifier allocaton scheme (see table below). These identifiers are available in the

pre-operational state after node initialization.

Object Identifier

NMT 0 hex

SYNC 80 hex

EMERGENCY 80 hex + address

st

TPDO 180 hex + address

1

st

RPDO 200 hex + address

1

nd

TPDO 280 hex + address

2

nd

RPDO 300 hex + address

2

rd

TPDO 380 hex + address

3

rd

RPDO 400 hex + address

3

th

TPDO 480 hex + address

4

th

RPDO 500 hex + address

4

TSDO 580 hex + address

RSDO 600 hex + address

NODE-GUARDING 700 hex + address

6.1.4. Error Control Service

To determine a non-active bus, the master must support one of the two error monitoring types, Node-Guarding or

Heartbeat.

Integration of one of the two error monitoring types, Node-Guarding or Heartbeat, is mandatory.

In error monitoring of a CAN-based network, the NMT object detects local errors within a node. These errors can

result in a reset or change of status, for example. The error definitions are not part of the specification.

Error monitoring occurs periodically during data transfer.

There are two methods of error monitoring:

Node-Guarding

Error monitoring involves the NMT master sending the Node-Guarding telegram. If the NMT slave does not

respond within a defined time or if the communication status of the NMT slave has changed, the NMT master

reports this to its NMT master application.

37

english

Page 38

MFC Family

CANopen Start-up

If runtime monitoring is supported, the slave using the Node-Guarding time and fail factor of its object library to

calculate the reacting time. If runtime monitoring is accessed, the NMT slave informs its local application of the

event. If the values of runtime monitoring and the fail factor are zero (0), no runtime monitoring occurs.

Runtime monitoring of the slave starts as soon as the slave receives the first monitoring request. Usually this

happens during the start phase or later.

Node Guarding is adjustable by the following objects:

Name Description Index, Subindex

CANopen

Node-Guarding Time

(monitoring time)

Read Write

Defines the monitoring time in ms.

Dec: 4108, 0

Hex: 100C, 0

UNSIGNED32

Node-Guarding Fail Factor Read Write

Defines the reacting time for detcting a timeout.

Dec: 4109, 0

Hex: 100D, 0

for example reacting time = monitoring time ×

UNSIGNED32

fail factor.

Heartbeat

With Heartbeat, a cyclical check determines whether the other node is still responding. If there is no Heartbeat

message from the node, the monitoring node is informed. If the heartbeat objects are written with values not

equal to 0, monitoring occurs after the change of status from INITIALIZING to PRE-OPERATIONAL. The Bootup

message is the first one to have the heartbeat message. Using both mechanisms (Node-Guarding and Heartbeat)

simultaneously is not permitted. If the objects of the heartbeat are not equal to zero (0), Heartbeat is used as the

monitoring mechanism.

Heartbeat is adjusted with the following objects:

Name Description Index, Subindex

CANopen

Consumer Heartbeat Time Read

Number of entries 1–127

Dec: 4118, 0

Hex: 1016, 0

UNSIGNED8

Read Write

Bits 31–24: Reserved

Dec: 4118, 1–127

Hex: 1016, 1–7

Bits 23–16: Node ID of generator

Bits 15–0: Heartbeat time

Producer Heartbeat Time Read Write

Defines the monitoring time in ms

FUNSIGNED32

Dec: 4109, 0

Hex: 100D, 0

38

english

Page 39

MFC Family

CANopen Start-up

6.2. CANopen emergency

The emergency functions that are implemented comply with the "CiA draft standards 301".

6.2.1. Emergency machine

A device may be in one of two emergency states (see “Fig. 1: Emergency states”). Emergency objects are sent

depending on transitions. Connections between the emergency status machine and the NMT status machine are

defined in the device profiles.

0

Error-free

1

2

Error occurred

Fig. 1: Emergency states

0 If no error is determined, the device goes into an error-free status after initialization. No error message is

sent.

1 The device determines there is an internal error, which is displayed in the first three bytes of the emer-

gency message (error code and error register). The device goes into error status. An emergency object

is sent with the corresponding error code and error register. The error code is entered in object 1003H

(pre-defined error field).

2 One, but not all errors have disappeared. An emergency message containing error code 0000

(error reset), can be sent with the remaining errors in the error register and in the manufacturer-specific

error field.

3 A new error has occurred in the device. The device remains in the error status and sends an emergency

object with the corresponding error code. The new error code is entered at the upper end of the array of

error codes (1003H). It must be guaranteed that error codes are sorted by time (oldest error - highest

subindex; see “Object 1003h: Pre-defined error field”).

4 All errors have been eliminated. The device goes into error-free status and sends an emergency object

with the error code "Reset error / no error".

4

3

english

39

Page 40

MFC Family

CANopen Start-up

6.2.2. Diagnostic object data

The diagnostic telegram consists of 8 bytes with the data shown in the following illustration:

Diagnostic object data.

Byte 0 1 2 3 4 5 6 7

Table of

Contents

Emergency error code

(see “Table of diag-

nostic error”, page

42)

The following two items are added to all errors:

Object 1001h: Error register

Error

register

(object

1001H)

Manufacturer-specific error field

Name

Error register All errors that occur on the

Description of the input

data attribute

device are mapped

Index, Subindex

Dec: 4097, 0

Hex: 1001, 0

on this object.

UNSIGNED8

This object is an error register for the device. The device is able to represent internal errors in this byte.

This entry is mandatory for all devices. It is part of an emergency object.

Bit M/O Description

0 M General error

1 O Current

2 O Voltage

3 O Temperature

4 O Communication error (overflow, error status)

5 O Device-specific

6 O Reserved (always 0)

7 O Manufacturer-specific

40

If a bit is set to 1, the specified error has occurred. The only mandatory error that must be indicated is a general

error. A general error is indicated in every error situation.

english

Page 41

MFC Family

CANopen Start-up

Object 1003h: Pre-defined error field

Name

Error Register The object contains errors that have occurred in the

Description of the input

data attribute

device.

Index, Subindex

Dec: 4099, 0-10

Hex: 1003, 0-A

UNSIGNED32

The object for index 1003h contains errors that have occurred in the device and were indicated by the emergency

object. Thus it returns an error history.

1. The entry for subindex 0 contains the number of actual errors that occurred in the array. Errors are recorded in

the array beginning at subindex 1.

2. The most recent error is saved in subindex 1, while older errors have been moved further down in the list.

3. Writing a "0" to subindex 0 deletes the entire error history (clears the array). Values greater than 0 must not be

be written. This results in an abort message (error code: 0609 0030h).

4. Error numbers are of type UNSIGNED32 and consist of a 16-bit error code and an additional 16-bit infor-

mation field which is manufacturer-specific. The 2 lower-order bytes (LSB) contain the error code, while

the 2 higher-order bytes contain the additional information (MSB). If the object is supported, it must consist of

at least two different entries: the length entry at subindex 0h and at least one error for subindex 1H.

MSBByte

Additional information

Fig. 2: Structure of the pre-defined error field

LSB

Error code

english

41

Page 42

The following table gives an overview of implemented diagnostic error codes:

Table of diagnostic error

MFC Family

CANopen Start-up

Error description Emergency

Error code

Content of error

register

(object 1001H)

Content of the

pre-defined error

field

(object 1003H)

Hex Hex Hex

Dec

Current out of range 2200 03 00002200

8704

Error LED

>power LED<

Error LED

>communication LED<

Error LED

>limit LED<

FF00 81 0001FF00

130816

FF00 81 0002FF00

196352

FF00 81 0003FF00

261888

Error LED FF00 81 0004FF00

327424

Error BinOut

>BinOut 1<

Error BinOut

>BinOut 2<

FF10 81 0001FF10

130832

FF10 81 0002FF10

196368

Error internal supply voltage 3200 05 00003200

Content of the manufacturer-specific

error field

Hex

Byte 0: 01

Byte 0: 02

Byte 0: 03

Byte 0: 04

Byte 0: 01

Byte 0: 02

42

12800

Error sensor supply voltage 3210 05 00003210

12816

Error sensor fault 5030 21 00005030

20528

Error after autotune FF20 81 0000FF20

65312

Error bus module MFI FF30 81 0000FF30

65328

Stack overflow 6100 21 00006100

24832

CAN queue overrun 8110 01 00008110

33040

CAN in error passive mode 8210 11 00008210

33296

english

Page 43

MFC Family

CANopen Start-up

6.3. CANopen – Service Data Transfer

Data transfer between two nodes is described in the client/server model. An SDO client (initiating node) has

direct access to individual entries in the object directory of an SDO server and is able to upload or download data

records of any length to or from a server. The data record to be transferred can be specified by indicating a 16-bit

index and 8-bit subindex. Since one message identifier is required for each transfer direction, two CAN identifiers

are required for a connection between an SDO client and an SDO server. The connection between a client and a

server is also referred to as an SDO channel.

The Bürkert field device has an SDO channel and supports the following transfer types:

Segmented Transfer

Segmented transfer makes it possible to transfer 7 bytes per transfer sequence. At the beginning, an initialization

sequence a 16-bit index and 8-bit subindex is transferred. This is followed by confirmed, segmented transfer of

data.

1)

Expedited

Transfer

Expedited transfer allows for faster transfer of 4 bytes per transfer sequence. It is normally used whenever the

size of the data being transferred does not exceed 4 bytes.

An SDO message is structured as follows:

ID DLC Byte1 Byte2 Byte3 Byte4 Byte5 Byte6 Byte7 Byte8

- 8 CMD Index Subindex Data bytes

The transfer is specified in byte 1 by control bytes. For an overview of the meaning of different control bytes, see

the following table.

Process CMD Note

Master requests data from slave 40h

Slave responds 42h (valid data bytes not specified)

43h (4 valid data bytes)

47h (3 valid data bytes)

4Bh (2 valid data bytes)

4Fh (1 valid data byte)

Master writes to slave 22h (valid data bytes not specified)

23h (4 valid data bytes)

27h (3 valid data bytes)

2Bh (2 valid data bytes)

2Fh (1 valid data byte)

Slave responds 60h

1)

Expedited: accelerated

43

english

Page 44

MFC Family

CANopen Start-up

6.4. CANopen – Process Data Transfer

All available process data objects are mapped. Only selected process data objects have valid values.

6.4.1. Received PDOs

Received PDOs are data that has been received by the device (MFC). This is output data as seen by the PLC.

Received PDO

Byte RxPDO0

0 Lower byte

1 Higher-order byte

2 Lower byte

3 Higher-order byte

4 Byte 0

5 Byte 1

6 Byte 2

7 Byte 3

The following bit field makes it possible to select objects for the process data transfer.

Process data Explanation Identification

BUS_PDOs Bit field to select objects for the

process data transfer (Tx)

Bit 0 Bit 1 Set-point value

Bit 2 Bit 3 Bit 4 Bit 5 Bit 6 Bit 7 Bit 8 Bit 9 Bit 10 Bit 11 Default values via bus

Bit 12 Bit 13 Bit 14 Bit 15 Set-point value as Float

Set-point value

Set binary output via bus

Set-point value as Float

Dec: 16896, 1

Hex: 4200, 1

INTEGER16

44

english

Page 45

MFC Family

CANopen Start-up

The bit field can be defined by SDO access.

ID DLC Byte0 Byte1 Byte2 Byte3 Byte4 Byte5 Byte6 Byte7

600h+ID 8 22 4200H 01H Bit field

6.4.2. Transmitted PDOs

Transmitted PDOs are data that has been sent to the device (MFC). This is input data as seen by the PLC.

Transmitted PDO

Byte TxPDO0 TxPDO1 TxPDO2 TxPDO3

0 Byte 0

1 Byte 1 Byte 1 Byte 1 Byte 1

Actual

value

Byte 0

Status

limits

Byte 0

Totalizer

(of the

2 Byte 0

Set-

point

3 Byte 1 Byte 1 Byte 3 Byte 3

4 Byte 0

5 Byte 1 Byte 1 Byte 1 Byte 1

6 Byte 0

7 Byte 1 Byte 3 Byte 3 Byte 3

value

Active

gas

Status

errors

Byte 0

Status

Byte 2 Byte 2

others

Byte 0

Byte 0

AddMea-

Byte 2 Byte 2 Byte 2

sureValue

active gas)

Flow rate

(of the

active gas)

The following bit field makes it possible to select objects for the process data transfer.

Byte 0

Actual value

as Float

Byte 0

Set-point

value as

Float

english

45

Page 46

MFC Family

CANopen Start-up

Process data Explanation Identification

BUS_PDIs Bit field to select objects for the

process data transfer (Tx)

Bit 0 Actual value

Bit 1 Set-point value

Bit 2 Active gas

Bit 3 Nominal flow gas 1

Bit 4 Nominal flow gas 2

Bit 5 Status limits

Bit 6 Status errors

Bit 7 Status others

Bit 8 Bit 9 Bit 10 Bit 11 Bit 12 Totalizer value gas 1

Bit 13 Totalizer value gas 1

Bit 14 Actual value as Float

Bit 15 Set-point value as Float

Bit 16 Bit 17 AddMeasureValue

Bit 18 Xp (not supported yet)

Dec: 16896, 2

Hex: 4200, 2

UNSIGNED32

46

The bit field can be defined by SDO access.

ID DLC Byte0 Byte1 Byte2 Byte3 Byte4 Byte5 Byte6 Byte7

600h+ID 8 22 4200H 02H Bit field

english

Page 47

MFC Family

CANopen Start-up

6.4.3. Transmission Type

Index Subindex Parameter Length Access

1800h 0 Number of subindices Read

1 COB ID used by the PDO Read/write

2 Transmission Type Read/write

5 Inhibit Time Read/write

The transfer type (subindex 2) defines the type of transmission/reception for the PDO.

The following table explains how the entry is used. If an attempt is made to set the value of the variable to an entry

that is not supported, an error message (abort code: 0609 0030h) is generated.

Transmission

Type

Trigger condition of the PDO

(B= both required, E= one required)

PDO

transfer

SYNC RTR Event

0 B - B synchronous, acyclic

1-240 E - - synchronous, cyclic

241-251 - - - reserved

252 B B - synchronous, after RTR

253 - E - asynchronous, after RTR

254 - E E asynchronous, manufacturer-

specific event

255 - E E asynchronous, device-specific event

english

47

Page 48

MFC Family

CANopen Start-up

6.4.4. Overview of the mapped objects

Process data Explanation Identification

Actual value Actual value

(1 word = 2 bytes)

Value range 0 – 1000

Set-point Set-point value

(1 word = 2 bytes)

Value range 0 – 1000

Active gas Calibration of this gas is used for control,

gas 1 or gas 2

(1 word = 2 bytes) value range 0 – 1

Nominal flow Gas 1 Nominal flow in Nl/min of

calibration for gas 1

float = 4 bytes

Nominal flow Gas 2 Nominal flow in Nl/min of

calibration for gas 2

float = 4 bytes

RX (receive)

Dec: 12288, 1

Hex: 3000, 1

INTEGER16

Tx, Rx

Dec: 12288, 2

Hex: 3000, 2

UNSIGNED16

RX (receive)

Dec: 12288, 3

Hex: 3000, 3

UNSIGNED16

RX (receive)

Dec: 12288, 4

Hex: 3000, 4

REAL32

RX (receive)

Dec: 12288, 5

Hex: 3000, 5

48

Status limits

Status errors

Status others

Bit field for states of device-internal threshold

value:

(1 word = 2 bytes)

see “9.1. Description of bit fields”

Bit field for device errors that are present.

(1 word = 2 bytes)

see “9.1. Description of bit fields”

Bit field for current states in the controller.

(1 word = 2 bytes)

see “9.1. Description of bit fields”

REAL32

RX (receive)

Dec: 12288, 6

Hex: 3000, 6

UNSIGNED16

RX (receive)

Dec: 12288, 7

Hex: 3000, 7

UNSIGNED16

RX (receive)

Dec: 12288, 8

Hex: 3000, 8

UNSIGNED16

english

Page 49

MFC Family

CANopen Start-up

Process data Explanation Identification

Default values via bus

Bit field for states of LEDs and binary outputs if

they can be assigned by the bus.

To do this, the relevant functions must be configured in the device with the PC program.

(1 word = 2 bytes)

see “9.1. Description of bit fields”

Totalizer value Gas 1 Totalizer value of calibration for gas 1 in Nl.

Float = 4 bytes

Totalizer value Gas 2 Totalizer value of calibration for gas 2 in Nl.

Float = 4 bytes

Actual value as float

Actual value as Float (4 bytes)

Value range 0 – 1000

Other units can be parameterized by the value

of the flow unit from the “7.4. S-Analog Sensor

Object”.

Tx (send)

Dec: 12288, 12

Hex: 3000, C

UNSIGNED16

RX (receive)

Dec: 12288, 13

Hex: 3000, D

REAL32

RX (receive)

Dec: 12288, 14

Hex: 3000, E

REAL32

Tx, Rx

Dec: 8960, 3

Hex: 2300, 3

REAL32

e.g. units per thousand, Nl/min and the calibrated

unit

Set-point as float

Set-point value as Float (4 bytes)

Value range 0 – 1000

Other units can be parameterized by the value of

the flow unit from the “7.6. S-Single Stage Controller Object”.

e.g. units per thousand, Nl/min and the calibrated

unit

AddMeasureValue Read only

Additional value as float (4 bytes)

Value as a percentage

This value is only supported by a few MFCs. If the

value is not supported, 0% is returned.

Xp (currently not

supported)

Read only

Additional pressure value (2 bytes)

Value in units per thousand

Value range 0 – 1000

This value is only supported by a few MFCs. If the

value is not supported, 0% is returned.

RX (receive)

Dec: 8448, 4

Hex: 2100, 4

REAL32

Dec: 12288, 46

Hex: 3000, 2E

REAL32

Dec: 12288, 47

Hex: 3000, 2F

UNSIGNED16

english

49

Page 50

MFC Family

CANopen Start-up

6.5. CANopen – Communication Object

Name Description of the input data attribute Index, Subindex

CANopen

Node ID Read Write

Bus address

Address by which the CANopen master

communicates with the device.

1 – 127

Default: 127

Baudrate Read Write

0 - 1000 kb

Dec: 16384, 1

Hex: 4000, 1

UNSIGNED8

Dec: 16384, 1

Hex: 4000, 1

1 – 800 kb

2 – 500 kb

3 – 250 kb

4 – 125 kb

5 – 100 kb

6 – 50 kb

7 – 20 kb

8 - 10 kb

Default: 4 = 125 kb

To activate modified values, an "NMT" reset must be sent.

If values are changed with the MassFlowCommunicator program, a hardware reset is required.

UNSIGNED8

6.6. Acyclic data

See “7. Acyclic Data Transfer with PROFIBUS, DeviceNet and CANopen”

50

english

Page 51

MFC Family

Acyclic Data Transfer with

PROFIBUS, DeviceNet and CANopen

7. ACYCLIC DATA TRANSFER WITH PROFIBUS,

DEVICENET AND CANOPEN

7.1. CANopen-Manufactory Object

Manufactory Object

Name

Device Type Read only

Device Name Read only

Hardware Version Read only

Software Version Read only

Description of the input data attributes Index, Subindex

CANopen profile

No profile supported

Entry 0

Device name

Hardware version

e.g. "A"

Software version

e.g. "A01.00"

7.2. CANopen-Identity Object

CANopen

Dec: 4096, 0

Hex: 1000, 0

UNSIGNED32

Dec: 4104, 0

Hex: 1008, 0

VISIBLE_STRING

Dec: 4105, 0

Hex: 1009, 0

VISIBLE_STRING

Dec: 4106, 0

Hex: 100A, 0

VISIBLE_STRING

Identity Object

Name Description of the input data attributes Index, Subindex

CANopen

Vendor ID Read only

vendor's ID number.

Bürkert's CANopen vendor ID 39h

Product Code Read only

product code of the device.

Revision Number Read only

This is a structure of two UNSIGNED16 values.

It is the Bürkert CANopen communications version

number.

Serial Number Read only

The device serial number specified on the rating plate.

Dec: 4120, 1

Hex: 1018, 1

UNSIGNED32

Dec: 4120, 2

Hex: 1018, 2

UNSIGNED32

Dec: 4120, 3

Hex: 1018, 3

UNSIGNED32

Dec: 4120, 4

Hex: 1018, 4

UNSIGNED32

51

english

Page 52

7.3. DeviceNet S-Identity Object

S-Identity Object

Name Description of the input data attributes

Vendor ID Read only

vendor's ID number.

Bürkerts DeviceNet vendor ID 57h

Device Type Read only

Numeric device identifier

Identification of the general product type.

This is type 0 (generic device).

Product Code Read only

The product code is 2, corresponding to the eds file.

MFC Family

Acyclic Data Transfer with

PROFIBUS, DeviceNet and CANopen

Attribute address

(class, instanceattribute; data type)

DVN

Dec: 1, 1, 1

Hex: 1, 1, 1

UINT

Dec: 1, 1, 2

Hex: 1, 1, 2

UINT

Dec: 1, 1, 3

Hex: 1, 1, 3

Revision Read only

Revision of the element representing the identity

object. This is a structure of two bytes.

Status Read only

Combined status of the device.

Serial Number Read only

Serial number that is unique for all Bürkert devices.

Product Name Read only

MFC/MFM

UINT

Dec: 1, 1, 4

Hex: 1, 1, 4

WORD

Dec: 1, 1, 5

Hex: 1, 1, 5

WORD

Dec: 1, 1, 6

Hex: 1, 1, 6

UDINT

Dec: 1, 1, 7

Hex: 1, 1, 7

SHORT_STRING

52

english

Page 53

MFC Family

Acyclic Data Transfer with

PROFIBUS, DeviceNet and CANopen

7.4. S-Analog Sensor Object

S-Analog Sensor Object

Name Description of the input data

attributes

Data Type Read Write

Describes the data format of the

actual value and the "Flow Full

Scale" (nominal flow)

Hex

0xC3 INT

0xCA REAL

Data Units

Reading Valid Read only

Read Write

min. value 2048,

max. value 4103

list of units see

“9.2. Table of units”

"% "

"Units per thousand"

and the calibrated device unit

Min. value 0, max. value 1

Attribute address

(class, instanceattribute; data type)

DVN DPV1 CANopen

Dec: 49, 1, 3

Hex: 31, 1, 3

USINT

Dec: 49, 1, 4

Hex: 31, 1, 4

UINT

Dec: 49, 1, 5

Hex: 31, 1, 5

Slot, Index Index, Subindex

Dec: 1, 3

Hex: 1, 3

Dec: 1, 4

Hex: 1, 4

Dec: 1, 5

Hex: 1, 5

Dec: 8448, 1

Hex: 2100, 1

UNSIGNED8

Dec: 8448, 2

Hex: 2100, 2

UNSIGNED16

Dec: 8448, 3

Hex: 2100, 3

Actual value Read only

Depends on the settings under

data type and data units.

Status Read only

This is not supported yet.

The return value is always 0.

BOOL

Dec: 49, 1, 6

Hex: 31, 1, 6

INT

Or

REAL

Dec: 49, 1, 7

Hex: 31, 1, 7

BYTE

Dec: 1, 6

Hex: 1, 6

Dec: 1, 7

Hex: 1, 7

UNSIGNED8

Dec: 8448, 4

Hex: 2100, 4

INTEGER16

Or

Dec: 8448, 5

Hex: 2100, 5

REAL32

Dec: 8448, 6

Hex: 2100, 6

UNSIGNED8

53

english

Page 54

S-Analog Sensor Object

MFC Family

Acyclic Data Transfer with

PROFIBUS, DeviceNet and CANopen

Name Description of the input data

attributes

Flow Full

Scale

Read only

Depends on the settings under

data type and data units.

Attribute address

(class, instanceattribute; data type)

DVN DPV1 CANopen

Dec: 49, 1, 10

Hex: 31, 1, A

INT

Or

REAL

7.5. S-Analog Actuator Object

S-Analog Actuator Object

Name Description of the input data

attributes

Data Type

Data Units Read Write

Read Write

Describes the data format of the

"value"

Hex

0xC3 INT

0xCA REAL

min. value 2048

max. value 4103

Possible units are:

"% "

"Units per thousand"

0x800 "Units per thousand"

0x1007 "% "

Attribute address

(class, instance

attribute; data

type)

DVN DPV1 DPV1

Dec: 50, 1, 3

Hex: 32, 1, 3

USiNT

Dec: 50, 1, 4

Hex: 32, 1, 4

UINT

Slot, Index Index, Subindex

Dec: 1, 10

Hex: 1, A

Slot, Index Index, Subindex

Dec: 1, 53

Hex: 1, 35

Dec: 1, 54

Hex: 1, 36

Dec: 8448, 7

Hex: 2100, 7

INTEGER16

Or

Dec: 8448, 8

Hex: 2100, 8

REAL32

Dec: 8704, 1

Hex: 2200, 1

UNSIGNED8

Dec: 8704, 2

Hex: 2200, 2

UNSIGNED16

54

english

Page 55

MFC Family

Acyclic Data Transfer with

PROFIBUS, DeviceNet and CANopen

S-Analog Actuator Object

Name Description of the input data

attributes

Actuator

Override

(overwrite

control output)

Read Write

0 Normal operation of the controller and binary input controls

the valve

1 off / closed

2 on / open -flow is restricted

by the pressure and orifice of the

valve

3 Hold function active for control

output to the valve

64 Valve control output is controlled by the set-point value. The

min. and max. ramp up and down

times (ramps, etc.) apply.

Read only

65 Similar to 64, except that the

percentage entry for the control

output is only within the working

range of the valve

66 Calibration mode active

67 Autotune mode active

68 Safety mode active

Valve Value

(control output

to valve)

Read only

The valve duty cycle.

The value format depends on the

data type.

The value unit is defined by the

value of the unit.

Attribute address

Slot, Index Index, Subindex

(class, instance

attribute; data

type)

DVN DPV1 DPV1

Dec: 50, 1, 5

Hex: 32, 1, 5

USINT

Dec: 50, 1, 6

Hex: 32, 1, 6

INT

Dec: 1, 55

Hex: 1, 37

Dec: 1, 56

Hex: 1, 38

Dec: 8704, 3

Hex: 2200, 3

UNSIGNED8

Dec: 8704, 4

Hex: 2200, 4

INTEGER16

Or

REAL

Or

Status Read only

This is not supported yet.

The return value is always 0.

Dec: 50, 1, 7

Hex: 32, 1, 7

BYTE

Dec: 1, 57

Hex: 1, 39

english

Dec: 8704, 5

Hex: 2200, 5

REAL32

Dec: 8704,6

Hex: 2200, 6

UNSIGNED8

55

Page 56

7.6. S-Single Stage Controller Object

S-Single Stage Controller Object

MFC Family

Acyclic Data Transfer with

PROFIBUS, DeviceNet and CANopen

Name Description of the input data

attributes

Data Type Read Write

Describes the data type of the

set-point value

Hex

0xC3 INT0

0xCA REAL

Data Units

Set-point Read Write

Read Write

min. value 2048,

max. value 4103

list of units see

“9.2. Table of units”

"% "

"Units per thousand"

and the calibrated device unit

The value format depends on the

data type.

The value unit is defined by the

value of the unit.

Attribute address

(class, instance

attribute; data

type)

DVN DPV1 CANopen

Dec: 51, 1, 3

Hex: 33, 1, 3

USINT

Dec: 51, 1, 6

Hex: 33, 1, 6

UINT

Dec: 51, 1, 6

Hex: 33, 1, 6

INT

Or

REAL

Slot, Index Index, Subindex

Dec: 1, 103

Hex: 1, 67

Dec: 1, 104

Hex: 1, 68

Dec: 1, 106

Hex: 1, 6A

Dec: 8960, 1

Hex: 2300, 1

UNSIGNED8

Dec: 8960, 2

Hex: 2300, 2

UNSIGNED16

Dec: 8960, 3

Hex: 2300, 3

INTEGER16

Or

Dec: 8960, 4

Hex: 2300, 4

56

Status Read only

This is not supported yet.

The return value is always 0.

english

Dec: 51, 1, 6

Hex: 33, 1, 6

BYTE

Dec: 1, 107

Hex: 1, 6B

REAL32

Dec: 8960, 5

Hex: 2300, 5

UNSIGNED8

Page 57

MFC Family

Acyclic Data Transfer with

PROFIBUS, DeviceNet and CANopen

7.7. Bürkert General Description Object

Bürkert General Description Object

Name Description of the input data

attributes

Device Ident

Number

Device Serial

Number

Device Type Read only

Ident Number

printed circuit

board

Revision

Number

Hardware

(Hardware

revision)

Read only

Bürkert identifications number

of the device

min. value 0,

max. value 99999999

Read only

Bürkert serial number of the

device

min. value 0,

max. value 4294967295

Bürkert type number of the

device

min. value 0, max. value 65535

Read only

Ident number of the printed

circuit board

min. value 0,

max. value 99999999

Read only

Revision number of the printed

circuit board

min. value A‘, max. value Z‘

Attribute address

(class, instance

attribute; data type)

DVN DPV1 CANopen

Dec: 101, 1, 1

Hex: 65, 1, 1

UDINT

Dec: 101, 1, 2

Hex: 65, 1, 2

UDINT

Dec: 101, 1, 3

Hex: 65, 1, 3

UINT

Dec: 101, 1, 4

Hex: 65, 1, 4

UDINT

Dec: 101, 1, 5

Hex: 65, 1, 5

USINT

Slot, Index Index, Subindex

Dec: 0, 101

Hex: 0, 65

Dec: 0, 102

Hex: 0, 66

Dec: 0, 103

Hex: 0, 67

Dec: 0, 104

Hex: 0, 68

Dec: 0, 105

Hex: 0, 69

Dec: 8192, 1

Hex: 2000, 1

UNSIGNED32

Dec: 8192, 2

Hex: 2000, 2

UNSIGNED32

Dec: 8192, 3

Hex: 2000, 3

UNSIGNED16

Dec: 8192, 4

Hex: 2000, 4

UNSIGNED32

Dec: 8192, 5

Hex: 2000, 5

UNSIGNED8

7.8. Bürkert MFC Family Object

Bürkert MFC Family Object

Name Description of the input

data attributes

Actual value

(actual value

(x))

Set-point

(set-point

(w))

Read only

Value in units per thousand

of the active gas

min. value 0, max. value 1000

Read Write

Set-point value in units per

thousand for the active gas

min. value 0, max. value 1000

Attribute address